Exothermic enamel glaze, and exothermic container coated with same

A heating container and enamel glaze technology, which is applied in the field of heating enamel glaze and heating containers coated with it, can solve the problems of difficult processing of complex shapes, and achieve the effects of high heating characteristics, high heating temperature and excellent heat resistance characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

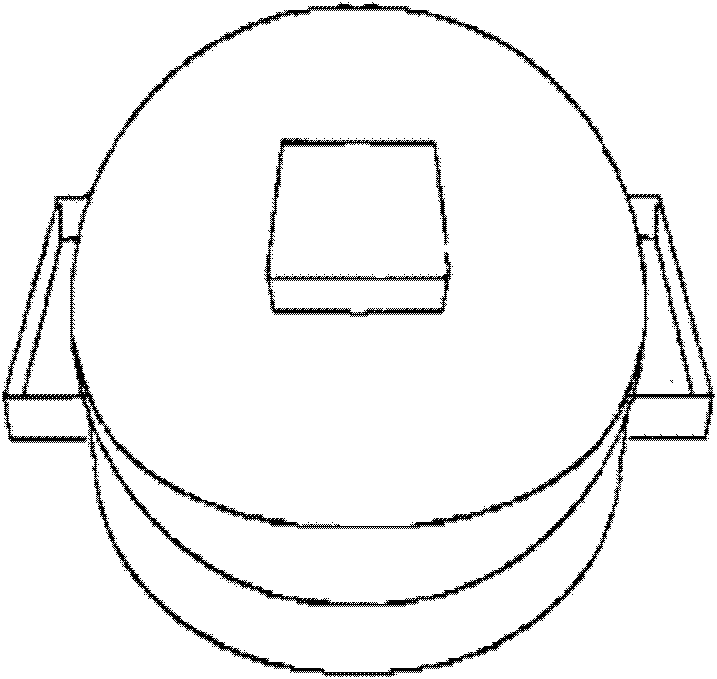

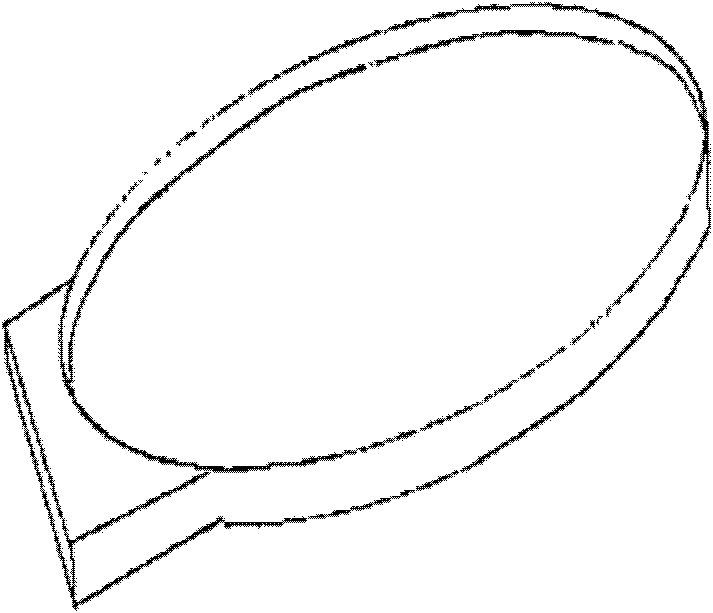

Image

Examples

Embodiment 1

[0068] Vitreous glaze [(Frit), SiO for enamel glaze commonly used 2 、Al 2 o 3 、Na 2 O, K 2 O, CaO, NiO, CoO, CuO, MnO, BaO, F, B 2 o 3etc.], add clay (clay) and sodium nitrite (NaNO 2 ) in the composition of commonly used glazes formed by changing the types and contents of soft magnetic materials, namely ferrite and soft magnetic metal alloy powders (FeSiAl, FeSi), to determine the composition ratio of 12 kinds of glazes. 40 wt % of water was added to the composition, and then pulverized to an average particle size of 100 μm by an alumina ball mill to manufacture a test piece of the glaze for heat-generating enamel.

[0069] A hot-rolled steel plate for common enamel is made into a quadrilateral test piece with a thickness of 0.8mm and 100*150mm. After the steel plate is degreased with sodium hydroxide (NaOH), the heating enamel glaze is coated with a thickness of more than 200 μm, and then After drying at 100°C for 2 hours, the dried test piece was vitrified and fired ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com