Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Improve Feedback Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

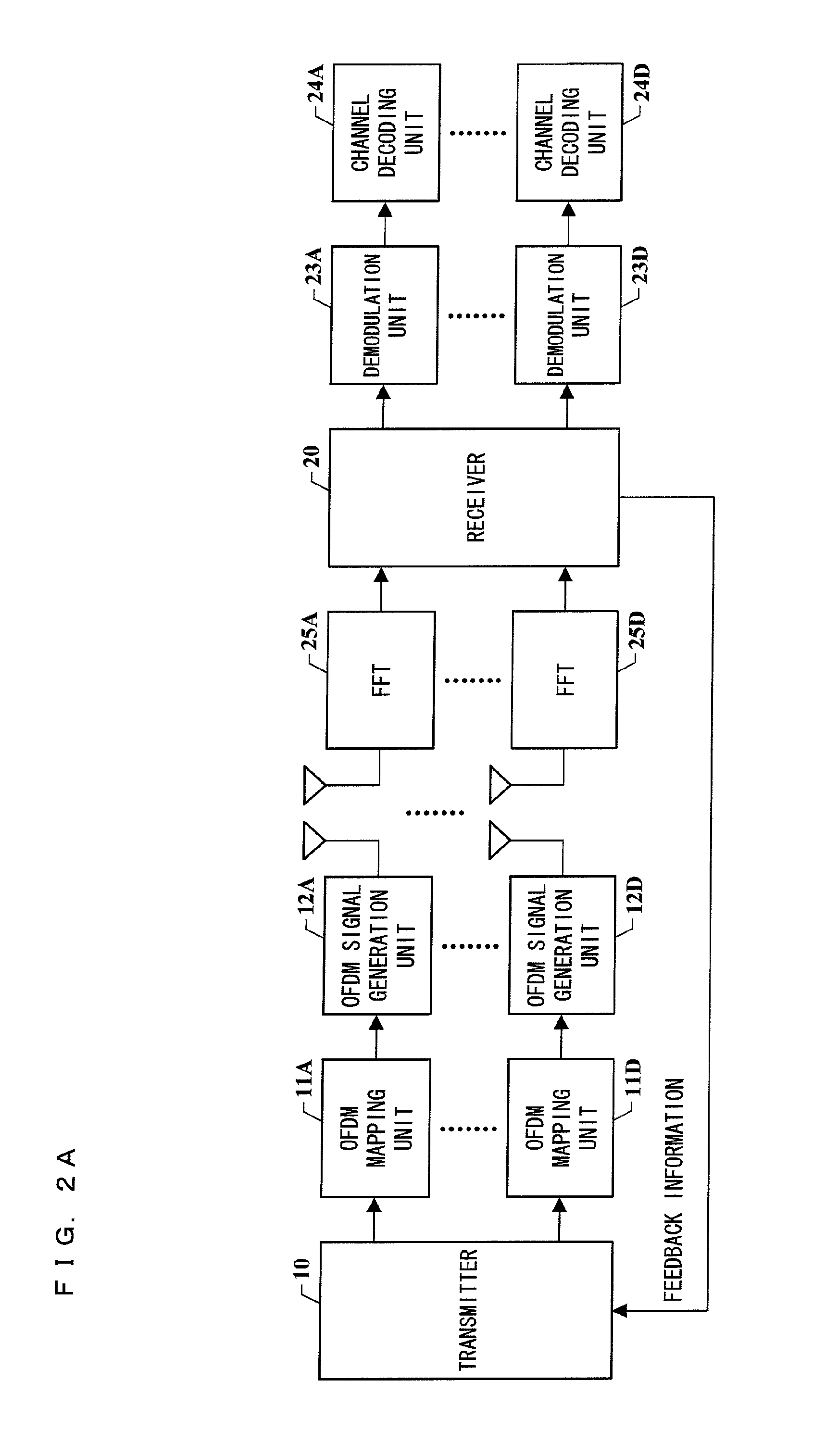

Method and system for channel information feedback

ActiveCN102271031AImprove Feedback AccuracyReduce overheadError prevention/detection by using return channelBack channelQuality information

Owner:ZTE CORP

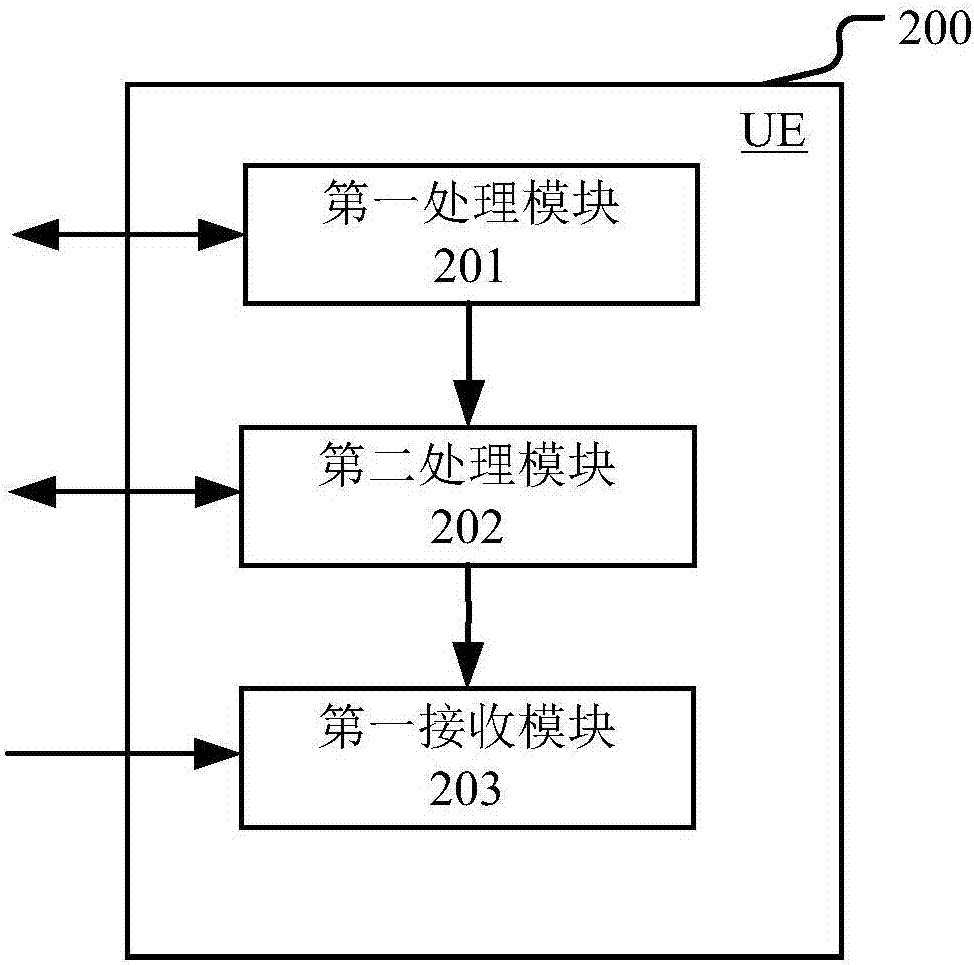

Channel state information feedback method and terminal

InactiveCN101969363ASolve expensive problemsImprove performanceSignalling characterisationError prevention/detection by diversity receptionCommunications systemComputer terminal

The invention discloses a channel state information feedback method and a terminal. The method comprises the following steps: the terminal acquires channel state information, wherein the channel state information comprises channel quality indicator (CQI) information, pre-coding matrix indicator (PMI) information and rank indicator (RI) information; in an eight-antenna system, the PMI comprises a first kind of pre-coding matrix indicators (PMI1) and a second kind of pre-coding matrix indicators (PMI2); in a four-antenna system, the PMI comprises single PMI; and the terminal feeds back the channel state information on a physical uplink shared channel (PUSCH) according to the preset feedback method. The invention improves the performance of a communication system.

Owner:ZTE CORP

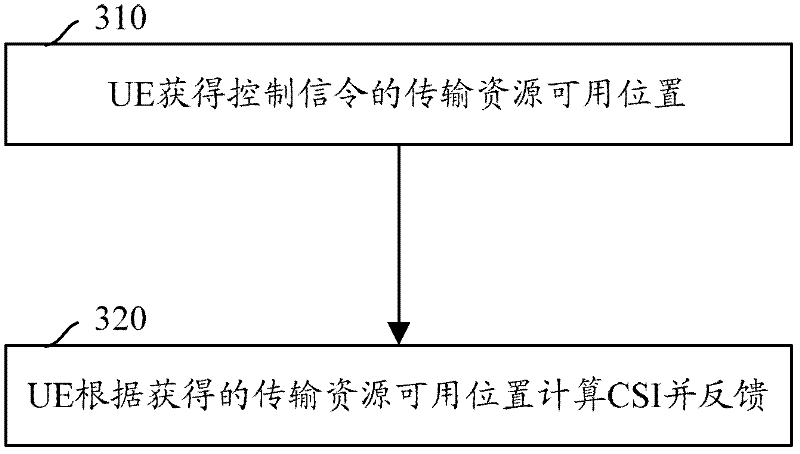

Channel state information transmission method and equipment

ActiveCN107888323AImprove Feedback AccuracyImprove accuracySpatial transmit diversitySignal allocationState parameterAlgorithm

The invention discloses a channel state information transmission method and equipment, aiming at solving the problems that the accuracy of channel state information that can be provided is limited dueto the limitation of a codebook structure in the prior art and a transmission scheme that a base station adopts an advanced preprocessing algorithm is not adapted. The method includes the following steps: a terminal determines a basis matrix according to a candidate beam vector set, wherein the basis matrix is a matrix formed by N beam vectors in the candidate beam vector set, and N is a positiveinteger; the terminal determines a merging coefficient matrix according to the basis matrix and channel state parameters; and the terminal feeds back identification information of the basis matrix and the merging coefficient matrix to the base station. Thereby, the accuracy of channel state information feedback can be effectively improved, and the performance of multi-antenna transmission, especially MU-MIMO transmission can be improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

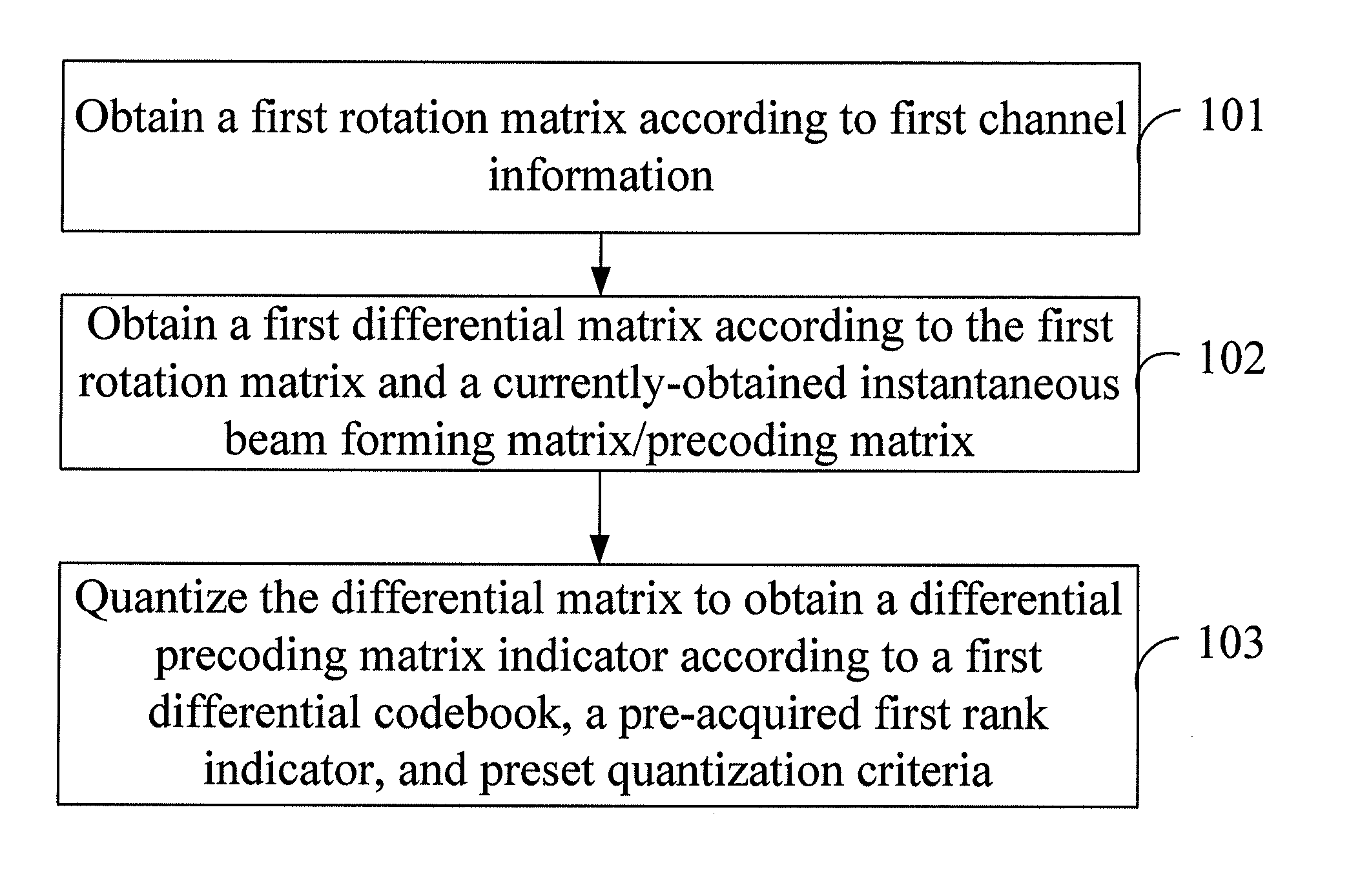

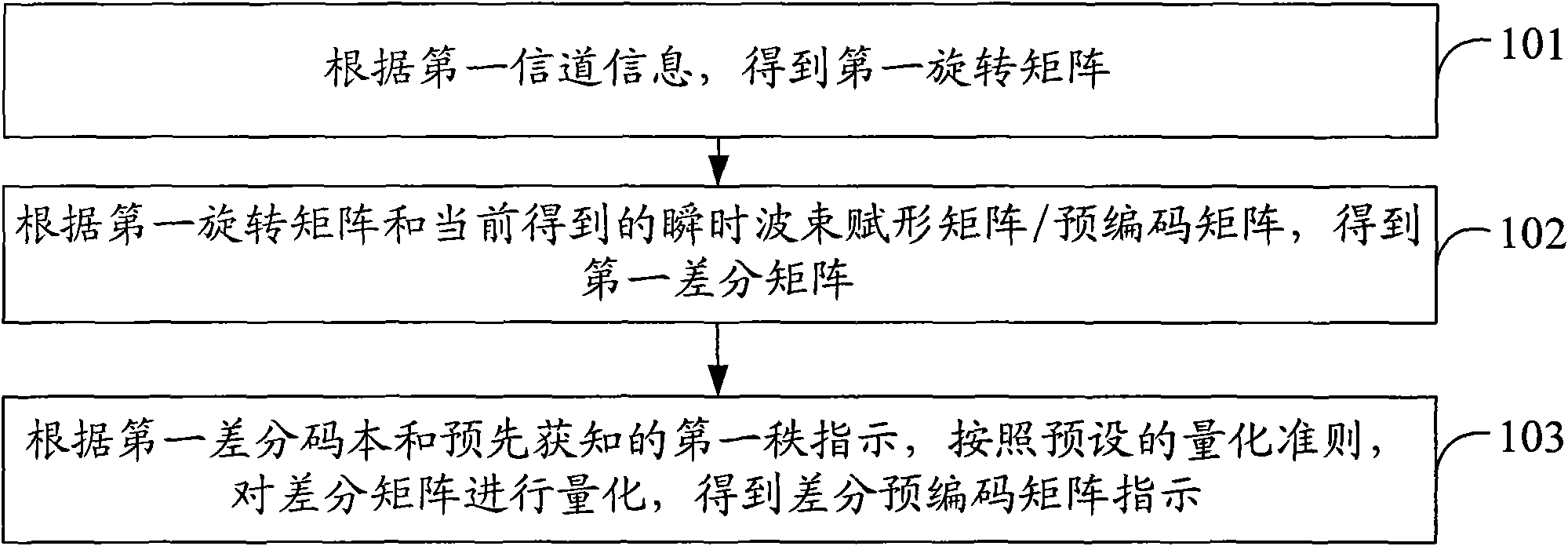

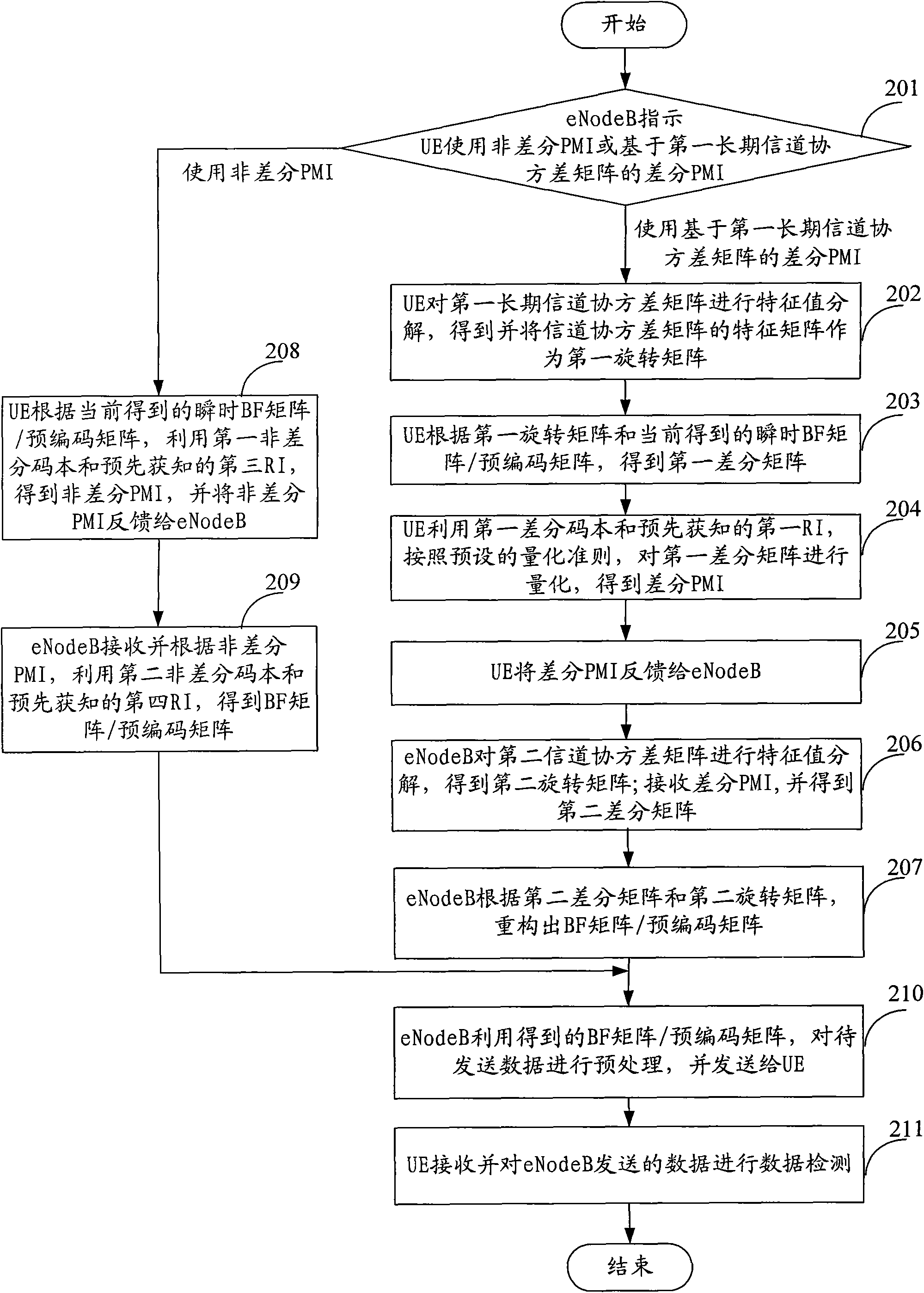

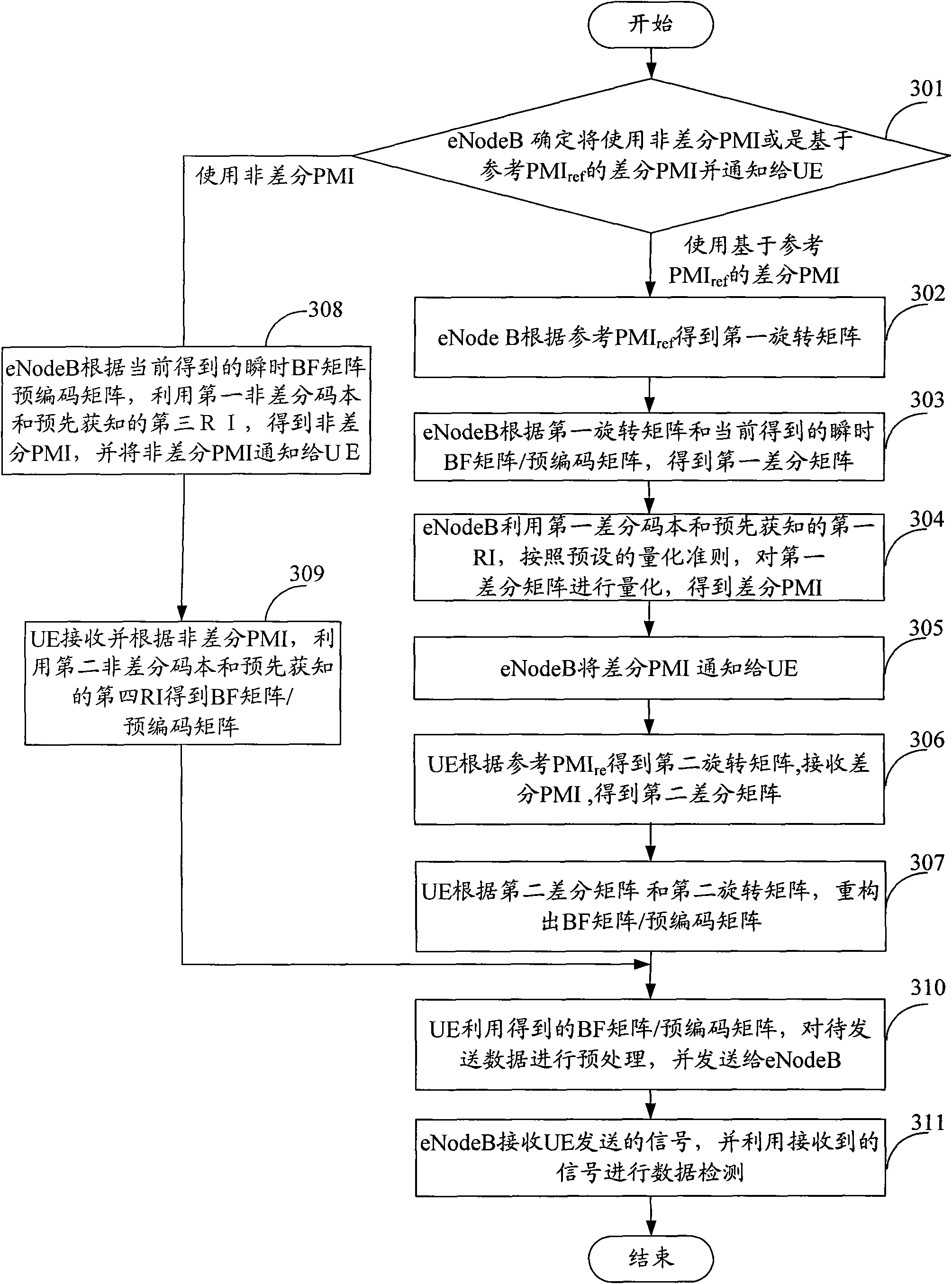

Method and apparatus for obtaining precoding matrix indicator

ActiveUS20120189075A1Improve accuracyReduce overheadDiversity/multi-antenna systemsSecret communicationComputer scienceRotation matrix

The present disclosure discloses a method and an apparatus for obtaining a precoding matrix indicator, and relates to the field of communication technologies. The method includes: obtaining a first rotation matrix according to first channel information; obtaining a first differential matrix according to the first rotation matrix and a currently-obtained instantaneous beam forming matrix / precoding matrix; and quantizing, according to a first differential codebook, a pre-acquired first rank indicator, and preset quantization criteria, the first differential matrix to obtain a differential precoding matrix indicator. The apparatus includes: a first rotation matrix obtaining module, a first differential matrix obtaining module, and a differential precoding matrix indicator obtaining module. In the present disclosure, the differential PMI is obtained according to the channel information, and the differential PMI is used for feedback, which not only reduces an overhead, but also improves feedback accuracy.

Owner:HUAWEI TECH CO LTD

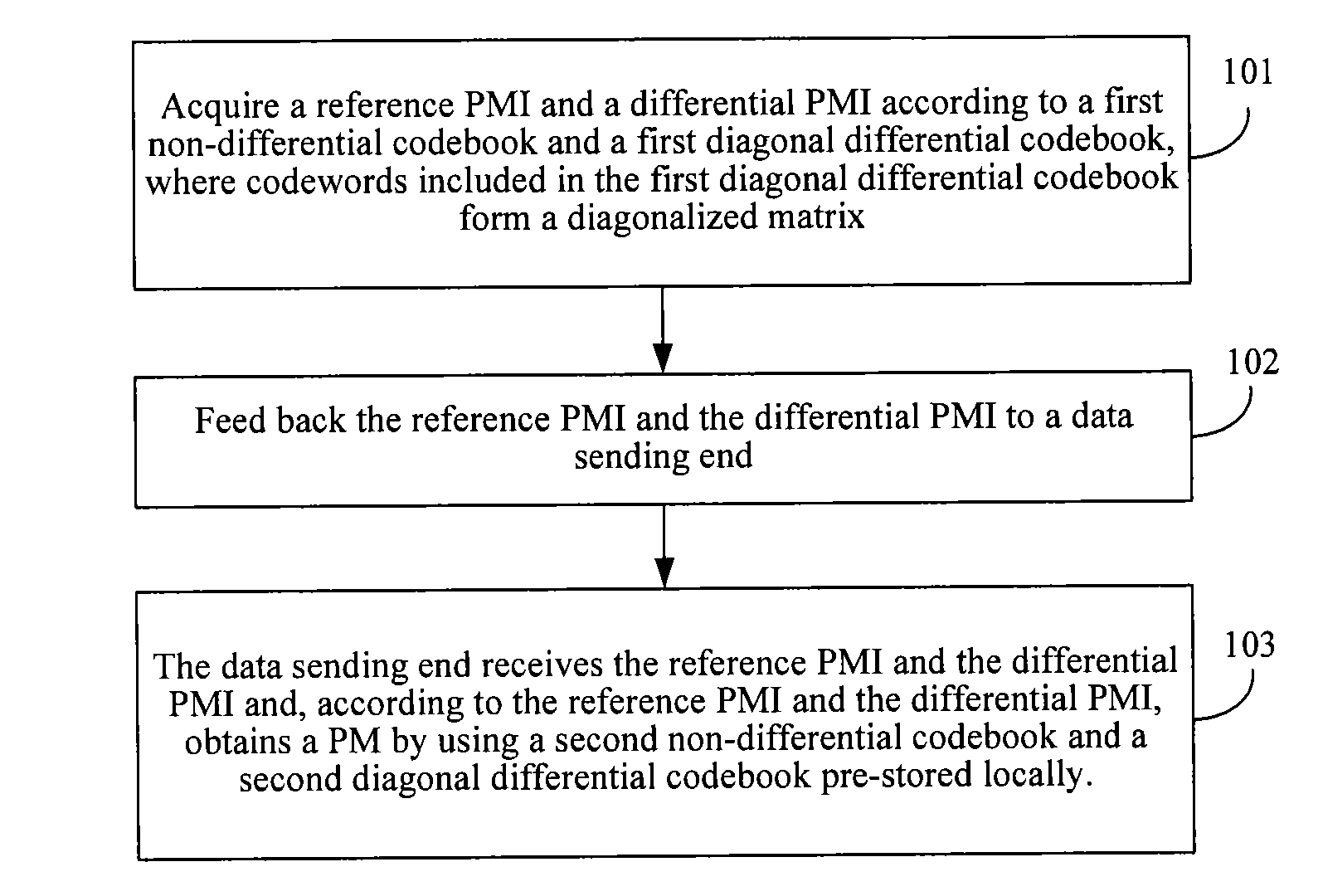

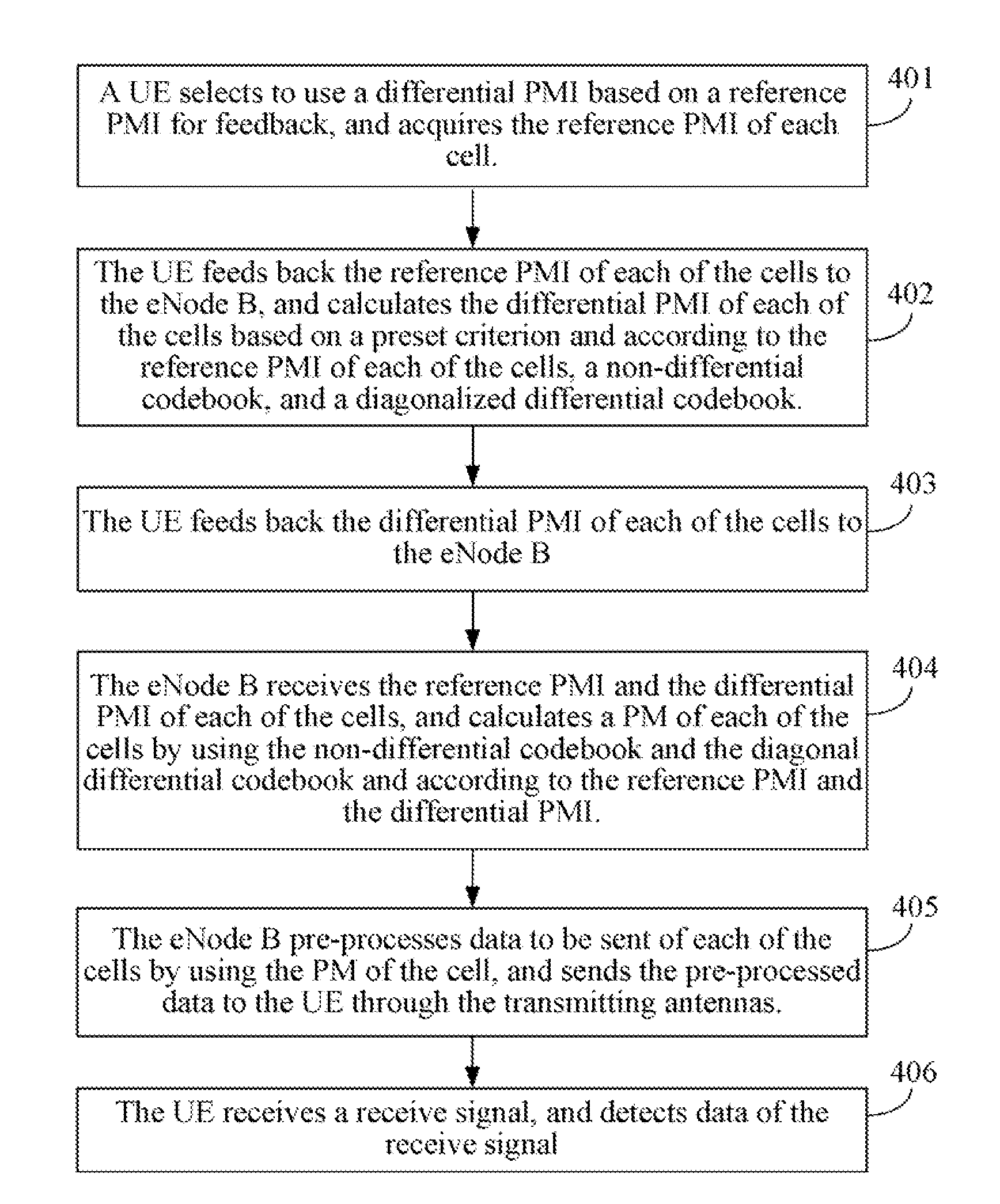

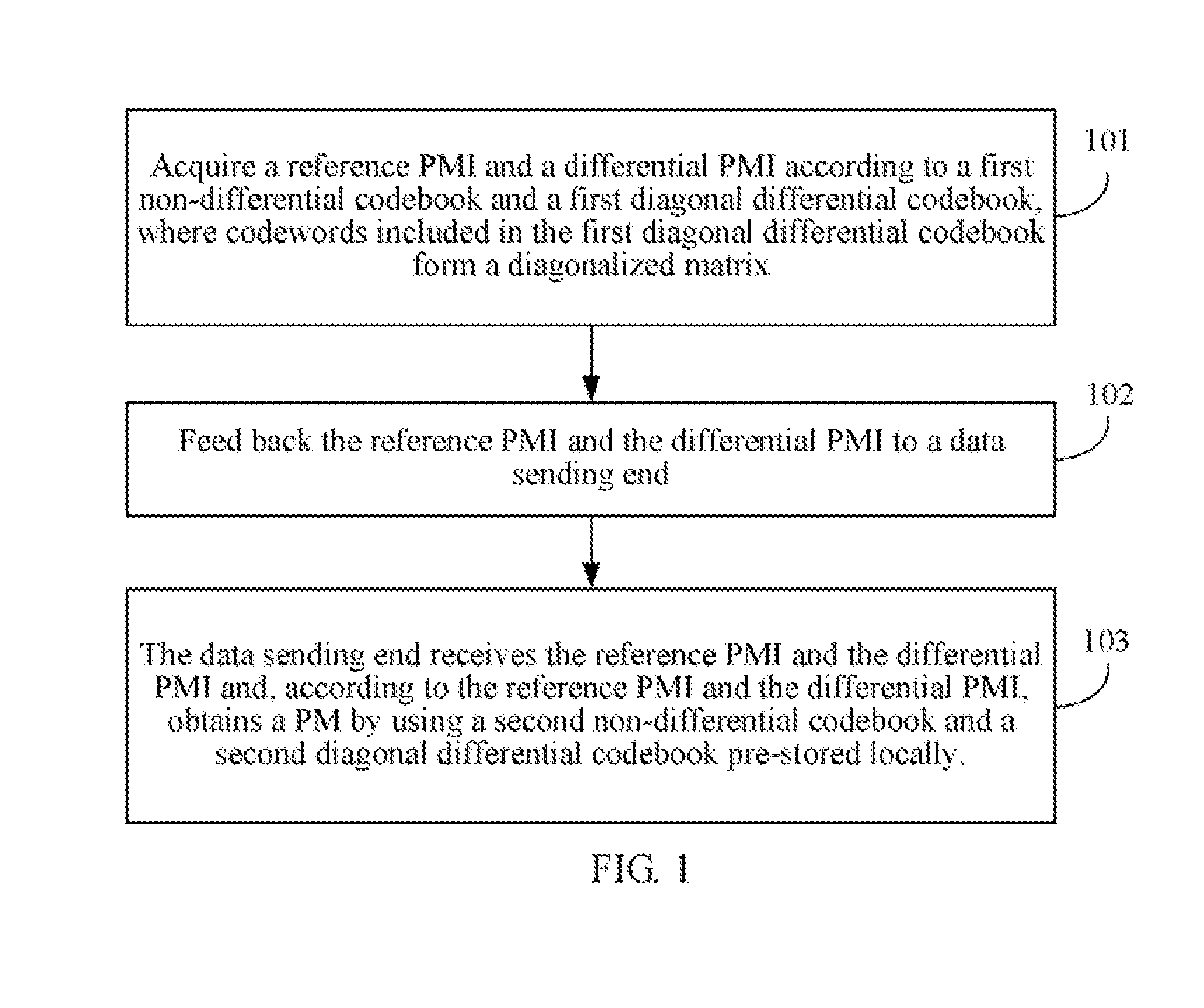

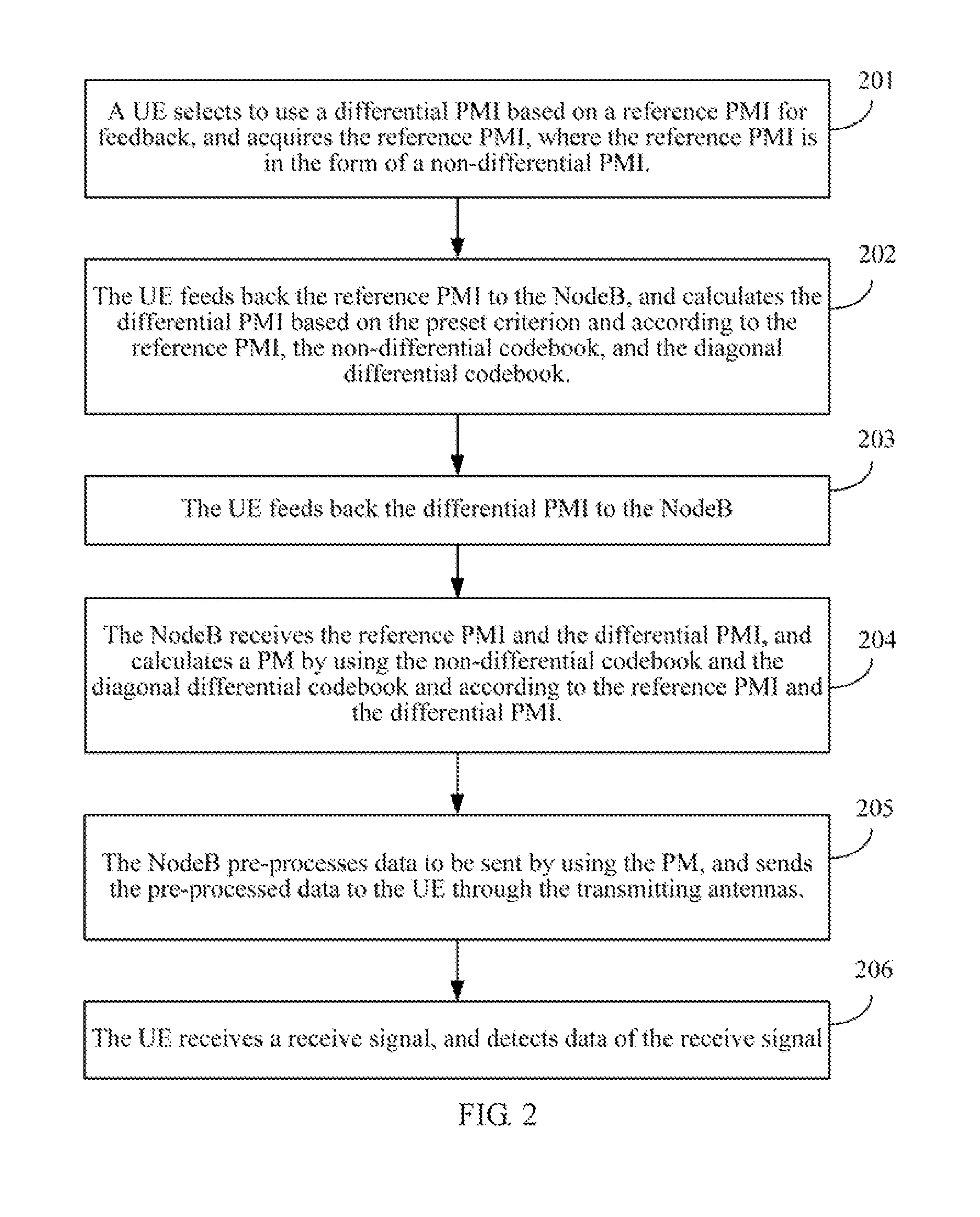

Method and apparatus for acquiring a precoding matrix indicator and a precoding matrix

ActiveUS20130121437A1Reduce Feedback OverheadImprove Feedback AccuracySpatial transmit diversityModulated-carrier systemsDiagonal matrixEngineering

In the field of communication technologies, a method and an apparatus for acquiring a Precoding Matrix Indicator (PMI) and a Precoding Matrix (PM) are provided. The method includes: acquiring a reference PMI and a differential PMI according to a first non-differential codebook and a first diagonal differential codebook, where codewords included in the first diagonal differential codebook form a diagonal matrix. The apparatus includes a PMI acquiring module. Acquiring a reference PMI and a differential PMI according to a non-differential codebook and a diagonal differential codebook can reduce the feedback overhead or improve the feedback precision; and the fact that codewords included in the diagonal differential codebook form a diagonal matrix can maintain amplitude characteristics (for example, a constant modulus characteristic, and a finite character set constraint characteristic) of elements of the non-differential codebook or facilitate power distribution among antennas.

Owner:HUAWEI TECH CO LTD

Method and device for acquiring pre-coding matrix index

ActiveCN102035626AReduce overheadImprove Feedback AccuracyRadio transmissionError prevention/detection by diversity receptionPurchasing managementComputer science

The invention discloses a method and device for acquiring a pre-coding matrix index, which belongs to the technical field of communication. The method comprises the steps of: acquiring a first rotation matrix according to first channel information, acquiring a first difference matrix according to the first rotation matrix and a currently obtained instantaneous beam figurate matrix / pre-coding matrix, acquiring a difference pre-coding matrix index by quantizing the first difference matrix according to a first difference codebook and a pre-informed first rank instruction on the basis of the pre-set quantitative criteria. The device comprises a first rotation matrix acquisition module, a first difference matrix acquisition module and a difference pre-coding matrix index acquisition module. A difference PMI (Purchase Management Index) is acquired according to the channel information, the difference PMI is used for feedback, which not only can reduce expenses, but also can improve the feedback accuracy.

Owner:HUAWEI TECH CO LTD

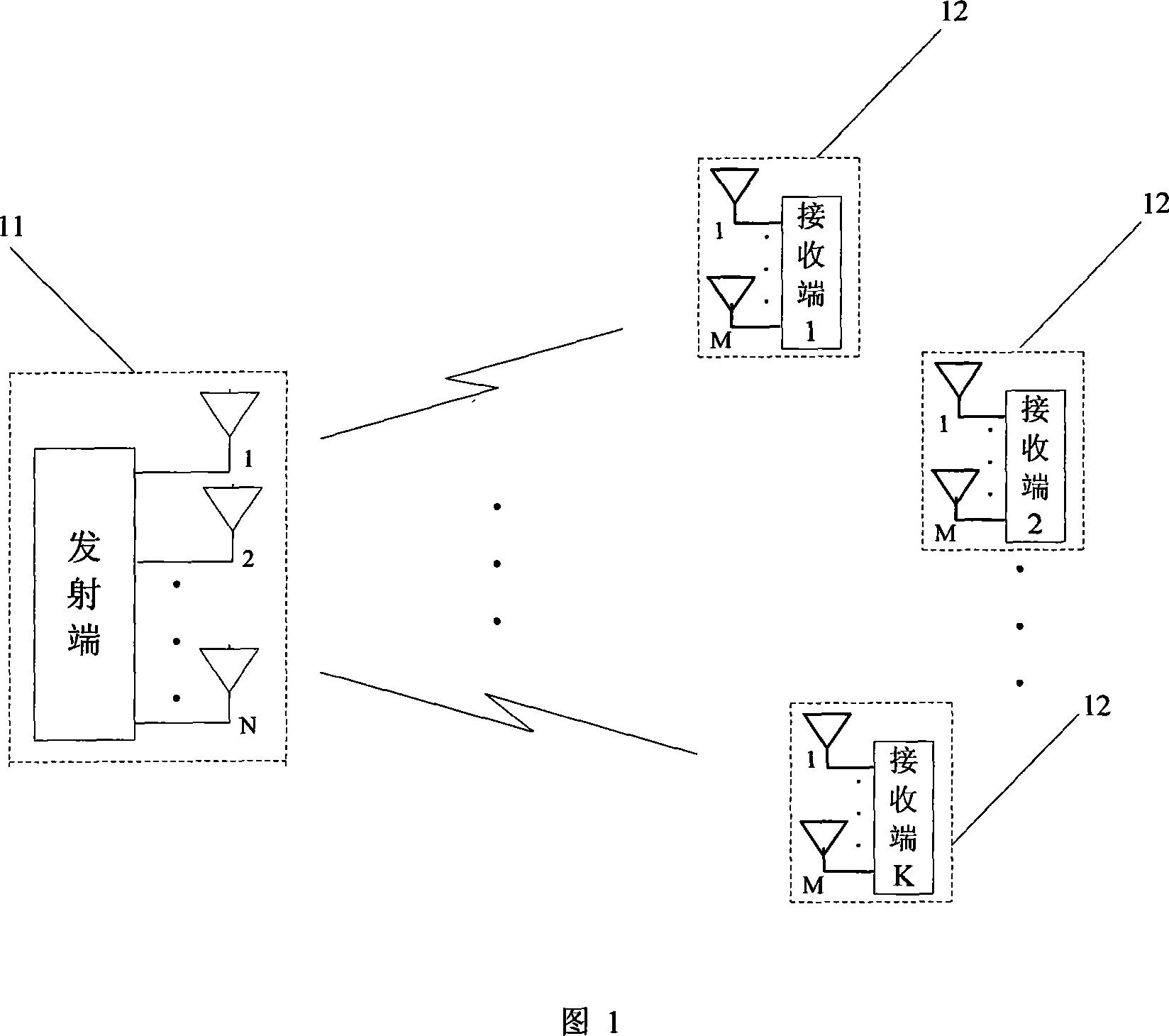

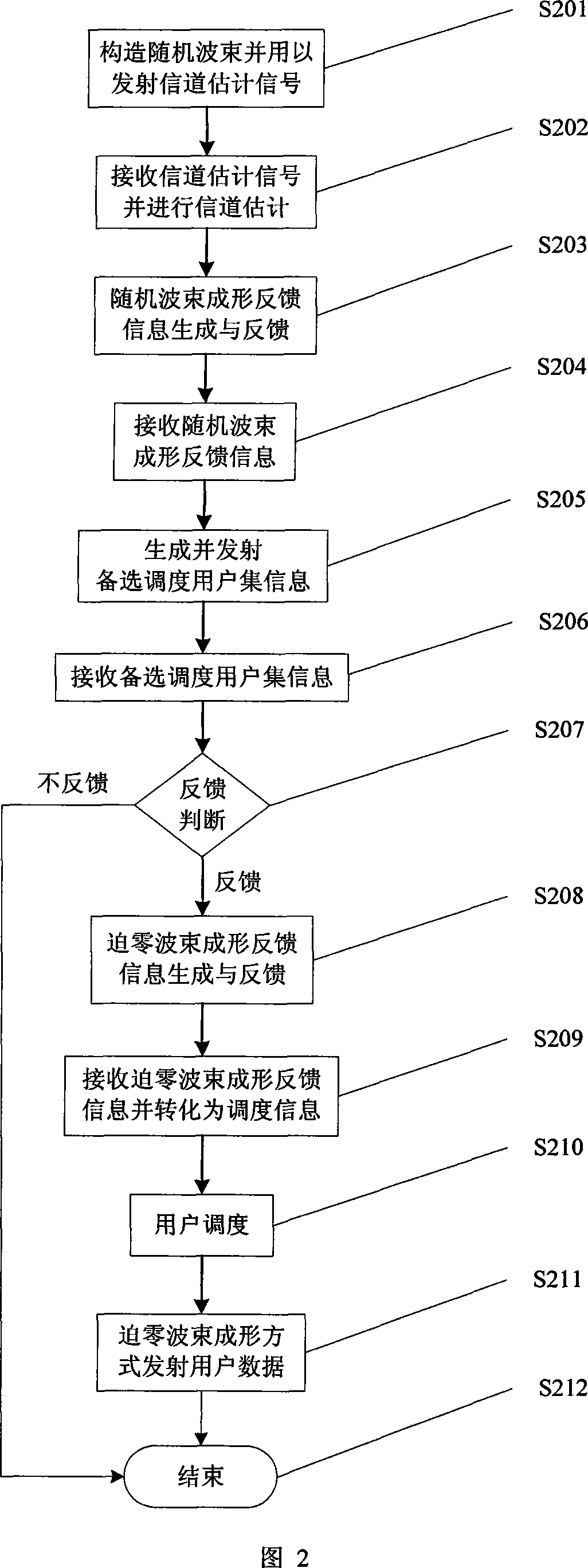

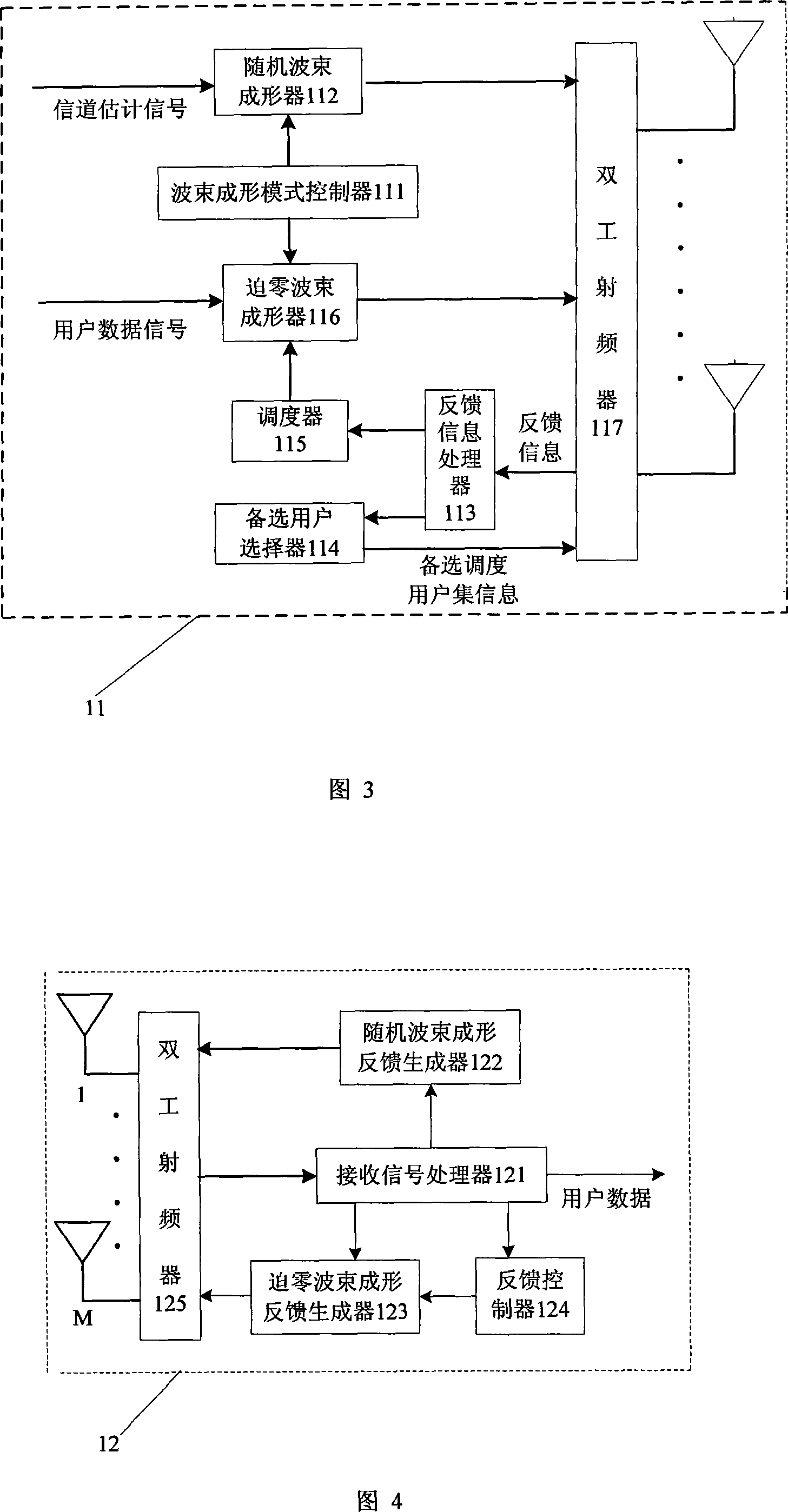

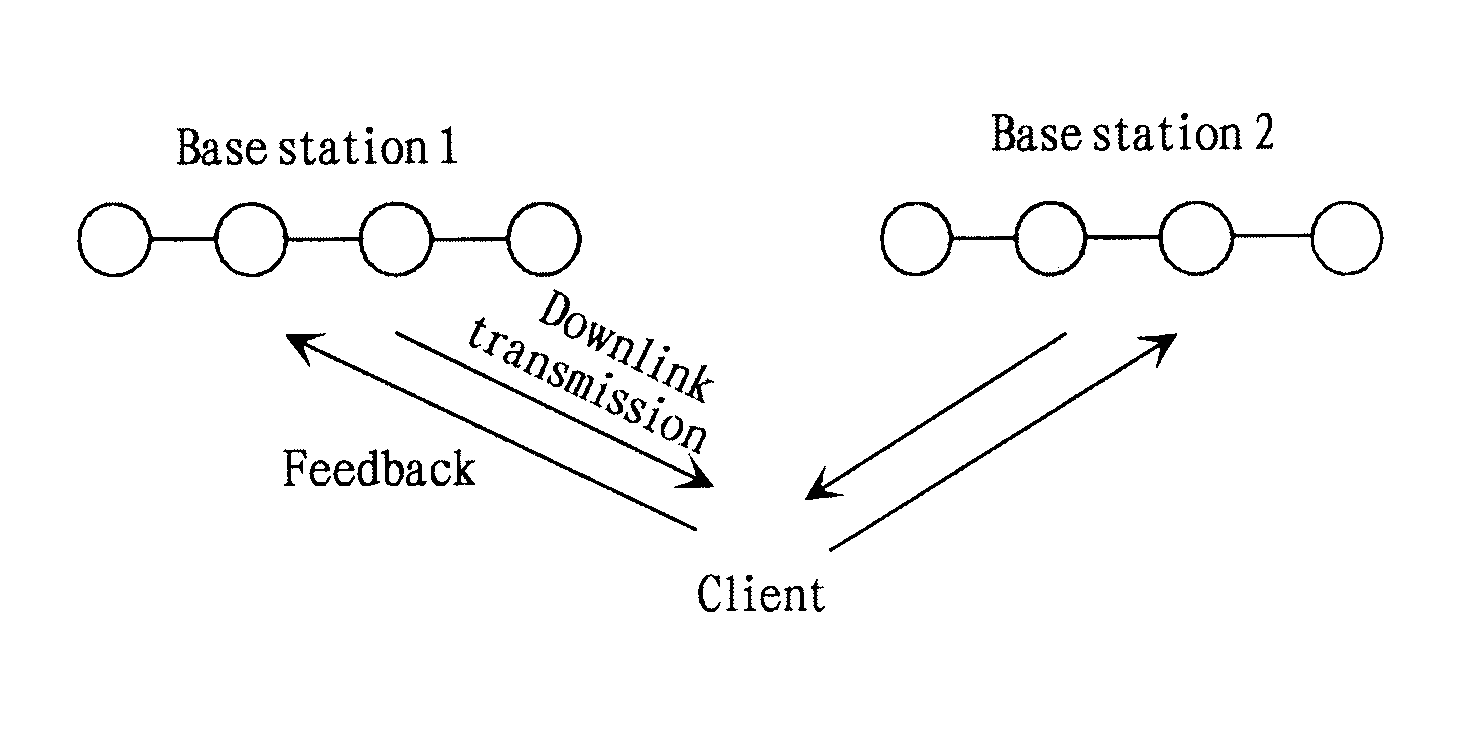

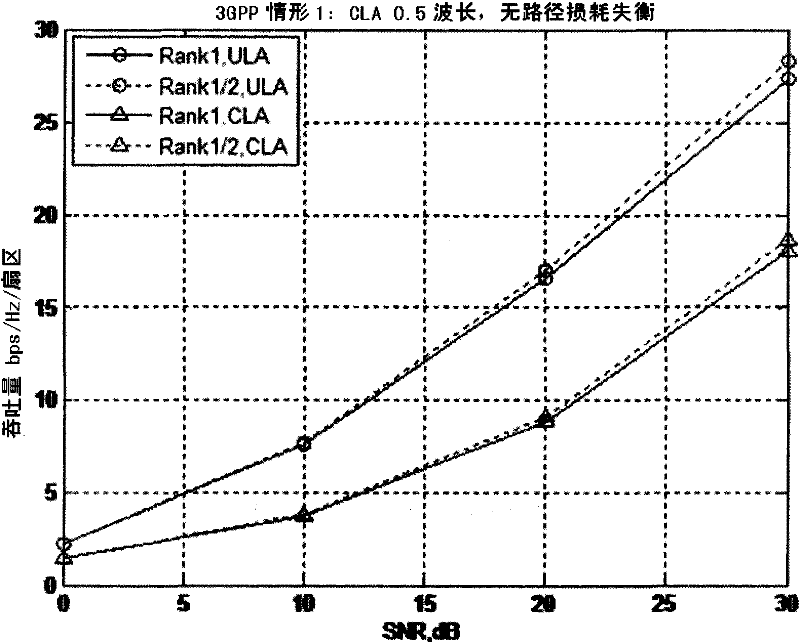

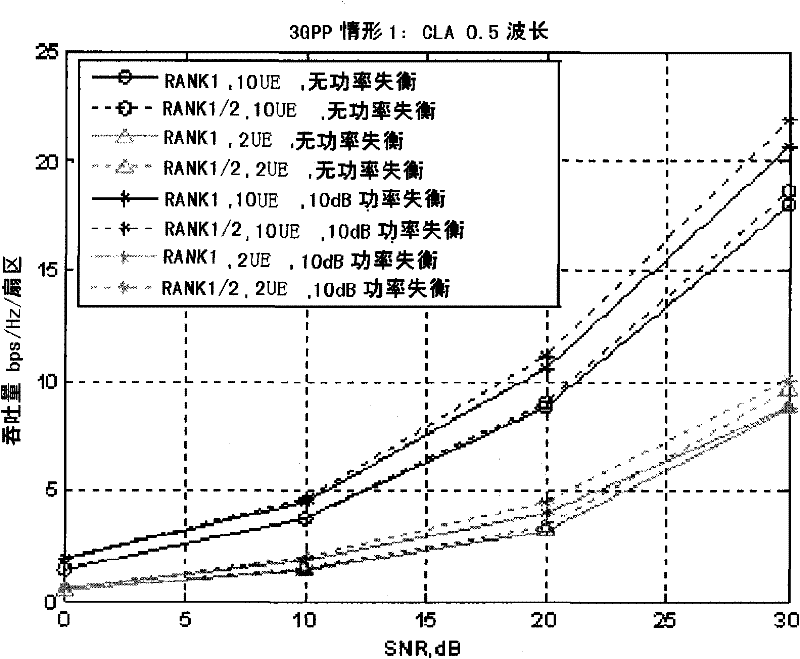

Method and system of MIMO transmission

InactiveCN101207590AReduce Feedback OverheadLarge capacitySpatial transmit diversityBaseband system detailsMulti inputSystem capacity

The invention provides a multi-input and multi-output (MIMO) transmission method as well as the system thereof. In the method, a transmitting end transmits the information estimated by a signal path, each receiving end generates random beam shaping feedback information and sends out the random beam shaping feedback information to the transmitting end, and the transmitting end carries out user preselection to generate an alternative scheduling user collection, which is sent to each receiving end; each receiving end carries out feedback judgement, if the feedback is allowed, zero forcing beam shaping feedback information is generated, and is sent to the transmitting end; the transmitting end carries out user scheduling to obtain scheduling users, and transmits user data to the scheduling users. The invention has the advantages of the random beam shaping feedback information and the zero forcing beam shaping feedback information at the same time, reduces the feedback spending of the system and the complexity of the implementation, and improves the system capacity.

Owner:HUAZHONG UNIV OF SCI & TECH

Wireless communication system, base station, terminal and method of generating codebook

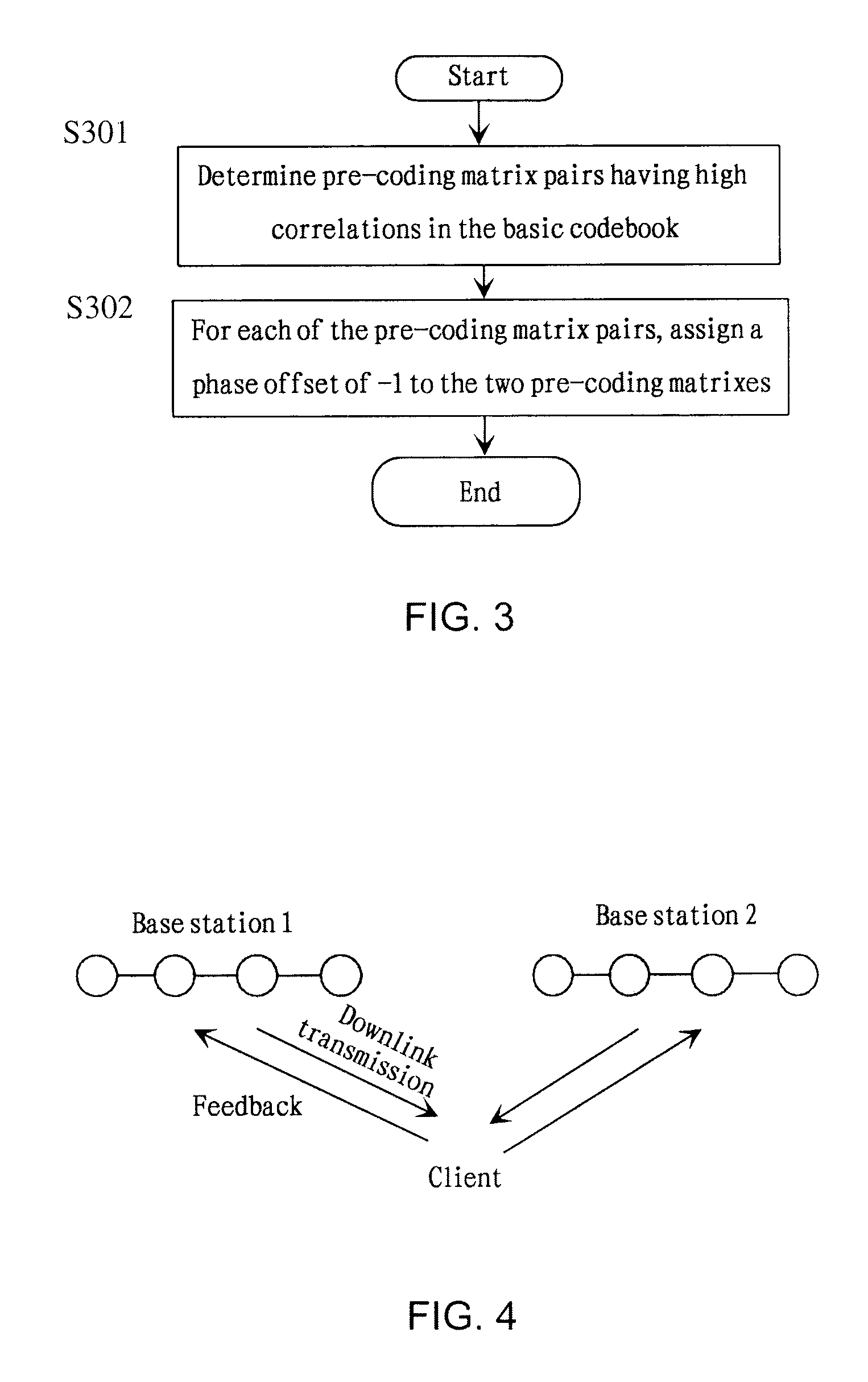

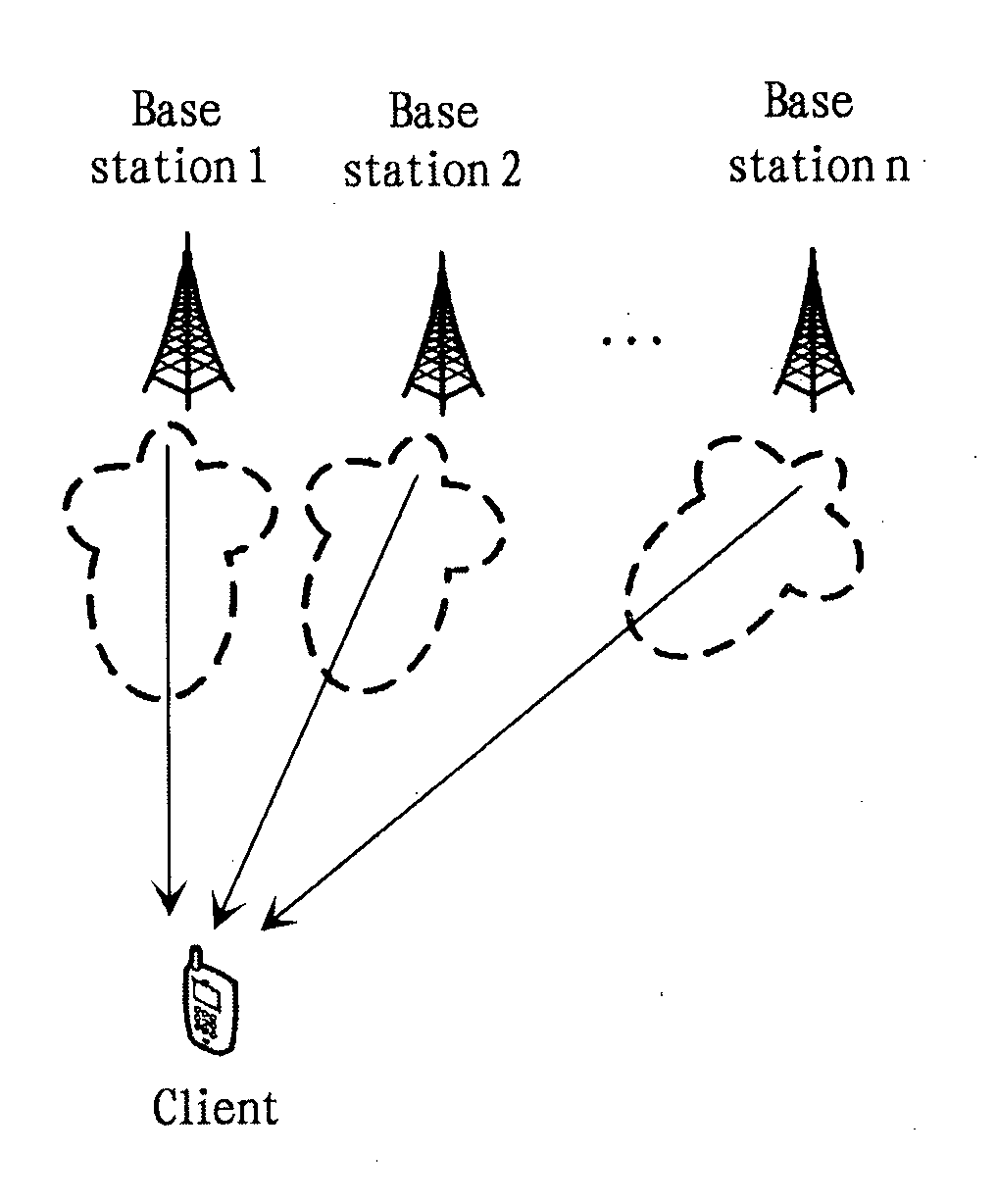

ActiveUS8798195B2Increase in sizeImprove Feedback AccuracySite diversitySpatial transmit diversityCommunications systemPrecoding matrix

The present disclosure provides a method of generating codebook in a wireless communication system with multiple antenna arrays, as well as a wireless communication system, base station and terminal using the codebook for communication. The method comprises steps of: providing a basic codebook which contains multiple pre-coding matrices; and assigning phase offsets to certain pre-coding matrices in the basic codebook to form a codebook with phase offset. The feedback overhead from a client to a base station side is reduced and a good precision of feedback for multi-antenna array is kept by applying the method of generating codebook and using the generated codebook in the wireless communication system, base station and terminal.

Owner:APPLE INC

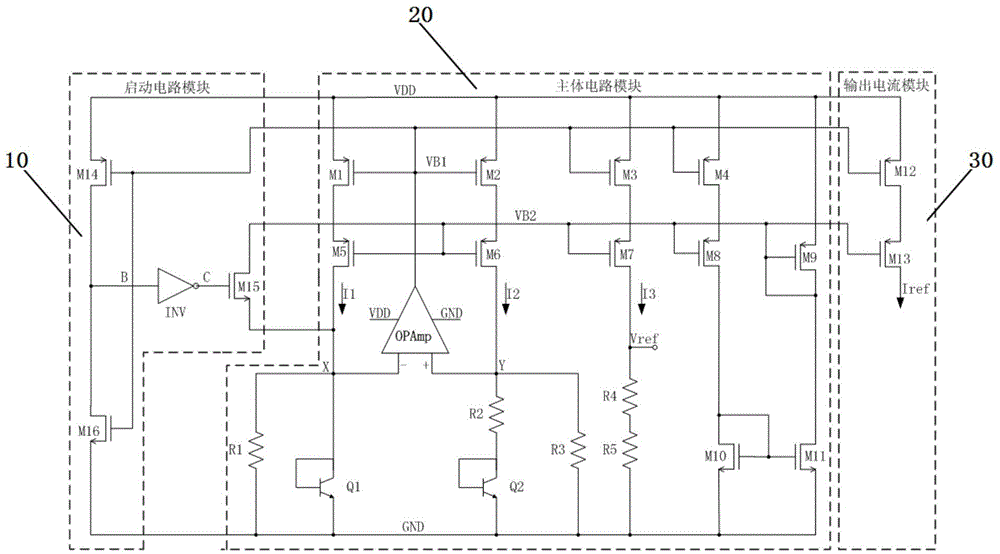

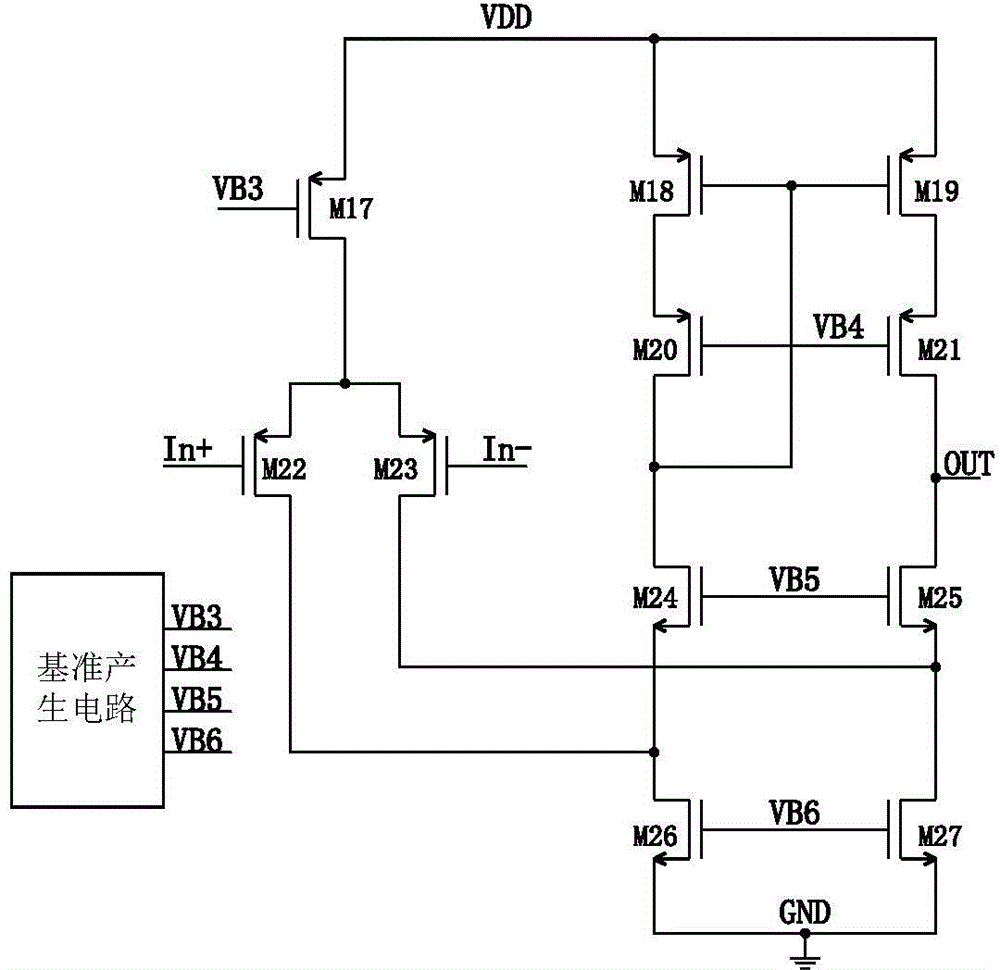

High-precision band-gap reference source

InactiveCN104793690AReduce complexityHigh precisionElectric variable regulationCircuit complexityAudio power amplifier

The invention relates to a high-precision band-gap reference source which comprises a body circuit module, an output current module and a starting circuit module. A band-gap reference source structure with the adjustable output reference voltage is adopted in the body circuit module, and the flexible reference voltage can be output. In addition, feedback precision is improved through an operational amplifier of a folded cascode structure, different temperature characteristics of different resistors are utilized, second-order compensation of the temperature characteristic of the reference voltage source is achieved in a resistor split mode, the circuit complexity is reduced, and the area is saved. In addition, a cascode current mirror is adopted in the output current module to improve the precision of the reference current, and the high-precision reference voltage and reference current are output at the same time.

Owner:XIDIAN UNIV

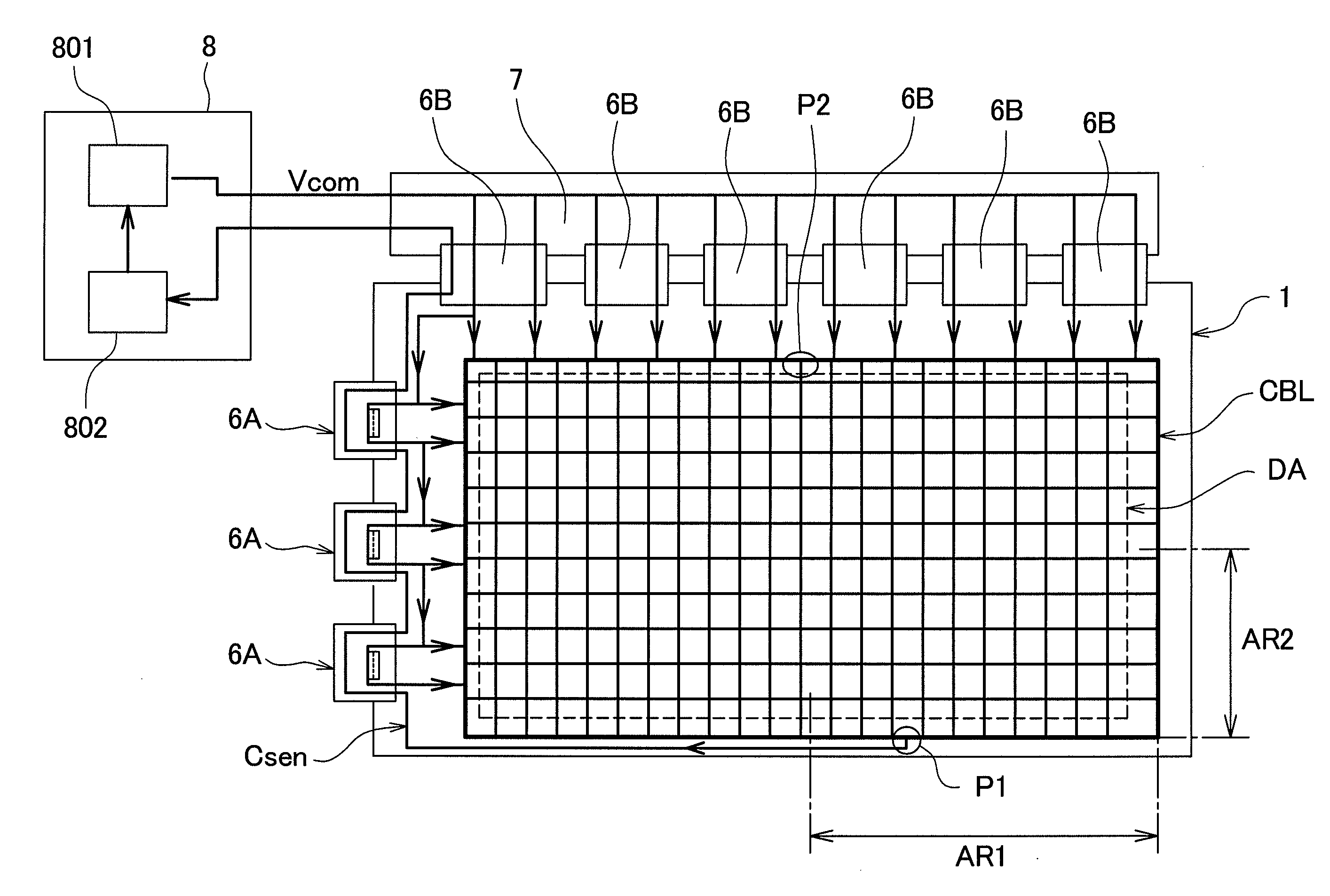

Display Device

InactiveUS20070279355A1Improve accuracyImprove Feedback AccuracyStatic indicating devicesElectricityDisplay device

The present invention enhances accuracy in feedbacking a common potential applied to common electricity supply lines. On a substrate of a display device, a plurality of scanning signal lines, a plurality of video signal lines which stereoscopically intersects the plurality of scanning signal lines by way of an insulation layer, common electricity supply lines arranged in a matrix array which intersect the plurality of scanning signal lines and the plurality of video signal lines by way of the insulation layer, and a common bus line which is arranged around an approximately quadrangular display region to surround the display region annularly and is electrically connected with the common electricity supply lines are formed. The substrate includes a common sensing line which feedbacks a voltage of the common bus line to a common voltage generating circuit, and the common sensing line is connected to a side of the common bus line opposite to a side of the common bus line to which the voltage of the common potential is applied. Further, the common sensing line is configured not to stereoscopically intersect other conductive layer formed on the substrate.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

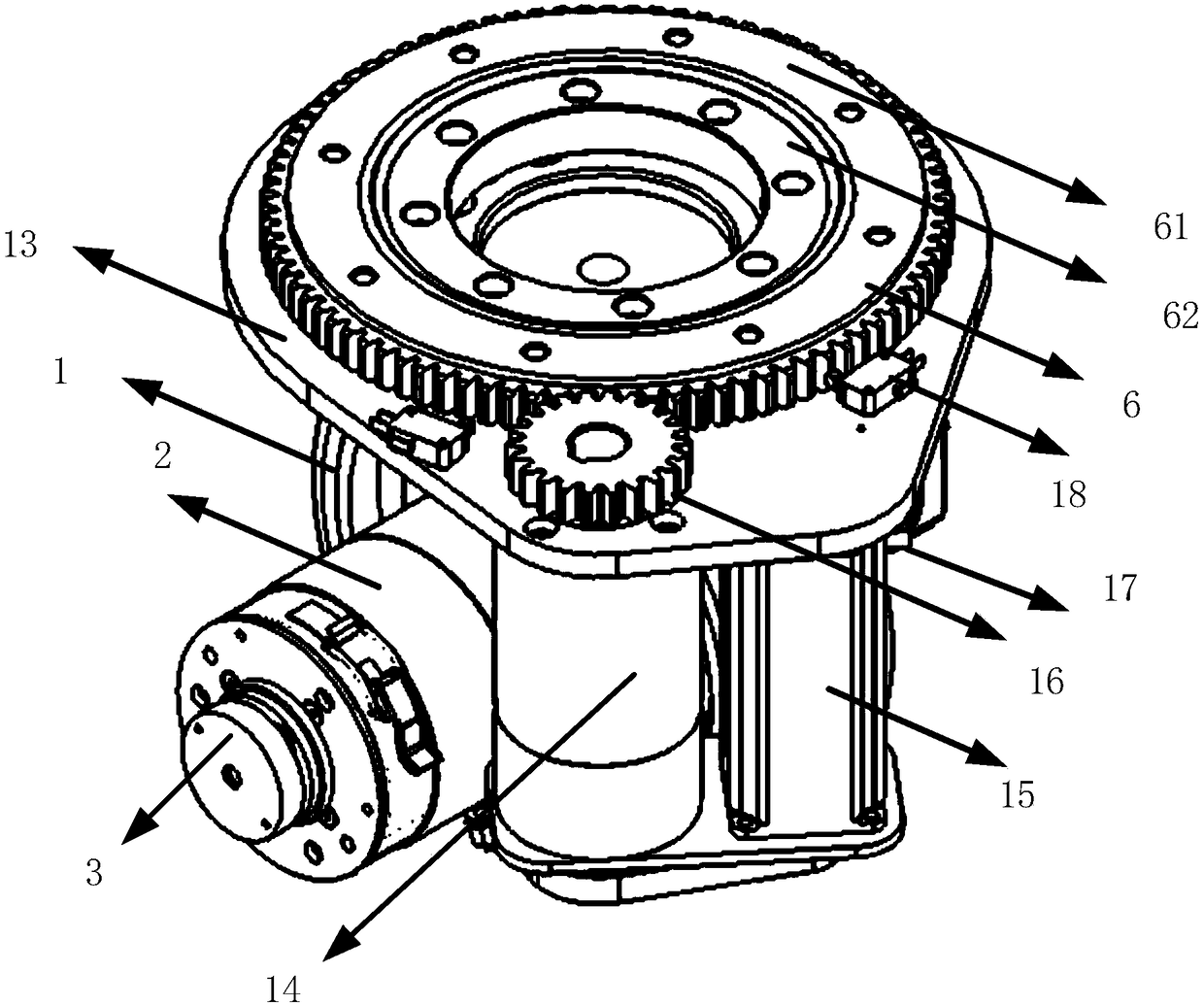

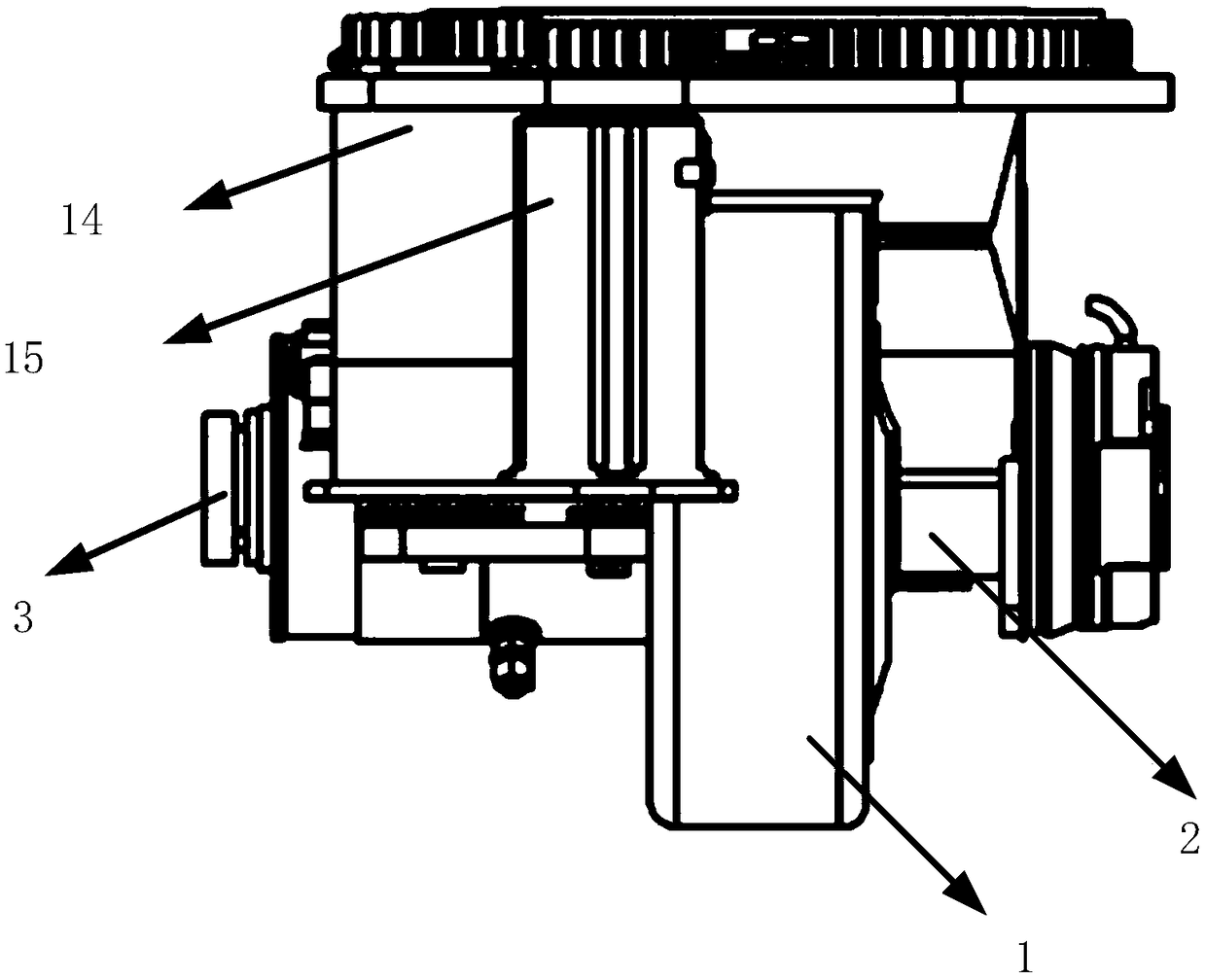

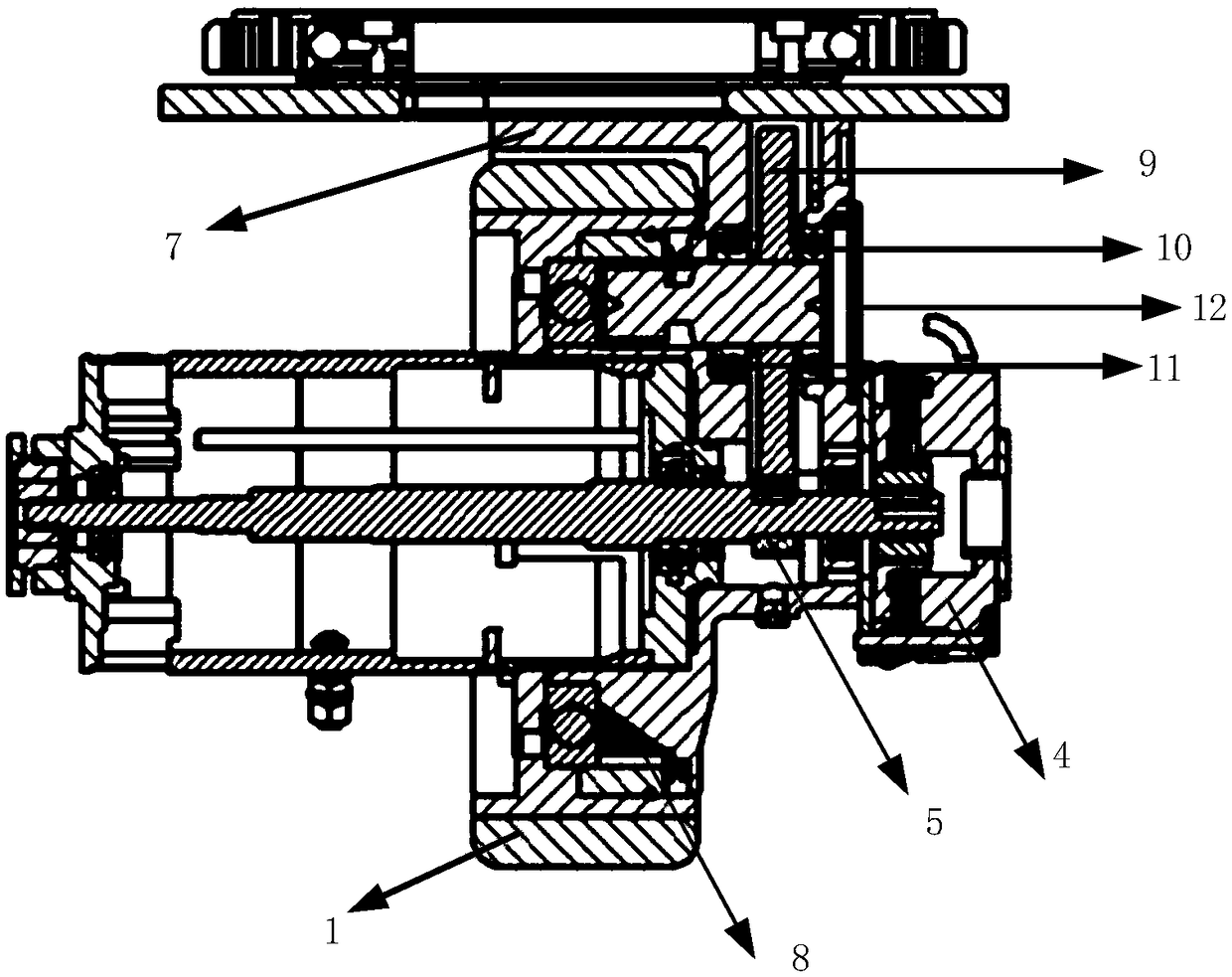

A high-precision AGV driving and steering integrated device and a control method thereof

ActiveCN109050244AImprove driving abilityAchieve speed controlElectrical steeringControl devicesDrive wheelReducer

A high-precision AGV driving and steering integrated device comprises a driving module and an independent steering module, wherein the driving module comprises a driving wheel, a traveling motor and aresolver; the integrated device further comprises a transmission module; and the transmission module comprises a support seat and a two-stage deceleration mechanism, wherein the independent steeringmodule is mounted on the support seat. The AGV driving and steering integrated device comprises a driving wheel, a traveling motor and a resolver. The steering reducer is installed vertically parallelto the steering motor, which greatly reduces the height between the independent steering module and the ground, and reduces the requirement of AGV for road smoothness. the invention also provides a high-precision AGV driving and steering integrated control method. The invention provides the high-precision AGV driving and steering integrated device with good flexibility, simplified structure, goodstability and easy control and a control method thereof.

Owner:浙江同筑科技有限公司

Method and apparatus for acquiring a precoding matrix indicator and a precoding matrix

ActiveUS20120275500A1Reduce Feedback OverheadEasy to FeedbackSpatial transmit diversityAmplitude-modulated carrier systemsDiagonal matrixComputer science

In the field of communication technologies, a method and an apparatus for acquiring a Precoding Matrix Indicator (PMI) and a Precoding Matrix (PM) are provided. The method includes: acquiring a reference PMI and a differential PMI according to a first non-differential codebook and a first diagonal differential codebook, where codewords included in the first diagonal differential codebook form a diagonal matrix. The apparatus includes a PMI acquiring module. Acquiring a reference PMI and a differential PMI according to a non-differential codebook and a diagonal differential codebook can reduce the feedback overhead or improve the feedback precision; and the fact that codewords included in the diagonal differential codebook form a diagonal matrix can maintain amplitude characteristics (for example, a constant modulus characteristic, and a finite character set constraint characteristic) of elements of the non-differential codebook or facilitate power distribution among antennas.

Owner:HUAWEI TECH CO LTD

Method determining pre-coding matrix indication, user equipment, and base station evolution node

ActiveCN106603136AImprove Feedback AccuracyImprove system throughputSpatial transmit diversityTransmitter/receiver shaping networksPartition matrixDiagonal matrix

The invention relates to a method determining a pre-coding matrix indication, user equipment UE, and a base station eNB and a system; the method comprises the following steps: receiving a reference signal sent by the base station; selecting a pre-coding matrix from a codebook according to the reference signal, wherein the codebook comprises a pre-coding matrix, the pre-coding matrix W refers to the product of two matrixes W1 and W2, the W1 refers to a partitioning diagonal matrix, and each partitioning matrix refers to the kronecker product of a matrix Ai and a matrix Bi; sending a pre-coding matrix indication PMI to the base station, wherein the PMI is matched with the selected pre-coding matrix, and the base station can obtain the pre-coding matrix according to the PMI. According to the pre-coding matrix formed by the matrix Ai and matrix Bi and supporting vertical direction and horizontal direction quantification, the method and system can fully utilize the degree of freedom in the horizontal direction and vertical direction, thus greatly improving channel state information feedback precision.

Owner:HUAWEI TECH CO LTD

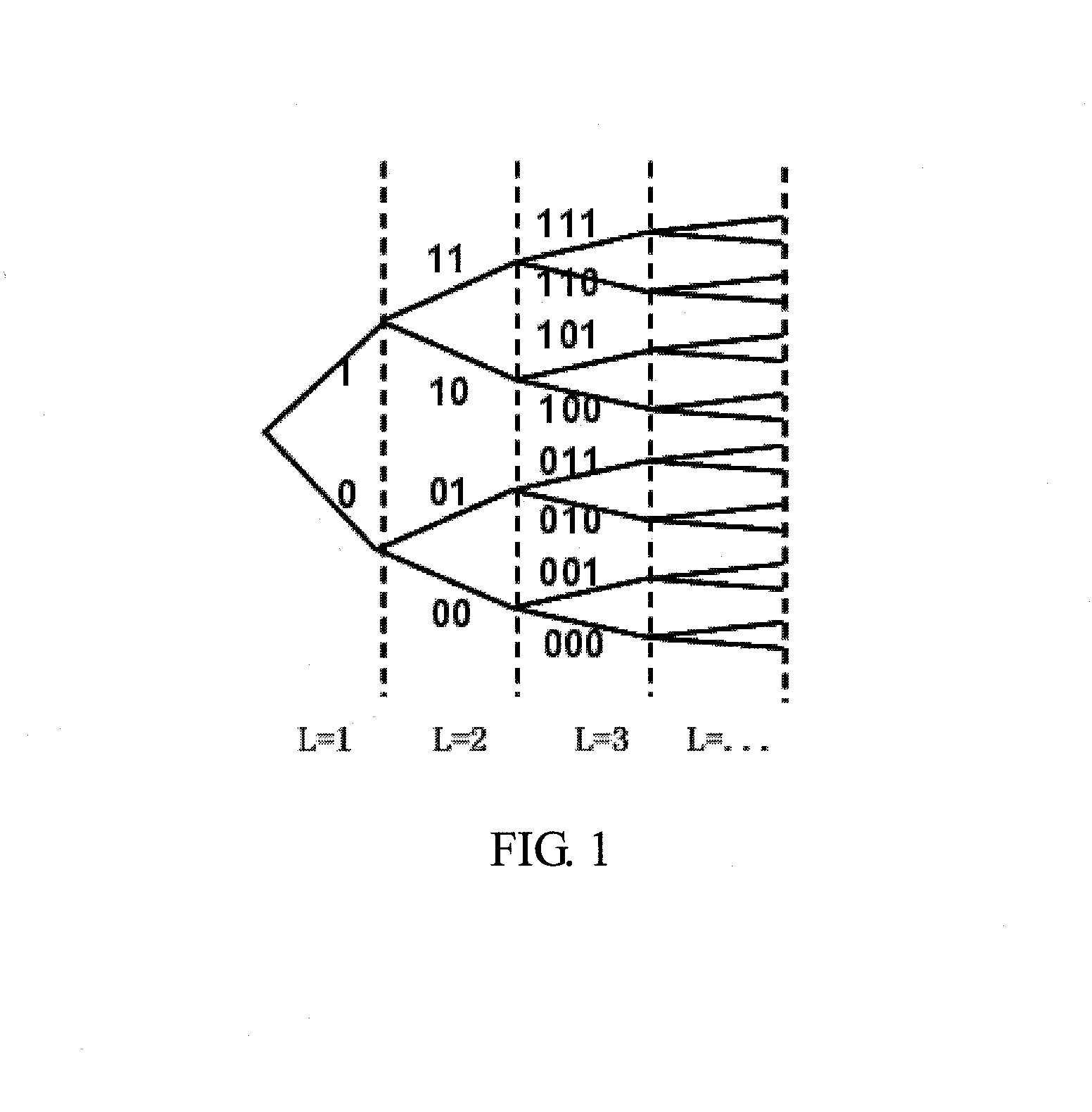

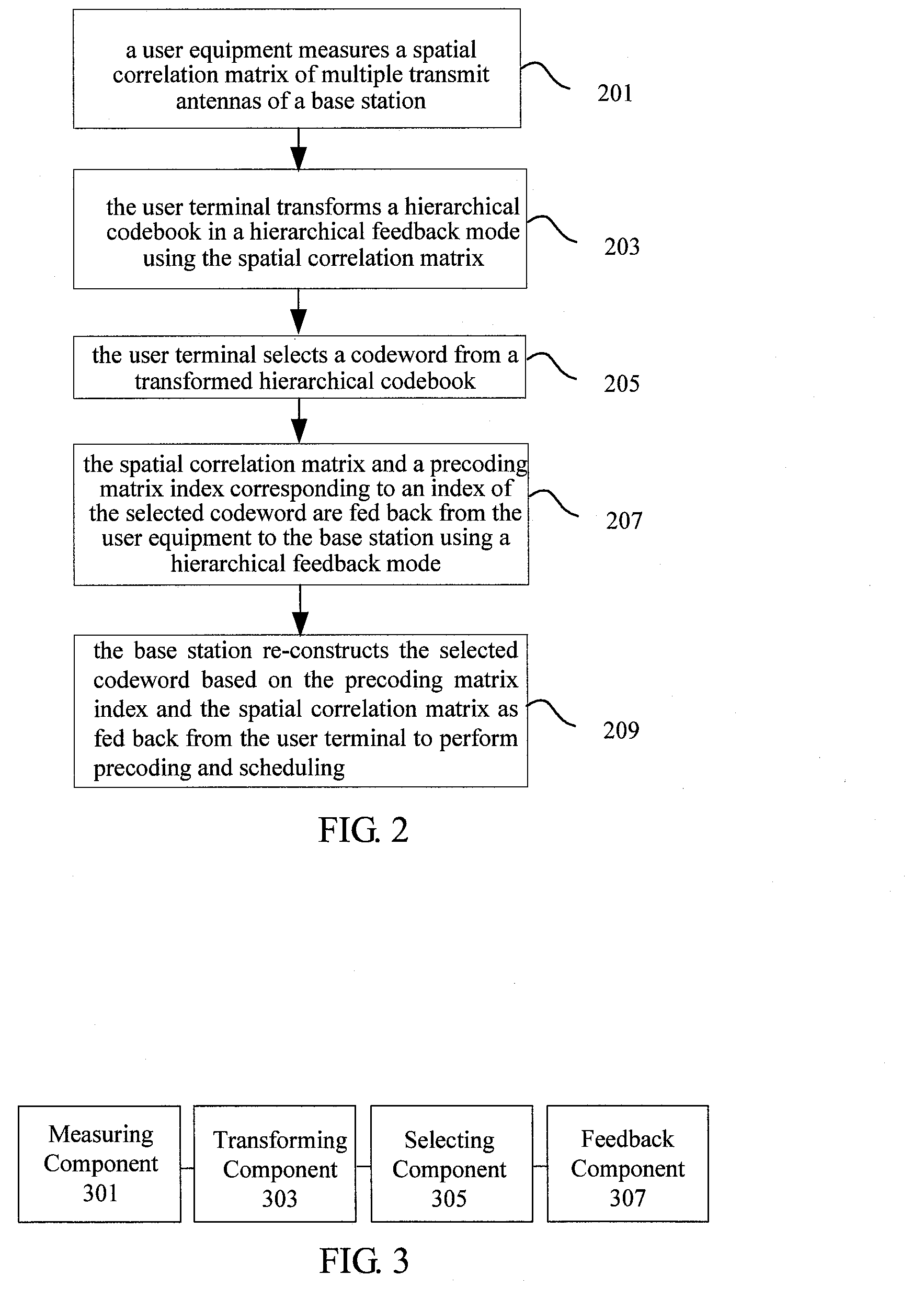

Method and device for performing hierarchy feedback with space information-assisted

InactiveUS20130088981A1Improve Feedback AccuracyError preventionTransmission systemsCode bookAlgorithm

A method for performing hierarchical feedback with space information assisted in a mobile communication system is provided. At the user terminal, the method comprises: measuring a space correlated matrix of multiple transmit antennas of a base station; converting a hierarchical code book in the mode of hierarchical feedback by using the spatial correlation matrix; selecting the code word from the converted hierarchical code book; and feedbacking a pre-coding matrix index corresponding to the index of the selected code word and the space correlated correlation matrix from the user terminal to the base station by using the mode of hierarchical feedback.

Owner:ALCATEL LUCENT SAS

Reference signal measurement method and device

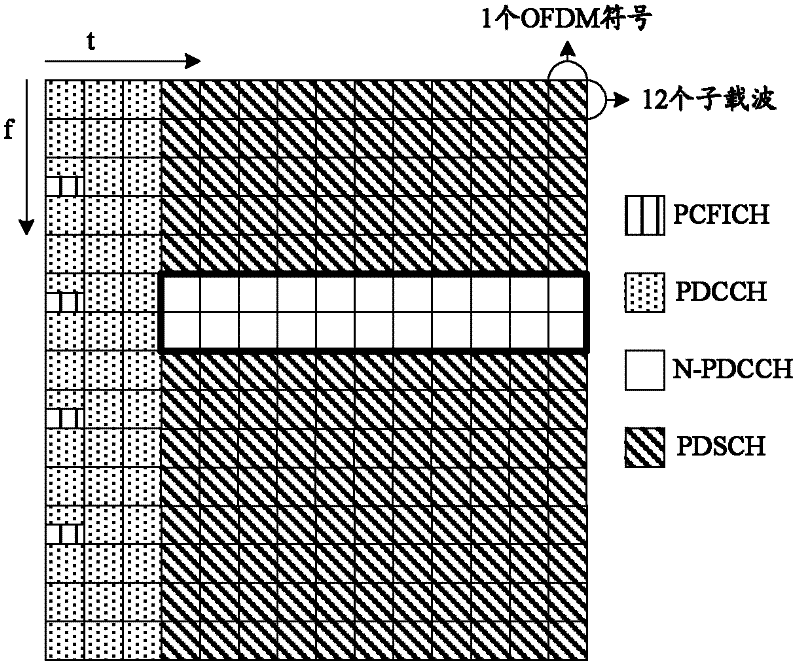

ActiveCN108023717AIncrease data transfer rateReduce overheadSignal allocationRadio transmissionCarrier signalVIT signals

The invention relates to a channel measurement method. The channel measurement method is characterized by comprising the steps that a base station sends first control information to UE, wherein the first control information is used for indicating a measurement reference signal of the UE on one carrier, and the first control information comprises at least one first measurement configuration set forindicating the UE to measure the measurement reference signal according to the at least one first measurement configuration set; the base station sends the measurement reference signal to the UE; andthe base station sends second control information to the UE, wherein the second control information comprises at least one second measurement configuration set for indicating the UE to report a measurement result according to the at least one second measurement configuration set and the measurement reference signal, and the at least one second measurement configuration set is different from one first measurement configuration set.

Owner:HUAWEI TECH CO LTD

Communication control server, base station, terminal and joint service system and method

InactiveCN102244567AImprove Feedback AccuracyImprove performanceError prevention/detection by using return channelChannel estimationChannel state informationComputer terminal

The invention aims to provide a communication control server, a terminal and a joint service system and method capable of improving the feedback precision to improve the system performance under the limited capacity of a feedback channel. The communication control server is provided with a network interface, a storage unit and a channel state information restoring part, wherein the storage unit stores a cluster information table and a channel state information table; the cluster information table keeps the joint codebook shared by the base stations in the cluster; the joint codebook keeps the channel state information distribution and the information identifier for determining the channel state information; and the channel state information restoring part obtains the feedback message of the terminal in the cluster from the base station through the network interface, extracts the channel state information corresponding to the information identifier included in the feedback message, and updates the channel state information table stored in the storage unit by use of the extracted channel state information, wherein the feedback message comprises the information identifier corresponding to the channel state information of the terminal.

Owner:TSINGHUA UNIV +1

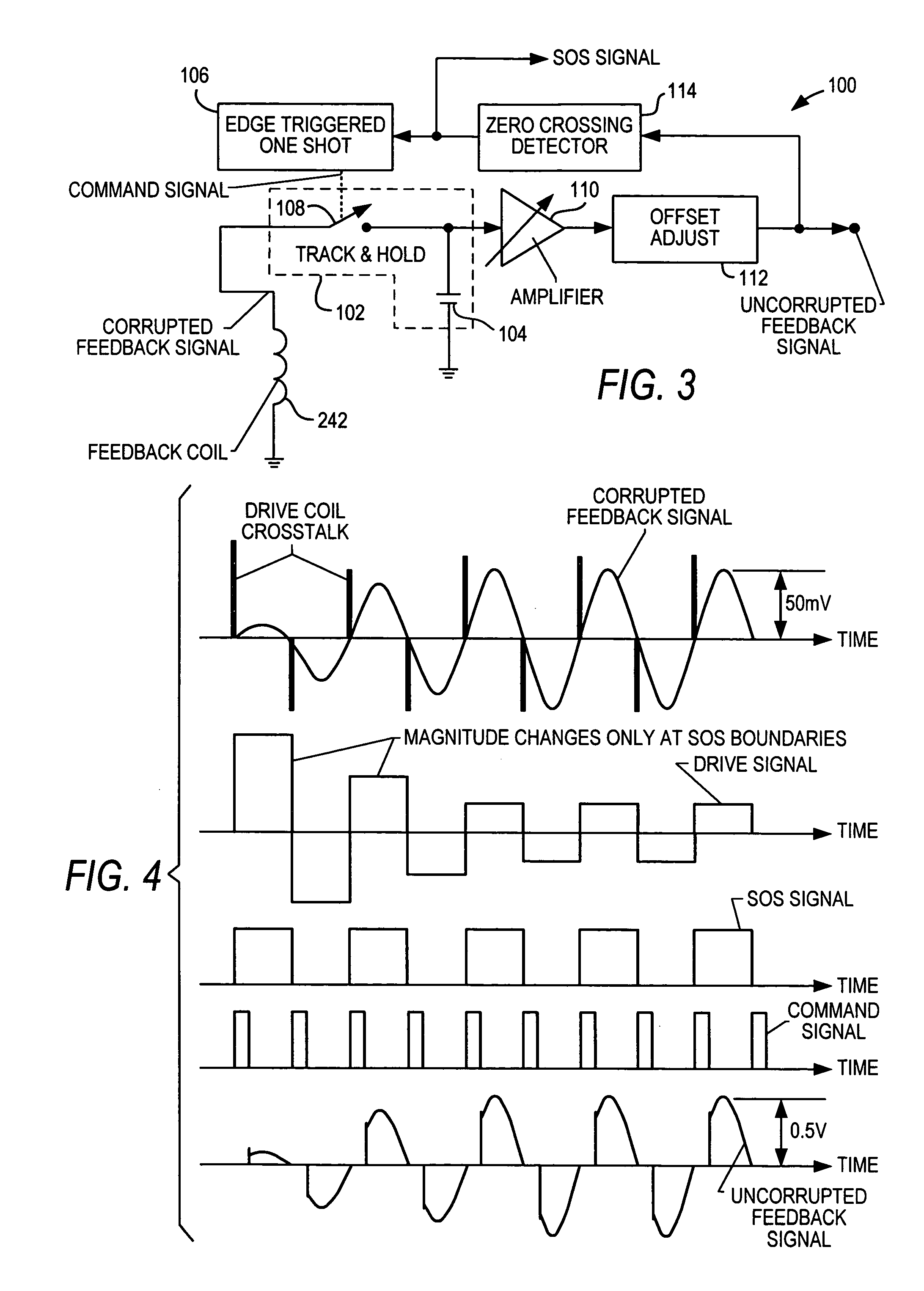

Motor drive circuit with reduced coil crosstalk in a feedback signal indicative of mirror motion in light scanning arrangements

ActiveUS7126734B1Improve Feedback AccuracyUnnecessary circuitSensing record carriersOptical elementsMotor driveSquare waveform

Crosstalk between a drive coil and a feedback coil is eliminated by a motor drive circuit operative for generating the drive coil as a square wave, and by removing the crosstalk which occurs at zero transitions of a feedback signal. The drive coil is used to oscillate a scan mirror employed in an image projection arrangement or an electro-optical reader.

Owner:SYMBOL TECH LLC

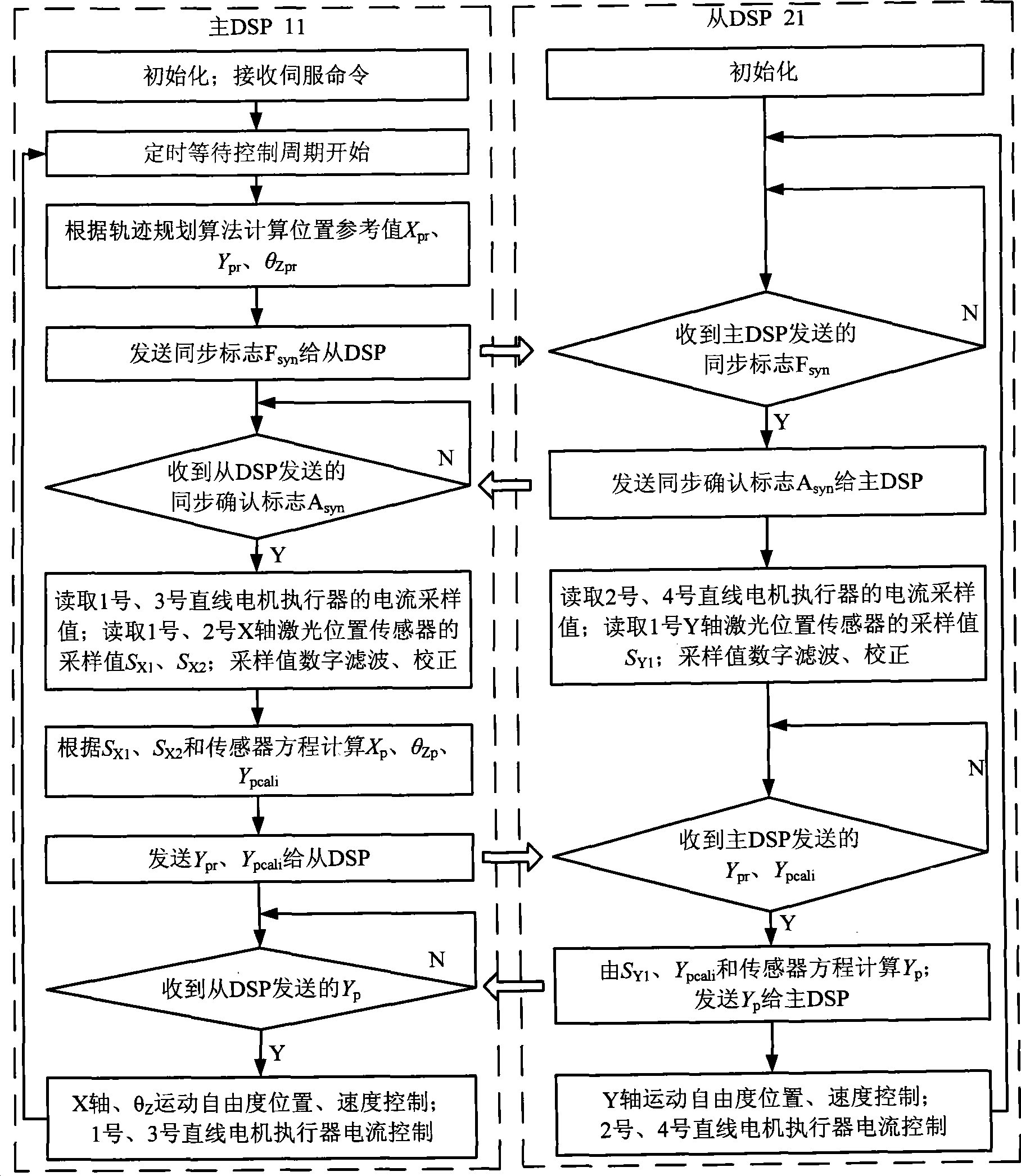

Three freedom degree plane motor servo controller based on dual-DSP

InactiveCN101510749ALow costFulfill control requirementsElectronic commutation motor controlAC motor controlFull bridgePwm signals

The invention relates to a servo controller of a dual-DSP-based 3-DOF (degrees of freedom) planar motor. The servo controller comprises a master control unit and a slave control unit, which respectively comprise a DSP chip, an optical coupling driving isolation module, a full-bridge power driving module and a position sensor module. The DSP chip of the master control unit transmits a PWM signal, controls the full-bridge power driving module to output 6-phase planar motor driving current after optical coupling isolation and collects the X-coordinate position of the two-path planar motor by a laser position sensor; the DSP chip of the slave control unit transmits a PWM signal, controls the full-bridge power driving module to output 6-phase planar motor driving current after optical coupling isolation and collects the X-coordinate position of the one-path planar motor by the laser position sensor; the DSP chips of the main control unit and the slave control unit exchange synchronous control signals in real time through a CAN bus and use a 3-DOF synchronous control strategy to control the planar motor to realize fast and accurate positioning of the degree of freedom on X coordinate, Y coordinate and Theta Z.

Owner:SOUTHEAST UNIV

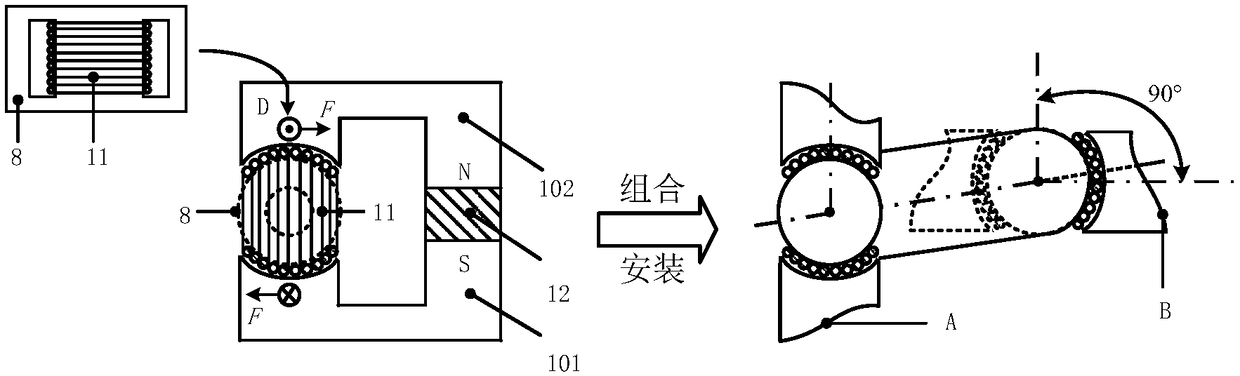

Electromagnetic damping precession force feedback operating handle for vascular intervention

An electromagnetic damping precession force feedback operating handle for vascular intervention is characterized in that the operating handle comprises an operating lever (8), and a frame (22), and also includes any one or more mechanisms of a push-pull force feedback mechanism , a rotational torque feedback mechanism, a rotational movement measuring mechanism, and non-contact reset mechanism which are mounted on the operating lever (8); the operating handle (8) is supported on the frame (22) by a left linear bearing (9), a right linear bearing (17), and the operating lever (8) is made of ferromagnetic material. The operating handle can realize the control command issuance of push-pull, rotation and clamping as well as the resistance feedback, adopts the non-contact design except the linear bearing support, and has the characteristics of strong function, light operation and compact structure.

Owner:SHANGHAI OPERATION ROBOT CO LTD

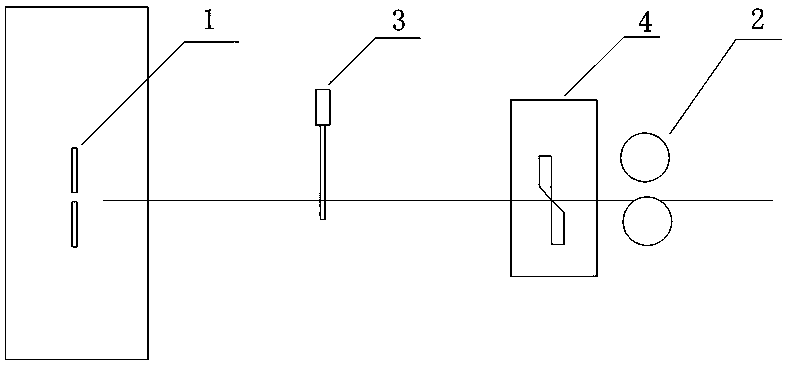

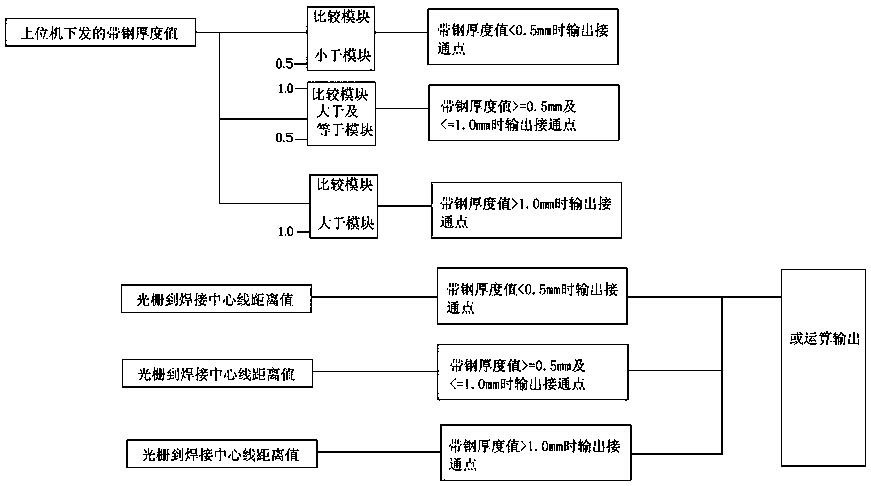

Location control method for strip head of thin strip steel

ActiveCN110315245AInertial Force ReleaseImprove Feedback AccuracyWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlGrating

The invention discloses a location control method for a strip head of thin strip steel, and belongs to the technical field of automatic control. The method comprises the following steps: 1) a weldingmachine, a pinch roll device and an optical grating detector are installed, and the pinch roll device comprises an upper press roll, a lower roll, a motor, a motor tail coder, a power cylinder and a lower roll coder; 2) three thickness specification interval sections of the strip steel are divided and input into a main-line PLC, the upper press roll is controlled to fall off by the main-line PLC until the strip steel is clamped between the upper press roll and the lower roll by virtue of a set clamping force separately; and 3) the running speed of the motor is calculated through the motor tailcoder, the strip steel is conveyed at a speed V1, when the optical grating detector detects the strip steel, the strip steel is conveyed at a speed V2, and meanwhile, the lower roll coder installed on the lower roll starts to calculate the length L of the strip steel passing through the optical grating detector, and location for the strip head is completed. According to the method, the distance error of the strip head at a welding stopping position is reduced, so that the compensation accuracy is increased; and the method is completely feasible, and capable of achieving a good effect.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

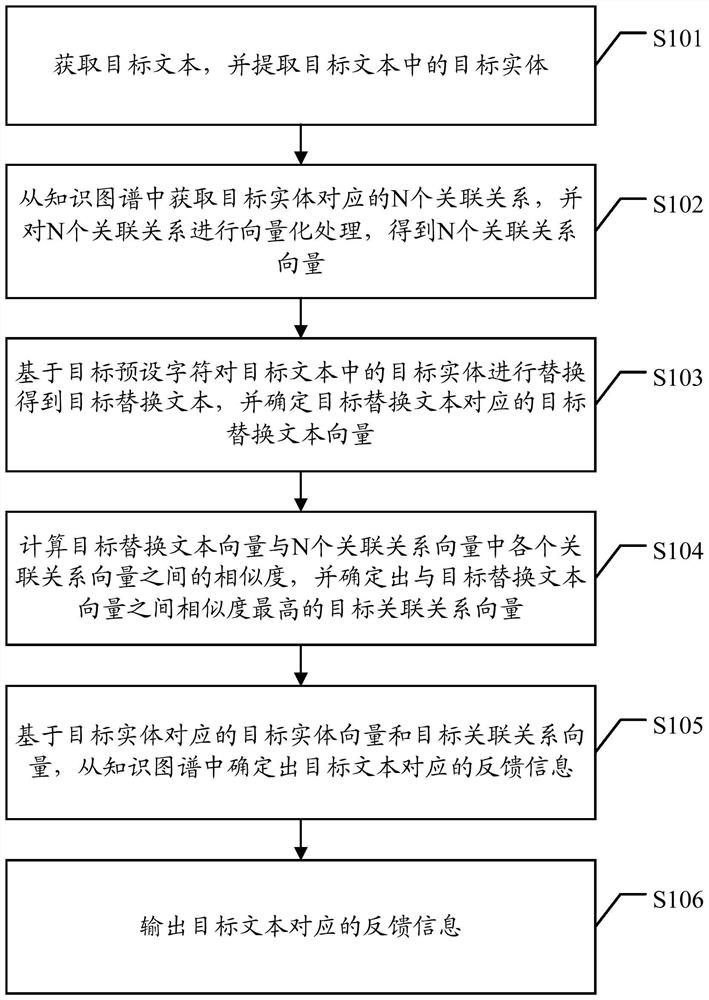

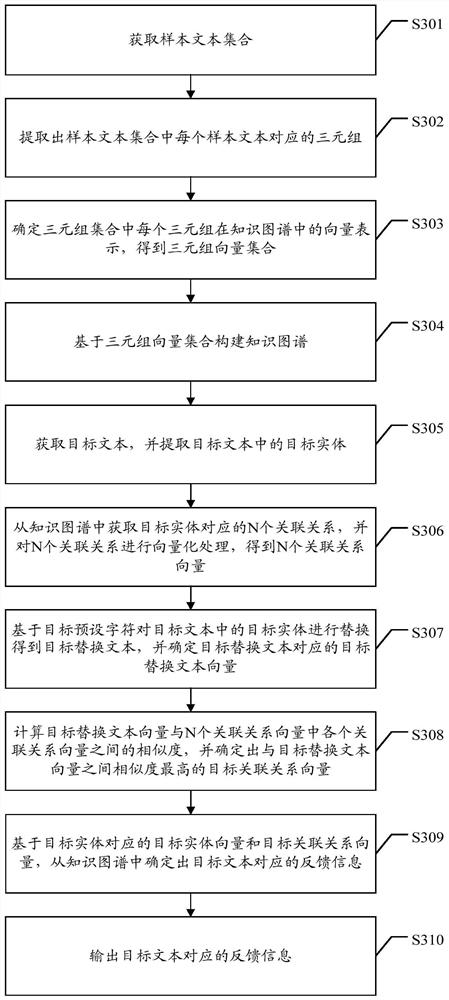

Information feedback method and device based on knowledge graph, terminal and storage medium

PendingCN112784066AImprove Feedback AccuracySpecial data processing applicationsSemantic tool creationTheoretical computer scienceKnowledge graph

The embodiment of the invention discloses an information feedback method and device based on a knowledge graph, a terminal and a storage medium. The method comprises the steps: extracting a target entity in a target text, obtaining N incidence relation vectors corresponding to the target entity based on the knowledge graph, and replacing the target entity in the target text based on a target preset character, obtaining a target replacement text, determining a target replacement text vector corresponding to the target replacement text, determining a target association relationship vector with the highest similarity with the target replacement text vector in the N association relationship vectors, and obtaining a target entity based on a target entity vector corresponding to the target entity and the target association relationship vector, and determining feedback information corresponding to the target text from the knowledge graph, and outputting the feedback information. By implementing the method, the knowledge graph can be constructed based on the vectors, and the corresponding feedback information is queried in the knowledge graph based on the correlation between the vectors, so that the information feedback accuracy based on the knowledge graph is improved.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

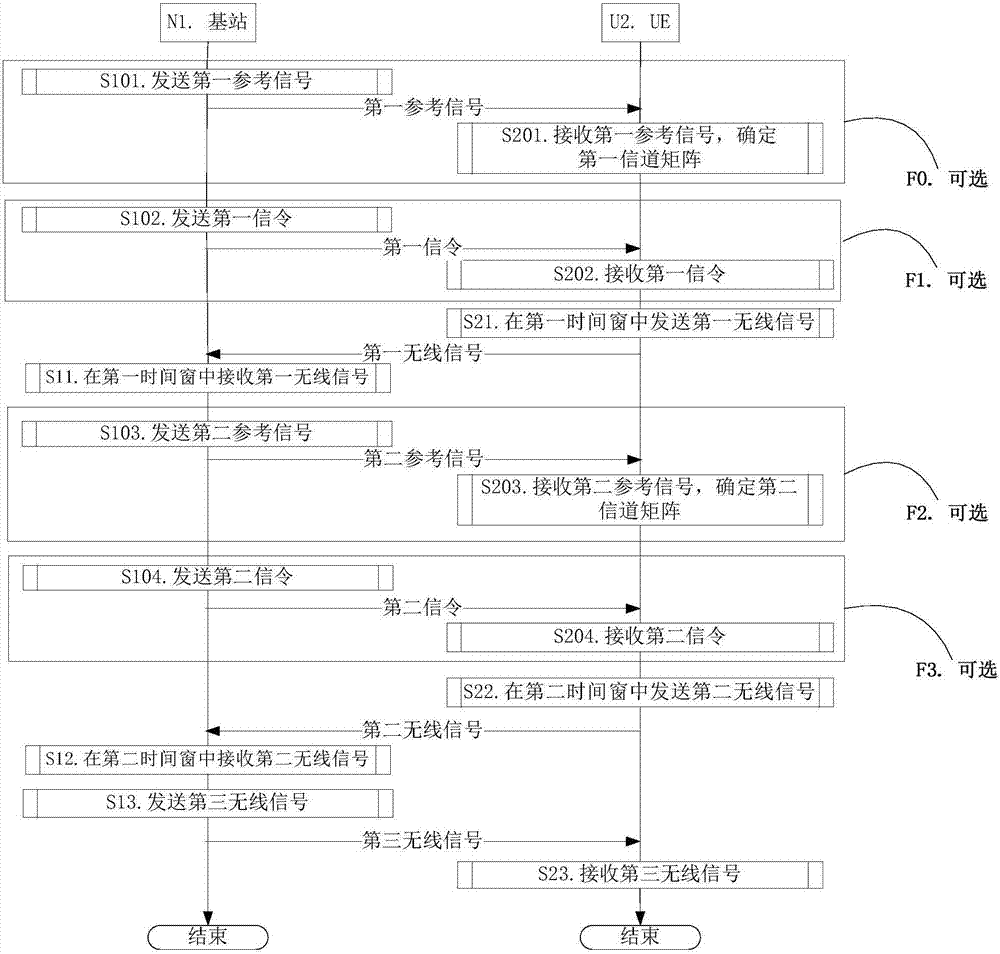

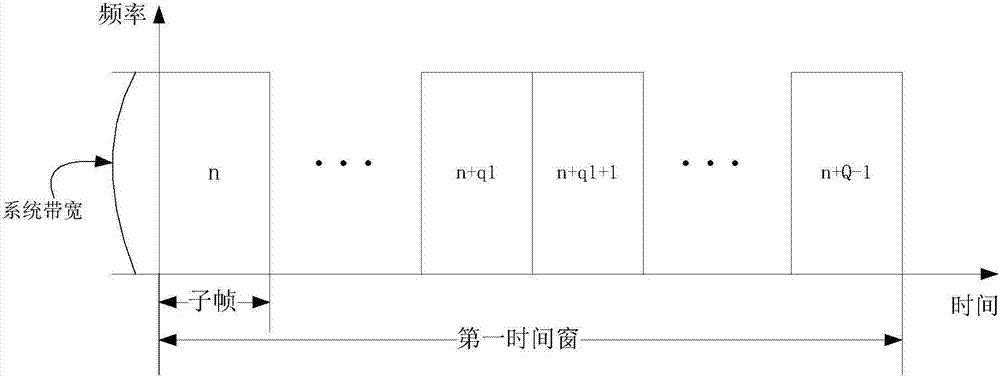

Method and device for wireless communication

ActiveCN107529691AGuaranteed Feedback AccuracyReduce Feedback OverheadSpatial transmit diversityUser equipmentComputer science

The invention provides a method and a device for wireless communication. The method comprises the following steps: transmitting a first wireless signal by UE (User Equipment) in a first time window; and transmitting a second wireless signal in a second time window, wherein the first wireless signal contains first information, and the second wireless signal contains second information; the first information and the second information are used for determining M merged vectors; the first information is used for determining M vector groups; the second information is used for determining M coefficient groups; the M vector groups correspond to the M coefficient groups one by one; and the merged vectors are generated from the vector groups and the corresponding coefficient groups. According to the method disclosed by the invention, CSI (Customer Satisfaction Index) feedback overland is reduced on premise of ensuring the CSI feedback precision.

Owner:SHANGHAI LANGBO COMM TECH CO LTD

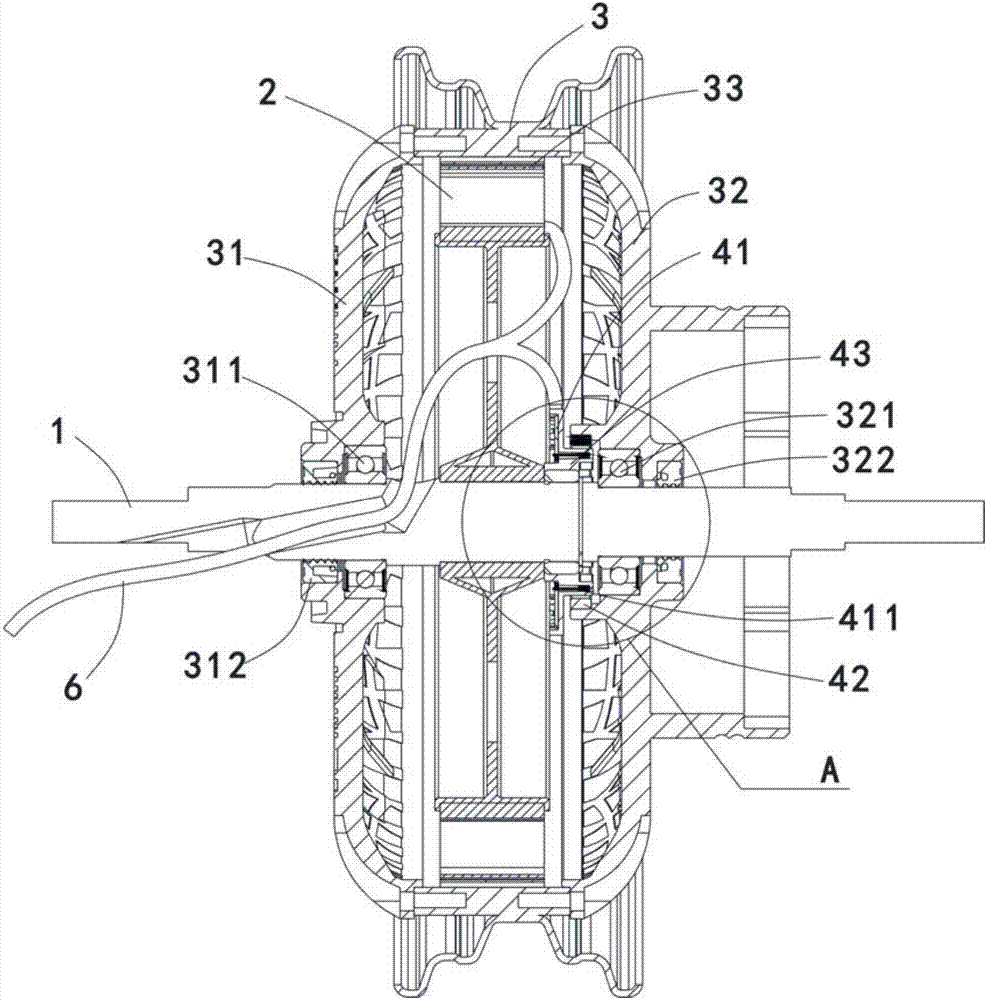

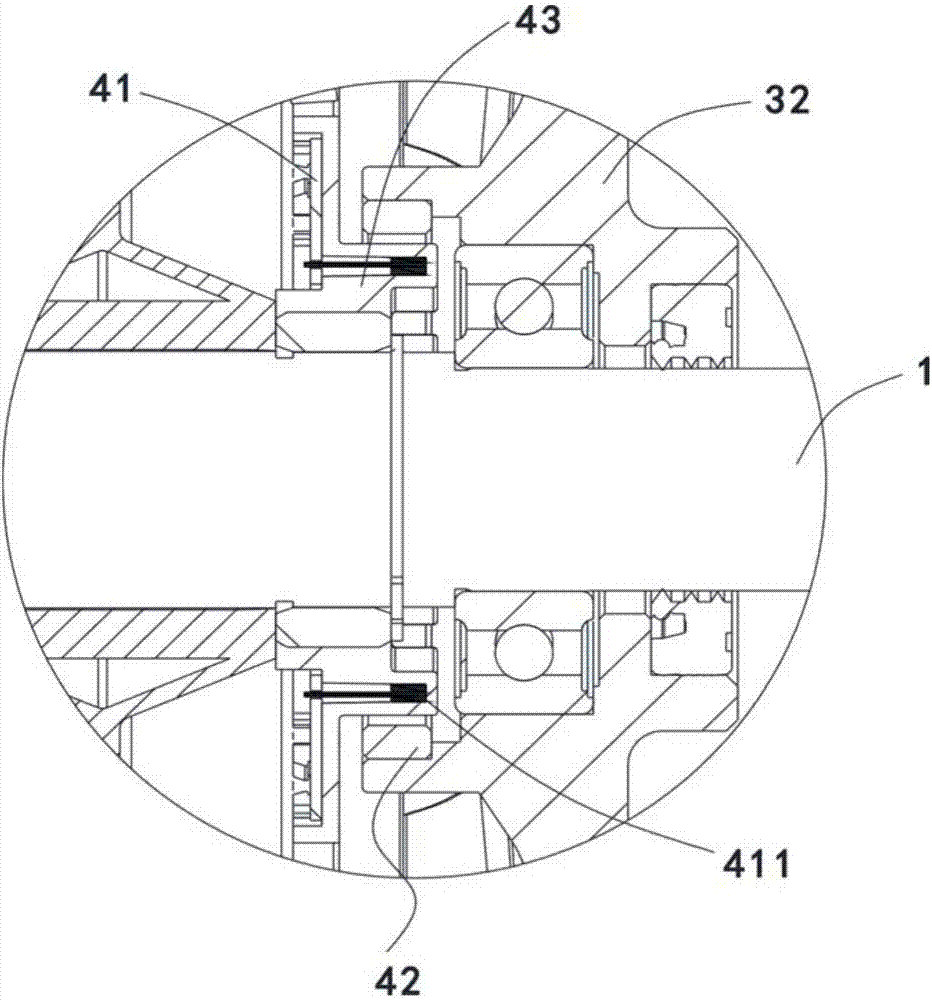

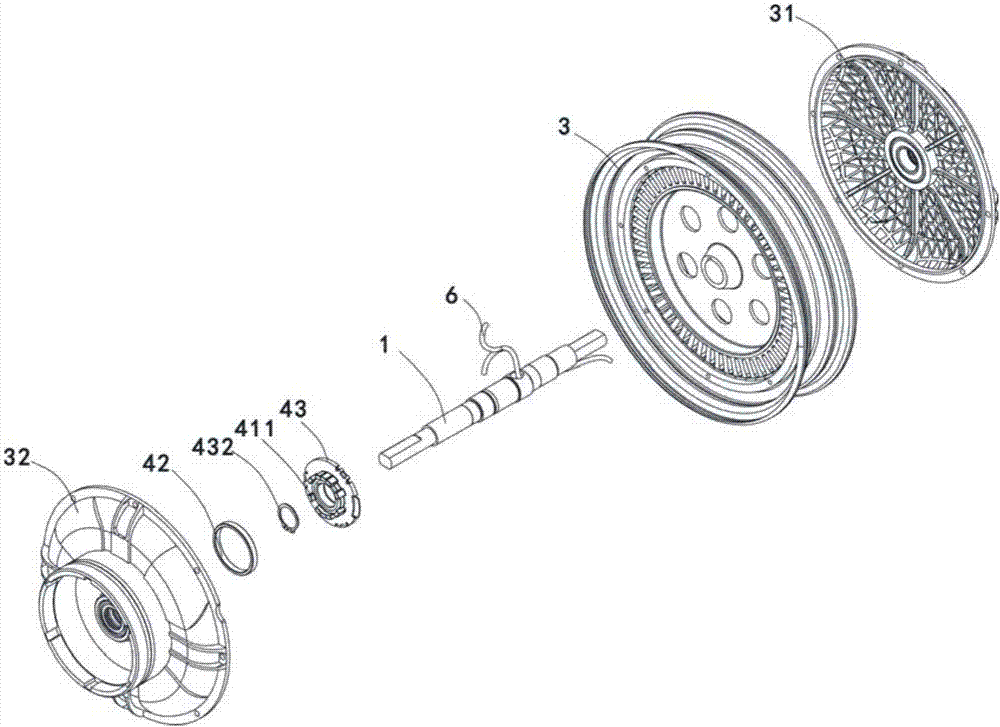

Wheel hub motor and position signal processing method thereof

ActiveCN107294337AImprove operational efficiencyLow costAssociation with control/drive circuitsElectronic commutatorsLocation detectionEngineering

The invention discloses a wheel hub motor. The wheel hub motor comprises a motor shaft, a stator, a rotor and a position detection device; the position detection device comprises a PCB (printed circuit board) and a magnetic ring; the PCB is provided with a plurality of magnetic induction components; when the magnetic ring is stationary or rotating, the magnetic induction components can sense the change of the magnetic flux of the magnetic ring; the rotor is provided with a left end cover and a right end cover which is used for installing a brake assembly; and the position detection device is arranged inside the right end cover. The invention also discloses an externally-arranged wheel hub motor; the rotor of the external wheel hub motor is provided with a left end cover and a right end cover which is used for installing a brake assembly; a motor shaft at the external side of the left end cover is provided with a housing; and a position detection device is arranged in the housing. The invention also discloses a position signal processing method of the wheel hub motor. The wheel hub motor of the invention has the advantages of simple structure, simple and reliable production process, reliable vibration resistance, low performance requirements for a controller and high accuracy. According to the wheel hub motor, position feedback avoids a heat source, mechanical angle and electrical angle output selections are provided, and the requirements of different control interfaces can be satisfied.

Owner:NINGBO BRANCH OF JIANGSU YADEA TECHNICAL DEV CO LTD +1

Method and device of guiding user with language context

InactiveCN106775649AImprove interactivityImprove timely feedbackExecution for user interfacesInput/output processes for data processingOperational costsUser input

The invention discloses a method and device of guiding a user with language context. The method includes the steps that guide language and options are displayed to the user, and the option selected by the user is received; the corresponding session context is connected in according to the option selected by the user; according to request information selected by the user in the session context, conversation information corresponding to the request information is displayed to the user; conversation information input by the user is received, corresponding response is given, user interactivity, in-time feedback performance and feedback accuracy of the application software guiding mode are improved, the user is researched in advance, all user mood types are combed as many as possible, corresponding reply and options are preset, user requirement is locked after multiple interaction, accurate information or service is provided, and the process substantially saves operation cost and effectively enhances the operation effect.

Owner:深圳市保臻社区服务科技有限公司

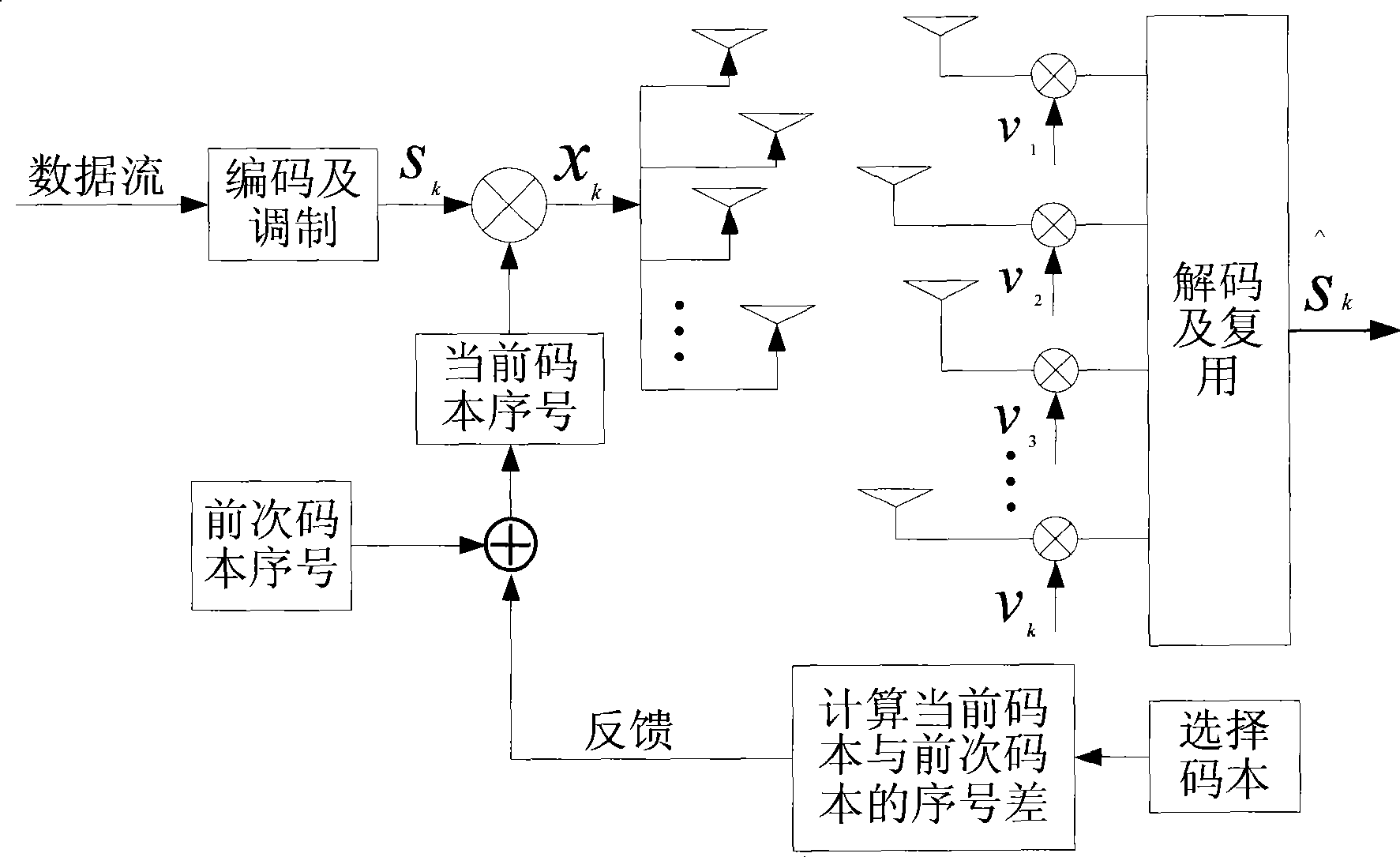

Method for transmitting signals of multi-input multi-output system and codebook feedback method

ActiveCN101374003AImprove Feedback AccuracyReduce Feedback OverheadSpatial transmit diversityError prevention/detection by diversity receptionMulti inputCurrent channel

The invention provides a signal transmission method and a codebook feedback method in a multiple-input multiple-output (MIMO) system. The codebook feedback method comprises the following steps: after receiving a signal transmitted from a transmitting end, a receiving end calculates the current codebook matching with the current channel estimation result, and feeds the codebook information back to the transmitting end; wherein the codebook information is the difference of the serial number of the current codebook and the previous codebook. The signal transmission method comprises the following steps: after receiving a signal transmitted from a transmitting end, a receiving end feeds the difference of the serial number of the current codebook and the previous codebook back to the transmitting end; and the transmitting end obtains the serial number of the current codebook according to the serial number of previous codebook and the difference, weighs the signal according to the codebook corresponding to the serial number of the current codebook, and transmits to the receiving end. The technical proposal provided in the invention can remarkably reduce feedback cost of a system under the same codebook design accuracy, or design more codebooks under the same feedback cost of the system, thereby remarkably improving the channel feedback accuracy.

Owner:盐城东方汽车广场投资发展有限公司

Channel information feedback method and equipment thereof

ActiveCN102447535AReduce Feedback OverheadImprove Feedback AccuracyError prevention/detection by diversity receptionUser equipmentInformation feedback

The invention discloses a channel information feedback method comprising the following steps: receiving a channel information feedback indication signal from a base station and indicating user equipment to feed back one or a plurality of channel information sets in N channel information sets to the base station by the channel information feedback indication signal, wherein N is equal to the rank of a channel matrix, and each channel information set comprises a plurality of channel information relevant to the number of various data flow layers which can be used at the position of the user equipment; and feeding back one or a plurality of channel information sets in the N channel information sets to the base station based on the channel information feedback indication signal. According to the method disclosed by the invention, the feedback expense relevant to the transmission of the higher rank of the channel matrix can be lowered, or the feedback accuracy is enhanced by utilizing a feedback channel of an uplink link more completely.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

Wireless communication system, base station, terminal and method of generating codebook

ActiveUS20130010895A1Increase in sizeImprove Feedback AccuracySite diversitySecret communicationCommunications systemPrecoding matrix

The present disclosure provides a method of generating codebook in a wireless communication system with multiple antenna arrays, as well as a wireless communication system, base station and terminal using the codebook for communication. The method comprises steps of: providing a basic codebook which cotains multiple pre-coding matrices; and assigning phase offsets to certain pre-coding matrices in the basic codebook to form a codebook with phase offset. The feedback overhead from a client to a base station side is reduced and a good precision of feedback for multi-antenna array is kept by applying the method of generating codebook and using the generated codebook in the wireless communication system, base station and terminal.

Owner:APPLE INC

Methods applied to user equipment and base station for wireless communication, and devices

ActiveCN109150412AHigh precisionReduce Feedback OverheadSpatial transmit diversitySignal allocationWireless communication systemsUser equipment

The present invention discloses methods applied to user equipment and a base station for wireless communication, and devices. According to the methods and devices, the user equipment receives first reference signals and then transmits first information, wherein the first information is used to determine a first integer; if the first integer is equal to 1, first channel information and second channel information are transmitted, otherwise, third channel information is transmitted; if the first integer is greater than 0, measurement for the first reference signals is used to determine the firstinteger; the second channel information is used to determine L1 first class vectors; the first channel information is used to determine the L1; the third channel information is used to determine L2 first class vectors; the L1 and the L2 are respectively positive integers; and the L1 is not greater than the L2. With the above methods adopted, a user is allowed to optimize a feedback mechanism according to an actual channel state on the basis of different feedback content and feedback overhead, and therefore, the accuracy of feedback can be improved, and the overhead of the feedback can be reduced.

Owner:SHANGHAI LANGBO COMM TECH CO LTD

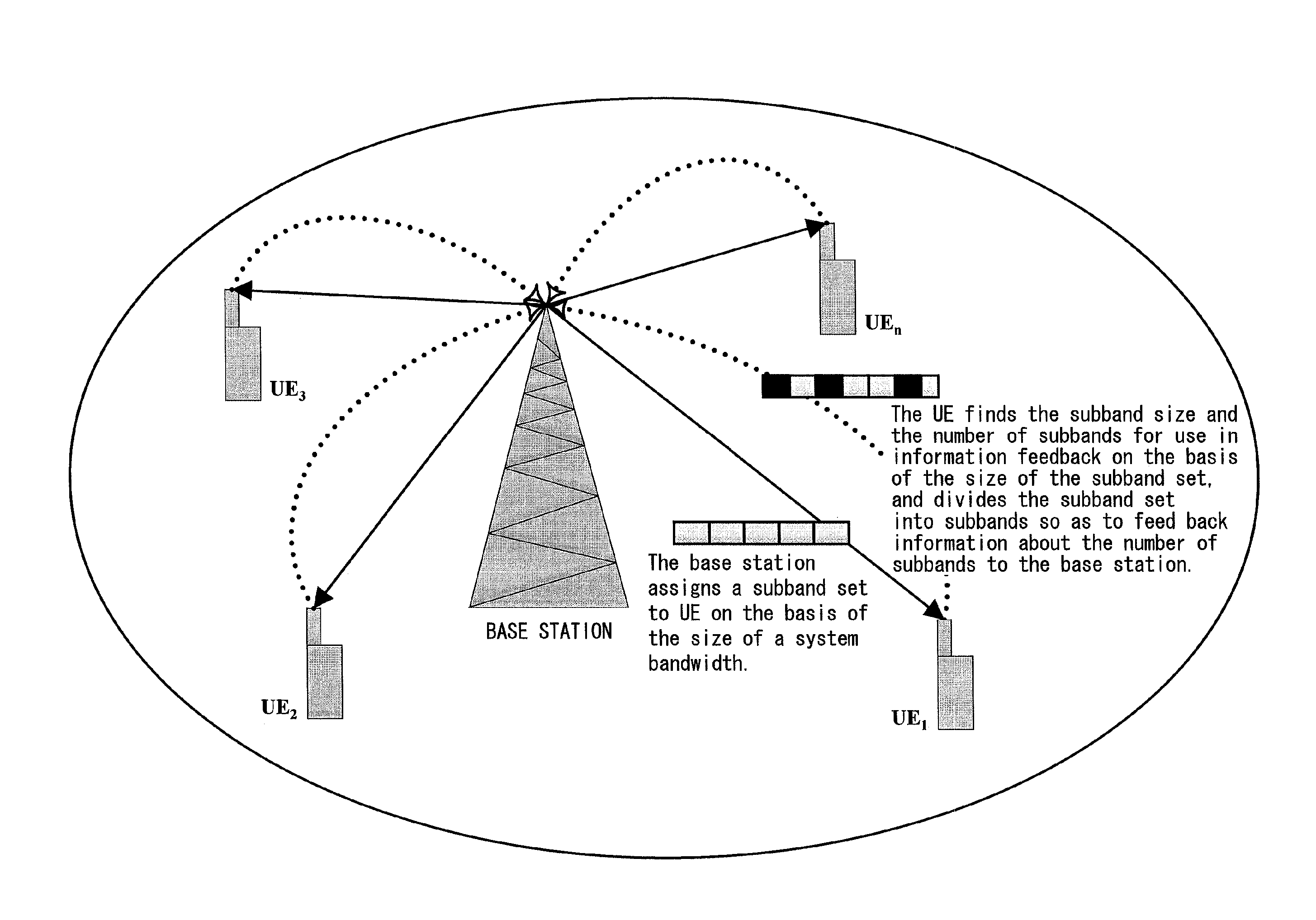

Determining method for use in information feedback, base station, user equipment, and communications system

InactiveUS8442568B2Improve service qualityReduce amountFrequency-division multiplexInter user/terminal allocationCommunications systemUser equipment

A subband determining method, a base station, user equipment, and a communications system are provided. The base station of the present invention finds the subband size on the basis of a system bandwidth and divides the system bandwidth into subbands. The base station further selects some subbands to form a subband set and assign the subband set to user equipment and notifies the user equipment of information about the subband set. The user equipment in turn finds its corresponding subband size and the number of subbands for use in feedback on the basis of the size of the assigned subband set. The user equipment further divides the subband set into its corresponding subbands on the basis of a result found and feeds back information about a predetermined number of subbands to the base station. The base station carries out optimization of its transmitter on the basis of the information.

Owner:SHARP KK

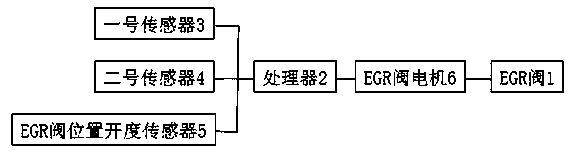

System for determining and regulating EGR (Exhaust Gas Recirculation) mass flow and use method thereof

ActiveCN103776503ALow application costSimple structureIndirect mass flowmetersReal-time dataEngineering

The invention provides a system for determining and regulating EGR (Exhaust Gas Recirculation) mass flow. The system comprises an EGR valve and a processor, wherein the EGR valve is connected with the output end of the processor by virtue of an EGR valve motor; the inlet of the EGR valve is provided with a sensor I; the outlet of the EGR valve is provided with a sensor II; the EGR valve motor is provided with a position opening sensor; the sensor I is a temperature and pressure sensor; the sensor II is a pressure sensor; The output ends of the sensor I, the sensor II and the position opening sensor are in signal connection with the input end of the processor. When the system is in use, the flow characteristic curve of the EGR valve is calibrated firstly and then stored into the processor, then the processor is used for calculating real-time EGR mass flow according the real-time data and the flow characteristic curve received by the processor and regulating the opening size of the EGR valve; due to the design, the cost is lowered, and the method is simple, convenient and practical.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com