Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "High degree of test automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

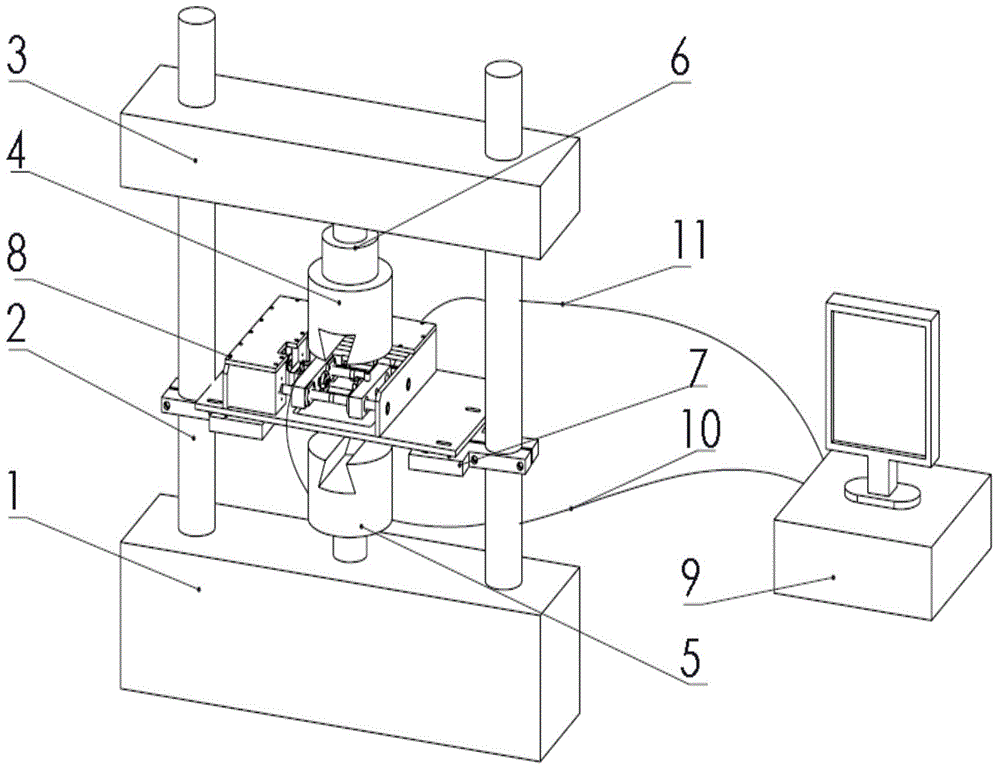

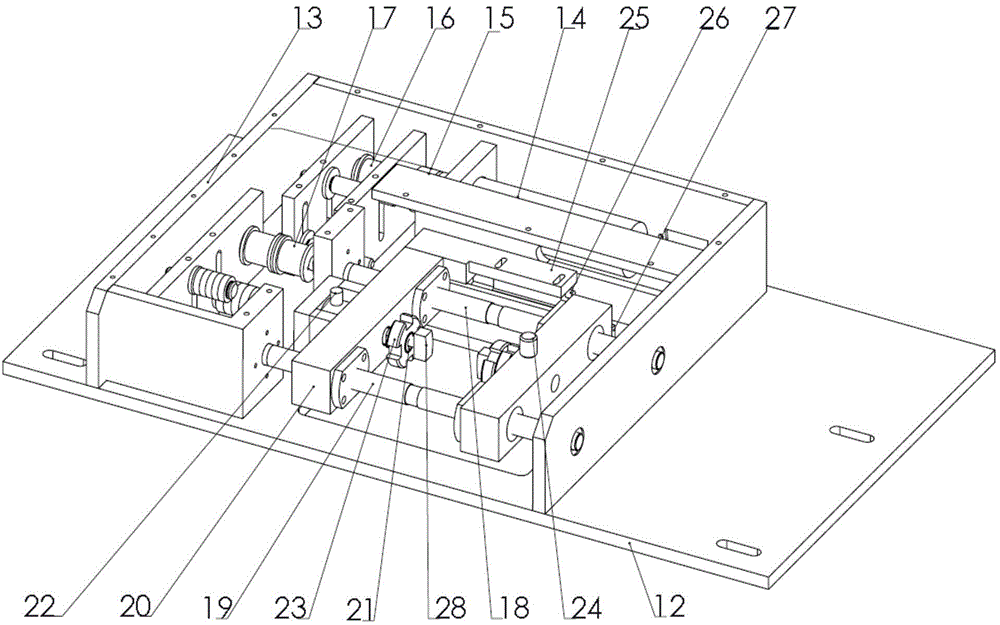

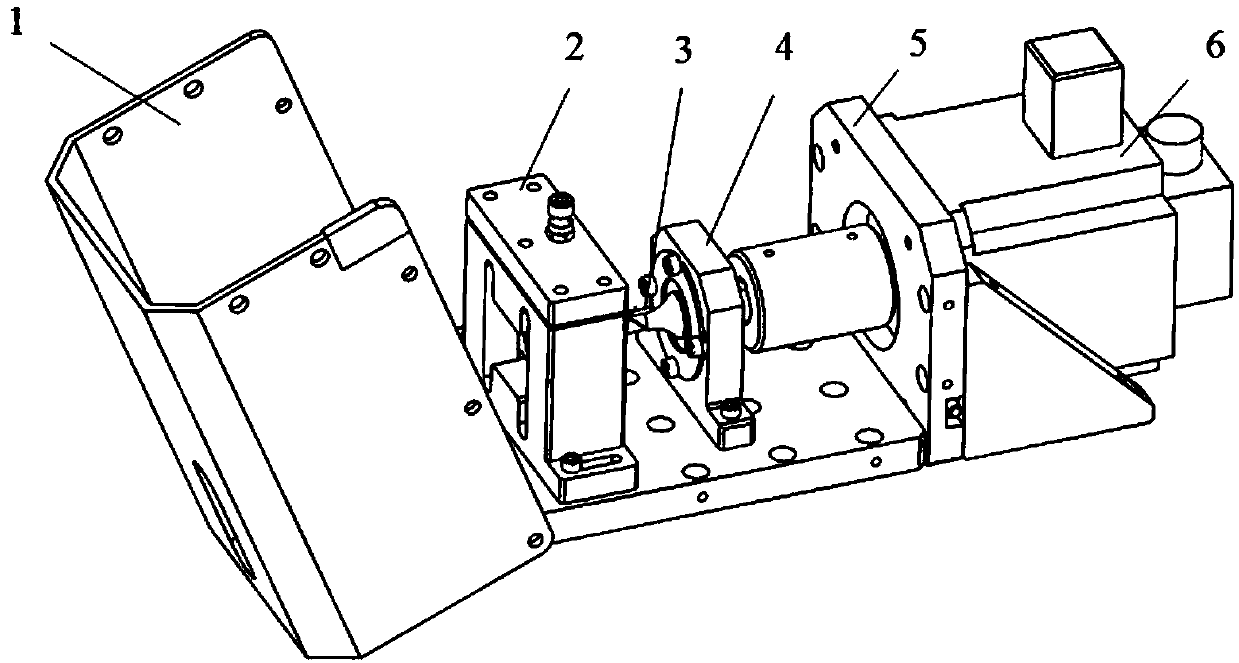

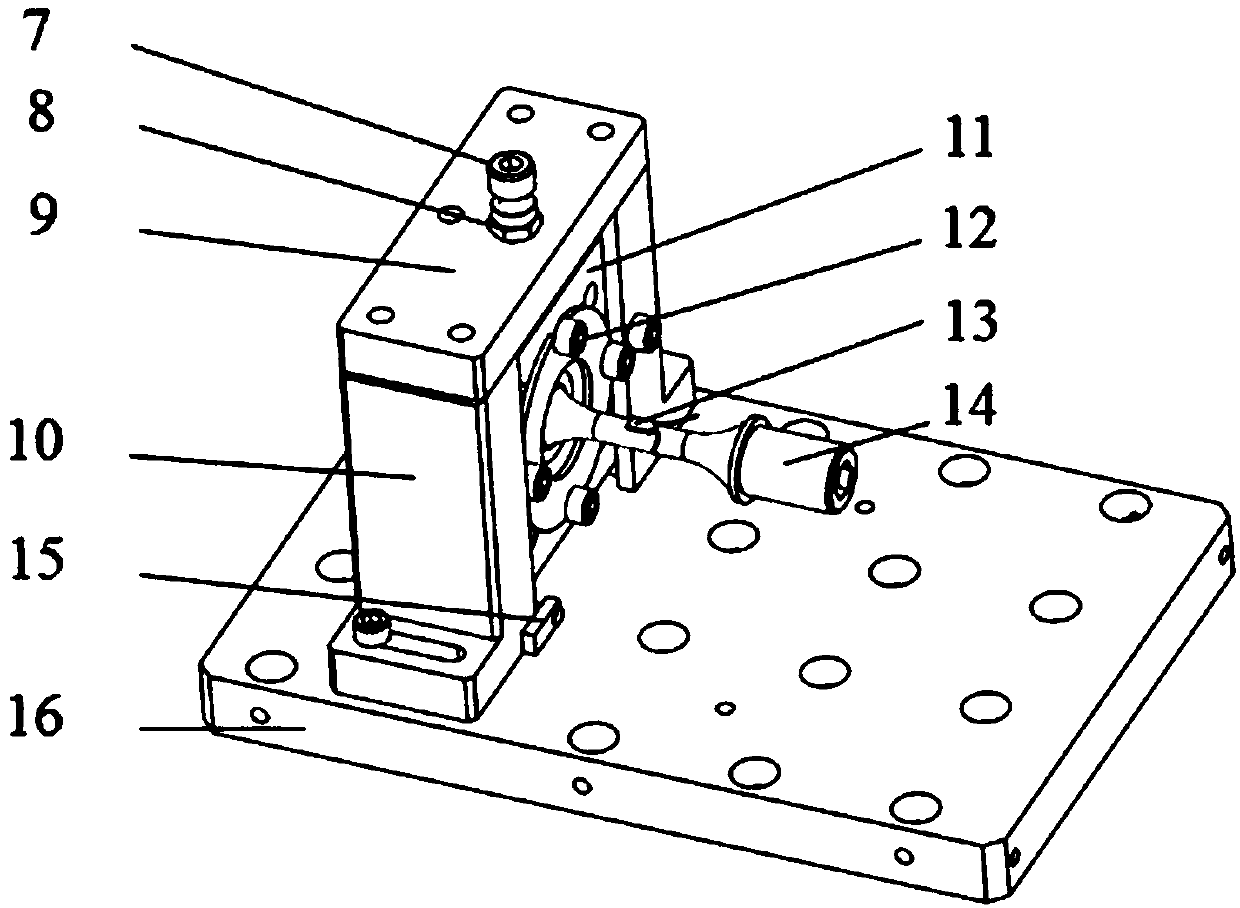

Fretting fatigue testing method allowing contact load to be adjusted in real time and testing machine adopting fretting fatigue testing method

InactiveCN104931366ASolve the problem that the fretting fatigue test that cannot simulate the component subjected to alternating contact loadsGood repeatabilityMachine part testingMaterial strength using repeated/pulsating forcesFatigue damageMotor drive

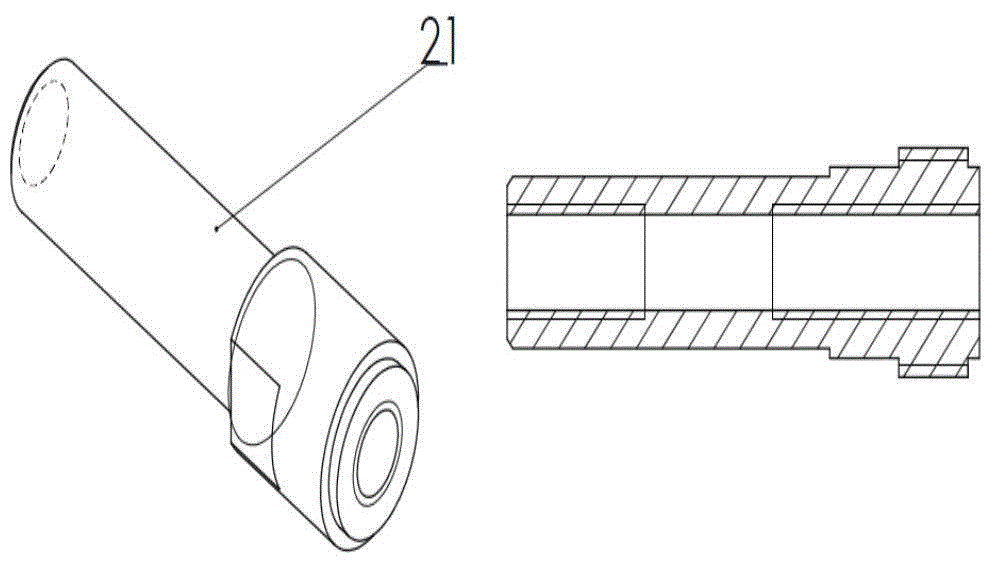

The invention relates to a fretting fatigue testing method allowing a contact load to be adjusted in real time and a testing machine adopting the fretting fatigue testing method. The testing machine comprises an electronic-hydraulic servo fatigue testing machine, fretting supporting platforms, a fretting device and a computer testing and controlling system, wherein the fretting supporting platforms are fixed on supporting stand columns of the fatigue testing machine; the fretting device is horizontally arranged on the fretting supporting platform; the fatigue testing machine comprises an upper clamp and a lower clamp which are used for fixing a test piece; a contact load sensor, a motor drive signal and a displacement signal of the fretting device are connected with a computer data acquisition control system. Two fretting pad clamps are fixed in middles of two lead screw cross beams, and two opposite fretting pads are mounted at two ends of each fretting pad clamp. A fretting fatigue test with the contact load changing in real time is performed through the fretting fatigue testing machine, influences of the contact load on fretting fatigue damage are researched, meanwhile, fretting fatigue tests at different amplitudes and frequencies can be researched, and an experiment method is provided for deeper understanding of a fretting fatigue damage mechanism.

Owner:TIANJIN UNIV

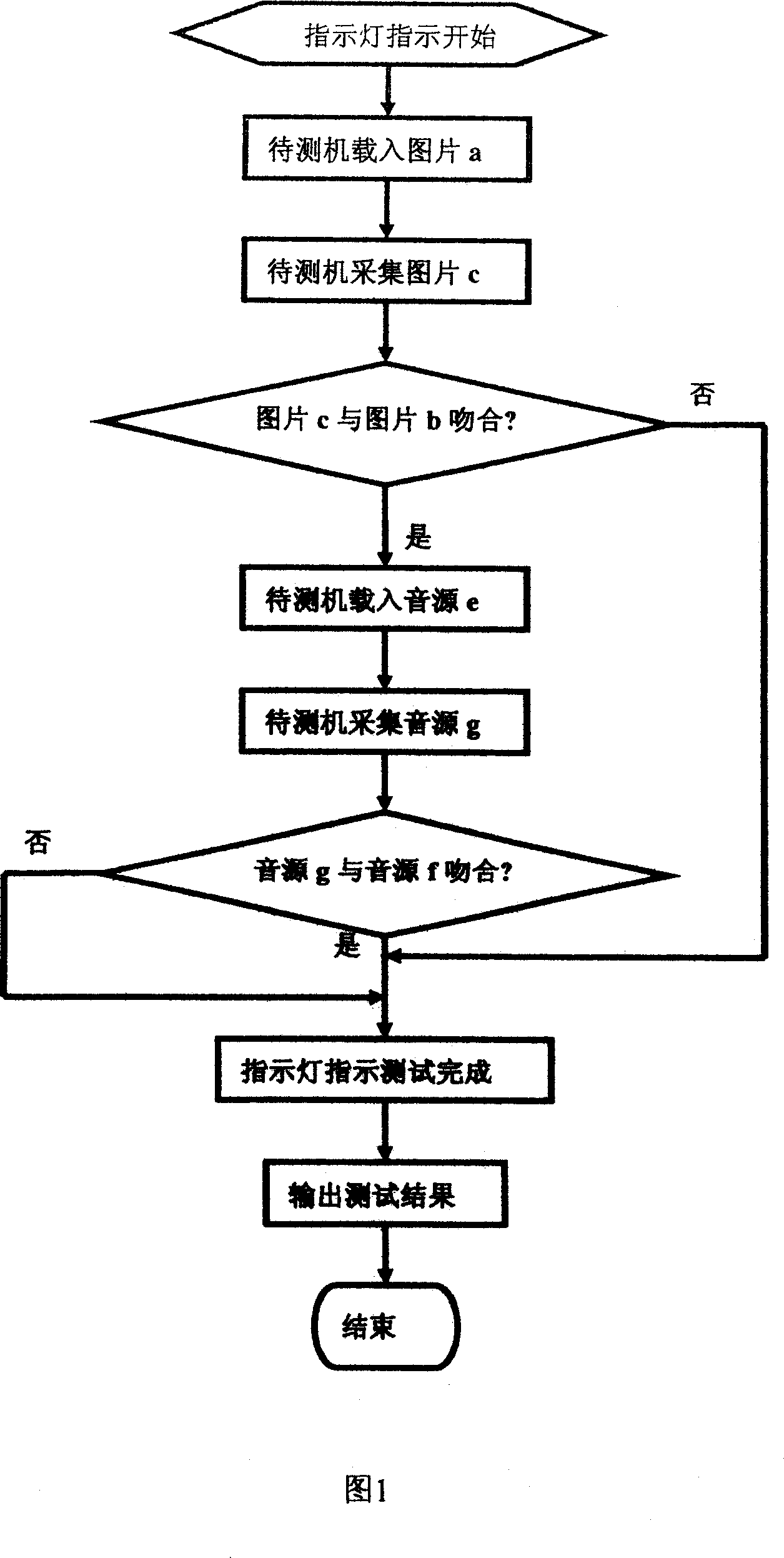

Method for testing digital products and special equipment thereof

InactiveCN101063641ASimple structureEasy to operateElectrical testingStructural/machines measurementAcoustic transmissionComputer hardware

This invention relates to one digital product test method, which adopts digital product and loads with test program software standard audio files and comprises the following steps: the product displaying the standard audio files and sending the sound to the microphone through sound isolation environment; then generating audio files on horn sound; the product uses audio comparison program to compare the audio file and standard frequency files; according to the comparison audio frequency test parameters comparing the audio frequency test parameters and standard parameters to output results. This invention also discloses one special device.

Owner:孙盈军

Reciprocating type shaft seal sealing performance testing method and device

ActiveCN104142215AThe test results are accurate and reliableGood repeatabilityDetection of fluid at leakage pointMeasurement of fluid loss/gain rateElectricityData collecting

The invention discloses a reciprocating type shaft seal sealing performance testing method and device. The device comprises a test bed frame, an outer cylinder, a sealing ring mounting loop for mounting of a sealing ring, a sealing main shaft, a pulling-pressing sensor, a supporting block, a reciprocating straight line moving device, an auxiliary device and a detecting device. The outer cylinder is fixedly arranged on the test bed frame through a support. The detecting device and the auxiliary device are connected with holes formed in the outer cylinder respectively. The sealing ring mounting loop is arranged in the outer cylinder. The two ends of the outer cylinder tightly press and seal the sealing ring mounting loop through end covers. The sealing main shaft is arranged in the outer cylinder and is connected with the pulling-pressing sensor through a coupler. The pulling-pressing sensor is connected with the supporting block which is connected with the reciprocating straight line moving device. The reciprocating straight line moving device, the pulling-pressing sensor and the auxiliary device are electrically connected with a data collecting control system.

Owner:菏泽建数智能科技有限公司

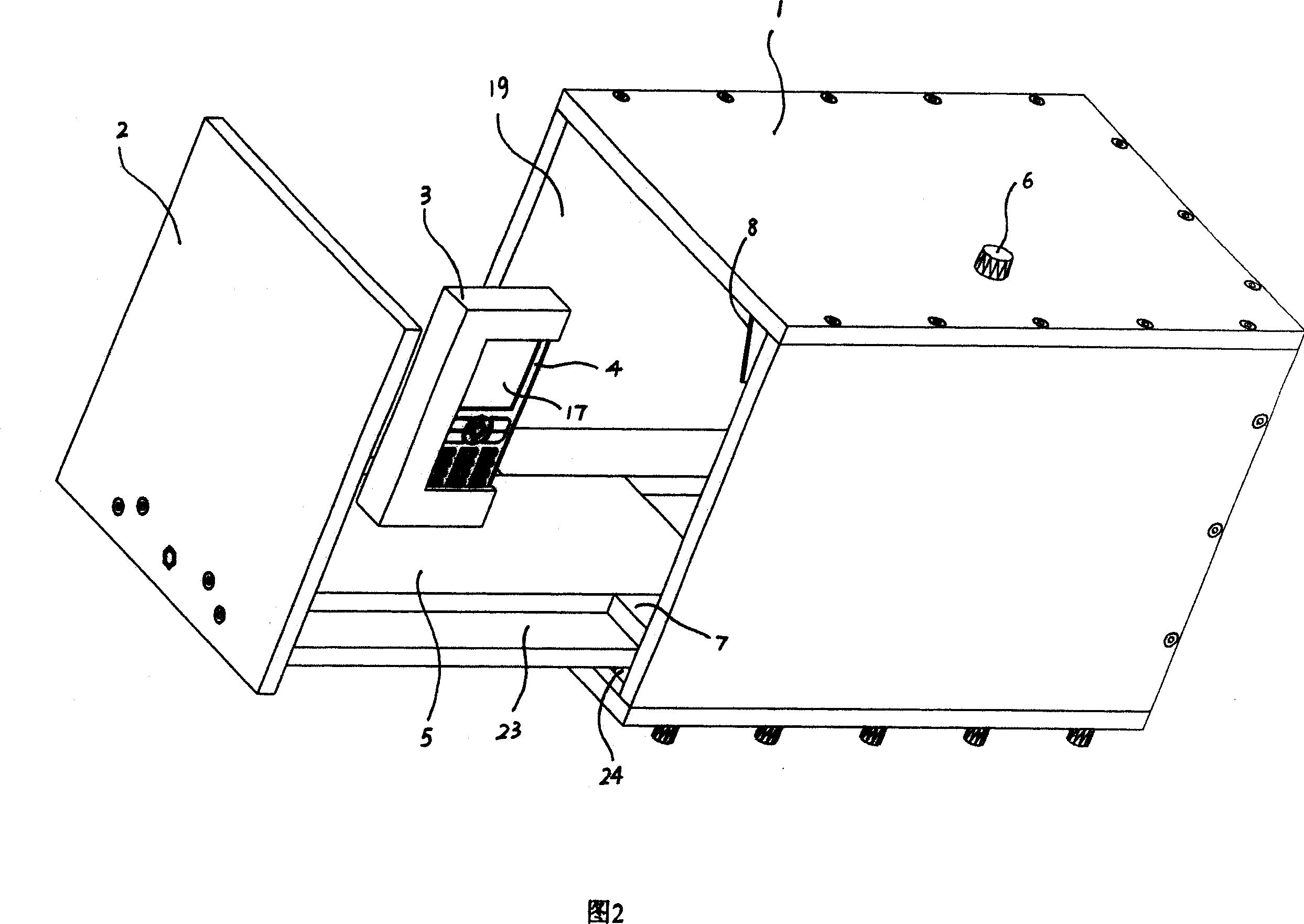

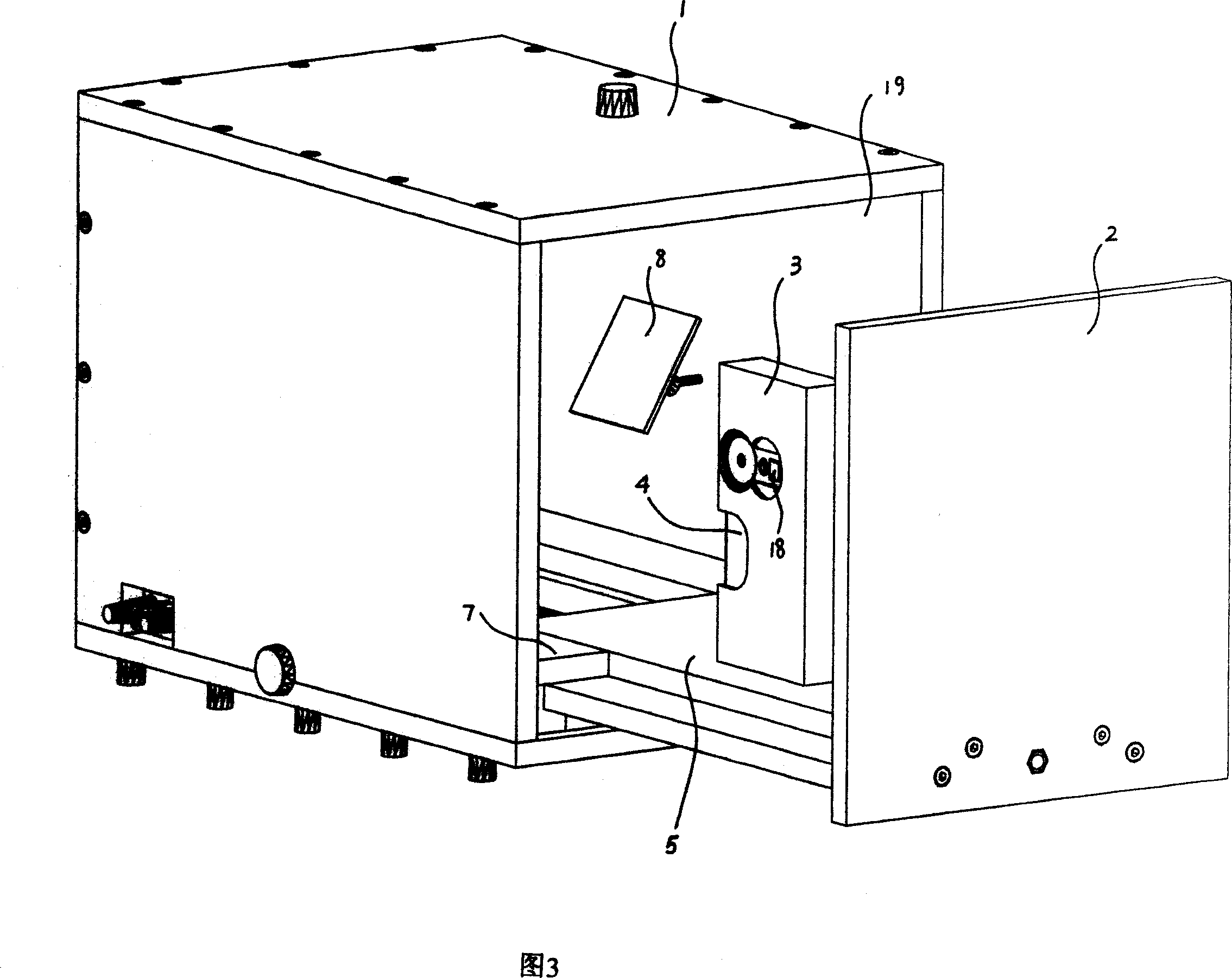

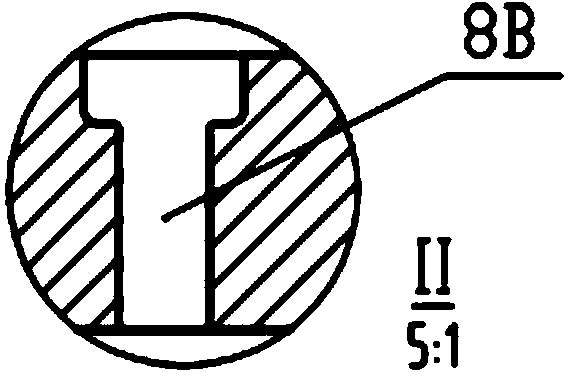

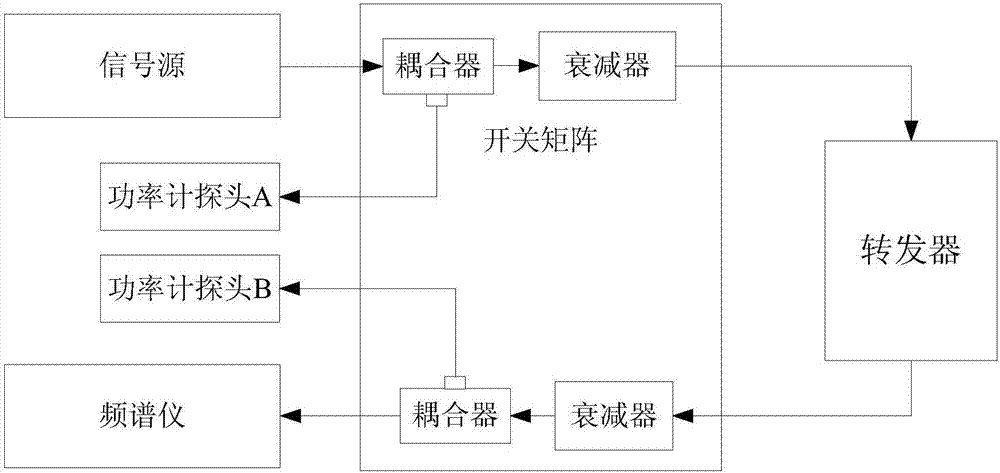

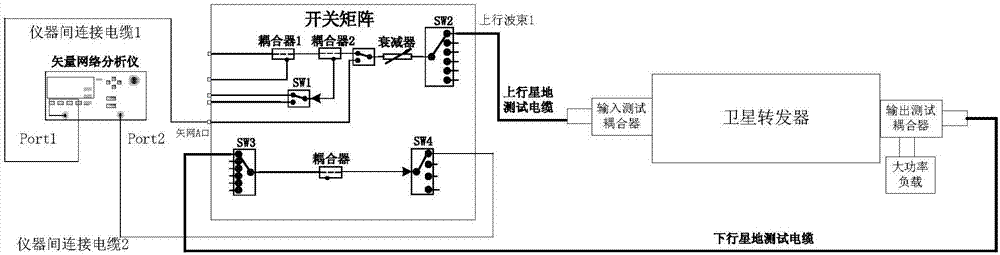

Testing method for transponder channel frequency response based on vector network

ActiveCN106911404AReduce workloadReduce the number of instrumentsTransmitters monitoringReceivers monitoringTest channelTime delays

A testing method transponder channel frequency response based on a vector network comprises the steps of (1), selecting a PNA-X-series vector network analyzer and a switching matrix with a vector network analyzer testing channel as testing equipment; (2), performing frequency scanning self-calibration on the vector network analyzer; (3), respectively calibrating an uplink testing channel and a downlink testing channel of the system by means of the vector network analyzer; (4), connecting the vector network analyzer with the switching matrix and a to-be-tested transponder, and constructing a testing channel; (5), setting related parameters in the vector network analyzer, finishing amplitude frequency characteristic measurement, outband inhibition measurement and group delay measurement through automatic controlling of the vector network analyzer, and simultaneously drawing a corresponding signal trace line; and (7), extracting testing result data of three testing items, and respectively deducing insertion loss and time delay of the testing channel, thereby obtaining a final channel frequency response testing result of the tested transponder.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

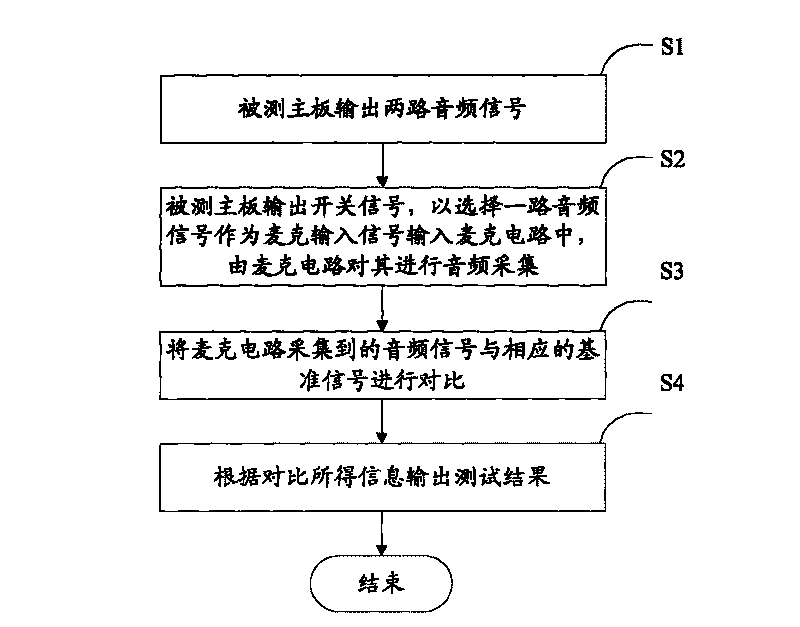

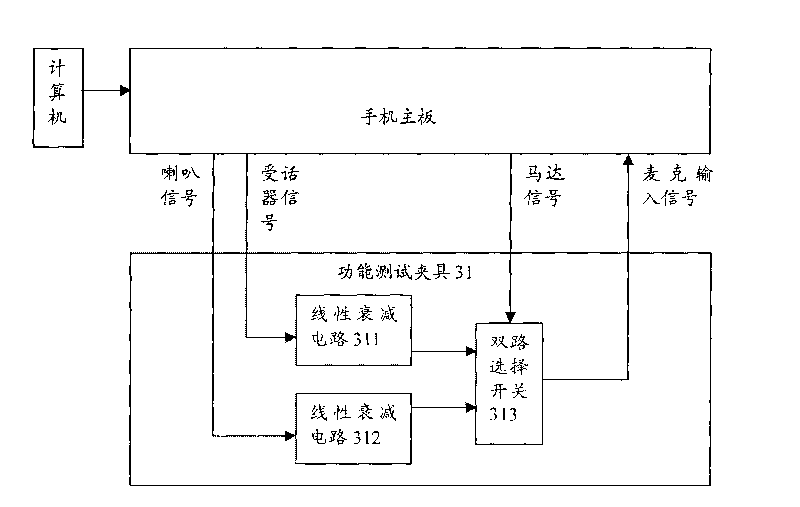

Method and device for testing audio loop of communication terminal

The invention discloses a method and a device for testing an audio loop of a communication terminal, relates to the field of communication, and aims to solve the problem that the prior art cannot test the audio loop of the communication terminal with a relatively low cost, high quality and high efficiency. The method comprises the following steps that: a tested motherboard outputs two routes of audio signals; the tested motherboard outputs a switching signal to select a route of audio signal as a Mac input signal which is input to a Mac circuit to perform audio acquisition; the audio signal acquired by the Mac circuit is compared with a corresponding reference signal; and a test result is output according to the information obtained according to the comparison. The device comprises an audio output comparison module, an audio selecting module and a test result output module. The method and the device can test the audio loop of the communication terminal under the condition of not being interfered by environment.

Owner:ZTE CORP

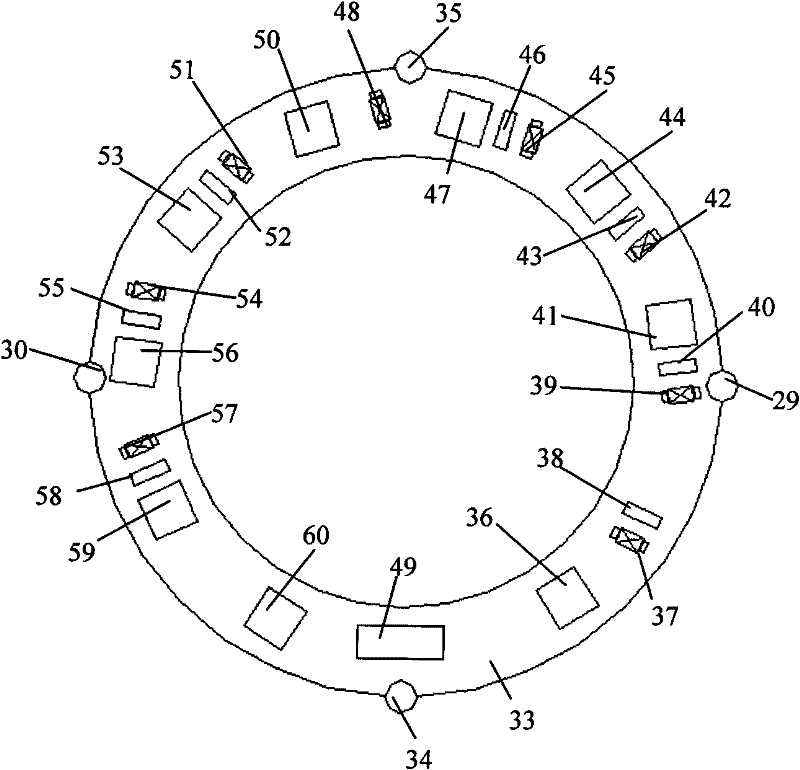

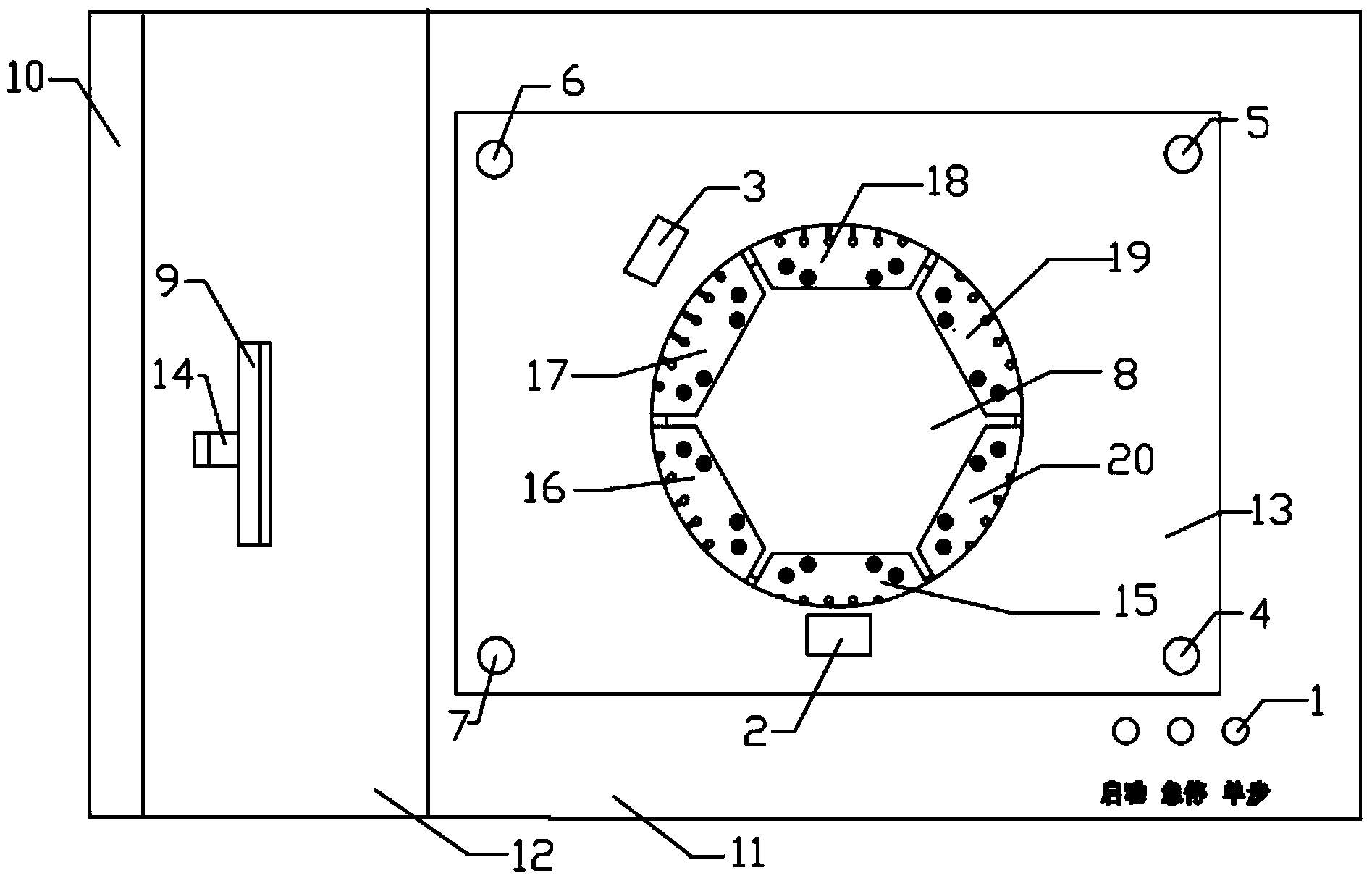

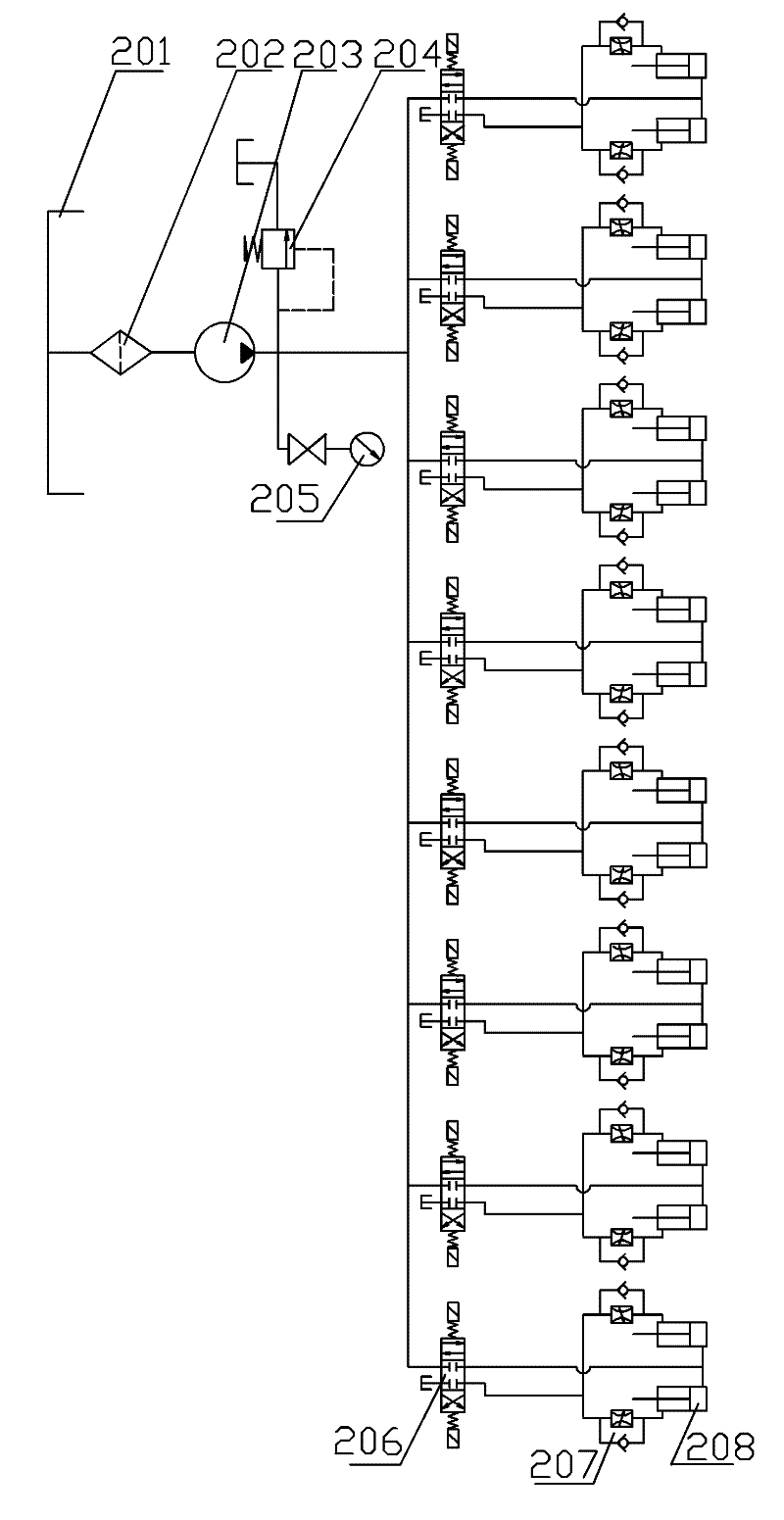

Electronic expansion valve rotary type multiple stations integration testing device

InactiveCN102230846AAddress the degree of automationSolve the disadvantage of re-clamping every time an index is measuredMachine part testingCombined testDifferential pressure

The invention discloses an electronic expansion valve rotary type multiple stations integration testing device. The device comprises a valve loading station, a valve closing station, a valve closing flow determination station, a valve opening point determination station 1, a valve opening point determination station 2, a zeroload flow determination station, a high pressure valve opening station, a loading flow determination station, a low flow determination station, a high flow determination station, a pulse setting station, a stationary work table, a swivelling angular table, an index dial, a control system and the like. During an operation, an operation worker takes down a measured valve from the valve loading station and put a valve to be measured in place after scanning. The valve to be measured is conveyed to each appointed station to realize operations of valve closing flow determination, valve opening point determination, maximal valve opening differential pressure, multi-pointflow determination, factory pulse setting and the like. In a present electronic expansion valve testing device, automation degree is low, a new clamp needs to be installed after testing each index, and a device can only test a performance index. According to the testing device in the invention, the above disadvantages are overcome, working time is saved and automation degree of testing is raised.

Owner:CHINA JILIANG UNIV

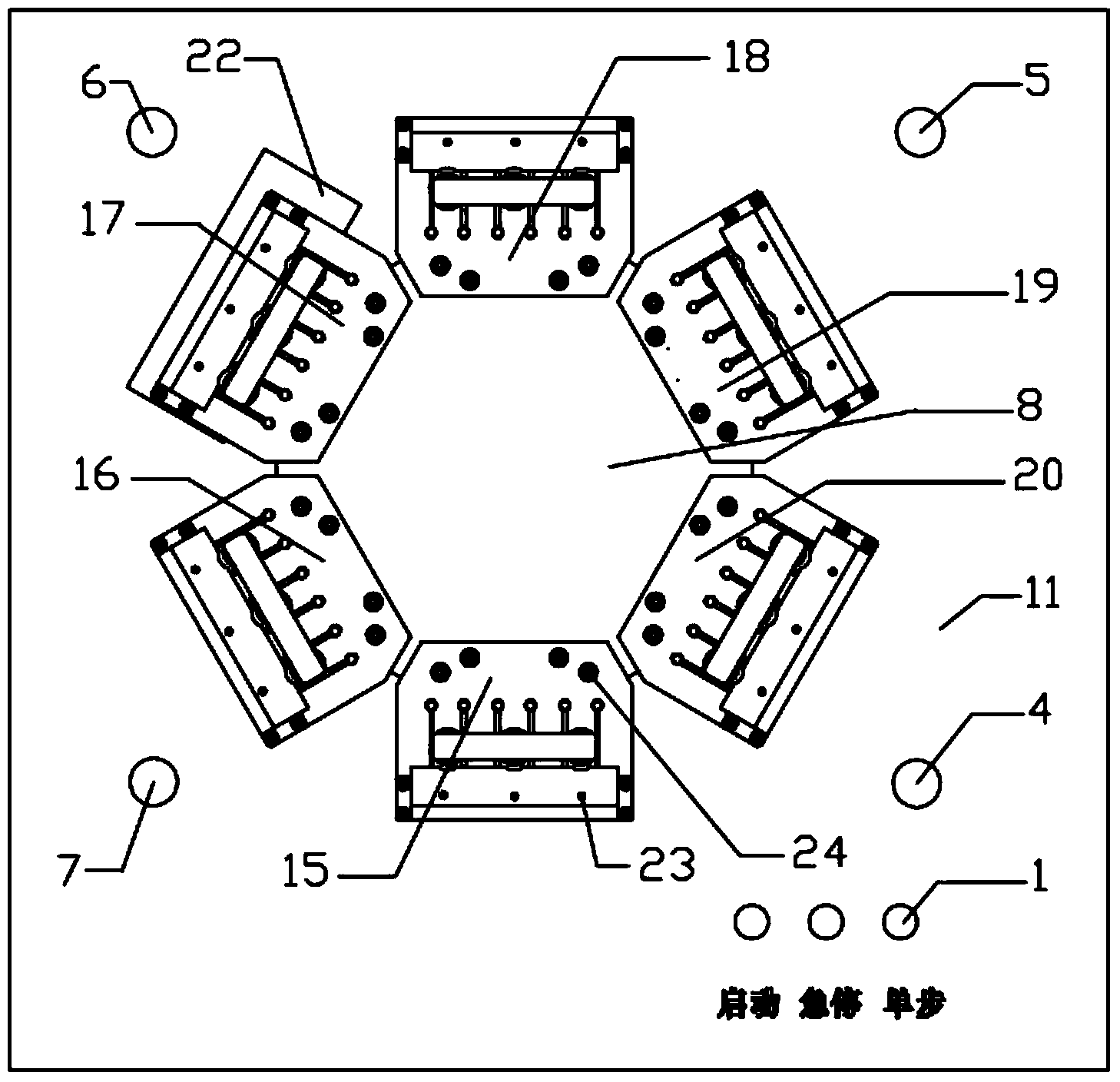

Rotation type multi-station combination property auxiliary testing device of solenoid valve coil

InactiveCN103472334AAddress the degree of automationSolve the disadvantage of re-clamping every time an index is measuredElectrical testingSolenoid valveEngineering

The invention discloses a rotation type multi-station combination property auxiliary testing device of a solenoid valve coil. A fixing bottom plate is arranged on a machine cabinet, a top plate is connected with the fixing bottom plate, a first connecting block is fixedly connected to the fixing bottom plate and connected with a stepping motor through a reduction gear, and a rotating shaft of the reduction gear is fixedly connected with a rotating working table. The rotating working table is installed on the fixing bottom plate through a rotating supporting column, the rotating working table, the rotating supporting column and the rotating shaft are coaxial, and an optoelectronic switch is installed on the fixing bottom plate through a first fixing block. Six blocking pieces are evenly installed on the lower bottom surface of the rotating working table in the circumferential direction in a partitioning mode. Same six measuring tools are evenly installed on the rotating working table in the circumferential direction, and four periphery tools are fixed over the top plate. Flow line production is adopted for the rotation type multi-station combination property auxiliary testing device, kinds of auxiliary measurement are achieved through one-time disassembly, production efficiency is high, labor cost is low, working time is saved, a gas circuit is simple, mutual interference is small, and production tempos of each product meet requirements of enterprise production.

Owner:CHINA JILIANG UNIV

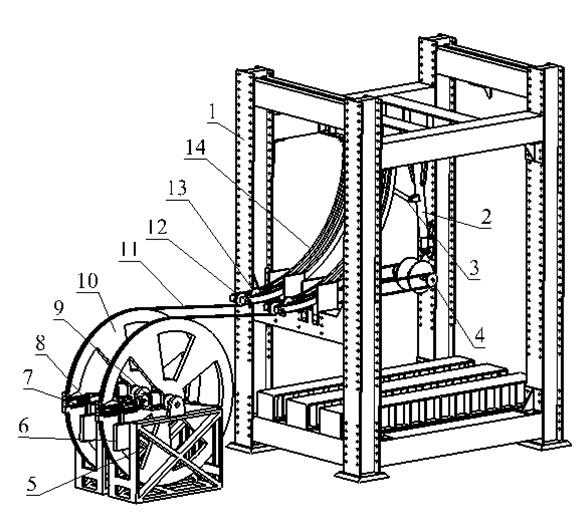

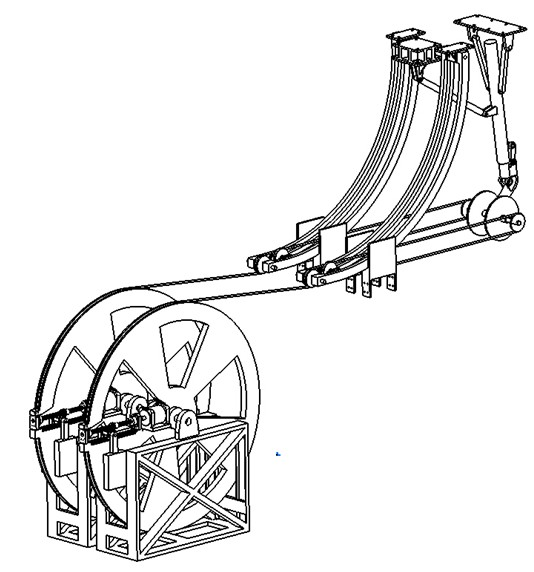

Pneumatic load simulator for undercarriage control test

ActiveCN102530264AThe effect of generating torqueReduce in quantityAircraft components testingPilot systemClosed loop

The invention discloses a pneumatic load simulator for an undercarriage control test, which belongs to undercarriage control test systems, and comprises a test bench, an undercarriage, an undercarriage jackstay actuating cylinder and a load loading device. The load loading device comprises slide rails, a loading pulley, a slide rail trolley, loading ropes and turntables, the undercarriage jackstay actuating cylinder is arranged on the test bench, an output end of the undercarriage jackstay actuating cylinder is connected in the middle of the undercarriage, the loading pulley is arranged at the lower end of the undercarriage, a lead screw, a linear guide rail, a servo motor and a mass block are radially arranged on each turntable which is arranged on a support frame, the upper end of each mass block is connected with a nut of the corresponding lead screw, one end of each loading rope is fixed onto the corresponding turntable, the other end of each loading rope bypasses the loading pulley to be fixed onto the slide rail trolley. The pneumatic load simulator adopting the closed-loop control technology has the advantages that test misoperation possibility is decreased, test precision is improved, and the pneumatic load simulator is applicable to undercarriages of various types.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

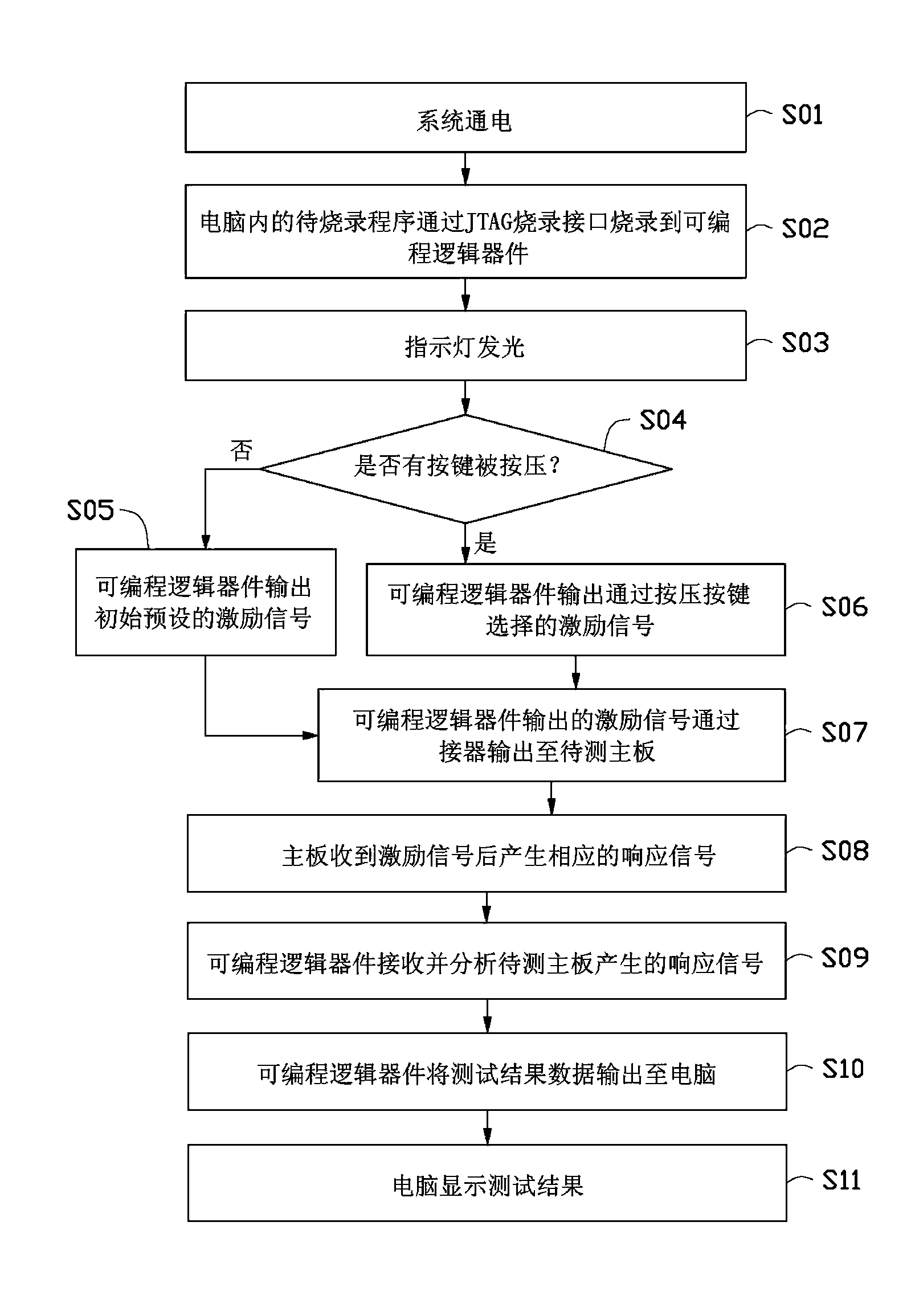

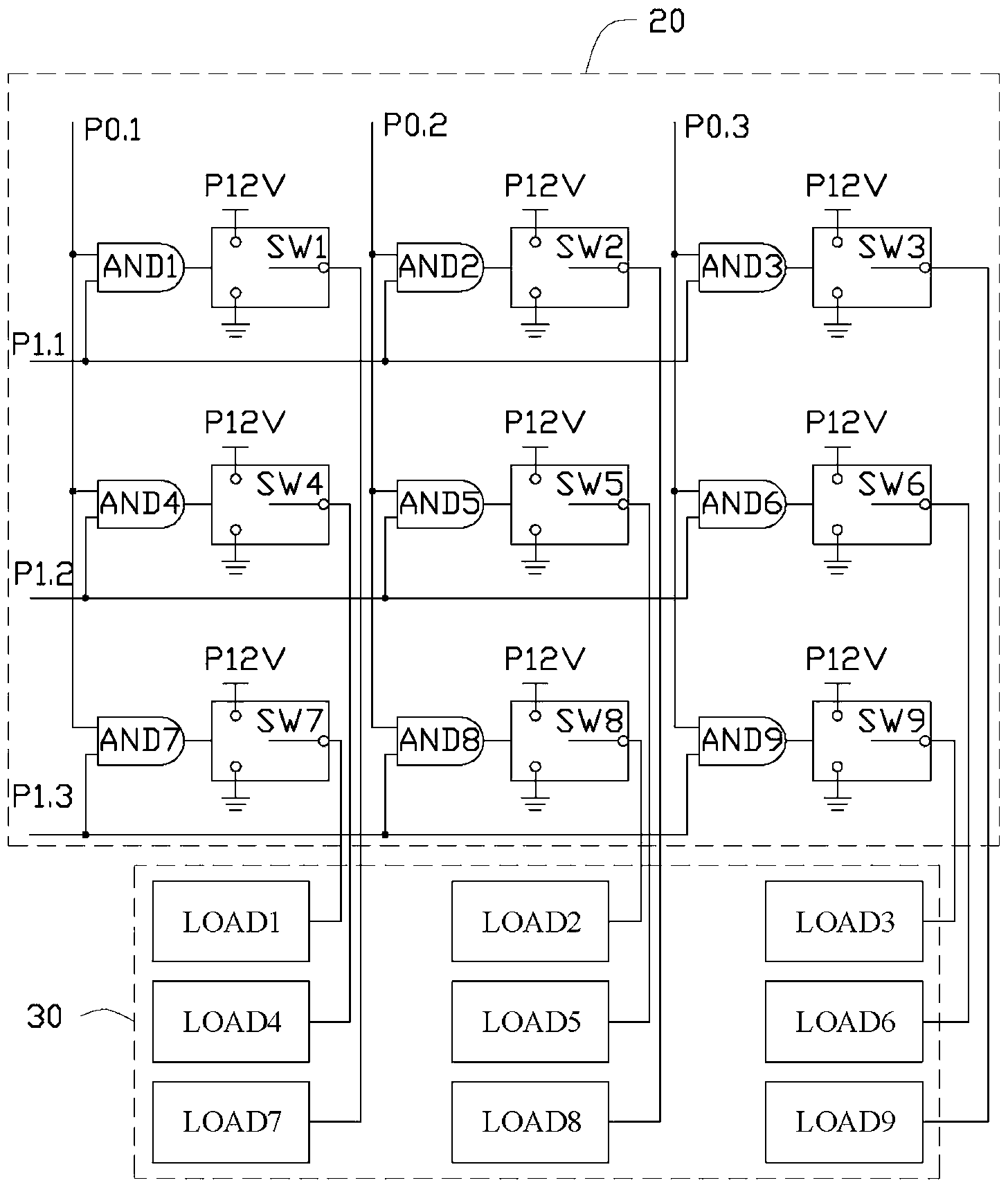

Motherboard test system and method

InactiveCN104133168AHigh degree of test automationElectronic circuit testingError detection/correctionProgrammable logic deviceExcitation signal

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Test method and device capable of switching multi-simulation accuracy

ActiveCN101551827AImprove unityHigh degree of test automationSpecial data processing applicationsComputer architectureTest platform

The invention provides a test method and a device capable of switching multi-simulation accuracy. The method comprises the following steps: building a test system comprising a plurality of simulation accuracy functional block models; switching the test system into one simulation accuracy functional block model suitable for a simulation current scene in the simulation accuracy functional block models during the simulation; and executing the simulation test by using the switched simulation accuracy functional block model. The invention realizes the unification of designing a front-end test platform and a rear-end test platform of an ASIC and improves the test degree of automation.

Owner:SANECHIPS TECH CO LTD

Intelligent relay protection device information transmission time automatic detection system and method

PendingCN106787215AHigh degree of test automationImprove work efficiencyCircuit arrangementsTime-division multiplexInformation transmissionMaster station

Disclosed are an intelligent relay protection device information transmission time automatic detection system and an intelligent relay protection device information transmission time automatic detection method. The intelligent relay protection device information transmission time automatic detection system comprises a simulation master station, a data communication gateway computer, an exchanger, relay protection devices, a relay protection testing device and a time synchronizing device, wherein the time synchronizing device respectively provides time synchronization signals to the simulation master station, the data communication gateway computer and each relay protection device, the simulation master station, the data communication gateway computer and a plurality of the relay protection devices simultaneously access the exchanger, the data communication gateway computer is communicated with the plurality of the relay protection devices, and the simulation master station is communicated with the data communication gateway computer. The intelligent relay protection device information transmission time automatic detection system and the intelligent relay protection device information transmission time automatic detection method adopt a unified time source time synchronizing mode, achieve time synchronization of all nodes in the system, complete automatic testing of transmission time at the simulation master station, and have the advantages of being high in testing automation degree, low in labor cost, and high in work efficiency.

Owner:XUCHANG KETOP DETECTION TECH CO LTD

Intelligent dynamic torque tester

ActiveCN103542972AEvenly loadedAdjustable loading speedMeasurement of torque/twisting force while tighteningControl systemEngineering

The invention discloses an intelligent dynamic torque tester which comprises a mechanical part and a control part. The mechanical part comprises an acting force applying transmission system and a damping loading system, the acting force transmitted by a tested device is applied to a brake disc through a dynamic torque sensor, and the counter-acting force transmitted by the damping loading system is also applied to the brake disc through a brake cylinder. The intelligent dynamic torque tester has the advantages that torque demarcating, aging and sampling tests and the like can be carried out on definite torque wrenches and other tested devices, the tested devices are connected to the brake disc through the dynamic torque sensor, the damping loading system applies the counter-acting force one the brake disc through the brake cylinder, test data are further automatically transmitted to an upper computer to be analyzed and stored through a control system, damping loading speed is adjustable, and loading is stable and noise free. The intelligent dynamic torque tester has the advantages of being simple in structure, low in cost, high in test automation degree, and high in reliability of testing results.

Owner:SHANDONG ZHONGXING ELECTRIC TOOLS

Monitoring system and method for server simulated load

InactiveCN103176880AHigh degree of test automationThe test result is accurateHardware monitoringMicrocontrollerMonitoring system

The invention discloses a monitoring system for server simulated load. The monitoring system for the server simulated load comprises a fan, a load module, a temperature sensor, a microcontroller, and a switch module which is connected with the microcontroller, wherein the fan, the load module, the temperature sensor, the microcontroller, and the switch module which is connected with the microcontroller are arranged inside a server chassis. The load module comprises a plurality of loads, the switch module comprises a plurality of switches which are respectively connected with the plurality of loads, the microcontroller inputs signals to control states of the switches to control the opening of one or more loads, the microcontroller is connected with the fan to control the rotation speed of the fan, the temperature sensor is connected with the microcontroller to input measured temperature information to the microcontroller, and the microcontroller judges whether the temperature detected by the temperature sensor is in a preset range or not. The invention further discloses a monitoring method for the server simulated load based on the monitoring system. The monitoring system and the method for the server simulated load are high in automation degree, and more accurate in test results.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

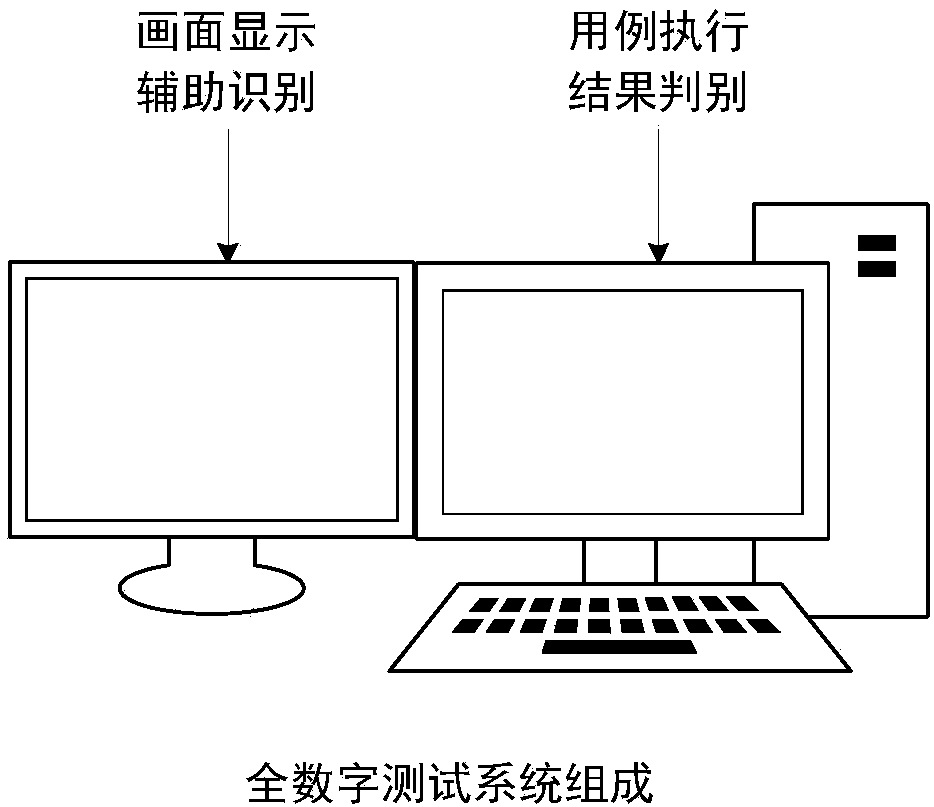

Full-digital test method for cockpit display control software

InactiveCN108052445AEnsure test adequacyHigh degree of test automationSoftware testing/debuggingSoftware development processTest script

The invention provides a full-digital test method for cockpit display control software, and belongs to the technical field of software testing. The method comprises the steps of firstly, writing a test case of the cockpit display control software, and according to the test case, generating a test script, a test input and an expected output; secondly, transplanting the cockpit display control software to a PC with the test script, and establishing communication between the cockpit display control software and the test script; and finally, running the test script, and comparing an actual outputof the cockpit display control software with the expected output, thereby finishing full-digital testing of the cockpit display control software. Through the method, the test automation level can be improved; the regression test cycle is shortened; a universal test environment is provided; and the method can be applied to all the stages of software development, debugging, verification and the like.

Owner:CHINA HELICOPTER RES & DEV INST

Rotating bending fatigue detecting device and rotating bending fatigue test method

ActiveCN107796717ASimple structureLow costMaterial strength using repeated/pulsating forcesEngineeringStrain gauge

The invention provides a rotating bending fatigue detecting device. The rotating bending fatigue detecting device comprises an aligning unit, a strain measuring unit, a supporting connecting part, a fixed mounting unit, a servo motor and a test control unit, wherein the fixed mounting unit is fixedly arranged on ground through a fixed bottom plate; a first end of a test part is connected with oneend of the aligning unit; a second end of the test part is connected with the first end of the supporting connecting unit; the second end of the supporting connecting unit is connected with the firstend of a shaft coupler through an adapting joint; the first end of the shaft coupler is connected with one end of the servo motor; and the aligning unit, the supporting connecting unit and the servo motor are fixedly arranged on the fixed mounting unit separately. A strain plate and an eccentric device are adopted to regulate a stress load value and a conventional rotating bending fatigue film, sothat a complex weight loading device is omitted, mounting use is more convenient, and loading precision is higher; and the tester is simpler, is lower in cost, is high in degree of automation of thetest, and is safety to use.

Owner:CHINA AERO POLYTECH ESTAB

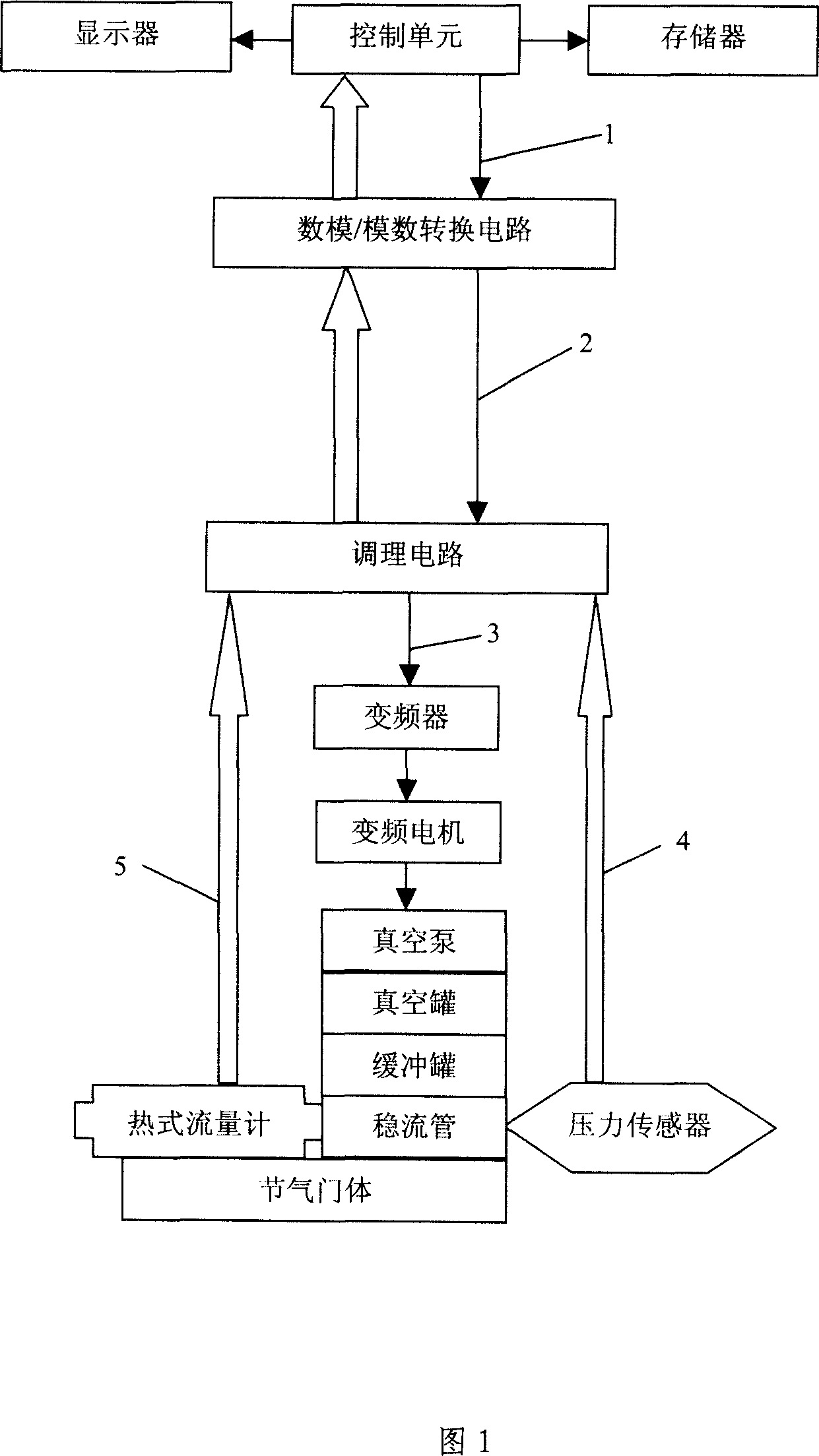

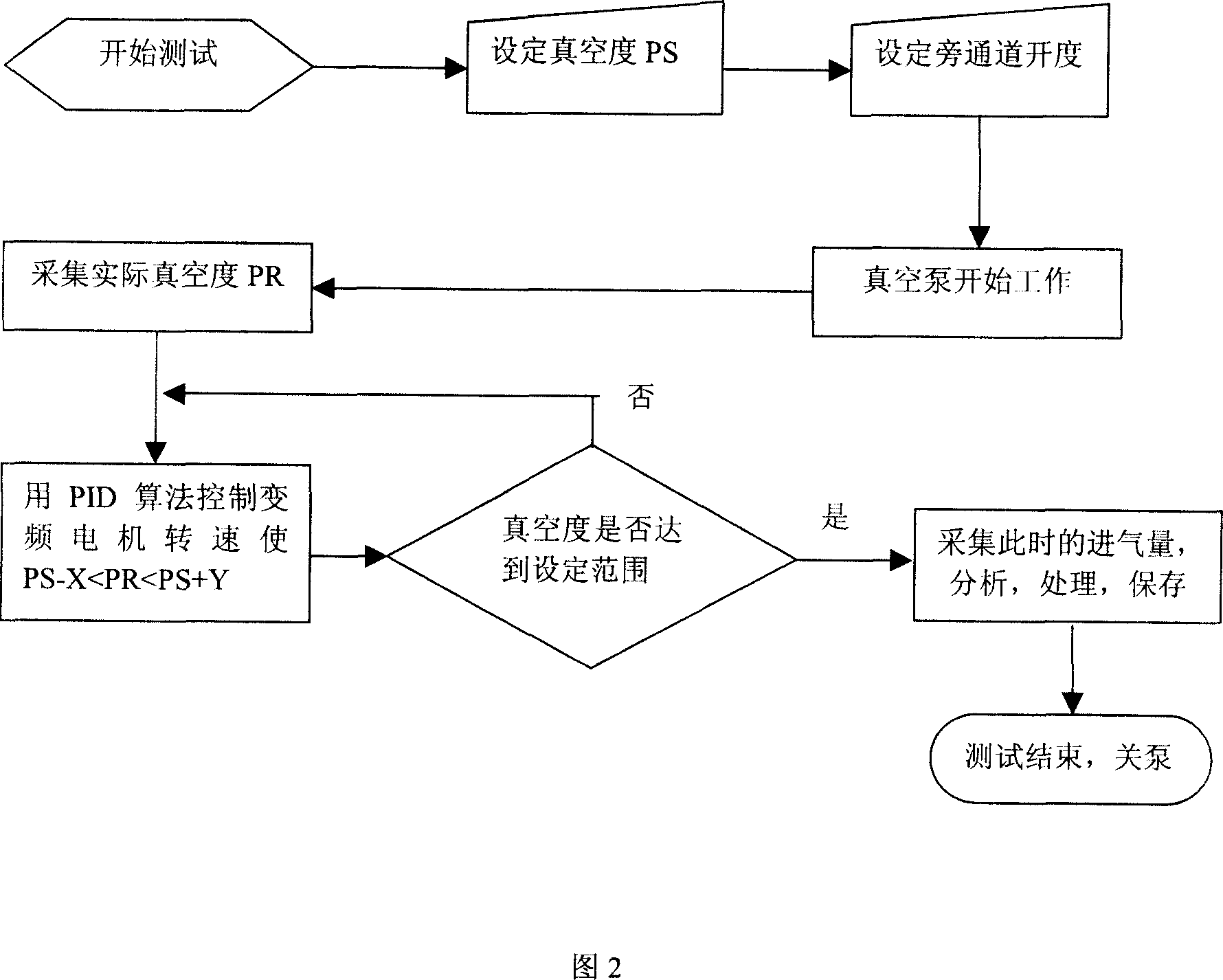

Vehicle air throttle air inflow test system and testing method

InactiveCN1932453AEasy to buyEasy CalibrationVolume/mass flow by thermal effectsIndirect mass flowmetersEngineeringThrottle

The invention discloses an air input testing system and testing method of the motor car air throttle which includes the vacuum source, the pressure sensor, the thermal gas flowmeter and the control unit. The vacuum source includes the air guiding hollow connected with the air vent of the throttle which provides the vacuum condition for the air vent; the control unit can keep the vacuum degree in a stable error range and collect the flow rate signal outputted by the thermal gas flowmeter and compute the air flow according to the airflow sectional area. The invention can measure the air flow directly and has the simple structure and low cost.

Owner:BYD CO LTD

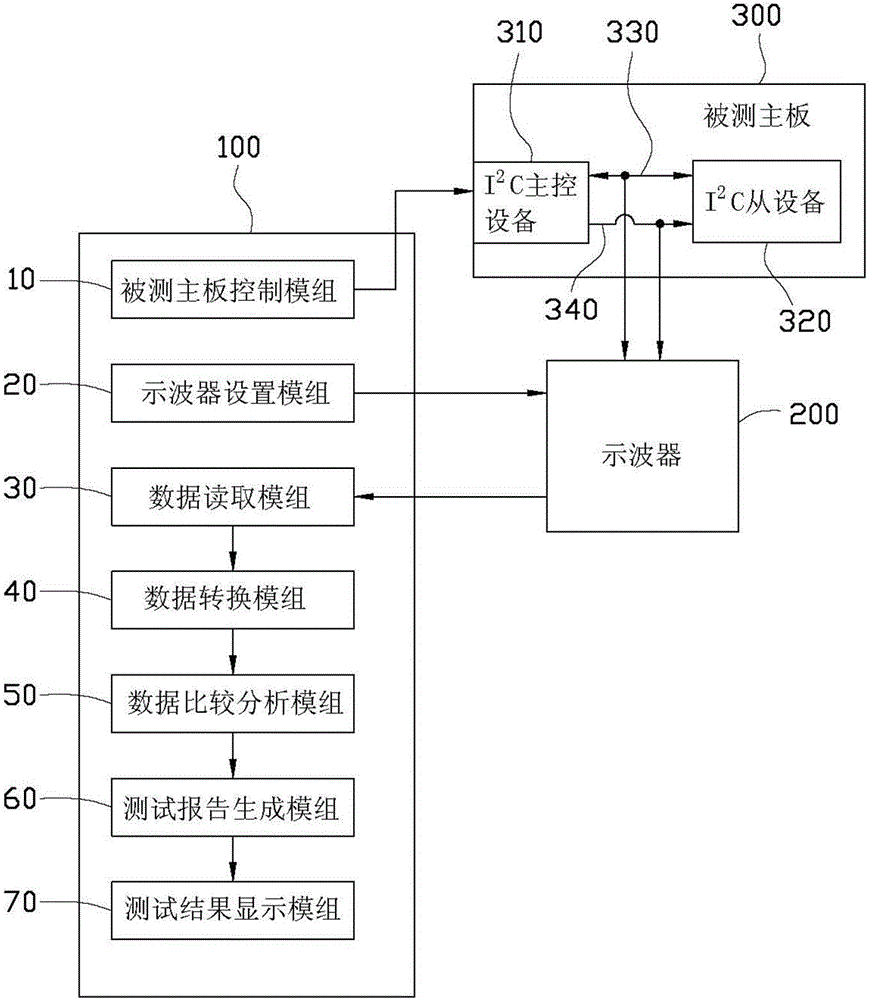

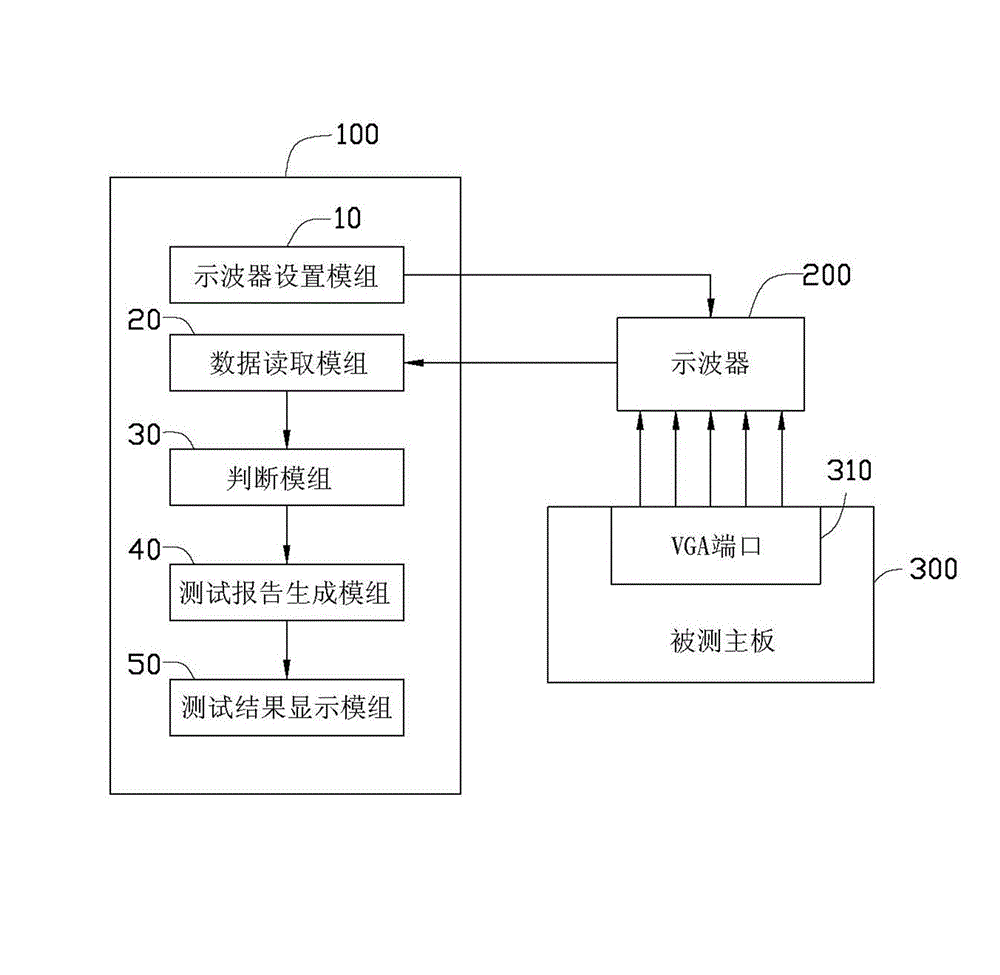

System and method for I2C bus testing

InactiveCN104008033AHigh degree of test automationThe test result is accurateError detection/correctionPrinted circuit testingEmbedded systemMotherboard

A system for I2C bus testing comprises an oscilloscope connected with an I2C bus of a tested mainboard. The oscilloscope is used for testing the waveform of signals transmitted on the I2C bus, the system for I2C bus testing further comprises a testing machine table, the testing machine table is connected with the tested mainboard and the oscilloscope and outputs test instructions to enable the I2C bus to start to transmit the signals and automatically adjust parameters of the oscilloscope, and a test report is automatically generated according to the waveform tested by the oscilloscope. The invention further discloses a testing method based on the system for I2C bus testing. The system and method for I2C bus testing are high in automation degree, and test results are accurate.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Plate surface wear resistance testing device for building indoor decoration

ActiveCN112525746AEasy to useEasy to operateInvestigating abrasion/wear resistanceStructural engineeringWear resistance

The invnetion discloses a plate surface abrasion resistance testing device for building interior decoration. The device comprises a supporting rack, a lifting driving piece, a lifting assembly, a mainmovement driving piece, a main movement middle transmission piece, a grinding head conversion driving piece, a grinding head mounting rotary disc and a plurality of abrasion resistance testing grinding head assemblies. The lifting driving piece is arranged on the supporting rack; the lifting assembly is connected to the lifting driving piece, the main motion driving piece is arranged on the lifting assembly, the main movement middle transmission piece is rotationally arranged on the lifting assembly, the grinding head conversion driving piece is arranged on the lifting assembly, and the grinding head mounting rotary disc is rotationally connected to the lower portion of the lifting assembly. A plurality of abrasion resistance testing grinding head assemblies are arranged on the outer peripheral wall of the grinding head mounting rotary disc, and a clamping assembly is arranged at the lower part of the supporting rack; the power input end of the main movement middle transmission pieceis in transmission connection with the main movement driving piece, and the power output end of the main movement middle transmission piece is in transmission connection with one of the abrasion resistance testing grinding head assemblies. The device greatly improves the test efficiency and applicability.

Owner:山东德才建设有限公司

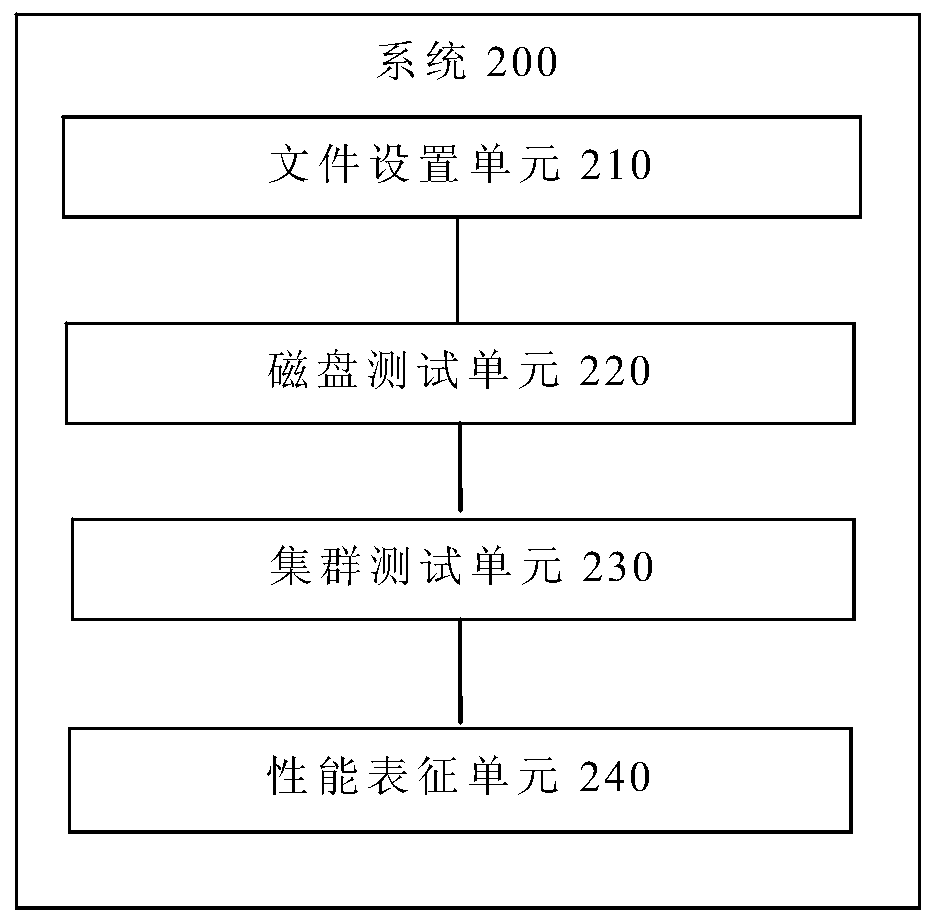

HDFS throughput performance test method, system, terminal and storage medium

ActiveCN110532187AImprove test accuracyHigh degree of test automationSoftware testing/debuggingThroughputAutomation

The invention provides an HDFS throughput performance test method, an HDFS throughput performance test system, a terminal and a storage medium. The HDFS throughput performance test method comprises the steps of setting a test file according to scale parameters of a storage cluster; distributing the test file to each node of a storage cluster, and obtaining an average read-write rate of a node diskof the storage cluster by utilizing a dd command and the test file; utilizing a cluster benchmark test tool Test DFSIO and the test file to obtain a cluster average read-write rate; and calculating adifference value between the average read-write rate of the disk and the average read-write rate of the cluster, and representing HDFS throughput performance by utilizing the difference value. The test accuracy is higher, the test automation degree is high, and manpower resources are saved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

System and method for VGA port testing

InactiveCN104008032AHigh degree of test automationThe test result is accurateStatic indicating devicesFunctional testingEmbedded systemMotherboard

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Testing device and testing method for input and output module function of control system

PendingCN109358604AReduce labor intensityLess investmentElectric testing/monitoringTransmissionControl systemMeasuring output

The invention discloses a testing device for the input and output module function of a control system. The system comprises a control cabinet, a network switcher, a high-precision universal meter, a channel switcher, and a monitoring computer, the control cabinet is in two-way communication connection with the network switcher, the network switcher is in two-way communication connection with the monitoring computer, the output end of the control cabinet is in communication connection with the input end of the channel switcher, and the output end of the control cabinet is in communication connection with the input end of the channel switcher, the output end of the channel switcher is in communication connection with the input end of the high-precision universal meter, the control cabinet isin two-way communication connection with the high-precision universal meter; the network switcher is used for the communication connection between the control cabinet and the monitoring computer, andthe high-precision universal meter is used for measuring output signals in the control cabinet and in communication connection with the control cabinet. The invention further provides a testing method for input and output module function of control system, and solving defects of existing a testing system and method for the input and output module function.

Owner:NANJING GUODIAN NANZI WEIMEIDE AUTOMATION CO LTD

Full-automatic control chair seat impact resistance test device and test method

ActiveCN104655386AImprove stabilityTest results are accurate and reliableShock testingElectricityAutomatic control

The invention discloses a full-automatic control chair seat impact resistance test device which comprises a bottom plate, a support bracket, a hammering mechanism and a control cabinet, wherein the control cabinet is used for controlling the hammering mechanism to act; the support bracket comprises two stand columns and a support cross beam which is arranged at the tops of the two stand columns; a plurality of chain wheels are arranged on the lower side of the support cross beam; the hammering mechanism comprises a hammering air cylinder, a balancing weight and a hammering chain; the direction of a piston rod of the hammering air cylinder is upward; one end of the hammering chain is connected with the piston rod of the hammering air cylinder and the other end of the hammering chain bypasses the chain wheels to be connected with the balancing weight; a chair fixing position is arranged on the bottom plate; the position of the chair fixing position corresponds to the position of the balancing weight; a PLC is arranged in the control cabinet; an operation panel is arranged at the top of the control cabinet; the PLC is electrically connected with the hammering air cylinder through an electromagnetic valve. The full-automatic control chair seat impact resistance test device and test method are high in stability in test process and accurate and reliable in test result, and can be used for randomly adjusting the hammering force to be suitable for different models of chairs.

Owner:GLOBAL FURNITURE ZHEJIANG

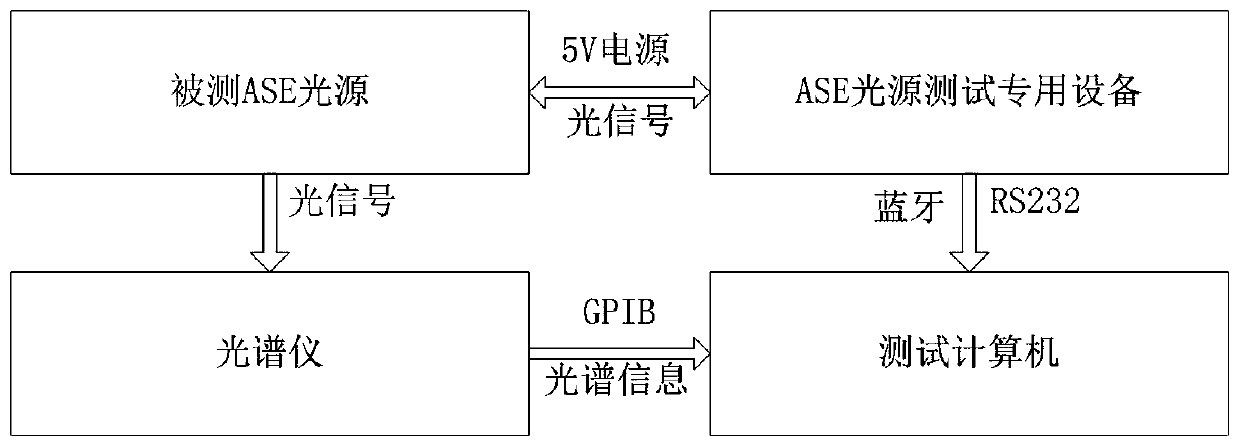

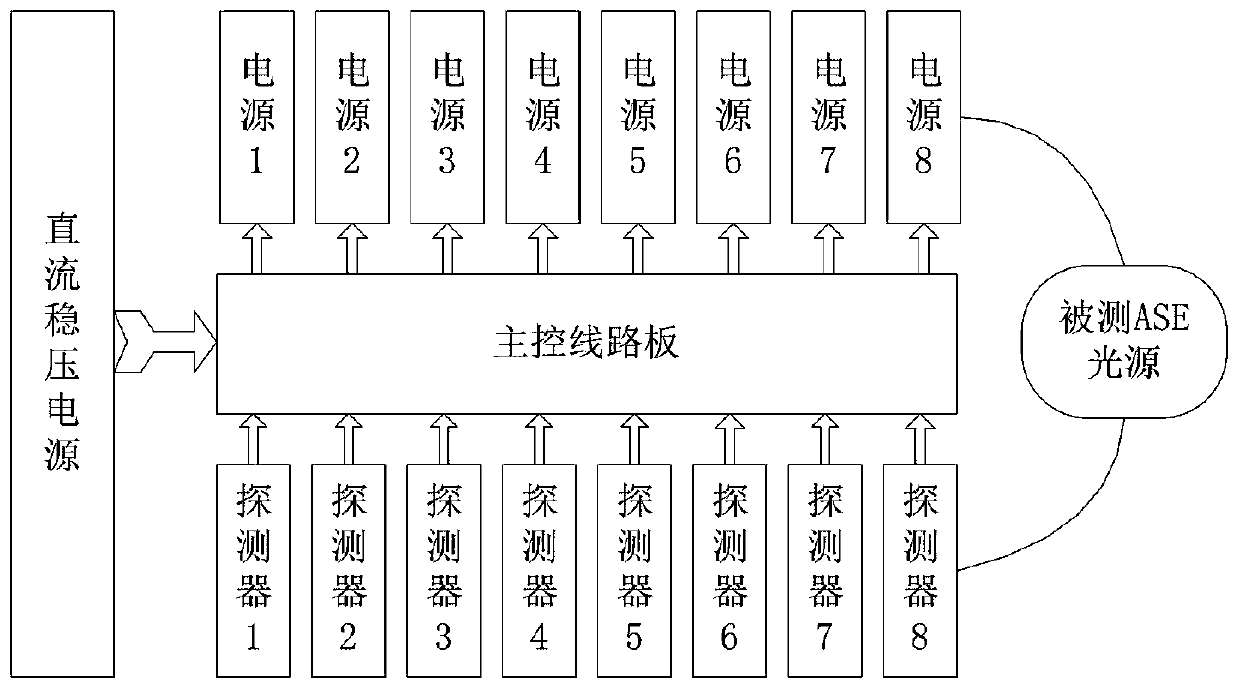

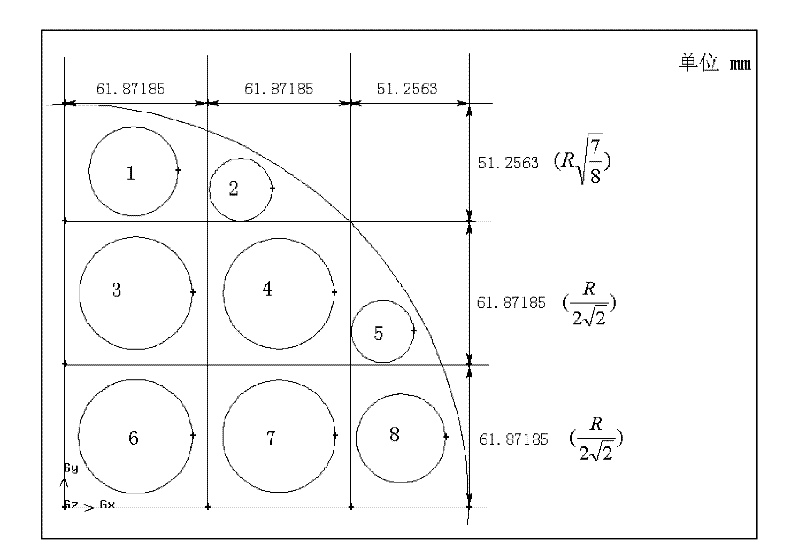

ASE light source test system

InactiveCN110553684ASolve the problem of high test cost and low efficiencyLow input costSpectrum investigationPhotometryFiberOptoelectronics

The invention relates to an ASE light source test system. The system comprises ASE light source test integrated equipment used for supplying power to a tested light source and acquiring light power and driving current information; and a test computer connected with the ASE light source test integrated equipment. The ASE light source test integrated equipment comprises a power supply module, a control circuit board and a plurality of detectors, wherein the power supply module is expanded to multi-path output through the control circuit board, and the detectors are connected with tail fibers ofa tested ASE light source. Eight light sources can be tested at the same time, each channel operates independently and does not interfere with each other, and the test capability is improved. Moreover, in hardware design, functions of a microprocessor are fully utilized, chips such as an external ADC are avoided, the design is simplified, and the development cost of test equipment is reduced.

Owner:TIANJIN NAVIGATION INSTR RES INST

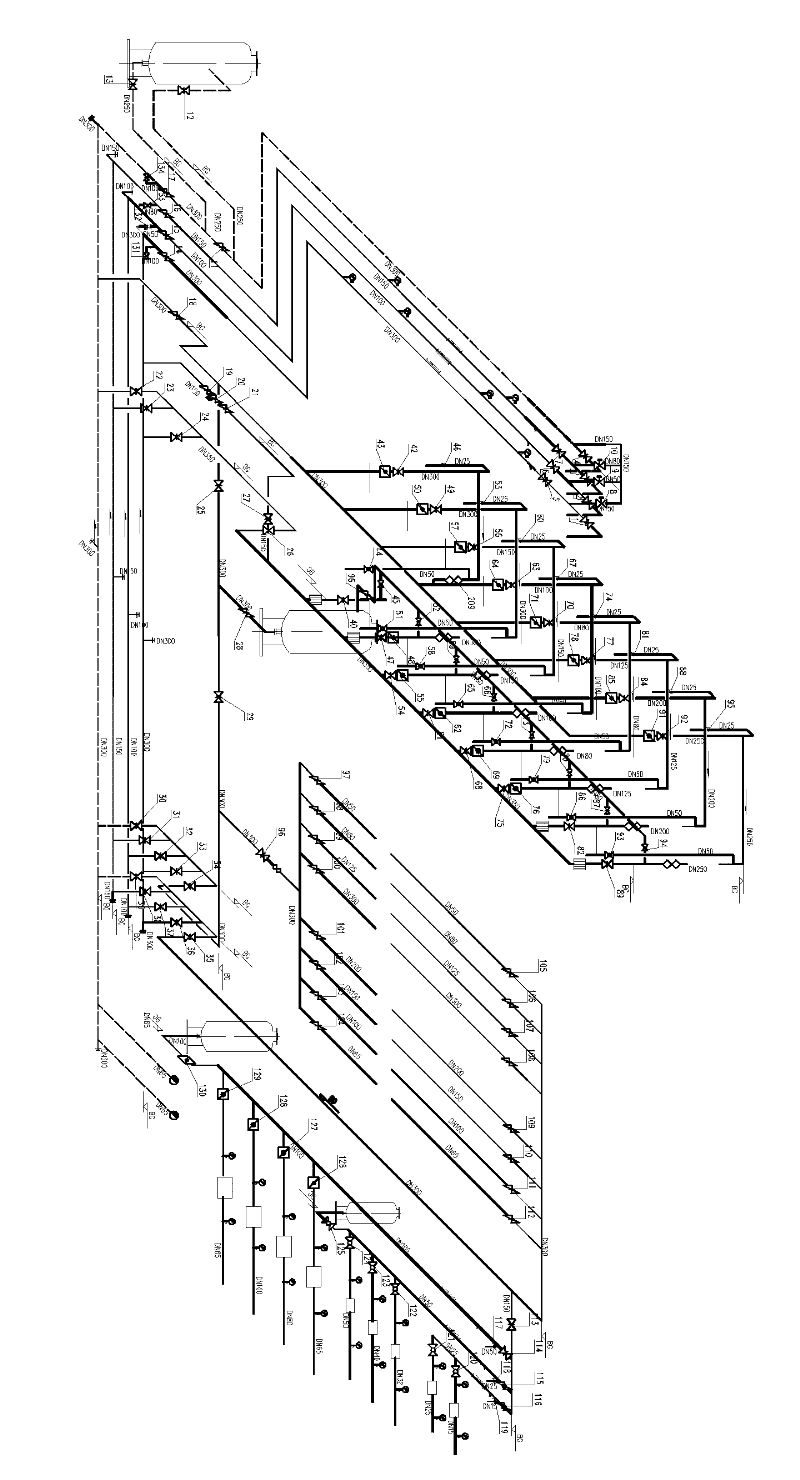

Multifunctional comprehensive testing device for fire control hydraulic valve

InactiveCN102192836AHigh measurement accuracyImprove detection efficiencyMachine part testingFire controlControl signal

The invention relates to a multifunctional comprehensive testing device for a fire control hydraulic valve. A water supply rectification system comprises a plurality of rectification grids; the outlet of each rectification grid is connected to a pipe network system; the pipe network system is integrated by a plurality of valve testing passages; each valve testing passage consists of pipelines with different pipe diameters; each pipeline is connected in series with a plurality of control valves and a sensor; the flow and a pressure signal are sampled by the sensor, and the acquired data is displayed on a paperless recorder in a centralized way so as to realize the simultaneous acquisition and centralized display of data; and the output of a direct-current control signal or an alternated-current control signal is controlled through an intermediate relay. Multiple testing functions are realized by simple adjustment of the control valves; and the measurement accuracy is high, the working stability is high, the detection efficiency is high and the application range is wide.

Owner:TIANJIN FIRE RES INST

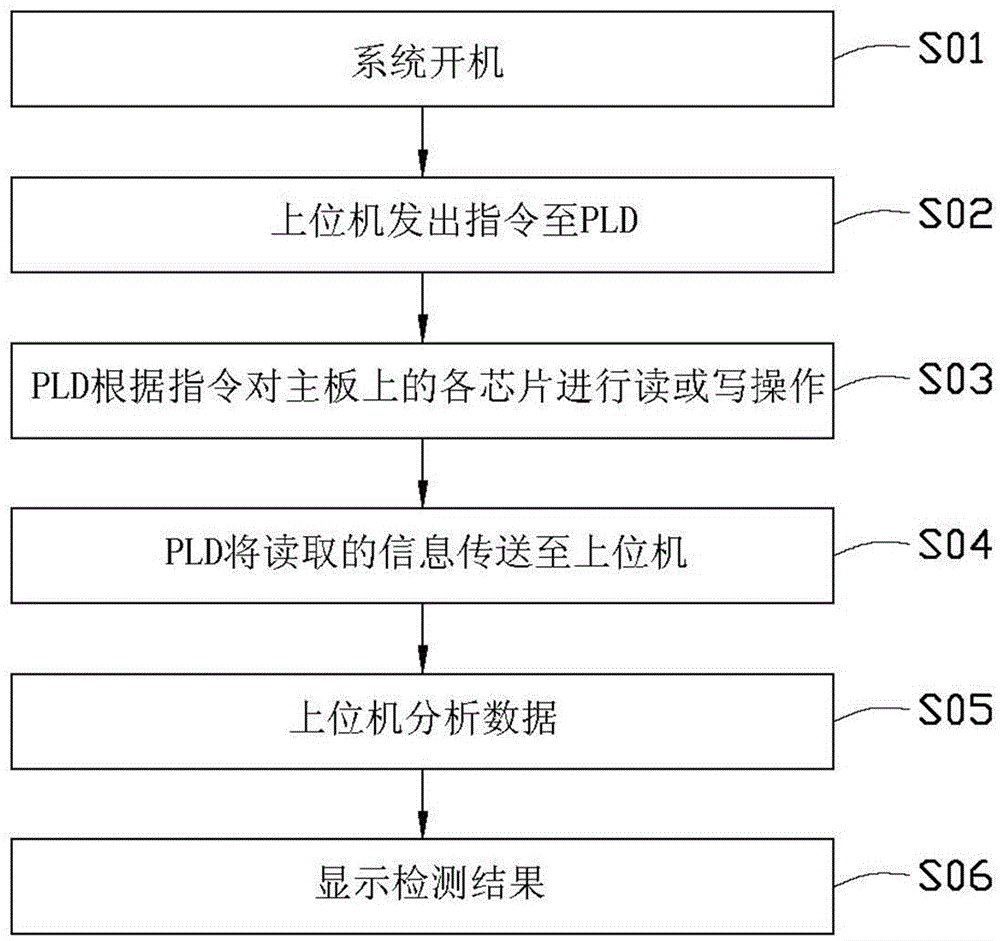

Server motherboard detection system and method

InactiveCN104038380AHigh degree of test automationThe test result is accurateError detection/correctionData switching networksConnected deviceEmbedded system

A server motherboard detection system is used for detecting a server motherboard. The server motherboard detection system comprises a principal computer connected with the server motherboard. The server motherboard comprises a plurality of devices connected with each other through an I2C bus. The server motherboard detection system further comprises a PLD connected with the plurality of devices of the server motherboard through an I2C bus. The principal computer sends a command to the PLD to enable the PLD to read information of the devices of the server motherboard and feed the information back to the principal computer, and the principal computer analyzes measured information and displays a detection result. The invention further discloses a detection method based on the server motherboard detection system. The server motherboard detection system and the detection method of the invention are high in degree of automation, and detection results are accurate.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

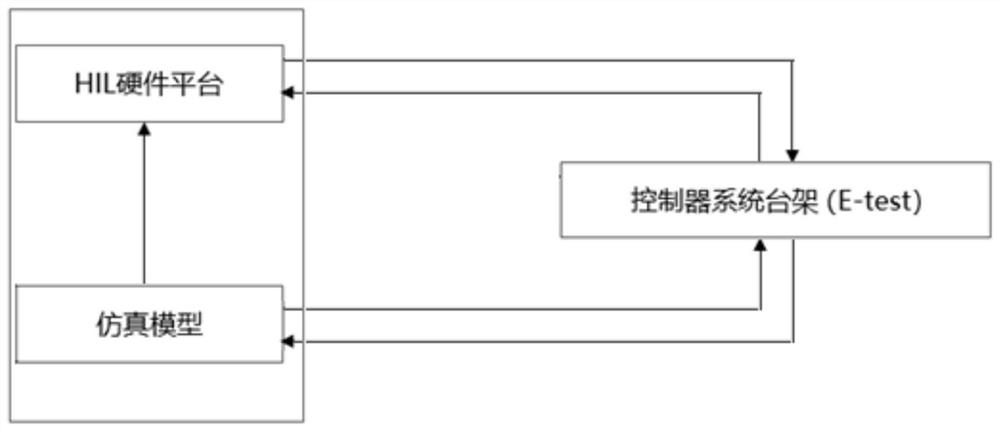

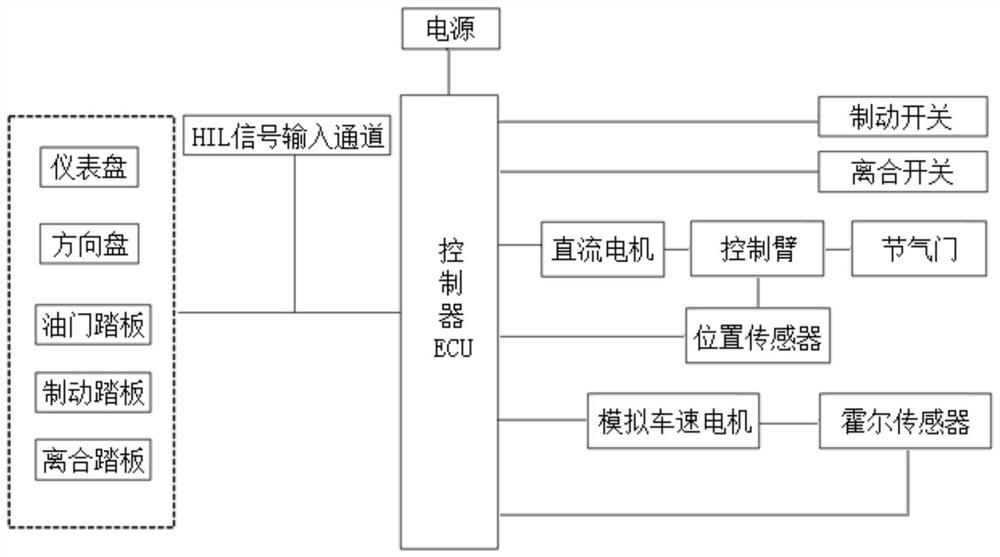

Cruise control test system based on automobile intelligent detection platform and test method thereof

ActiveCN112462733ASolve the problem of low accuracy of manual testingImprove automated testingProgramme controlElectric testing/monitoringSteering wheelCruise control

The invention discloses a cruise control test system based on an automobile intelligent detection platform, which comprises an HIL hardware platform and a controller system rack. The controller systemrack comprises a controller ECU, and an instrument panel, a steering wheel, an accelerator pedal, a brake pedal, a clutch pedal, a power supply, a brake switch, a clutch switch, a simulation vehiclespeed motor, a direct current motor, a Hall sensor and a position sensor which are connected with the controller ECU, and the controller ECU is connected with the HIL hardware platform. The Hall sensor is fixed above the simulated vehicle speed motor rotating shaft magnet and used for measuring the rotating speed of the simulated vehicle speed motor to replace the actual vehicle speed. The position sensor is used for detecting the position information of the throttle valve and transmitting a signal to the controller ECU; the controller ECU is used for receiving signals of the cruise control switch, the Hall sensor and the position sensor on the steering wheel and outputting control signals to drive the direct-current motor to adjust the opening degree of the throttle valve. The design is not only high in test precision, but also high in test automation degree.

Owner:DONGFENG AUTOMOBILE COMPANY

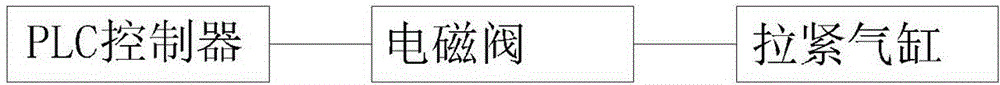

Full-automatic control chair back crushing resistance and fatigability test device and test method

ActiveCN104655412AImprove stabilityTest results are accurate and reliableMachine part testingElectricityAutomatic control

The invention discloses a full-automatic control chair back crushing resistance and fatigability test device which comprises a support bracket, a tensioning bracket, a tensioning mechanism and a control cabinet, wherein the tensioning bracket comprises four first stand columns and a plurality of support frames; the tensioning mechanism comprises a tensioning air cylinder, a balancing weight, two tensioning support rods which are arranged on one side of the balancing weight and an upper tensioning wheel and a lower tensioning wheel, which are arranged between the two tensioning support rod; a tensioning chain is connected with the balancing weight; the tensioning chain bypasses each of the upper tensioning wheel and the lower tensioning wheel to be connected with the chair back; the support bracket comprises a plurality of stand columns and a top frame and a bottom frame, which are arranged between the second stand columns; a turnover platform for supporting the chair is arranged in the top frame; a PLC is arranged in the control cabinet; an operation panel is arranged at the top of the control cabinet; the PLC is electrically connected with the tensioning air cylinder through an electromagnetic valve. The full-automatic control chair back crushing resistance and fatigability test device and test method are high in stability in test process and accurate and reliable in test result, and can be used for testing various models of chairs.

Owner:GLOBAL FURNITURE ZHEJIANG

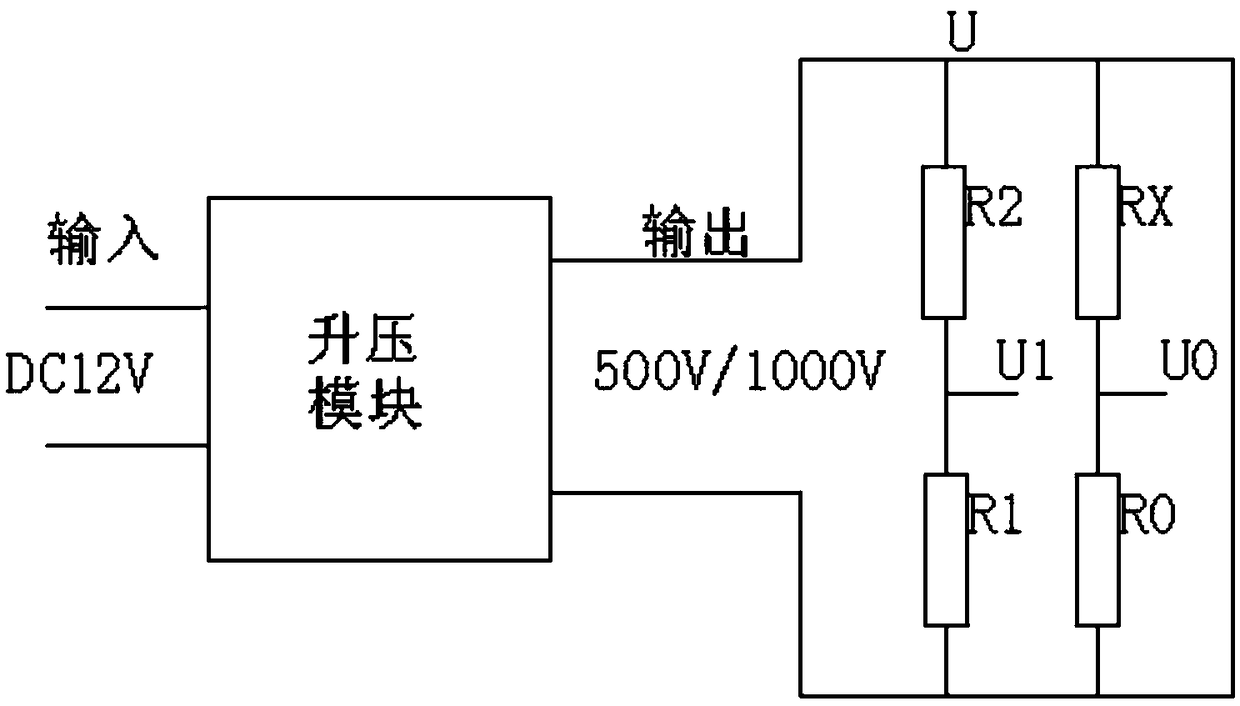

Train insulation wireless transmission automatic detector

PendingCN108710075AAvoid repetitive operationsEasy to transfer and saveVery high resistance measurementsTesting circuitsMicrocontrollerMicrocomputer

The invention discloses a train insulation wireless transmission automatic detector which comprises a storage battery and a single-chip microcomputer microcontroller. An output end of the storage battery is connected to a boosting module, an output end of the single-chip microcomputer microcontroller is connected to the boosting module, an output end of the boosting module is connected to the single-chip microcomputer microcontroller through a sampling and testing circuit, and the single-chip microcomputer microcontroller is further connected with a relay array. The automatic detector solves the problems that a megger and an electronic megameter are used for measuring train insulation, and efficiency and accuracy are low in the prior art.

Owner:北京九方宏信交通装备有限公司

Current and voltage equalizing test method for SCR set and its device

InactiveCN1391108AReduce capacityReduce power consumptionElectrical testingTransformerAverage current

An average current and voltage measuring method and equipment for SCR set is disclosed. The current and voltage equalizing coefficient of each bridge arm for SCR set is measured in intermittent pulse mode of pulse power supply, which is composed of average voltage measuring power supply and average current measuring power supply, both of which are switched by switch and relay. Two synchronizing transformers are used to provide synchronizing signals for synchronizing sampling with measuring. Its advantages are low cost, less electric consumption, and high measuring precision and speed.

Owner:胡振民

Automatic detecting device and method of relay protection information system pressure processing capability

PendingCN108152684AImplement automated testingHigh degree of test automationFault locationPower gridData source

The invention discloses an automatic detecting device of the relay protection information system pressure processing capability. The device comprises a power grid data source library, a data source simulation mechanism, a data analysis and comparison mechanism and a result displaying device, wherein one end of the data source simulation mechanism is connected with the power grid data source library, and the other end of the data source simulation mechanism is connected with a protection information substation; the input end of the data analysis and comparison mechanism is connected with the power grid data source library and a protection information master station separately, and the output end of the data analysis and comparison mechanism is connected with the result display device. The invention further discloses an automatic detecting method of the relay protection information system pressure processing capability. By means of the automatic detecting device and method of the relay protection information system pressure processing capability, the method of automatically comparing a power grid fault data occurring source with information of the master station is adopted, automatictesting of the relay protection information system pressure processing capability is achieved, the testing automated degree can be greatly increased before a protection information system is put intooperation and when the protection information system is in laboratory detection, the labor cost is lowered, and the working efficiency is improved.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com