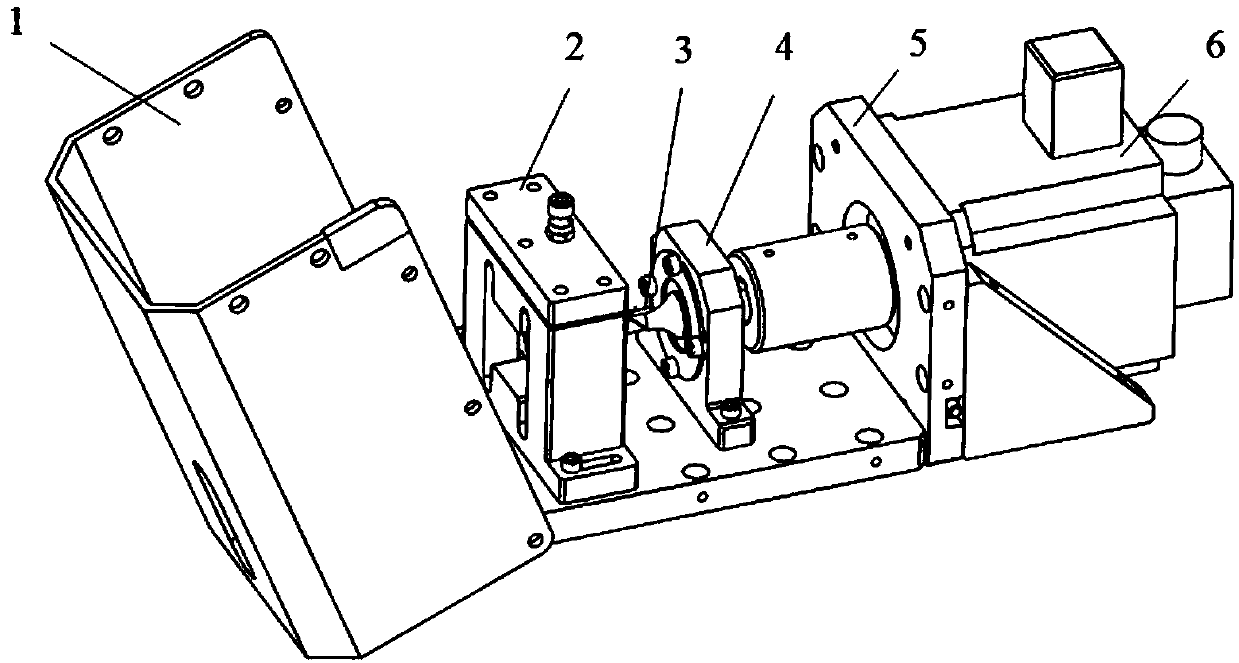

Rotating bending fatigue detecting device and rotating bending fatigue test method

A bending fatigue detection device technology, applied in the field of bending fatigue test, can solve problems such as complex structure, poor loading accuracy, cumbersome assembly of parts, etc., and achieve the effects of high safety, low cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

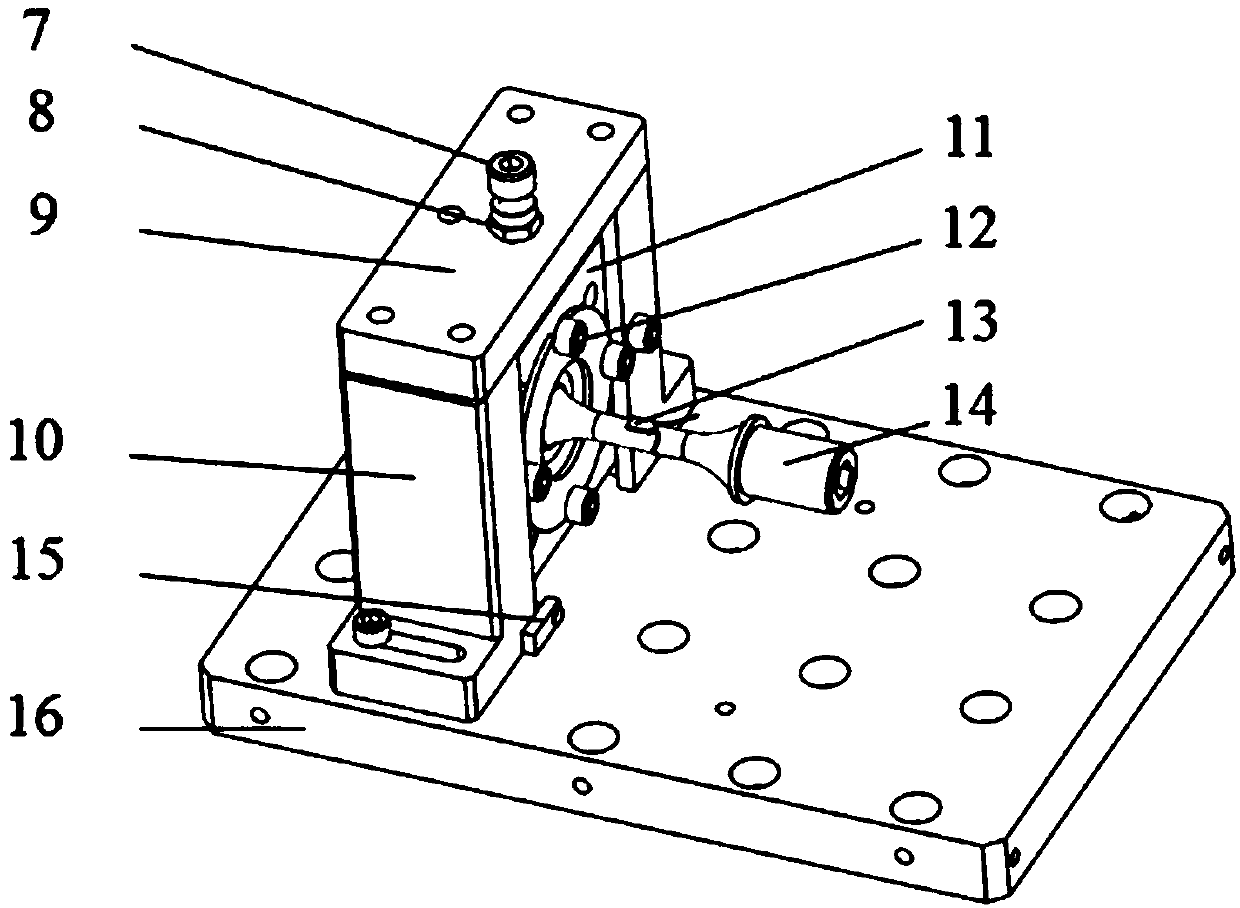

specific Embodiment

[0057] The following is an example of the rotating bending fatigue test of the rotating bending smooth test piece of No. 45 steel after normalizing treatment, where E=200.1Gpa, σ max =250Mpa,k t =1.

[0058] Calculate strain gauge ε=,, σmax / E=, 250×1000 / 200.1≈1250

[0059] E - modulus of elasticity

[0060] σmax———Test stress value

[0061] Kt - stress concentration factor

[0062] ε——strain value.

[0063] According to the test requirements, the test piece is connected with the self-aligning unit and the supporting connection unit respectively and the strain gauges are installed.

[0064] Connect the strain gauge and strain tester, and adjust to zero. A prescribed loading stress is applied by adjusting the loading bolt. In this embodiment, the reading of the strain tester is adjusted to 1250 microstrain, and the locking nut is fixed. According to the test requirements, the speed is set to 3000r / min, the speed can be adjusted during the test, and the number of test life...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com