Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Help to distinguish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

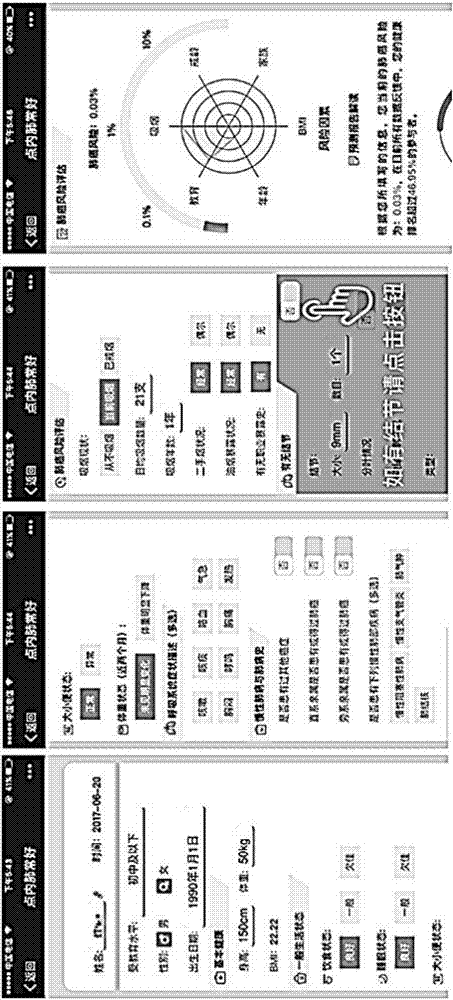

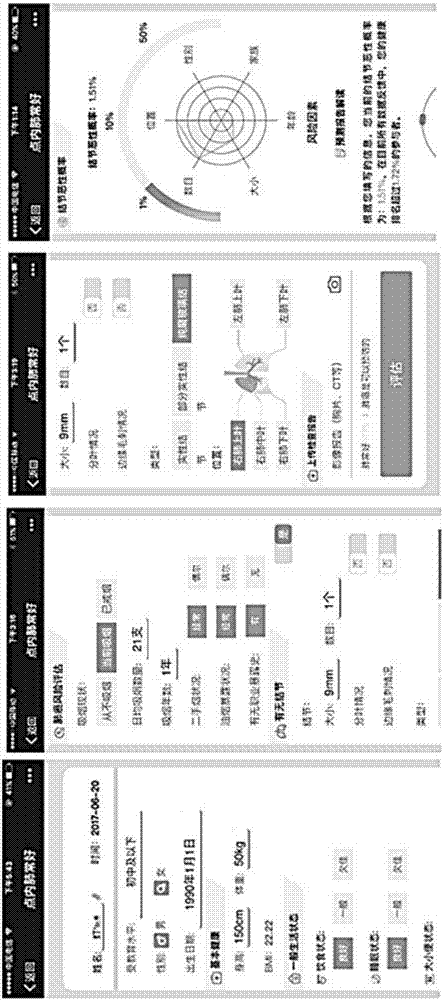

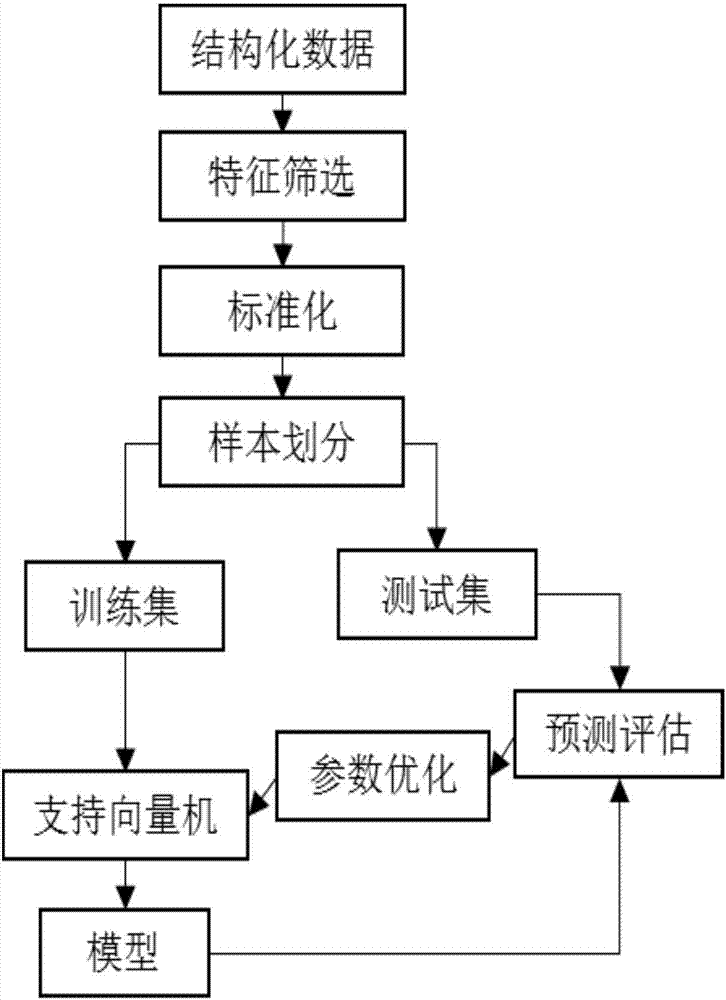

Method and system for assisting in screening lung cancer based on artificial intelligence

InactiveCN107247887AHelp to distinguishSpecial data processing applicationsPulmonary noduleMalignancy

A method and system based on artificial intelligence to assist lung cancer screening. By generating a model for distinguishing lung cancer and a benign and malignant evaluation model for pulmonary nodules, the basic information, basic health information, general living conditions, and current status of the subject are collected in real time during online detection. Respiratory symptoms, chronic disease and lung disease history and smoking status, and the risk value of cancer and the probability of malignancy of nodules were detected through the identification model of lung cancer and the evaluation model of benign and malignant pulmonary nodules. The present invention fully utilizes various related features, divides high- and low-risk groups of lung cancer and evaluates benign and malignant pulmonary nodules through multi-dimensional information, and can help to distinguish high-risk groups.

Owner:点内(上海)生物科技有限公司

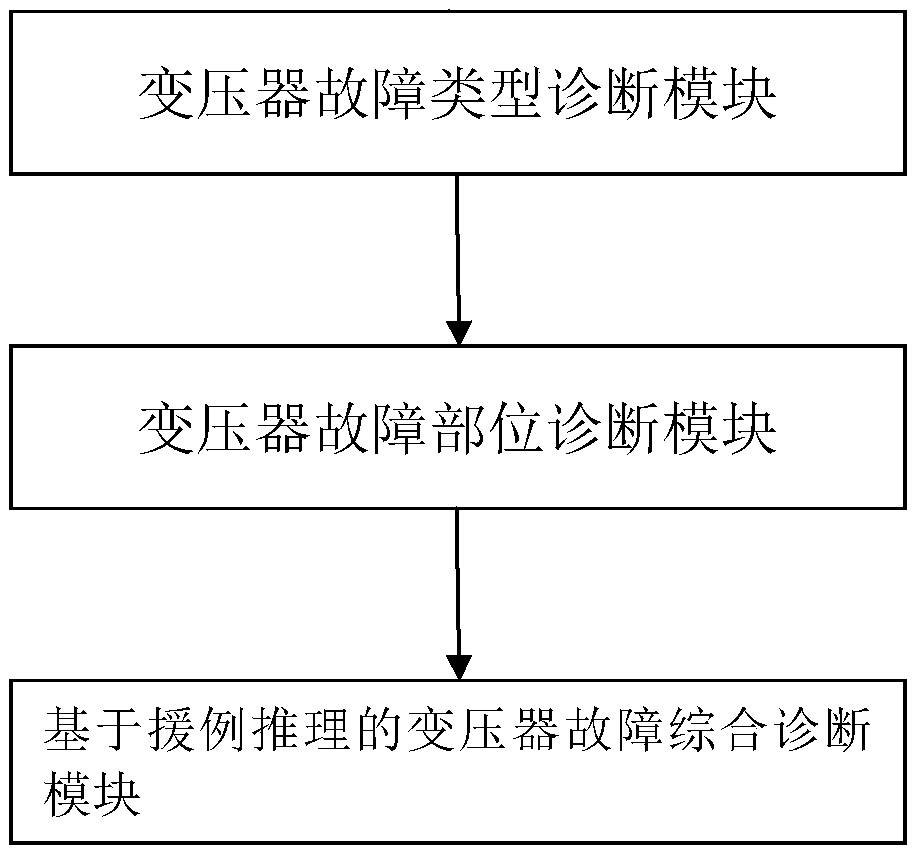

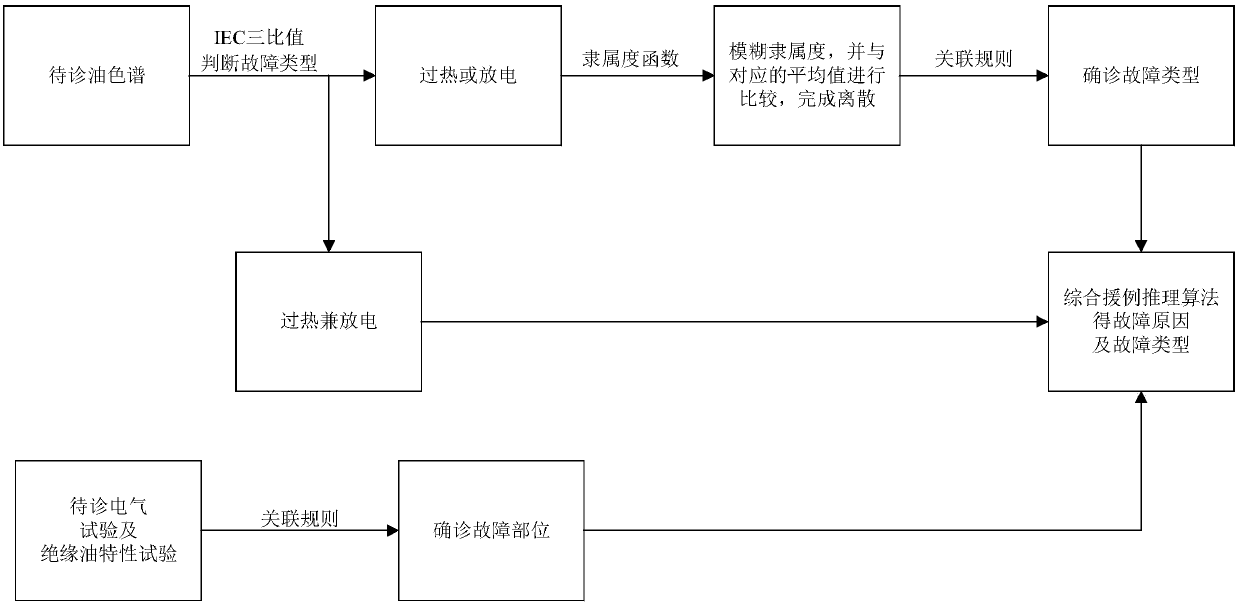

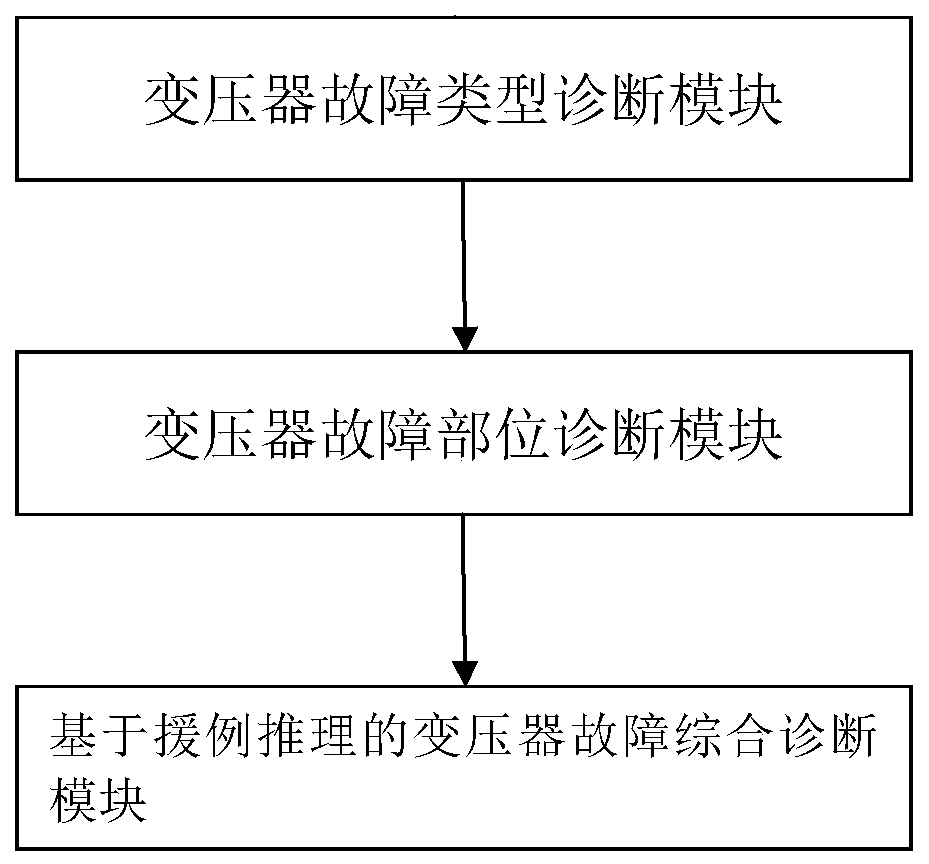

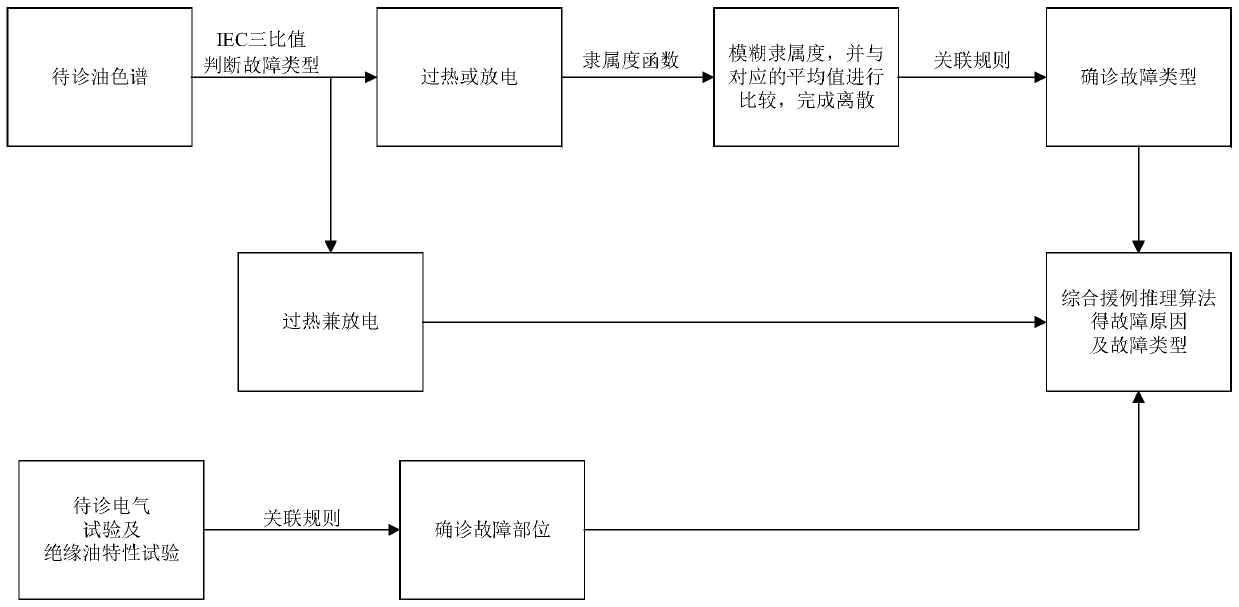

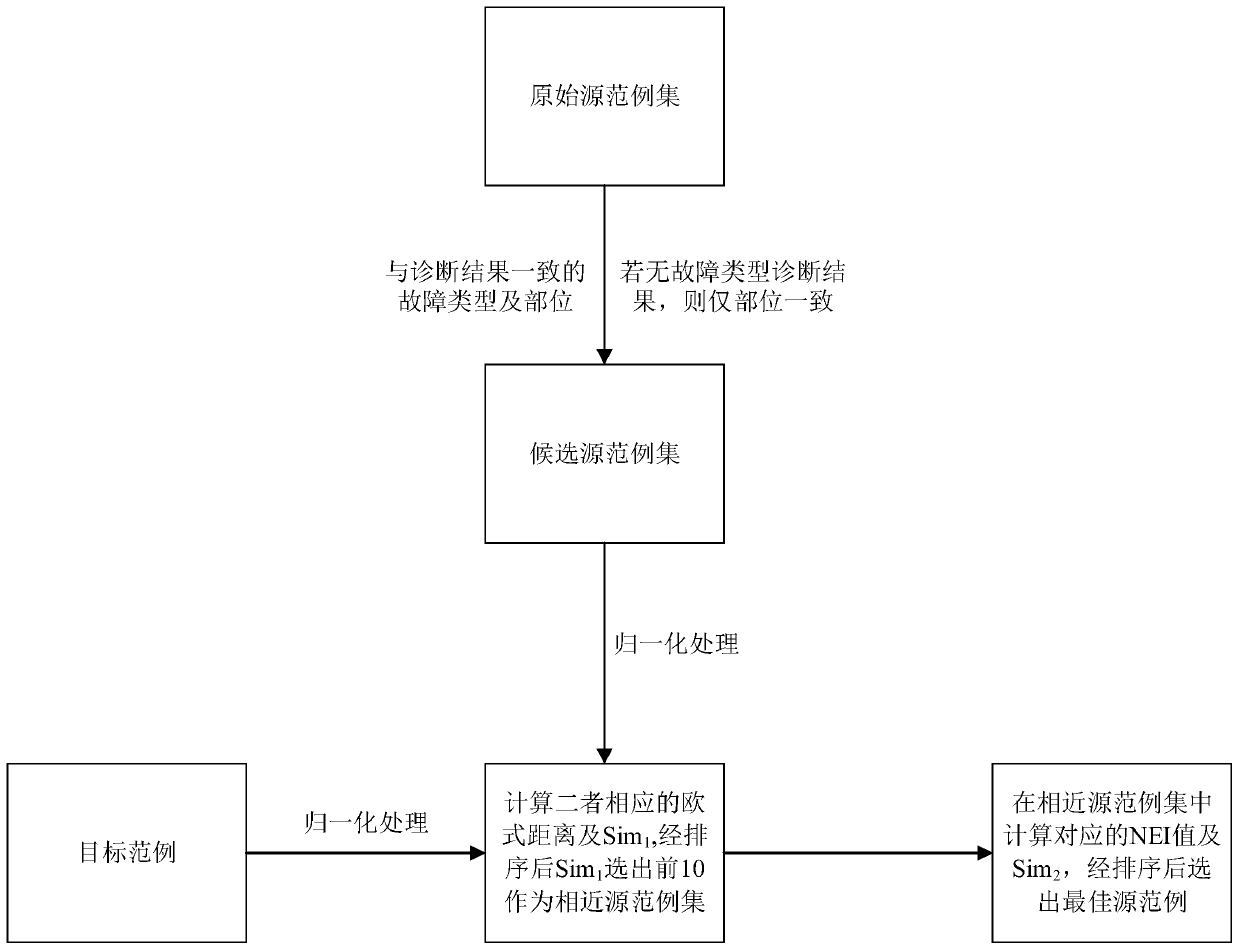

Transformer fault comprehensive diagnosis system and method based on fuzzy association rule

ActiveCN107907783AReflect the actual relationshipImplement diagnosticsTesting dielectric strengthTransformers testingDiagnosis methodsTransformer

The disclosure provides a transformer fault comprehensive diagnosis system based on a fuzzy association rule. The system includes a transformer fault type diagnosis module, a transformer fault location diagnosis module, and a transformer fault comprehensive diagnosis module based on case-based reasoning. The disclosure also provides a transformer fault comprehensive diagnosis method based on a fuzzy association rule. The diagnosis system diagnoses the fault type, the fault location and the fault cause of a transformer, can help the field staff to complete discrimination, and is suitable for the diagnosis of a variety of transformer faults.

Owner:HUNAN WULING POWER TECH CO LTD

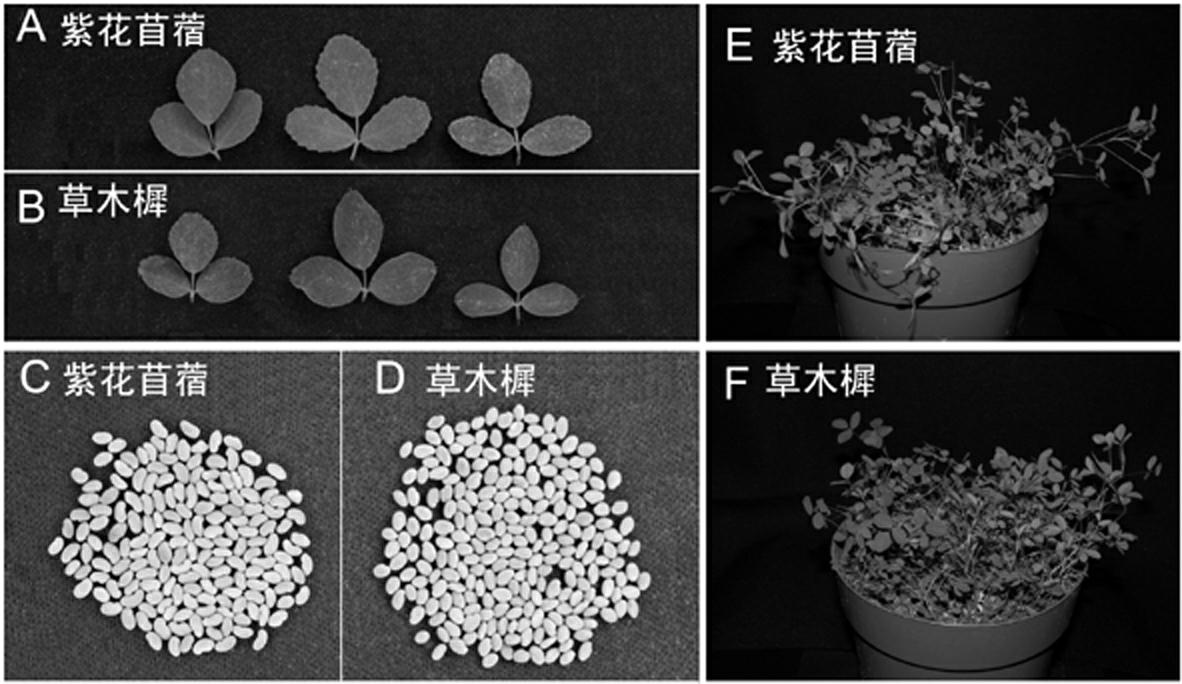

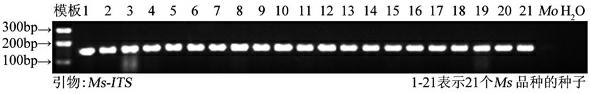

Kit for identifying authenticity of medicago sativa seed and detection method thereof

InactiveCN102643896ARapid identificationEfficient and accurate identificationMicrobiological testing/measurementDNA/RNA fragmentationMelilotus albusPastoralism

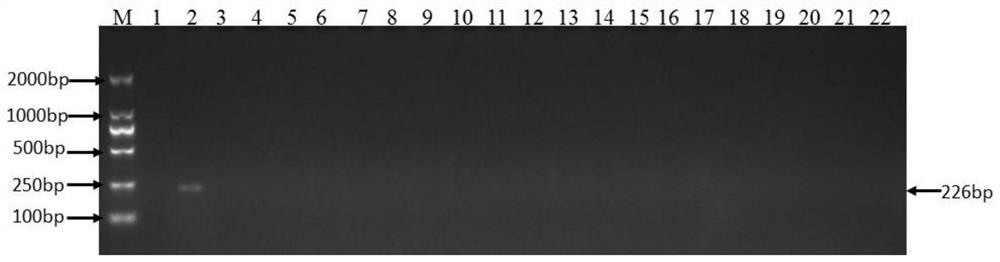

The invention mainly relates to a method for identifying authenticity of a medicago sativa seed and special primers thereof, in particular to a gene detection kit of medicago sativa and melilotus albus and a detection method thereof. The kit for identifying the authenticity of the medicago sativa seed is mainly characterized in that: the total volume of a medicago sativa PCR (Polymerase Chain Reaction) detection system is 20 mul; and the kit comprises 2*PCR Master, the special primer MsITS-F (5'-3'): TTTTTGAACGCAAGTTGCGC and the special primer MsITS-R (5'-3'): CAACCAACCACGAGACAGA and ddH2O. Detection result shows that the technology can be used for identifying the authenticity of the medicago sativa seed, has the characteristics of high sensitivity, high accuracy, high repeatability, quickness, convenience and the like, has broad application prospect in medicago sativa industrial promotion of China, can guarantee that the production of livestock husbandry of China is served by the medicago sativa well and lays a solid foundation for guaranteeing grain safety of China.

Owner:LANZHOU UNIVERSITY

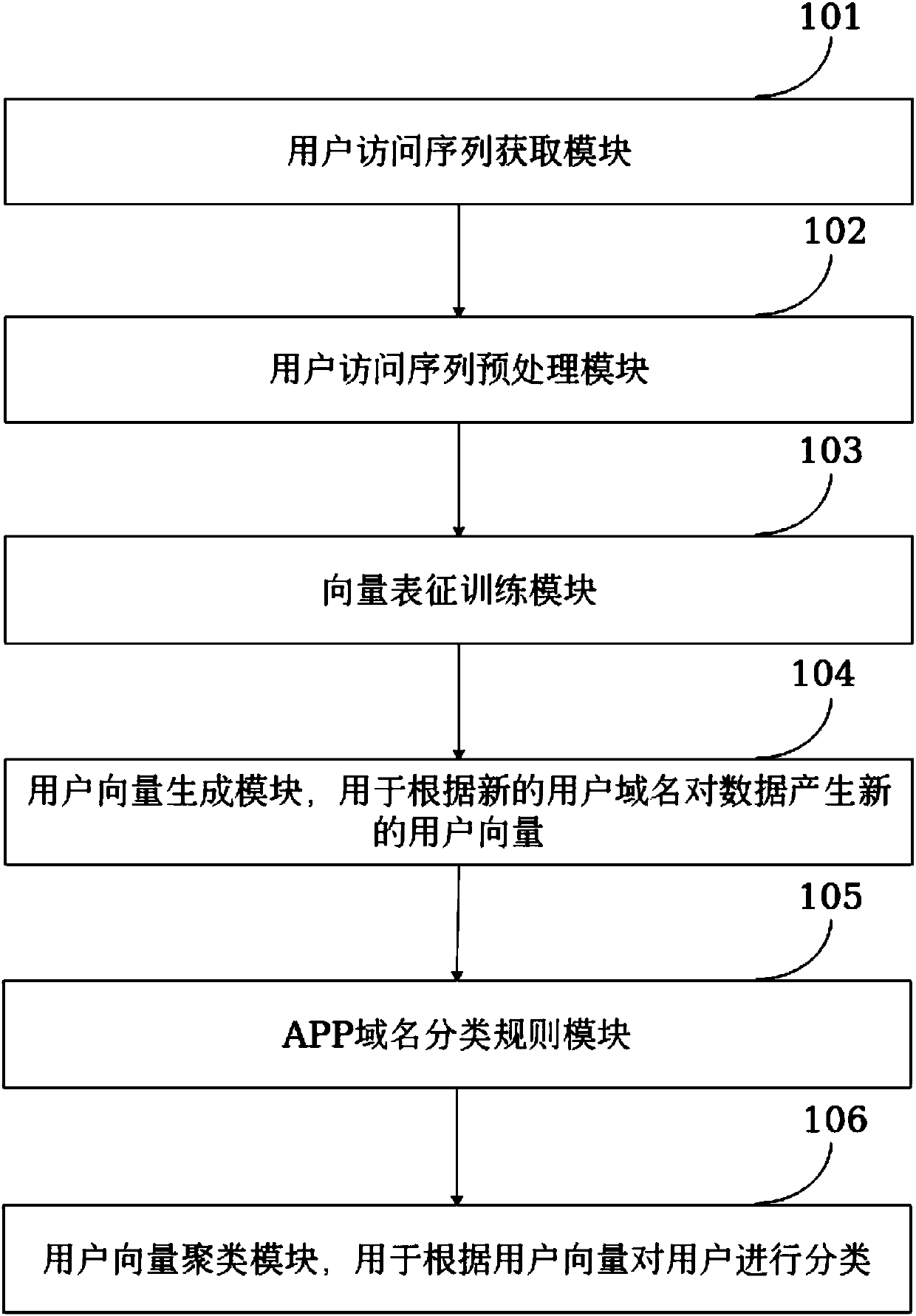

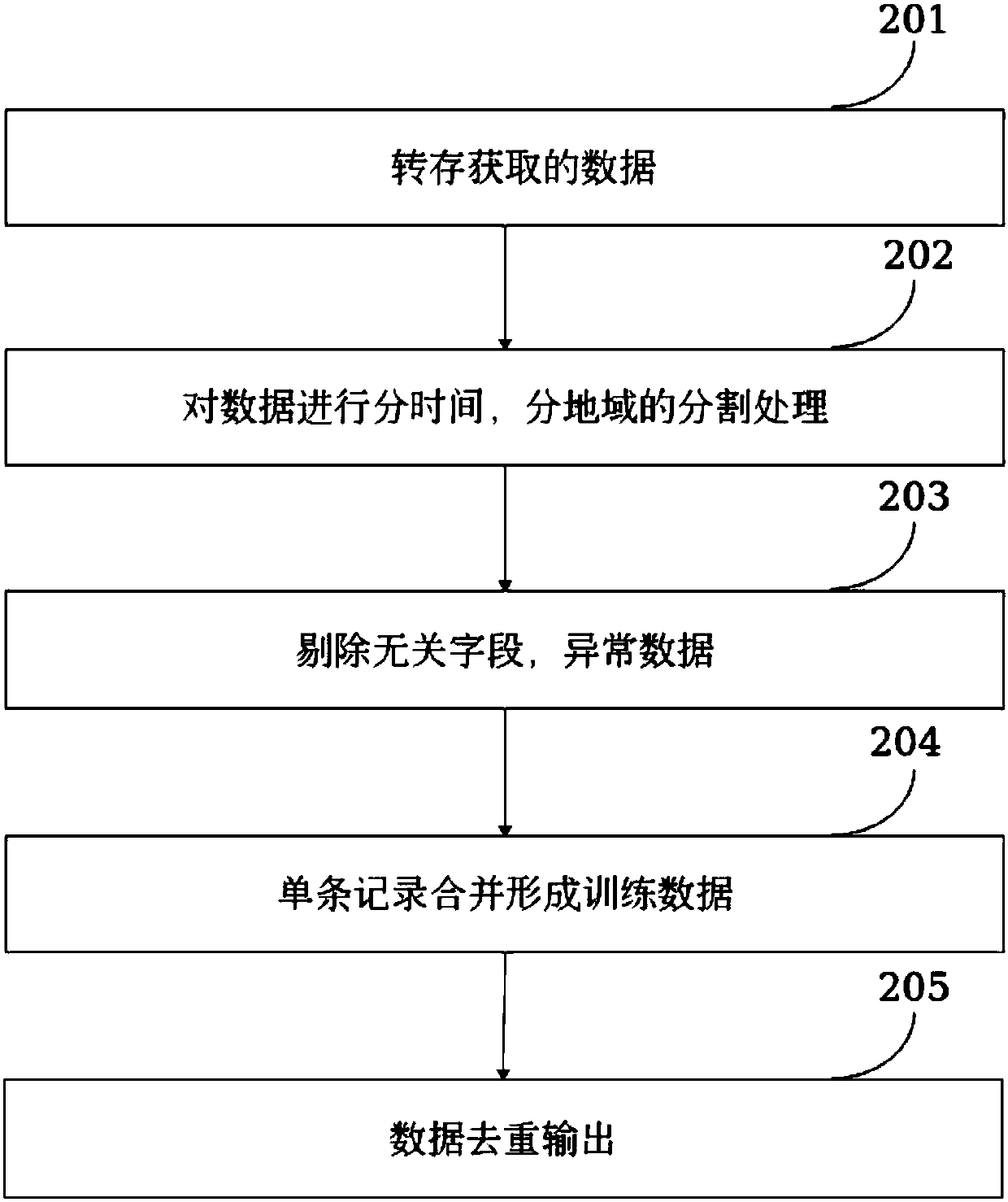

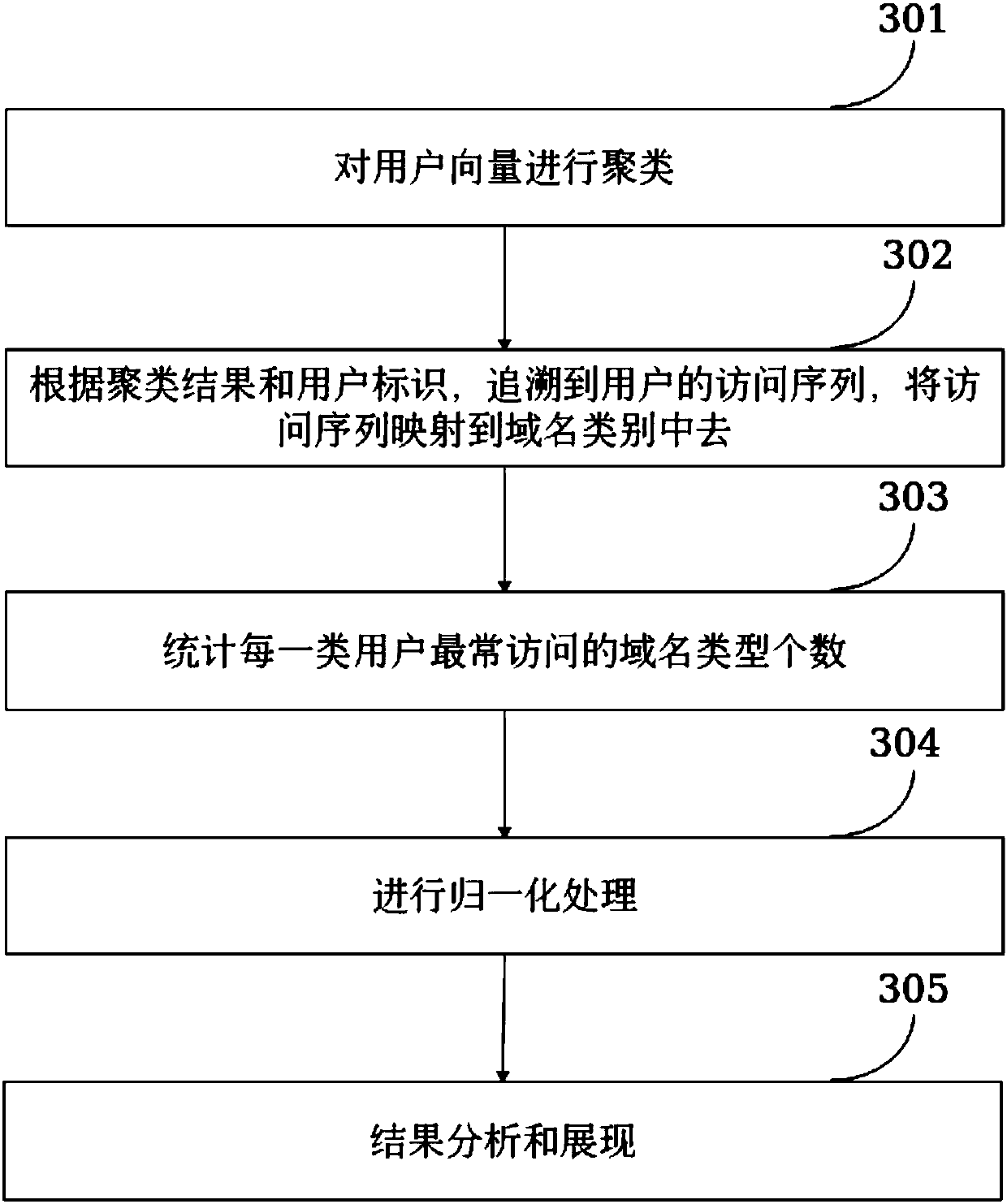

Mobile Internet user access mode representing and clustering method

InactiveCN107818334AHelp to distinguishEasy to digWeb data indexingCharacter and pattern recognitionTraining data setsSequencing data

The invention provides a mobile Internet user access mode representing and clustering method. The method comprises that a domain name access sequence of mobile Internet users is acquired; preprocessing is performed on the mobile Internet domain name user access sequence, and training data and actual data of a preset data type are generated; a vector representation training module performs trainingon a training data set by using an algorithm; a user vector generation module performs generation calculation on the actual data by using a training model acquired by the training algorithm; APP domain name classification rules are set, and manual classification is performed according to belonging fields and purposes of domain names in the domain name access sequence; and a user vector clusteringmodule performs clustering and analysis on users by using an acquired user vector. The mobile Internet user clustering method provided by the invention is based on domain name access sequence data ofthe users, clustering for the users is achieved, and behavioral habits and characteristics of the users are extracted.

Owner:BEIJING UNIV OF POSTS & TELECOMM +1

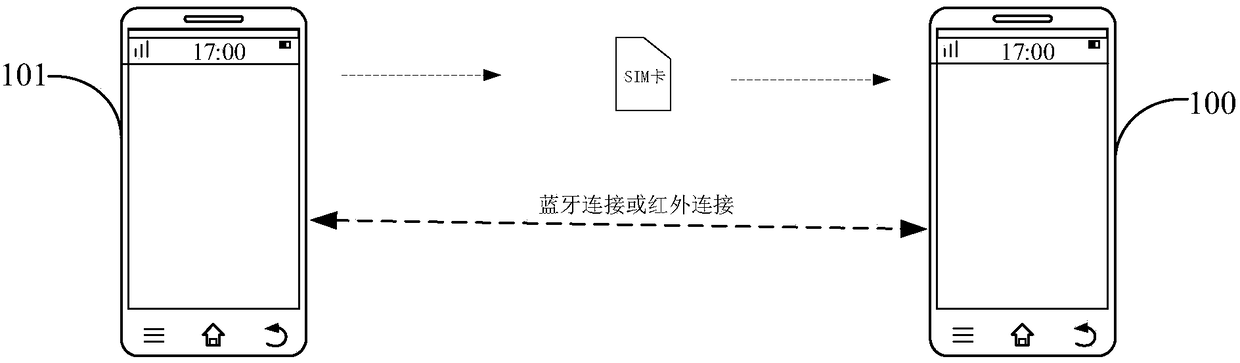

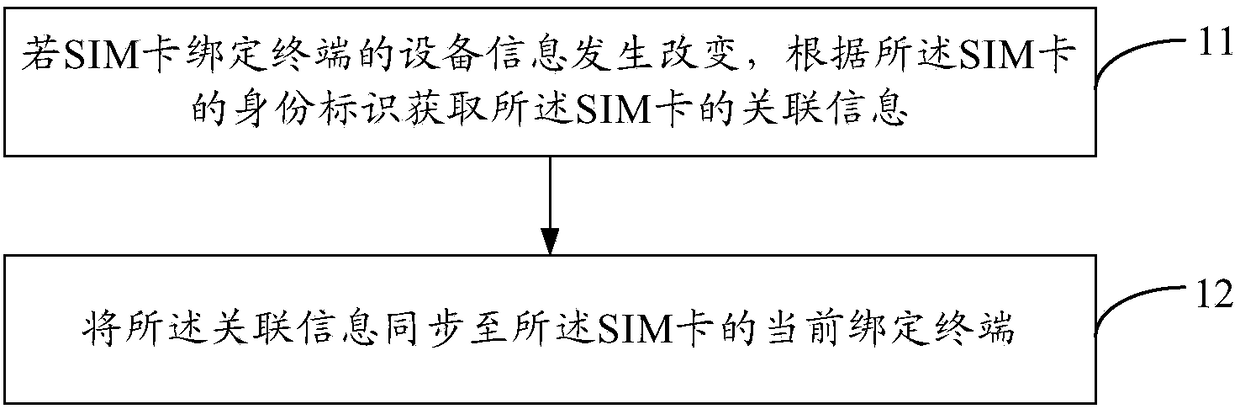

Terminal information acquisition method and device

InactiveCN108206998AHigh degree of intelligenceIncrease data access burdenNetwork data managementComputer hardwareRelevant information

The invention provides a terminal information acquisition method and device. The method comprises steps that if the device information of an SIM card binding terminal changes, the association information of an SIM card is acquired according to an identity identifier of the SIM card; the association information is synchronized to a present binding terminal of the SIM card. The method is advantagedin that when the device information of the SIM card binding terminal changes, for example, the SIM card is transferred to a new terminal, or the present binding terminal of the SIM card performs factory reset operation, the present binding terminal of the SIM card has not any of the relevant information of the SIM card, the association information of the SIM card can be automatically acquired by the present binding terminal of the SIM card according to the identity identifier of the SIM card, and the association information is locally synchronized. Compared with the prior art, the informationis acquired without manual operation of a user, the intelligent degree of the user terminal is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

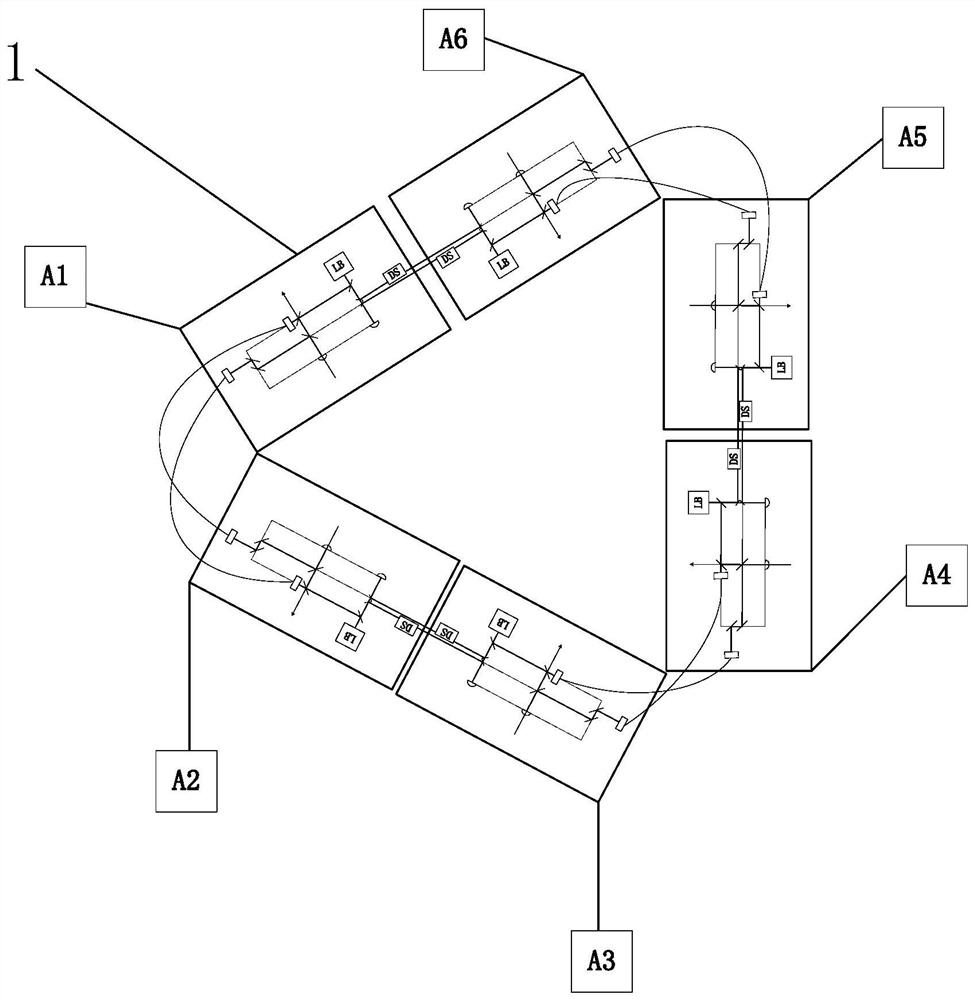

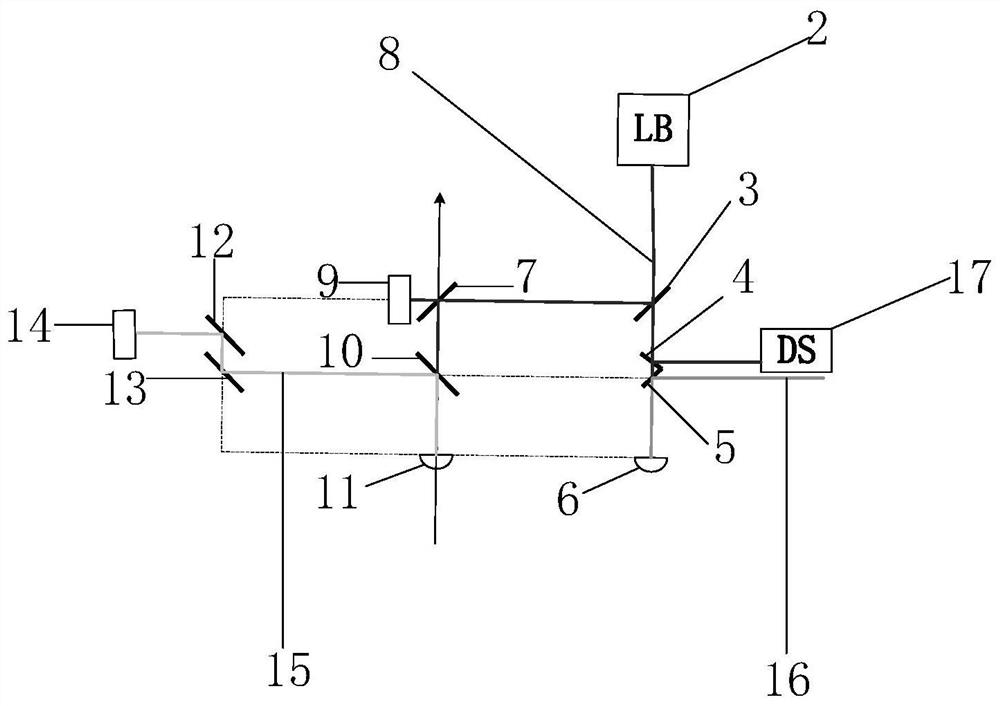

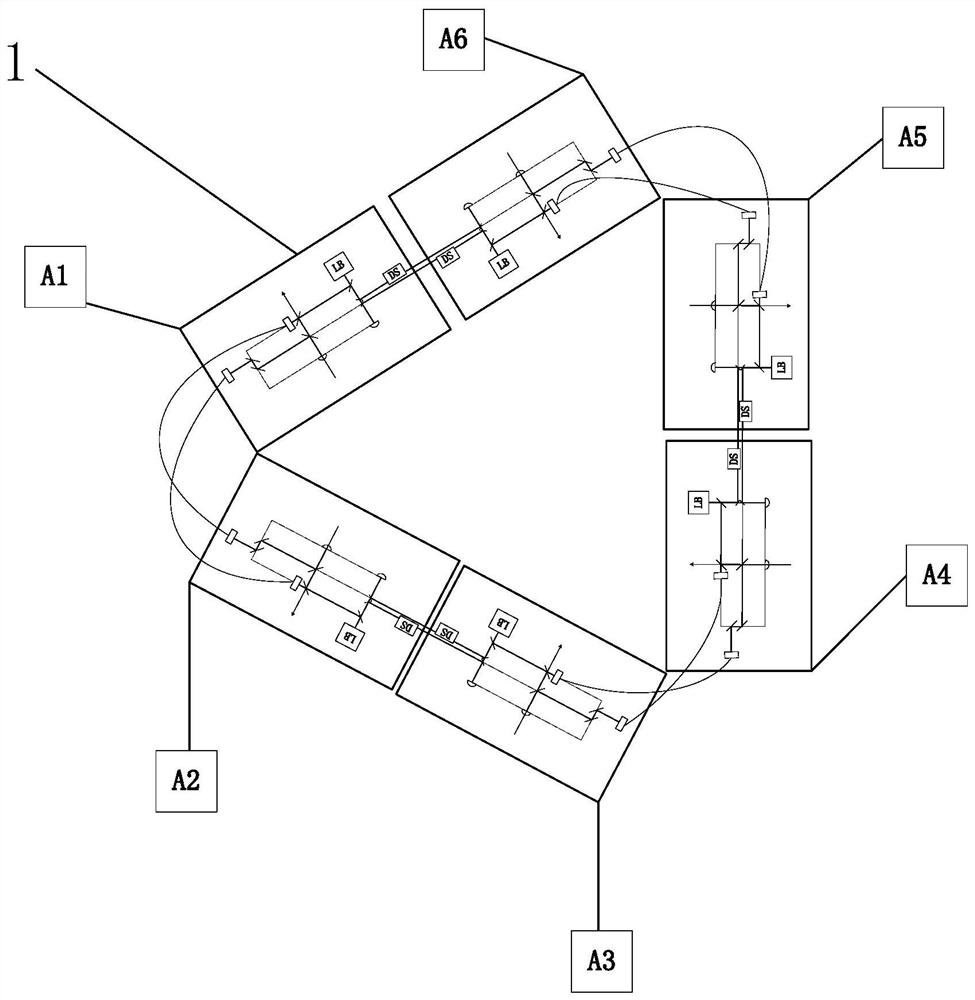

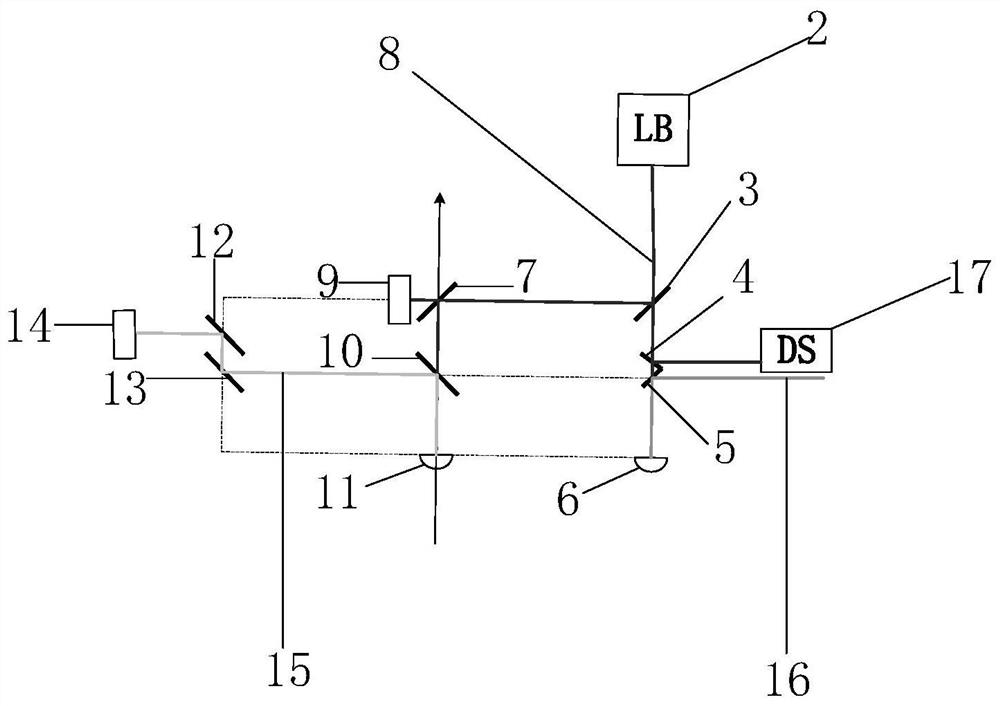

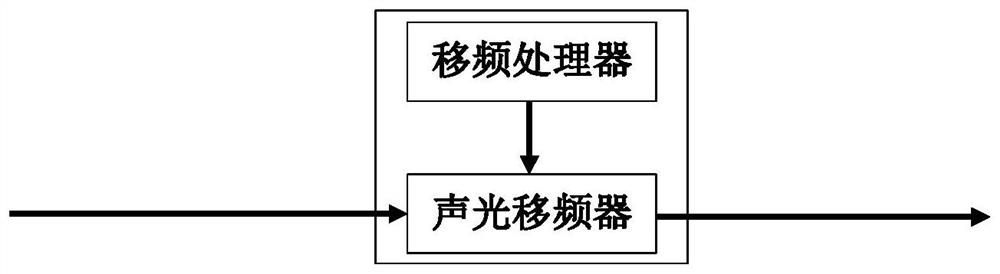

Inter-satellite laser interference frequency planning simulation verification system for time sequence reinforcement learning

ActiveCN113609755AGuaranteed superiorityIncrease flexibilityDesign optimisation/simulationMachine learningDecision modelSimulation

The invention discloses an inter-satellite laser interference frequency planning simulation verification system for time sequence reinforcement learning. The system comprises a laser interference optical platform group, a storage assembly and a display terminal, wherein the laser interference optical platform group comprises six laser interference optical platforms with the same structure, every two laser interference optical platforms form a pair, the frequency and the phase of laser are adjusted in real time according to a frequency planning scheme, and frequency shift is carried out on incident laser according to Doppler interference frequency information, so that the interference of the satellite in the space due to the Doppler phenomenon is simulated; the storage component is used for storing a pre-established and trained decision model, a frequency planning scheme determined by the decision model and Doppler interference frequency information corresponding to each moment of an experiment, and storing a frequency planning scheme selected in the experiment; the decision model is obtained by training through a time sequence backtracking reinforcement learning method; and the display terminal is used for displaying the Doppler interference frequency information and the laser beat frequency information in real time.

Owner:NAT SPACE SCI CENT CAS

A passive human body identification method based on narrow-band radio frequency link sampling

PendingCN109948481AAvoid Forced FitsAvoid visual effectsCharacter and pattern recognitionHuman bodyProbability estimation

The invention relates to a passive human body identification method based on narrowband radio frequency link sampling. The method comprises the following steps: collecting biological characteristic information generated by walking of a pedestrian to be identified through a plurality of radio frequency links, matching the biological characteristic information with a radio frequency signal receivingintensity sequence, fusing the radio frequency signal receiving intensity sequences of all the radio frequency links to obtain a fused radio frequency signal receiving intensity value vector; carrying out maximum likelihood probability estimation matching on the fusion radio frequency signal receiving intensity value vector and each Gaussian mixture model in an identity database, and carrying outidentity recognition on the to-be-recognized pedestrian according to an output probability value. According to the invention, biological characteristic information generated by walking of a pedestrian to be identified is sampled and acquired through the constructed multi-angle interleaved radio frequency links; forced cooperation and visual privacy invasion of a user in a limited environment areeffectively avoided, the dependence of correct recognition on illumination and different wearing clothes is remarkably reduced, and the advantages of being free of invasion, difficult to hide, difficult to camouflage and the like are achieved.

Owner:HUIZHOU UNIV

Chinese address compound word segmentation technology based on rules and statistic model

InactiveCN104850538AImprove accuracyHelp to distinguishSpecial data processing applicationsConditional random fieldData set

The invention discloses a Chinese address compound word segmentation technology based on rules and a statistic model. The word segmentation processing is carried out on addresses by comprehensively utilizing a condition random field model and a maximum matching algorithm optimized by the rules; and the condition random field model extracts related characteristics of address inner information, and a training data set established by a pre-processing phase to train the model so that the Chinese address compound word segmentation technology has the capabilities of automatically segmenting address information and identifying address factors. The condition random field model has a strong model identification capability and can be used for successfully identifying cells with database omission, and also has a good ambiguous address identification capability so that the address factors can be successfully distinguished. An MMSEG algorithm has the characteristics of rapid speed, high precision and the like under the good condition of dictionary data support. According to the Chinese address compound word segmentation technology, the two algorithms are combined and can be mutually supplemented and identified, so that the address matching accuracy is effectively improved, and the word segmentation accuracy is improved under the condition that the efficiency is guaranteed.

Owner:裴克铭管理咨询(上海)有限公司

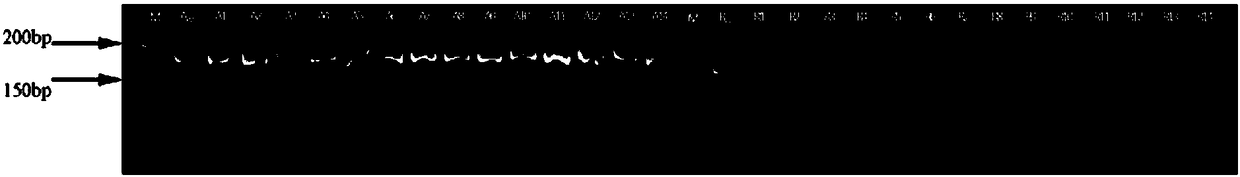

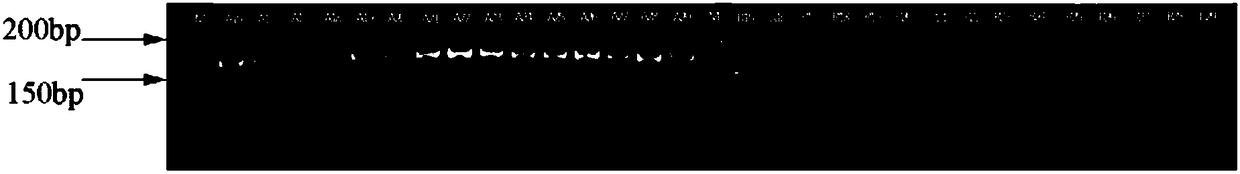

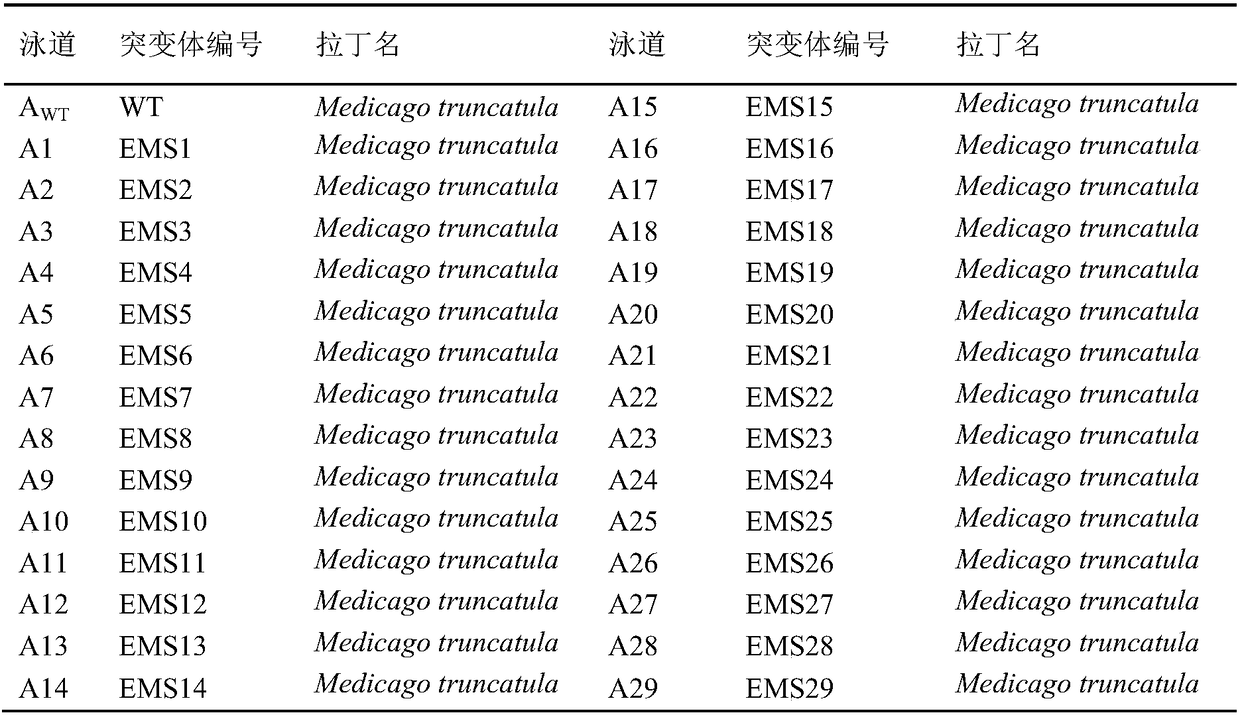

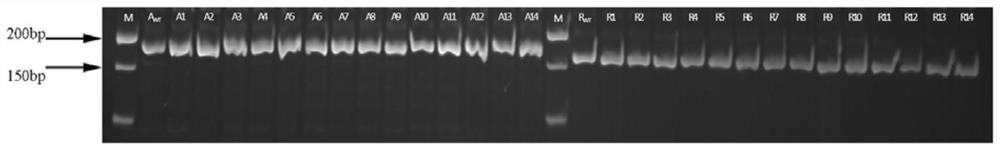

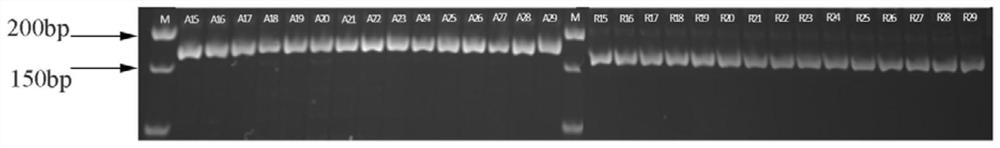

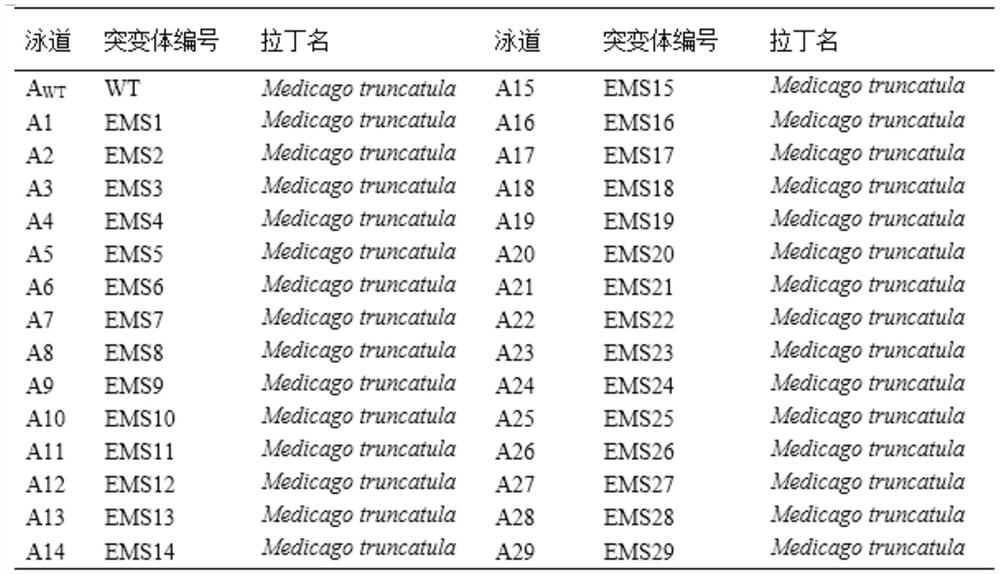

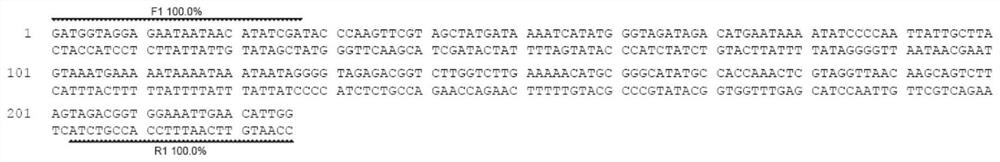

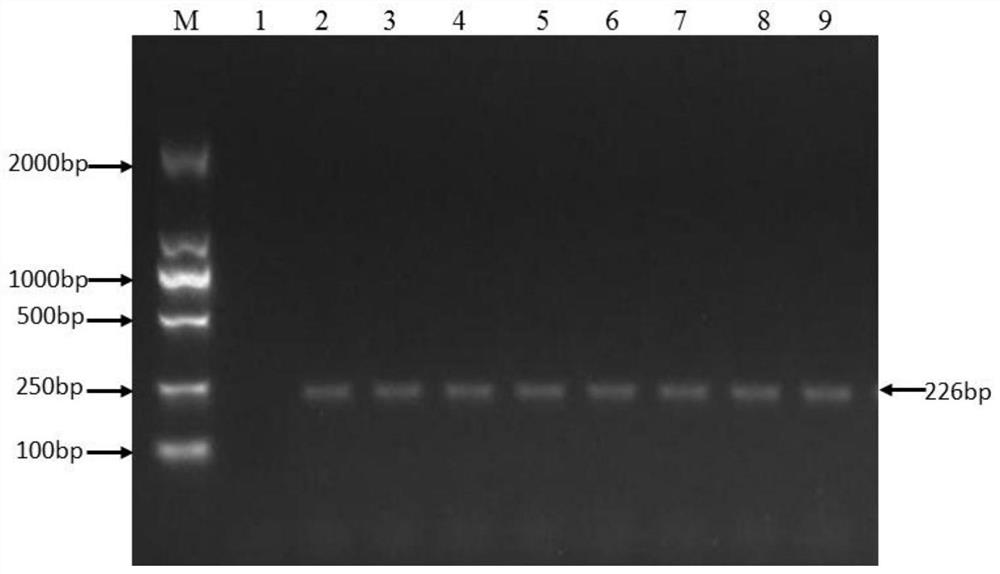

Primer pair, kit comprising same, application of primer pair and method for detecting medicago truncatula ecotypic A17 and R108

ActiveCN108411030AAvoid false positivesAvoid false negativesMicrobiological testing/measurementDNA/RNA fragmentationDNA fragmentationRepeatability

The invention provides a primer pair, a kit comprising the same, application of the primer pair and a method for detecting medicago truncatula ecotypic A17 and R108 and relates to the field of biotechnology. The primer pair comprises a primer NST480-F and a primer NST480-R, which have sequences separately shown as SEQ ID NO.1 and SEQ ID NO.2 and meanwhile can simultaneously amplify DNA (deoxyribonucleic acid) fragments of different lengths of the medicago truncatula ecotypic A17 and R108, so that a user can distinguish whether a sample to be detected contains the medicago truncatula ecotypic A17 and R108 through one amplification. When applied to detecting the medicago truncatula ecotypic A17 and R108, the primer pair has the advantages of being high in sensitivity, accuracy and repeatability, rapid, convenient and the like and solves the problem that the prior art lacks a rapid and accurate method for detecting and identifying the medicago truncatula ecotypic A17 and R108.

Owner:LANZHOU UNIVERSITY

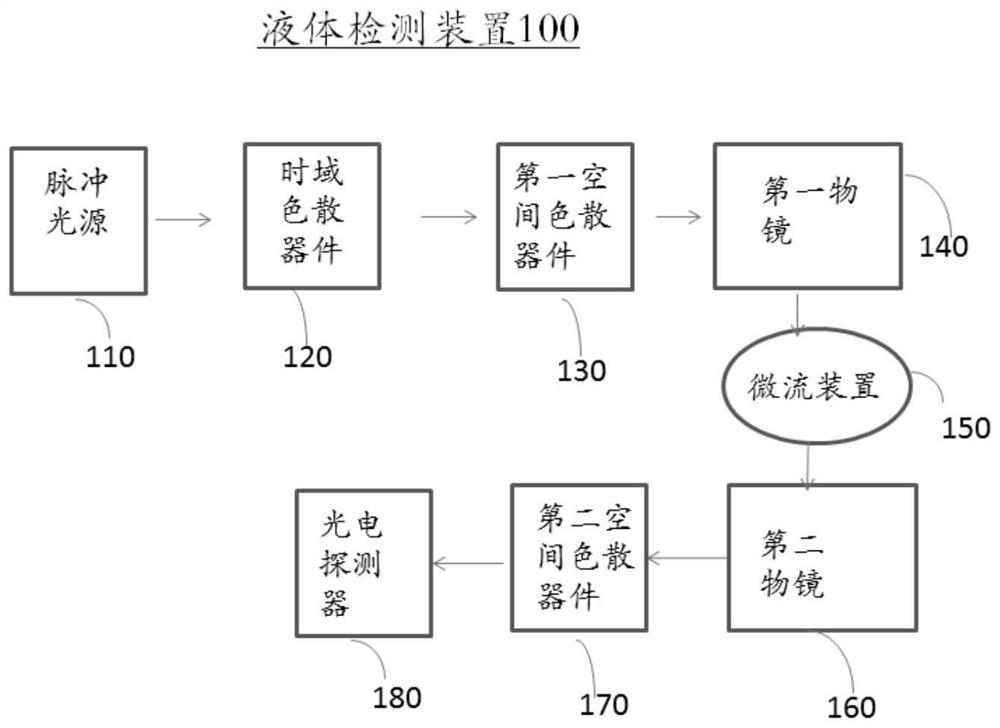

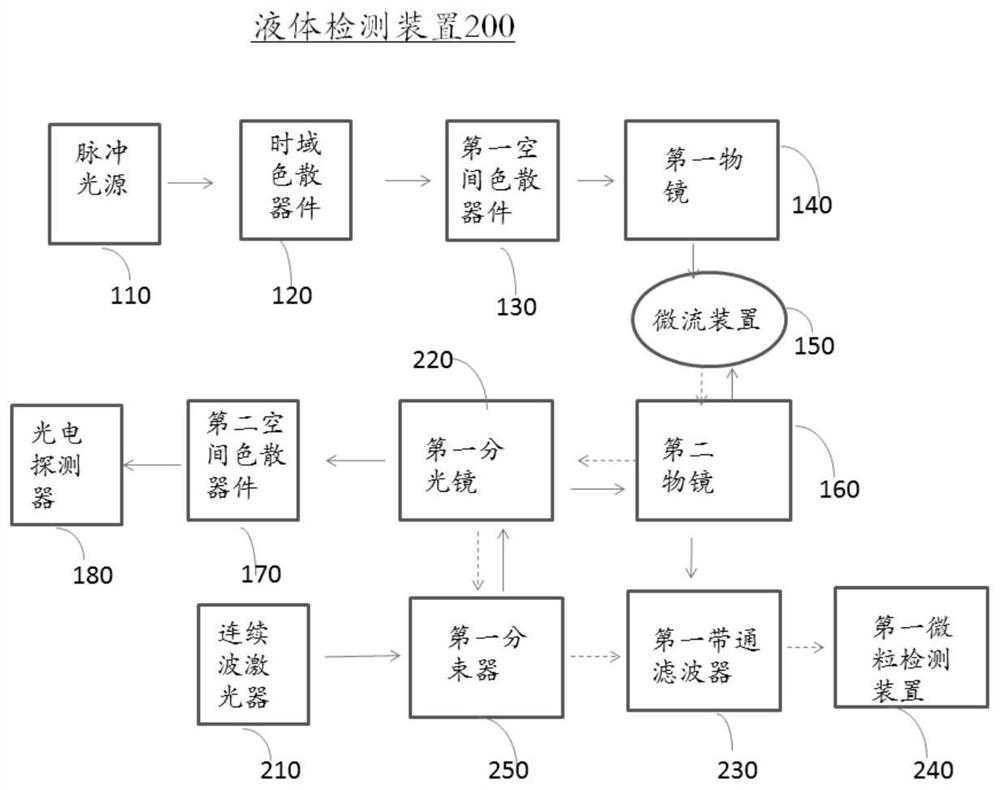

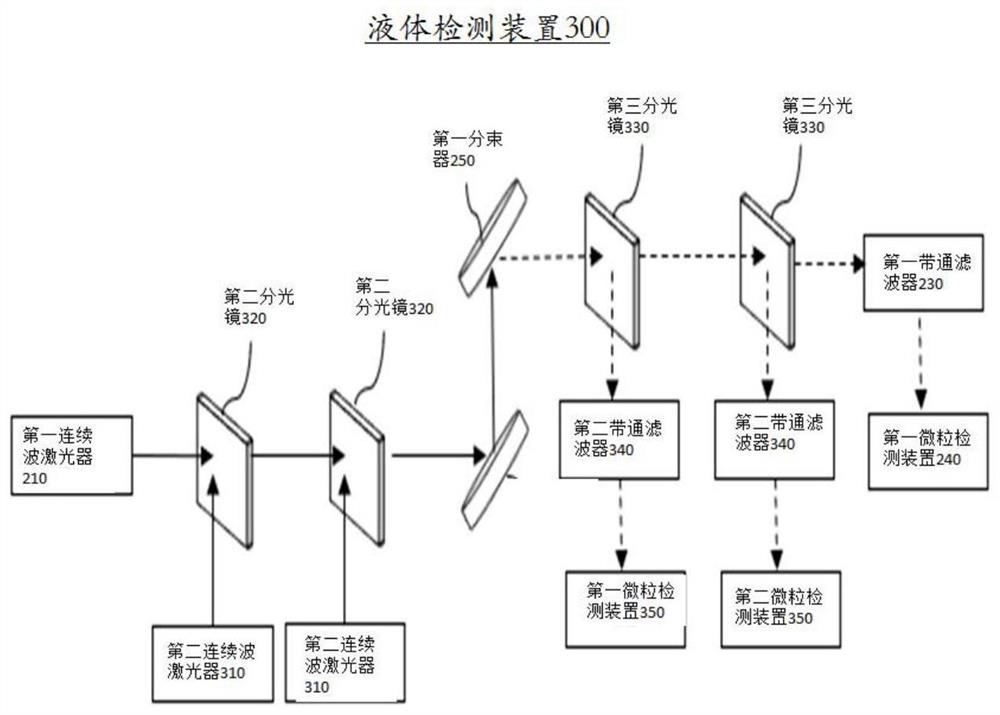

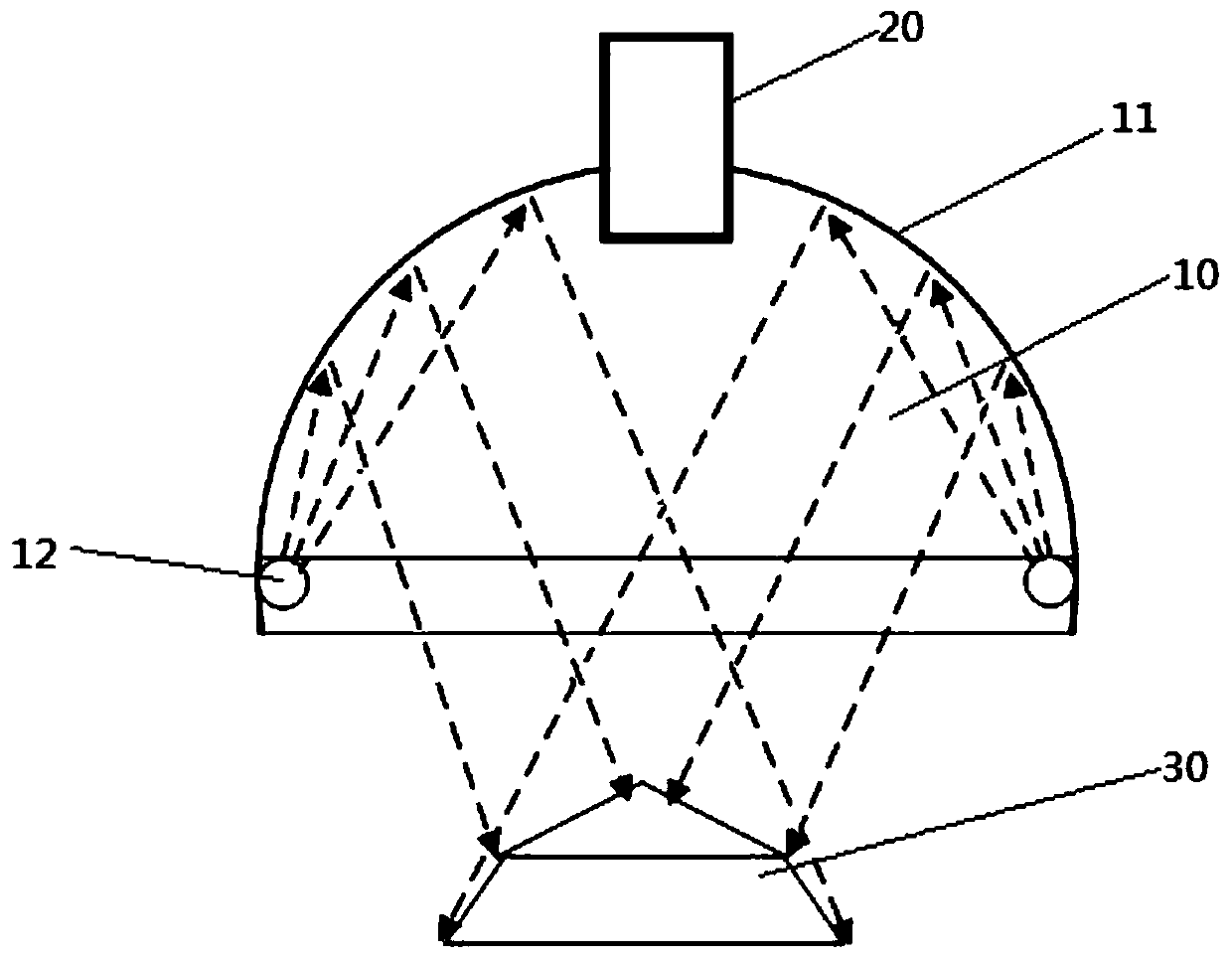

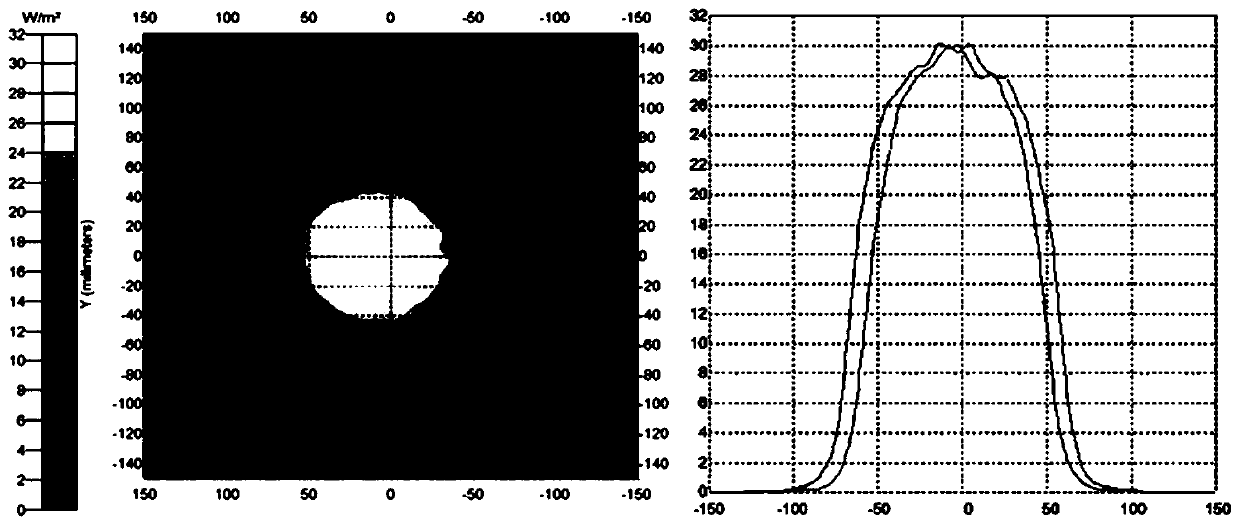

Liquid detection device and method

PendingCN111855508AHelp to distinguishDetection speedMaterial analysis by optical meansMicroscope objectiveSpatial dispersion

The invention provides a liquid detection device and method. The liquid detection device comprises: a pulse light source configured to emit pulse light; a time domain dispersion device configured to convert the pulse light emitted by the pulse light source from a frequency domain to a time domain to form pulse light after time domain broadening; a first spatial dispersion device configured to change the propagation direction of the light with different frequencies in the pulse light after time domain broadening in space; a first objective lens configured to converge the pulse light of which the propagation direction is changed by the first spatial dispersion device to a micro-flow device; the micro-flow device configured to enable a to-be-detected liquid in the micro-flow device to flow ata preset speed; a second objective lens configured to collect the light which is converged by the first objective lens and passes through the micro-flow device; a second spatial dispersion device forspatially recombining the light collected by the second objective lens; and a photoelectric detection device configured to image the light recombined by the second spatial dispersion device so as todetect the micro particles in the liquid.

Owner:天津凌视科技有限公司

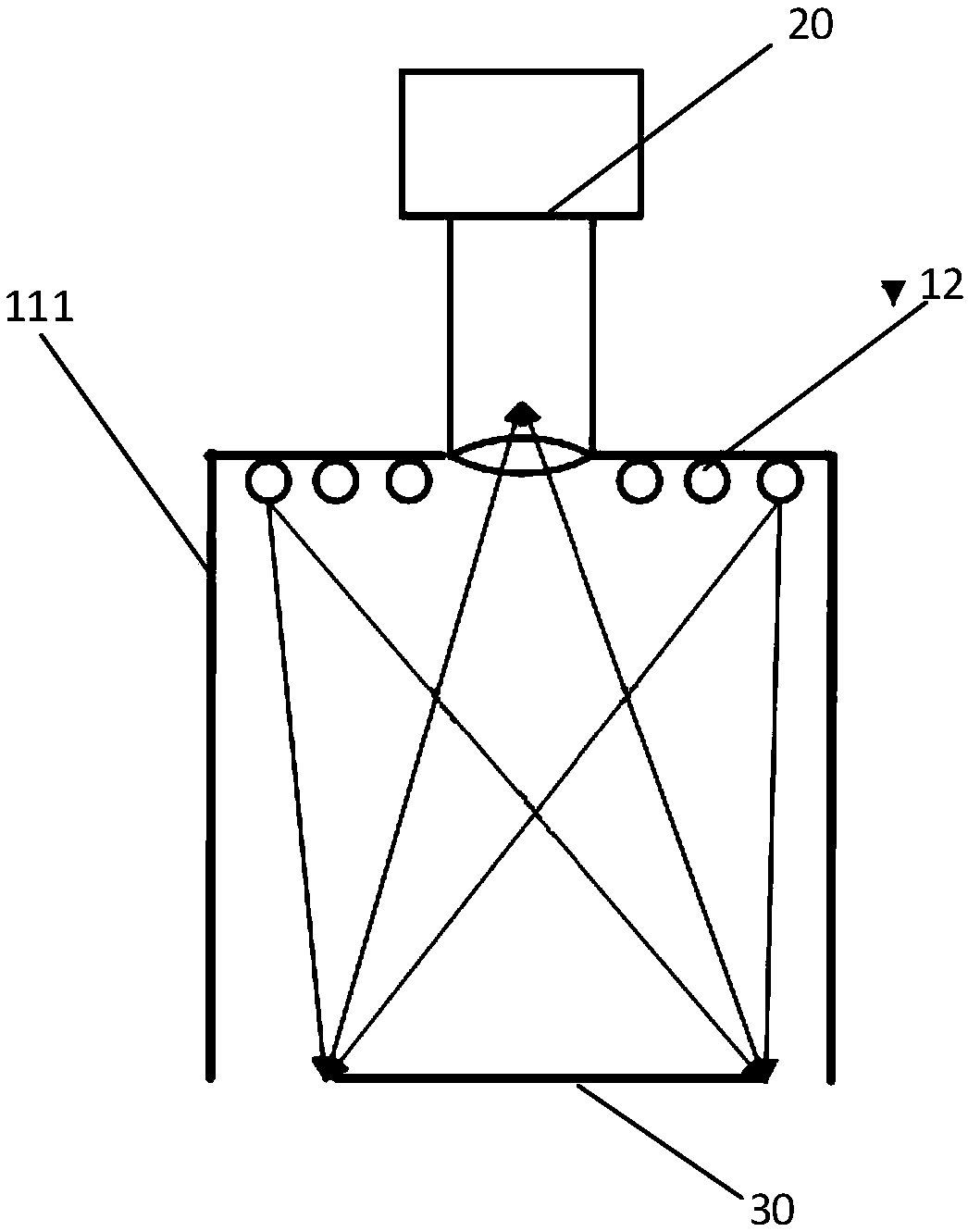

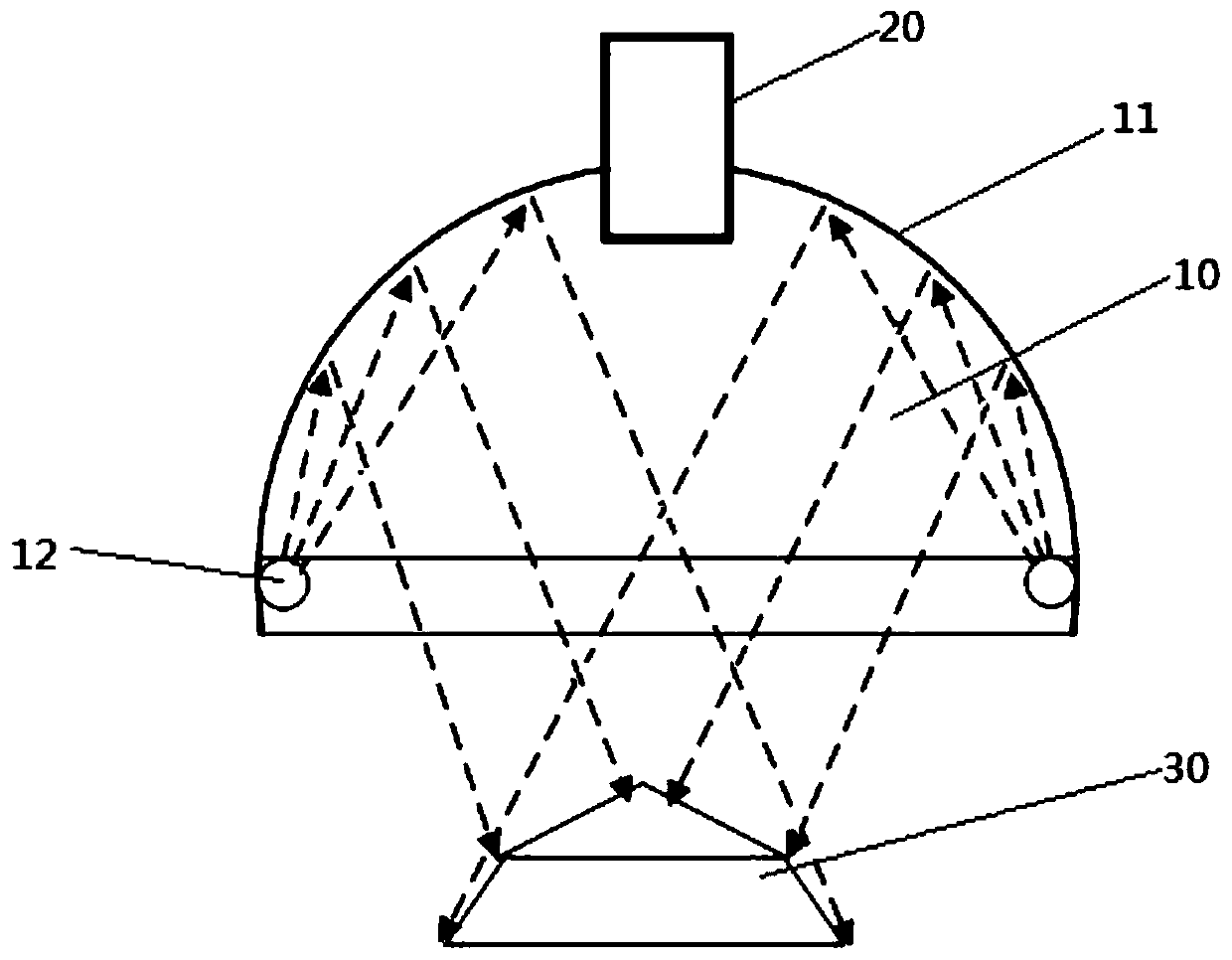

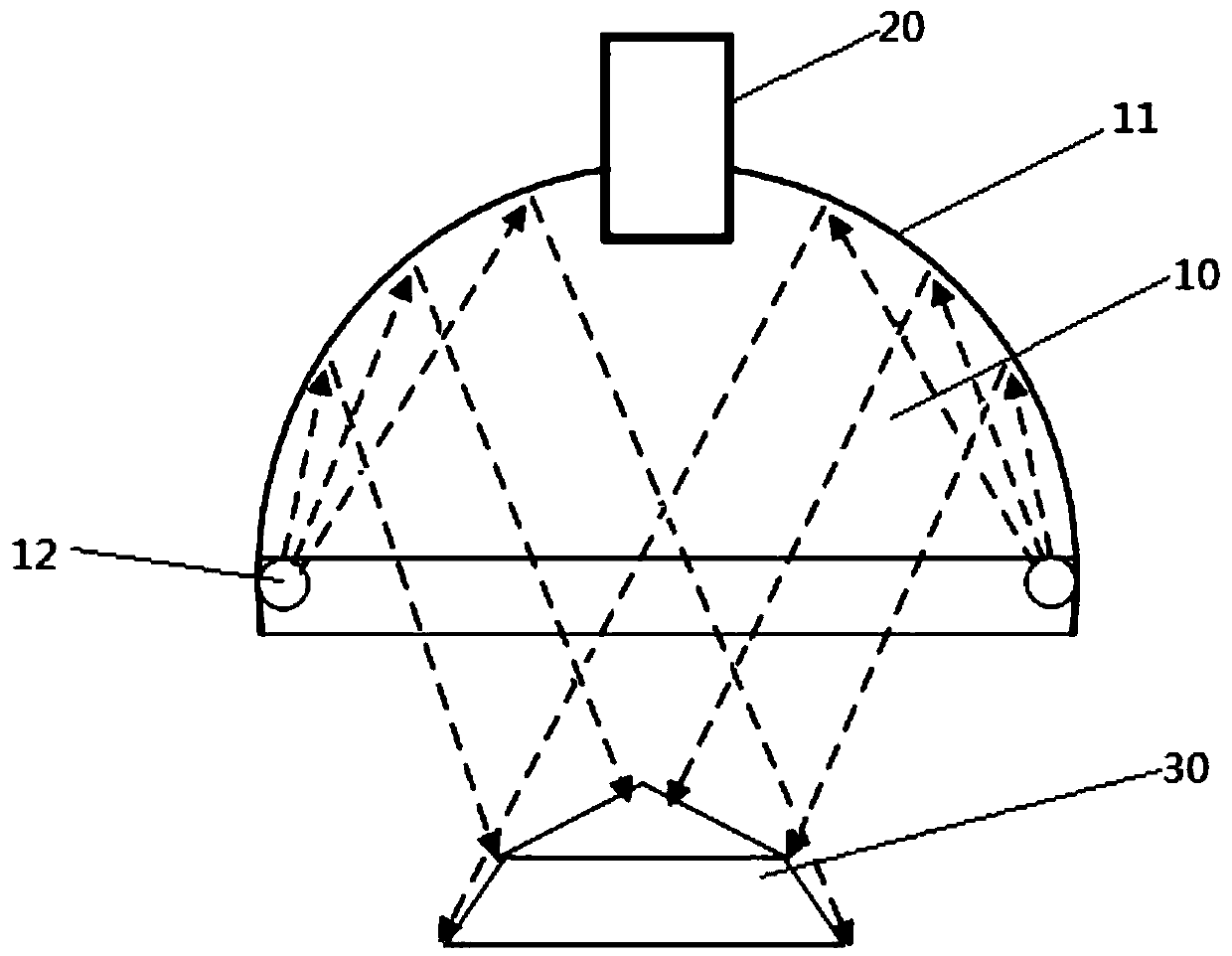

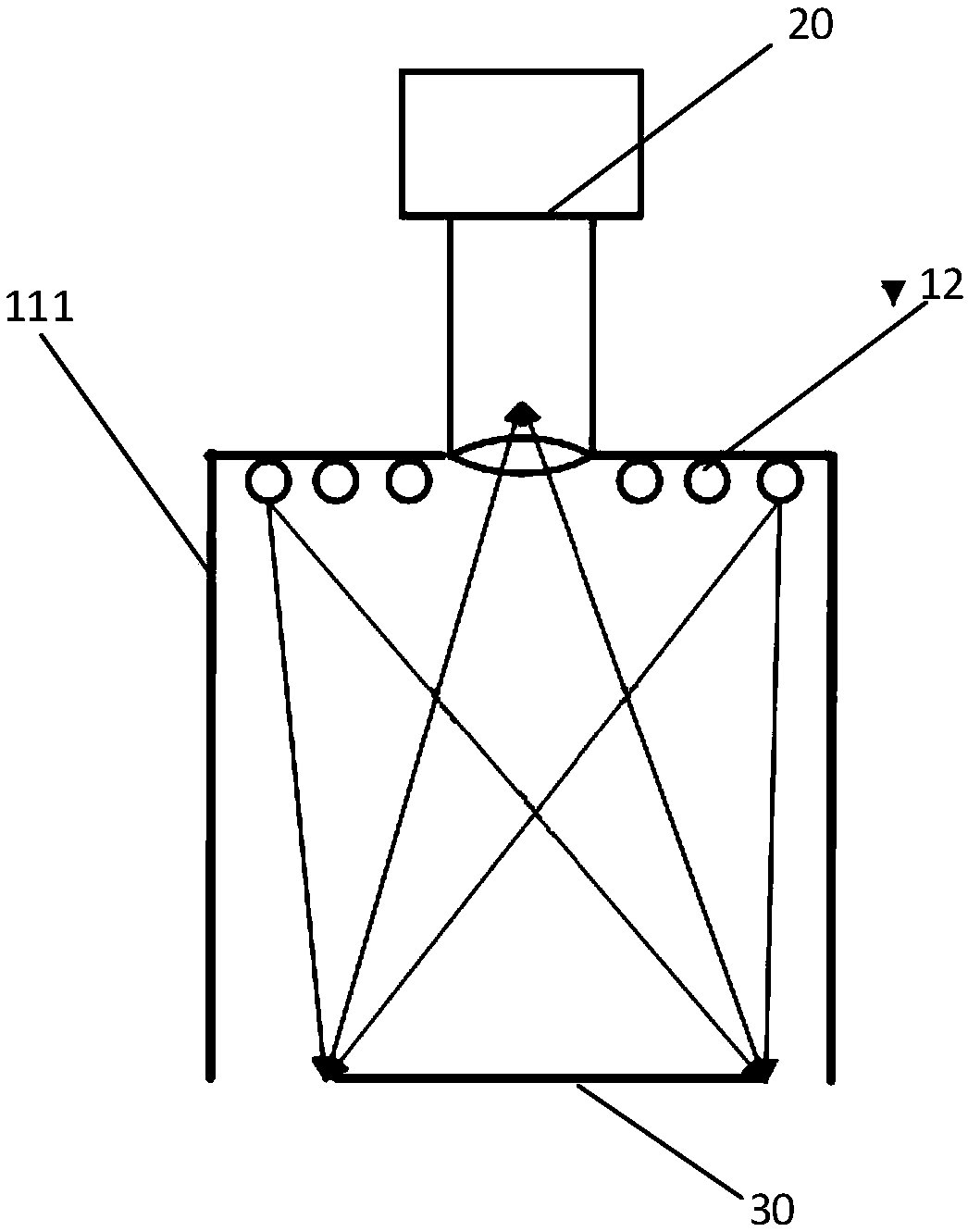

Illumination control method and device for controlling illumination equipment

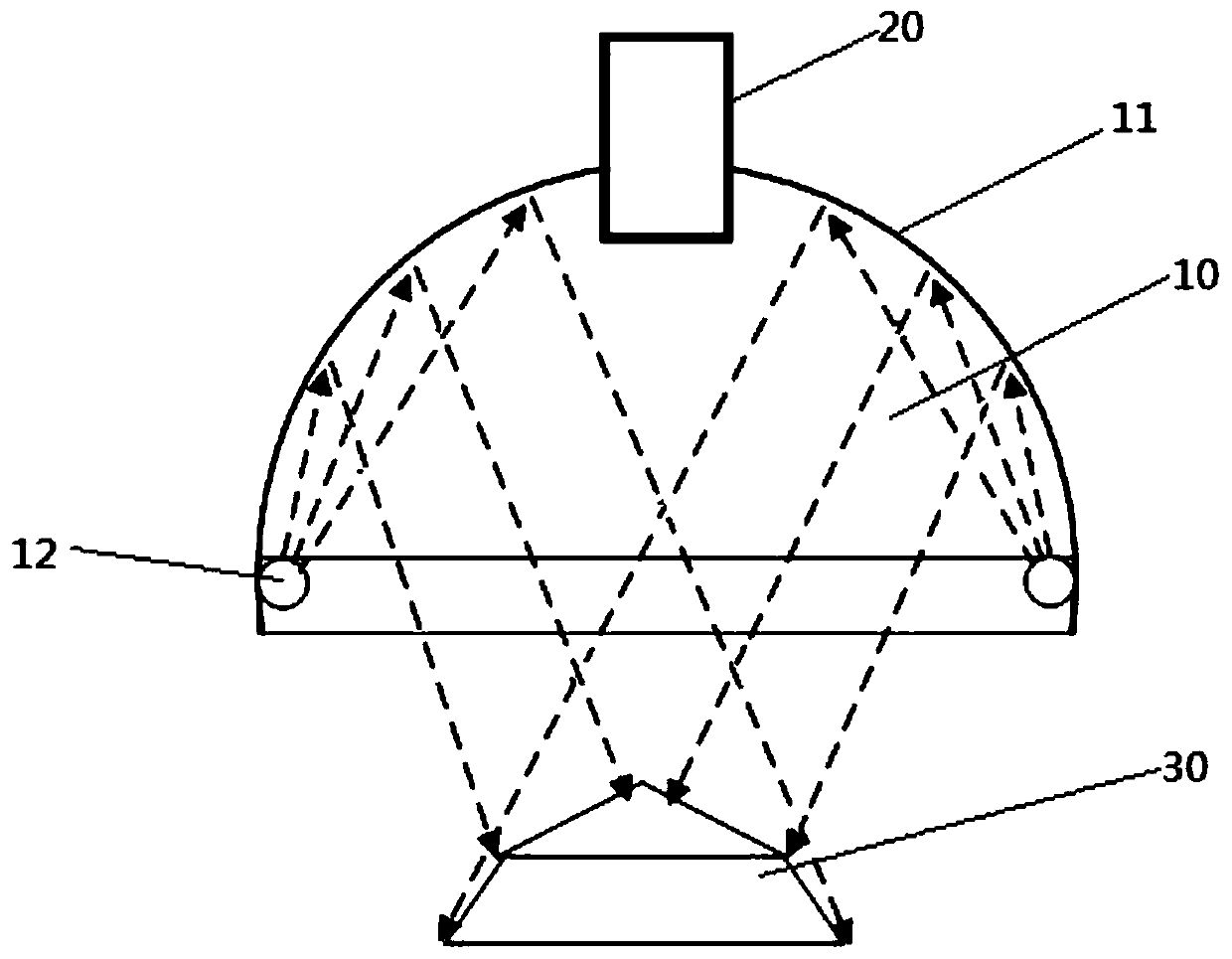

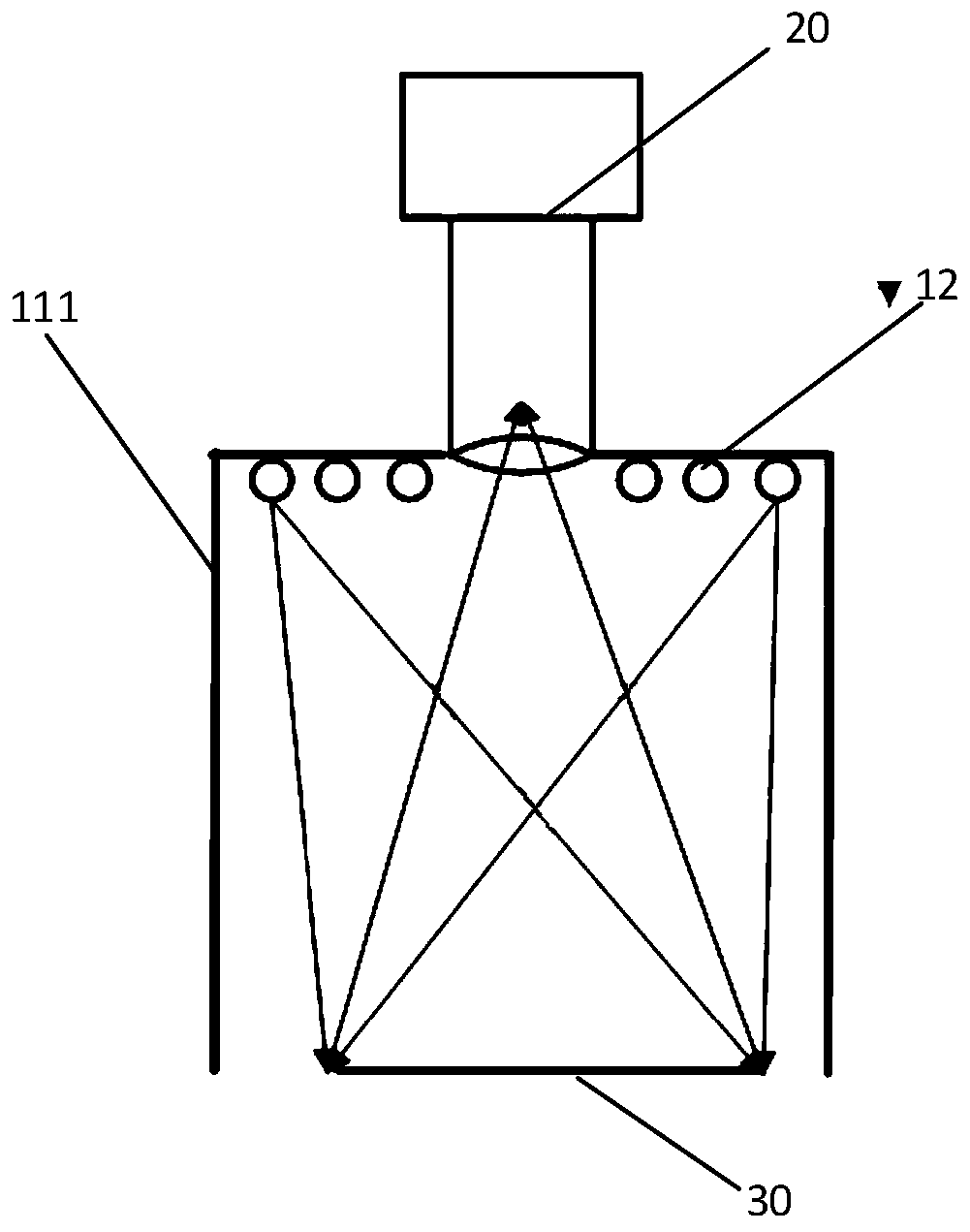

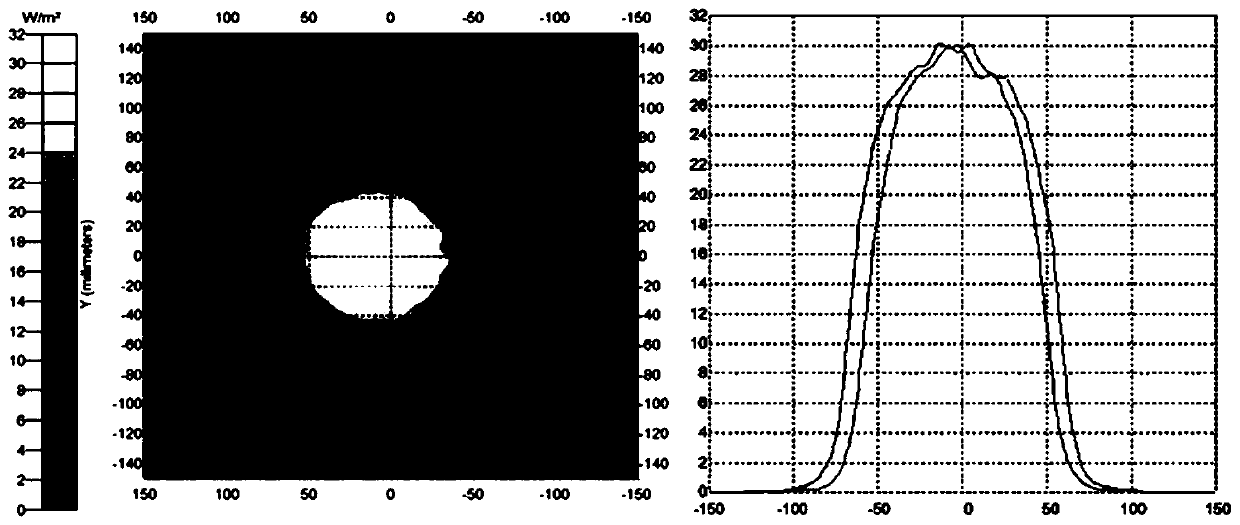

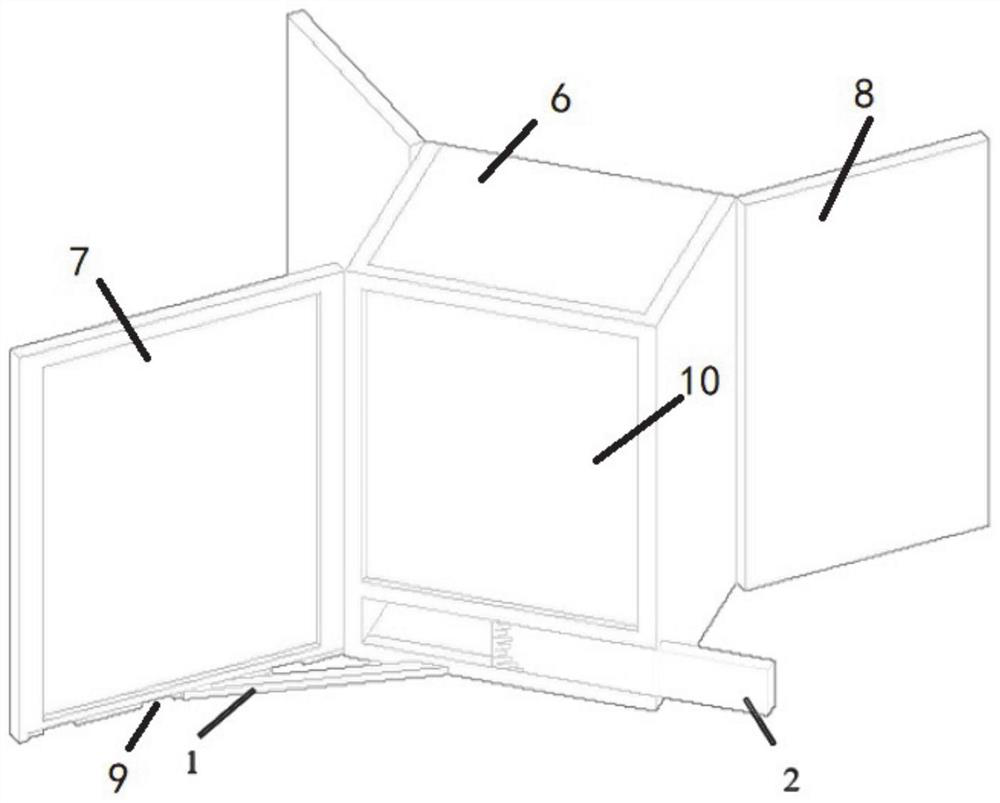

ActiveCN109709101AHelp to distinguishShield interference factorsSemiconductor/solid-state device testing/measurementElectric light circuit arrangementIlluminanceMonochrome

The invention relates to an illumination control method and device for controlling illumination equipment. The illumination equipment includes a curved surface mask with a concave surface and multiplemonochrome visible light sources arranged on the concave surface. Positions of the multiple monochromatic visible light sources and the shape of the curved surface enable the monochromatic visible light emitted by the multiple monochromatic visible light sources to form the illumination light having illuminance deviation of not greater than 10% within a predetermined illumination range to illuminate a to-be-inspected object. The illumination control method includes steps that the illuminance of the monochromatic visible light in the environment in which the to-be-inspected object is located is obtained; when the acquired illuminance of the monochromatic visible light does not reach the predetermined monochromatic visible light illumination threshold, the luminance of the monochromatic visible light sources is controlled for making the illuminance of the monochromatic visible light in the environment in which the to-be-inspected object is placed reaches the monochromatic visible lightilluminance threshold. The method is advantaged in that clear object images can be obtained, and whether the to-be-inspected object is abnormal is determined based on the object images.

Owner:INTEL PROD CHENGDU CO LTD +1

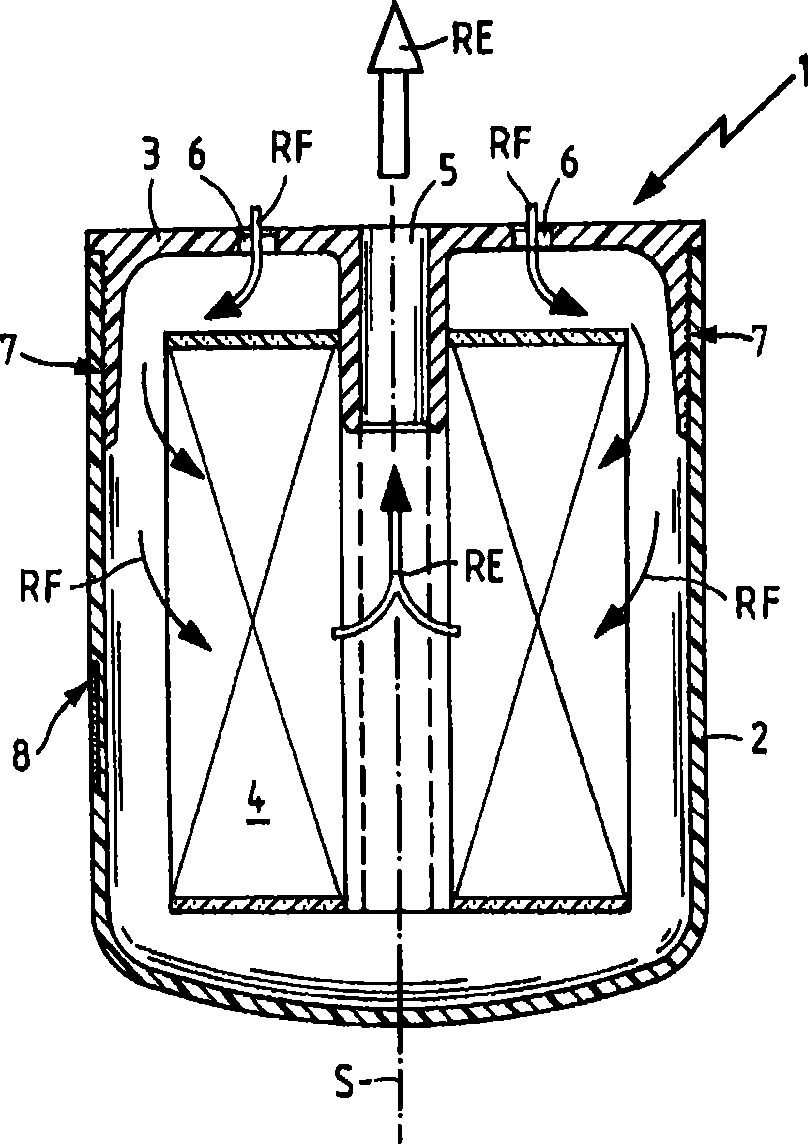

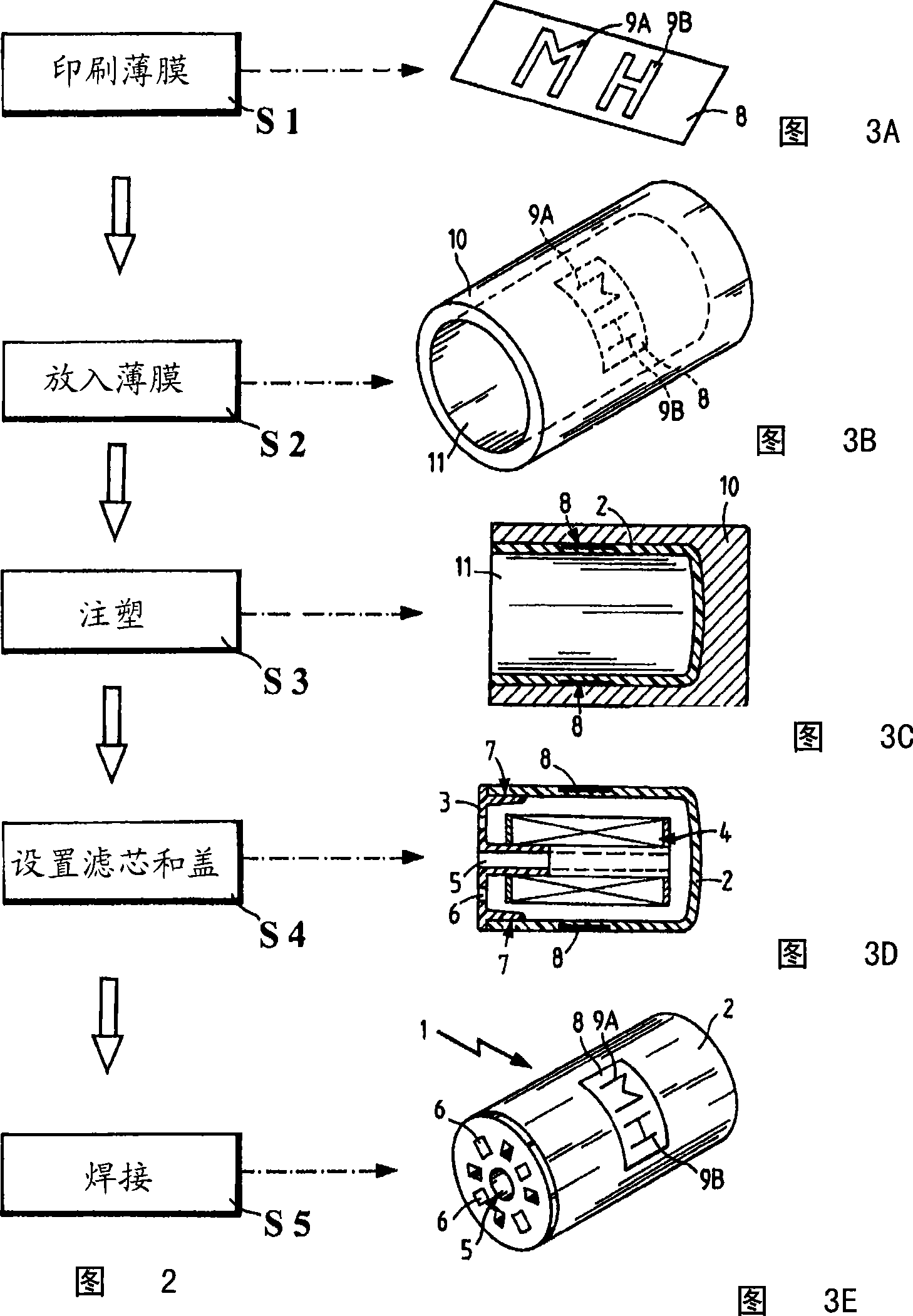

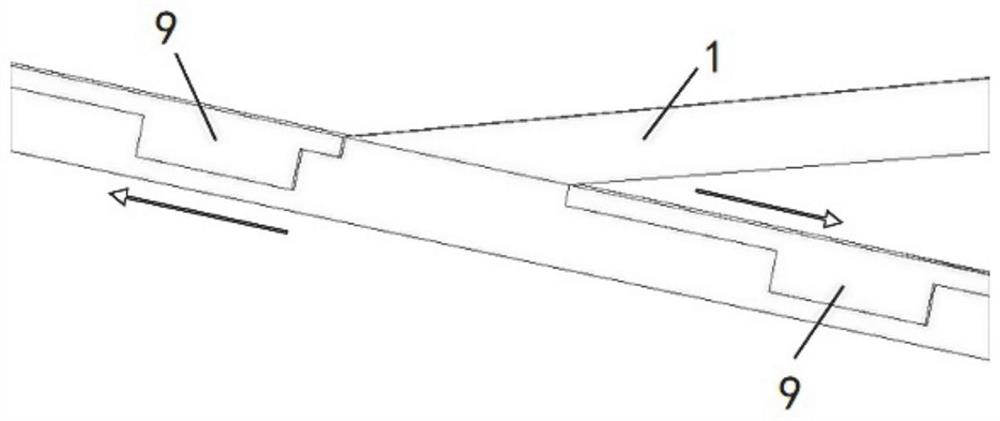

Filtering device and method for its manufacture

InactiveCN101411953AHelp to distinguishResistantMembrane filtersCartridge filtersPlastic filmFilter element

The invention relates to a filtering device and manufacturing method thereof. A filtering device (1) comprises a filter bottom shell (2) having plastic materials, filter cover (3) for closing the filter bottom shell (2), and a filtering element (4) set in the filter bottom shell (2), wherein the filter bottom shell (2) owns a mark face with at least one mark (9), the mark face is formed by using plastic film (8) with the mark (9) to do injection molding behind the film. A method for manufacturing filtering device composed of filter bottom shell (2), filter cover (3) and filtering element (4), wherein filter bottom shell (2) is formed by injection molding and provided with the mark face with the mark (9) formed behind the film by injection molding.

Owner:MANN HUMMEL GMBH

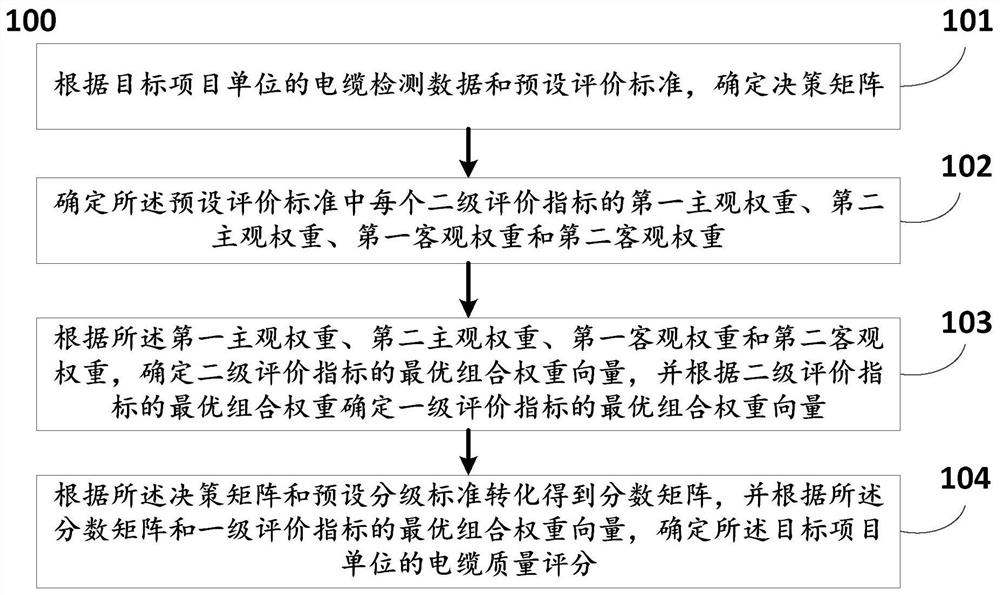

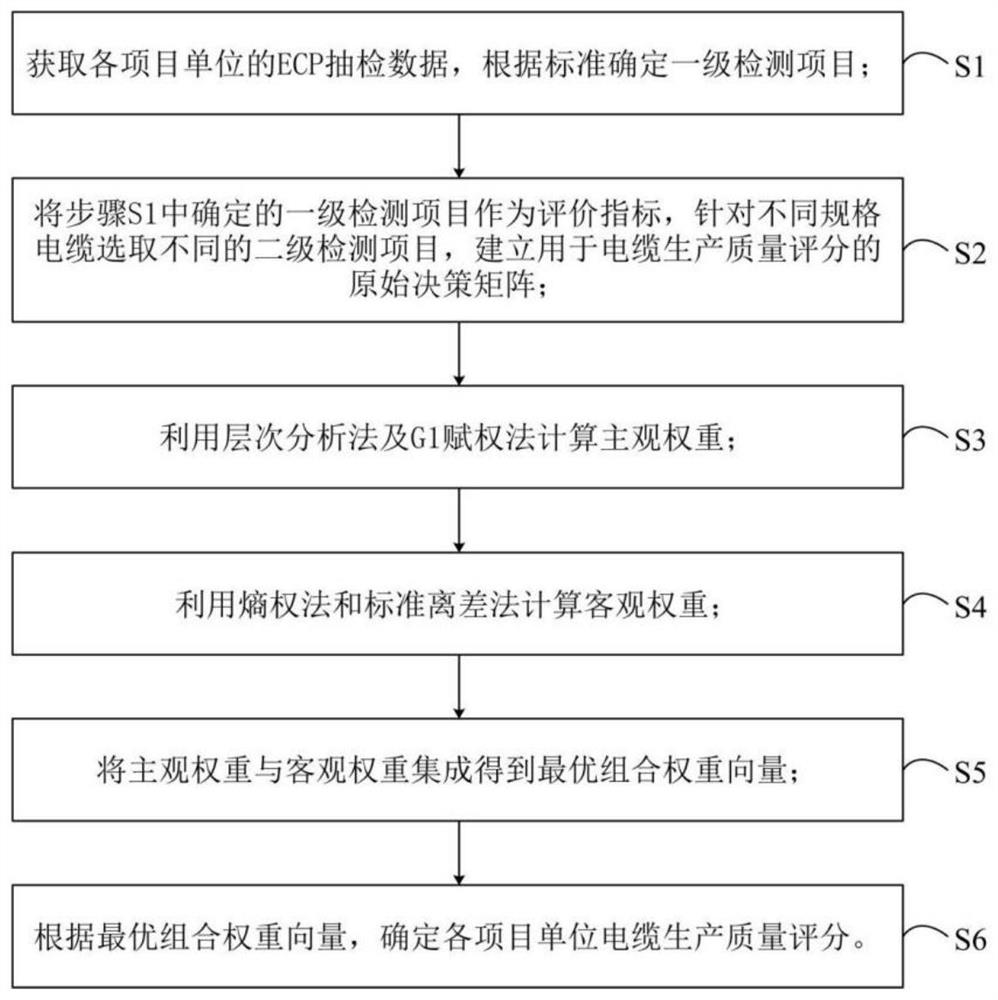

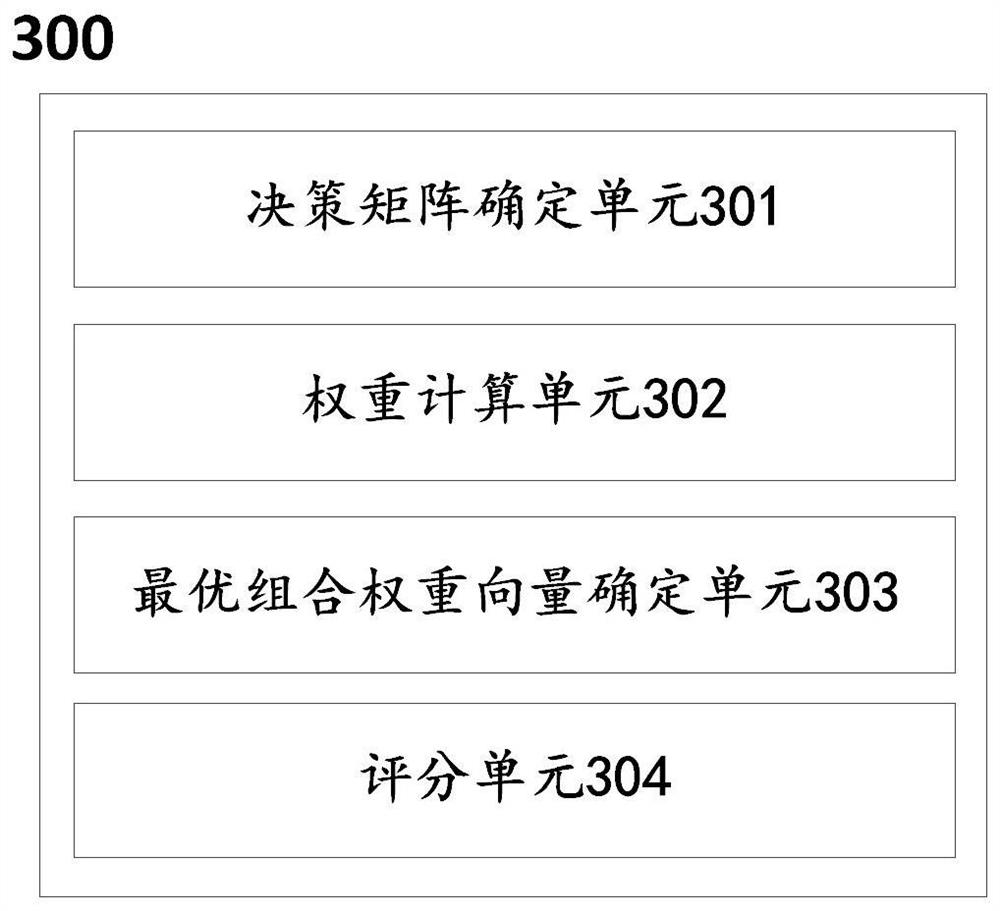

Cable quality scoring method and system

PendingCN114880828AHelp to distinguishIncrease the rationality of the weightDesign optimisation/simulationConstraint-based CADElectric cablesScore matrix

The invention discloses a cable quality scoring method and system, and the method comprises the steps: determining a decision matrix according to the cable detection data of a target project unit and a preset evaluation standard; determining a first subjective weight, a second subjective weight, a first objective weight and a second objective weight of each secondary evaluation index in the preset evaluation standard; according to the first subjective weight, the second subjective weight, the first objective weight and the second objective weight, determining an optimal combination weight vector of the second-level evaluation index, and according to the optimal combination weight of the second-level evaluation index, determining an optimal combination weight vector of the first-level evaluation index; and converting according to the decision matrix and a preset grading standard to obtain a score matrix, and determining a cable quality score of the target project unit according to the score matrix and an optimal combination weight vector of a first-level evaluation index.

Owner:CHINA ELECTRIC POWER RES INST

Socket

Owner:天津市天佑元化工贸易有限公司

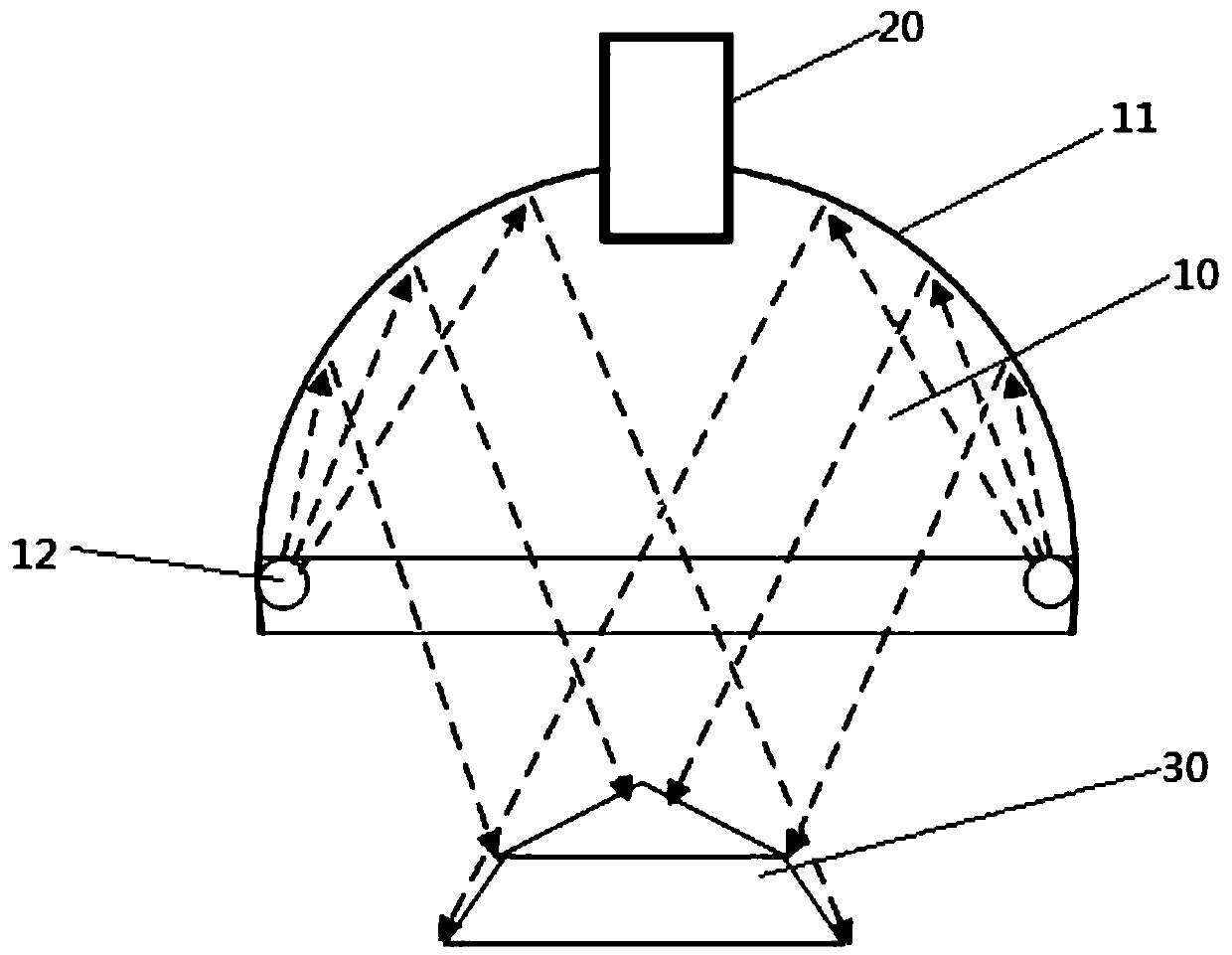

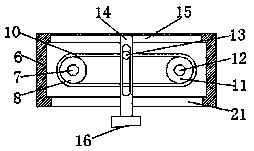

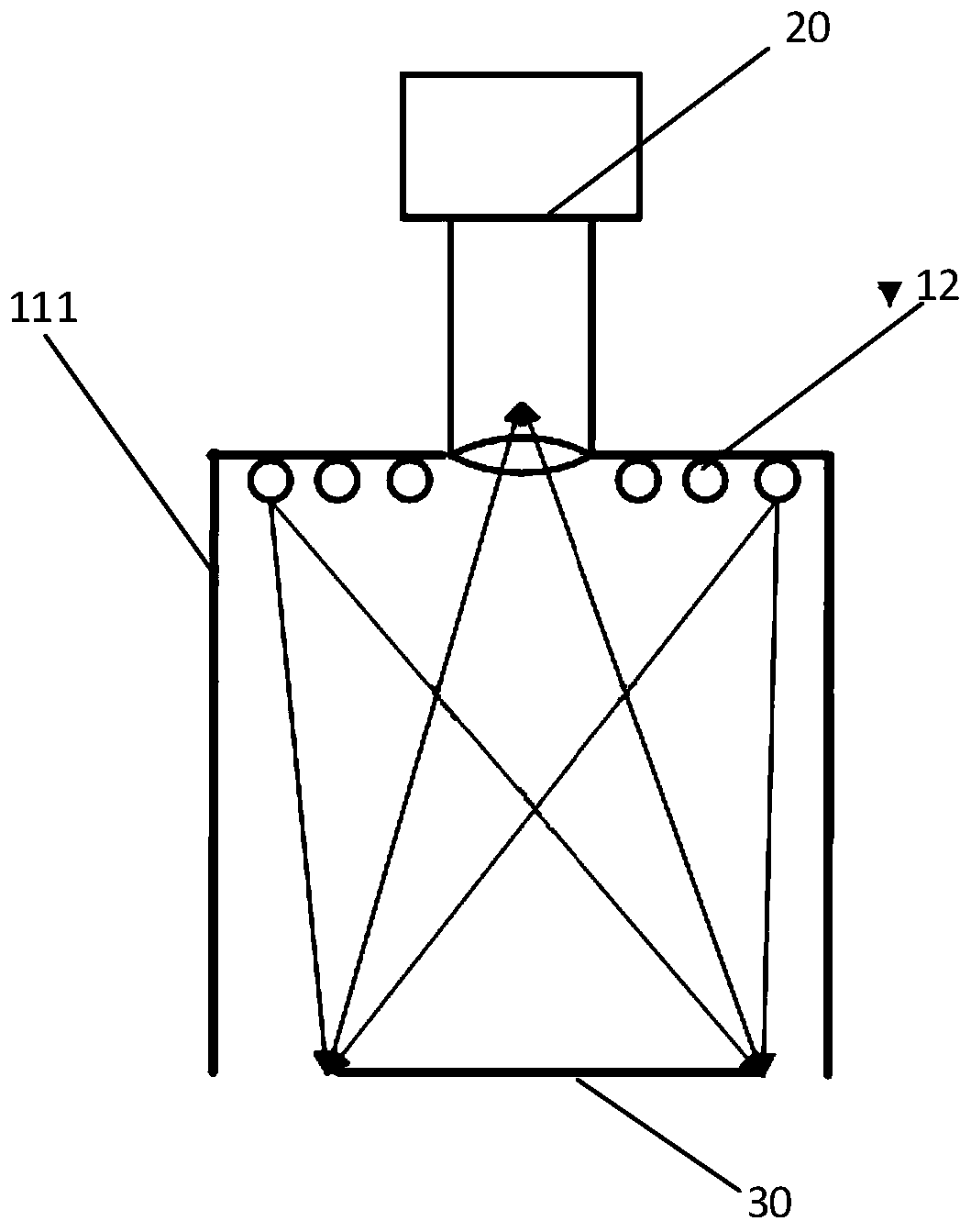

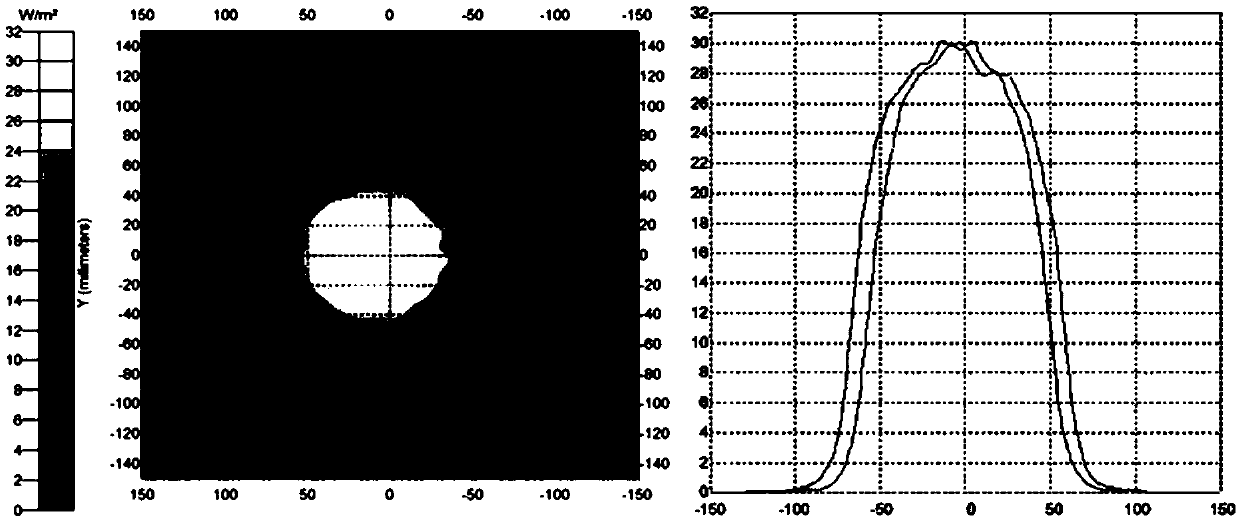

Illumination device used for object inspection

InactiveCN109632812AEasy to implementLow costOptically investigating flaws/contaminationIlluminanceIrradiation

The invention relates to the object inspection technology field and especially relates to an illumination device used for object inspection. The illumination device comprises a curved surface light cover and a plurality of monochromatic visible light sources, wherein the curved surface light cover has a concave curved surface which is arranged to face an object to be inspected; the plurality of monochromatic visible light sources are arranged on the concave curved surface of the curved surface light cover and are used for irradiating the object to be inspected; and the positions of the plurality of monochromatic visible light sources and the shape of the concave curved surface can make irradiation light formed by monochromatic visible light emitted by the plurality of monochromatic visiblelight sources in a predetermined illumination range irradiate the object to be inspected, and the illumination deviation of the irradiation light does not exceed 10%. The illumination device can irradiate the object to be inspected so as to acquire a clear object image, and whether the object to be inspected is abnormal can be determined based on the object image.

Owner:INTEL PROD CHENGDU CO LTD +1

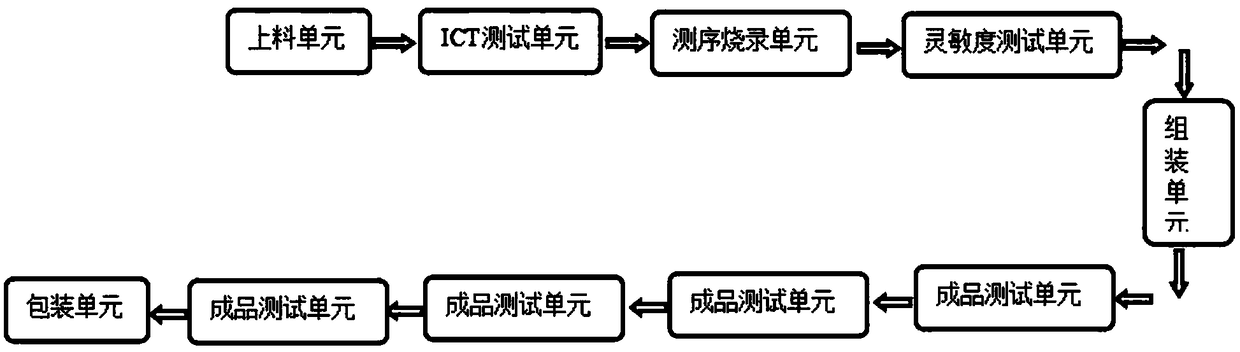

U-shaped assembly line for intelligent manufacturing of automotive electronics

InactiveCN109189035AAvoid missing testAvoid mixingAssembly machinesTotal factory controlBurn unitsBarcode

The invention relates to the field of intelligent manufacturing of automotive electronics, in particular to a U-shaped assembly line for intelligent manufacturing of automotive electronics. The U-shaped assembly line comprises a feeding unit, an ICT test unit, a program burning unit, a sensitivity test unit, an assembling unit, a finished product function test unit and a packing unit, wherein theunits are arranged in a U shape according to production processes and transmitted through a conveyer belt. The assembly line is built by adoption of lean pipes, a cell ideal is fused; manual transferis matched with belt transfer, workers stand to carry out operation, and automatic processes are adopted, so that the labor demand can be greatly reduced, the production efficiency can be improved, the degree of dependency, on operation levels of operators, of product quality can be reduced at the same time; the completion effect of each process is automatically detected, so that the detection efficiency and detection result errors can be improved; an unqualified product placing box is set to be red, so that the operators can distinguish the unqualified products and the probability of mixing unqualified products into qualified products can be greatly reduced; and through setting a barcode fool-proof device for each unit, non-detected products at upper stations can be effectively preventedfrom flowing into lower stations.

Owner:重庆佰节成测控技术有限公司

Transformer fault comprehensive diagnosis system and diagnosis method based on fuzzy association rules

ActiveCN107907783BReflect the actual relationshipImplement diagnosticsTesting dielectric strengthTransformers testingTransformerDiagnosis methods

The disclosure provides a transformer fault comprehensive diagnosis system based on a fuzzy association rule. The system includes a transformer fault type diagnosis module, a transformer fault location diagnosis module, and a transformer fault comprehensive diagnosis module based on case-based reasoning. The disclosure also provides a transformer fault comprehensive diagnosis method based on a fuzzy association rule. The diagnosis system diagnoses the fault type, the fault location and the fault cause of a transformer, can help the field staff to complete discrimination, and is suitable for the diagnosis of a variety of transformer faults.

Owner:HUNAN WULING POWER TECH CO LTD

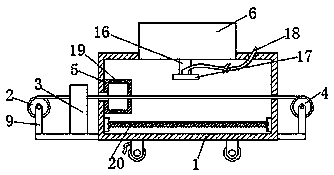

Cable sheath material dyeing device

InactiveCN108654942AImprove dyeing effectSolve the problem of poor dyeing effectLiquid surface applicatorsCoatingsDrive wheelElectric machinery

The invention discloses a cable sheath material dyeing device. The cable sheath material dyeing device comprises a machine body; the left side of the machine body is fixedly connected with an unreeling device and a dyeing device sequentially from left to right through a supporting plate; the right side of the machine body is fixedly connected with a reeling device through a supporting plate; one side of an inner cavity of the machine body is welded with a heating device; a box body is embedded at the top of the machine body; and the left side of the back side of an inner cavity of the box bodyis fixedly connected with a motor through a fixing piece. Through cooperation of the unreeling device, the dyeing device, the reeling device, the heating device, the motor, a driving wheel, a belt, adriven wheel, a rotating rod, a fixed shaft, an annular groove plate, a sliding groove, a connecting plate, an air outlet spray head and an air inlet, the effect of dyeing a cable sheath is achieved,so that the advantage of good effect of dyeing the cable sheath is achieved, the quality of a cable product is improved, the post processing of the cable is guaranteed and the cable can be differentiated by installation personnel.

Owner:何盼

Object Inspection System for Object Anomaly Inspection

ActiveCN109632824BEasy to implementLow costOptically investigating flaws/contaminationIlluminanceEngineering

Owner:INTEL PROD CHENGDU CO LTD +1

Primer pair, kit containing same, use and method for detecting ecotypes a17 and r108 of Medicago truncatula

ActiveCN108411030BWide range of usesIncrease productionMicrobiological testing/measurementDNA/RNA fragmentationDNAVirology

The invention provides a pair of primers, a kit containing the same, a use and a method for detecting ecotypes A17 and R108 of Medicago truncatula, and relates to the field of biotechnology. The primer pair comprises primer NST480‑F and primer NST480‑R, which have the sequences shown in SEQ ID NO.1 and SEQ ID NO.2 respectively, and can simultaneously amplify DNA fragments of different fragment lengths of Medicago truncatula ecotypes A17 and R108 , so one amplification can distinguish whether the test sample contains Medicago truncatula ecotypes A17 and R108. Using the above primers to detect Medicago truncatula ecotypes A17 and R108 has the characteristics of strong sensitivity, high accuracy, strong repeatability, fast and convenient, and alleviates the lack of a fast and accurate method for detection and identification in the prior art. Problems with Medicago truncatula ecotypes A17 and R108.

Owner:LANZHOU UNIVERSITY

Illumination control method and device for controlling illumination equipment

ActiveCN109709101BHelp to distinguishShield interference factorsSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationIlluminanceMonochrome

The invention relates to an illumination control method and device for controlling illumination equipment. The illumination equipment includes a curved surface mask with a concave surface and multiplemonochrome visible light sources arranged on the concave surface. Positions of the multiple monochromatic visible light sources and the shape of the curved surface enable the monochromatic visible light emitted by the multiple monochromatic visible light sources to form the illumination light having illuminance deviation of not greater than 10% within a predetermined illumination range to illuminate a to-be-inspected object. The illumination control method includes steps that the illuminance of the monochromatic visible light in the environment in which the to-be-inspected object is located is obtained; when the acquired illuminance of the monochromatic visible light does not reach the predetermined monochromatic visible light illumination threshold, the luminance of the monochromatic visible light sources is controlled for making the illuminance of the monochromatic visible light in the environment in which the to-be-inspected object is placed reaches the monochromatic visible lightilluminance threshold. The method is advantaged in that clear object images can be obtained, and whether the to-be-inspected object is abnormal is determined based on the object images.

Owner:INTEL PROD CHENGDU CO LTD +1

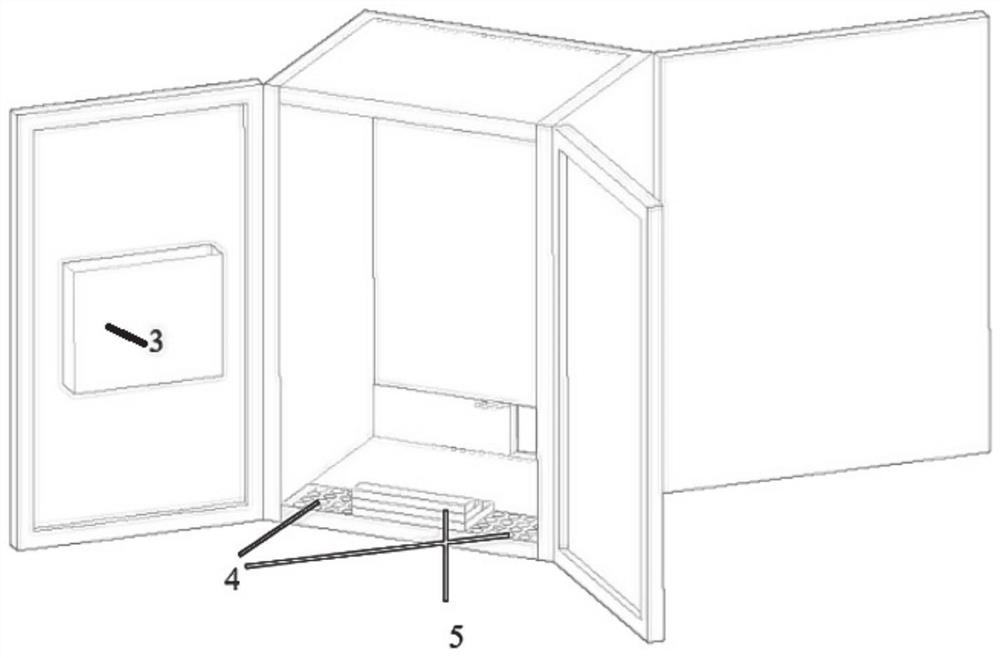

Relay protection device secondary screen cabinet and method

ActiveCN112701575AEasy to operateHelp to distinguishBus-bar/wiring layoutsSubstation/switching arrangement casingsStructural engineeringMechanical engineering

The invention discloses a relay protection device secondary screen cabinet and a method. The relay protection device secondary screen cabinet comprises a cabinet body which is of a box-type structure; a first cabinet door is arranged on one side of the box-shaped structure, and a second cabinet door is arranged on the other side of the box-shaped structure; a windproof rod is arranged at the bottom of the box-shaped structure; a plurality of clamping grooves are formed in the bottom of the first cabinet door; the windproof rod can be clamped in different clamping grooves; a plurality of holes are formed in the bottom, close to the second cabinet door, of the interior of the box-shaped structure, so that cables can penetrate through the holes;and a folding step is arranged at the bottom, close to the second cabinet door, of the interior of the box-shaped structure.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

A standard gene sequence of kudzu dna barcode and its application

ActiveCN108220472BFacilitate the realization of molecular identificationAchieve molecular identificationMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyMolecular identification

The present invention relates to a standard gene sequence of a kudzu DNA barcode and its application. The standard detection gene sequence of the barcode is shown in SEQ ID NO.1. The genome of Pueraria mirifica was amplified by polymerase chain reaction. According to the size judgment result of the amplified product of the tested sample, if a band of 226bp can be specifically amplified, it can be judged that the tested sample contains kudzu components. . The invention provides a method for specifically detecting kudzu components, which is helpful for the identification of kudzu components, prevents adulteration and ensures the health of consumers. Compared with the traditional morphological identification method, the gene sequence obtained by the invention is beneficial to realize the molecular identification of kudzu, and can effectively shorten the identification time of kudzu.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

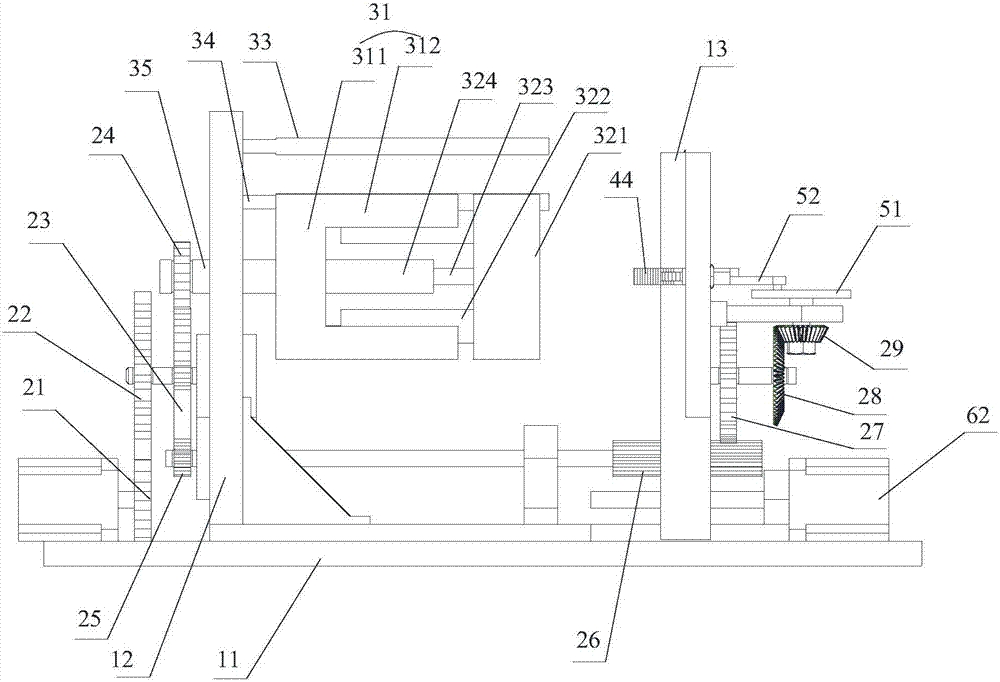

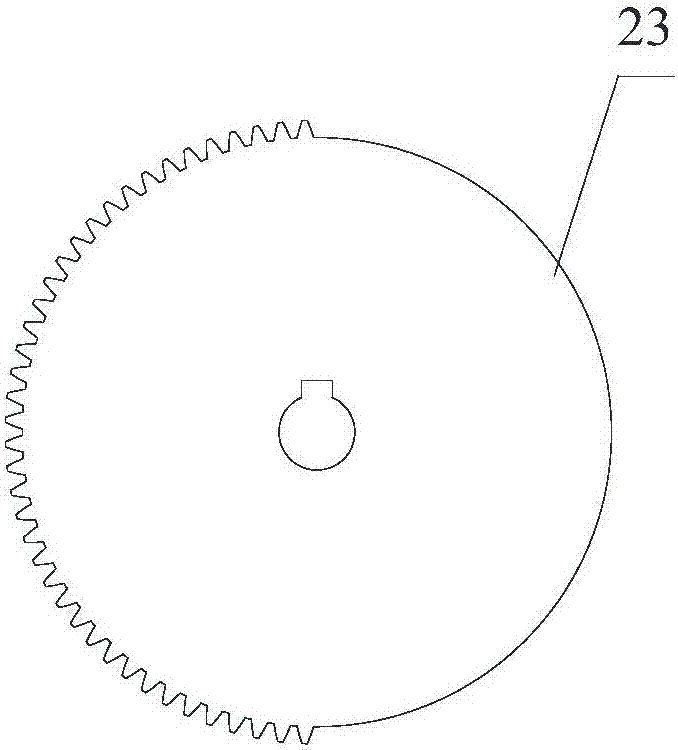

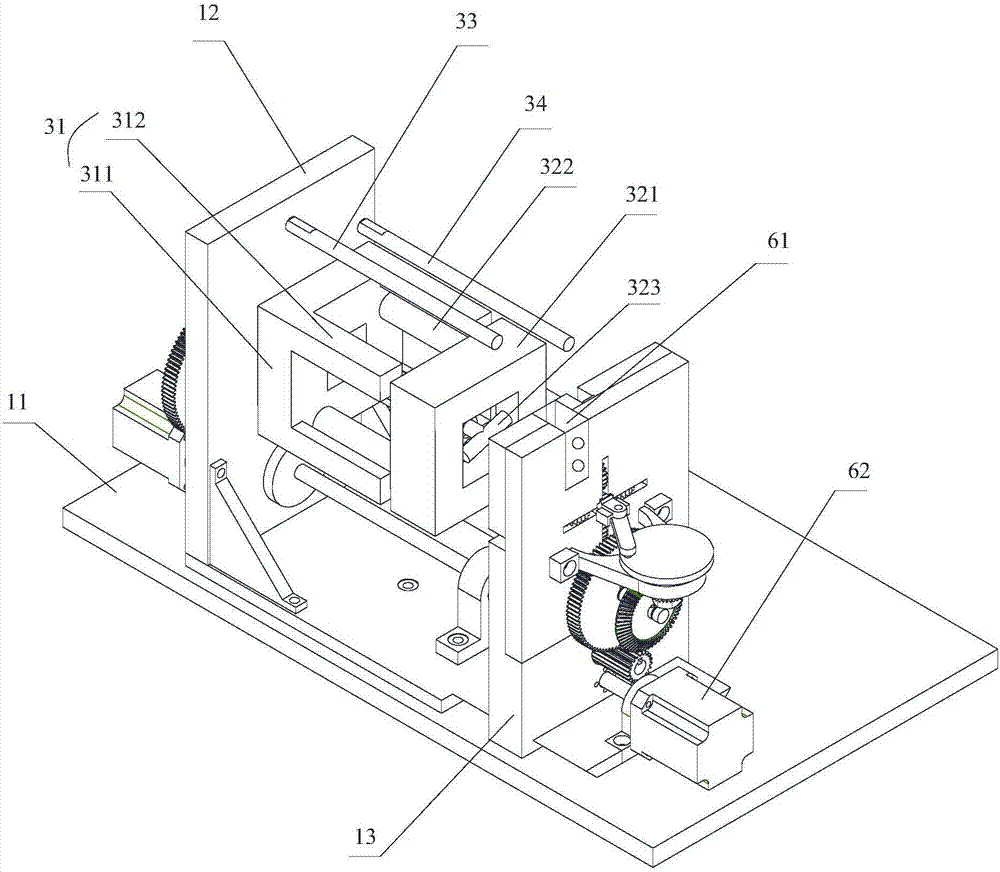

Packaging carton forming machine

InactiveCN105774042BReduce volumeReduce weightBox making operationsPaper-makingMolding machineCarton

Owner:WUHAN BUSINESS UNIV

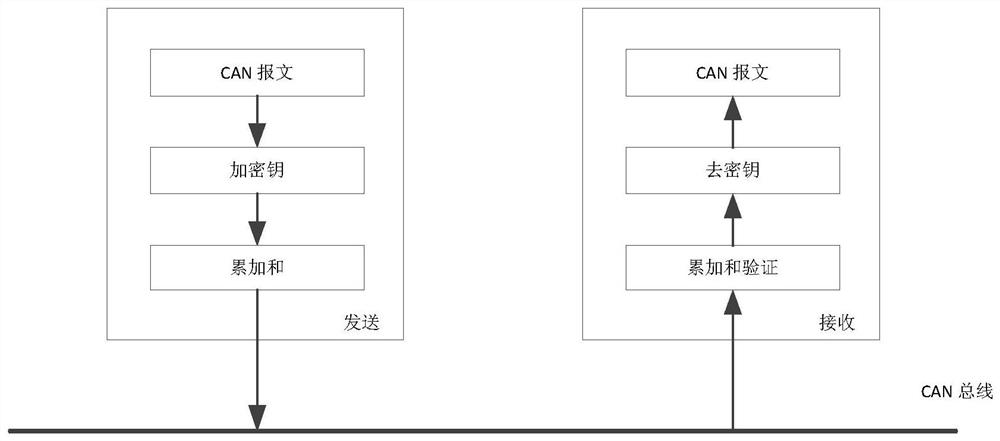

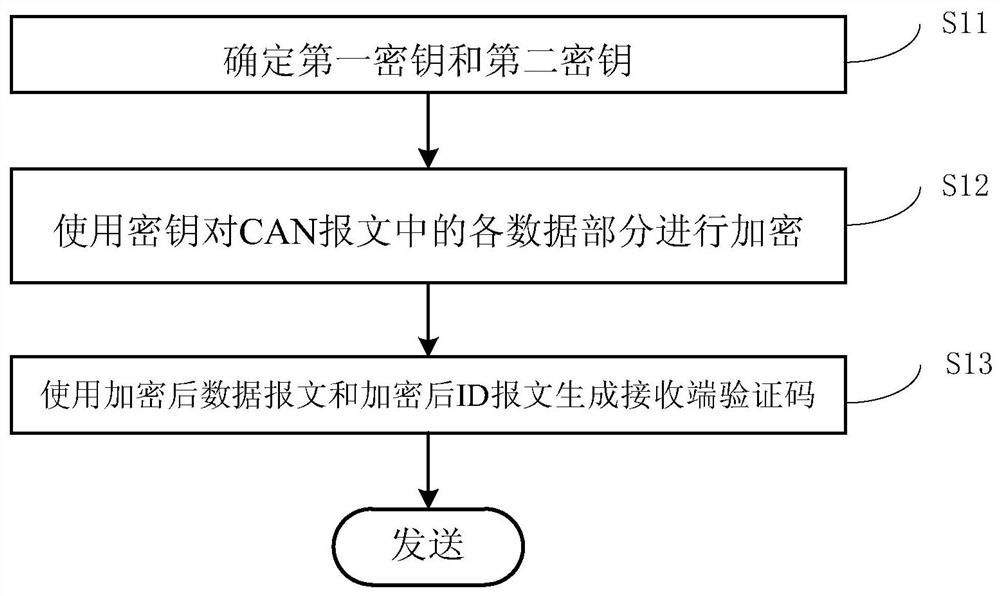

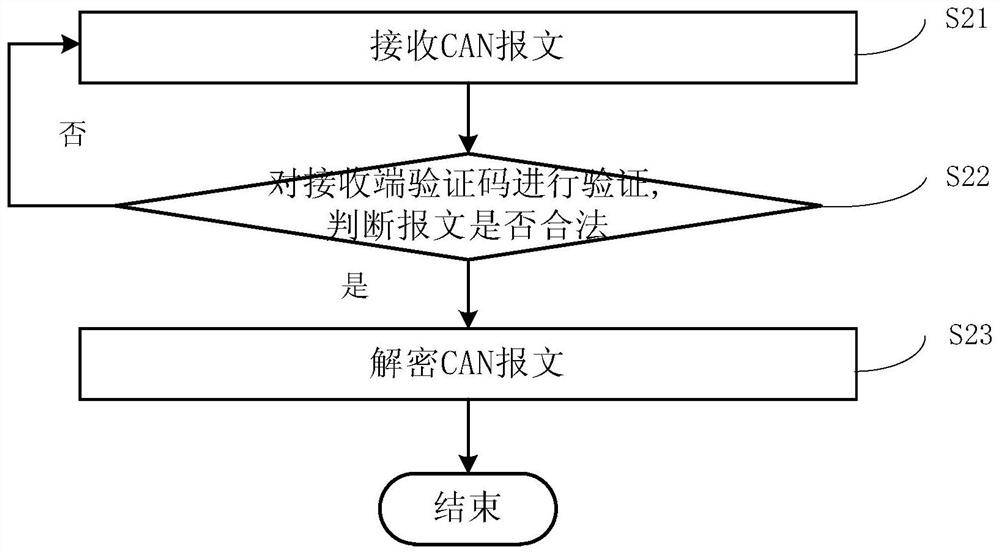

A security encryption method and decryption method for train CAN bus communication

ActiveCN110661746BImprove securityHelp to distinguishKey distribution for secure communicationBus networksCommunications securityInformation transmission

The invention discloses a train CAN bus communication security encryption method and a decryption method. The encryption method includes: determining the first key and the second key; using the first key to encrypt the data message in the CAN message to be encrypted; using the second key to encrypt the identity authentication message in the CAN message to be encrypted Encryption; use the encrypted data message and the encrypted identity authentication message to generate the receiving end verification code; determine and send the encrypted CAN message, the encrypted CAN message includes the encrypted data message, the encrypted identity authentication message and Receiver verification code. The invention greatly enhances the difficulty of deciphering data messages and identity authentication messages, effectively prevents CAN messages from being tampered with, and increases the security of information transmission.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

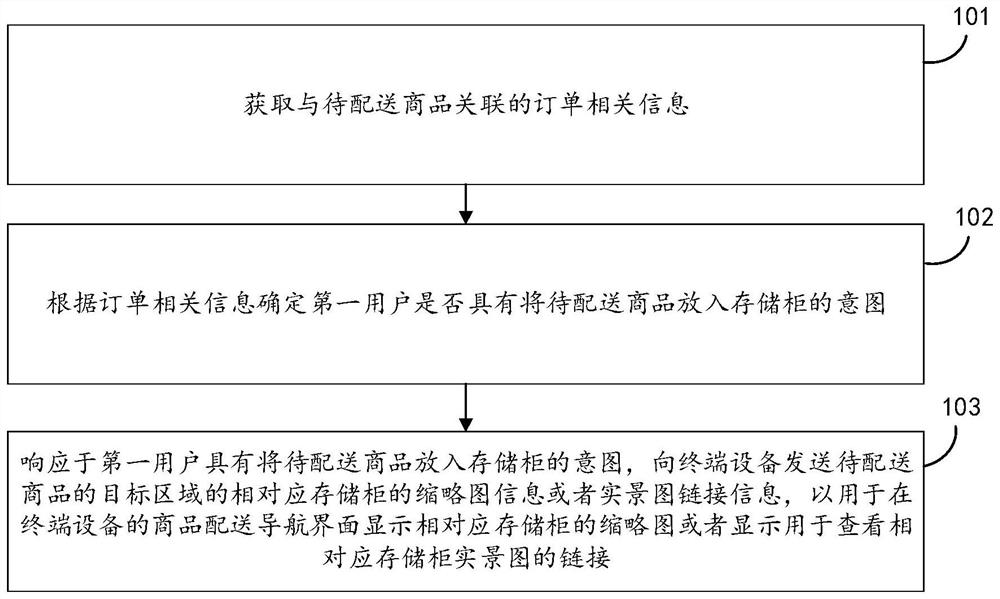

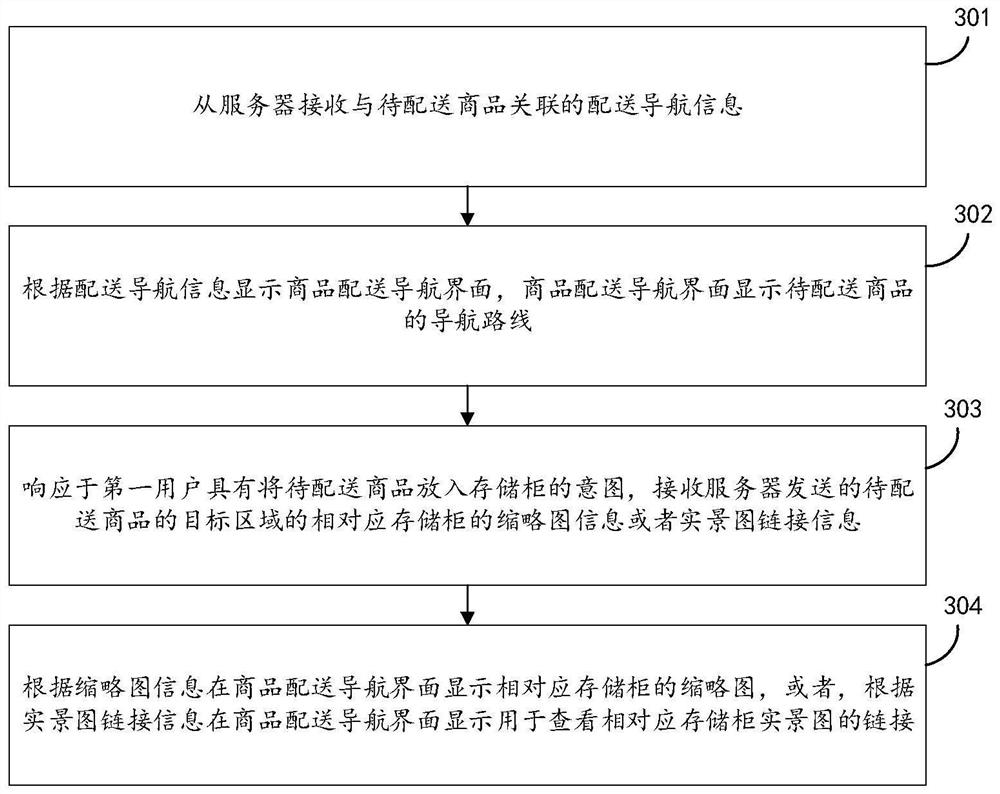

Commodity distribution navigation method, device and equipment

PendingCN114757604AHelp to distinguishImprove distribution efficiencyGeographical information databasesTransmissionTerminal equipmentThumbnail

The invention relates to the technical field of computers, in particular to a commodity distribution navigation method, device and equipment. The method comprises the steps of firstly obtaining order related information associated with a to-be-delivered commodity, then determining whether a first user has an intention of putting the to-be-delivered commodity into a storage cabinet according to the order related information, and then responding to the intention of putting the to-be-delivered commodity into the storage cabinet of the first user. And sending the thumbnail information or the live-action picture link information of the corresponding storage cabinet of the target area of the to-be-distributed commodity to the terminal equipment, so as to display the thumbnail of the corresponding storage cabinet or display a link for viewing the live-action picture of the corresponding storage cabinet on a commodity distribution navigation interface of the terminal equipment. By determining the user intention and displaying the corresponding storage cabinet thumbnail on the commodity distribution navigation interface, distribution personnel can distinguish different storage cabinets, and the distribution efficiency is improved.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

Visual field compensation method and near-to-eye display equipment using same

PendingCN114690407AExpand the field of viewHelps to seeOptical elementsComputer graphics (images)Radiology

The invention provides a visual field compensation method for near-eye display equipment, the near-eye display equipment is provided with a camera and a display screen, and the method comprises the following steps: S101: collecting an image around a wearer of the near-eye display equipment through the camera; s102, determining a reduced actual display area on the display screen according to the field of view of the wearer; and S103, reducing the image and displaying the image in the actual display area. The invention further provides near-to-eye display equipment capable of executing the method, the visual ability of the low-vision user with the incomplete visual field can be improved or improved, and the visual field range is expanded.

Owner:北京翠鸟视觉科技有限公司

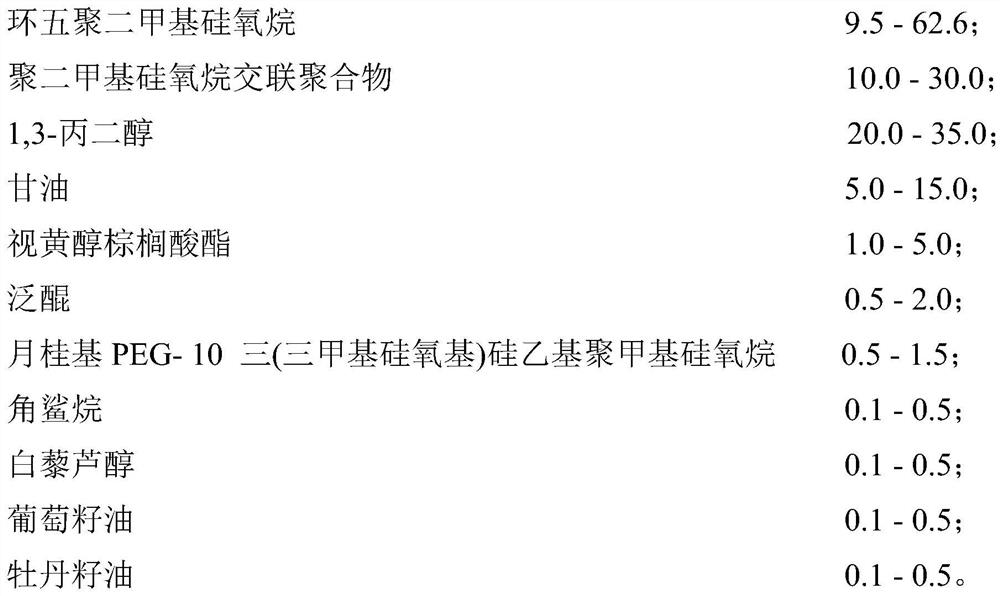

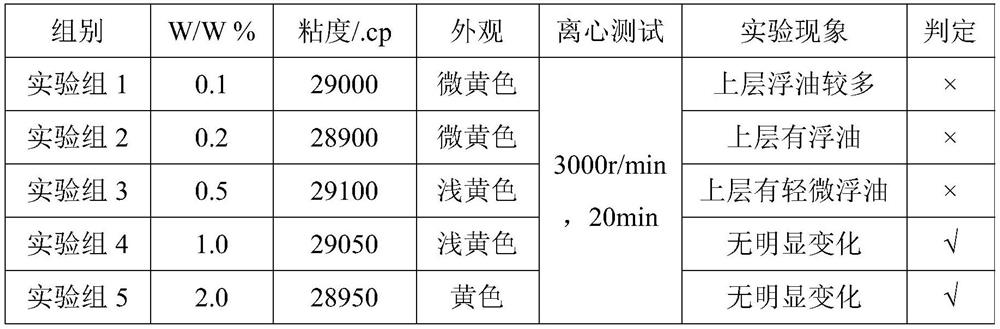

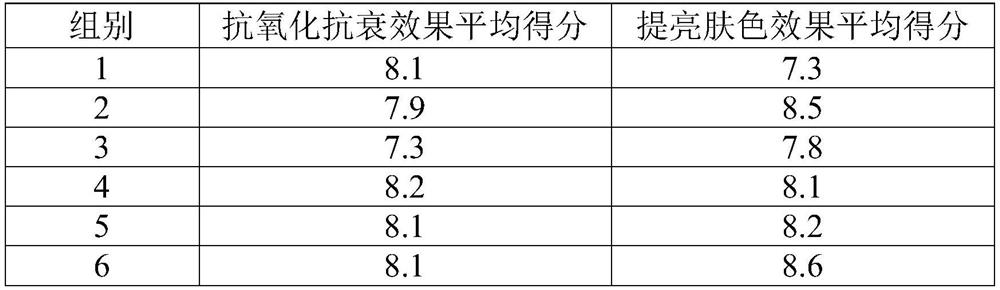

A kind of vitamin A water-free emulsion and preparation method thereof

ActiveCN110101611BMaintain and promote growthPromote growthCosmetic preparationsToilet preparationsPolymer scienceGlycerol

The invention provides an anhydrous vitamin A emulsion, which comprises the following components: cyclopentasiloxane, polydimethylsiloxane crosslinked polymer, 1,3-propylene glycol, glycerin, retinol Palmitate, Ubiquinone, Lauryl PEG‑10 Tris(trimethylsiloxy)silylethyl Methicone, Squalane, Resveratrol, Grape Seed Oil, Peony Seed Oil. The present invention also provides a preparation method for the above vitamin A anhydrous emulsion. The vitamin A anhydrous emulsion and the preparation method thereof of the present invention adopt an alcohol-in-oil system as a solvent of cosmetics, which can reduce the inactivation of active ingredients that are easily oxidized or volatile when encountering water, and improve the utilization rate of active ingredients; Raw materials can effectively use preservatives, thereby improving the safety of the product, reducing the risk of irritation, and can also have good anti-oxidation and anti-aging effects and the effect of brightening the complexion.

Owner:广州市庚晖精细化工有限公司

Object inspection system for object abnormity inspection

ActiveCN109632824AEasy to implementLow costOptically investigating flaws/contaminationIlluminanceIrradiation

The invention relates to an object inspection system for object abnormity inspection. The object inspection system comprises illumination equipment which is configured to irradiate an object to be inspected and camera equipment which is configured to carry out image shooting on the object to be inspected under the irradiation of the illumination equipment. The illumination device comprises a curved surface light cover and a plurality of monochromatic visible light sources, wherein the curved surface light cover has a concave curved surface which is arranged to face the object to be inspected;the plurality of monochromatic visible light sources are arranged on the concave curved surface of the curved surface light cover and are used for irradiating the object to be inspected; and the positions of the plurality of monochromatic visible light sources and the shape of the concave curved surface can make irradiation light formed by monochromatic visible light emitted by the plurality of monochromatic visible light sources in a predetermined illumination range irradiate the object to be inspected, and the illumination deviation of the irradiation light does not exceed 10%. The object inspection system can acquire a clear object image, and whether the object to be inspected is abnormal can be determined based on the object image.

Owner:INTEL PROD CHENGDU CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com