Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Heat dissipating structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

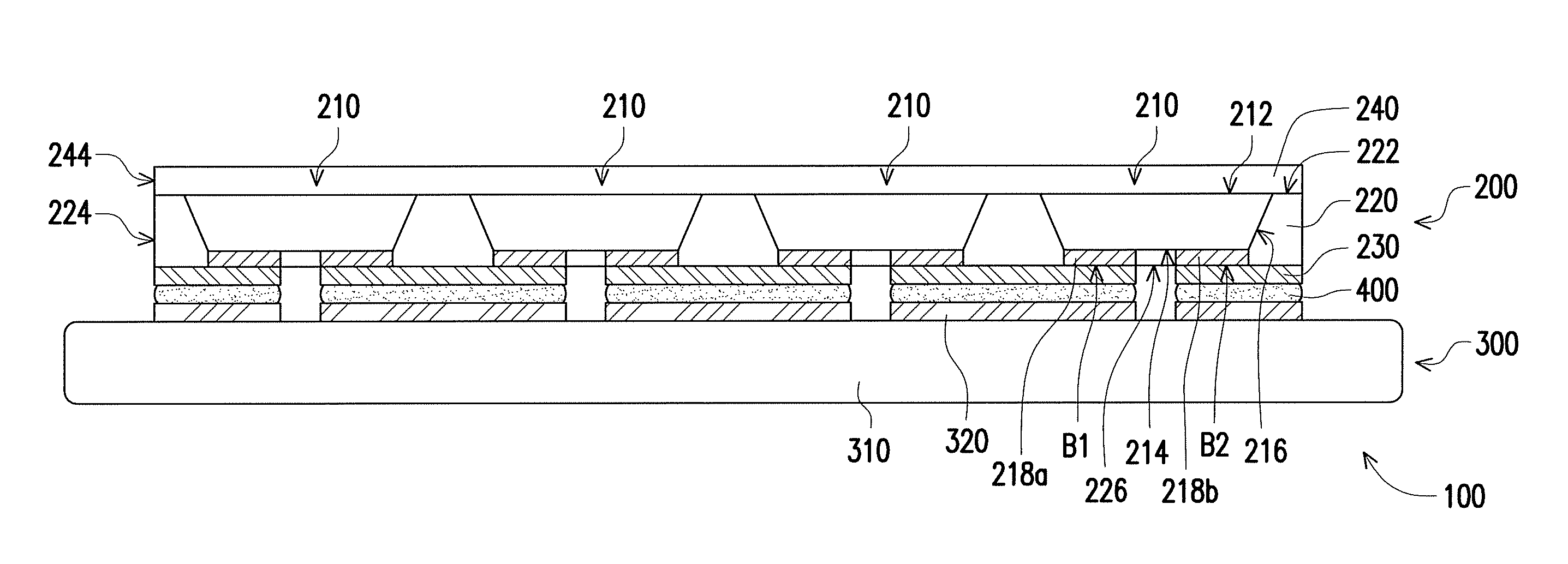

Chip-stacked semiconductor package and method for fabricating the same

ActiveUS20060172457A1Heat dissipating structureImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

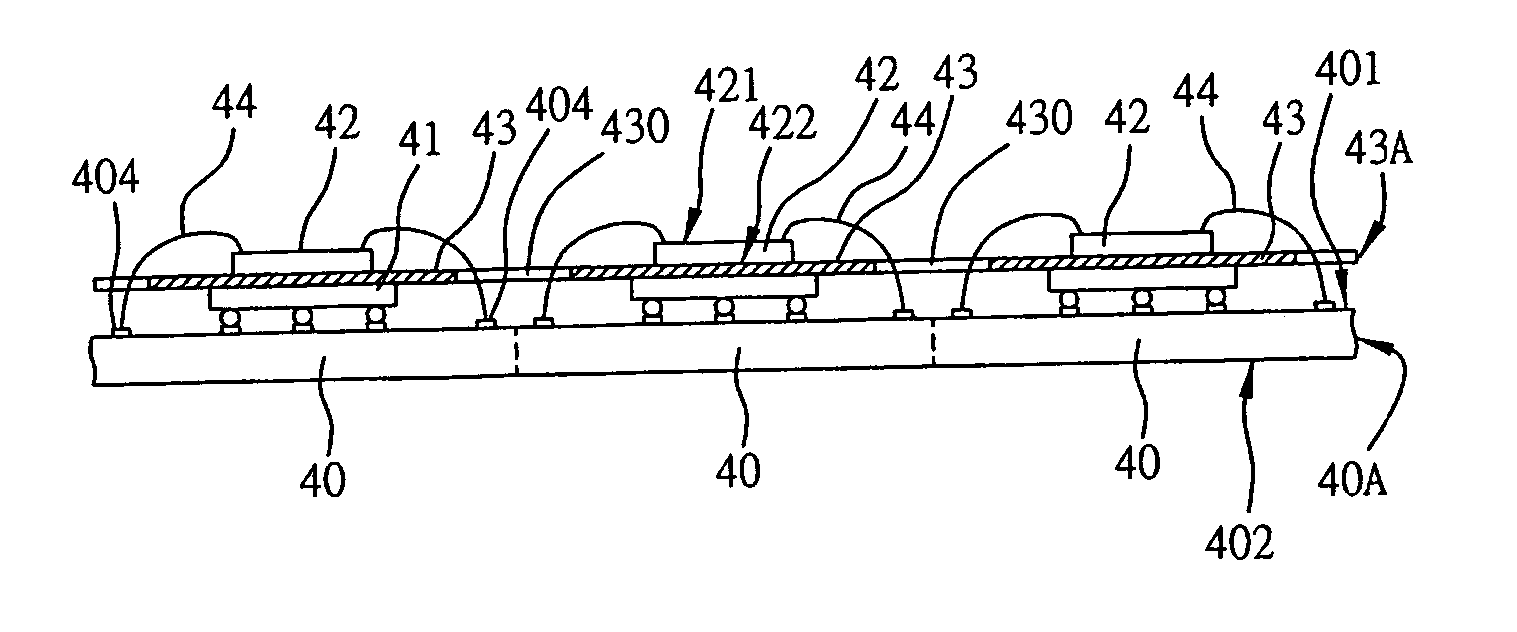

A chip-stacked semiconductor package and a method for fabricating the same are proposed. A chip carrier module plate including a plurality of chip carriers, and a heat sink module plate including a plurality of heat sinks are provided, wherein a plurality of through holes are formed around each of the heat sinks. First chips, the heat sink module plate, and second chips are successively stacked on the chip carrier module plate, wherein the second chips are electrically connected to the chip carrier module plate by conductive wires penetrating the through holes of the heat sink module plate. After a molding process is completed, a singulation process can be performed to separate the chip carriers and the heat sinks, and thus individual semiconductor packages for integrating the heat sinks with the stacked chips are fabricated.

Owner:SILICONWARE PRECISION IND CO LTD

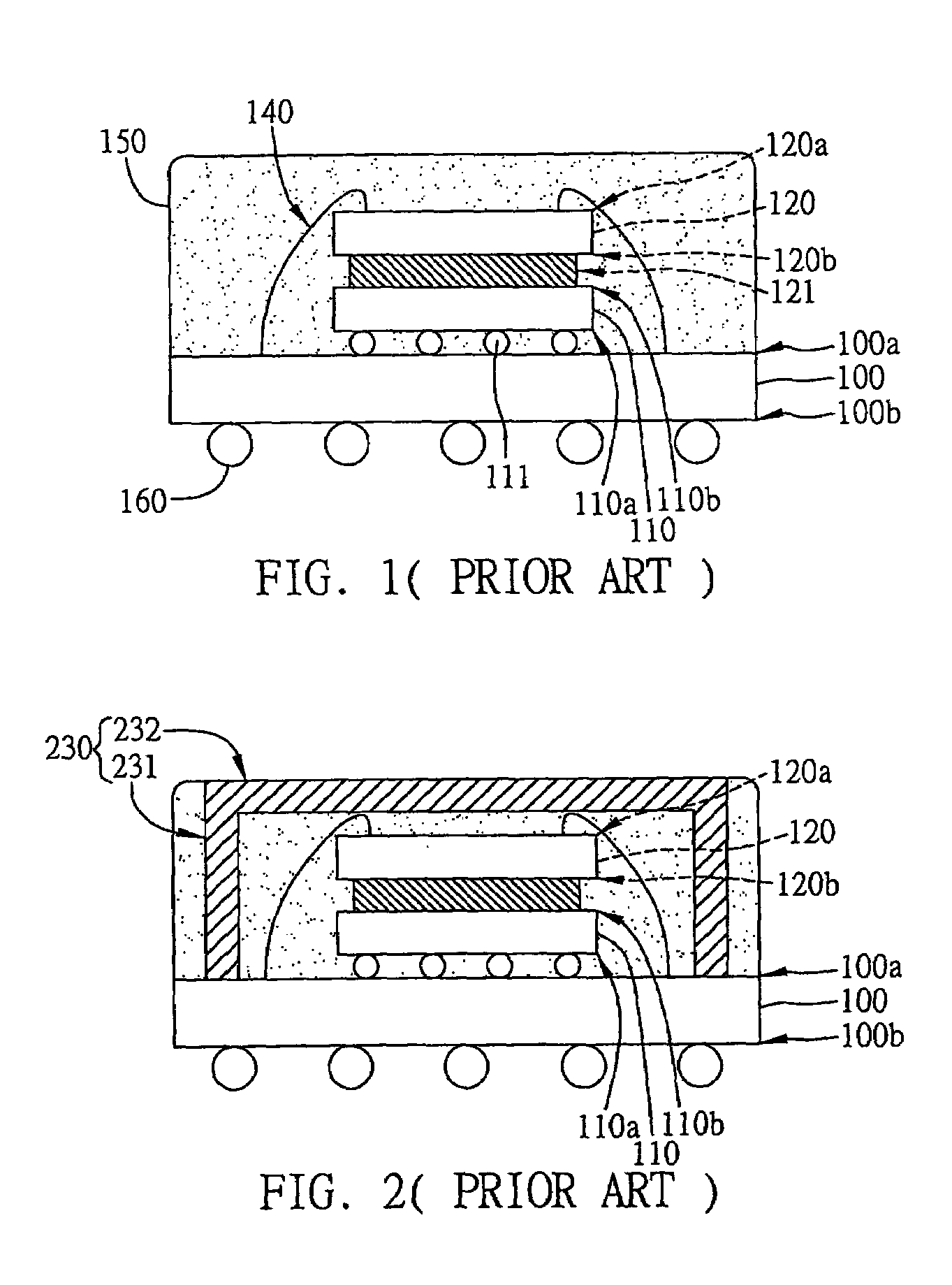

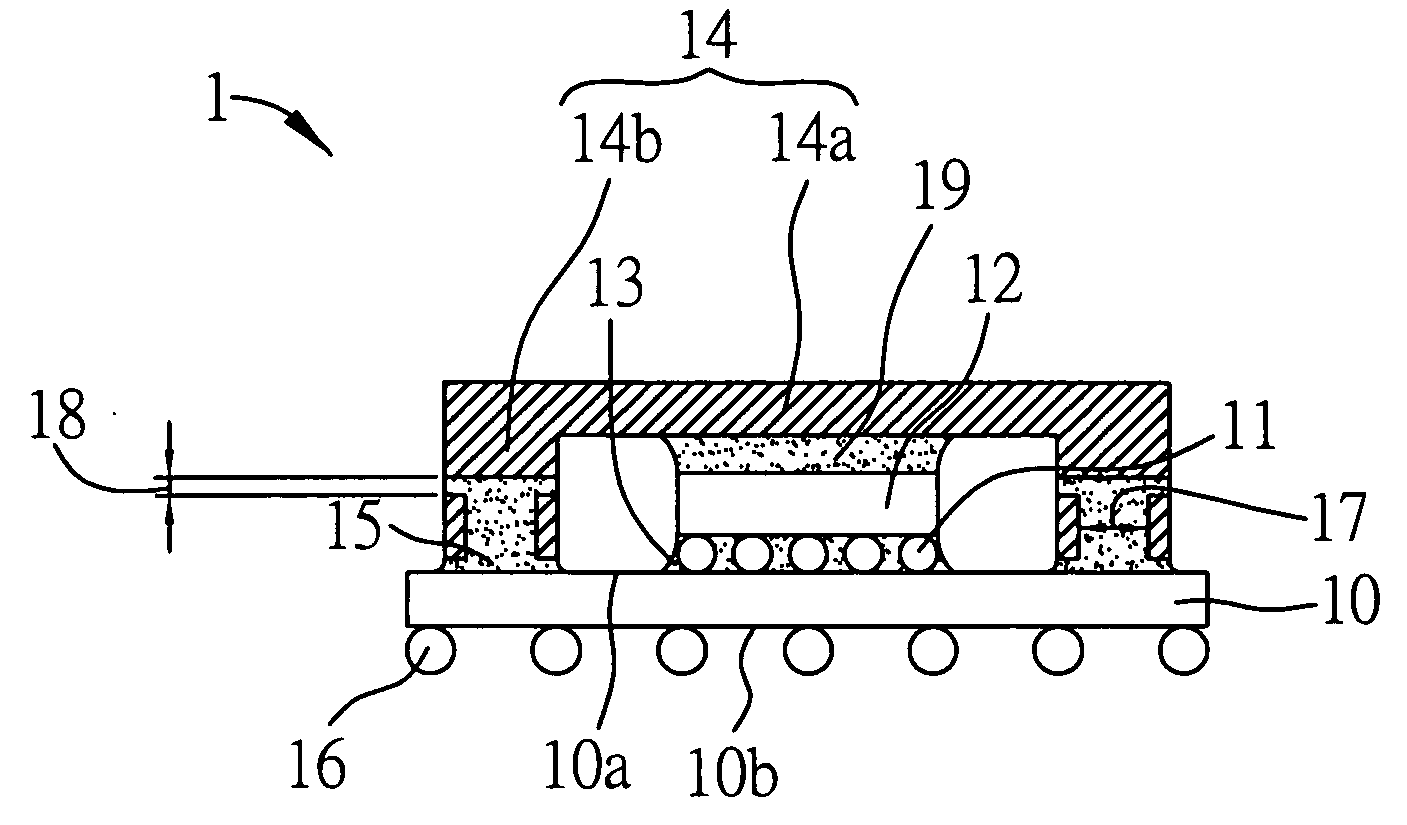

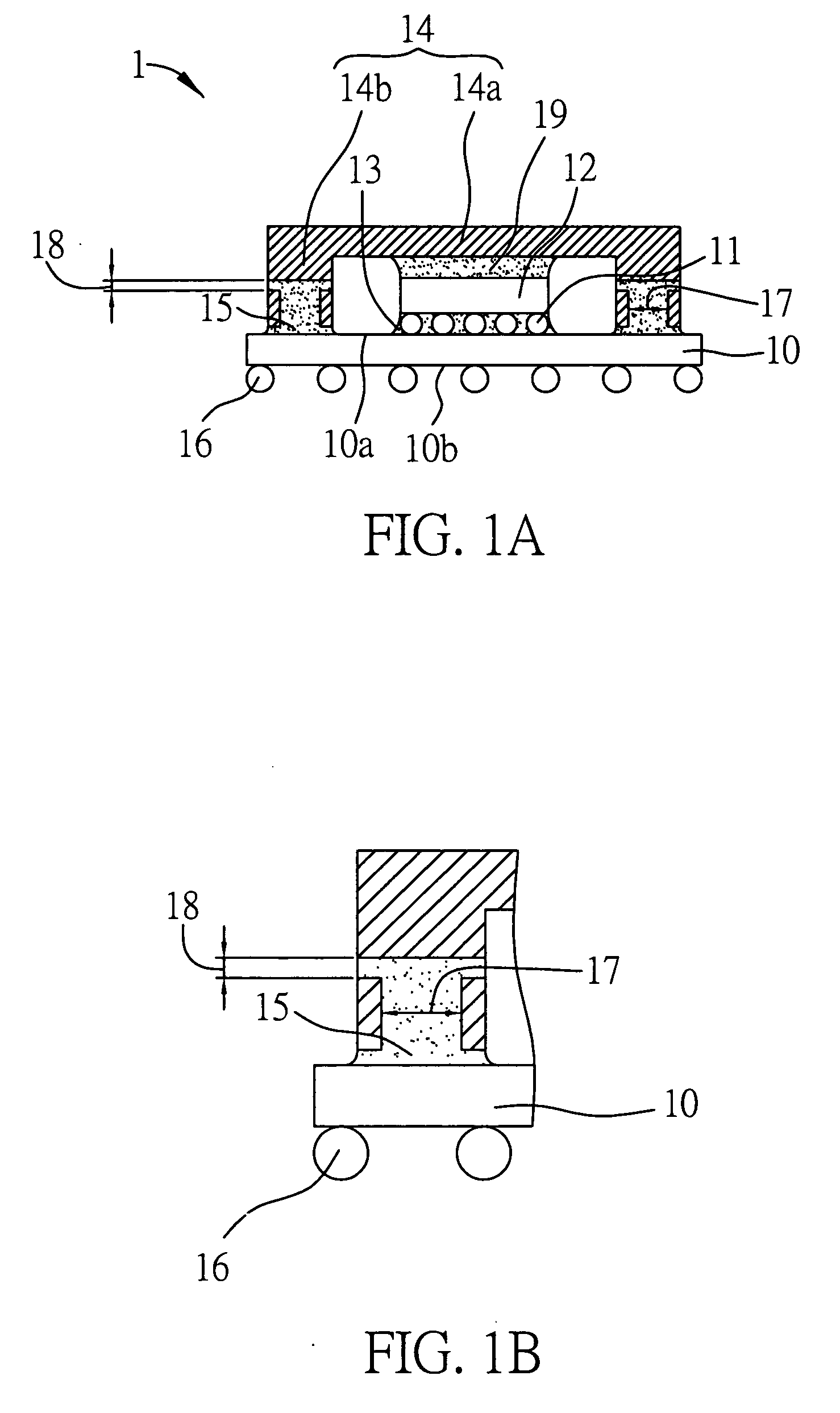

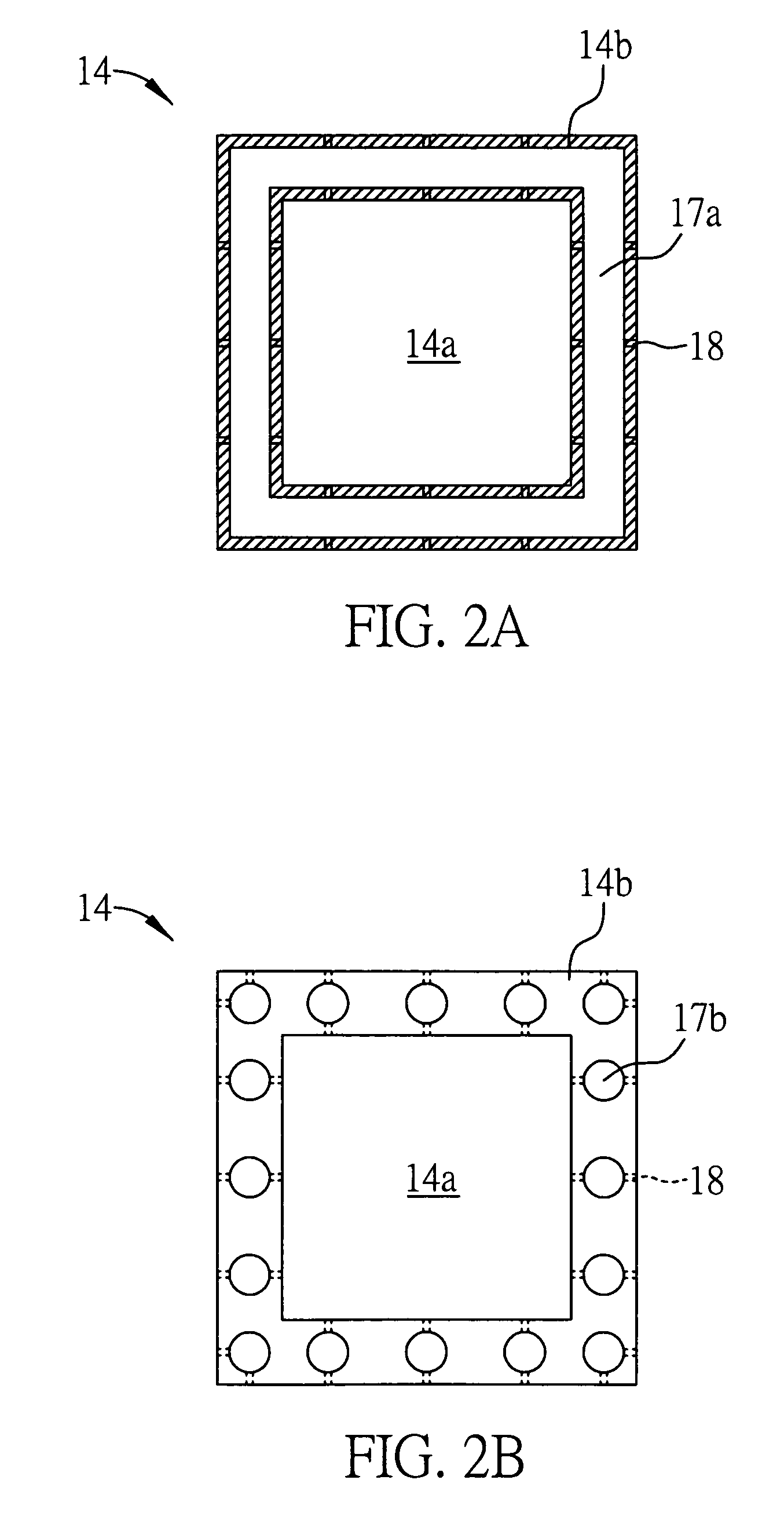

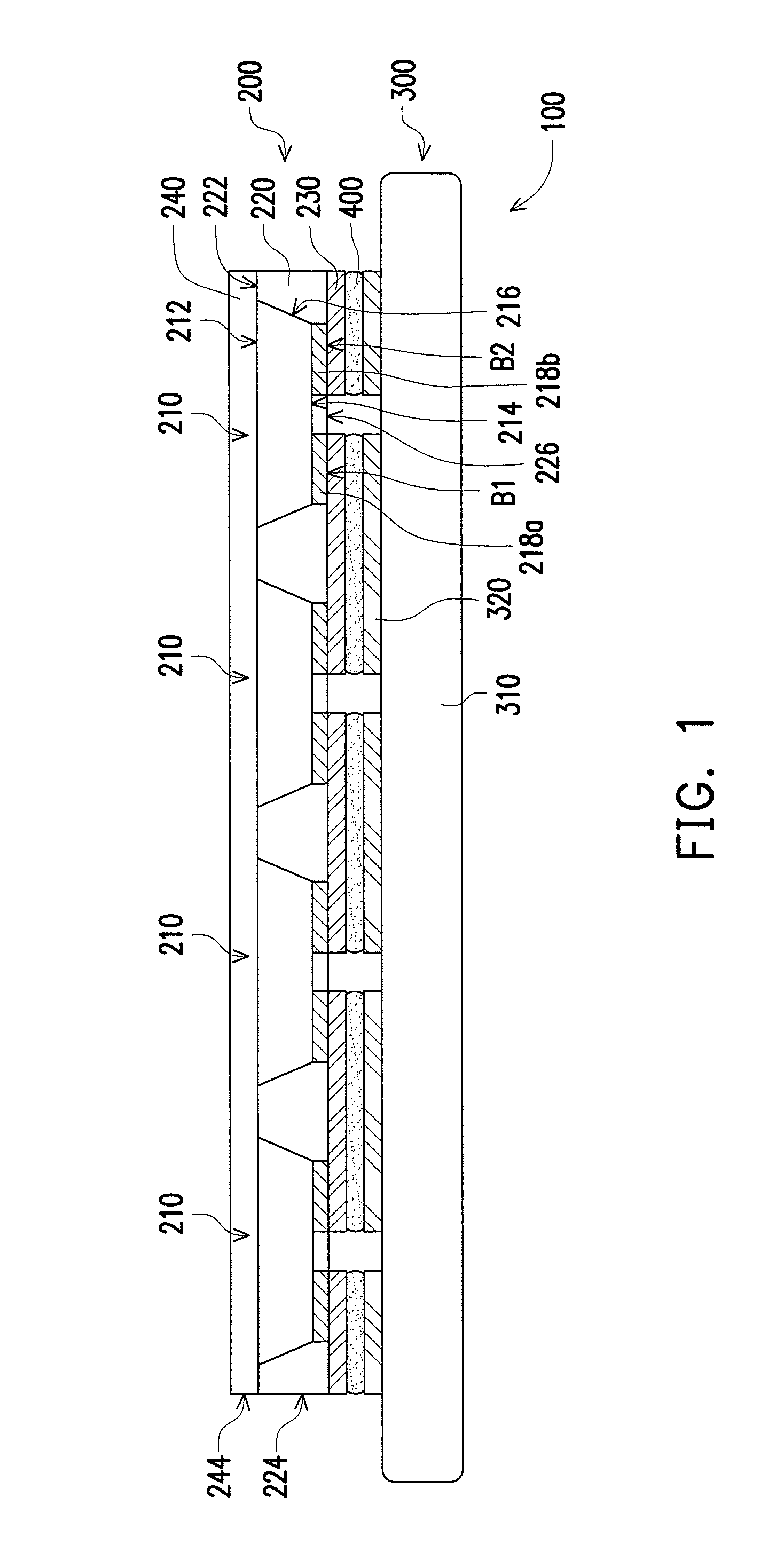

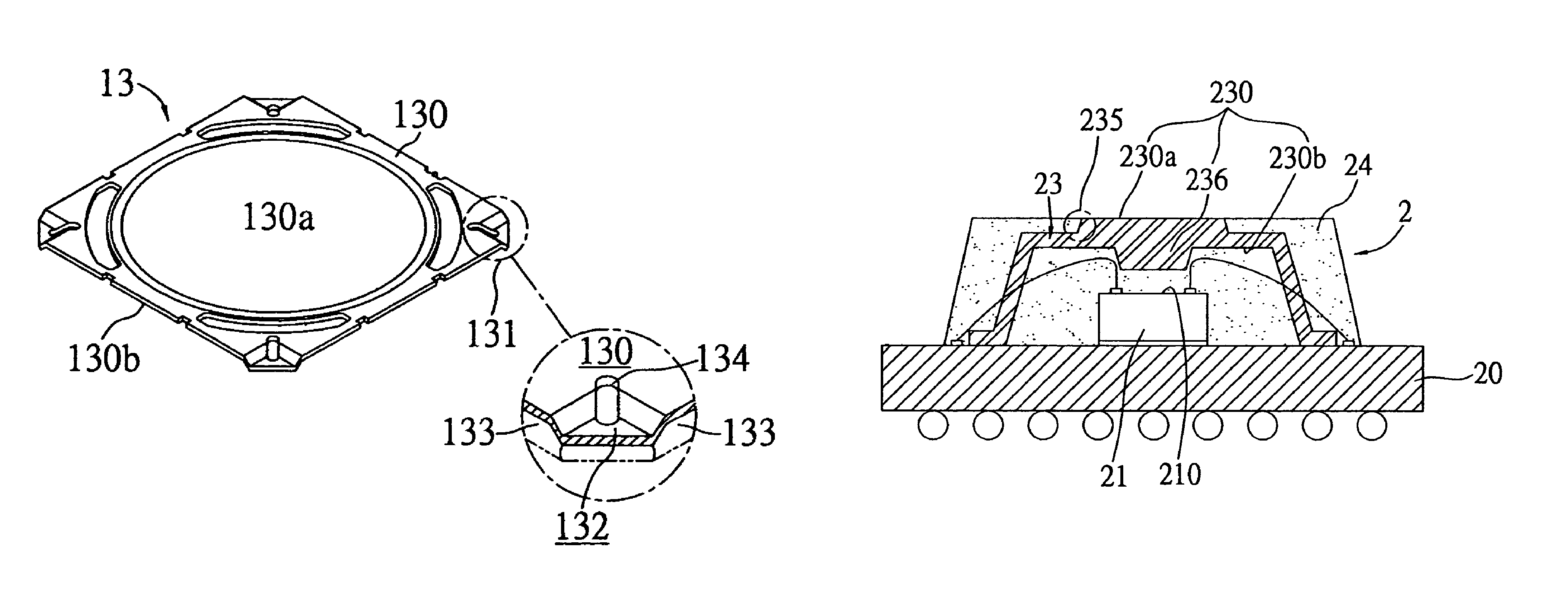

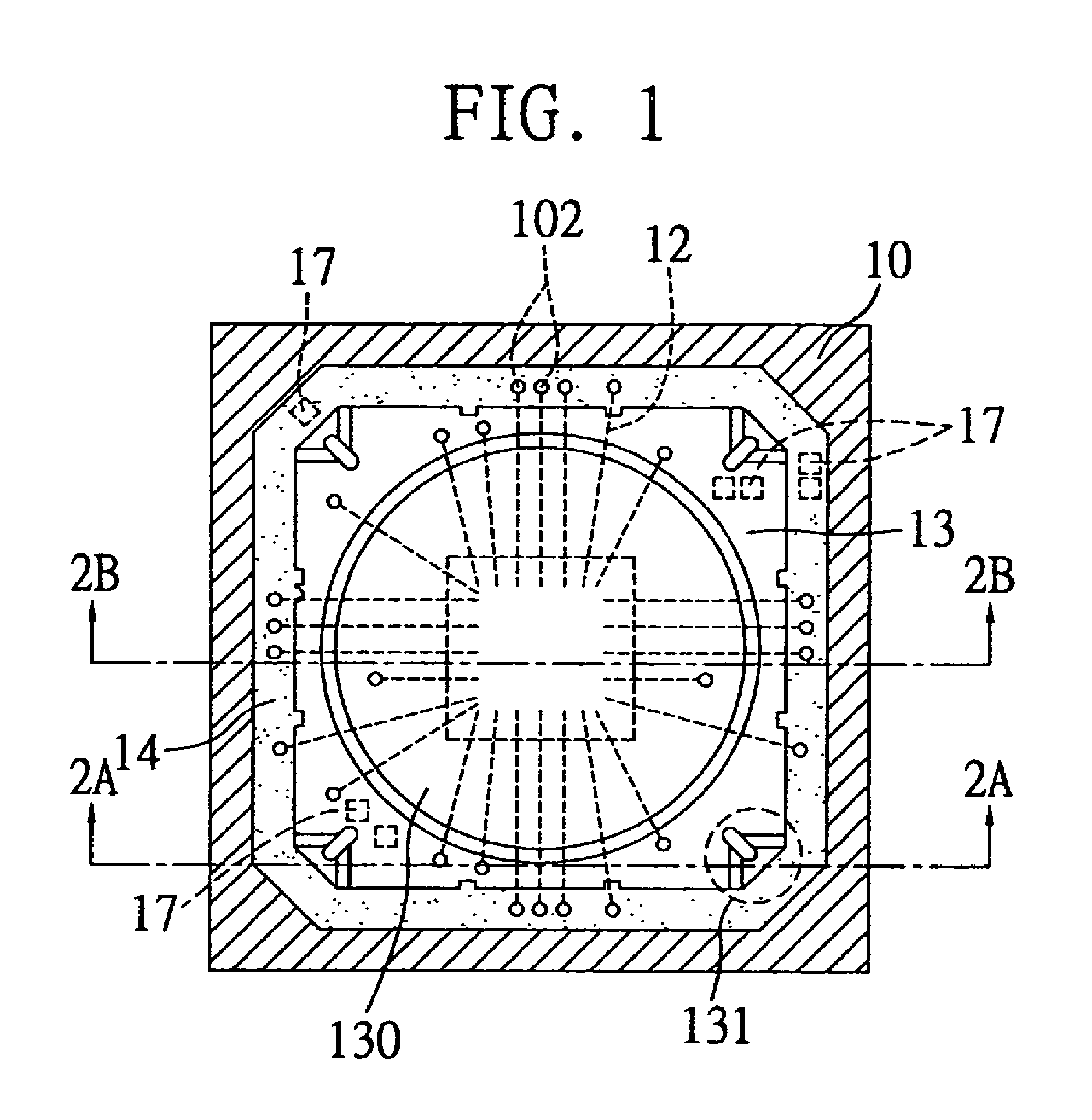

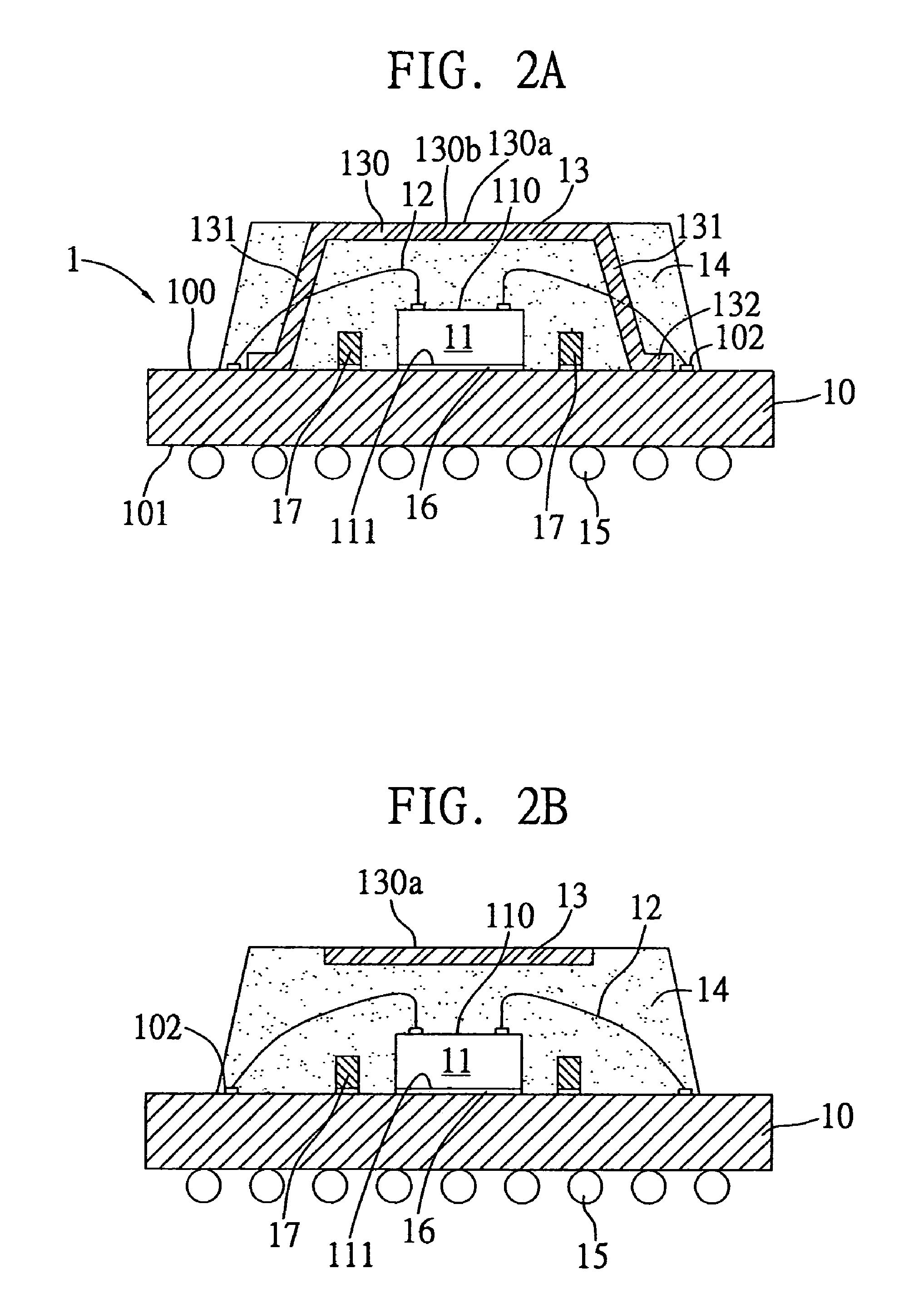

Semiconductor package with heat dissipating structure

ActiveUS20050036291A1Low costHeat dissipating structureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageDeuteron radiation

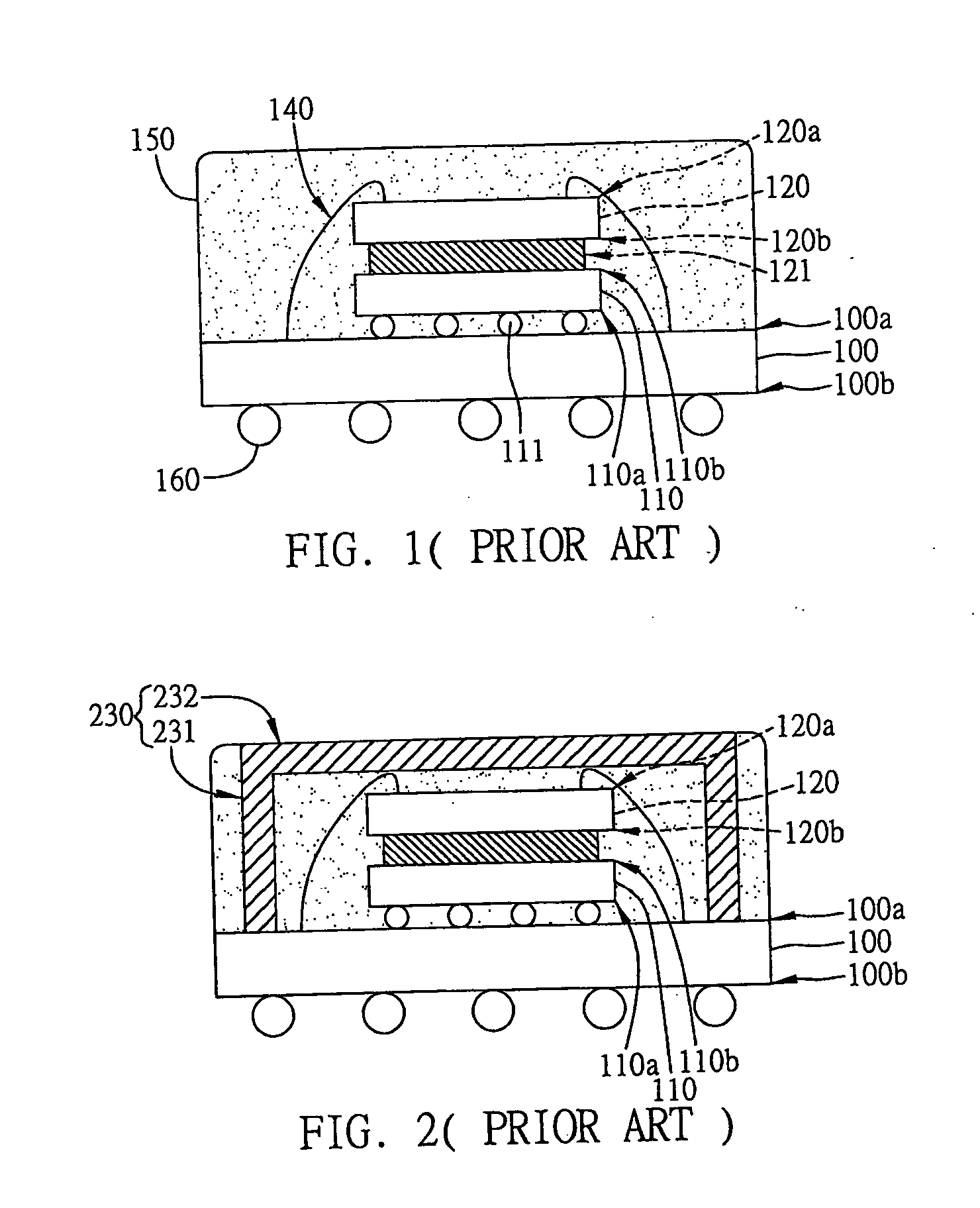

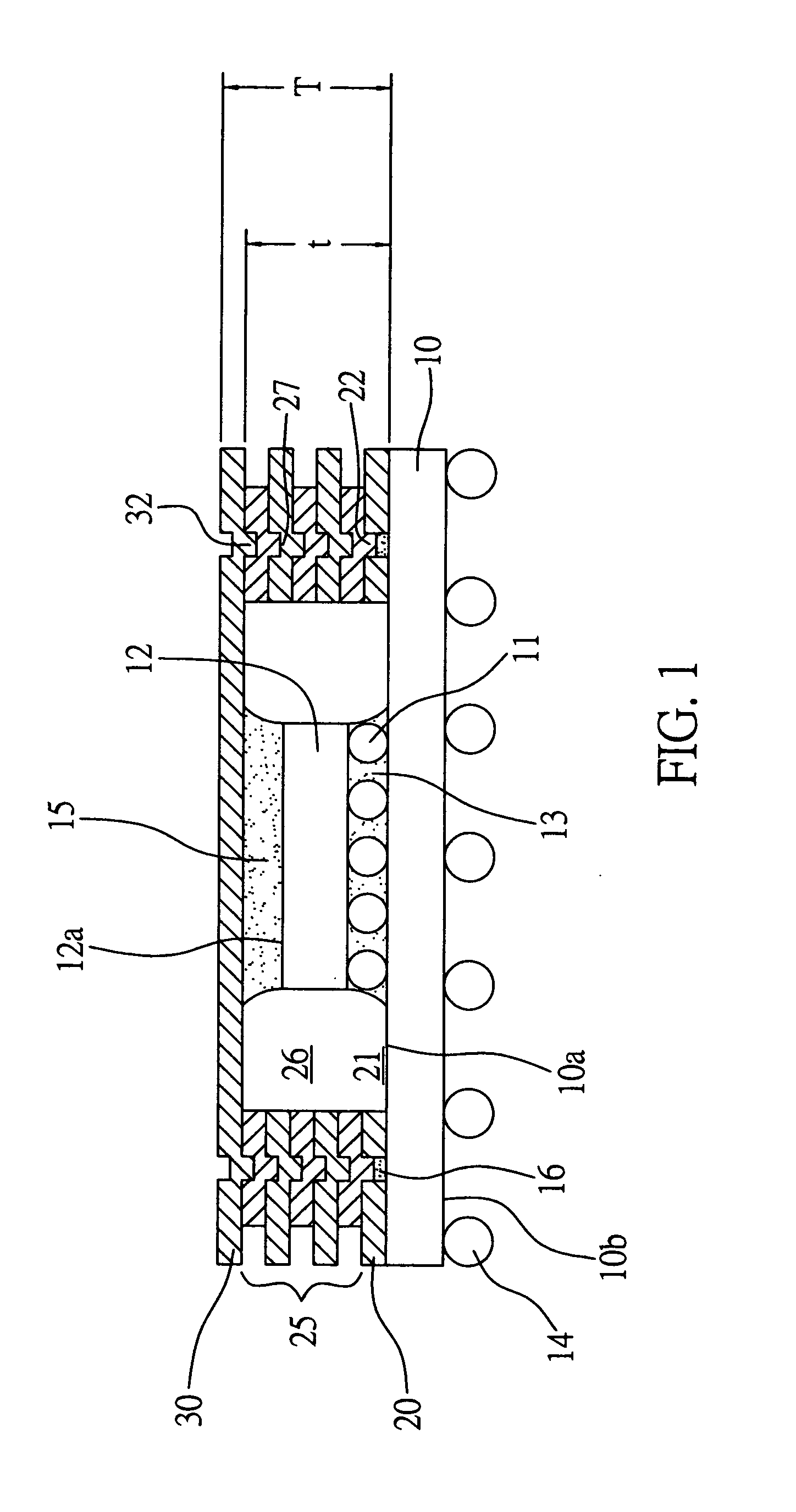

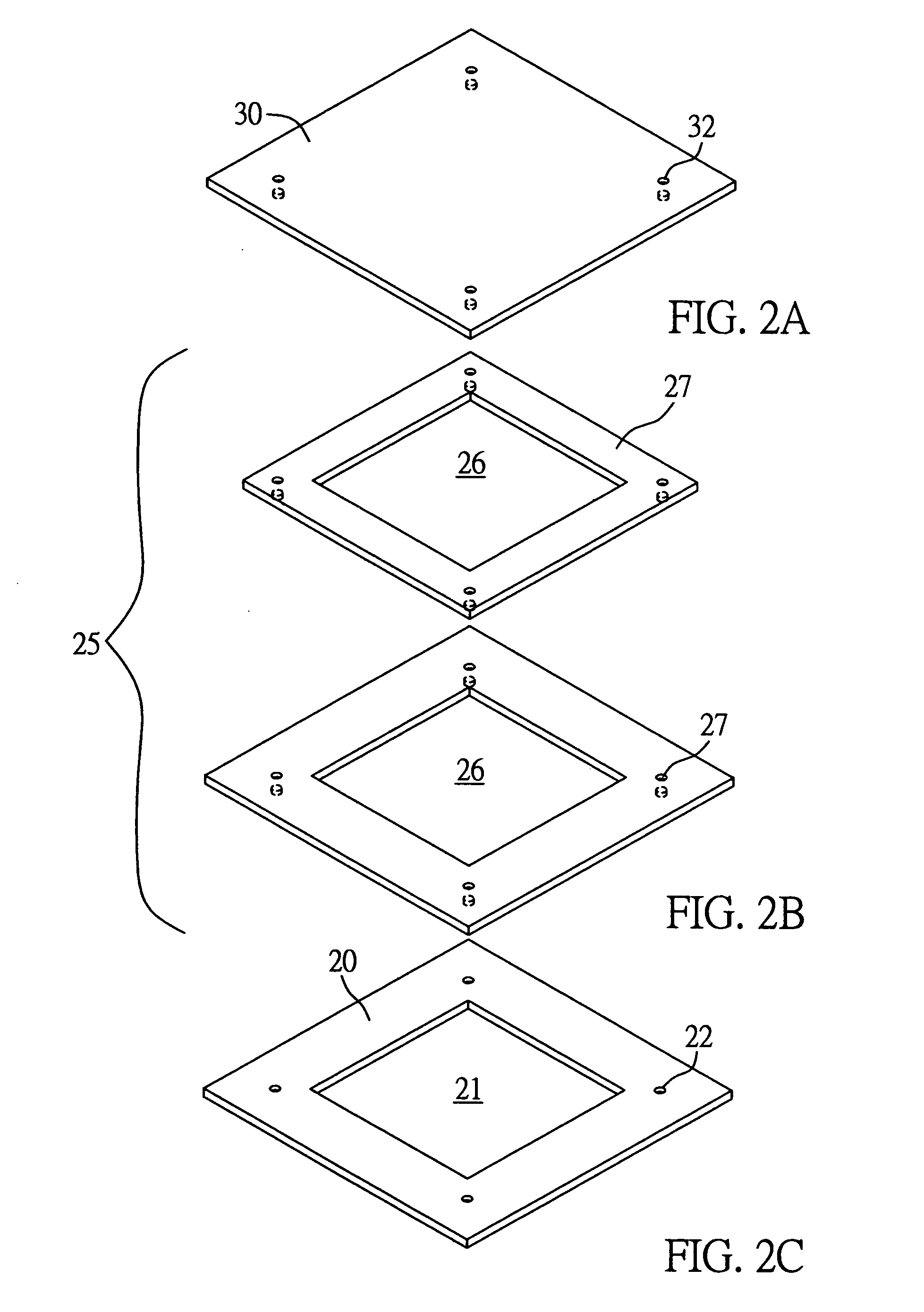

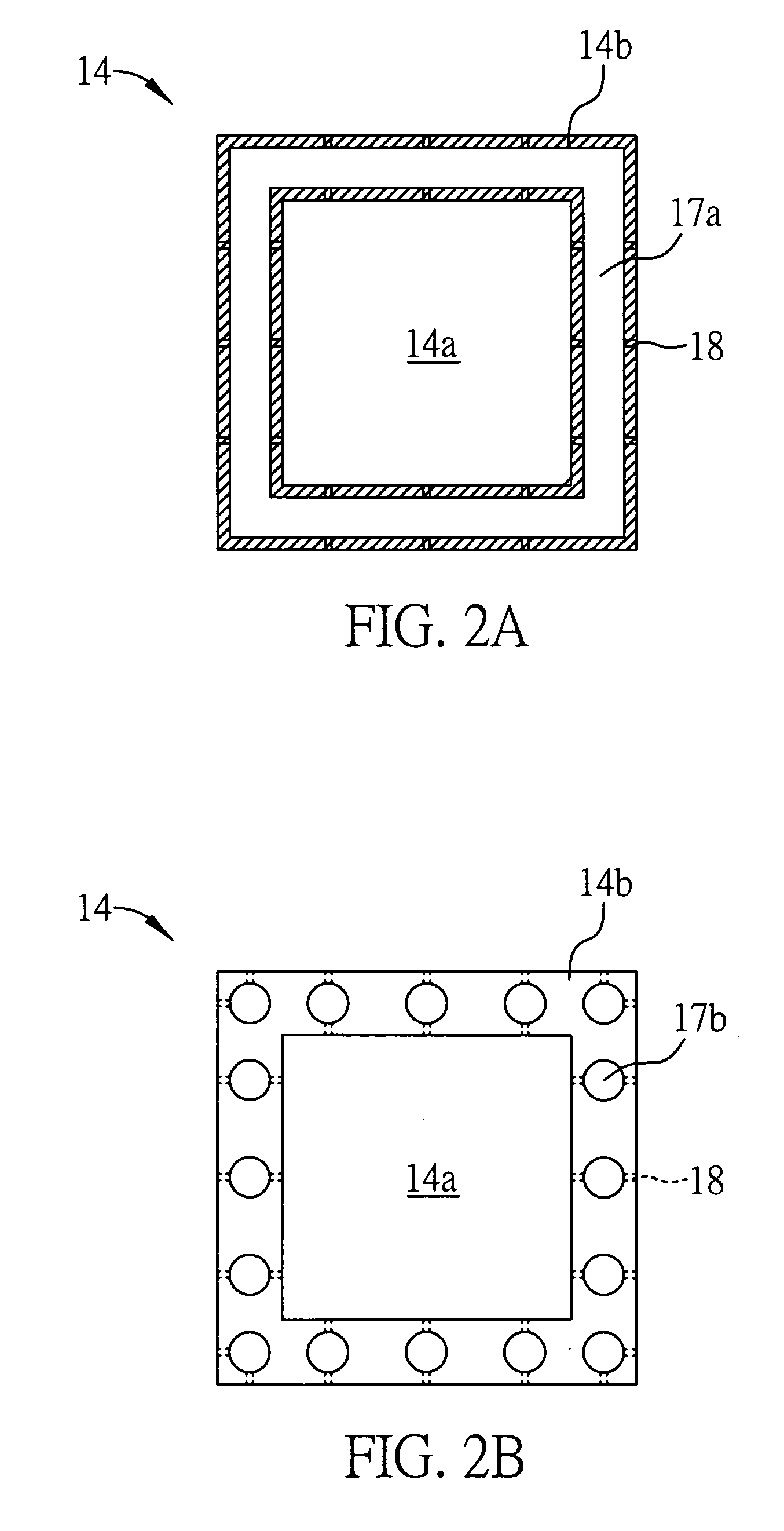

A semiconductor package with a heat dissipating structure includes a substrate, a chip and a heat dissipating structure. The chip is mounted on and electrically connected to the substrate. The heat dissipating structure includes a first heat sink having at least one positioning portion, and at least one second heat sink having at least one second positioning portion and at least one hollow portion. The second heat sink is mounted on the substrate, and the first positioning portion of the first heat sink is attached to the second positioning portion of the second heat sink, allowing the chip to be accommodated in a space defined by the first heat sink, the hollow portion of the second heat sink and the substrate. This semiconductor package has good heat dissipating efficiency and is cost-effective to fabricate.

Owner:SILICONWARE PRECISION IND CO LTD

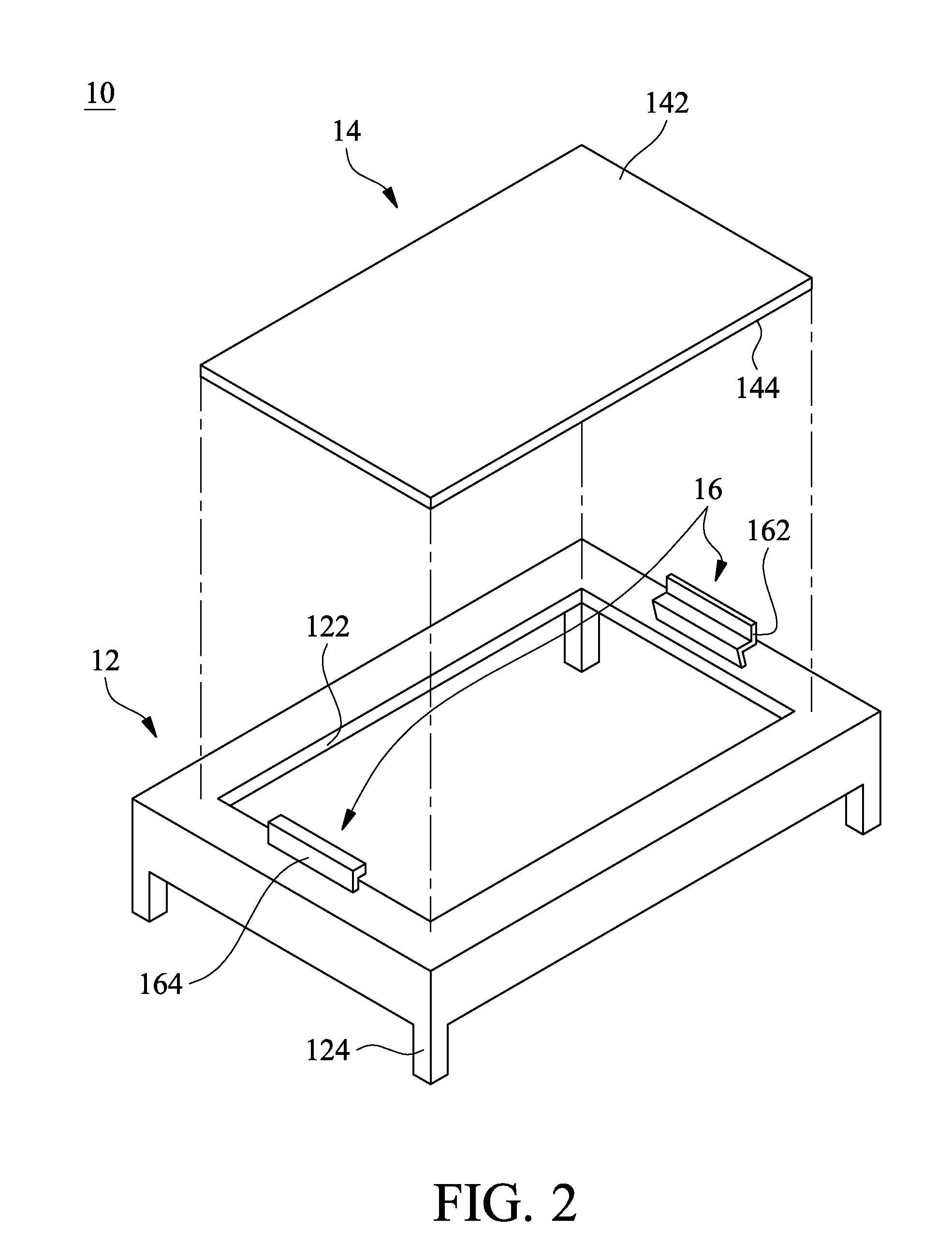

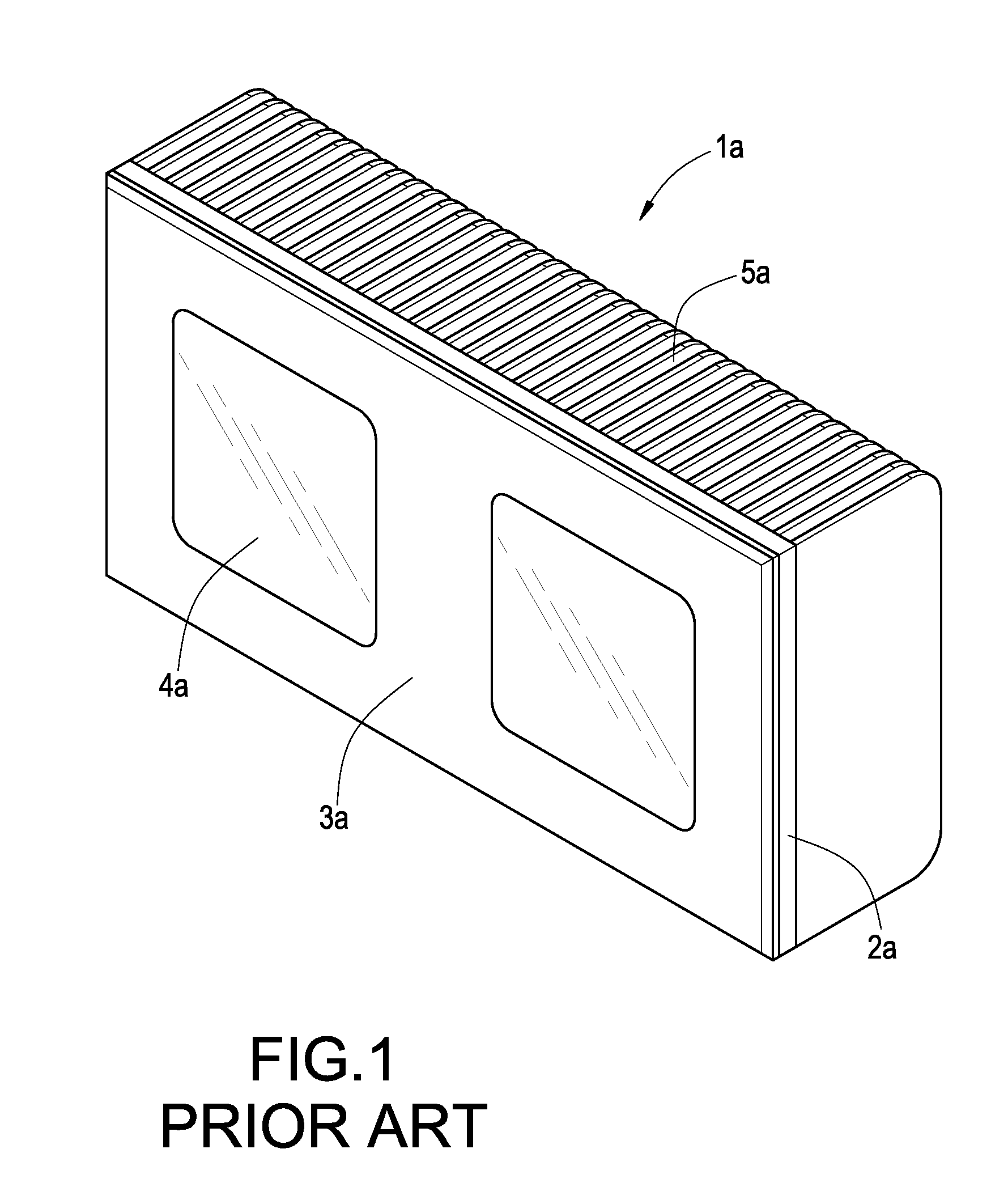

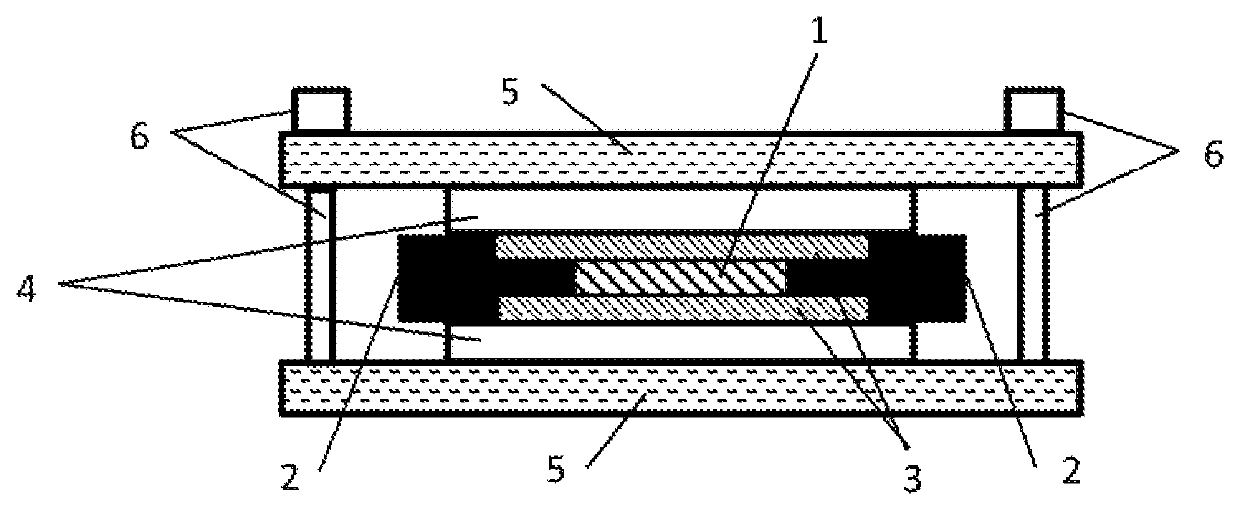

Assembled electromagnetic shielding case

InactiveUS20130235528A1Conveniently changedChanging an electronic component convenientlyMagnetic/electric field screeningCooling/ventilation/heating modificationsPrinted circuit boardElectromagnetic interference

An assembled electromagnetic shielding case conducive to electromagnetic interference shielding and heat dissipation of an electronic component on a printed circuit board includes a body, a shielding element, and a fixing element. The body has an opening and an engagement portion. The engagement portion connects the body and the printed circuit board. The shielding element has a bottom side and a heat-dissipating side opposing thereto. The shielding element closes the opening for effectuating electromagnetic interference shielding. The shielding element dissipates heat generated from the electronic component by transferring the heat from the bottom side to the heat-dissipating side for dissipating the heat. The fixing element couples the body and the shielding element. Accordingly, with the assembled electromagnetic shielding case, not only is the electronic component insusceptible to electromagnetic interference and easy to change, but it is feasible to provide highly efficient heat dissipation and a miniaturized heat dissipation structure.

Owner:ASKEY TECH JIANGSU +1

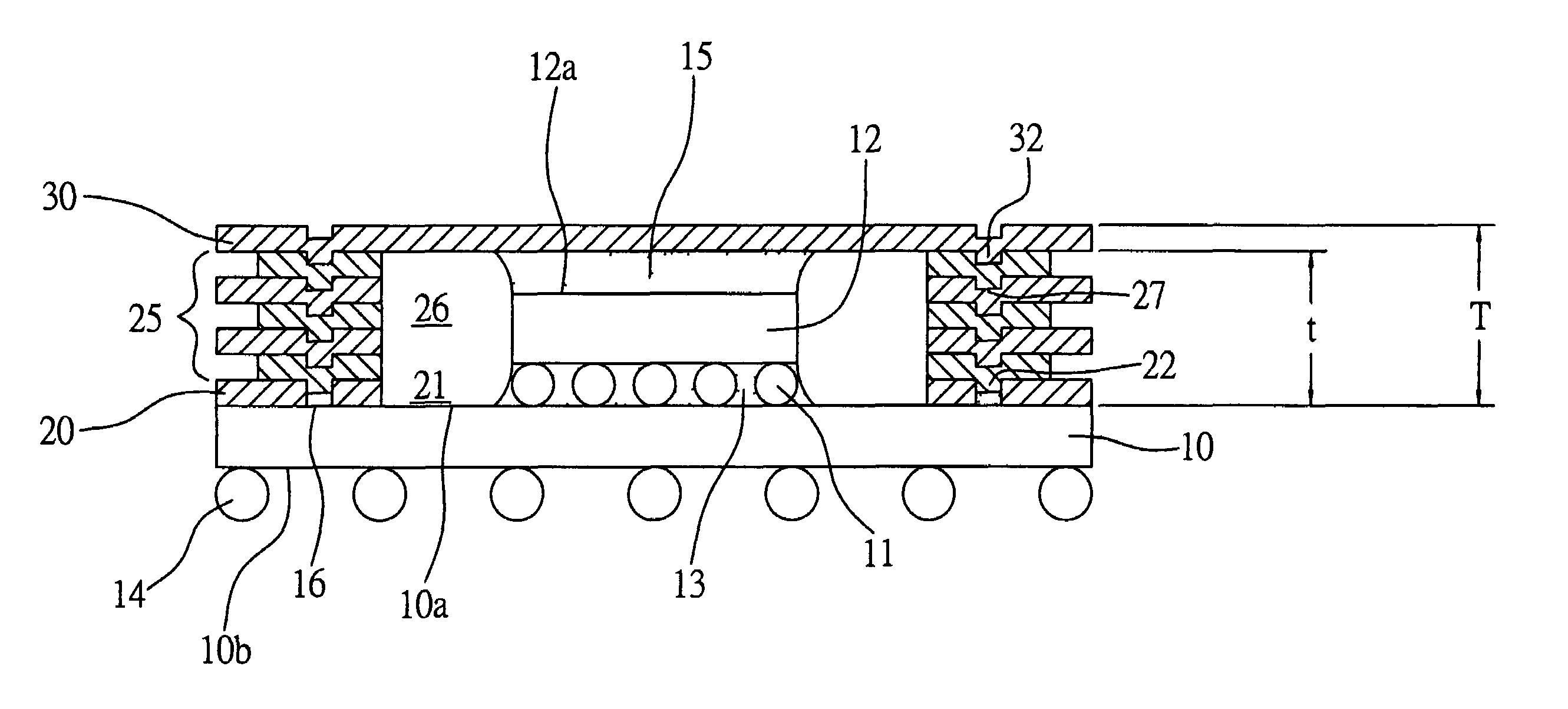

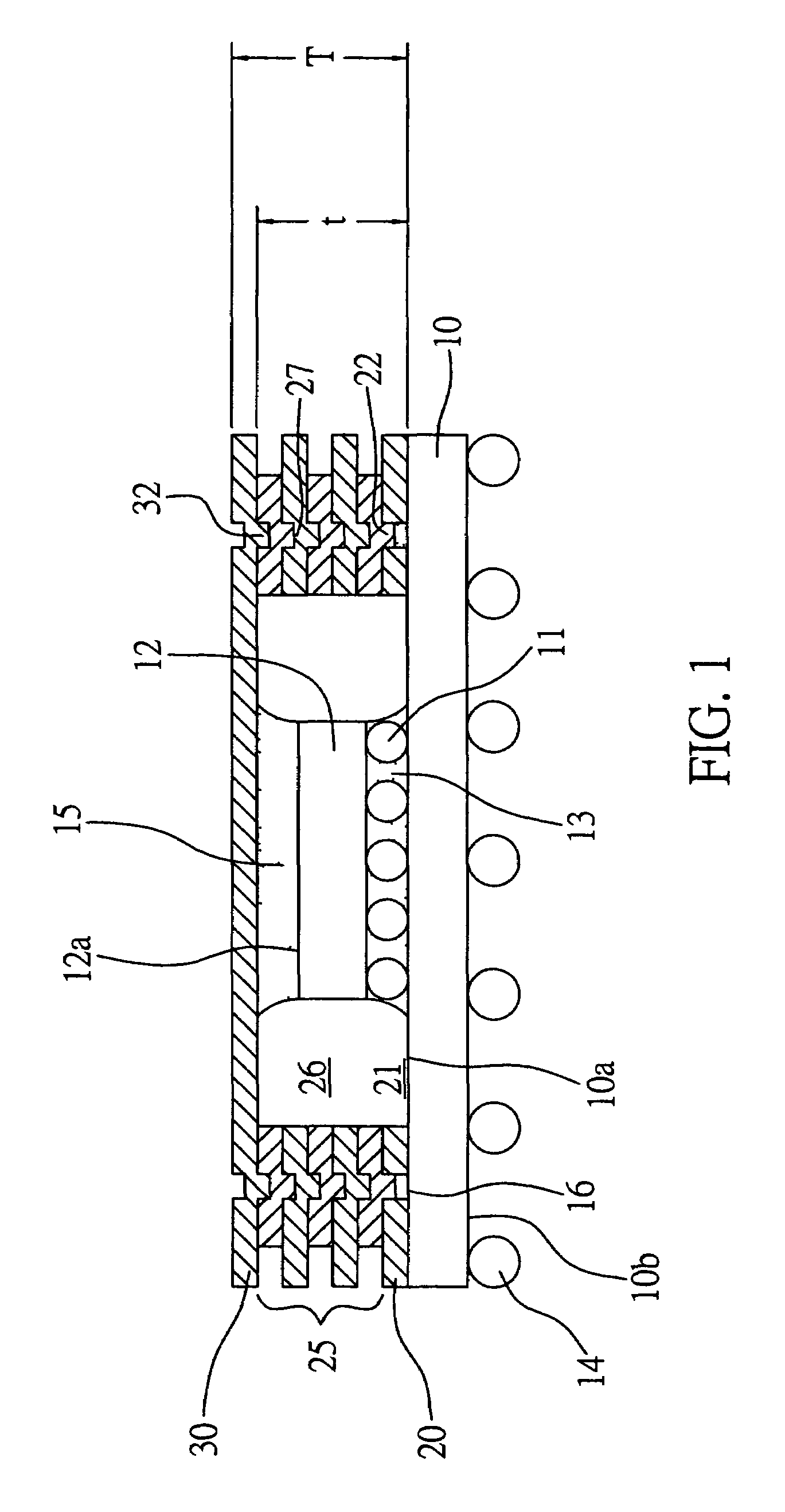

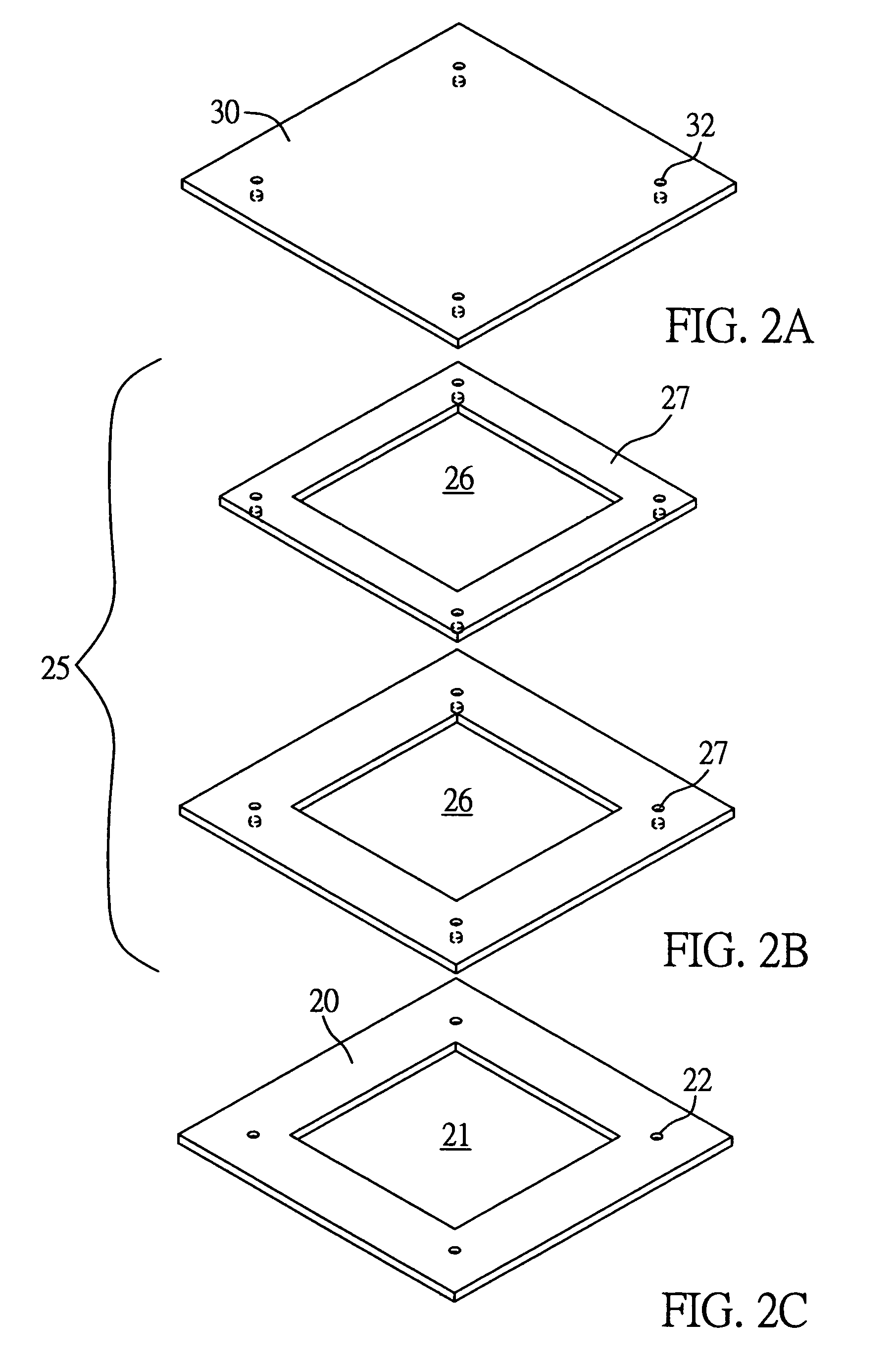

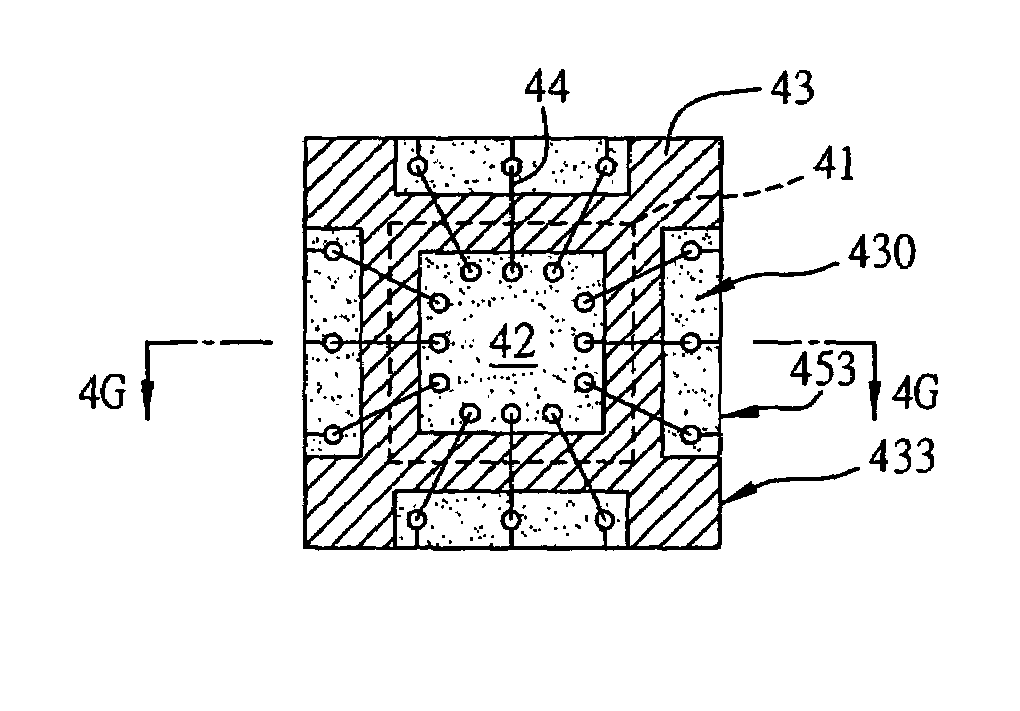

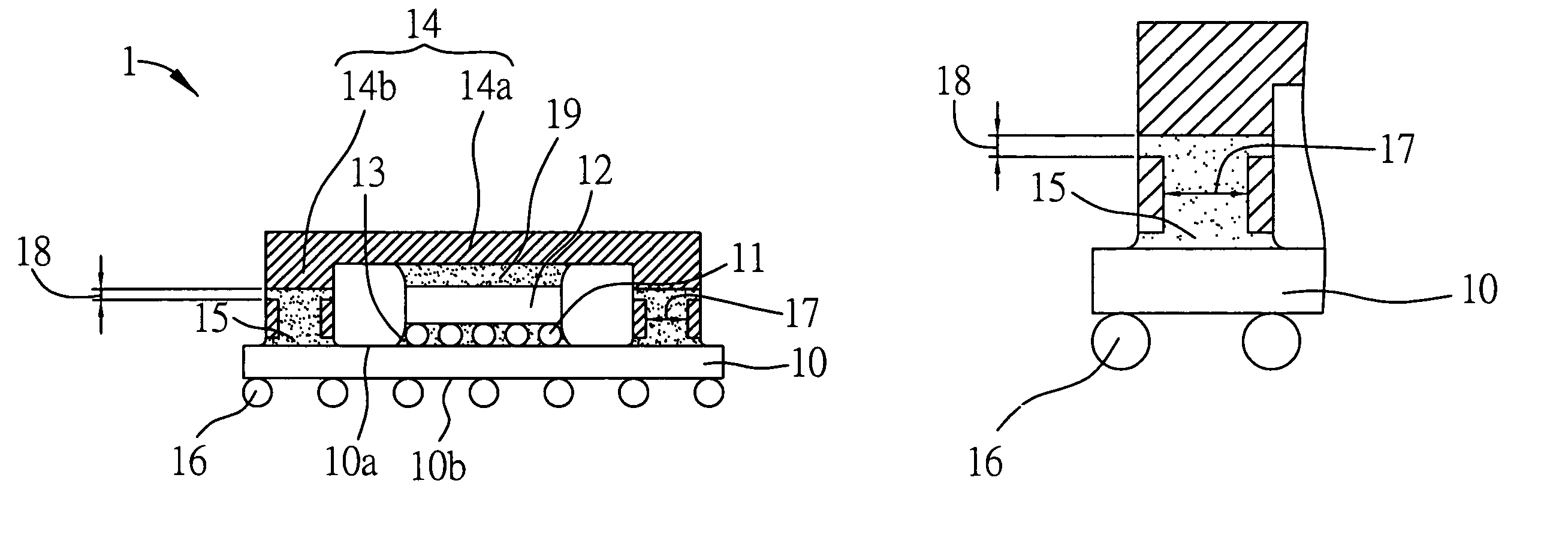

Semiconductor package with heat dissipating structure

ActiveUS6980438B2Low costHeat dissipating structureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageDeuteron radiation

A semiconductor package with a heat dissipating structure includes a substrate, a chip and a heat dissipating structure. The chip is mounted on and electrically connected to the substrate. The heat dissipating structure includes a first heat sink having at least one positioning portion, and at least one second heat sink having at least one second positioning portion and at least one hollow portion. The second heat sink is mounted on the substrate, and the first positioning portion of the first heat sink is attached to the second positioning portion of the second heat sink, allowing the chip to be accommodated in a space defined by the first heat sink, the hollow portion of the second heat sink and the substrate. This semiconductor package has good heat dissipating efficiency and is cost-effective to fabricate.

Owner:SILICONWARE PRECISION IND CO LTD

Chip-stacked semiconductor package and method for fabricating the same

ActiveUS7315078B2Heat dissipating structureImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageChip stacking

A chip-stacked semiconductor package and a method for fabricating the same are proposed. A chip carrier module plate including a plurality of chip carriers, and a heat sink module plate including a plurality of heat sinks are provided, wherein a plurality of through holes are formed around each of the heat sinks. First chips, the heat sink module plate, and second chips are successively stacked on the chip carrier module plate, wherein the second chips are electrically connected to the chip carrier module plate by conductive wires penetrating the through holes of the heat sink module plate. After a molding process is completed, a singulation process can be performed to separate the chip carriers and the heat sinks, and thus individual semiconductor packages for integrating the heat sinks with the stacked chips are fabricated.

Owner:SILICONWARE PRECISION IND CO LTD

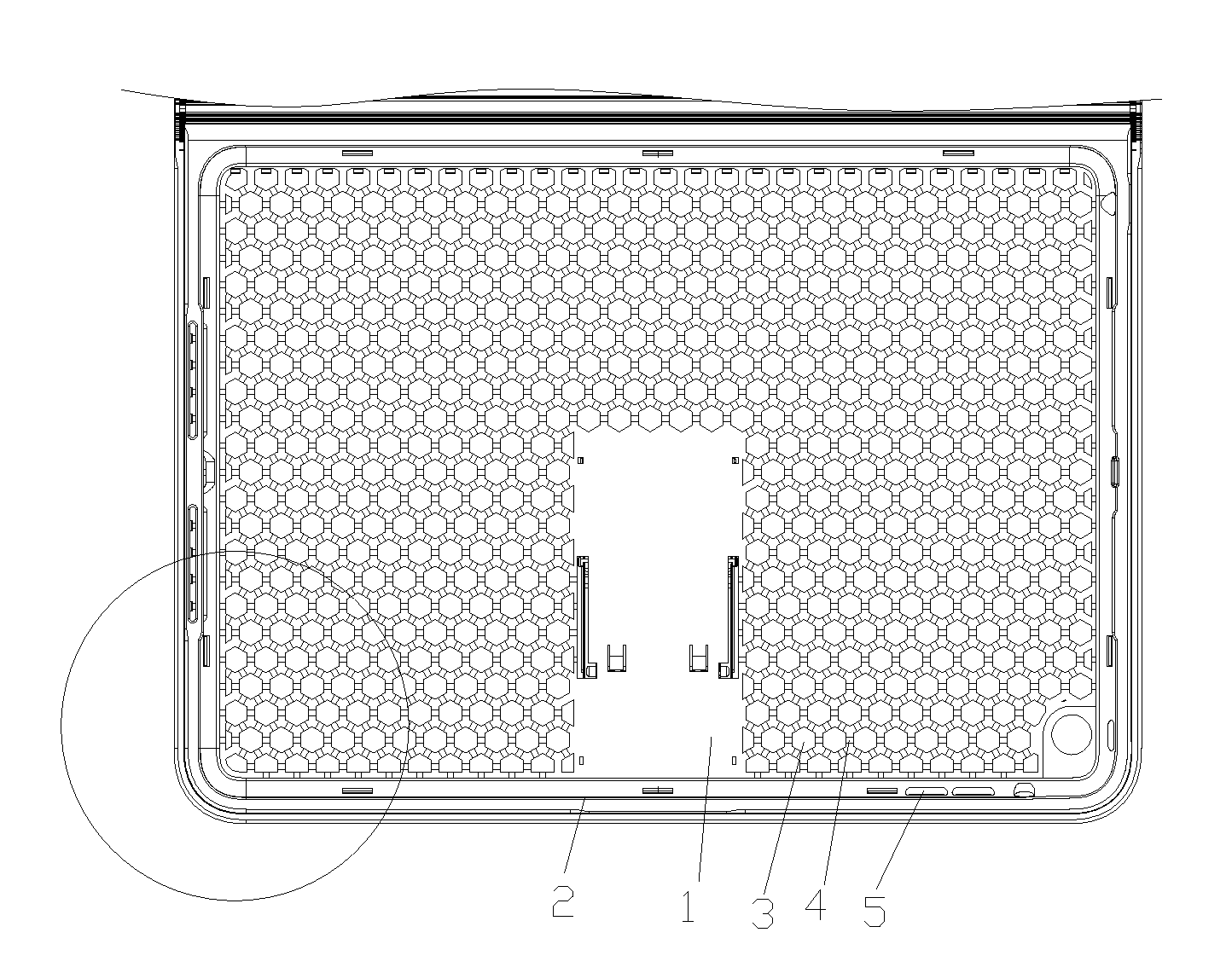

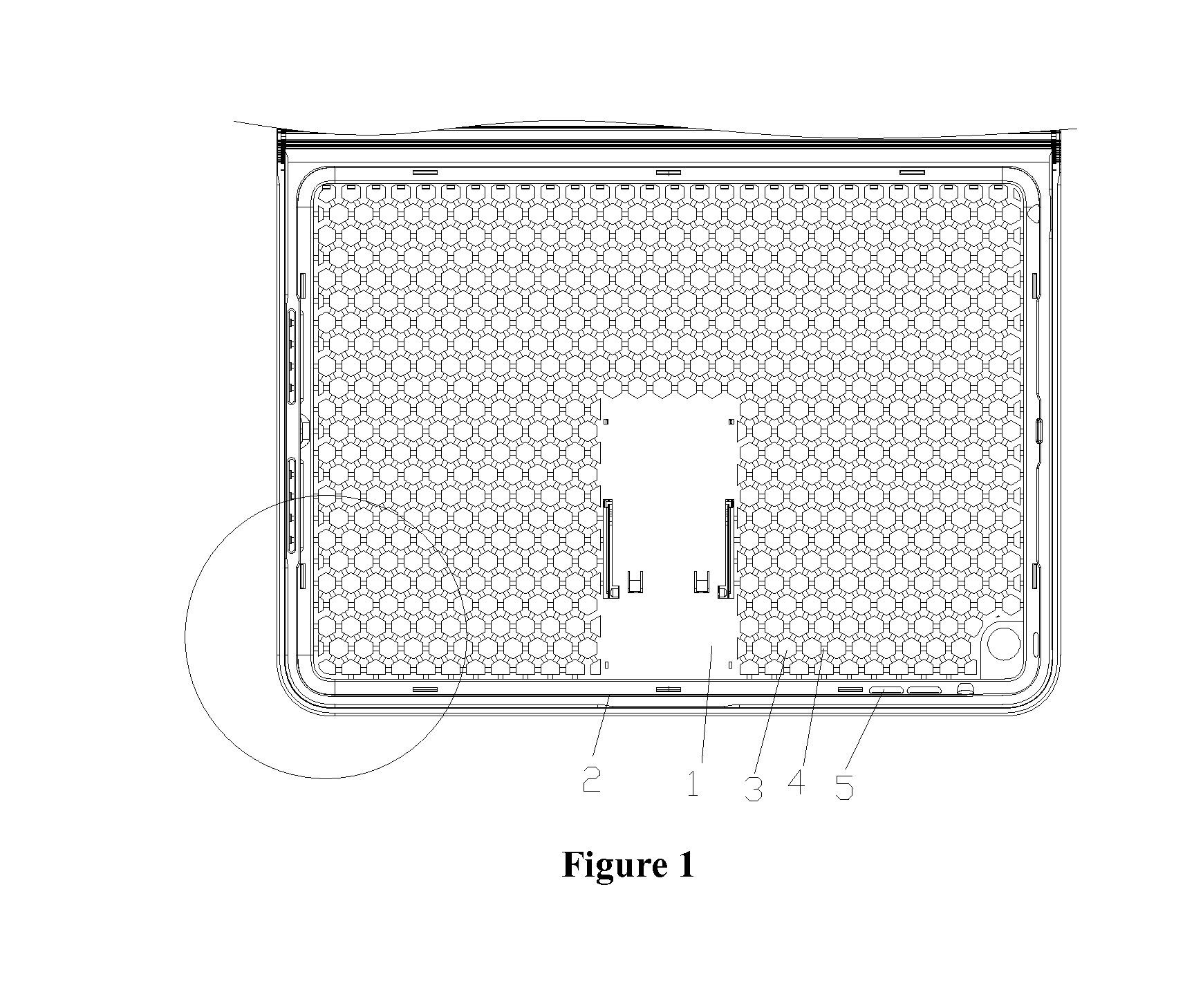

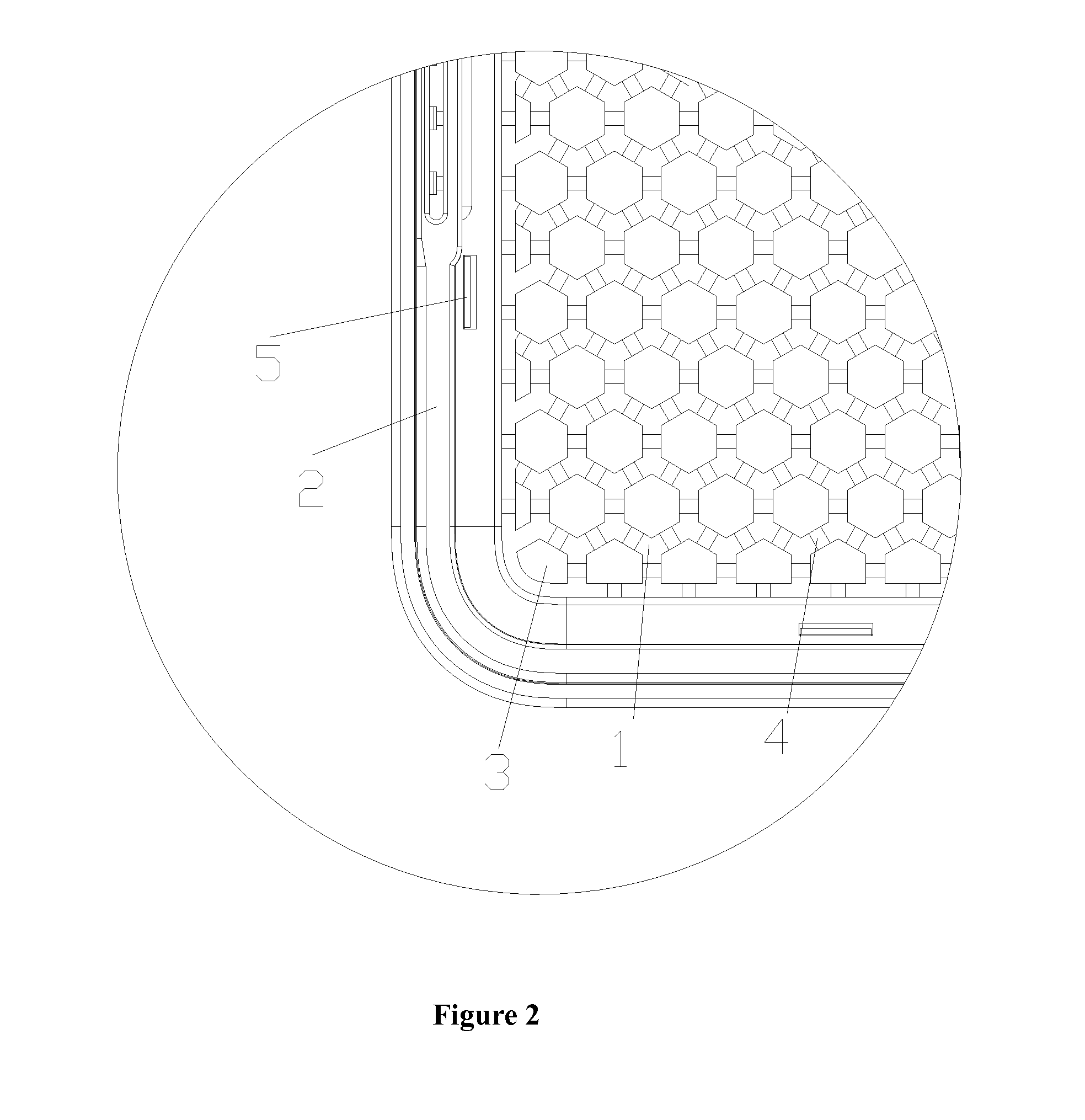

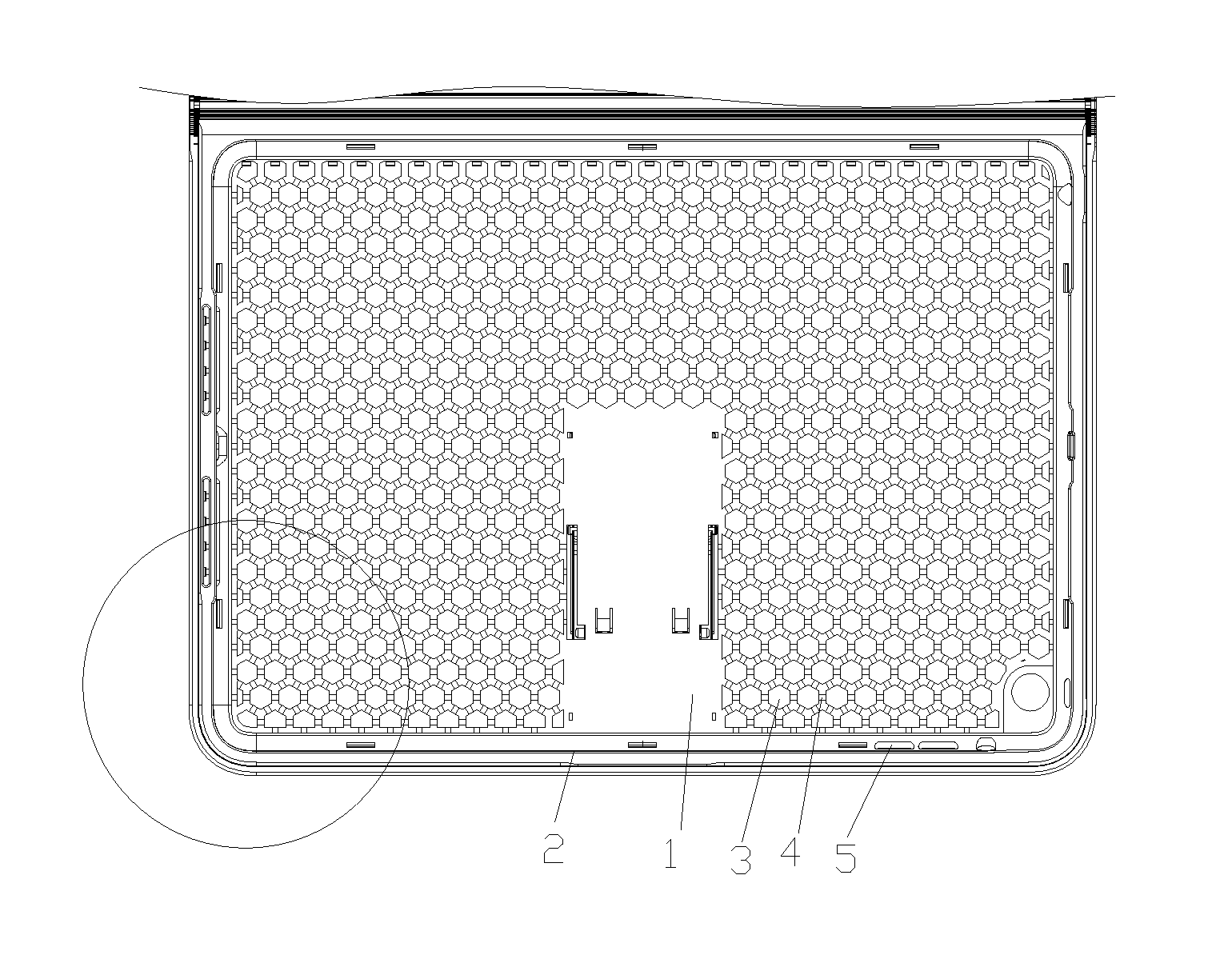

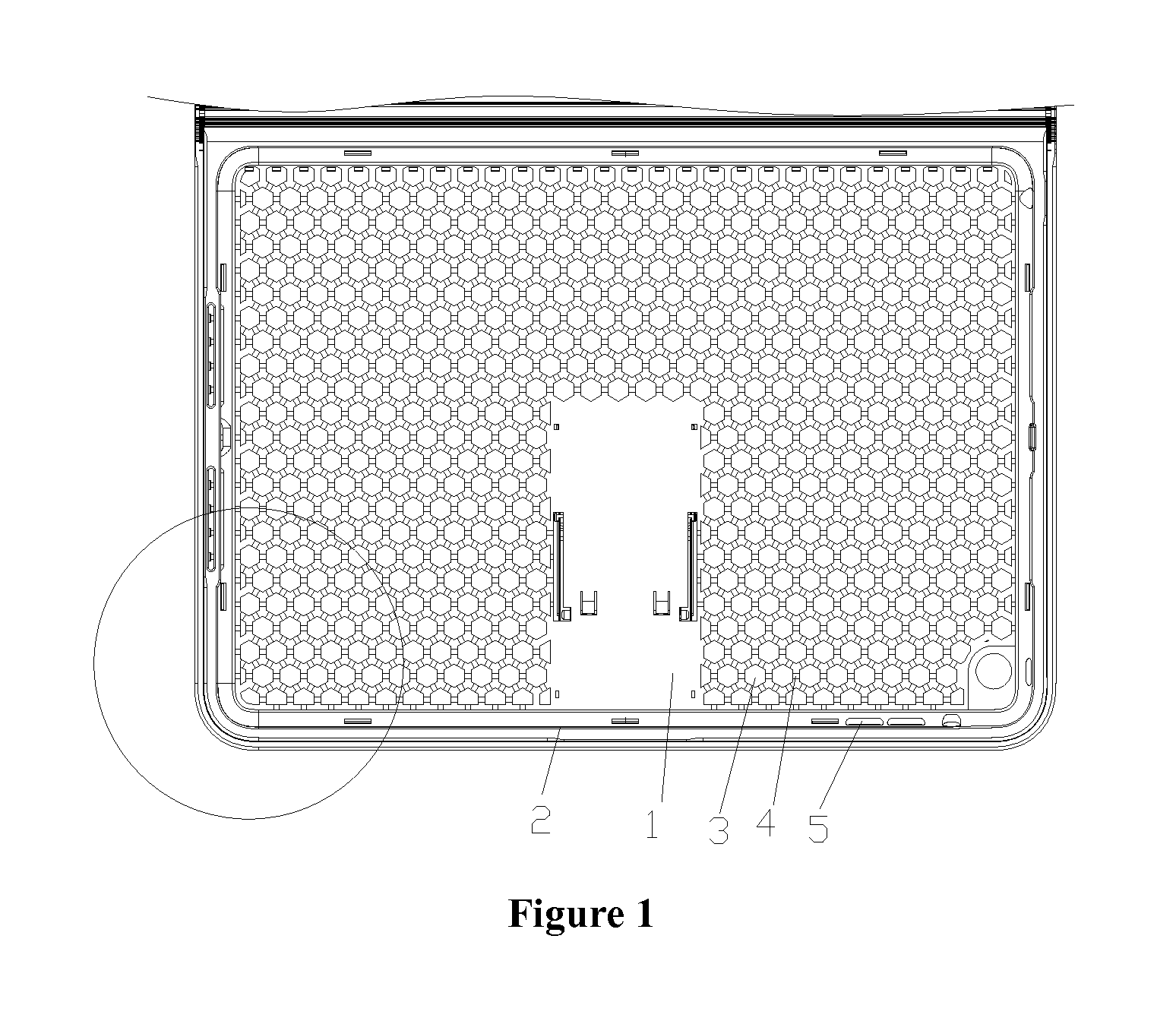

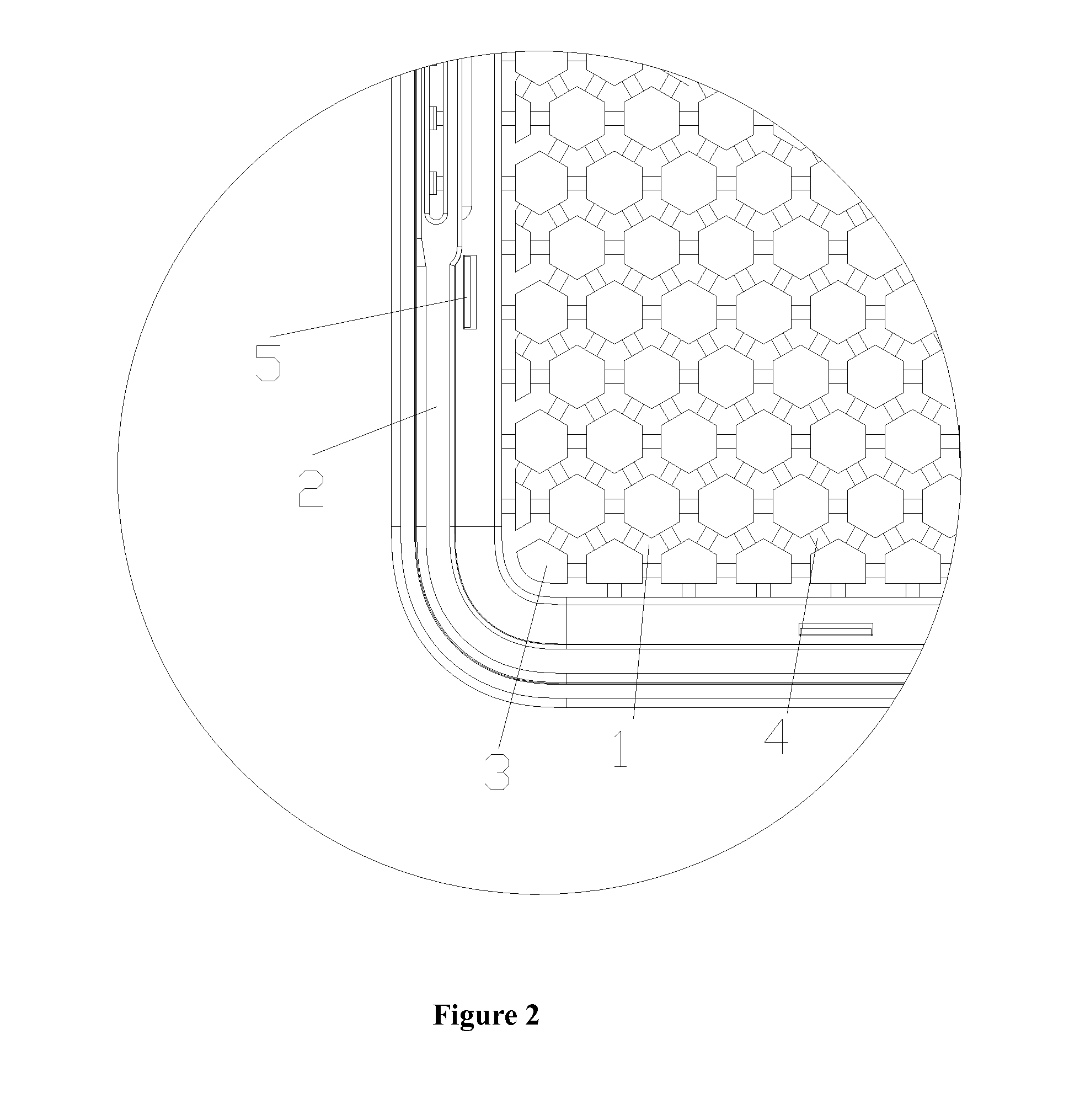

Protective case with heat dissipation structure for electronic products

InactiveUS20150036291A1Facilitates quick air exhaustionAvoid problemsDigital data processing detailsCooling/ventilation/heating modificationsCold airVentilation tube

A protective case with multiple air tunnels for the protective case, so the heat absorbed by contact blocks from the electronic equipment is radiated rapidly out of the protective case through vent pipes. When the electronic equipment is supported up to watch movie or play games, because the hot air will raise and be exhausted from the upper part, and the fresh cool air will come inside from lower part of the protective case, as a result, the ventilation is accelerated and the heat dissipation performance is greatly improved.

Owner:YUAN LUHUI

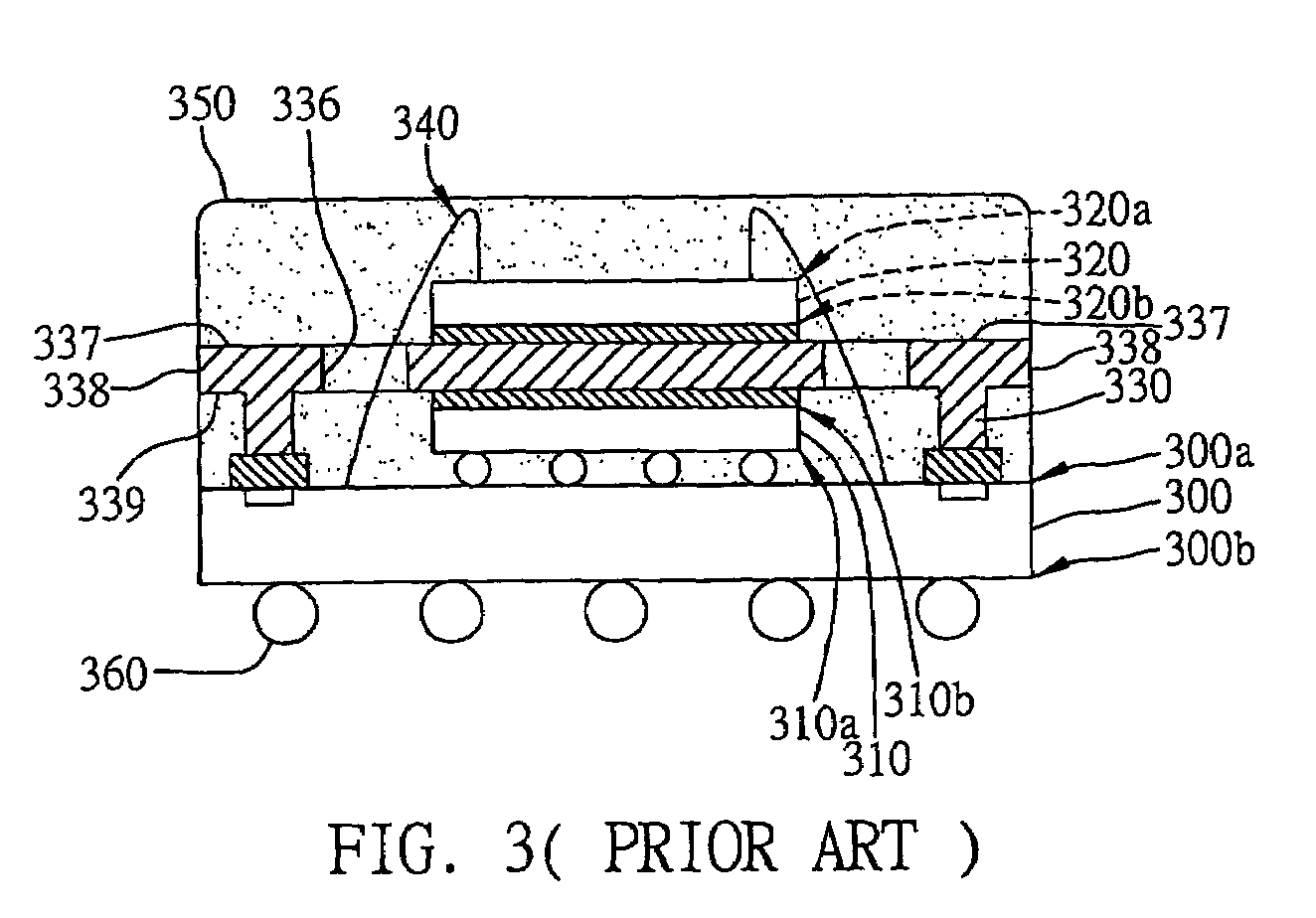

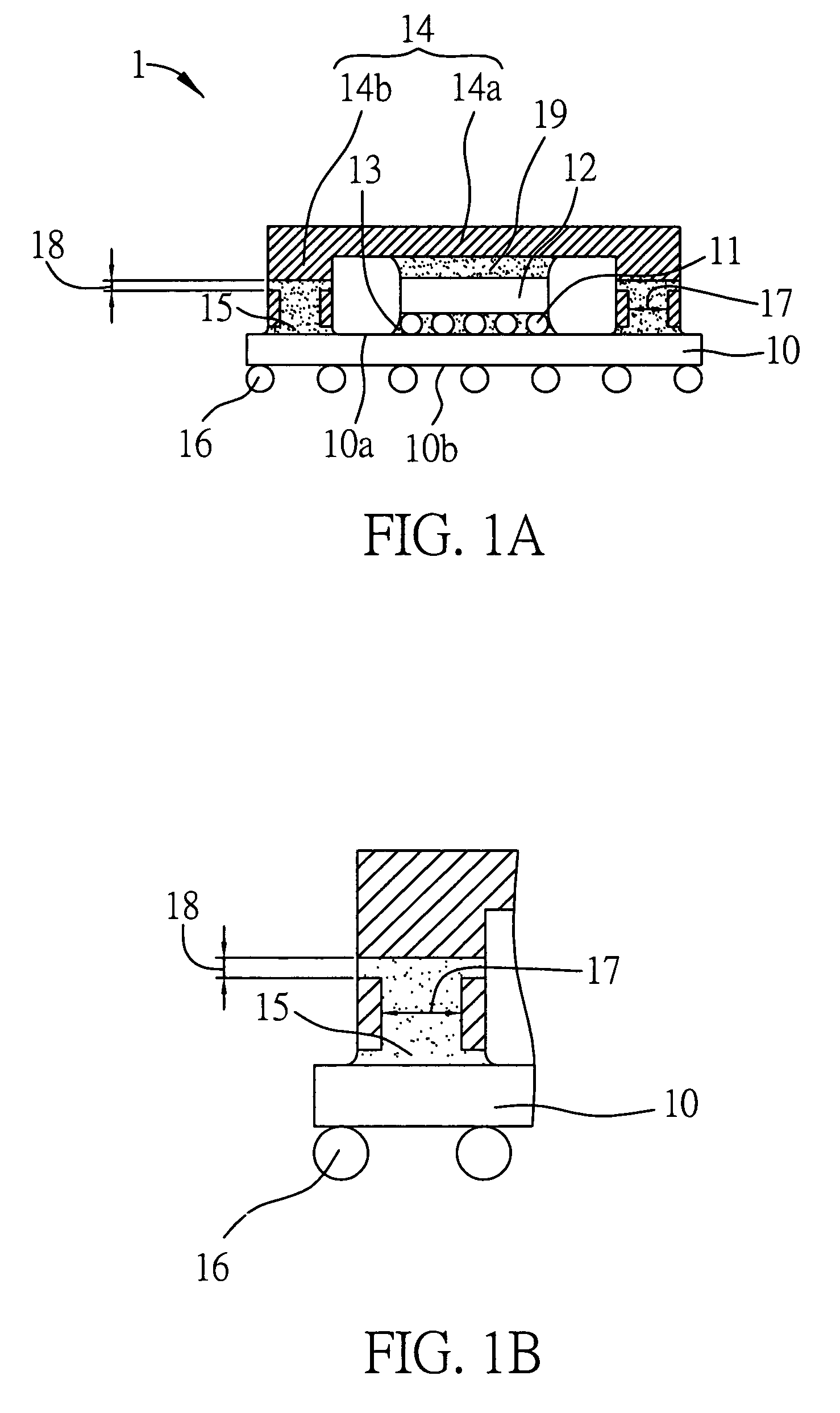

Heat dissipating structure and semiconductor package with the same

InactiveUS20050056926A1Easy to checkImprove bond reliabilitySemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor package

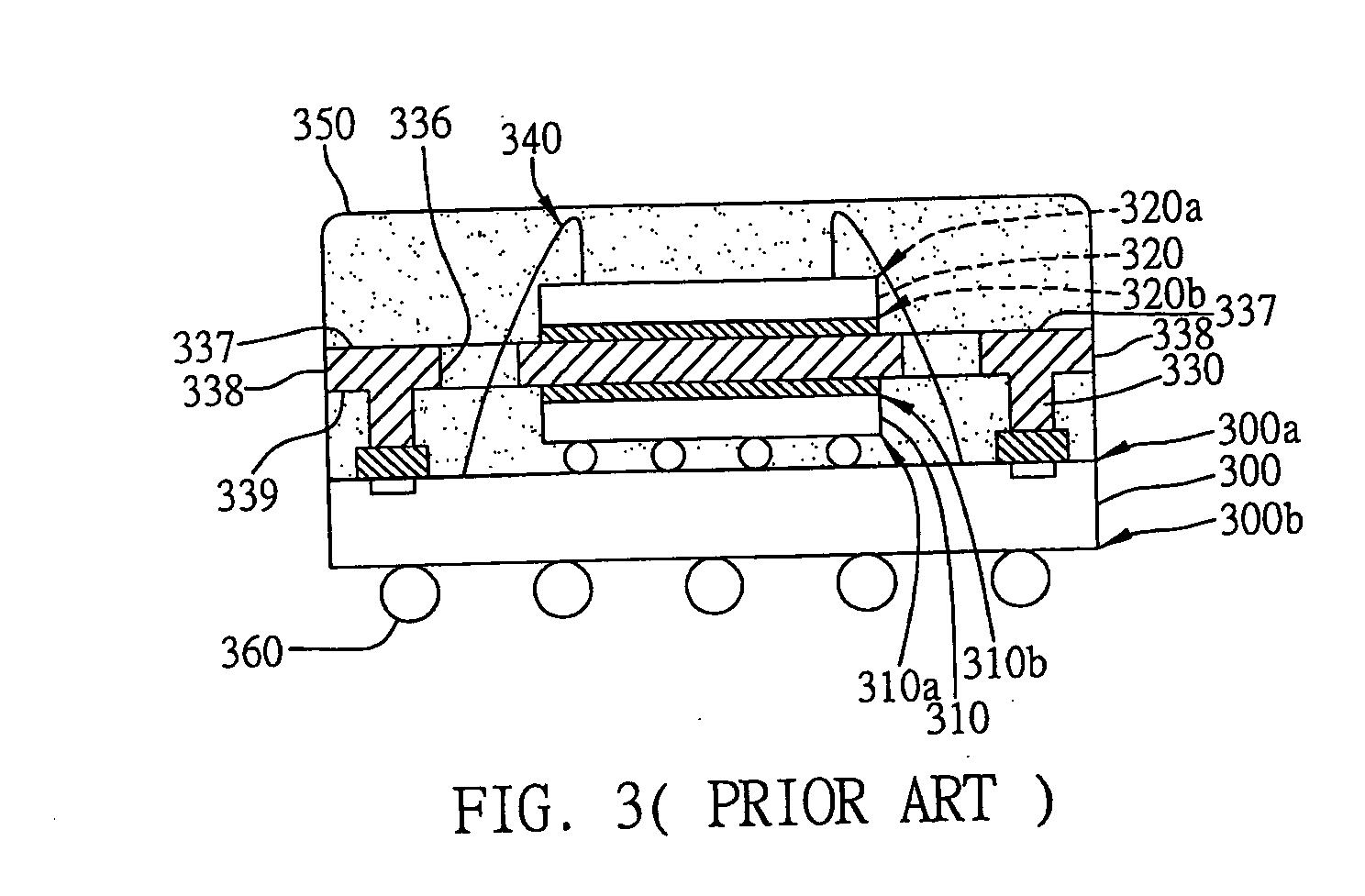

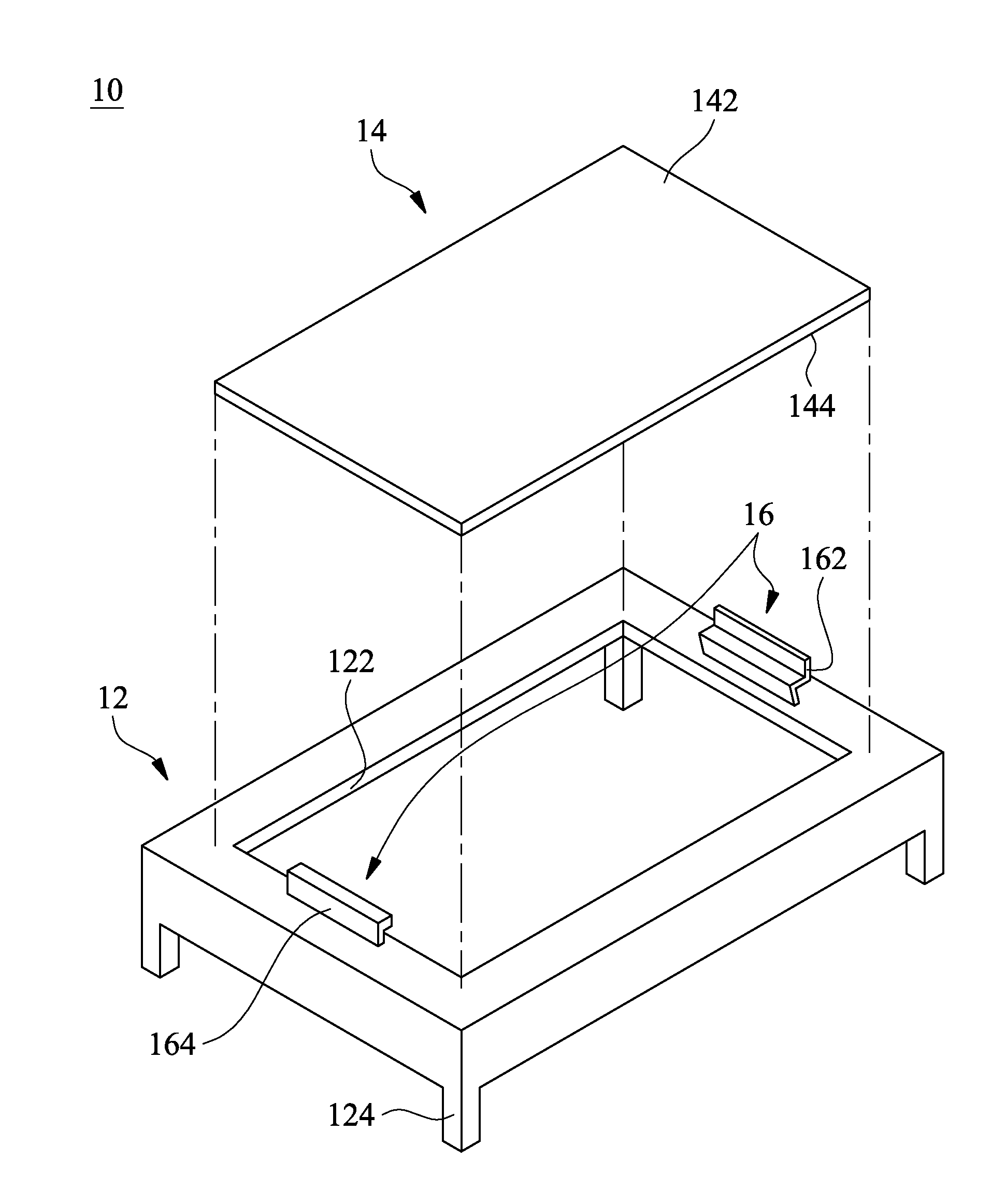

A heat dissipating structure and a semiconductor package with the same are proposed. A substrate is used to accommodate at least one chip thereon, and the chip is electrically connected to the substrate. A heat dissipating structure having a flat portion and a support portion is mount on the substrate via the support portion by means of an adhesive. At least one groove is formed on the support portion and at least one air vent is formed around the groove to allow the groove to communicate with the outside via the air vent, such that the adhesive is allowed to fill the groove to expel air from the groove to the atmosphere through the air vent, thereby preventing the air from trapped in the groove.

Owner:SILICONWARE PRECISION IND CO LTD

Heat dissipation structure for electronic device

InactiveUS20130088836A1Adequate heat dissipationImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

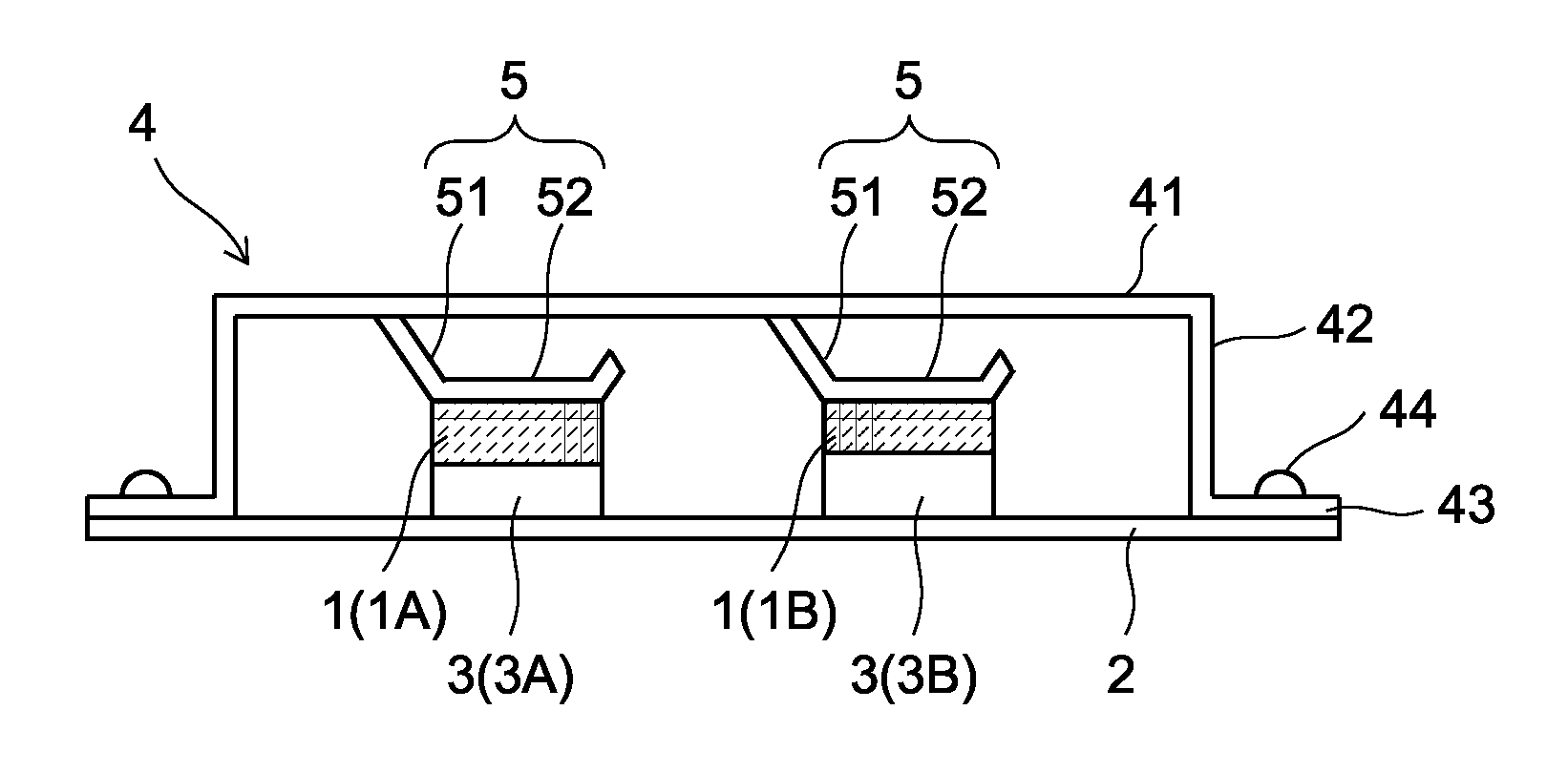

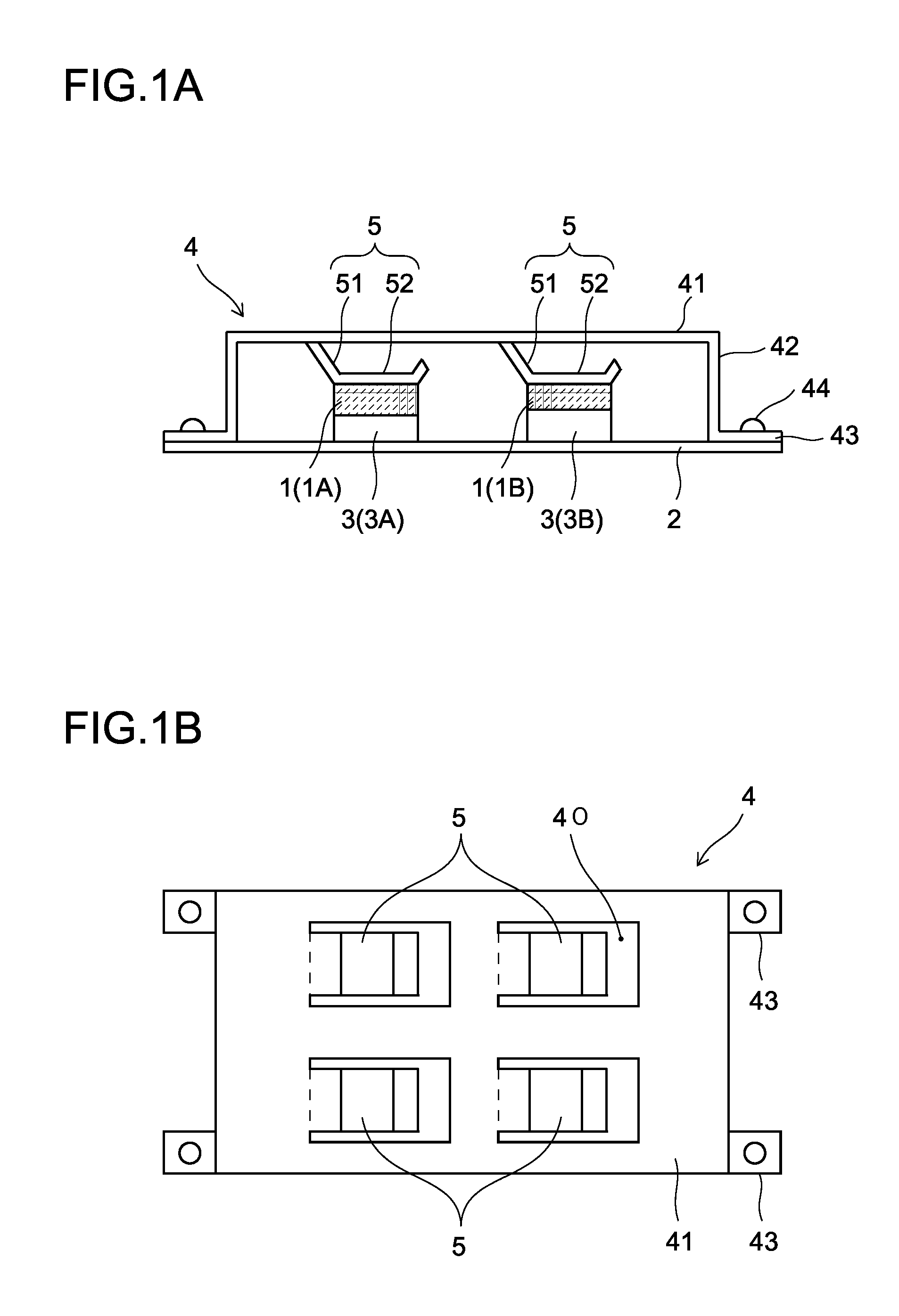

A heat dissipation structure in which an IC chip that generates heat is mounted on a substrate and a heat dissipation sheet is interposed between a cover member and the IC chip to dissipate heat, wherein chip-pressing parts (5) are provided to a cover member (4), so that IC chips (3) are pressed against heat dissipation sheets (1) by the chip-pressing parts (5), and each chip-pressing part (5) is configured from an elastic pressing part equipped with an elastically deformable elastic section (51), and a contact section (52) that comes into contact with a heat dissipation sheet (1), in order to provide an electronic device heat dissipation structure that exhibits sufficient heat dissipation properties and improves the reliability of the electronic device, and has a structure such that it is possible to reliably interpose a heat dissipation sheet between an IC chip and a cover member.

Owner:SHARP KK

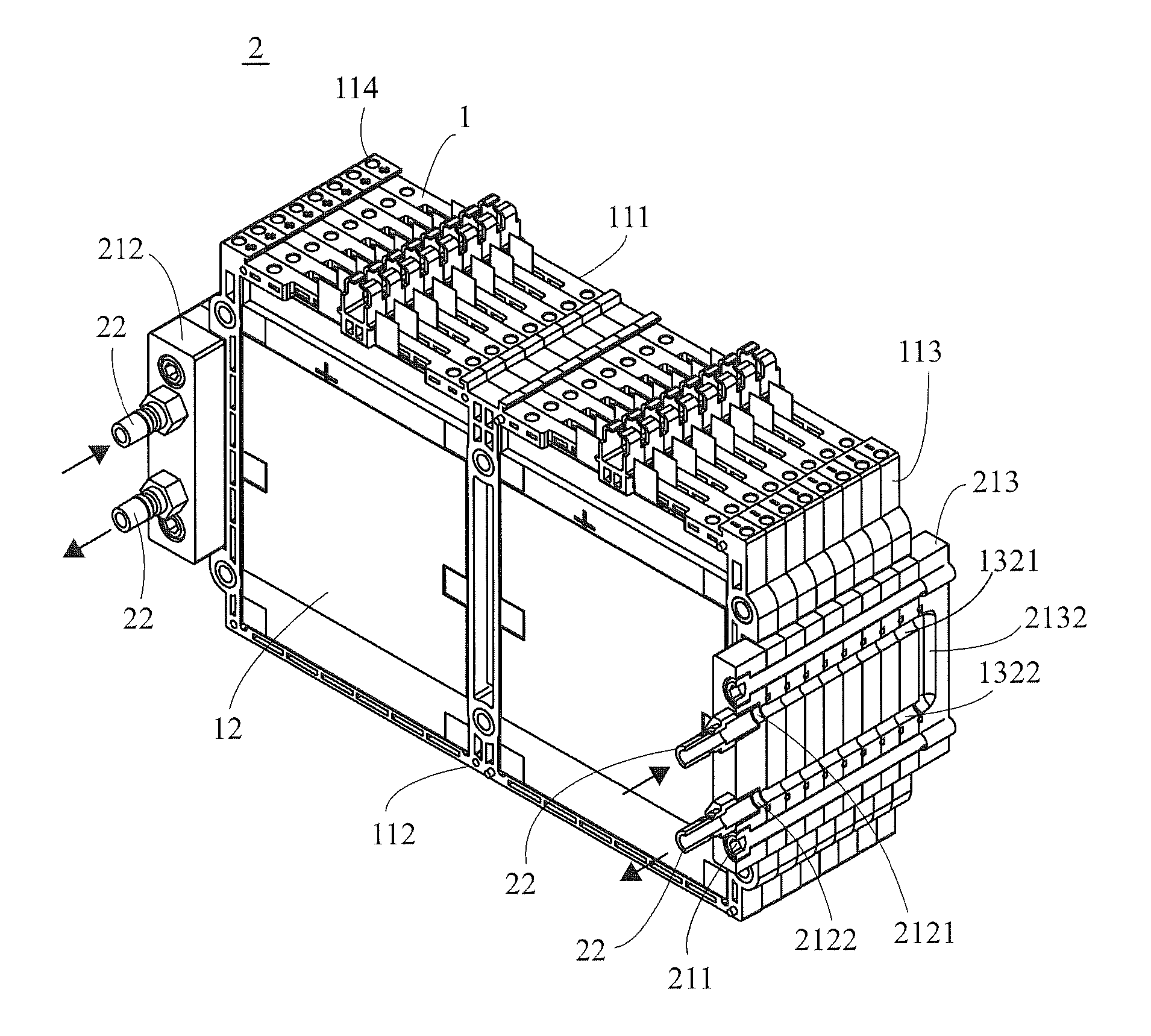

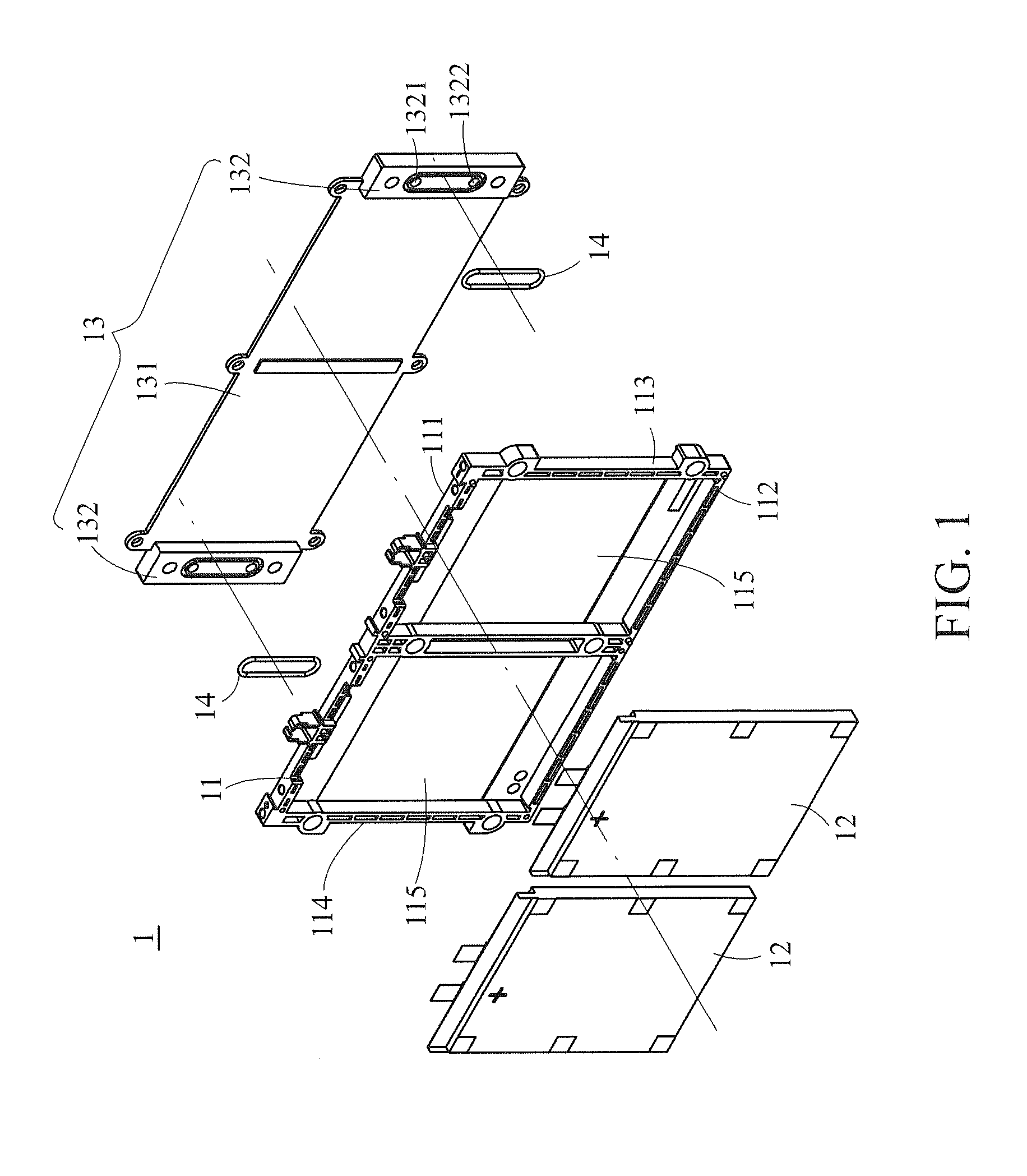

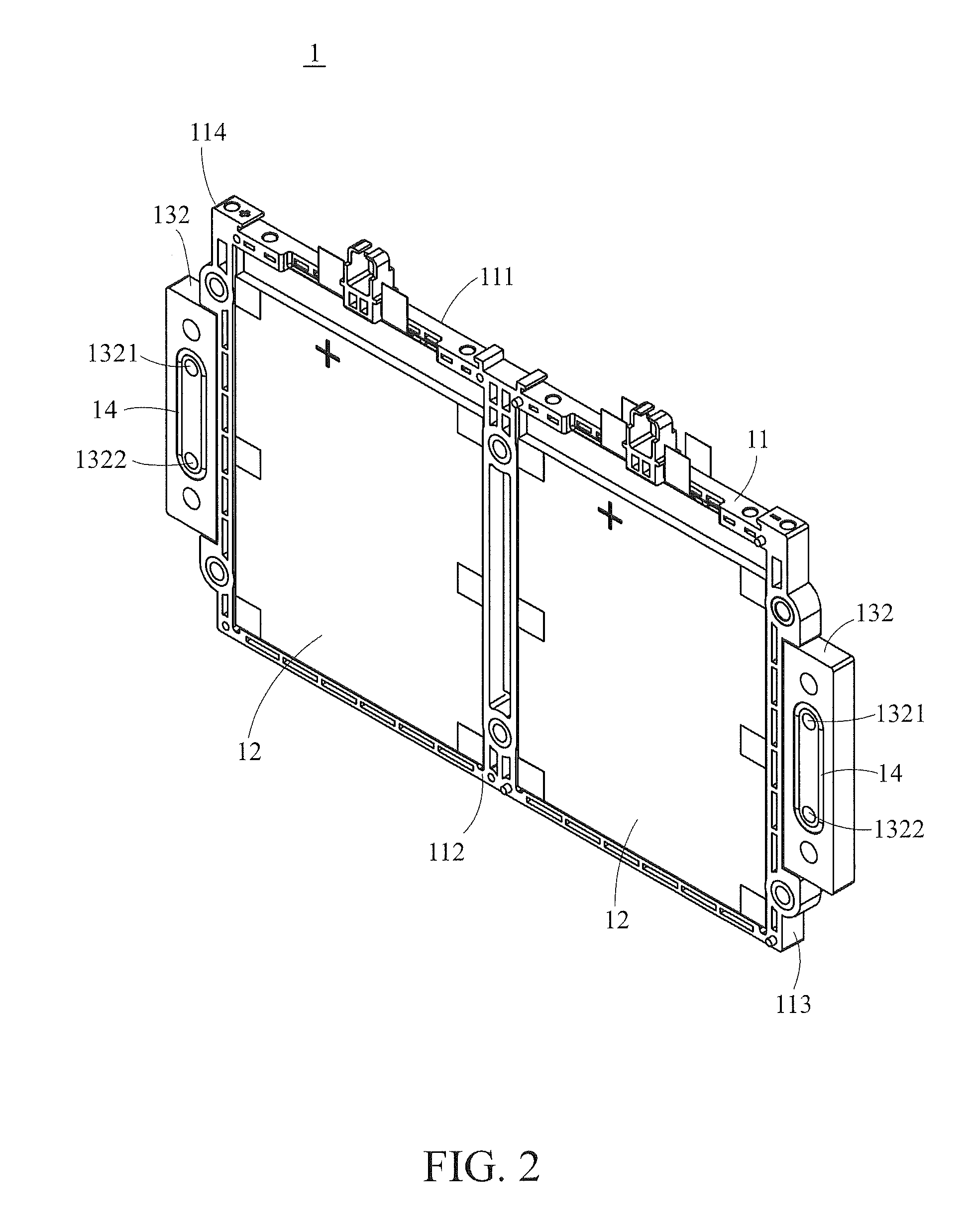

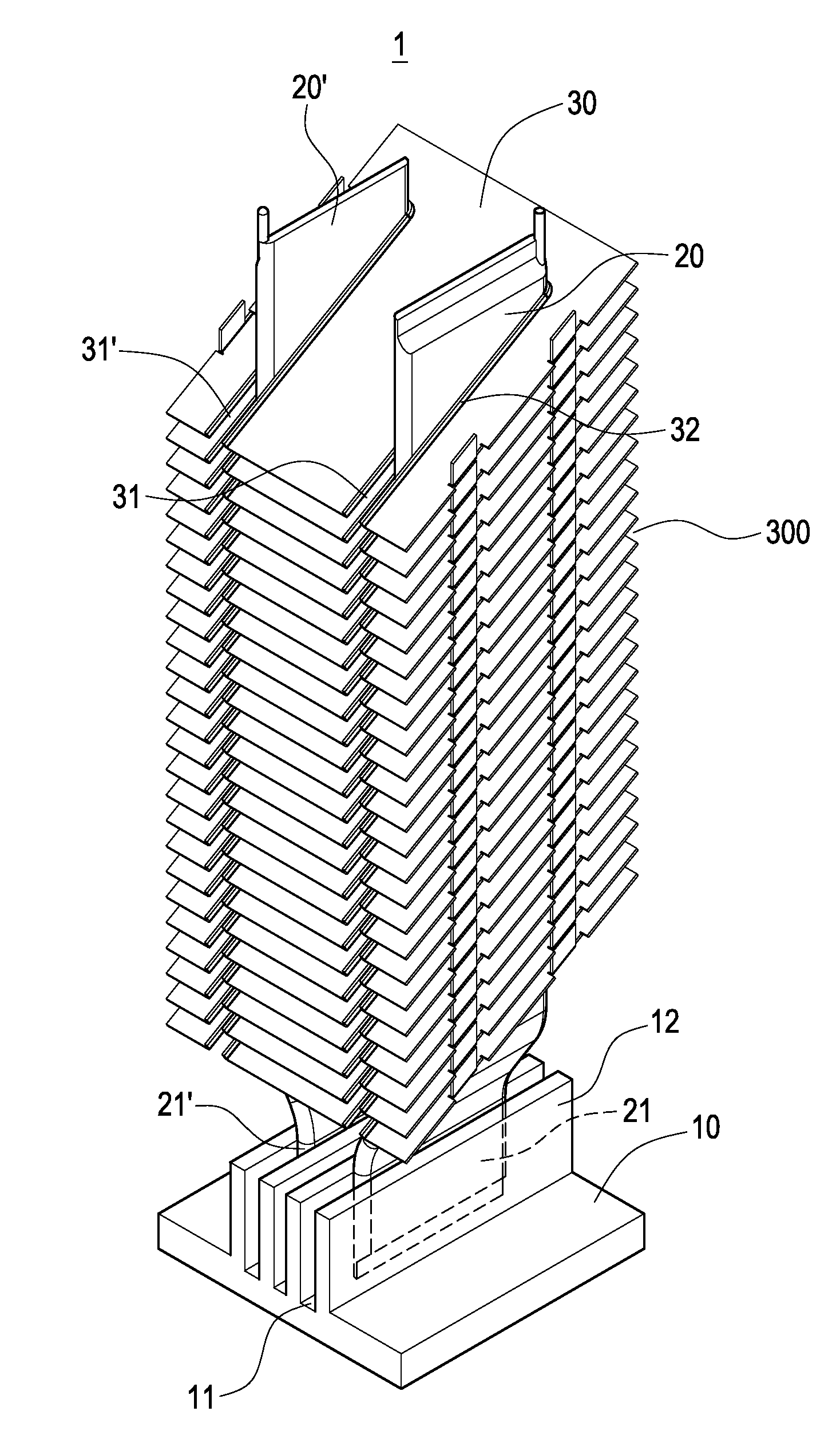

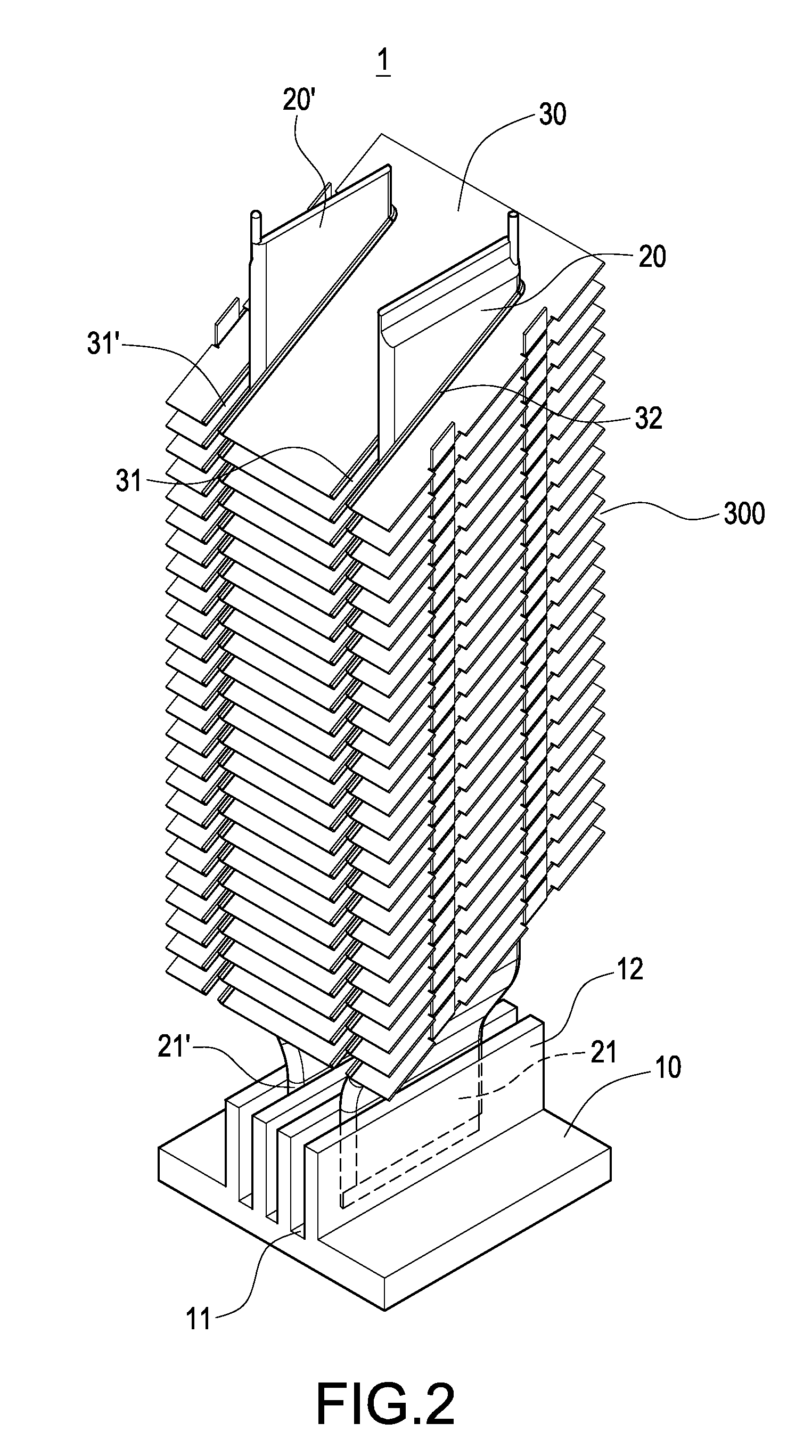

Battery device and battery device module

InactiveUS20130022855A1Increasing the thicknessHeat dissipating structureCell temperature controlCell component detailsElectrical batteryElectrical and Electronics engineering

Owner:DELTA ELECTRONICS INC

Heat dissipating structure of high power LED projector lamp

InactiveUS20100243211A1Efficiently dissipatedHeat dissipationElectric discharge tubesLighting heating/cooling arrangementsHeat conductingEngineering

A heat dissipating structure is capable of dissipating heat quickly in a high power LED projector lamp to improve the heat dissipating efficiency. The structure includes a heat-conducting plate, a plate type heat pipe and a plurality of heat dissipating fins. One side of the heat-conducting plate provides a plurality of grooves for mounting one end of the plate type heat pipe, wherein those two are perpendicular to each other. Furthermore, the heat dissipating fins having a plurality of slots are stacked and arranged at intervals for disposing the plate type heat pipe with an inclined angle. Hence, the heat generated from the high power LED will be conducted quickly and the heat dissipating efficiency will be improved.

Owner:CELSIA TECH TAIWAN INC

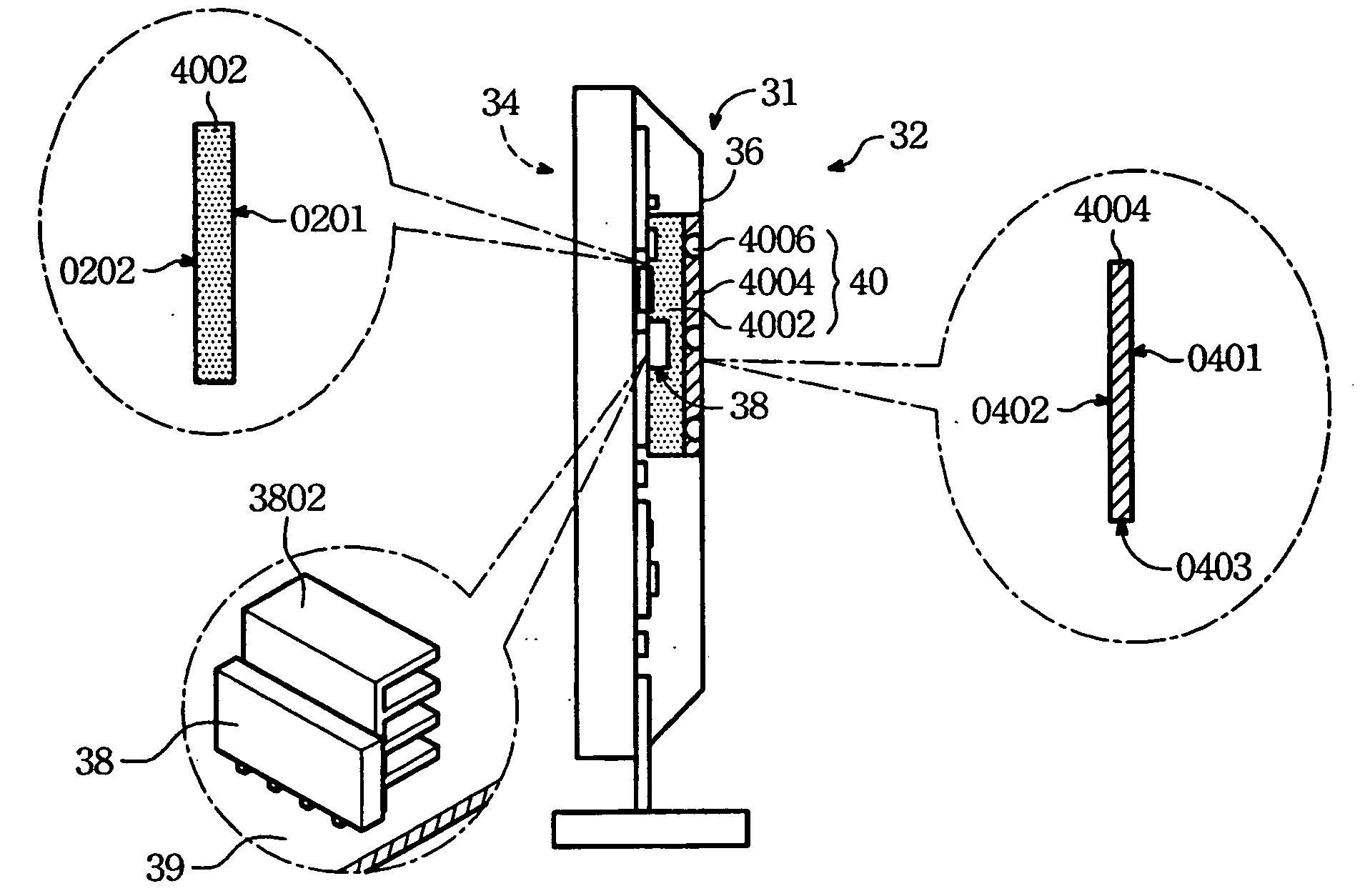

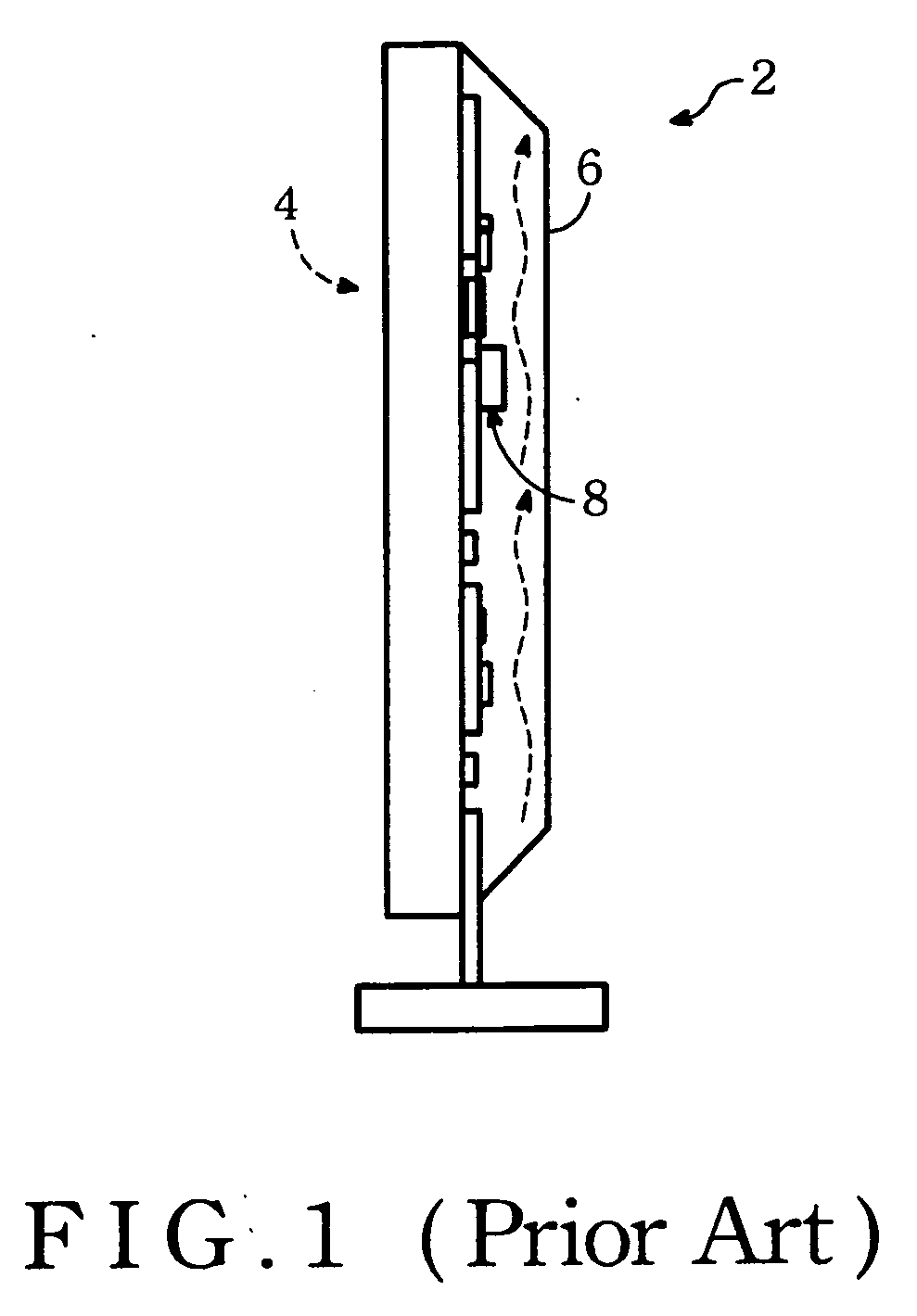

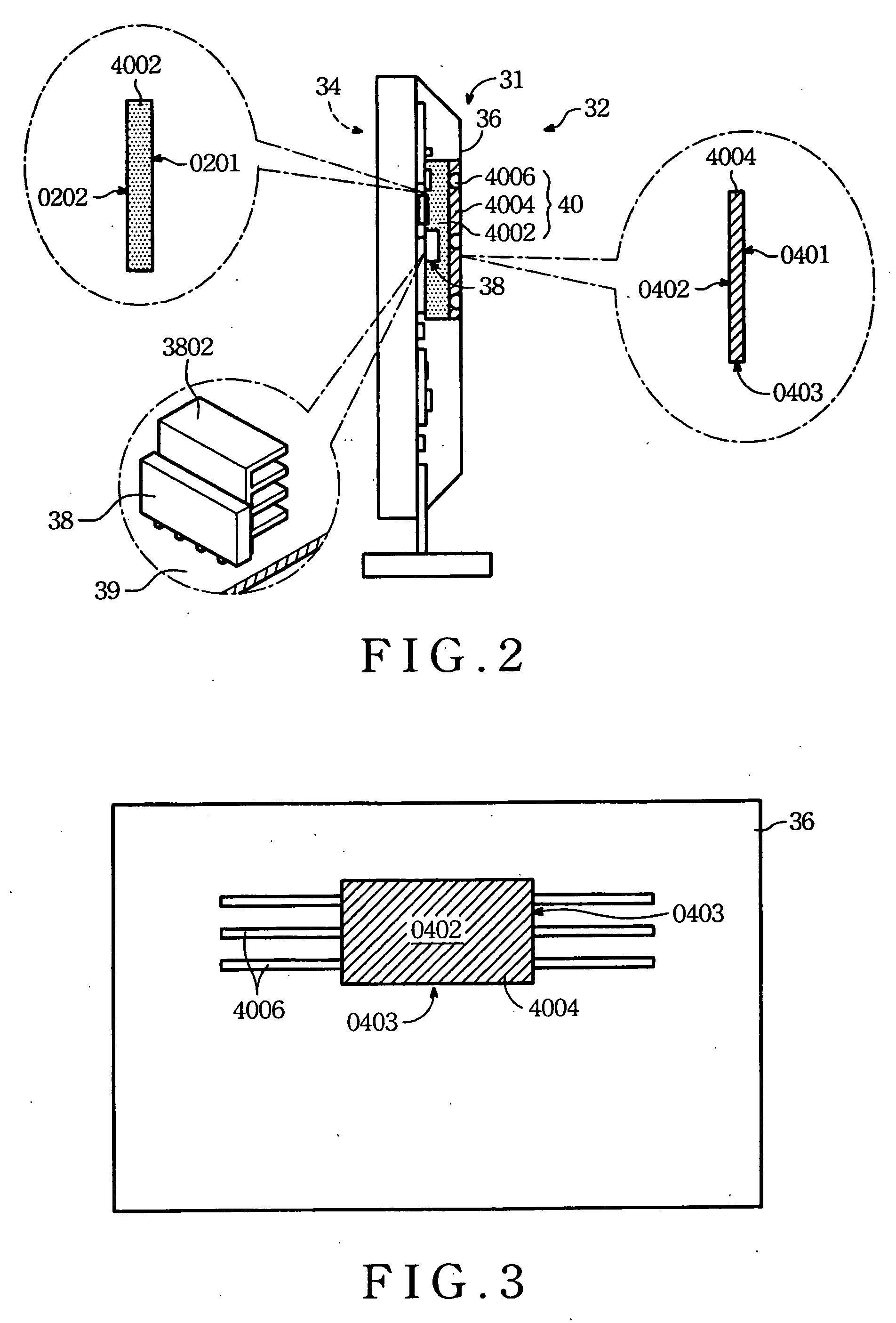

Heat-dissipating structure for flat panel display

InactiveUS20060203445A1Improve the heating effectImprove cooling efficiencyDigital data processing detailsNon-linear opticsDisplay deviceMetallic materials

A heat-dissipating structure for a flat panel display comprises a heat-collector plate, a soft thermal-pad and at least one heat-sink component. The heat-collector plate is made of metal material having a first-face, a second-face and a plurality of edge-sides. The first-face is contact with a back-bezel of the flat panel display. The soft thermal-pad is made of soft material with high thermal conductivity. The soft thermal-pad has a bottom-face and a top-face. The bottom-face is contact with the second-face. The top-face is contact with a heat-sink structure of an electric unit of the flat panel display. The heat-sink component is connected with at least one of the edge-side of the heat-collector plate. The heat-sink component is capable of conducting heat and expanding heat sink area.

Owner:CORETRONIC

Heat dissipating structure and semiconductor package with the same

InactiveUS7203072B2Improve bond reliabilityCost-effective fabricationSemiconductor/solid-state device detailsSolid-state devicesAdhesiveAtmospheric air

A heat dissipating structure and a semiconductor package with the same are proposed. A substrate is used to accommodate at least one chip thereon, and the chip is electrically connected to the substrate. A heat dissipating structure having a flat portion and a support portion is mount on the substrate via the support portion by means of an adhesive. At least one groove is formed on the support portion and at least one air vent is formed around the groove to allow the groove to communicate with the outside via the air vent, such that the adhesive is allowed to fill the groove to expel air from the groove to the atmosphere through the air vent, thereby preventing the air from trapped in the groove.

Owner:SILICONWARE PRECISION IND CO LTD

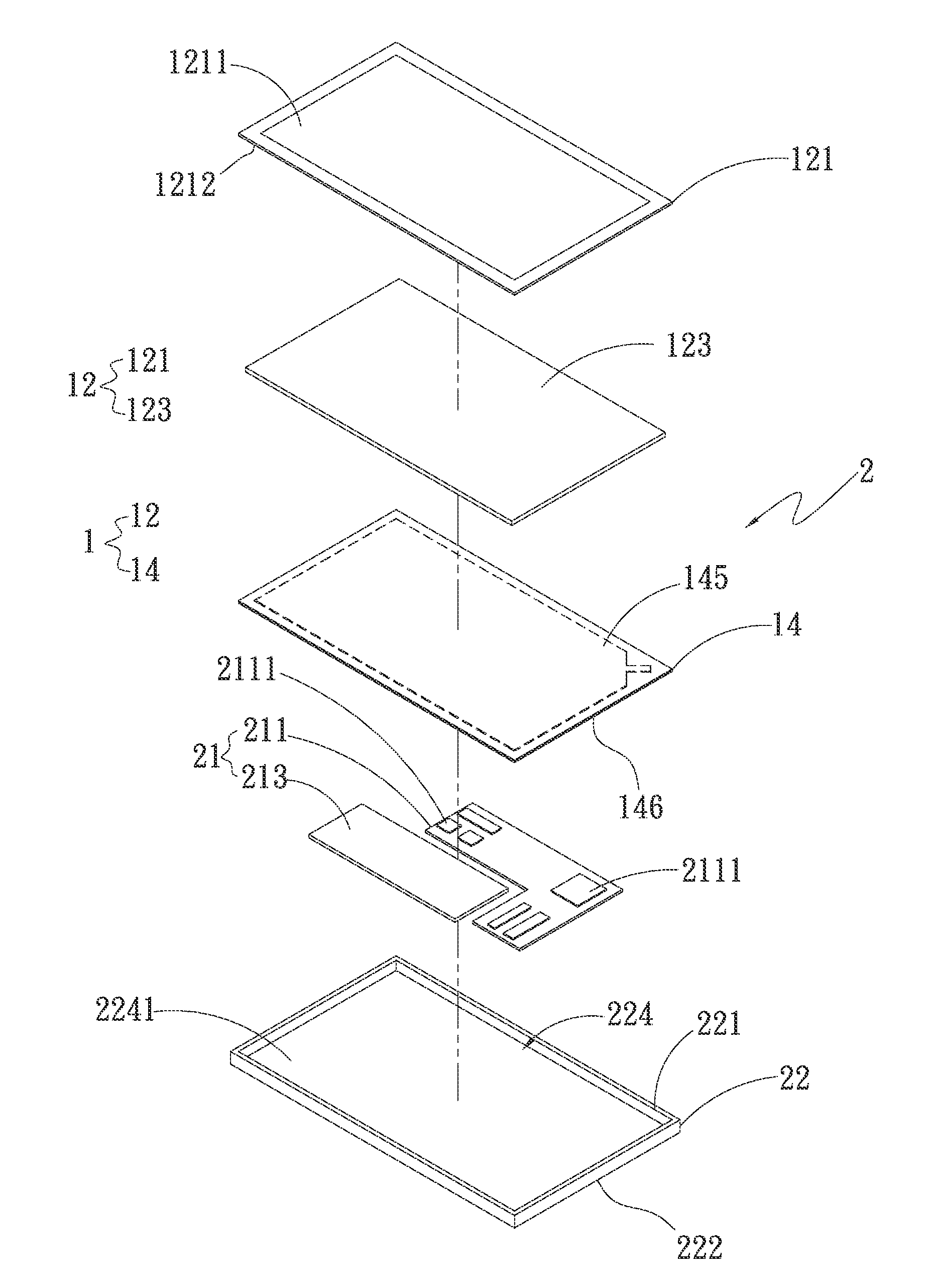

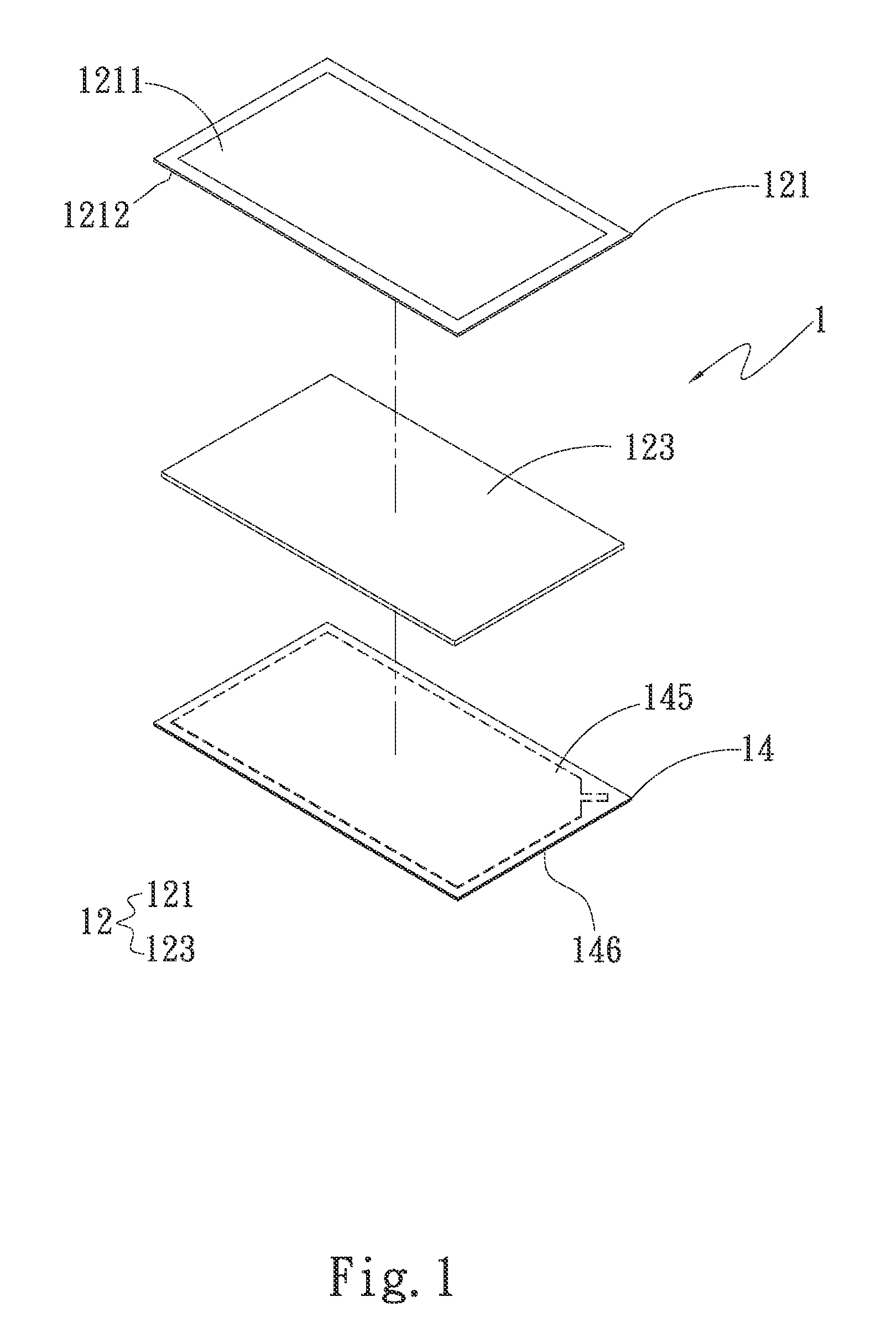

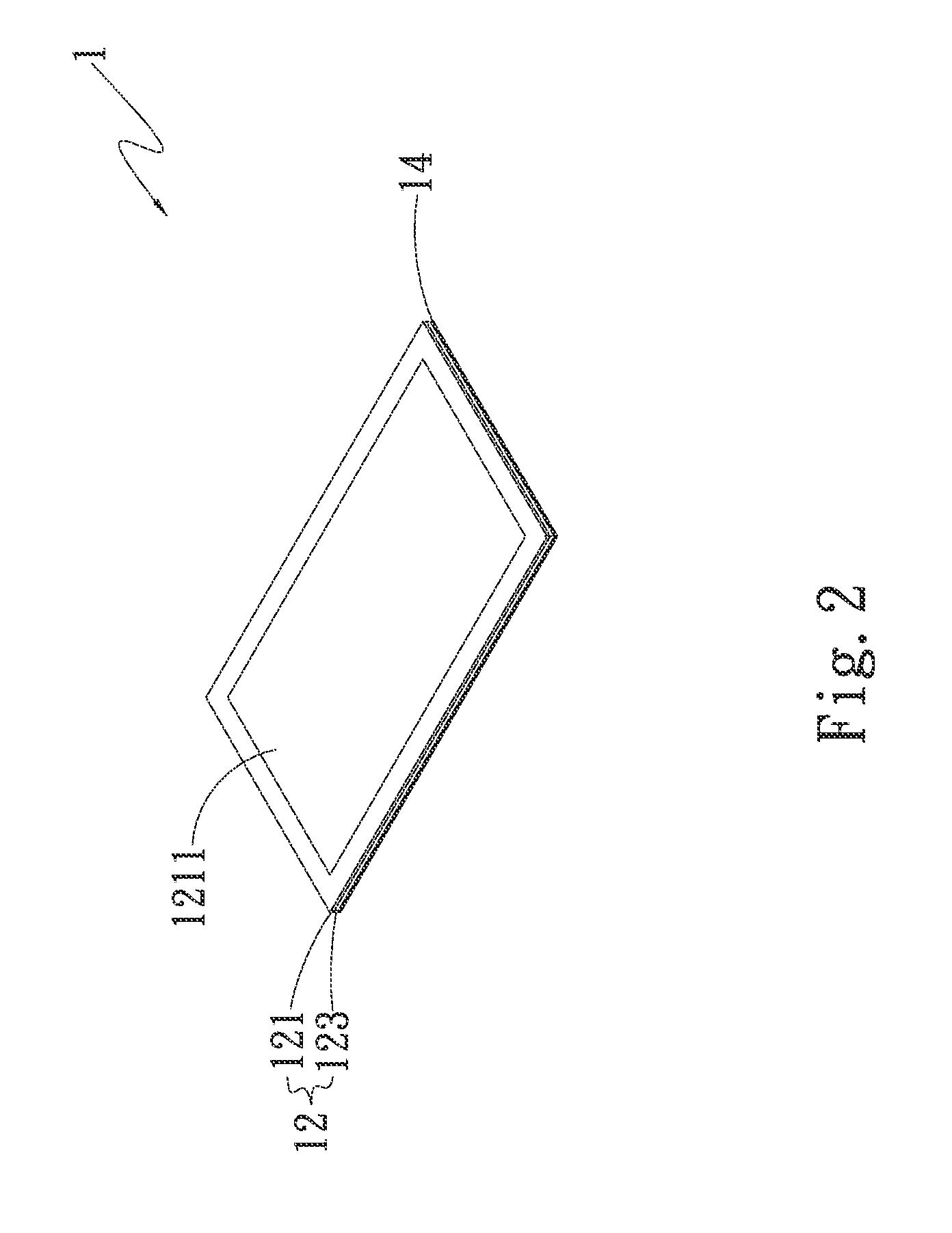

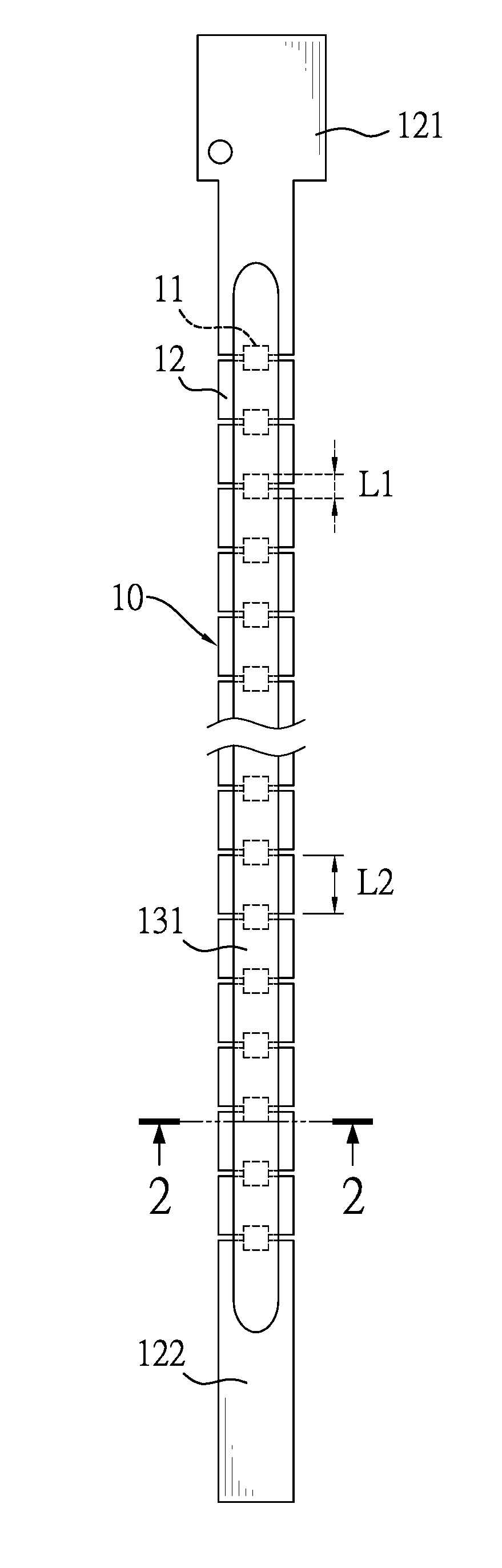

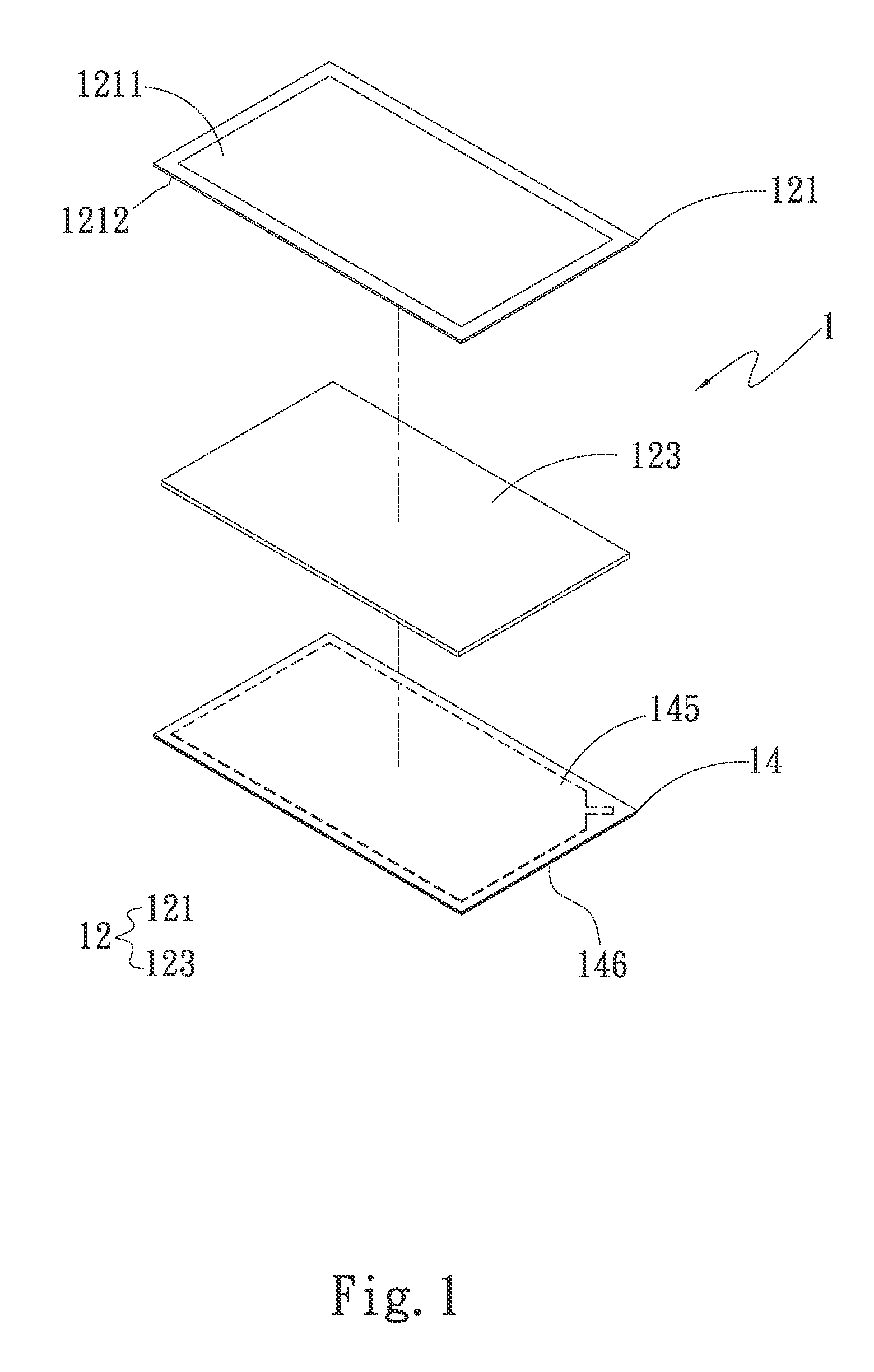

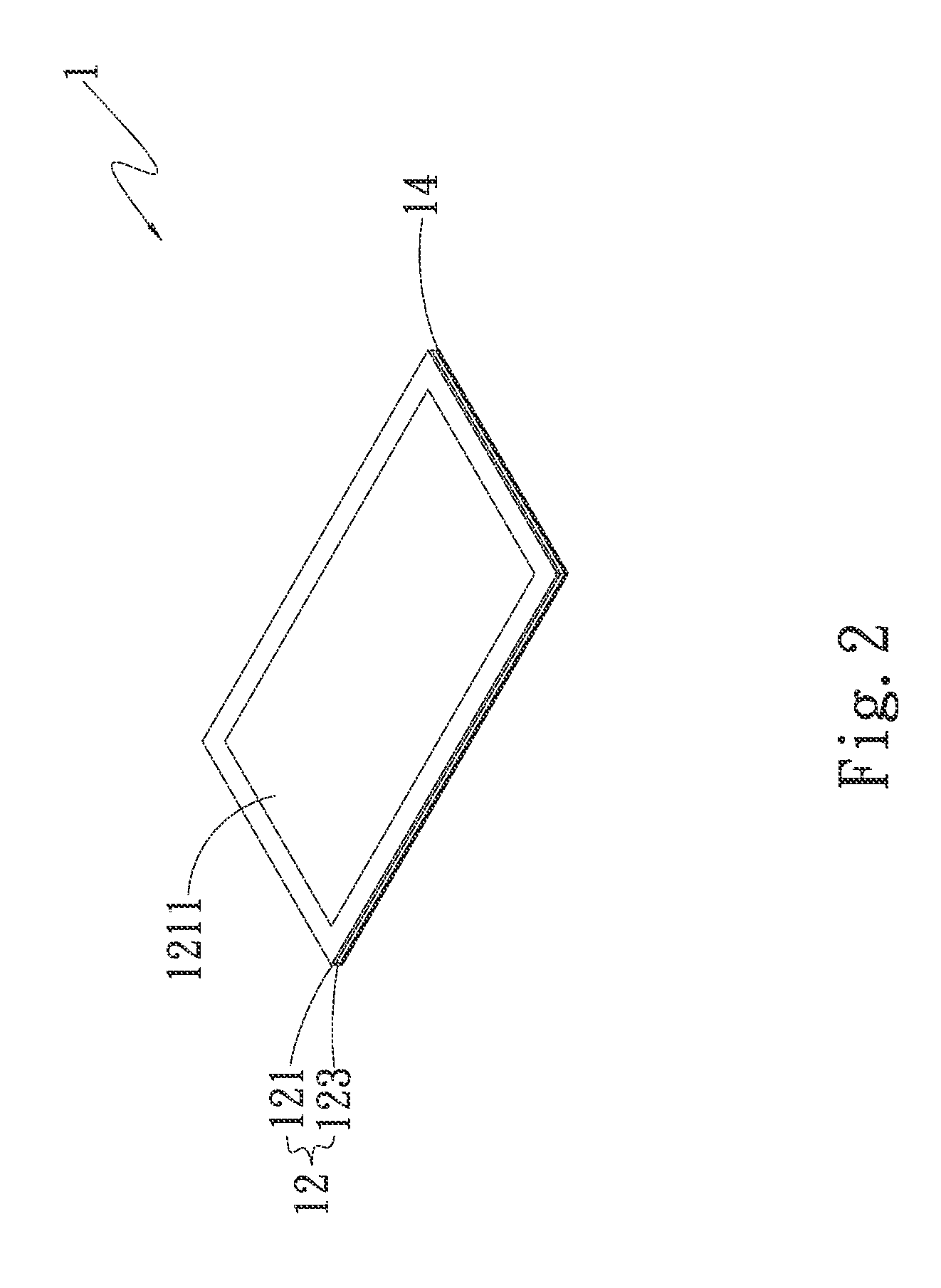

Display module with heat dissipation structure and handheld device thereof

ActiveUS20160135331A1Quickly and uniformly spreadHeat dissipating structureDigital data processing detailsSubstation equipmentEngineeringElectronic component

A display module with heat dissipation structure and a handheld device thereof. The display module includes a touch panel, a display panel and a vapor chamber. One face of the display panel is correspondingly attached to the touch panel, while the other face of the display panel is correspondingly attached to the vapor chamber. The vapor chamber serves to support the touch panel and the display panel. Moreover, the vapor chamber serves to absorb the heat generated by the electronic component and quickly and uniformly spread the heat to dissipate the heat to achieve a heat spreading effect.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

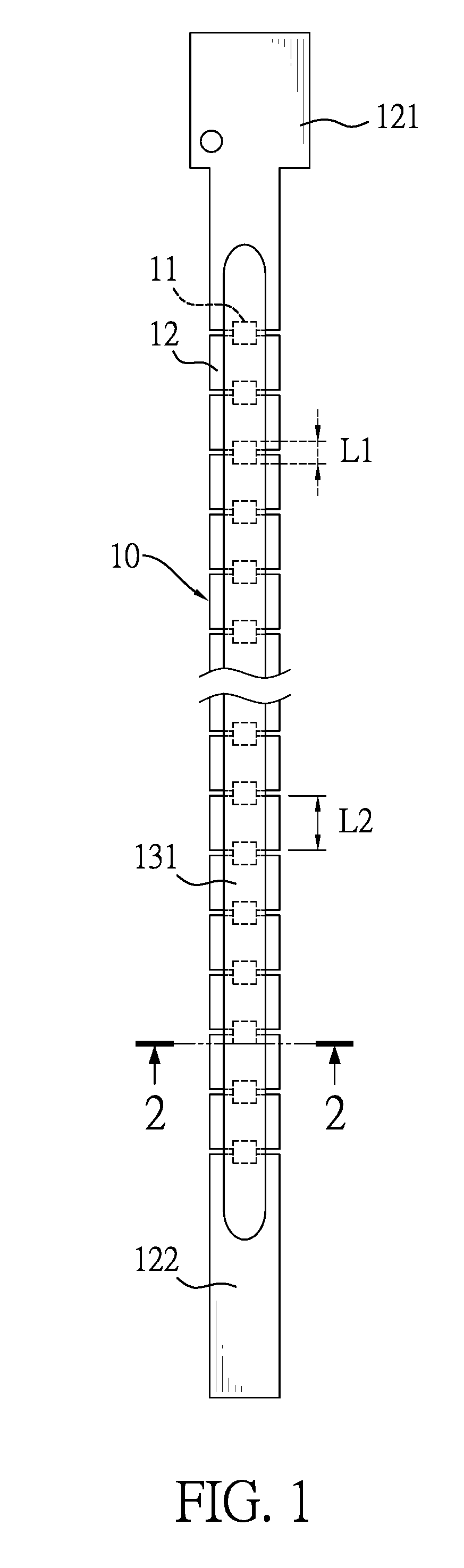

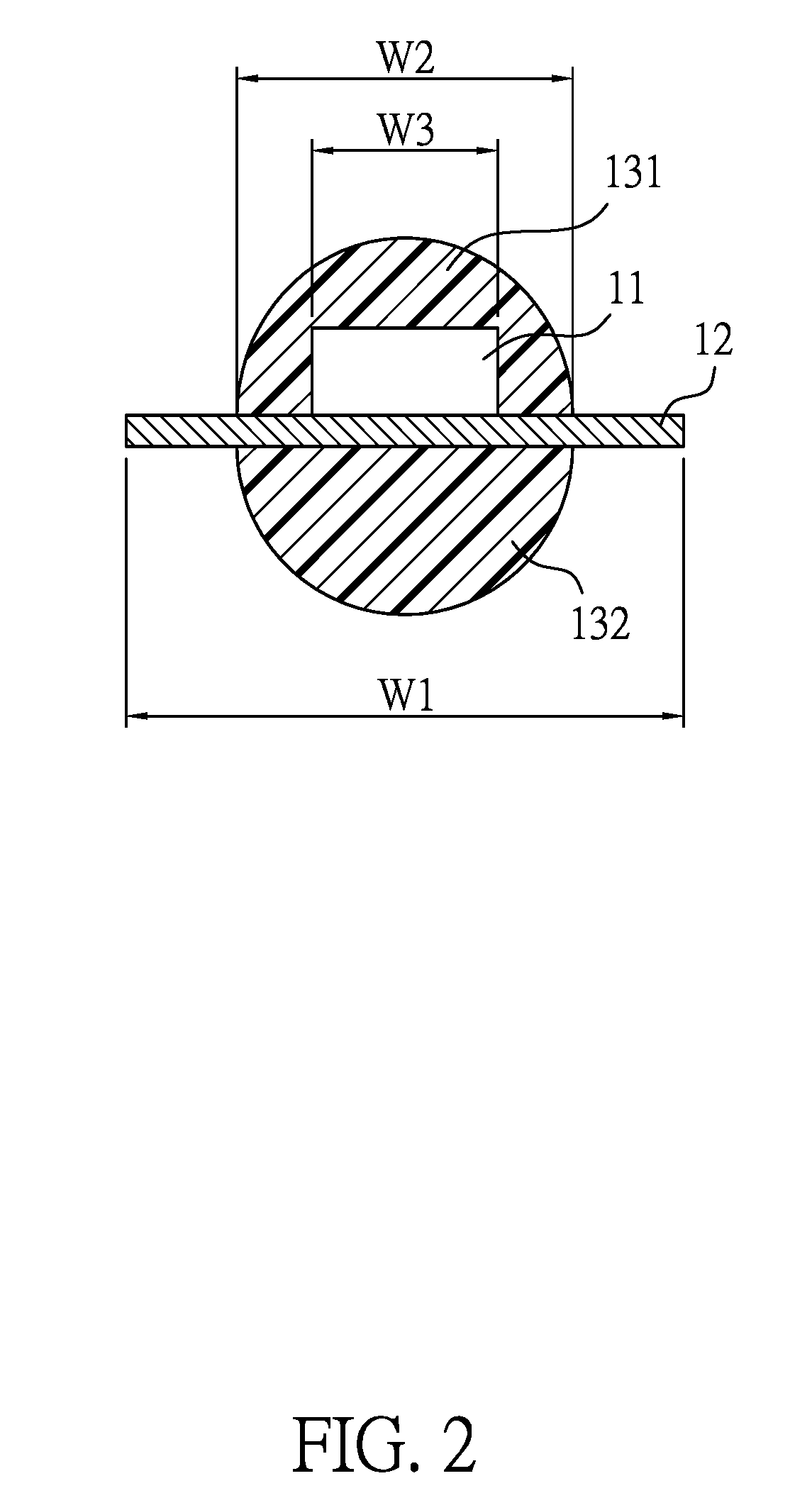

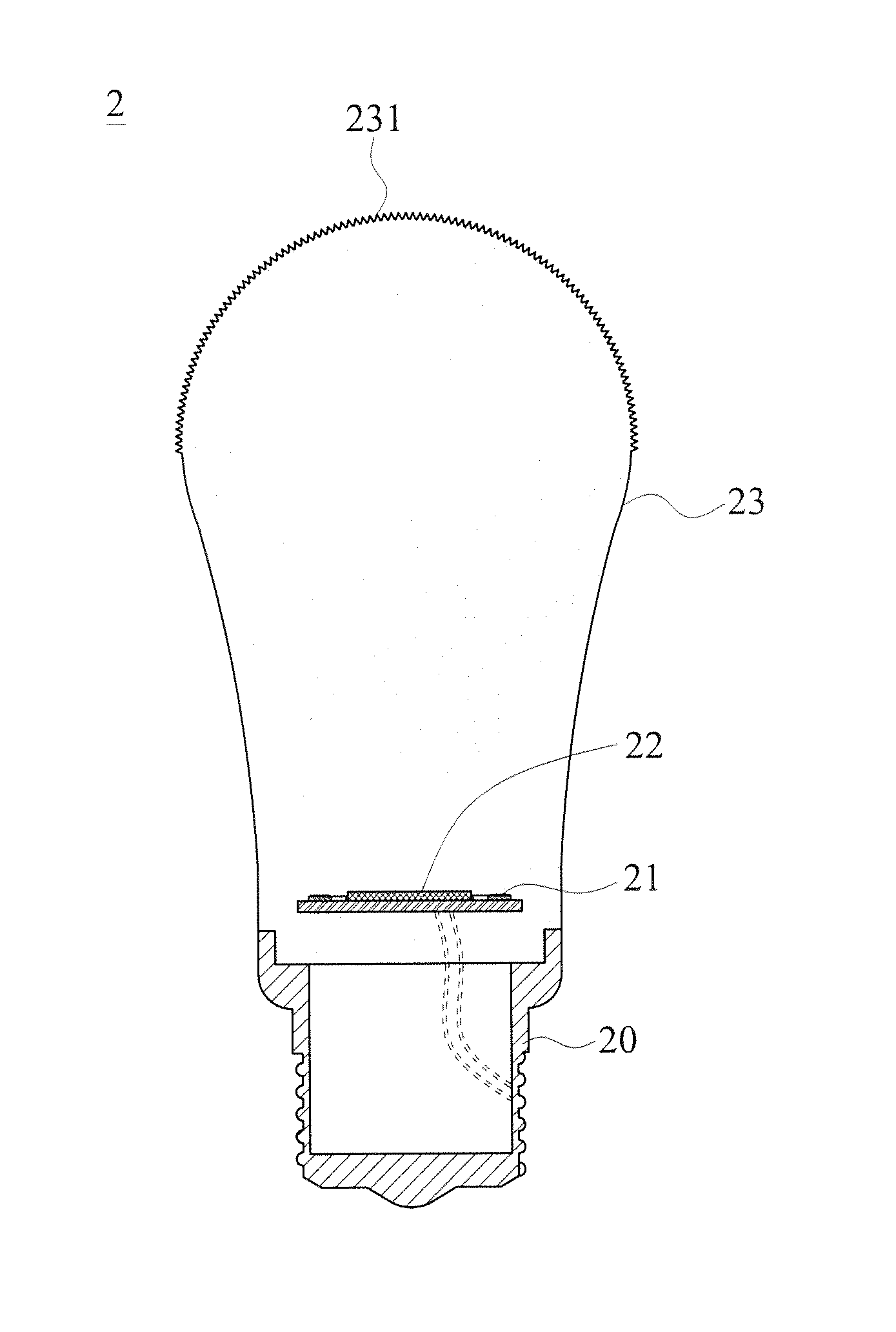

Light-emitting diode filament with a heat-dissipating structure and light-emitting diode filament light bulb using the same

ActiveUS20180112831A1Improve lighting efficiencyHeat dissipating structureElectric circuit arrangementsLighting heating/cooling arrangementsElectrically conductiveElectricity

A light-emitting diode (LED) filament with a heat-dissipating structure includes multiple LED chips, multiple conductive carriers and a package layer. Each conductive carrier takes the form of a metal sheet and the multiple conductive carriers are spaced apart from each other. Each LED chip is commonly carried by and is electrically connected to two of the multiple conductive carriers adjacent to the LED chip. The package layer covers the multiple LED chips and the multiple conductive carriers with two lateral edge portions of each conductive carrier exposed from the package layer. The LED filament is mounted inside a light bulb. Because the multiple conductive carriers are partially exposed from the package layer, heat generated by the multiple LED chips can be dissipated to an ambient environment without affecting lighting efficiency and light output as a result of accumulated heat.

Owner:LIQUIDLEDS LIGHTING

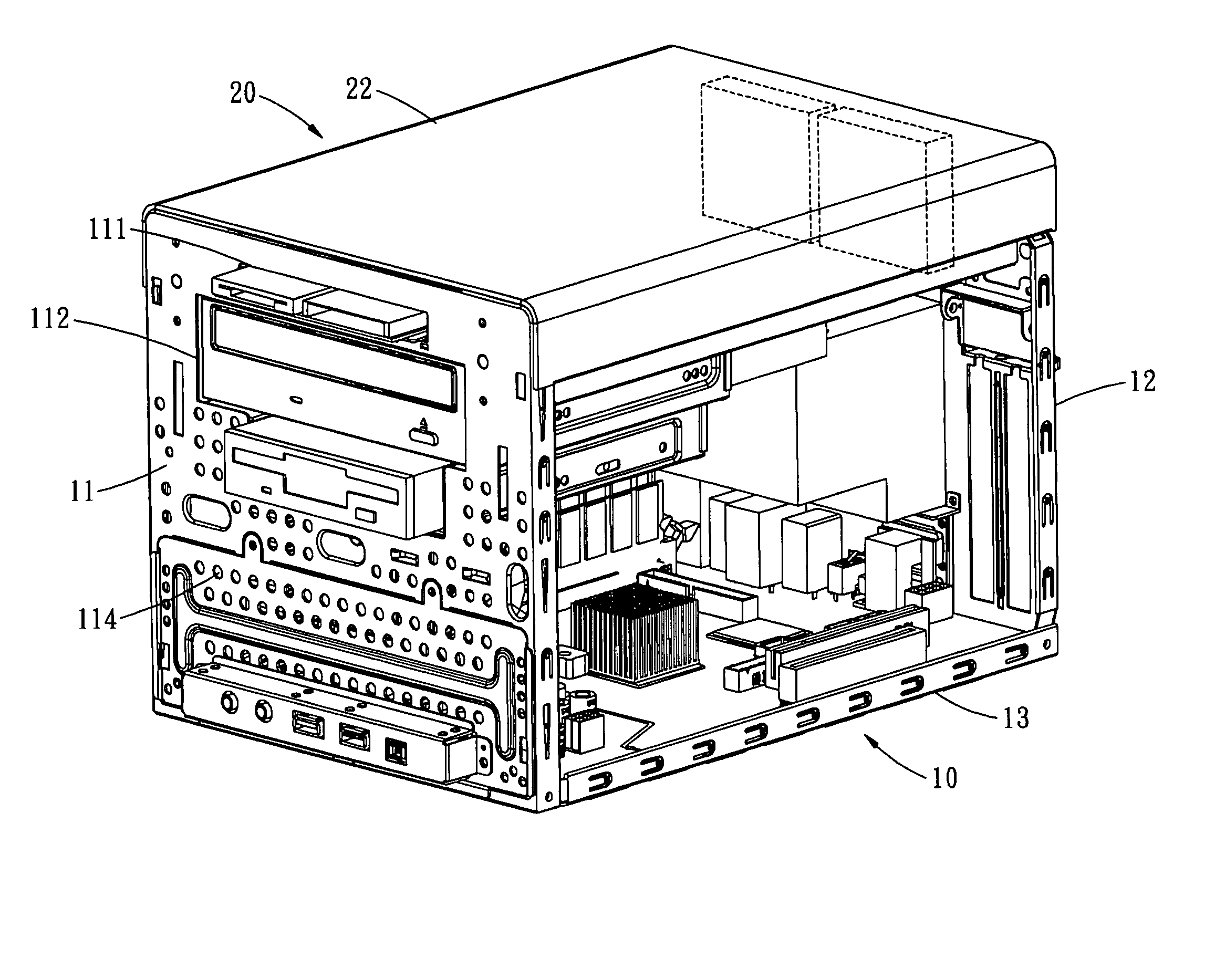

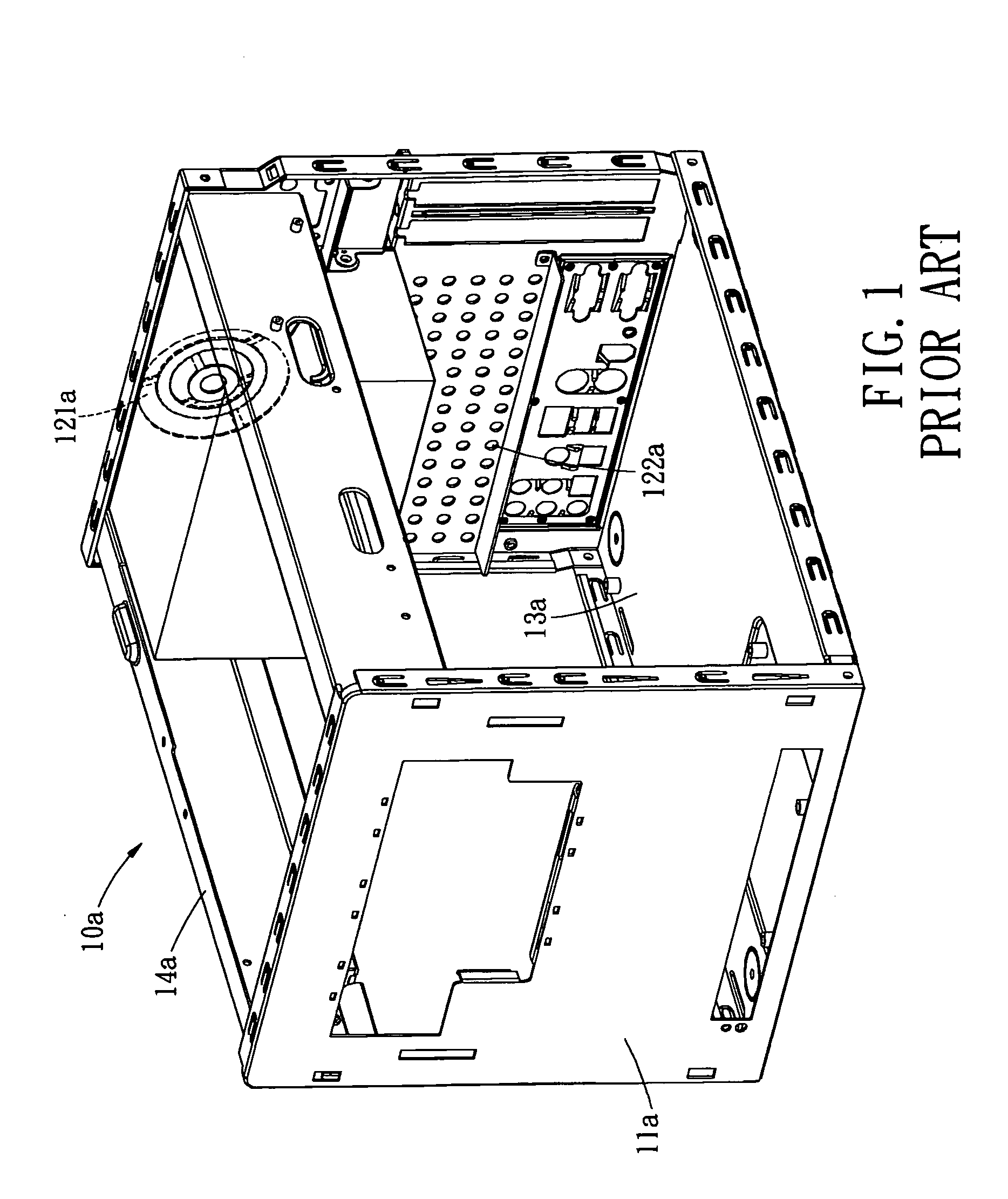

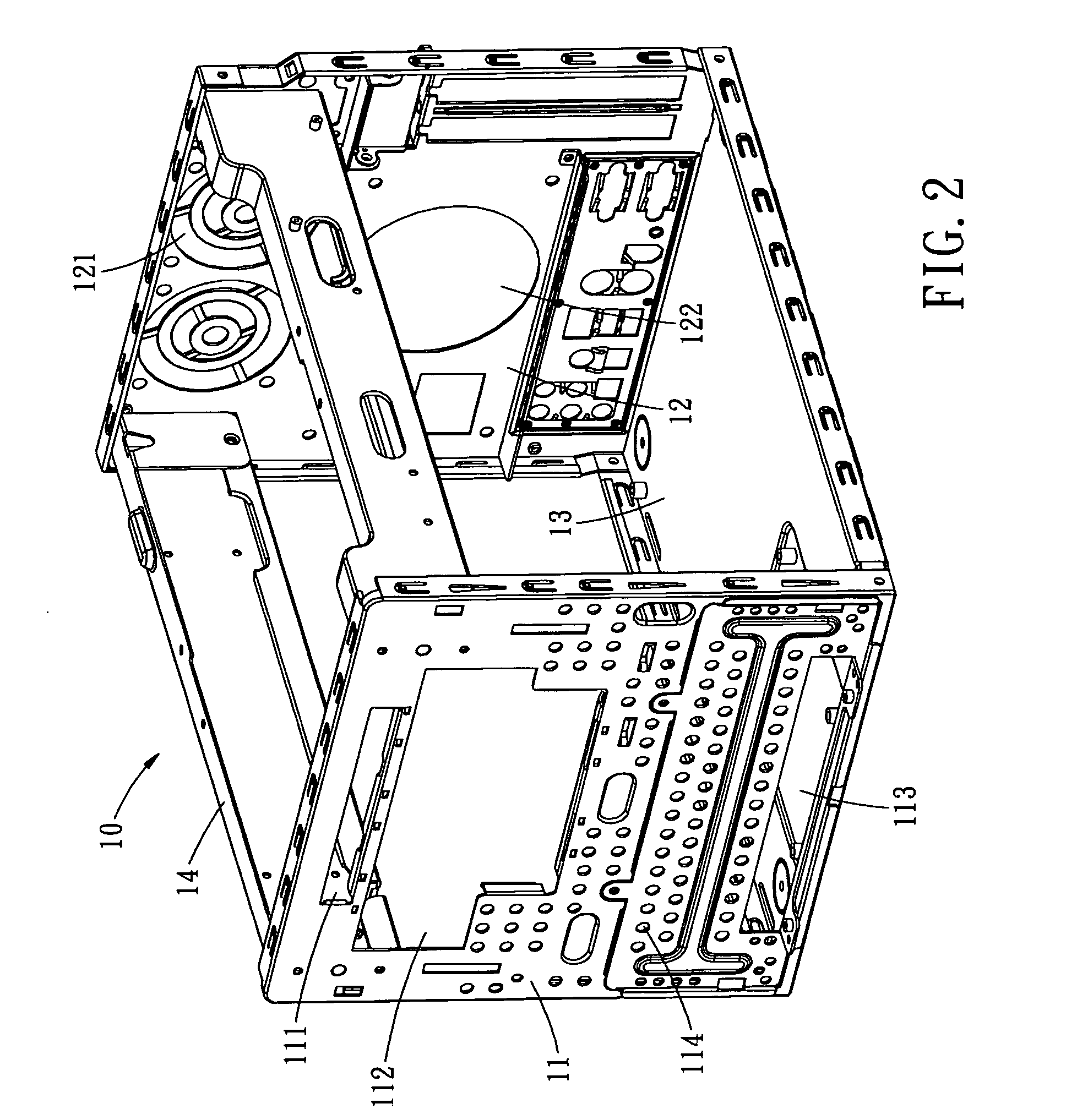

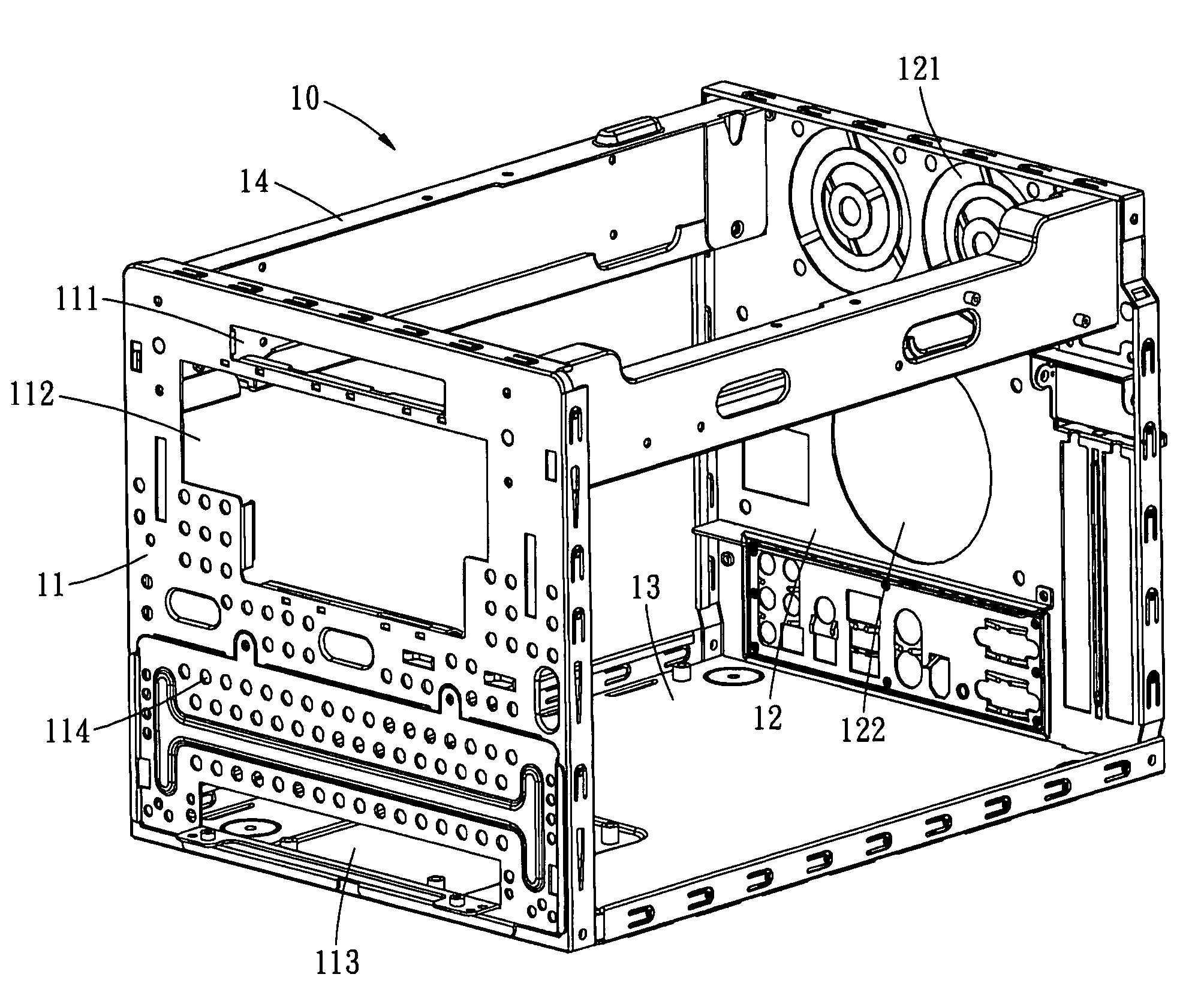

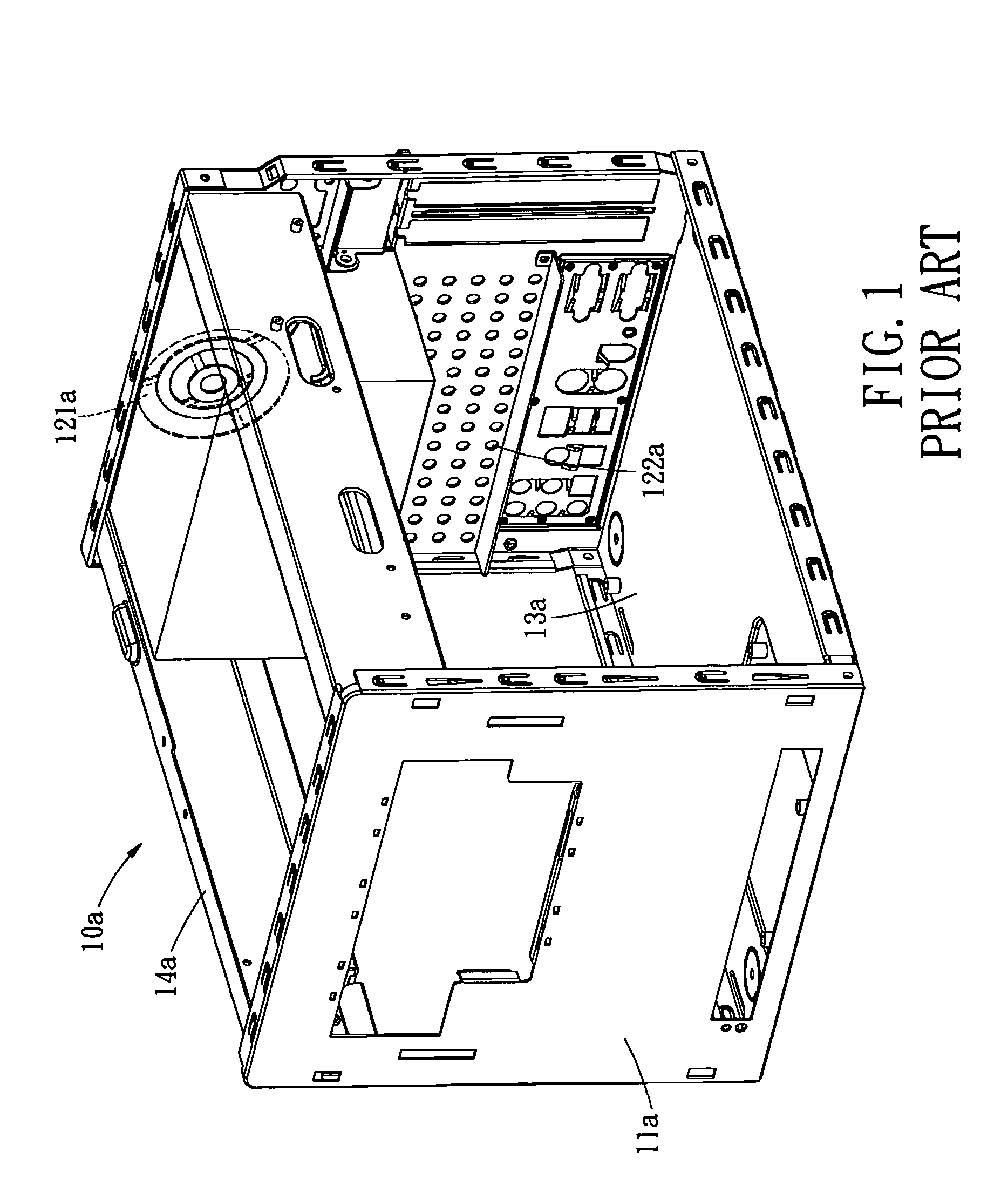

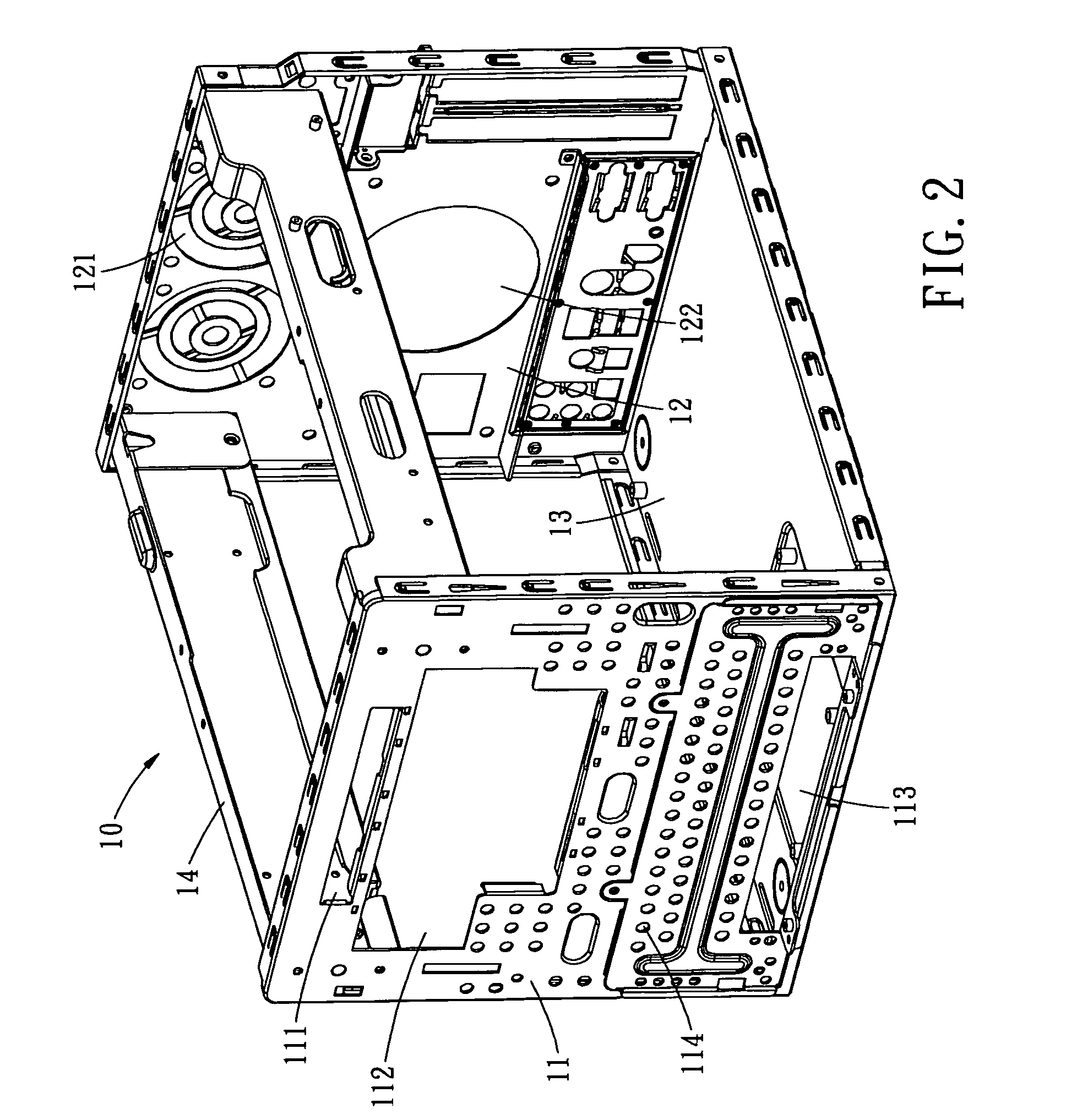

Heat dissipating structure for computer casing

InactiveUS20050237710A1Better heat dissipation effectivenessHeat dissipating structureDigital data processing detailsInsulated cablesEngineeringMechanical engineering

A heat dissipating structure for a computer casing includes a computer casing having a front board, a back board, and a bottom board, wherein the front board and the back board are parallel and correspond to each other by being connected together on the bottom board. There are two supporting frames mounted at an opposite side corresponding to the bottom board for respectively connecting with the upper sides of the front board and the back board so as to form a rectangular hexahedron. There are plural placing slots mounted on the front board for placing a disk drive, a CD-ROM drive, and plural connectors therein, wherein the front board further has the plural heat dissipating openings mounted thereon between the positions of the placing slots. Through the heat dissipating openings, the air flowing outside is drawn into the inside computer casing so that the heat generated by the electrical elements can be exhausted to the outside and a better heat dissipating effectiveness is achieved.

Owner:SHUTTLE

Protective case with heat dissipation structure for electronic products

InactiveUS9075570B2Simple structureImprove production efficiencyDigital data processing detailsCooling/ventilation/heating modificationsCold airEngineering

A protective case with multiple air tunnels for the protective case, so the heat absorbed by contact blocks from the electronic equipment is radiated rapidly out of the protective case through vent pipes. When the electronic equipment is supported up to watch movie or play games, because the hot air will raise and be exhausted from the upper part, and the fresh cool air will come inside from lower part of the protective case, as a result, the ventilation is accelerated and the heat dissipation performance is greatly improved.

Owner:YUAN LUHUI

Electrical device heat dissipation structure

InactiveUS20180014430A1Heat dissipating structureAvoid failureCoupling device connectionsDigital data processing detailsElectrical connectorElectrical equipment

An electrical device heat dissipation structure includes an air blowing device, a casing, and a mating connector. The casing is disposed with at least one air outlet, an electrical connector and a power supply. The power supply provides power to the air blowing device. The mating connector has a chip. The mating connector is electrically connected with the electrical connector. The air blowing device is configured to blow air to the mating connector through the at least one air outlet, so as to improve dissipation of heat generated by the chip at work, and to reduce a temperature of the mating connector.

Owner:LOTES

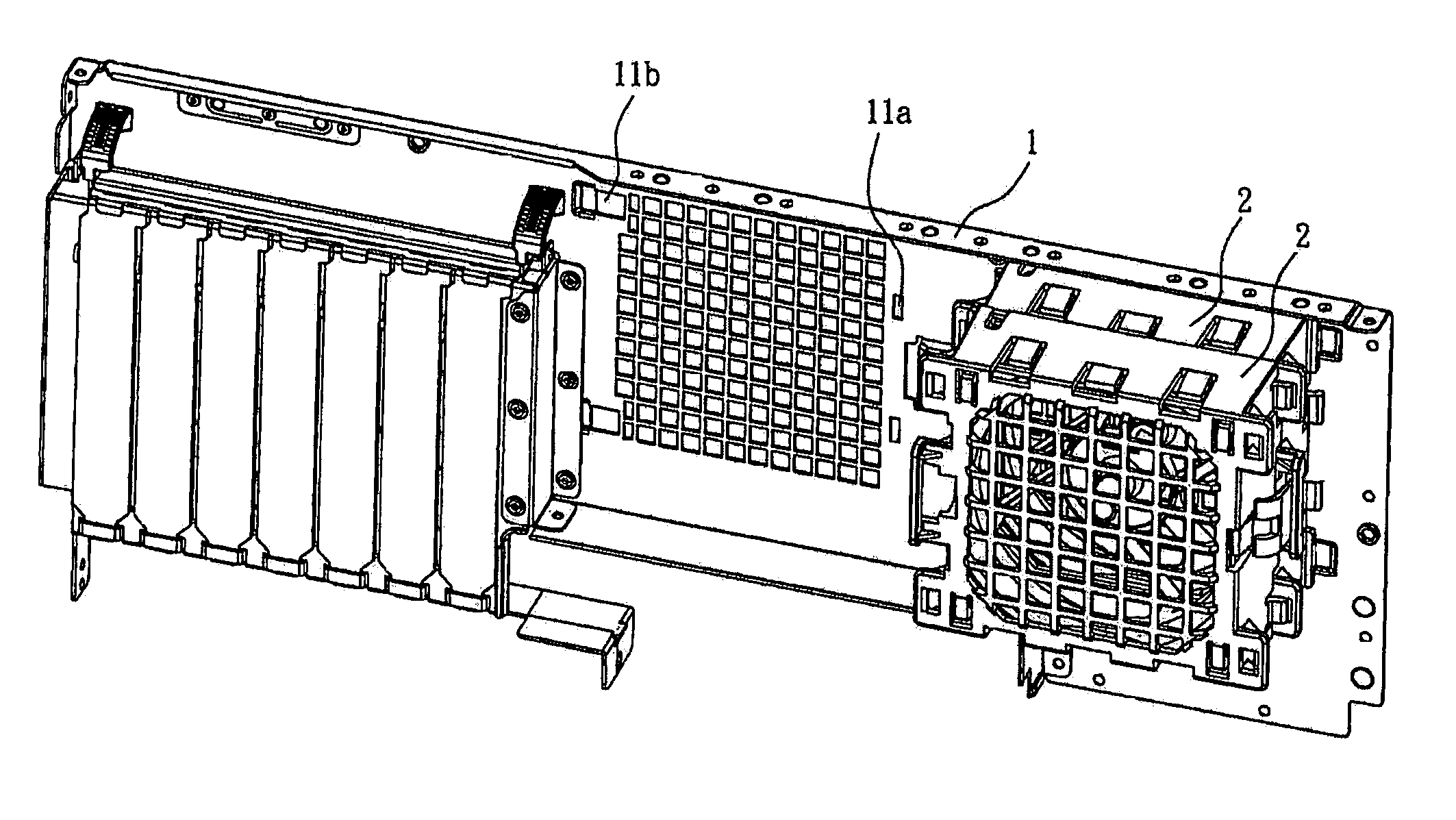

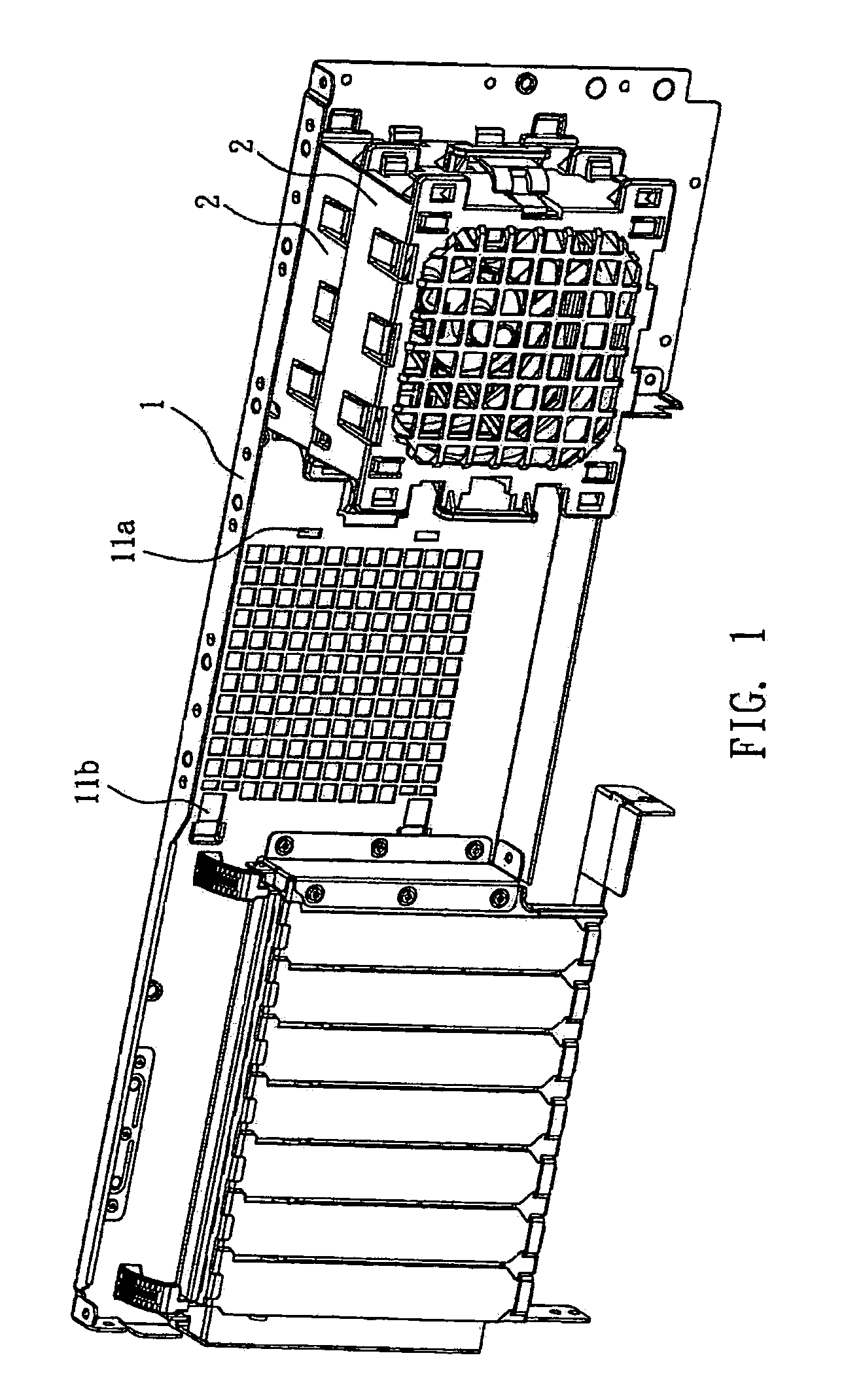

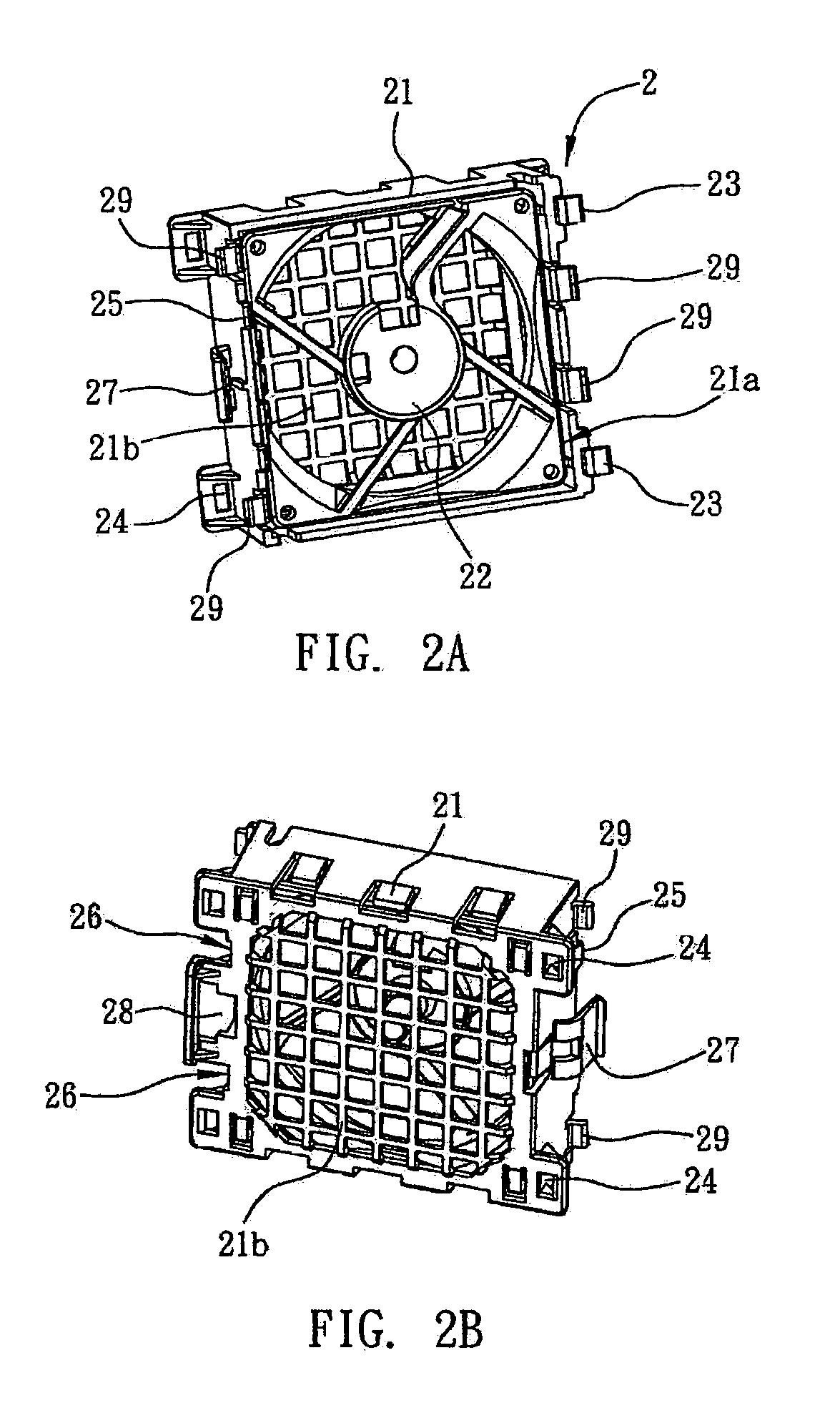

Heat dissipating structure applicable to a computer host

InactiveUS7292436B2Easy detachmentEasy to fixSubstation/switching arrangement detailsPump componentsEngineeringElectrical and Electronics engineering

A heat dissipating structure for a computer host is disclosed. The heat dissipating structure is fixable to a housing of the computer host and is provided for a heat dissipating fan for dissipating heat. The heat dissipating structure includes a fan fixing housing including a front opening and a hollow network, the fan fixing housing being a hollow frame; a plurality of first fixing portions formed in a peripheral region around the front opening of the fan fixing housing; and a plurality of second fixing portions corresponding to the first fixing portions and formed on a peripheral region of the hollow network of the fan fixing housing.

Owner:INVENTEC CORP

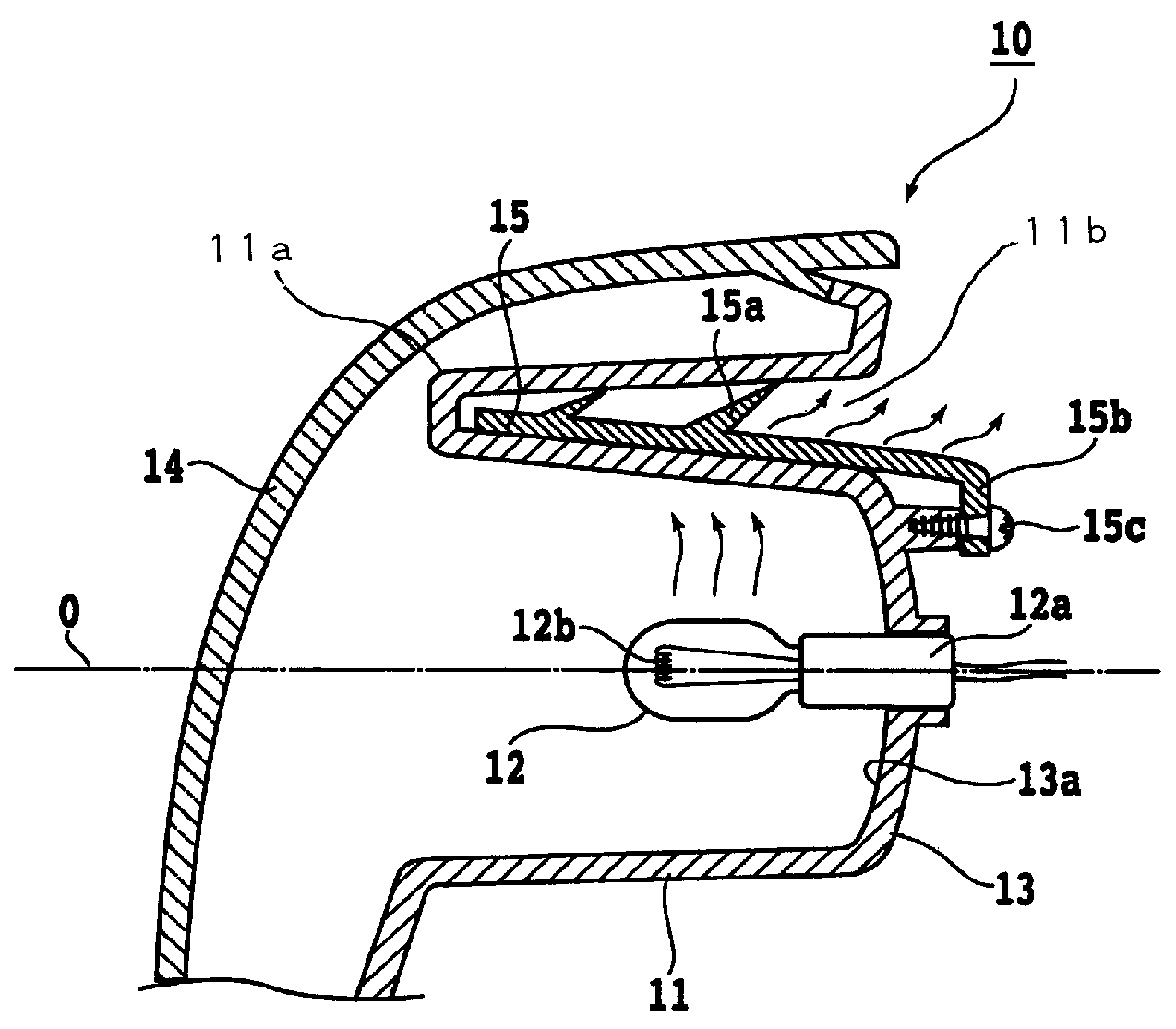

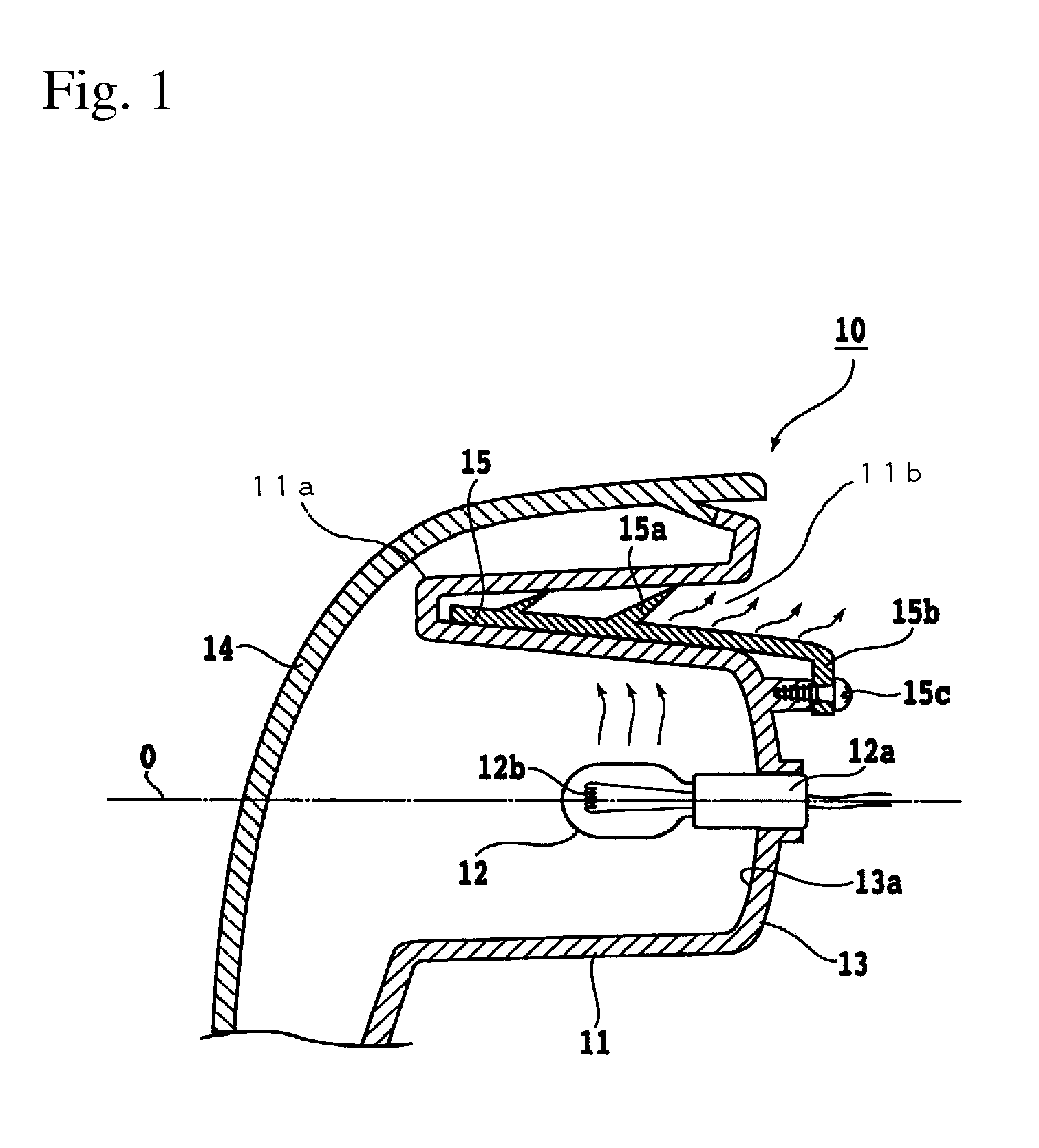

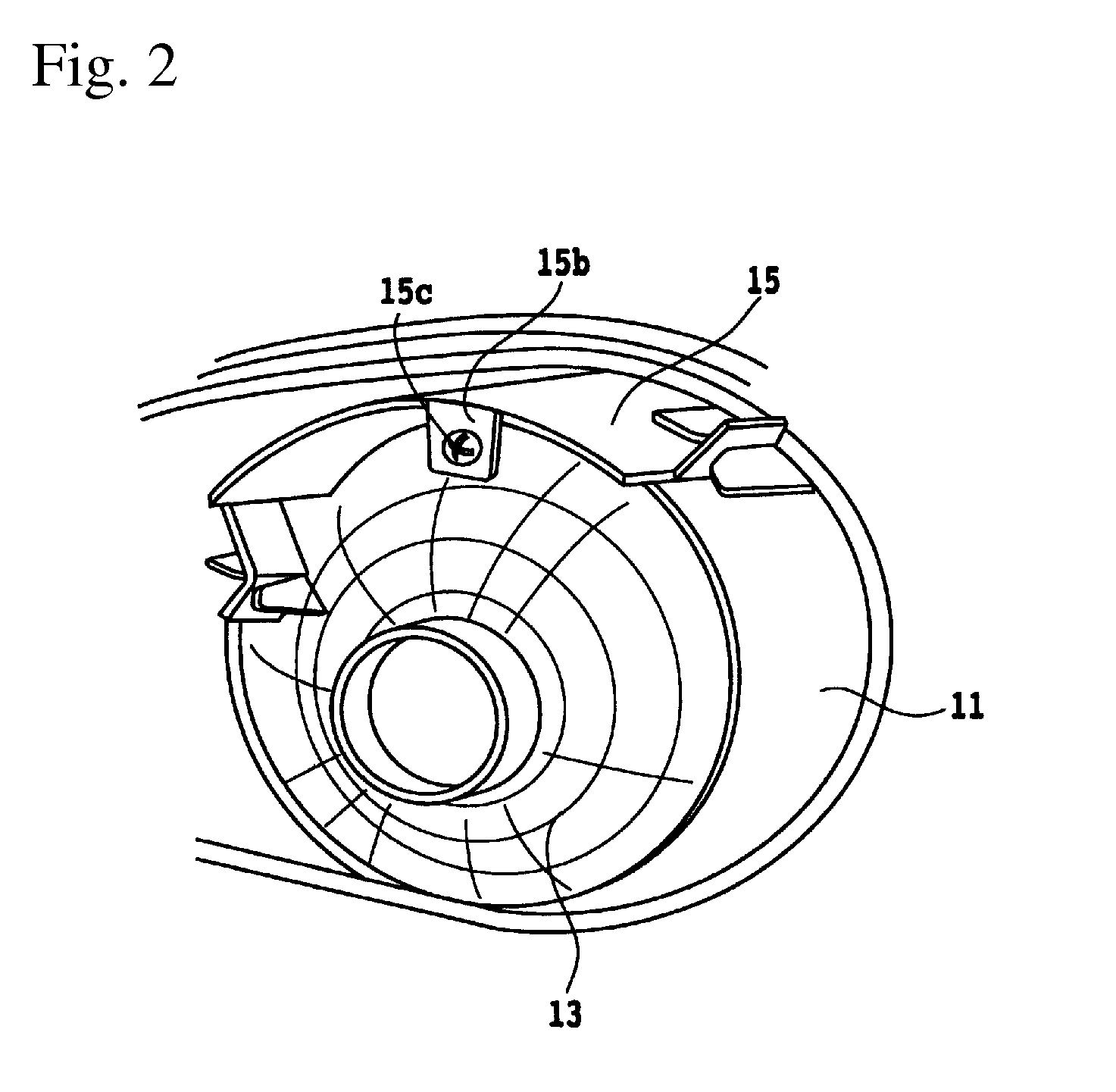

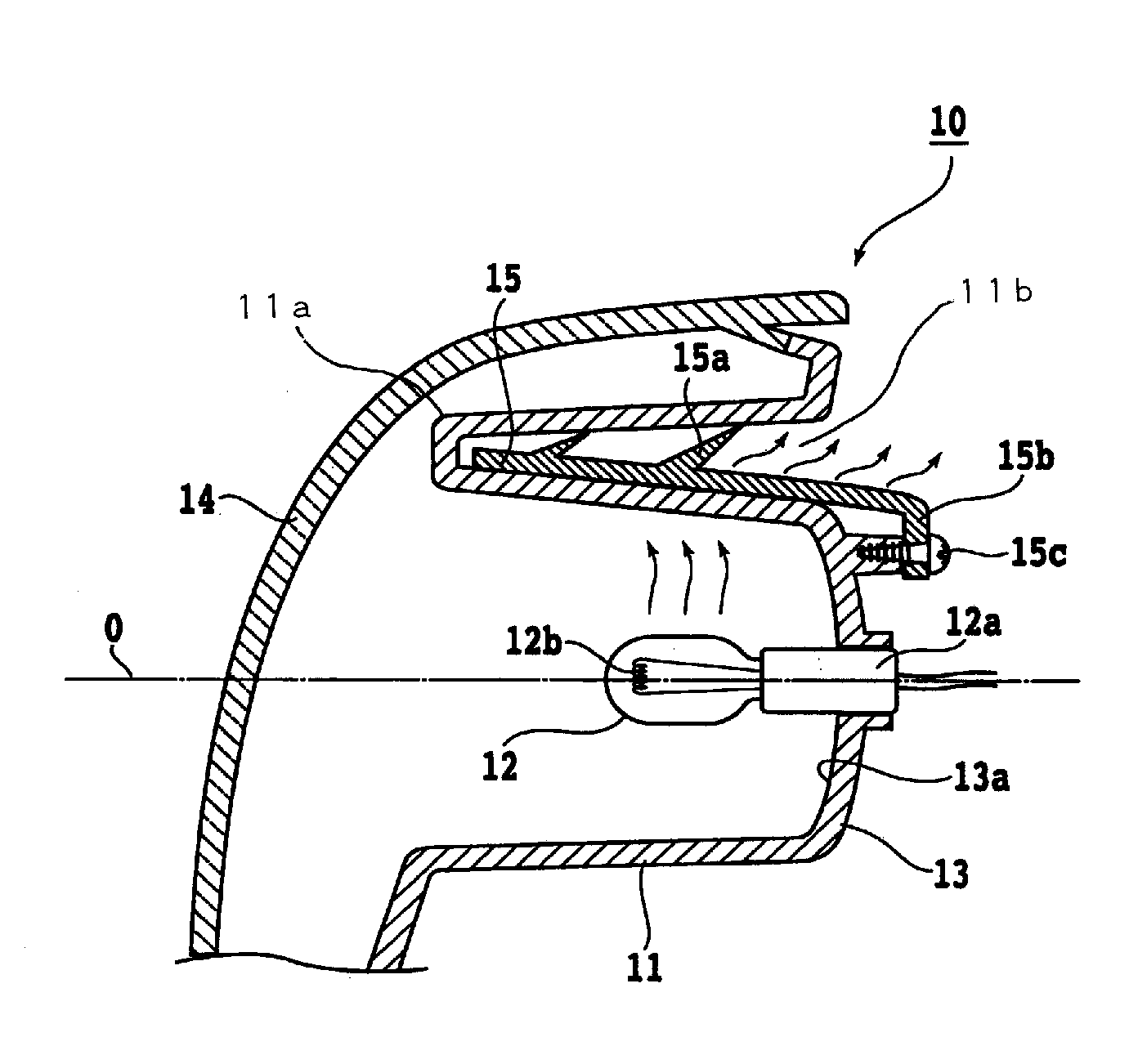

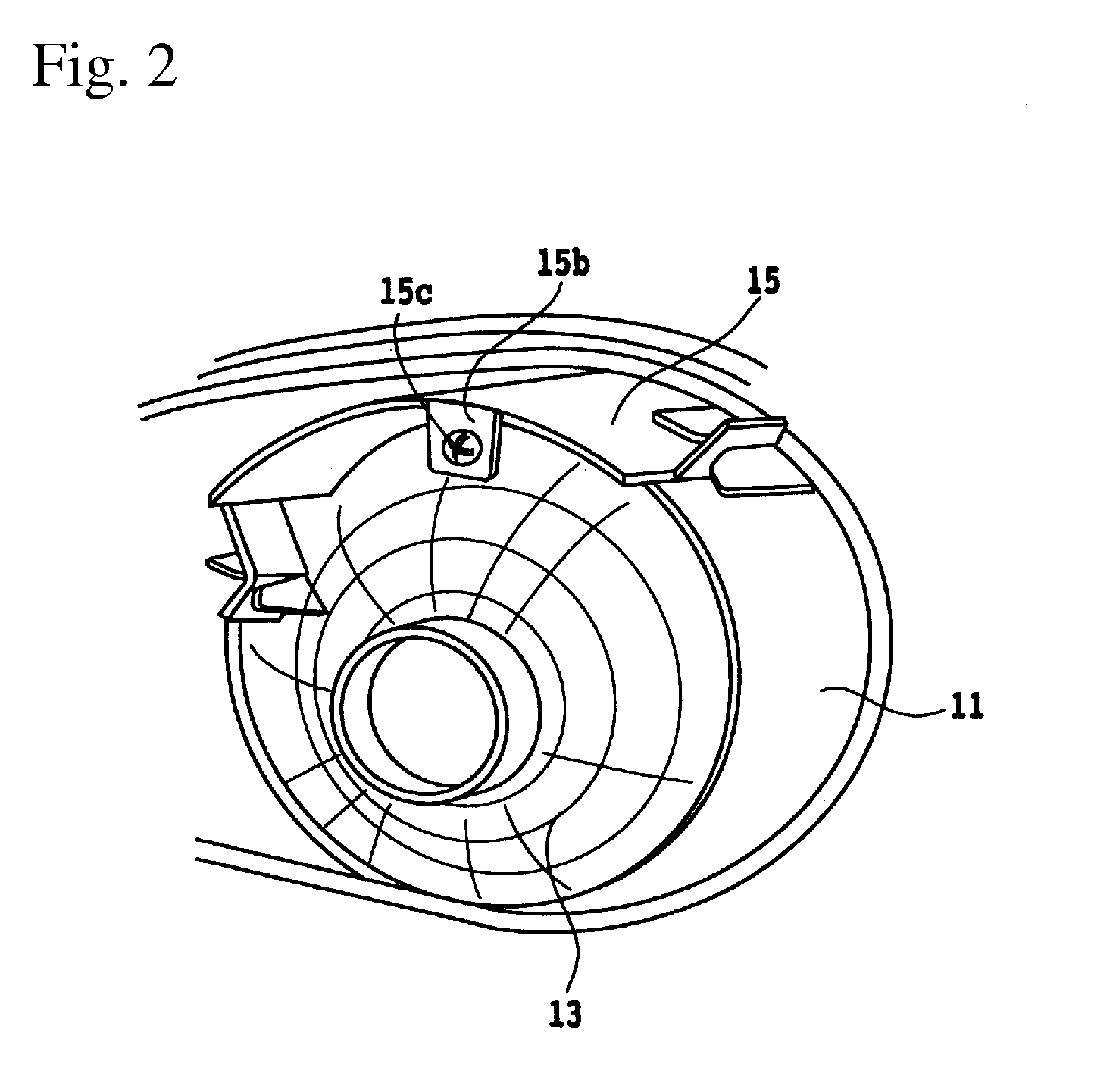

Vehicle lamp

InactiveUS7665868B2Good light distributionHeat dissipating structurePoint-like light sourceLighting heating/cooling arrangementsSubject matterMiniaturization

The disclosed subject matter can include a vehicle lamp having a favorable light distribution and an effective heat dissipation structure. The vehicle lamp can include a light source and a casing in which the light source is sealed. The casing can be configured in a tubular shape and a reflector can be configured in a hollow of the casing. The casing can be sealed between the reflector and a front lens configured to allow light emitted from the light source to pass therethrough. The inner surfaces of the casing and the reflector can be configured to form a predetermined light distribution via the front lens. The outer surfaces of the casing and the reflector can be exposed to the outside and can be configured to radiate heat generated from the light source to the outside using heat conductive material. Thus, the lamp can be miniaturized and provide favorable light distribution.

Owner:STANLEY ELECTRIC CO LTD

Vehicle lamp

InactiveUS20080316757A1Good light distributionHeat dissipating structurePoint-like light sourceLighting heating/cooling arrangementsMiniaturizationSubject matter

The disclosed subject matter can include a vehicle lamp having a favorable light distribution and an effective heat dissipation structure. The vehicle lamp can include a light source and a casing in which the light source is sealed. The casing can be configured in a tubular shape and a reflector can be configured in a hollow of the casing. The casing can be sealed between the reflector and a front lens configured to allow light emitted from the light source to pass therethrough. The inner surfaces of the casing and the reflector can be configured to form a predetermined light distribution via the front lens. The outer surfaces of the casing and the reflector can be exposed to the outside and can be configured to radiate heat generated from the light source to the outside using heat conductive material. Thus, the lamp can be miniaturized and provide favorable light distribution.

Owner:STANLEY ELECTRIC CO LTD

Heat dissipating structure for computer casing

InactiveUS7075787B2Heat dissipating structureHigh energyDigital data processing detailsInsulated cablesCD-ROMEngineering

A heat dissipating structure for a computer casing includes a computer casing having a front board, a back board, and a bottom board, wherein the front board and the back board are parallel and correspond to each other by being connected together on the bottom board. There are two supporting frames mounted at an opposite side corresponding to the bottom board for respectively connecting with the upper sides of the front board and the back board so as to form a rectangular hexahedron. There are plural placing slots mounted on the front board for placing a disk drive, a CD-ROM drive, and plural connectors therein, wherein the front board further has the plural heat dissipating openings mounted thereon between the positions of the placing slots. Through the heat dissipating openings, the air flowing outside is drawn into the inside computer casing so that the heat generated by the electrical elements can be exhausted to the outside and a better heat dissipating effectiveness is achieved.

Owner:SHUTTLE

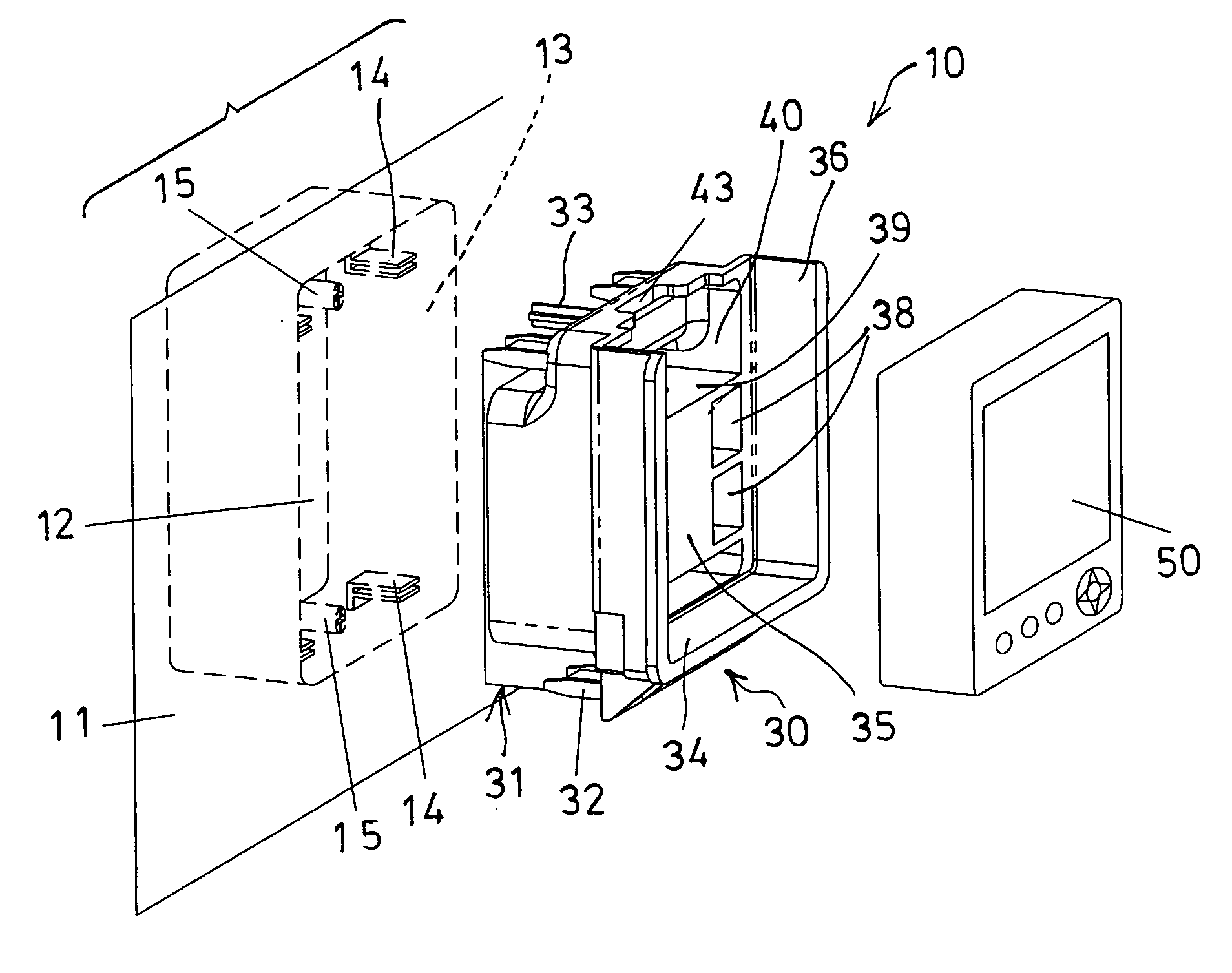

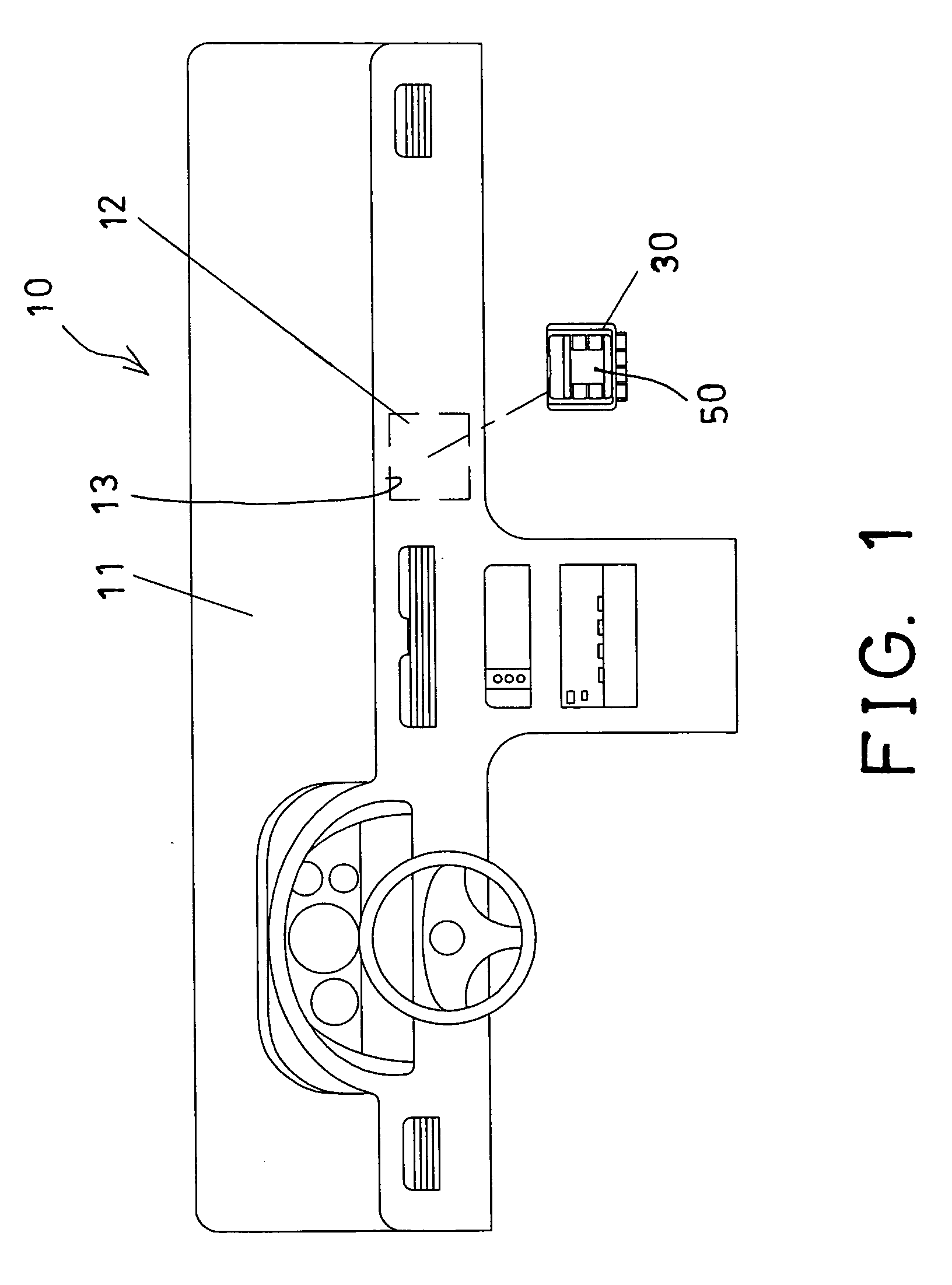

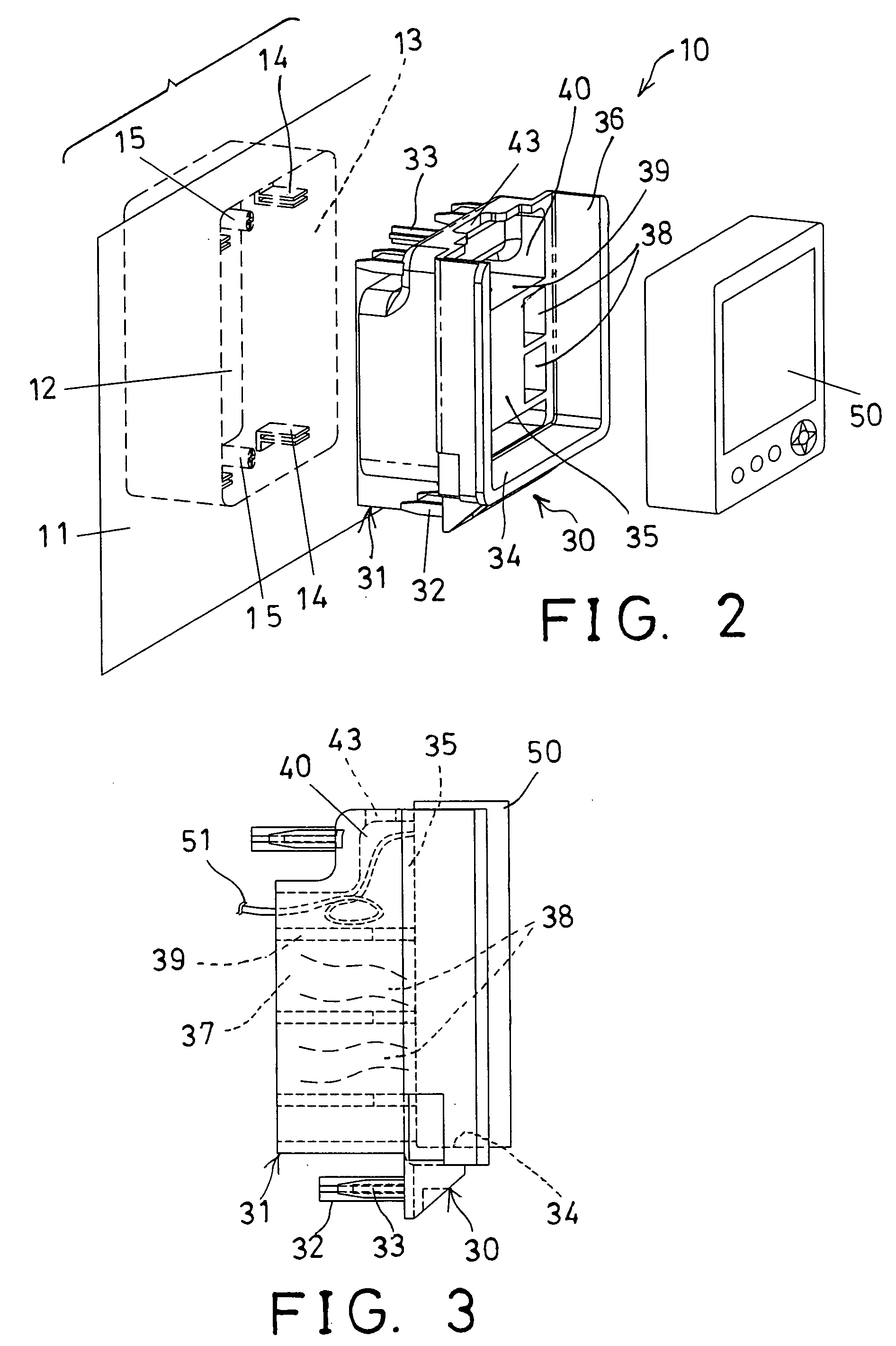

Monitor supporting combination for vehicle

InactiveUS20060238963A1Avoid damageDissipating structureDigital data processing detailsVehicle componentsWorking lifeEngineering

A monitor supporting device for vehicle includes a control panel having a chamber formed by an inner peripheral surface, for receiving a housing and for detachably attaching the housing to the control panel with catches and protrusions. The housing includes a front recess formed by a partition for receiving an electronic device, and includes a rear space located behind the partition, and includes one or more orifices formed in the partition and communicating with the rear space of the housing, for forming an air passage and for air circulating and heat dissipating purpose, and for preventing the electronic device from over-heating, and thus for allowing the working life of the electronic device to be increased.

Owner:HSU LI HSIU CHU

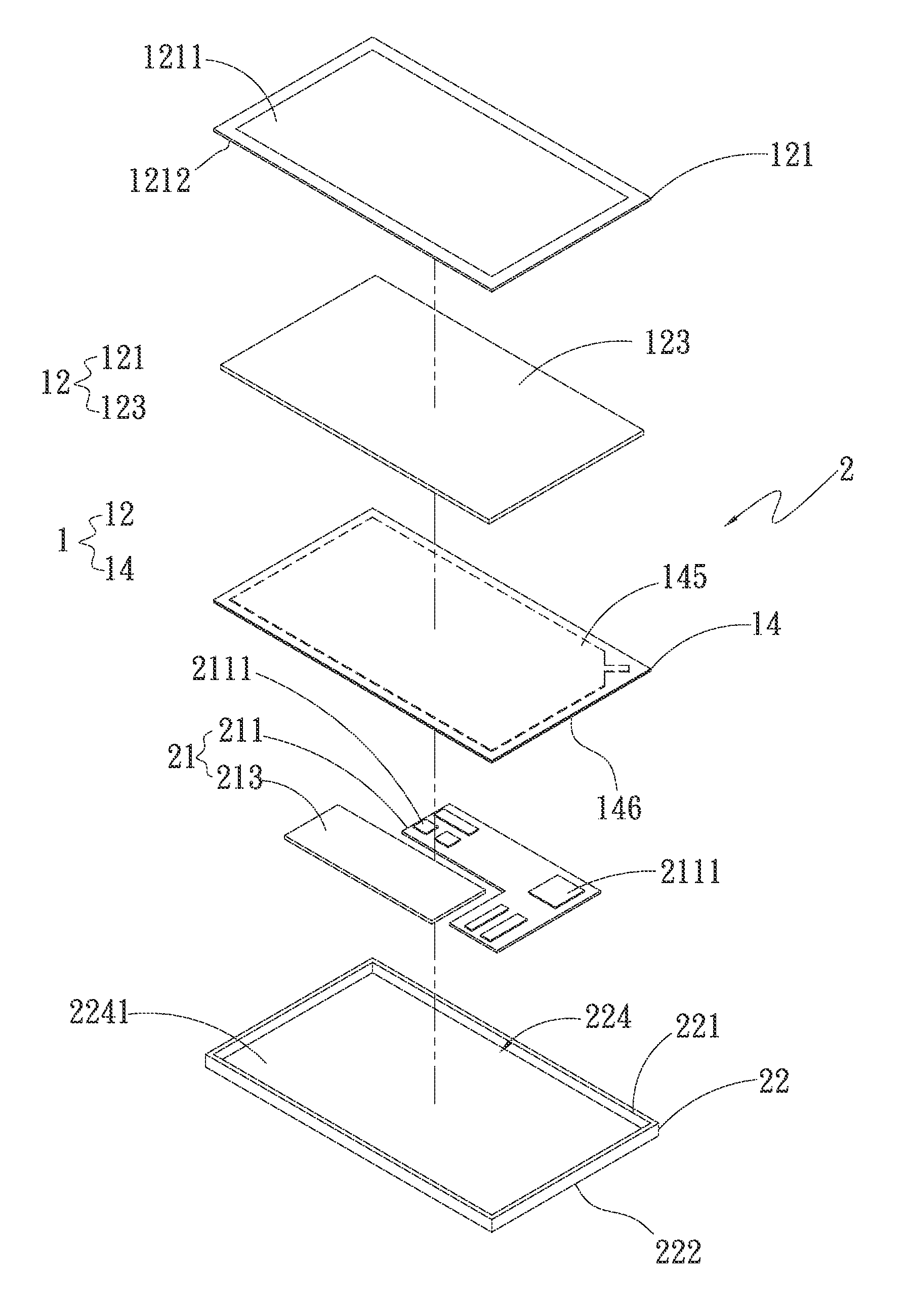

Display module with heat dissipation structure and handheld device thereof

ActiveUS9569024B2Quickly and uniformly spreadHeat dissipating structureDigital data processing detailsTelephone set constructionsComputer moduleEngineering

A display module with heat dissipation structure and a handheld device thereof. The display module includes a touch panel, a display panel and a vapor chamber. One face of the display panel is correspondingly attached to the touch panel, while the other face of the display panel is correspondingly attached to the vapor chamber. The vapor chamber serves to support the touch panel and the display panel. Moreover, the vapor chamber serves to absorb the heat generated by the electronic component and quickly and uniformly spread the heat to dissipate the heat to achieve a heat spreading effect.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

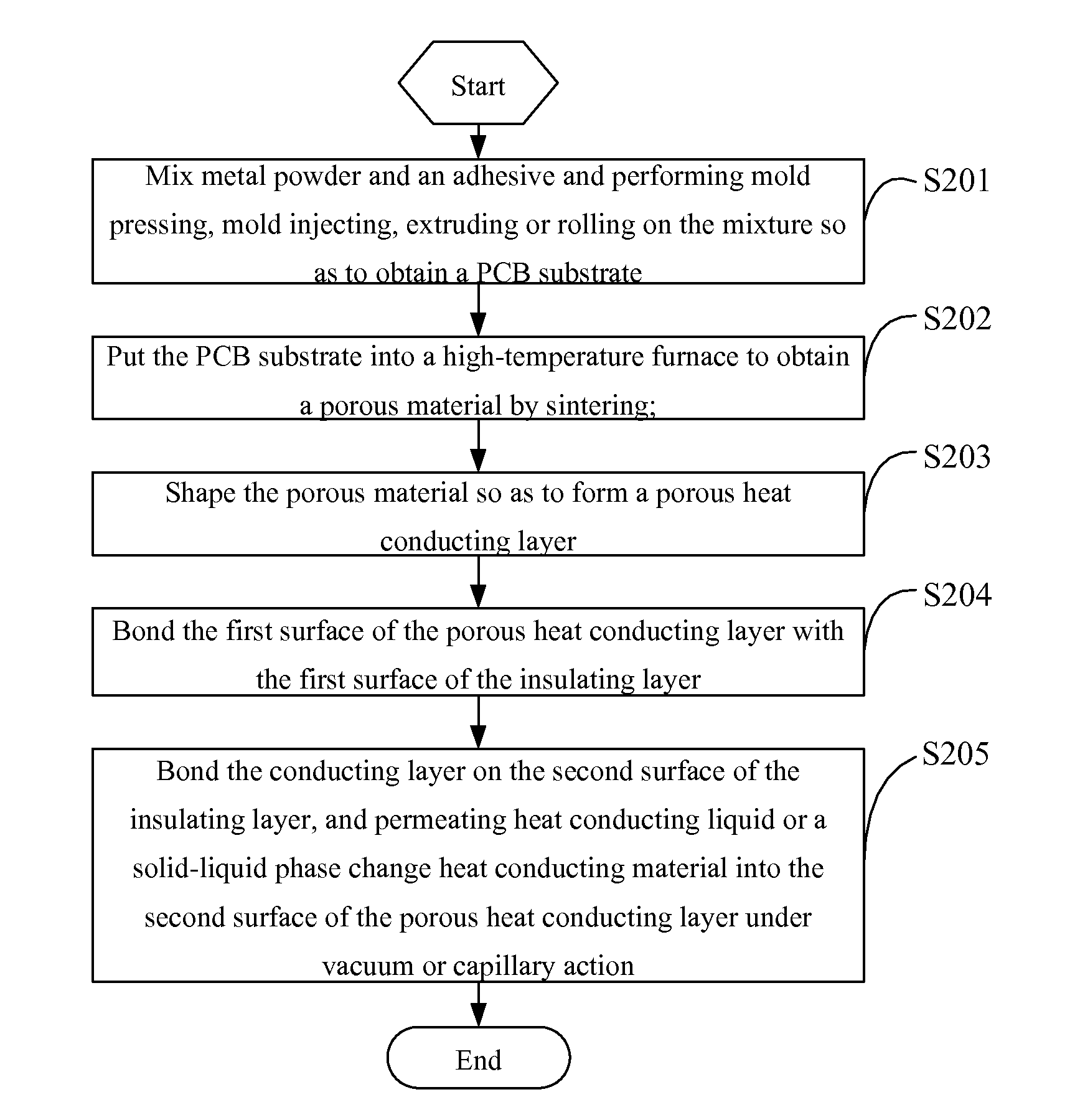

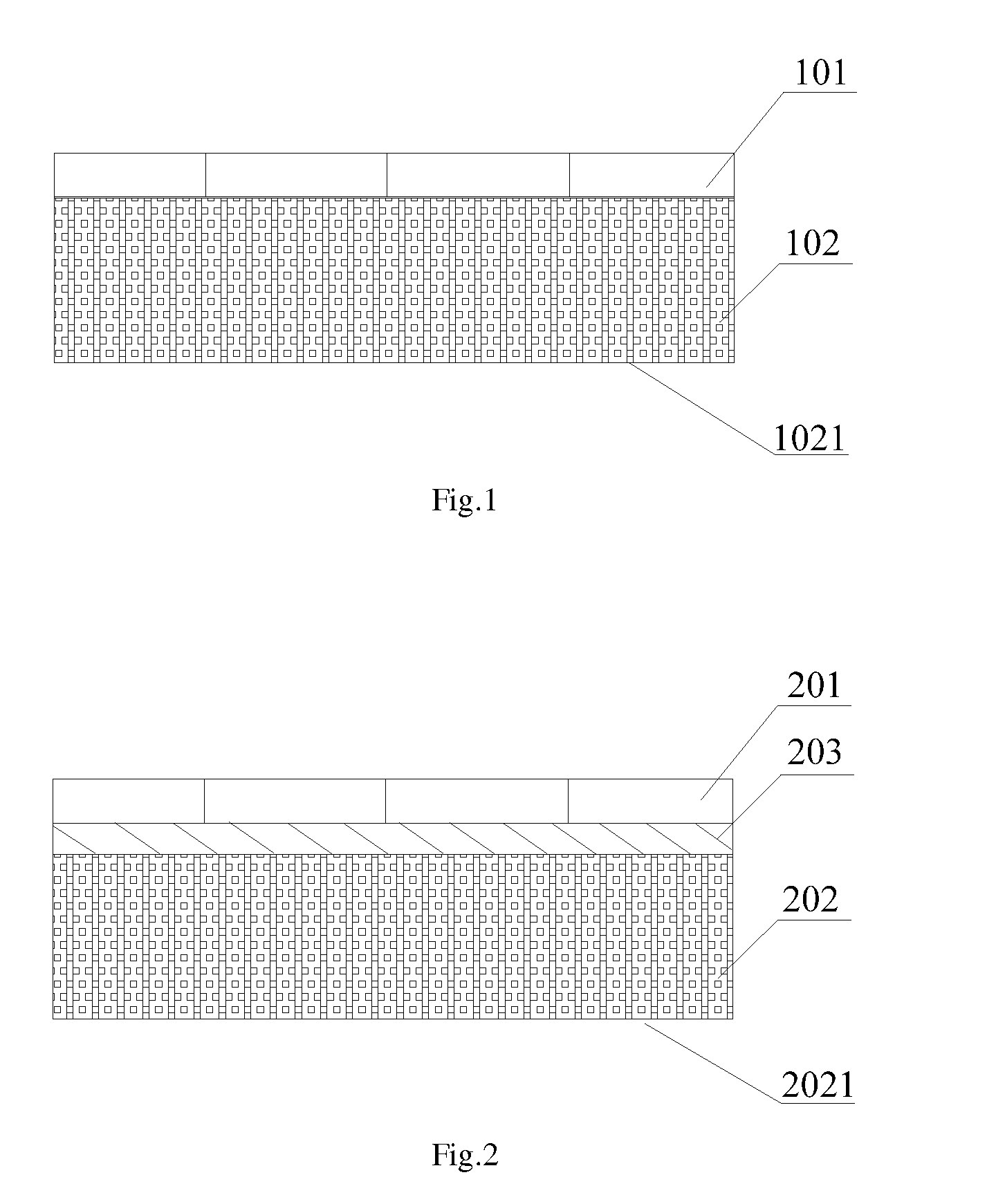

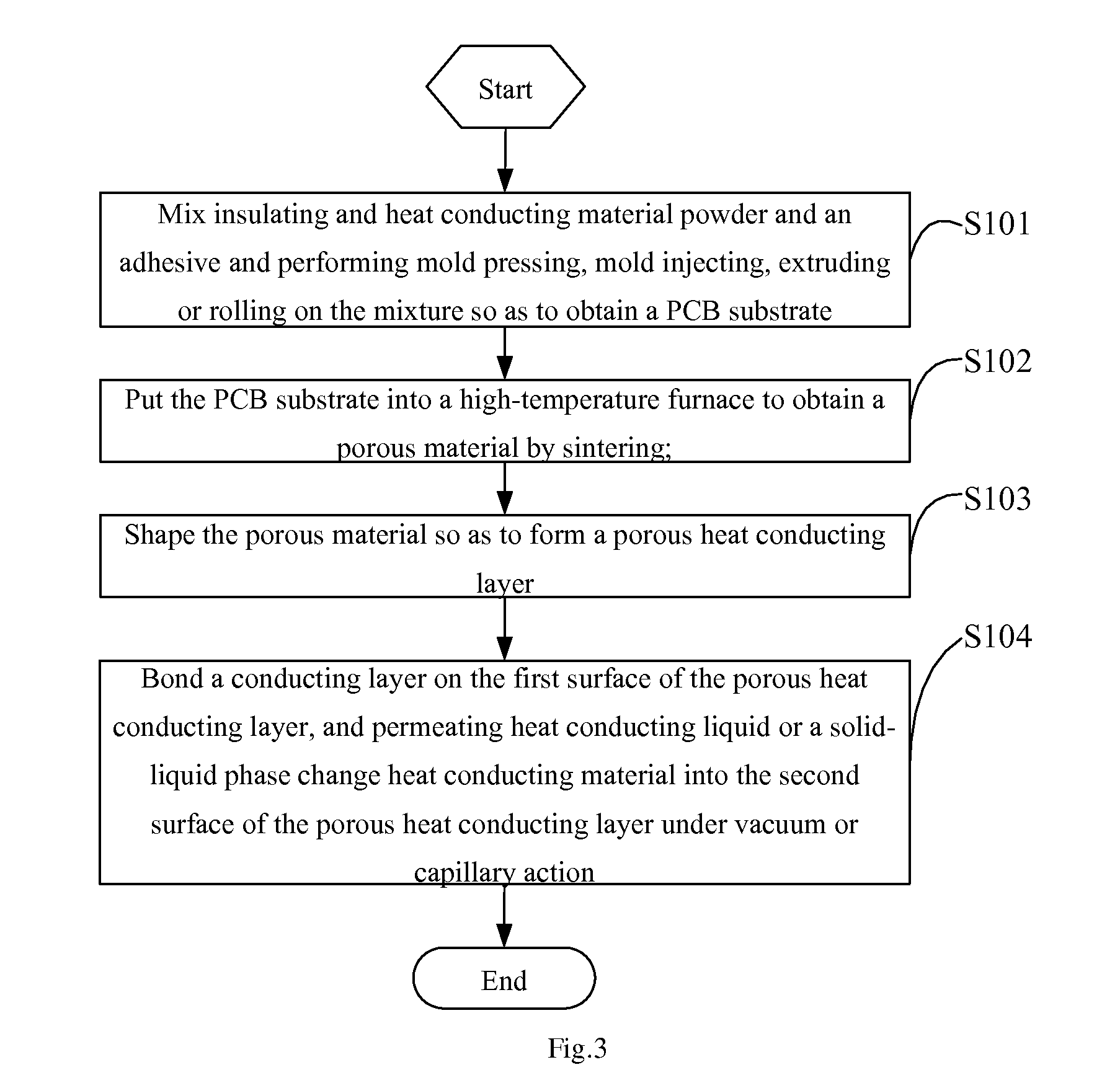

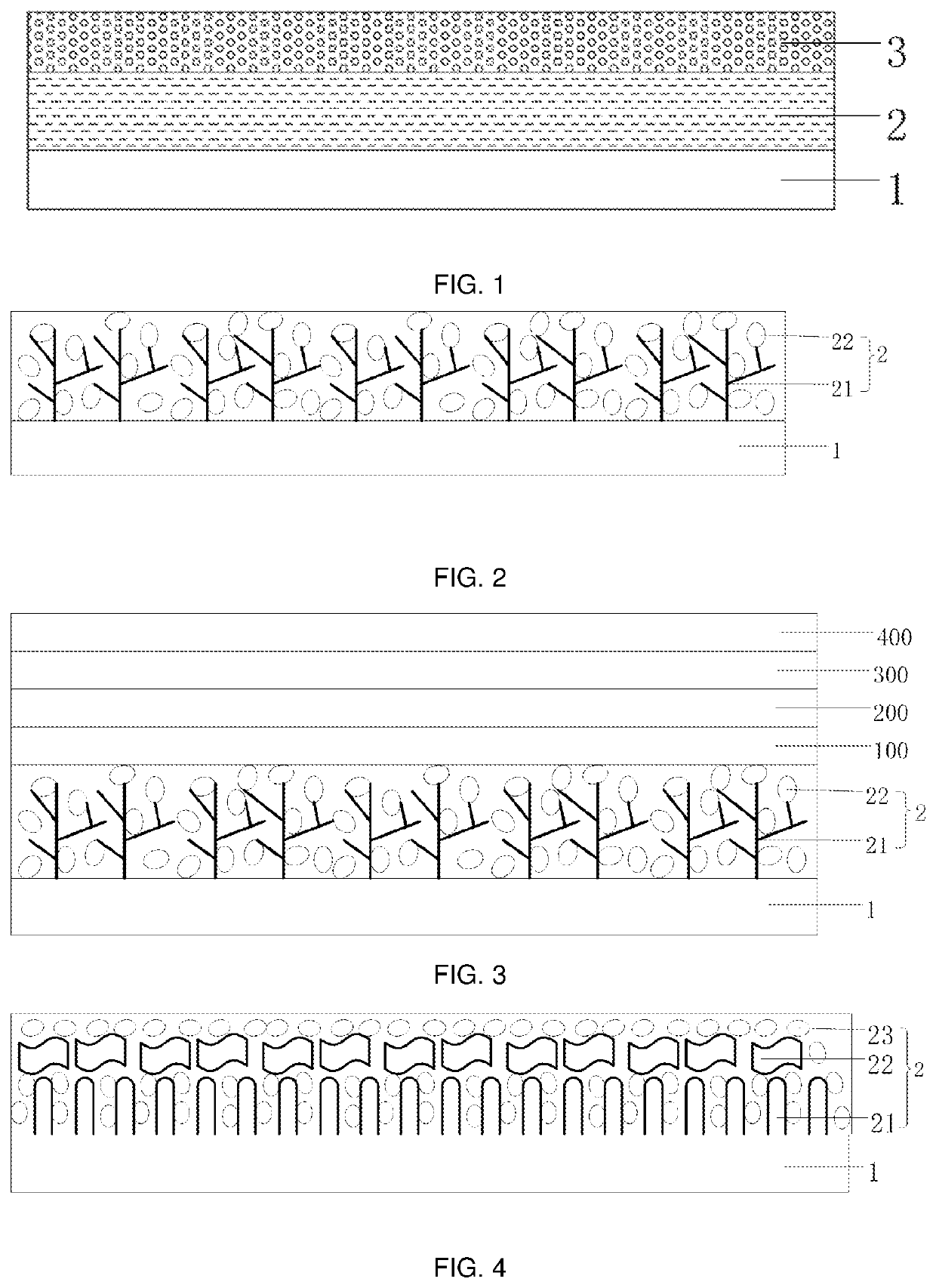

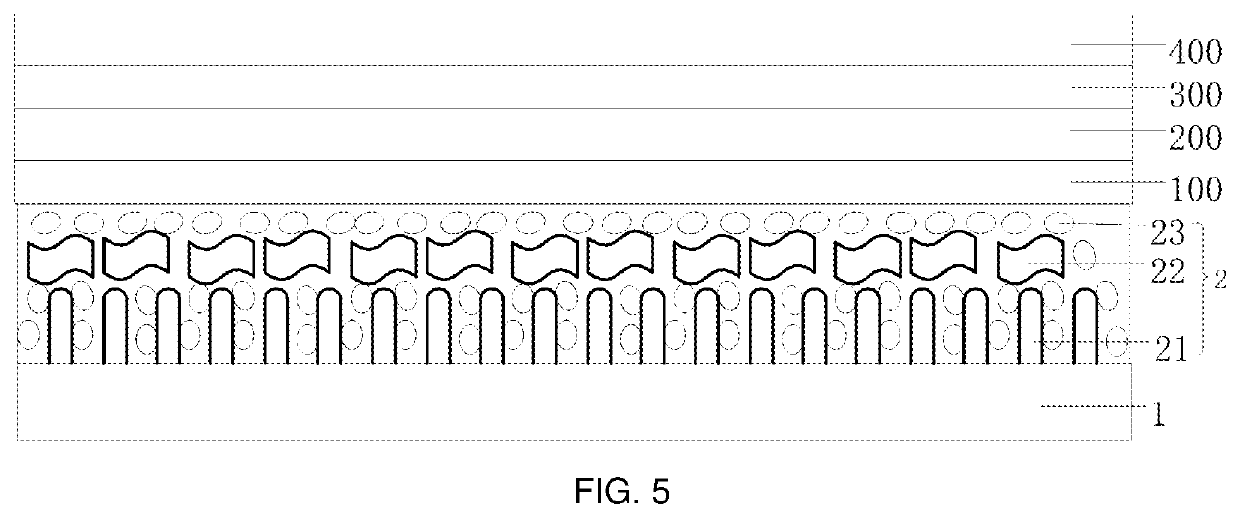

PCB with heat dissipation structure and processing methods thereof

InactiveUS20120222888A1Simple structureLow costPorous dielectricsCooling/ventilation/heating modificationsHeat resistanceHeat conducting

The invention relates to a printed circuit board (PCB) with a heat dissipating structure. The PCB comprises a conducting layer and a PCB carrier layer, wherein the PCB carrier layer is a porous heat conducting layer; heat conducting liquid or a solid-liquid phase change heat conducting material is injected into holes of the porous heat conducting layer; the conducting layer is arranged on a first surface of the porous heat conducting layer; and a second surface of the porous heat conducting layer is a contact interface with external media. In the invention, the carrier layer of the PCB is a porous heat conducting layer which is made of a porous material with high thermal conductivity, heat conducting liquid such as heat conducting ink or the solid-liquid phase change heat conducting material permeates into the holes of the porous heat conducting layer; when the PCB is heated, the heat conducting ink is separated out of the porous material because the expansion coefficient of the porous material is inconsistent with that of the heat conducting ink, and the separated heat conducting ink fills air gaps between the contact interface and the external medium in the contact interface of the PCB via capillary phenomenon, so that heat resistance between a light-emitting diode (LED) and the contact interface is reduced greatly and the thermal conductivity of the PCB is enhanced; moreover, the PCB has low cost, simple structure and easy installation.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

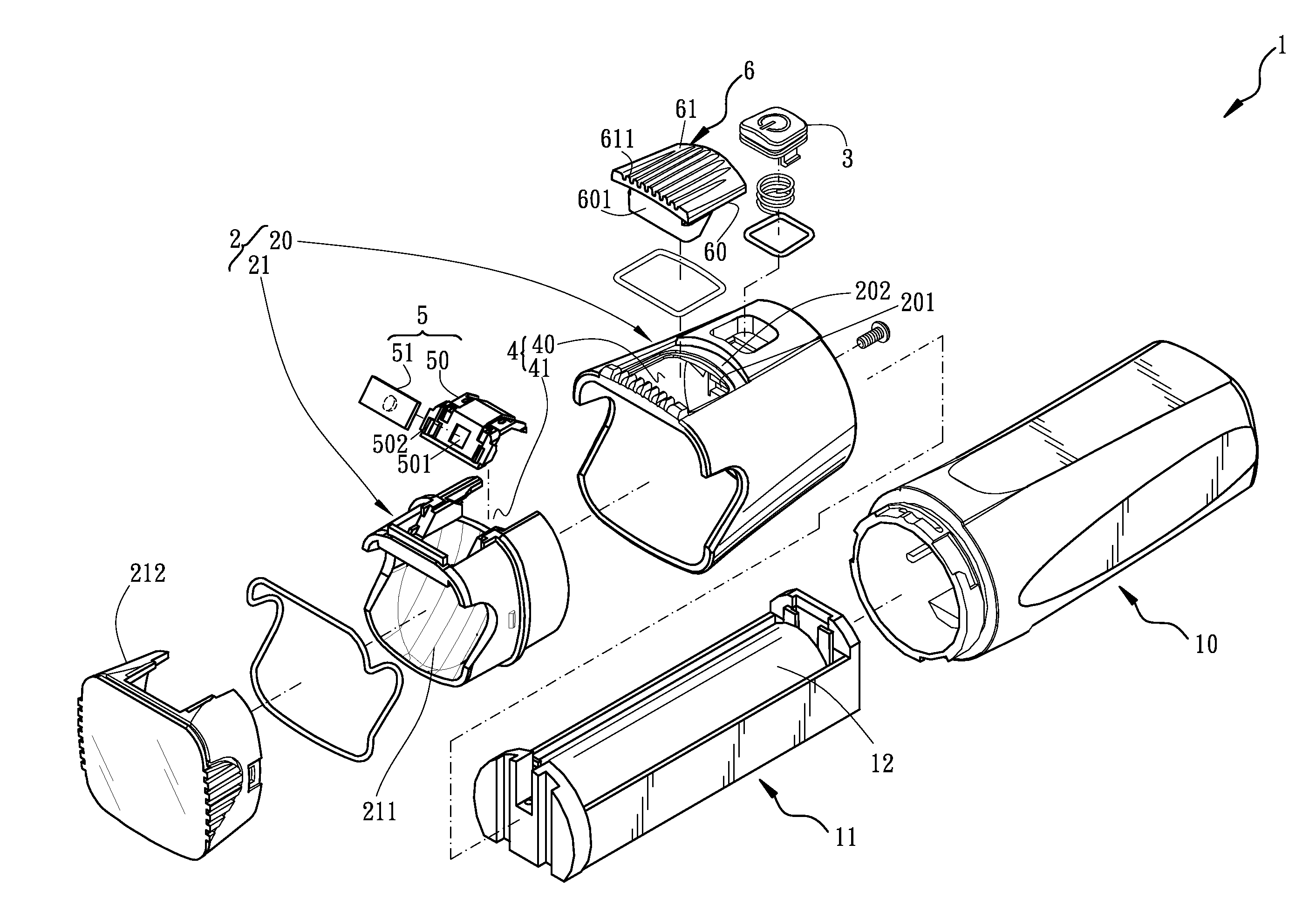

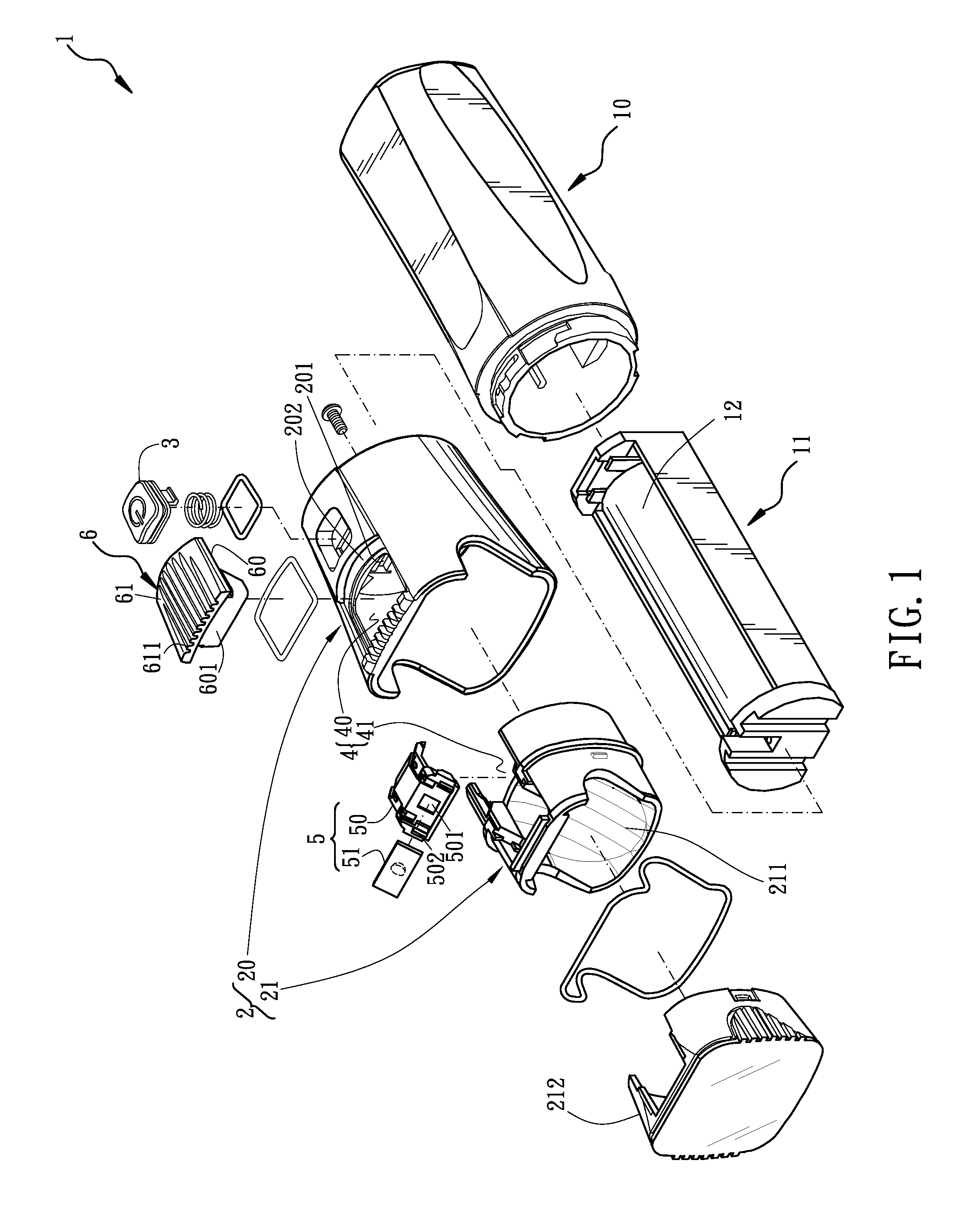

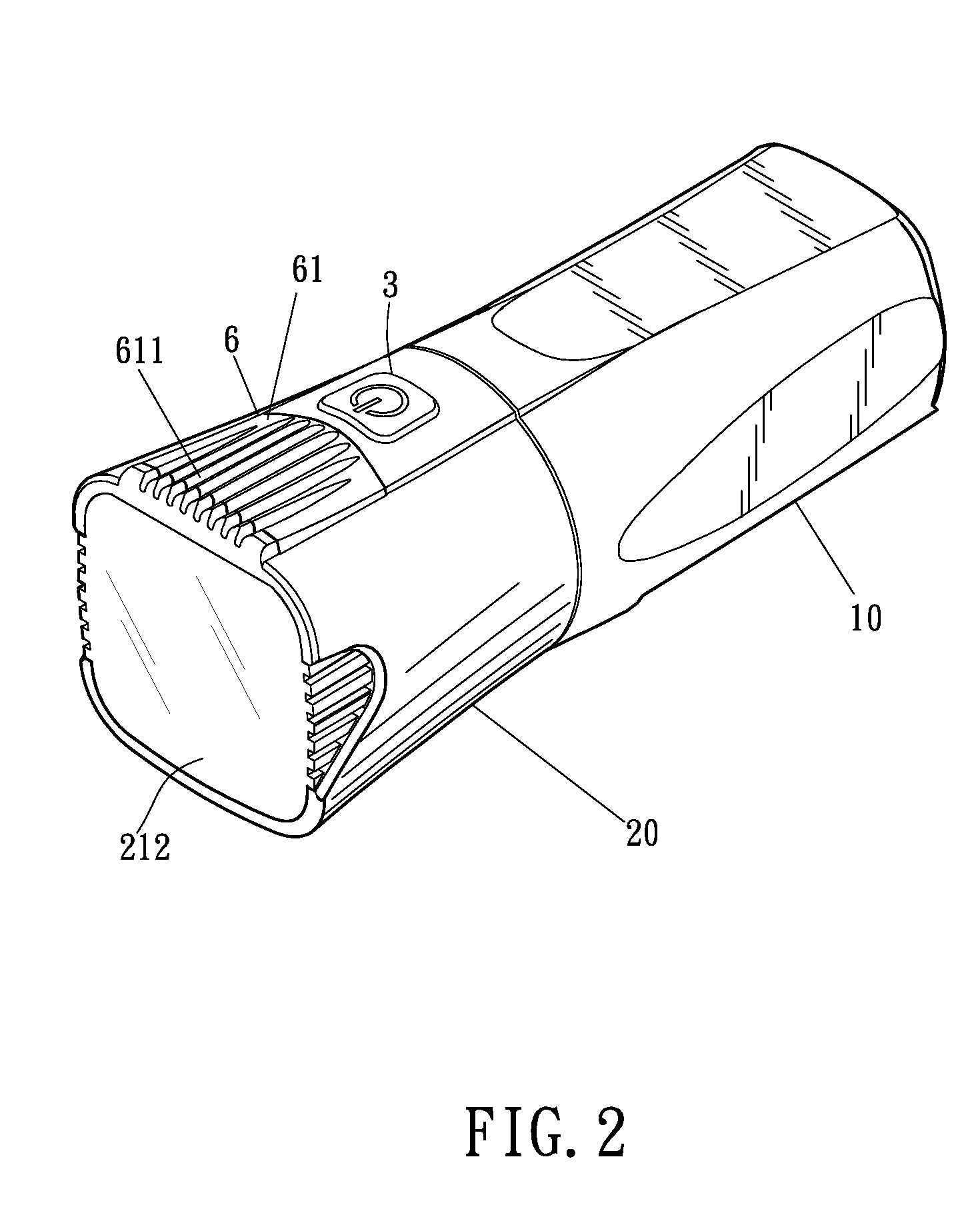

Flashlight assembly

InactiveUS20100238652A1Heat dissipating structurePoint-like light sourceLighting heating/cooling arrangementsFlashlightBiomedical engineering

A flashlight assembly includes a head portion having a receiving space, a light assembly received in the receiving space, and a radiator. The radiator is received in the receiving space and abuts against the light assembly. The radiator has an inner surface and an outer surface both defined therein. The inner surface has a protrusion extended therefrom. The protrusion abuts against the light assembly. Heat generated by the light assembly is conducted to the radiator via the protrusion and dissipated from the outer surface.

Owner:LIAO SU CHANG +1

Light emitting module

InactiveUS20160013166A1Increase cooling areaImprove cooling effectSolid-state devicesSemiconductor devicesLight emitting devicePhysics

A light emitting module including a light emitting device package structure and a heat dissipation structure is provided. The light emitting device package structure includes light emitting devices, a patterned reflective element and a patterned conductive layer. The patterned reflective element is disposed around side surfaces of the light emitting devices and exposes a first bottom surface of a first pad and a second bottom surface of a second pad. The patterned conductive layer is disposed on the first bottom surface of the first pad and the second bottom surface of the second pad. The light emitting devices are electrically connected to each other in a series connection, a parallel connection or a series-parallel connection through the patterned conductive layer. The heat dissipation structure is disposed below the light emitting device package structure and includes a heat dissipation unit and a patterned circuit layer disposed on the heat dissipation unit.

Owner:GENESIS PHOTONICS

Heat dissipation structure for electric circuit device

ActiveUS10615096B2Improve cooling effectMaintain performanceSemiconductor/solid-state device detailsSolid-state devicesCeramic sinteringHemt circuits

Provided is a heat dissipation structure for an electric circuit device excellent in mass-productivity and heat radiation performance. A heat dissipation structure for an electric circuit device, the structure including a layered structure comprising: a heatsink exposed on the electric circuit device; a thermal conductive member; and a cooler, wherein the thermal conductive member is a ceramic-resin composite in which a resin composition is impregnated in a ceramic sintered body, the ceramic sintered body comprising ceramic primary particles integrated into a three-dimensional structure, and wherein the thermal conductive member is arranged such that the thermal conductive member directly contacts with at least one of the heatsink and the cooler.

Owner:DENKA CO LTD

Heat dissipation structure for display panel, and manufacturing method and application thereof

InactiveUS20210360827A1Shorten the heat conduction pathImprove cooling effectModifications by conduction heat transferHeat conductingCopper foil

Provided are a heat dissipation structure for a display panel, and a manufacturing method and an application thereof. The heat dissipation structure includes a copper foil layer and a heat conducting layer disposed on the copper foil layer; wherein a material of the heat conducting layer includes a heat conducting material having a three-dimensional structure, and a gap in the three-dimensional structure of the heat conducting material is filled with a buffer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Solid-filled encapsulated LED bulb

InactiveUS20160363271A1Improve light uniformityReduce the numberPoint-like light sourceElectric circuit arrangementsLight guideEngineering

A solid-filled encapsulated LED bulb with a base, at least one LED light source and at least one power supply element includes a transparent solid-filled heat-dissipating light guide member attached and covered onto the LED light source and the power supply element. A side of the heat-dissipating light guide member is packaged with the base to form the LED bulb. The heat of the LED light source is conducted and dissipated to the outside through the heat-dissipating light guide member. A light of the LED light source is outputted with an intensity IA through the heat-dissipating light guide member. The intensity IA of the light and the intensity IB of the LED light source satisfy the condition of (IA / IB)>70%. The use of a conventional dissipating structure is skipped to reduce the production cost and expedite the assembling and packaging processes while maintaining excellent heat dissipation and light output effects.

Owner:UNITY OPTO TECH CO LTD

Semiconductor package with heat dissipating structure

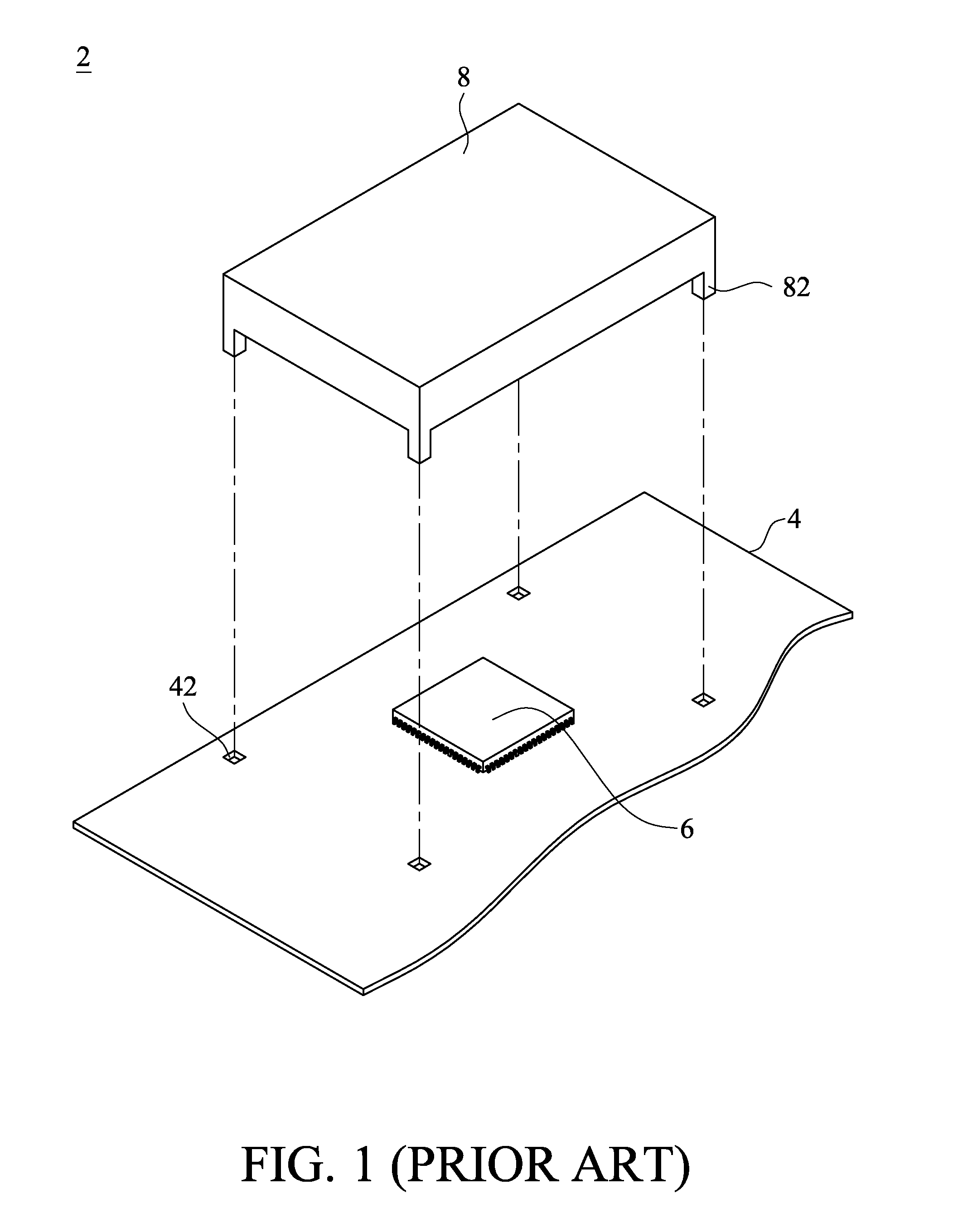

InactiveUSRE42653E1Increase flexibilitySmall surface areaSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

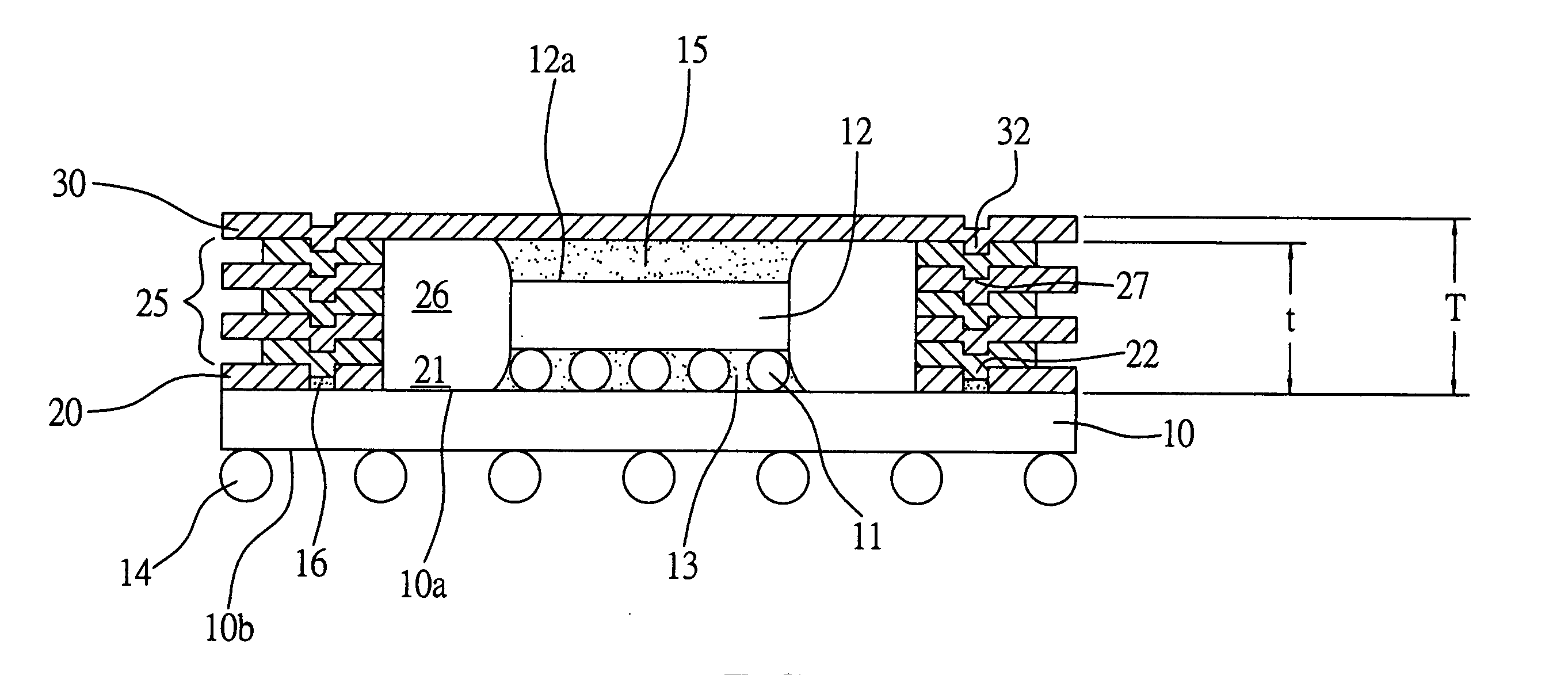

A semiconductor package with a heat dissipating structure is provided. The heat dissipating structure includes a flat portion, and a plurality of support portions formed at edge corners of the flat portion for supporting the flat portion above a chip mounted on a substrate. The support portions are mounted at predetermined area on the substrate without interfering with arrangement of the chip and bonding wires that electrically connect the chip to the substrate. The support portions are arranged to form a space embraced by adjacent supports and the flat portion, so as to allow the bonding wires to pass through the space to reach area on the substrate outside coverage of the heat dissipating structure; besides, passive components or other electronic components can be mounted on the substrate at area within or outside the coverage of the heat dissipating structure, thereby improving flexibility in component arrangement in the semiconductor package.

Owner:SILICONWARE PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com