Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Guaranteed deburring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

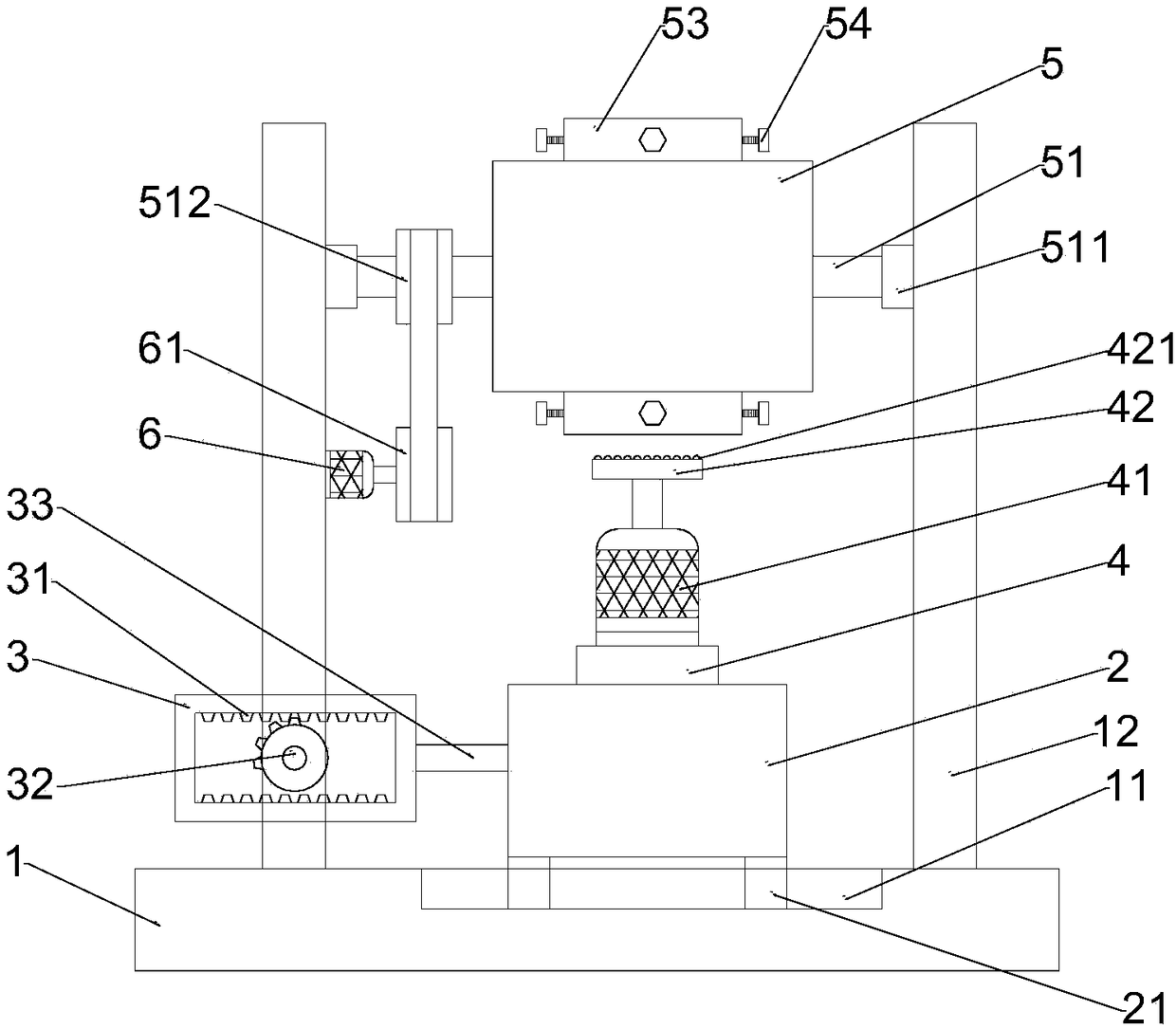

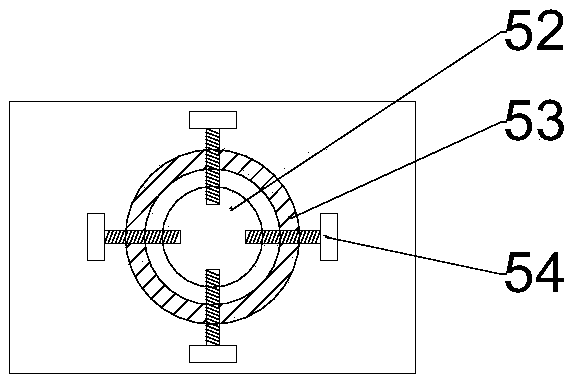

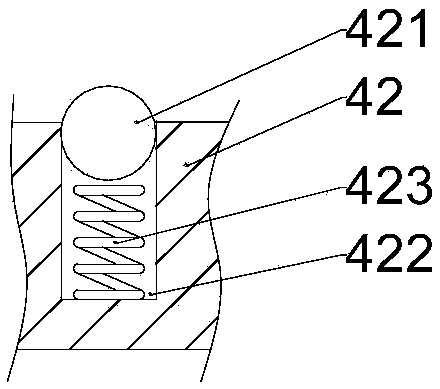

Deburring apparatus for columnar plastic products

ActiveCN108115506AAchieve back and forth grindingGuaranteed continuityEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention discloses a deburring apparatus for columnar plastic products, comprising a base, a moving block, a polishing disc and a workpiece holding table; pillars are symmetrically fixed on two sides of the top of the base; the moving block is movably disposed on the base; a lifting device is mounted at the top center of the moving block, the moving end of the lifting device is fitted with arotary motor, an output shaft of the rotary motor is connected with the polishing disc, and floating polishing balls are densely arranged on the polishing disc; the workpiece holding table is disposedabove the moving block and is fitted with a turnover motor; the workpiece holding table is provided with a workpiece through hole, each end face of the workpiece holding table is provided with a fixing ring outside the workpiece through hole, and a plurality of lock bolts are additionally provided and are in threaded fit connection with the fixing rings. The deburring apparatus for columnar plastic products can provide efficient deburring for end faces of columnar workpieces, has good deburring effect, is simple to operate and is worthy of popularization and use.

Owner:重庆天骄塑料包装有限责任公司

Deburring device applied to automobile exhaust pipes

The invention discloses a deburring device applied to automobile exhaust pipes. The deburring device comprises an installation frame, a motor, an output shaft, a driving gear, an inner gear, a rotary gear and a shaping cutter, wherein the motor is arranged on the installation frame, the output shaft is connected with the motor, the driving gear is arranged on the output shaft, the inner gear is fixed to the installation frame and shares the same axis with the driving gear, the rotary gear is meshed with outer teeth of the driving gear and inner teeth of the inner gear, and the shaping cutter is coaxially connected with the rotary gear, can shape pipe openings of the exhaust pipes and can perform deburring on outer walls and inner walls of the exhaust pipes at the same time. The deburring device disclosed by the invention can shape the pipe openings of the exhaust pipes and perform deburring on the outer walls and the inner walls of the exhaust pipes at the same time, so that the pipe openings are round and neat, used time is small, and deburring efficiency is high.

Owner:浙江新诚汽车部件有限公司

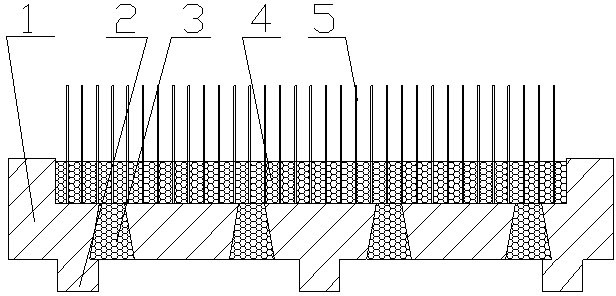

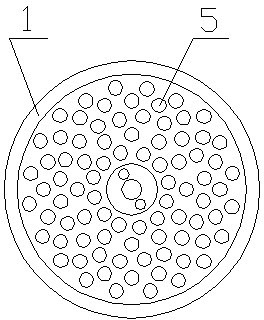

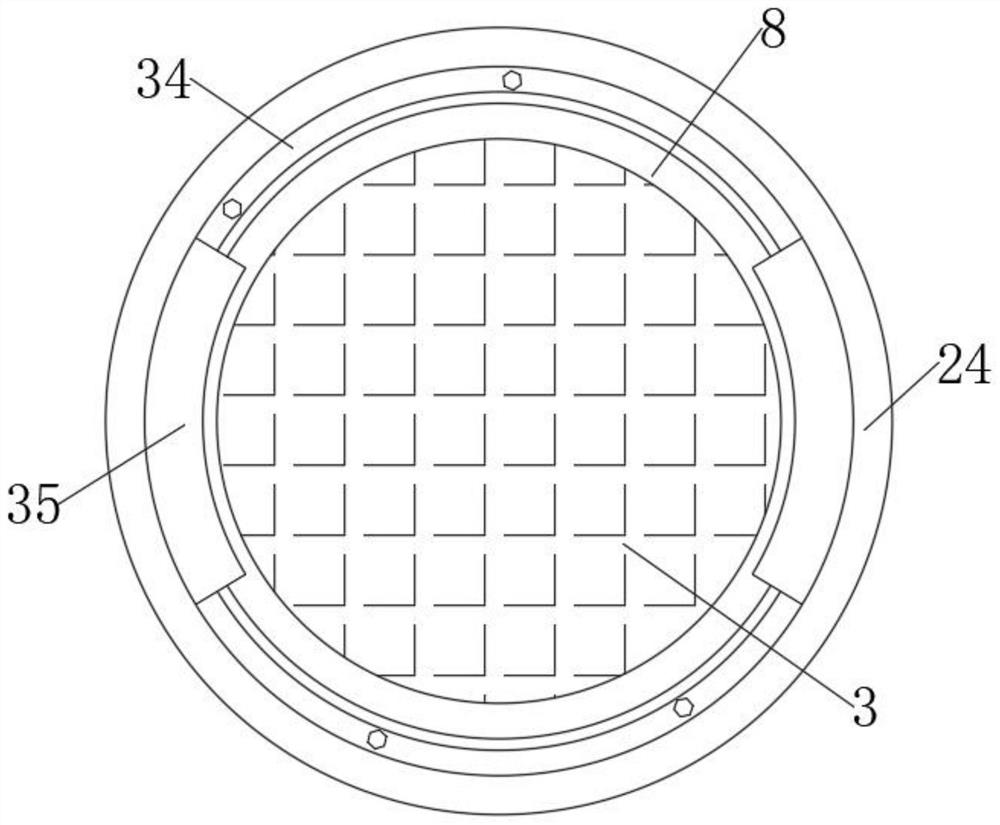

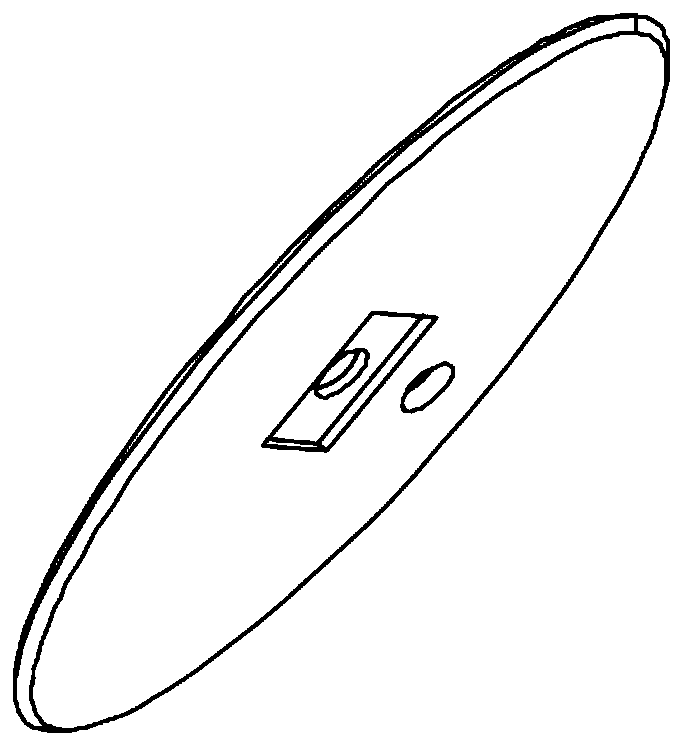

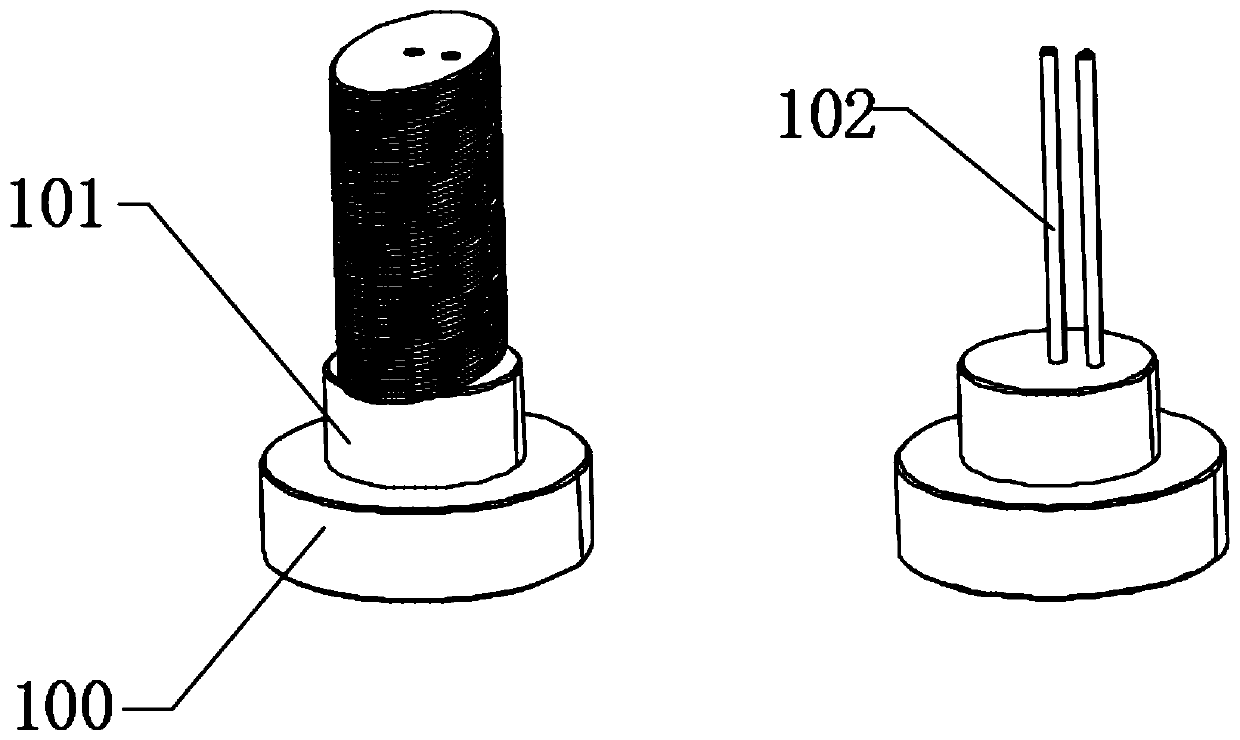

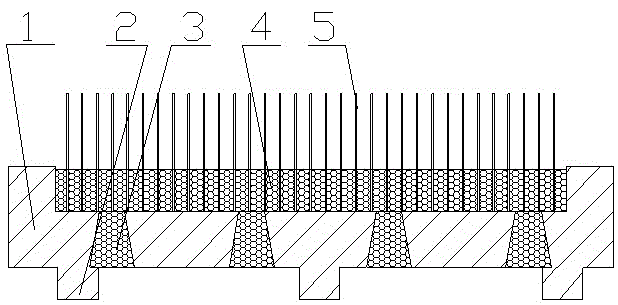

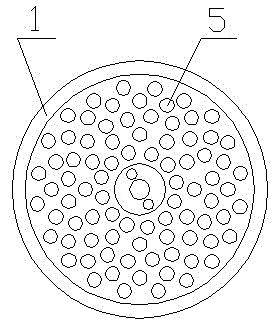

Special polishing plate for deburring machine and manufacturing method thereof

ActiveCN102350668AImprove straightnessWon't fallBonded abrasive wheelsGrinding devicesEngineeringSupport point

The invention relates to a special polishing plate for a deburring machine and a manufacturing method thereof, and the special polishing plate is used for ensuring the consistent evenness of the end face of a polishing head in the special polishing plate for the deburring machine while realizing the quick planting for a grinding material head. The polishing plate comprises a polishing plate shell and a grinding material head, wherein the polishing plate shell is of a circular groove structure; a plurality of conical pillar holes are formed at the bottom of a circular groove; and the grinding material head is located in the circular groove and solidified resins are arranged in the circular groove and the conical pillar holes. The special polishing plate for the deburring machine has the following advantages: 1) the evenness and height of the end face of a planted grinding material head are kept consistent, and the deburring effect is ensured; 2) the planted straight degree is high, and a planting hole for planting a mold core is fixed at the root of the grinding material head and the upper part of the root of the grinding material head is fixed by resins, so that a non-polishing part in the groove of the polishing plate shell has a resin supporting point, the straight degree of a grinding material in the grinding material head is high, the grinding material never falls off and the service life is long; and 3) the planting efficiency is high, the cost is low and the quality is high.

Owner:HANGZHOU XIANGSHENG ABRASIVE MACHINE MFG

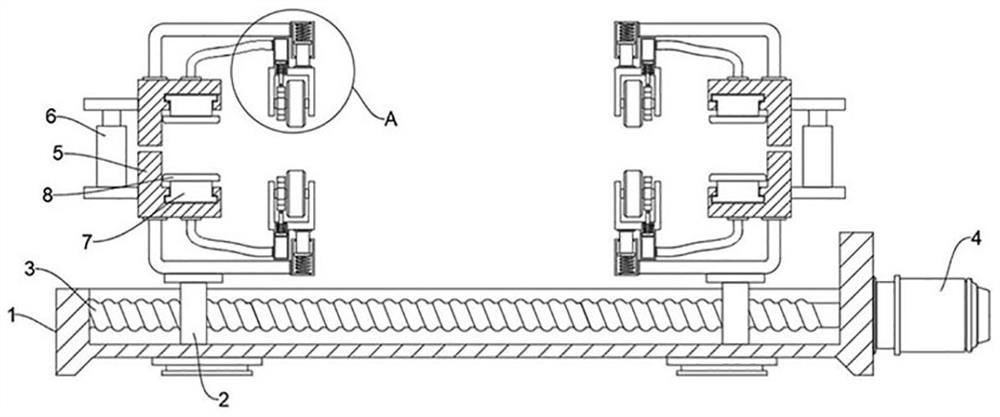

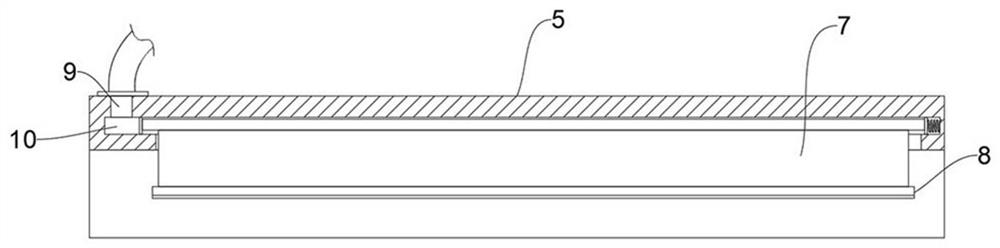

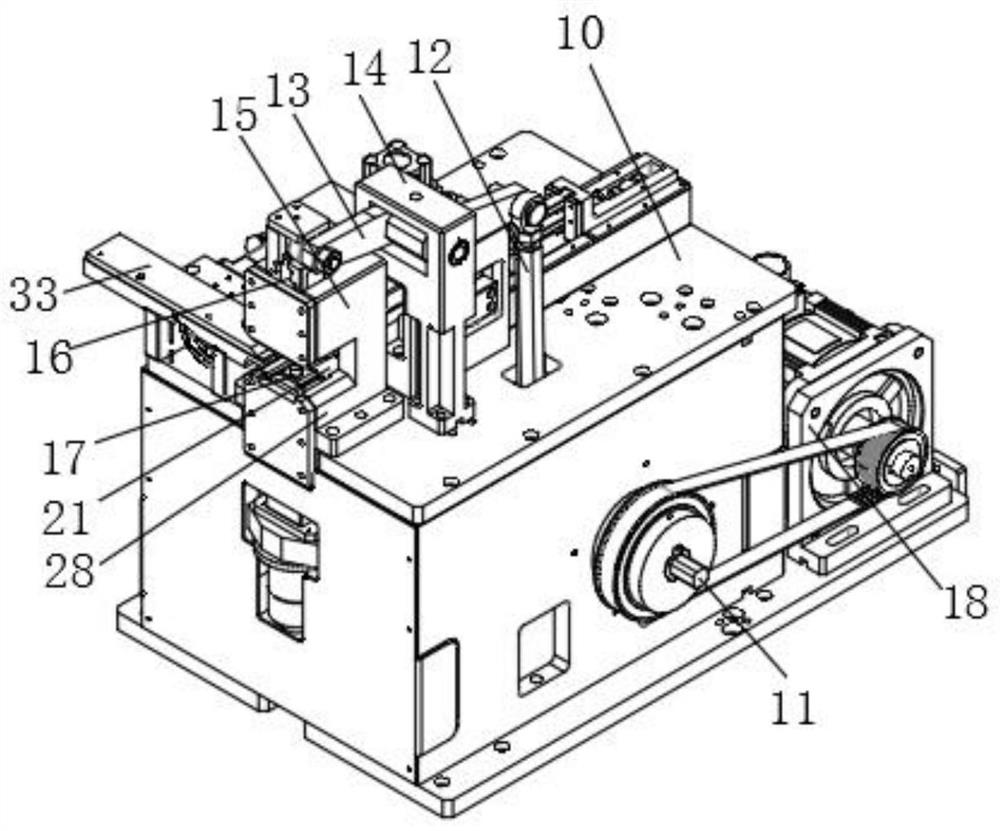

Double-side deburring device

ActiveCN111300199AExtend sanding timeImprove stabilityEdge grinding machinesGrinding drivesStructural engineeringGrinding process

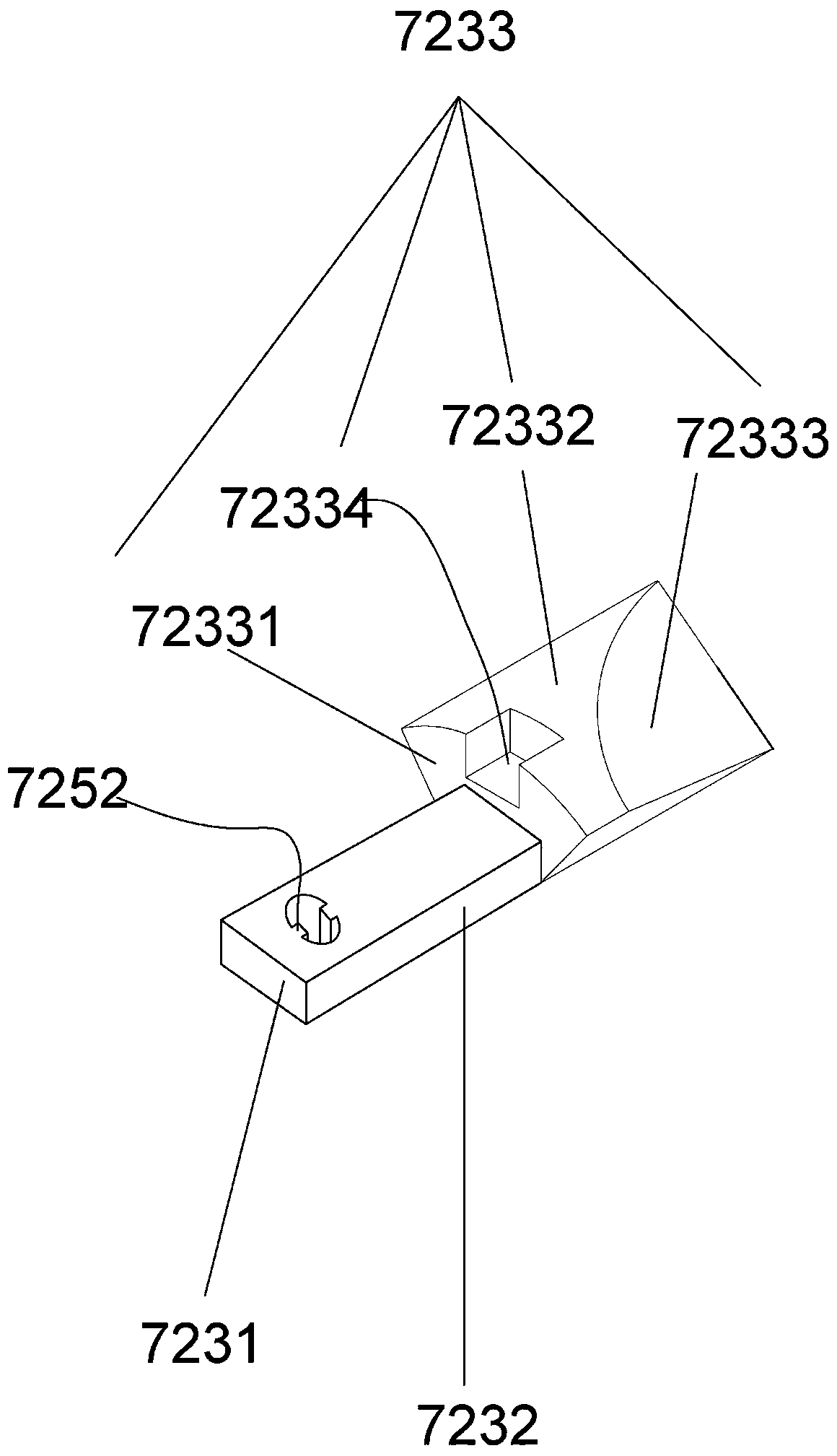

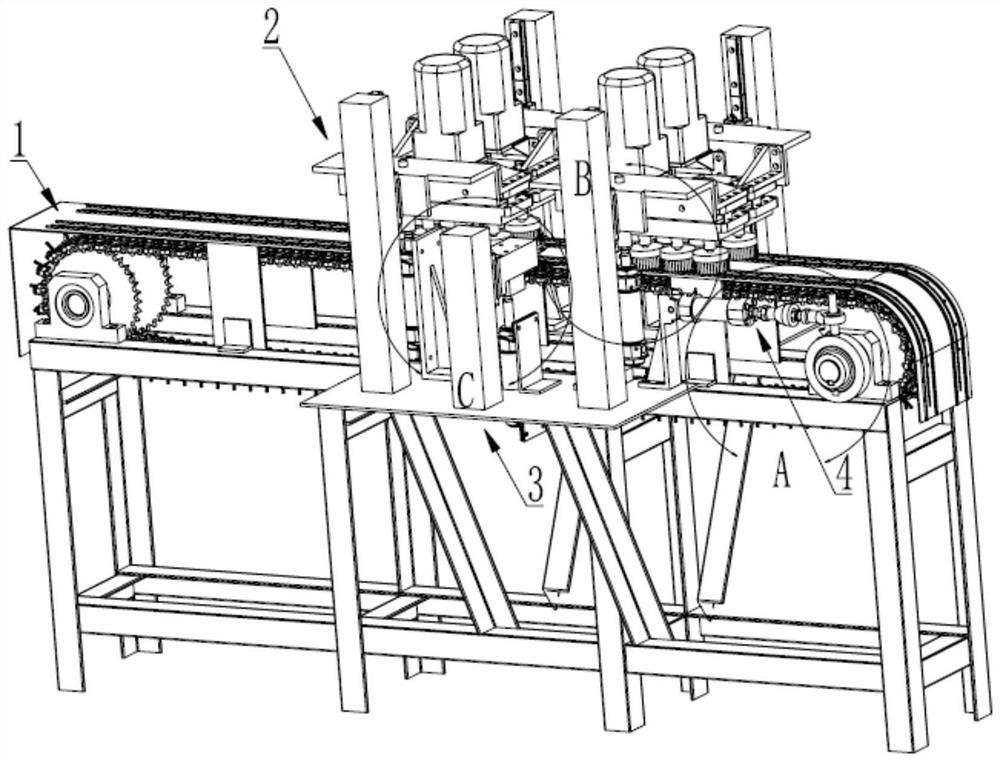

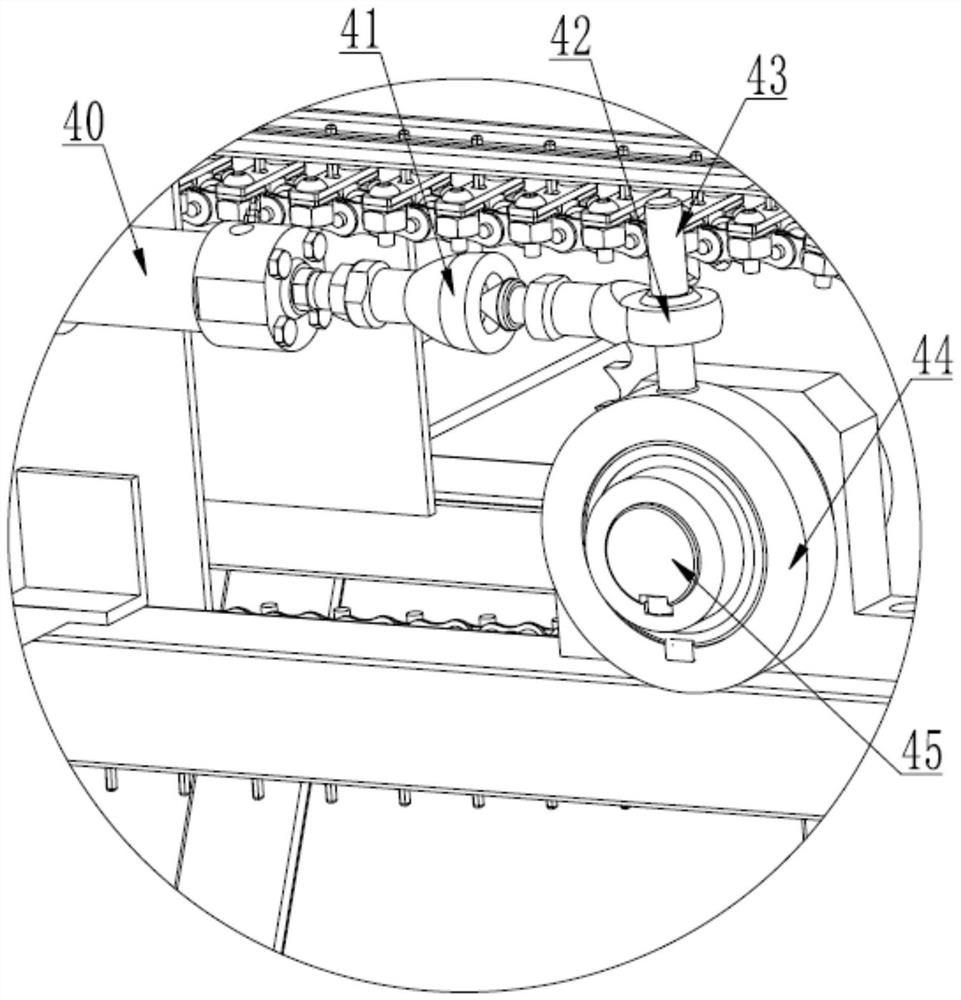

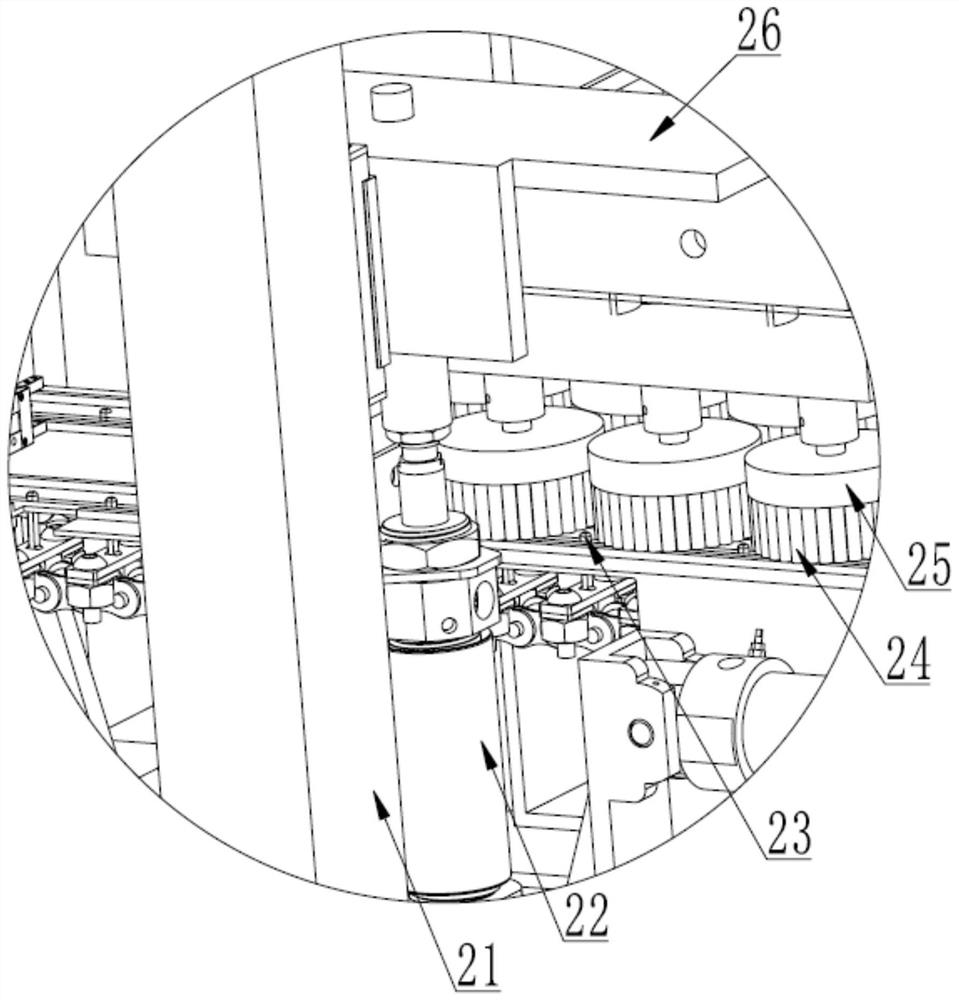

The invention discloses a double-side deburring device. The double-side deburring device comprises a controller, a conveying mechanism, at least four deburring mechanisms and two turnover mechanisms.The controller is connected with the conveying mechanism, the deburring mechanisms and the turnover mechanisms. The conveying mechanism comprises a one-way intermittent driving mechanism and a plurality of fixing pins arranged linearly and driven through the one-way intermittent driving mechanism. The four deburring mechanisms are divided into two sets and are oppositely arranged on the left and right sides above the fixing pins arranged linearly. The two turnover mechanisms are arranged between the deburring mechanisms located on the same sides of the fixing pins arranged linearly. The double-side deburring device can drive workpieces intermittently through the intermittent driving mechanism so as to prolong the grinding time of the workpieces in one working position. Moreover, in the grinding process, the driving mechanism can also improve the stability of the workpieces to prevent the workpieces from deviating from the grinding position, and accordingly the grinding and deburring effects are ensured.

Owner:LISHUI UNIV

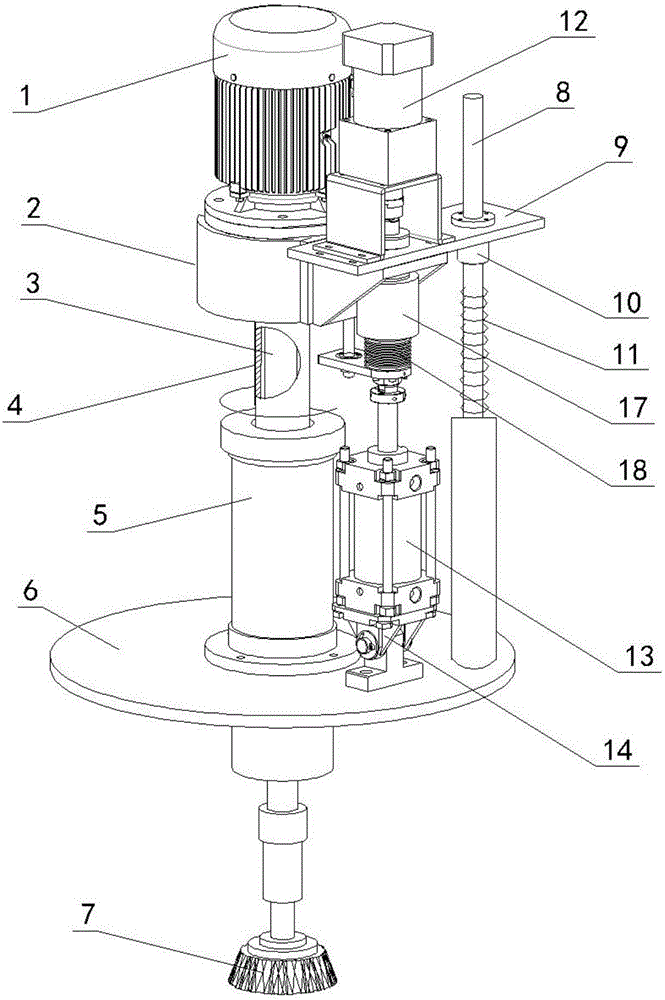

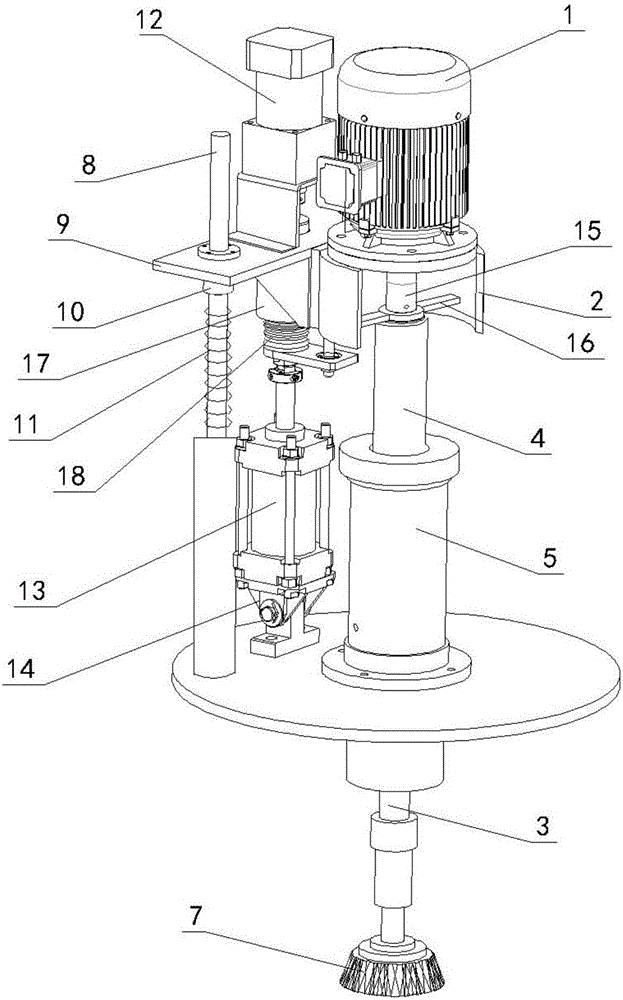

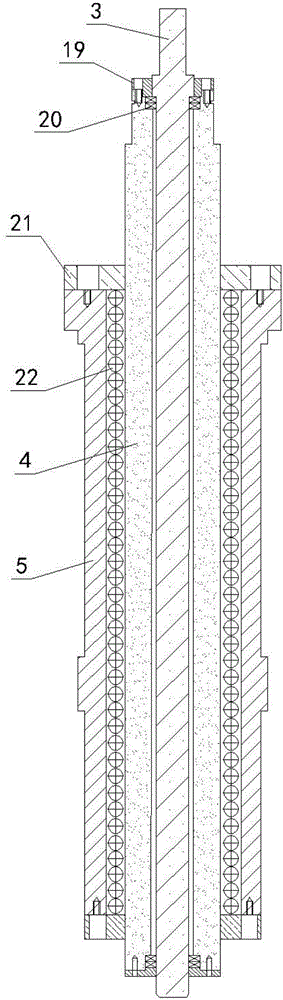

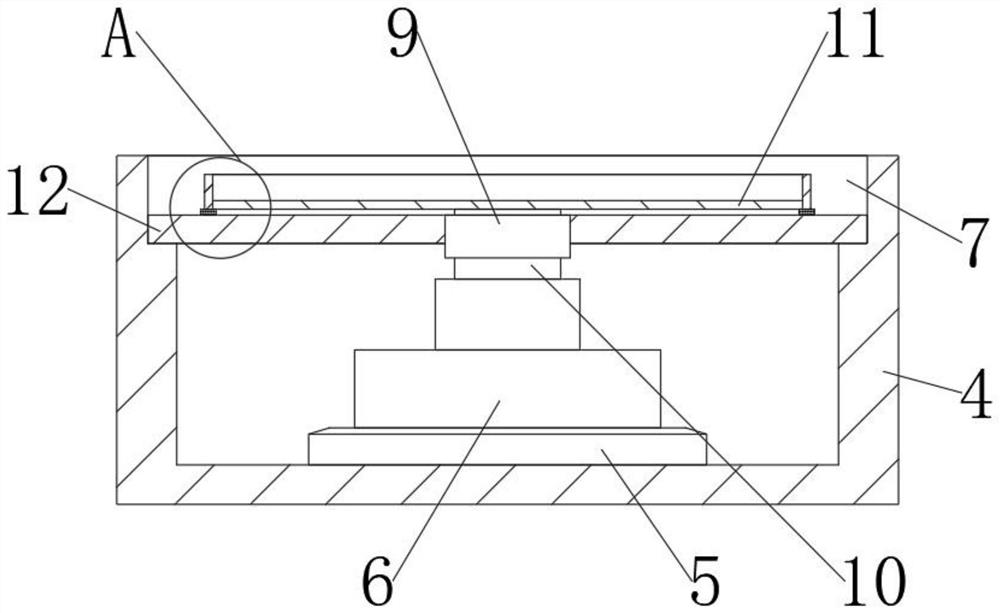

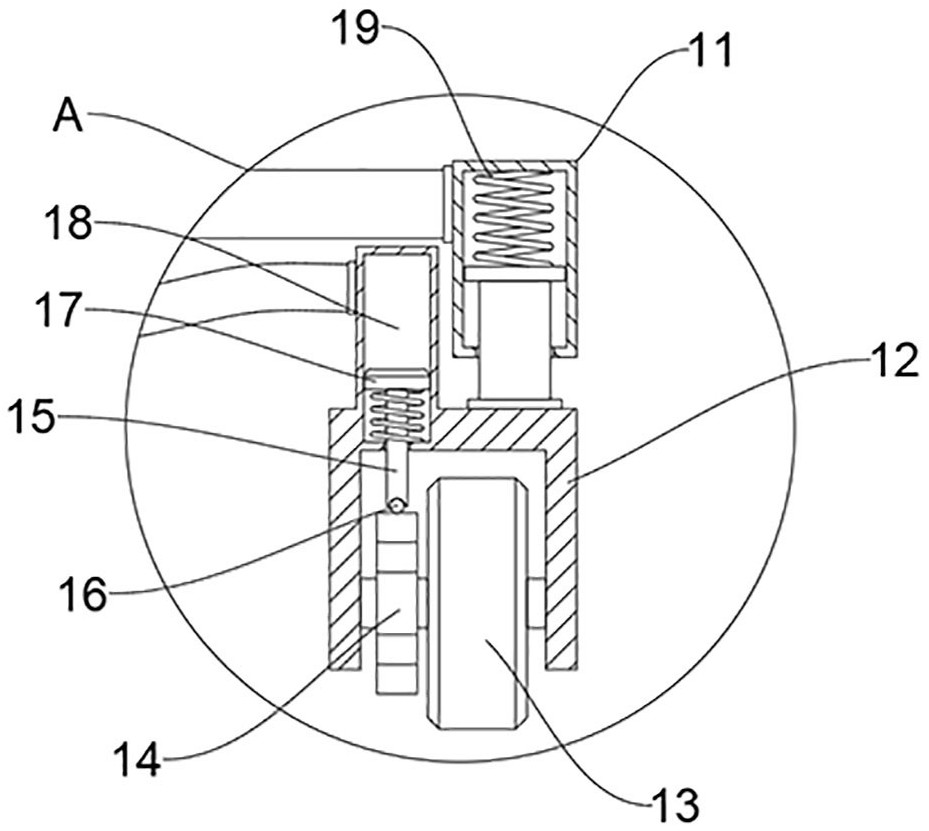

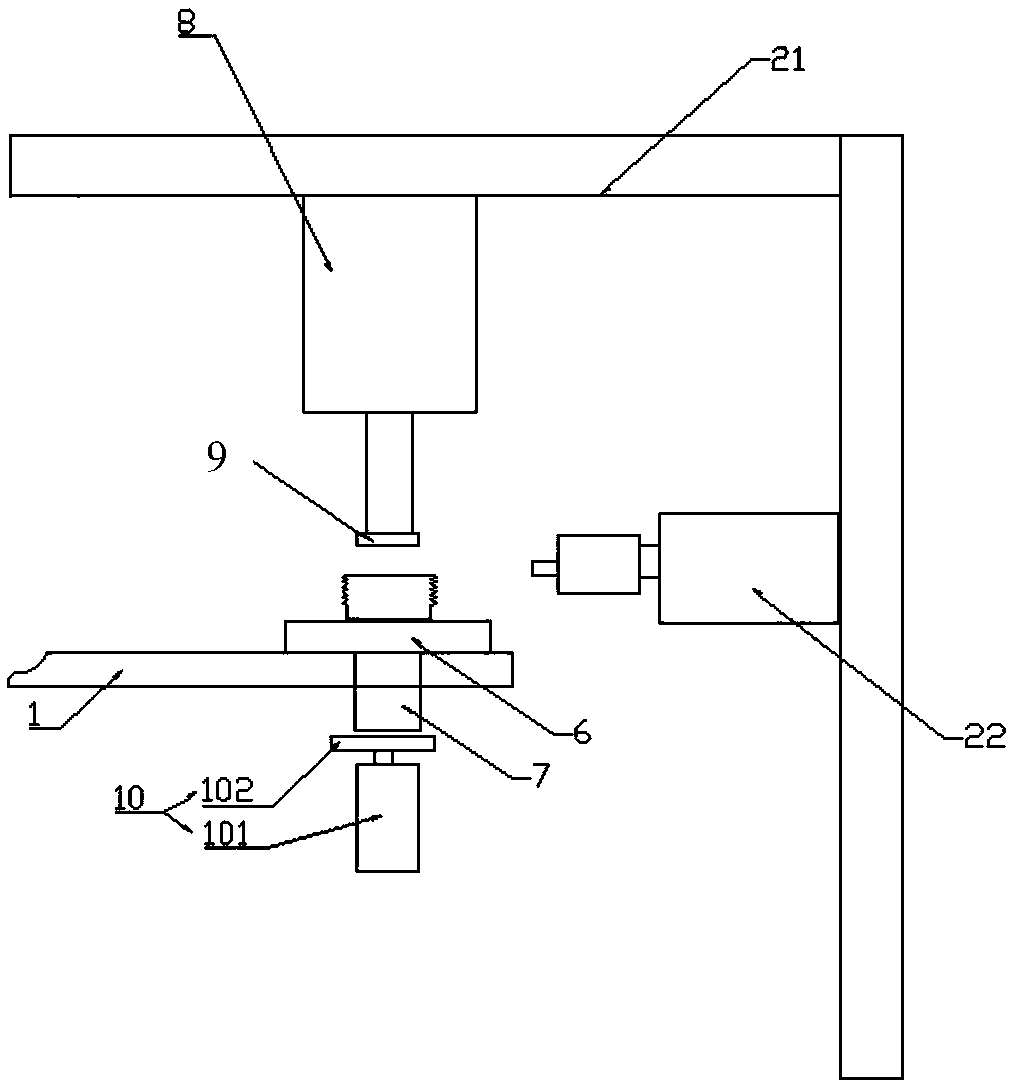

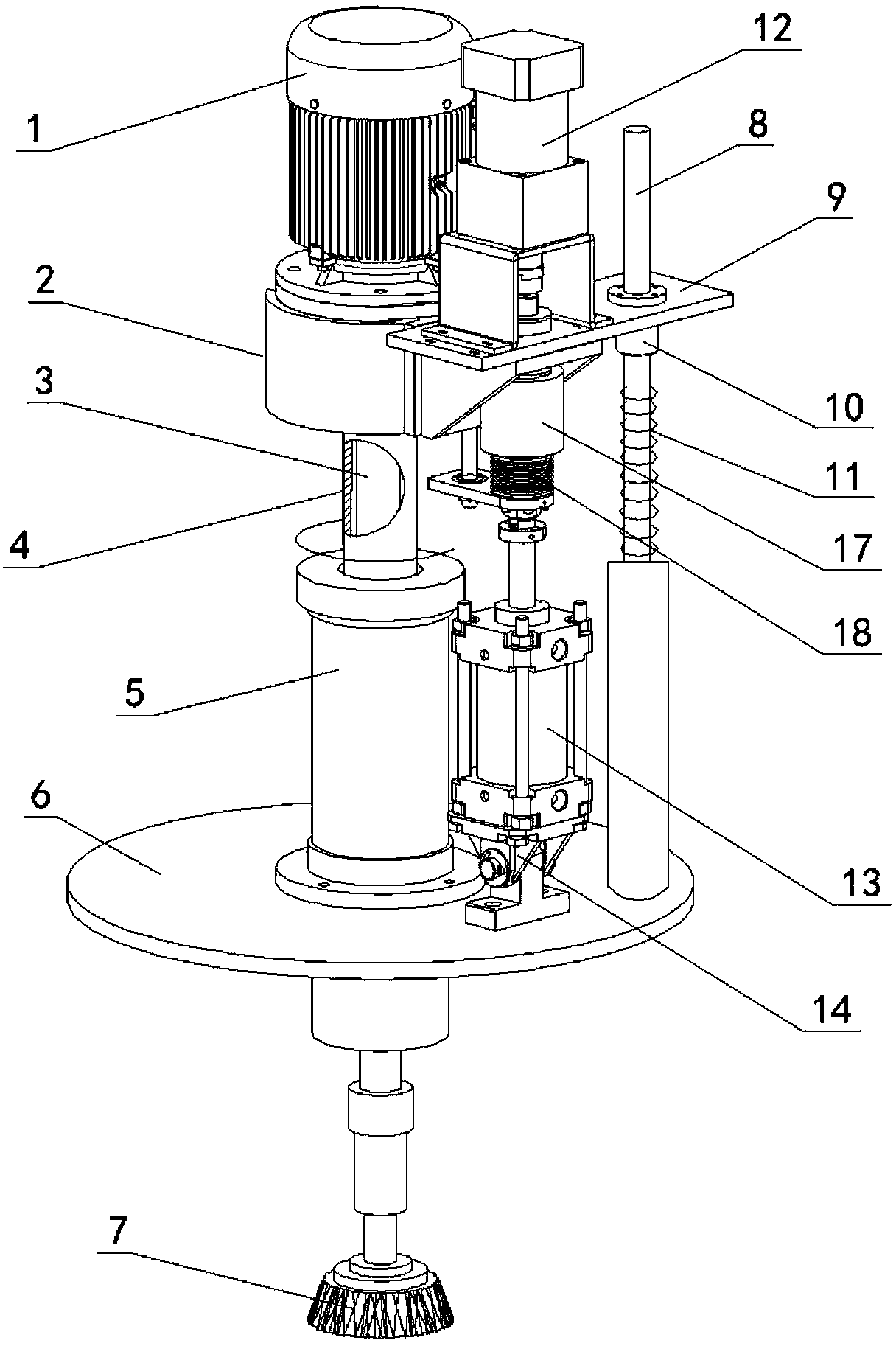

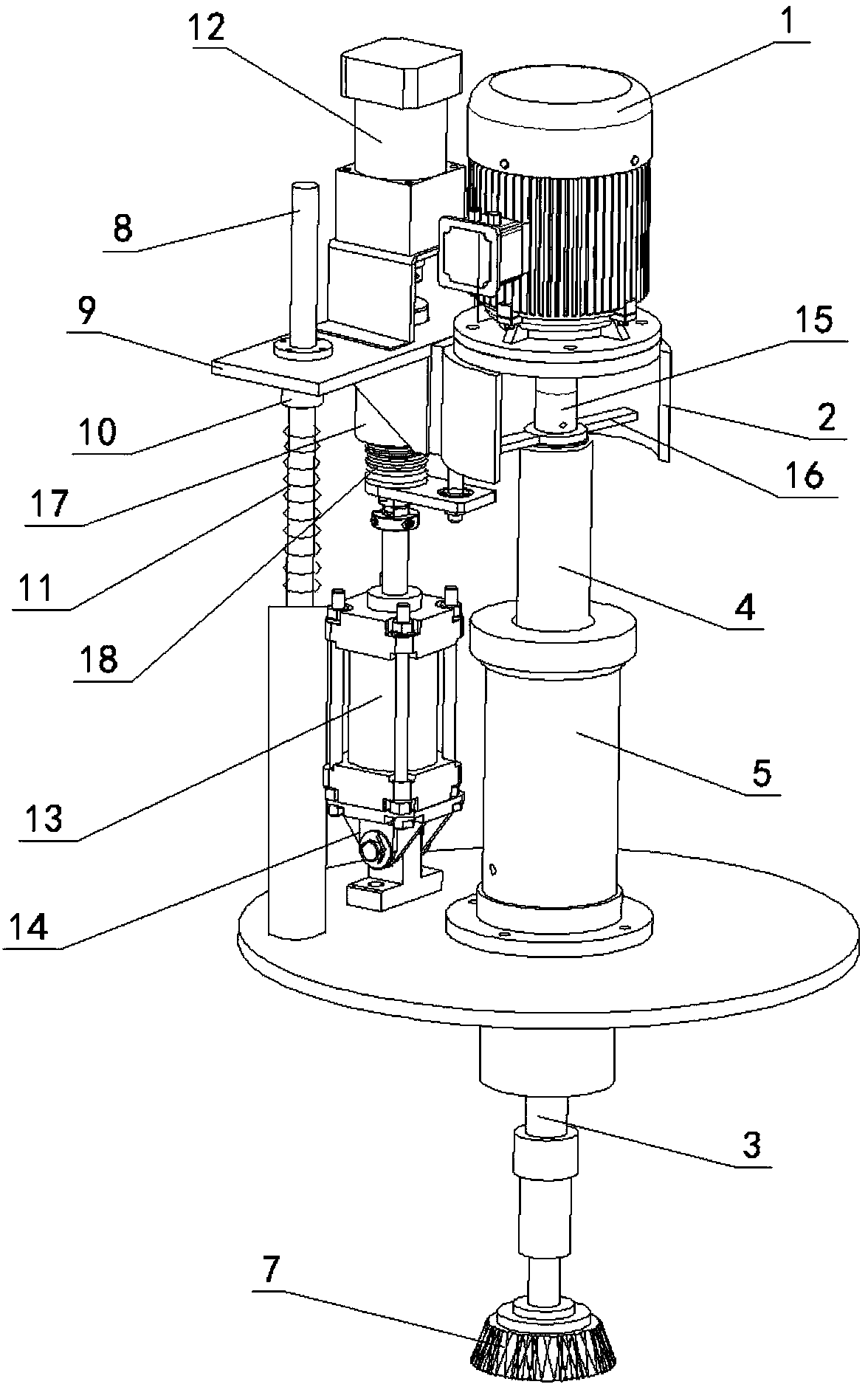

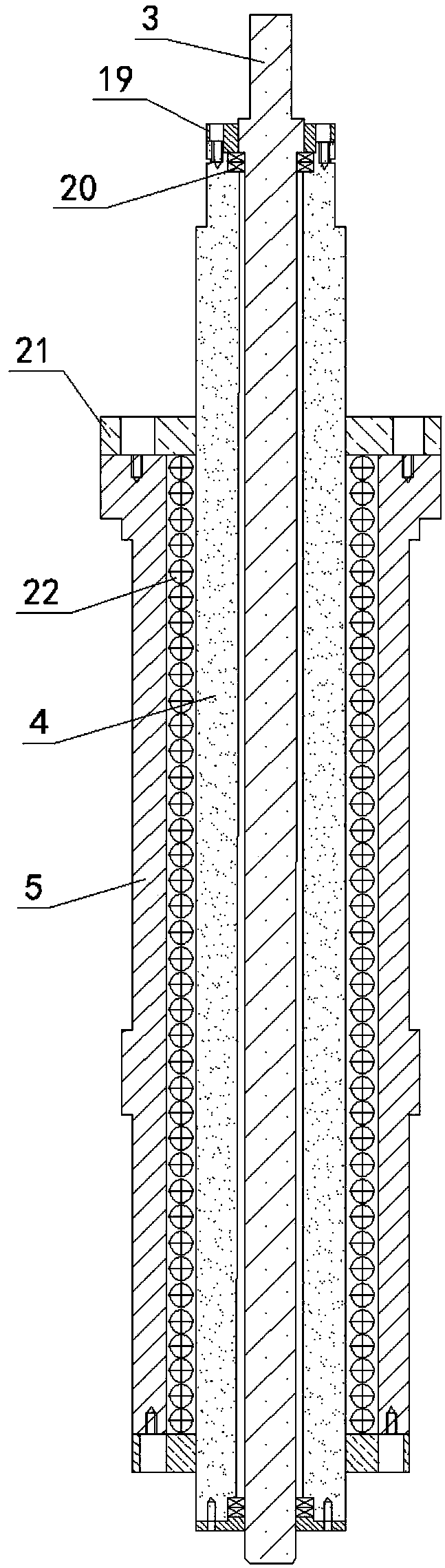

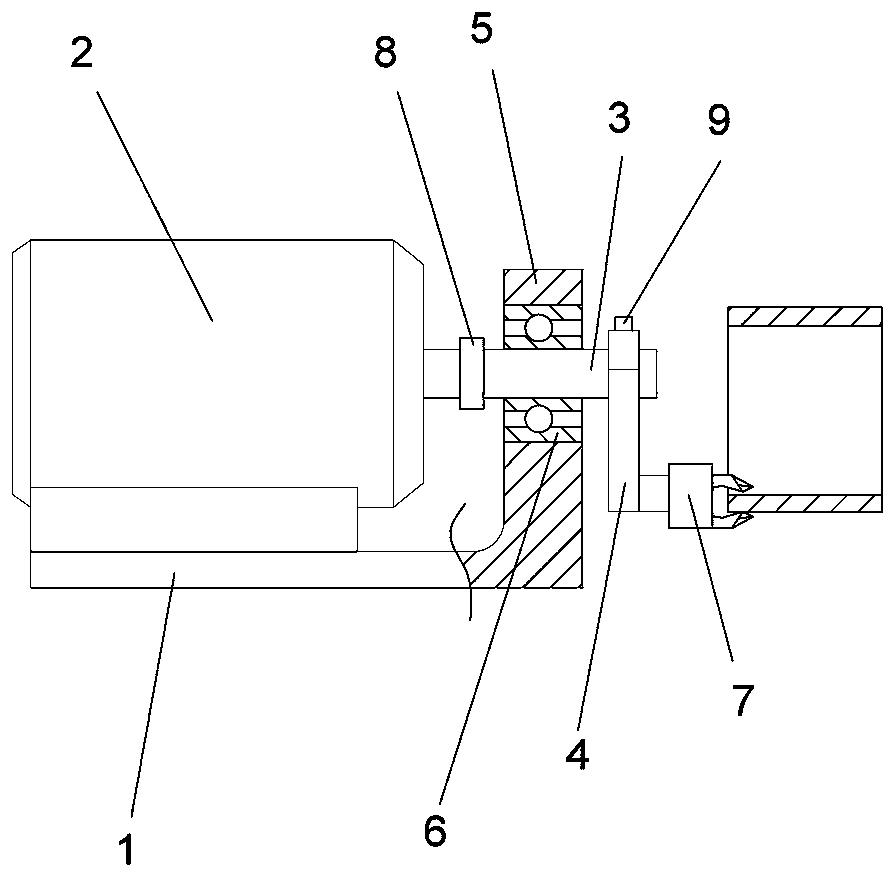

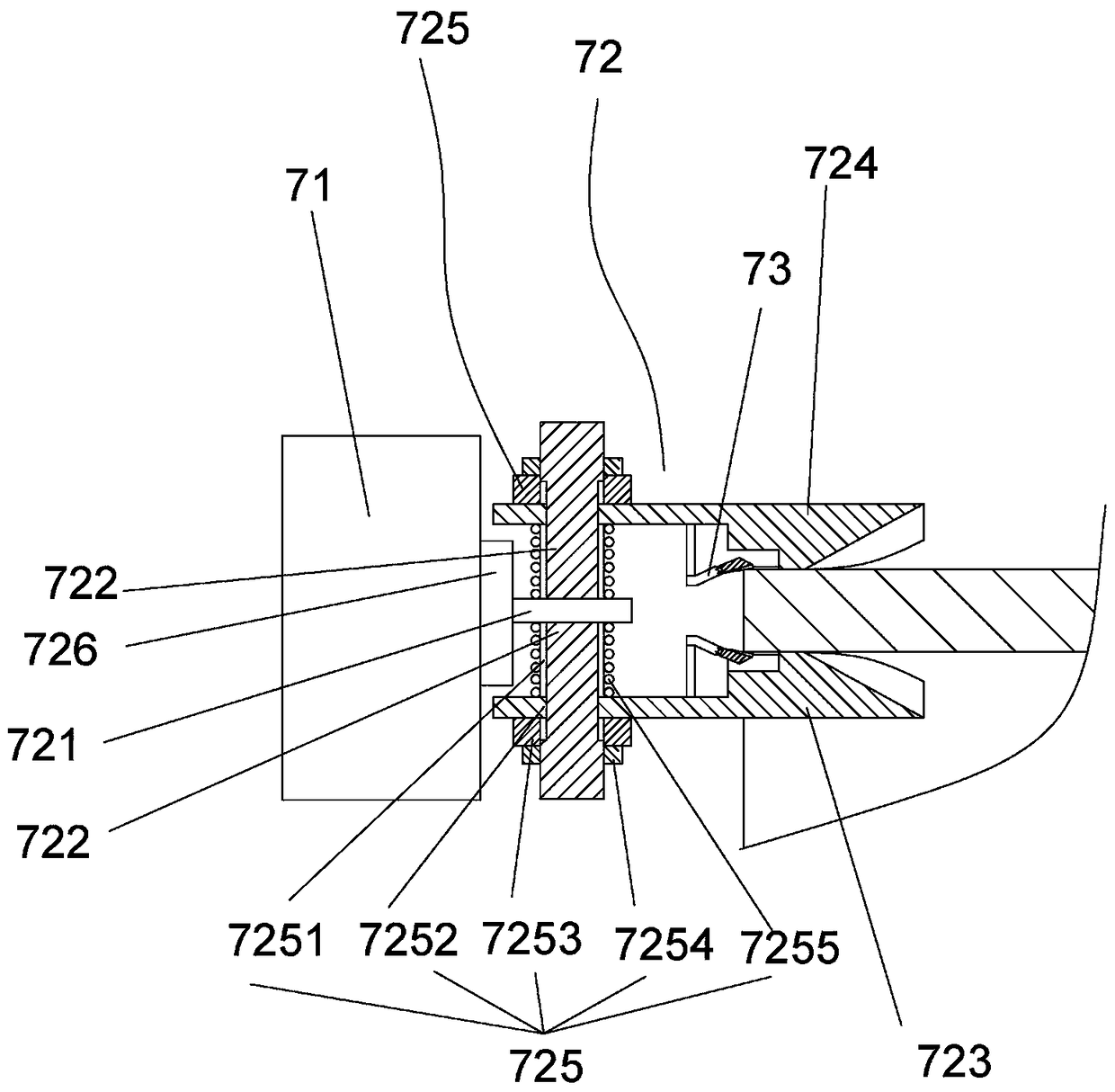

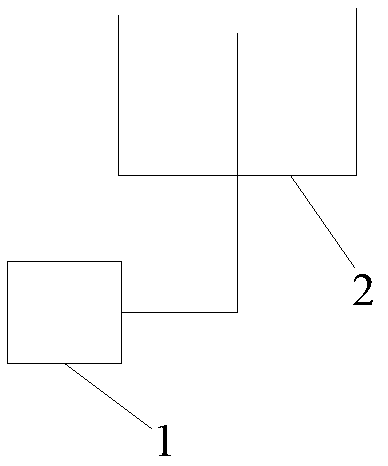

Automatic deburring device capable of realizing accurate compensation

ActiveCN106625093ARealize automatic deburring functionGuaranteed deburring effectEdge grinding machinesGrinding drivesMechanical engineeringPiston rod

The invention discloses an automatic deburring device capable of realizing accurate compensation. The automatic deburring device is characterized in that an output shaft of a motor is vertically downward, a rotary shaft fixedly connected with the output shaft of the motor penetrates through a fixed guide seat, a brush rotating with the rotary shaft is installed at the bottom shaft end of the rotary shaft, and the fixed guide seat is installed on a horizontal base plate; a hollow guide shaft fixedly connected with a motor installation seat is arranged between the rotary shaft and the fixed guide seat, the rotary shaft is capable of rotating in the hollow guide shaft, and the hollow guide shaft is capable of moving up and down along the fixed guide seat; and a lifting guide seat is arranged on the motor installation seat in a manner of horizontally overhanging, a compensation motor is installed on the lifting guide seat, a lifting cylinder is installed on the base plate, thread fit is formed between an output shaft of the compensation motor and a piston rod of the lifting cylinder, and the wear amount of the brush is compensated through the driving of the compensation motor. The automatic deburring device disclosed by the invention is used for carrying out deburring treatment on the surface of a workpiece, and capable of realizing accurate compensation and prolonging the service life of the brush.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

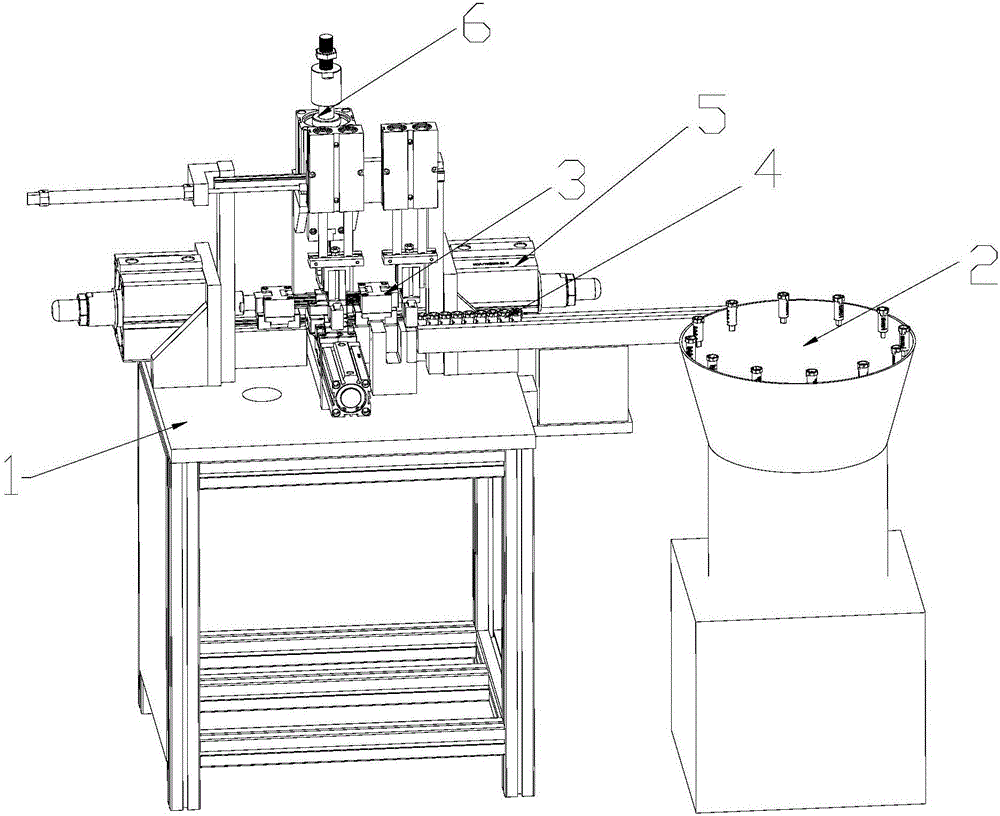

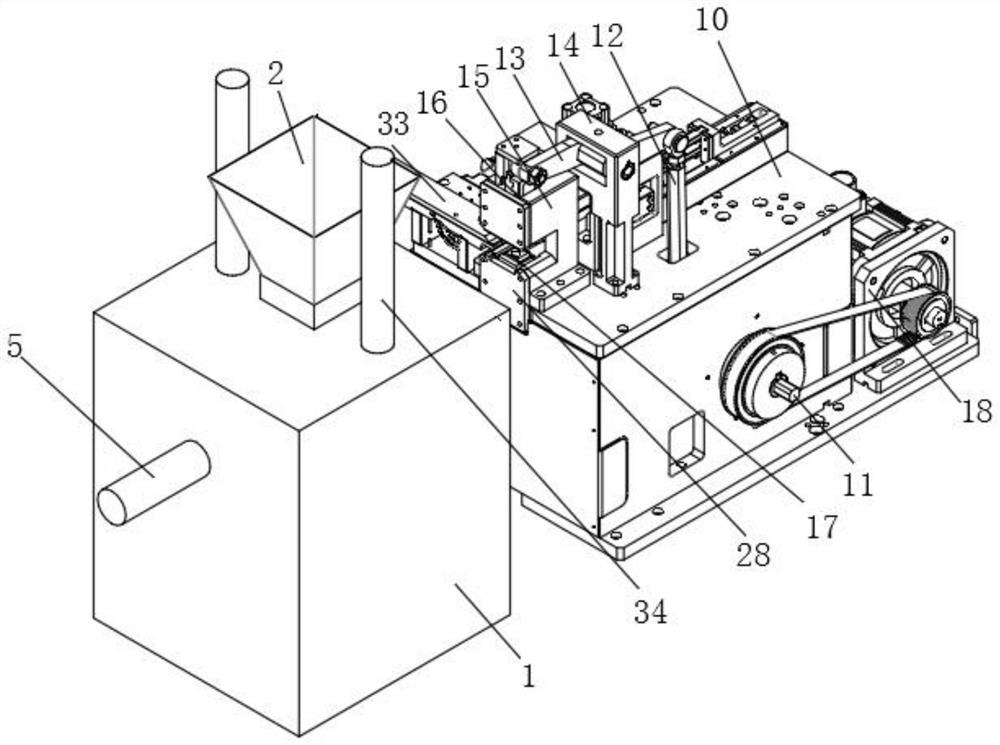

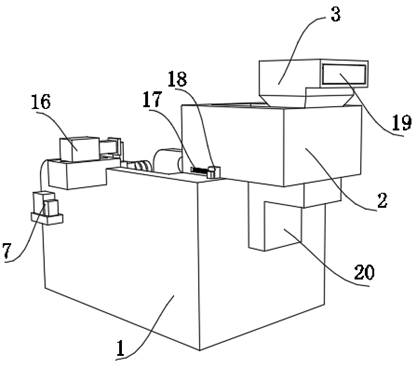

Full-automatic lock cylinder deburring tool

InactiveCN106425661AEasy to handleHigh degree of automationMetal working apparatusEngineeringAutomation

The invention relates to a deburring tool, in particular to a full-automatic lock cylinder deburring tool, which comprises a rack. A vibrating disk is arranged beside the rack; a deburring mechanism and a conveying mechanism are arranged on the rack; and the vibrating disk conveys a lock cylinder into the deburring mechanism for deburring through the conveying mechanism. The invention provides the full-automatic lock cylinder deburring tool which is reasonable in design, convenient to use and high in automation degree; by utilizing the device, the production efficiency can be improved, and a deburring effect is ensured; and the lock cylinder processed by the device cannot damage a lock, so that the service life of the lock is greatly prolonged.

Owner:浙江正东机车部件有限公司

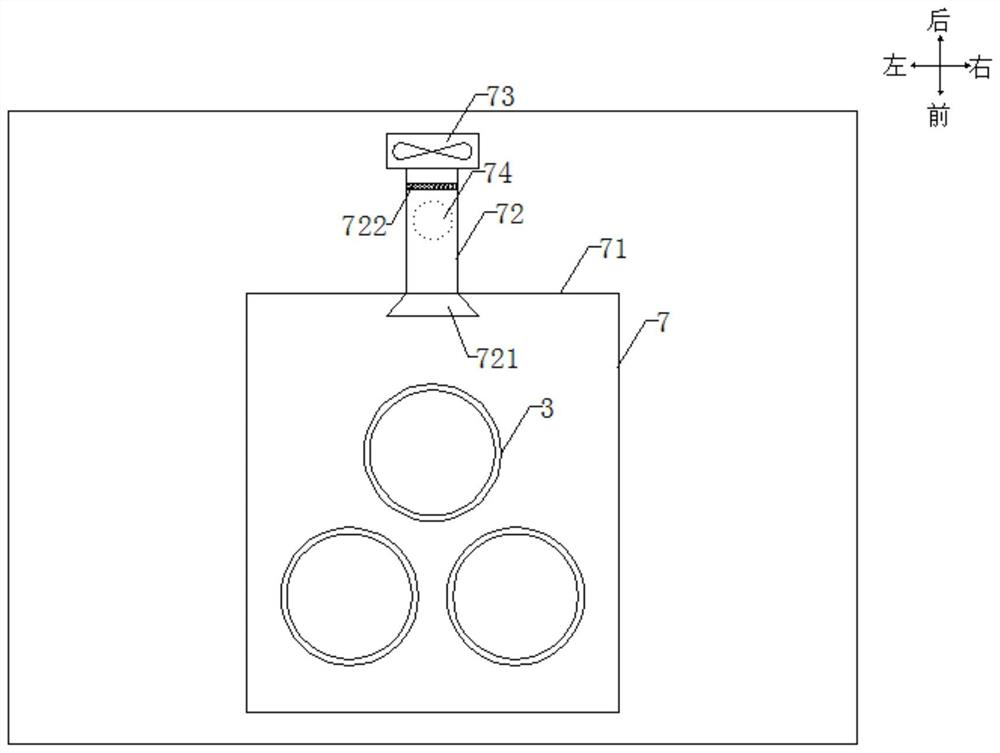

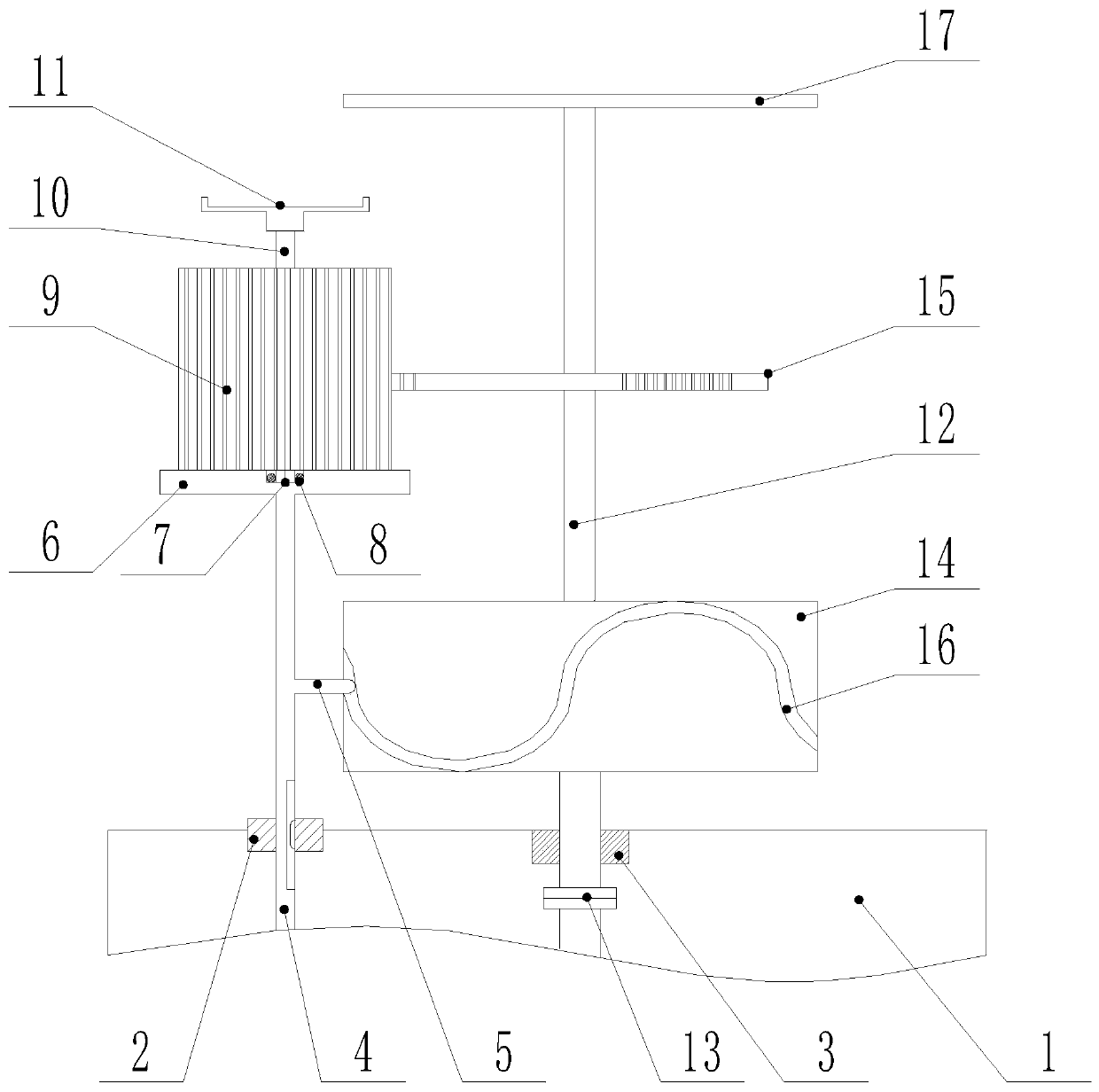

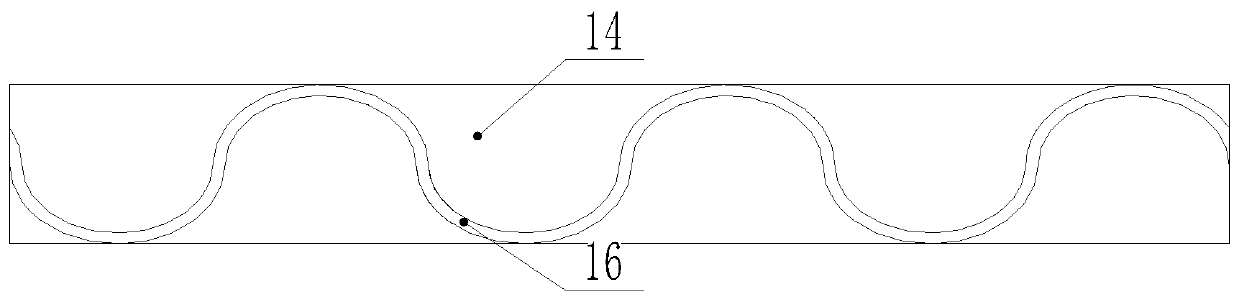

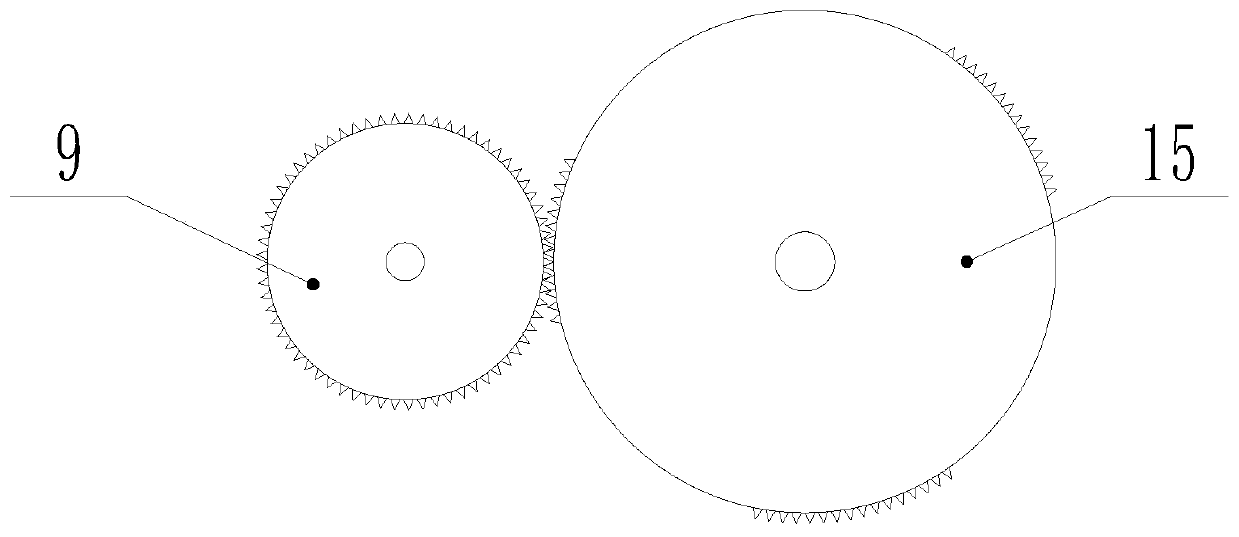

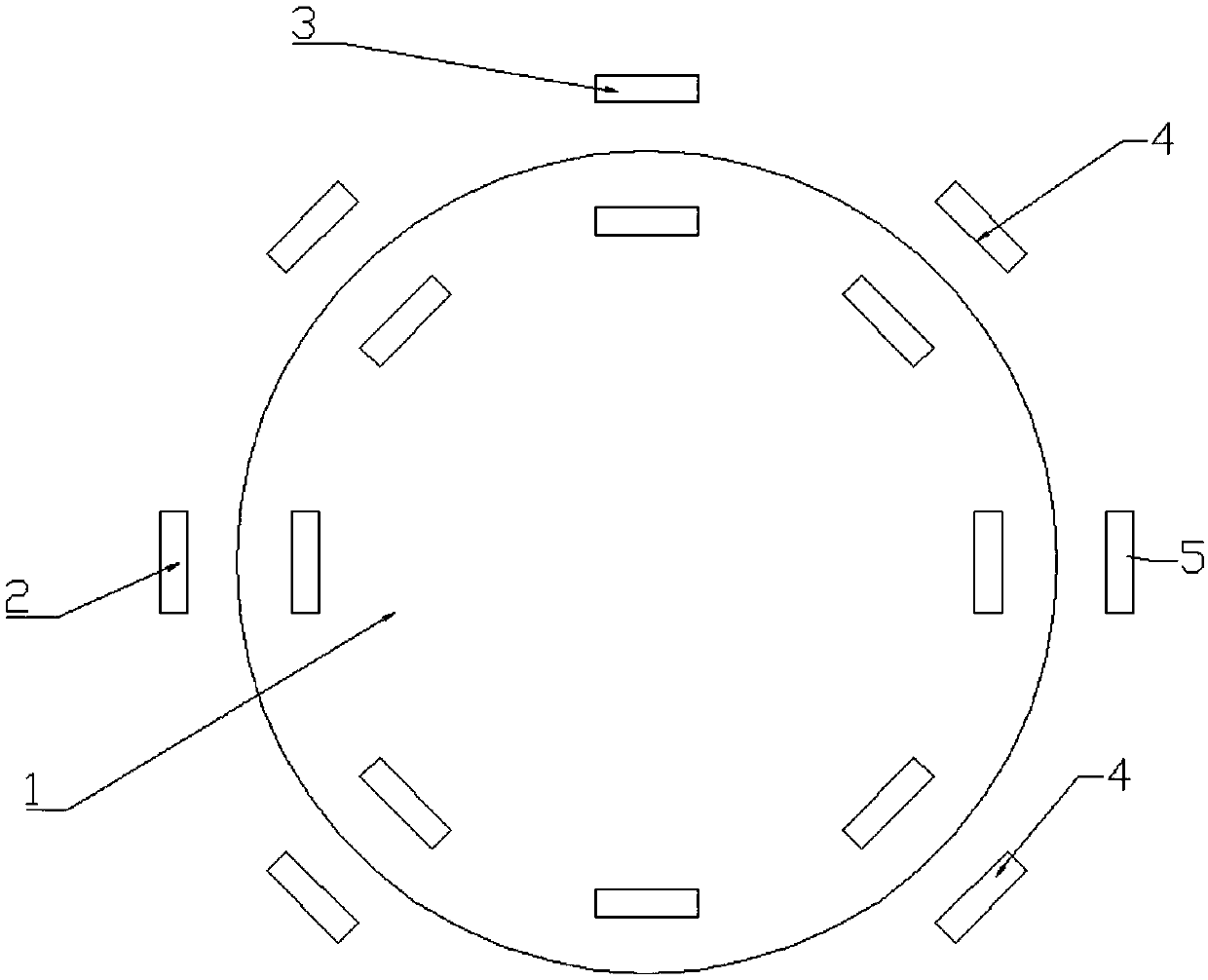

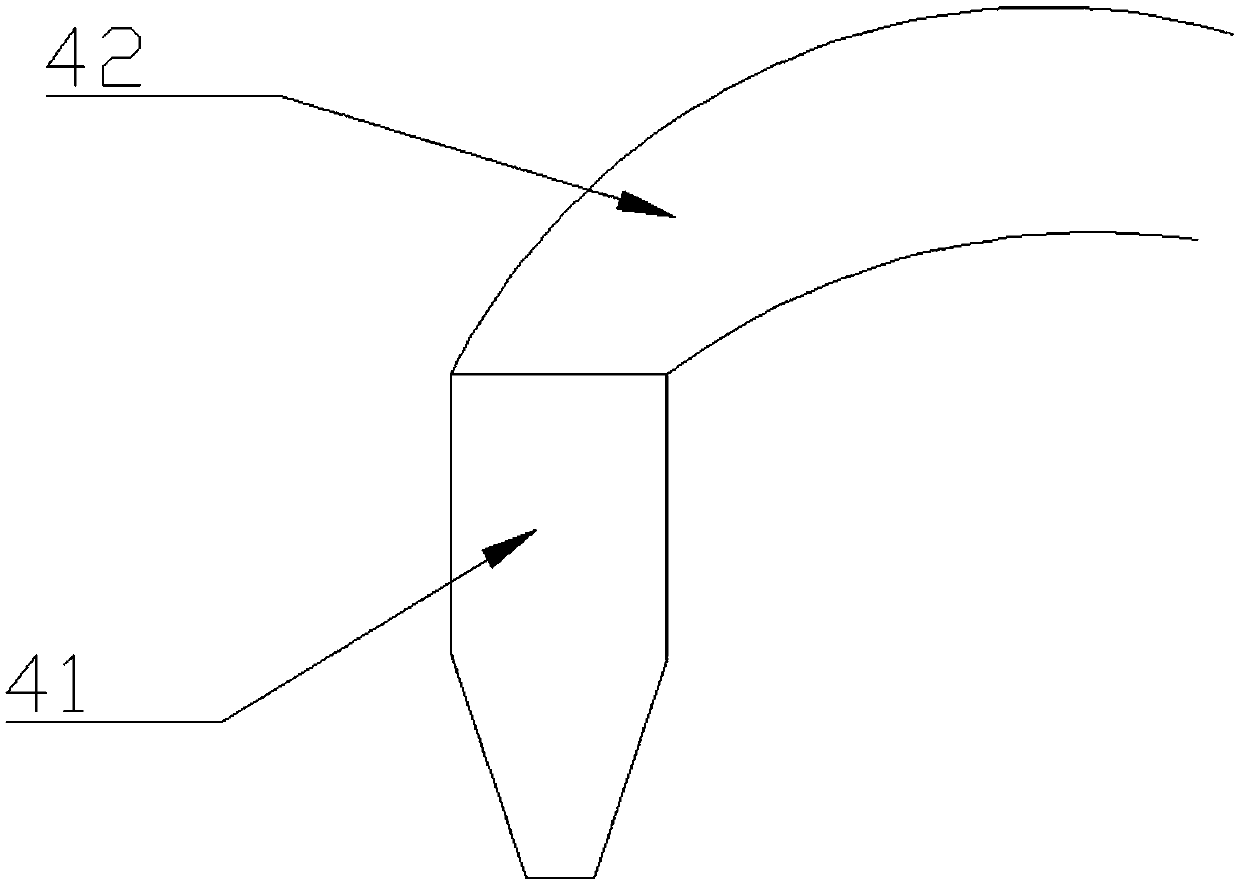

Stator core production device for motor

PendingCN113352170AImprove deburring efficiencyNo vibrationEdge grinding machinesGrinding drivesPhysicsEngineering

The invention relates to a stator core production device for a motor, and belongs to the technical field of stator core production and manufacturing. The stator core production device comprises an operation platform. Three bearing bases which are arranged in a triangle shape and used for bearing stator cores are arranged on the operation platform, fastening devices which are used for clamping the stator cores in the bearing bases are arranged on the bearing bases, end shafts are arranged at the bottoms of the bearing bases, and the end shafts are connected with the operation platform through a bearing and connected with a driving device. A grinding head which can deburr the end faces of the stator cores in the three bearing bases at the same time is arranged in the middle of the tops of the three bearing bases, the bottom surface of the grinding head is a plane, and a grinding head driving motor which is connected with the grinding head and can move in the vertical direction is arranged on the top of the grinding head. The stator core production device can solve the problems that an existing deburring device is low in deburring efficiency and poor in deburring effect and cannot meet the requirements of modernized production of the stator cores.

Owner:宁国井田机电有限公司

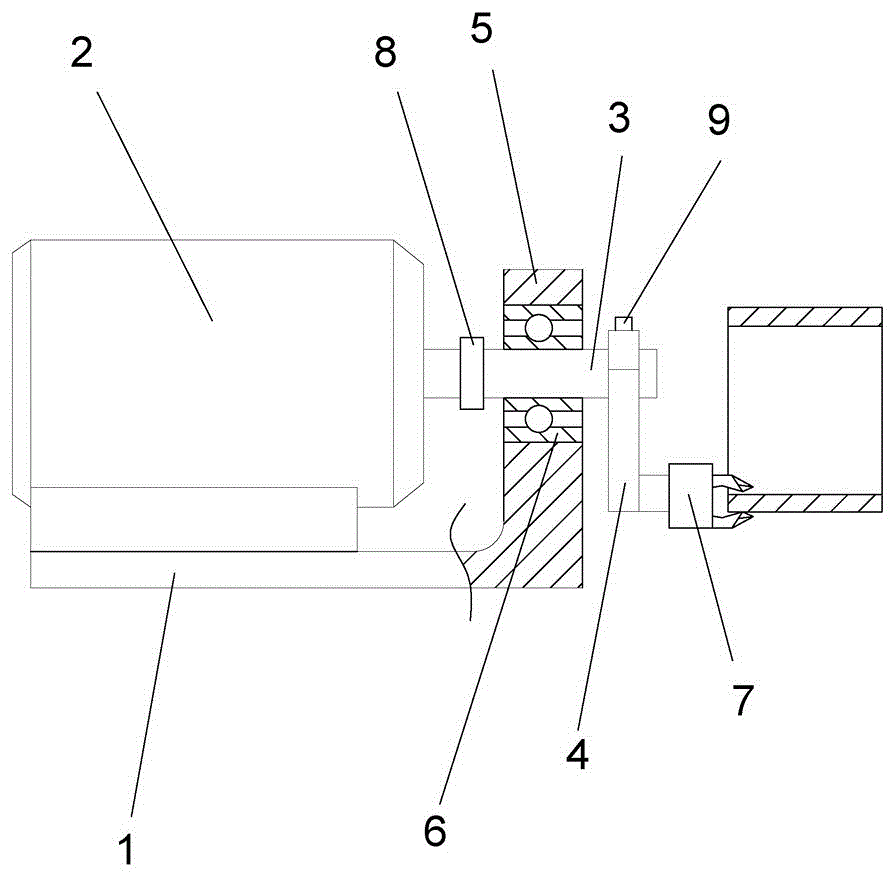

Energy-saving numerical control machine tool convenient to use

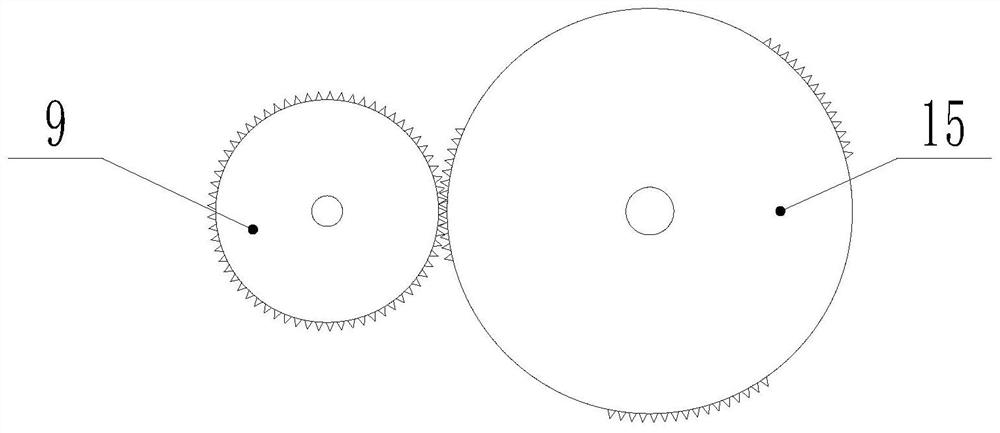

InactiveCN110814439AReduce consumptionGuaranteed deburring effectFeeding apparatusDriving apparatusNumerical controlGear wheel

The invention discloses an energy-saving numerical control machine tool convenient to use. The energy-saving numerical control machine tool includes a machine tool base, an axle sleeve and a bearing are arranged on the upper surface of the machine tool base, a motor is fixedly installed in the machine tool base, a lifting rod is inserted in the axle sleeve, the lifting rod is inserted in the axlesleeve by means of key matching, the lifting rod moves up and down relative to the axle sleeve, a shifting rod is arranged on the side face of the lifting rod, a bearing plate is fixedly installed atthe top end of the lifting rod, a groove is formed in the center of the upper surface of the bearing plate, a gear is movably installed on the bearing plate, the lower end of a central shaft of the gear is inserted into the groove, and a workpiece bearing and placing plate is installed at the upper end of the center shaft. The energy-saving numerical control machine tool has the beneficial effectsthat the structure is simple, and energy conservation and the practicality are achieved.

Owner:常亮

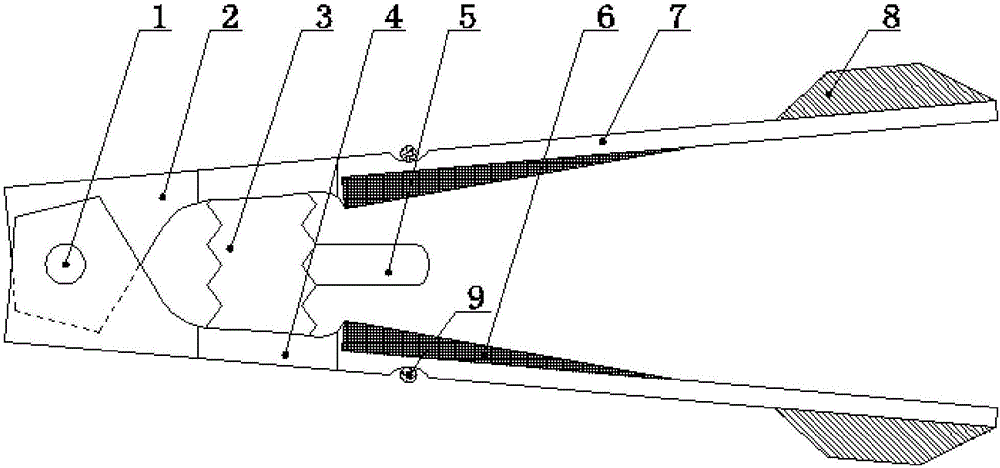

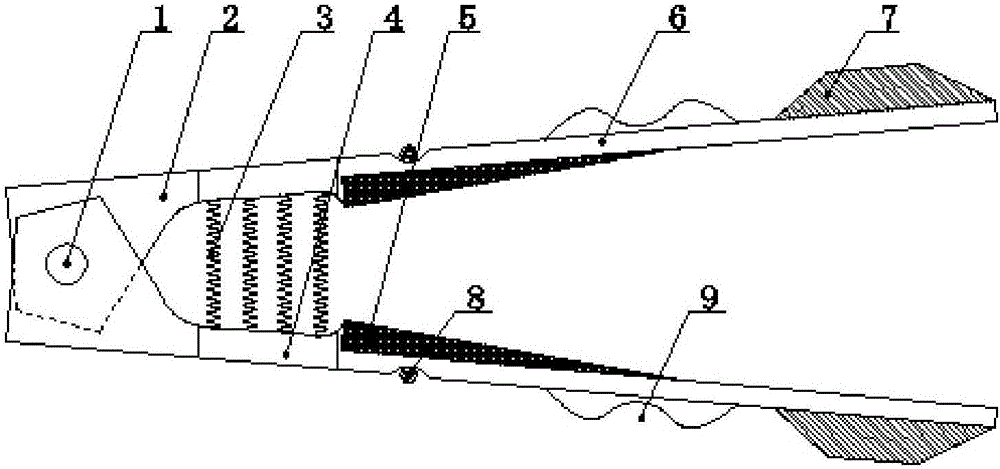

Industrial drill hole deburring tool with small damage and good deburring effect

The invention discloses an industrial drill hole deburring tool with small damage and a good deburring effect. The deburring tool comprises two cutter strip single bodies. One ends of the two cutter strip single bodies are hinged simultaneously through a pivotal shaft. Each cutter strip single body comprises a rotary part, an expansion part and a force bearing part, wherein the rotary part is hinged to the pivotal shaft, and the expansion part is arranged at the rear end of the rotary part. A telescopic gasbag is arranged between the expansion parts of the two cutter strip single bodies. An expansion gasbag is connected to the telescopic gasbag. The force bearing parts are arranged at the rear ends of the expansion parts. The outer side walls of the two cutter strip single bodies are sleeved with elastic force rings correspondingly. Cutting edges are arranged on the outer side walls of the rear ends of the force bearing parts. According to the deburring tool, through expansion of the expansion gasbag, the tension of the telescopic gasbag to the expansion parts is effectively relieved, the effects that the acting force of the cutting edges to the inner wall of an industrial drill hole is enough but not too large are ensured, and large damage does not occur to the inner wall of the industrial drill hole while the deburring effect is ensured.

Owner:成都君华睿道科技有限公司

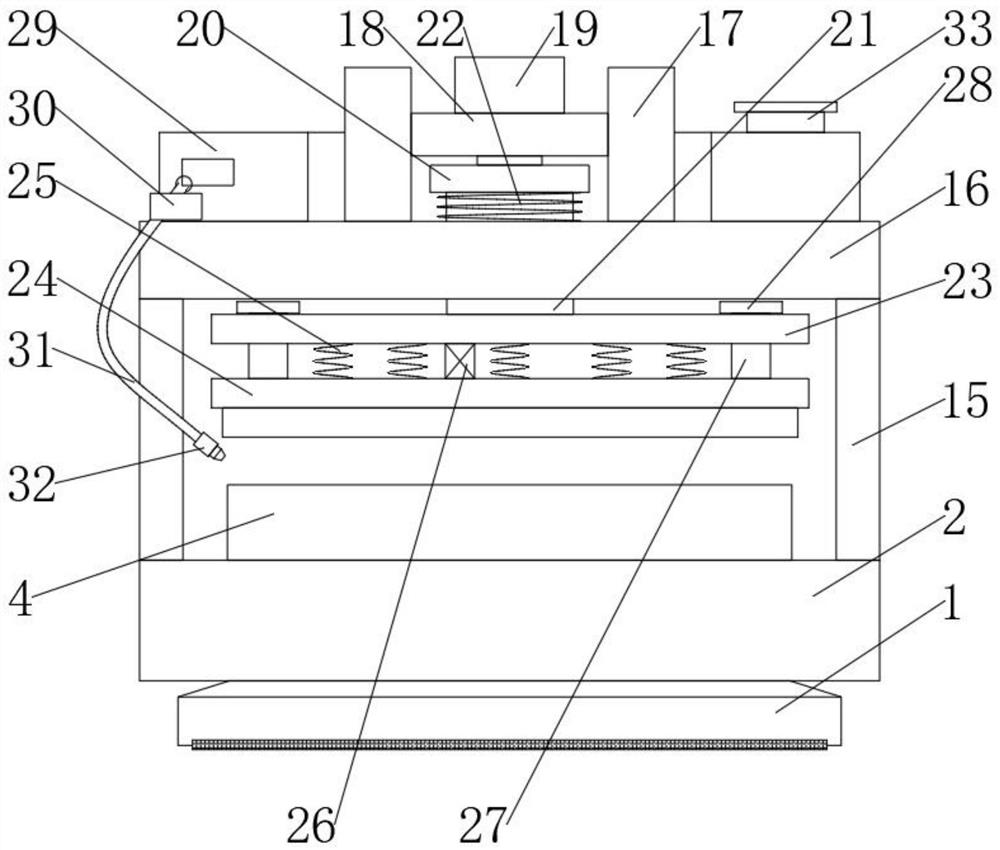

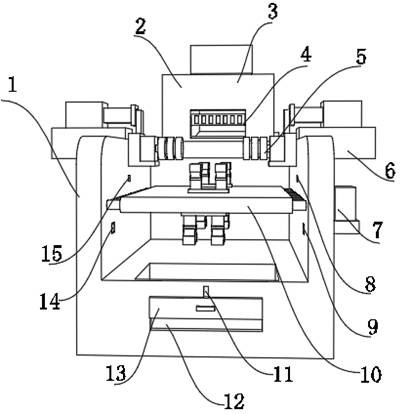

Deburring equipment for hardware stamping part

InactiveCN112045524AGuaranteed deburring effectGuaranteed uniformityEdge grinding machinesGrinding drivesElectric machineEngineering

The invention provides a deburring equipment for a hardware stamping part, and relates to the technical field of deburring of hardware stamping parts. The deburring equipment for the hardware stampingpart comprises a fixing base; the top of the fixing base is fixedly connected with a bottom installation base; a first grinding disc installation base is fixedly connected with the inner base of thebottom installation base; the inner bottom of the first grinding disc installation base is fixedly connected with a motor installation base; the top of the motor installation base is fixedly connectedwith a driving motor; a stepped hole is formed in the top of the inner side of the first grinding disc installation base; the inner side of the stepped hole is fixedly connected with a fixing round plate; a center base is arranged in the center of the fixing round plate; the inner side of the center base is movably connected with a rotary shaft through a bearing; and the top of the rotary shaft is fixedly connected with a lower grinding disc. The hardware stamping part is ground and deburred by using an upper grinding disc and the lower grinding disc; the two sides can be quickly deburred; and high-speed and efficient deburring is achieved.

Owner:惠州市宏达五金制品有限公司

Stainless steel plate deburring equipment for high-voltage switch cabinet

PendingCN114714190AEasy to replaceAchieve installationEdge grinding machinesGrinding carriagesSS - Stainless steelMachining

The invention discloses stainless steel plate deburring equipment for a high-voltage switch cabinet, and particularly relates to the technical field of high-voltage switch cabinet machining. An upper grinding roller, a lower grinding roller and grinding paper make contact with the cutting section of a stainless steel plate, and the grinding paper grinds the section of the stainless steel plate; the upper grinding roller and the lower grinding roller are driven by the driven shaft to grind the section of the stainless steel plate, grinding of the upper surface, the lower surface and the side surface of the stainless steel plate is achieved, the deburring effect is guaranteed, the grinding efficiency is improved, meanwhile, the grinding rollers and the supporting frame are designed to be of a detachable structure, the guide blocks enter the guide grooves, and the grinding efficiency is improved. The synchronous transmission of the grinding roller and the driven shaft is realized; the grinding mechanism is matched with the sliding table to slide on the linear guide rail, drives the supporting column to move in the same direction and drives the upper grinding roller, the lower grinding roller and the grinding paper in the grinding mechanism to do reciprocating linear motion on the section of the stainless steel plate, the grinding automation degree is improved, and the efficiency is high.

Owner:CHINA SCI TIANGONG ELECTRICAL HLDG

Injection molding equipment for lower shell of direct-current brushless motor and working method of injection molding equipment

ActiveCN111917257AImprove work efficiencyQuick take outManufacturing dynamo-electric machinesEngineeringBrushless motors

The invention discloses injection molding equipment for a lower casing of a direct-current brushless motor and a working method of the injection molding equipment. The equipment comprises a first casing, a lower die and an upper die are mounted at the inner side of the first casing, an injection molding hopper is fixedly mounted at the top of the first casing, and an air cylinder mounting plate isfixedly mounted at the end of an output rod of a movable air cylinder; a lifting air cylinder is fixedly mounted on the upper surface of the air cylinder mounting plate, a suction cup is fixedly mounted at the bottom end of an output rod of the lifting air cylinder, and a base is fixedly mounted at the top of the second shell; a top seat is fixedly mounted above the base, a scraping rod is movably mounted on the top seat along the vertical direction, the bottom end of the scraping rod is connected with the top seat in a penetrating manner, and a storage plate is fixedly mounted on the upper surface of the base. According to the injection molding equipment, the lower shell of the motor can be rapidly taken out and moved to the storage plate, the working efficiency is high, the deburring effect of the lower shell of the motor is guaranteed; the outer circumferential face and the inner circumferential face of a fixing column are polished through a steel brush, and the polishing effect isgood.

Owner:阜南县特立电子有限公司

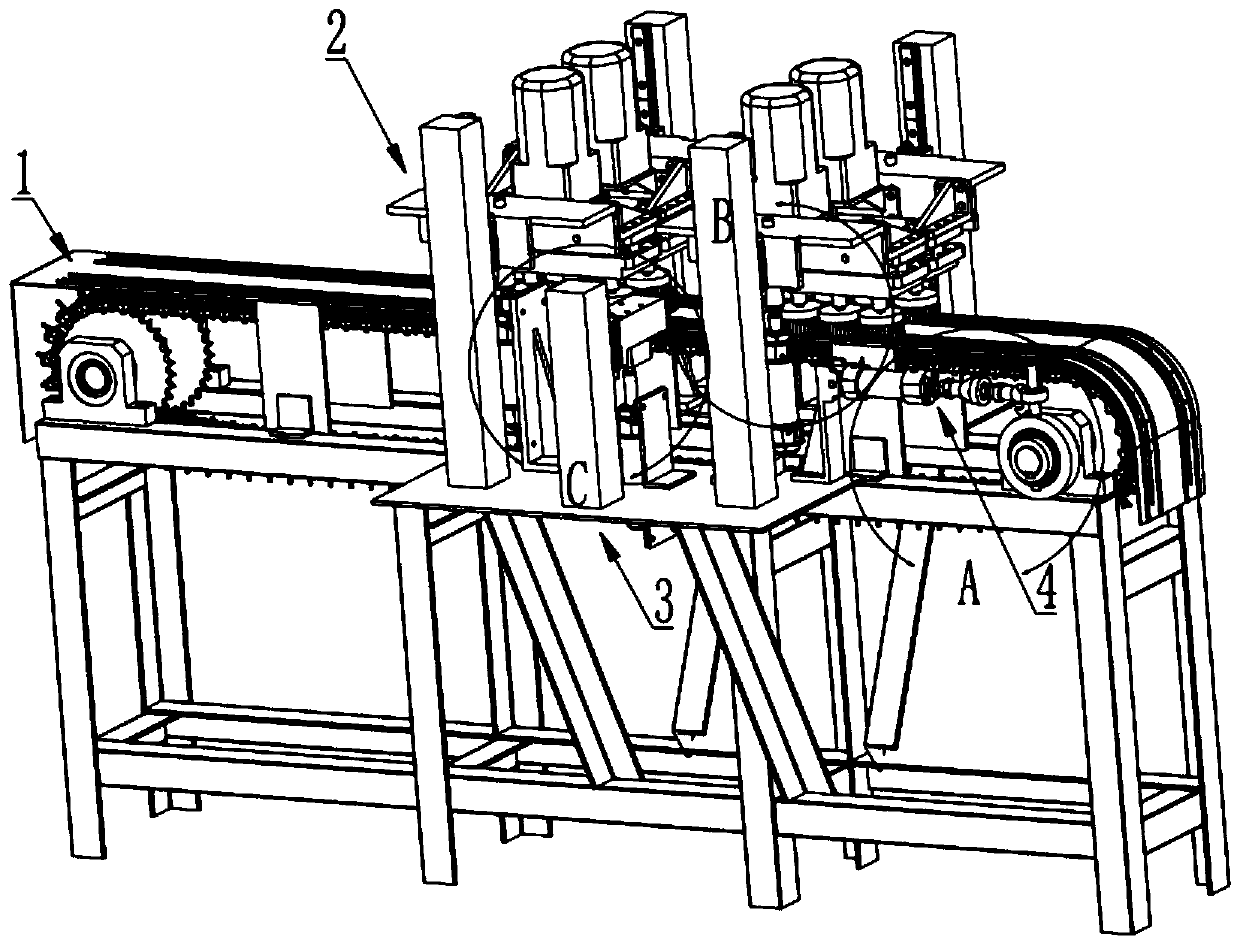

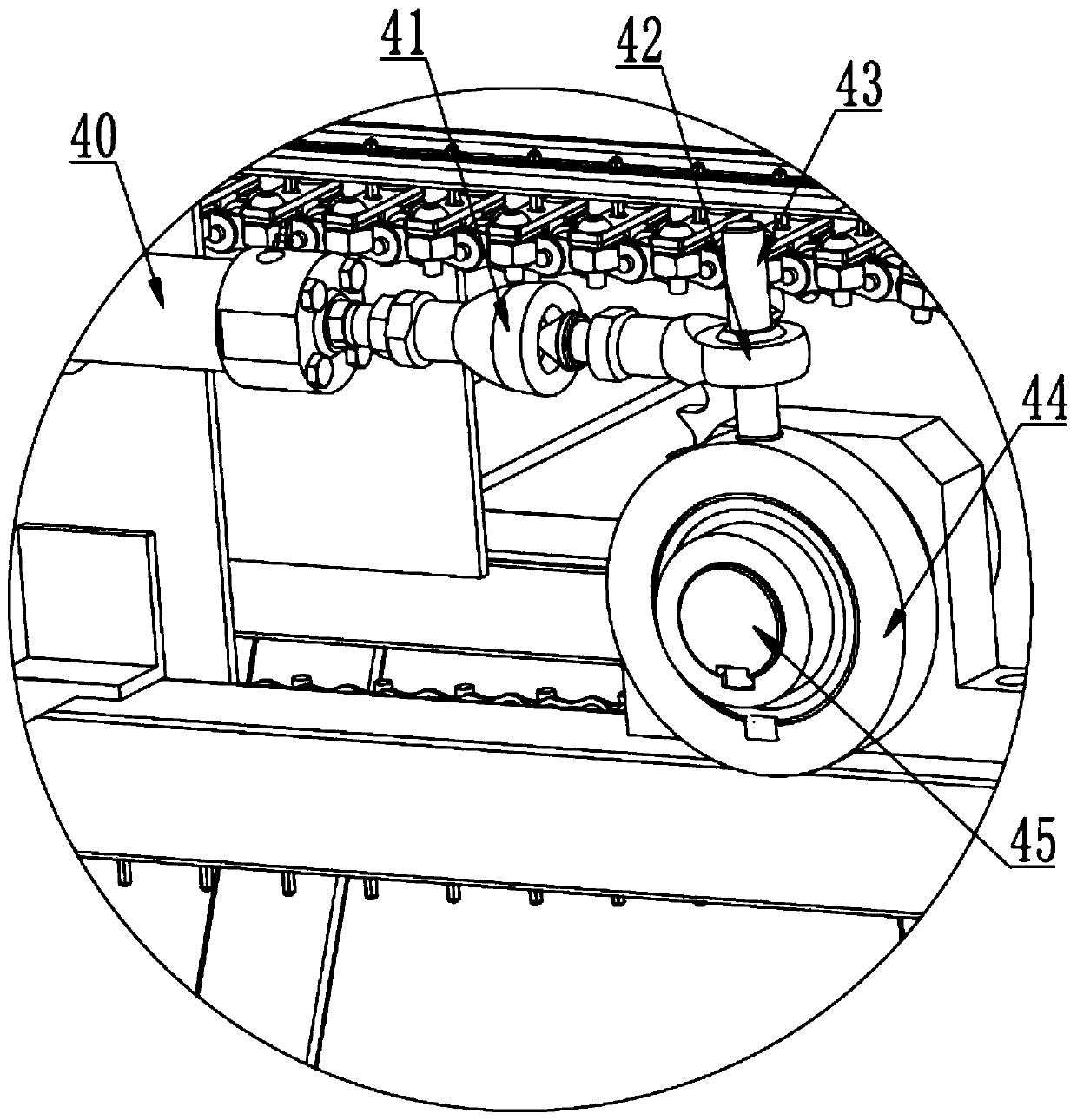

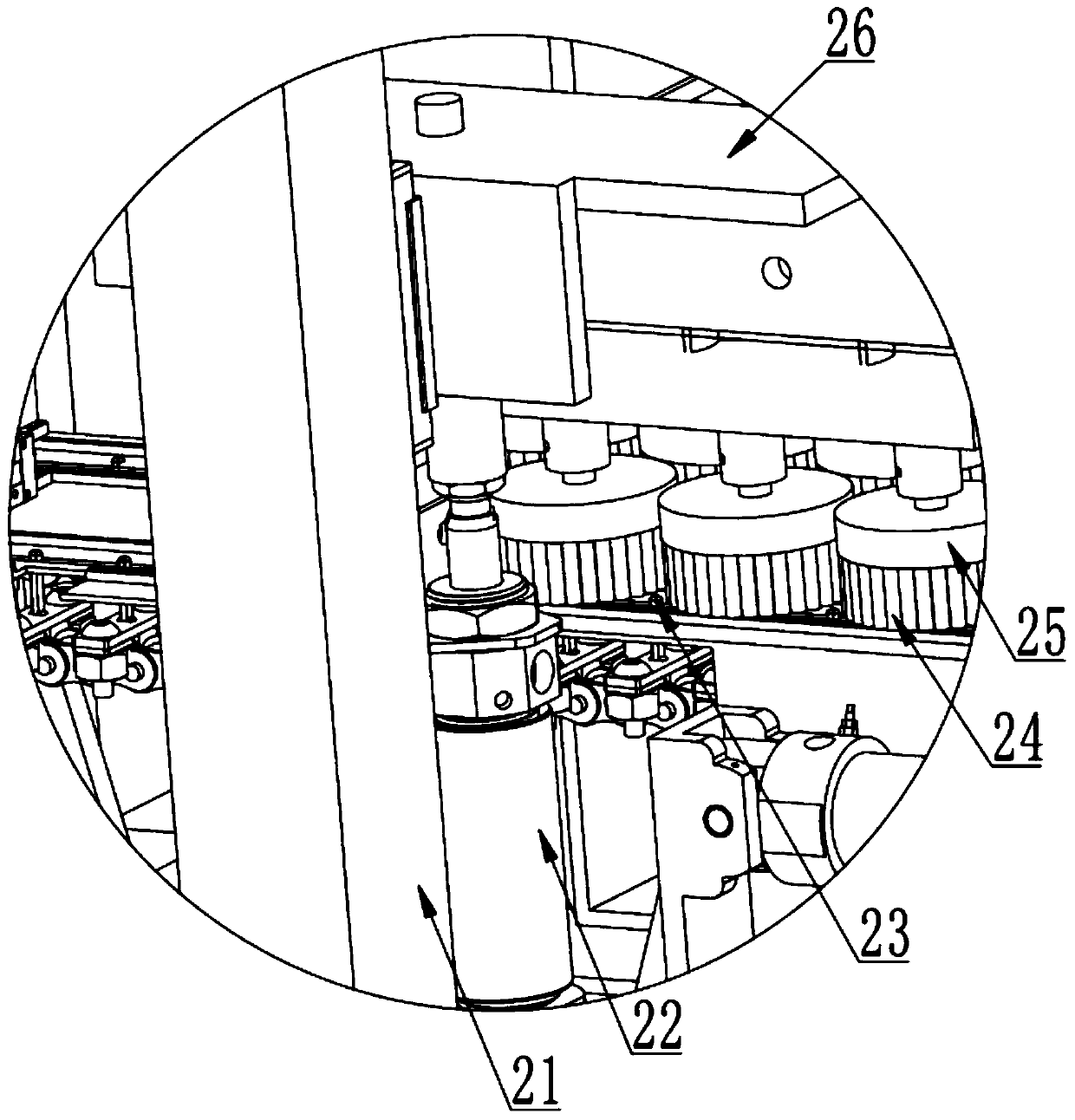

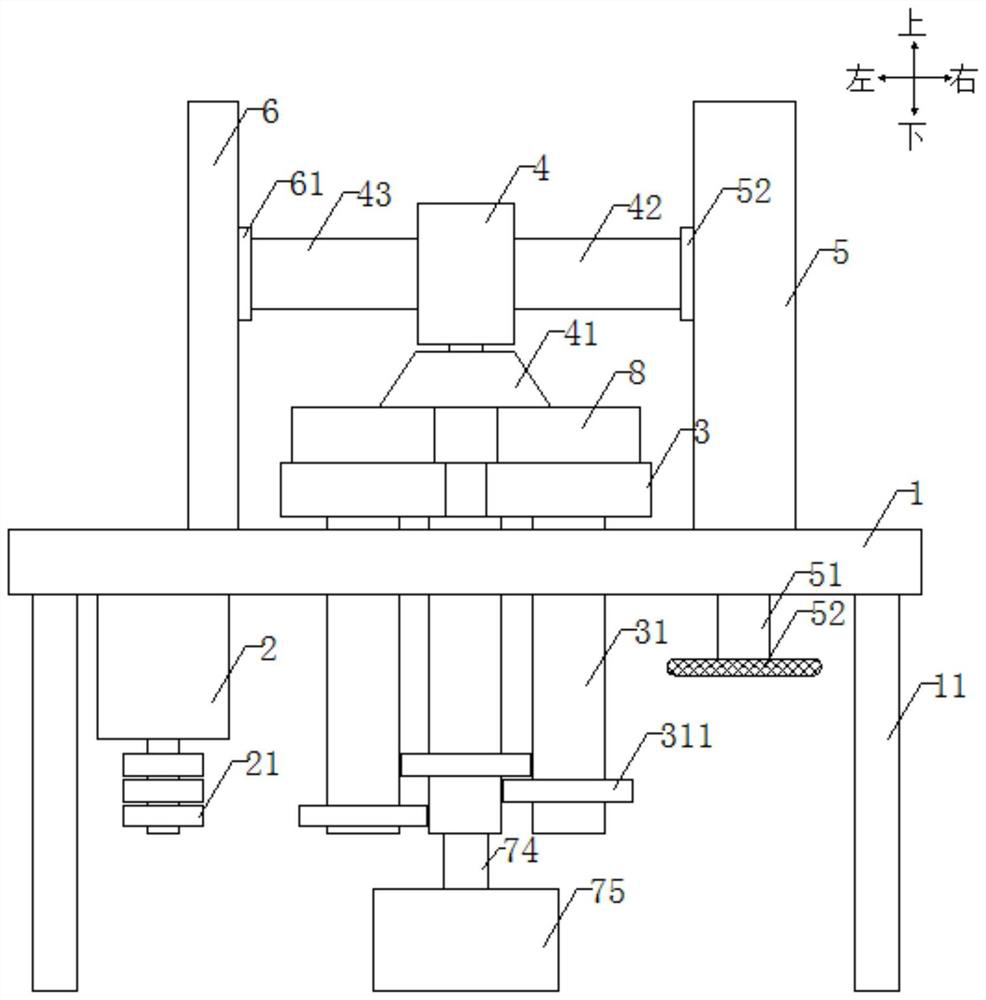

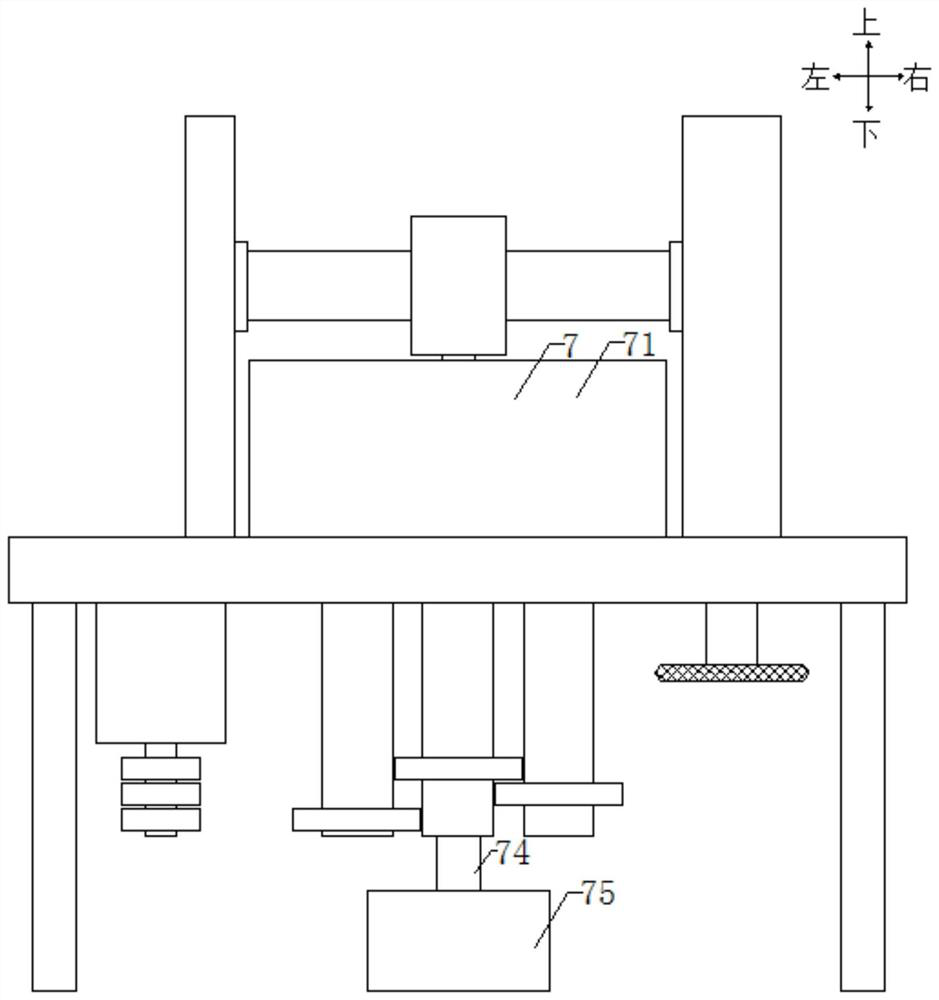

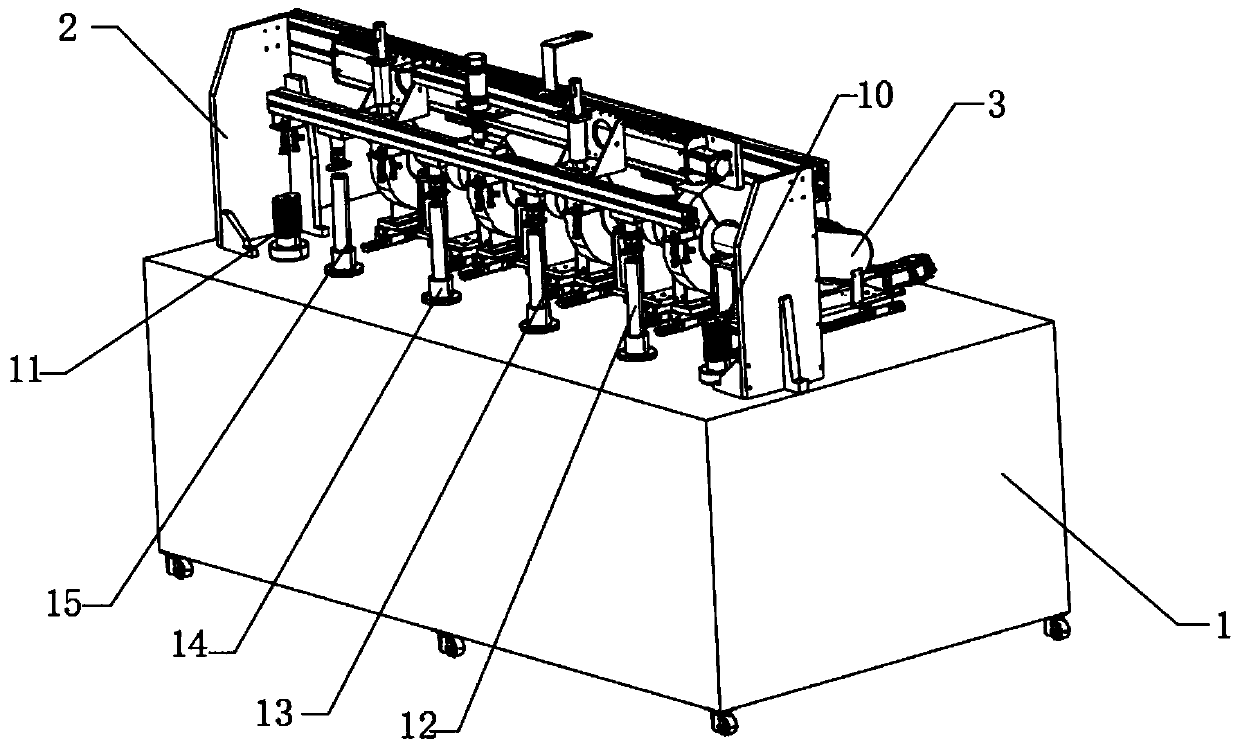

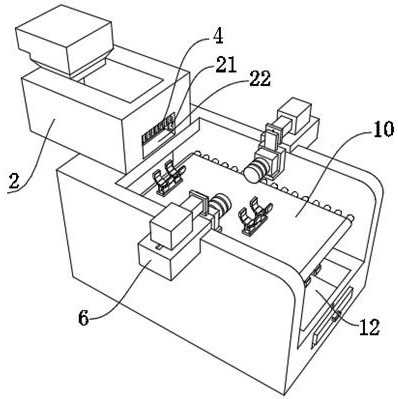

Double-sided deburring method of ultra-large-curvature valve plate

ActiveCN110014358AGuaranteed deburring effectImprove processing efficiencyEdge grinding machinesPolishing machinesTransfer mechanismEngineering

The invention provides a double-sided deburring method of an ultra-large-curvature valve plate. The double-sided deburring equipment is adopted, automatic feeding and discharging are realized by virtue of a feeding assembly and a discharging assembly, then the workpiece is subjected to upper surface rough grinding , upper surface fine polishing, lower surface rough grinding and lower surface finepolishing sequentially through a transferring mechanism, one-time clamping is realized, so that the double-sided deburring process of the workpiece can be completed, manual handheld is avoided, and the operation safety and the machining efficiency are improved.

Owner:万泰机电工业(昆山)有限公司

Furniture manufacturing plate burr treatment equipment

PendingCN113829170AGuaranteed deburring effectSave electricityEdge grinding machinesGrinding drivesElectric machineryManufacturing engineering

The invention relates to the technical field of furniture manufacturing, in particular to furniture manufacturing plate burr treatment equipment. The equipment comprises a base, at least two sets of machining bases and telescopic elements; every two sets of machining bases are symmetrically and movably arranged on the base; a reserved area for plate installation is arranged between every two adjacent machining bases in the same set; and the adjacent machining bases are connected through the telescopic elements. The equipment further comprises: adjusting units arranged on the base and connected with the machining bases; burr cleaning modules arranged between the adjacent machining bases in the same group; and driving modules arranged on the machining bases and connected with the burr cleaning modules, the driving modules being in sliding fit with plates in the reserved area. Compared with a traditional grinding machine driven by a motor, the device can effectively utilize the friction resistance between rolling wheels and the plates, so that grinding strips are driven to grind the surfaces of the plates, electric energy is saved while the deburring effect is guaranteed, the whole structure is simple, and later maintenance work is facilitated.

Owner:深圳市文锦佳华贸易有限公司

Thread shaping sealing ring groove machining integrated equipment

PendingCN109531174AEnsure safetyImprove efficiencyOther manufacturing equipments/toolsMotor driveEngineering

The invention discloses thread shaping sealing ring groove machining integrated equipment, which comprises an indexing rotary table, an electric motor, a groove deburring device, a thread shaping device, a cleaning device and a discharging device. Eight fixtures are arranged at equal intervals on the indexing rotary table, and eight work positions are arranged around the indexing rotary table, thefixture is horizontally rotating at one end of an ejector rod, a through hole allowing the ejector rod to move vertically is arranged at the corresponding position of the indexing rotary table, and the other end of the ejector rod passes through the through hole and is arranged in the through hole. The motor drives the indexing rotary table to switch among the stations. The first station is usedas a feeding station, the second and fourth stations are retained, the third station is provided with the groove deburring device, the fifth station is provided with the thread shaping device, the sixth station and the eighth station are provided with the cleaning device, and the seventh station is provided with the discharging device. The invention uses a plurality of work stations to process different processes in parallel, thereby improving efficiency and saving labor cost.

Owner:FOEHL CHINA CO LTD

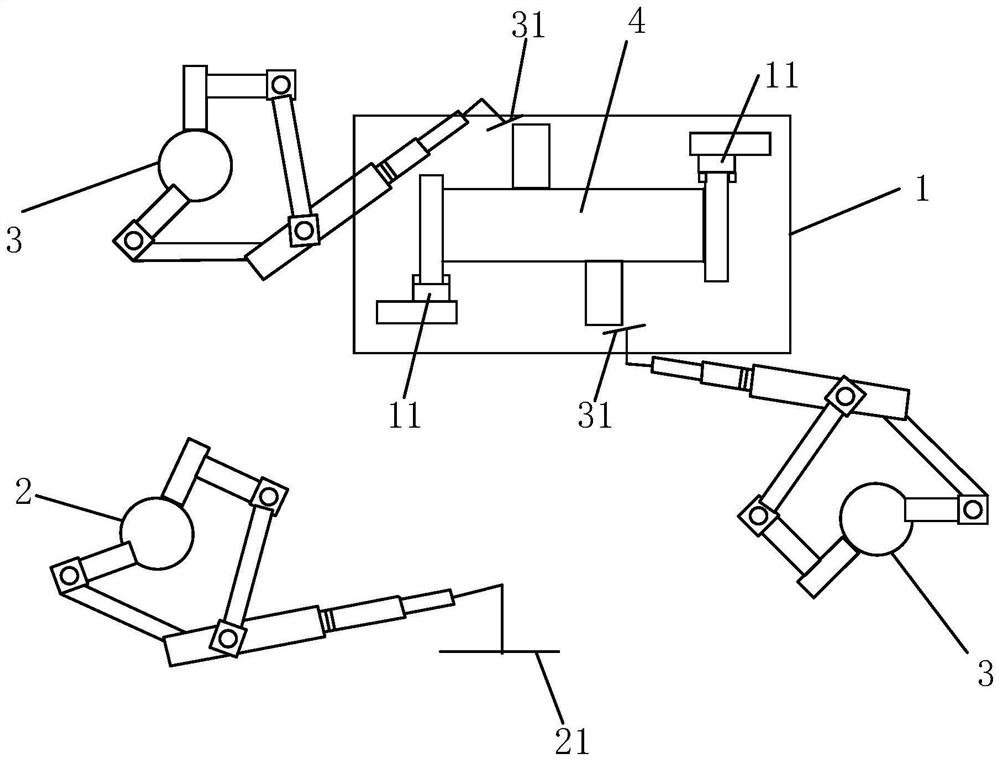

Equipment for deburring after machining

PendingCN114310547AAvoid the risk of missed pick-upRun orderlyEdge grinding machinesAutomatic grinding controlVisual monitoringRobot hand

The invention relates to equipment for deburring after machining. The equipment comprises a workpiece loading platform (1) used for loading a workpiece (4) to be deburred after machining; the loading manipulator (2) is used for loading a workpiece (4) to be deburred onto the workpiece loading platform (1); the grinding manipulator (3) is used for grinding a workpiece (4) to be deburred; the visual positioning assembly is used for performing visual monitoring in the action process of the loading manipulator (2) and the grinding manipulator (3); one loading manipulator (2) is arranged, the multiple grinding manipulators (3) are arranged and distributed along the peripheral side of the workpiece loading platform (1), and the loading manipulator (2), the grinding manipulators (3) and the visual positioning assembly are all connected to a linkage controller. Compared with the prior art, the equipment is fast in production rhythm and high in reliability.

Owner:SHANGHAI CENSI AUTOMOBILE PARTS

An Automatic Deburring Device with Accurate Compensation

ActiveCN106625093BRealize automatic deburring functionGuaranteed deburring effectEdge grinding machinesGrinding drivesEngineeringMechanical engineering

The invention discloses an automatic deburring device capable of realizing accurate compensation. The automatic deburring device is characterized in that an output shaft of a motor is vertically downward, a rotary shaft fixedly connected with the output shaft of the motor penetrates through a fixed guide seat, a brush rotating with the rotary shaft is installed at the bottom shaft end of the rotary shaft, and the fixed guide seat is installed on a horizontal base plate; a hollow guide shaft fixedly connected with a motor installation seat is arranged between the rotary shaft and the fixed guide seat, the rotary shaft is capable of rotating in the hollow guide shaft, and the hollow guide shaft is capable of moving up and down along the fixed guide seat; and a lifting guide seat is arranged on the motor installation seat in a manner of horizontally overhanging, a compensation motor is installed on the lifting guide seat, a lifting cylinder is installed on the base plate, thread fit is formed between an output shaft of the compensation motor and a piston rod of the lifting cylinder, and the wear amount of the brush is compensated through the driving of the compensation motor. The automatic deburring device disclosed by the invention is used for carrying out deburring treatment on the surface of a workpiece, and capable of realizing accurate compensation and prolonging the service life of the brush.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

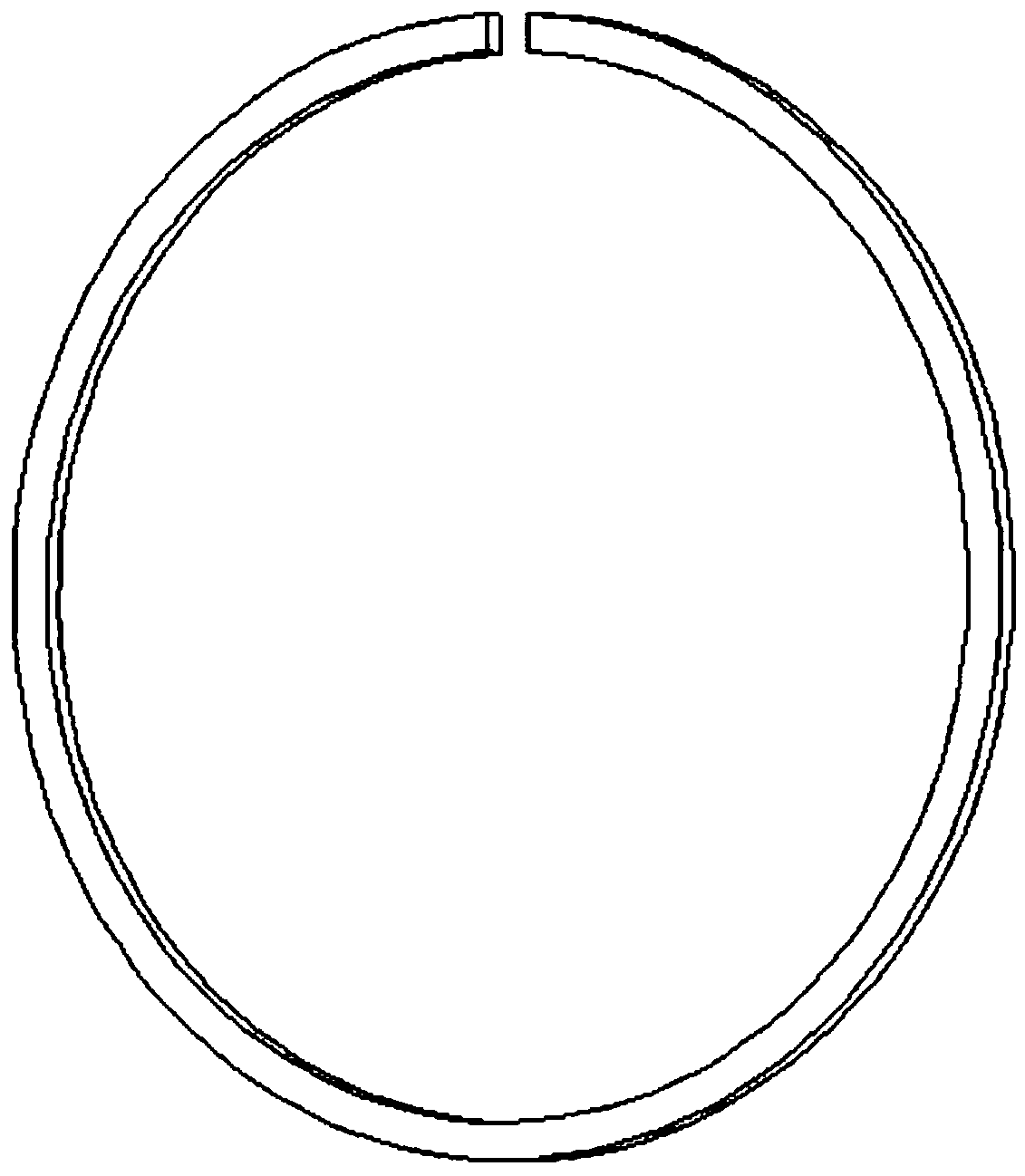

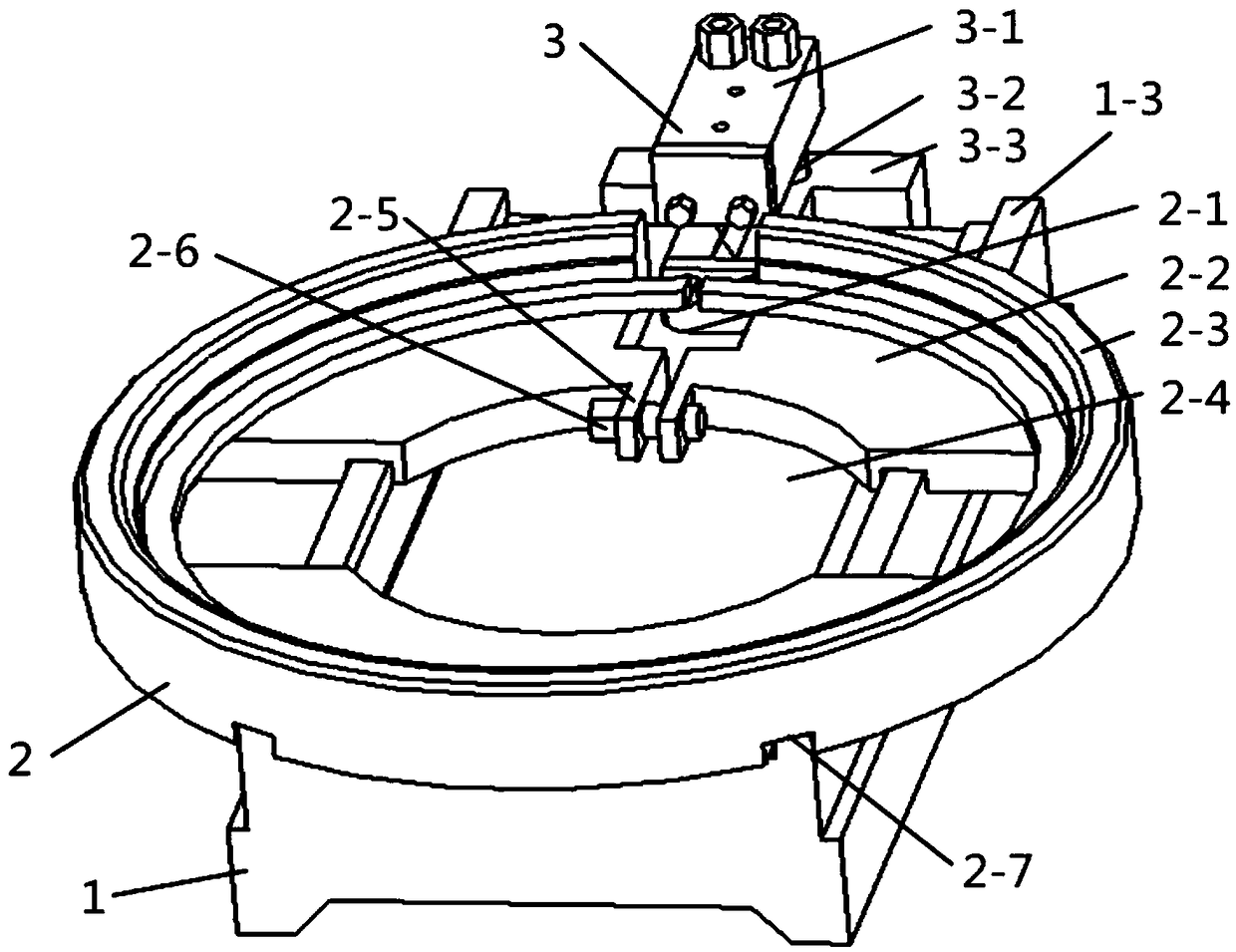

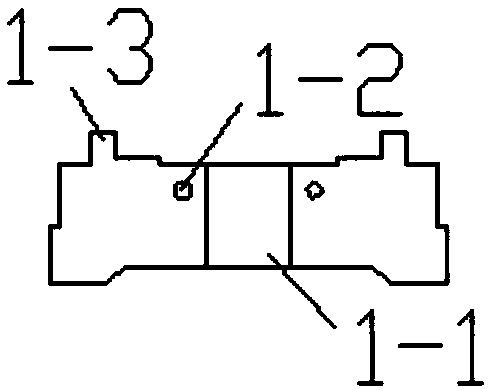

A device for removing burrs from the opening edge of a piston ring

ActiveCN106625084BReduce workloadReduce uniformityEdge grinding machinesGrinding wheel securing apparatusPiston ringEngineering

The invention discloses a piston ring opening edge burr removing device which comprises a burr removing disc base, a burr removing disc and a tool rest mechanism. The upper end face of the burr removing disc base is slidably connected with the lower end face of the burr removing disc, and the tool rest mechanism is fixedly connected to the back end face of the burr removing disc base; the back end of the burr removing disc is provided with a working opening of which the position corresponds to that of the tool rest mechanism arranged at the back side of the burr removing disc; an upper tool rest and a lower tool rest of the tool rest mechanism are provided with an upper grinding device and a lower grinding device, and the upper grinding device and the lower grinding device correspond to the upper edge and the lower edge of an opening of a piston ring placed in the burr removing disc. According to the piston ring opening edge burr removing device, the piston ring is installed in the burr removing disc, the burr removing disc is pushed to enable the four edges of the opening of the piston ring to rub against the tool grinding devices, edge burrs are ground off through the grinding effect of the tool grinding devices under the moderate friction force, therefore, the effect of removing the four edge burrs of the opening of the piston ring at a time is achieved, the workload of operators is reduced, the problem that burr removing is not uniform is solved, and the product quality and the production efficiency are improved.

Owner:CRRC CHANGZHOU DIESEL ENGINE COMPONENTS CO LTD

A deburring device for automobile exhaust pipe

The invention discloses a deburring device applied to automobile exhaust pipes. The deburring device comprises an installation frame, a motor, an output shaft, a driving gear, an inner gear, a rotary gear and a shaping cutter, wherein the motor is arranged on the installation frame, the output shaft is connected with the motor, the driving gear is arranged on the output shaft, the inner gear is fixed to the installation frame and shares the same axis with the driving gear, the rotary gear is meshed with outer teeth of the driving gear and inner teeth of the inner gear, and the shaping cutter is coaxially connected with the rotary gear, can shape pipe openings of the exhaust pipes and can perform deburring on outer walls and inner walls of the exhaust pipes at the same time. The deburring device disclosed by the invention can shape the pipe openings of the exhaust pipes and perform deburring on the outer walls and the inner walls of the exhaust pipes at the same time, so that the pipe openings are round and neat, used time is small, and deburring efficiency is high.

Owner:浙江新诚汽车部件有限公司

A double-sided deburring device

ActiveCN111300199BExtend sanding timeImprove stabilityEdge grinding machinesGrinding drivesControl engineeringControl theory

Owner:LISHUI UNIV

Injection molding equipment for lower case of DC brushless motor and working method thereof

ActiveCN111917257BQuick take outImprove work efficiencyManufacturing dynamo-electric machinesBrushless motorsControl engineering

The invention discloses an injection molding device for the lower casing of a DC brushless motor and a working method thereof. The device includes a first casing, a lower mold and a lower mold are installed on the inner side of the first casing, The top is fixed with an injection plastic bucket, the end of the output rod of the moving cylinder is fixed with a cylinder mounting plate, the upper surface of the cylinder mounting plate is fixed with a lifting cylinder, and the bottom of the output rod of the lifting cylinder is fixed with a suction cup. The top of the body is fixedly installed with a base, the top of the base is fixedly installed with a top seat, and a scraper rod is installed on the top seat movable along the vertical direction. ;This injection molding equipment can quickly take out the lower casing of the motor and move it to the storage plate. It has high work efficiency and ensures the deburring effect of the lower casing of the motor. The outer and inner peripheral surfaces of the fixed column are polished by steel brushes. , good polishing effect.

Owner:阜南县特立电子有限公司

A deburring device and deburring method for cast steel joints

ActiveCN111975526BAvoid cloggingGuaranteed deburring effectEdge grinding machinesGrinding work supportsHydraulic cylinderStructural engineering

The invention discloses a deburring device and a deburring method for cast steel joints, and relates to the technical field of joint deburring; in order to solve the problem that the inner hole of the joint is easily blocked; the equipment includes a body, and the top outer wall of the body is provided with Two fixed seats, the top outer walls of the two fixed seats are provided with electric chute, the inner walls of the two electric chute are provided with hydraulic cylinders, the extension ends of the two hydraulic cylinders are provided with partition plates, and the two partitions The outer wall of one side of the board is provided with a second electric slide rail, and the inner wall of the two second electric slide rails is provided with a connecting plate; the deburring method of the equipment includes the following steps: feeding; conveying and fixing; grinding; conveying and discharging; Collect materials. The invention adjusts the size of the inner hole of the distance grinding joint to ensure complete grinding, and removes burrs by grinding during rotation, so that the grinding wheel is in full contact with the inner cavity of the joint, avoiding the blockage of the inner hole and ensuring the deburring effect after grinding.

Owner:济宁运河机械有限公司

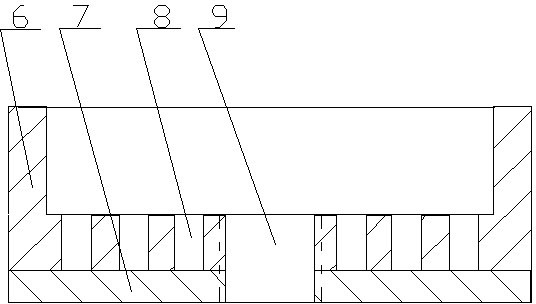

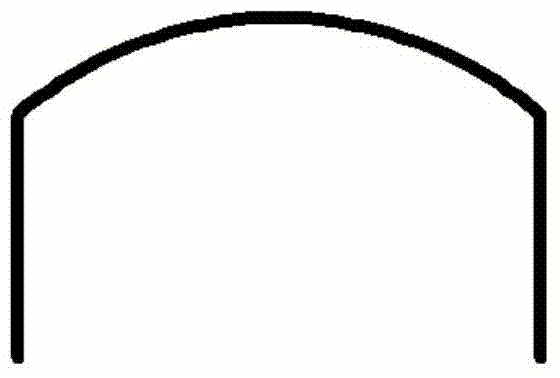

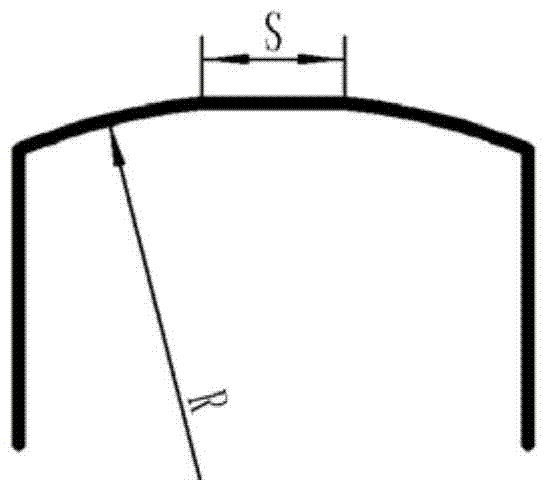

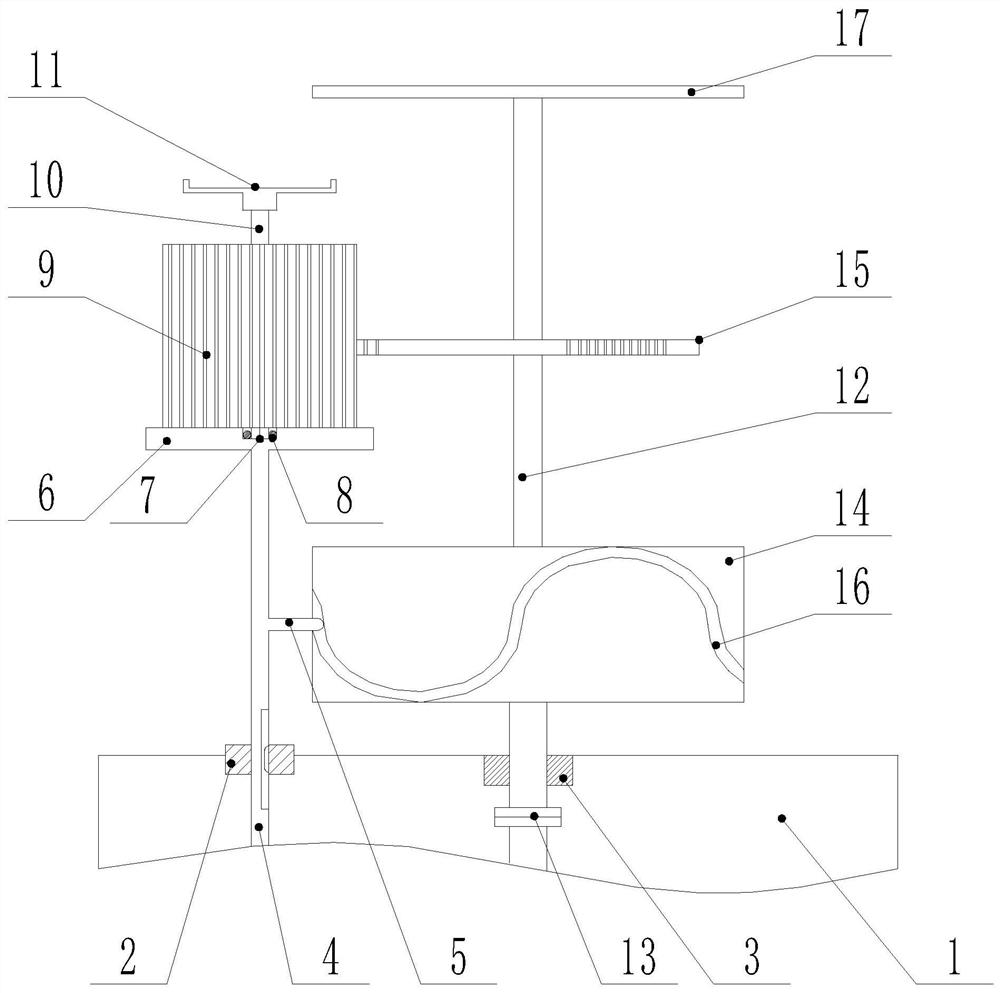

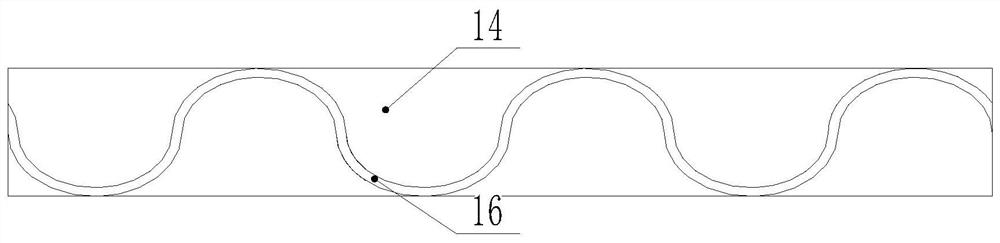

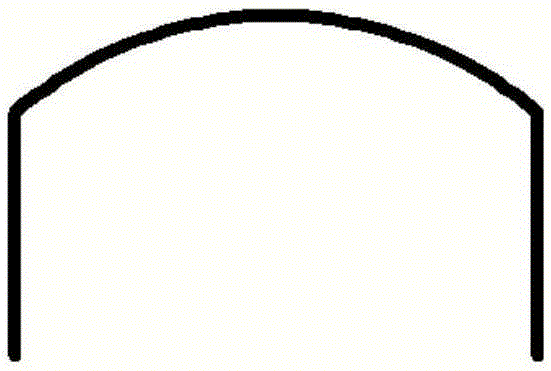

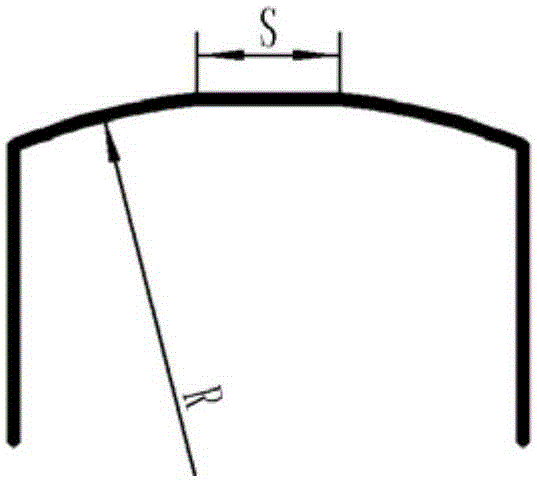

A roll profile optimization method for deburring machine used in recoiling unit

The invention discloses a roll type optimization method used for a presser of a recoiling unit, belonging to the field of cold rolling. The roll type optimization method comprises improvement design for the roll type of a burr pressing roll and reasonable determination for parameters of a burr pressing section of the burr pressing roll; on the basis of a current flat roll structure, the roll type of the burr pressing roll is improved into two parts of a flat burr pressing section and arc transition sections; the flat part of the middle position of the burr pressing roll is the burr pressing section; and the arc transition sections with the radius of R are located on the two ends of the burr pressing section. The roll type optimization method aims to overcome defects existing in the current roll type of the burr presser; the roll type of the burr pressing roll is improved by combining equipment and technical characteristics of a recoiling process of strip steel; by reasonably determining the parameters of the burr pressing section of the burr pressing roll, strip steel indentation during the burr pressing process can be avoided, and burr pressing force is concentrated, so that the burr pressing effect is ensured; meanwhile, a positioning margin value in the width direction of the strip steel can be well given to the burr pressing roll; strict requirement of the unit on electrical control is lowered; and burr defects are effectively avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

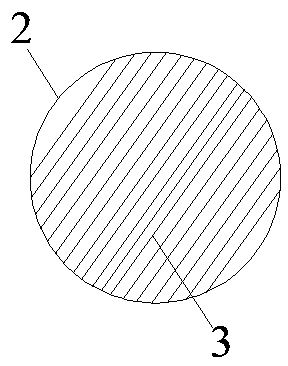

Magnetic ring deburring device

ActiveCN103434013BImprove work efficiencyReduce labor costsEdge grinding machinesCeramic shaping apparatusElectric machineryEngineering

The invention discloses a magnet ring deburring device which comprises a motor and a revolving drum driven by the motor. The revolving drum is of a solid of revolution structure. The inner wall of the revolving drum and the bottom wall of the revolving drum are provided with a plurality of protruding lines, the height of each protruding line is smaller than 1mm, and the distance between every two protruding lines is 0.5mm. The magnet ring deburring device has the advantages that a magnet ring is arranged inside the revolving drum, and due to the fact that the inner wall of the revolving drum and the bottom wall of the revolving drum are provided with the protruding lines, burrs on the surface of the magnet ring are removed through collision and friction in the process of rotating; burrs inside the magnet ring are removed by adopting a deburring shaft with certain roughness to drive the magnet ring to rotate to rub; working efficiency is greatly improved, labor cost is saved, the deburring effect is guaranteed, and the magnet ring deburring device is suitable for various types of magnet rings.

Owner:徐州惠华磁性材料有限公司

Special polishing disc for deburring machine and manufacturing method thereof

ActiveCN102350668BImprove straightnessWon't fallBonded abrasive wheelsGrinding devicesEngineeringSupport point

The invention relates to a special polishing plate for a deburring machine and a manufacturing method thereof, and the special polishing plate is used for ensuring the consistent evenness of the end face of a polishing head in the special polishing plate for the deburring machine while realizing the quick planting for a grinding material head. The polishing plate comprises a polishing plate shell and a grinding material head, wherein the polishing plate shell is of a circular groove structure; a plurality of conical pillar holes are formed at the bottom of a circular groove; and the grinding material head is located in the circular groove and solidified resins are arranged in the circular groove and the conical pillar holes. The special polishing plate for the deburring machine has the following advantages: 1) the evenness and height of the end face of a planted grinding material head are kept consistent, and the deburring effect is ensured; 2) the planted straight degree is high, and a planting hole for planting a mold core is fixed at the root of the grinding material head and the upper part of the root of the grinding material head is fixed by resins, so that a non-polishing part in the groove of the polishing plate shell has a resin supporting point, the straight degree of a grinding material in the grinding material head is high, the grinding material never falls off and the service life is long; and 3) the planting efficiency is high, the cost is low and the quality is high.

Owner:HANGZHOU XIANGSHENG ABRASIVE MACHINE MFG

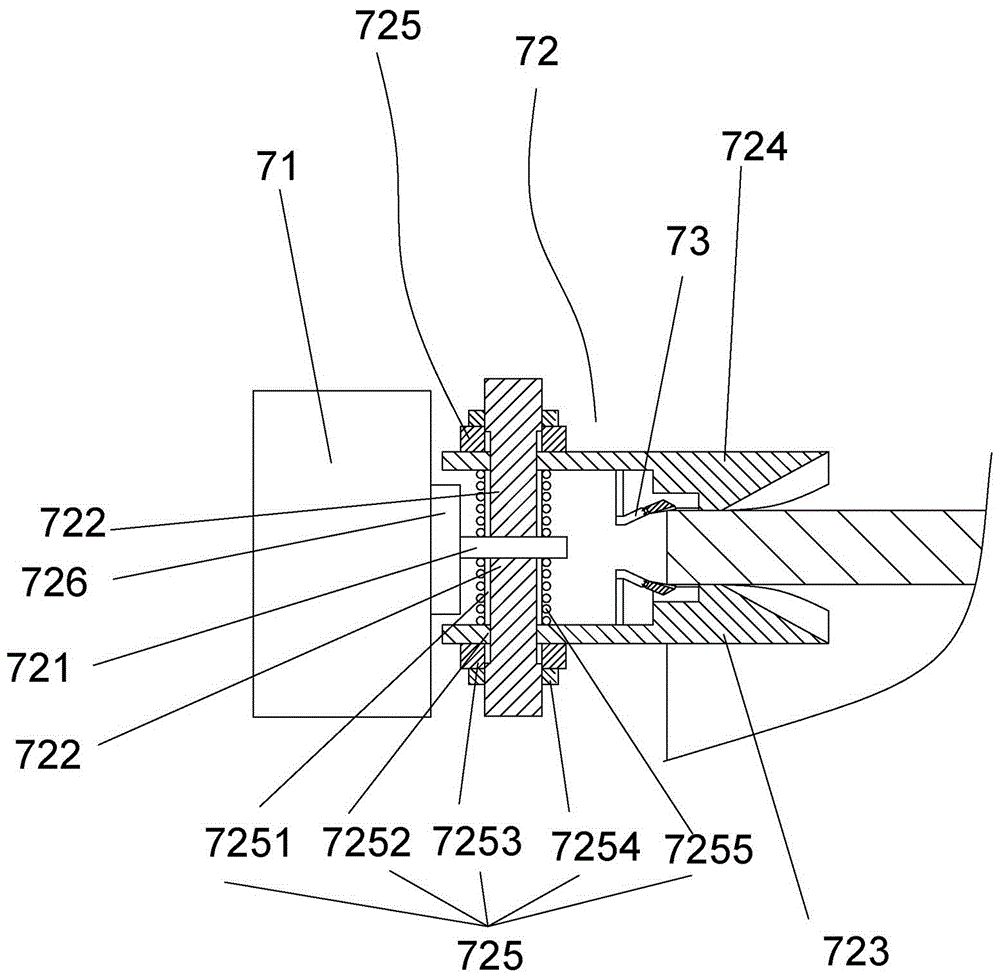

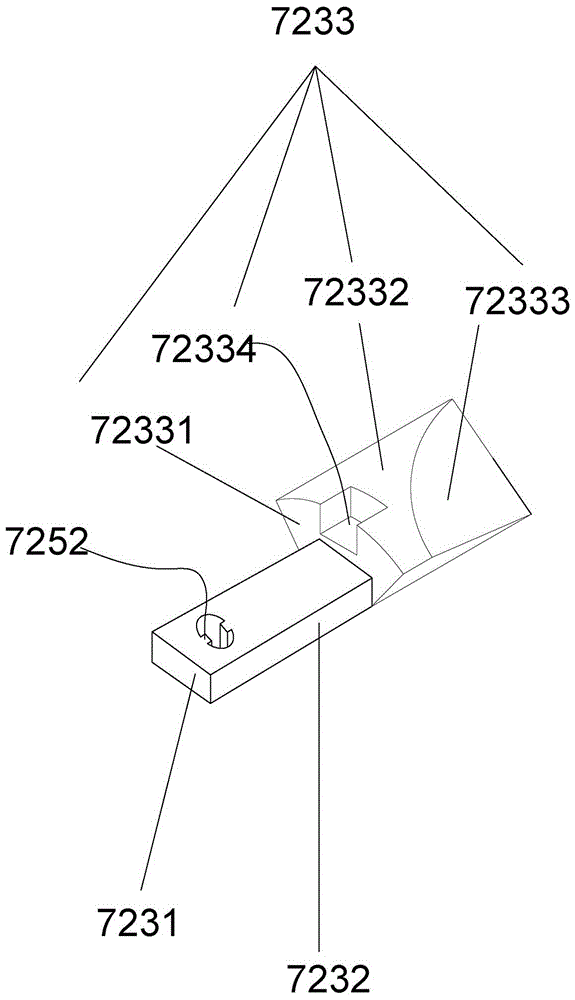

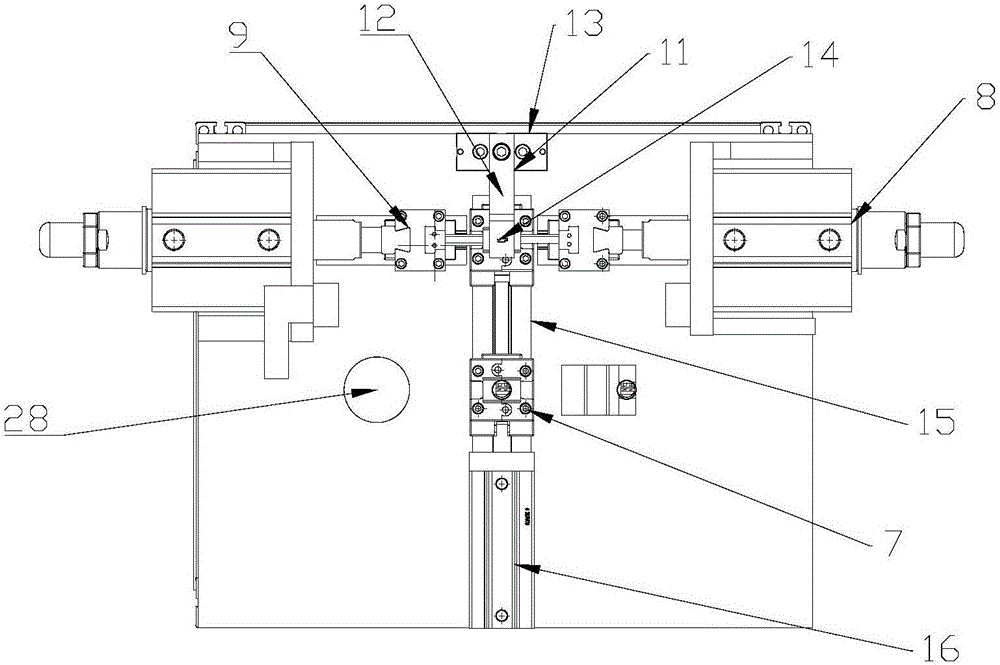

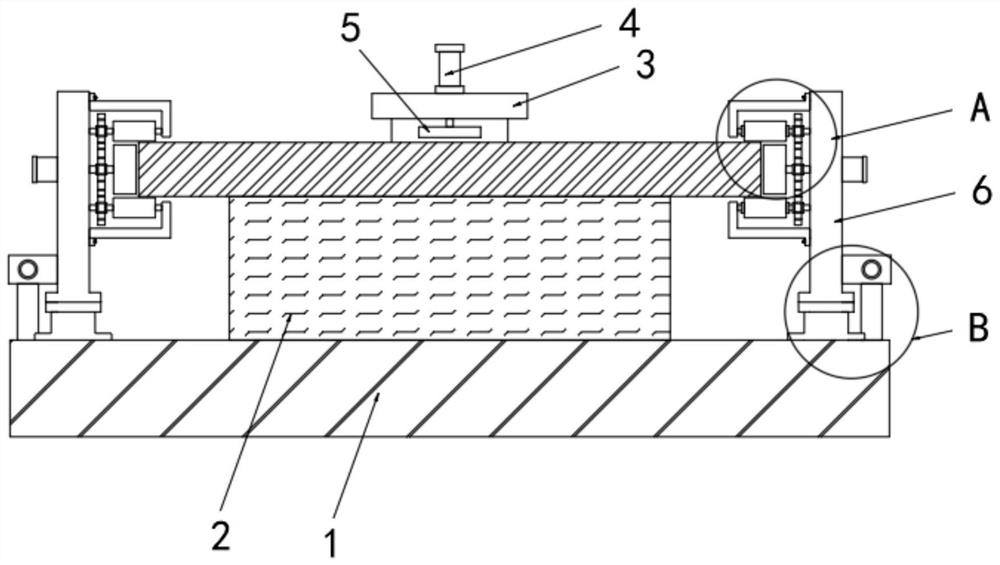

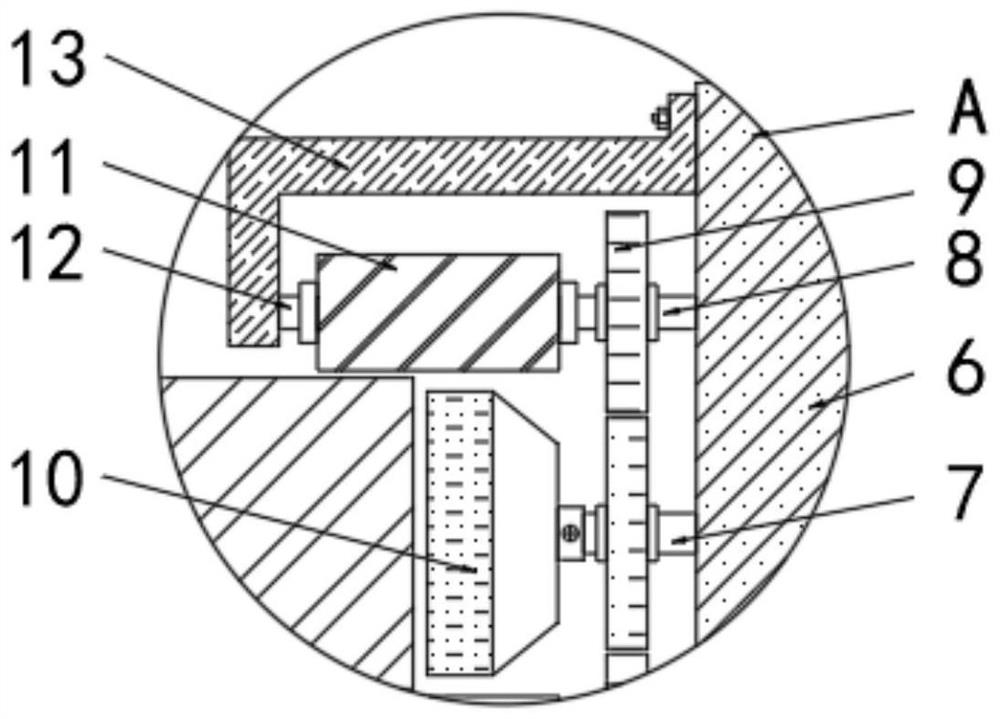

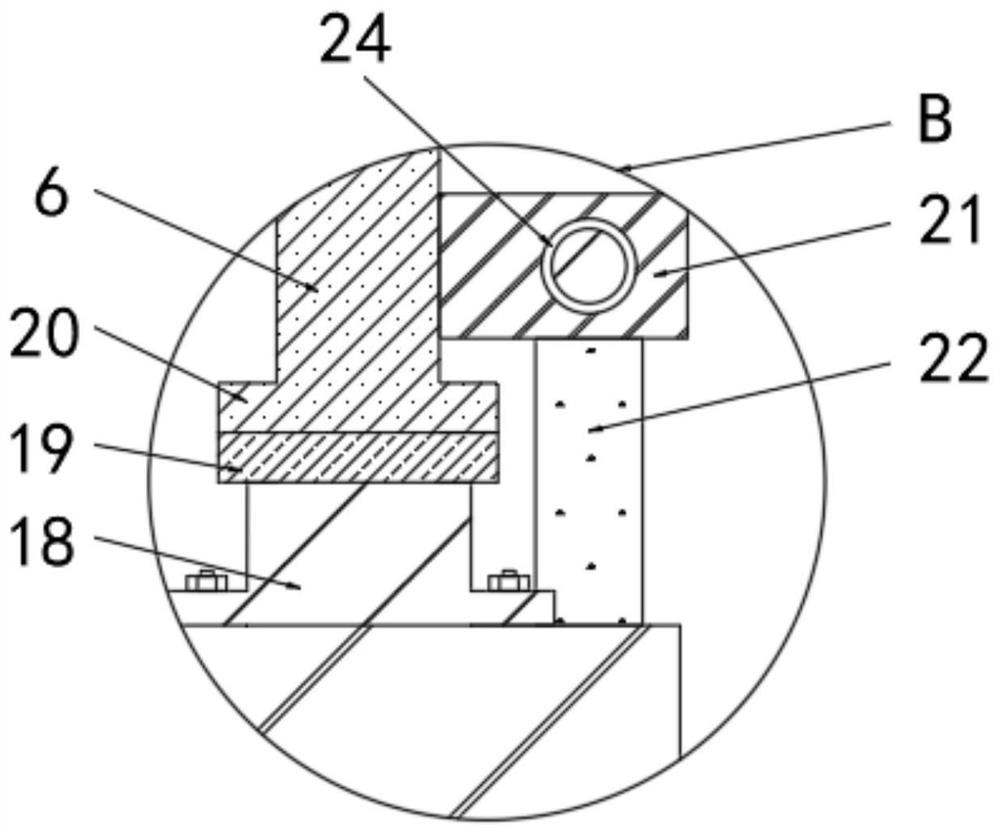

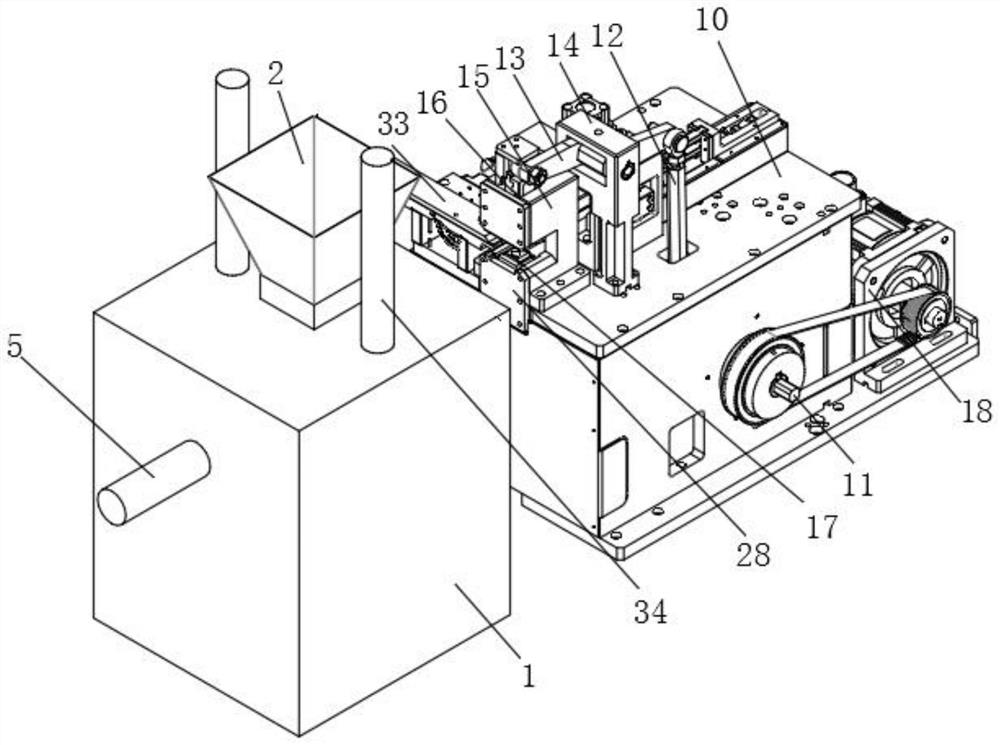

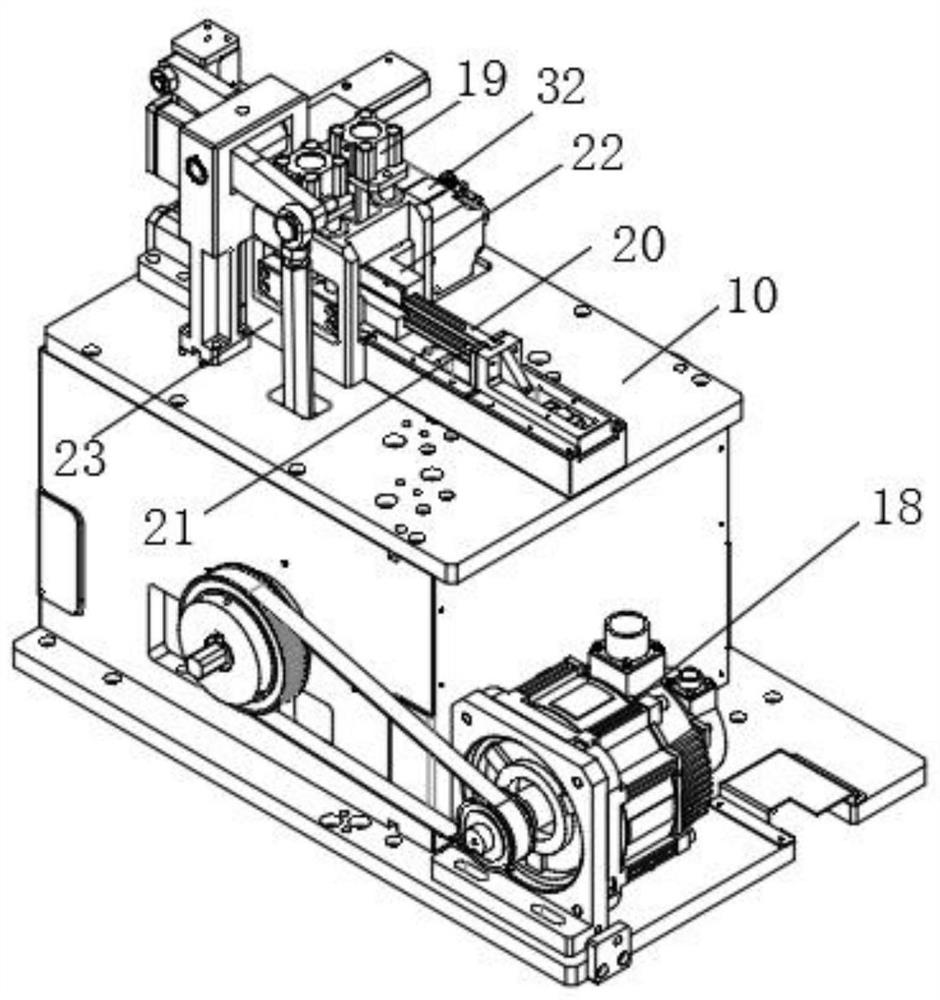

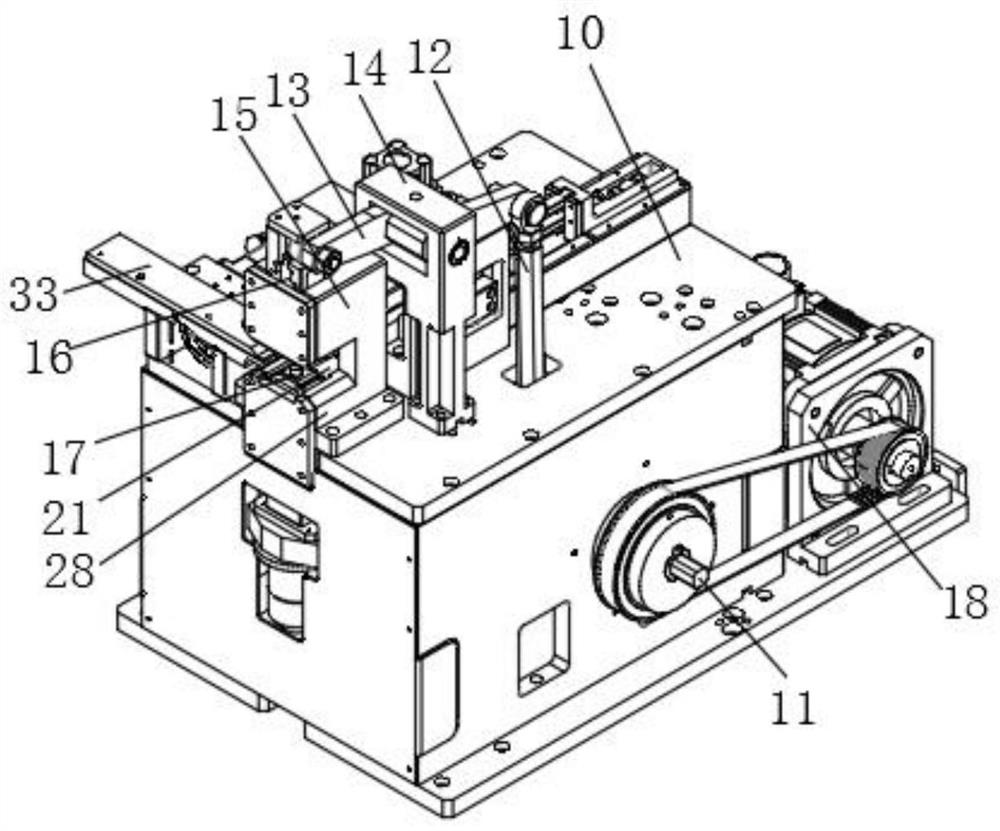

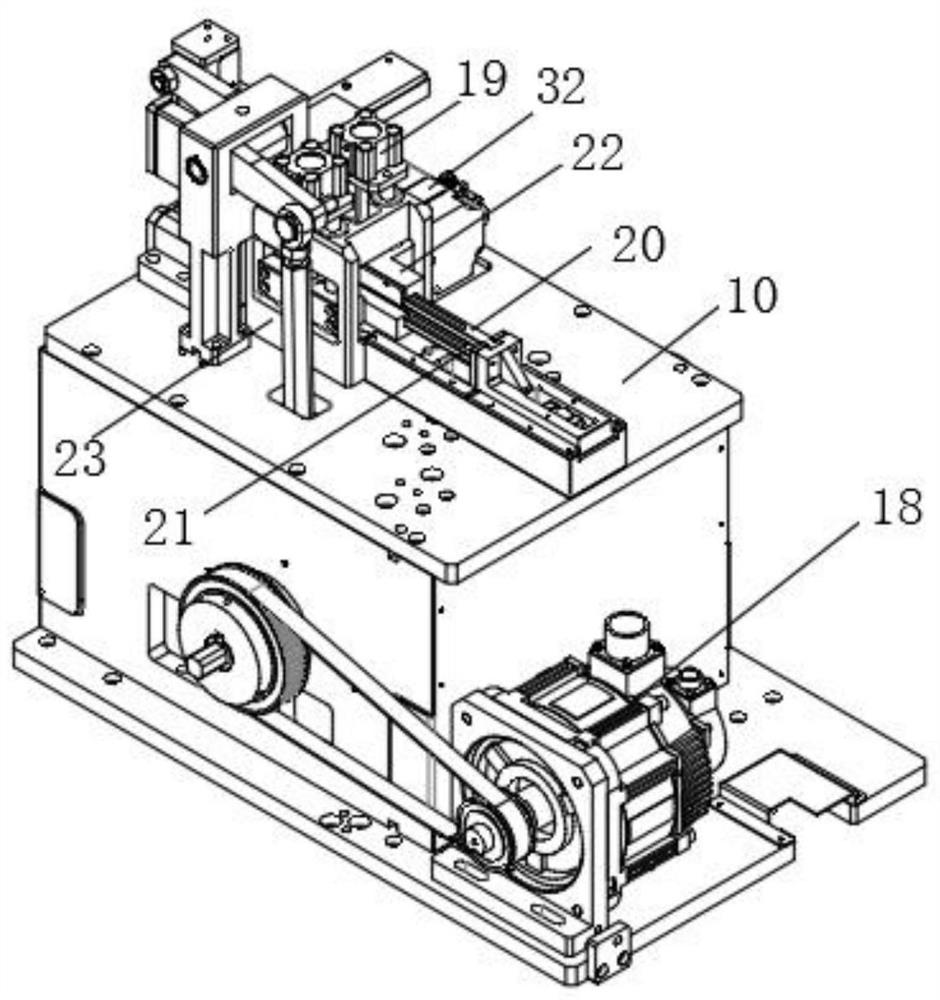

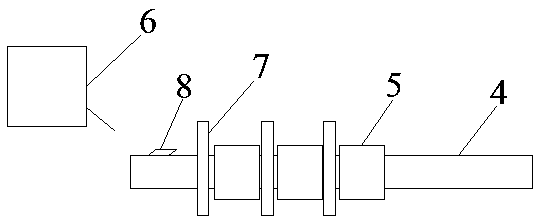

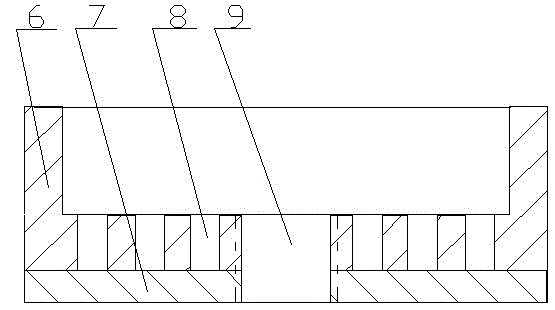

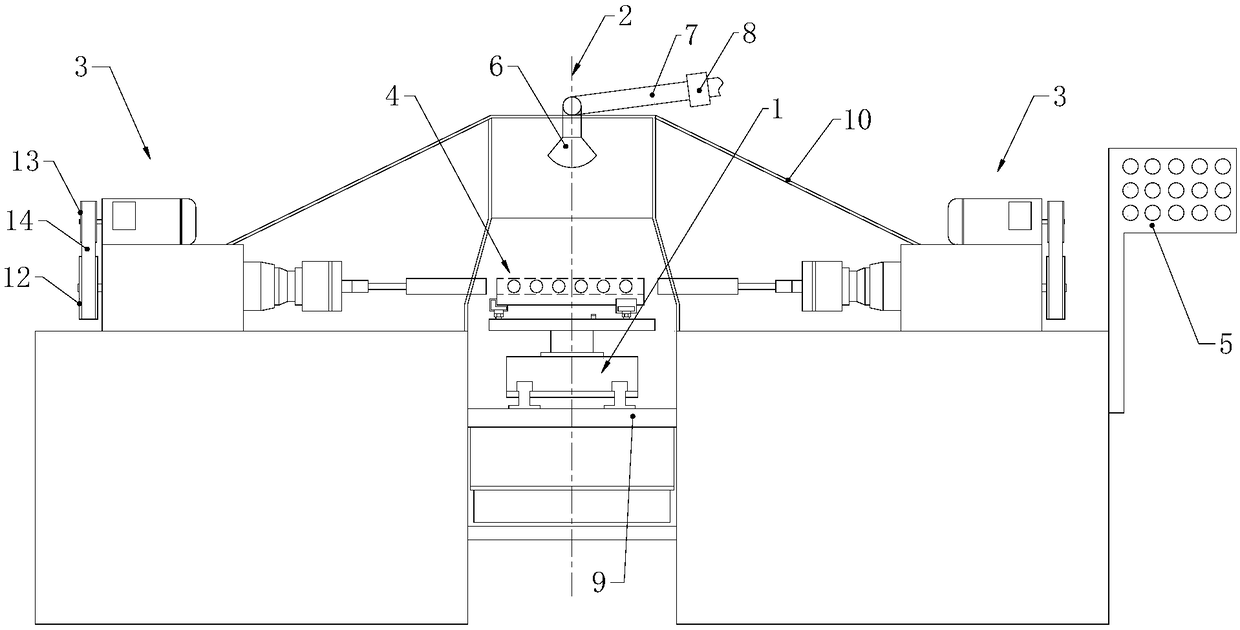

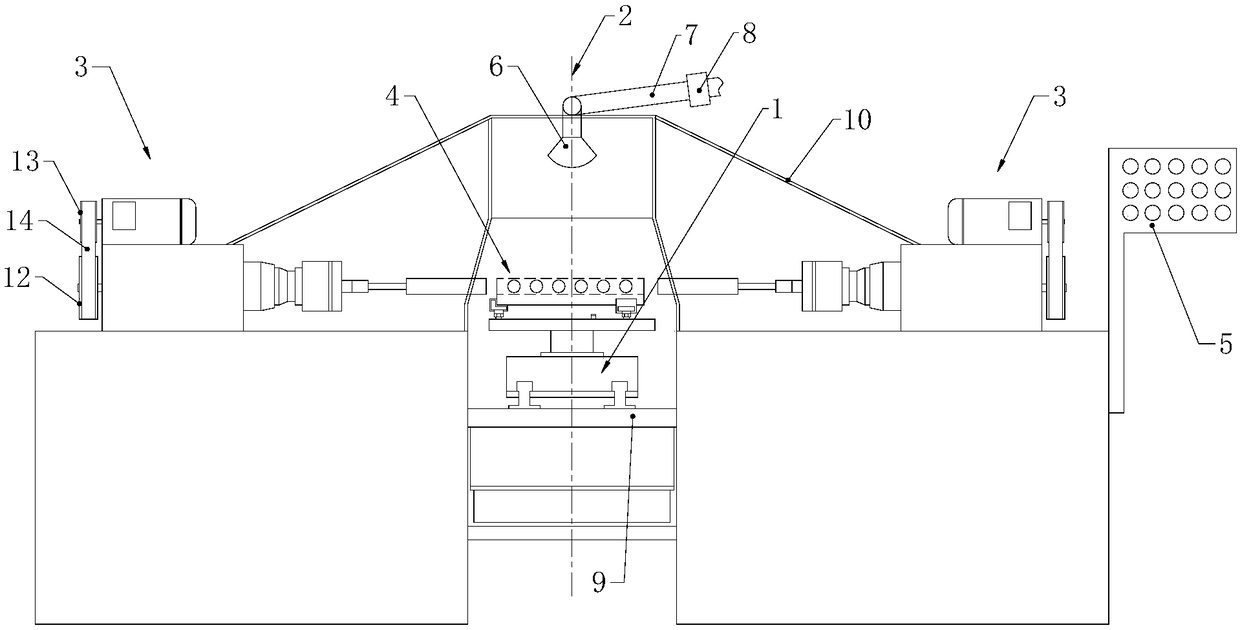

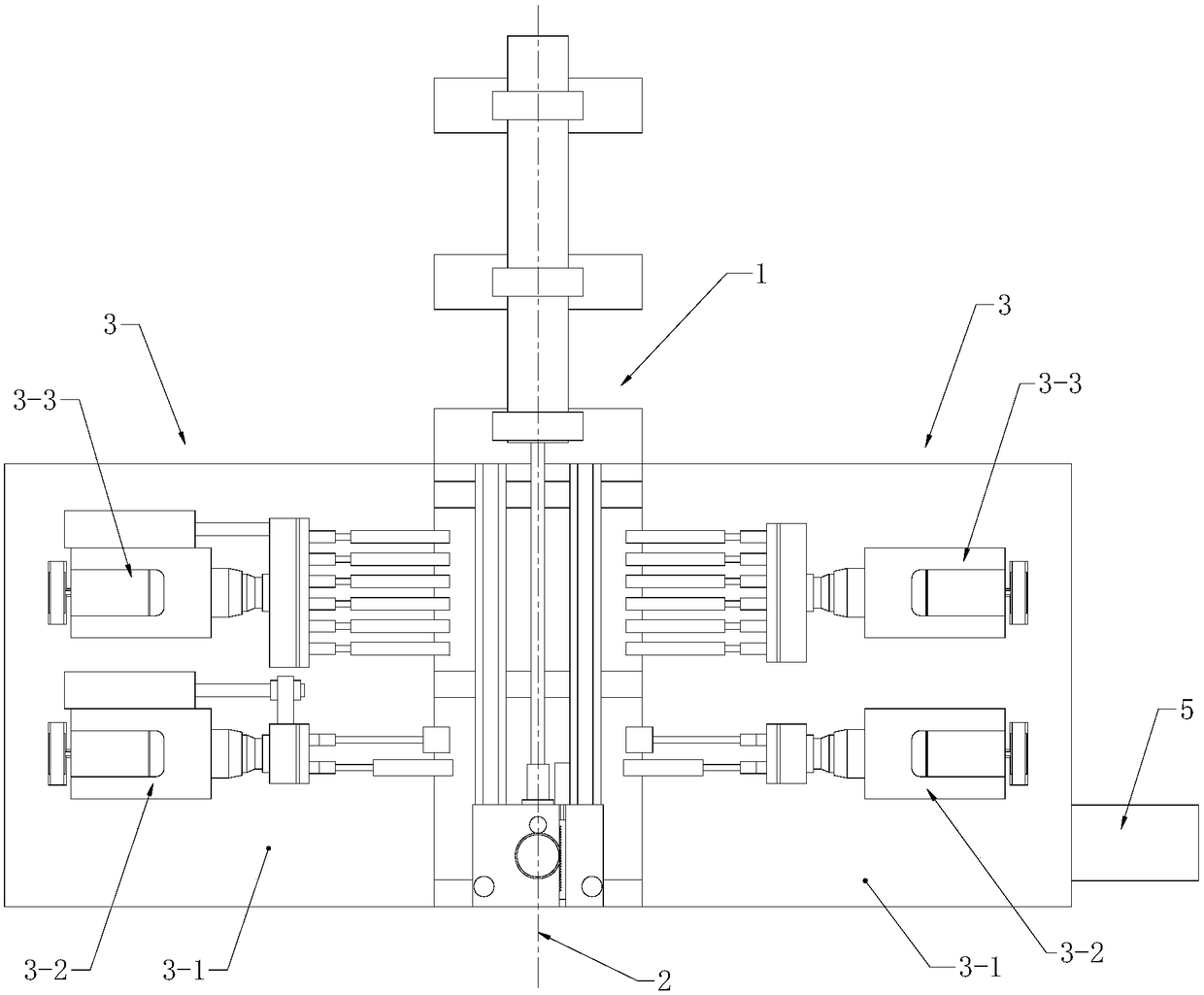

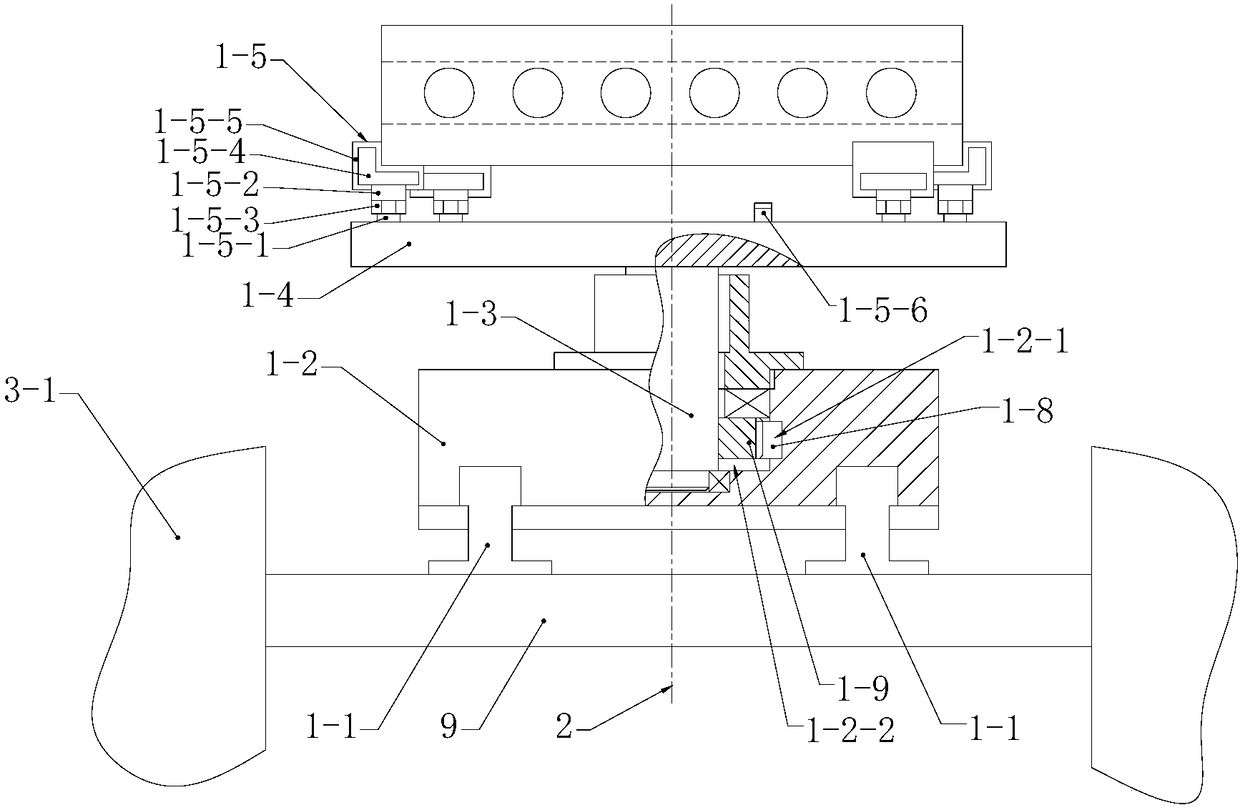

Equivalent scrubbing machine for fuel injection pump body cavity

ActiveCN108067969BGuaranteed deburring effectEnsure scrub strengthEdge grinding machinesGrinding carriagesFuel oilEngineering

The invention relates to an equivalent scrubbing machine for inner chambers of pump bodies of fuel oil injection pumps. The equivalent scrubbing machine comprises a workpiece locating device, scrubbing devices and a controller, wherein the scrubbing devices are symmetrically arranged at the two sides of the workpiece locating device. The central axis of the workpiece locating device serves as thesymmetry axis of the two scrubbing devices. Each scrubbing device comprises cam shaft hole scrubbing mechanisms and plunger hole scrubbing mechanisms, wherein the cam shaft hole scrubbing mechanisms and the plunger hole scrubbing mechanisms are arranged in the axial direction of the central axis of the workpiece locating device. The workpiece locating device comprises tracks, a sliding seat, a rotating column, a containing plate and a locating device. A linear driver is arranged at one ends of the tracks, wherein the linear driver drives the sliding seat to move along the tracks. The sliding seat is provided with a reversing driver, wherein the reversing driver can drive the rotating column to rotate. The controller controls actions of a first driver, a second driver, the linear driver andthe reversing driver so that scrubbing of the pump bodies can be completed. Equivalent scrubbing is conducted on cam shaft holes and plunger holes through the scrubbing devices, and it is guaranteedthat all the inner chambers of the pump bodies are the same in deburring scrubbing intensity, speed and angle; and the quality problem that the finish degree of the inner chambers of the pump bodies is lowered is avoided.

Owner:无锡富泰盛精模科技有限公司

An energy-saving CNC machine tool

InactiveCN110814439BReduce consumptionGuaranteed deburring effectFeeding apparatusDriving apparatusNumerical controlGear wheel

The invention discloses an energy-saving numerical control machine tool convenient to use. The energy-saving numerical control machine tool includes a machine tool base, an axle sleeve and a bearing are arranged on the upper surface of the machine tool base, a motor is fixedly installed in the machine tool base, a lifting rod is inserted in the axle sleeve, the lifting rod is inserted in the axlesleeve by means of key matching, the lifting rod moves up and down relative to the axle sleeve, a shifting rod is arranged on the side face of the lifting rod, a bearing plate is fixedly installed atthe top end of the lifting rod, a groove is formed in the center of the upper surface of the bearing plate, a gear is movably installed on the bearing plate, the lower end of a central shaft of the gear is inserted into the groove, and a workpiece bearing and placing plate is installed at the upper end of the center shaft. The energy-saving numerical control machine tool has the beneficial effectsthat the structure is simple, and energy conservation and the practicality are achieved.

Owner:常亮

Roll type optimization method used for burr presser of recoiling unit

The invention discloses a roll type optimization method used for a presser of a recoiling unit, belonging to the field of cold rolling. The roll type optimization method comprises improvement design for the roll type of a burr pressing roll and reasonable determination for parameters of a burr pressing section of the burr pressing roll; on the basis of a current flat roll structure, the roll type of the burr pressing roll is improved into two parts of a flat burr pressing section and arc transition sections; the flat part of the middle position of the burr pressing roll is the burr pressing section; and the arc transition sections with the radius of R are located on the two ends of the burr pressing section. The roll type optimization method aims to overcome defects existing in the current roll type of the burr presser; the roll type of the burr pressing roll is improved by combining equipment and technical characteristics of a recoiling process of strip steel; by reasonably determining the parameters of the burr pressing section of the burr pressing roll, strip steel indentation during the burr pressing process can be avoided, and burr pressing force is concentrated, so that the burr pressing effect is ensured; meanwhile, a positioning margin value in the width direction of the strip steel can be well given to the burr pressing roll; strict requirement of the unit on electrical control is lowered; and burr defects are effectively avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

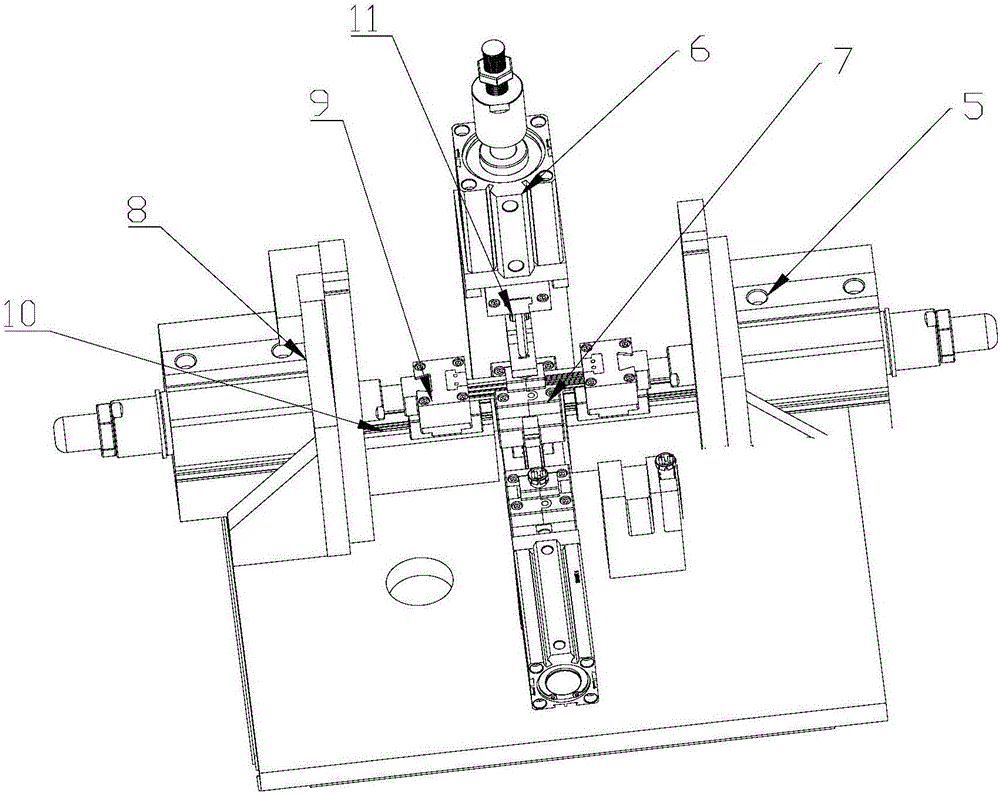

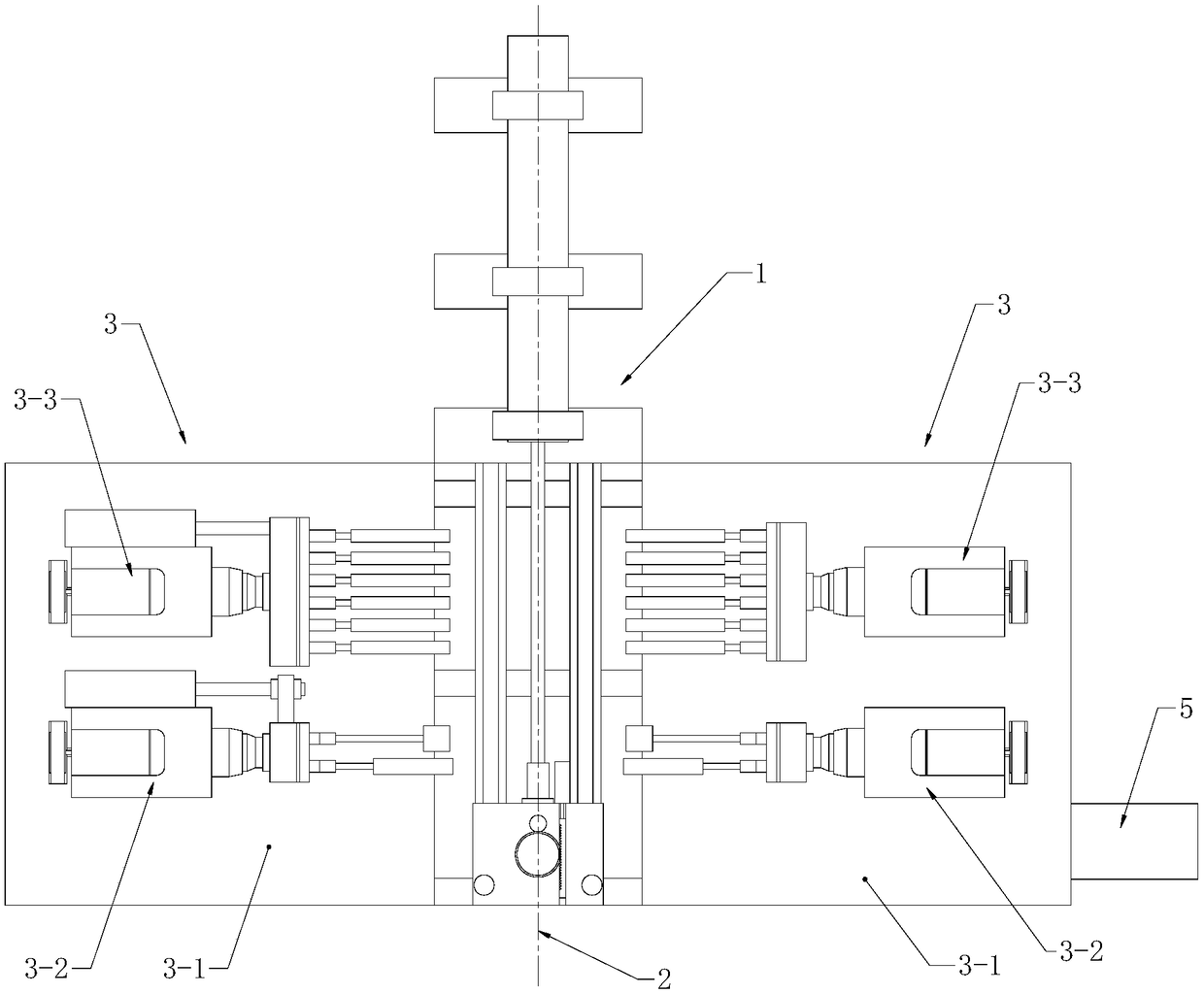

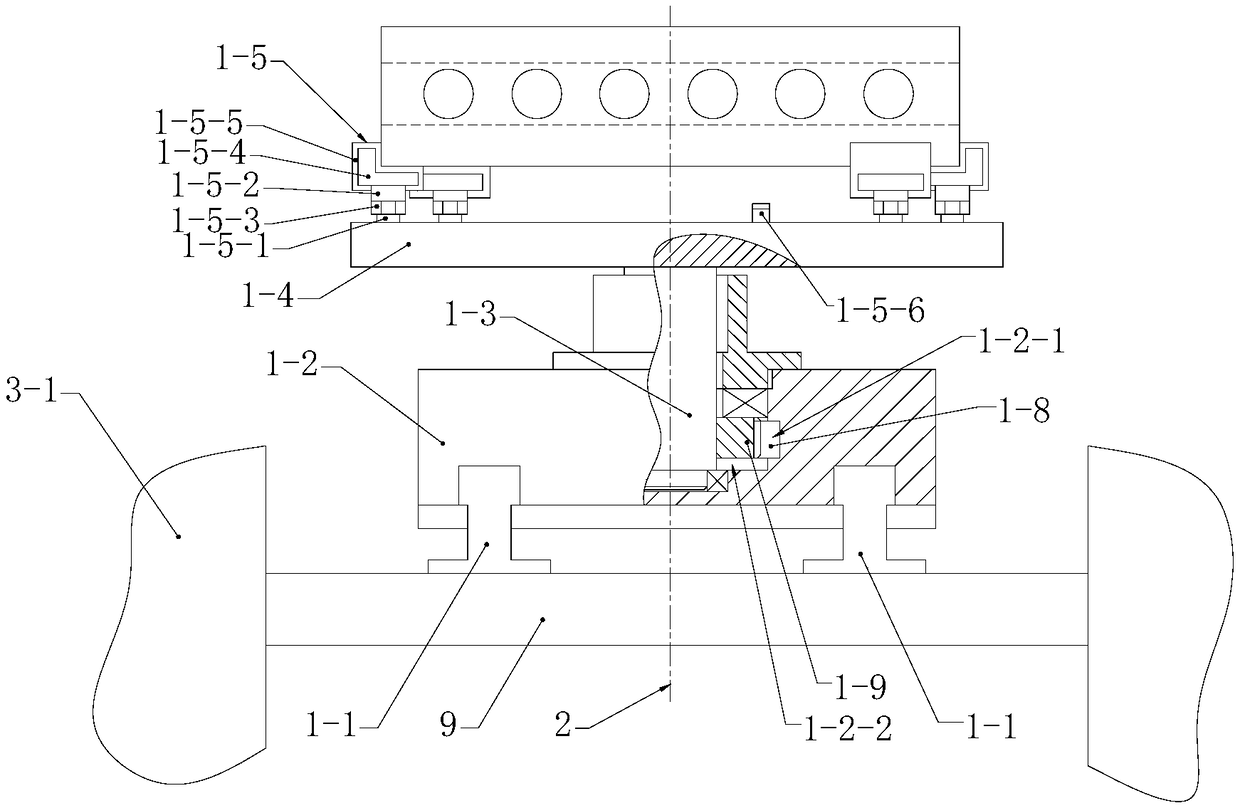

Equivalent scrubbing machine for inner chambers of pump bodies of fuel oil injection pumps

ActiveCN108067969AGuaranteed deburring effectEnsure scrub strengthEdge grinding machinesGrinding carriagesFuel oilEngineering

The invention relates to an equivalent scrubbing machine for inner chambers of pump bodies of fuel oil injection pumps. The equivalent scrubbing machine comprises a workpiece locating device, scrubbing devices and a controller, wherein the scrubbing devices are symmetrically arranged at the two sides of the workpiece locating device. The central axis of the workpiece locating device serves as thesymmetry axis of the two scrubbing devices. Each scrubbing device comprises cam shaft hole scrubbing mechanisms and plunger hole scrubbing mechanisms, wherein the cam shaft hole scrubbing mechanisms and the plunger hole scrubbing mechanisms are arranged in the axial direction of the central axis of the workpiece locating device. The workpiece locating device comprises tracks, a sliding seat, a rotating column, a containing plate and a locating device. A linear driver is arranged at one ends of the tracks, wherein the linear driver drives the sliding seat to move along the tracks. The sliding seat is provided with a reversing driver, wherein the reversing driver can drive the rotating column to rotate. The controller controls actions of a first driver, a second driver, the linear driver andthe reversing driver so that scrubbing of the pump bodies can be completed. Equivalent scrubbing is conducted on cam shaft holes and plunger holes through the scrubbing devices, and it is guaranteedthat all the inner chambers of the pump bodies are the same in deburring scrubbing intensity, speed and angle; and the quality problem that the finish degree of the inner chambers of the pump bodies is lowered is avoided.

Owner:无锡富泰盛精模科技有限公司

Stable-performance automatic resilience deburring cutter for industrial drilled hole

InactiveCN106270805AOvercome the defects that the elastic force is easy to decay and the performance is not stable enoughGuaranteed deburring effectUltrasound attenuationEngineering

The invention discloses a stable-performance automatic resilience deburring cutter for an industrial drilled hole. The cutter comprises two single blade bodies, wherein two corresponding ends of the two single blade bodies are hinged through a pivotal shaft; each of the two single blade bodies comprises a rotary part, an expansion part and a strength-bearing part; the rotary parts are hinged to the pivotal shaft; the expansion parts are arranged at the rear ends of the rotary parts; a return spring in a compression state is arranged between the expansion parts of the two single blade bodies; the strength-bearing parts are arranged at the rear ends of the expansion parts; elasticity rings are arranged on the outer side walls of the strength-bearing parts of the two single blade bodies; cutting blades are arranged on the outer side walls of rear ends of the strength-bearing parts. The stable-performance automatic resilience deburring cutter overcomes the defects that elastic force of an elasticated arm of the existing deburring cutter is prone to attenuation and is instable in performance; the return spring is arranged, and elastic force of the return spring is utilized to enable the cutting blades to cling to the inner wall of an industrial drilled hole, so that the deburring effect is ensured.

Owner:成都君华睿道科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com