Full-automatic lock cylinder deburring tool

A deburring and fully automatic technology, applied in metal processing, etc., can solve problems such as laborious, poor cleaning effect, cumbersome deburring process, etc., to achieve the effect of improving processing stability, reducing production costs, and ensuring deburring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

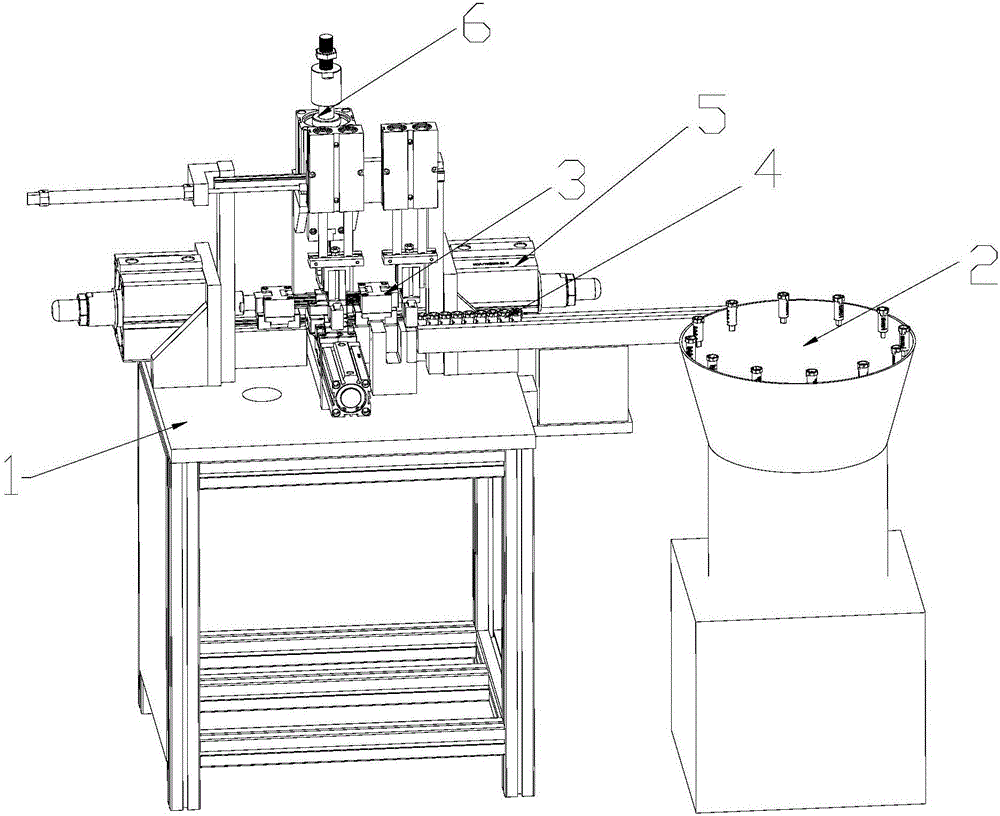

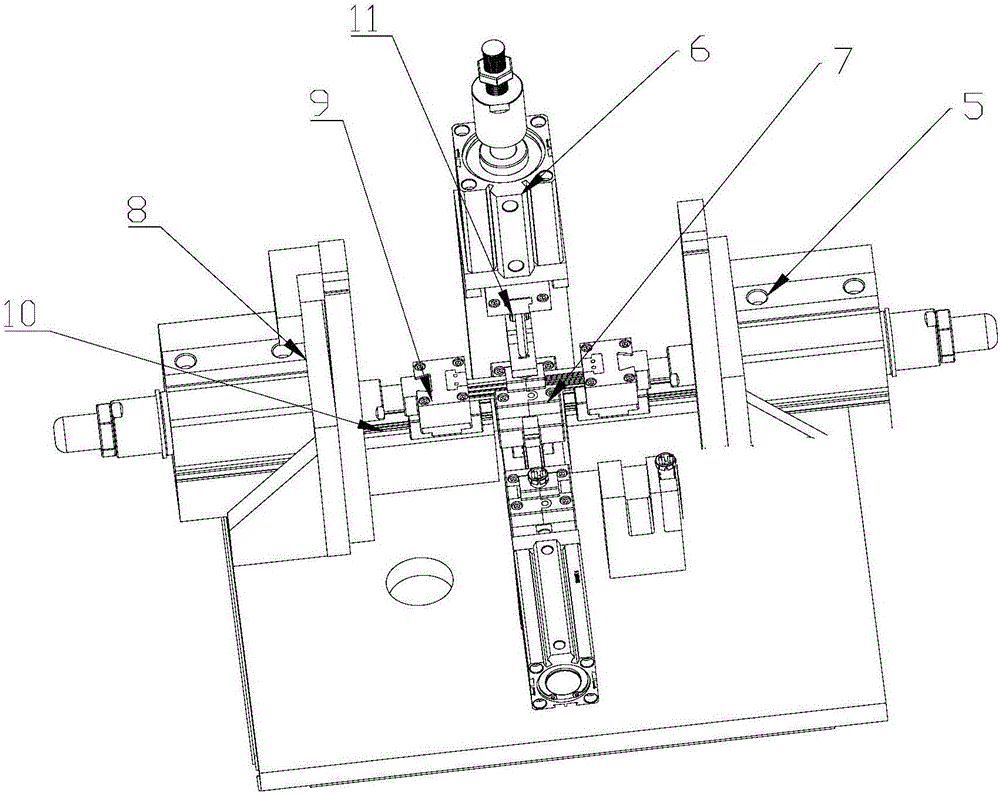

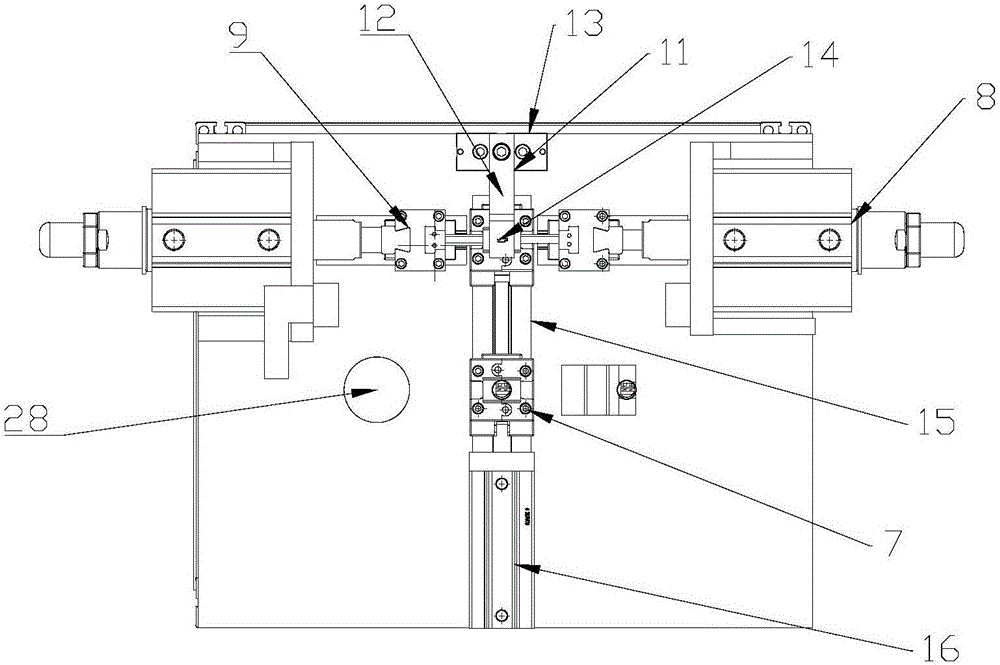

[0025] like figure 1 , shown in 2, a fully automatic lock cylinder deburring tooling, the tooling includes a frame 1, a vibrating plate 2 is set beside the frame 1, and a deburring mechanism 3 and a conveying mechanism 4 are set on the frame 1 , the vibrating plate 2 transports its lock core to the deburring mechanism 3 through the conveying mechanism 4 for deburring. The deburring mechanism 3 includes a left and right lockhole deburring mechanism 5, an upper lockhole Destab mechanism 6 and lock core holder 7, the left and right ends of the lock cylinder holder 7 are respectively provided with left and right lockhole destab mechanisms 5, and the lock cylinder holder 7 is directly above the upper lockhole. Stab mechanism 6, described left and right lockhole destab mechanism 5 and upper lockhole destab mechanism 6 comprise driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com