Stainless steel plate deburring equipment for high-voltage switch cabinet

A high-voltage switchgear and stainless steel technology, which is applied to machine tools, metal processing equipment, grinding/polishing equipment, etc., which are suitable for grinding the edge of workpieces, and can solve the problem of burr cleaning equipment without a transmission structure, low grinding efficiency, and difficult to grind parts Replacement and other issues to achieve the effect of avoiding shaking, improving grinding efficiency and reducing error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

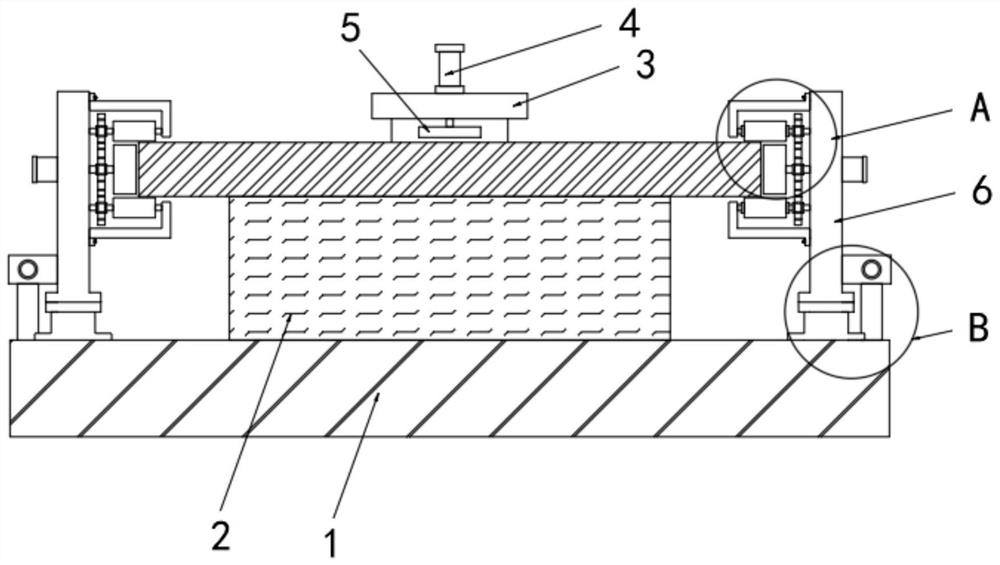

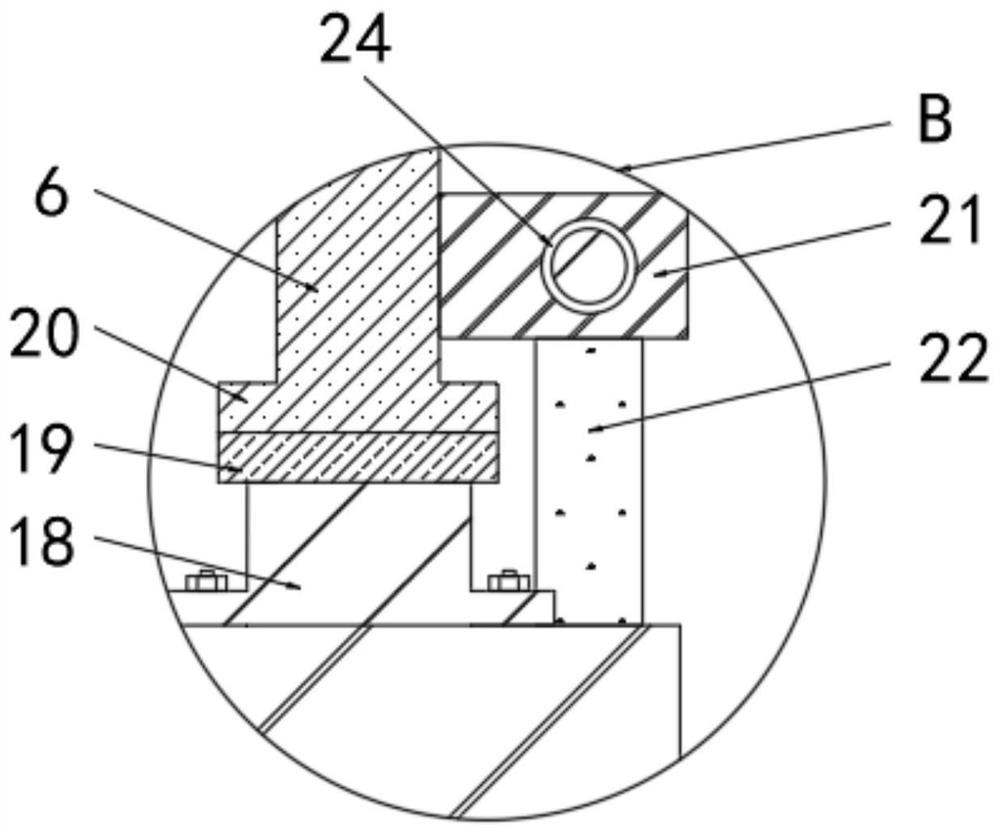

[0031] see Figure 1-Figure 6 As shown, the present invention provides a stainless steel plate deburring equipment for high-voltage switch cabinets, including a processing table 2, a stainless steel plate is placed on the top of the processing table 2, support columns 6 are installed on both sides of the processing table 2, and the processing table 2 The end surface of the stainless steel plate is equipped with a grinding mechanism for grinding the stainless steel plate;

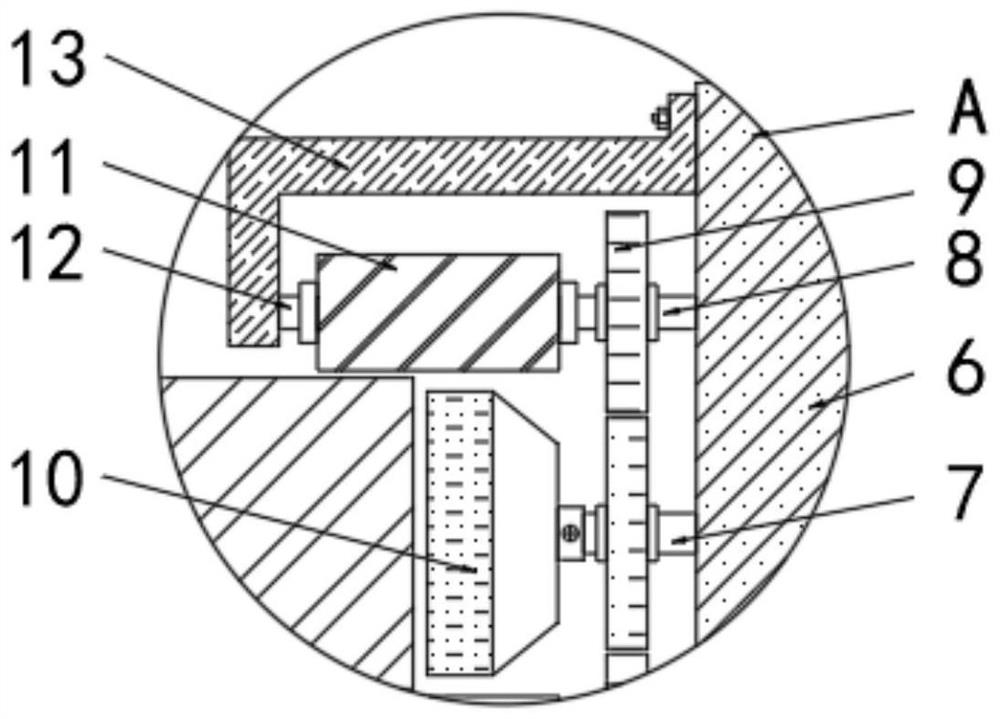

[0032] The grinding mechanism includes two upper and lower sanding rollers 11 and sanding paper 10. One end of the sanding paper 10 is connected with the main shaft 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com