Equivalent scrubbing machine for fuel injection pump body cavity

A fuel injection pump, brushing machine technology, applied in the direction of grinding frames, grinding machine parts, machine tools suitable for grinding workpiece edges, etc. The control is difficult to balance and other problems, so as to ensure the effect and avoid the decline of the finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

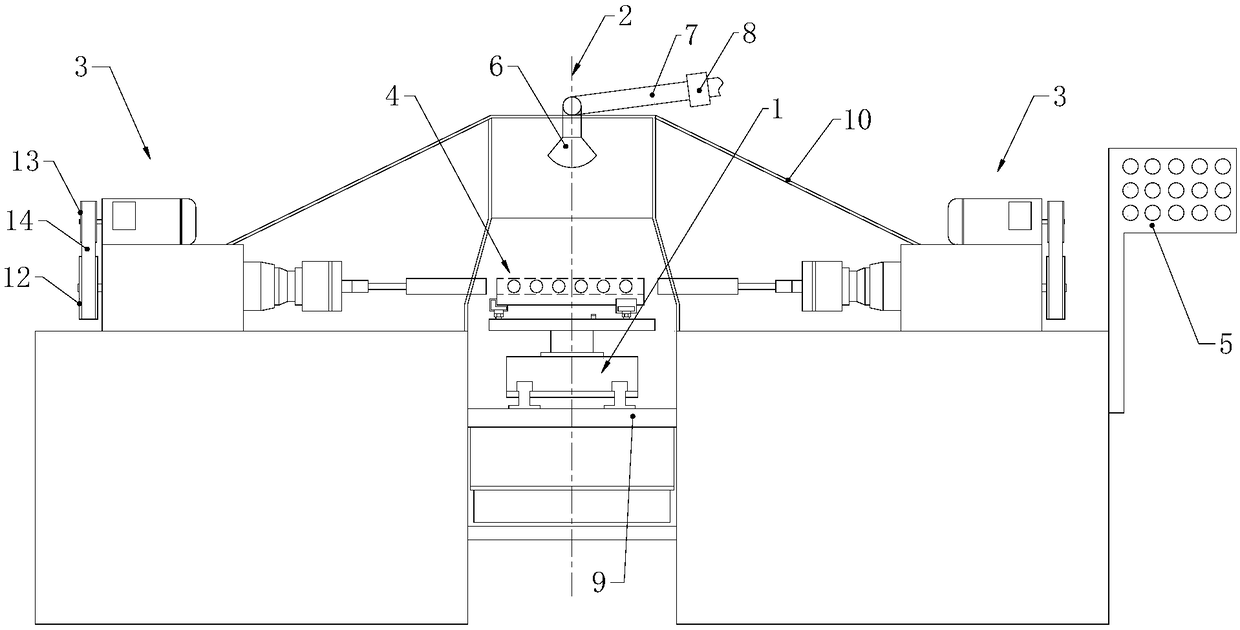

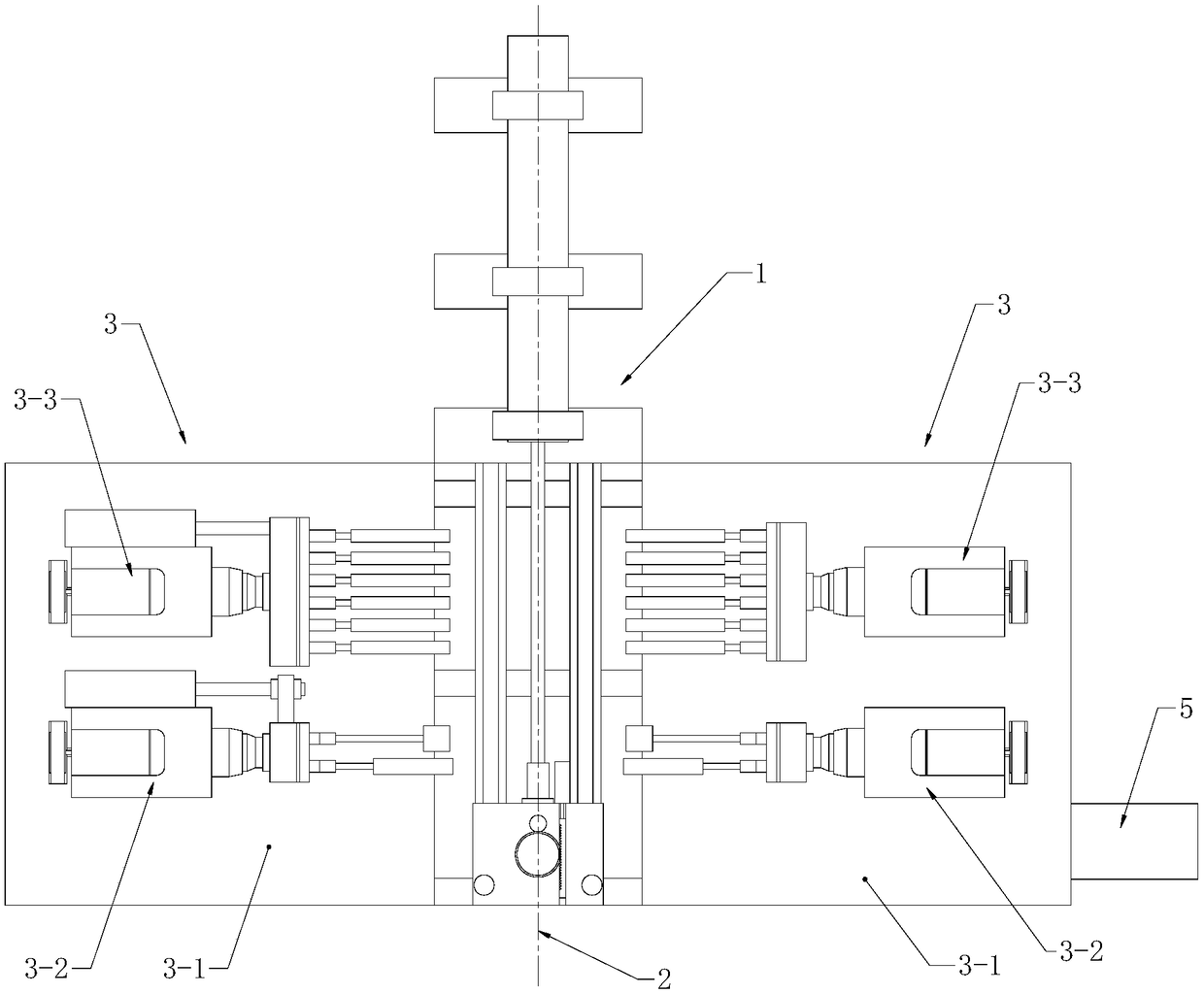

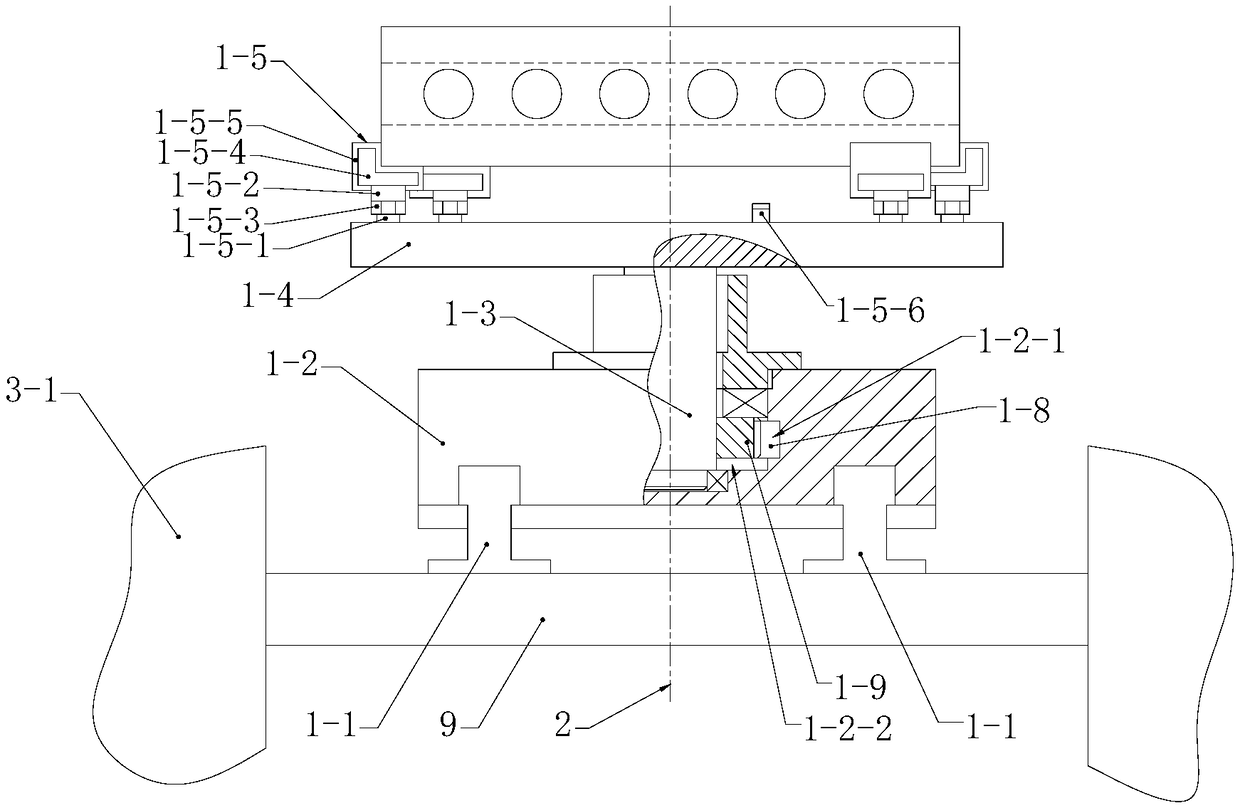

[0024] Such as Figure 1 to Figure 6The fuel injection pump body cavity brushing machine shown in the figure includes a workpiece positioning device 1, a brushing device 3 and a controller 5 symmetrically arranged on both sides of the workpiece positioning device 1, and the two brushing devices 3 are centered around the central axis of the workpiece positioning device 1. 2 is a symmetrical axis, and the scrubbing device 3 includes a machine platform 3-1, and a camshaft hole scrubbing mechanism 3-2 and a plunger arranged axially along the central axis 2 of the workpiece positioning device 1 are arranged on the upper end surface of the machine platform 3-1. A hole brushing mechanism 3-3, the camshaft hole brushing mechanism 3-2 includes a first driver 3-2-1 and a camshaft hole brush roller 3-2-2, and the first driver 3-2-1 drives the camshaft The hole brush roller 3-2-2 rotates and performs telescopic movement toward the workpiece positioning device 1 perpendicular to the centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com