Stable-performance automatic resilience deburring cutter for industrial drilled hole

A deburring and stable technology, which is applied in the field of automatic springback deburring tools for industrial drilling, can solve the problems of unstable performance and easy attenuation of the elastic force of the elastic arm, and achieve the effect of simple operation, convenient operation and enhanced experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

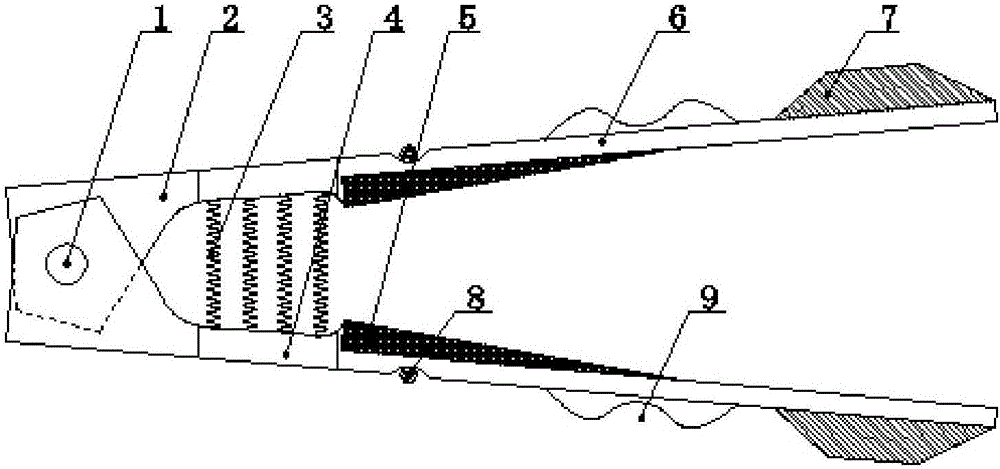

[0023] see figure 1 , an automatic rebound deburring tool for industrial drilling with stable performance, including two single blades, one end of the two blades is hinged by a hinge shaft 1 at the same time, and the single blade includes a rotating part 2 , the expansion part 4 and the force bearing part 6, the rotating part 2 is hinged with the pivot shaft 1, the rear end of the rotating part 2 is the expanding part 4, and the recovery part in the compressed state is provided between the two blade single expansion parts 4 Spring 3, the rear end of the expansion part 4 is a load-bearing part 6, and an elastic ring 8 is set on the outer wall of the two blade monomer load-bearing parts 6, and a cutting edge is provided on the outer wall of the rear end of the force-bearing part 6 7.

[0024] When the present invention is in use, pinch the outer side wall of the blade monomer to reduce the distance between the two blade monomers to ensure that the blade monomer can smoothly ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com