An energy-saving CNC machine tool

A CNC machine tool, energy-saving technology, applied in metal processing machinery parts, manufacturing tools, drive devices, etc., can solve the problems of reducing production efficiency, complex transmission structure design, increasing processes, etc., to reduce energy consumption and ensure deburring effect. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

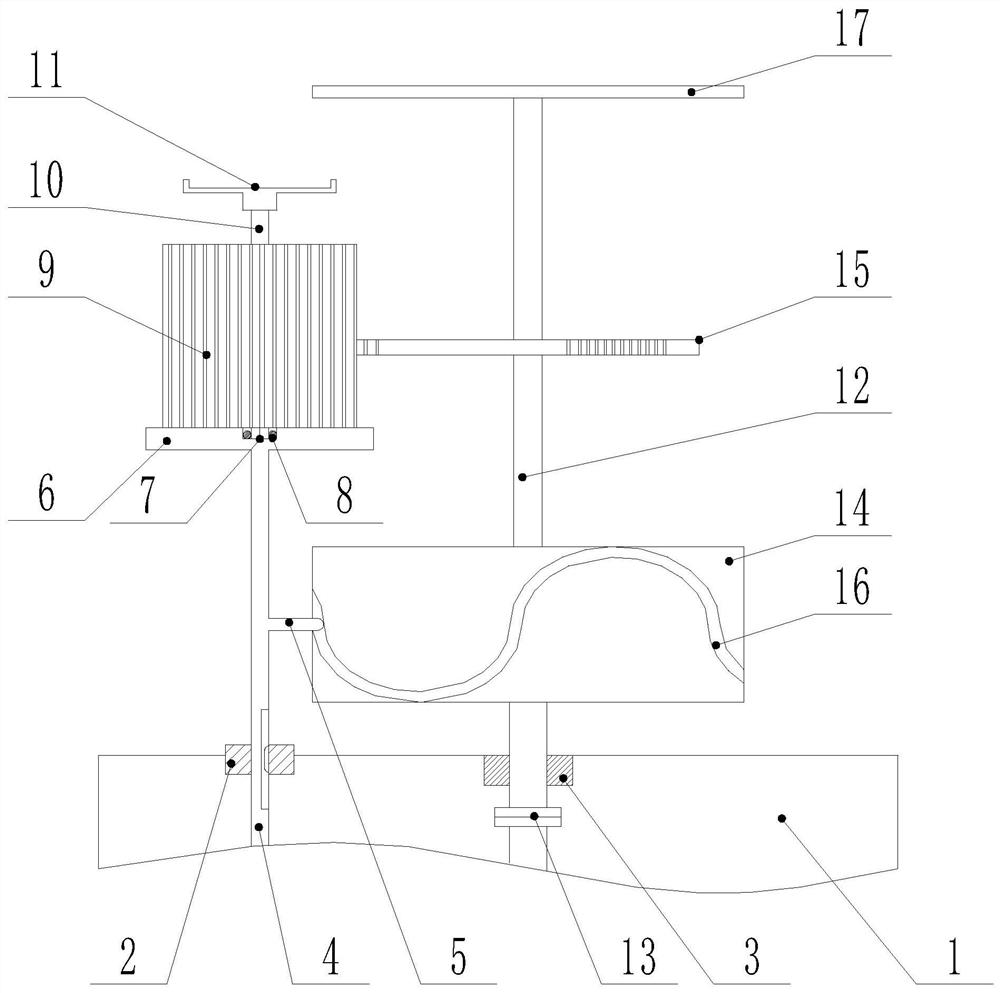

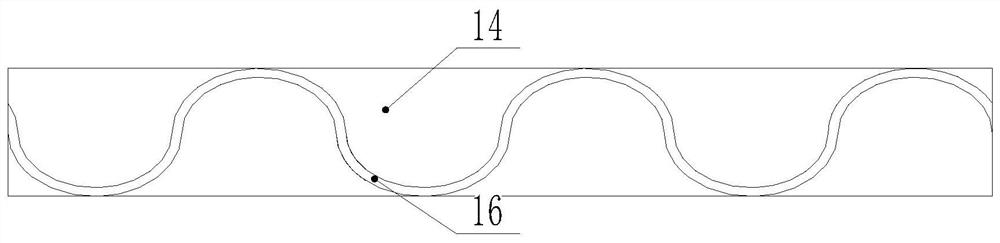

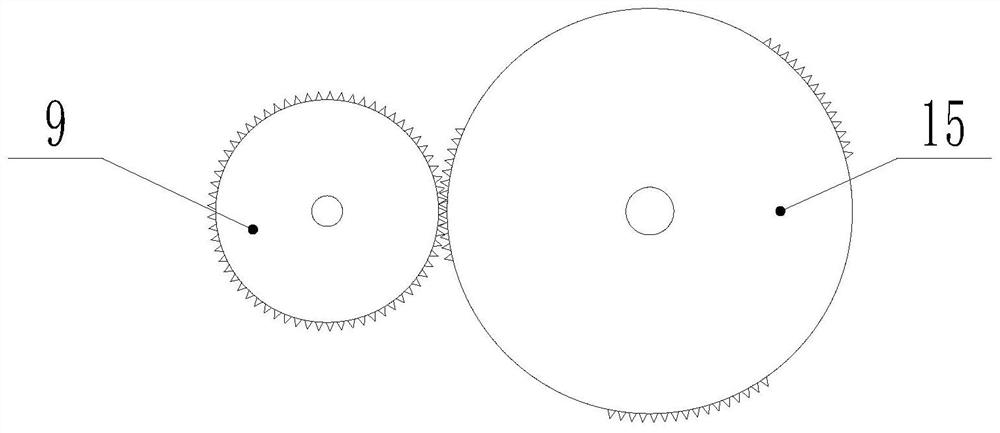

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, the inventive point of the present application is that the lifting rod 4 is inserted into the shaft sleeve, and the lifting rod is inserted into the shaft sleeve through key fit, the lifting rod moves up and down relative to the shaft sleeve, and the lifting rod 4 moves up and down relative to the shaft sleeve. There is no relative rotation between the rod and the bushing, the side of the elevating rod is provided with a driving rod 5, the top of the elevating rod is fixedly mounted with a bearing plate 6, and the center of the upper surface of the bearing plate is provided with a groove 7. The gear 9 is movable on the plate, and the lower end of the central shaft 10 of the gear is inserted into the groove, and the workpiece bearing plate 11 is installed on the upper end of the central shaft; the driving shaft 12 is inserted on the bearing, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com