Equipment for deburring after machining

A deburring and equipment technology, which is applied in metal processing equipment, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of slow beat, prolong processing time, missing, etc., and increase production capacity , to ensure versatility, to avoid the effect of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

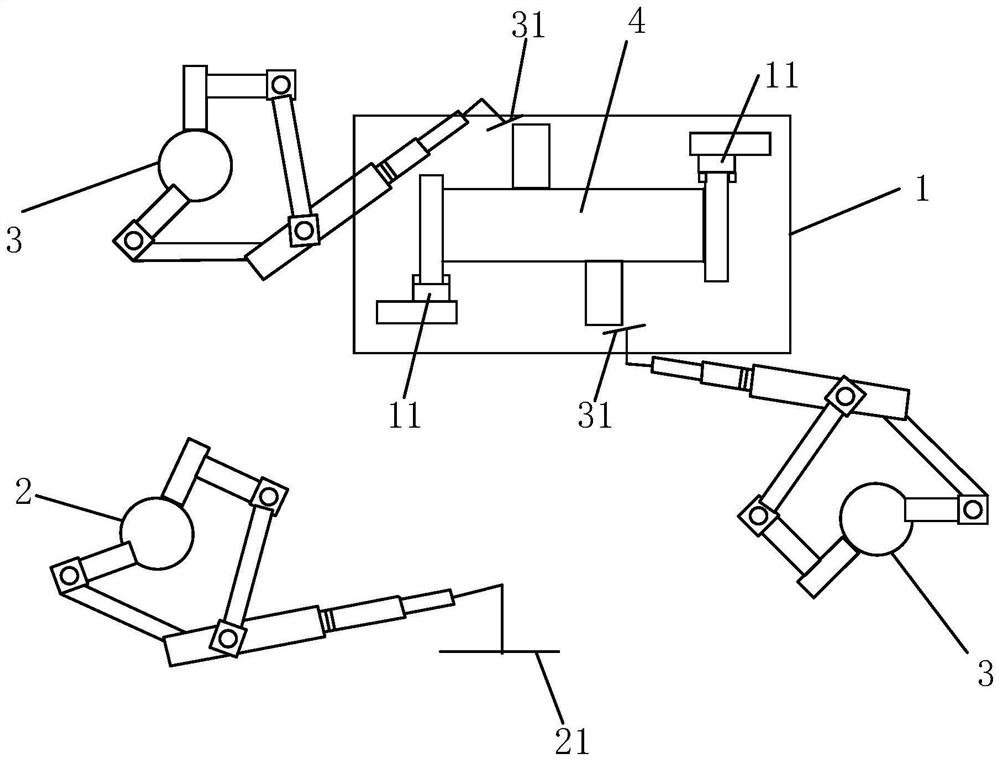

[0030] Such as figure 1 As shown, the present embodiment provides a device for deburring after processing, which includes:

[0031] Workpiece loading platform 1: used for loading the workpiece 4 to be deburred after processing;

[0032] Loading manipulator 2: used to load the workpiece 4 to be deburred onto the workpiece loading platform 1;

[0033] Grinding manipulator 3: used for grinding the workpiece 4 to be deburred;

[0034] Visual positioning component: used for visual monitoring during the action of loading manipulator 2 and grinding manipulator 3;

[0035] One loading manipulator 2 is configured, and multiple grinding manipulators 3 are configured and distributed along the side of the workpiece loading platform 1. The loading manipulator 2, grinding manipulator 3 and visual positioning components are all connected to a linkage controller.

[0036] In this embodiment, the linkage controller includes a PLC controller, and the visual positioning component includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com