Double-sided deburring method of ultra-large-curvature valve plate

A super-large curvature and deburring technology, which is applied to the parts of grinding machine tools, surface polishing machine tools, and machine tools suitable for grinding the edge of workpieces, etc. Safety and other issues, to improve safety and processing efficiency, ensure the effect of deburring, and avoid the effect of manual hand-holding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

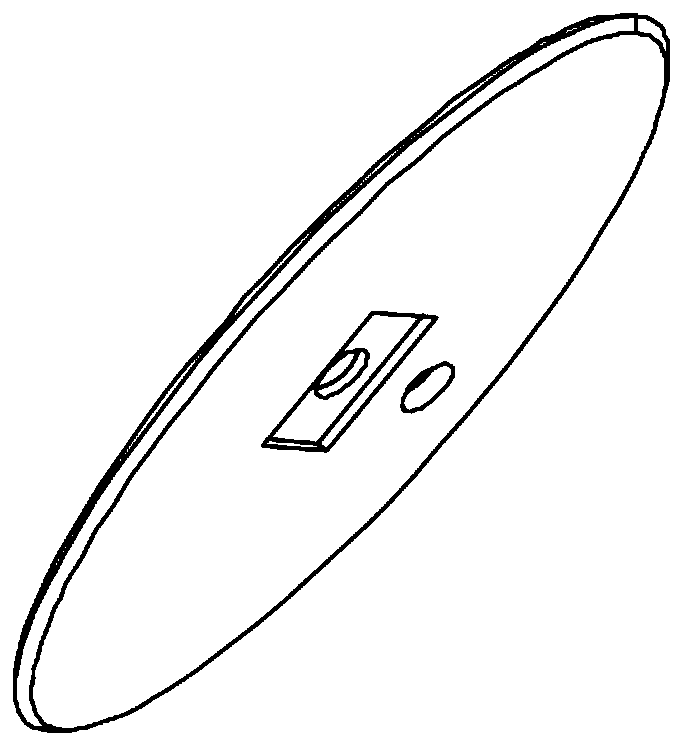

[0032] Please refer to Figure 1 to Figure 6 . The double-sided deburring method proposed by the present invention is aimed at the valve plate with super large curvature, and the structure of the valve plate workpiece to be processed is as follows: figure 1 As shown, the valve plate to be treated is an angled elliptical valve plate (similar to a pressed and inclined cylinder), with two through holes opened on it. The double-sided deburring method proposed by the present invention can realize automatic loading and unloading, avoid manual hand-held operation, and improve the safety of operation. improved processing efficiency.

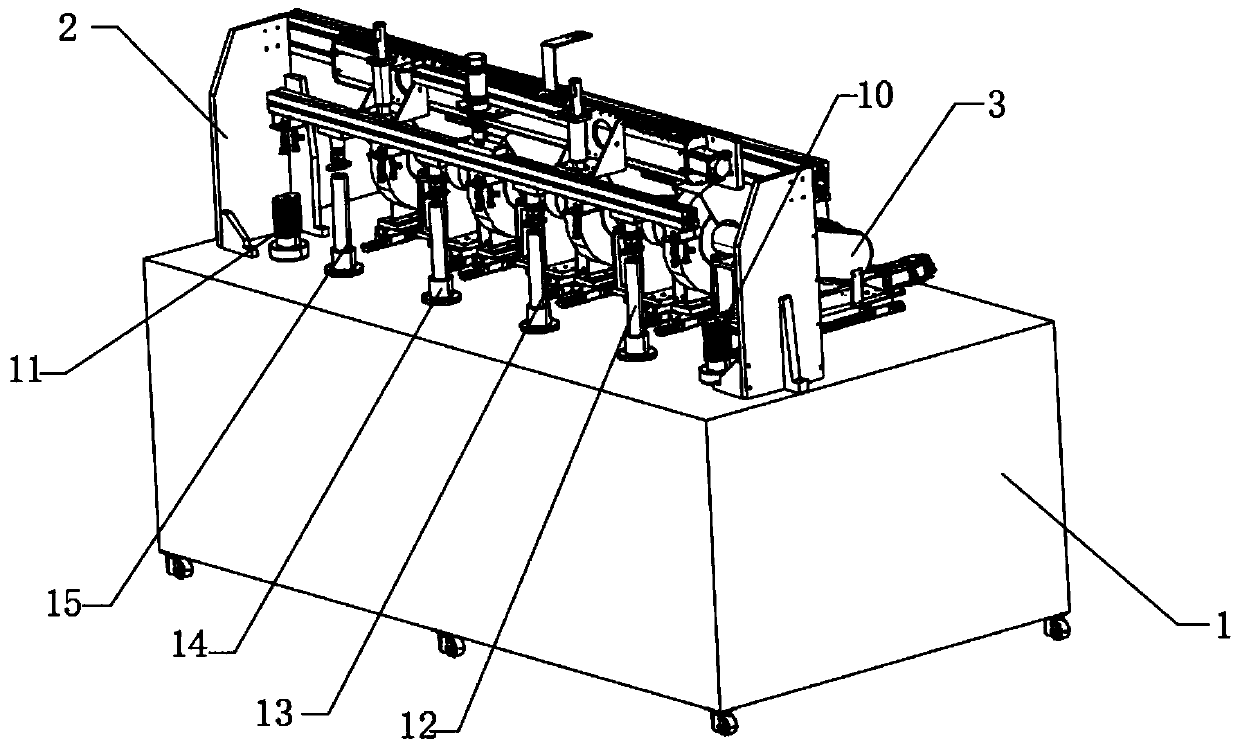

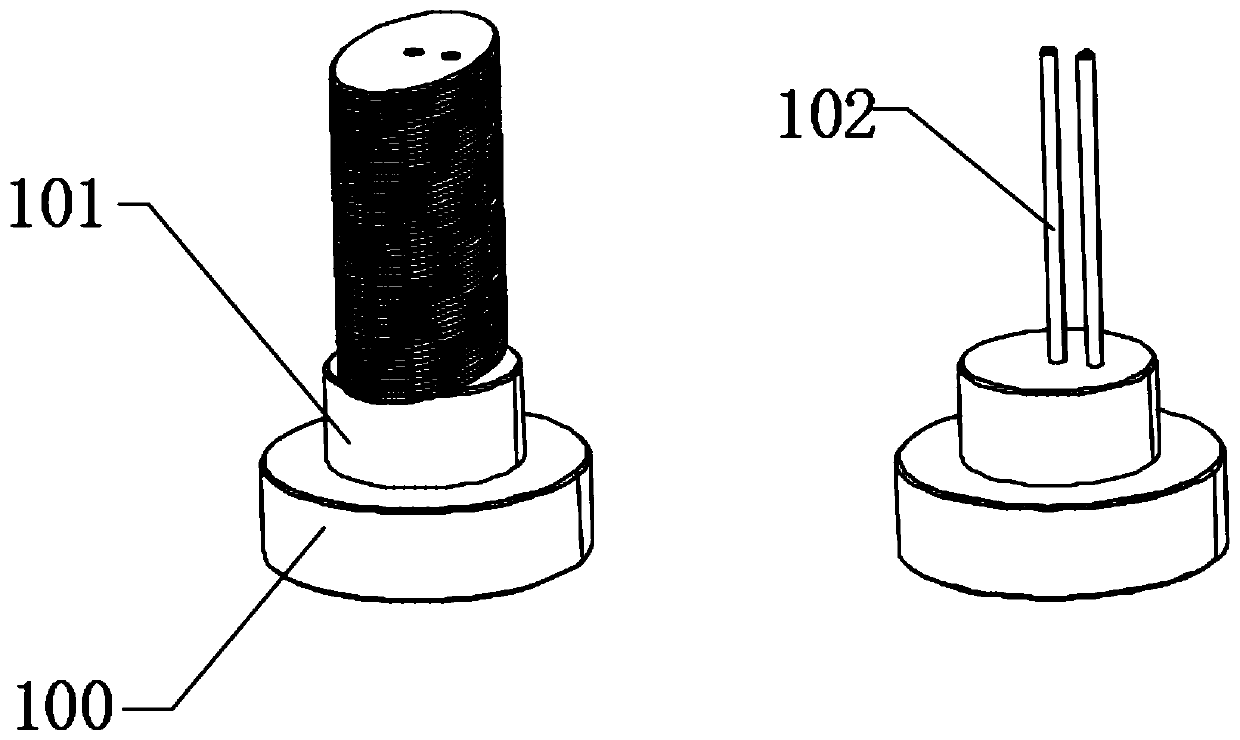

[0033] The double-sided deburring method proposed by the present invention is realized by using double-sided deburring equipment, specifically, as Figure 2 to Figure 5 As shown, the double-sided debu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com