A device for removing burrs from the opening edge of a piston ring

A technology for deburring and piston rings, which is applied to fixed grinding wheel devices, grinding/polishing safety devices, and machine tools suitable for grinding the edge of workpieces. Achieve the effect of reducing workload, ensuring deburring effect and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

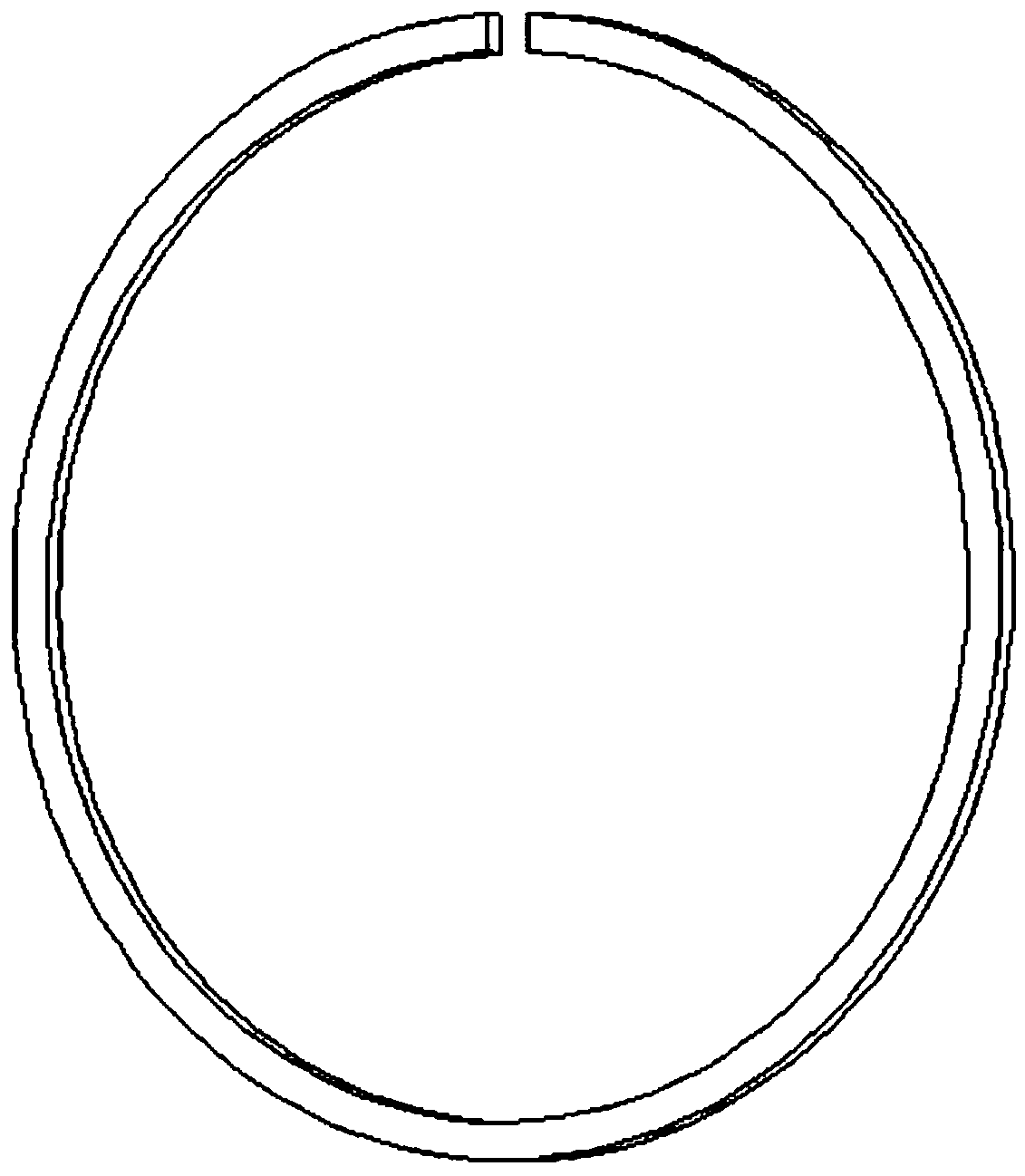

[0040] figure 1 Shown is a schematic diagram of the OEM piston ring structure.

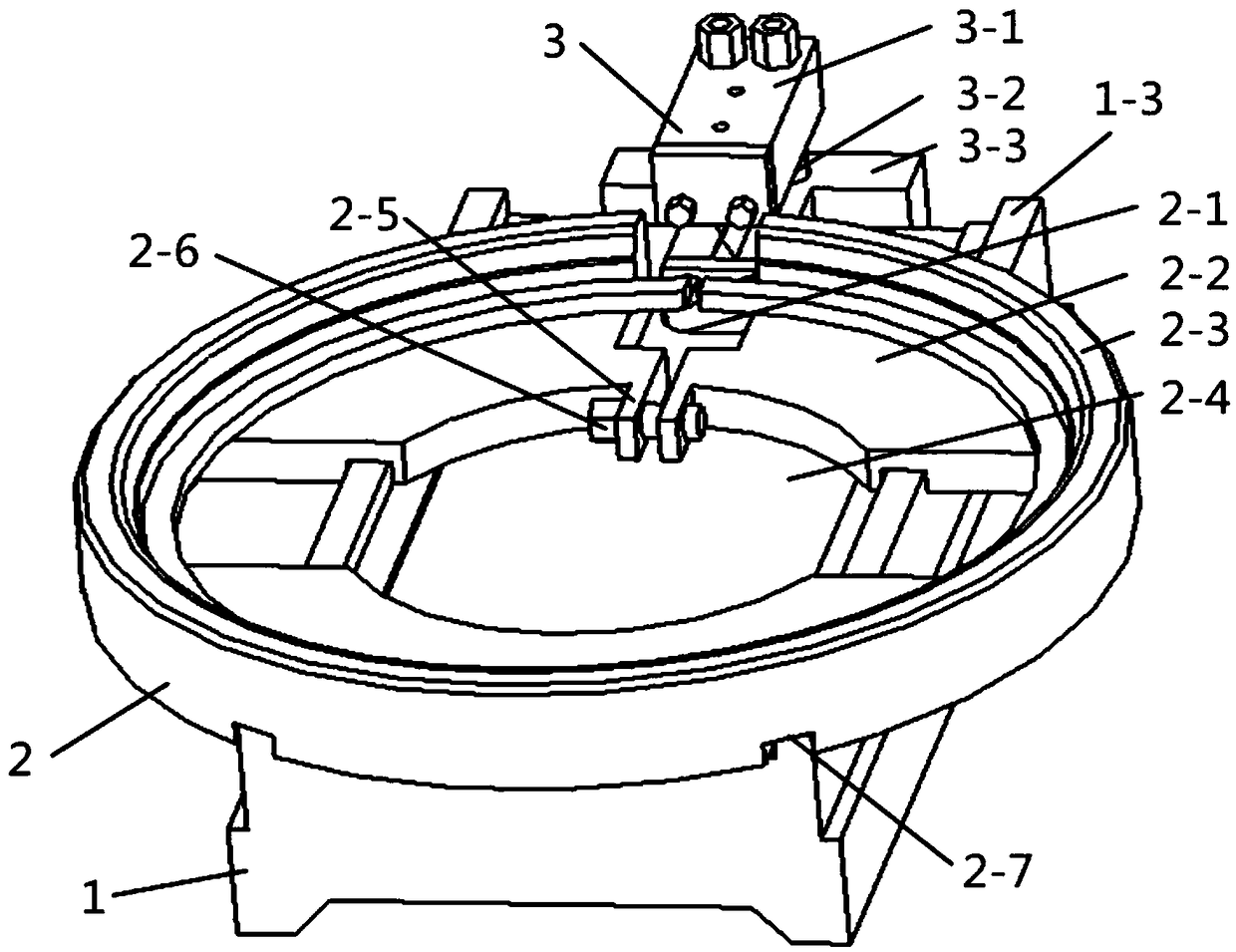

[0041] Figure 2 to Figure 13 The device for removing burrs from the edge of the piston ring opening in this embodiment includes a deburring disc seat 1 , a deburring disc 2 and a knife holder mechanism 3 .

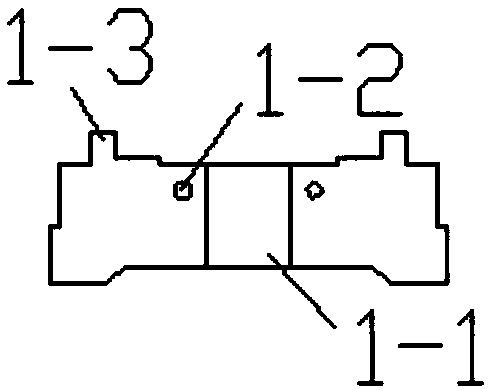

[0042] The lower end surface of the deburring disc base 1 is installed on the workbench, the upper end surface of the deburring disc base 1 is slidingly connected with the lower end surface of the deburring disc 2, and the rear end surface of the deburring disc base 1 is fixedly connected with a knife rest mechanism 3 . The lower end surface of the deburring disc seat 1 is provided with 4 workbench mounting holes 1-4 that are installed in cooperation with the workbench.

[0043] The deburring disk 2 is a disc structure with an upper end opening, and the rear end of the deburring disk 2 is provided with a working port 2-1, and the position of the working port 2-1 corresponds to the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com