A roll profile optimization method for deburring machine used in recoiling unit

An optimization method and deburring technology, applied in the field of cold rolling, to achieve the effect of ensuring concentration, reducing harsh requirements, and avoiding strip steel indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further illustrate the application process of the technology of the present invention, a certain recoiling unit is taken as an example to introduce in detail the roll shape optimization process and optimized working effect of the deburring machine of the recoiling unit.

[0055] The method for optimizing the roll shape of the deburring machine described in the technical solution of the present invention includes the design of the roll shape of the deburring roller and the determination of the parameters of the deburring section of the deburring roller;

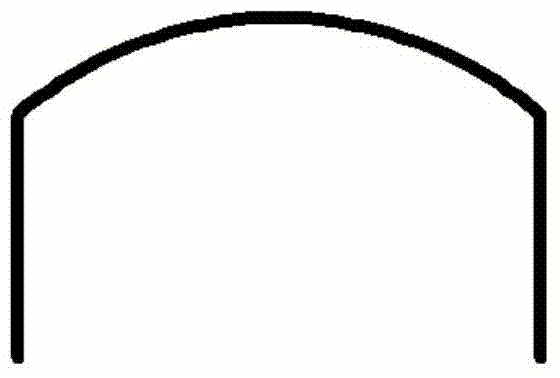

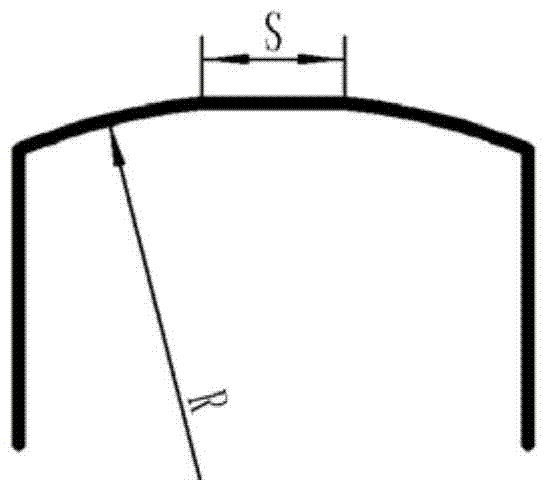

[0056] Such as image 3 Shown in, the roll shape design of described deburring roller, on the basis of existing straight roller structure, the roll shape design of dematting roller is straight deburring section and arc-shaped transition section two parts, The straight part in the middle of the deburring wheel is a deburring section with a width S; the two ends of the deburring section are arc-shaped transiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com