Deburring equipment for hardware stamping part

A technology for deburring and stamping parts, applied in the field of burr removal equipment for metal stamping parts, can solve the problems of labor-intensive processing efficiency for deburring, and achieve the effect of fast and efficient deburring, uniform deburring, and uniformity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

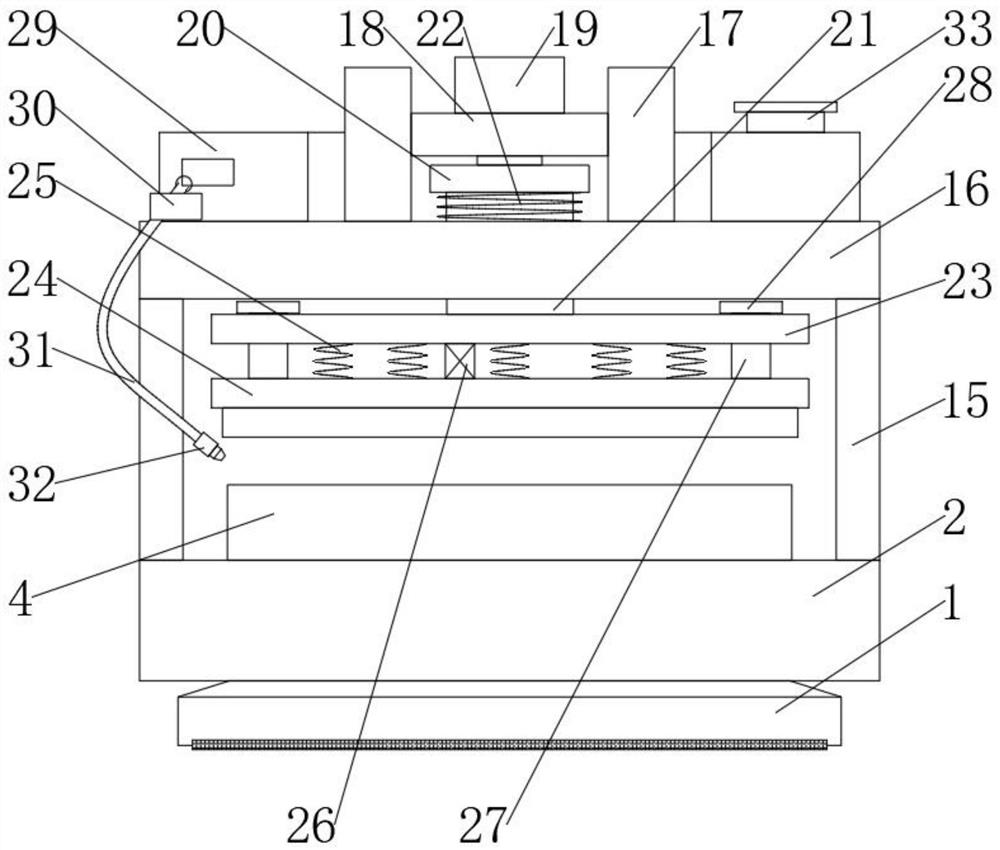

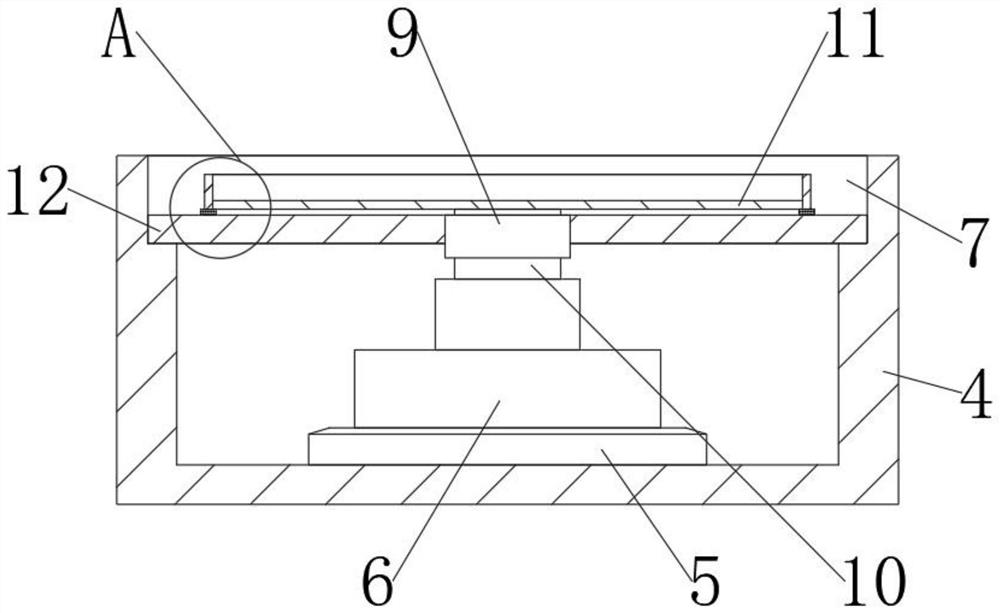

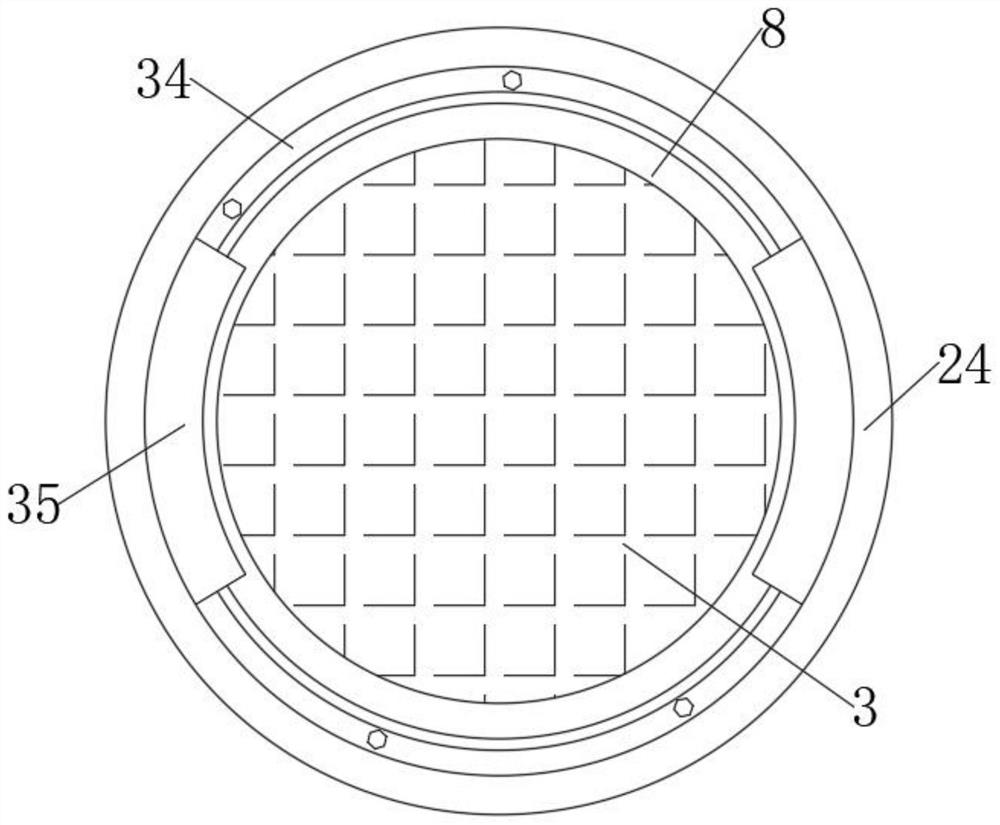

[0029] Such as Figure 1-5 As shown, the embodiment of the present invention provides a metal stamping parts deburring equipment, including a fixed base 1, the top of the fixed base 1 is fixedly connected with a bottom mounting seat 2, and the inner bottom of the bottom mounting seat 2 is fixedly connected with a first grinding disc mounting seat 4. A water hole is provided on the side and near the bottom of the first grinding disc mounting base 4, and at the same time, the cleaning water sprayed by the nozzle 32 can be collected. The inner bottom of the first grinding disc mounting base 4 is fixedly connected with the motor mounting base 5, and the motor mounting base 5 The top of the top is fixedly connected with a drive motor 6, and the inner top of the first disc mount 4 is provided with a step opening 7, and the inner side of the step opening 7 is fixedly connected with a fixed circular plate 12, and the center position of the fixed circular plate 12 is provided with a cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com