Special polishing plate for deburring machine and manufacturing method thereof

A technology for deburring machines and polishing discs, which is applied in the direction of grinding/polishing equipment, manufacturing tools, abrasives, etc. It can solve the problems of poor abrasiveness, low planting efficiency, and impact on service life, and achieve good abrasiveness and planting High efficiency, ensure the effect of deburring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

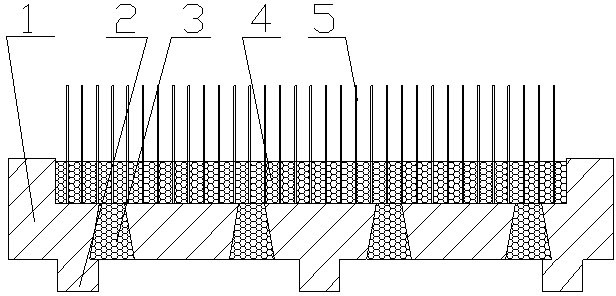

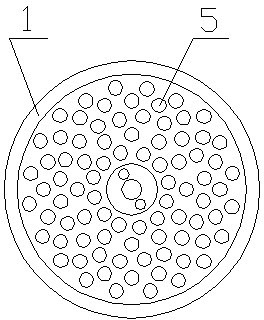

[0013] Embodiment 1: with reference to attached figure 1 and 2 . A special polishing disk for a deburring machine, which includes a polishing disk shell 1 and an abrasive head 5, the polishing disk shell 1 is a circular groove structure, and a plurality of tapered column holes 3 are opened at the bottom of the circular groove; The abrasive head 5 is located in the circular groove, and the circular groove and the tapered hole are resin solidified body 4 (epoxy resin solidified body). The diameter of the conical solidified resin in the conical hole is small at the top and large at the bottom. The back of the polishing disk shell 1 is provided with one or more rings of reinforcing ribs 2 and is integrated with the polishing head shell 1 . An annular boss is arranged around the mounting screw hole in the center of the polishing disk shell 1, and the annular boss and the groove bottom of the mounting screw hole form an annular convex groove.

Embodiment 2

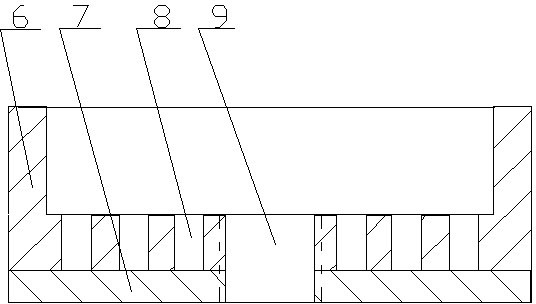

[0014] Embodiment 2: with reference to attached image 3 and 4 . A special polishing disc molding die for deburring machines, which is composed of a forming die ring 6, a die base plate 7 and a planting die core 8, the die base plate 7 is fixed on the peripheral end face of the die ring 6 and constitutes a polishing disc forming die frame, and the center of the die base plate 7 is opened There are ejection screw holes 9, the planting mold core 8 is located in the polishing disk forming mold frame, and the ejection bolts are screwed in the ejection screw holes 9. The planting core 8 has a plurality of planting holes and is covered with a molding frame. The planting holes are in the form of round holes, rectangular holes, slanted holes, and chip holes, and the holes are separated by partitions.

Embodiment 3

[0015] Embodiment 3: On the basis of Examples 1 and 2, a method for making a special polishing disc for a deburring machine, (1) select the planting core 8 according to the shape of the abrasive, and insert the planting core 8 into the special polishing disc for the deburring machine The polishing disc of the forming mold is formed into the mold frame, and then the abrasive is inserted into the planting hole of the planting core 8 and the inserting end face of the abrasive is in contact with the mold bottom plate 7; (2) the special polishing disc shell of the deburring machine is concave The tapered hole of the groove is stuck from the outside, and the limit steel plate is placed in the annular convex groove of the special polishing disc molding die for the deburring machine. The caliber is the same, so fasten the molding die of the polishing disc with the planted abrasive head 5 on the special polishing disc of the deburring machine, so that the other end of the abrasive head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com