Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Good high temperature oxidation stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

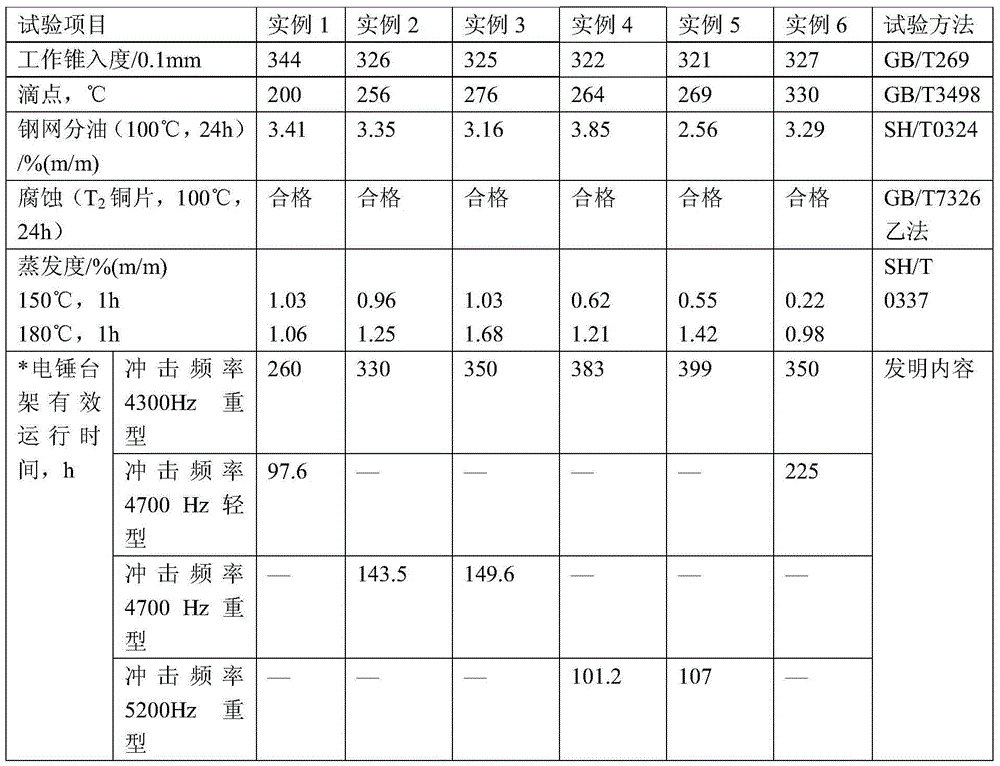

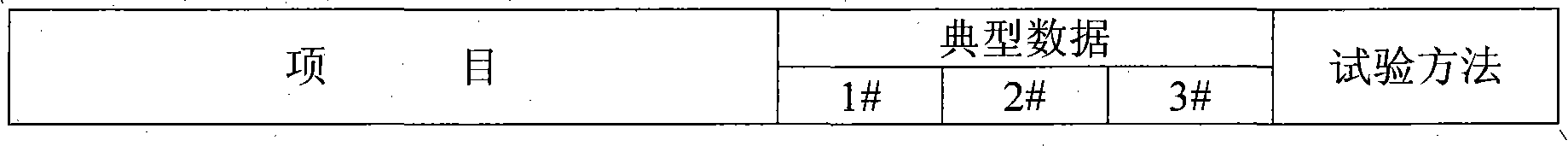

A lubricating grease composition used for cylinders of electric tools and a preparing method thereof

ActiveCN105586121ALow evaporation loss performanceImprove extreme pressure and anti-wear performanceAdditivesBase-materialsLithium soapAntioxidant

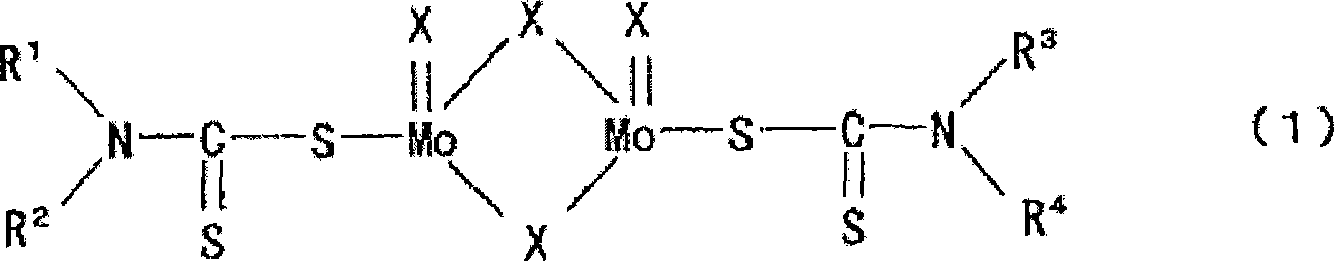

A lubricating grease composition used for cylinders of electric tools is provided. The composition comprises base oil, a thickening agent and functional additives, wherein the base oil is one of or a mixture of at least two substances selected from HVI hydrogenated base oil, metallocene PAO, trimethylolpropane trioleate, alkyl silicone oil or methylphenyl silicone oil, the thickening agent is one of or a mixture of at least two substances selected from lithium soap, composite aluminum soap or polyurea, the functional additives are an extreme pressure antiwear agent, an antioxidant or a rubber compatibility modifier or a mixture thereof, the extreme pressure antiwear agent comprises an organic molybdenum salt and a heavy-load diesel engine oil complexing agent, and the rubber compatibility modifier is dimethyl silicone oil or / and alkyl silicone oil. The lubricating grease prepared with the composition is excellent in impact load resistance, free of loss at high temperature, long in service lifetime and low in high-temperature evaporation loss and can be widely used for cylinders of various electric hammers and electric picks.

Owner:杭州得润宝油脂股份有限公司

Lubricating grease special for front furnace roller way bearing of metallurgy industry and preparation method thereof

The invention discloses lubricating grease special for a front furnace roller way bearing of metallurgy industry and a preparation method thereof. The lubricating grease comprises the following raw materials in percentage by weight: 3 to 8 percent of diphenylmethane-4,4'-diisocyanate MDI, 0.5 to 2 percent of octadecylamine, 1 to 5 percent of cyclohexane, 40 to 50 percent of base oil 1, 30 to 45 percent of base oil 2, 0.4 to 0.6 percent of antioxidant, 0.4 to 0.6 percent of anti-rusting agent, 2 to 6 percent of extreme pressure anti-wear additive, 0.5 to 3 percent of adhesive and 1 to 8 percent of filling agent. During preparation, the raw materials are added into an oil tank and a saponification kettle for stirring and mixing at different temperatures and in certain order.

Owner:安徽中天石化股份有限公司

Lubricating grease specially used in high-temperature kiln car, and preparation method thereof

ActiveCN103497814AImprove high temperature resistanceGood colloidal stabilityLubricant compositionDiphenylmethaneAntioxidant

The invention discloses a lubricating grease specially used in a high-temperature kiln car, and a preparation method thereof. The grease comprises the raw materials of, by weight: 40-60 parts of base oil A, 30-50 parts of base oil B, 4-8 parts of octadecylamine, 3-5 parts of ethylene diamine, 3-6 parts of MDI (diphenylmethane-4,4'-diisocyanate), 1-2 parts of an antioxidant A, 2-3 parts of an antioxidant B, 2-3 parts of a rust inhibitor, 1-2 parts of an extreme-pressure anti-wear agent A, 1.5-3 parts of an extreme pressure anti-wear agent B, and 5-10 parts of a tackifier. During preparation, the raw materials are stirred and mixed according to different temperatures and a certain order, and are treated according to a related process requirement. The lubricating grease provided by the invention has good high-temperature resistance, good colloidal stability, good oxidation stability, good water resistance, good pumpability, low coking tendency, and low ash. During application, coking is prevented under high temperature, and cleaning is not needed. The lubricating grease is directly added. The preparation method is simple and easy to operate. Product application effect is good.

Owner:安徽中天石化股份有限公司

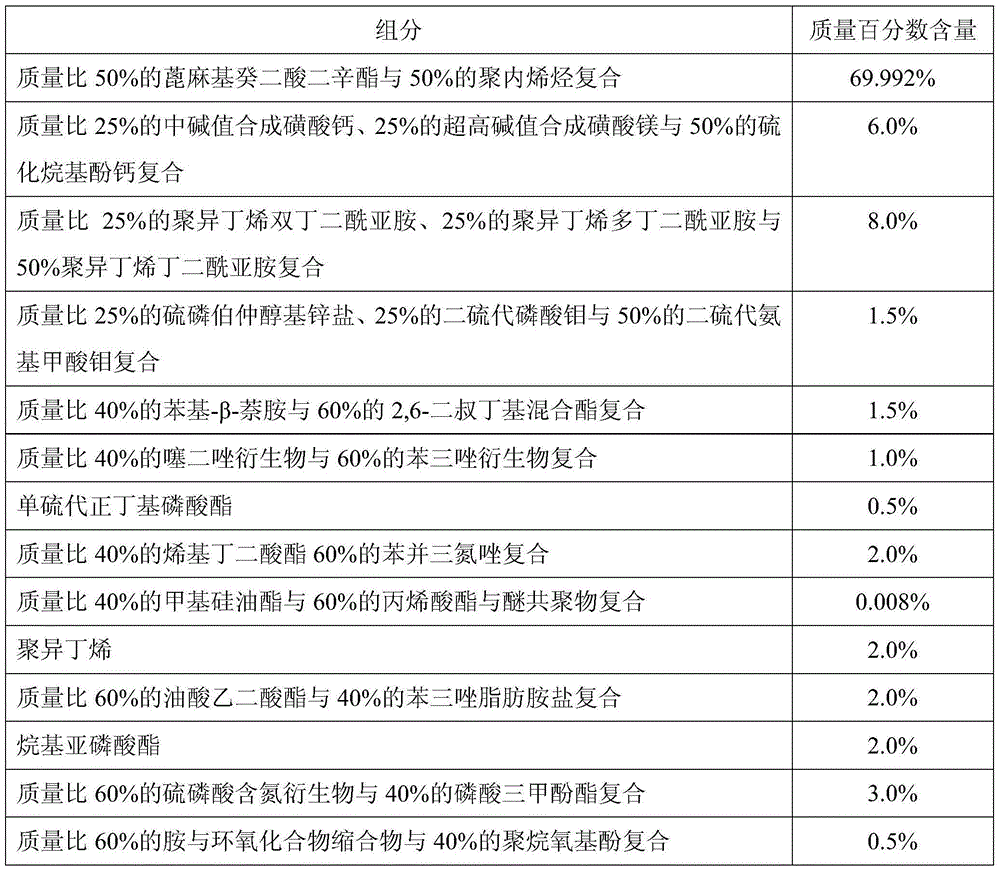

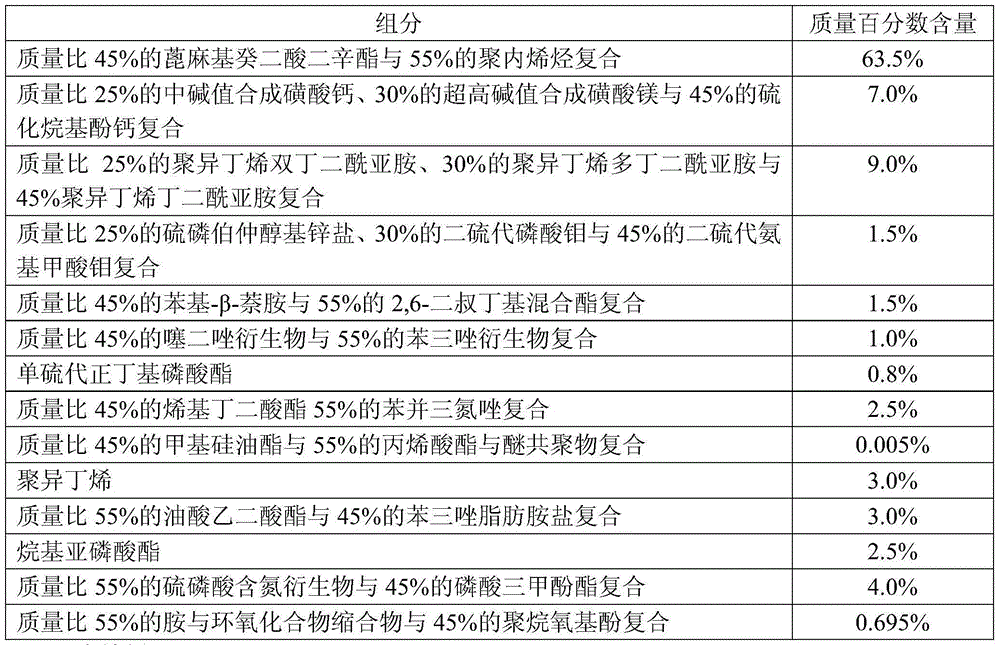

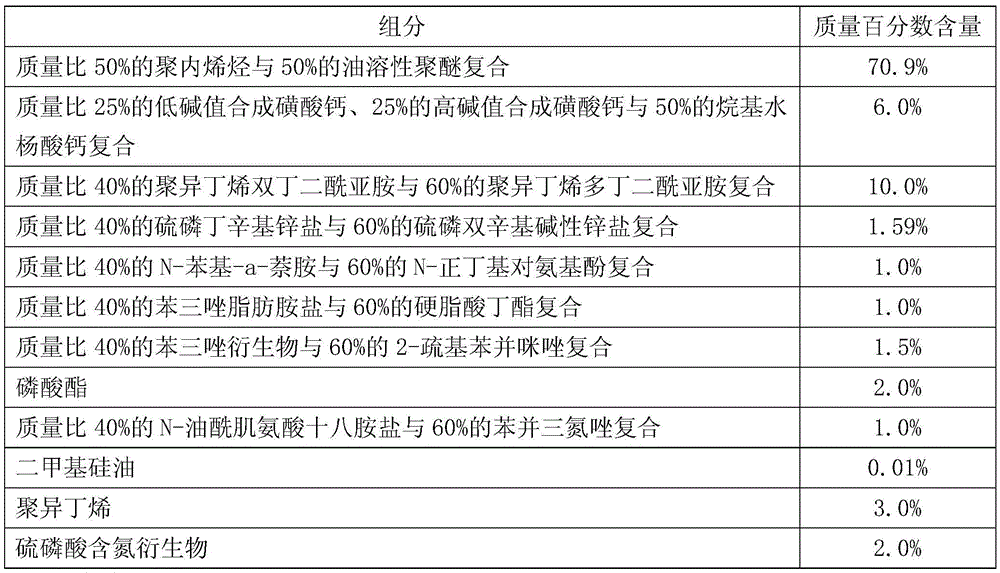

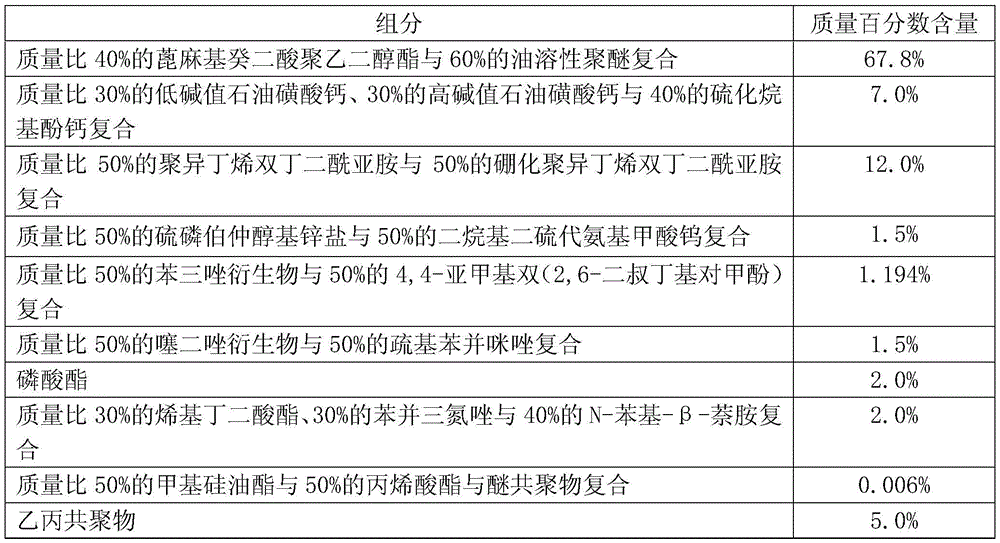

Coal water slurry blended fuel engine oil composition

ActiveCN104087375AExcellent viscosity-temperature propertiesAvoid stickingLubricant compositionOil sludgeBlack oil

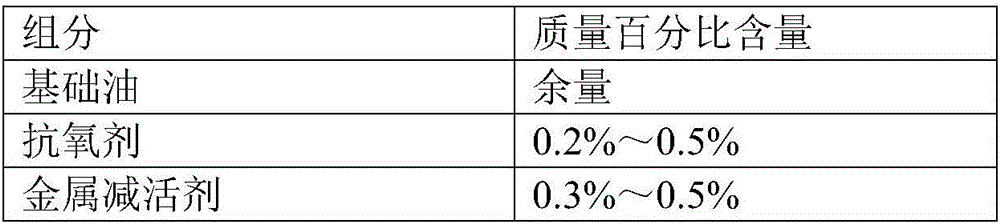

The invention discloses a coal water slurry blended fuel engine oil composition. Polyinternalolefins and castor-bsae dioctyl sebacate used as base oil are matched with multiple composite additives to obtain the composition. The composite additives comprise an antiwear additive, an antioxidant preservative, an antifoam agent, a demulsifying compound, a viscosity index improver, a metal passivator, a detergent agent, a dispersing agent, an antioxidant, an oily agent, a friction improver, a reinforcing agent and a rust inhibitor. The engine oil composition has excellent cleaning and dispersion effects, prevents the piston ring from sticking, and keeps the engine clean. Due to excellent viscosity-temperature characteristic, excellent alkali number retentivity, acid neutralizing capacity and demulsifying capacity, the engine oil composition can inhibit the black oil sludge from generation, so that the engine is cleaner. Due to favorable high-temperature oxidation stability, high shear stability, favorable rubber compatibility, favorable cold-starting property and excellent fuel economical efficiency, the engine oil composition can not corrode or tarnish the moving parts, ensures the oil product to maintain sufficient oil film strength, has better extreme-pressure abrasion resistance, and lowers the abrasion and engine oil consumption.

Owner:GUANGXI UNIV

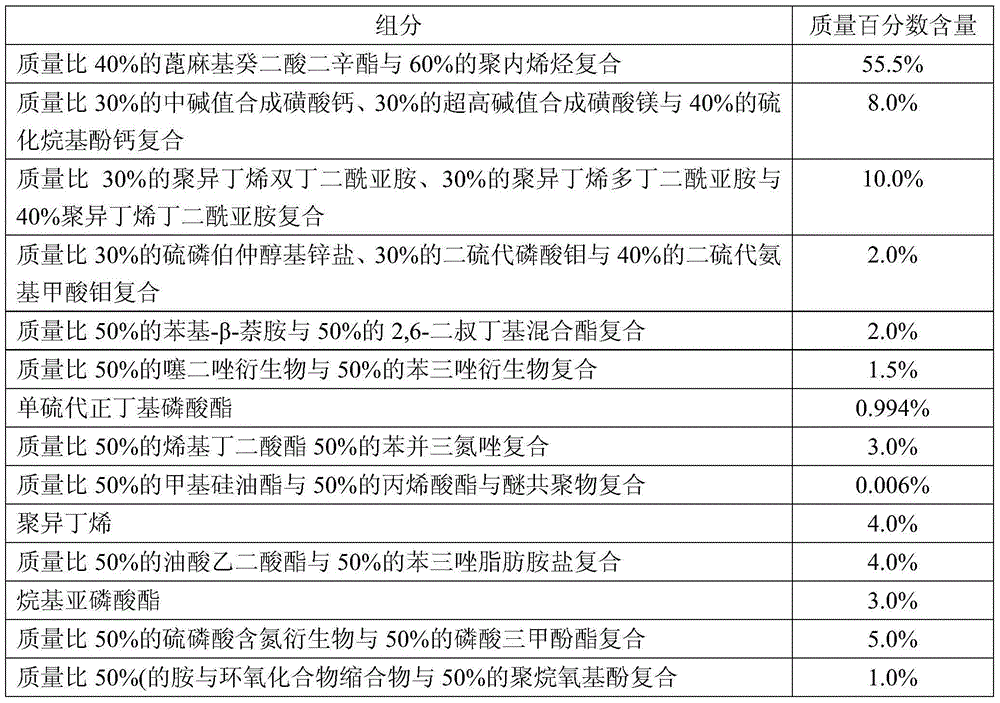

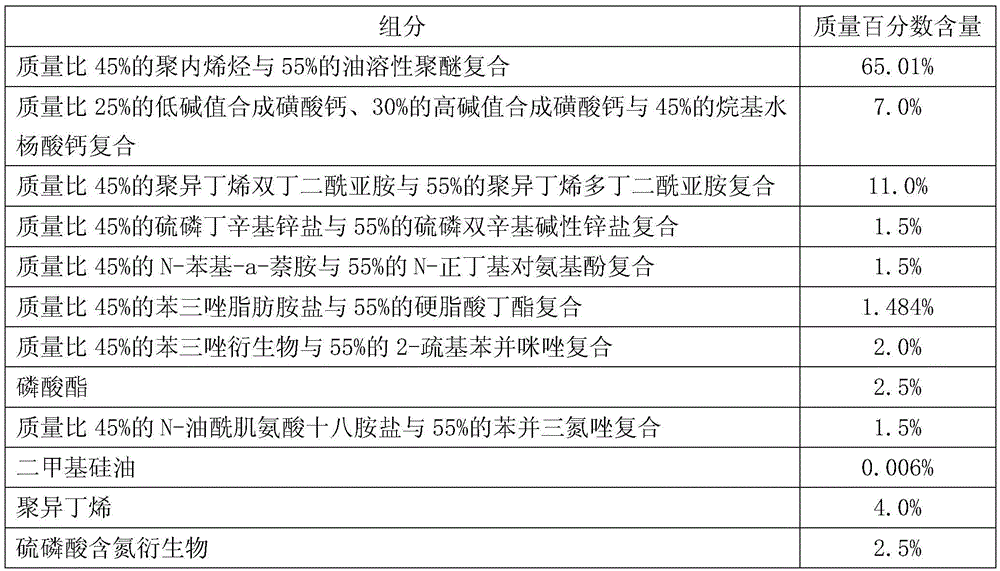

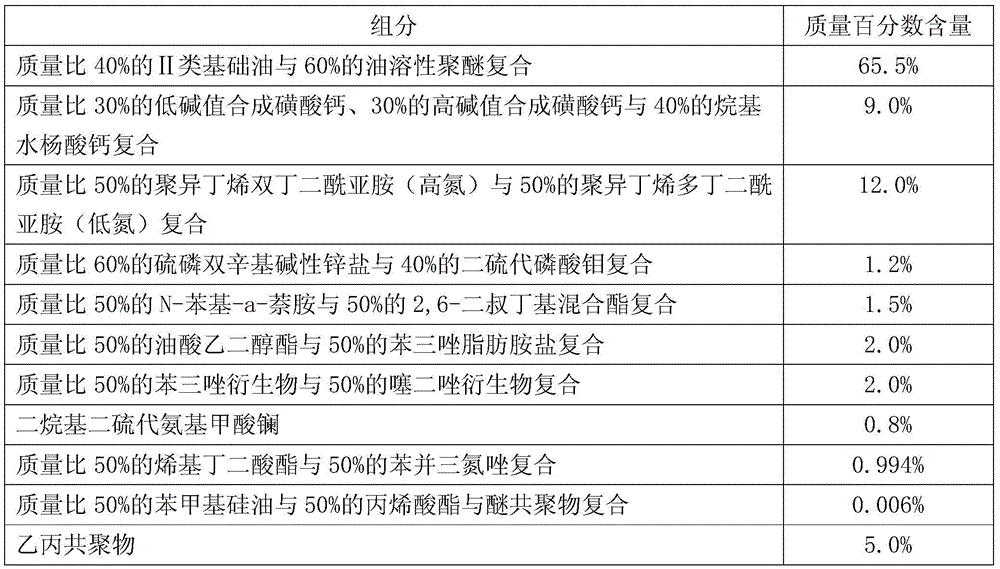

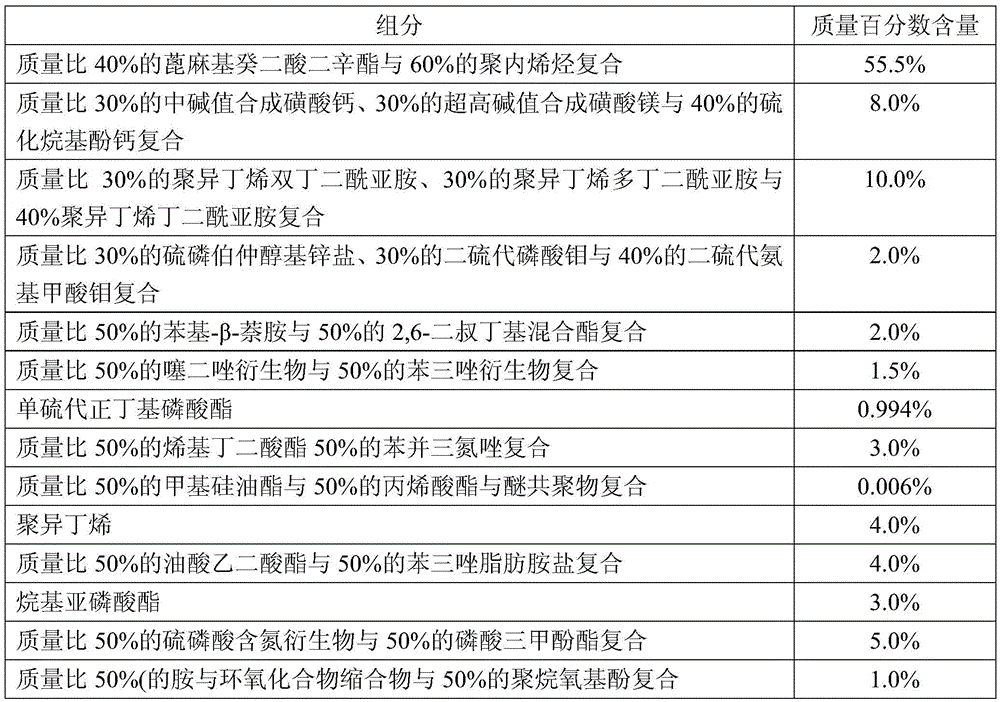

Oil composition for emulsified diesel oil engines

The invention discloses an oil composition for emulsified diesel oil engines. According to the oil composition, II-class base oil and polyinternalolefins are used as base oil, and a plurality of additives are matched. The oil composition comprises an antirusting agent, an oxidation-corrosion inhibitor, an anti-foaming agent, a viscosity index improver, a metal deactivator, a clearing agent, a dispersing agent, an antioxidant, a reinforcing agent, an oiliness agent and an anti-creaming agent. The oil composition for the engines has excellent clean dispersion effect, so that sediments of piston rings are reduced; the oil composition has excellent viscosity-temperature characteristics, alkali value retentivity and acid neutralization capacity, and can inhibit the generation of black oil sludge, so that the engines are relatively clean; the oil composition has good high temperature oxidation resistance stability, high shear stability, anti-emulsifying property, rubber compatibility, good low temperature startability, excellent fuel economy performance and has no corrosion and rusting for moving parts, enough oil film strength of oil is guaranteed, and the abrasion and the oil consumption are reduced.

Owner:广西谛恒生物能源投资有限公司

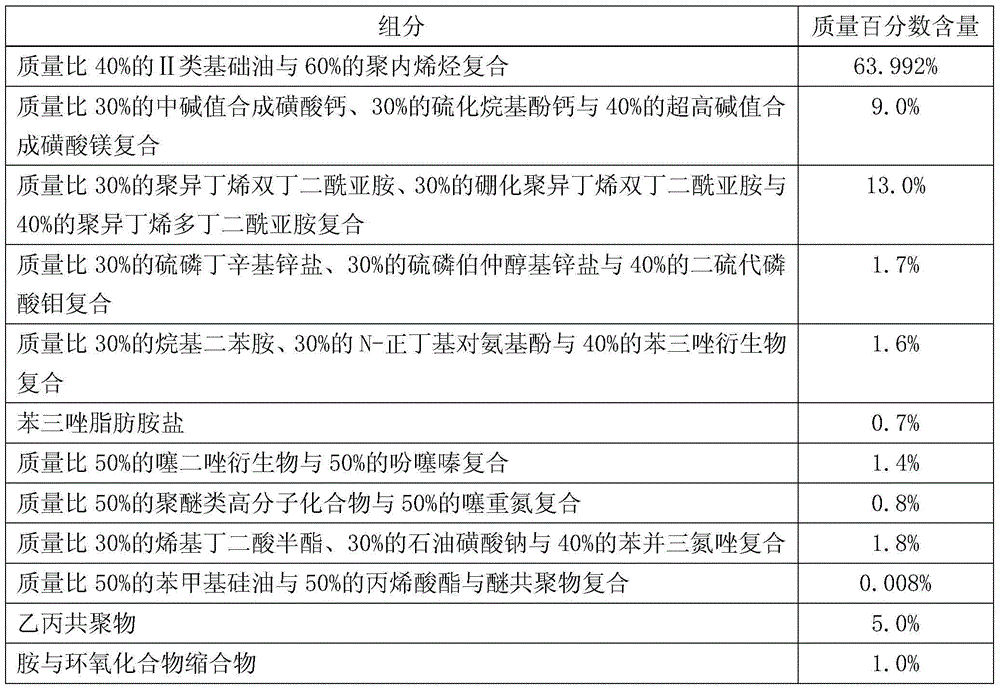

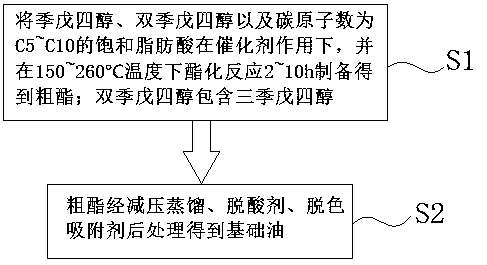

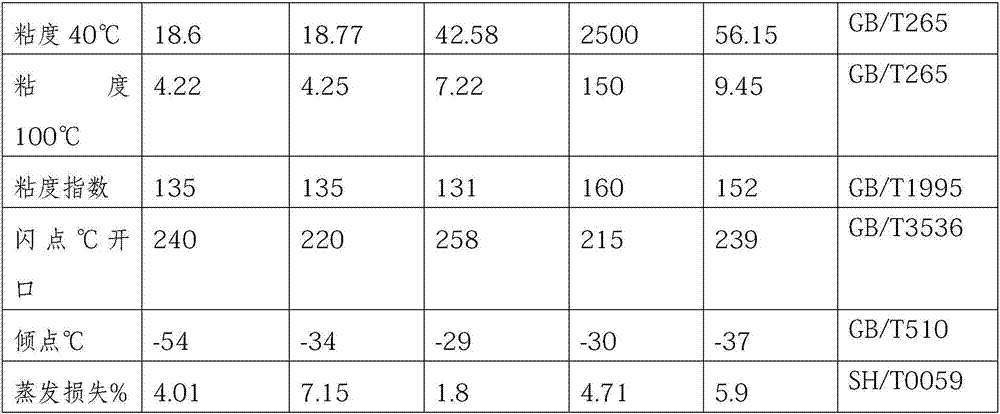

Pentaerythritol ester lubricating oil base oil and preparation method thereof

InactiveCN111218322AMeet the use requirementsGood viscosity and temperatureBase-materialsPentaerythritolPolyol

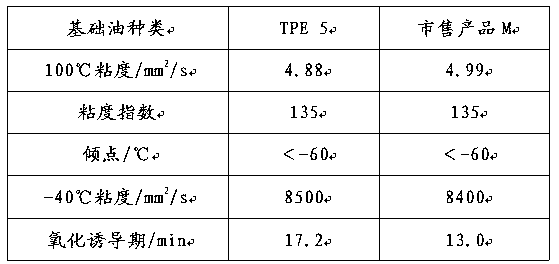

The invention relates to pentaerythritol ester lubricating oil base oil and a preparation method thereof. The base oil is prepared from the following components: polyol and saturated fatty acid with the carbon atom number of C5-C10, wherein the polyol comprise pentaerythritol and dipentaerythritol, and the dipentaerythritol is prepared from tripentaerythritol. According to the invention, the synthesized 5-cst pentaerythritol ester base oil has excellent viscosity-temperature performance, low-temperature fluidity and high-temperature oxidation stability, has the high-temperature oxidation stability superior to that of similar base oil on the market, and has good industrial application prospect.

Owner:北京蓝星清洗有限公司

Compressor oil composition

InactiveCN103232881AImprove uniformityNot prone to carbon depositionAdditivesBase-materialsSolubilityFoaming agent

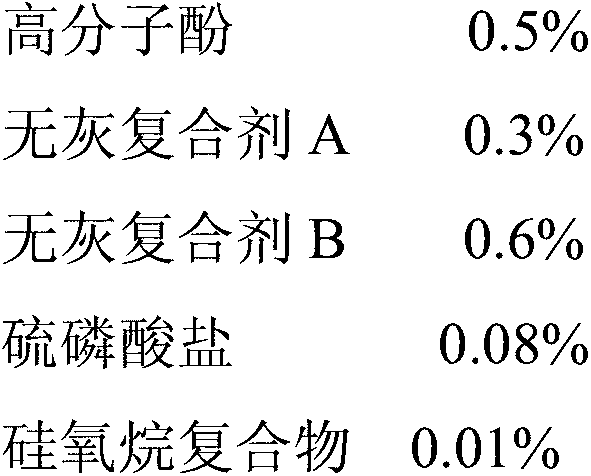

The invention discloses a compressor oil composition which comprises the following components in percentage by weight: 0.2-0.6 percent of antioxidant, 0.2-0.8 percent of ashless complexing agent A, 0.2-0.8 percent of ashless complexing agent B, 0.01-0.3 percent of ashless antiwear agent, 0-0.1 percent of anti-foaming agent and the balance of basic oil, wherein the basic oil comprises cut narrow fraction hydrogenated mineral oil and cycloparaffin basic oil. According to the compressor oil composition, the two complexing agents are matched and play a synergic enhancement effect, so that the compressor oil composition has comprehensive, balanced and excellent properties, such as oxidation stability, extreme pressure antiwear property, anti-rust property and demulsification property and is not easy to generate greasy filth; and meanwhile, the basic oil has high dissolubility, excellent low-temperature property and other properties, so that the compressor oil composition has excellent high-temperature oxidation stability, cooling property and extreme pressure antiwear property on the whole, and especially has excellent detergency and dispersancy and greasy filth and carbon deposit resistance property.

Owner:SUZHOU HUIFENG LUBRICANT

Improved type compressor oil composition

The invention discloses an improved type compressor oil composition. The improved type compressor oil composition is prepared from the following raw materials in parts by weight: 21-29 parts of phosphite ester, 17-19 parts of fatty sulfurized isobutylene, 5-8 parts of thiadiazole polysulfide, 11-15 parts of borate, 11-15 parts of dialkyl naphthalene-sulfonic-acid metal salt, 9-11 parts of polyether modified organic silicon, 20-30 parts of synthetic ester oil, 23-25 parts of biodegradable lipid oil, 6-8 parts of dialkyl zinc dithiophosphate, 5-8 parts of succinate, 7-10 parts of polyallyl metacylate, 6-8 parts of dialkyl zinc dithiophosphate salt and 5-7 parts of dithiophosphate. The improved type compressor oil composition disclosed by the invention has the advantages that the high-temperature oxidation stability, the cooling property and the extreme-pressure anti-wear property are excellent, the environmental pollution is reduced, high-load resistance, high-temperature resistance and high-pressure resistance are achieved and the cost is low.

Owner:QINGDAO KERUN PLASTIC MACHINERY

Pedal motorcycle special-purpose long-life low-noise lubricating oil

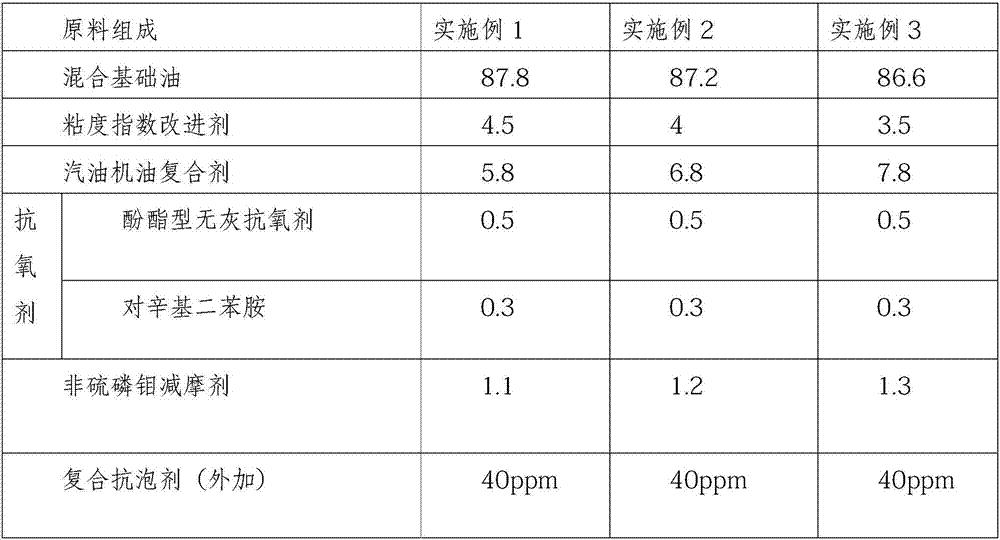

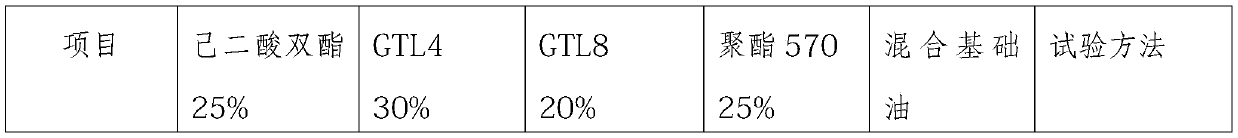

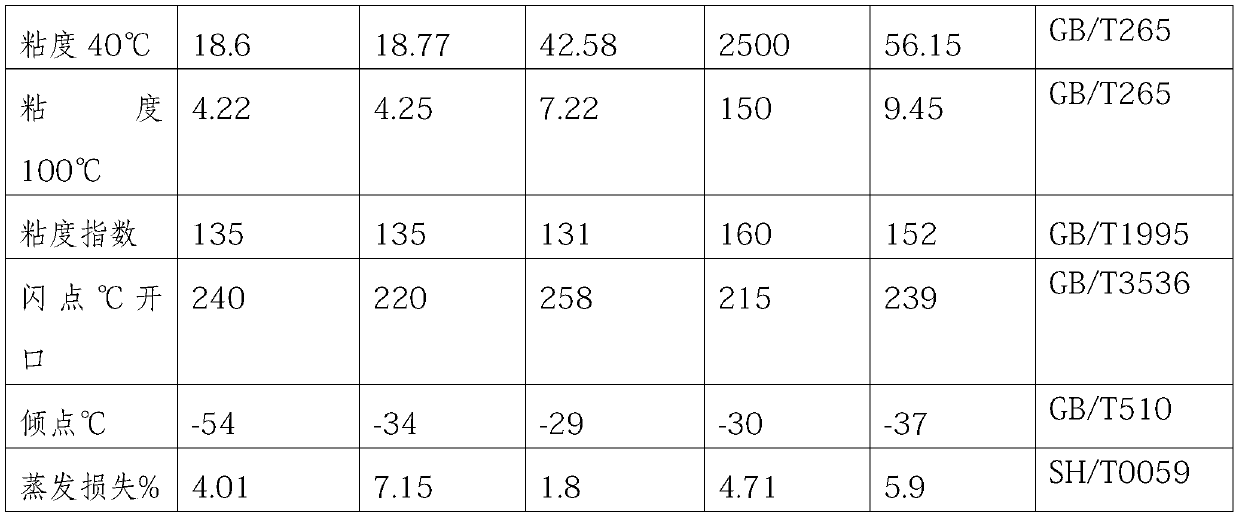

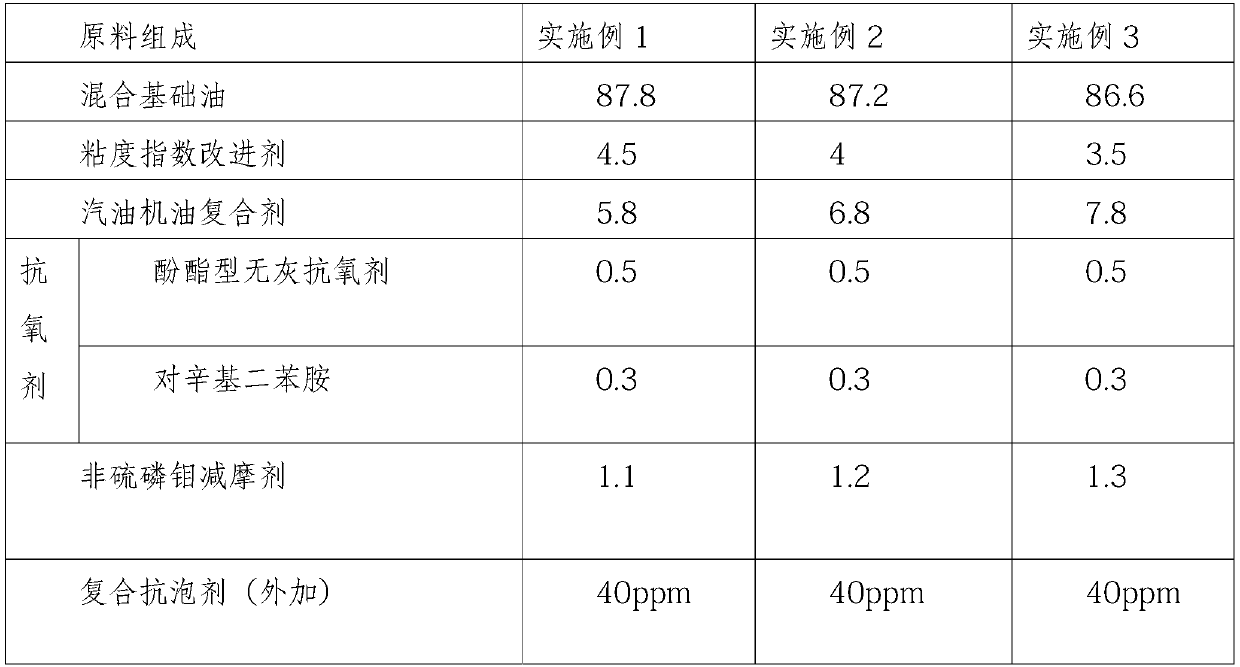

The invention relates to pedal motorcycle special-purpose long-life low-noise lubricating oil. The pedal motorcycle special-purpose long-life low-noise lubricating oil at least comprises 5.8%-7.8% of a gasoline-engine oil compound, 0.8% of an antioxidant, 1.1%-1.3% of an anti-wear friction reducer, 3.5%-4.5% of a viscosity index improver and 86.6%-87.8% of mixed base oil. The lubricating oil also comprises a compound anti-foaming agent. The gasoline-engine oil compound comprises an ashless dispersant and a total calcium-based detergent. The anti-wear friction-reducing agent is one or more of molybdenum dialkyldithiocarbamate, a molybdate and a molybdenum-amine complex. The viscosity index improver is ethylene-propylene copolymer liquid sol. Compared with the commercial oil, the lubricating oil needs longer time in consumption of the same amount of oxygen and has good oxidation resistance and abrasion resistance and a long service life. The pedal motorcycle using the lubricating oil has low noise and friction.

Owner:北京雅士科莱恩石油化工有限公司

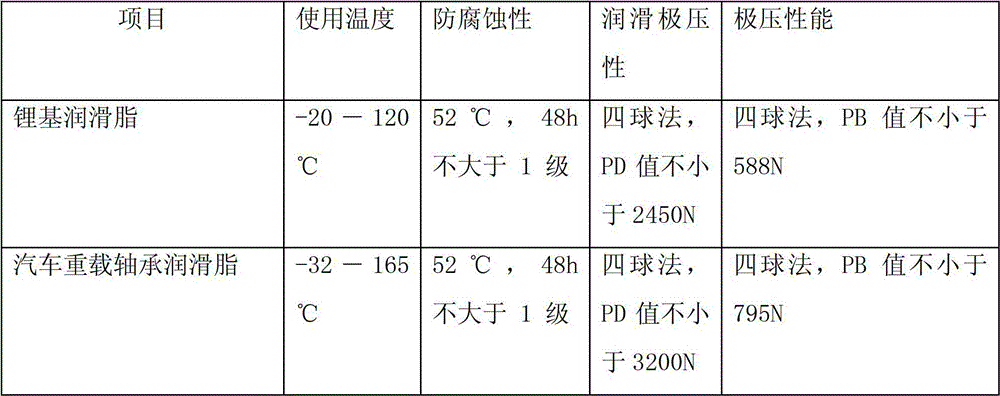

Automobile heavy load bearing lubricating grease and its preparation method

ActiveCN102816630BImprove protectionExtend your lifeLubricant compositionOxidation stabilityBase oil

Owner:AMER TECH CO LTD

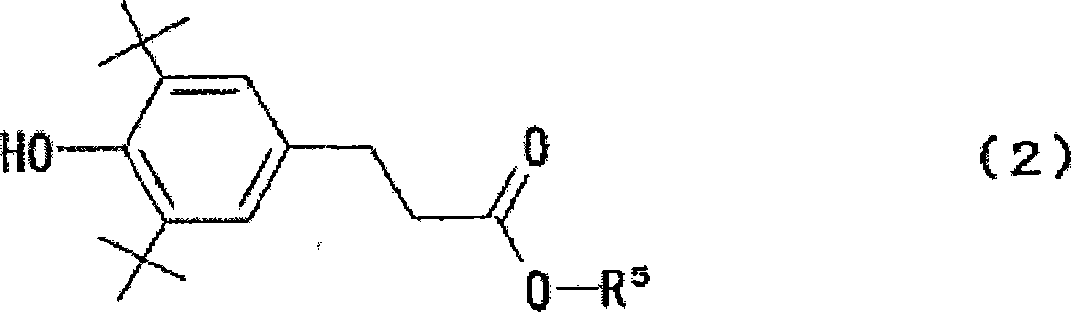

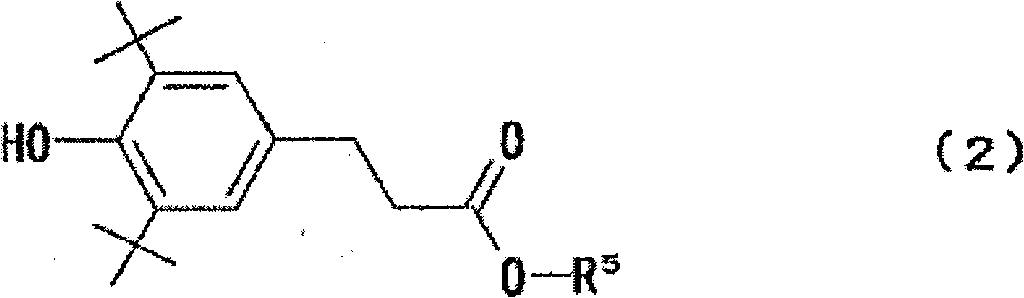

Long-life fuel-saving engine oil composition

ActiveCN101218330AReduce consumptionGood high temperature oxidation stabilityAdditivesNitrogenPhenolic antioxidant

A long-life fuel-saving engine oil composition which comprises a mineral and / or synthetic base oil; an amine antioxidant and a phenolic antioxidant added to the oil in a total amount of 1.2 mass % or larger in which the ratio of the mass amount of nitrogen (N) contained in the amine antioxidant to the mass amount of oxygen (O) contained in the phenolic antioxidant, (N / O), is 0.20-0.50; and MoDTC incorporated in an amount of 0.055 mass % or larger as molybdenum element amount. There is provided the long-life fuel-saving engine oil composition which has excellent oxidative stability at high temperatures and retains low-frictional properties over long.

Owner:JAPAN ENERGY CORP

High-temperature valve lubricating oil and processing method thereof

InactiveCN106833826AReduce evaporation lossGood stabilityLubricant compositionCarboxylateSodium carboxymethylcellulose

The invention provides a high-temperature valve lubricating oil and a processing method thereof. The lubricating oil is prepared from 10 to 15 parts by weight of tricaprylin, 7 to 16 parts by weight of polyisobutene, 7 to 11 parts by weight of polytetrafluoroethylene, 5 to 10 parts by weight of polyisobutylene succinimide, 1 to 3 parts by weight of sodium carboxymethyl cellulose, 3 to 5 parts by weight of acrylic glyceride, 3 to 7 parts by weight of sodium dodecylbenzene sulfonate, 5 to 8 parts by weight of fatty alcohol polyoxyethylene ether carboxylate, 2 to 5 parts by weight of triphenylphosphorothioate, 2 to 7 parts by weight of basic zinc dioctyl primary alkyl dithiophosphate, 4 to 6 parts of para aminobenzoic acid, 6 to 9 parts of octylphenol, 3 to 5 parts of calcium alkyl salicylate and 4 to 8 parts of petroleum ether. All the components are centrifugally stirred to be uniformly mixed according to parts by weight. Under the condition of high temperature, the evaporation loss of the lubricating oil produced by the invention is little, the high-temperature oxidation stability is good, and the influence on sealing media is minimal; high service temperature can reach 360 DEG C or more; and the lubricating property is good.

Owner:天长市天龙泵阀成套设备厂

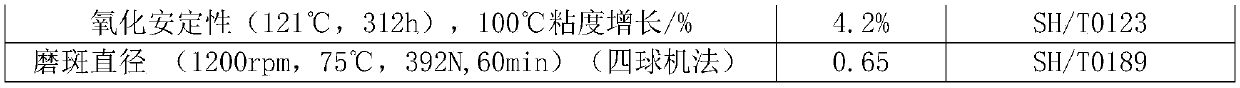

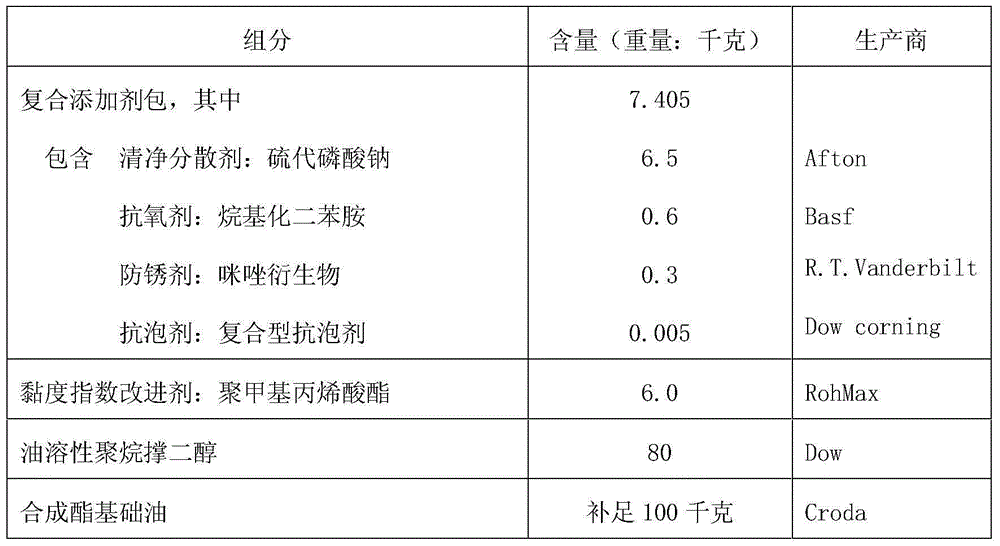

Gear oil for assembly of new energy automobiles

The invention discloses gear oil for assembly of new energy automobiles, and belongs to the technical field of gear oil. The gear oil comprises, by mass, 88-95% of base oil, 0.4-3.0% of antioxidants,0.4-1.8% of rust inhibitors, 2-4.2% of anti-wear agents, 0.001-0.05% of antifoaming agent, 0.1-1.5% of pour point depressants, 0.03-0.12% of oily agent and 1.2-2.2% of tackifiers. The gear oil has theadvantages that the gear oil does not contain sulfurized isobutylene, has no odor in the production process, and is neutral in itself, thereby not having corrosive effect on transmissions; the base oil, mostly vegetable oil, is economical and environmentally friendly, and the biodegradability can reach more than 95%; the viscosity of the oil is low, the flowability at a low temperature is high, normal lubrication can be ensured during start-up of a motor in winter, and rapid cooling can be guaranteed during high-speed operation.

Owner:郑州正赢石化有限公司

A kind of synthetic gasoline engine oil and preparation method thereof

Owner:TEXAS PETROCHEM YANTAI

A kind of synthetic diesel engine oil and preparation method thereof

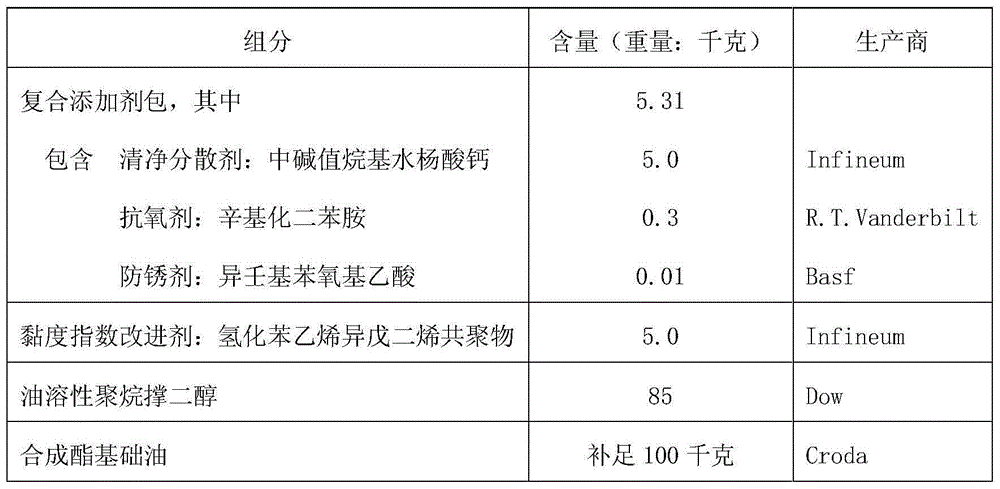

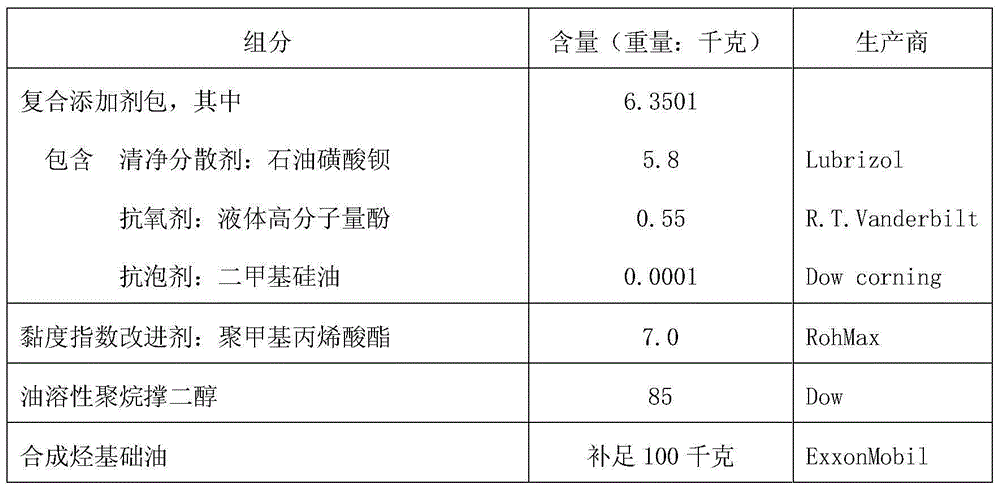

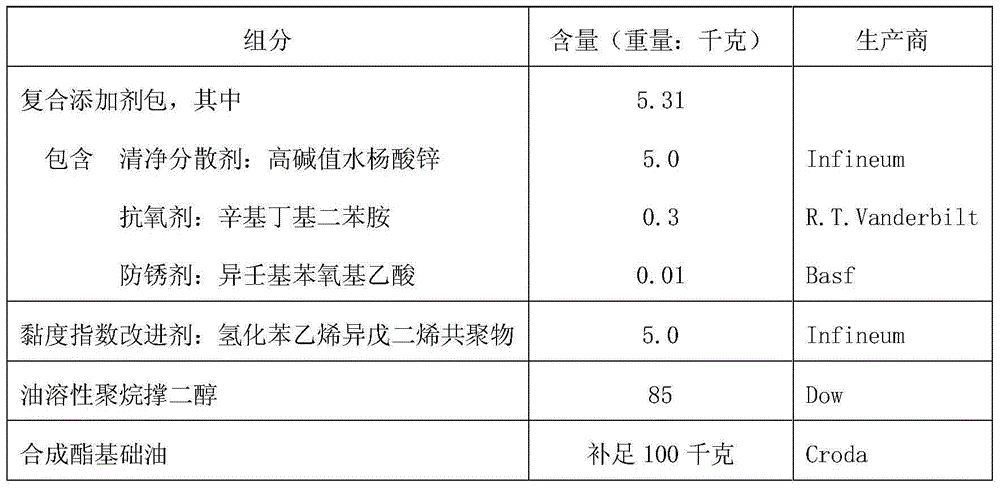

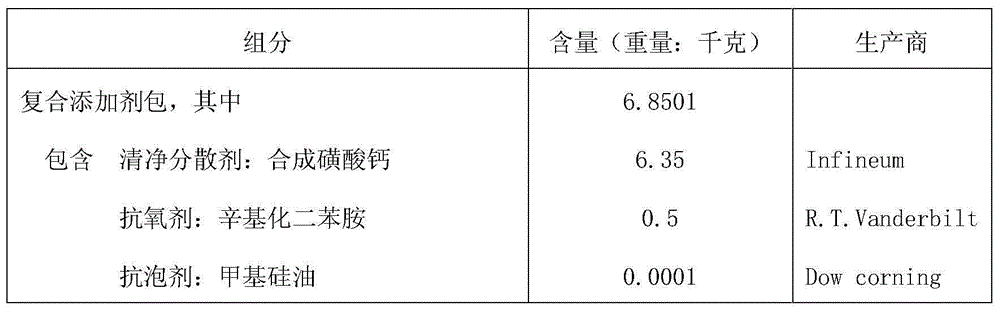

ActiveCN103666706BReasonable compositionGood high temperature oxidation stabilityLubricant compositionTerrainWorking environment

The invention relates to the field of engine oil and particularly discloses synthetic diesel engine oil and a preparation method thereof. The synthetic diesel engine oil comprises the following components in percentage by weight: 5.31-11.5% of a composite additive, 5.0-9.0% of a viscosity index improver, 70-85% of oil soluble polyalkylene glycol and the balance of base oil. The synthetic diesel engine oil has the following benefits: the composition is reasonable, and the high-temperature oxidation stability, thermal stability, detergent-dispersibility and long oil change period are highlighted; at high temperature, the synthetic diesel engine oil film is tougher, and at low temperature, the synthetic diesel engine oil has higher flow rate and higher starting protective capacity, so that oil is saved; in addition, the synthetic diesel engine oil has excellent detergency property, is suitable for a vehicle which is frequently under long-distance, heavy-load and climbing working environments and frequently goes to areas with greatly different climates and terrains, and can be used for lubricating a naturally aspirated diesel engine or turbocharging heavy loading diesel engine equipped with an EGR, a DPF, and an SCR emission control device.

Owner:TEXAS PETROCHEM YANTAI

High-performance methanol gasoline catalyst

InactiveCN105038870ALow saturated vapor pressureReduced burning propertiesLiquid carbonaceous fuelsCombustionAntioxidant

The invention relates to a high-performance methanol gasoline catalyst which consists of the following components in parts by weight: 10-20 parts of isopentane, 18-25 parts of dimethyl benzene, 5-15 parts of a combustion catalyst, 1-8 parts of isopropanol, 2-8 parts of an antioxidant, 1-3 parts of 3-nitrophenyl hydrazine, 3-6 parts of a T1201 metal passivating agent, 12-16 parts of diethyl ether, 15-22 parts of C-12, 8-15 parts of acetylacetone and 9-21 parts of sodium diethyldithiocarbamate. The high-performance methanol gasoline catalyst can be used for improving the compatibility and low-temperature stability of methanol gasoline and ensuring that the methanol gasoline has certain water resistance.

Owner:CRPC INNOVATION ENERGY

Lubricating grease special for front furnace roller way bearing of metallurgy industry and preparation method thereof

InactiveCN101962593BAvoid metal catalysisImprove antioxidant capacityLubricant compositionDiphenylmethaneMetallurgy

The invention discloses lubricating grease special for a front furnace roller way bearing of metallurgy industry and a preparation method thereof. The lubricating grease comprises the following raw materials in percentage by weight: 3 to 8 percent of diphenylmethane-4,4'-diisocyanate MDI, 0.5 to 2 percent of octadecylamine, 1 to 5 percent of cyclohexane, 40 to 50 percent of base oil 1, 30 to 45 percent of base oil 2, 0.4 to 0.6 percent of antioxidant, 0.4 to 0.6 percent of anti-rusting agent, 2 to 6 percent of extreme pressure anti-wear additive, 0.5 to 3 percent of adhesive and 1 to 8 percent of filling agent. During preparation, the raw materials are added into an oil tank and a saponification kettle for stirring and mixing at different temperatures and in certain order.

Owner:安徽中天石化股份有限公司

A special long-life and low-noise lubricating oil for scooter

ActiveCN107267265BExcellent cleaning and dispersing functionAnti-friction attenuationLubricant compositionMolybdateFoaming agent

The invention relates to pedal motorcycle special-purpose long-life low-noise lubricating oil. The pedal motorcycle special-purpose long-life low-noise lubricating oil at least comprises 5.8%-7.8% of a gasoline-engine oil compound, 0.8% of an antioxidant, 1.1%-1.3% of an anti-wear friction reducer, 3.5%-4.5% of a viscosity index improver and 86.6%-87.8% of mixed base oil. The lubricating oil also comprises a compound anti-foaming agent. The gasoline-engine oil compound comprises an ashless dispersant and a total calcium-based detergent. The anti-wear friction-reducing agent is one or more of molybdenum dialkyldithiocarbamate, a molybdate and a molybdenum-amine complex. The viscosity index improver is ethylene-propylene copolymer liquid sol. Compared with the commercial oil, the lubricating oil needs longer time in consumption of the same amount of oxygen and has good oxidation resistance and abrasion resistance and a long service life. The pedal motorcycle using the lubricating oil has low noise and friction.

Owner:北京雅士科莱恩石油化工有限公司

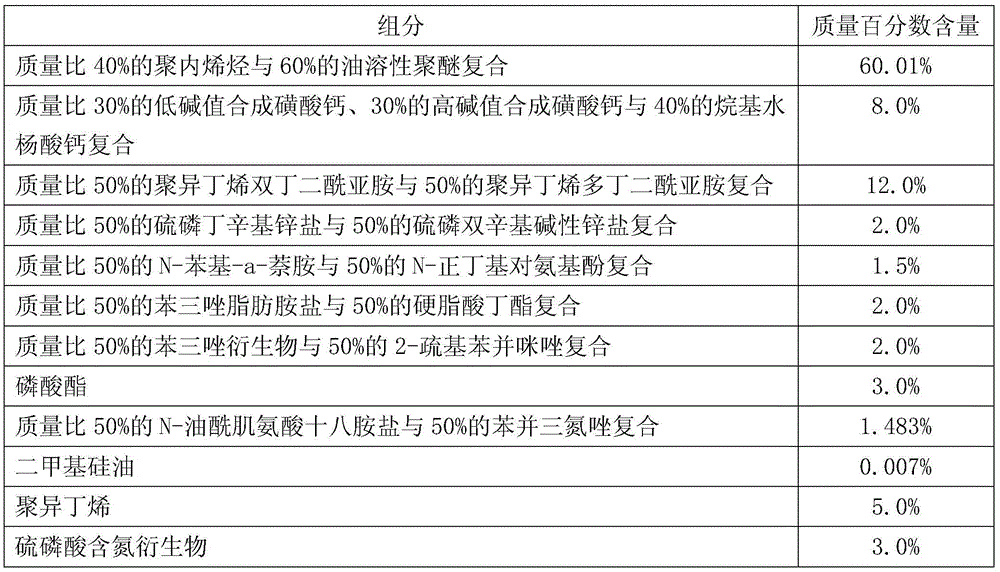

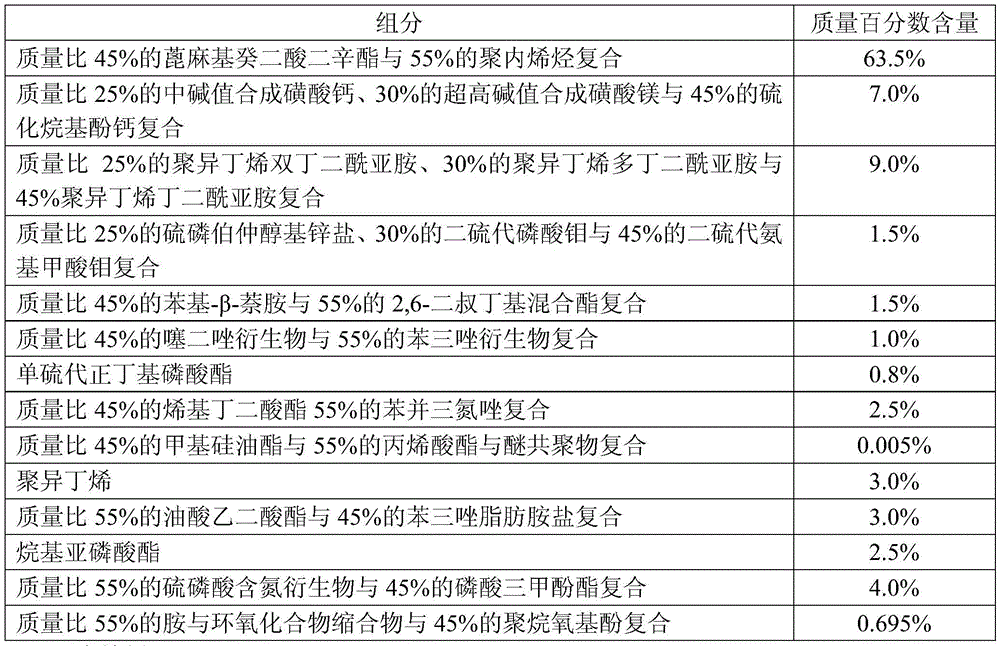

A kind of coal slurry oil fuel engine oil composition

Owner:GUANGXI UNIV

Long-life fuel-saving engine oil composition

ActiveCN101218330BReduce consumptionGood high temperature oxidation stabilityAdditivesNitrogenPhenolic antioxidant

A long-life fuel-saving engine oil composition which comprises a mineral and / or synthetic base oil; an amine antioxidant and a phenolic antioxidant added to the oil in a total amount of 1.2 mass% or larger in which the ratio of the mass amount of nitrogen (N) contained in the amine antioxidant to the mass amount of oxygen (O) contained in the phenolic antioxidant, (N / O), is 0.20-0.50; and MoDTC incorporated in an amount of 0.055 mass% or larger in terms of molybdenum amount. The long-life fuel-saving engine oil composition has excellent oxidative stability at high temperatures and retains low-frictional properties over long.

Owner:JAPAN ENERGY CORP

Method of preparing hydraulic oil for mechanical equipment

InactiveCN107353979AImprove wear resistanceImprove wettabilityLubricant compositionAntioxidantMechanical equipment

The invention provides a method of preparing hydraulic oil for mechanical equipment. The method comprises the preparing steps that firstly, nanometer bentonite powder, 32N third class hydrogenation base oil, 32NS third class hydrogenation base oil, phthalic acid dioctyl ester and poly alpha-olefin synthetic oil are added into a reaction kettle, and after uniform stirring, a first mixture is obtained; secondly, a viscosity modifier, an extrusion anti-wear agent, an antioxidant and a metal deactivation agent are added in the first mixture in sequence and mixed uniformly, after stirring, a second mixture is obtained; thirdly, a lubricant is added into the second mixture, and after stirring, a third mixture is obtained; fourthly, an anti-foaming agent is added into the third mixture, and after stirring and filtering, the hydraulic oil for the mechanical equipment is prepared. The prepared hydraulic oil has good abrasion resistance, wetting property and oxidation stability performance, the service life of the hydraulic oil and hydraulic components is prolonged, and the working efficiency of the hydraulic machinery is improved.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Miller cycle engine lubricant composition

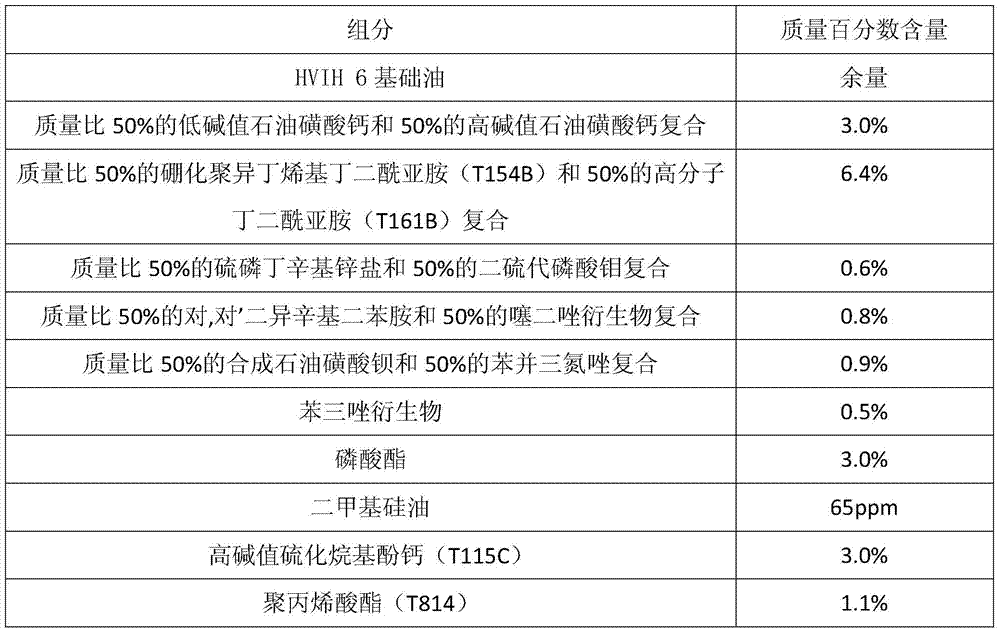

ActiveCN104911001BGood high temperature oxidation stabilityImprove rust resistanceLubricant compositionAntioxidantSludge

The invention discloses a miller cycle engine lubricant composition, using HVIH 6 base oil as the base oil, compounding various additives, including: detergent, dispersant, anti-oxidation and anticorrosion agent, antioxidant, anti-rust agent, metal reducer Activator, friction modifier, antifoam agent, auxiliary agent, pour point depressant. The lubricant composition of the present invention has good high-temperature oxidation stability, rust resistance, low-temperature fluidity, acid neutralization ability, shear resistance, and can inhibit the formation of low-temperature sludge, paint film and carbon deposition, low ash content, Features that reduce emissions of nitrogen oxides, soot, carbon monoxide, and hydrocarbons.

Owner:GUANGXI UNIV

A kind of biomass pyrolysis liquid fuel engine oil composition

ActiveCN104087376BSuppress generationReduce generationLubricant compositionAntioxidantPolyethylene glycol

Owner:GUANGXI UNIV

A kind of coal tar diesel engine oil composition

Owner:GUANGXI UNIV

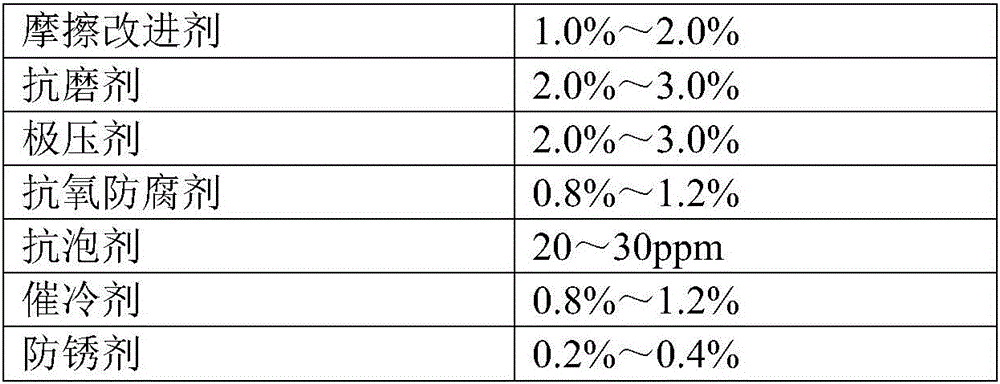

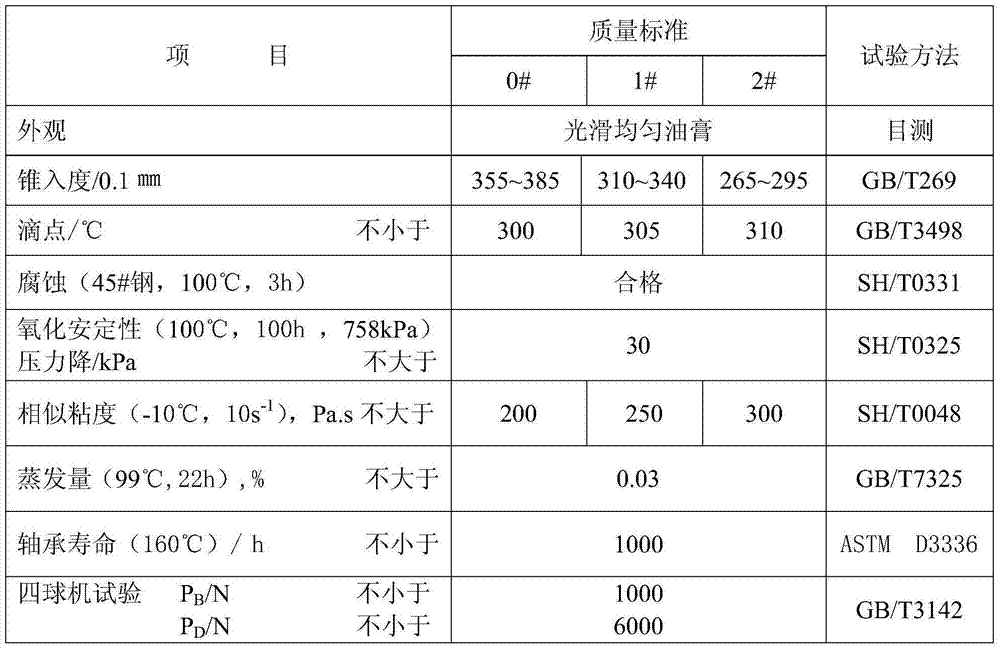

Lubricant composition for whole-floating high-speed bearing

InactiveCN106590872AExcellent viscosity-temperature propertiesImprove thermal conductivityLubricant compositionAntioxidantAlloy

The invention discloses a lubricant composition for whole-floating high-speed bearing. In the lubricant composition, 66.66% by mass of oil soluble polyether and 33.34% by mass of trimethylolpropane oleate are compounded to obtain composite basic oil, which is then matched with a plurality of composite additives. The lubricant composition includes the basic oil, an antioxidant, a metal deactivator, a friction improver, an anti-wear agent, an extreme pressure agent, an anti-oxidizing and anti-corrosion agent, an anti-foaming agent, a cooling accelerant, and an antirust agent. The lubricant composition has excellent viscosity-temperature character, heat conductivity, heat capacity and anti-oxidizing and anti-corrosion property, low friction coefficient, is vibration-attenuating and anti-creeping, has noise reduction and high-temperature oxidizing stability, is anti-wear, has compatibility with rubber, is anti-shear, can effectively control increase of viscosity of oil product and is free of zinc, and is suitable for motion pairs in various alloy.

Owner:GUANGXI UNIV

Improved air compressor oil

InactiveCN104673434AGood high temperature oxidation stabilityImprove cooling effectAdditivesTemperature resistanceAir compressor

The invention discloses an improved air compressor oil which is prepared from the following raw materials in parts by weight: 25-50 parts of synthetic ester oil, 11-19 parts of phosphite, 17-19 parts of fatty vulcanized isobutylene, 11-15 parts of borate, 3-7 parts of dialkyl naphthalenesulfonic acid metal salt, 4-7 parts of polyether modified organosilicon, 2-6 parts of polyalkaneneglycol, 3-7 parts of thiadiazole derivative, 4-8 parts of dibutyl phosphite, 5-9 parts of dithiophosphate, 2-7 parts of thiadiazole polysulfide and 4-9 parts of siloxane composite. The improved air compressor oil has the advantages of excellent high-temperature oxidation stability, excellent cooling property, excellent-extreme pressure abrasion resistance, lower environmental pollution, high load resistance, high temperature resistance, high pressure resistance and low cost.

Owner:QINGDAO KERUN PLASTIC MACHINERY

Lubricating grease specially used in high-temperature kiln car, and preparation method thereof

ActiveCN103497814BImprove high temperature resistanceGood colloidal stabilityLubricant compositionDiphenylmethaneAntioxidant

The invention discloses a lubricating grease specially used in a high-temperature kiln car, and a preparation method thereof. The grease comprises the raw materials of, by weight: 40-60 parts of base oil A, 30-50 parts of base oil B, 4-8 parts of octadecylamine, 3-5 parts of ethylene diamine, 3-6 parts of MDI (diphenylmethane-4,4'-diisocyanate), 1-2 parts of an antioxidant A, 2-3 parts of an antioxidant B, 2-3 parts of a rust inhibitor, 1-2 parts of an extreme-pressure anti-wear agent A, 1.5-3 parts of an extreme pressure anti-wear agent B, and 5-10 parts of a tackifier. During preparation, the raw materials are stirred and mixed according to different temperatures and a certain order, and are treated according to a related process requirement. The lubricating grease provided by the invention has good high-temperature resistance, good colloidal stability, good oxidation stability, good water resistance, good pumpability, low coking tendency, and low ash. During application, coking is prevented under high temperature, and cleaning is not needed. The lubricating grease is directly added. The preparation method is simple and easy to operate. Product application effect is good.

Owner:安徽中天石化股份有限公司

Grease used specially for sintering machine in metallurgical industry and preparation method thereof

ActiveCN102746930BImprove high temperature resistanceImprove Oxidation StabilityLubricant compositionDiphenylmethaneAntioxidant

Owner:安徽中天石化股份有限公司

A kind of coal-water slurry mixed fuel engine oil composition

ActiveCN104087375BExcellent viscosity-temperature propertiesAvoid stickingLubricant compositionAntioxidantOil sludge

Owner:GUANGXI UNIV

Anti-extreme pressure engine oil

InactiveCN105567394AGood high temperature oxidation stabilityExcellent extreme pressure lubricityLubricant compositionPhosphateMechanical wear

The present invention discloses extreme pressure engine oil comprising the following raw materials in parts by weight: 95-98 parts of base oil with less than 3% of sulfur and more than 94% of saturated hydrocarbons, 0.05-0.8 part of a semi-hindered phenol type antioxidant, 0.1-0.7 part of an anti-wear agent, 0.05-0.3 part of a metal deactivating agent, 0.2-0.9 part of screen phenol, 0.4-1.5 parts of sulfur phosphate, 0.05 - 0.7 part of ZDDP (T202), 0.3-1.2 parts of benzotriazole amine salt, 0.06-0.5 part of a benzotriazole derivative, 2-5 parts of dimethylsilicone fluid and 0.1-0.5 part of an anti-foaming agent. The extreme pressure engine oil is lubricant oil having good oil sludge control and dispersion capability, excellent high temperature oxidation stability, extreme pressure lubrication, rust and corrosion resistance, anti-foaming property and water separation characteristic, can withstand heavy loads and impact loads, and can reduce mechanical wear.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com