Long-life fuel-saving engine oil composition

A technology of composition and engine oil, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of disappearance, deterioration of MoDTC, deterioration of fuel saving effect, etc., and achieve good mileage, reduce fuel consumption, and excellent high temperature. Effects of Oxidative Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The present invention will be described below by way of examples.

[0044] The following was used as the base oil: Mineral base oil (kinematic viscosity: 20.3 mm 2 / sec (40°C), 4.34mm 2 / sec (100°C); viscosity index: 124).

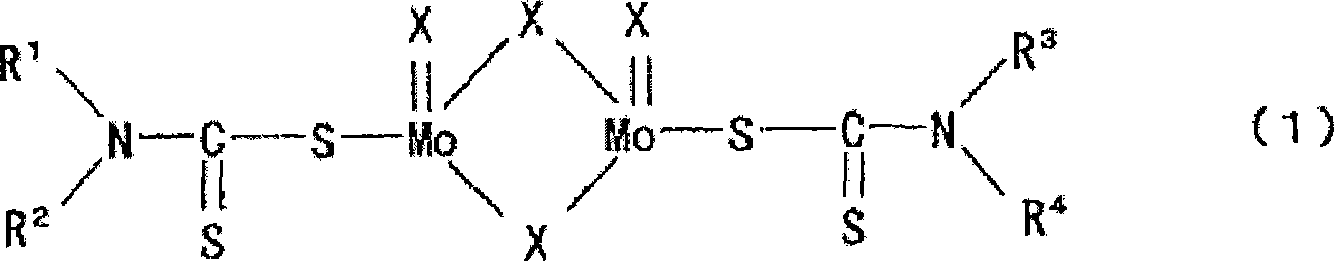

[0045] The phenolic antioxidant A, amine antioxidant B, MoDTC and other additives described below were mixed into the base oil at the ratio shown in Table 1 to prepare the engine oils of Example 1 and Comparative Examples 1-3. Table 1 also shows the ratio of the nitrogen content (N) of the amine antioxidant to the oxygen content (O) of the phenolic antioxidant (mass ratio: N / O) and the Mo content. The additional additive is an additive mixture comprising zinc alkyl dithiophosphates (ZnDTP), calcium sulfonate, alkenyl succinimide, viscosity index improver, pour point depressant and antifoam. In Examples and Comparative Examples, the additives were added in equal amounts.

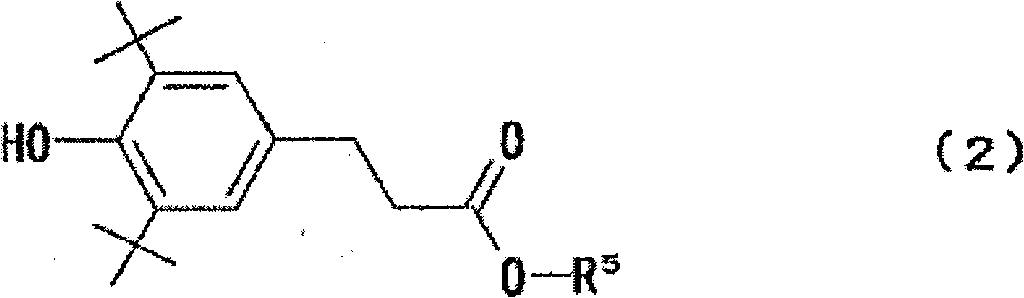

[0046] Use the phenolic antioxidant represented by general formula (2) (wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com