A lubricating grease composition used for cylinders of electric tools and a preparing method thereof

A technology for grease compositions and power tools, applied in the directions of lubricating compositions, petroleum industry, base materials, etc., can solve the problems of low frequency and working time, inability to adapt to high-speed and high-impact load power tools, etc., and achieve high-temperature evaporation loss. The effect of small size, excellent extreme pressure wear resistance, and excellent shock load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

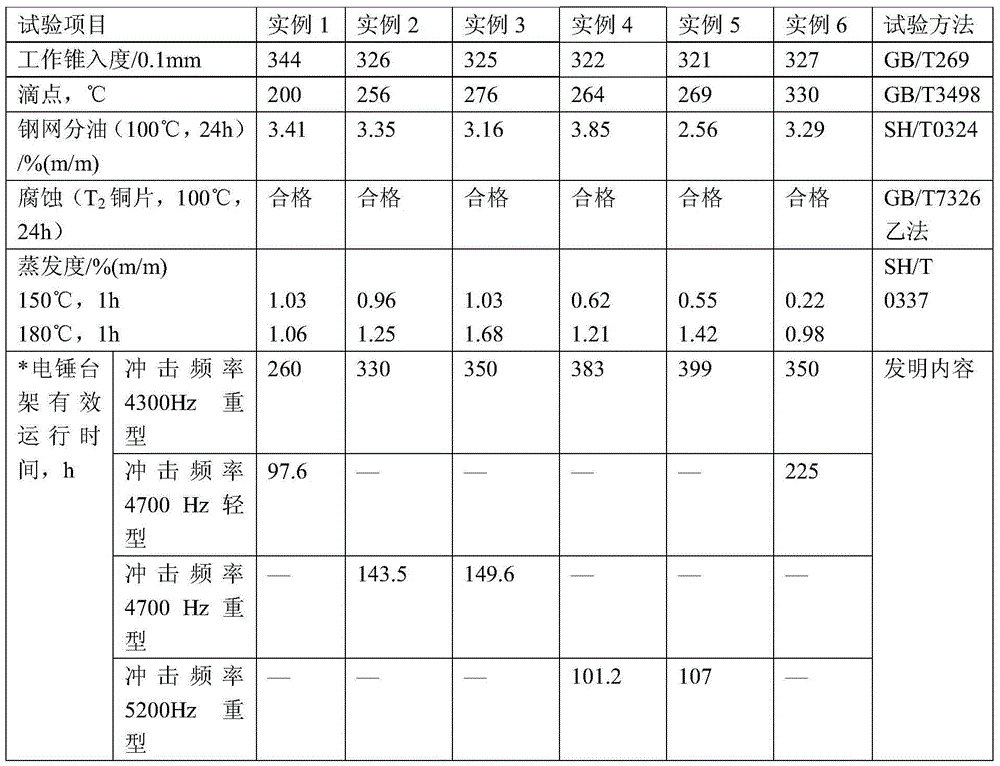

Examples

Embodiment 1

[0053] Heat and stir 51g of 12-hydroxystearic acid, 25g of stearic acid and 115g of alkyl silicone oil (viscosity of 600cSt at 25°C) until dissolved at 90°C, add 11.5g of lithium hydroxide monohydrate dissolved in 9 times of water, and slowly heat up to 160°C For reaction, add 100g of alkyl silicone oil (viscosity is 600cSt25°C), continue to heat up to 210°C for high temperature refining and keep it in the state of true solution for 10 minutes, add 135g of alkyl silicone oil and cool to 70-110°C, add 15g of T351, 10g of HiTEC8799B, mix well, and cool Out of the kettle, homogenized, ground, packaged, and finished.

Embodiment 2

[0055] Mix 22.7g of aluminum isopropoxide, 33.9g of stearic acid and 289.8g of 150BS, heat and stir until dissolved at 120°C, add 11.9g of benzoic acid to react for 10min, cool down to 90-95°C, and add 18.6g of water. Slowly raise the temperature again until the temperature rises to 160° C. after the smell of isopropanol disappears, and add 60.3 g of trimethylolpropane oleate (viscosity is 130 cSt 40° C.). Continue to heat up to 210°C for 10 minutes, then cool to 70-110°C, add 60g of methyl silicone oil (viscosity of 500cSt at 25°C), 11.4g of T351 and 15g of HiTEC8799B, mix evenly, cool out of the kettle, homogenize, grind, pack, and finish.

Embodiment 3

[0057] Heat and stir 27.15g of 4,4'-diphenylmethane diisocyanate and 251.85g of HVI150BS and metallocene PAO150cSt (in a ratio of 7:3) to 70°C for dissolution, then add the above-mentioned HVI150BS and metallocene PAO150cSt (in a ratio of 7:3) 3 ratio) of a mixture of 14.85g octadecylamine and 16.15g cyclohexylamine, slowly warming up to 160-170°C and keeping it for 10min, then cooling to 80°C, adding 15gT351 and 25gHiTEC8799B, mixing evenly, cooling out of the kettle, homogenizing, grinding, Packaging, finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com