Lubricating grease special for front furnace roller way bearing of metallurgy industry and preparation method thereof

A kind of technology of roller table and grease in front of furnace, applied in the field of lubricating grease, can solve the problems of bearing damage and grease loss, and achieve the effect of long service life, excellent extreme pressure and anti-wear performance, and good bearing working ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

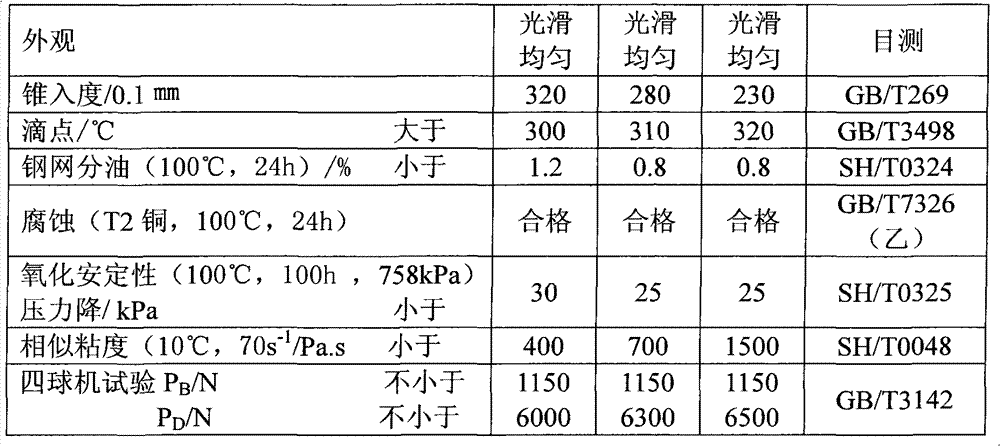

Image

Examples

Embodiment Construction

[0032] A lubricating grease specially used for roller table bearings in front of furnaces in the metallurgical industry. The weight percentage of each component of the raw materials is:

[0033] Diphenylmethane-4,4'-diisocyanate MDI 3-8%

[0034] Octadecylamine 0.5-2%

[0035] Cyclohexylamine 1-5%

[0036] Base oil 1 40-50%

[0037] Base Oil 2 30-45%

[0038] Antioxidant 0.4-0.6%

[0039] Rust inhibitor 0.4-0.6%

[0040] Extreme pressure antiwear agent 2-6%

[0041] Adhesive 0.5-3%

[0042] Filler 1-8%

[0043] Wherein, the base oil 1 is highly refined mineral oil with high viscosity; the base oil 2 is a base oil synthesized by esters; the antioxidant is phenyl-2-naphthylamine; the antioxidant The rust agent is sodium sebacate; the extreme pressure antiwear agent is T306 extreme pressure antiwear agent; the adhesive is polyisobutylene, and the filler is melamine

[0044] The preparation method of the lubricating grease specially used for the roller table bearing in fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com