Lubricating grease special for plastic gear and preparation method of lubricating grease

A lubricating grease and gear technology, which is applied in the field of lubricating grease for plastic gears and its preparation, can solve the problems of poor compatibility of plastic materials, large starting resistance at low temperature, poor oxidation resistance, etc., and achieve good adhesion, small low temperature resistance, The effect of small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

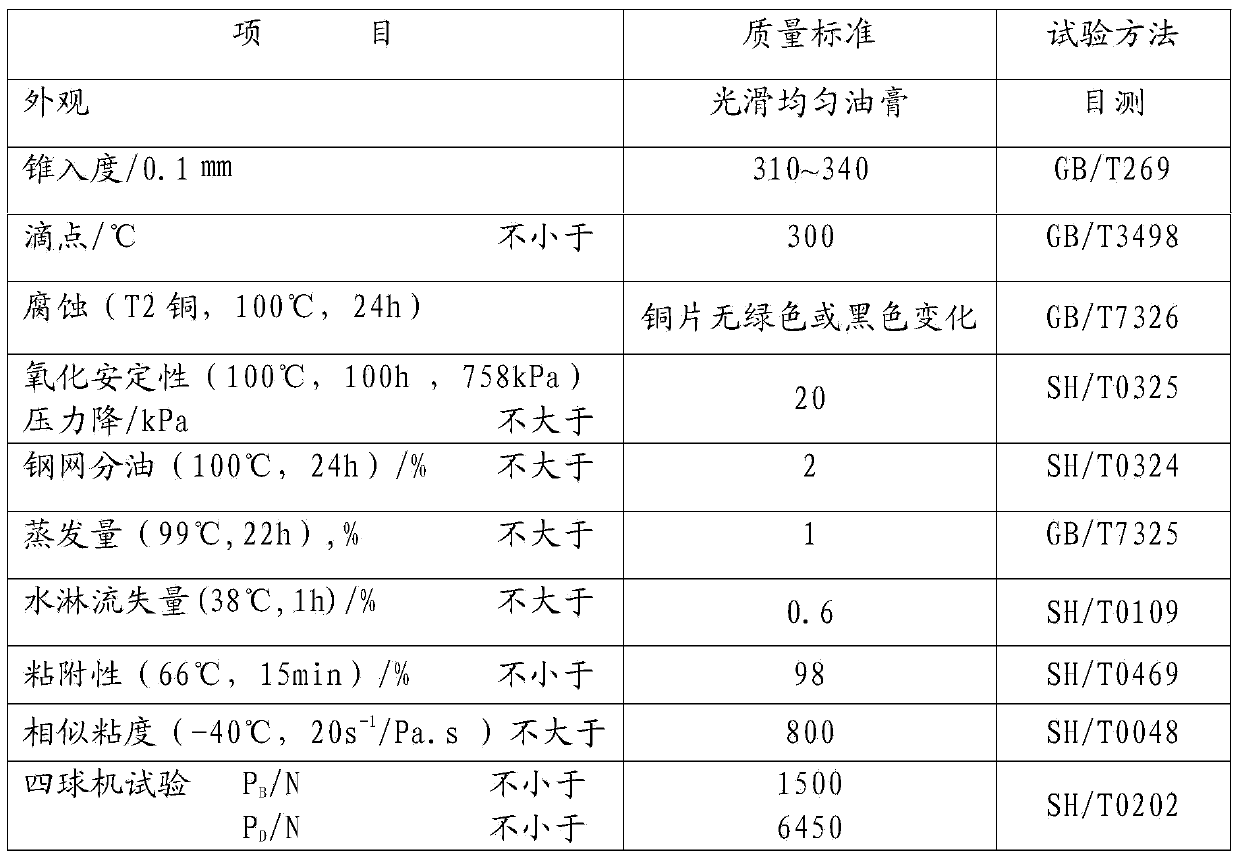

Image

Examples

Embodiment 1

[0022] The embodiment of the present invention provides a kind of lubricating grease specially used for plastic gears, which comprises: 4-8 parts of aniline, 3-5 parts of cyclohexylamine, MDI (diphenylmethane-4,4'-diisocyanate) 3 -6 parts, 60-80 parts of base oil, 1-2 parts of antioxidant A, 2-3 parts of antioxidant B, 1-2 parts of extreme pressure and anti-wear agent, 5-10 parts of tackifier, 1.5- parts of solid lubricant 3 copies.

[0023] Wherein said base oil adopts PAO-8 synthetic oil; said antioxidant A is diphenylamine; said antioxidant B is butyl octyl zinc salt; said extreme pressure antiwear agent is trimethyl phosphate Phenol ester; the tackifier is low molecular weight polyisobutylene PB2400; the solid lubricant is boron nitride.

Embodiment 2

[0025] A preparation method of lubricating grease specially used for plastic gears,

[0026] First provide according to the weight ratio: 4-8 parts of aniline, 3-5 parts of cyclohexylamine, 3-6 parts of MDI (diphenylmethane-4,4'-diisocyanate), 60-80 parts of base oil, antioxidant A1 -2 parts, 2-3 parts of antioxidant B, 1-2 parts of extreme pressure anti-wear agent, 5-10 parts of tackifier, 1.5-3 parts of solid lubricant, and then carry out the following steps:

[0027] (1) 80% base oil is put into saponification kettle by weight proportion, and is heated up to 40-60 ℃;

[0028] (2) drop aniline and cyclohexylamine into the saponification kettle by weight and stir evenly with the mixture of step (1), and the stirring time is 5-10 minutes;

[0029] (3) Warm up to 60-80°C, put MDI into the mixture of step (2) according to specific gravity and mix, fully stir until fully dissolved;

[0030] (4) Slowly heat up for 2-3 hours, stop heating when the temperature is raised to 180-200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com