A kind of synthetic gasoline engine oil and preparation method thereof

A gasoline engine and blended oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of shortened engine oil deterioration time, vehicle mechanical wear, failure, etc., and achieve excellent deposition control and equipment cleanliness, high and low temperature performance Excellent and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

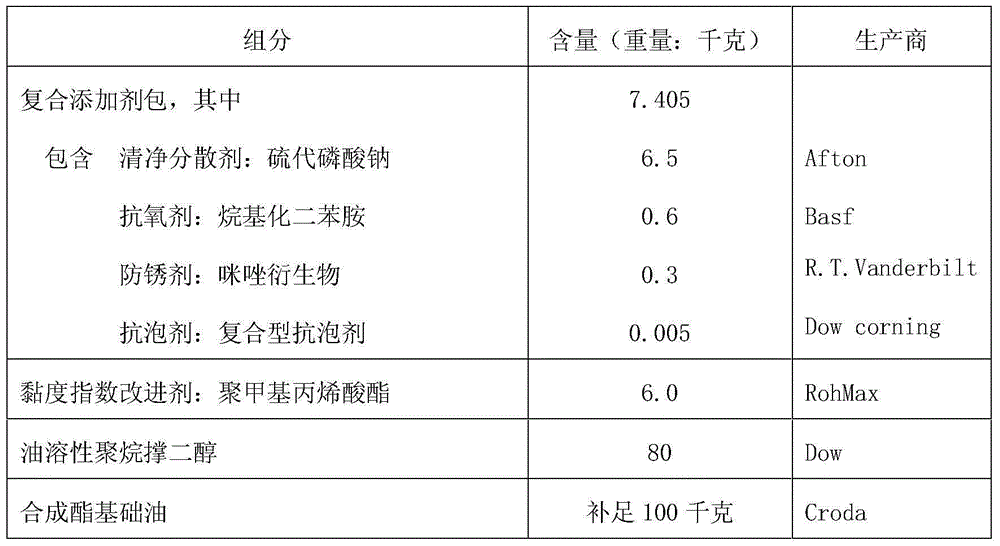

Embodiment 1

[0025] Embodiment 1: (in terms of 100 kilograms, the same below)

[0026]

[0027] The composite additive package contains 3.41% calcium, 1.62% zinc, 0.99% nitrogen, 1.47% phosphorus, 0.16% molybdenum and 3.85% sulfur.

[0028] The preparation method of this synthetic gasoline engine oil adopts the following steps:

[0029] (1) Pump the oil-soluble polyalkylene glycol and synthetic ester base oil of the above weight into the blender with a gear pump, heat and stir, and mix evenly at a constant temperature of 60°C to obtain a mixed oil A;

[0030] (2) Add the above-mentioned compound additive package and viscosity index improver (polymethacrylate) to the mixed oil A prepared in step (1), and continue mechanical stirring at a constant temperature of 60°C for 2 hours to prepare mixed oil B ;

[0031] (3) Filter the blended oil B prepared in step (2), and filter it through a filter with a filter bag device under a pressure of 0.2 MPa to obtain a clear and transparent syntheti...

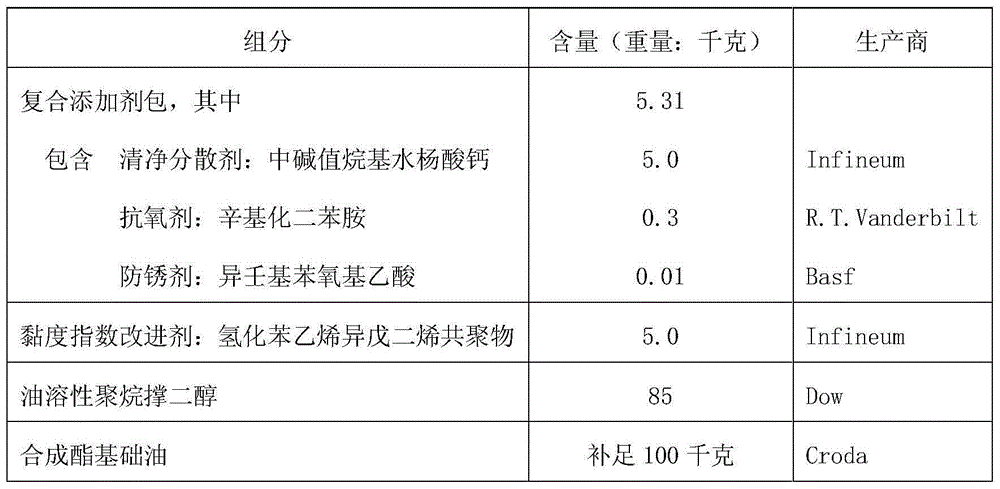

Embodiment 2

[0033]

[0034] The composite additive package contains 2.44% calcium, 1.10% zinc, 0.86% nitrogen, 1.02% phosphorus and 0.12% molybdenum.

[0035] The preparation method of this synthetic gasoline engine oil adopts the following steps:

[0036] (1) Pump the oil-soluble polyalkylene glycol and synthetic ester base oil of the above weight into the blender with a gear pump, heat and stir, and mix evenly at a constant temperature of 55°C to obtain a mixed oil A;

[0037] (2) Add the above-mentioned compound additive package and viscosity index improver (hydrogenated styrene isoprene copolymer) to the mixed oil A prepared in step (1), and continue mechanical stirring for 1.5 hours at a constant temperature of 55°C. Prepare mixed oil B;

[0038] (3) Filter the blended oil B prepared in step (2), and filter it through a filter with a filter bag device under a pressure of 0.15 MPa to obtain a clear and transparent synthetic gasoline engine oil.

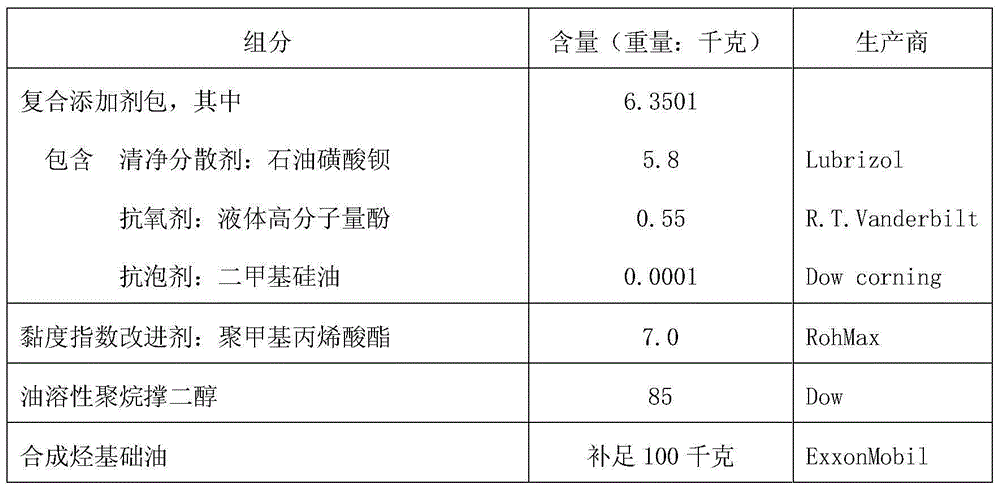

Embodiment 3

[0040]

[0041] The composite additive package contains 2.19% calcium, 0.97% zinc, 0.76% nitrogen, 0.88% phosphorus and 0.11% molybdenum.

[0042] The preparation method of this synthetic gasoline engine oil adopts the following steps:

[0043] (1) Pump the oil-soluble polyalkylene polyglycol and synthetic hydrocarbon base oil of the above weight into the blender with a gear pump, heat and stir, and mix evenly at a constant temperature of 50°C to obtain a mixed oil A;

[0044] (2) Add the above-mentioned compound additive package and viscosity index improver (polymethacrylate) to the mixed oil A prepared in step (1), and continue mechanical stirring at a constant temperature of 50°C for 1 hour to prepare mixed oil B ;

[0045] (3) Filter the blended oil B prepared in step (2), and filter it through a filter with a filter bag device under a pressure of 0.1 MPa to obtain a clear and transparent synthetic gasoline engine oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com