Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Fully loose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

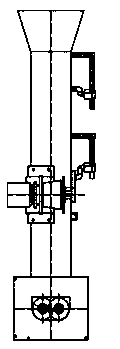

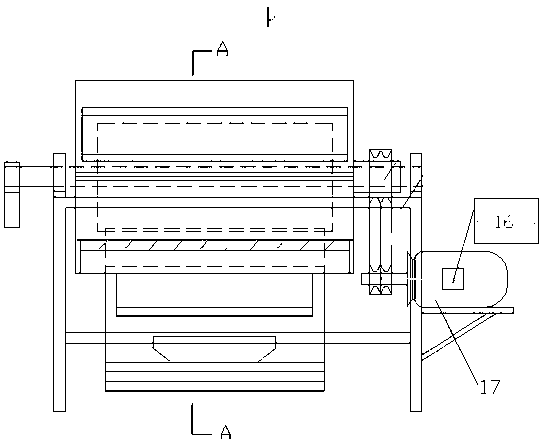

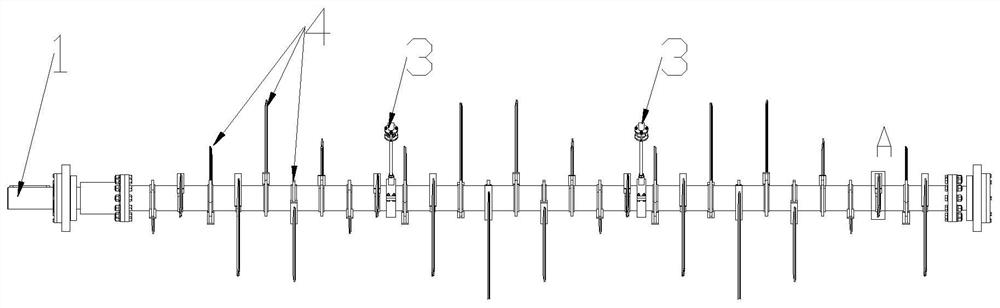

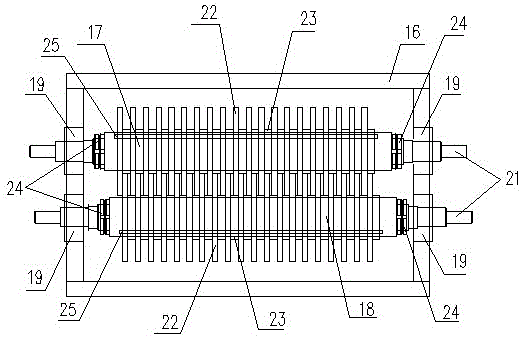

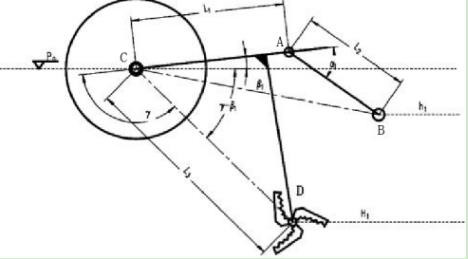

Retting hemp water resolved loose washer

InactiveCN101139790AFull water degummingFully looseSucessive textile treatmentsTextile treatment by spraying/projectingSelf weightEngineering

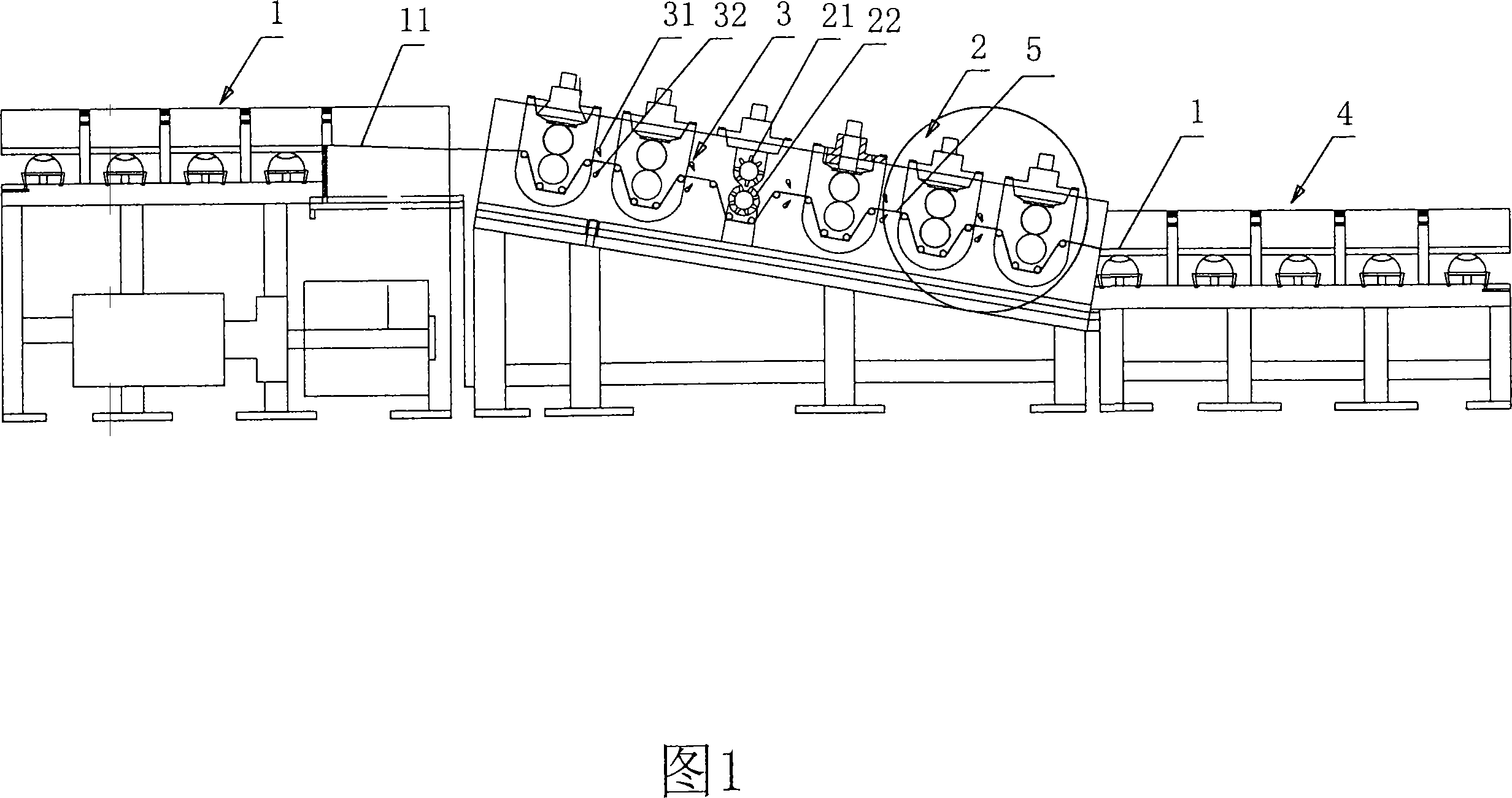

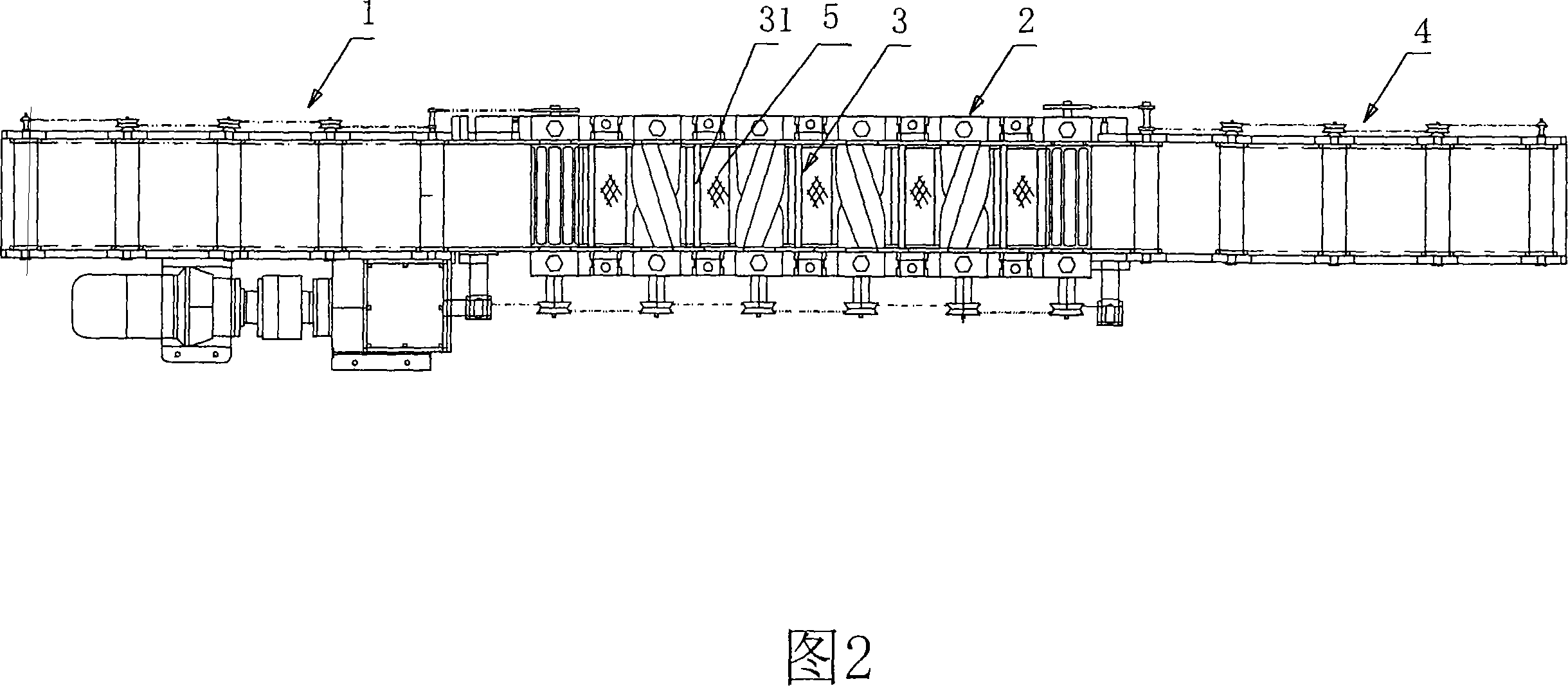

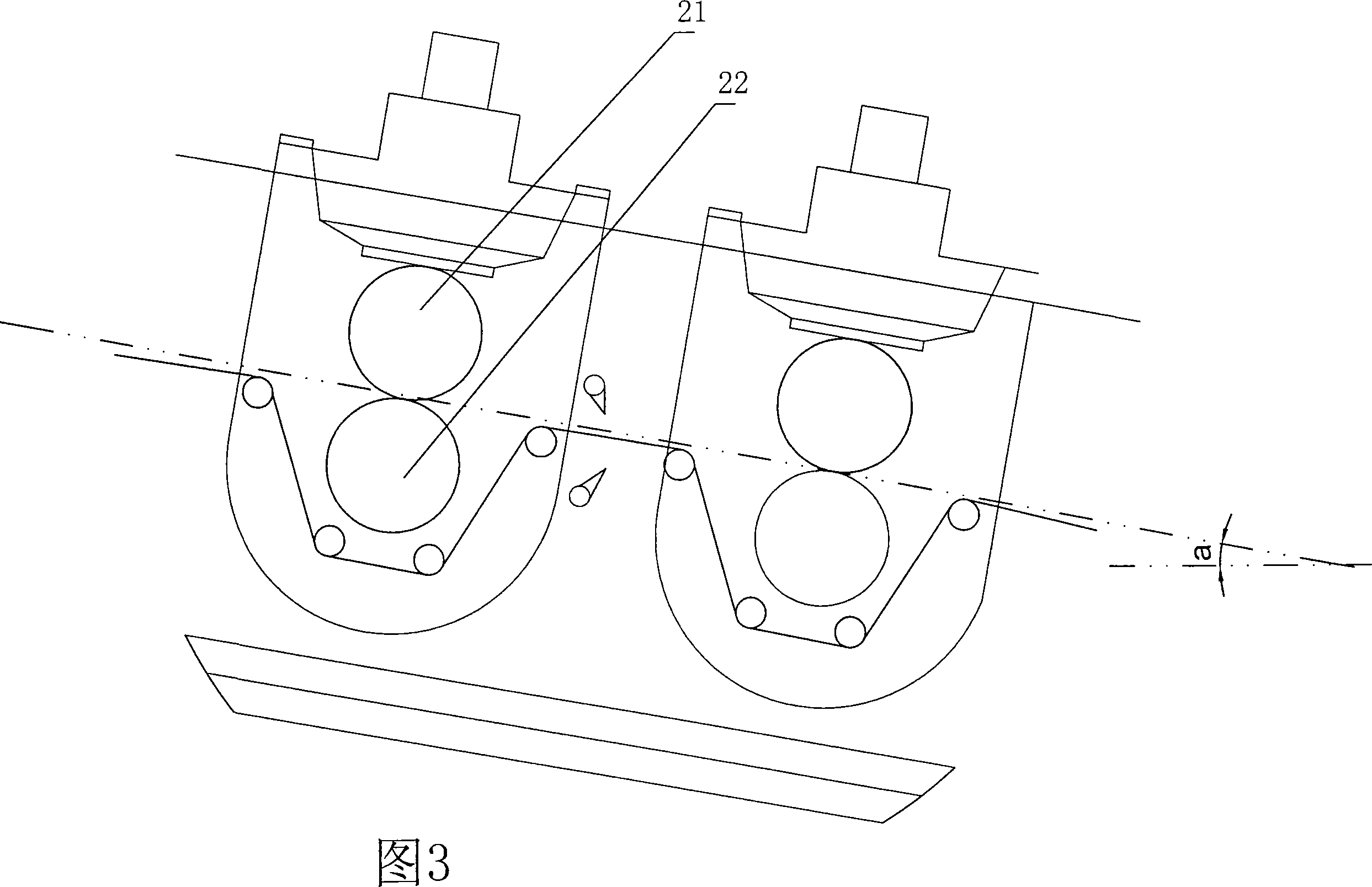

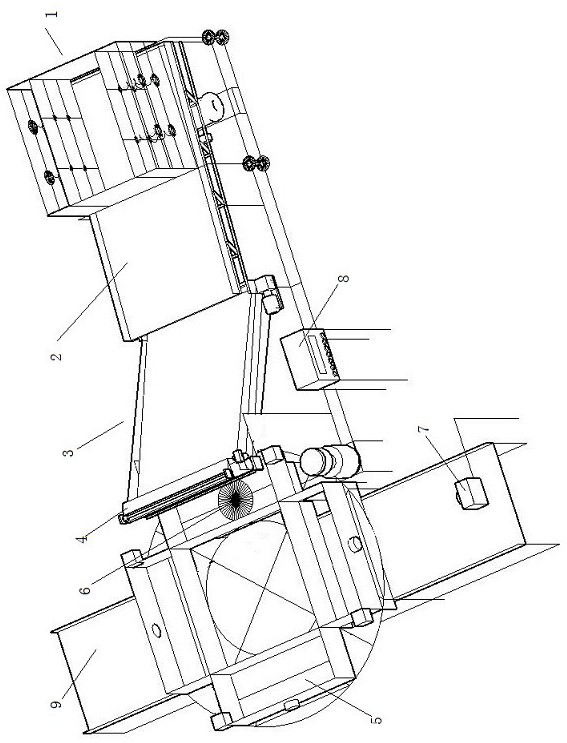

The invention discloses a hemp degumming, water finishing and loosening washer. The washer comprises a hemp feeding mechanism, a roll-pressing mechanism, a spraying mechanism and a hemp output mechanism. The hemp feeding mechanism and the hemp output mechanism are respectively arranged on both ends of the roll-pressing mechanism; the roll-pressing mechanism is composed of a plurality of pairs of driving and driven rollers that are mutually meshed with each other. The washer is characterized in that the hemp feeding mechanism is higher than the hemp output mechanism; all the roller pairs in the roll-pressing mechanism are gradually shrunk from one end, where the hemp feeding mechanism is positioned, to the other end, where the hemp output mechanism is fixed; the spraying mechanism comprises an upper spraying pipe and a lower spraying pipe that are distributed between all roller pairs; the upper spraying pipe is above a hemp channel; the lower spraying pipe is below the hemp channel. The invention can make the hemp utilize self-weight lower approaching resistance, improve hemp washing speed and reduce water consumption volume. Especially when the inclination angle of the roll-pressing mechanism is rather high, both the upper and lower spraying pipes in the spraying mechanism can directly clamp the hemp vertically to approach forward, so that the hemp can be more sufficiently processed through water finishing degumming and loosening.

Owner:湖南润久科技有限公司

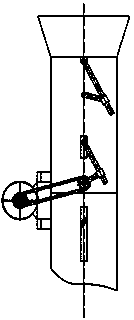

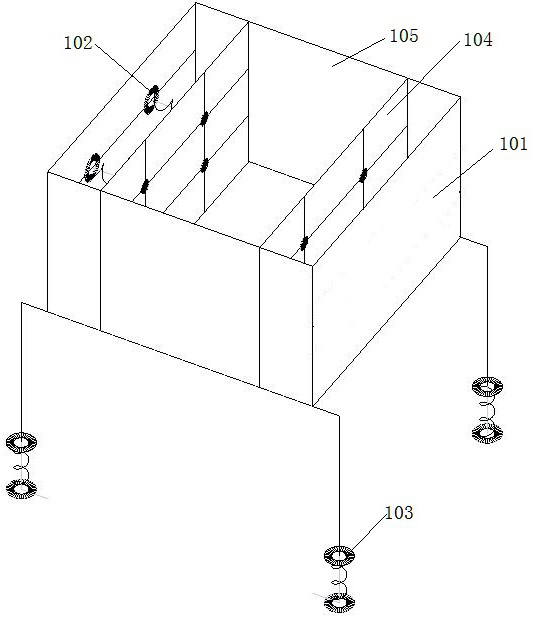

Biomass feeding device

ActiveCN103723489APrevent material from sheddingAvoid problems such as entanglementLarge containersConveyor partsEngineeringDistributor

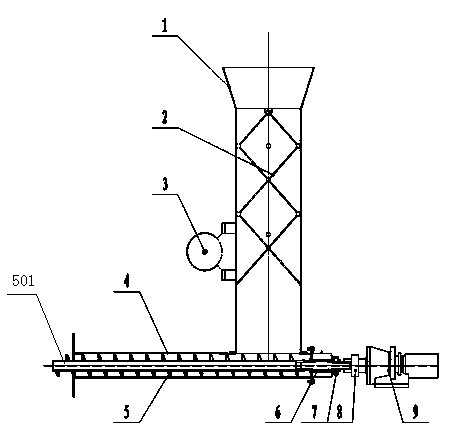

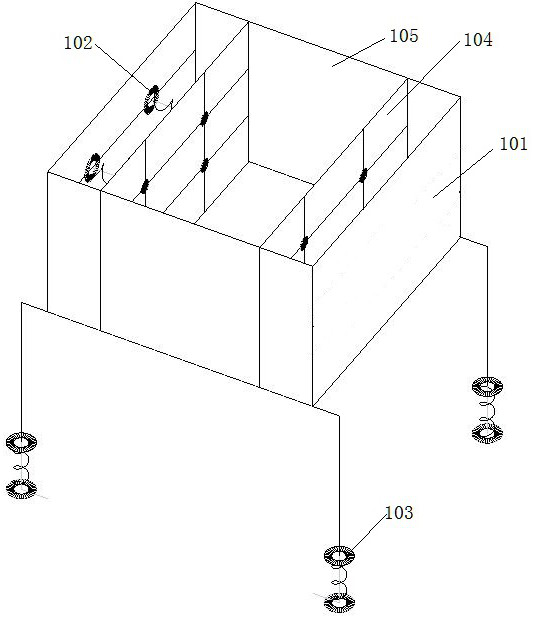

The invention provides a biomass feeding device. By using the biomass feeding device, blockage of materials can be avoided, the application range of the materials is wide, and the materials can be fed continuously. The biomass feeding device comprises a barrel, a distributor and a feeder, wherein the distributor comprises a distributing motor and a connecting rod mechanism; an output shaft of the distributing motor is connected with a transmission mechanism; the transmission mechanism is connected with the connecting rod mechanism; the connecting rod mechanism is arranged in the barrel; the feeder comprises a shell, an auger and a feeding motor; the shell is combined with the barrel in a right-angled manner; the shell is positioned at the lower end of the barrel and is communicated with the inside of the barrel; one end of the auger is connected with the feeding motor; and the other end of the auger penetrates in the shell and outwards extends to form a retention section.

Owner:山东知周环境科技有限公司

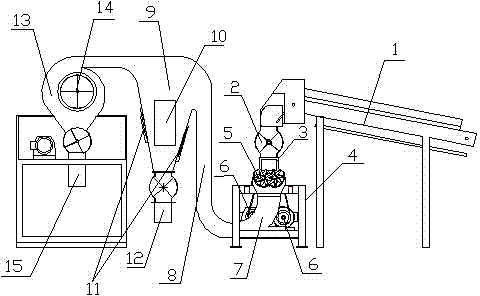

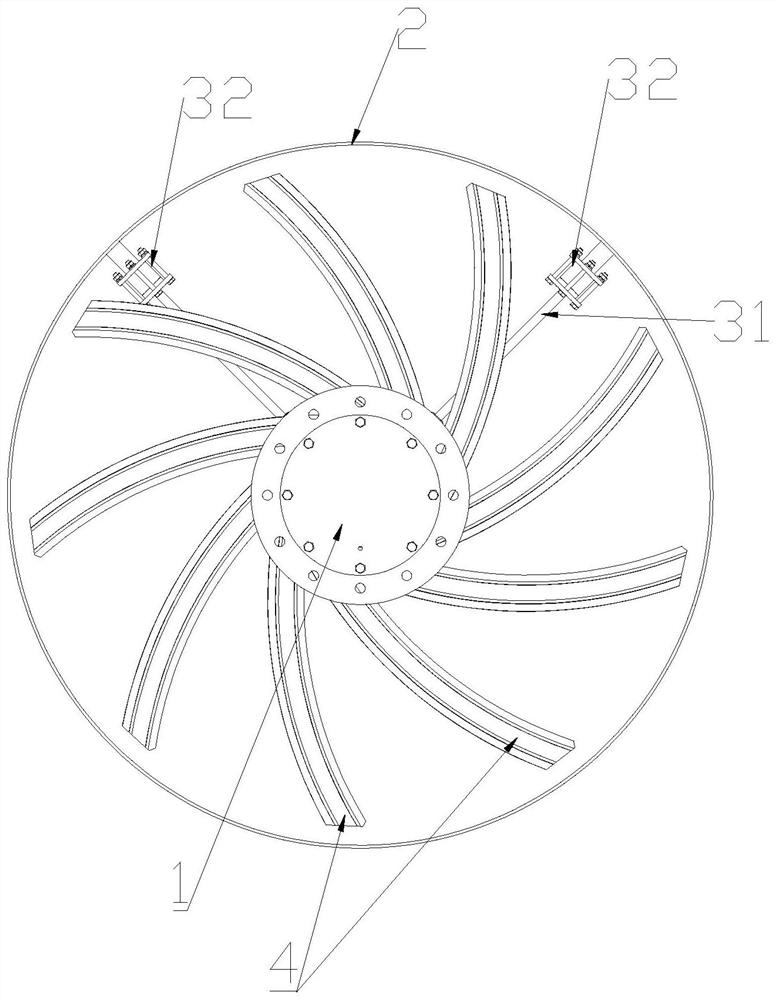

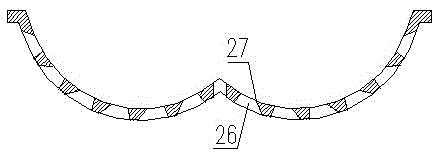

Reconstructed cut tobacco shredding and winnowing system

ActiveCN104839882AUniform lengthMeet the length requirementTobacco preparationTobacco treatmentTobacco productFixed length

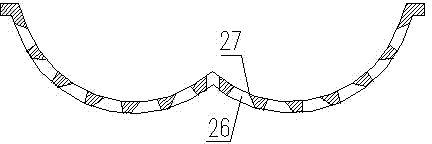

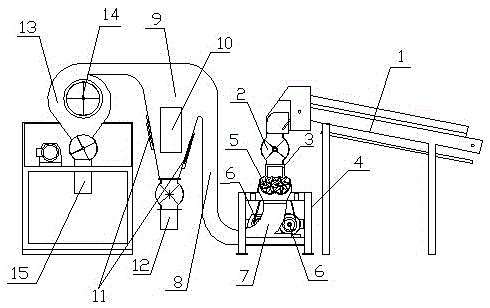

The invention discloses a reconstructed cut tobacco shredding and winnowing system which comprises a high-frequency vibrating tank, a shredding device, a shred cleaning device and a blanking device. The shredding device comprises a feeding device, a shredding machine, a shell and a rack, the shred cleaning device comprises a conveying pipe and a winnowing machine, the shredding machine comprises a shredding knife and a power device, the shredding knife comprises a quick knife disc, a slow knife disc, a knife rest and a shredding frame bar, the quick knife disc and the slow knife disc are fixed on the knife rest side by side through a bearing, blades of the knife discs are arranged in a staggered manner, the power device drives the quick knife disc and the slow knife disc to be in differential running and opposite-direction rotating, cutting edges of the blades are staggered for cutting, the shredding frame bar is mounted below the quick knife disc and the slow knife disc and comprises two arc-shaped net plates which are fixedly connected, each arc-shaped net plate is provided with multiple shred-leaking square holes. By the reconstructed cut tobacco shredding and winnowing system, cut tobacco can be cut off in a fixed-length manner according to different process requirements, beating missing is avoided, beaten short cut tobacco is winnowed and purified, and clean cut tobacco uniform in size and moderate in length is output finally, so that blending uniformity of cut tobacco products is improved.

Owner:CHINA TOBACCO HENAN IND

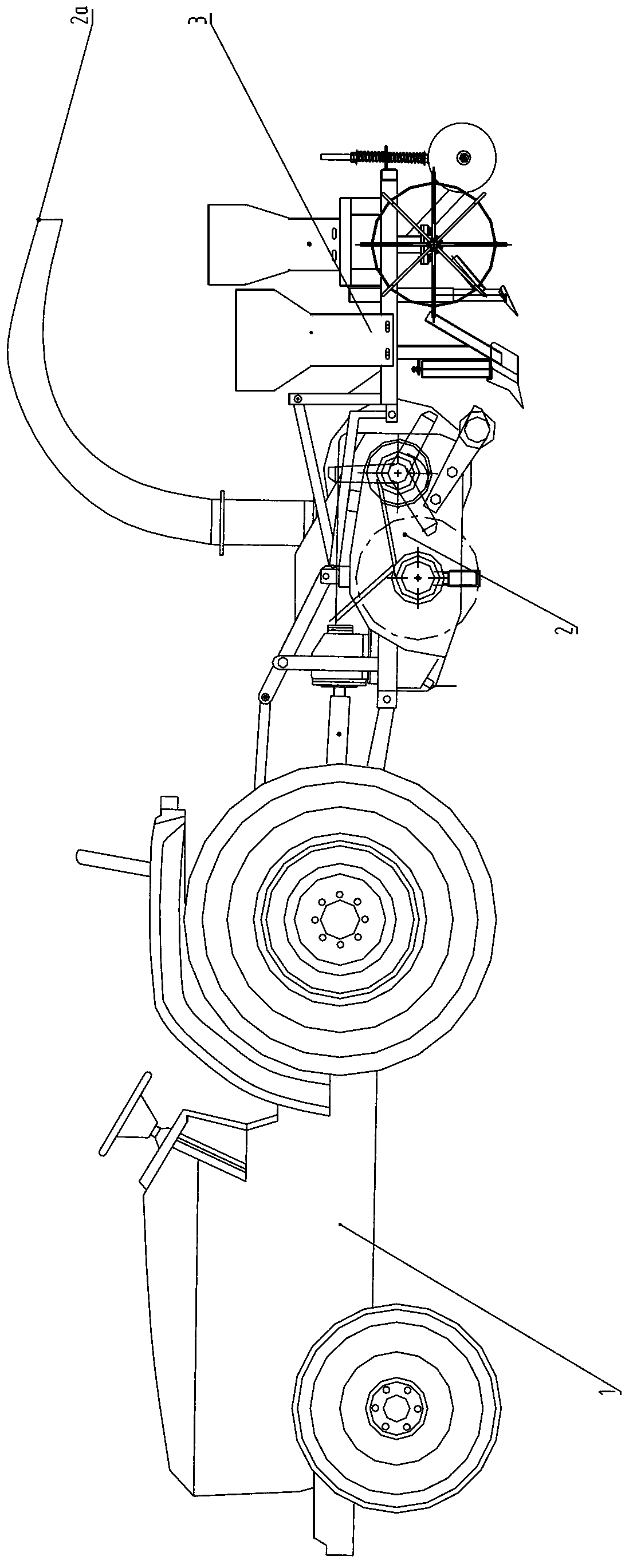

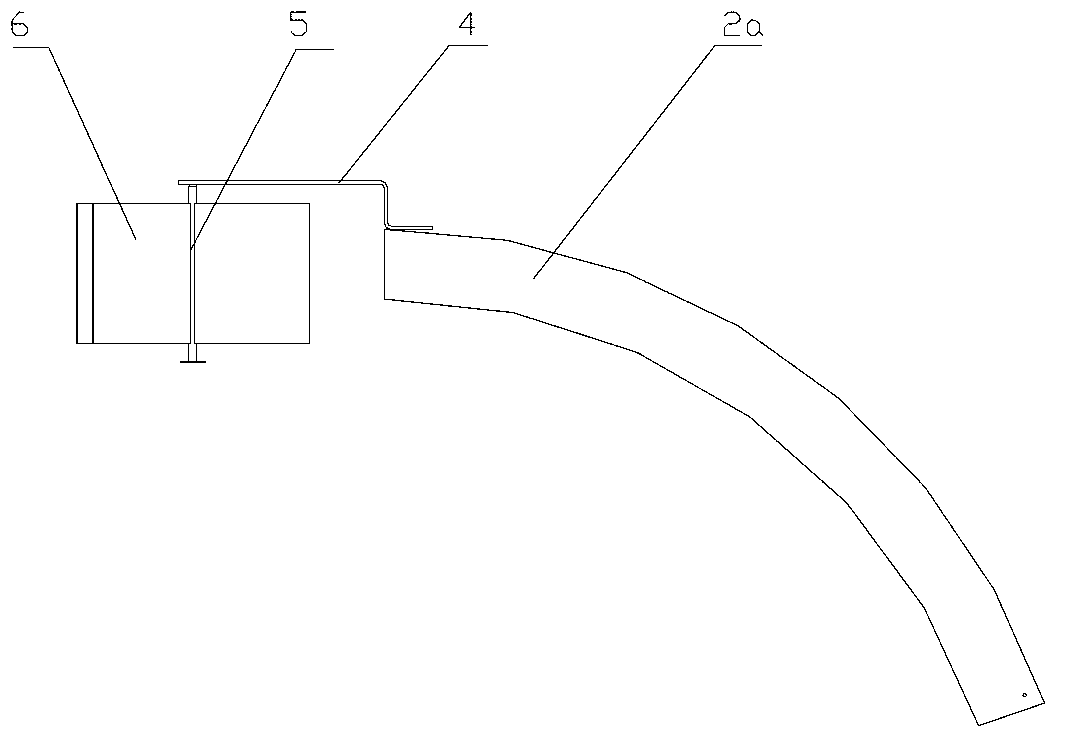

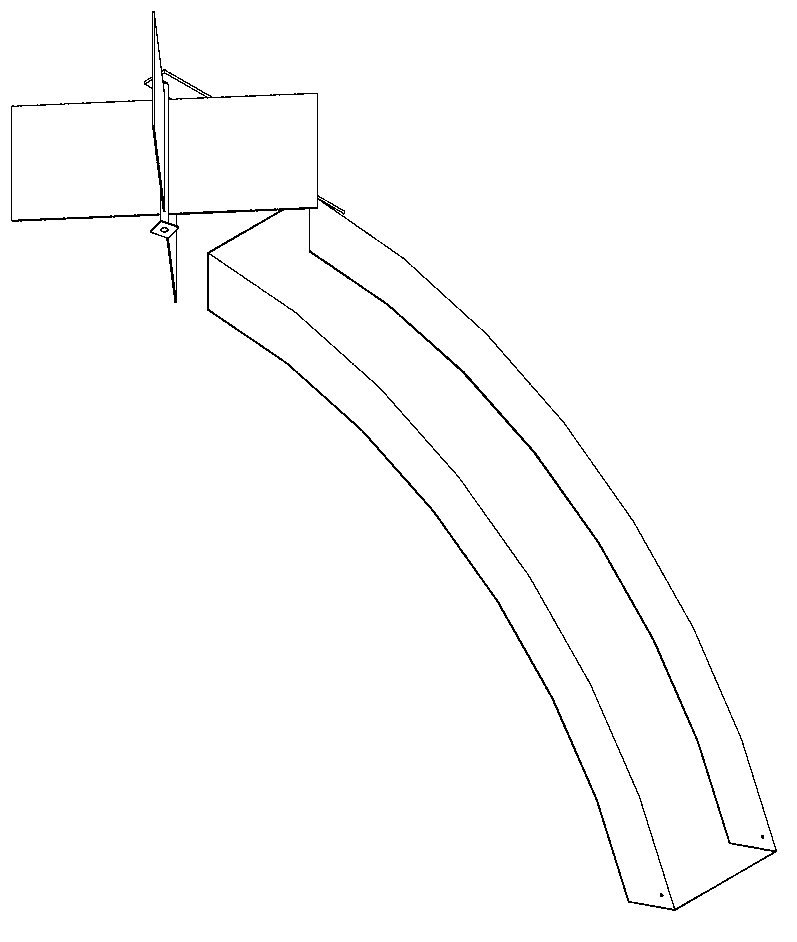

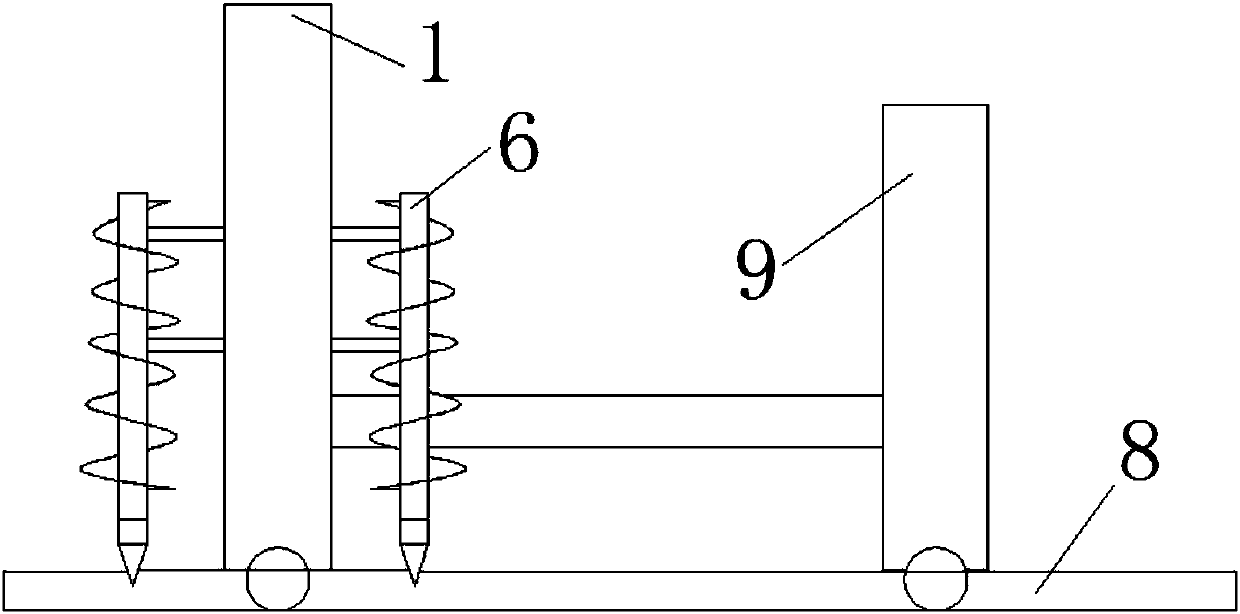

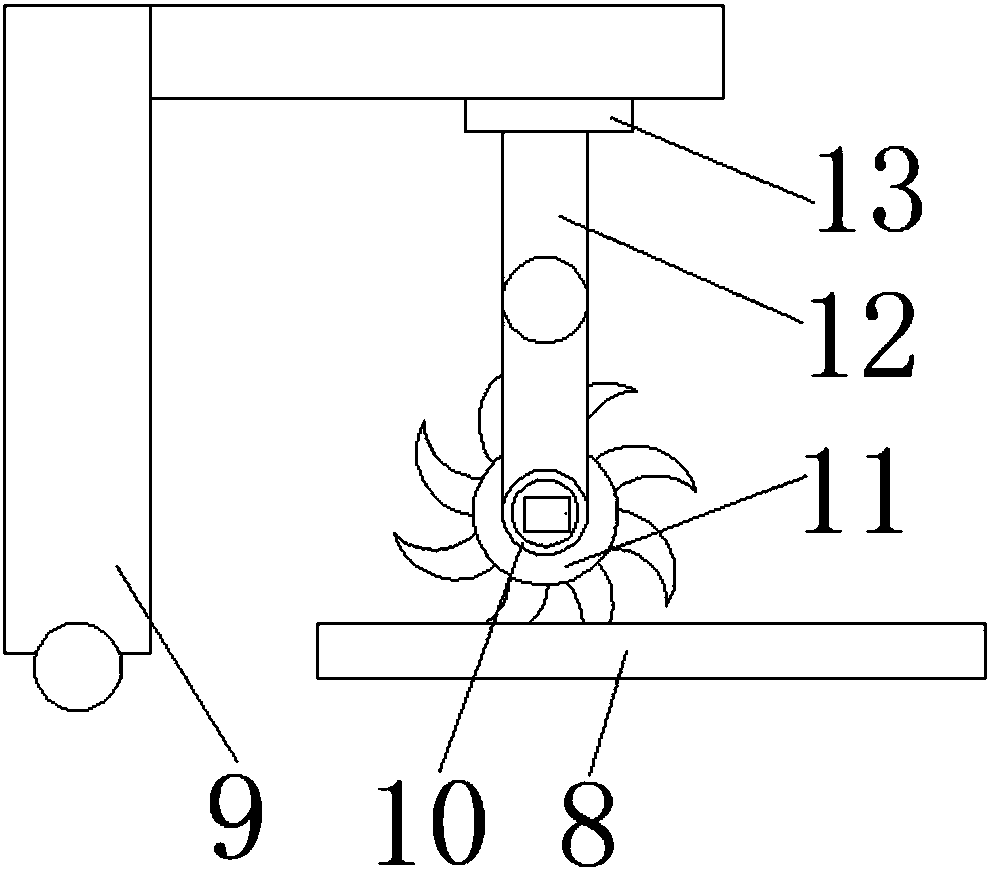

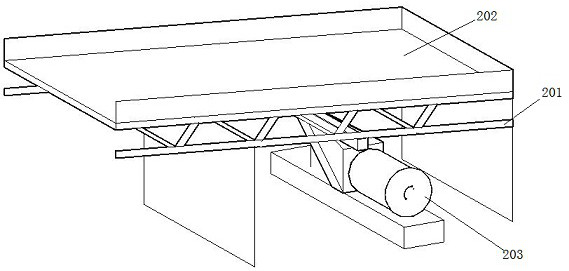

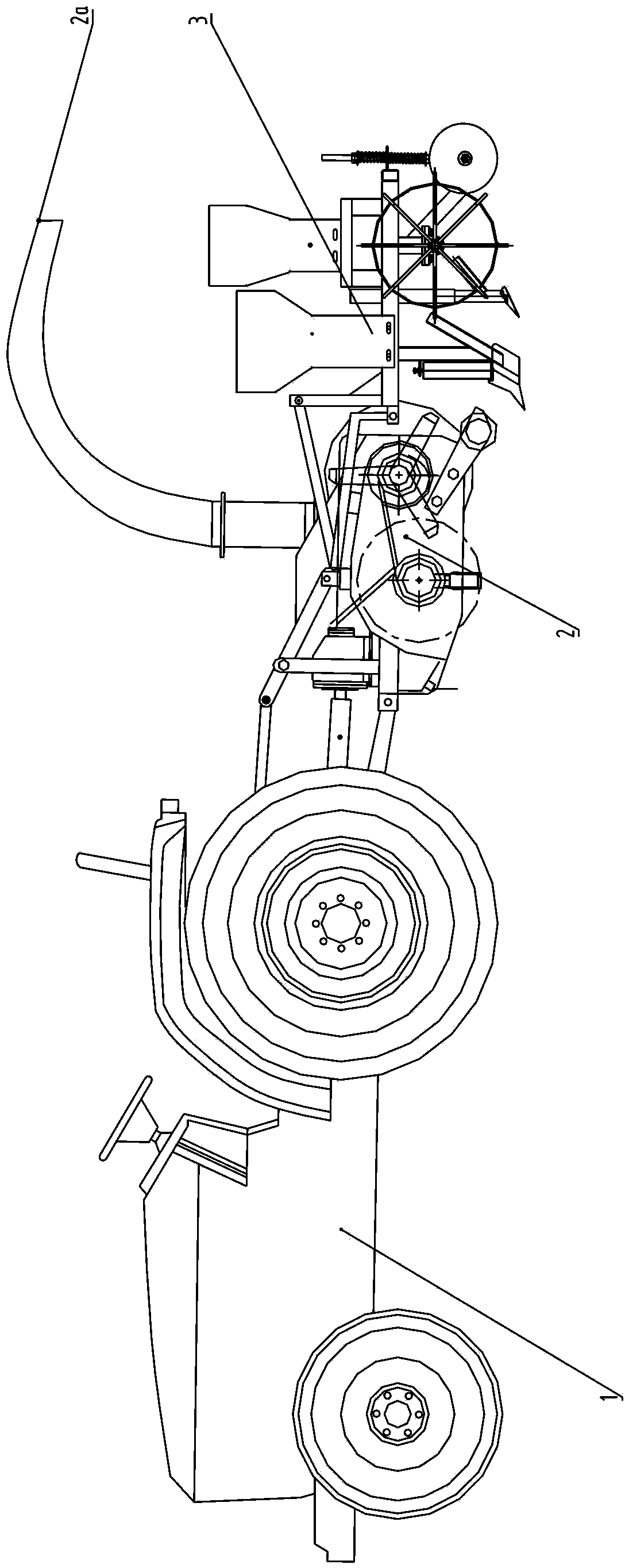

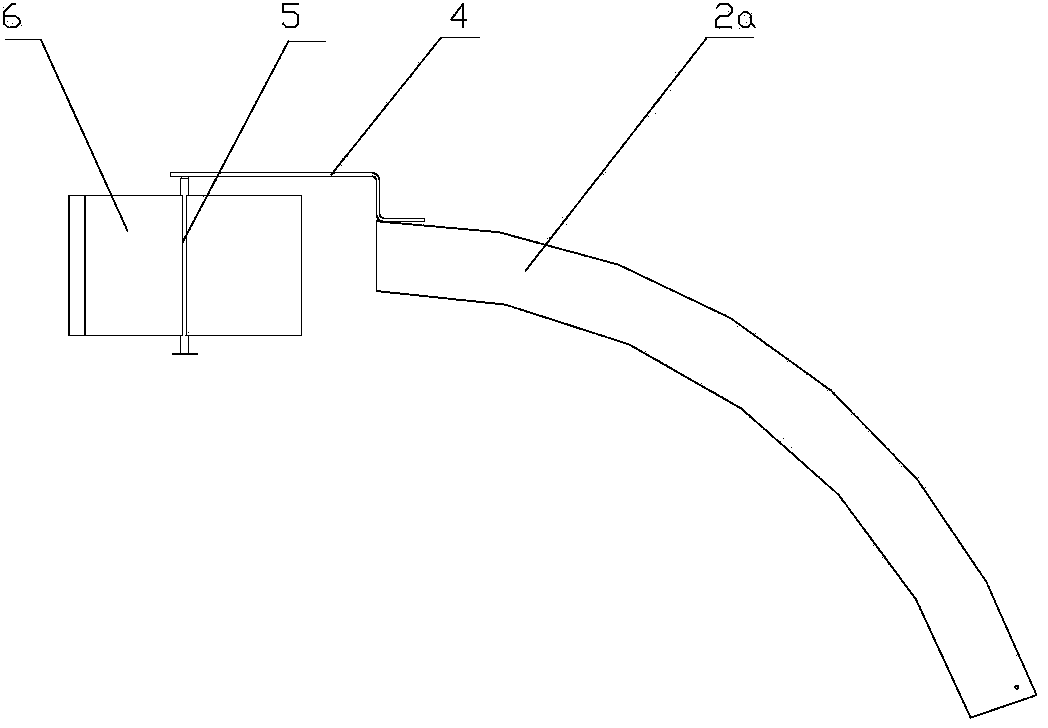

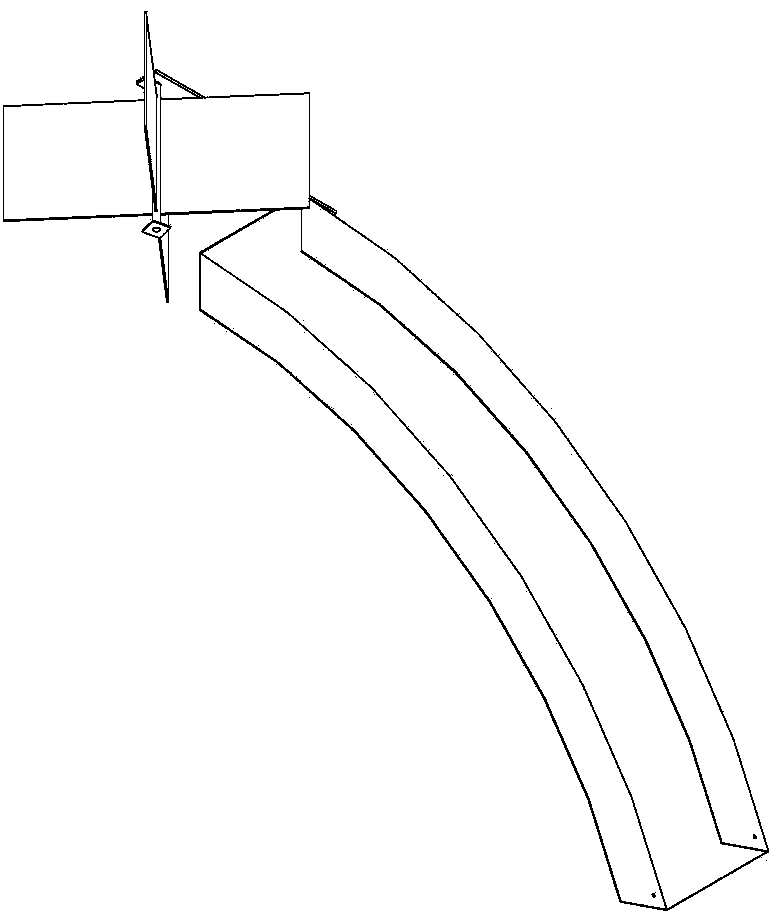

Improved straw outlet device of machine capable of crushing straw, applying fertilizer, performing sowing and covering straw

The invention relates to an improved device of a part of a fertilizer applying and sowing machine and particularly relates to an improved straw outlet device of a machine capable of crushing straw, applying fertilizer, performing sowing and covering straw. The improved straw outlet device comprises a pipeline (7) and a cantilever (8), the pipeline (7) backward crosses the upper portion of the fertilizer applying and sowing integrated machine, the cantilever (8) backward stretches out of the left side or the right side of an outlet of the pipeline (7), a rotation shaft (9) is vertically arranged at one end of the cantilever (8), and a plurality of blades (10) which can rotate around the rotation shaft (9) are configured on the rotation shaft (9); the vertical height of the blades (10) is 1-1.8 times of the open height of the outlet of the pipeline (7); the horizontal width of the blades (10) is 1-1.5 times of the open width of the outlet of the pipeline (7); and the distance from the position where the rotation shaft (9) is located to the outlet of the pipeline (7) is 1-1.5 times of the width of the blades (10). According to the improved device, additional power is not required, the blades rotate in a high speed under the action of wind for the pipeline to send out the straw, the crushed straw is scattered and thrown, and the crushed straw evenly covers sowed fields so that foundation and conditions are provided for good quality and high yield of crops of peanuts and soybeans.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

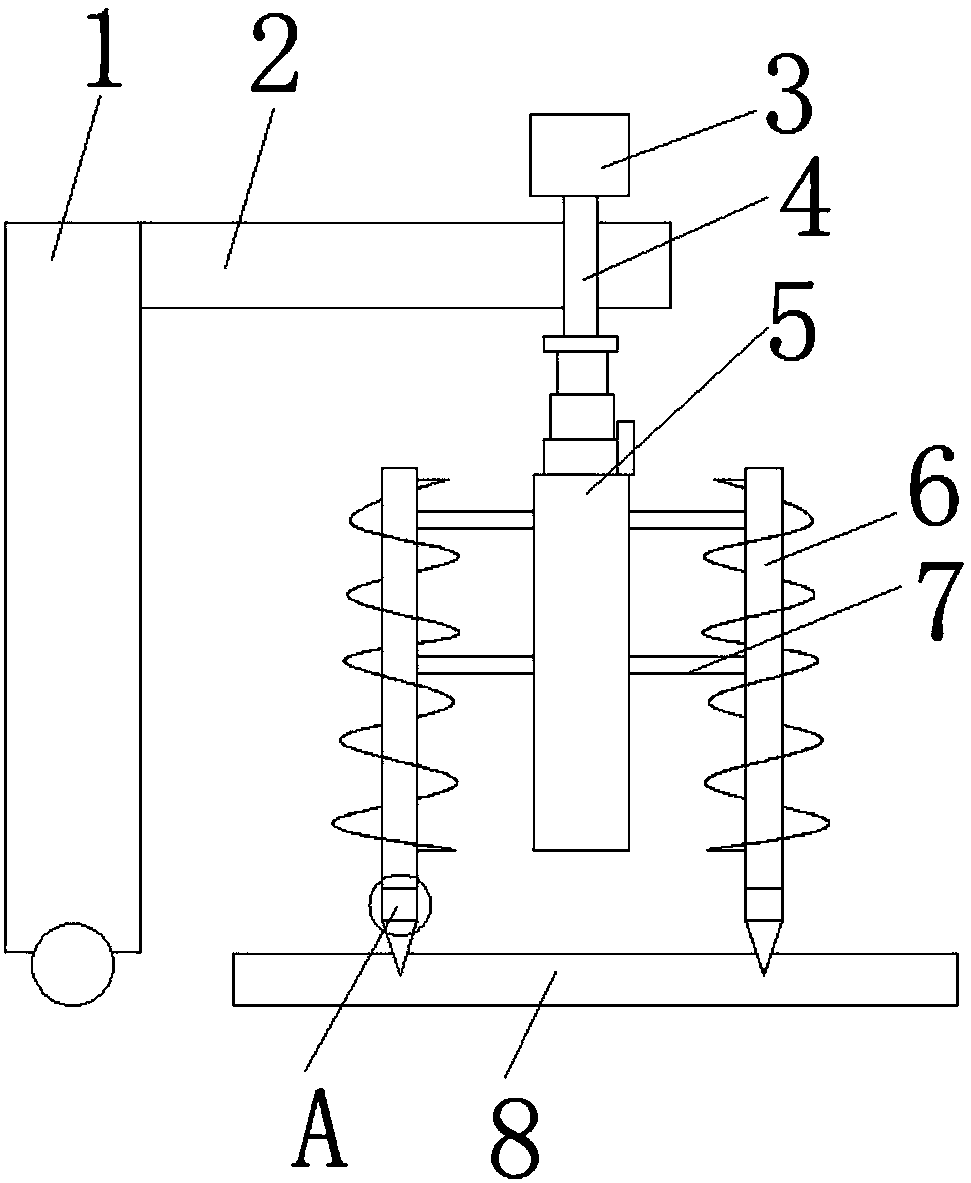

Ripper for crop planting

The invention discloses a ripper for crop planting, which comprises a first supporting frame, wherein a hanging plate is horizontally arranged on one side at the top end of the first supporting frame,a motor is arranged at the upper end of the hanging plate, the lower end of the motor is connected with a transmission shaft through an output end, a connecting rod is arranged on the side wall of the outer end of a rotating shaft, a ripping rod is arranged on one side of the connecting rod, a spring is arranged inside a fixing rod, a shock absorption rod is arranged at the upper end of the spring, the hanging plate is arranged on one side at the top end of a second supporting frame, a connecting plate is arranged on the side wall at the bottom of the hanging plate, the lower end of the connecting plate is connected with a folding rod, one end of the folding rod is connected with and installed on the side wall of the outer end of a shaft sleeve, the motor is arranged inside the shaft sleeve, the output end of the motor is connected with a rotating rod, and the outer end of the rotating rod is provided with ripping blades. The ripper for crop planting first rips soil by use of the ripping blades and then stirs and rips the soil by use of the ripping rod; after two ripping of the soil, the soil is more loose and the permeability of the soil is better, which is of great benefit to crop planting.

Owner:贵州宏源泰康生态科技发展有限公司

Planting method of vegetables

InactiveCN107173006AImprove qualityMaintain nutrientsExcrement fertilisersBioloigcal waste fertilisersCrop cultivationInsect pest

The invention discloses a planting method of vegetables and relates to the technical field of crop planting. According to the planting method of the vegetables, after soil is deeply ploughed, base fertilizer is applied, the soil can be sufficiently loosened, sufficient soil fertilizer is provided and a fertilizer supplying environment of the soil is improved; the infection intensity of diseases is reduced from the essence of the soil; a seedling culture medium with small environment pollution is mixed with seeds and then seedling culture is carried out, so that the germination rate of the vegetable seeds is improved and the yield of vegetable seedlings is increased; the cultured seedlings are not easily invaded by diseases and insects; the survival rate of the transplanted seedlings is high; fixed-period fertilizer, insect pest, weed and moisture management is carried out on the transplanted vegetables so that sufficient nutrients and conditions are provided for rapid growth of the vegetables and the utilization of chemical fertilizer is reduced; and the environment pollution is reduced, the quality of the soil is improved, the quality of the vegetables is improved and nutrient components of the vegetables are ensured.

Owner:蒙宗勇

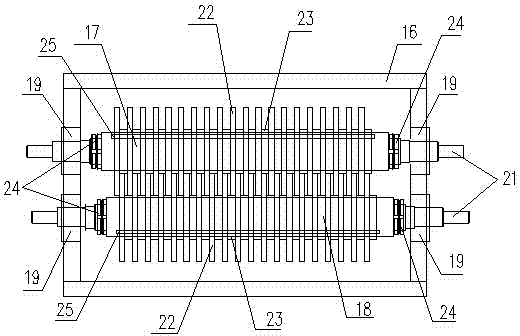

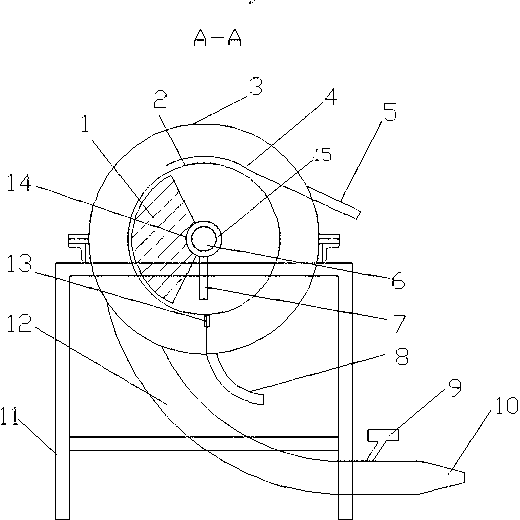

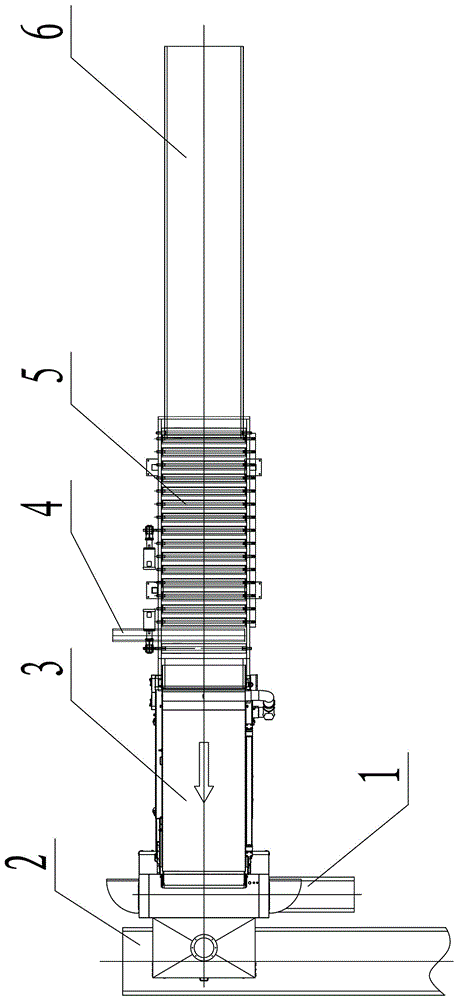

Suspended dry type low-intensity magnetic field magnetic separation equipment for fine-grained materials

InactiveCN103008105AReduce pollutionReduce packageMagnetic separationFrequency changerStructural engineering

The invention relates to suspended dry type low-intensity magnetic field magnetic separation equipment for fine-grained materials, and belongs to the technical field of mineral processing engineering. The equipment adopts the structure that a motor is connected with a frequency converter; the output shaft of the motor is connected with a support shaft; the support shaft is connected with a bracket; an outer cylinder is fixed on the bracket; an inner cylinder is connected with the support shaft, and rotates with the support shaft; the support shaft is connected with a circular ring through a bearing; a separating plate is arranged between the inner cylinder and the outer cylinder, and is fixed on the outer cylinder; a tailing outlet is formed in the upper part on the outer wall of the outer cylinder; a concentrate outlet is formed in the bottom on the outer wall of the outer cylinder; the top of a pipeline is connected with the outer cylinder; the tail of the pipeline is an airflow interface; the airflow interface is connected with air compressing equipment; a feed port is arranged above the airflow interface; and a fur brush is fixed on the circular ring. According to the invention, energy consumption and water resource pollution are reduced; separation of the fine-grained materials can be realized; ore is fed from the lower part of a magnetic separator; separation is carried out in a suspended state, so as to ensure sound looseness of the materials and improve the grade and the recovery of concentrate; the device is simple in structure; and the operation is convenient.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

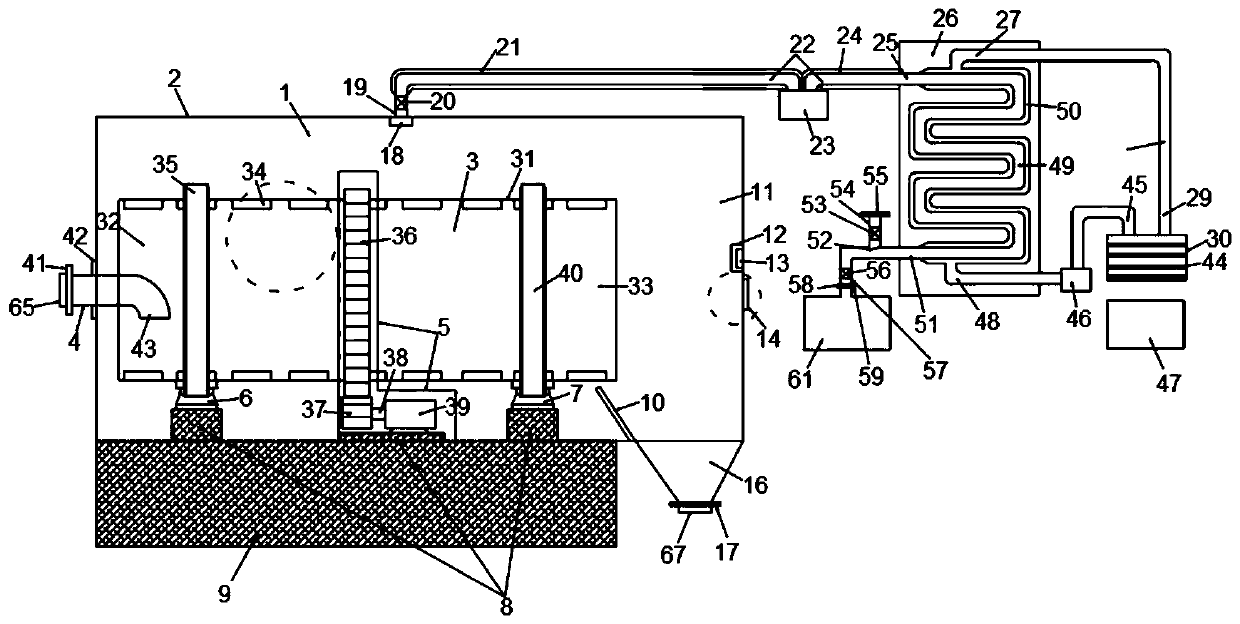

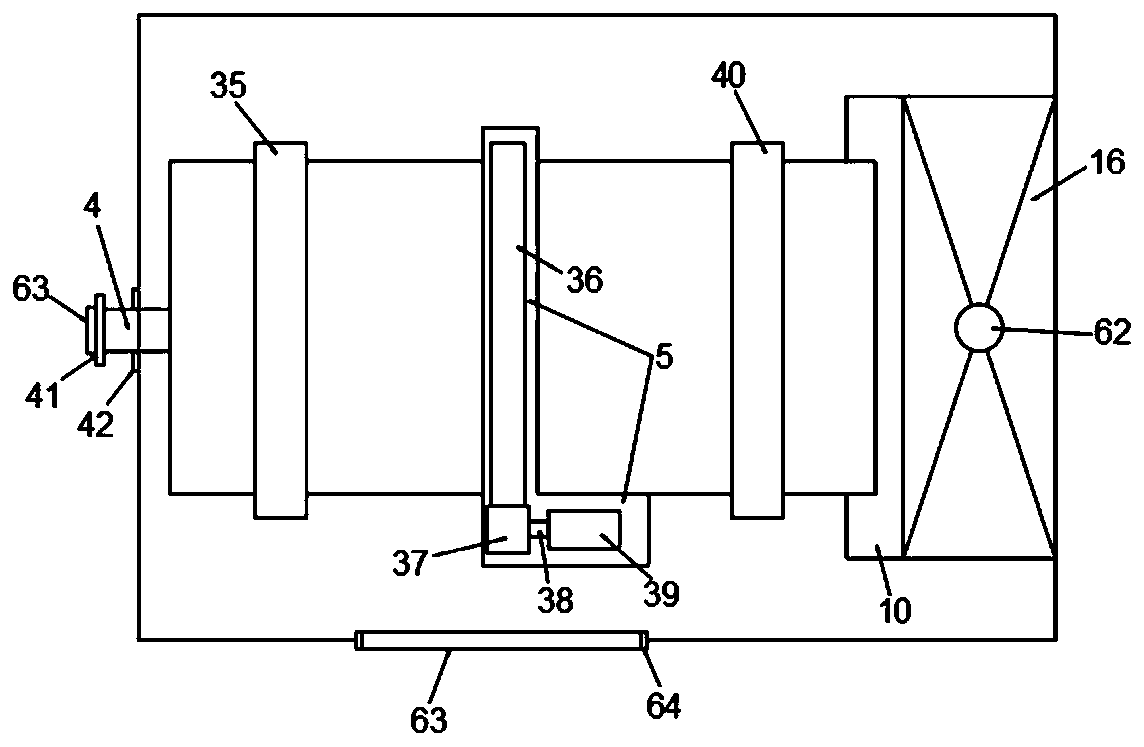

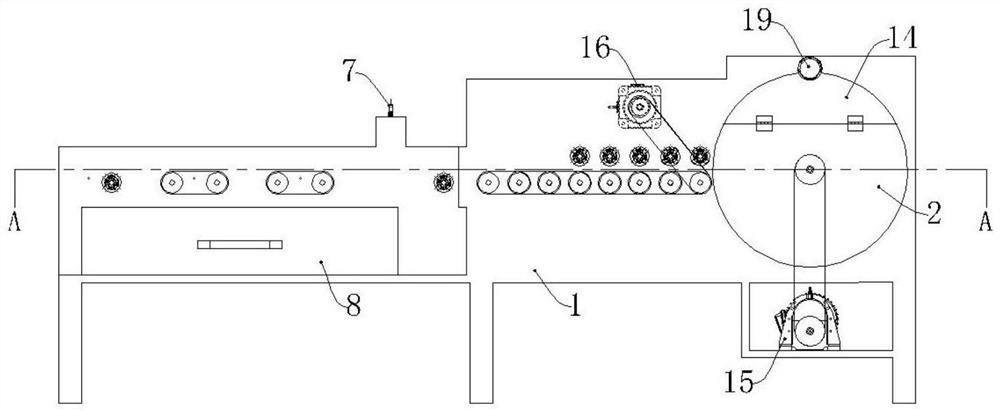

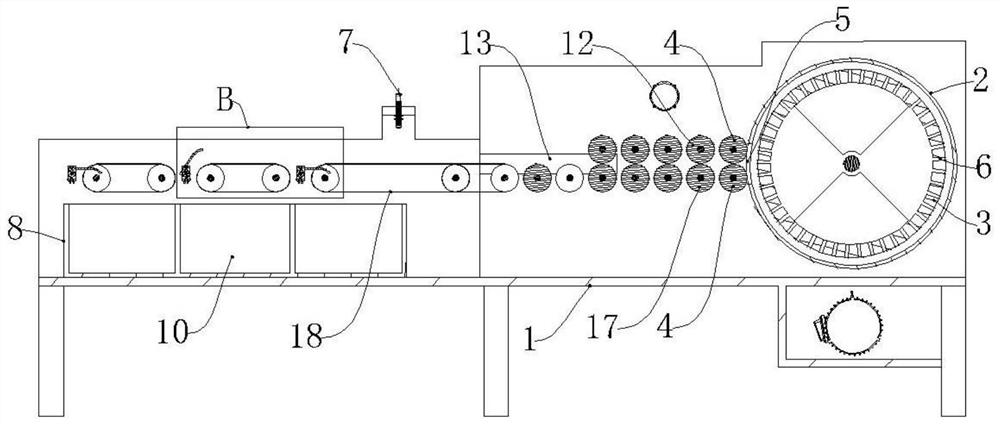

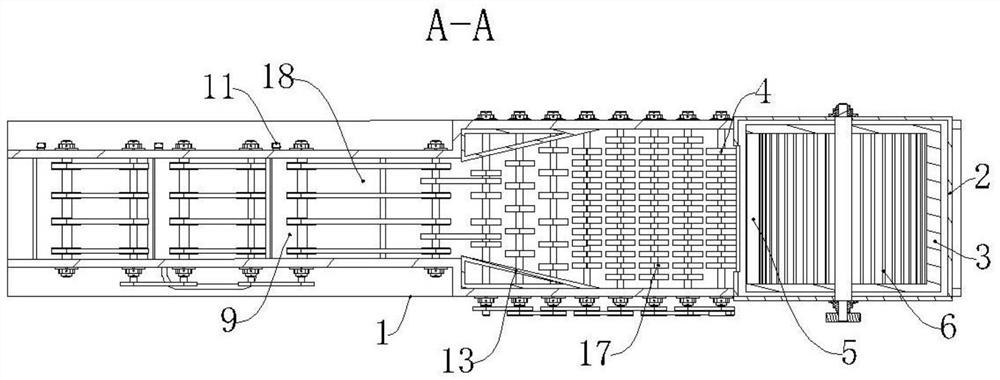

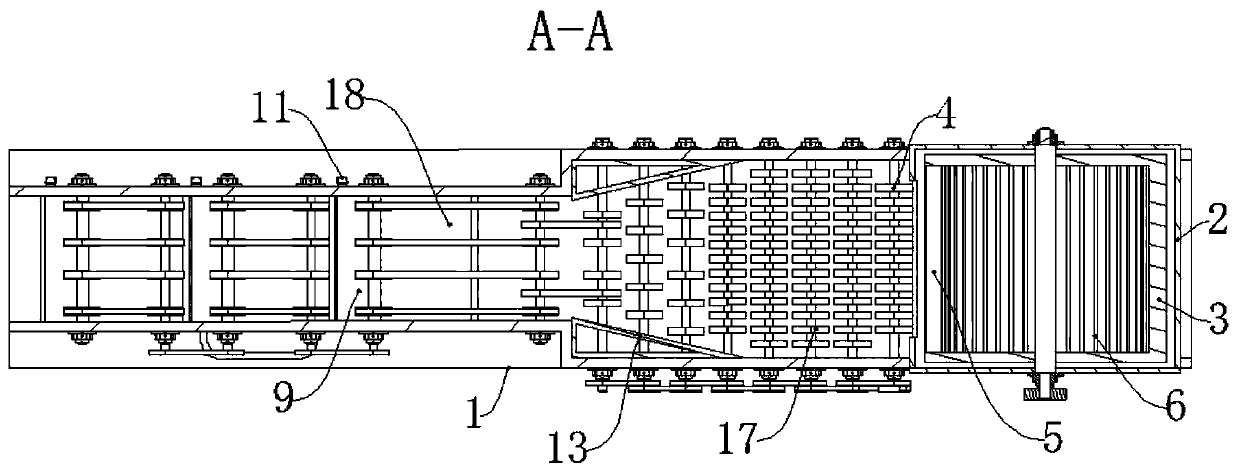

A rice flour ripening and loosening integrated equipment

ActiveCN110787695BImprove product qualityAvoid accumulationTransportation and packagingRotary stirring mixersAgricultural engineeringRipening

The invention discloses a kind of rice flour ripening and loose integration equipment, which comprises a constant temperature oven and a mixing cylinder with an opening at one end. A rack is arranged inside the constant temperature oven, and a feeder, a conveyor and a discharger are installed in sequence from top to bottom of the rack. , the feeding machine includes feeding cloth and several rollers A, the two ends of the roller A are installed on the frame through the bearing seat, the feeding cloth is wound on the outer peripheral surface of the roller A, the conveyor or the discharging machine includes a machine installed on the There are several rollers B on the frame, and the two ends of the rollers B are equipped with sprockets, and the sprockets are driven by chain meshing. There are several steel wires fixedly connected between the two chains. The slurry pipe sends the rice flour slurry to the upper surface of the feeding cloth. Adopting the technical scheme of the present invention, the vibration of the sprocket during the transmission process is used to vibrate the load-carrying steel wire in a small range at the same time, so that the rice noodle slurry in the process of cooking is continuously loosened, which lays a foundation for reasonable packaging of the finished rice noodle in the later stage.

Owner:贵州金晨农产品开发有限责任公司

Cyclic utilization method of rock wool production waste

The invention relates to the technical field of rock wool waste utilization, and discloses a cyclic utilization method of rock wool production waste. The method comprises the following steps: S1, firstly, collecting rock wool production wastes together by using a loading vehicle, and then loading the wastes into the stock bin of a crusher; S2, then the crusher is started, the crusher crushes the waste in the stock bin of the crusher, and the crushed waste is conveyed into a screening machine; S3, then the screening machine is started, and the screening machine divides the waste crushed by thecrusher into coarse aggregate, fine aggregate and slag wool according to the hole diameters of the two screens; and S4, taking out the slag cotton material. The cyclic utilization method of the rock wool production waste has the advantages that the cyclic utilization rate of the rock wool waste is increased, the production cost of rock wool is reduced, the defects that a large amount of waste is accumulated to occupy the site and pollute the surrounding environment can be overcome, ecological balance is protected, zero emission of solid waste is achieved, and the energy-saving and environment-friendly properties of rock wool production are improved.

Owner:NANJING TONTECH ROCKWOOL CO LTD

Device for recycling electrolyte of waste lithium ion battery at normal temperature

InactiveCN111389547AAchieve recyclingFully looseSolid waste disposalWaste accumulators reclaimingElectrolytic agentVacuum pumping

The invention relates to the technical field of waste lithium ion battery recycling, and provides a device for recycling electrolyte of a waste lithium ion battery at normal temperature. The device comprises a material inlet connecting pipe, vacuum drying equipment, a condensing device, a nitrogen collecting device and an electrolyte collecting box; the discharge end of the material inlet connecting pipe is hermetically connected with the vacuum drying equipment, a vacuum extraction opening is formed in the top of the vacuum drying equipment, the vacuum extraction opening is connected with a condensate inlet end of the condensing device, and a vacuum pump used for extracting electrolyte steam of the waste lithium ion battery is arranged between the vacuum extraction opening and the condensing device; and a condensate outlet end of the condensing device is connected with the electrolyte collecting box, a nitrogen outlet connecting pipe is connected between the condensate outlet end andthe electrolyte collecting box, and the nitrogen outlet connecting pipe is connected with the nitrogen collecting device. According to the device, recycling of the electrolyte in crushed material of the waste lithium ion battery at normal temperature is realized.

Owner:江门市恒创睿能环保科技有限公司

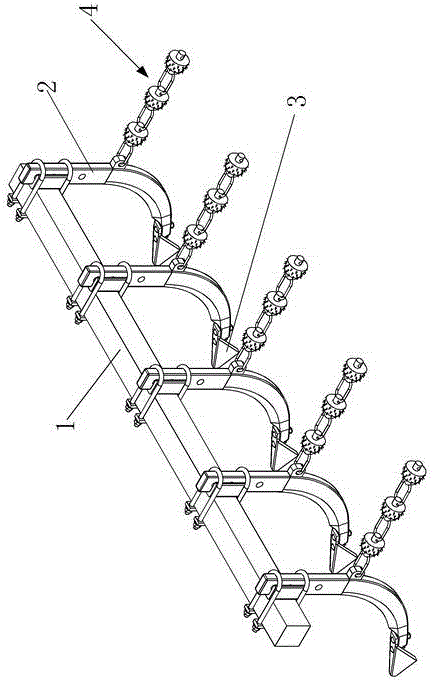

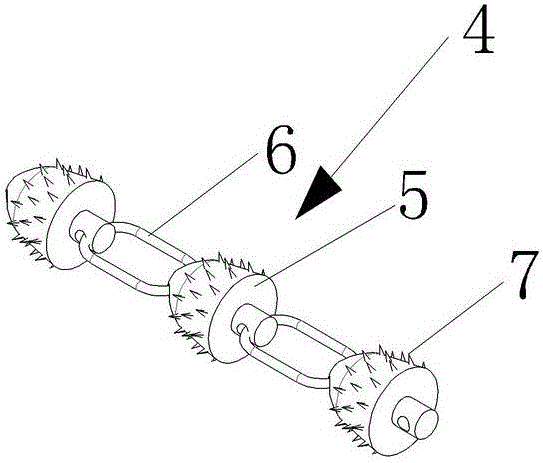

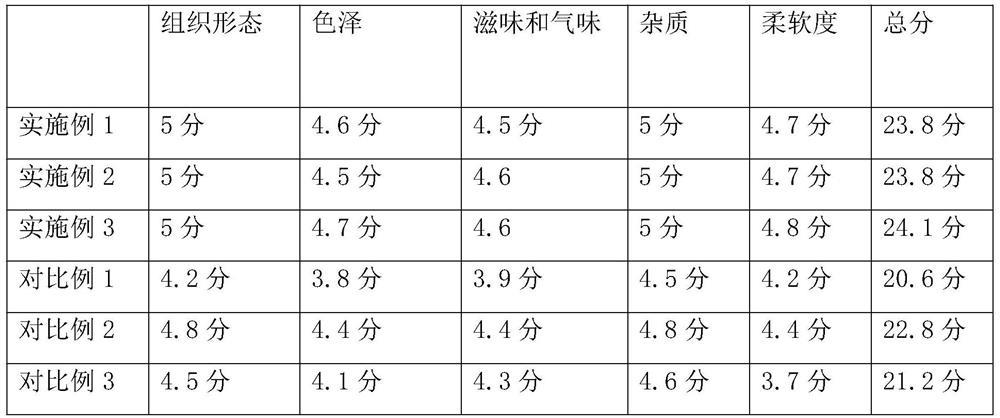

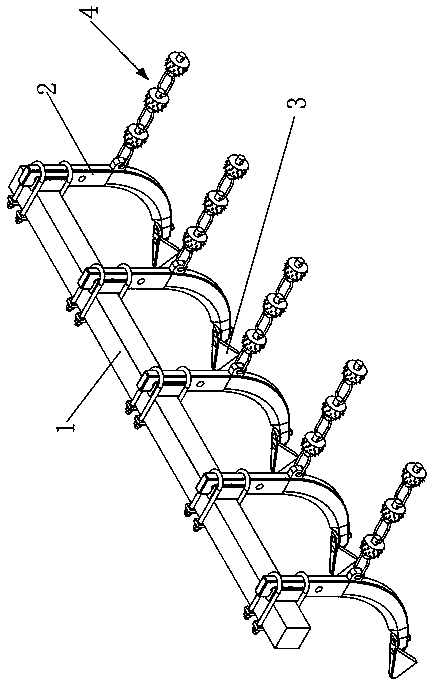

Dynamic bionic sub-soiling device with soil crusher

The invention discloses a dynamic bionic sub-soiling device with a soil crusher. The dynamic bionic sub-soiling device is composed of a transverse beam, a shovel handle, a shovel wing and a chain-shaped dynamic bionic soil crusher, wherein the shovel handle is fixed on the transverse beam and the shovel wing is fixed under the shovel handle; the rear side of the shovel handle is connected with the chain-shaped dynamic bionic soil crusher; the chain-shaped dynamic bionic soil crusher is composed of soil crushing heads and a connection circular ring; the soil crushing heads are connected together through the connection circular ring; tapered bulges are arranged on the surfaces of the soil crushing heads; and the tapered bulges are arranged toward the inclined front side. In a sub-soiling process, a sub-soiling shovel is used for breaking a plough pan, but cannot completely crush the plough pan; then the chain-shaped dynamic bionic soil crusher following the sub-soiling shovel is used for crushing the soil through the sharp tapered bulges on the surface of the chain-shaped dynamic bionic soil crusher, so that the disadvantage that a traditional sub-soiling shovel cannot sufficiently crush the soil can be overcome, and the effect of sub-soiling work is given a full play.

Owner:JILIN UNIV

Method for manufacturing leather

InactiveCN104232806ASufficient separationFully loosePre-tanning chemical treatmentHair removalLime sulfur

The invention provides a method for manufacturing leather, and belongs to the technical field of leather processing. The method for manufacturing leather comprises a raw hide liming step and a raw hide re-liming step, wherein waste liquor produced in the raw hide limiting step and the raw hide re-liming step enter a same storage tank. According to the method for manufacturing the leather, raw hide with hairs firstly enter a liming bath (new lime) and then enter a re-liming bath (old lime) after hairs are removed by virtue of a modified less-bath lime-soda process, wherein the difference is that the re-liming action is strengthened. And thus, hide collagen fibers can be sufficiently and properly separated and loosened really. In both liming bath and re-liming bath, waste liquor enters the same storage tank, and the improved new system utilizes the advantages of a liming and re-liming waste liquor recycling technology. And meanwhile, more importantly, the recycling of the liming and re-liming waste liquor is realized by virtue of the combination and linkage, and thus, the pollution of limes and sodium sulfide on environment is radically removed.

Owner:潘龙祥

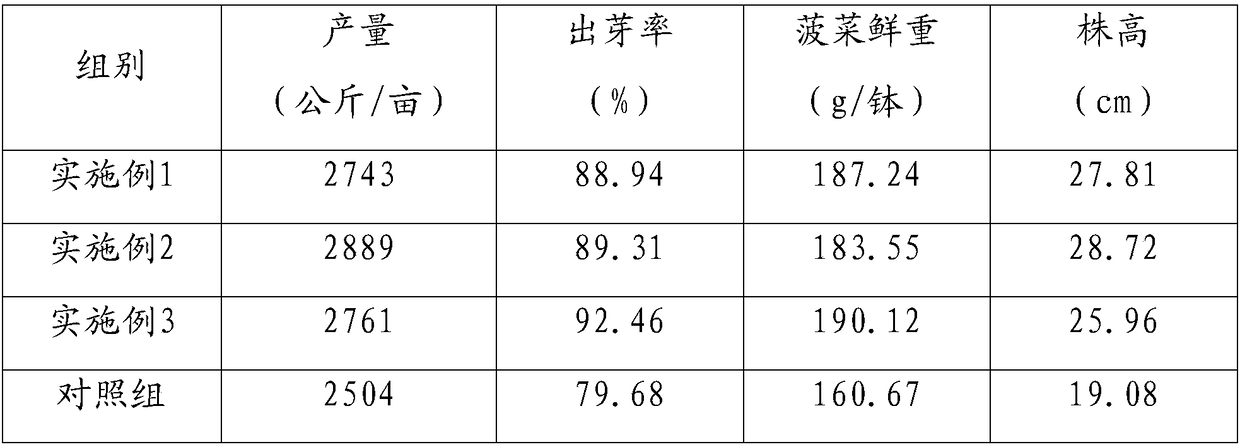

Vegetable planting method

InactiveCN108617429AFully looseImprove permeabilityBioloigcal waste fertilisersAmmonium salt fertilisersPest controlPlant disease

The invention belongs to the technical field of planting, and particularly relates to a vegetable planting method. The vegetable planting method comprises the following steps of soil preparation, seedsoaking and pretreatment, seeding, fertilization and irrigation management, pest control, and harvesting. According to the vegetable planting method, disease control is enhanced from the aspects of the nature of soil and seeds, and in the later stage, natural, pollution-free and low-cost fertilizer and periodical water management are used, so that nutrients required in the vegetable growth stateis guaranteed, the yield and quality of vegetables are improved, and the vegetables can be eaten by people conveniently.

Owner:DAWU HONGYUAN AGRI TECH CO LTD

Supporting structure of horizontal stirring tank and horizontal stirring tank

PendingCN112546895AHigh strengthIncrease stiffnessBio-organic fraction processingRotary stirring mixersEngineeringElasterell

The invention discloses a supporting structure of a horizontal stirring tank and the horizontal stirring tank. The supporting structure of the horizontal stirring tank comprises a transversely-arranged tank body and a stirring shaft arranged in the tank body, the stirring shaft is sleeved with a supporting component, a connecting rod extends out of the supporting component, and the free end of theconnecting rod is fixedly connected with the inner wall of the upper half portion of the tank body; and the connecting rod is a bendable and telescopic elastic piece. According to the invention, theconnecting rod of the supporting component is positioned at the upper half part of the tank body, so that the blockage of materials at the lower half part of the tank body is reduced, and the flowability of materials in the tank body is enhanced; the connecting rod is the elastic piece, when the materials in the tank body are unevenly paved or the stirring shaft is extruded by the materials to deform, the whole stirring shaft adjusts the position of the stirring shaft according to the state of the materials, the connecting rod provides a force for returning to the original position for the deformed stirring shaft, and continuous rotation of the stirring shaft is guaranteed. Materials can be favourably and smoothly pushed into the tank body, and the stirring shaft is effectively prevented from being blocked and drooping.

Owner:CHONGQING CHANGZHENG HEAVY IND

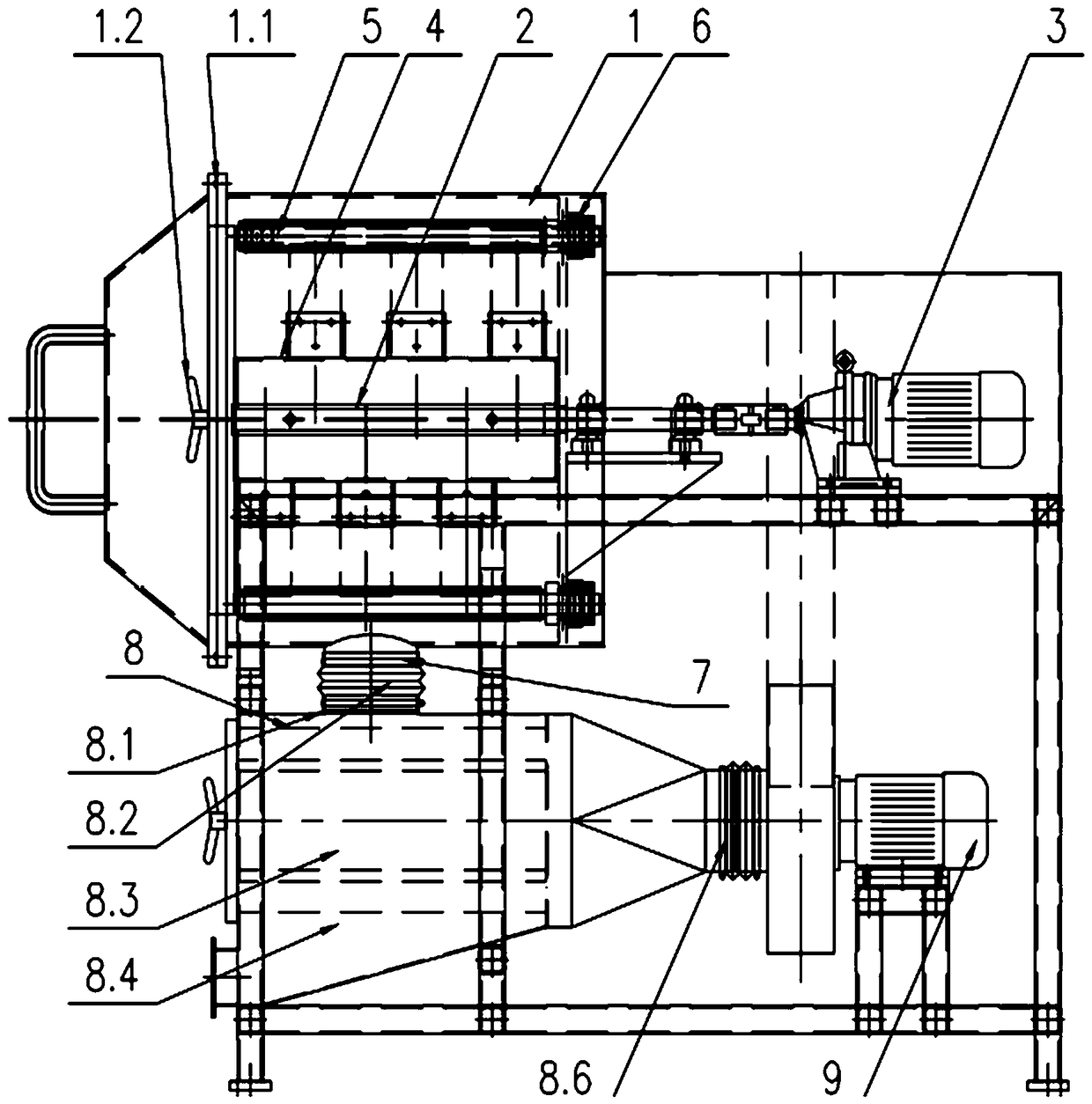

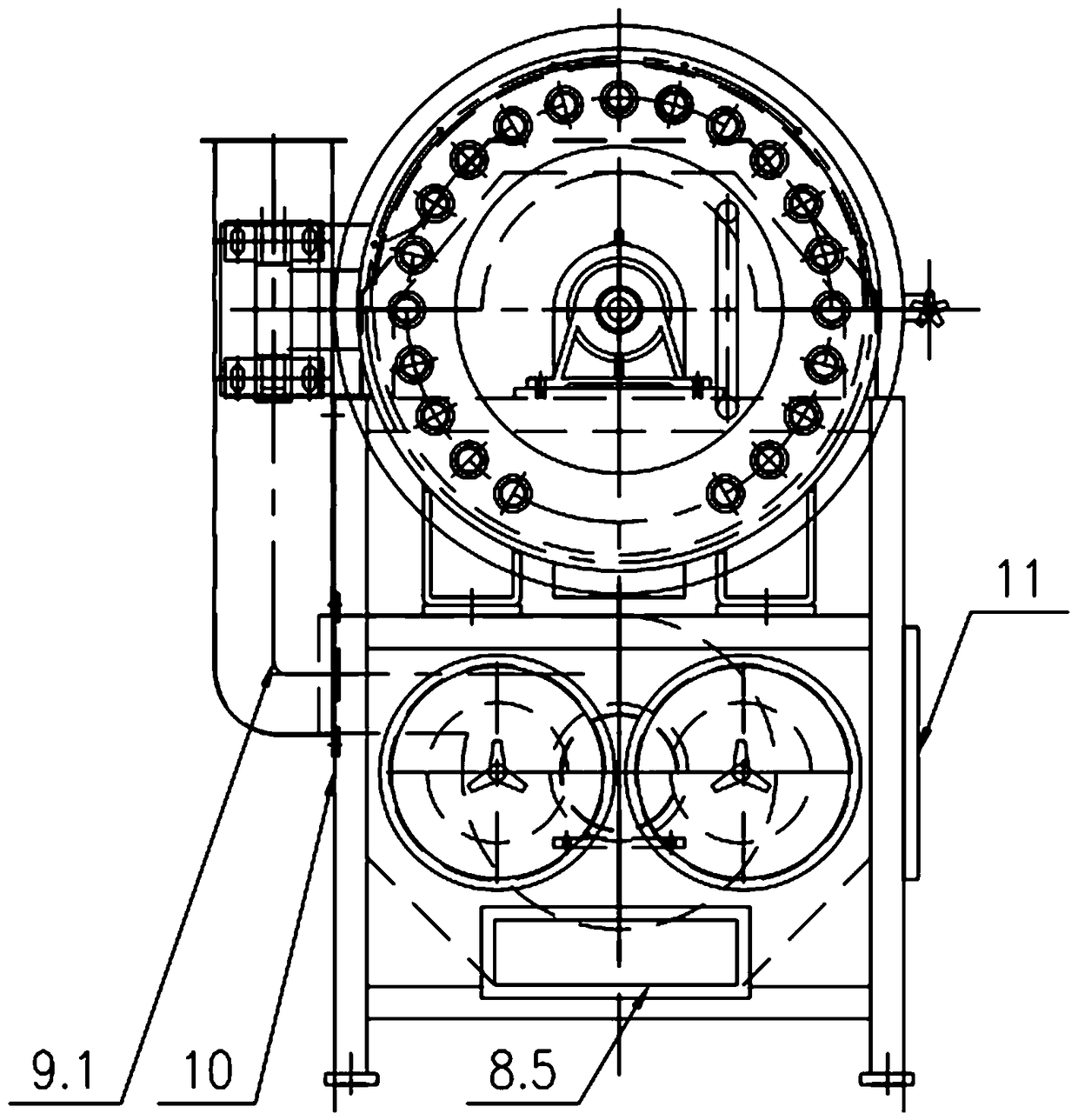

Environment-friendly dusting machine for multilayer draped net cover of melt filter

PendingCN108579238AFully looseGreat suctionDispersed particle filtrationTransportation and packagingDrive shaftSmall hole

The invention relates to an environment-friendly dusting machine for a multilayer draped net cover of a melt filter. The machine comprises a rack, a sealed cavity is formed in the rack, and a sealinggasket and a sealing and locking device are arranged on the sealed cavity; a transmission shaft is arranged at the center of the sealed cavity and connected with a transmission motor outside the sealed cavity, a roller is arranged in the sealed cavity, and a plurality of rubber flapping pieces are installed on the outer periphery of the roller; multiple connecting rods are installed in the sealedcavity, a plurality of small holes are formed in the connecting rods in the radial directions, one end of each connecting rod is sealed, the other end of each connecting rod is connected with the exterior of the sealed cavity through a bearing, a dust discharging orifice is formed in the outer wall of the sealed cavity, and a filtering and dust collecting device is installed below the dust discharging orifice. The machine has the functions of cleaning efficiently, saving energy and protecting the environment.

Owner:张家港伟奥机械科技有限公司

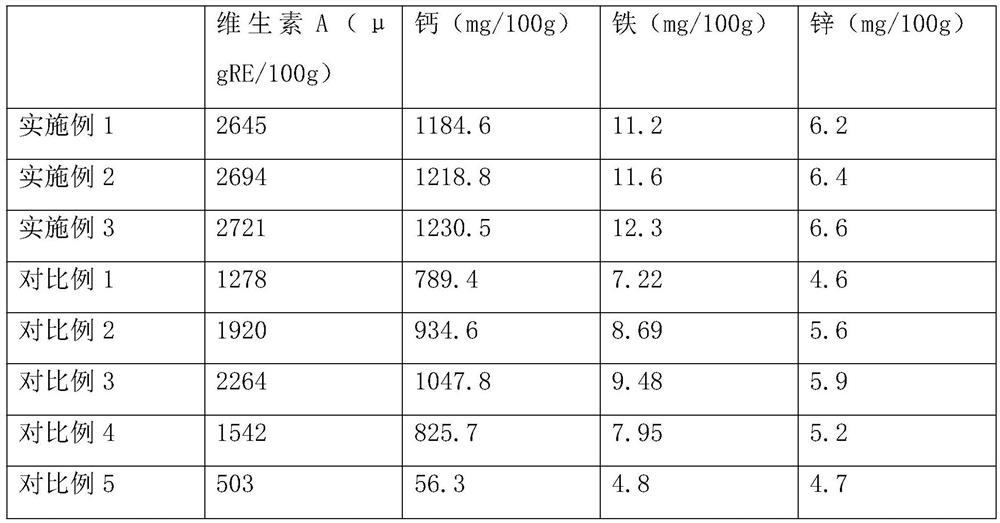

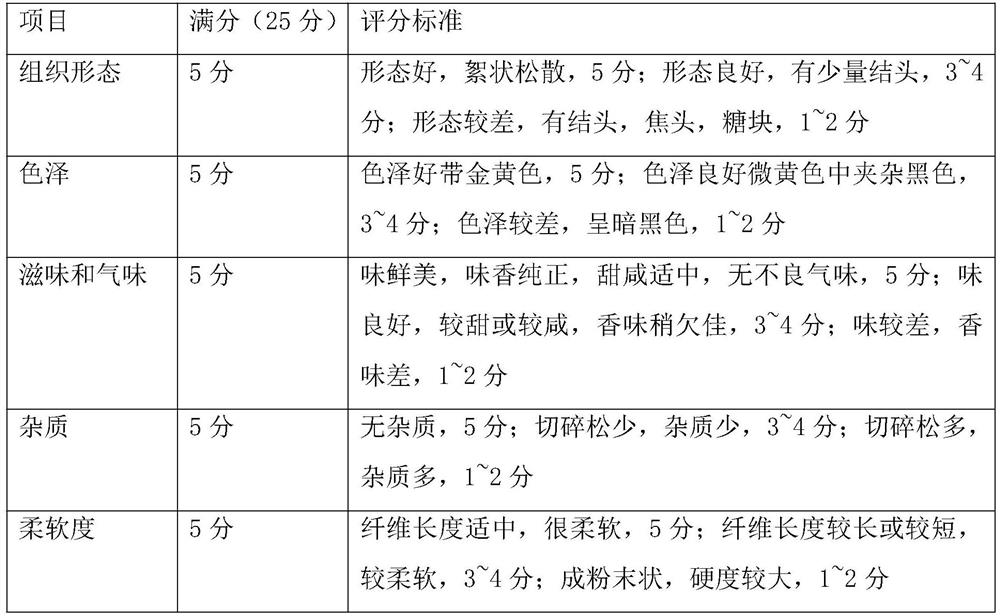

Method for preparing dried meat floss with good flavor and high nutritive value

InactiveCN111616304AImprove the processing application fieldGreat tasteNatural extract food ingredientsMeat/fish preservation using chemicalsBiotechnologyNutritive values

The invention discloses a method for preparing dried meat floss with a good flavor and high nutritive value and belongs to the technical field of dried meat floss processing. The method comprises thefollowing steps of (1) raw meat pretreatment; (2) dried meat floss material preparation; (3) variable-pressure modification treatment; and (4) finished product preparation. The method disclosed by theinvention is reasonable in overall process step collocation and beneficial to popularization and application, and the prepared dried meat floss has a special complex meat flavor, is good in taste andchewy, has a good fluffy state and a golden color in appearance and is high in nutritive value.

Owner:漳州鑫阳食品有限公司

Dynamic Bionic Subsoiler with Breaker

Owner:JILIN UNIV

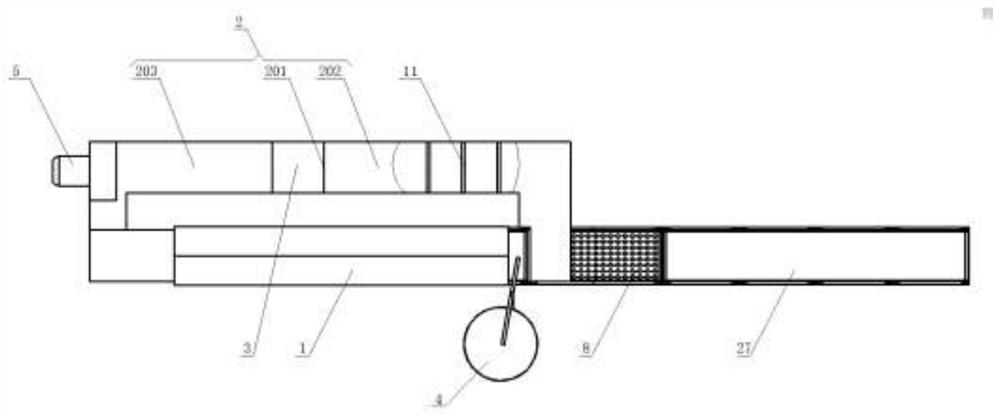

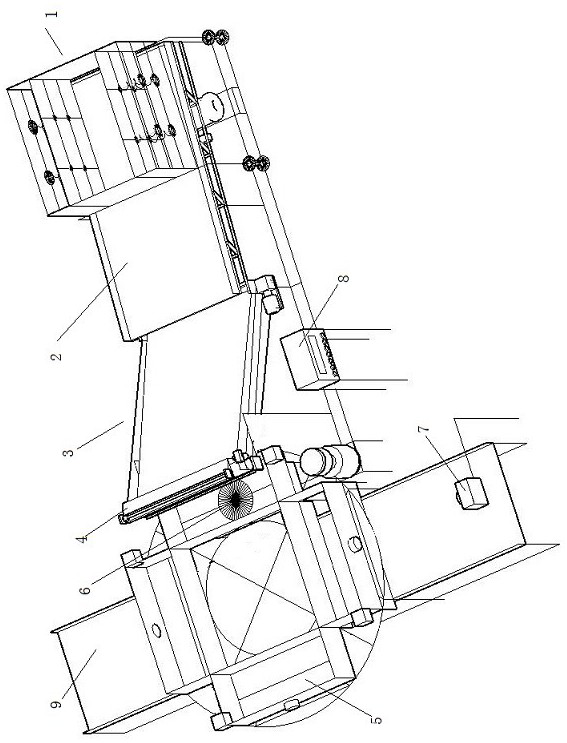

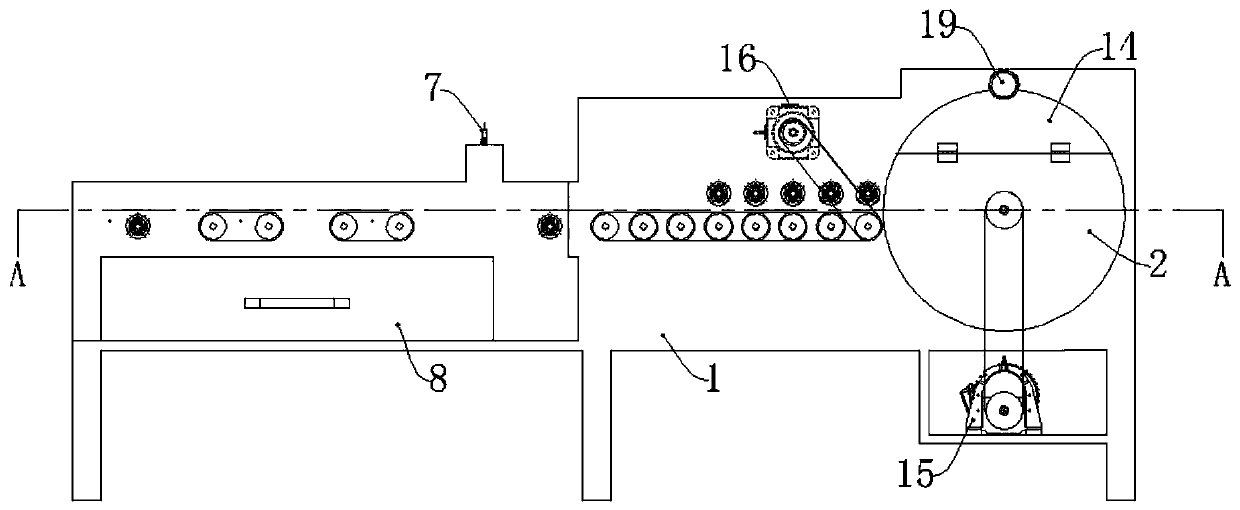

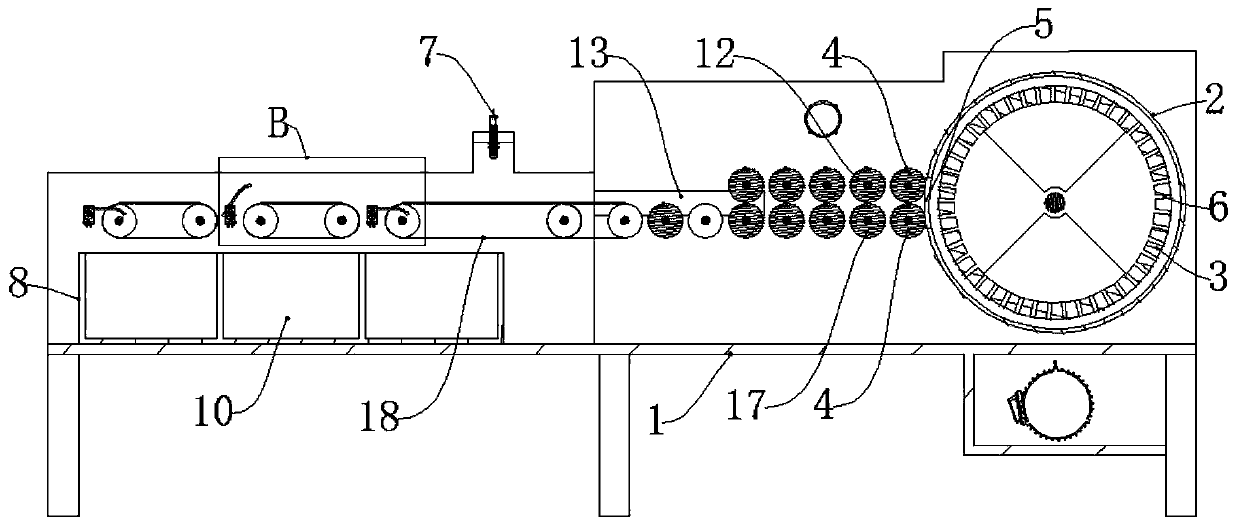

Tobacco leaf re-drying homogenizing processing device

ActiveCN112385875AFully looseOrderly transportTobacco preparationTobacco treatmentControl systemAgricultural engineering

The invention provides a tobacco leaf re-drying homogenizing processing device. The tobacco leaf re-drying homogenizing processing device comprises an adjustable tobacco frame assembly, a vibration conveying assembly, a belt conveying assembly, an air knife assembly, a rotary homogenizing unit frame assembly, an intelligent scale assembly, a photoelectric induction assembly and an intelligent regulation and control system. By means of the device, the single leaf laying amount (smaller than or equal to 2.0 kg) of tobacco leaves is regulated and controlled orderly, loosely, accurately and reasonably, the tobacco leaves are placed to a leaf laying table in order, and the problem of related quality fluctuation caused by manual objective or subjective operation and vacancy is solved; accordingto the device, the production cost is effectively saved, the productivity is improved, the single leaf laying amount is effectively controlled, the slitting rate is increased, and the homogenization of cured tobacco leaves is effectively improved.

Owner:CHINA TOBACCO HENAN IND +2

Wind Separation System for Shredded Reconstituted Tobacco

ActiveCN104839882BUniform lengthMeet the length requirementTobacco preparationTobacco treatmentEngineeringTobacco product

The invention discloses a winnowing system for shredded reconstituted tobacco, which comprises a high-frequency vibrating trough, a shredded device, a shredded device and a blanking device. The shredded device includes a feeder, a shredded machine, a shell and a frame, and The device includes a conveying pipe and a winnowing machine. The shredding machine includes a shredding cutter and a power unit. The shredding cutter includes a fast cutter disc, a slow cutter disc, a knife holder and a shredding frame bar. The fast cutter disc and the slow cutter disc are fixed side by side on the knife through bearings On the frame, the blades of the two sets of cutterheads are set alternately, the power device drives the fast cutterhead and the slow cutterhead to rotate in opposite directions at a differential speed, the cutting edges of the two sets of blades are staggered to form a shear, and the shredded frame is installed under the fast cutterhead and the slow cutterhead , including two fixedly connected arc-shaped net plates, the arc-shaped net plates are provided with a plurality of square holes for leaking wire. The invention can cut the shredded tobacco to a fixed length according to different technological requirements, avoid the phenomenon of missed beating, and carry out winnowing and purification on the shredded shredded tobacco, finally output clean shredded tobacco with uniform size and moderate length, and improve the blending uniformity of shredded tobacco products.

Owner:CHINA TOBACCO HENAN IND

A banknote sorting machine

The invention relates to the technical field of banknote flattening and sorting equipment, in particular to a banknote sorting machine, comprising a frame, a conveying mechanism arranged on the frame, a feeding mechanism and a sorting mechanism, and the feeding mechanism is connected with the conveying mechanism The clearing mechanism is connected; the feeding mechanism includes an outer cylinder, an inner cylinder, an inner cylinder driving mechanism, a feeding roller and a feeding roller driving mechanism; the outer cylinder is fixedly arranged on the frame and its axis is horizontal, so The end of the outer cylinder is provided with a coin inlet, and the outer circular surface of the outer cylinder is provided with a horizontal coin outlet; the inner cylinder is rotatably installed inside the outer cylinder, and the outer circular surface of the inner cylinder is provided with There is a slot for coin output; there are two feeding rollers, which are respectively arranged on the upper and lower sides of the coin output port. Compared with the prior art, the banknote sorting machine of the present invention loosens and unfolds the banknotes through the outer cylinder and the rotating inner cylinder, which is not easy to damage the banknotes, and prevents the feed roller from pulling out multiple banknotes at a time by setting the currency outlet and the currency outlet gap.

Owner:XIAN JIAOTONG UNIV CITY COLLEGE

A device for redrying and homogenizing tobacco leaves

ActiveCN112385875BFully looseOrderly transportTobacco preparationTobacco treatmentAgricultural scienceAgricultural engineering

The invention provides a device for re-curing and homogenizing tobacco leaves, which includes an adjustable tobacco frame assembly, a vibration conveying assembly, a belt conveying assembly, an air knife assembly, a rotary homogenizing unit frame assembly, an intelligent scale assembly, and a photoelectric sensor assembly and intelligent control system. Through this device, the tobacco leaves are orderly and loose, and the amount of single leaf laying (≤2.0 kg) can be precisely and reasonably regulated, and the handle can be placed neatly on the leaf laying table, and the related quality fluctuation problems caused by manual objective or subjective operation and absence are solved; The device effectively saves production cost, improves productivity, effectively controls the amount of single leaf laying, increases the cutting rate, and effectively improves the homogenization of cured tobacco leaves.

Owner:CHINA TOBACCO HENAN IND +2

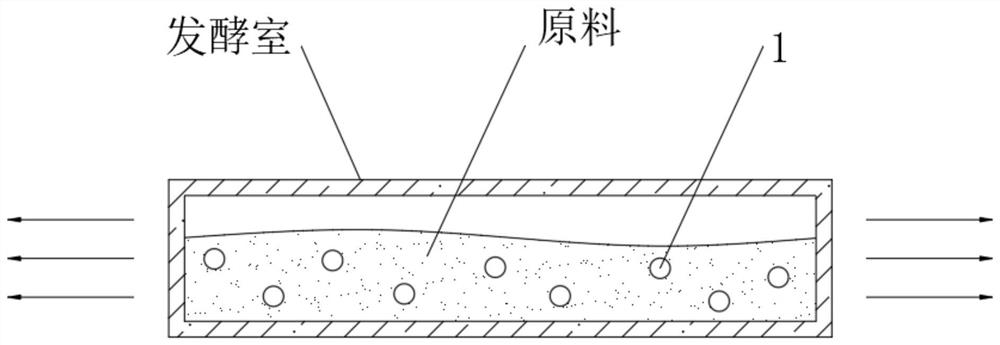

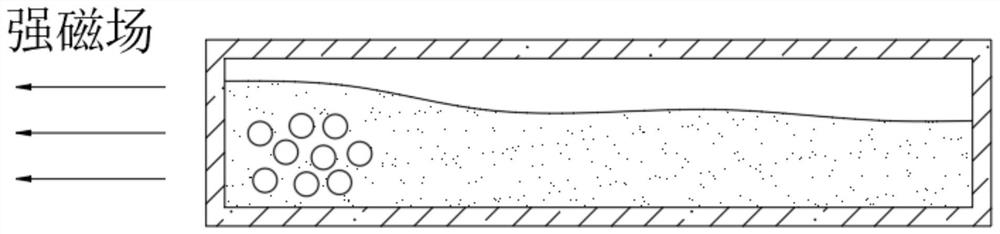

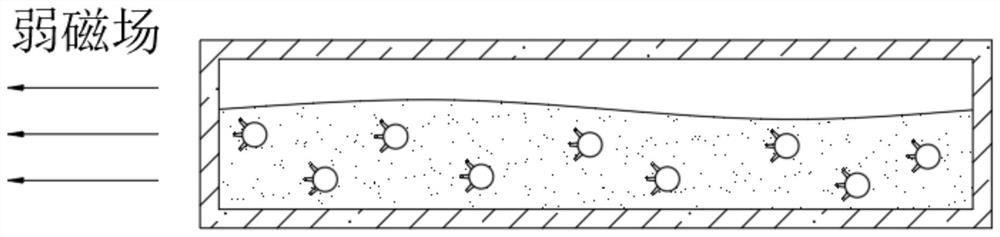

Dynamic fermentation method of organic feed

PendingCN113832001AImprove loosenessImprove distributionBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringFodder

The invention discloses a dynamic fermentation method of an organic feed, and belongs to the technical field of organic feeds, in a manner of uniformly mixing fermentation-assisting balls in raw materials, magnetic fields with different intensities are applied in a fermentation process, and when a weak magnetic field is applied, fermentation-assisting balls do not migrate, but locally deform towards a direction of the magnetic field, the raw materials are locally loosened, a caking phenomenon is not prone to occurring, meanwhile, oxygen can be supplied in real time in multiple directions, when a strong magnetic field is applied, the fermentation assisting balls are locally deformed and migrated at the same time, and therefore the raw materials are wholly turned over, and a distribution situation of the raw materials in a fermentation chamber is further improved. Compared with the prior art, the method can loosen raw materials better and supply oxygen from the inside in real time, make the raw materials fully aerobic fermentation, and improve fermentation effect and molding quality of organic feed.

Owner:王伟波

Improved straw outlet device of machine capable of crushing straw, applying fertilizer, performing sowing and covering straw

The invention relates to an improved device of a part of a fertilizer applying and sowing machine and particularly relates to an improved straw outlet device of a machine capable of crushing straw, applying fertilizer, performing sowing and covering straw. The improved straw outlet device comprises a pipeline (7) and a cantilever (8), the pipeline (7) backward crosses the upper portion of the fertilizer applying and sowing integrated machine, the cantilever (8) backward stretches out of the left side or the right side of an outlet of the pipeline (7), a rotation shaft (9) is vertically arranged at one end of the cantilever (8), and a plurality of blades (10) which can rotate around the rotation shaft (9) are configured on the rotation shaft (9); the vertical height of the blades (10) is 1-1.8 times of the open height of the outlet of the pipeline (7); the horizontal width of the blades (10) is 1-1.5 times of the open width of the outlet of the pipeline (7); and the distance from the position where the rotation shaft (9) is located to the outlet of the pipeline (7) is 1-1.5 times of the width of the blades (10). According to the improved device, additional power is not required, the blades rotate in a high speed under the action of wind for the pipeline to send out the straw, the crushed straw is scattered and thrown, and the crushed straw evenly covers sowed fields so that foundation and conditions are provided for good quality and high yield of crops of peanuts and soybeans.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

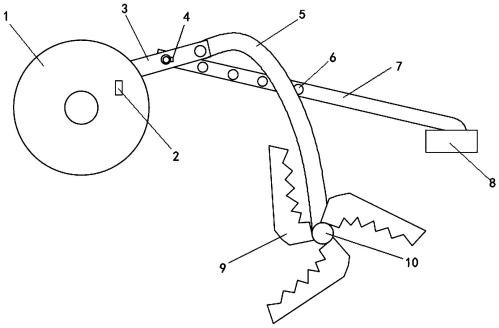

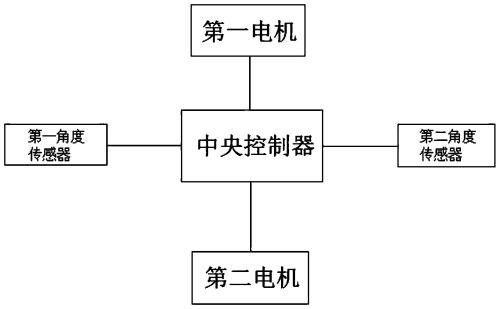

A rotary tillage and stubble embedding device for wheat seeders suitable for wet rotten fields

ActiveCN111279816BSimple structureEasy detachable connectionSpadesAgricultural machinesSeederRotational axis

The invention discloses a rotary tillage and stubble embedding device for wheat seeders suitable for wet and rotten fields. The installation part that matches the above connection part, the rotary tiller includes a rotating shaft, several rotating blades, and a first motor that drives the rotation shaft to rotate, the connecting part includes first connecting rods arranged at both ends of the rotating shaft, and the installation part includes a rotating wheel , the second motor for controlling the rotation angle of the rotating wheel, the extending rod integrally connected with the rotating wheel, the lower end of the first connecting rod is connected with the rotating shaft, the upper end of the first connecting rod is detachably connected with the extending rod, and the height adjustment mechanism includes a second The connecting rod and the end of the extending rod are hinged floating blocks, the rotating wheel is provided with a first angle sensor, and the hinge of the second connecting rod and the extending rod is provided with a second angle sensor. The invention realizes the precise adjustment of the rotary tillage depth , suitable for farmland with different wet and rotten degrees.

Owner:淮安文信科技有限公司

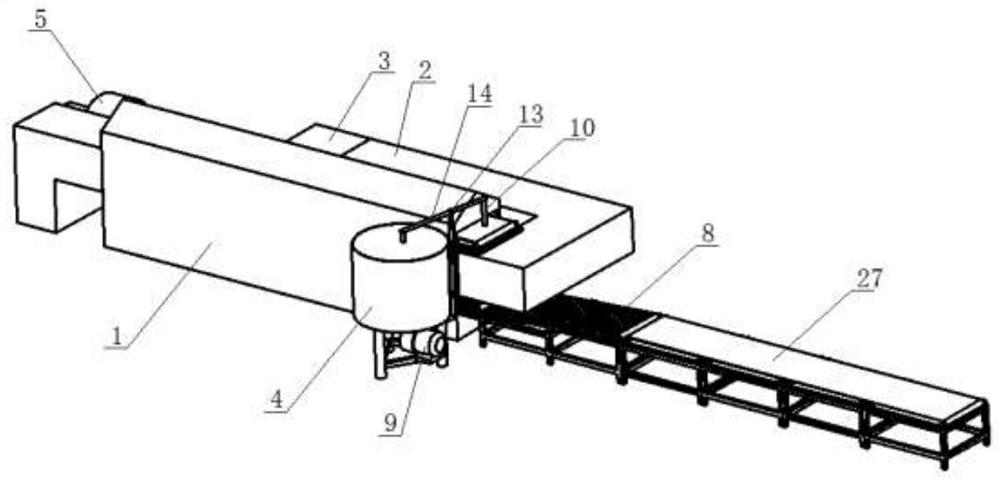

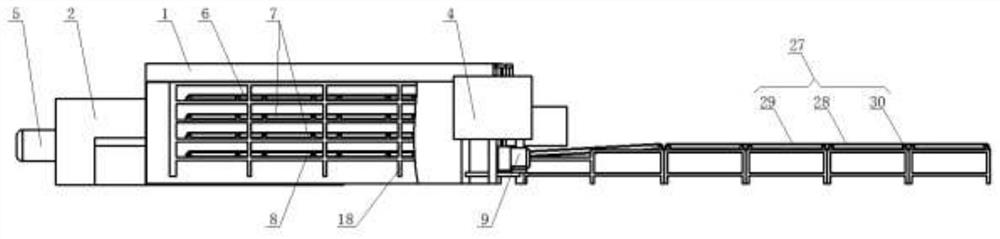

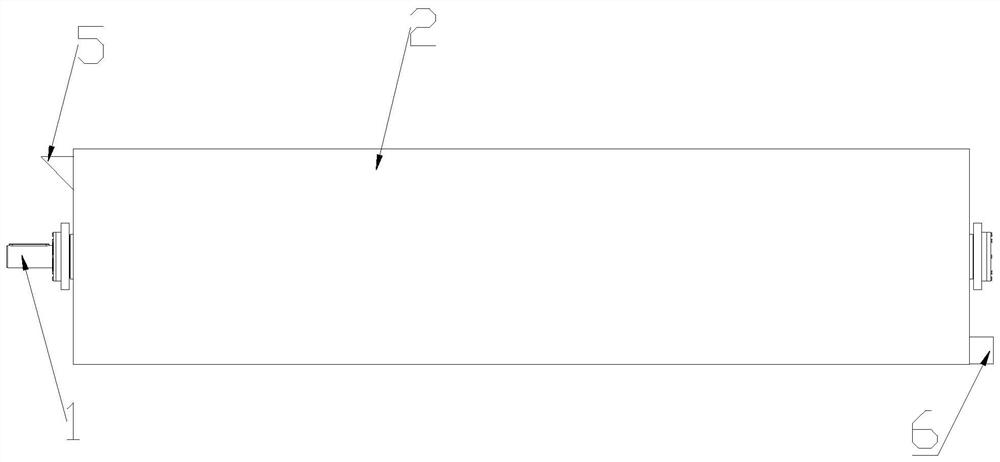

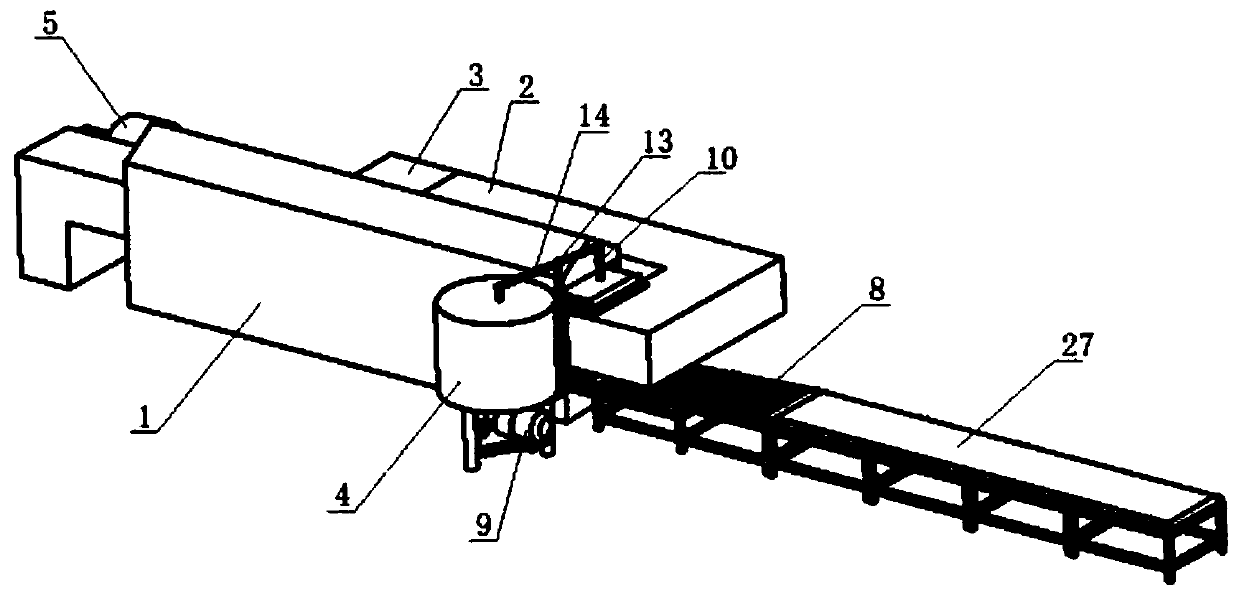

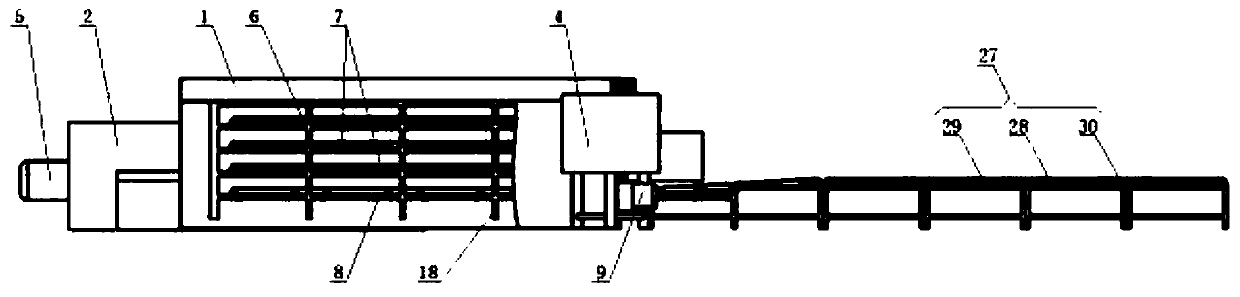

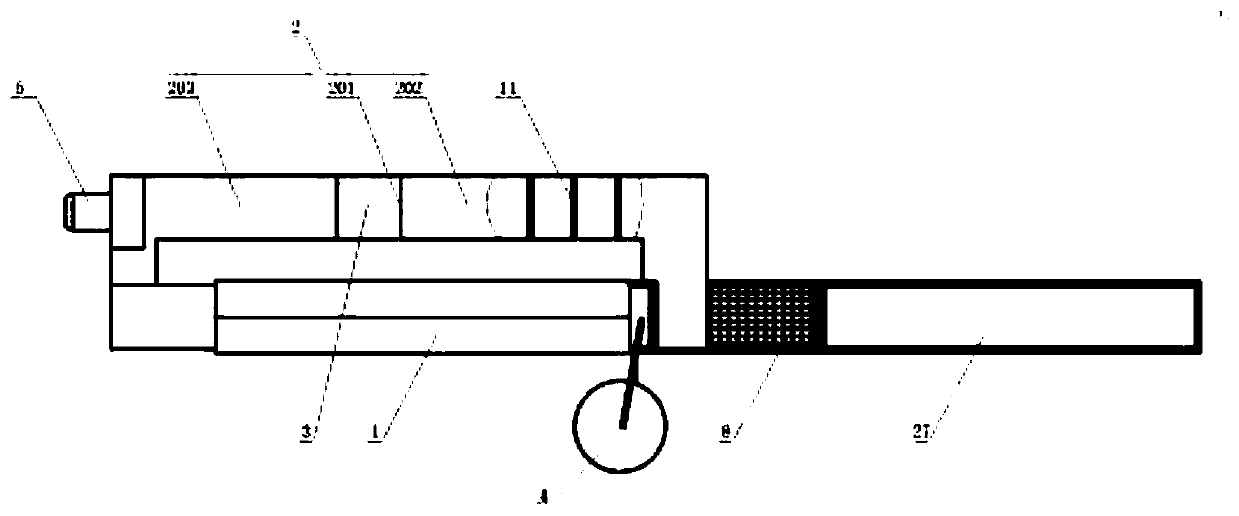

Rice noodle curing and loosening integrated equipment

ActiveCN110787695AImprove product qualityAvoid accumulationRotary stirring mixersTransportation and packagingChain linkIndustrial engineering

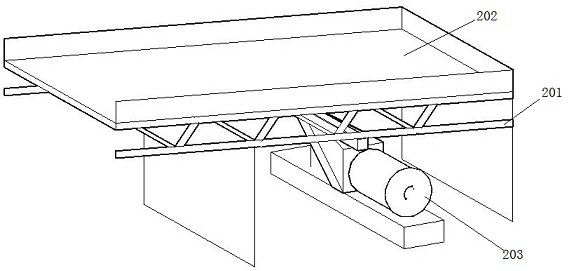

The invention discloses rice noodle curing and loosening integrated equipment. The equipment includes a constant-temperature oven and a mixing barrel with an opening in one end, wherein a rack is arranged in the constant-temperature oven; a feeding machine, a conveying machine and a discharging machine are sequentially installed on the rack from top to bottom; the feeding machine comprises feedingcloth and a plurality of carrier rollers A; the two ends of each carrier roller A are mounted on the rack through bearing seats; the feeding cloth is wound on the peripheral surfaces of the carrier rollers A; the conveying machine or the discharging machine comprises a plurality of carrier rollers B installed on the rack; chain wheels are arranged at the two ends of each carrier roller B and arein meshing transmission through chains; a plurality of carrying steel wires are fixedly connected between the two chains; and rice flour pulp is fed into the upper surface of the feeding cloth througha feeding pump and a pulp feeding pipe at the bottom of the mixing barrel. By adopting the technical scheme of the invention, shaking of the chain wheels in the transmission process is utilized to enable the carrying steel wires to vibrate at a small amplitude, so that the rice flour slurry being cured is continuously loosened, and a foundation is laid for reasonably packaging the finished rice noodles in the later period.

Owner:贵州金晨农产品开发有限责任公司

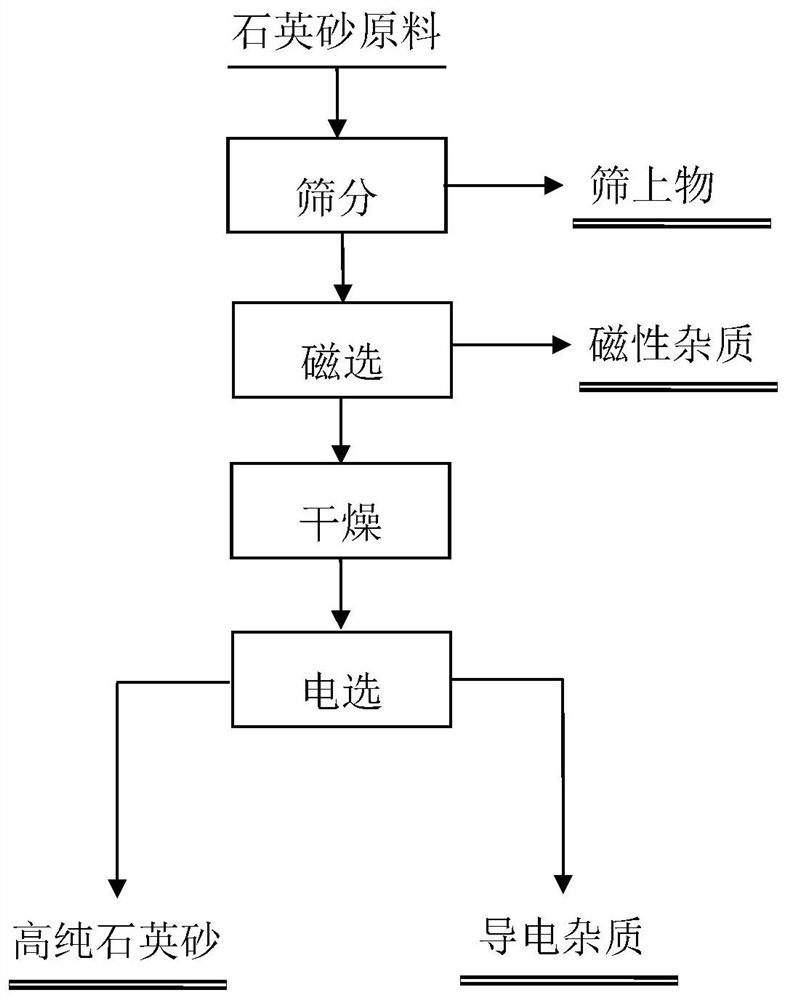

Purification method for quartz sand raw material

ActiveCN113894034AIncrease productivityHigh recovery rateSievingElectrostatic separationPhysical chemistryMagnetic separator

The invention provides a purification method for a quartz sand raw material. The purification method comprises the following steps of (1) screening, specifically, conducting screening treatment to obtain quartz sands with the granularity of 0.83mm or below and the water content controlled below 3%; (2) magnetic separation, specifically, conveying the quartz sands into a double-drum magnetic separator for magnetic roughing treatment and magnetic concentration treatment in sequence; (3) drying, specifically, controlling a discharging temperature of the dried quartz sands to be 70-120 DEG C; and (4) electric separation, specifically, conducting electric separation on the quartz sands, and controlling a separation voltage and a rotating speed of each drum to obtain the high-purity quartz sands. The purification process disclosed by the invention has the advantages of simple flow, environmental protection without pollution, low production cost, excellent quality of a product, high production efficiency, high recovery rate and the like and can be suitable for purification treatment of quartz ores with relatively high iron oxide content; and the purified quartz sands can reach the quality standard of the high-purity quartz sands.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

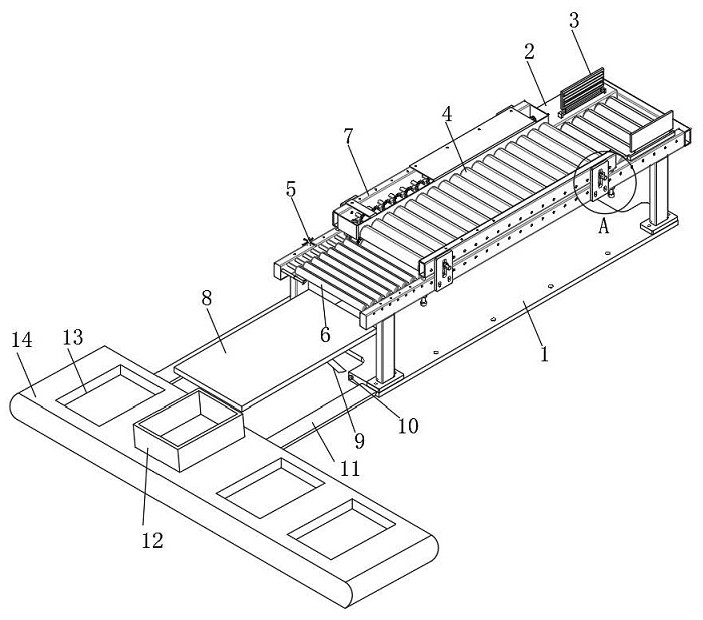

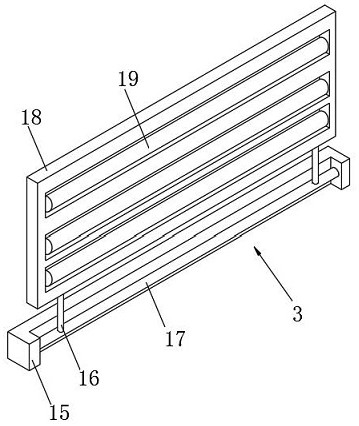

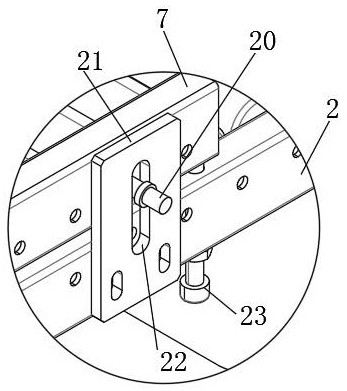

Device for Improving Impurity Removal Efficiency of Tobacco Impurity Remover

ActiveCN103340475BIncrease chance of cullingEasy detectionTobacco preparationRollersPulp and paper industryBelt conveyor

The invention discloses a device capable of improving the sundry removing efficiency of a tobacco sundry removing machine. The device is mainly composed of a vibrating conveyer, a star roller conveyor and a tobacco sundry removing machine sequentially. The star roller conveyor comprises wheel rollers which are arranged at intervals and a conveying bottom band arranged under the wheel roller, wherein the first wheel roller in the wheel rollers is a round roller, and the rest are star rollers. A horizontal tobacco block removing belt conveyor is arranged at the discharge end of the last wheel roller of the star roller conveyor. The conveying bottom band of the star roller conveyor comprises the discharge end connected with a vibrating tank of the vibrating conveyor and the feed end connected with the tobacco sundry removing machine. The width of a conveying section and the width of the vibrating conveyor are larger than or equal to the effective width of the tobacco sundry removing machine, and the width of the discharge section is smaller than or equal to the effective width of the tobacco sundry removing machine. The device effectively improves the sundry removing efficiency and the sundry removing capability of the sundry removing machine.

Owner:XIAMEN TOBACCO IND

Paper money sorter

ActiveCN110400414ARelief forceFully looseCoin/currency accepting devicesPulp and paper industryCircular surface

The invention relates to the technical field of paper money flattening sorting equipment, specifically a paper money sorter. The paper money sorter comprises a rack, and a conveying mechanism, a feeding mechanism and a sorting mechanism which are set on the rack. The feeding mechanism is connected with the sorting mechanism through utilization of the conveying mechanism. The feeding mechanism comprises an inner cylinder, an outer cylinder, an inner cylinder drive mechanism, feeding rollers and a feeding roller drive mechanism. The outer cylinder is fixedly set on the rack. An axis of the outercylinder is horizontal. An end part of the outer cylinder is equipped with a paper money inlet. An outer circular surface of the outer cylinder is equipped with a horizontal paper money outlet. The inner cylinder is rotationally mounted in the outer cylinder. The outer circular surface of the inner cylinder is equipped with paper money outlet gaps. Two feeding rollers are set and are set at upperand lower sides of the paper money outlet. Compared with the prior art, the paper money sorter provided by the invention has the advantages that through utilization of the outer cylinder and the rotary inner cylinder, paper money is loosen and unfolded, and the paper money is not liable to damage; and through setting of the paper money outlet and the paper money outlet gaps, a plurality of piecesof paper money are prevented from being pulled out by the feeding rollers.

Owner:XIAN JIAOTONG UNIV CITY COLLEGE

Preparation method of sofa leather

InactiveCN108531668AGood degreasing effectGood anti-fog performanceTanning treatmentPre-tanning chemical treatmentFiberOrganic solvent

The invention discloses a preparation method of sofa leather. The method comprises the steps of presoaking, main dipping, ash alkalinity soaking, deashing, tanning and fat liquoring. In order to improve permeability of chemical materials on leather in the later period, presoaking and main dipping are carried out; interfibrillar substance is sufficiently removed through ash alkalinity soaking, collagenous fiber is sufficiently loosened, certain fiber space and transmissibility are formed, and therefore follow-up work procedures can achieve permeation better; chrome-free tanning is carried out;and fat liquoring is carried out in multiple layers step by step. The process is simple and environmentally friendly, and the finally-prepared automobile seat mat leather is resistant to atomization,organic solvent, combustion, wear and folding, and free of discoloration after long-time solarization.

Owner:海宁玖洲家具有限公司

Conveying system for plastic bags

ActiveCN113581522AStack will notImprove fullyPaper article packagingStructural engineeringDelivery system

The invention relates to the field of plastic bag preparation, and particularly discloses a conveying system for plastic bags. The conveying system comprises a base frame and a plurality of bearing rollers rotationally mounted in the base frame, and an unfolding area, an extrusion area and a folding area are sequentially arranged on the base frame. By arranging a flapping mechanism, the stacked and cut plastic bags are put into the unfolding area of the base frame, a flapping plate flaps the upper portion of plastic, unfolding rollers at the two sides drive the edges of the plastic bags to move towards the two sides, the plastic bags can be fully unfolded, the edges of the plastic bags are prevented from being folded and bent, and the shapes of the unfolded plastic bags are better; and fluffy plastic bag stacks can be compressed through flapping of the flapping plate, so that the plastic bags enter the extrusion area more conveniently and rapidly in the follow-up process and are not prone to being blocked, and the plastic bags on the upper layer cannot be lifted and stacked.

Owner:常州盛沅新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com