Purification method for quartz sand raw material

A purification method, quartz sand technology, applied in chemical instruments and methods, lighting and heating equipment, dryers, etc., can solve problems such as inability to function, achieve low production costs, excellent product quality, and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

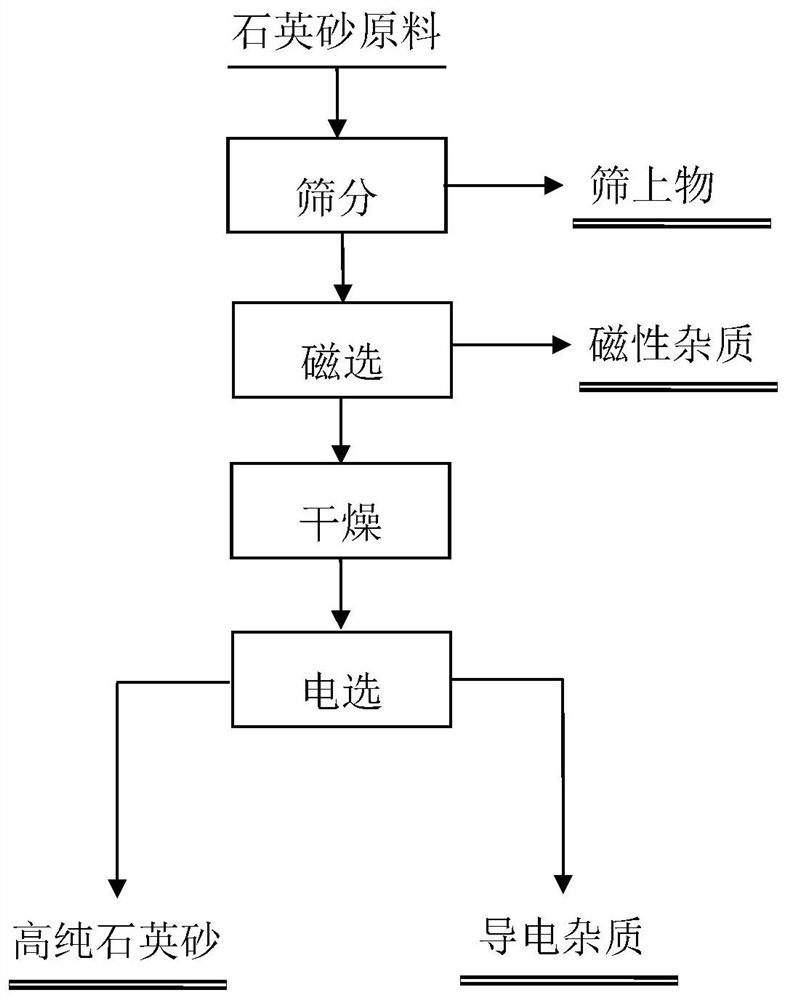

[0037] A method for purifying quartz sand raw materials, such as process flow diagram figure 1 As shown, including the following steps:

[0038] (1) is selected from the material: 4mm or less in size, SiO 2 Ordinary quartz sand content of approximately 95% (crude concentrate quartz sand), quartz sand iron oxide content of 0.02% to 0.50%.

[0039] (2) Screening: quartz sand material delivered to the first vibrating sieve (pore diameter 0.83mm) for a sieved to give a particle size below 0.83mm quartz sand; and the particle size of quartz sand 0.83mm or less conveyed to another vibrating sieve (pore diameter 0.15mm) for secondary sieved to give a particle size between 0.15 ~ 0.83mm quartz sand and silica sand in particle sizes of 0.15mm or less; and then the particle size of 0.15mm or less quartz sand conveyed to another vibrating screen (0.045mm sieve aperture) to a tertiary sieved to give a particle size between 0.045 ~ 0.15mm quartz sand and silica sand in particle sizes of 0.045m...

Embodiment 2

[0050] A method for purifying quartz sand material, comprising the steps of:

[0051] (1) is selected from the material: 4mm or less in size, SiO 2 Ordinary quartz sand content of approximately 96% (crude concentrate quartz sand), quartz sand iron oxide content of 0.02% to 0.50%.

[0052] (2) Screening: quartz sand material delivered to the first vibrating sieve (pore diameter 0.83mm) for a sieved to give a particle size below 0.83mm quartz sand; and the particle size of quartz sand 0.83mm or less conveyed to another vibrating sieve (pore diameter 0.15mm) for secondary sieved to give a particle size between 0.15 ~ 0.83mm quartz sand and silica sand in particle sizes of 0.15mm or less; and then the particle size of 0.15mm or less quartz sand conveyed to another vibrating screen (0.045mm sieve aperture) to a tertiary sieved to give a particle size between 0.045 ~ 0.15mm quartz sand and silica sand in particle sizes of 0.045mm or less; selected particle size 0.15 quartz sand between ...

Embodiment 3

[0063] A method for purifying quartz sand material, comprising the steps of:

[0064] (1) is selected from the material: 4mm or less in size, SiO 2 Ordinary quartz sand content of approximately 97% (crude concentrate quartz sand), quartz sand iron oxide content of 0.02% to 0.50%.

[0065](2) Screening: quartz sand material delivered to the first vibrating sieve (pore diameter 0.83mm) for a sieved to give a particle size below 0.83mm quartz sand; and the particle size of quartz sand 0.83mm or less conveyed to another vibrating sieve (pore diameter 0.15mm) for secondary sieved to give a particle size between 0.15 ~ 0.83mm quartz sand and silica sand in particle sizes of 0.15mm or less; and then the particle size of 0.15mm or less quartz sand conveyed to another vibrating screen (0.045mm sieve aperture) to a tertiary sieved to give a particle size between 0.045 ~ 0.15mm quartz sand and silica sand in particle sizes of 0.045mm or less; selected particle size 0.15 quartz sand between ~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com