Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

191results about How to "Fast clamping and fixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

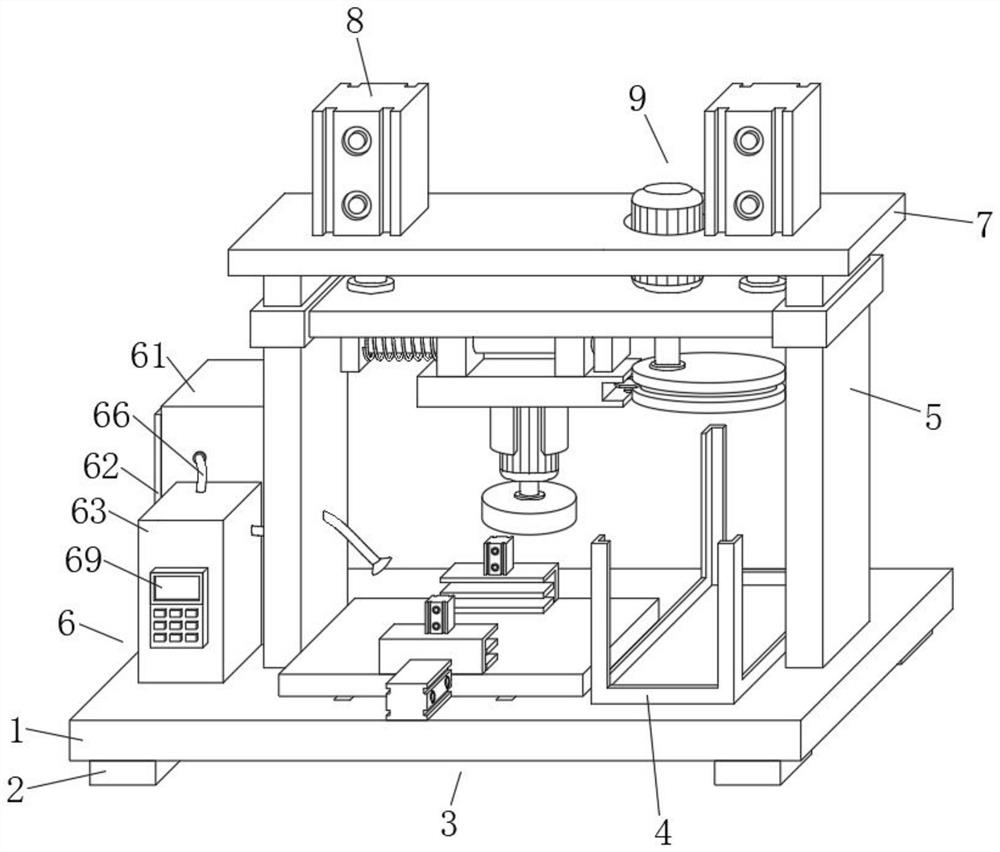

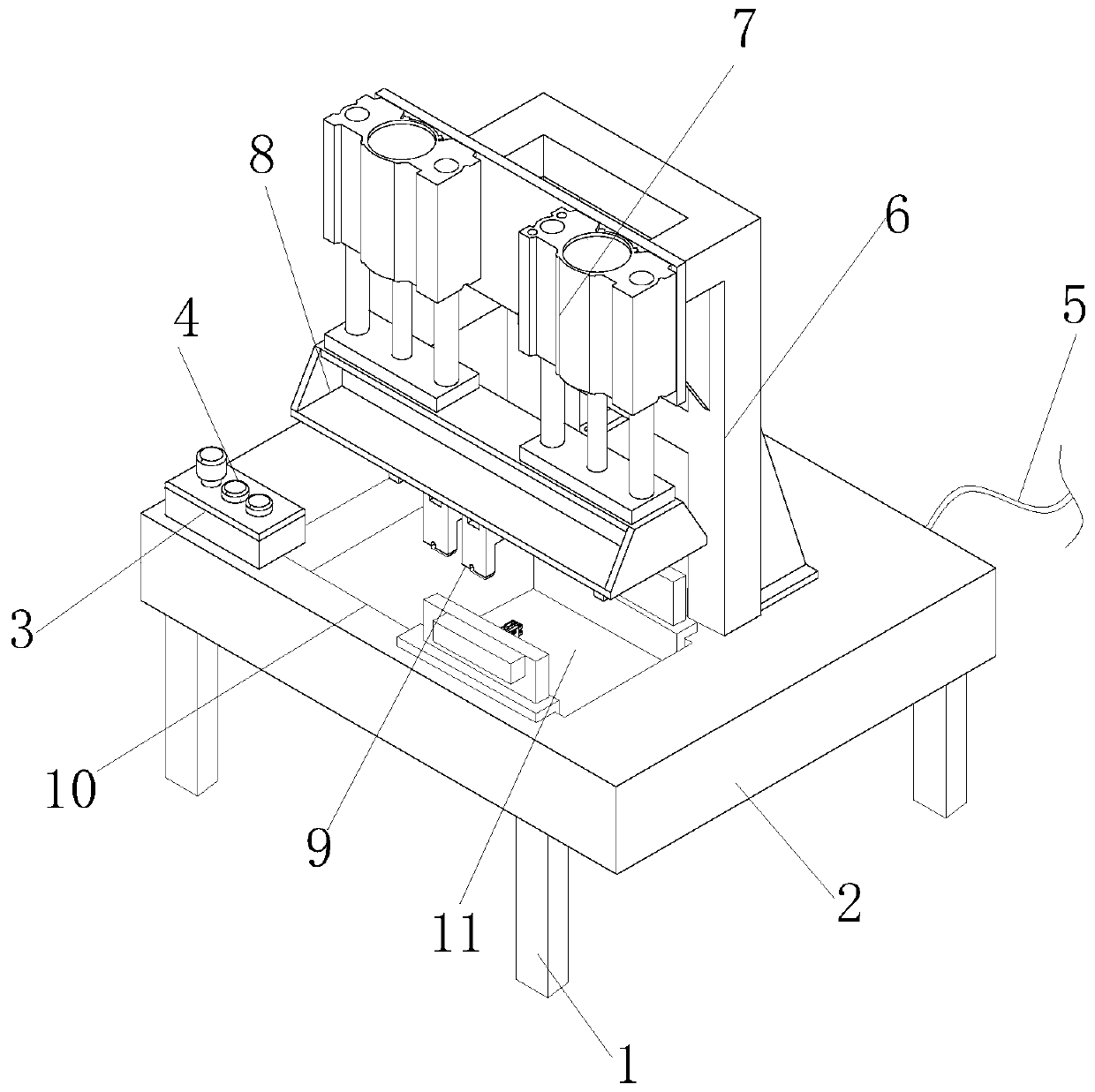

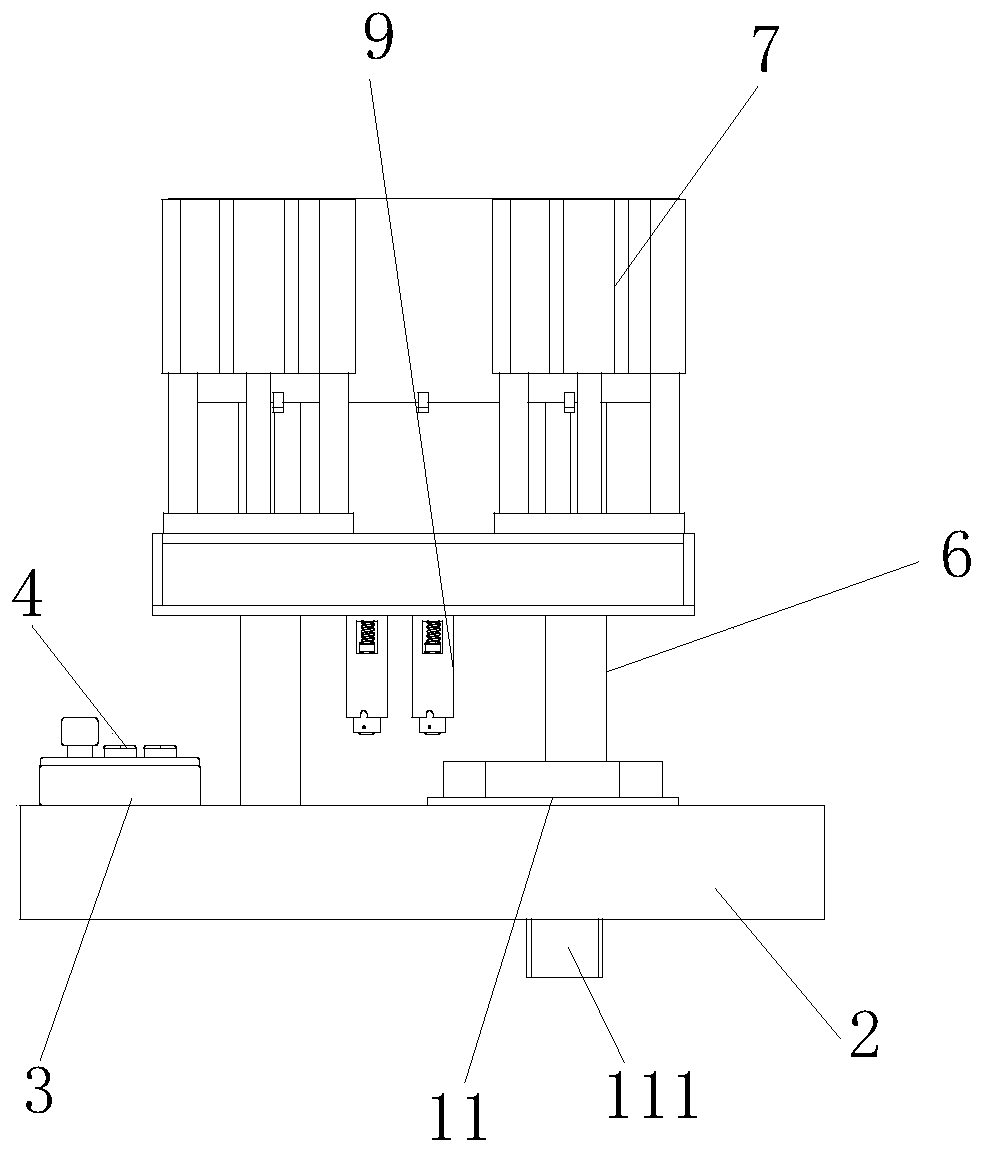

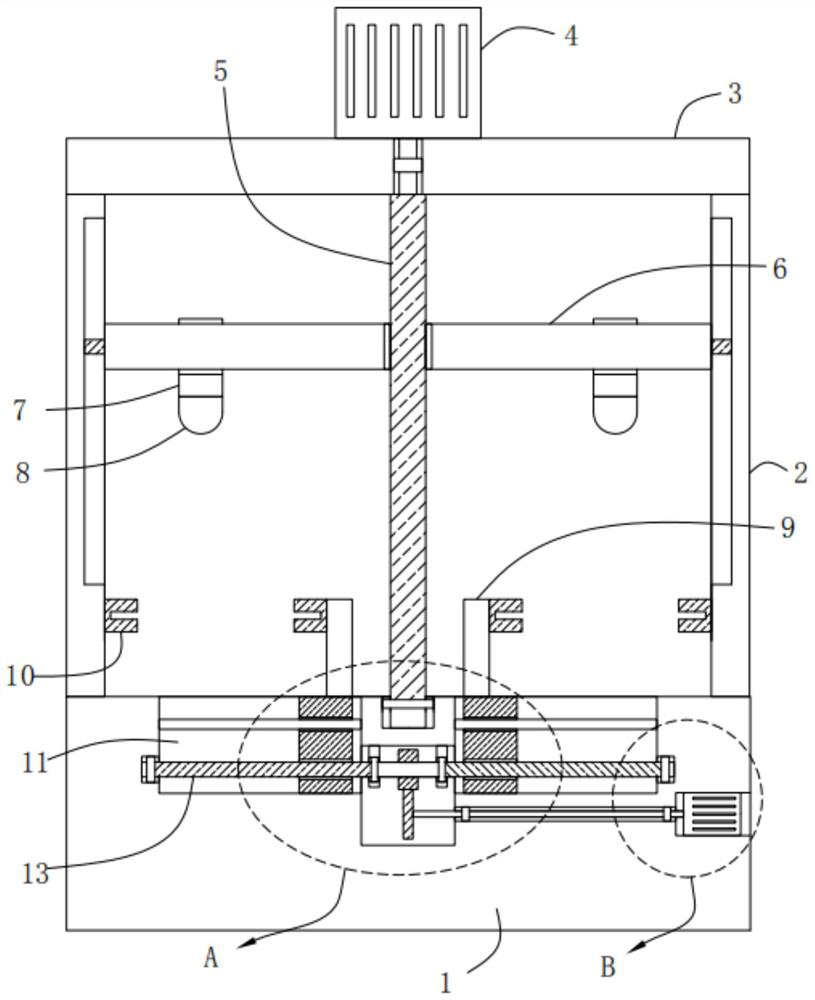

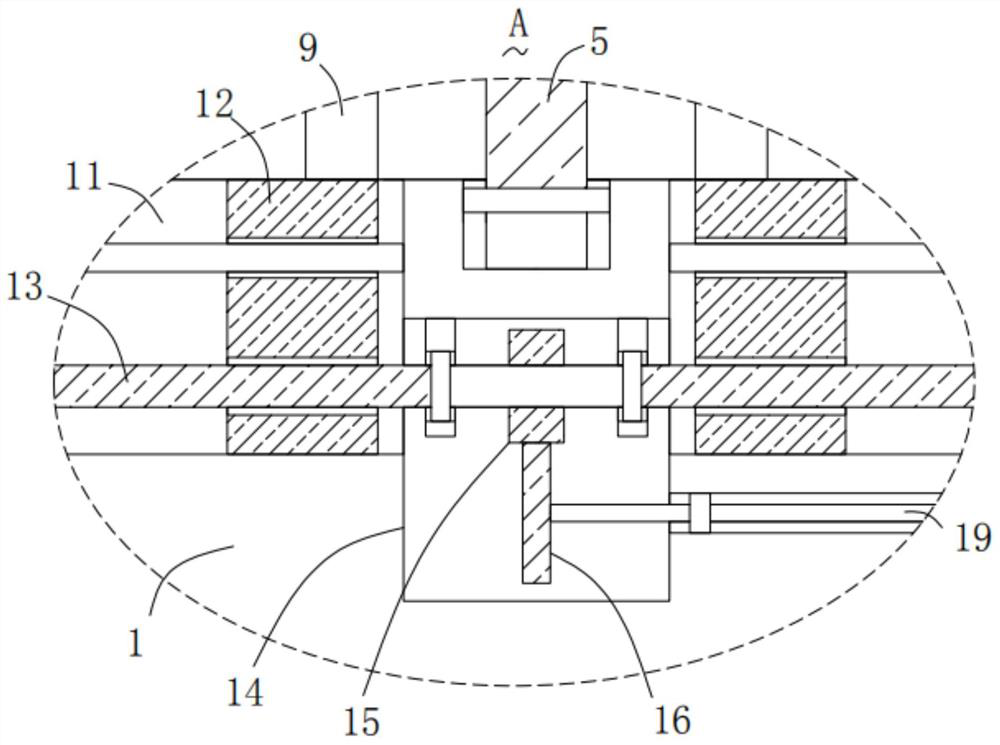

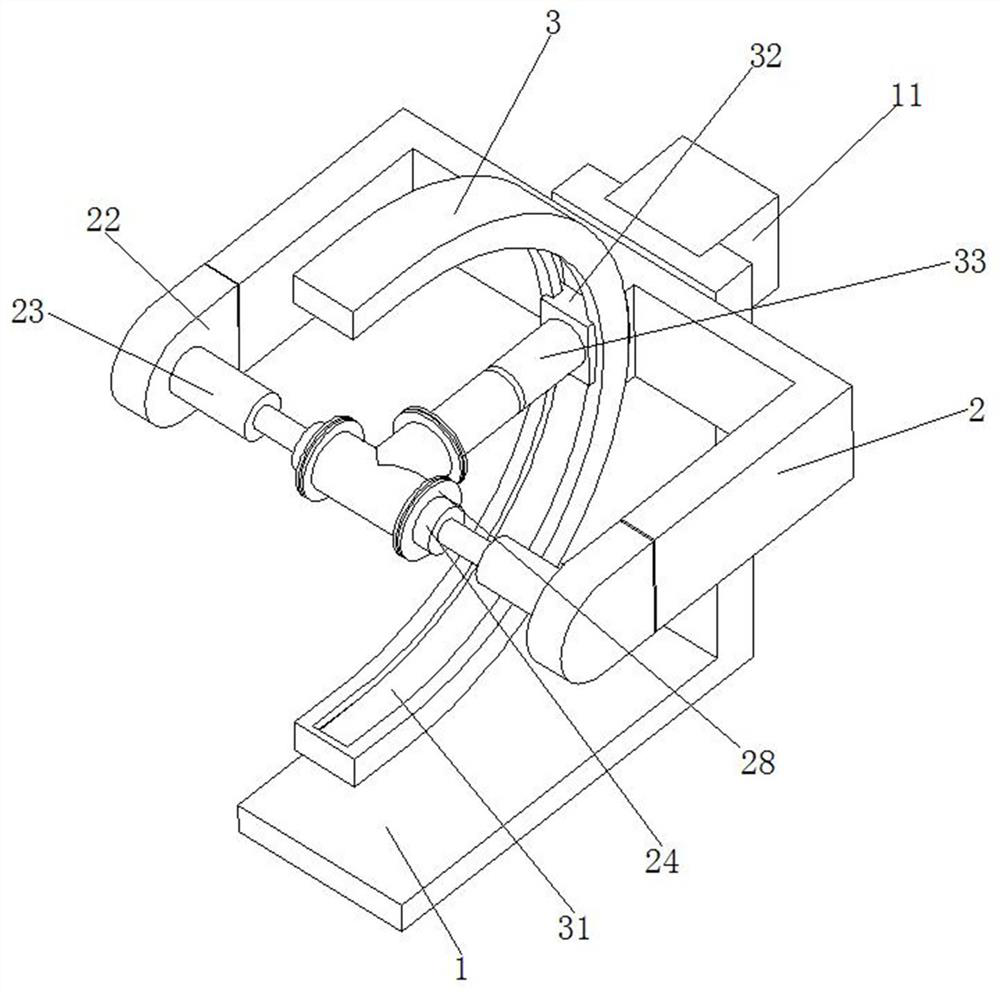

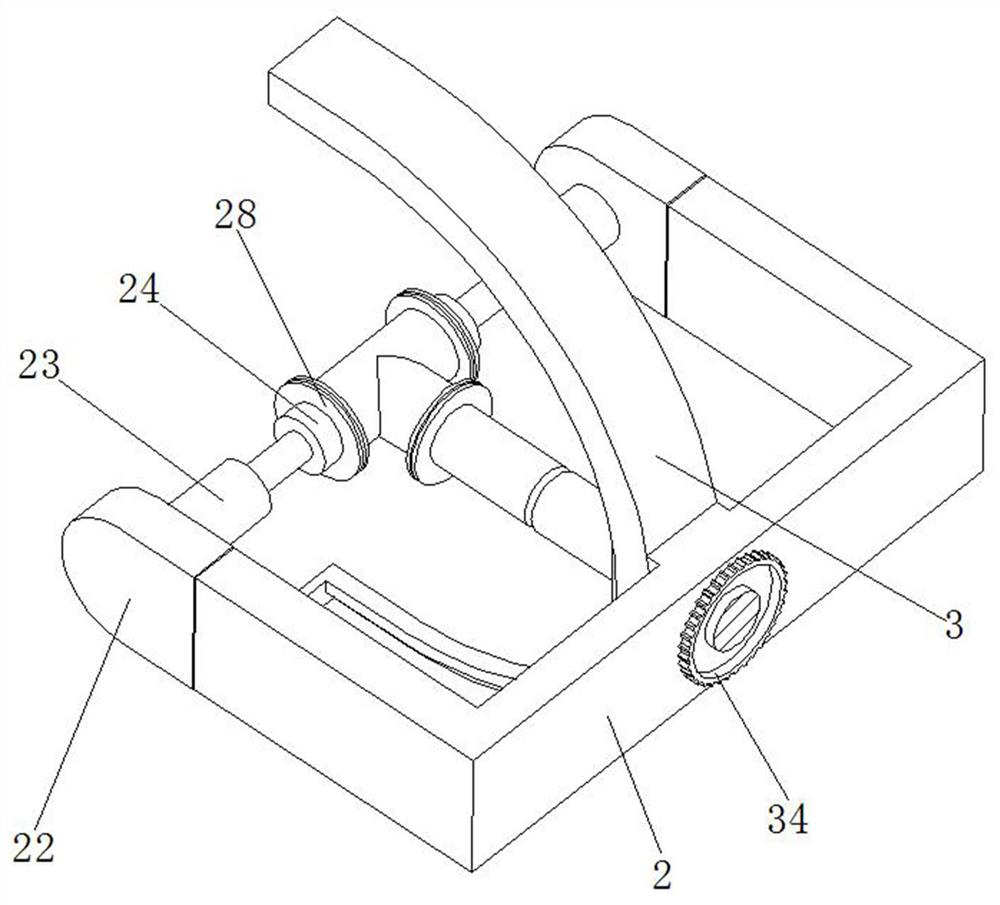

Grinding device for anti-corrosion pipeline production

InactiveCN113245990AFast clamping and fixingImprove grinding efficiencyEdge grinding machinesGrinding carriagesEngineeringMaterials science

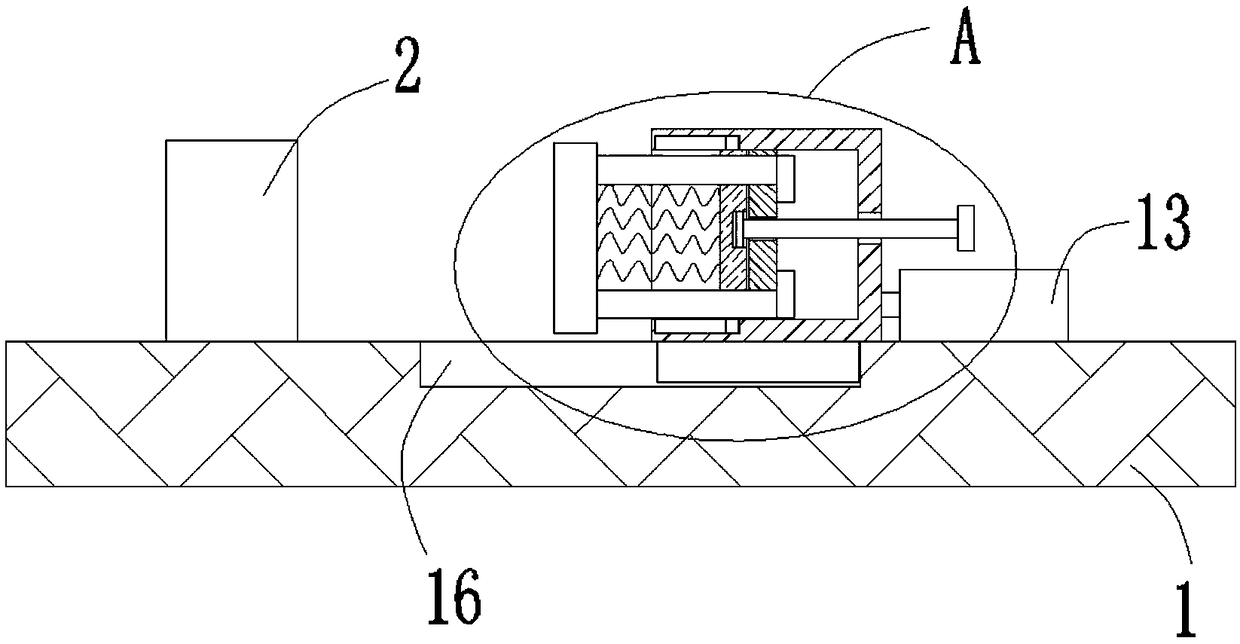

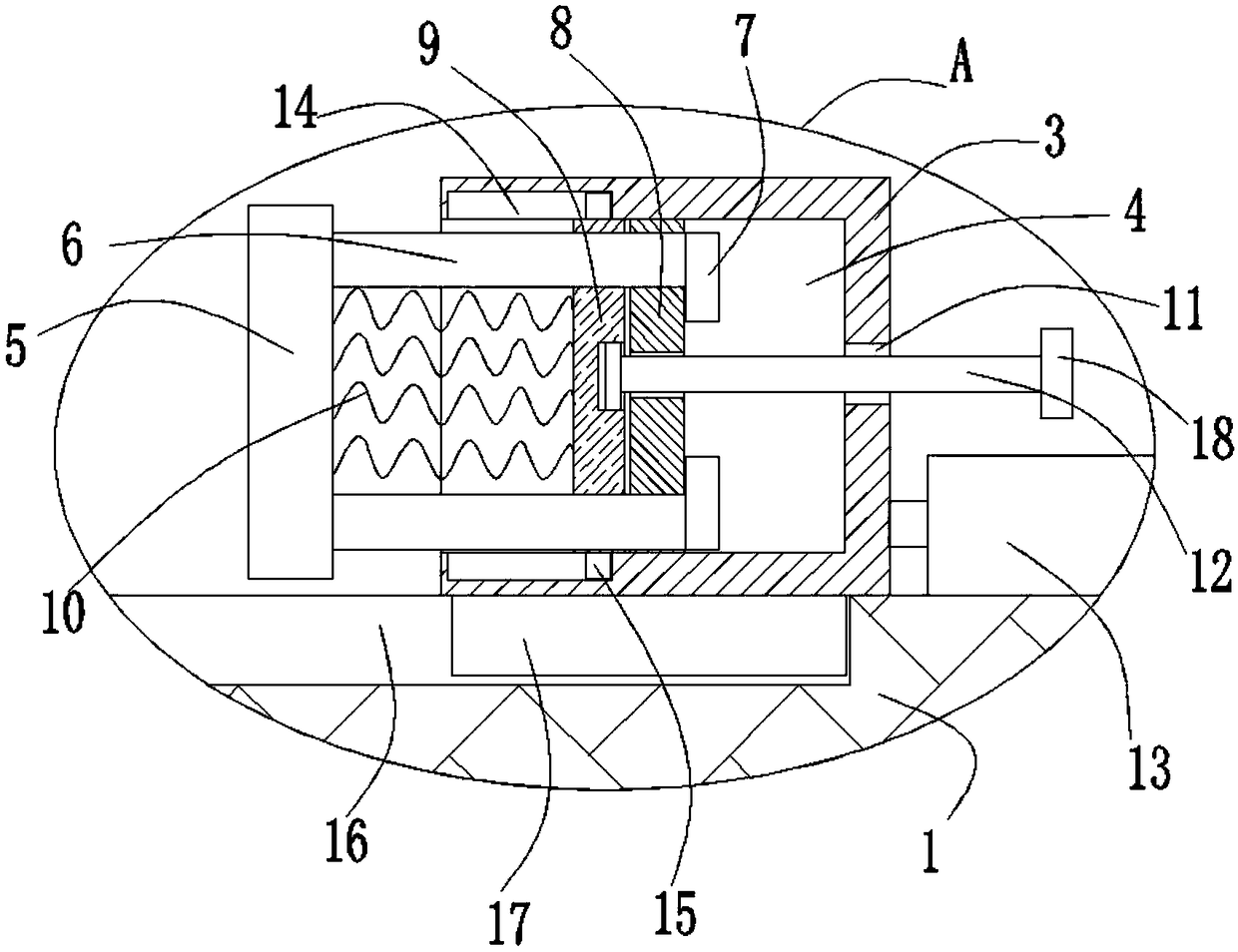

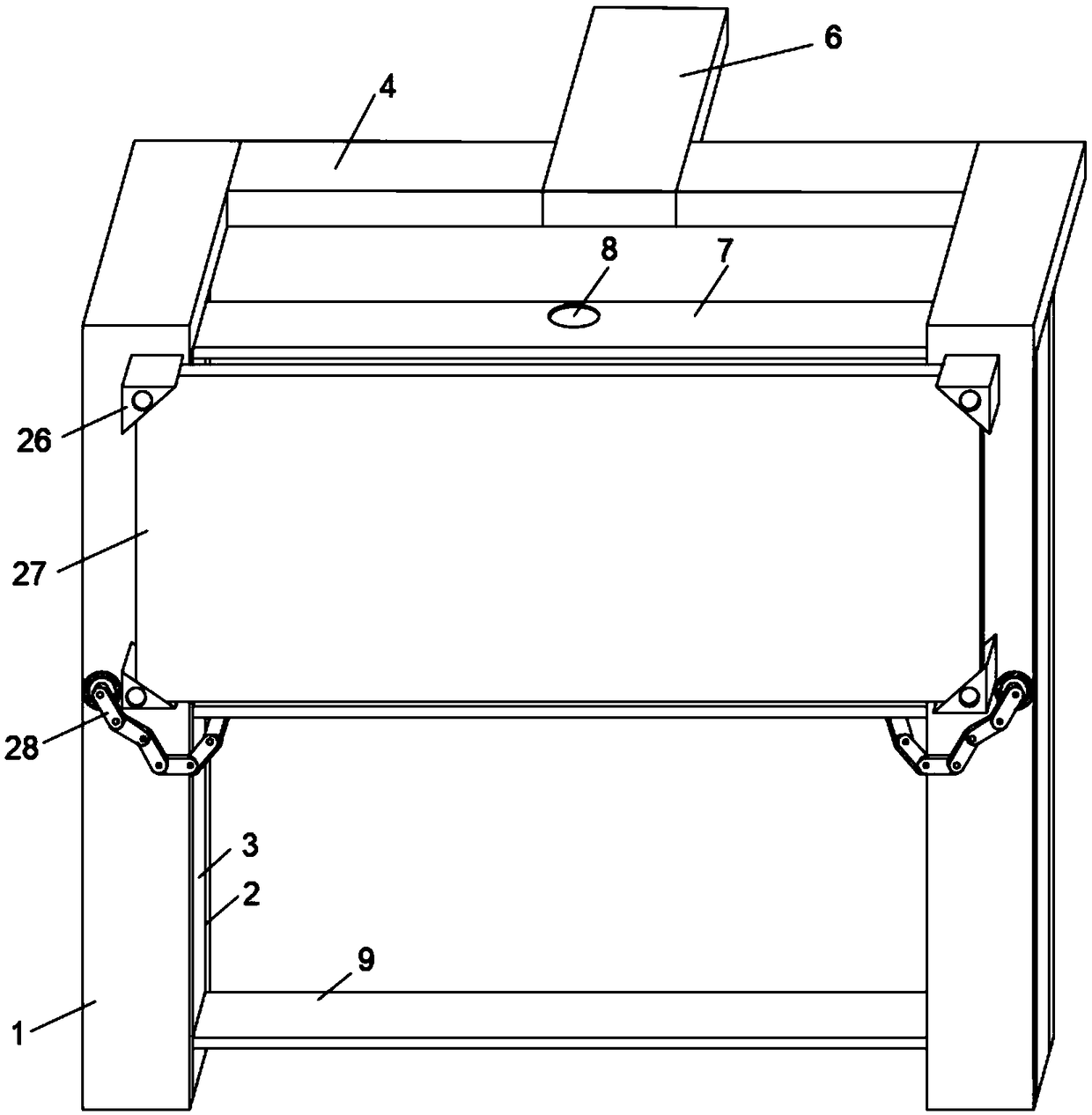

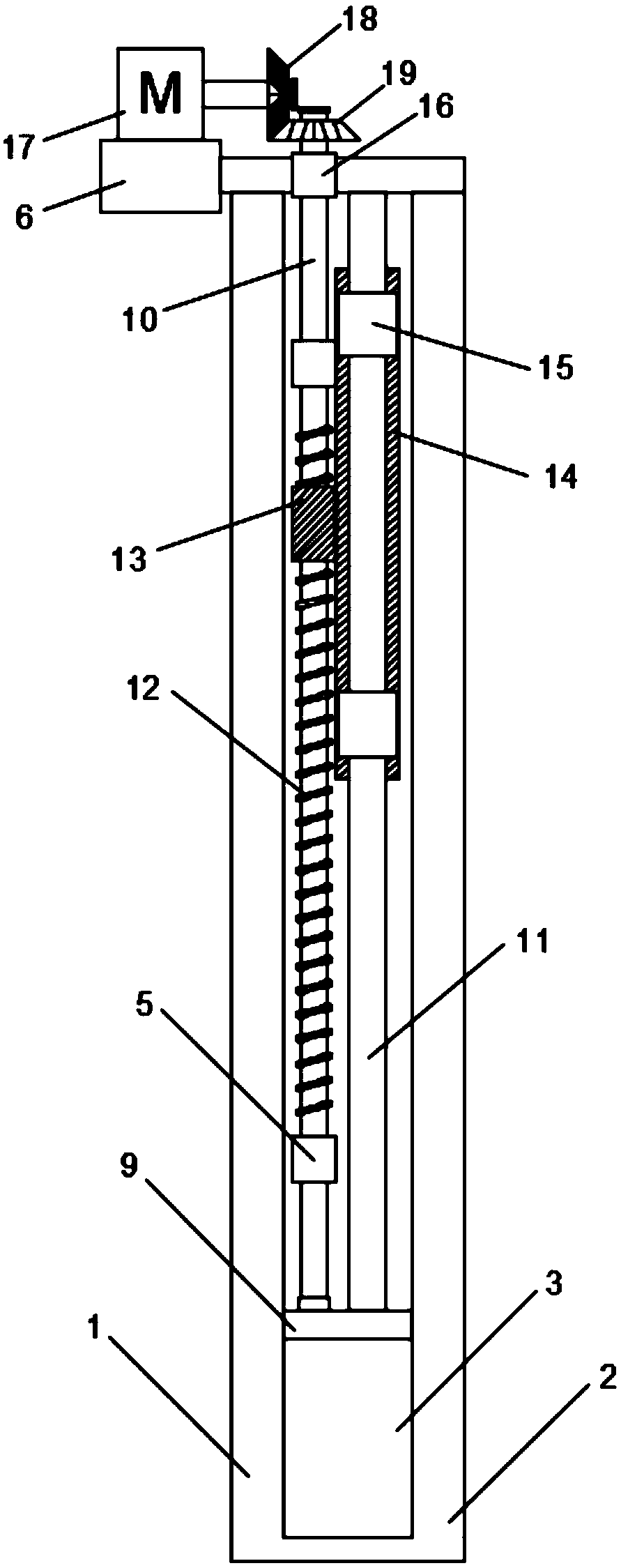

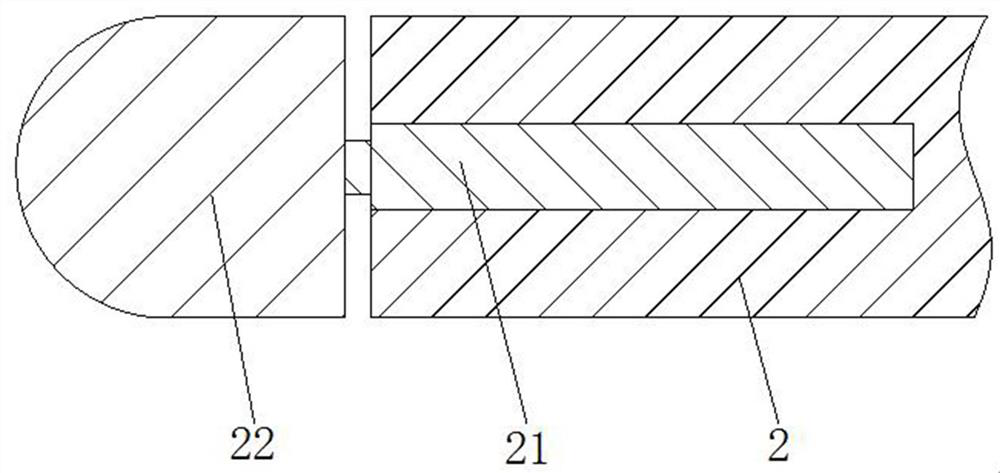

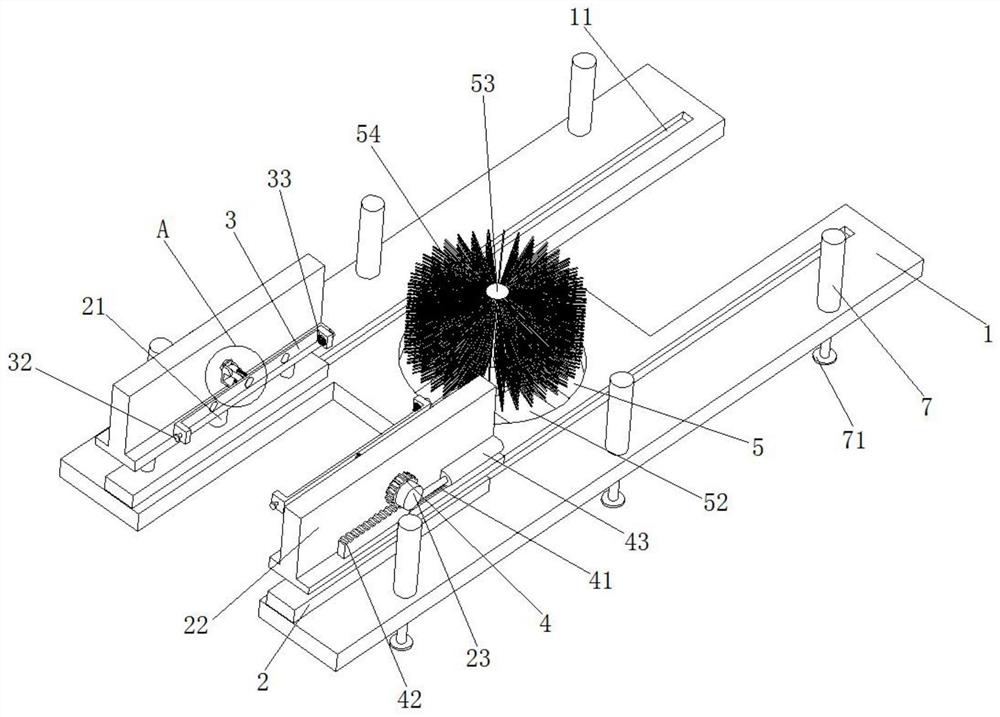

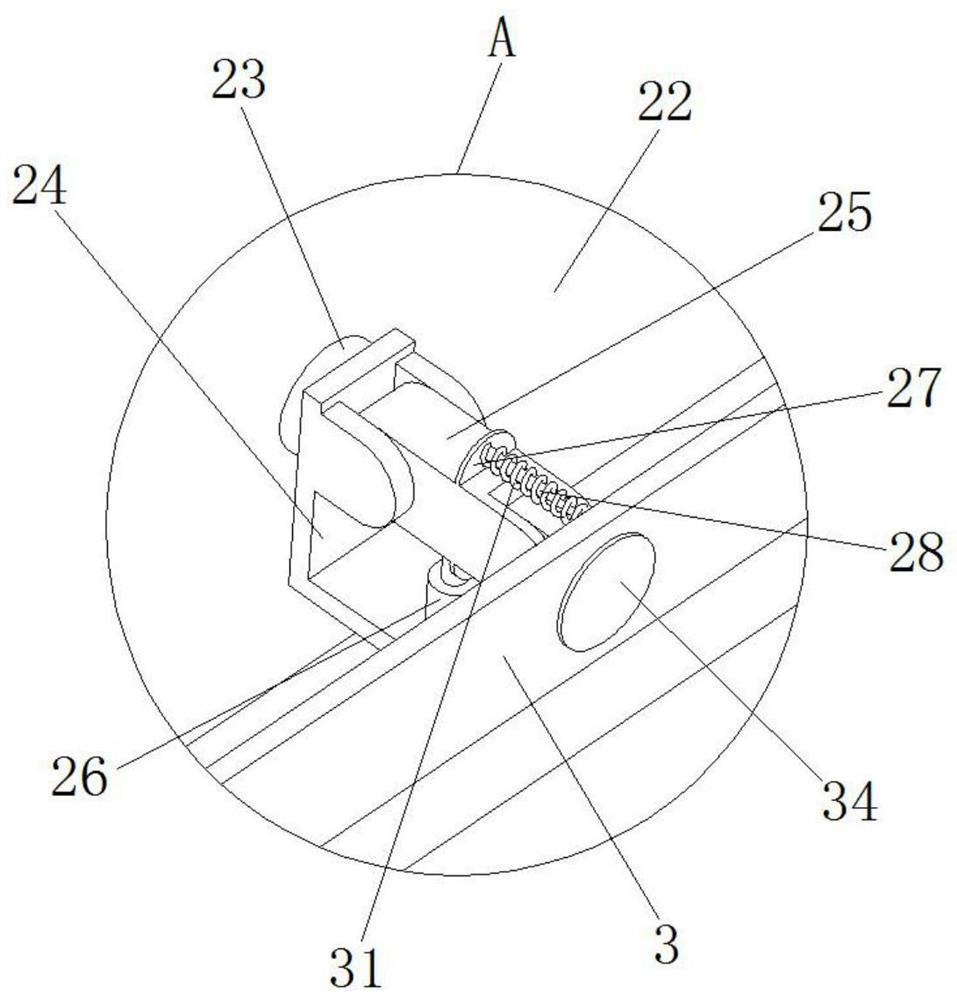

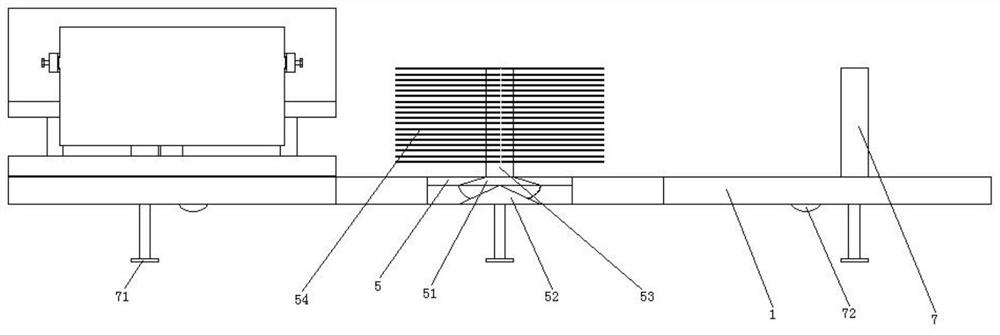

The invention discloses a grinding device for anti-corrosion pipeline production, and relates to the technical field of grinding. The grinding device comprises a base and further comprises a grinding assembly arranged on the base, the grinding assembly comprises a fixing frame fixedly installed on the base, one side of the fixing frame is connected with a multi-mode grinding mechanism, the multi-mode grinding mechanism comprises an end grinding disc rotationally connected to the fixing frame, the end grinding disc rotates to grind the end of an anti-corrosion pipeline, the side, away from the fixing frame, of the end grinding disc is connected with an inner and outer wall grinding device, the inner and outer walls of the pipeline are ground through the inner and outer wall grinding device, and a second driving part used for driving the multi-mode grinding mechanism is fixedly arranged on the fixing frame. According to the grinding device for anti-corrosion pipeline production, by arranging a pipeline clamping mechanism, the anti-corrosion pipeline can be rapidly clamped and fixed, by arranging the end grinding disc and the inner and outer wall grinding device, the end, the inner wall and the outer wall of the pipeline can be rapidly and selectively ground, the grinding efficiency is high, the structural integration degree is high, and the occupied space is small.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

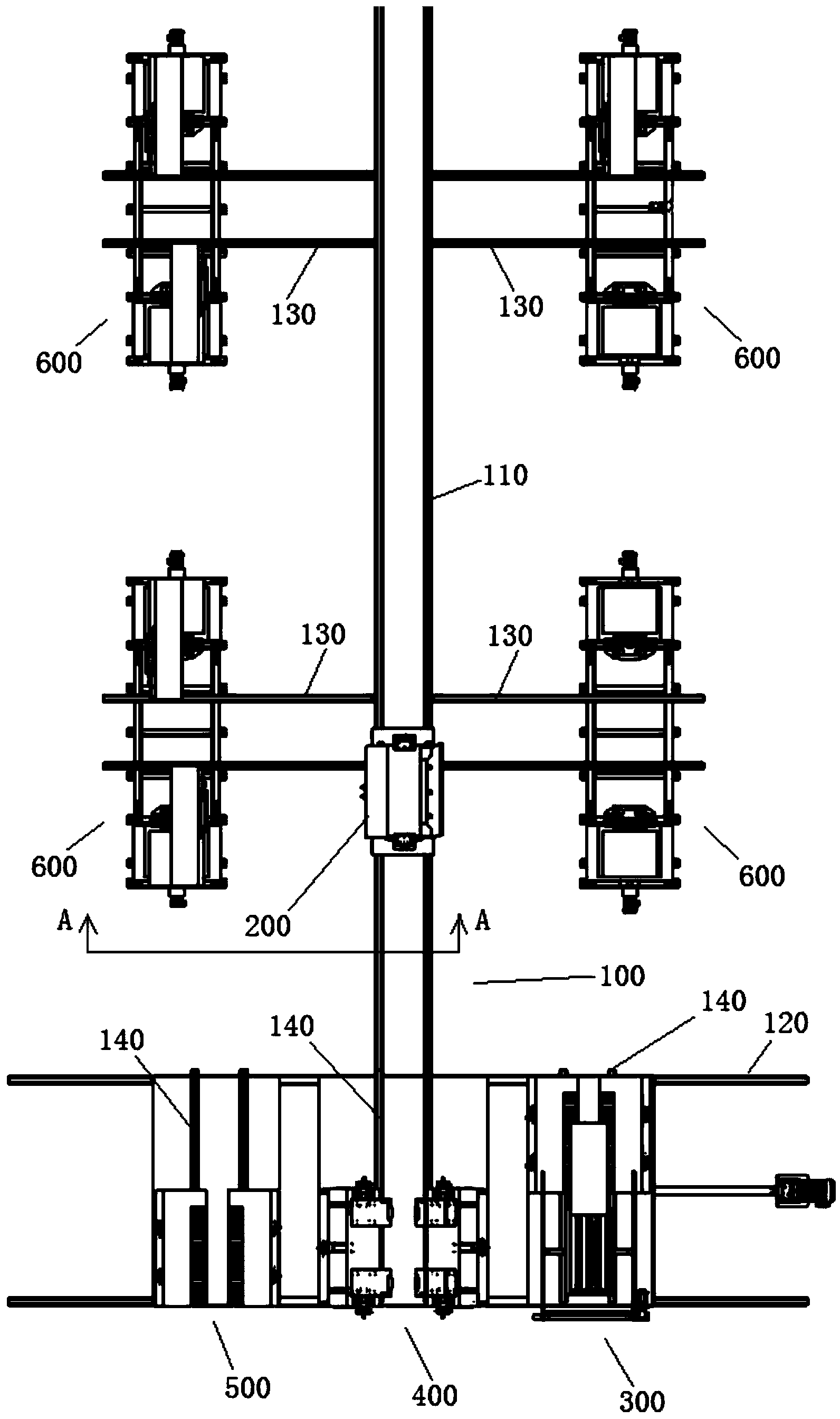

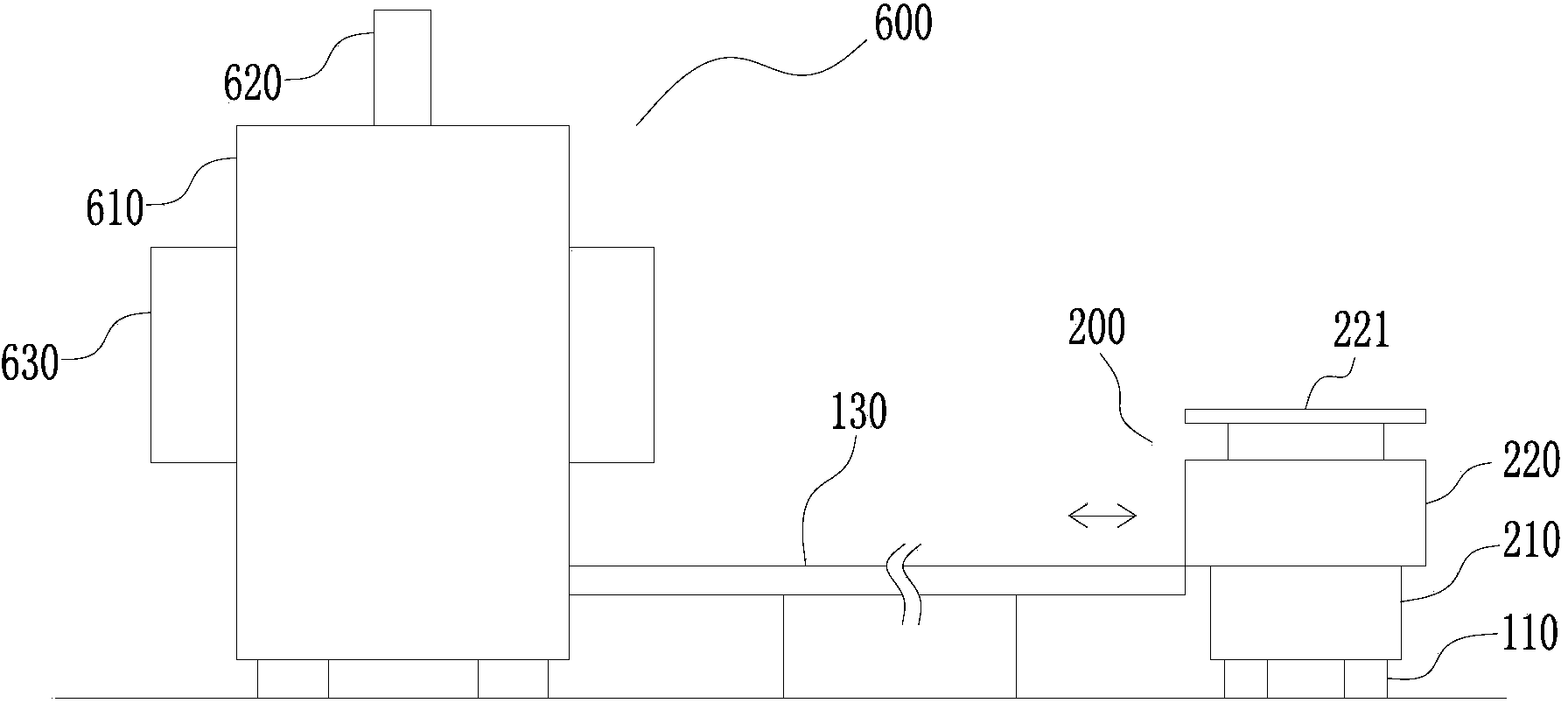

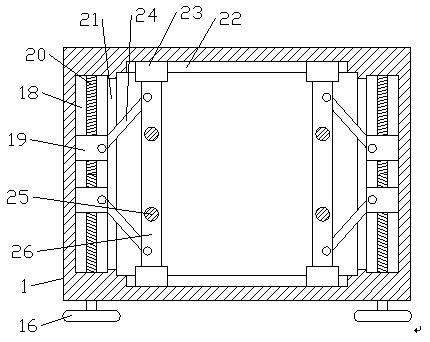

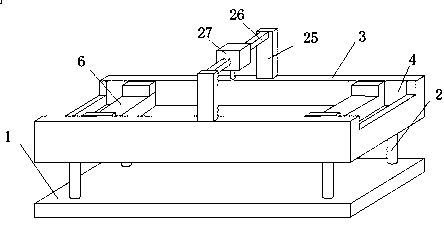

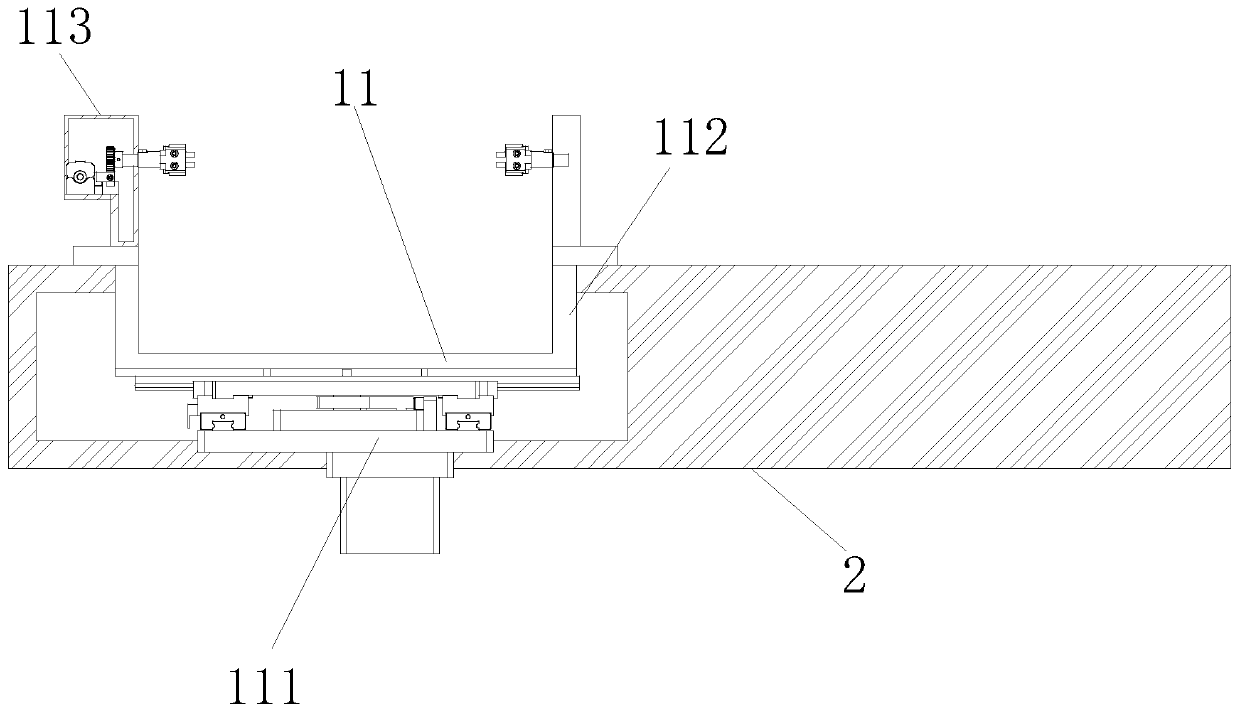

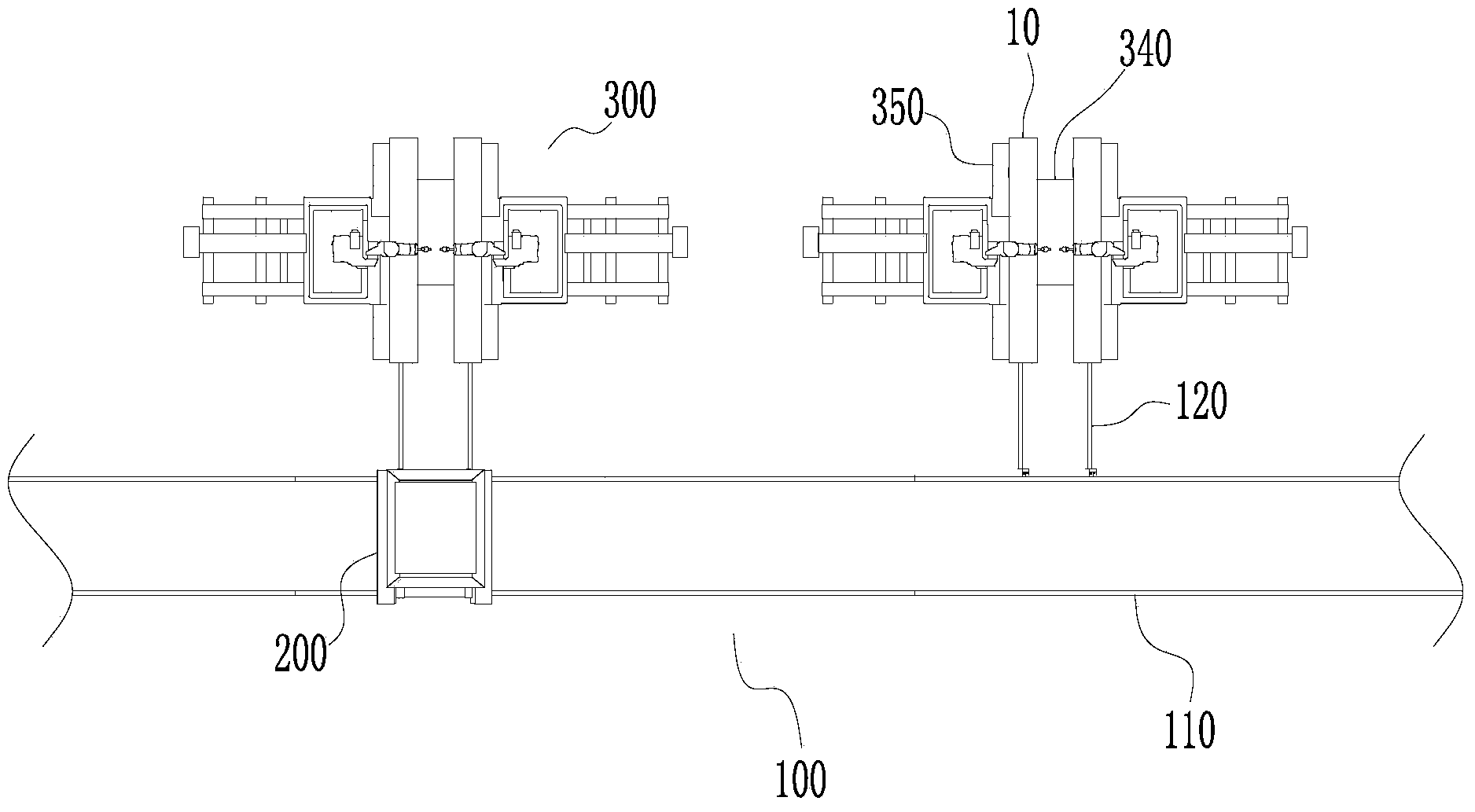

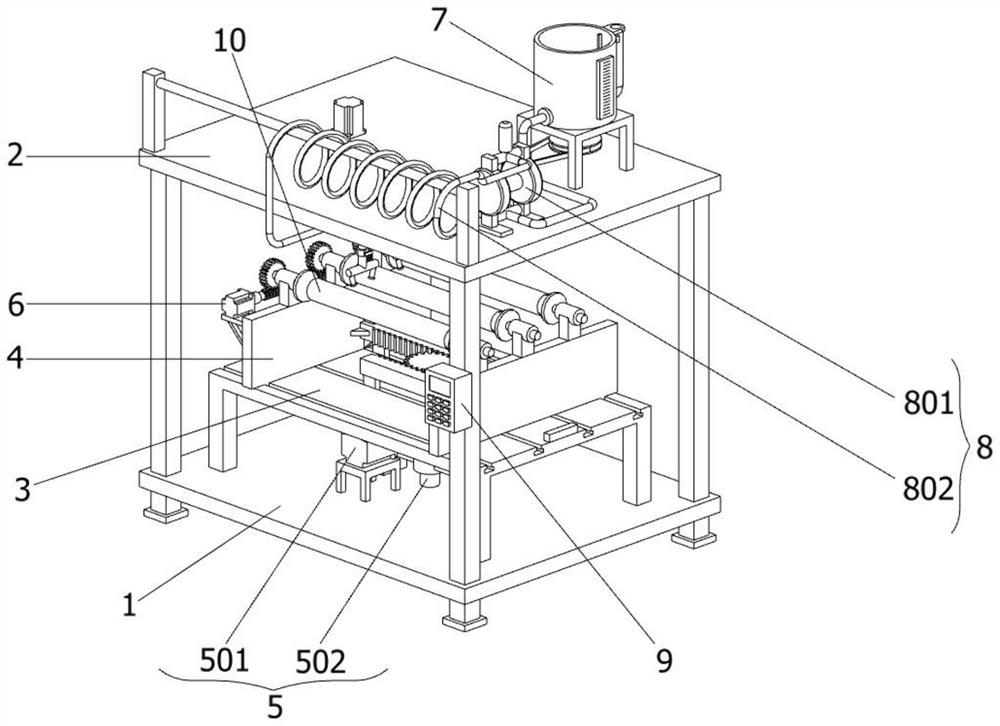

Middle trough welding system

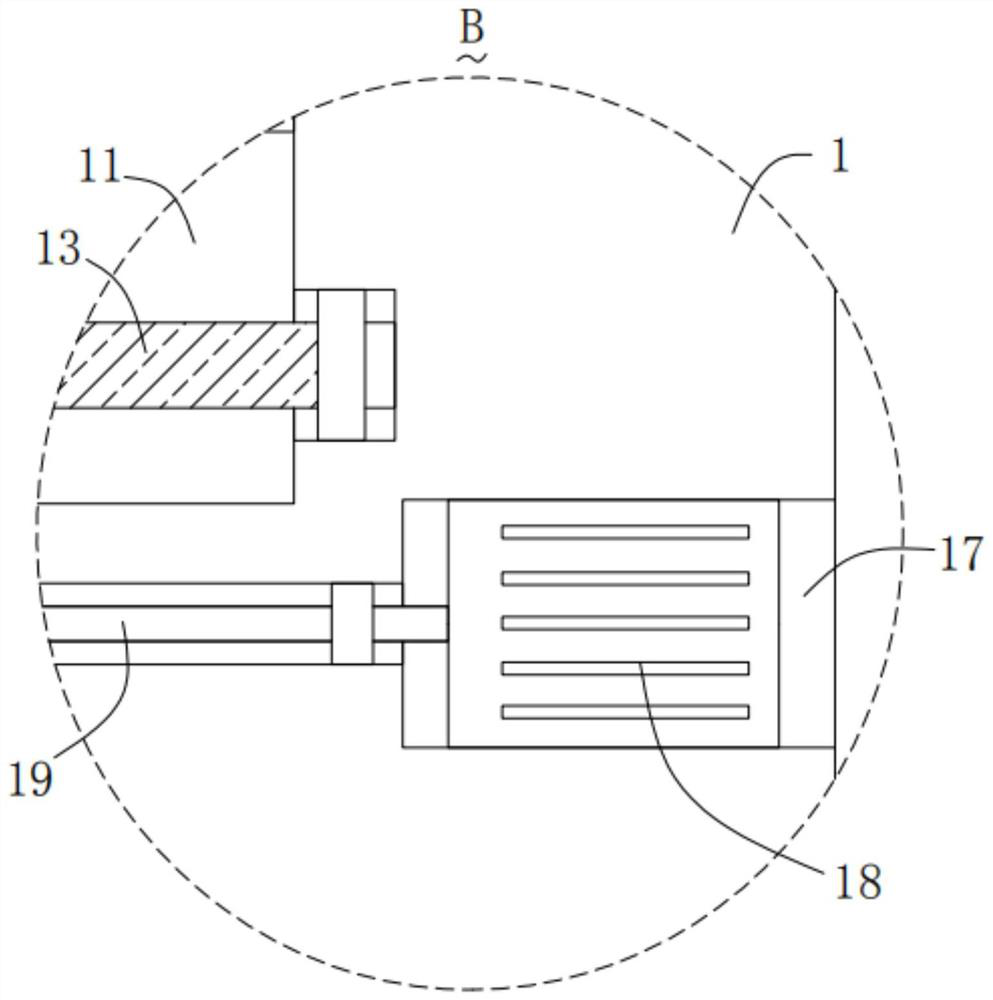

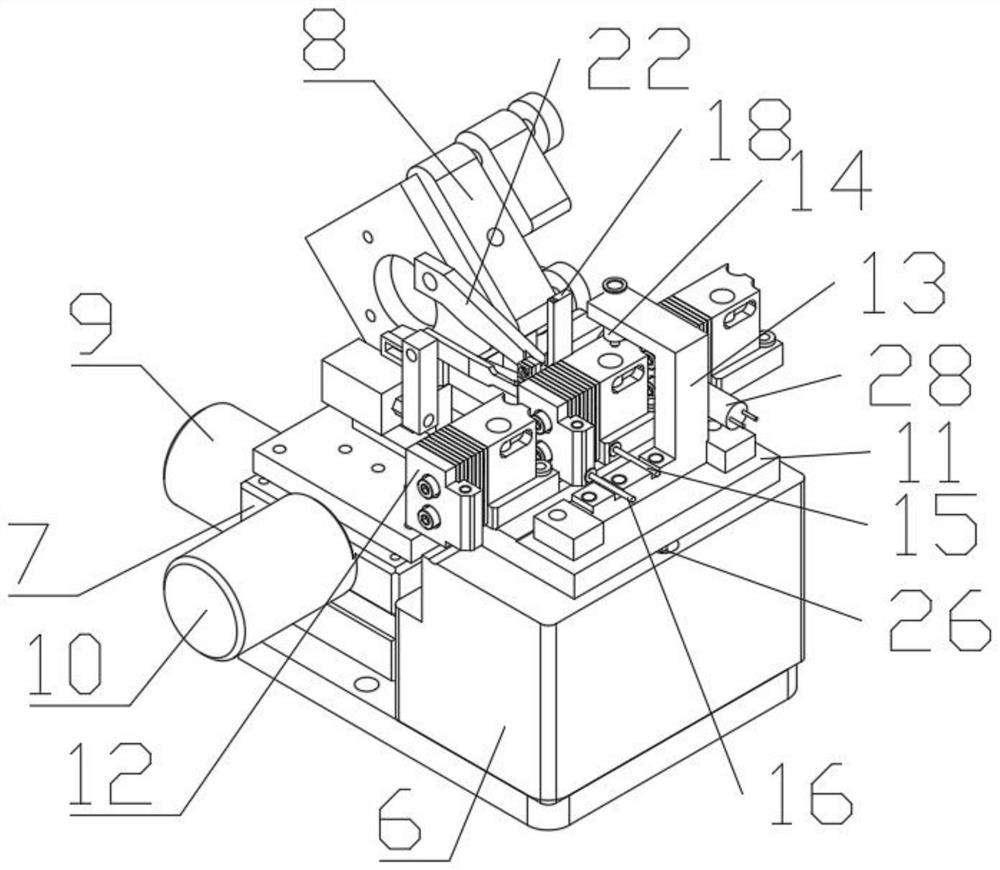

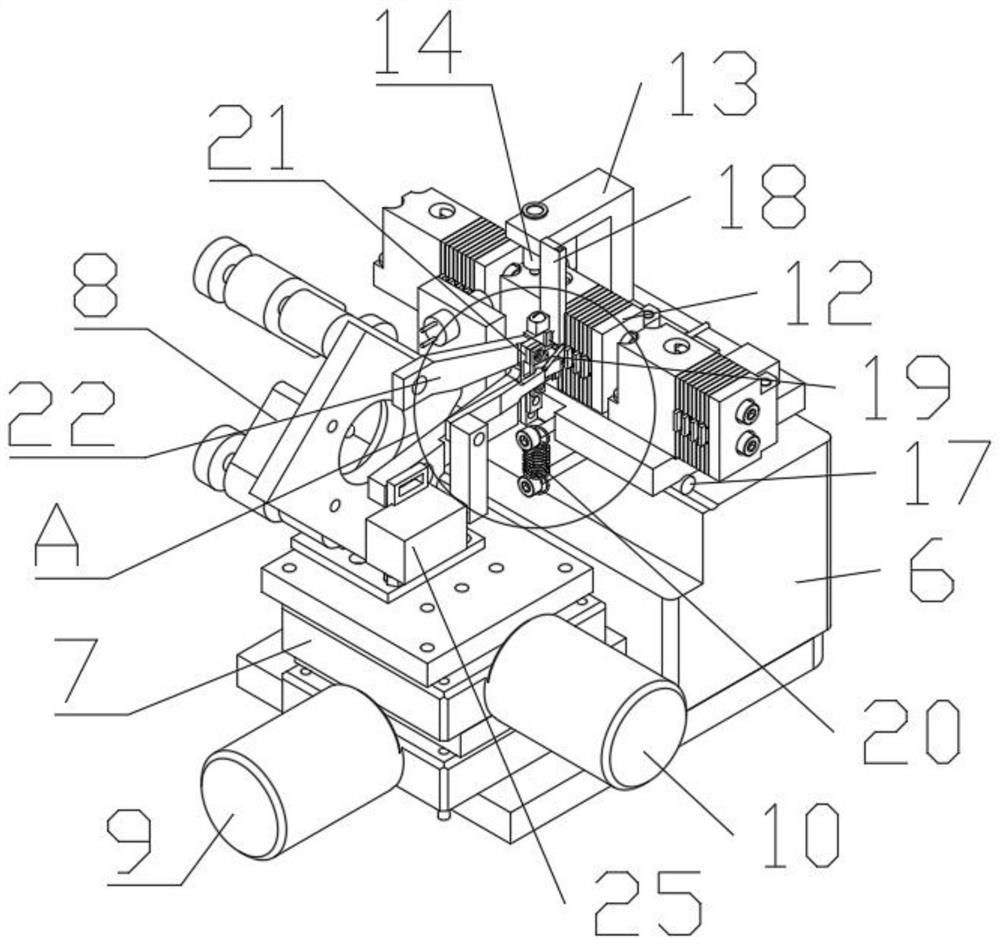

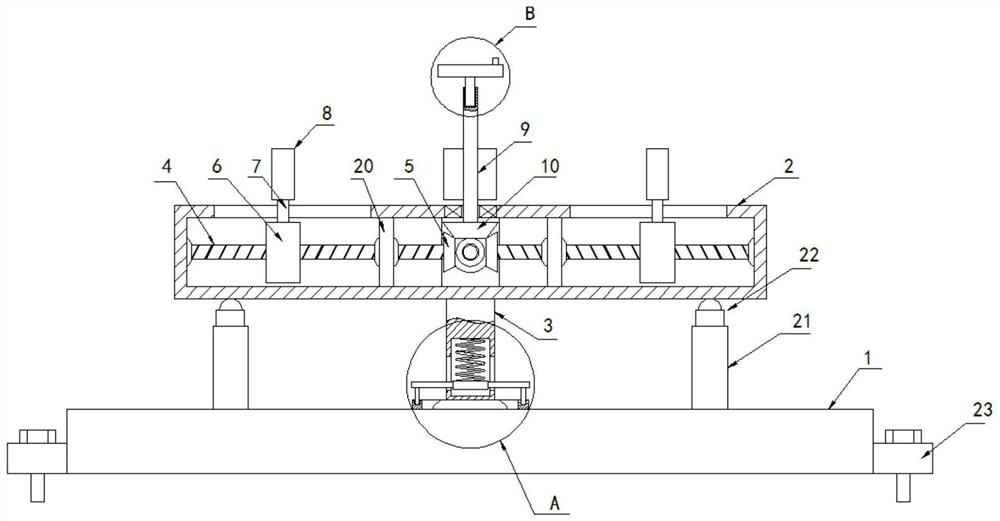

ActiveCN103464913AFast clamping and fixingPrecise clamping and fixingWelding/cutting auxillary devicesAuxillary welding devicesBatch operationTransport medium

The invention discloses a middle trough welding system. The system comprises a rail net, primary and secondary transport vehicles, a bottom plate feeding machine for transporting bottom plates, a medium plate feeding machine for transporting medium plates and steel channels, a middle trough blanking machine for outputting middle troughs, and a plurality of middle trough welding machines for welding the bottom plates, the medium plates and the steel channels into the middle troughs, wherein the bottom plate feeding machine, the medium plate feeding machine and the middle trough blanking machine are respectively positioned at different positions of the rail net; the primary and secondary transport vehicles run on the rail net for transporting the bottom plates and the medium plates and the steel channels of the bottom plate feeding machine and the medium plate feeding machine to the corresponding middle trough welding machines, and transporting the middle troughs welded by the middle trough welding machine to the middle trough blanking machine. On the basis of guaranteeing the welding quality, the automatic and batch operation of welding the middle troughs is realized.

Owner:斯图加特航空自动化(青岛)有限公司

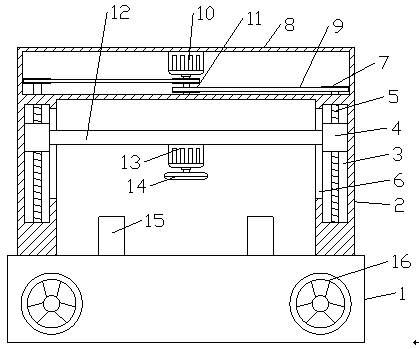

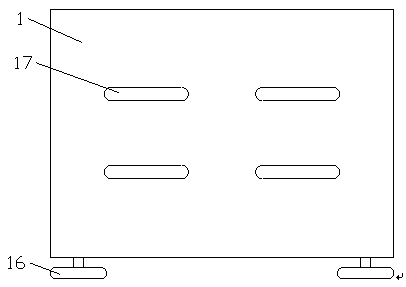

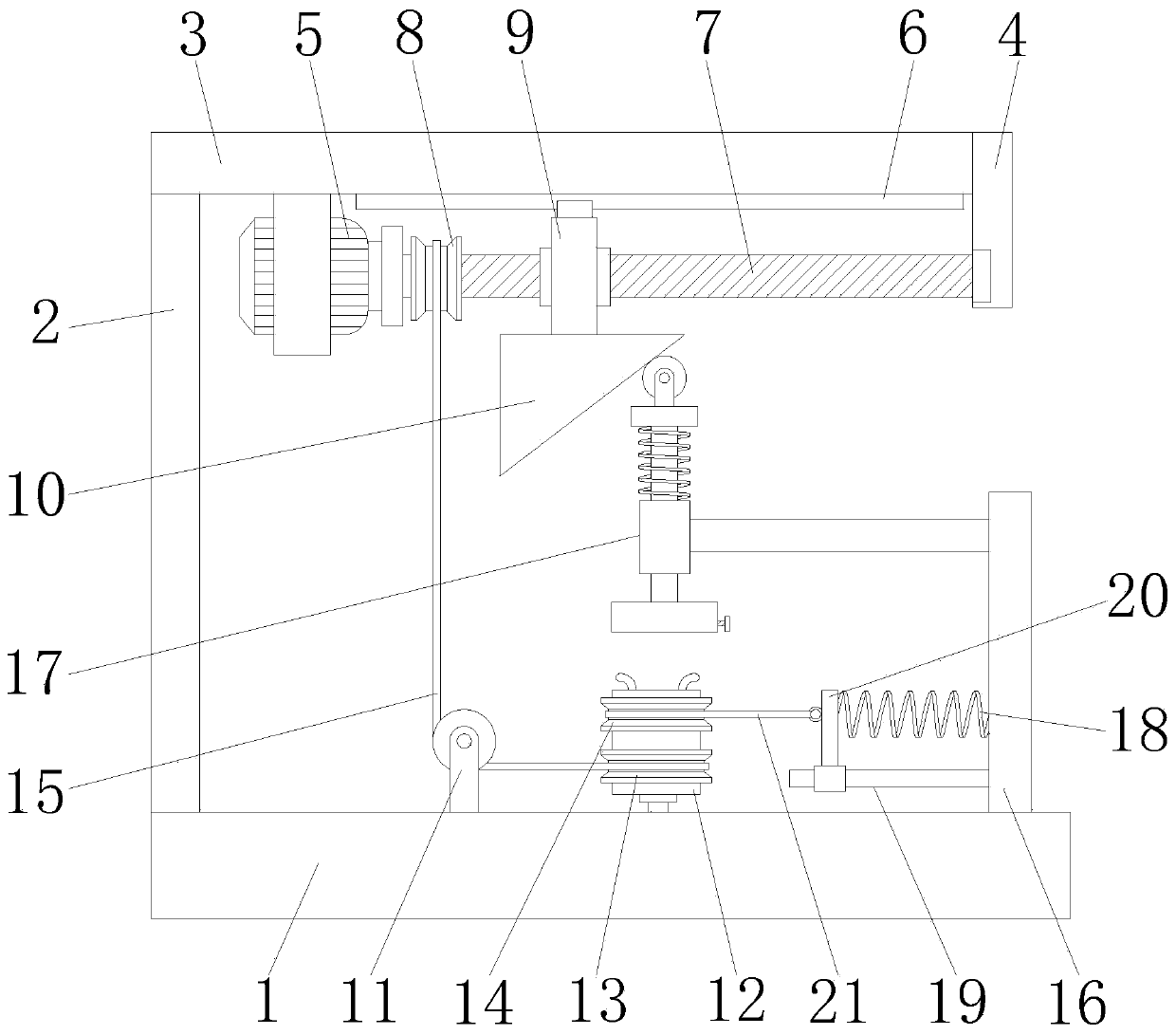

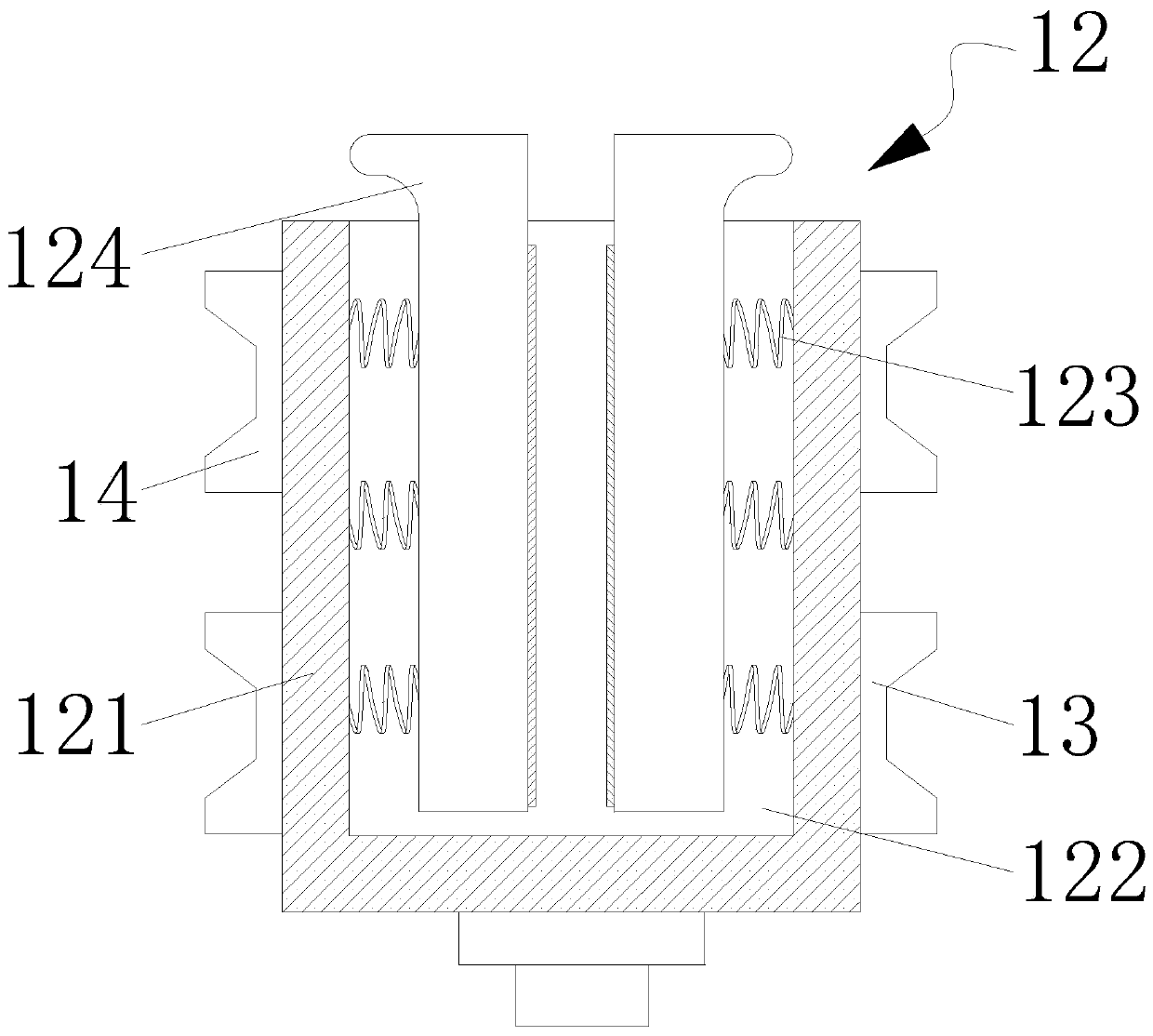

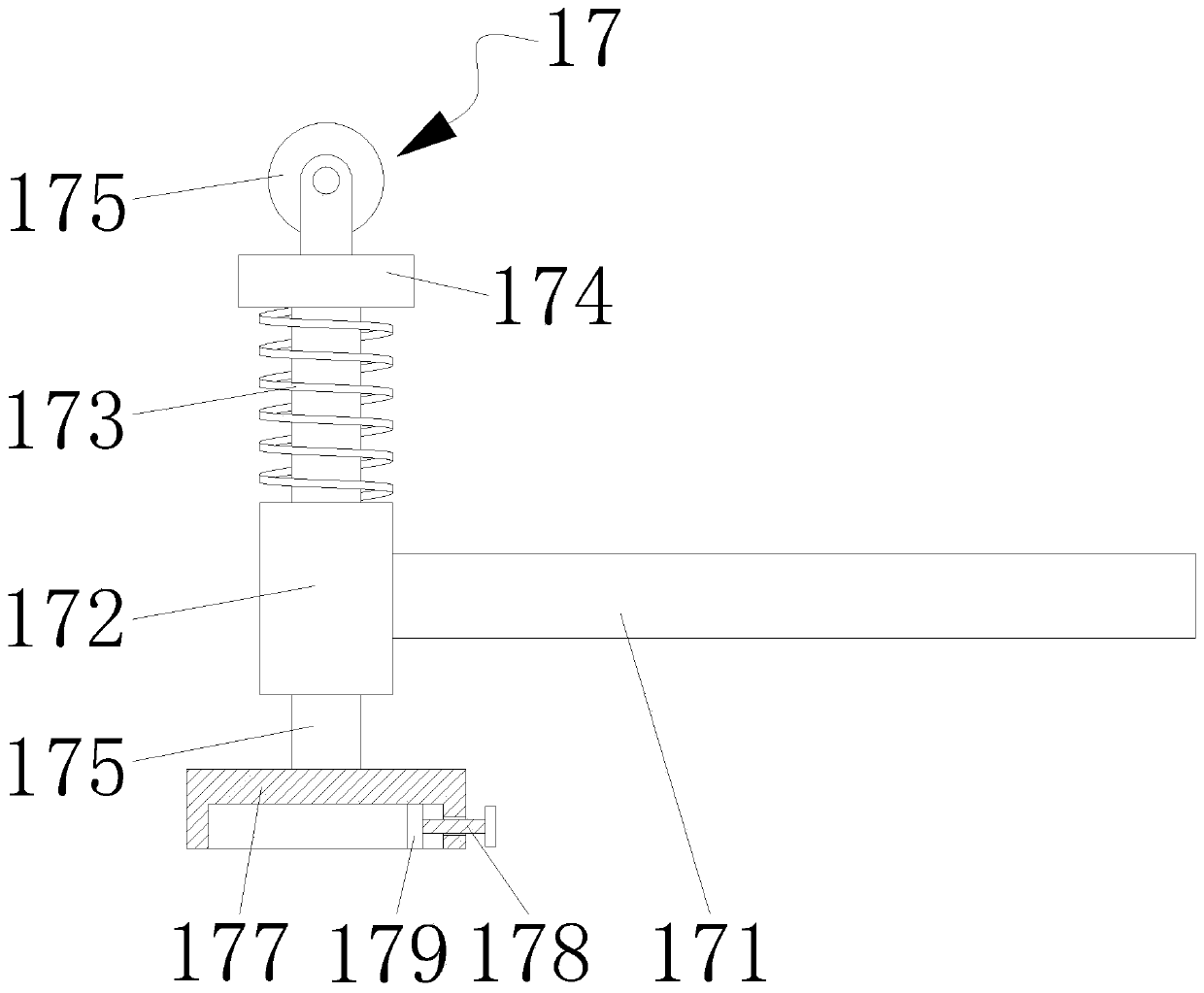

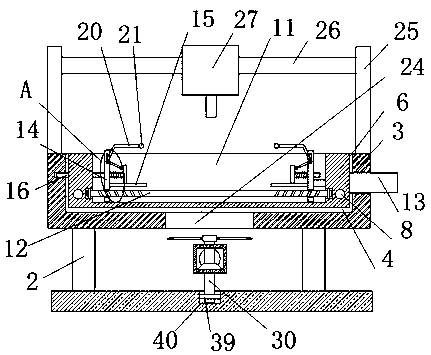

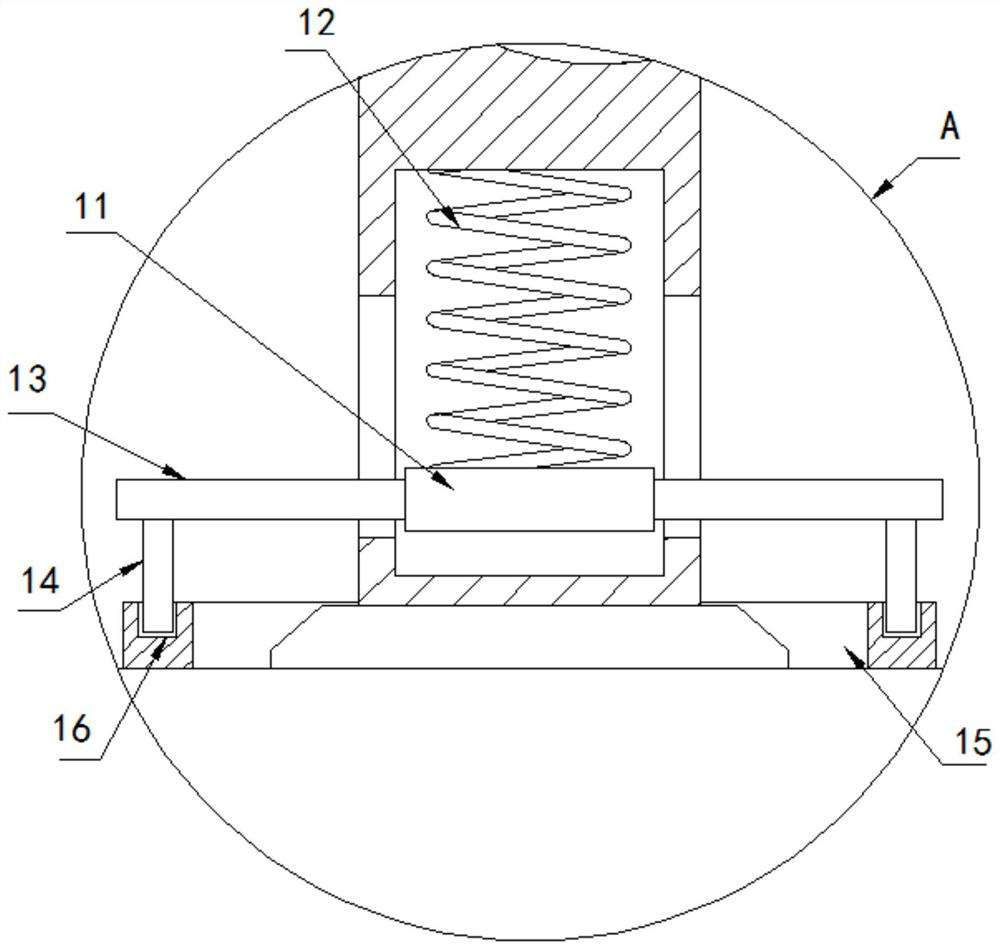

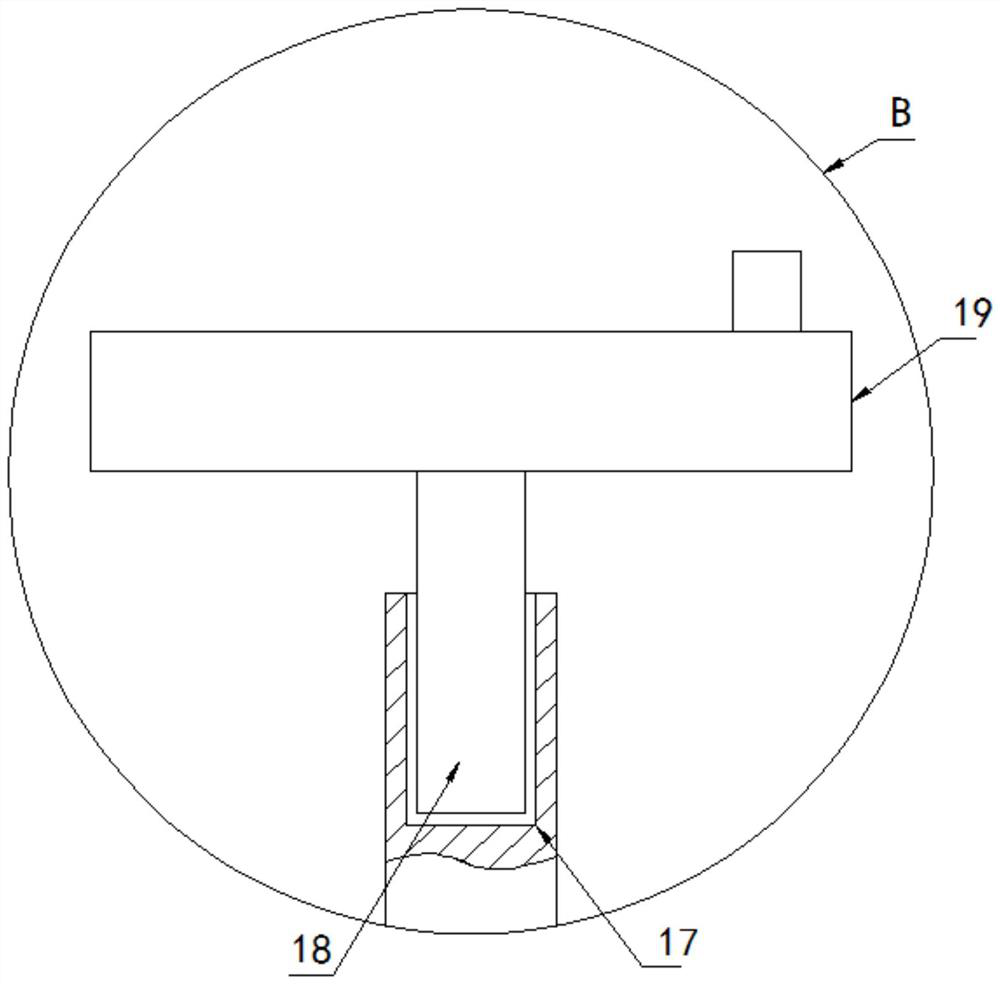

Grinding device for motor bearing bush machining

ActiveCN109454511AEasy to operateEasy to clamp and fixEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention discloses a grinding device for motor bearing bush machining. The grinding device comprises a base, a grinding wheel and clamping blocks, supporting vertical columns which are verticallyarranged are fixedly installed at the tops of the two ends of the base, a lifting mechanism used for adjusting the height of a grinding assembly in the vertical direction is installed on the supporting vertical columns, rectangular sliding cavities are formed in two side plates of the base, screw rods are erected in the rectangular sliding cavities in a rotating mode, outer threads on the outer circumferences of the two ends of each screw rod are opposite in rotation direction, two moving sliding blocks in each rectangular sliding cavity are installed on the outer circumferences of the two ends of the corresponding screw rod in a threaded connection mode correspondingly, and a connecting pressing rod is connected between one side of each moving rod and one of the moving sliding blocks inthe corresponding rectangular sliding cavity in a hinged mode. According to the grinding device, a workpiece to be ground can be rapidly clamped and fixed, moreover, the lifting mechanism is arrangedso that the height of the grinding assembly can be rapidly adjusted, then the workpiece on the base can be conveniently ground, and the use is convenient.

Owner:泰州市乐太食品有限公司

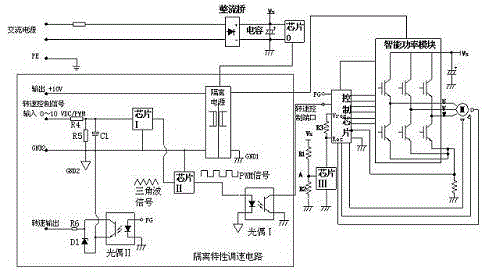

Outer rotor electronic control fan and speed regulating method

ActiveCN102979748AAvoid burnt deficienciesAvoid damagePump componentsPump controlCapacitanceEngineering

The invention relates to an outer rotor electronic control fan and a speed regulating method. A +10V power supply is output by the power supply output end of an isolating power supply in an isolating characteristic speed regulating circuit; the ground terminal GND2 of the isolating power supply is connected with the ground terminal of an operational amplifier chip I, the ground terminal of a comparator chip II, the signal output end of an optical coupler II, the cathode of a capacitor C1 and the cathode of a diode D1; the anode of the capacitor C1 is connected with the signal input end of the operational amplifier chip I; the anode of the diode D1 is connected with a rotating speed output end; the signal input terminal of the optical coupler II is connected with an FG signal end; the signal end of the isolating power supply is connected with the signal input end of an intelligent power module; the signal output end of the operational amplifier chip I is connected with the signal input end of the comparator chip II; the signal output end of the comparator chip II is connected with the signal input end of an optical coupler I; and the signal output end of the optical coupler I is connected with the signal input end of a logical driving chip of a direct-current brushless fan. The outer rotor electronic control fan and the method have the advantages that the isolating characteristic speed regulation of the outer rotor electronic control fan is realized, and the defect of easiness in burning of a power supply system existing in the prior art is overcome.

Owner:HANGZHOU DUNLI ELECTRIC APPLIANCES

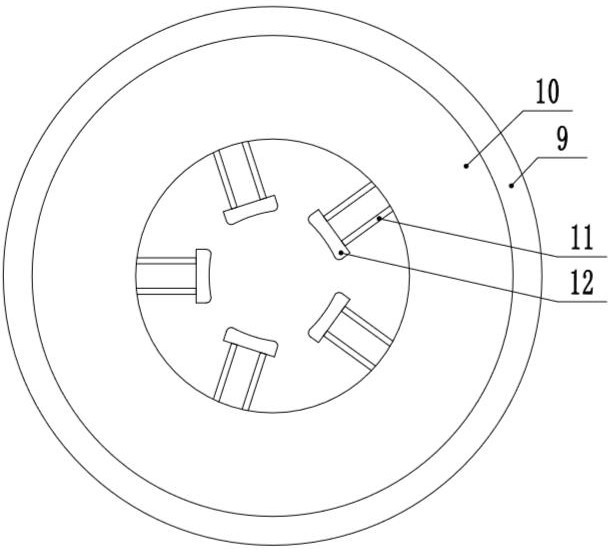

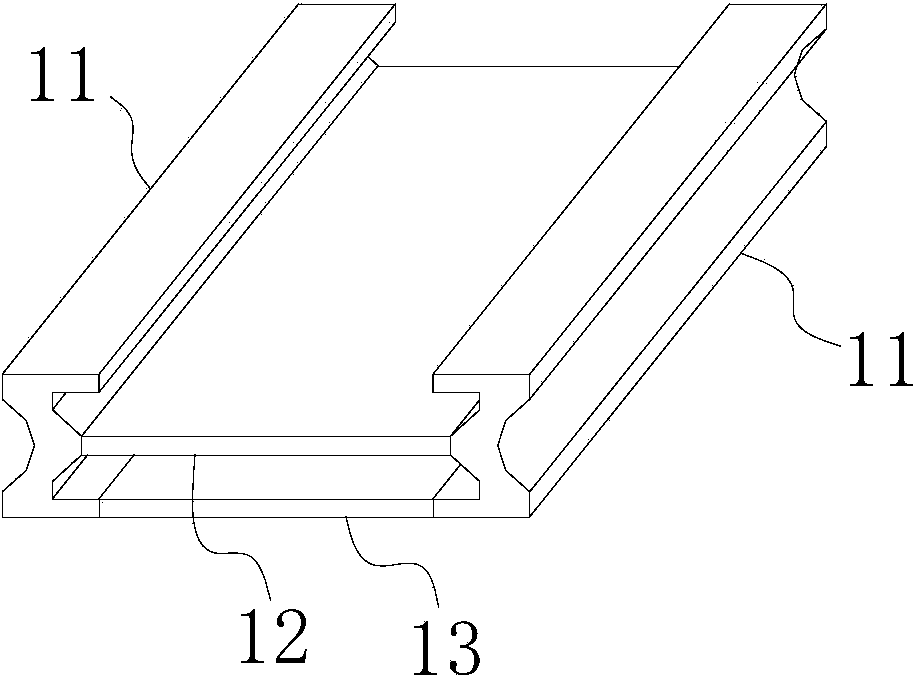

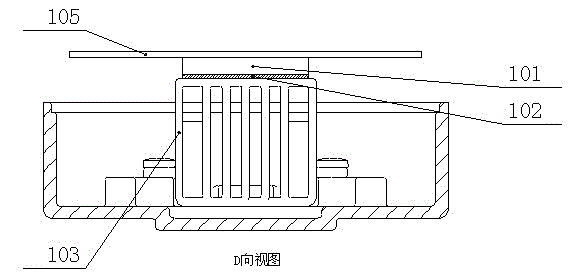

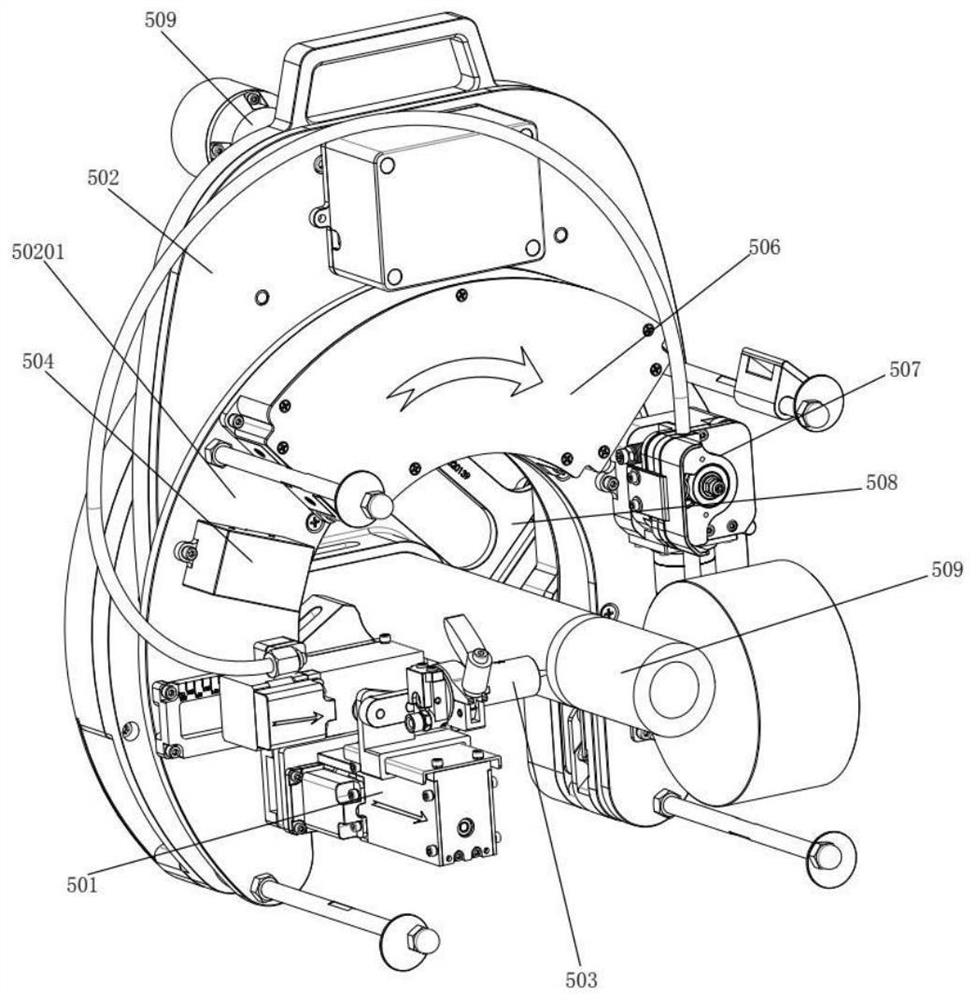

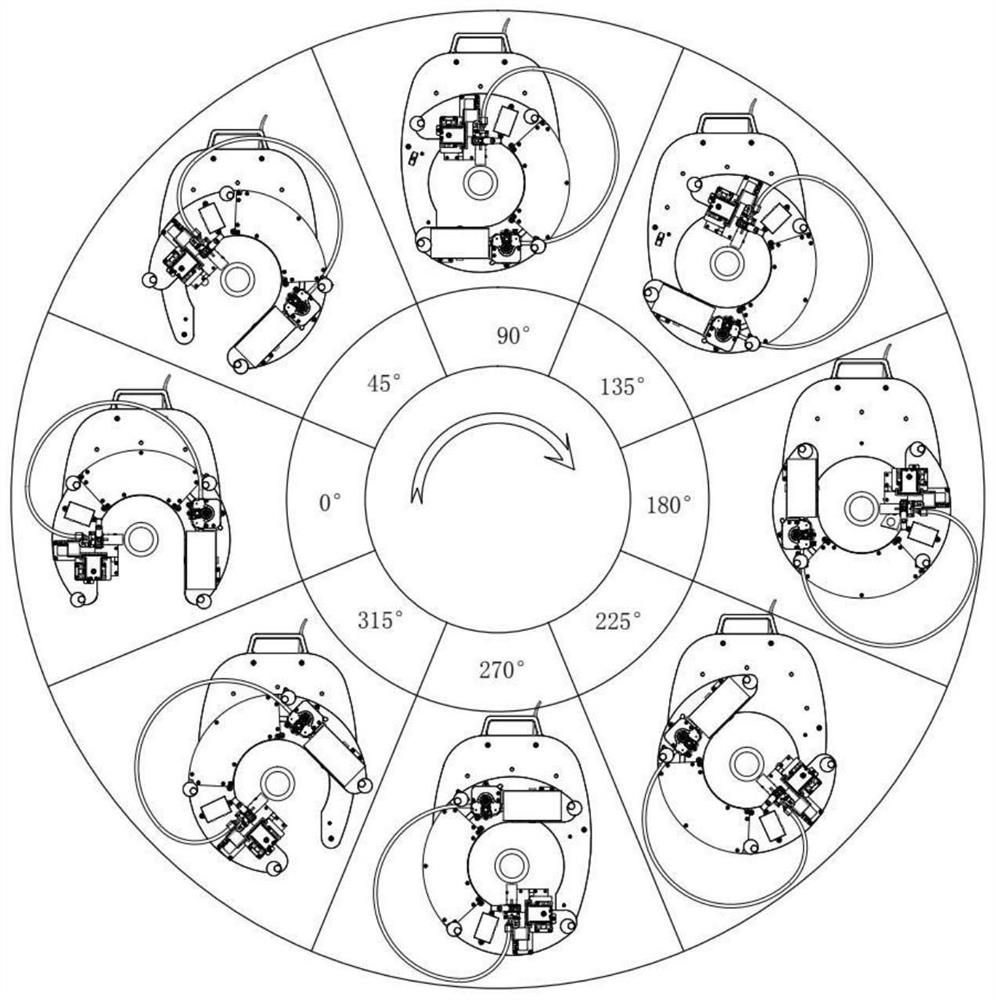

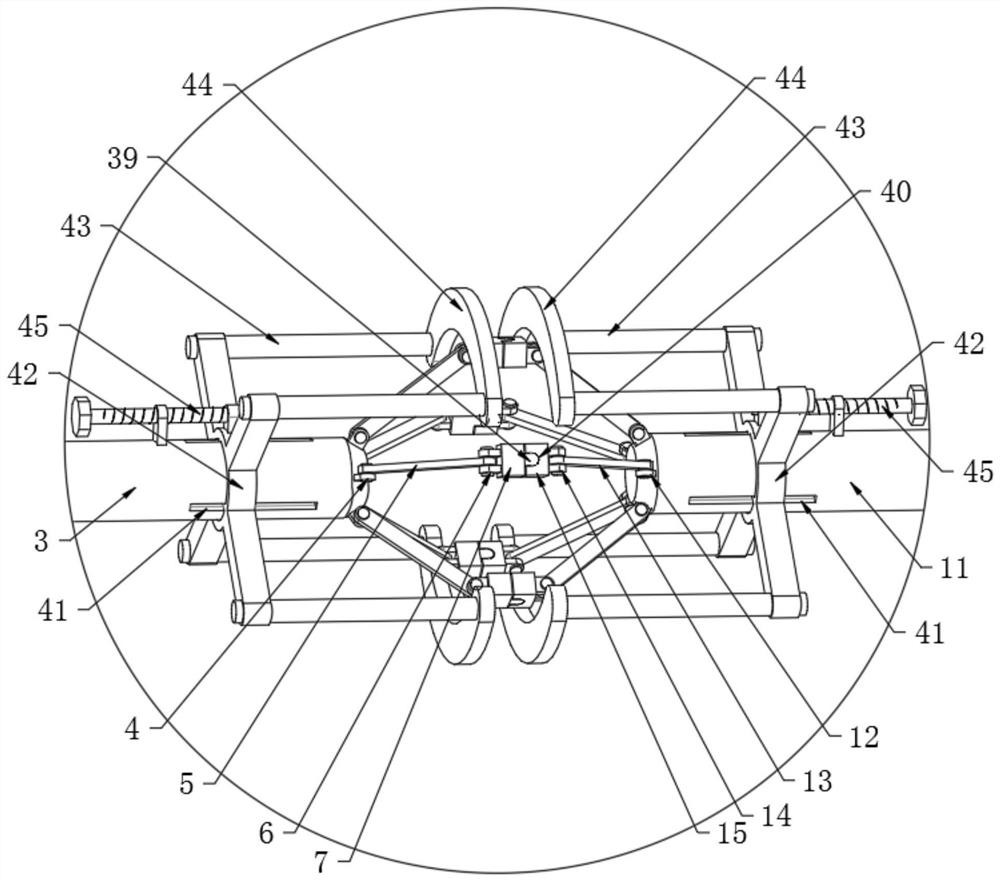

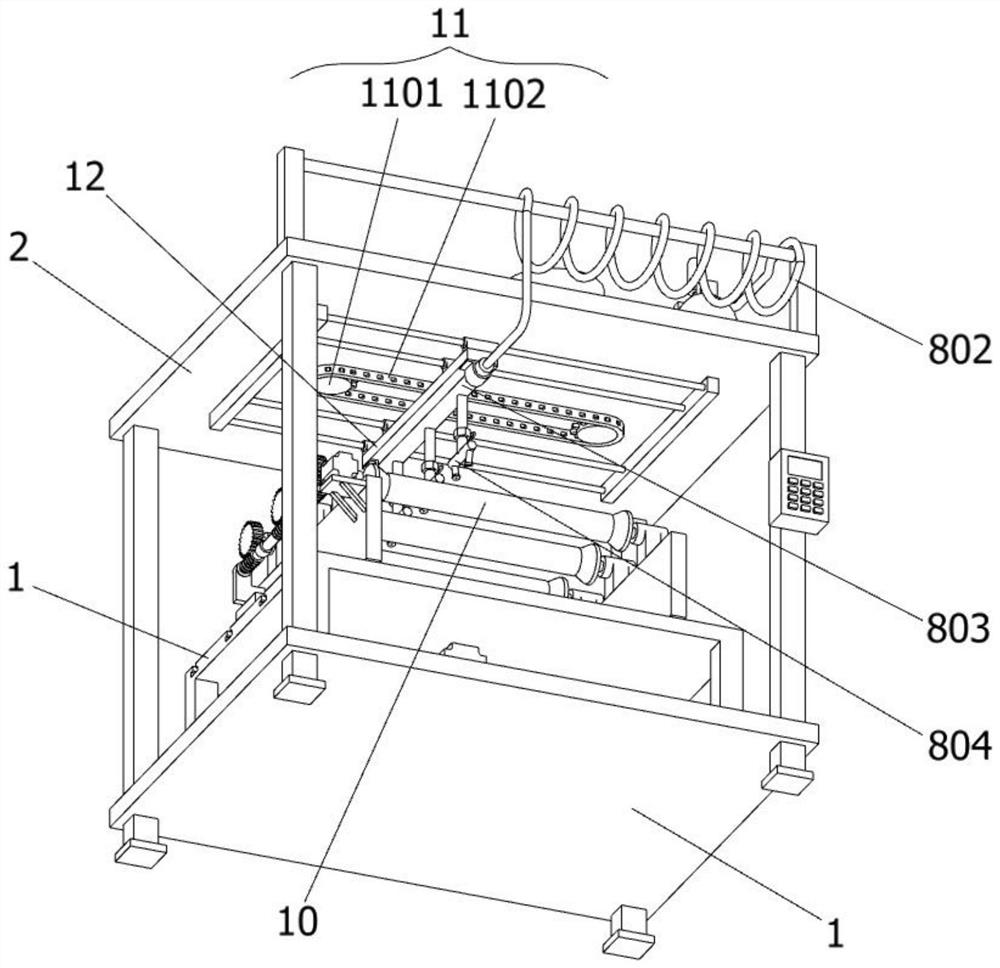

Welding system and welding method for all-position automatic welding of small-diameter pipeline

ActiveCN113385786AMeet the needs of high-quality and efficient production operationsGuarantee welding qualityWelding accessoriesPipe fittingPipe welding

The invention discloses a welding system and a welding method for all-position automatic welding of a small-diameter pipeline, and relates to the technical field of pipe welding. The welding system comprises a supporting main body with an opening, wherein a rotating disc and a clamp holder base are arranged on the supporting main body, and the rotating disc can rotate on the supporting main body; a welding gun is further arranged on the rotating disc; and a rapid clamping device is arranged on the clamp holder base and comprises clamping positioning angle blocks and clamping rotating blocks which are oppositely arranged around the rotating circle center of the rotating disc, and the clamping positioning angle blocks and the clamping rotating blocks can move relative to each other. The welding system can effectively meet the requirements of factory sites and other pipeline systems with small pipe diameters, high pipeline concentration, multiple pipeline turning points, multiple crossed positions and narrow construction space, and welding equipment is small in size and convenient to assemble and disassemble.

Owner:CHENGDU XIONGGU JIASHI ELECTRICAL

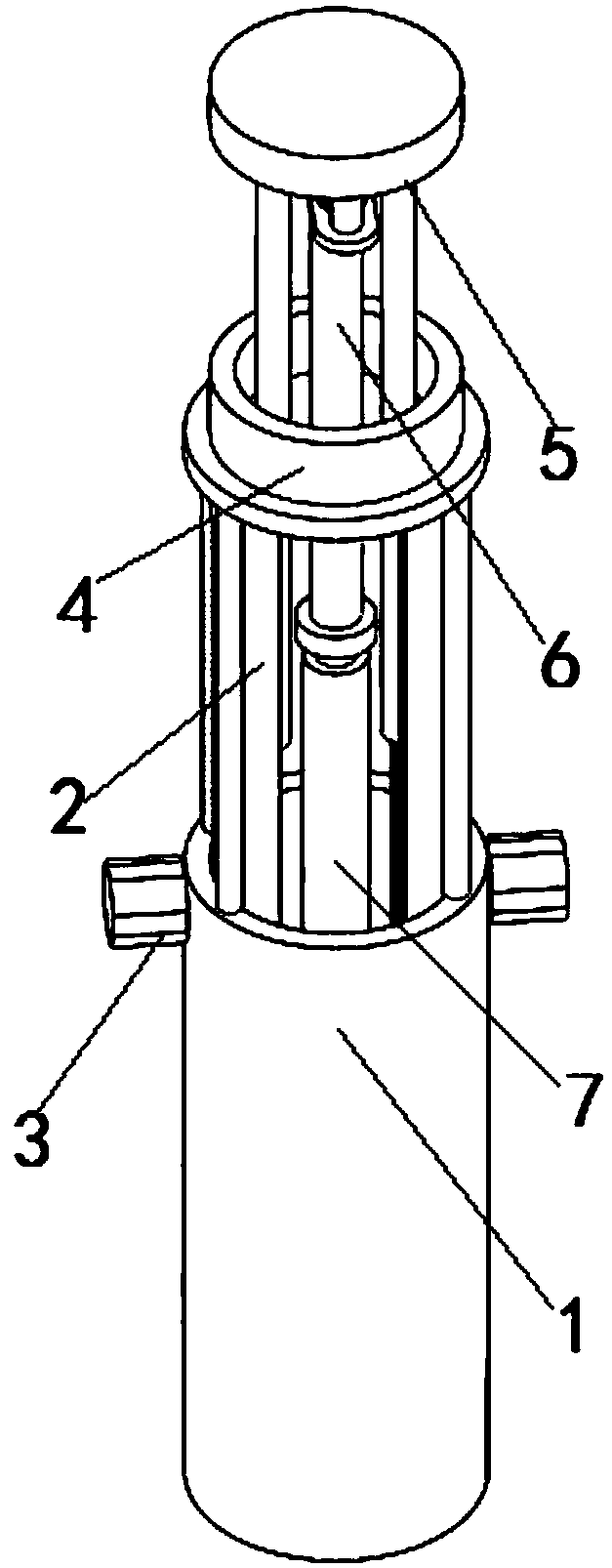

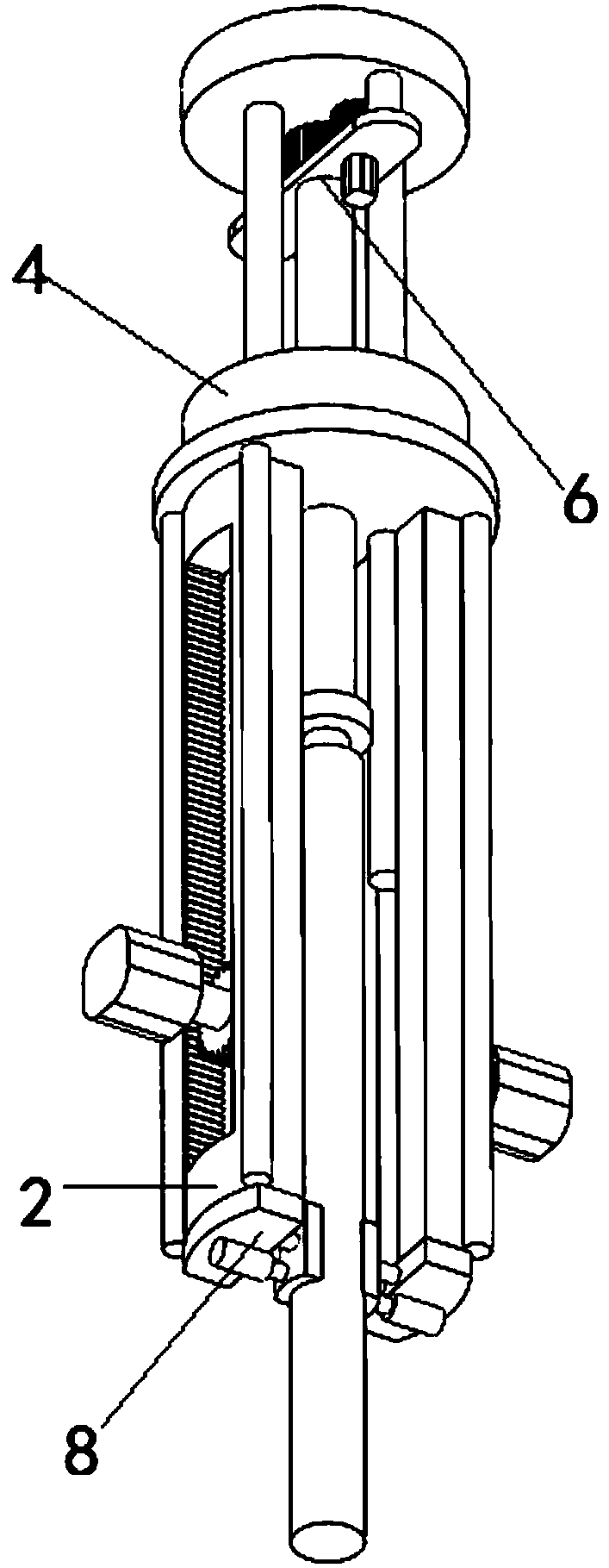

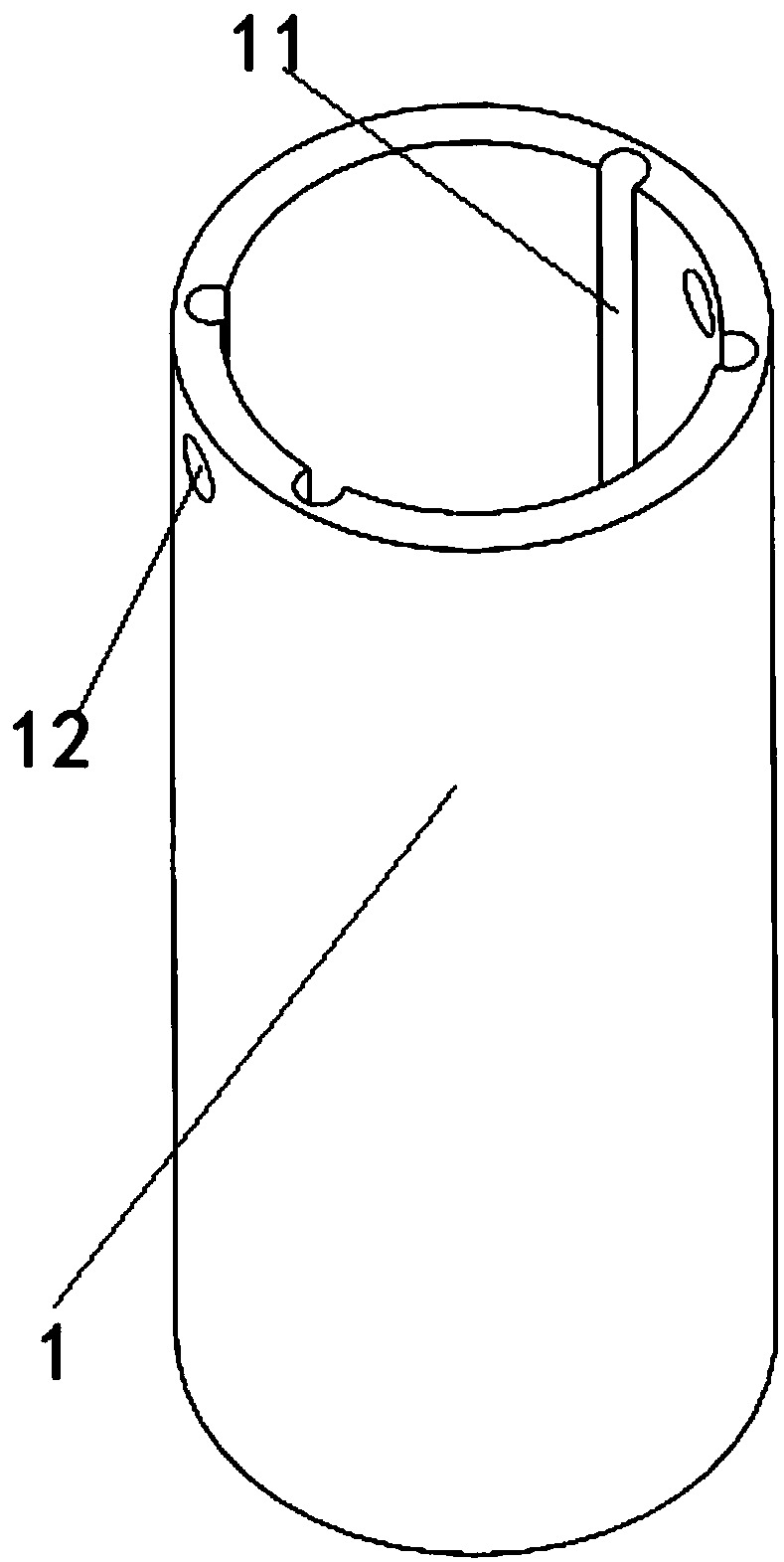

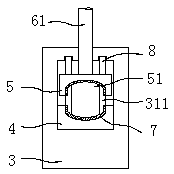

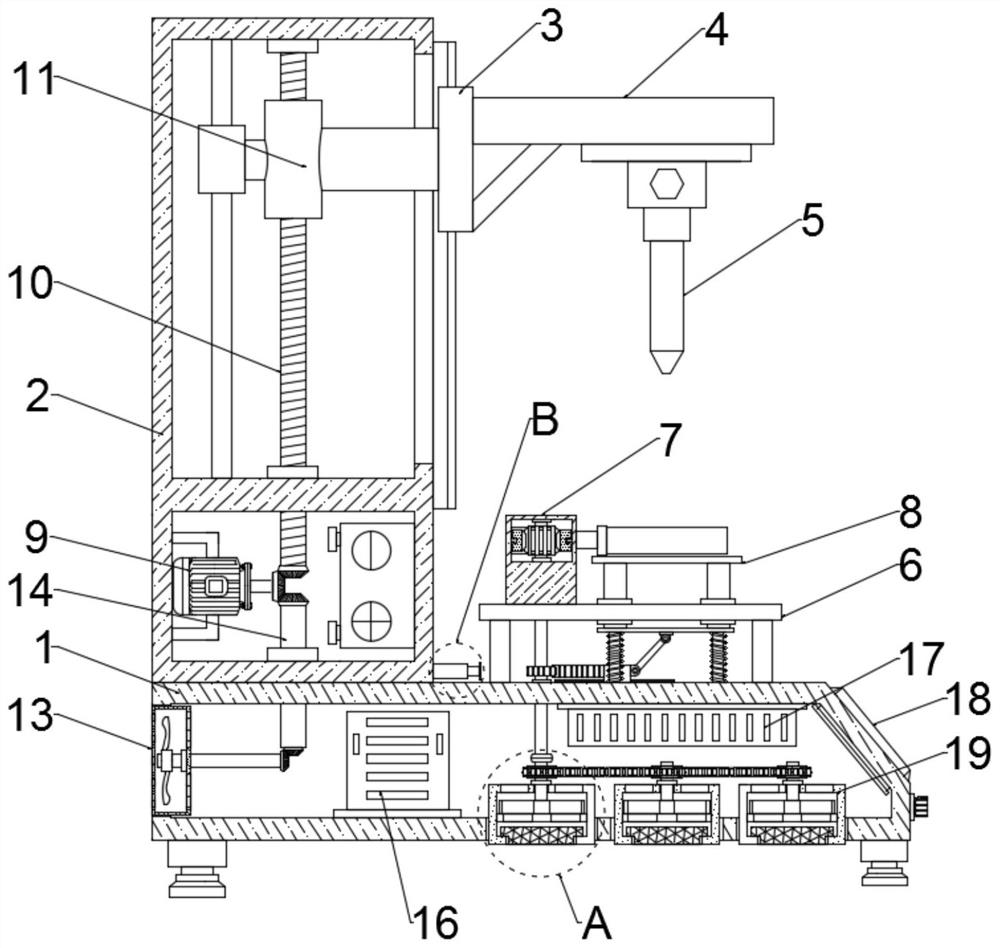

While-drilling casing directional drilling device for soft coal seam under coal mine

PendingCN108915593ARealize automatic liftingFast clamping and fixingDirectional drillingEngineeringDirectional drilling

The invention discloses a while-drilling casing directional drilling device for a soft coal seam under a coal mine. The while-drilling casing directional drilling device for the soft coal seam under the coal mine comprises a casing body. Two vertically distributed lifting vertical plates are symmetrically mounted on the inner side of the top of the casing body. Two gear driving mechanisms which are matched with the lifting vertical plates are symmetrically mounted on the outer side of the top of the casing body. A guide connecting seat is horizontally mounted on the tops of the two lifting vertical plates, and a bit pressure driving seat is mounted on the guide connecting seat. A drilling connection mechanism is vertically mounted at the center of the bottom of the bit drilling pressure driving seat, a drilling rod is connected to the bottom of the drilling connection mechanism, and a guide clamping mechanism is mounted at the bottoms of the lifting vertical plates. The while-drillingcasing directional drilling device for the soft coal seam under the coal mine can automatically apply force to the drilling rod, manpower is saved, meanwhile, different types of drilling rods can be replaced according to the sizes of drilled holes, and under the action of the guiding clamping mechanism, the good positioning guidance effect on the movement of the lower part of the drilling rod is achieved, and the situation that the drilling rod is oblique during drilling is avoided.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

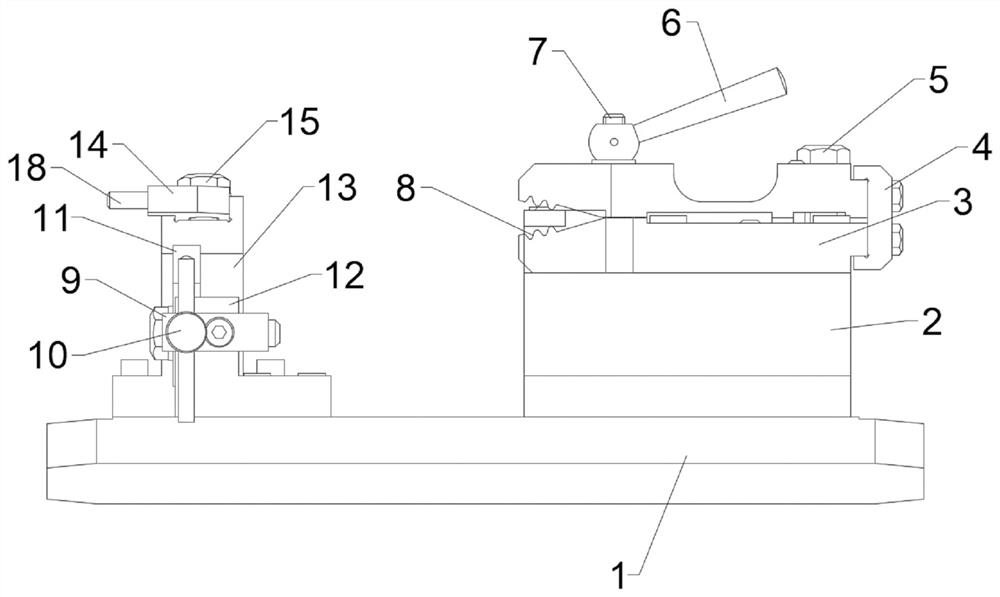

Fixing tool for turbine blade machining

The invention relates to a fixing tool for turbine blade machining, and belongs to the technical field of aero-engine manufacturing. The fixing tool comprises a bottom plate, a chuck, a transverse self-adaptive adjustment supporting assembly and a longitudinal self-adaptive adjustment supporting assembly; the chuck is used for clamping tenon teeth and is fixedly connected to one end of the bottomplate; the transverse self-adaptive adjustment supporting assembly is used for supporting the blade back of a blade, the transverse self-adaptive adjustment supporting assembly is fixedly connected toone side of the other end of the bottom plate, and the output end of the transverse self-adaptive adjustment supporting assembly abuts against the blade back; and the longitudinal self-adaptive adjustment supporting assembly is used for supporting the shroud of the blade, the longitudinal self-adaptive adjustment supporting assembly is fixedly connected to the other side of the other end of the bottom plate, and the output end of the longitudinal self-adaptive adjustment supporting assembly makes contact with the shroud. The fixing tool can well fix the turbine blade, the reliability of machining quality is improved, operation is convenient, and the labor intensity of an operator can be relieved.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Extruding device for mould welding

InactiveCN108971843AFast clamping and fixingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineering

The invention discloses an extruding device for mould welding. The extruding device comprises a base, a first clamping plate is fixedly mounted at the top of the base, a mounting seat slidably mountedat the top of the base is arranged on one side of the first clamping plate, and one side, close to the first clamping plate, of the mounting seat is provided with a mounting groove. One side, close to the first clamping plate, of the mounting seat is provided with a second clamping plate matched with the first clamping plate. Two transverse shafts are fixedly mounted on one side, away from the first clamping plate, of the second clamping plate. One end, away from the second clamping plate, of each transverse shaft extends into the mounting groove to enable fixed mounting of a retaining rod. Asame first vertical plate slidably sleeves outer sides of the two transverse shafts. The extruding device is simple in structure and capable of quickly clamping and fixing to-be-welded moulds, laborintensity of workers is relieved, operating efficiency in batch mould welding is improved, and the extruding device is beneficial for the workers to use.

Owner:柳州市钜嘉机械有限公司

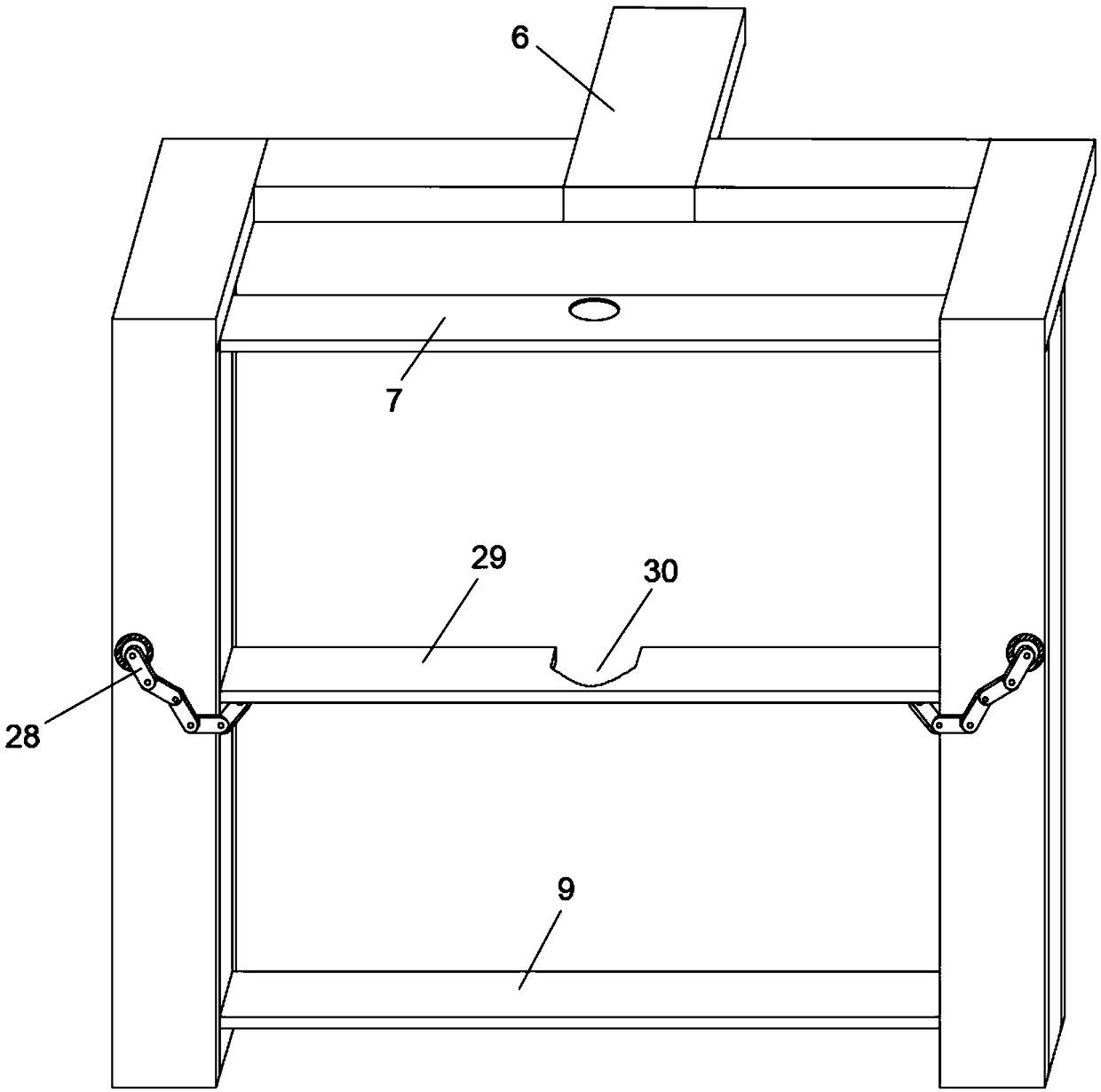

Environmental protection propaganda board facilitating propaganda paper replacement

The invention discloses an environmental protection propaganda board facilitating propaganda paper replacement. The environmental protection propaganda board comprises two main support plates and secondary support plates, the bottom ends of the main support plates and the bottom ends of the secondary support plates are welded to form two bearing frames, a cavity is formed between each main supportplate and the corresponding secondary support plate, a transmission assembly is arranged at the top ends of the two bearing frames, and a cover plate and a carrier plate are welded between the upperends and the lower ends of two bearing frames respectively. A transmission rod and a roller screw rod are electrically driven to rotate in situ, a display board is driven to move vertically with upright rods as the fulcrums through transmission between the roller screw rod and a roller nut, the display board also moves in the limited range of the bearing frames, sealed protection can be conveniently performed on the display board and propaganda paper through tempered glass, by rapidly clamping and fixing the propaganda paper on the display board, rapid detachment and installation are realized,direct contact with the outside is reduced, the installation stability of the propaganda paper is easily guranateed, then the service life of the propaganda paper is prolonged, and the propaganda board can be repeatedly used.

Owner:连云港凤凰传媒广告有限公司

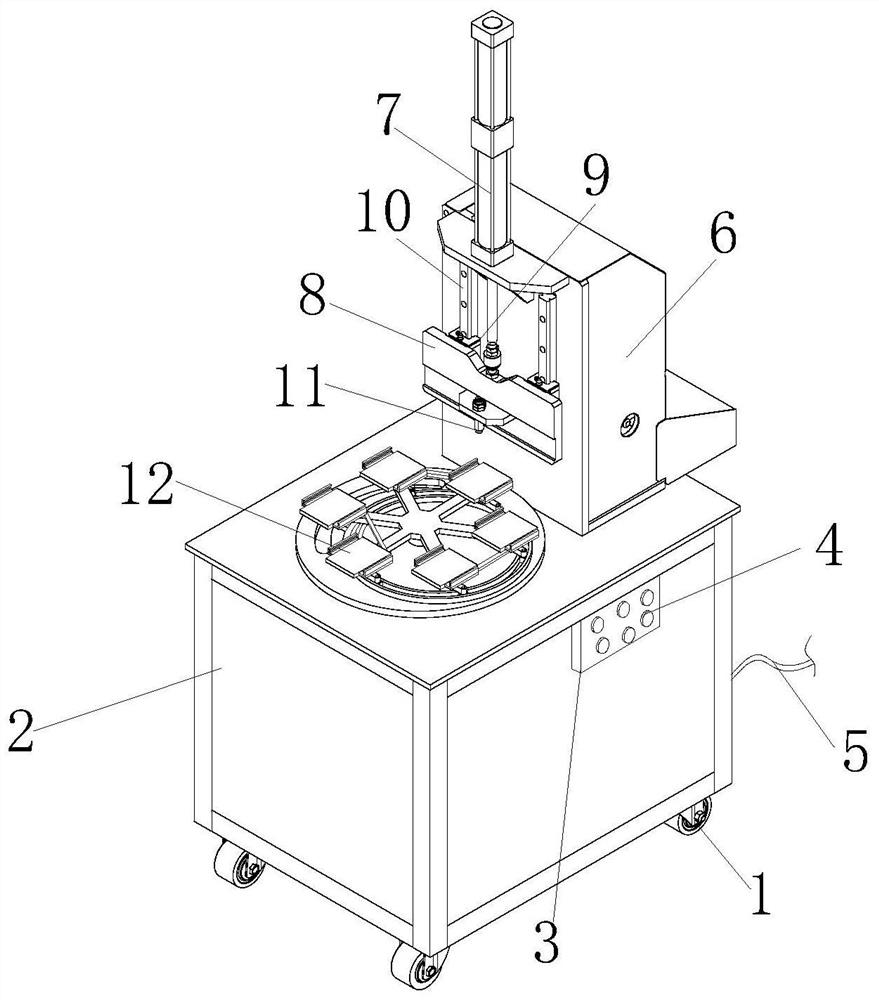

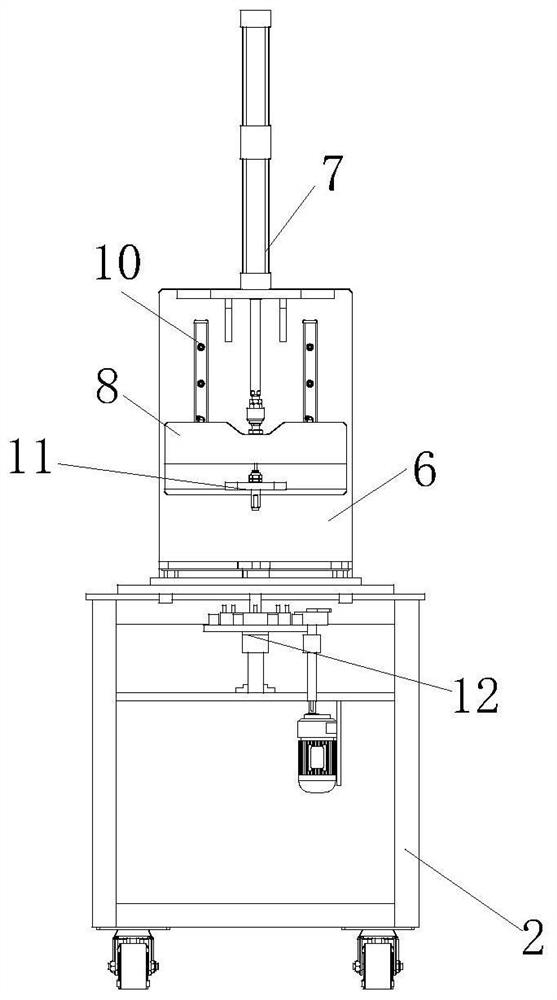

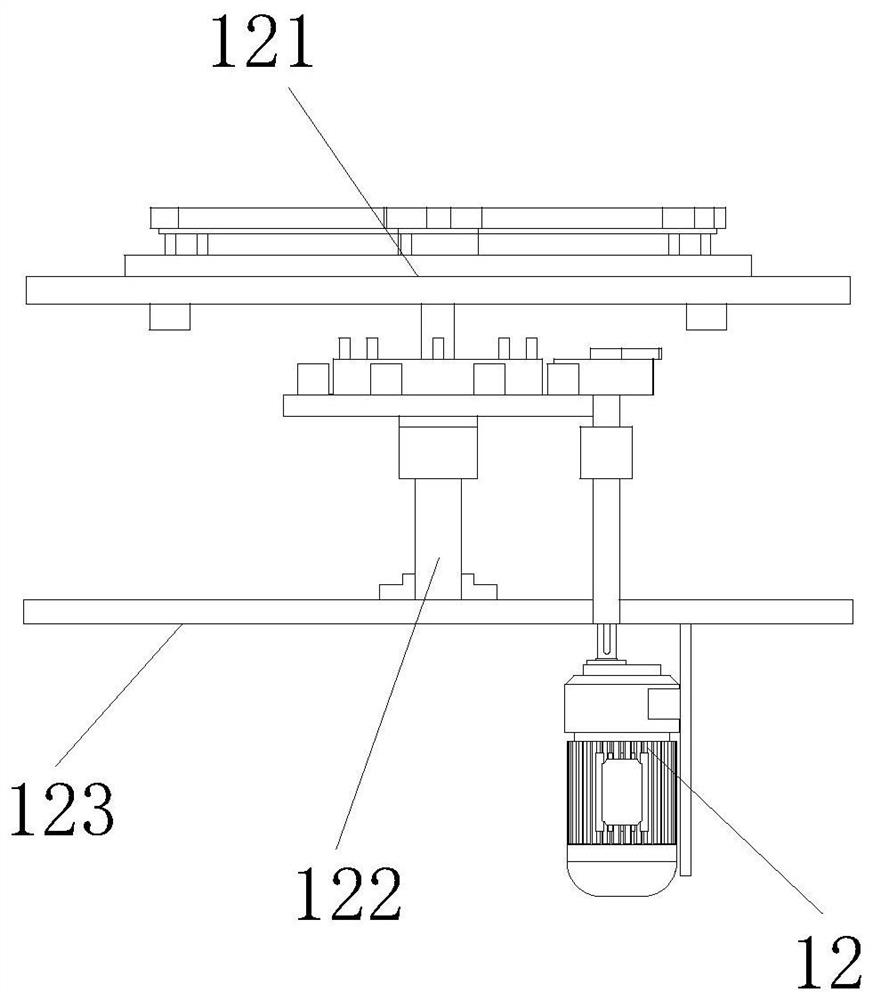

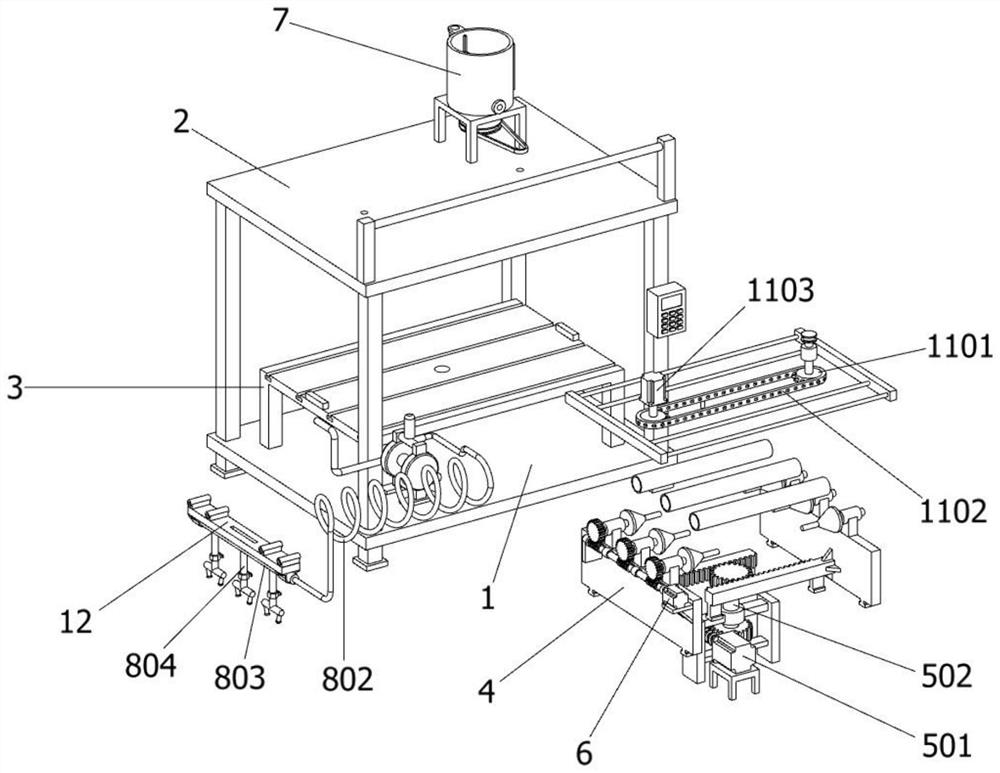

Efficient glue dispenser for producing LED electronic boards

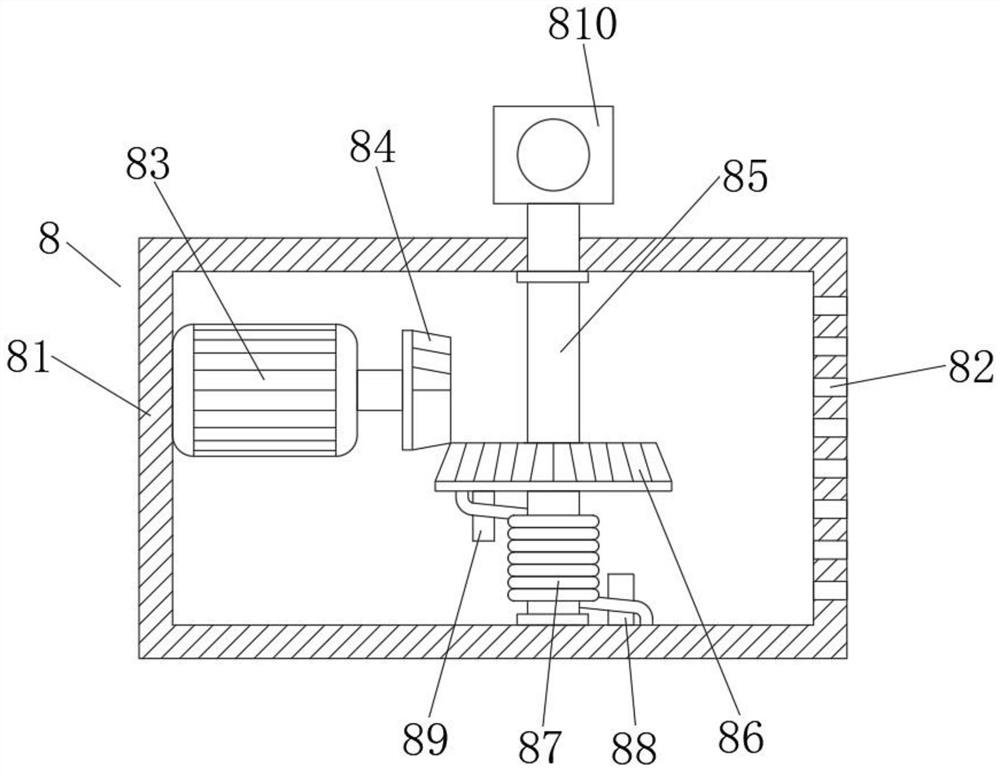

InactiveCN111672705AAchieve intermittent deliveryAchieve circular deliveryLiquid surface applicatorsCoatingsCircular discElectric machinery

The invention discloses an efficient glue dispenser for producing LED electronic boards. The efficient glue dispenser comprises a glue dispensing head and an intermittent circulating conveying mechanism. According to the efficient glue dispenser for producing the LED electronic boards, an intermittent rotating mechanism is arranged at the top of a fixed frame, a motor drives a rotating rod to rotate, then the rotating rod drives a pushing block to rotate through a disc, and after the pushing block rotates one circle, a second driving disc is driven by second convex shafts to rotate sixty degrees, so that the second driving disc drives a rotating block to move intermittently through a rotating shaft, and the advantage that the LED electronic boards can be intermittently conveyed is achieved; and through arranging a circulating rotating mechanism at the upper end of the intermittent rotating mechanism, the rotating block rotates to drive clamping plates to slide on the inner side of a sliding rail through sliding shafts, and the clamping plates are kept in a state parallel to a fixed plate all the time in the conveying process, so that the LED electronic boards are sequentially conveyed to a machining area to be machined, and the advantage that the LED electronic boards can be circularly conveyed is achieved.

Owner:惠安县辰杰科技有限公司

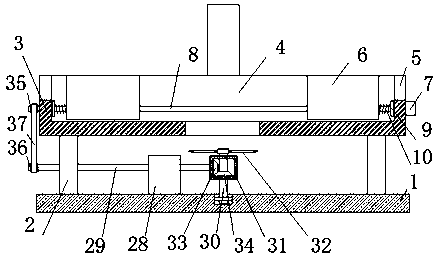

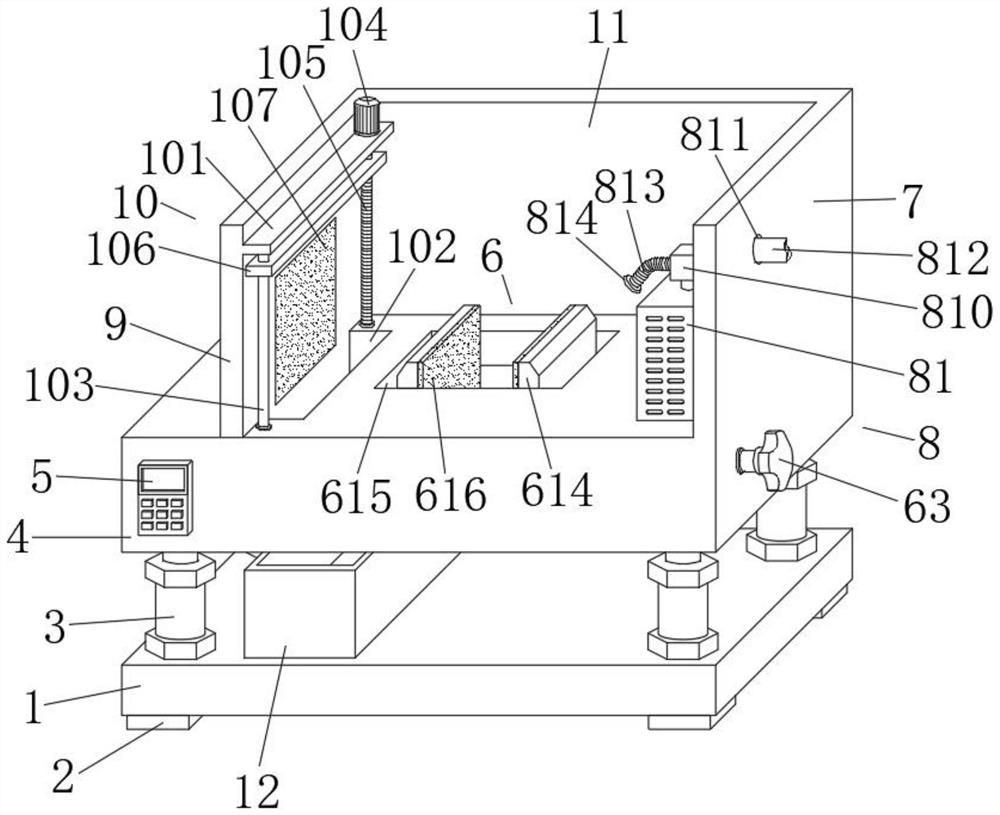

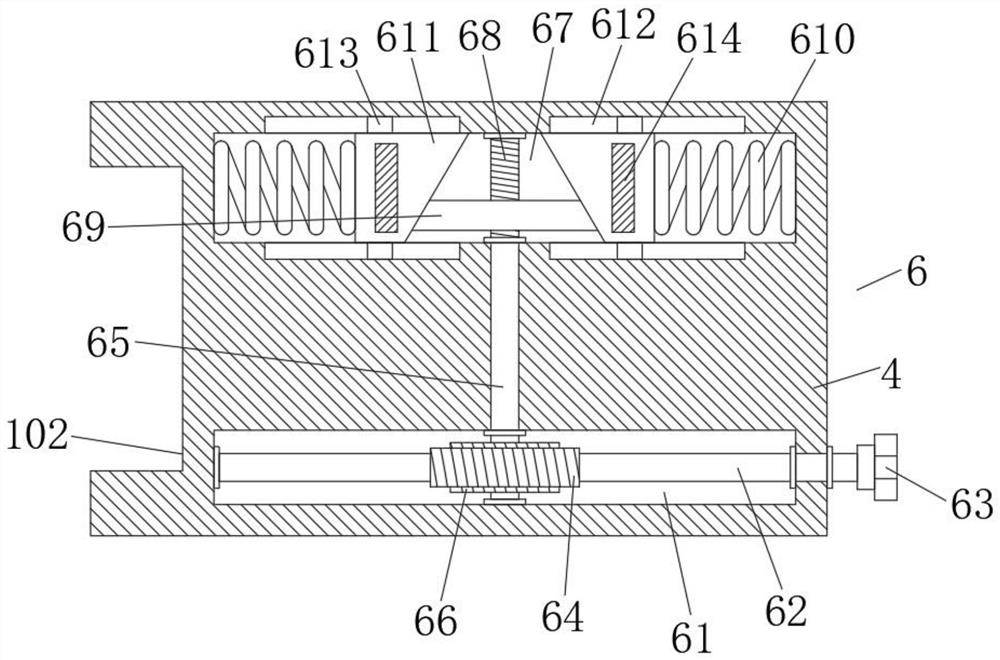

Flowmeter shell assembling device

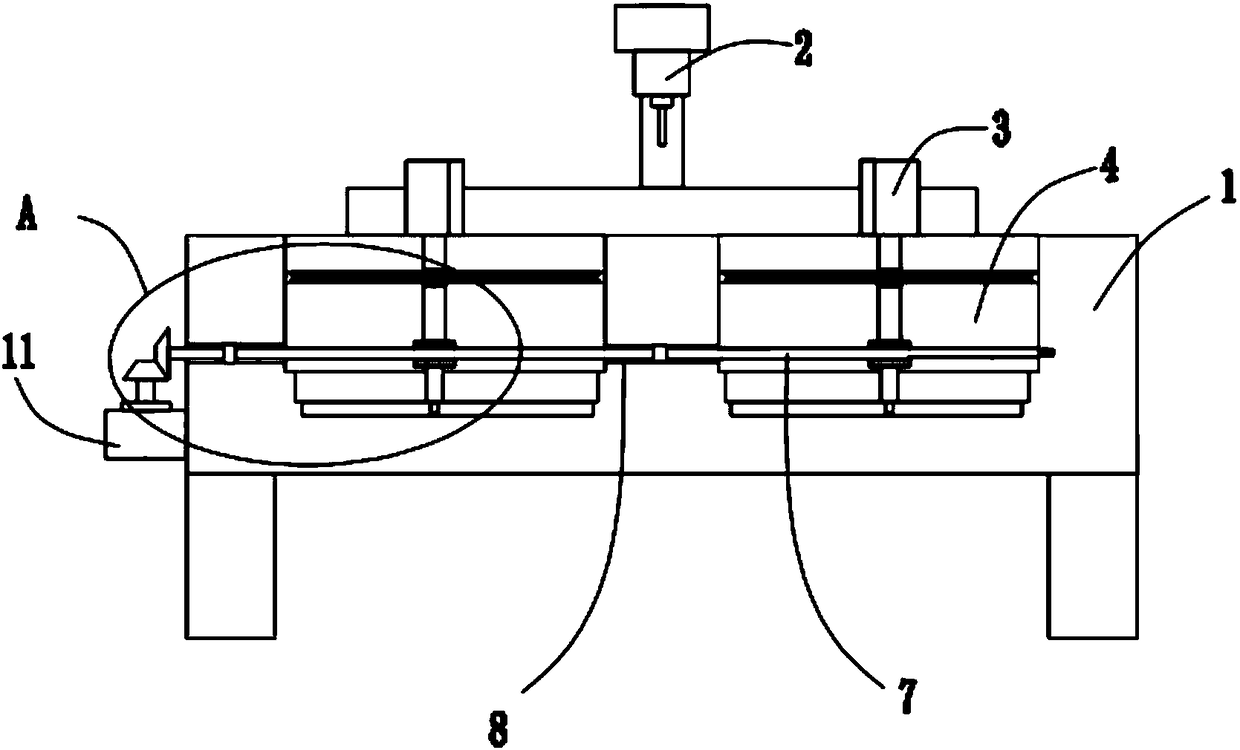

ActiveCN109822497ACooperate accuratelyOperations run synchronouslyWork holdersVolume meteringAgricultural engineeringScrew thread

The invention relates to the technical field of meter assembling and machining, and discloses a flowmeter shell assembling device. The flowmeter shell assembling device comprises a base, a supportingcolumn is fixedly arranged on the left side of the top of the base, a hanging plate is fixedly arranged at the top of the supporting column, a vertical plate is fixedly arranged at the right end of the hanging plate, a motor and a guide rail are fixedly arranged at the bottom of the base, the output end of the motor is fixedly provided with a threaded rod, the right end of the threaded rod is rotationally connected with the left side surface of the vertical plate through a bearing, a first belt wheel is connected to the outer circle surface of the threaded rod in a sleeving mode, a fixing plate is arranged on the threaded rod, and the middle part of the side surface of the fixing plate is in threaded connection with the threaded rod through a threaded sleeve. The flowmeter shell assemblingdevice solves the problems that the existing equipment for automatically assembling a flowmeter shell is complicated to operate, inconvenient to use and easy to skew in clamping a workpiece, so thatthreaded ends of two matching parts are not effectively installed, frequent disassembly and clamping are required, and the working efficiency is low.

Owner:安徽九星仪表壳体股份有限公司

Plate-shaped part polishing device for hardware tool processing and using method thereof

InactiveCN112296848AGuaranteed cleanlinessFast clamping and fixingGrinding carriagesPolishing machinesGas cylinderPolishing

The invention discloses a plate-shaped part polishing device for hardware tool processing and a using method thereof. The plate-shaped part polishing device comprises a bottom plate, wherein the fourcorners of the bottom of the bottom plate are fixedly connected to supporting cushions; the top of the bottom plate is fixedly connected to a placing frame; and the position, at one side of the placing frame, on the top of the bottom plate is equipped with a fixing mechanism. The plate-shaped part polishing device is compact in structure, is simple and convenient in operation and is high in practicability; the fixing mechanism can be arranged for quickly clamping and fixing the plate-shaped part to be processed, so that follow-up polishing operation is normally performed; meanwhile, a drive gas cylinder is arranged at one side of the fixing mechanism, and can be matched with a polishing mechanism capable of transversely moving, so that all-around polishing operation on the plate-shaped part to be processed can be achieved, and thus, a polishing range is greatly increased; beside, a cleaning mechanism can be arranged for cleaning the polished plate-shaped part, so that cleanliness of the processed plate-shaped part can be guaranteed, and follow-up processing can be avoided.

Owner:湖南精专自动化技术有限公司

Stabilizing device for steel plate welding

InactiveCN111451694AEasy to useEasy accessWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding process

The invention belongs to the technical field of steel plate welding and fixing equipment, and particularly relates to a stabilizing device for steel plate welding. The stabilizing device aims at solving the problems that when most of existing steel plates are welded, no good fixing device is used for fixing the steel plates, the steel plates are prone to position deviation in the welding process,and the steel plate welding error is large. According to the scheme, the stabilizing device comprises a base, wherein four symmetrically-arranged supporting legs are fixedly installed on the top of the base; the same operation table is fixedly installed on the top ends of the four supporting legs; a sliding groove is formed in the top of the operation table; through grooves are formed in the innerwalls of the two sides of the sliding groove; and two symmetrically-arranged moving plates are connected into the sliding groove in a sliding mode. The stabilizing device is easy to operate and convenient to use, two steel plates needing to be welded can be rapidly clamped and fixed, the steel plates can be stably welded, meanwhile, the welded steel plates can be rapidly cooled, and taking is convenient.

Owner:易明端

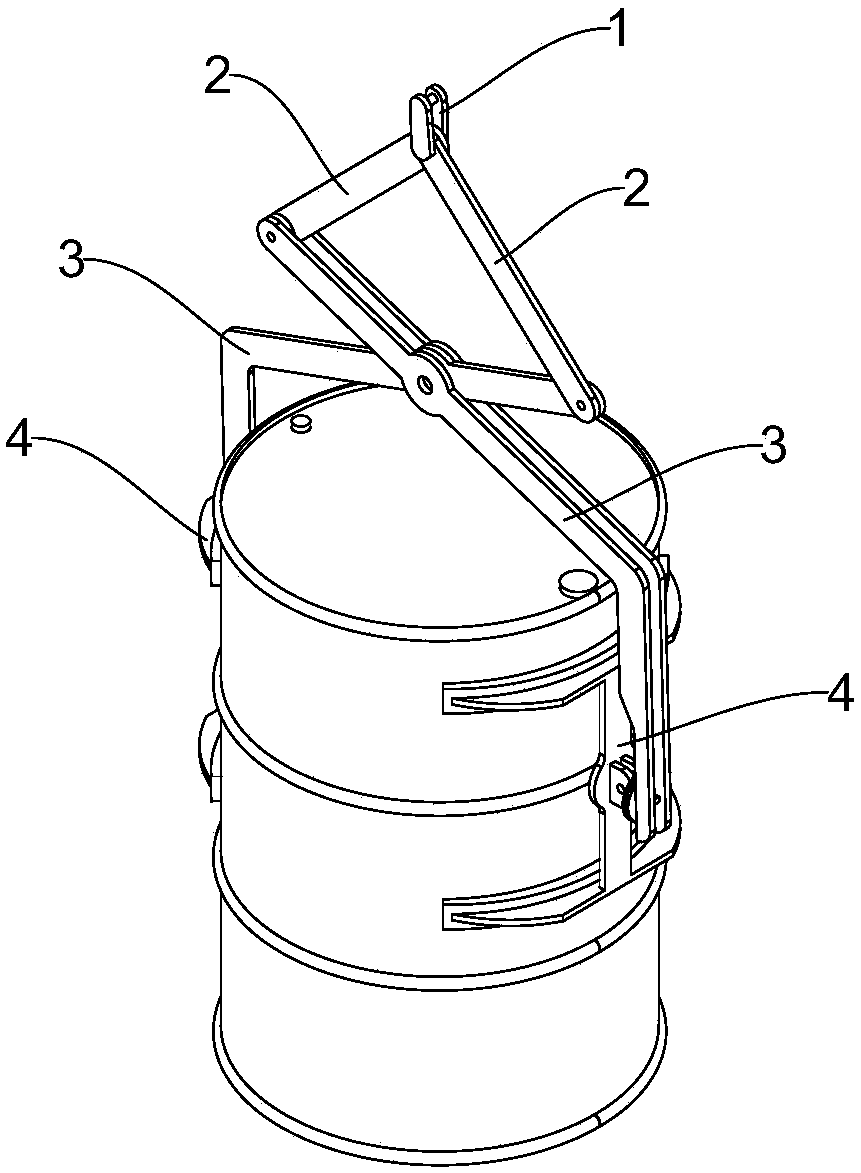

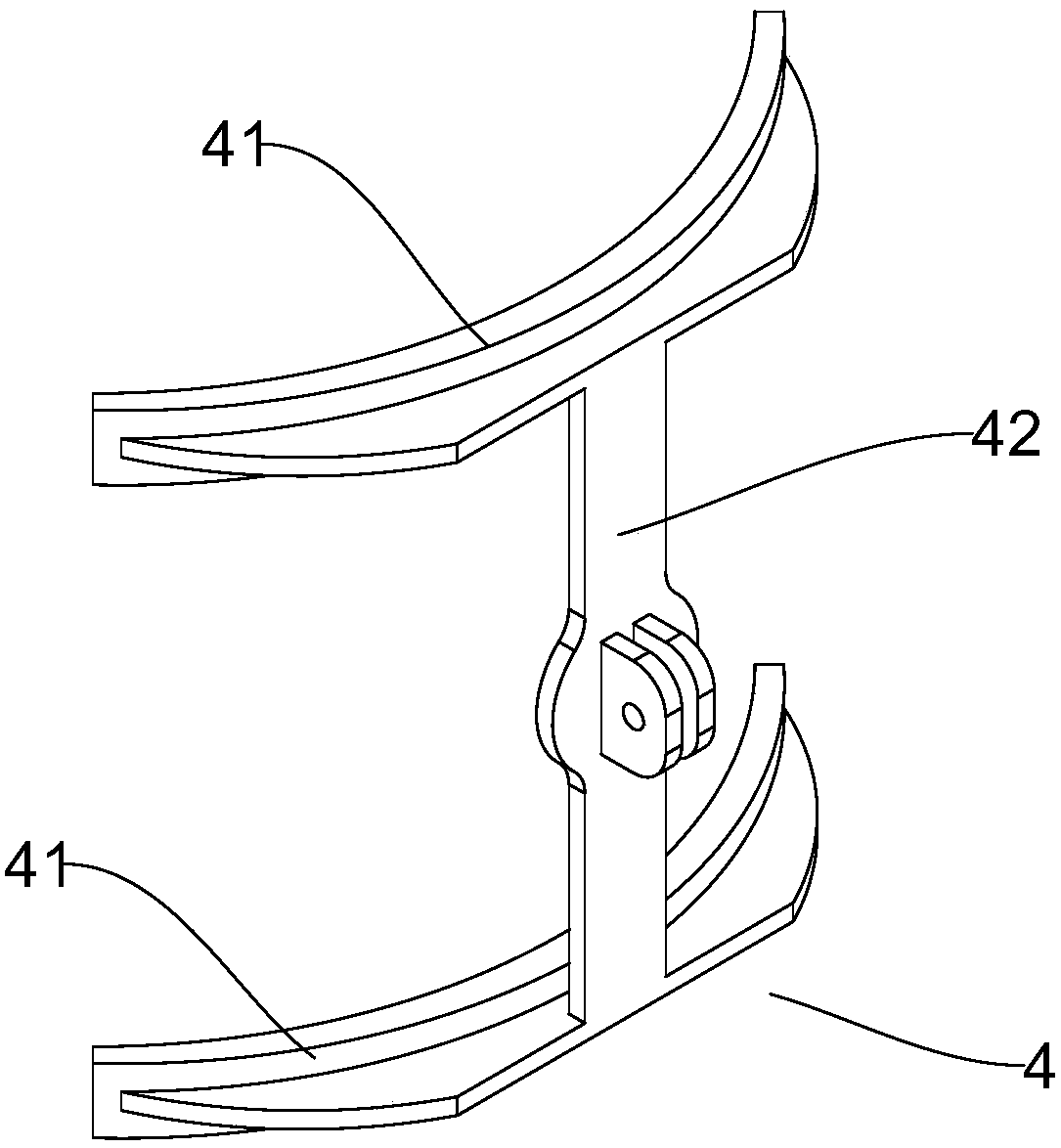

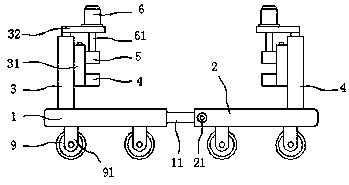

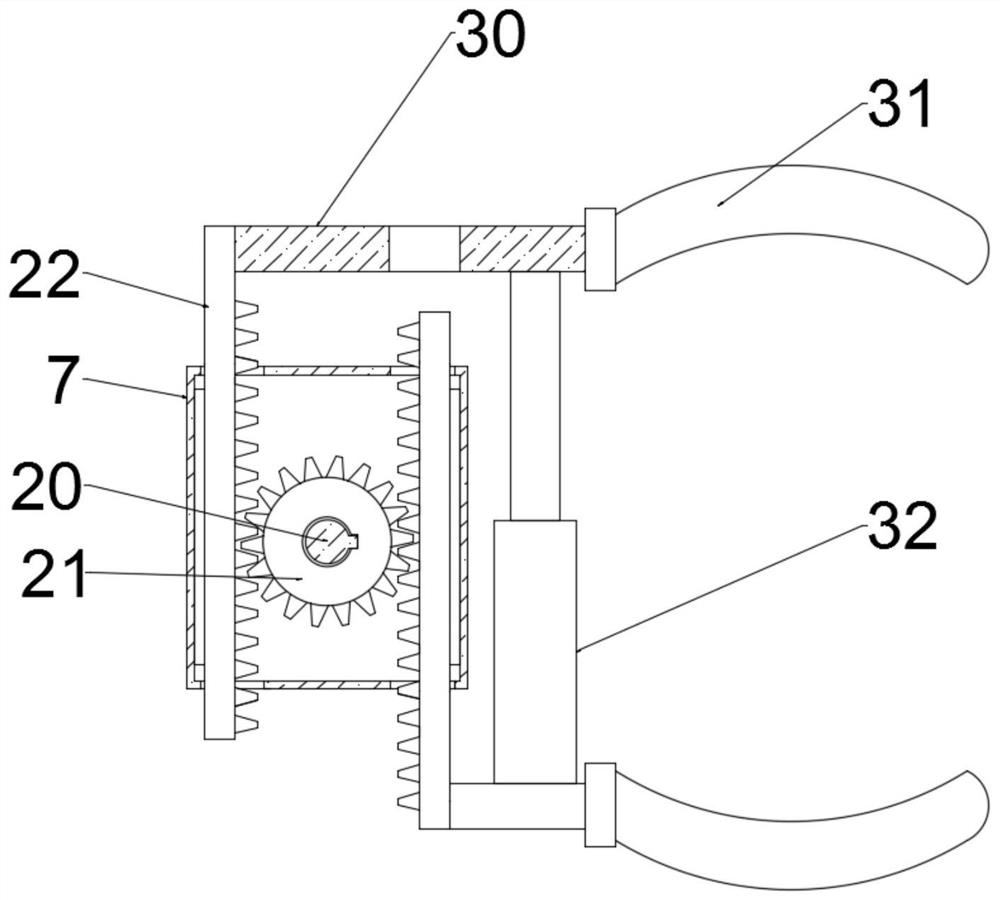

Clamper for transporting oil barrel

InactiveCN107640699AFast clamping and fixingStable clampingLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a clamper for transporting an oil barrel. The clamper comprises a lifting ring and two connection rods, wherein the lifting ring is connected to the upper ends of the connection rods, the clamper further comprises two clamping arms and two clamping parts, the two clamping arms respectively have a L-shaped structure, are mutually arranged in a cross manner, and are rotatablyconnected at the cross position through a pin column, the upper ends of the clamping arms are hinged to the lower ends of the connection rods, and the lower ends of the clamping arms are hinged to the clamping parts. According to the present invention, the clamper is provided with a pair of the connection rods 2 and a pair of the clamping arms arranged in the cross manner, such that the oil barrel can be automatically clamped during the lifting so as to achieve the rapid clamping purpose; and the I-shaped structure of the clamping part comprises the two arc-shaped clamping plates, and the twoarc-shaped clamping plates can be snapped below the annular projection of the oil barrel, such that the clamping is firm, and the use is safe and reliable.

Owner:潘素云

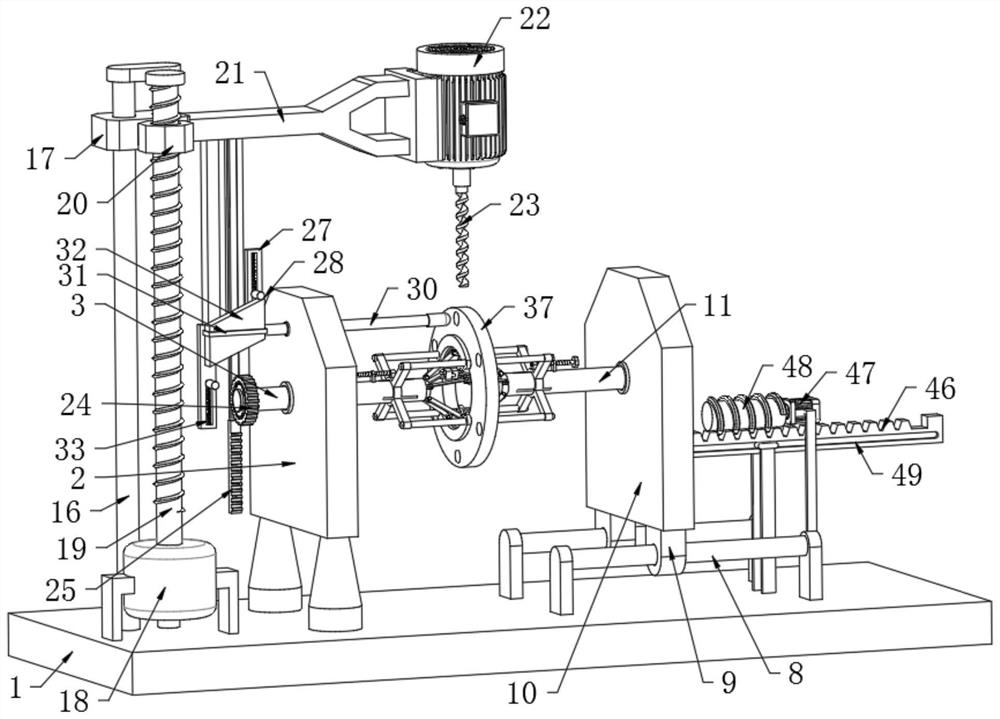

Drilling clamp for multi-spindle drilling machine

ActiveCN112975464AFast clamping and fixingImprove processing efficiencyFeeding apparatusPositioning apparatusPhysicsElectric machinery

The invention discloses a drilling clamp for a multi-spindle drilling machine, and relates to the technical field of multi-spindle drilling machine clamps. The drilling clamp for the multi-spindle drilling machine comprises a base, a first supporting plate is fixedly connected to the left portion of the upper end face of the base through supporting legs, a first rotating shaft is rotatably connected to the right end face of the first supporting plate in a penetrating mode, first supporting rods are rotatably connected to the right portion of the outer surface wall of the first rotating shaft at equal intervals through the circumference of first convex lugs, the left portion of the upper end face of the base is fixedly connected with a first driving motor through a fixing frame, the first driving motor is coaxially and fixedly connected with a lead screw through an output shaft, the exterior of the lead screw is in threaded connection with a threaded sleeve block, the rear end face of the threaded sleeve block is fixedly connected to the front end face of a supporting table, and the right end face of the supporting table is fixedly connected with a Y-shaped plate. According to the drilling clamp, circular ring disc parts with different diameter sizes can be rapidly positioned and clamped, time and labor are saved, the machining efficiency is improved, the outer side walls of the circular ring disc parts can be drilled, the drilling positions can be automatically adjusted, and the machining efficiency is improved.

Owner:杭州佳克威机械制造有限公司

Clamp for detecting PCB

InactiveCN111537866AFast deliveryFast clamping and fixingPrinted circuit testingMeasurement instrument housingGear wheelFixed frame

The invention discloses a clamp for PCB detection. The clamp comprises supporting legs, a fixed frame, a first air cylinder, a pressing plate, a fixing groove and a pushing turnover mechanism. According to the invention, a moving mechanism is arranged in the fixed frame; a motor drives a swing rod to swing on the inner side of a sliding groove through a positioning shaft, so that the positioningshaft drives a sliding plate to move towards the left end through a sliding rod; the sliding plate drives the PCB to be located at the bottom of a detection head through a sliding frame for detection,and the advantage that the PCB can be rapidly conveyed to a detection area is achieved; a rack linkage mechanism is arranged in a connecting frame; a second air cylinder extends towards the front end; a rack is driven by a connecting piece to move towards the inner side of a guide rail, so that the rack drives a rotating shaft to rotate through a gear; the PCB at the upper end of a clamping jaw mechanism is driven to turn over, and the advantage that the PCB can be turned over quickly is achieved.

Owner:龙岩市远尚工贸有限公司

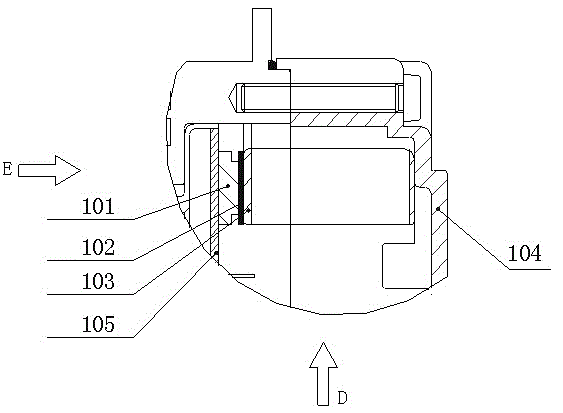

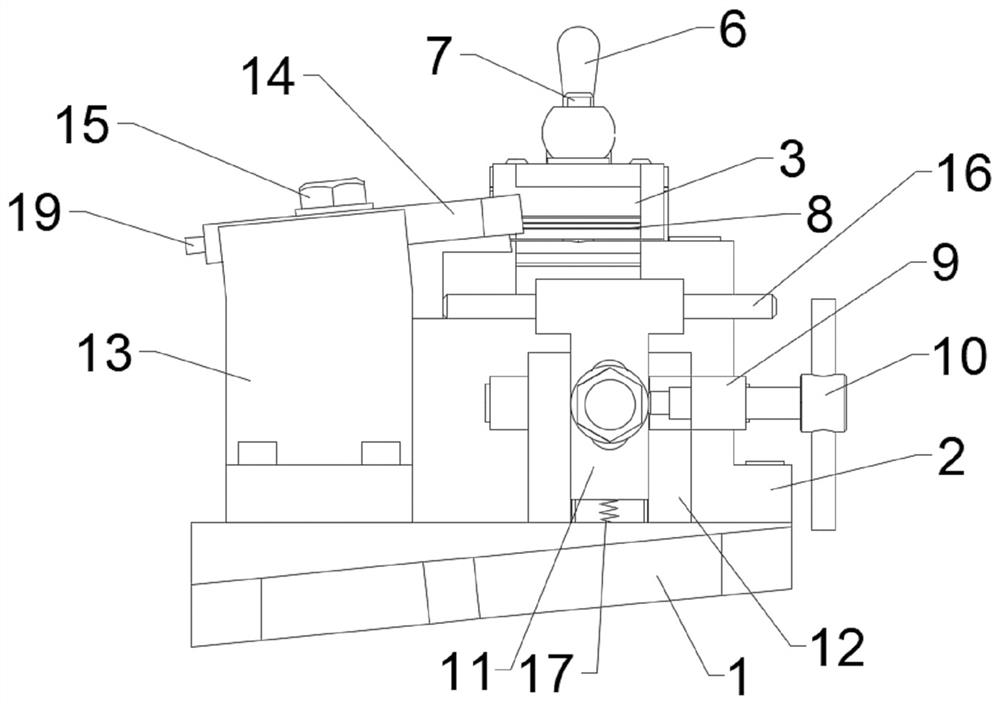

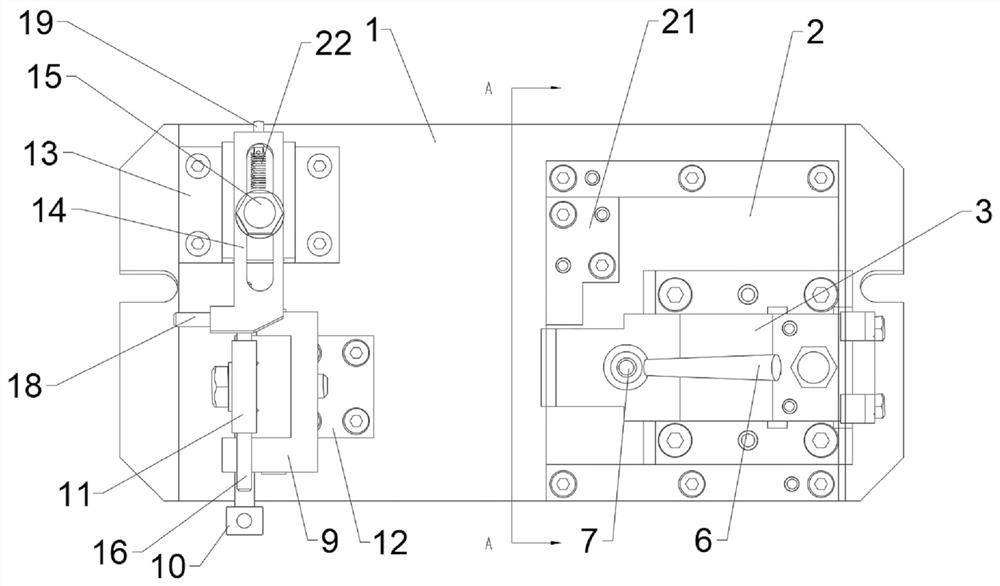

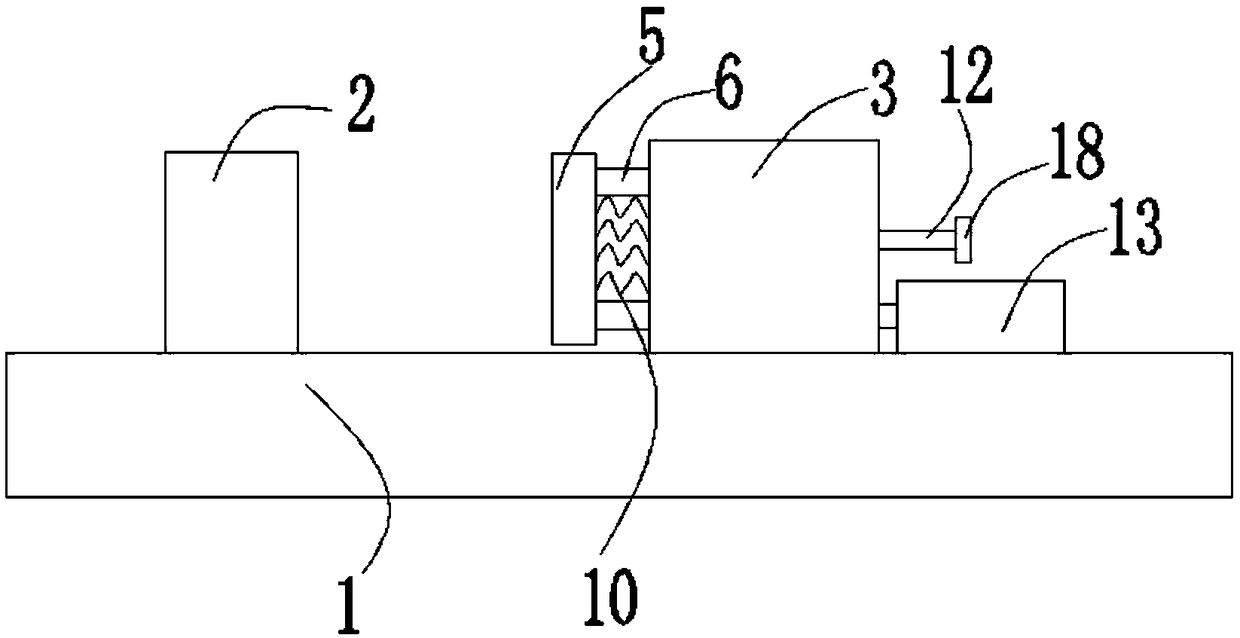

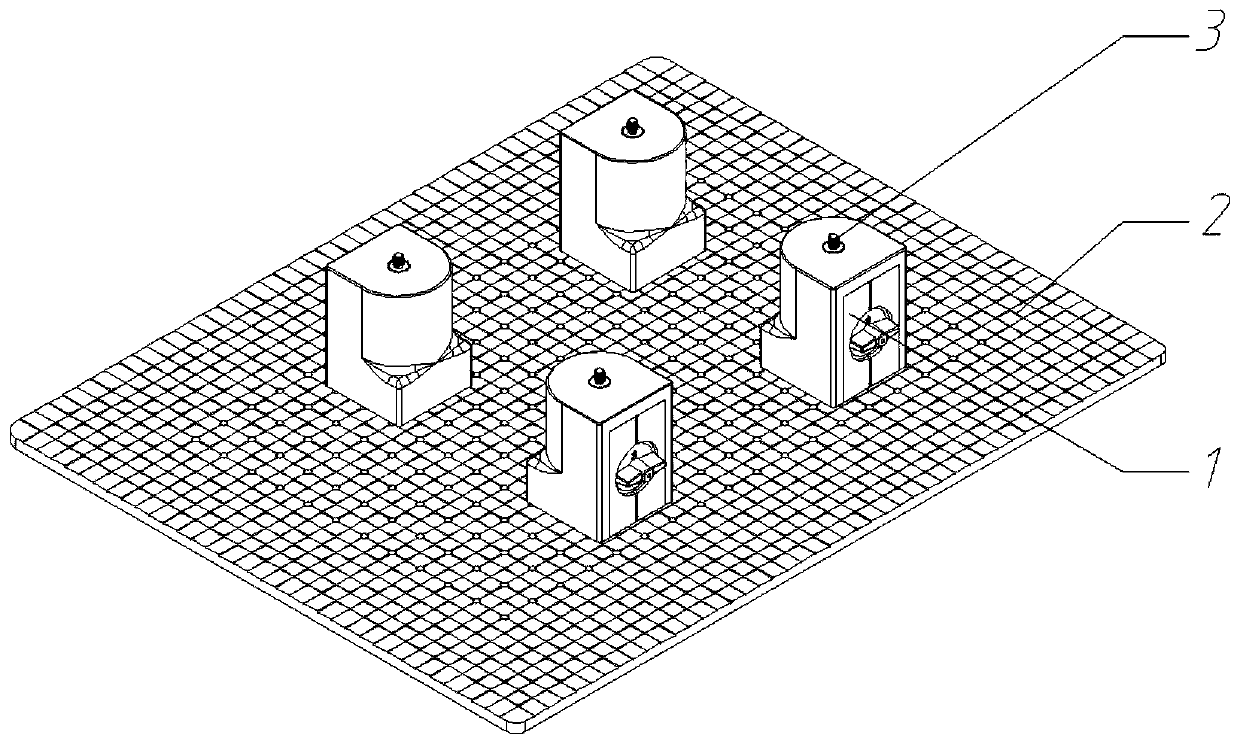

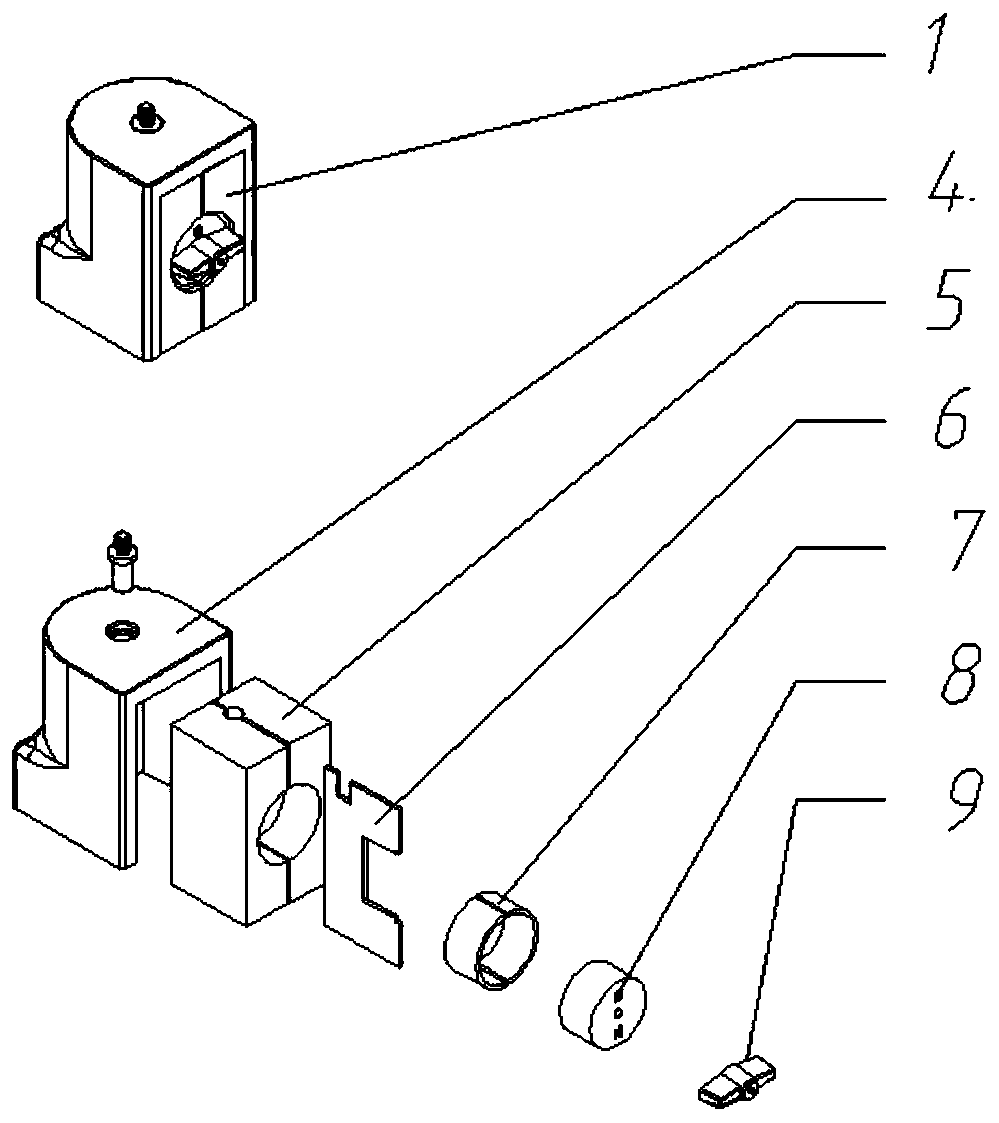

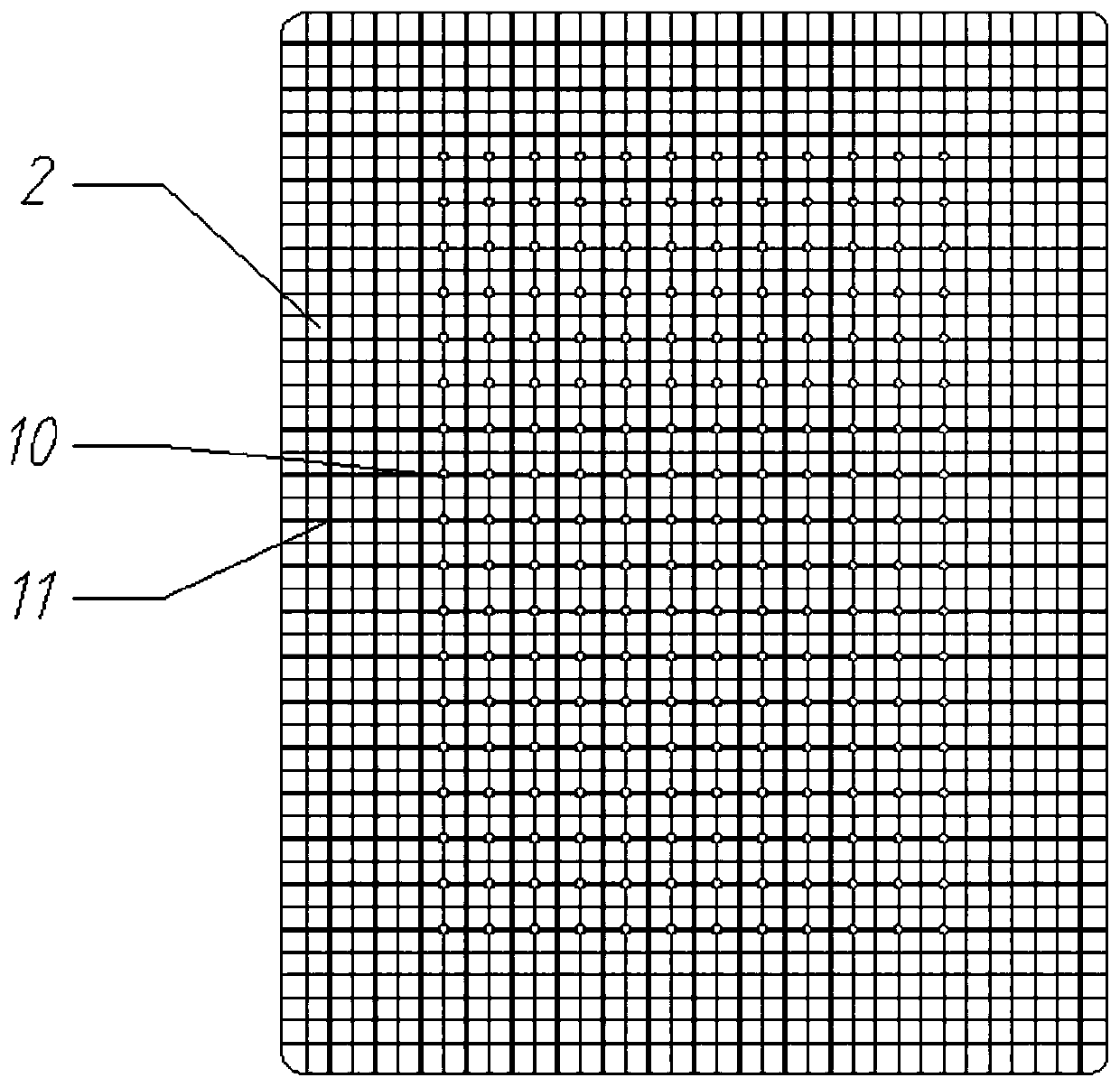

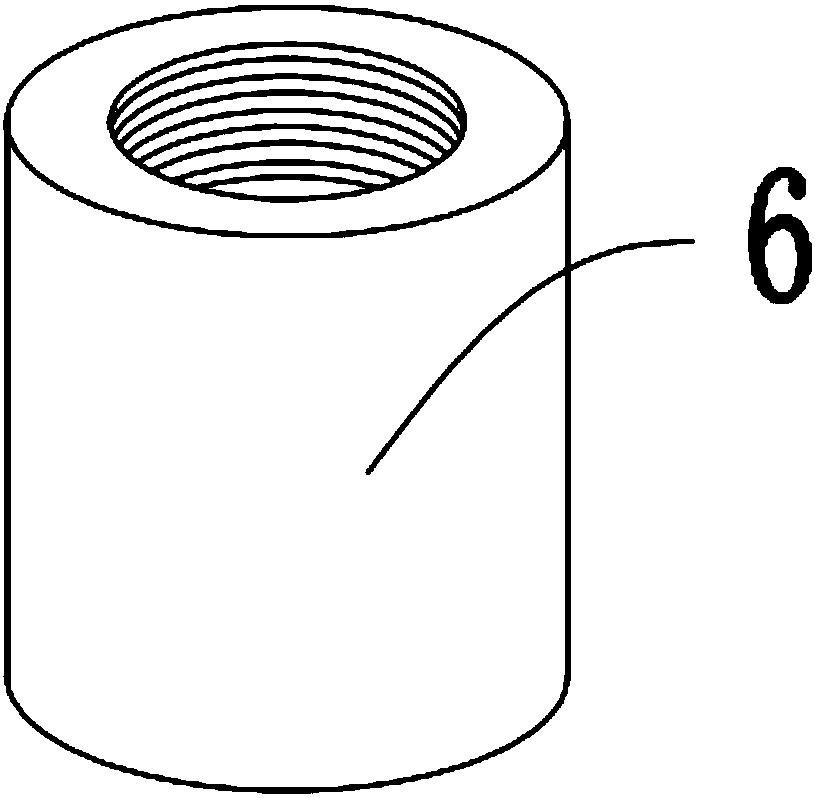

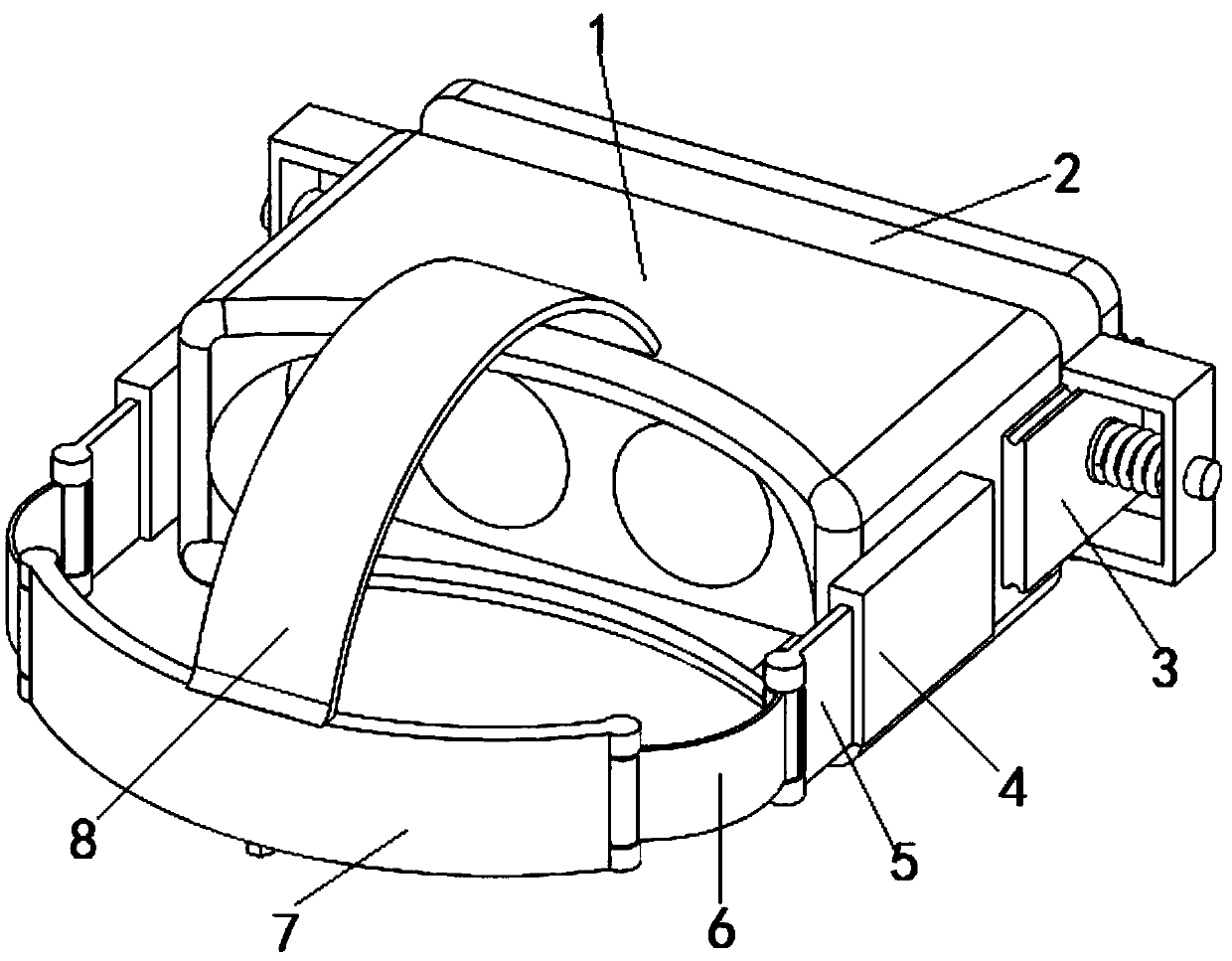

Magnetic-force-based rapid clamping device for measuring shell parts

InactiveCN109708601AFast clamping and fixingStrong specificityMeasurement devicesWork holdersMagnetic tension forceMachining

The invention, which belongs to the field of mechanical processing inspection, in particular relates to a magnetic-force-based rapid clamping device for measuring shell parts. The device comprises magnetic seats (1), a positioning substrate (2) and magnetic connecting heads (3). The magnetic seats (1) serve as a core and are installed on the positioning substrate (2). The corresponding magnetic connecting heads (3) are selected based on fixed screw hole sizes of parts. The magnetic connecting heads (3) are fixed with and in threaded connection with threaded holes formed in the bottom surfacesof the parts and, together with the magnetic seats, are installed on the magnetic seats (1). Circular tenons of the magnetic connecting heads (3) are inserted into fixed holes of the magnetic seats (1). Compared with the current part fixing modes, the provided magnetic-force-based rapid clamping device is able to realize rapid clamping and fixation of shell type and valve type parts with mountingthreaded holes; and the specificity and pertinence are high. Therefore, the operation is simplified and reliability is improved. After proper adjustment of different series of parts, the provided device has the high adaptability and good generalization performance.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC

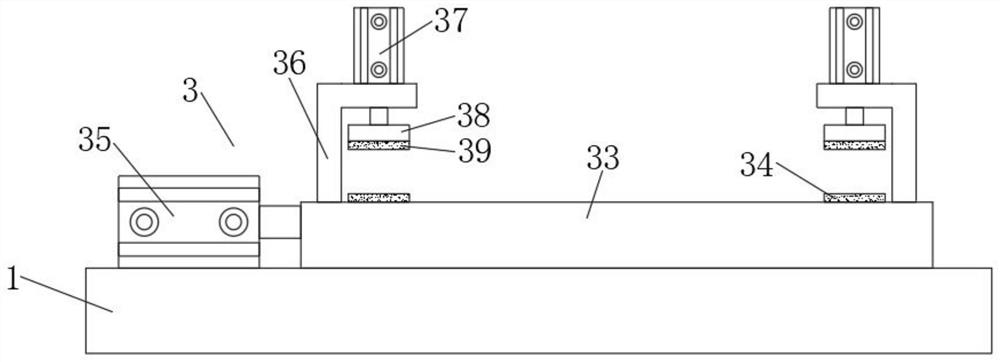

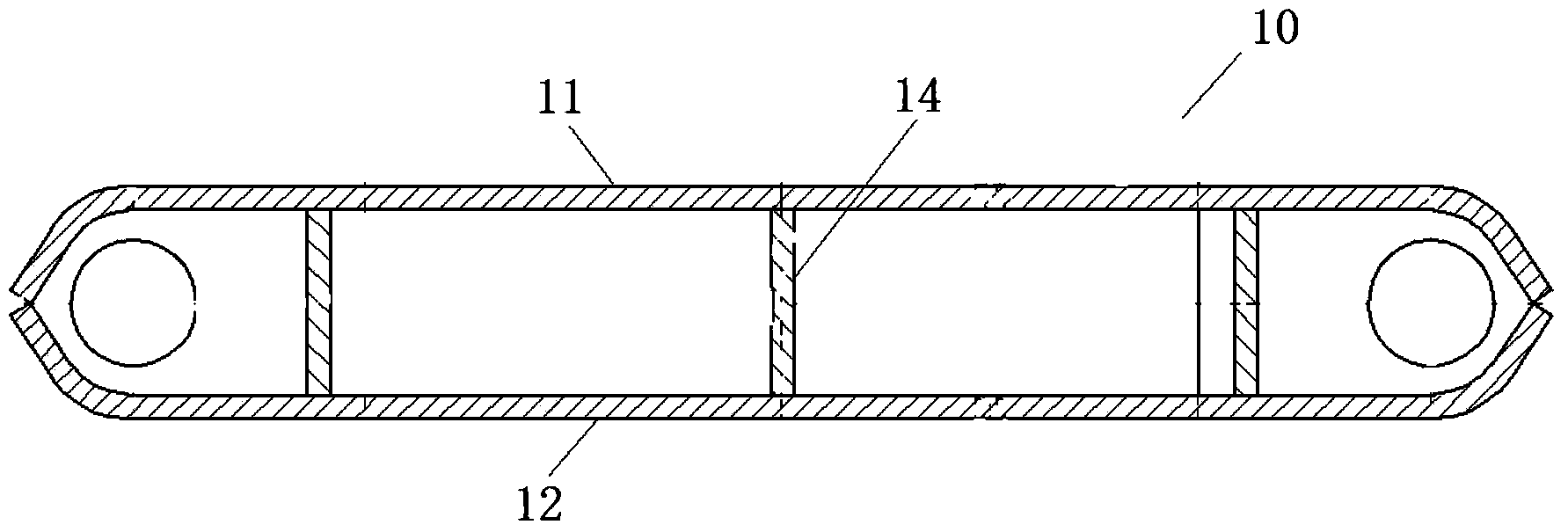

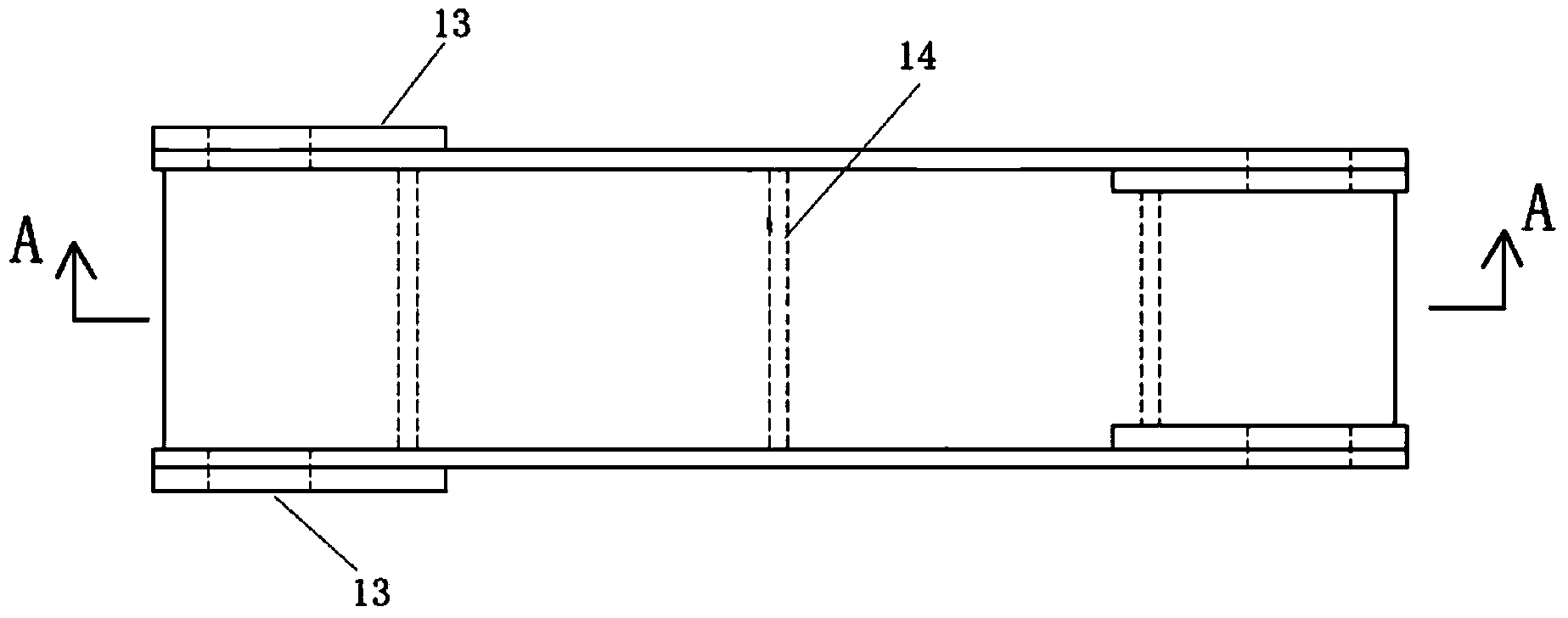

Connecting rod welding system

ActiveCN103481003AImprove welding efficiency and qualityPrecise clamping and fixingWelding/cutting auxillary devicesAuxillary welding devicesAutomotive engineeringWelding

The invention discloses a connecting rod welding system. The system comprises a rail net, a dual conveying vehicle and a plurality of connecting rod welding machines of automatic connecting rod welding. The connecting rod welding machines are respectively located at different positions of the rail net. A rail car operates on the rail net and used for conveying to-be-welded connecting rods to idle connecting rod welding machines and conveying out welded connecting rods. By the connecting rod welding system, automatic connecting rod welding and batch welding are achieved.

Owner:斯图加特航空自动化(青岛)有限公司

Clamping device on steel structure welded frame

InactiveCN108145359AEasy to carry and useQuick clampingWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderArchitectural engineering

Owner:中电装备青岛豪迈钢结构有限公司

Operation table for hardware tool machining and using method of operation table

The invention disclsoes an operation table for hardware tool machining and a using method of the operation table. The operation table comprises a bottom plate, supporting feet are fixedly connected tothe four corners of the bottom of the bottom plate correspondingly, hydraulic cylinders are fixedly installed at the four corners of the top of the bottom plate correspondingly, a base is fixedly connected among piston rods of the hydraulic cylinders, and a control panel is fixedly installed on the outer side of the base. The operation table is compact in structure, easy and convenient to operateand high in practicability, the height of a device can be freely adjusted by arranging the hydraulic cylinders, so that the device can be suitable for people with different heights to use, meanwhile,by arranging a clamping mechanism, iron raw materials needing to be machined can be rapidly clamped and fixed, so that shaking of the raw materials during a machining process is avoided, in addition,a cleaning mechanism and an auxiliary mechanism are arranged to be matched with each other, so that scrap iron generated after machining can be quickly cleaned and recycled, the labor amount of operators is reduced, and waste of the raw materials is avoided.

Owner:湖南精专自动化技术有限公司

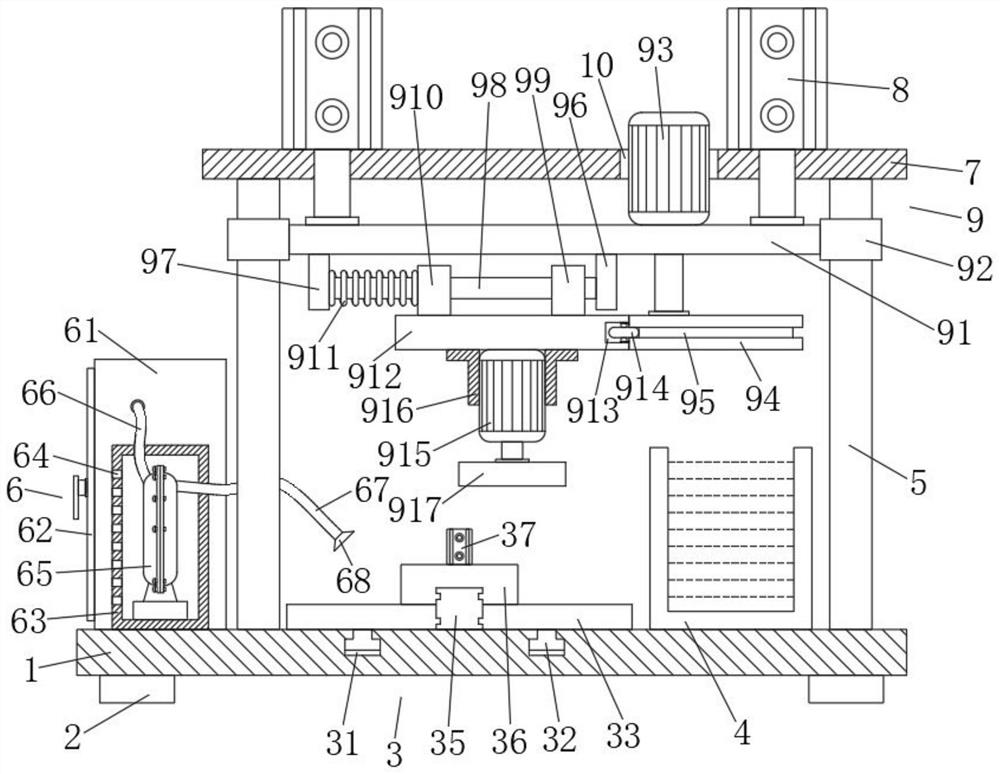

Sliding mechanism of surface treatment equipment for synthesizing and processing new polymer material

InactiveCN111536404AStart fastFast clamping and fixingLinear bearingsConveyor partsElectric machineControl engineering

The invention discloses a sliding mechanism of surface treatment equipment for synthesizing and processing a new polymer material. The sliding mechanism comprises auxiliary wheels and a clamping oil delivery mechanism. A clamping and fixing mechanism is arranged inside a fixed frame, and an electric push rod is contracted, so that the distance between two clamping blocks is shortened, the new material is fixed, and the advantage of quickly clamping and fixing the new material is achieved; an intermittent mechanism is arranged at the upper end of an intermittent oil delivery mechanism, and whena slider moves, a first power lead block and a second power contact block are mutually socketed, so that a micro motor is enabled to operate after being electrified, an intermittent pole is driven torotate through a rotating shaft, and an intermittent wheel is driven to do intermittent rotation; when the intermittent wheel drives a salient pole to move to the lower end of a steel ball, and the steel ball can be propped up through a lug, so that lubricating oil is discharged and adhered to the upper end of an oil brush; and the upper end of a guide rail is lubricated through the oil brush, sothat the guide rail can be quickly lubricated.

Owner:郑瑞飞

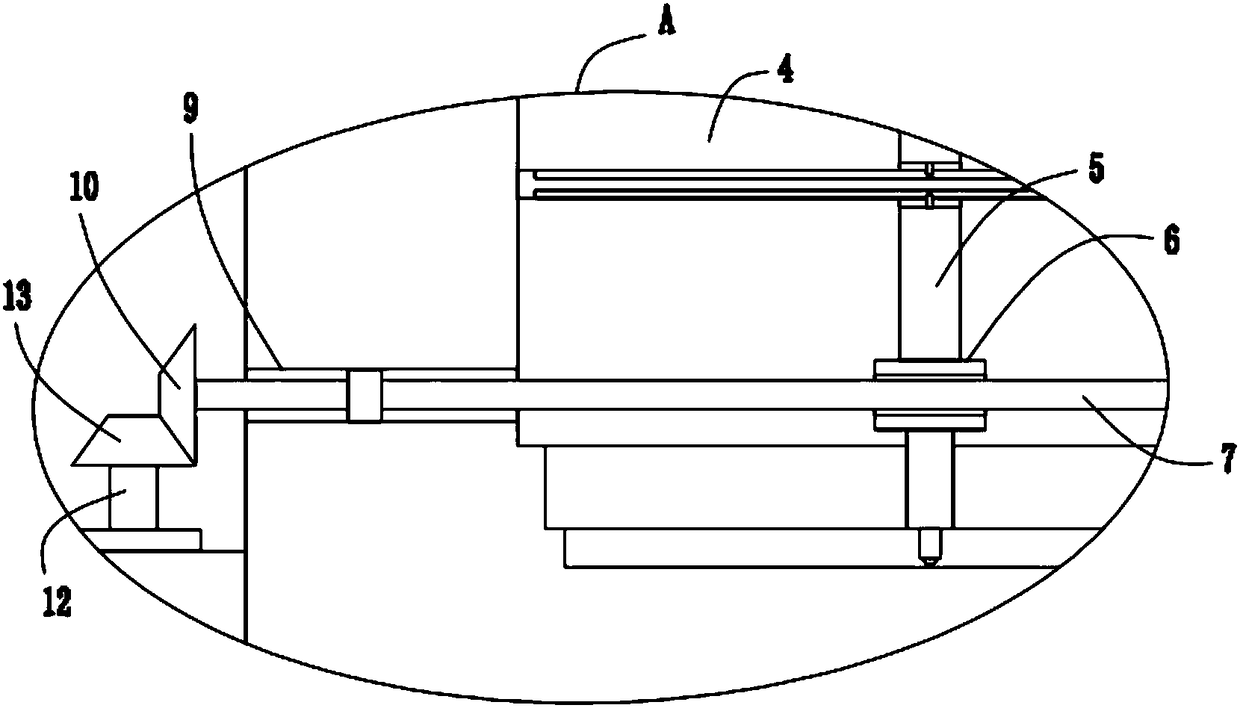

Table type drilling machine jig

InactiveCN108188428ASimple structureEasy to operatePositioning apparatusBoring/drilling componentsEngineeringDrilling machines

The invention discloses a table type drilling machine jig. The table type drilling machine jig comprises an operating floor, the top of the operating floor is provided with a drilling machine body, and two fixture blocks are slidably mounted on the top of the operating floor; two first grooves are formed in the top of the operating floor, and vertical rods are slidably mounted in the first grooves; the top ends of the vertical rods are welded to the bottom portions of the corresponding fixture blocks, and screw sleeves are welded to the bottom portions of the vertical rods; a same first through hole is formed in the inner walls of one sides, adjacent to each other, of the two first grooves, and screws are rotatably mounted in the first through hole; both ends of the screws separately extend into the corresponding first grooves, and the screws are installed in the two screw sleeves in a threaded mode; and a servo motor is fixedly mounted on one side of the operating floor. According tothe table type drilling machine jig, the structure is simple, the operation is convenient, and workpieces can be clamped and fixed quickly by the power provided by the servo motor; and the degree of automation is high, the time and labor are saved, the production speed is improved, and great convenience is brought to people.

Owner:唐筠

Soybean protein isolate gel strength determination device and determination method

InactiveCN113984526AEasy accessEasy dischargeMaterial strength using tensile/compressive forcesEngineeringStructural engineering

The invention discloses a soybean protein isolate gel strength determination device and determination method, the device comprises a mounting box, a lifting assembly, a transmission assembly, a linkage assembly, a clamping mechanism, ventilation assemblies and a sensing assembly, one side of the top surface of the mounting box is provided with a stand column, and the bottom of a cross beam is provided with a detection head; a transmission assembly is arranged in the mounting cavity; the clamping mechanism is arranged on the top surface of a supporting plate; the linkage assembly is arranged between the bottom surface of the fixing plate and the top surface of the mounting box; the ventilation assemblies are arranged in the ventilation boxes; an induction cavity is formed in one end of the rod, and an induction assembly is arranged in the induction cavity; the device is easy to operate, and the clamping assembly is conveniently driven to rapidly clamp and fix a container through the linkage assembly and the transmission assembly; the fan is matched with the ventilation assemblies so that the influence of high temperature generated during working of internal electric appliance elements on the strength of the protein gel during detection can be conveniently prevented; the problem that high temperature generated by an existing detection device easily affects protein gel detection data is solved.

Owner:范胜华

Strength detection device for circuit board production

ActiveCN112525689AStrength detectionFast clamping and fixingMaterial strength using tensile/compressive forcesElectronic waste recyclingElectric machineryStructural engineering

Owner:益阳市明正宏电子有限公司

FAC mirror adjusting device and adjusting method thereof

PendingCN112014977AEasy to adjustImprove regulation stabilityOptical elementsElectric machineEngineering

The invention relates to the technical field of FAC mirror adjustment, in particular to an FAC mirror adjusting device and method. The adjusting device comprises a base; an adjusting base is arrangedat the upper end of the base; a two-dimensional translation table is arranged on the outer side of the adjusting base; a pneumatic push rod is arranged on the two-dimensional translation table; a pulse motor adjusting frame is arranged at the upper end of the two-dimensional translation table; a pulse motor is arranged on the pulse motor adjusting frame; a material guide plate is arranged on the upper end surface of the adjusting base; piezoelectric ceramic is arranged at the bottom end of the material guide plate; a BAR strip array to be adjusted is arranged on the upper end face of the material guide plate; an infrared position sensor is arranged on the material guide plate; an FAC material box is arranged at the upper end of the material guide plate; a force arm rod is connected betweenthe pulse motor adjusting frame and the material guide plate; and an FAC fixing clamp is arranged on the force arm rod. According to the FAC mirror adjusting device, through cooperative use of the adjusting mechanism and the clamping mechanism, the FAC mirror can be rapidly adjusted, the adjusting stability of the FAC mirror is high, and the adjusting work efficiency and the adjusting accuracy ofthe FAC mirror are improved.

Owner:WENZHOU FIBER LASER

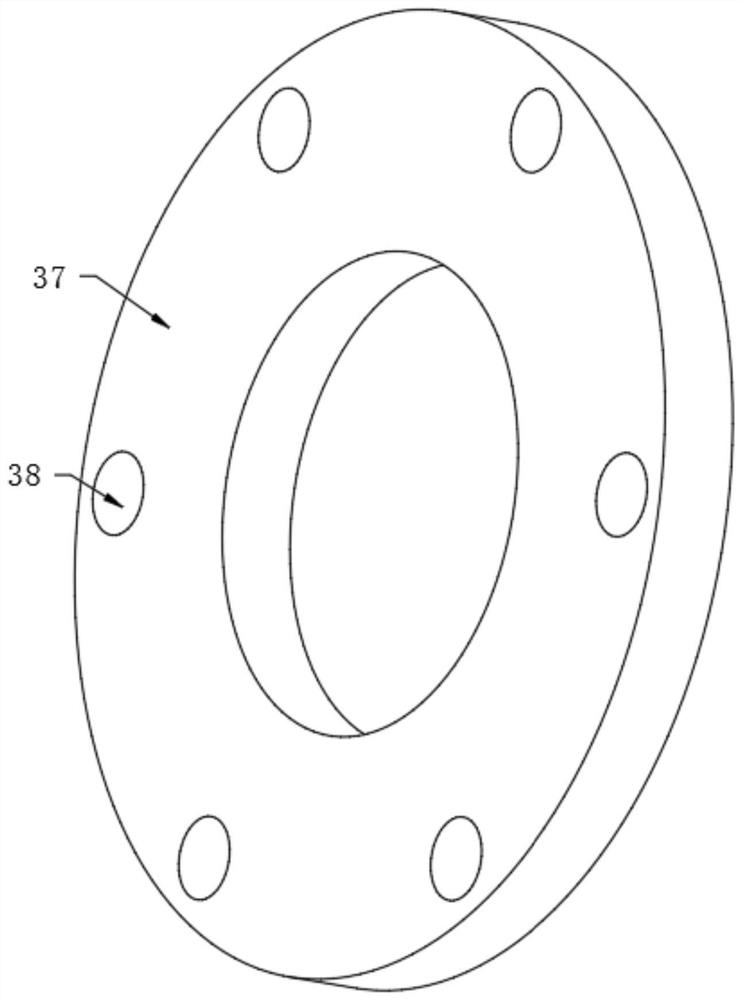

Processing fixture for aluminum alloy automobile wheel processing centers

InactiveCN111745432AAvoid auto-rotateFast clamping and fixingPositioning apparatusMetal-working holdersStructural engineeringMechanical engineering

The invention relates to the technical field of wheel processing fixtures, and discloses a processing fixture for aluminum alloy automobile wheel processing centers. The processing fixture comprises abase, wherein a placing plate is horizontally arranged above the base, a rotating column is fixedly arranged at the center of the lower surface of the placing plate, a first rolling bearing is embedded in the center of the upper surface of the base, and the lower end of the rotating column is rotationally connected with the upper surface of the base through the first rolling bearing; a limiting mechanism for being clamped with the base is arranged on the wall of the rotating column; the placing plate is hollow, and four screws are arranged inside the placing plate oppositely; and second rolling bearings are embedded in the inner side walls of the periphery of the placing plate. The processing fixture for aluminum alloy automobile wheel processing centers can quickly clamp an aluminum alloy automobile wheel, can randomly adjust the angle of the aluminum alloy automobile wheel, and improves the machining efficiency of the aluminum alloy automobile wheel.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

Valve body crack welding repair fixing clamp

ActiveCN114043154AFast clamping and fixingGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesElectric machineEngineering

The invention relates to the technical field of valve body repair fixing clamps, in particular to a valve body crack welding repair fixing clamp which comprises a supporting frame, the supporting frame is of an L-shaped structure, a rotating motor is fixedly installed on the supporting frame, a connecting frame of a concave structure is fixedly installed at the output end of the rotating motor, and spring pull rods are symmetrically and fixedly installed in the connecting frame. The telescopic ends of the two spring pull rods penetrate through the connecting frame and are fixedly provided with connecting blocks, and first air cylinders are rotationally installed on the sides, close to each other, of the two connecting blocks. An existing valve body crack treatment mode is low in efficiency and high in labor cost, and the stability of a valve body cannot be guaranteed through manual supporting. A valve body with cracks can be rapidly clamped and fixed, multi-angle adjustment can be conducted on the valve body according to the positions of the cracks, the problem that an existing repairing mode is low in repairing efficiency is solved, and the labor cost is reduced.

Owner:江苏德邦流体控制有限公司

Precoated sand mold casting sand box treatment device and treatment method

InactiveCN111957933AImprove efficiencyHigh speedHollow article cleaningMould handling equipmentsHydraulic cylinderStructural engineering

The invention relates to the field of sand mold casting, in particular to a precoated sand mold casting sand box treatment device and treatment method. The precoated sand mold casting sand box treatment device comprises a base, the base is of an H-shaped structure, first sliding grooves are symmetrically formed in the top of the base, and moving blocks are symmetrically arranged at the top of thebase and slidably connected into the first sliding grooves; first hydraulic cylinders are fixedly mounted at the tops of the moving blocks, lifting plates are fixedly mounted at the output ends of thefirst hydraulic cylinders, second hydraulic cylinders are inserted in the lifting plates and rotationally connected to the lifting plates, and connecting frames of L-shaped structures are fixedly mounted at the output ends of the second hydraulic cylinders; and connecting rods are hinged to the sides, away from the second hydraulic cylinders, of the connecting frames, clamping plates of concave structures are hinged to the ends, away from the connecting frames, of the connecting rods, and third hydraulic cylinders are fixedly installed on the connecting frames and located below the connectingrods. The sand base in the sand box can be automatically cleaned, and the treatment device is suitable for popularization.

Owner:许丽

Pipe fitting paint spraying equipment capable of quickly fixing pipe fitting based on constructional engineering

InactiveCN112934528AImprove operational efficiencyGood uniformitySpraying apparatusEngineeringStructural engineering

The invention provides pipe fitting paint spraying equipment capable of quickly fixing a pipe fitting based on constructional engineering, and belongs to the technical field of paint spraying equipment. The invention aims to solve the problem that the operation efficiency of the paint spraying equipment is greatly reduced during pipe fitting fixing due to the fact that manual adjustment is needed when the existing paint spraying equipment fixes the pipe fitting. The pipe fitting paint spraying equipment comprises a base, wherein the upper portion of the base is fixedly connected with a top plate through four supporting columns, and a supporting table is arranged on the upper end face of the base; two clamping mechanisms are arranged on the upper end face of the supporting table in an annular array shape; and a clamping driving mechanism is arranged at the position, located on the upper end face of the base, of the bottom of the supporting table. Two driving racks move in the opposite directions through the clamping driving mechanism, then two clamping plates are driven to move in the opposite directions, and therefore six driving clamping blocks move in the opposite directions, and three pipe fittings can be rapidly clamped and fixed. In the whole fixing process, due to the fact that manual adjustment is not needed, the operation efficiency of the paint spraying equipment during pipe fitting fixing is greatly improved.

Owner:韩坤

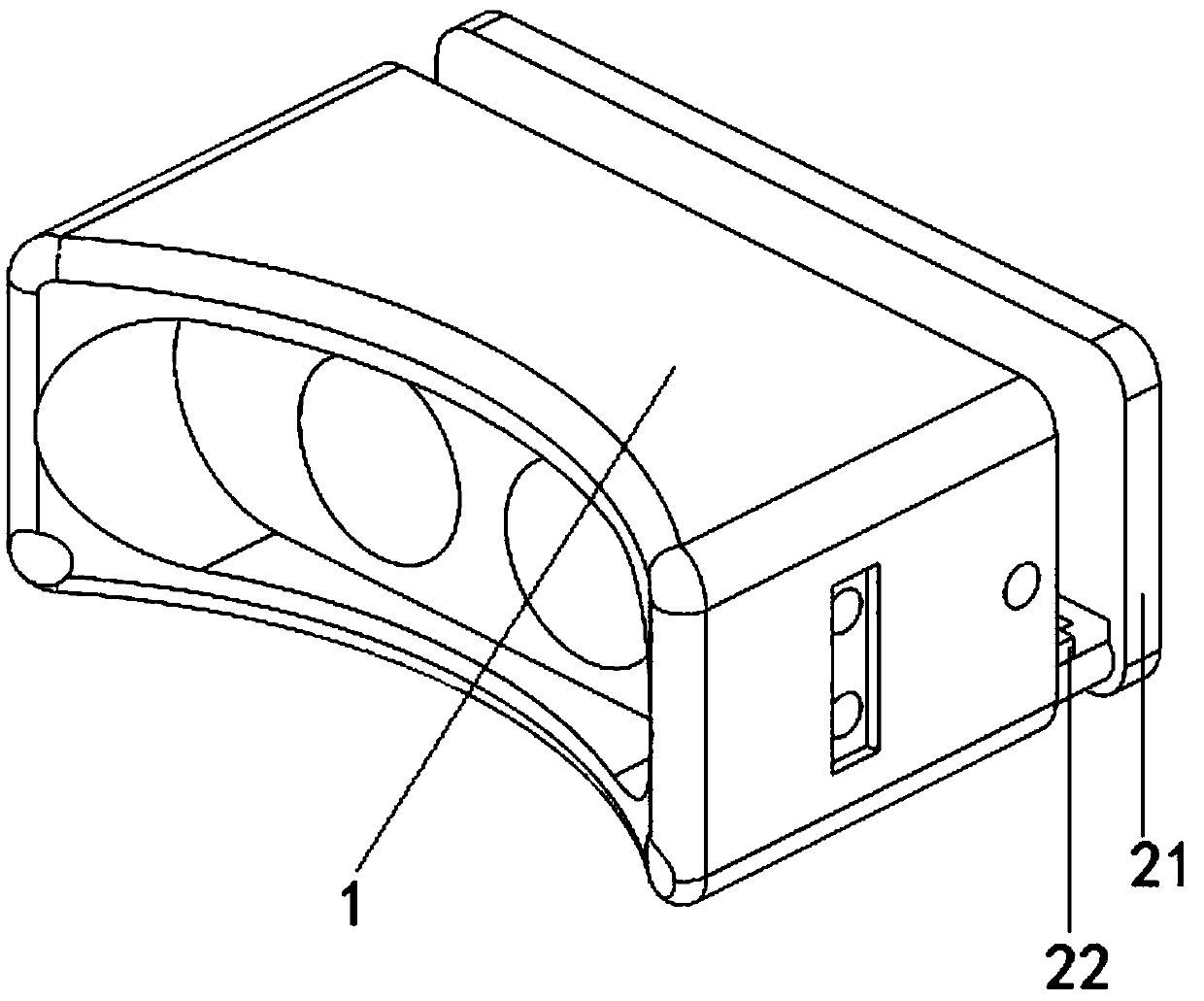

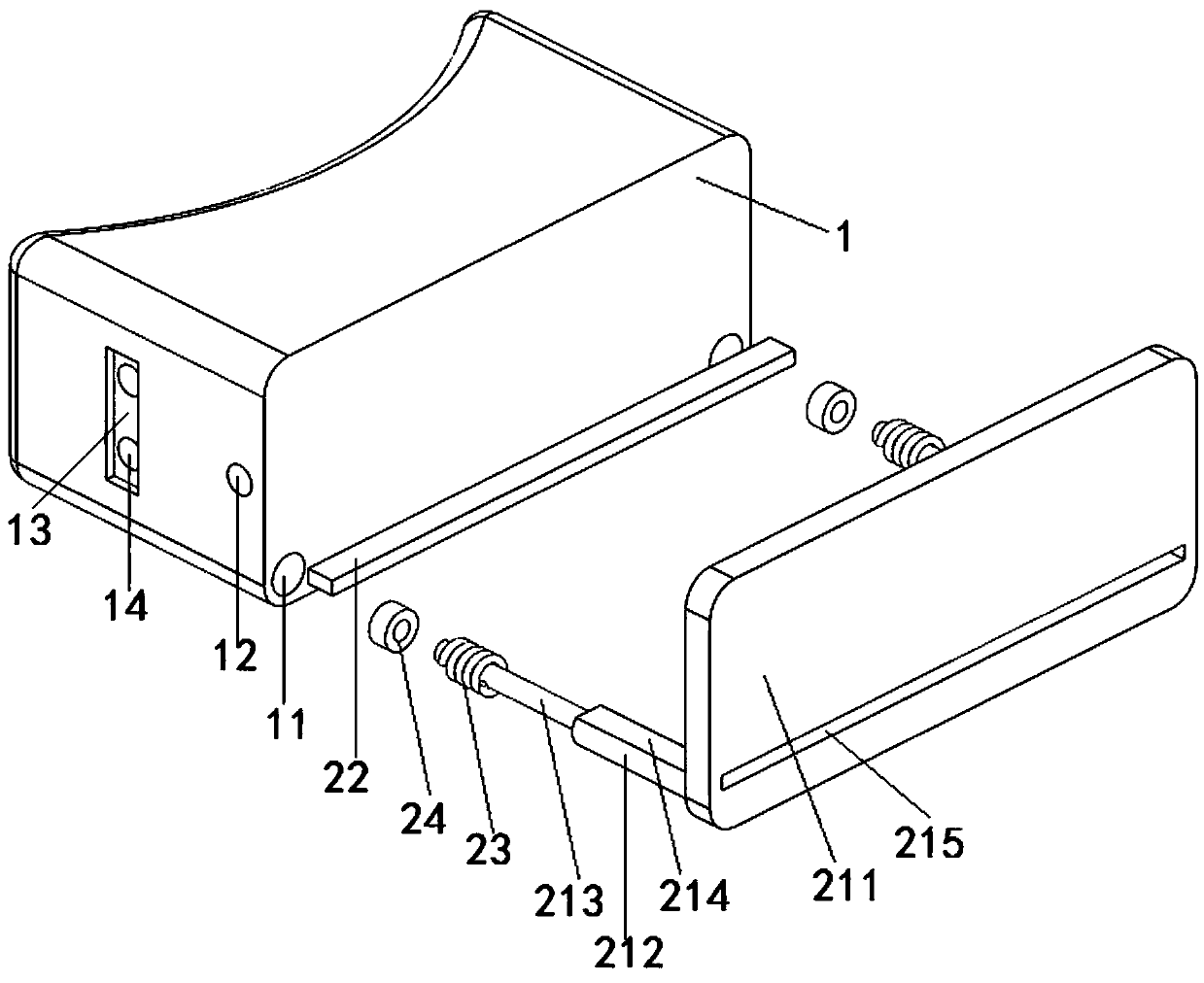

VR technology-based teaching experience device and experience system thereof

ActiveCN109633911AFast clamping and fixingMeet the needs of useElectrical appliancesOptical elementsEngineeringMobile phone

The invention discloses a VR technology-based teaching experience device and an experience system thereof. The VR technology-based teaching experience device comprises a VR helmet body and a mobile phone clamping mechanism arranged at the rear side of the VR helmet body, wherein the left side and the right side of the mobile phone clamping mechanism are symmetrically provided with two clamping mechanisms; two ends of the front side of the VR helmet body are symmetrically provided with stretching clamping seats; the middle of the stretching clamping seat is horizontally provided with a stretching connector; the front end of the stretching connector is connected with an arc elastic piece; the front ends of the two arc elastic pieces are connected through an arc protection plate; and an arch-shaped support plate is arranged between the top end of the arc protection plate and the VR helmet body. The experience system comprises a mobile terminal, an information acquisition terminal, a fixing terminal and an information output terminal. Various types of mobile phones can be quickly clamped and fixed, shaking during the use process is avoided, the mobile phone clamping mechanism can be quickly returned when the mobile phone is taken out, a certain sealing protection role is played, quick adaptive adjustment can be carried out according to the personal condition of a user when the userwears the device, and the use needs of the user are met.

Owner:黄山徽岭电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com