Table type drilling machine jig

A desktop drilling machine and fixture technology, applied in the direction of boring machine/drilling machine parts, clamping, manufacturing tools, etc., can solve the problems of unfavorable rapid production, cumbersome operation, time-consuming and laborious, etc., and achieve simple structure, high production speed, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

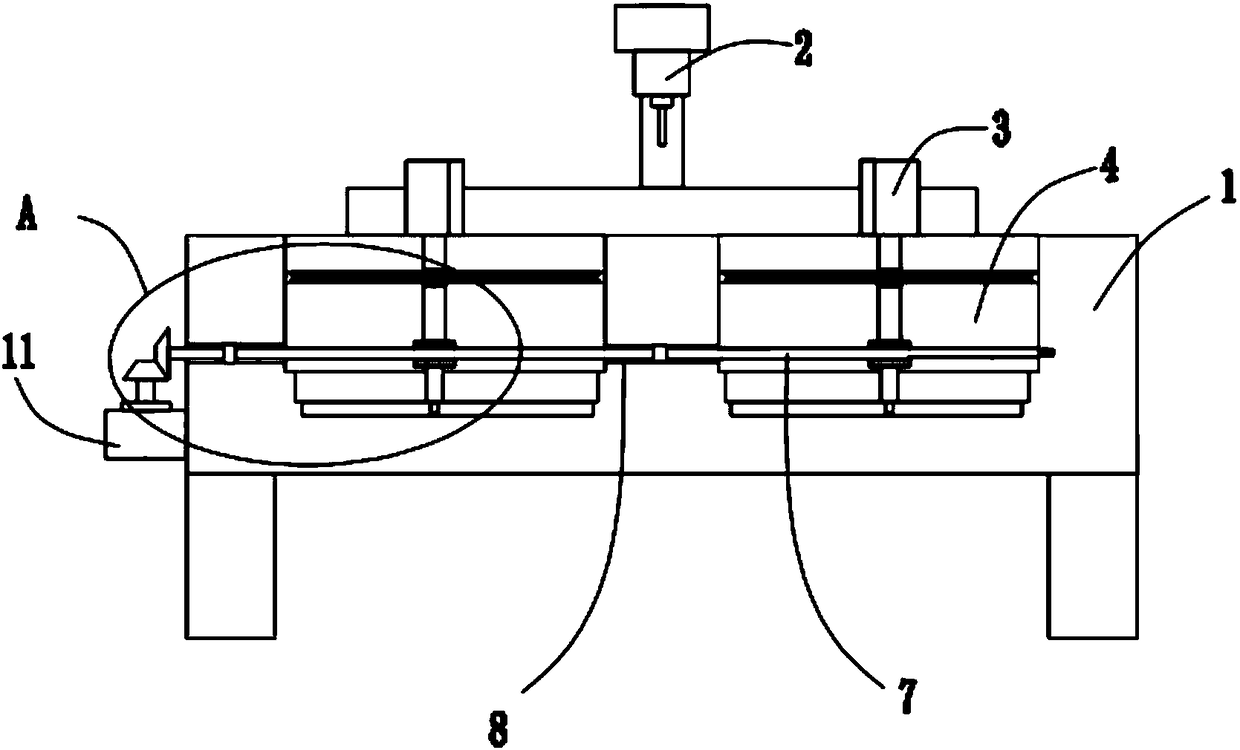

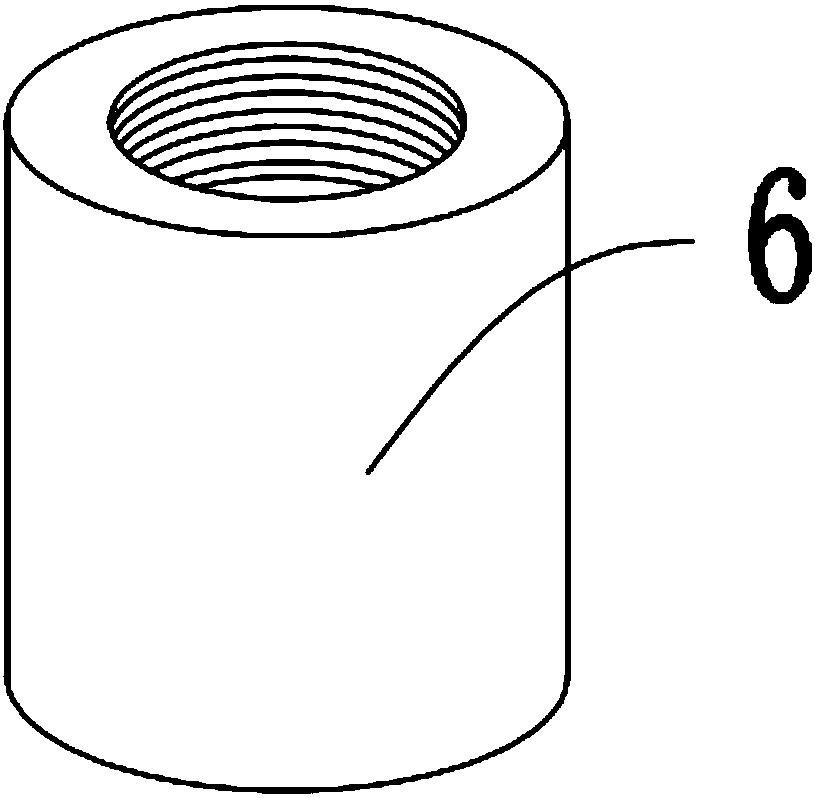

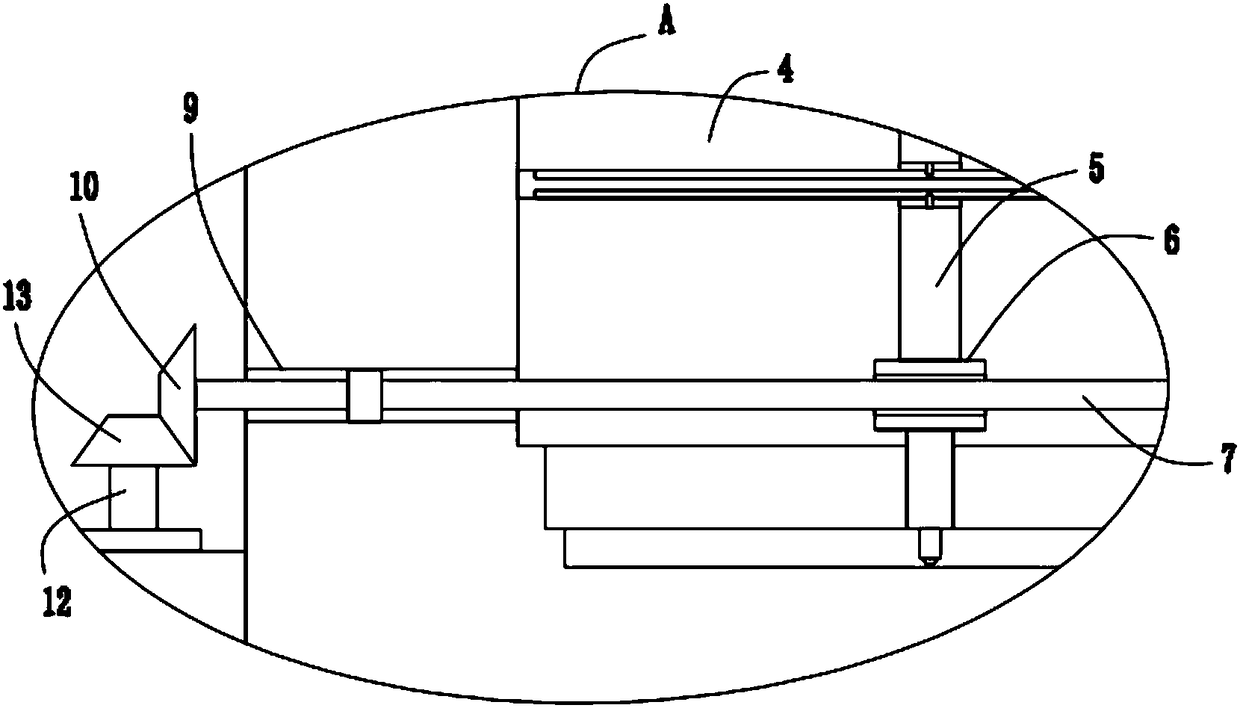

[0021] refer to Figure 1-3 , a desktop drilling machine fixture, including a console 1, the top of the console 1 is provided with a drill body 2, and the top of the console 1 is slidingly installed with two blocks 3, and the top of the console 1 is provided with two first recesses Groove 4, a vertical rod 5 is slidably installed in the first groove 4, and the top of the vertical rod 5 is welded to the bottom of the corresponding block 3; the bottom of the vertical rod 5 is welded with a threaded sleeve 6, and the two first grooves 4 The same first through hole 8 is provided on the inner wall of the side close to each other, and a screw rod 7 is rotated in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com