Plate-shaped part polishing device for hardware tool processing and using method thereof

A technology for hardware tools and polishing devices, which is used in grinding/polishing safety devices, metal processing equipment, cleaning methods using gas flow, etc. Cleaning of plate-shaped parts, etc., to achieve the effect of improving the polishing range, compact structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

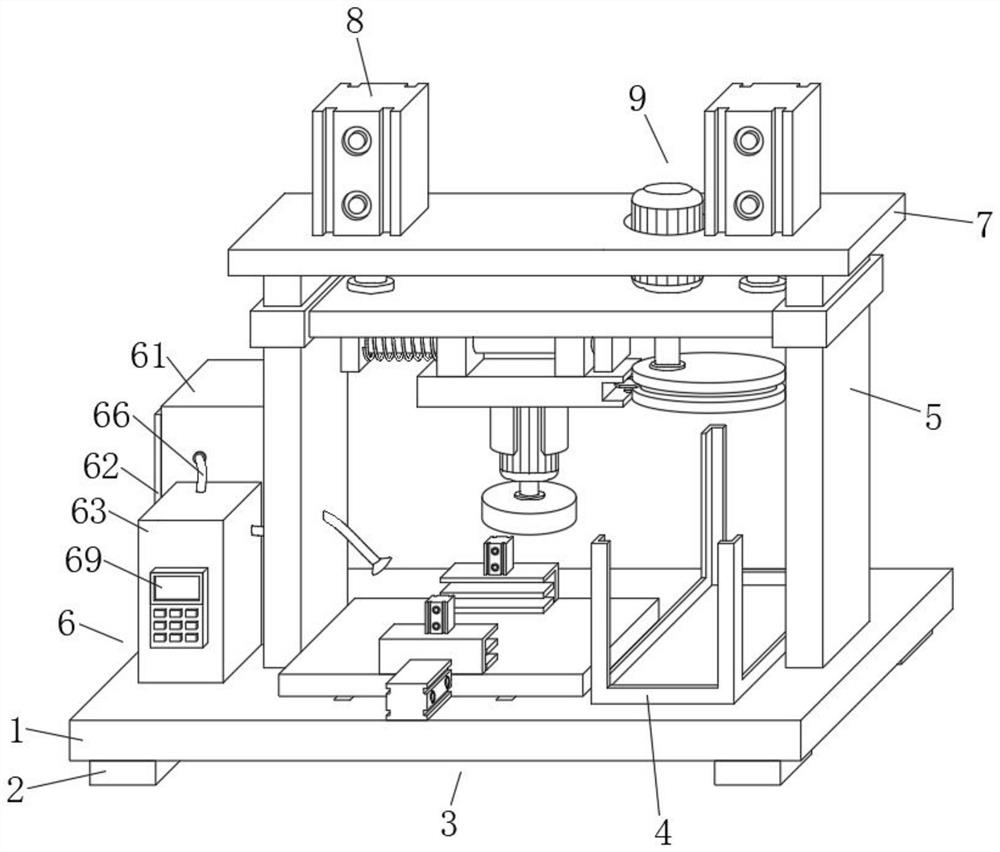

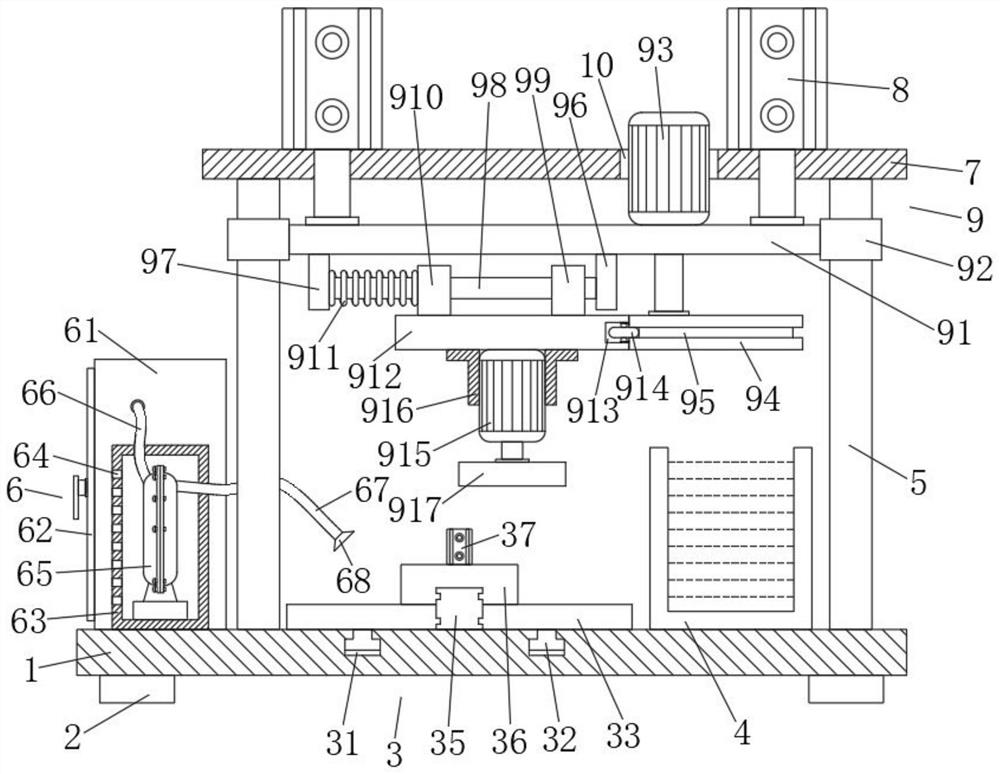

[0029] A polishing device for plate-shaped parts for hardware tool processing, comprising a base plate 1, the four corners of the bottom of the base plate 1 are fixedly connected with support pads 2, and the support pads 2 are used to facilitate better stable placement of equipment; the base plate 1 The top is fixedly connected with a placement frame 4, which facilitates better placement of plate-shaped parts by the placement frame 4; Fixedly connected with vertical plates 5, the top of the base plate 1 and one side of one of the vertical plates 5 are provided with a cleaning mechanism 6, and a top plate 7 is fixedly connected between the tops of the two vertical plates 5, so Both ends of the top plate 7 are fixed with a third cylinder 8, the piston rods of the third cylinder 8 extend to the bottom of the top plate 7, and a polishing mechanism 9 is arranged between the piston rods of the third cylinder 8.

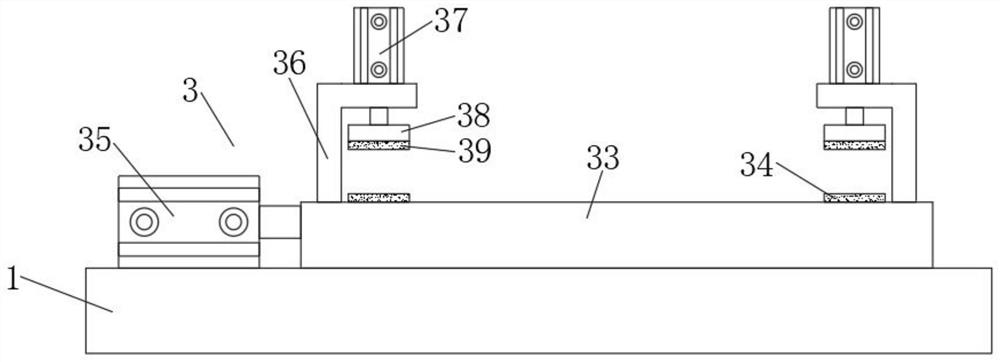

[0030] Wherein, the fixing mechanism 3 includes a slide groove 31, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com