Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Extended chemical cleaning cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

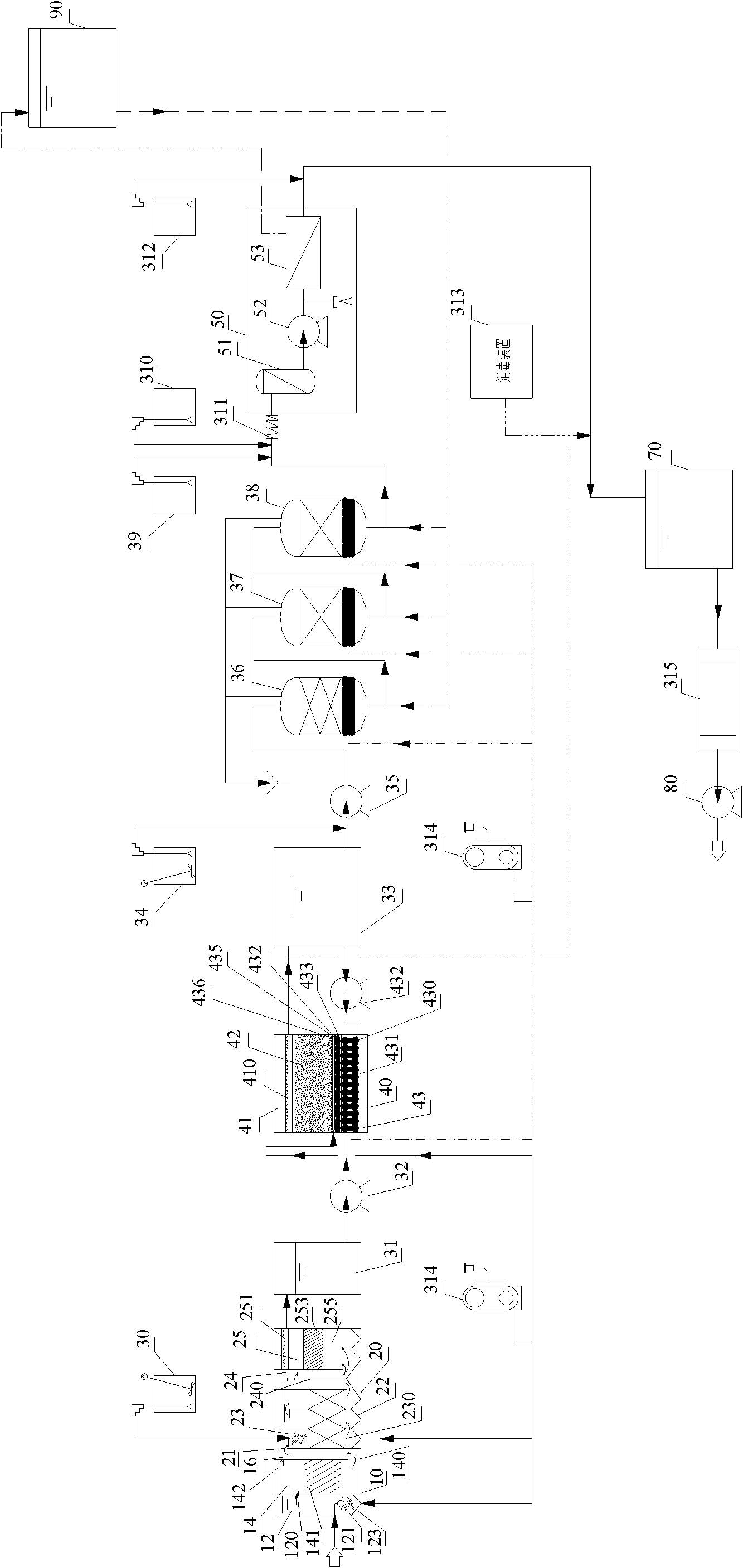

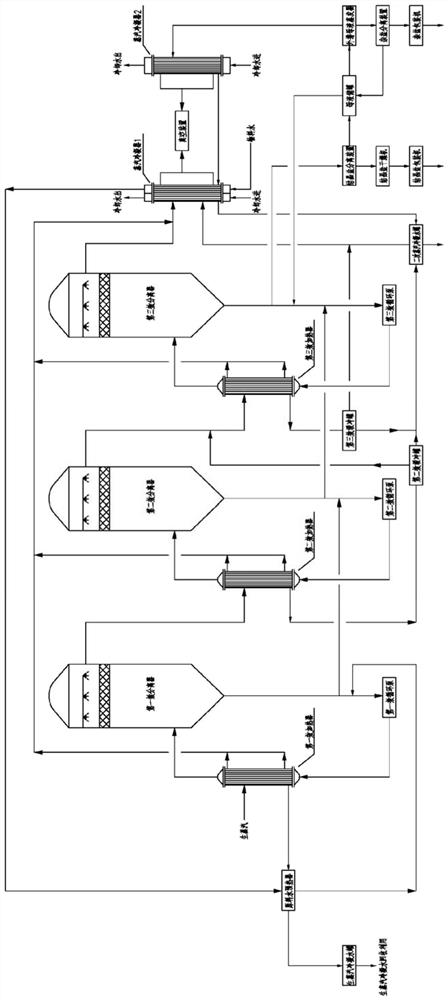

Purification system for micro-polluted raw water and purification method thereof

InactiveCN102557350AImprove recycling ratesStrong shock adaptabilityWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisPurification methodsActivated carbon filtration

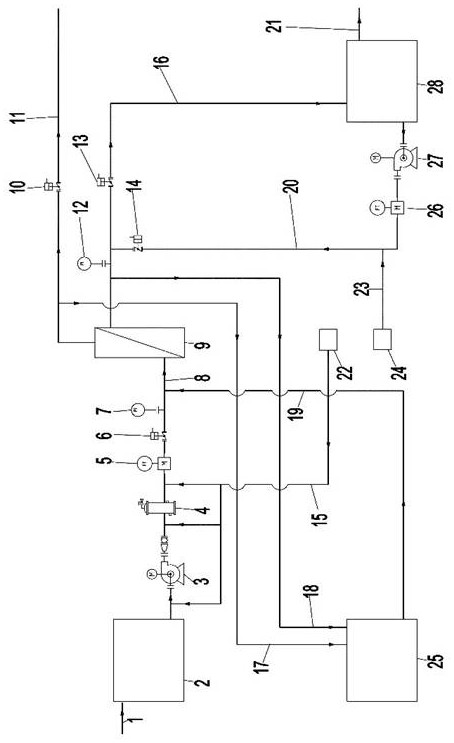

The invention relates to a purification system for micro-polluted raw water, comprising a stripping oil separation tank, a coagulating sedimentation tank, a coagulating chemical dosing device, a first middle water tank, a water feeding pump, a biological aerated filter, a second middle water tank, a coagulating chemical dosing unit, a filtering lift pump, a multi-media filter, a manganese sand filter, an active carbon filter, an acid dosing device, a scale inhibitor dosing device, a mixer, a reverse osmosis device, an alkali dosing device, a disinfection device and an ultraviolet sterilization device. The purification system for micro-polluted raw water disclosed by the invention has the following advantages that: main pollutants are especially removed at first, and then a reverse osmosis technology is used as a safety guarantee; the reverse osmosis pre-treatment is designed adequately, and the operation of the system is safe and stable, so that the occurrence frequency of pollution and blockage phenomena is greatly decreased, chemical cleaning period is greatly prolonged, and the recycling rate of water is up to 75%; and the purification system is suitable for the occasions of treating the drinking water of municipal administration, villages, industrial enterprises and mine fields or for the occasions of reusing the reclaimed water which needs advanced treatment. The invention further refers to a purification method of the purification system for micro-polluted raw water.

Owner:HEFEI DEAN WATER TREATMENT EQUIP

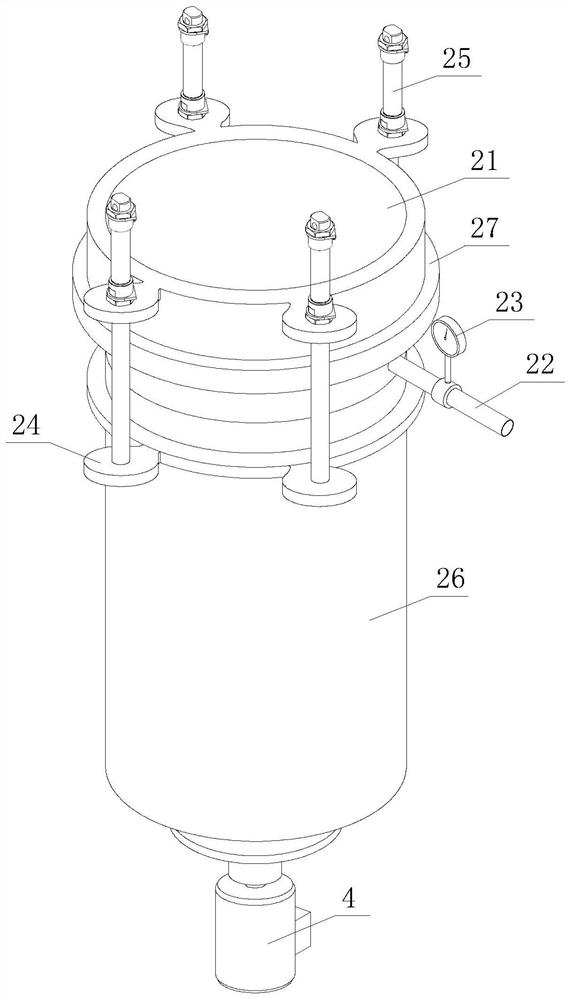

Rotating cross-flow flat ceramic membrane separation turntable

InactiveCN104841277AHigh strengthEasy to implement high pressure backwashUltrafiltrationSeparation technologyHigh pressure

The invention relates to a rotating cross-flow flat ceramic membrane separation turntable, which comprises a hollow central shaft, a support component fixedly arranged on the hollow central shaft, a plurality of flat ceramic membrane components supported by the support component and a driving mechanism for driving the hollow central shaft to rotate, wherein each flat ceramic membrane component comprises a hollow cavity type flat ceramic membrane; each hollow cavity type flat ceramic membrane comprises two separated surface membrane layers; a plurality of liquid collection accommodation cavities and liquid outlets are formed around the hollow cavity type flat ceramic membranes; a plurality of cavities are formed in the hollow cavity type flat ceramic membranes. According to the turntable, a flat ceramic membrane filtering technology is adopted, the characteristics of strong strength, convenience in high-pressure back washing and the like of the ceramic membranes are fully utilized, and the application fields of a rotating cross-flow membrane separation technology are well extended.

Owner:SUZHOU MOHAI SEPARATION TECH

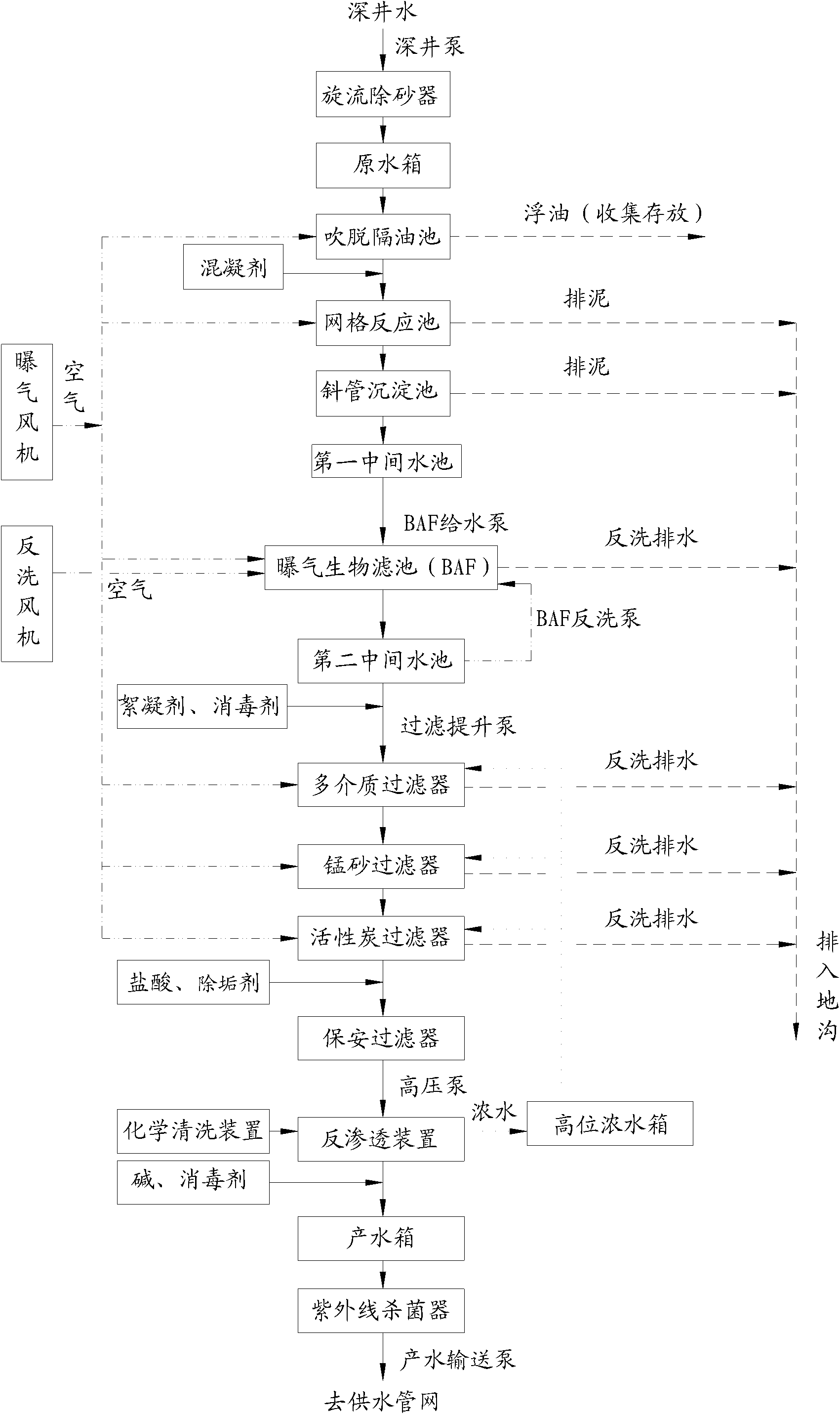

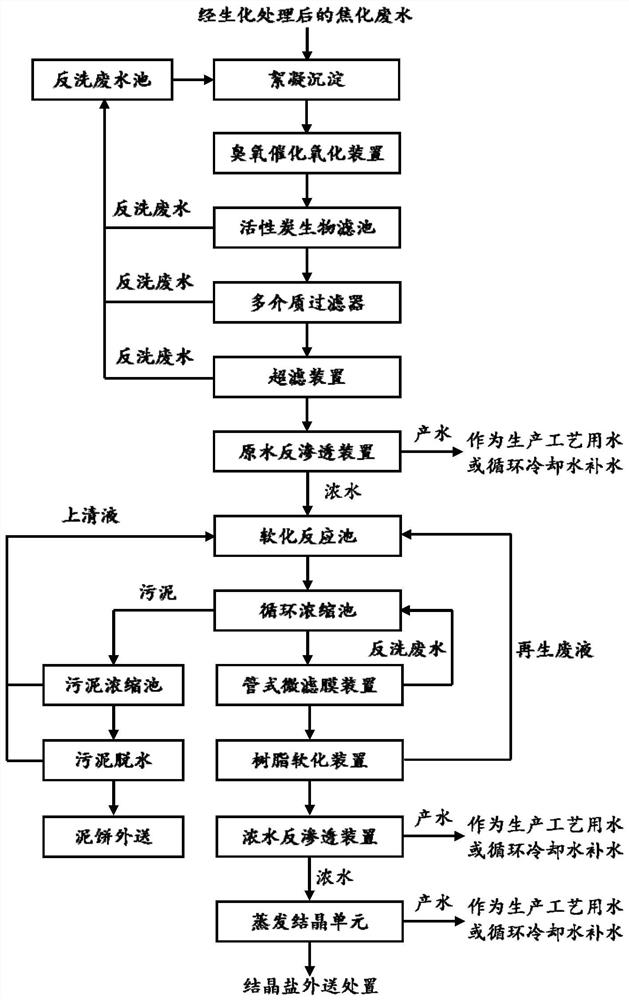

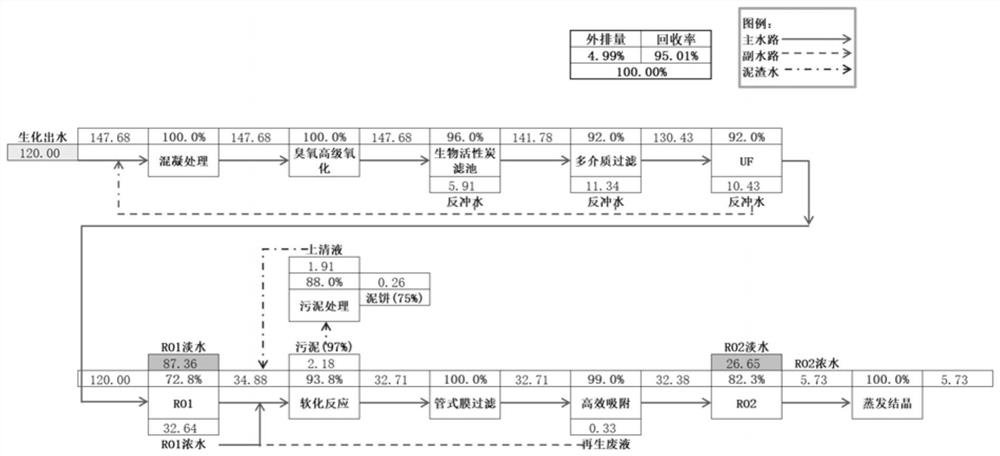

Coking wastewater advanced treatment and evaporative crystallization zero discharge process

PendingCN112919734AReduce the risk of organic contaminationPrevent scalingScale removal and water softeningTreatment involving filtrationChemistryUltrafiltration

The invention provides a coking wastewater advanced treatment and evaporative crystallization zero discharge process which comprises the following steps: A) sequentially performing flocculation treatment, catalytic ozonation treatment, biological activated carbon filter treatment, multi-medium filtration, ultrafiltration treatment and first reverse osmosis concentration treatment on coking wastewater subjected to biochemical treatment, so as to obtain first treated water and first concentrated water; (B) sequentially subjecting the first concentrated water to two-stage softening treatment and second reverse osmosis concentration treatment to obtain second treated water and second concentrated water, wherein the first-stage softening adopts chemical softening and microfiltration combined filtration treatment, the second-stage softening adopts resin softening; and C) carrying out evaporative crystallization on the second concentrated water to obtain third treated water and crystal salt. The process is reasonable in linkage, stable, efficient and safe to operate and good in treatment effect, the treated water can be used as production process water or circulating cooling water replenishing water, finally zero emission of the coking wastewater is achieved, and economic benefits are remarkable.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

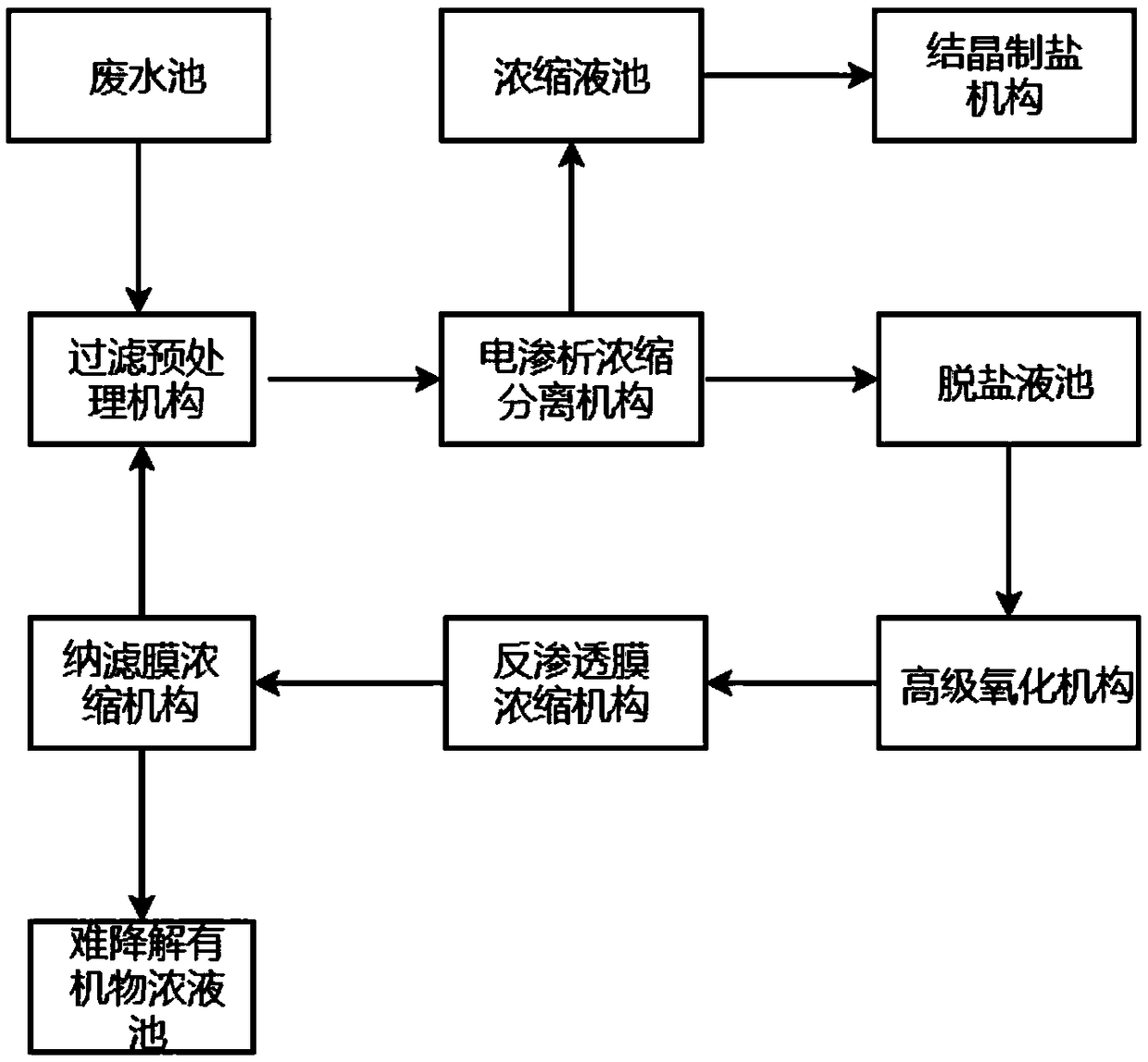

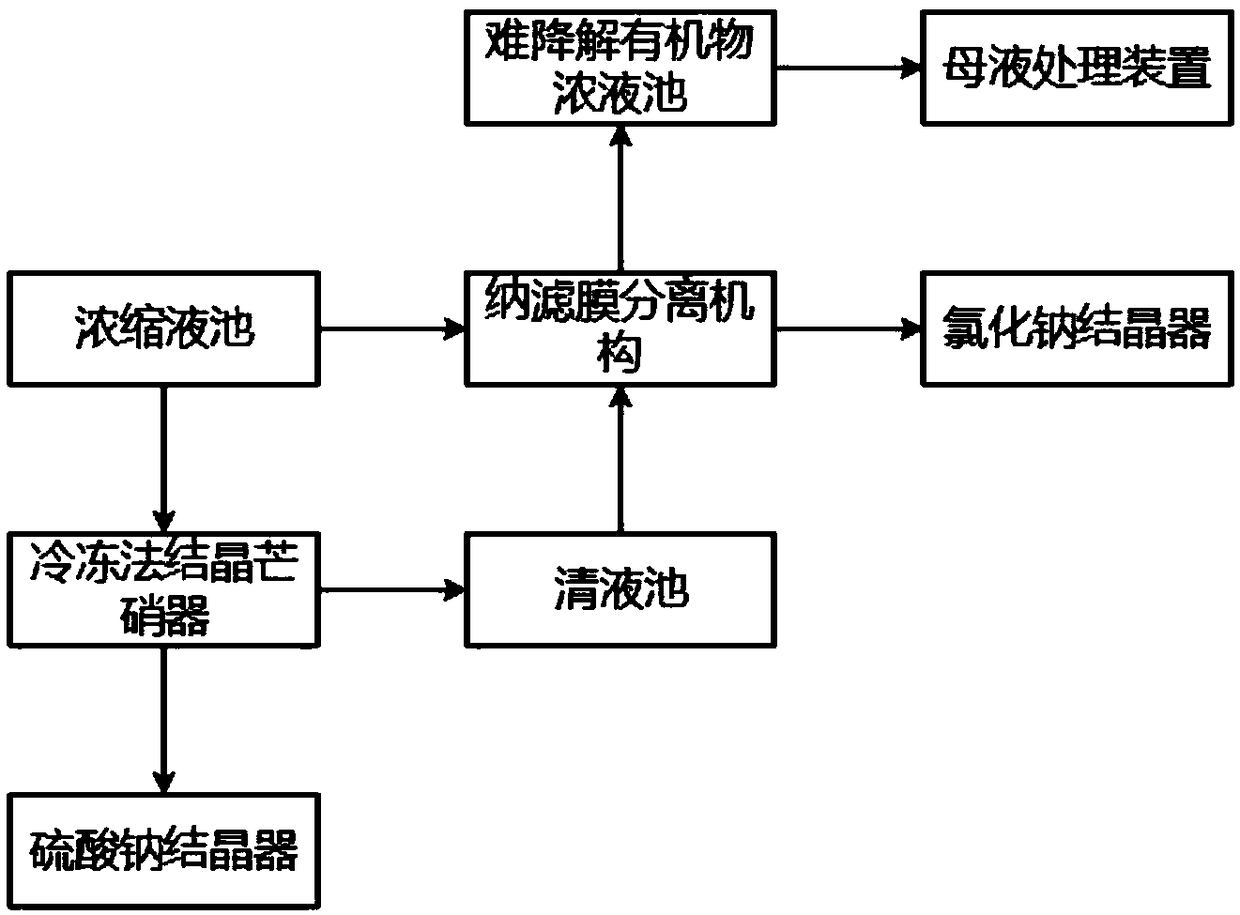

Zero-discharge treating system and zero-discharge treating method for industrial high-salinity wastewater with abundant refractory organics

InactiveCN109354241AMitigate the problem of organic foulingExtended chemical cleaning cycleWater treatment parameter controlGeneral water supply conservationChemistryNanofiltration

The invention discloses a zero-discharge treating system and a zero-discharge treating method for industrial high-salinity wastewater with abundant refractory organics. The zero-discharge treating system comprises a wastewater pond, a filtering pretreatment mechanism, an electrodialysis concentrating and separating mechanism, a desalination liquid pond, an advanced oxidation mechanism, a reverse osmosis membrane concentration mechanism and a nanofiltration membrane concentration mechanism which are communicated successively, the electrodialysis concentrating and separating mechanism is connected with a concentrated liquid pond, the concentrated liquid pond is communicated with a crystalizing and salt producing mechanism, and a water outlet end of the nanofiltration membrane concentration mechanism is connected to the filtering pretreatment mechanism and a concentrated liquid pond with the refractory organics. The zero-discharge treating method and a process route have the advantages that in a process of treating the industrial high-salinity wastewater with the abundant refractory organics, blockage problem of the organics can be alleviated, a chemical cleaning period can be prolonged, service lives of membranes can be prolonged, normal operation of a salt distribution and crystallization system is guaranteed, purities of sodium sulfate crystal salt and sodium chloride crystal salt are guaranteed, the amount of mother liquid discharge is decreased, operation cost of the integral zero-discharge treating system is reduced, and increasement of investment cost on the system is not significant.

Owner:杭州匠容道环境科技有限公司

Advanced treatment method for sewage water from oil production

InactiveCN101367564AImprove protectionImprove throughputFatty/oily/floating substances removal devicesMultistage water/sewage treatmentFiltrationWater quality

The invention relates to an oil extraction sewage depth-processing method, and relates to a sewage processing process. The invention resolves the problems of the multi-level precise-filter method in the prior art that the produced water quality is unstable, the flux of the pure hyper-filtration method film is rather low, the cleaning is frequent and the sewage processing cost is high. The method comprises the following steps: pre-treating, micro-filtration treating and cycling hyper-filtration film depth treating. The invention adopts the method integrating the conventional craftwork and the integrated film craftwork to effectively improve the flux of the hyper-filtration film, to prolong the film running period and to reduce the sewage processing cost. The sewage after being processed with the method can reach the A1-level water-injection standard in Recommended Index and Analysis Method for the Water Quality Injected in Clastic Rock Reservoirs (SY / T5329-94).

Owner:HARBIN INST OF TECH +1

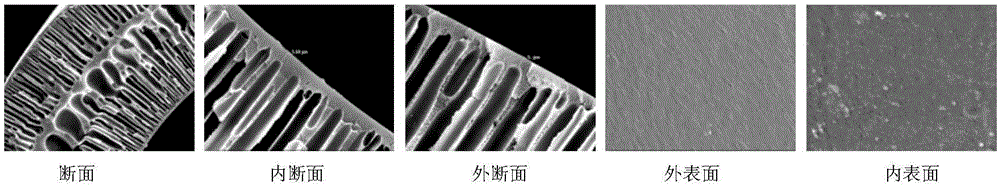

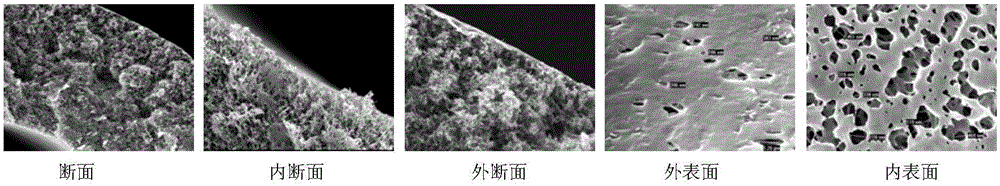

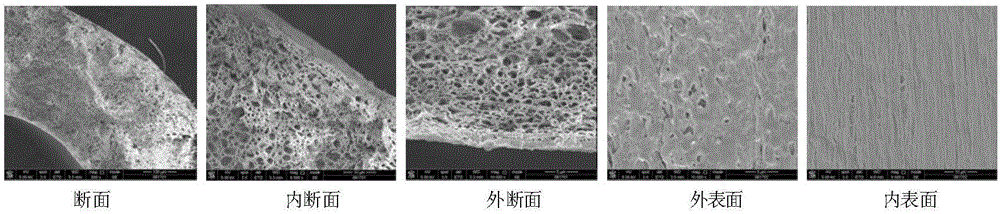

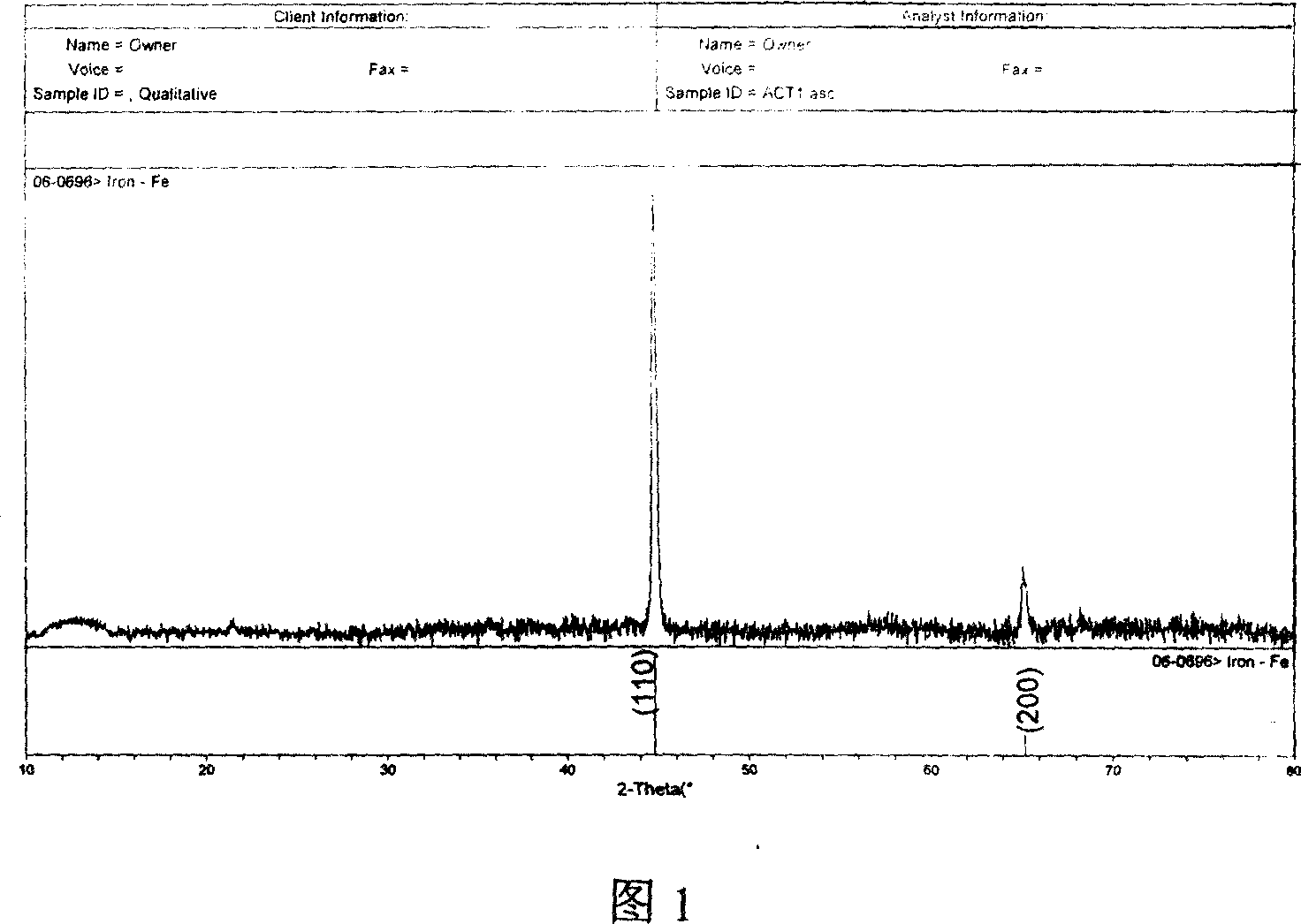

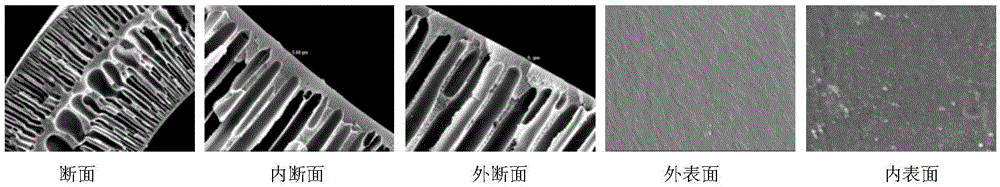

Hollow fiber ultra-filtration membrane preparation method

ActiveCN106474942AHigh film strengthMembrane pore size is smallSemi-permeable membranesFiberFiltration membrane

The present invention provides a hollow fiber ultra-filtration membrane preparation method, which comprises: preparing a membrane casting liquid, wherein the membrane casting liquid comprises a polymer, a pore forming agent, and a solvent; preparing a first gel bath, a second gel bath and a third gel bath, wherein the first gel bath comprises triethylene glycol and diethylene glycol, the second gel bath comprises glycerol or triethylene glycol, and the third gel bath is water; preparing a core liquid; extruding the membrane casting liquid and the core liquid through a spinning device to obtain hollow fibers having a nascent state; and sequentially immersing the hollow fibers having the nascent state in the first gel bath, the second gel bath and the third gel bath to obtain the hollow fiber ultra-filtration membrane. With the preparation method of the present invention, the hollow fiber ultra-filtration membrane with characteristics of compact inner surface, compact outer surface and topological structure cross section from the skin layer to the cross section can be obtained, and further has characteristics of high membrane strength, small membrane pore size, narrow pore size distribution, and high membrane flux.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for directly treating air cooling drum boiler unit water supply

ActiveCN1945115AReduce depositionAdd lessSteam boilersSteam boilers componentsFlow-accelerated corrosionCorrosion

The present invention relates to boiler feed water treating technology, and is especially water treating method for directly air cooled steam drum boiler. Under the reductive condition, the condensed water from the condensing water tank is added with ammonia before entering the boiler directly under the condition of closing the oxygen discharging door of deaerator and the water hydrogen conductivity is controlled below 0.2microS / cm. In case of poor water quality, the oxygen discharging door is opened to convert into reductive mode. The present invention alters the traditional concept that dissolved oxygen will result in corrosion, and has double compact oxide film formed on surface of metal to inhibit the flow corrosion in thermal system, fine treatment of condensed water for long running time, no use of carcinogenic hydrazine and lowered ammonia adding amount for environment protection and health, and raised equipment utilization.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

Method for cleaning polypropylene fiber rope filtering elements of powdered resin filter

ActiveCN102078713AReduce dosageExtended operating cycleLoose filtering material filtersGravity filtersAcid washingSalt water

The invention discloses a method for cleaning polypropylene fiber rope filtering elements of a powdered resin filter, which is designed to prolong the running period of the filter, prolong the service life of filter filtering elements and reduce the running cost. The method comprises the following steps of: firstly carrying out the deoiling circulation cleaning, establishing the cleaning circulation after fully filling water into the filter, starting heat-tracing steam to heat the filter, charging the compressed air into the filter for cleaning in a shaking manner, and completely discharging the residual liquid; secondly carrying out the deferrization circulation acid washing, establishing the cleaning circulation after fully filling water into the filter, starting heat-tracing steam to heat the filter, adding a raw liquid of a citric acid corrosion inhibitor to a membrane paving box, filling demineralized water into the membrane paving box, adding a mixed solution of the citric acid and ammonia water in the membrane paving box to the filter by a membrane paving injection pump, adding industrial ammonia water to the filter by the membrane paving injection pump, charging the compressed air into the filter for cleaning in a shaking manner, and completely discharging the residual liquid; finally carrying out the explosion membrane cleaning on the filter according to a conventional process.

Owner:STATE GRID CORP OF CHINA +1

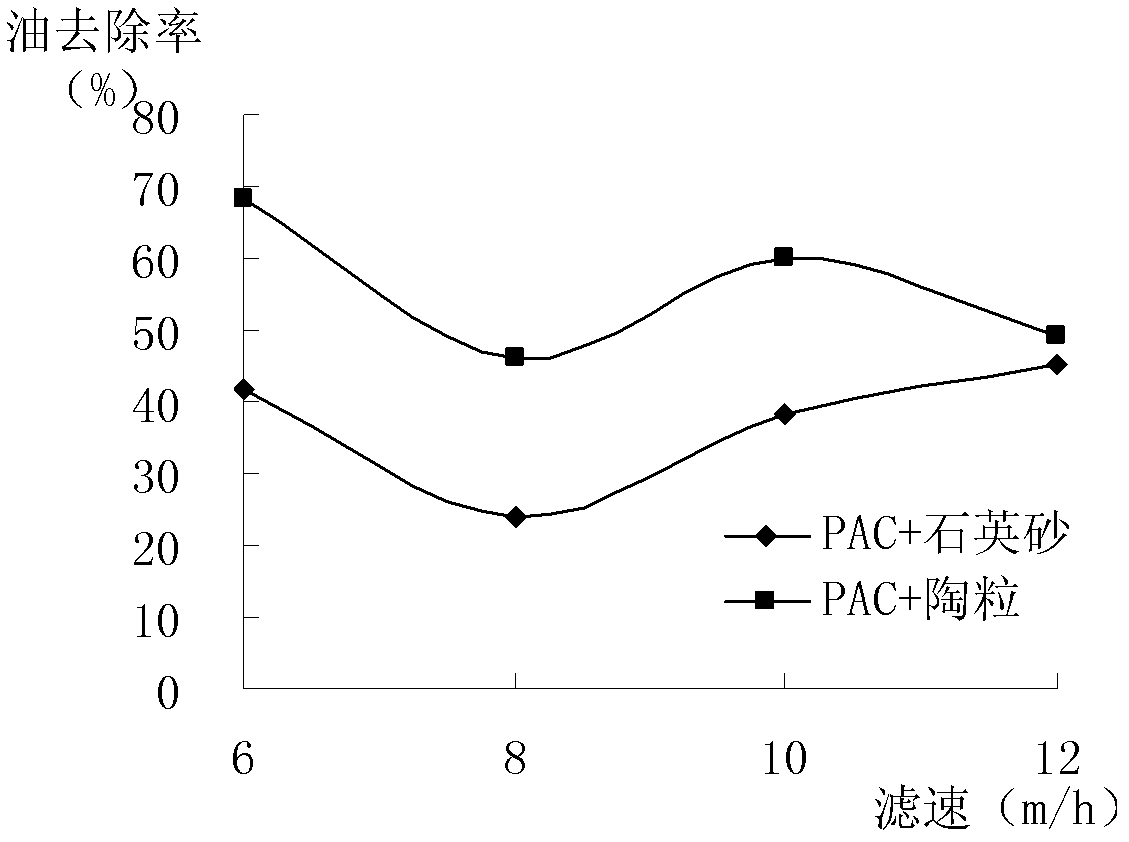

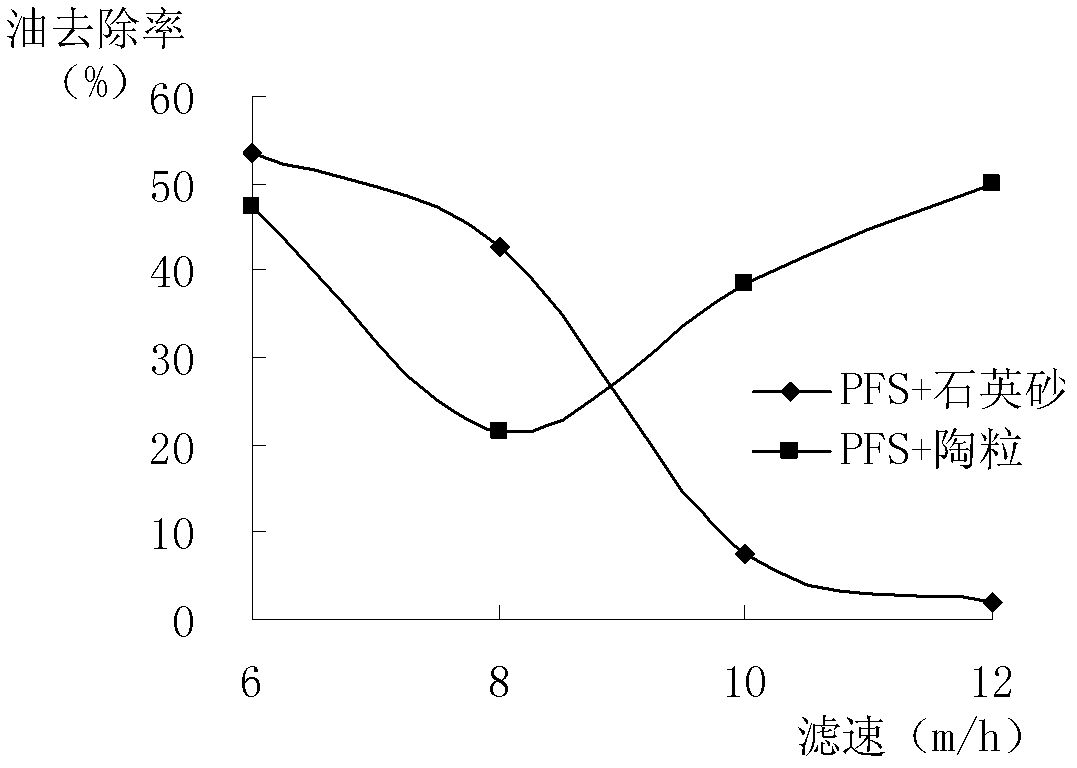

Reverse osmosis pretreatment deep oil-removal process for cold rolling oily wastewater

InactiveCN102311184AExtended chemical cleaning cycleGuaranteed uptimeMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSilt Density IndexChloride

The invention discloses a reverse osmosis pretreatment deep oil-removal process for cold rolling oily wastewater, which comprises the following steps of: (1) before the cold rolling oily wastewater enters a chemical film dipping filter, adding sodium hypochlorite with the volume concentration of 8-12ppm, basic aluminum chloride with the volume concentration of 2-4ppm and anionic polyacrylamide with the volume concentration of 0.05-.-0.2ppm into the cold rolling oily wastewater; (2) intercepting the flocculated cold rolling oily wastewater by using a multi-medium filter, controlling the filtering speed to be 4-6m / s, and controlling a silt density index (SDI) to be less than 3; and (3) allowing the pretreated cold rolling oily wastewater to enter a filter with a chemical film dipping filter element, and controlling the flux value of the filter element to be 0.1-0.4m<3> / m<2>s.

Owner:宝钢日铁汽车板有限公司

Sewage treatment system and sewage treatment method

InactiveCN102923875AIncrease the operating concentration ratioImprove water qualityMultistage water/sewage treatmentCooling towerUltrafiltration

The invention provides a sewage treatment system, which comprises an unwatering water tank, a low-speed decarbonizing device, a filter tank, a wastewater forebay and an industrial wastewater treatment system which are connected sequentially by using a water pipe, wherein the filter tank is connected to a clear water tank by the water pipe; the clear water tank is connected to a first-stage cooling tower and a second-stage cooling tower; the first-stage cooling tower and the second-stage cooling tower are connected to the wastewater forebay; one end of the industrial wastewater treatment system is connected to the clear water tank, and the other end of the industrial wastewater treatment system is connected to a sewage drainage tank; and a backwashing tank is connected to the wastewater forebay by the water pipe. In addition, the invention also provides a sewage treatment method using the sewage treatment system. By the method, the problem of high possibility of sewage blockage of an ultrafiltration and reverse osmosis system of the industrial wastewater treatment system caused by high salt content, hardness, alkalinity and content of organic matters and silicon of sewage of the industrial wastewater treatment system in the prior art is solved.

Owner:陕西陕煤黄陵矿业有限公司

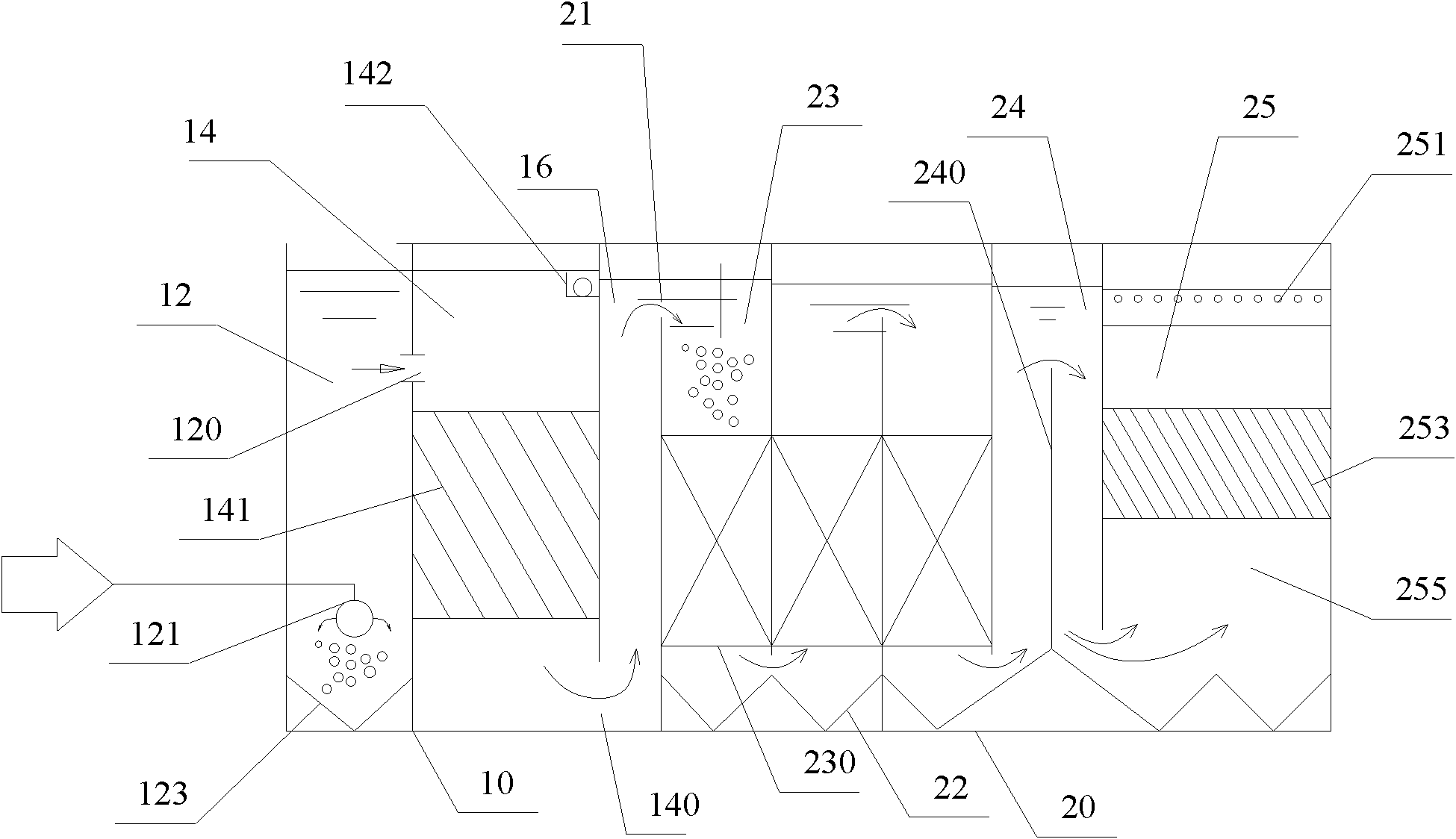

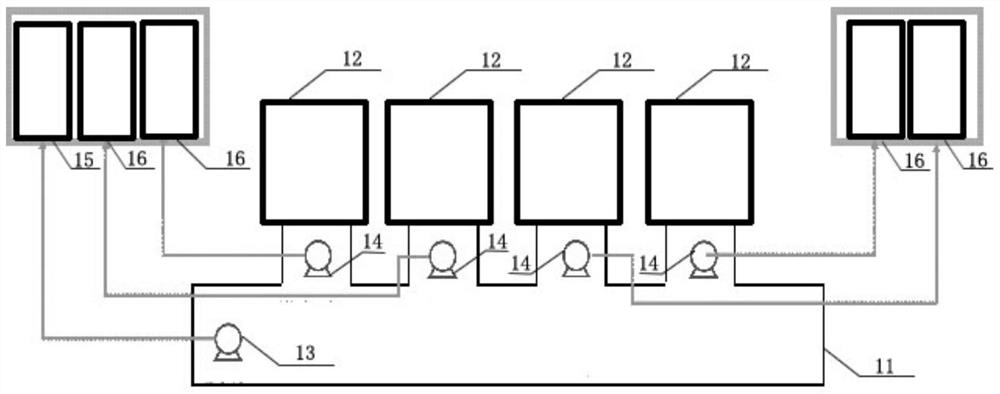

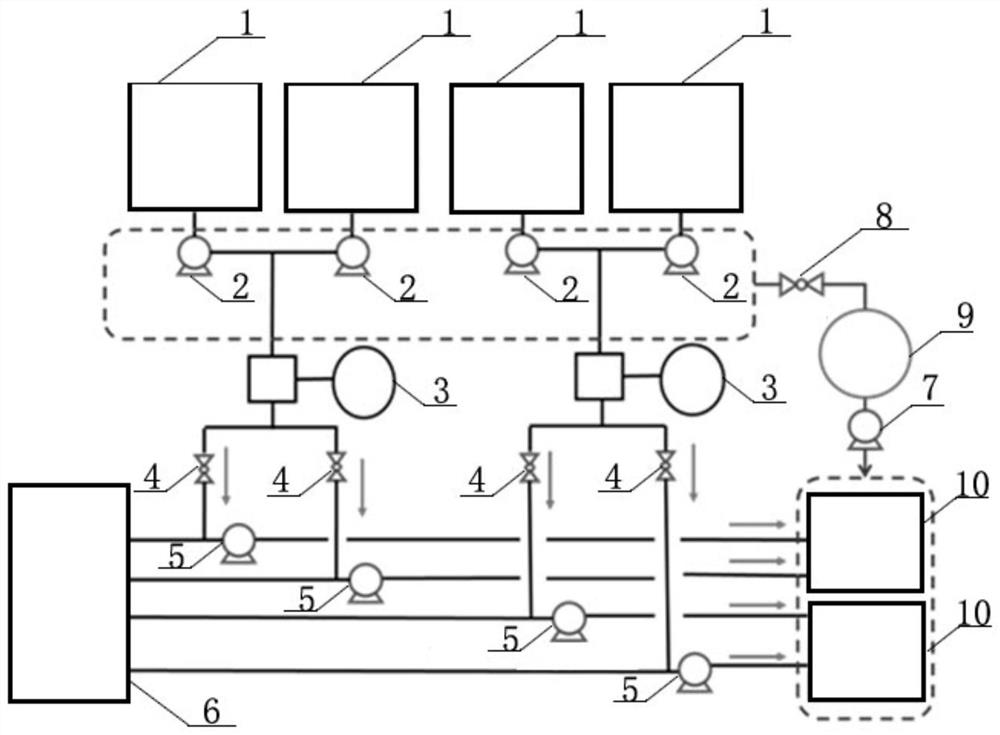

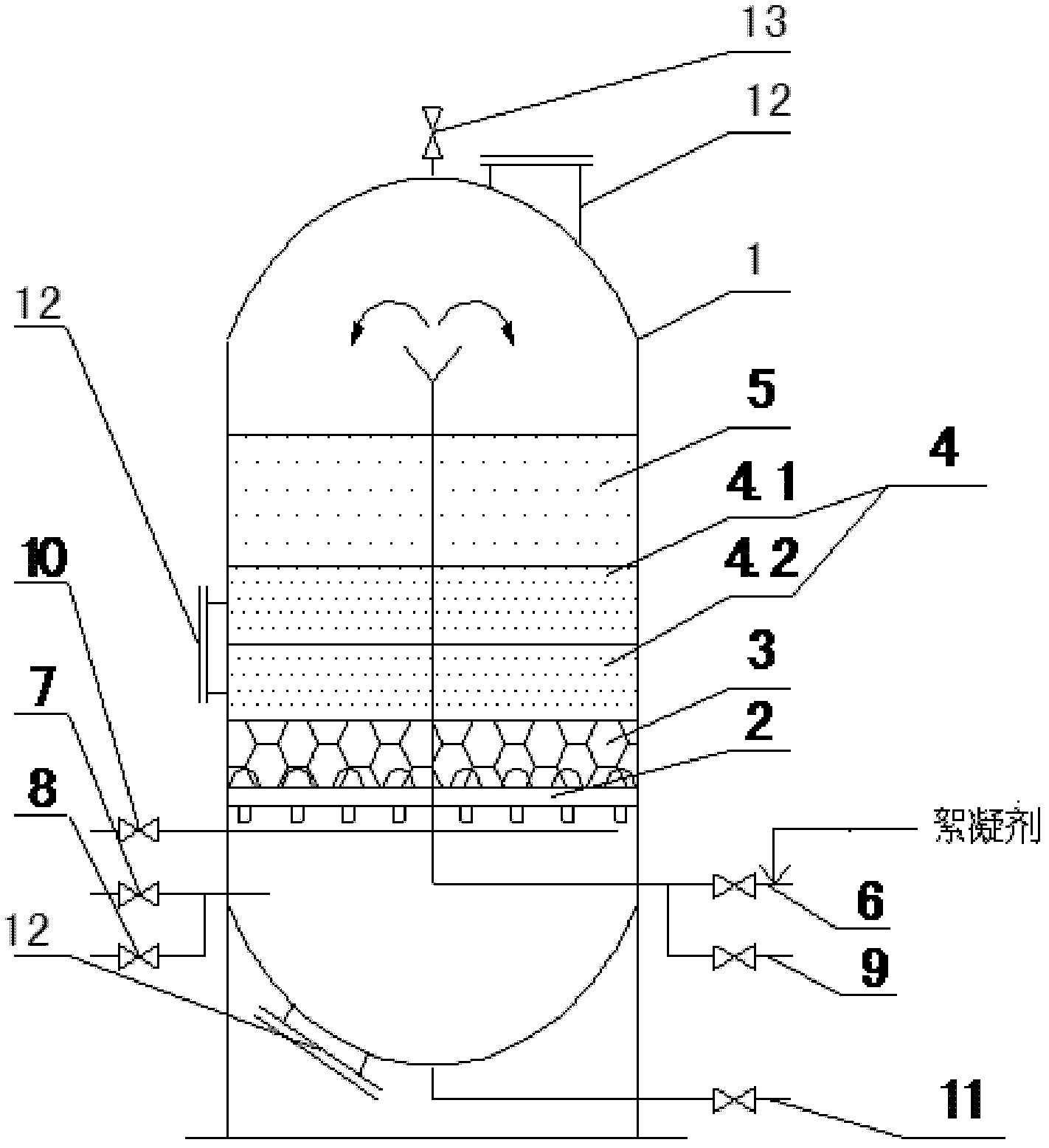

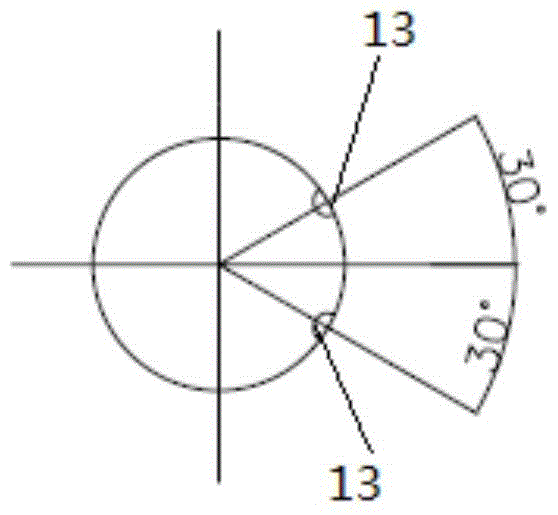

Advection sedimentation/immersion type ultrafiltration integrated water treatment device

InactiveCN103341285AShort processSmall footprintSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltration membraneVacuum pressure

The invention discloses an advection sedimentation / immersion type ultrafiltration integrated water treatment device, relating to an ultrafiltration integrated water treatment device and solving the technical problems of long process and large occupation area of an existing ultrafiltration water treatment device. The advection sedimentation / immersion type ultrafiltration integrated water treatment device comprises an advection sedimentation tank, an immersion type ultrafiltration membrane assembly, a membrane assembly supporting tool, an ultrafiltration water outlet pipe, an ultrafiltration water outlet valve, an ultrafiltration sucking pump, an online vacuum pressure sensing device, an ultrafiltration backwashing valve, an ultrafiltration backwashing pump, a bubble diffusing device, an aerating pipe, a gas flow meter, an aerating valve, an aerating pump, a steady flow plate, a mud collecting tank, a perforation mud discharging pipe, a mud discharging valve and a sawtooth-shaped backwashing overflow weir, wherein one end of the ultrafiltration water outlet pipe is communicated with the immersion filtration membrane assembly, the other end of the ultrafiltration water outlet pipe is communicated with the ultrafiltration water outlet valve, the ultrafiltration water outlet valve is connected with the ultrafiltration sucking pump, one end of the aerating pipe is connected with the bubble diffusing device, the other end of the aerating pipe is connected with the aerating valve, and the mud discharging valve is arranged at one end of the perforation mud discharging pipe, outside a tank. The advection sedimentation / immersion type ultrafiltration integrated water treatment device is mainly applied to the field of water treatment.

Owner:HARBIN INST OF TECH

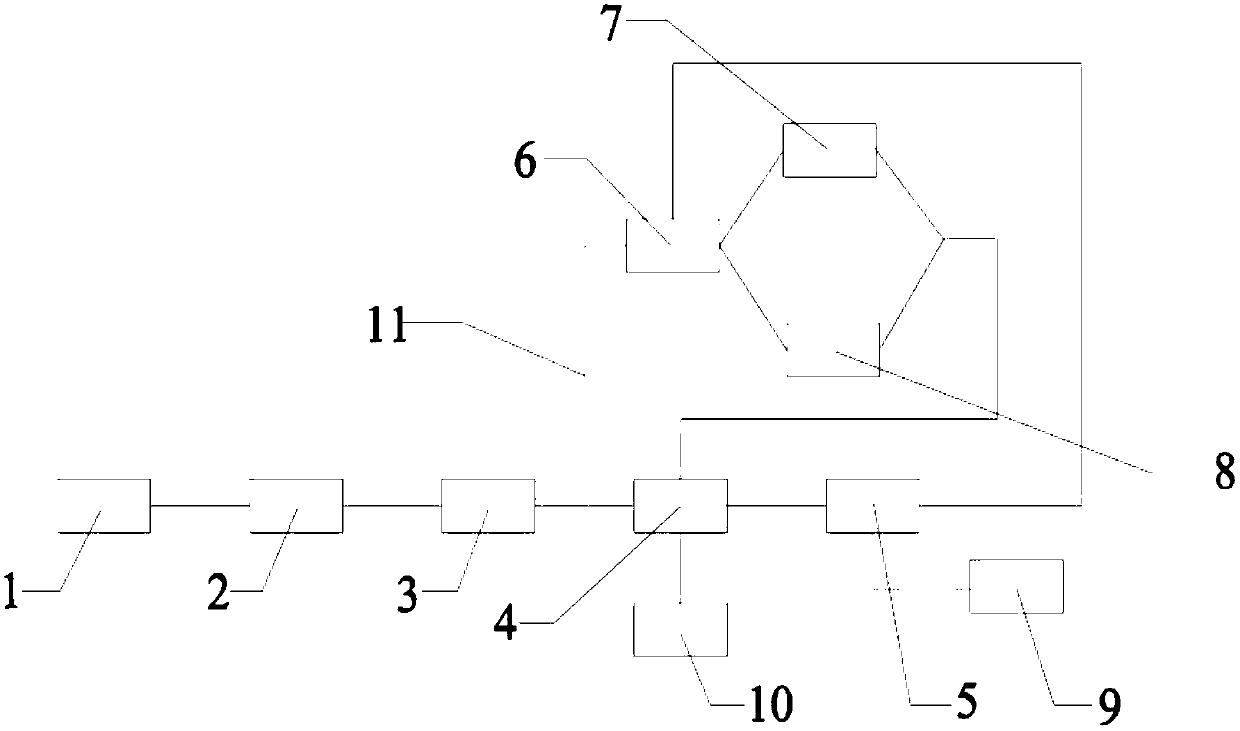

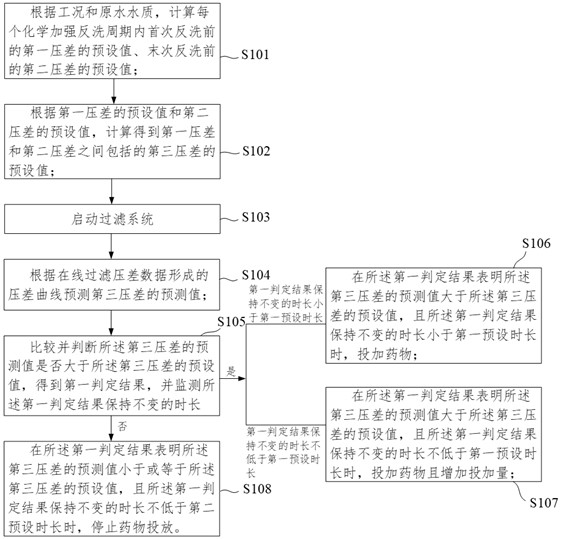

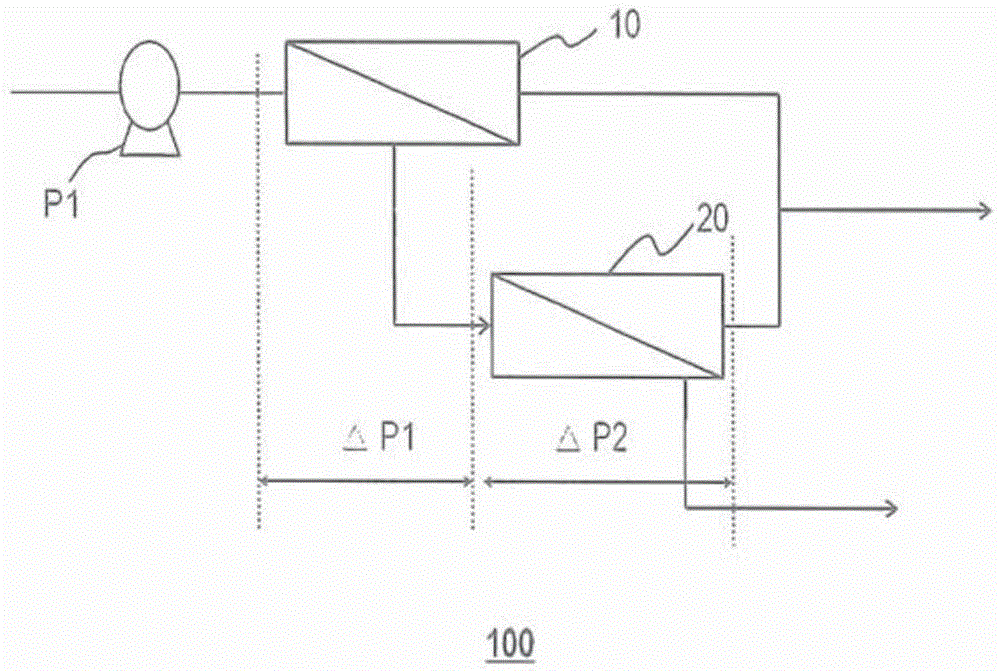

Ultrafiltration micro-flocculation accurate dosing control method and system

ActiveCN113044928AReduce dosageExtended chemical cleaning cycleWater treatment parameter controlMembranesFlocculationThermodynamics

The invention relates to the technical field of sewage treatment, and in particular, relates to an ultrafiltration micro-flocculation accurate dosing control method and system. The method comprises the steps: calculating a preset value of a first pressure difference before first backwashing and a preset value of a second pressure difference before last backwashing in each chemical enhanced backwashing period; calculating to obtain a preset value of a third pressure difference between the first pressure difference and the second pressure difference; predicting a predicted value of the third pressure difference; and comparing the preset value of the third pressure difference with the predicted value of the third pressure difference, and judging whether the chemical is continuously added or not. In the method provided by the invention, the preset value of the third pressure difference is obtained according to the preset value of the first pressure difference and the preset value of the second pressure difference, the predicted value of the third pressure difference is predicted according to the pressure difference curve formed by the online filtration pressure difference data, and the ultrafiltration operation state can be speculated by comparing the preset value of the third pressure difference and the predicted value of the third pressure difference; and the dosing state or dosage of a chemical can be adjusted in time according to the running state of ultrafiltration, so that good and stable running of an ultrafiltration system is ensured.

Owner:GREENTECH ENVIRONMENTAL CO LTD

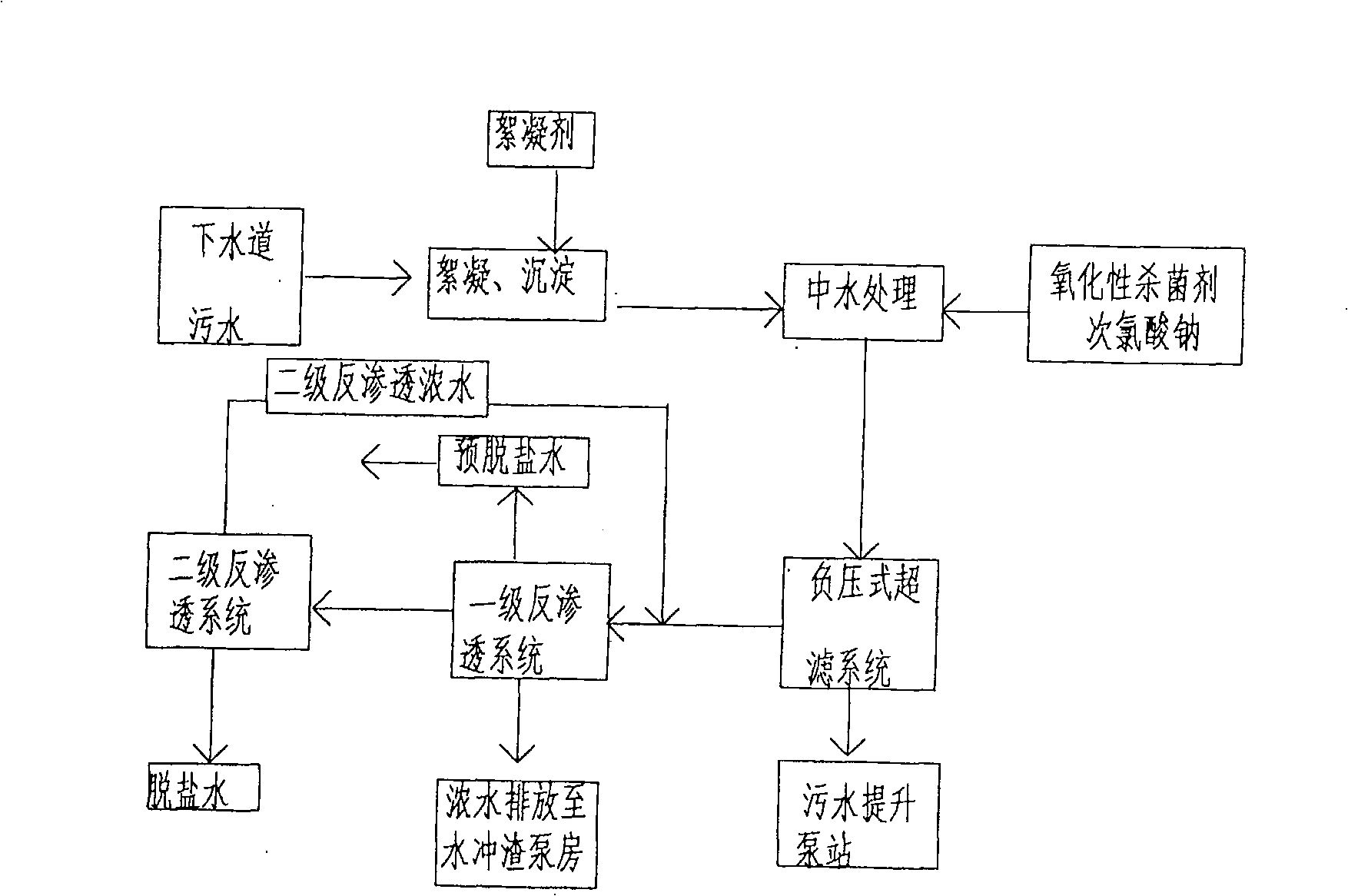

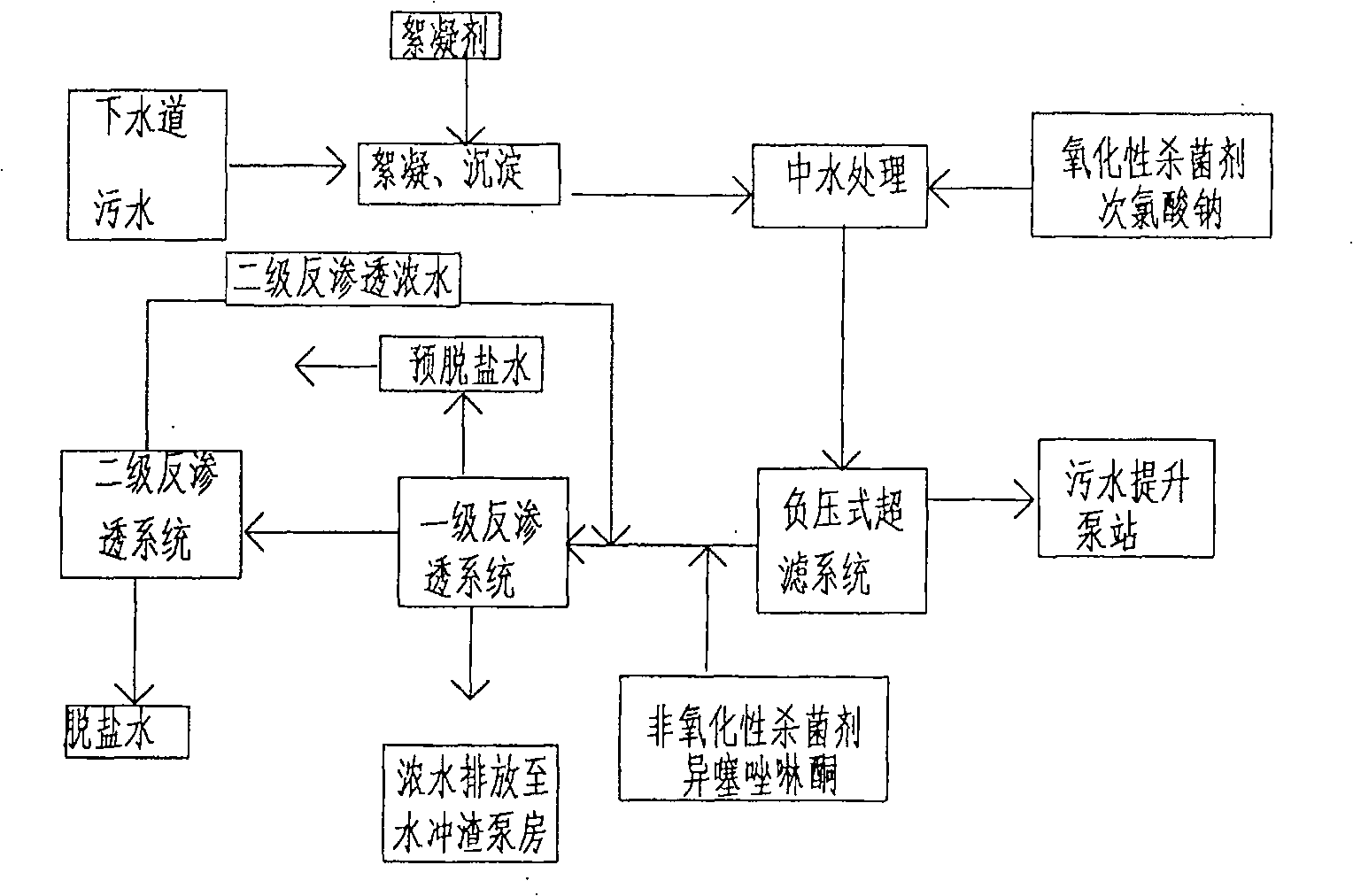

Efficient and antibacterial chemical sewage treatment method

InactiveCN106145434ALow running costGuaranteed uptimeGeneral water supply conservationMultistage water/sewage treatmentIsothiazolinoneFlocculation

An efficient and antibacterial chemical sewage treatment method is characterized by including the following procedures that firstly, sewage is recycled and reclaimed water is prepared, wherein sewage of chemical sewer is obtained and subjected to flocculation and precipitation, and the requirement for reclaimed water that the concentration of suspended solids in outflow water is smaller than 100 mg / l is met; secondly, primary sterilization is conducted, wherein the reclaimed water is filtered by means of a 1-mm grating filter, an oxidizing antibacterial agent, namely sodium hypochlorite, is added for sterilization, and the dosage is 2-3 mg / l; thirdly, ultrafiltration treatment and secondary sterilization are conducted, wherein the reclaimed water in the second step is subjected to ultrafiltration treatment, SDI is smaller than 3, a non-oxidizing antibacterial agent, namely isothiazolinone, is added in an impact mode in an ultrafiltration water generating mother tube for secondary sterilization, dosage is conducted every 5-8 days and each dosage lasts for 60 min, and the dosage is 30-50 mg / l; fourthly, reverse osmosis desalination treatment is conducted, wherein water subjected to ultrafiltration and secondary sterilization enters a reverse osmosis device for desalination treatment.

Owner:陈留成

Hollow fiber ultrafiltration membrane

The invention provides a hollow fiber ultrafiltration membrane which comprises an outer skin layer, an inner skin layer, a first inner layer adjacent to the outer skin layer and a second inner layer adjacent to the inner skin layer. The hollow ultrafiltration membrane provided by the invention has the advantages of high membrane strength, small membrane pore size, narrow pore size distribution and high membrane flux. A hollow fiber ultrafiltration membrane product can effectively remove pollutants in wastewater, such as colloid, suspended matters, microorganisms and the like, in an actual sewage deep treatment and reusing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic-phosphonate-based organic energy-saving and emission-reduction agent for industrial boiler

InactiveCN104773848AReduce sewage rateReduce rateScale removal and water softeningPhosphateMorpholine

The invention discloses an organic-phosphonate-based organic energy-saving and emission-reduction agent for an industrial boiler. The organic-phosphonate-based organic energy-saving and emission-reduction agent comprises, by mass, 15%-25% of 1-Hydroxyethylidene-1,1-diphosphonic acid, 10%-15% of butane phosphate-1,2,4-tricarboxylic acid, 5%-10% of maleic acid-acrylic copolymer, 2%-3% of morpholine, 1%-2% of diethylhydroxylamine, 0.2 %-0.8% of tannin alkali metal salt and the balance water. The organic-phosphonate-based organic energy-saving and emission-reduction agent is free of inorganic chemical ingredients, all the components in the formula are organic, the water dissolved solid matter, the blowdown rate and the heating surface scaling rate of the industrial boiler are lowered effectively, and the chemical cleaning period of the boiler is prolonged; the agent is high in scale inhibition corrosion inhibition efficiency, small in feeding quantity, free of poison, low in cost, wide in ingredient source, stable in high-temperature performance, capable of adjusting the return condensate quality and lowering the return water system corrosion rate and suitable for industrial boilers of various types and various supply water quality conditions, and the boiler operation water quality index of the boilers is not affected in use.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Chemical cleaning method for RO/NF membrane system consisting of two arrays

ActiveCN105592915ALow costImprove cleaning efficiencyMembranesUltrafiltrationFiltrationMembrane fouling

The present invention relates to a chemical cleaning method for an RO / NF membrane system consisting of two arrays and, more particularly, to a chemical cleaning method for an RO / NF membrane system consisting of two arrays, capable of predicting a substance that causes membrane fouling and chemically cleaning a reverse osmosis membrane module and a nanofiltration membrane module using a chemical cleaning agent suitable for the substance, thereby restoring and maintaining the filtration performance of the membrane. The membrane fouling phenomenon occurs due to various causes during the membrane filtering process. In this case, the present invention can enhance cleaning efficiency by predicting a substance that causes membrane fouling and performing chemical cleansing with a chemical cleaning agent suitable for the substance. Accordingly, a longer chemical cleaning cycle is guaranteed, thereby reducing the time consumed for chemical cleaning, chemical costs, etc.

Owner:COWAY ENTECH CO LTD

Outer-layer coating tubular microfiltration membrane as well as preparation method and assembly thereof

PendingCN108043250AHigh strengthSolution to short lifeUltrafiltrationVolumetric Mass DensityProduced water

The invention discloses an outer-layer coating tubular microfiltration membrane. The outer coating tubular microfiltration membrane comprises a macromolecular microporous filter tube, wherein one endof the macromolecular microporous filter tube is sealed, and only the outer layer and micropores of the macromolecular microporous filter tube are coated with tubular microfiltration membranes adopting an anchored structure. The outer-layer coating tubular microfiltration membrane has the advantages of high strength, long service life, high filling density and the like. An assembly of the outer-layer coating tubular microfiltration membrane is operated in external pressure type and dead-end filtration manners, the proportion of concentrated water to produced water can be adjusted, backwashingand aeration can be conducted periodically, the chemical cleaning cycle of the membrane assembly can be prolonged, and the energy consumption and the wastewater treatment cost can be reduced.

Owner:SUZHOU KAHO POLYMER TECH CO LTD

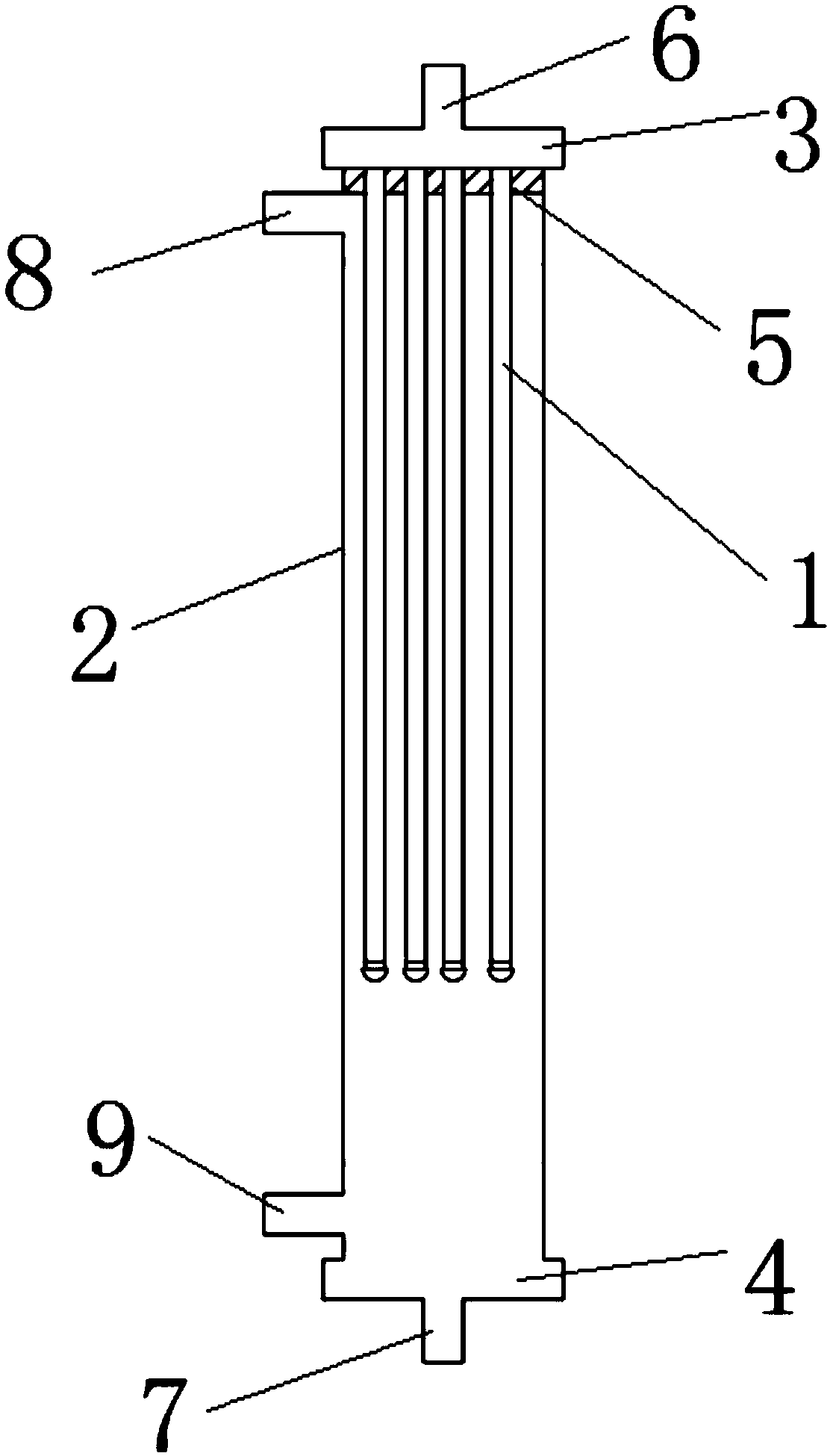

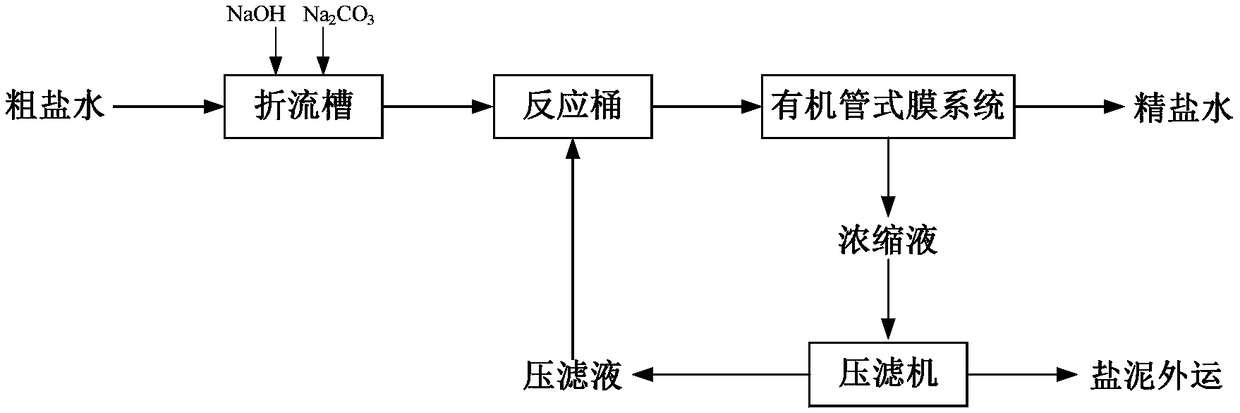

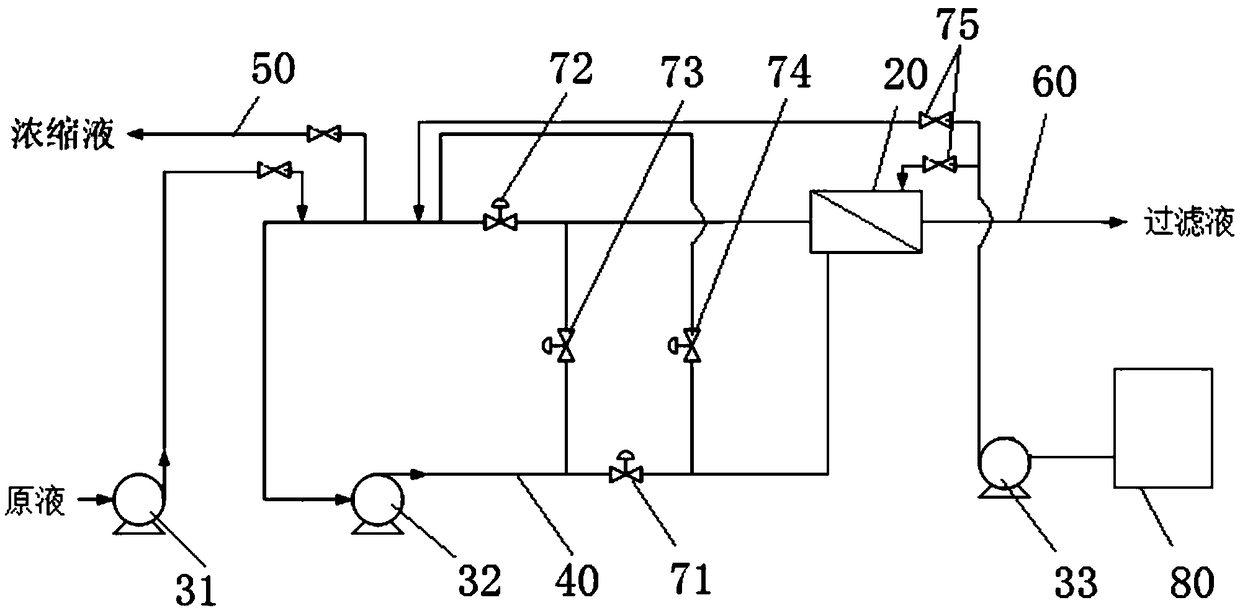

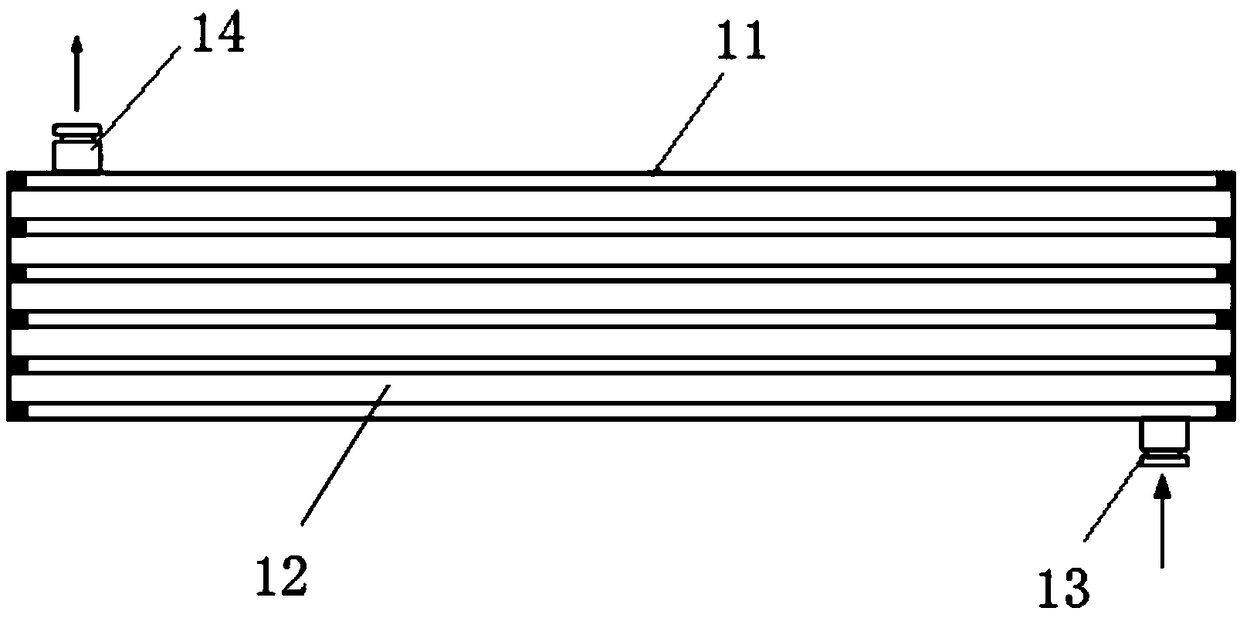

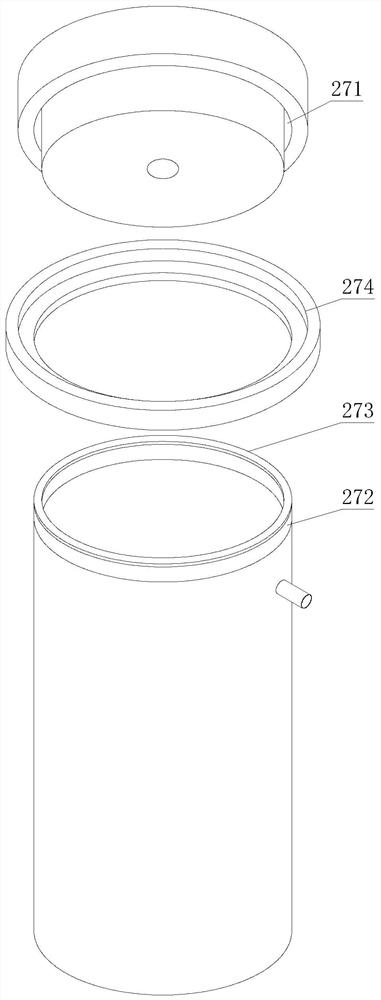

Technology and device of refining brine through organic tubular membrane

InactiveCN109133112ARestore performanceNot easy to accumulateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltrationSmall footprint

The invention relates to a technology and a device of refining brine through an organic tubular membrane. The technology comprises the steps of crude brine refining reaction and brine filtration, wherein the brine filtration is to filter crude brine after the refining reaction through an organic tubular membrane system to form the refined brine; the organic tubular membrane system comprises at least one organic tubular membrane stack; membrane stack inlets and membrane stack outlets of the organic tubular membrane stacks are connected by circulating pipes and circulating pumps to form a circulating system; and at least two organic tubular membrane components are in series connection to form each entire organic tubular membrane stack. The technology is advanced; a technical process is simple; the refined brine is high in quality; and the organic tubular membrane system is high in integration level, small in floor area and strong in anti-pollution ability.

Owner:安徽星奇达膜科技有限公司

Highly effective sterilization metallurgy sewage treatment method

InactiveCN100534930CLow running costGuaranteed uptimeGeneral water supply conservationWaste water treatment from metallurgical processLiquid wasteDisinfectant

The metallurgical effluent treating process with high bactericidal efficiency belongs to the field of waste water treating technology, and aims at raising the bactericidal efficiency of metallurgical effluent treating process. The process includes the following steps: 1, recovering effluent and preparing intermediate water; 2. the primary sterilizing with oxidant disinfectant; 3. ultrafiltering and secondary sterilizing with non-oxidant disinfectant; and 4. reverse osmosis desalting. The process can ensure the normal running of the reverse osmosis system, prolong its chemical cleaning period, lower metallurgical effluent treating cost and reduce environmental pollution caused by the exhausted waste detergent solution.

Owner:HEBEI IRON AND STEEL

Method and system for improving and transforming water production rate of membrane system

PendingCN112755797AGuaranteed stabilityReduce pollutionSemi-permeable membranesWater treatment parameter controlFiltration membraneWater production

The invention belongs to the technical field of sewage treatment, and discloses a method and a system for improving and transforming the water production rate of a membrane system. The method comprises the following steps: monitoring the quality of water produced by the membrane system in real time by using a bio-filter effluent quality monitoring subsystem, if the quality of the water produced exceeds a threshold value, evaluating membrane pollution by using an ultra-filtration membrane pollution analysis subsystem, and formulating the operation parameters of a membrane workshop back-washing dosing subsystem according to an evaluation result, so that the membrane component is subjected to back-washing. Through the evaluation of the ultra-filtration membrane pollution analysis subsystem, the operation parameters of the membrane workshop back-washing dosing subsystem are formulated, and the real-time monitoring of the bio-filter effluent quality monitoring subsystem is matched, so that the stable operation of the membrane system is realized.

Owner:BEIJING DRAINAGE GRP CO LTD

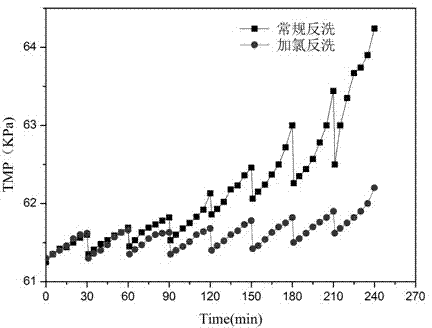

Backwashing method applicable to control of pollution of internal compression type membrane

InactiveCN103894071APollution controlExtended chemical cleaning cycleSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisChemistryPollutant

The invention relates to a backwashing method applicable to control of pollution of an internal compression type membrane and belongs to the field of water treatment. The backwashing method is applicable to ultra-filtration systems, microfiltration systems and the like. The backwashing method comprises the steps of directionally washing in the membrane, adding chlorine and backwashing and the like. The backwashing method applicable to control of pollution of the internal compression type membrane adopts a method of adding chlorine to carry out backwashing on account of the characteristics that pollutants in membrane filaments are strong in adhesion to the surface of the membrane and have small possibility of being removed by using a normal backwashing method; the back washing method comprises the following steps: oxidizing and modifying the pollutants adhered to the inner surfaces of the membrane filaments by adopting the oxidization performance of the chlorine, reducing the adhesion of the pollutants to the membrane, loosening and even peeling off a pollution layer of the membrane, carrying out backwashing and directional washing to wash the pollutants out of the internal compression membrane system, thus controlling the pollution of the ultra-filtration systems. In addition, by adopting the bactericidal performance of the chlorine, the membrane pollution caused due to bacterial growth can be effectively controlled. Since the method is capable of effectively controlling the membrane pollution, the chemical washing period of the internal compression type membrane can be prolonged, thus the service life of the membrane can be greatly prolonged.

Owner:HOHAI UNIV

Multilayer positive and negative reverse rotation ceramic membrane

PendingCN113578058AImprove stabilityEasy to assemble and disassembleSemi-permeable membranesMembrane technologyCeramic membrane

The invention discloses a multilayer positive and negative reverse rotation ceramic membrane, and belongs to the technical field of rotary ceramic membranes, the multilayer positive and negative reverse rotation ceramic membrane comprises a fixed support, a mounting platen is arranged above the fixed support, a mounting notch is formed in the mounting platen, a filtering tank is mounted in the mounting notch, and a ceramic filtering membrane group is arranged in the filtering tank; the ceramic filtering membrane set is sleeved on a power component, and the upper end of the power assembly penetrates through the bottom end of the filtering tank and is arranged in the filtering tank in a sealing manner. According to the multilayer positive and negative reverse rotation ceramic membrane, the stability of air pressure in the tank is improved, the filtering efficiency is improved, leakage is prevented, so that the whole pollution resistance is improved, the filtering effect is also improved, the sleeving hose is convenient to disassemble and replace through the sleeving ring, the chemical cleaning period of the filter membrane is greatly prolonged, the system does not need high flow and high pressure, the energy consumption is greatly saved, the output quality of the feed liquid is effectively ensured, and the feed liquid which does not meet the requirement can be conveyed through a return pipe and filtered again.

Owner:南京艾宇琦膜科技有限公司

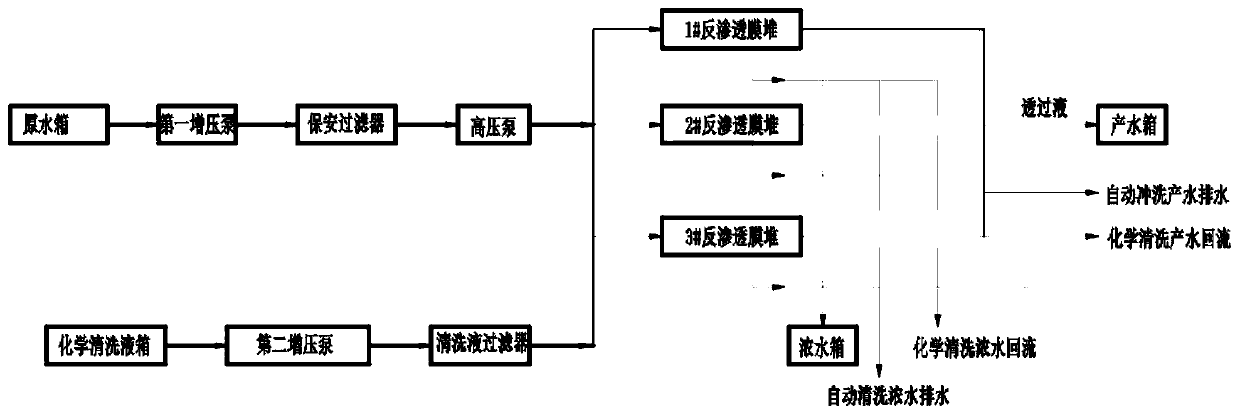

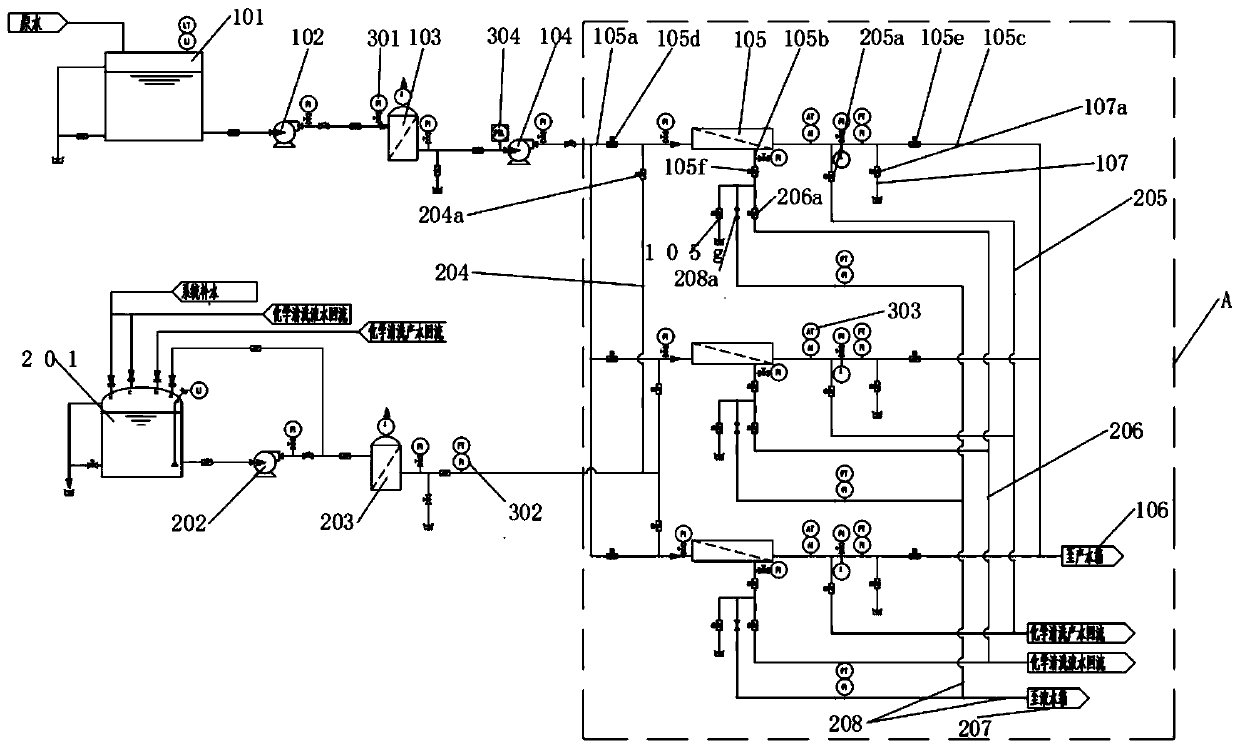

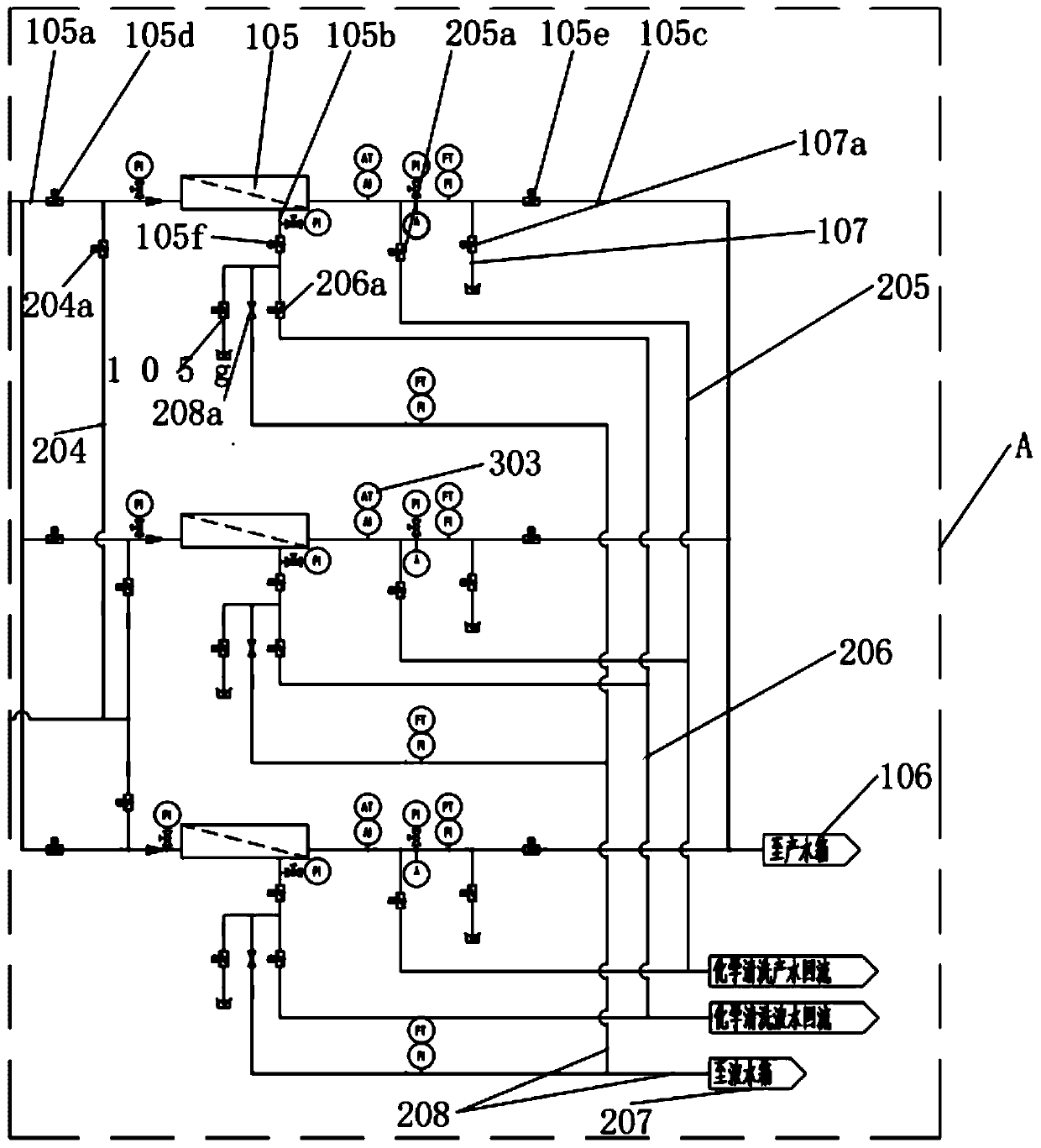

Reverse osmosis system capable of continuously operating and continuously chemically cleaning

PendingCN111362443AExtended chemical cleaning cycleReduce the frequency of chemical cleaningSpecific water treatment objectivesTreatment involving filtrationPollutantProcess engineering

The invention discloses a reverse osmosis system capable of continuously operating and continuously chemically cleaning. The system comprises a purification system and a cleaning system, the purification system comprises at least two groups of reverse osmosis assemblies, which are arranged in parallel; and the cleaning system comprises a plurality of branch cleaning assemblies arranged in parallel. The branch cleaning assemblies and the reverse osmosis assemblies are arranged in one-to-one correspondence; at least two reverse osmosis assemblies are arranged in parallel, when part of the reverse osmosis assemblies are polluted, the reverse osmosis assemblies can be seamlessly switched to other reverse osmosis assemblies to purify produced water, at the moment, the polluted reverse osmosis assemblies can be cleaned, it is guaranteed that the purification system continuously outputs purified water, and the water use requirements of production enterprises are met. Due to the fact that pollutants on the reverse osmosis surface can be flushed regularly, shutdown of the system is avoided, operation of the whole system is not affected, the chemical cleaning period of reverse osmosis is prolonged, the frequency of chemical cleaning of reverse osmosis is reduced, and the service life of membrane elements in the reverse osmosis system is prolonged.

Owner:率氢技术(北京)股份有限公司

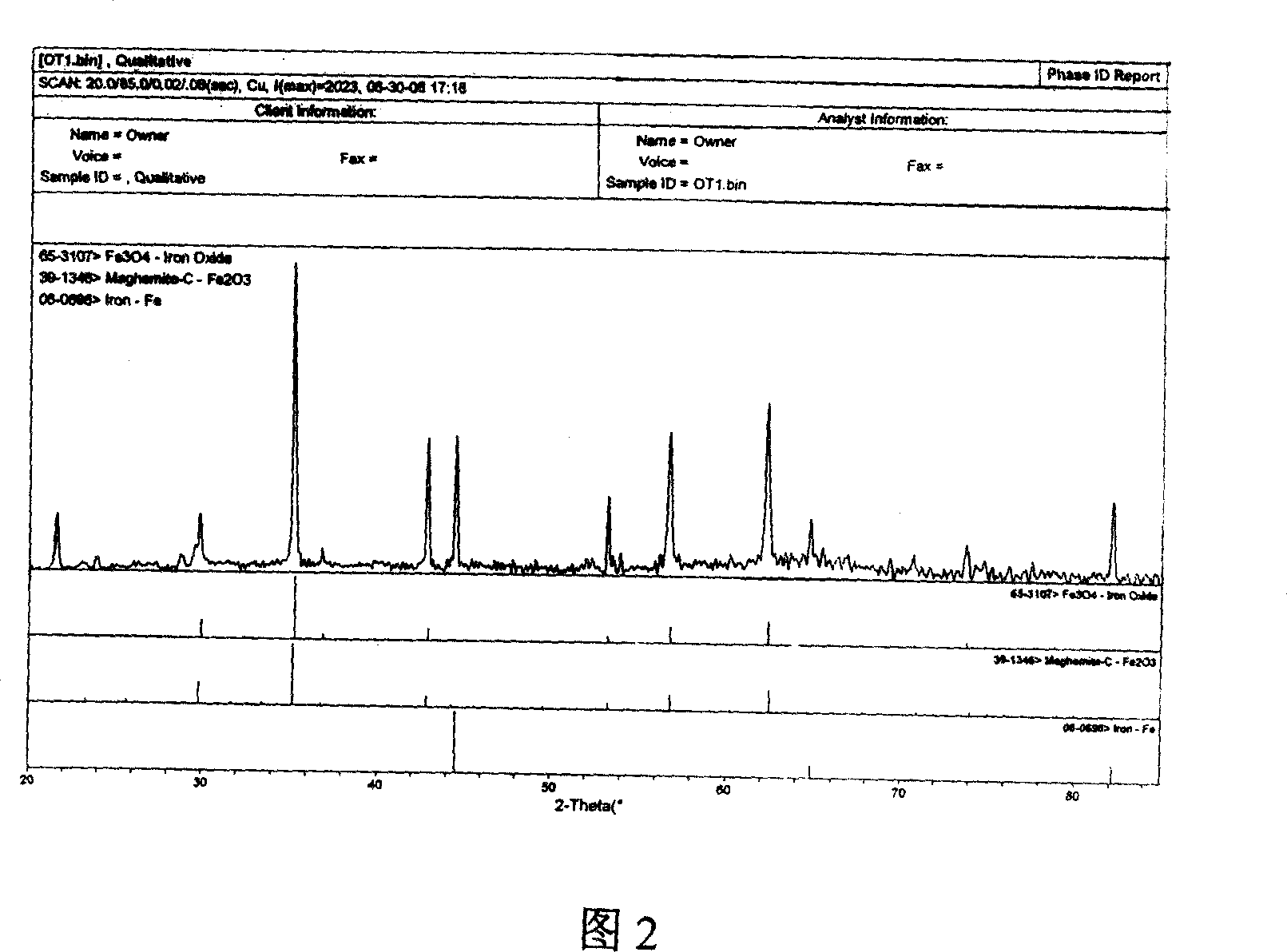

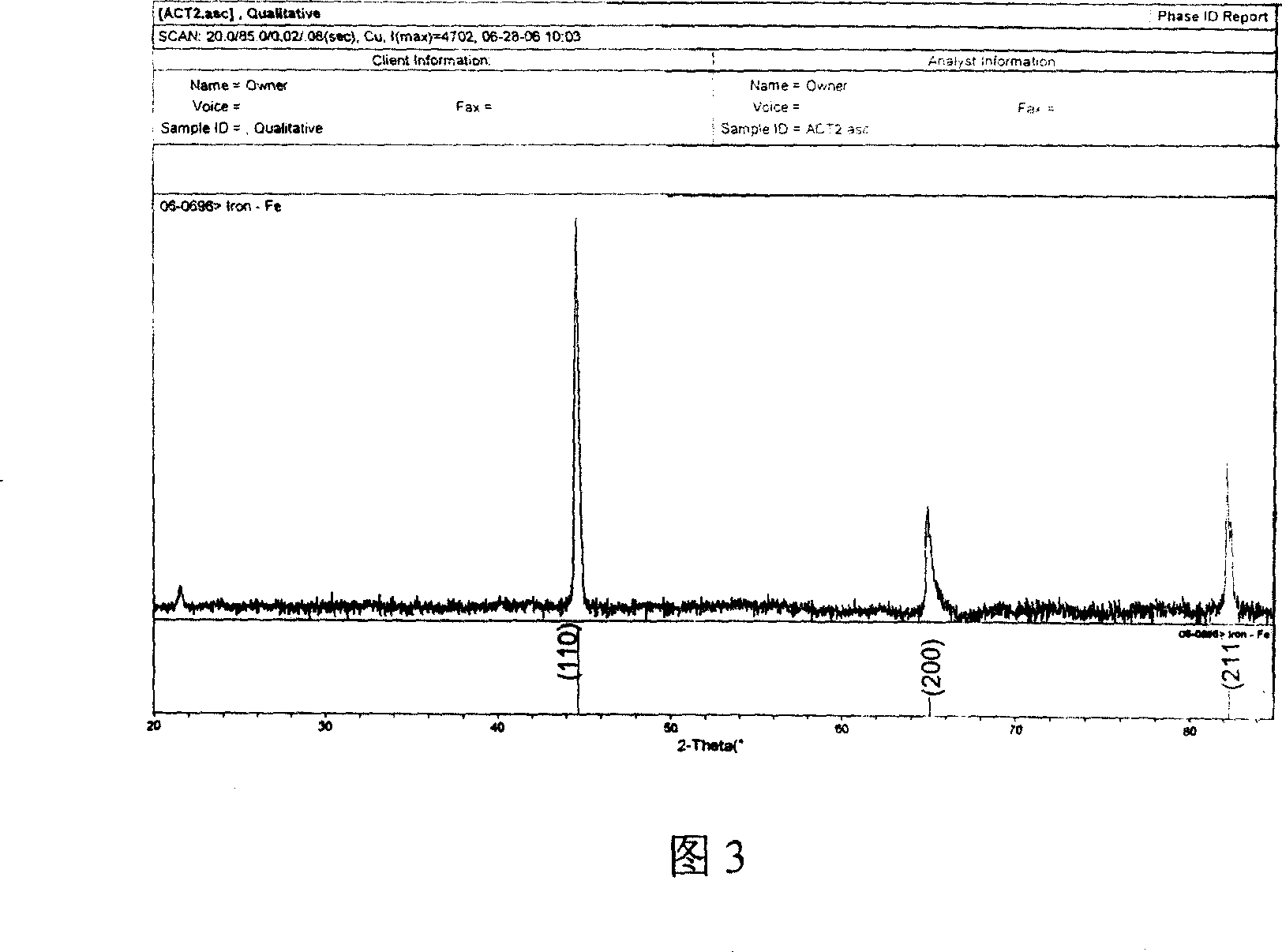

Advanced treatment technology for comprehensive wastewater of iron and steel enterprises

InactiveCN102491574BReduce Reuse CostsImproved permeate fluxWaste water treatment from metallurgical processWater/sewage treatment bu osmosis/dialysisUltrafiltrationTurbidity

Owner:武钢集团有限公司

Immersed membrane biological integrated reactor for up-to-standard reinjection of oilfield produced water into ultra-low permeable layer and application of immersed membrane biological integrated reactor

ActiveCN114804358AReduce pollutionExtended chemical cleaning cycleWaste water treatment from quariesWater treatment parameter controlAnaerobic chamberWater flow

The invention relates to an immersed membrane biological integrated reactor and application, in particular to an immersed membrane biological integrated reactor for standard reinjection of oilfield produced water into an ultra-low permeable layer and application. The invention aims to solve the problems that the organic matter degradation efficiency is low and the treated water quality does not reach the standard when the existing device is used for treating the reinjection ultra-low permeable layer produced water. An immersed membrane biological integrated reactor for an ultra-low permeable layer for standard reinjection of oilfield produced water comprises a box body, and the interior of the box body is divided into a plurality of reaction chambers by baffle plates along the water flow direction; the plurality of reaction chambers comprise a first anaerobic chamber, a second anaerobic chamber, a third anaerobic chamber, an anoxic chamber, a first aerobic chamber, a second aerobic chamber and an immersed membrane reaction chamber which are sequentially connected in series. The invention relates to a submerged membrane biological integrated reactor for reinjecting oilfield produced water to an ultra-low permeable layer after reaching the standard, which is used for treating the produced water of the ultra-low permeable layer after being reinjected. According to the invention, the immersed membrane biological integrated reactor for reinjection of oilfield produced water to the ultra-low permeable layer after reaching the standard can be obtained.

Owner:DAQING OILFIELD ENG +1

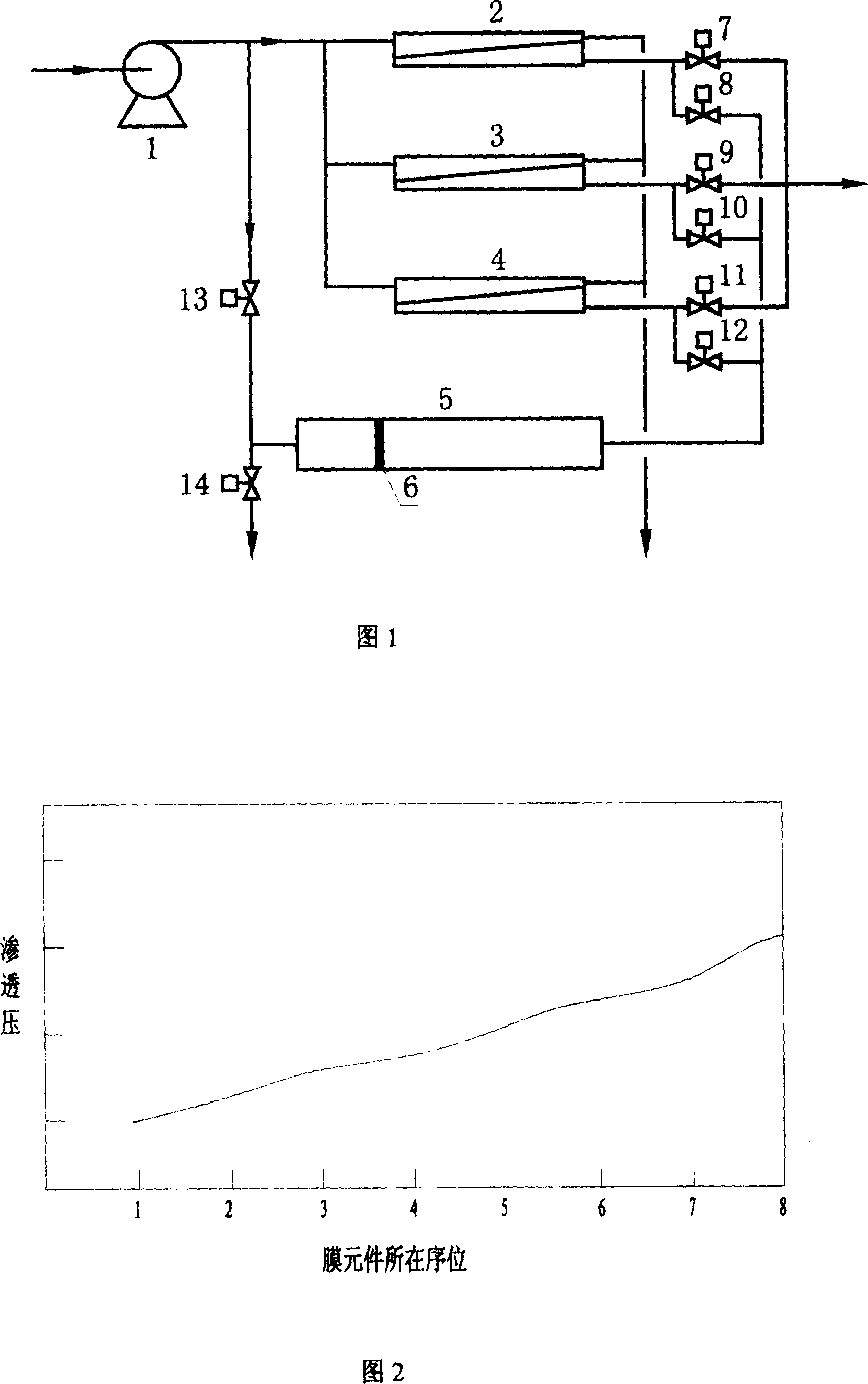

Reverse osmosis desalinization system capable of on-line back washing

InactiveCN1328179CLow water quality requirementsPlay a protective effectGeneral water supply conservationReverse osmosisWater qualityFresh water

The present invention discloses a reverse osmosis desalination equipment capable of implementing on-line back-purge. It includes high-pressure pump, reverse osmosis membrane component whose concentrated water side is connected with water outlet end of high-pressure pump, water-producing pipe and water-producing valve which are connected with water-producing side of the described reverse osmosis membrane component. Besides, said equipment also includes raw water-supplying valve and back-purge water cylinder with piston. Said invention also provides the connection mode of all the above-mentioned components.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Hollow Fiber Ultrafiltration Membrane

The invention provides a hollow fiber ultrafiltration membrane which comprises an outer skin layer, an inner skin layer, a first inner layer adjacent to the outer skin layer and a second inner layer adjacent to the inner skin layer. The hollow ultrafiltration membrane provided by the invention has the advantages of high membrane strength, small membrane pore size, narrow pore size distribution and high membrane flux. A hollow fiber ultrafiltration membrane product can effectively remove pollutants in wastewater, such as colloid, suspended matters, microorganisms and the like, in an actual sewage deep treatment and reusing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

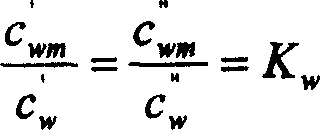

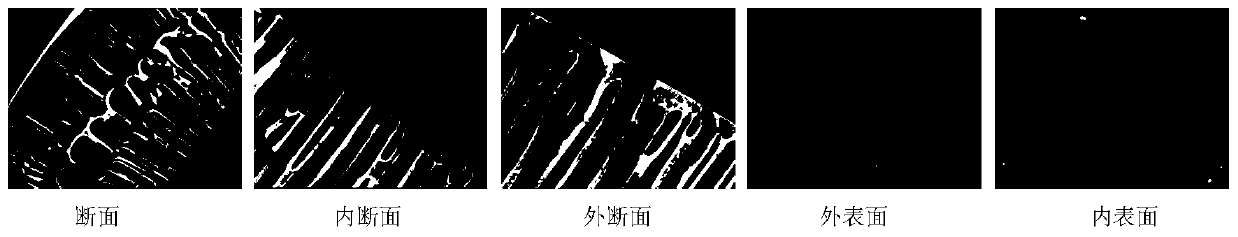

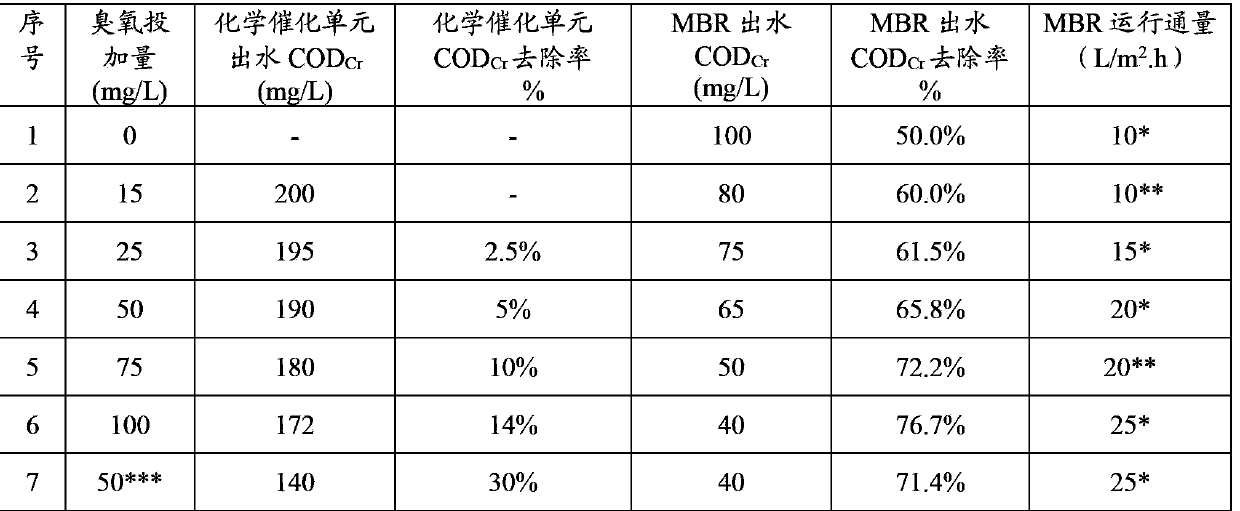

Slack coal pressure gasification wastewater recycling treatment method and treatment system as well as application

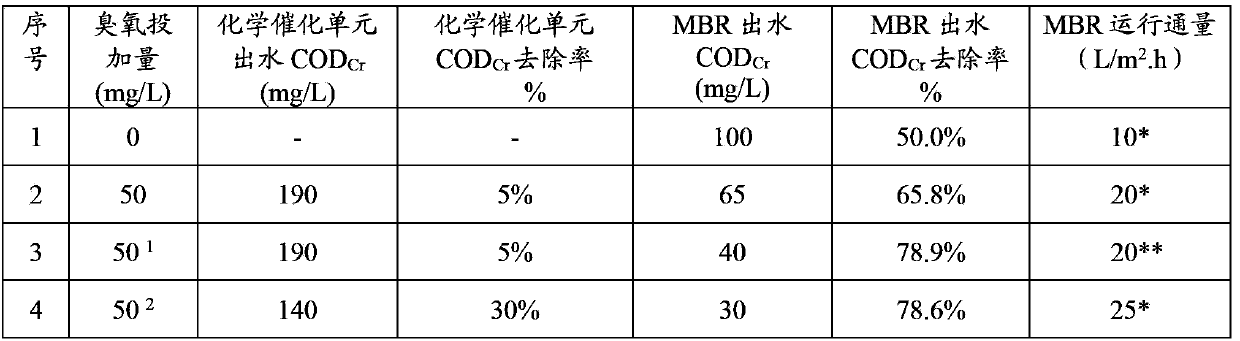

InactiveCN103288308BReduce investment and construction costsSmall footprintWater/sewage treatment with mechanical oscillationsDispersed particle separationWater useCatalytic oxidation

The invention provides a slack coal pressure gasification wastewater recycling treatment method and treatment system as well as application. The treatment method sequentially comprises the following steps of: (1) performing coagulating sedimentation on the wastewater to obtain wastewater after the coagulating sedimentation treatment; (2) performing chemical catalysis on the wastewater obtained by the step (1) to obtain wastewater after the catalytic oxidation treatment; (3) performing membrane bioreaction on the wastewater obtained by the step (2) to obtain wastewater after the membrane bioreaction treatment; and (4) performing reverse osmosis on the wastewater obtained by the step (3) to obtain recycling water.

Owner:DATANG INT CHEM TECH RESINST

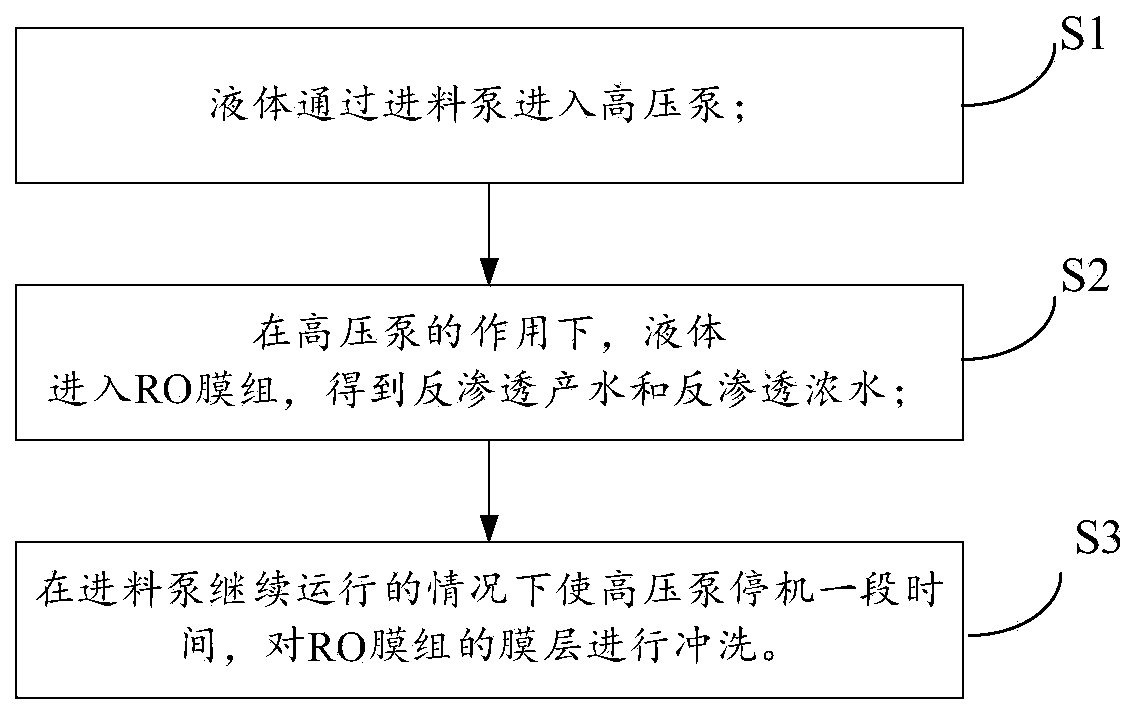

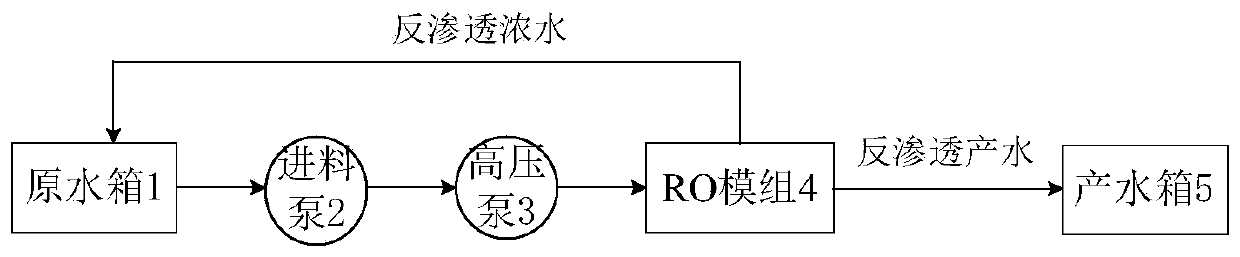

RO membrane module system and operation method

InactiveCN111470585AReduce pollutionExtended chemical cleaning cycleSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisThermodynamicsReverse osmosis

The invention provides an RO membrane module system and an operation method. Liquid enters a high-pressure pump through a feeding pump; under the action of the high-pressure pump, the liquid enters anRO membrane module to obtain reverse osmosis produced water and reverse osmosis concentrated water; and under the condition that the feeding pump continues to operate, the high-pressure pump is stopped for a period of time, and a membrane layer in the RO membrane module is flushed. By utilizing the principle of a reverse osmosis membrane, the pollution of the RO membrane module can be effectivelydelayed, and the chemical cleaning period of the RO membrane module is prolonged by 1.5-2 times. The chemical cleaning period of the RO membrane module is prolonged so that the cost of chemical agents for cleaning the RO membrane module is reduced, the long-time stable operation of the system is ensured, the enterprise investment cost can be effectively reduced, and energy conservation and emission reduction are realized for enterprises. The whole process flow of the system is simple, and the system has the characteristics of simple device structure, strong operability, small occupied area and the like.

Owner:XIAMEN JIARONG TECH CO LTD

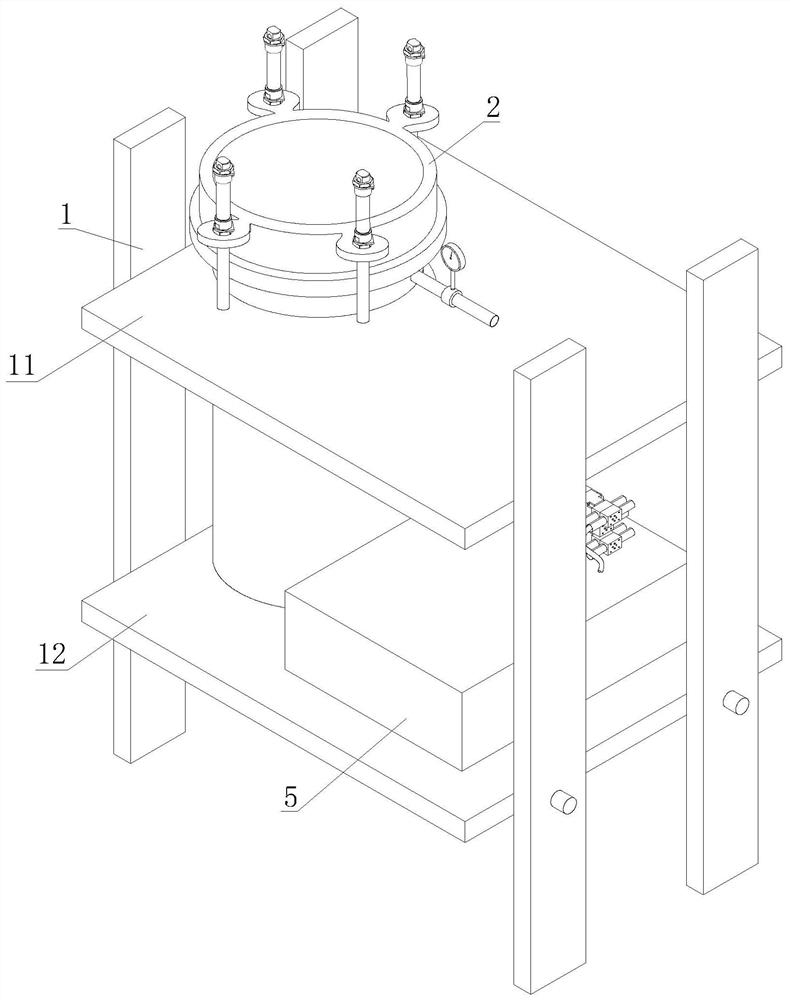

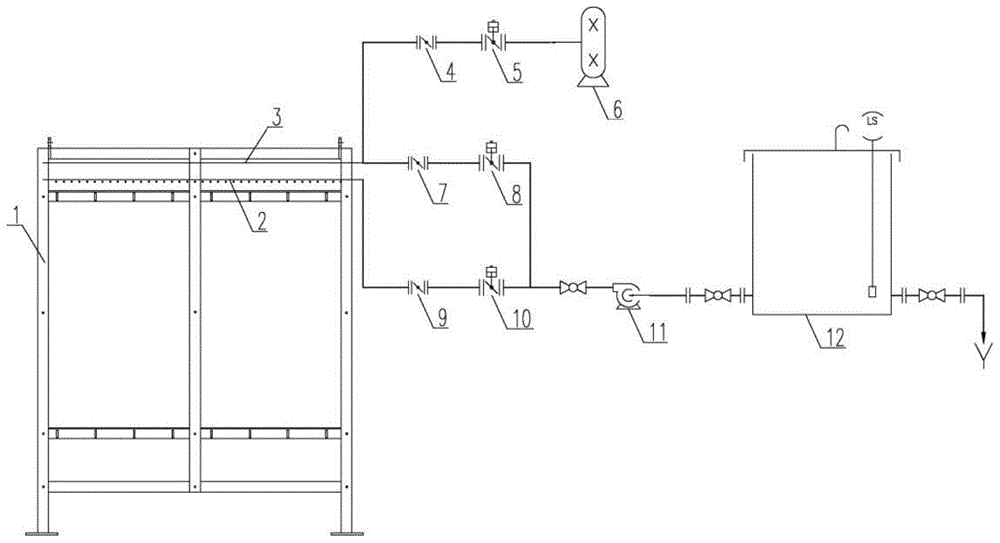

A pulse type flat membrane bioreactor flushing device and flushing method thereof

ActiveCN104944571BRealize fully automatic controlWash thoroughlySemi-permeable membranesSustainable biological treatmentJet flowGas phase

The invention discloses an impulse type flushing device for a flat membrane bioreactor and a flushing method thereof. The impulse type flushing device for the flat membrane bioreactor comprises a flat membrane bioreactor body, a water distributing pipe, an air blower, a back flushing water tank, a water pump, a first electromagnetic valve, a second electromagnetic valve and a third electromagnetic valve. According to the flushing device, off-line flushing and any chemical reagent are not needed; spiral jet flows are ejected from spiral jet holes and / or spiral jet nozzles to the flat membrane in multiple directions by the outer surface of the flat membrane, so that effective and uniform flushing for the outer surface of the flat membrane can be achieved, and the defect that in the past, sludge adheres to the surface of the flat membrane and blocks hole channels is solved; liquid phase back flushing and gas phase back flushing are carried out alternatively on the inner surface of the flat membrane in an impulse manner, so that the dirt in the membrane can be extruded out reversely, and the flow channels are dredged; the dirt on the surfaces of the hole channels is blown off by gas phase and washed away by liquid phase later, and gas phase back flushing and liquid phase back flushing are circulated, so that the hole channels of the membrane are cleaned thoroughly; the flushing method is efficient and thorough.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com