Advanced treatment technology for comprehensive wastewater of iron and steel enterprises

A comprehensive wastewater and advanced treatment technology, applied in metallurgical wastewater treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc. Chemical cleaning cycle, the effect of reducing the cost of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

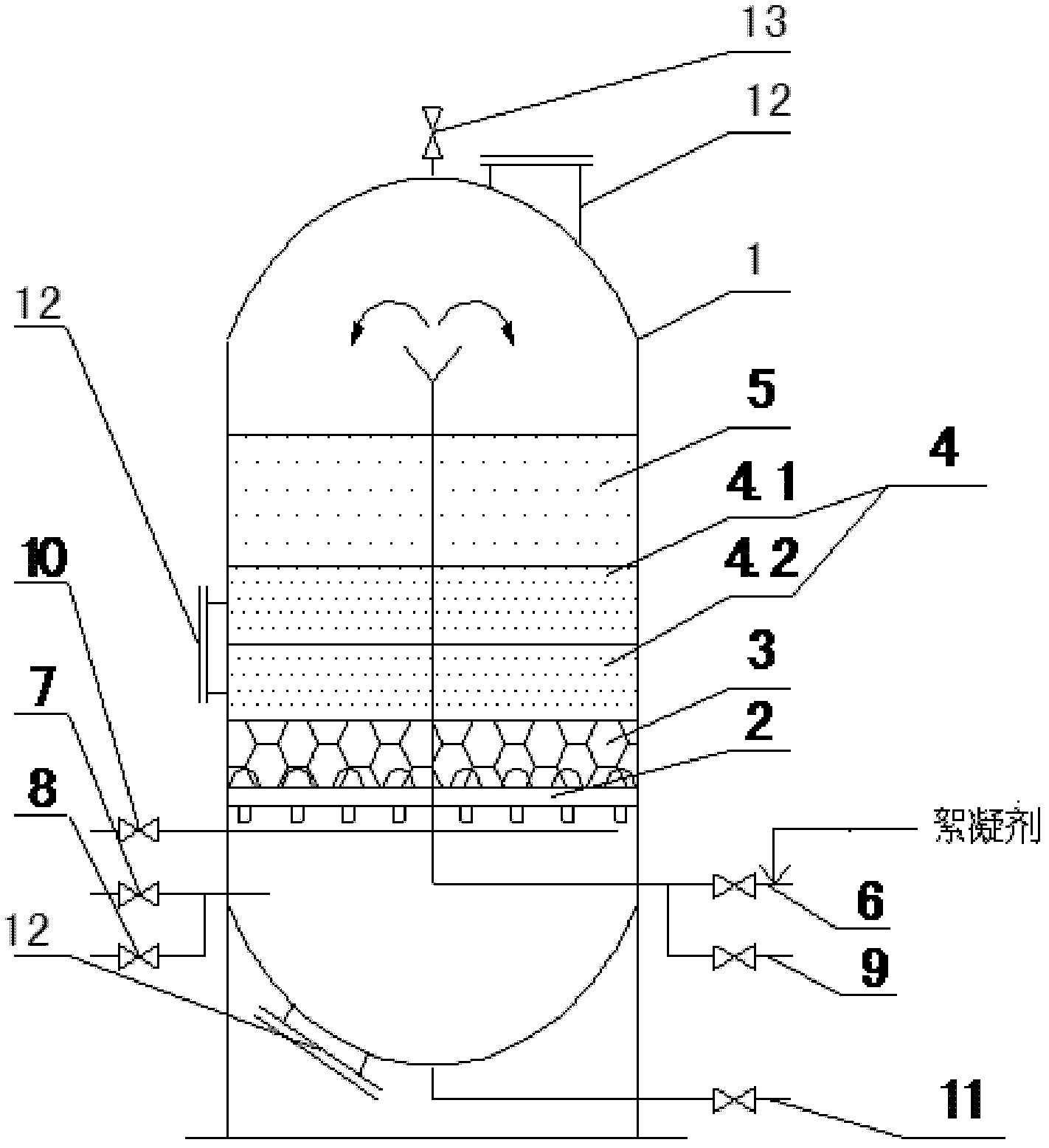

[0026]Pass the reused wastewater through the pressure pipeline (according to the oil content index of the reused wastewater in the pipeline, it is judged not to add or add flocculant for micro-flocculation) from the filter water inlet 6 through the pipeline to the top of the filter material area of the tank body 1, and then After filtering through the coarse filter layer 5, the upper fine filter layer 4.1, the lower fine filter layer 4.2, and the supporting area to remove oil and turbidity, it flows out through the filter outlet 7 below the water distribution area 2; the reused waste water is filtered through multi-media After filter pretreatment, ultrafiltration and reverse osmosis treatment are carried out. In addition, under normal circumstances, the multi-media filter needs to be backwashed with air and water every 24 hours. The backwashing process is: first perform air washing for 3-5 minutes, then perform water-air mixed washing for 8-10 minutes, and finally wash with w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com