System for separating plastic from city garbage

A technology for urban garbage and plastics, which is applied in the field of garbage recycling and plastic recycling, which can solve the problems of poor operating environment for workers, high manual operation intensity, and complex components, so as to save recycling costs, avoid dust, and follow-up processing cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specification and specific embodiment, the present invention is described in further detail and completely, but the present invention is not limited, and the present invention is not limited to the content of the following examples. conventional methods in the art.

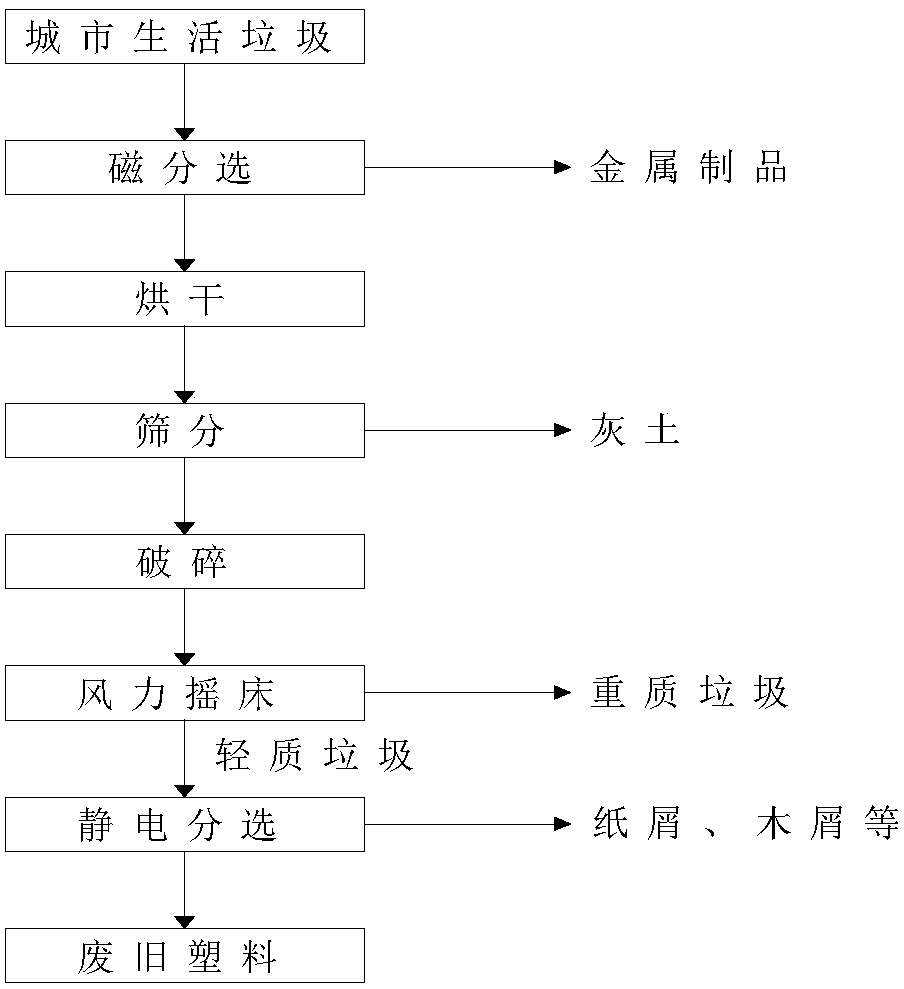

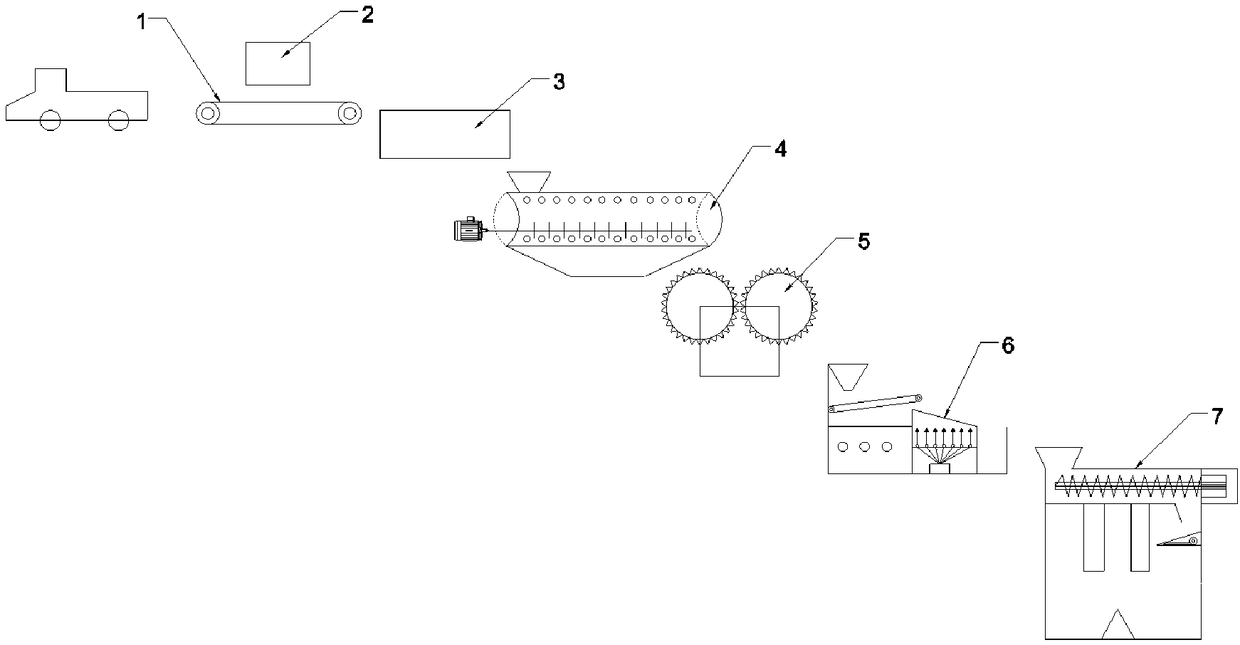

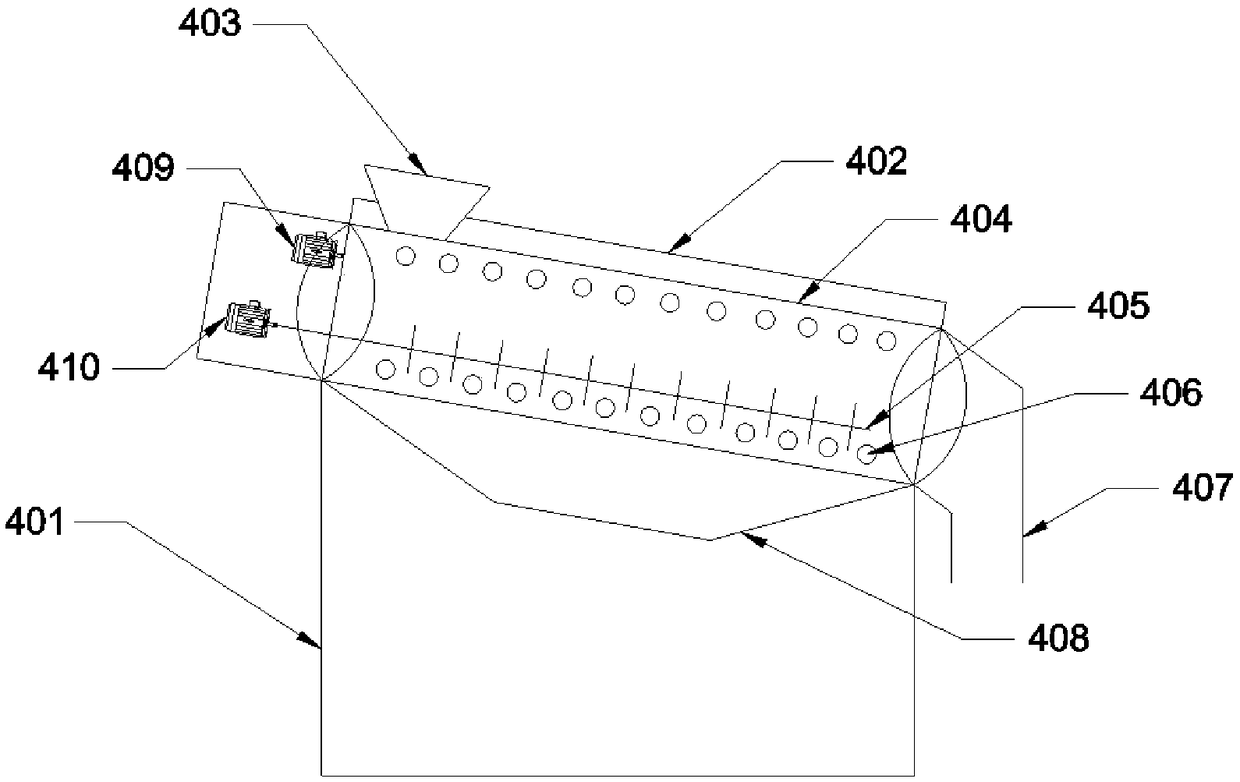

[0036] The present invention proposes a new process for sorting plastics: household garbage→magnetic separation→drying→sieving→crushing→wind shaker sorting→electrostatic sorting→waste and old plastics, municipal solid waste first undergoes magnetic sorting, Sorting out the metal products in the domestic waste is beneficial to the subsequent crushing of the domestic waste and then screening. The main purpose of this process is to remove the dust in the domestic waste components, and then carry out the crushing of the domestic waste to make the domestic waste homogeneous Then, the heavy garbage and light garbage are separated by wind shaker sorting, and then the light garbage enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com