Method and system for improving and transforming water production rate of membrane system

A membrane system and water production rate technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

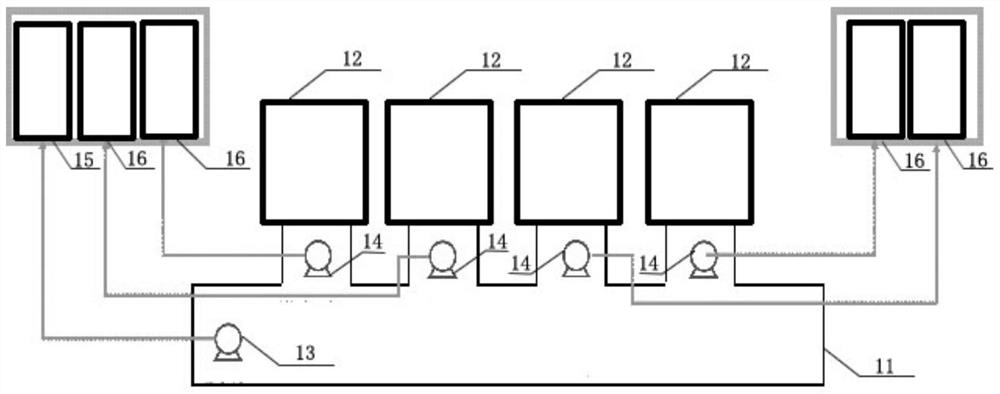

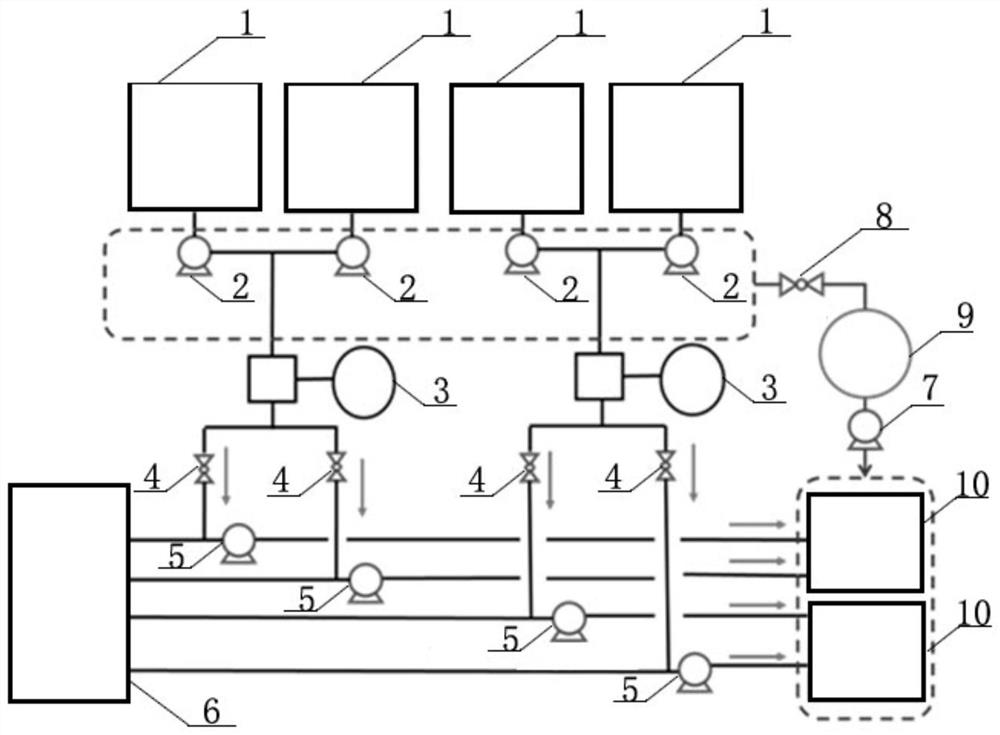

[0060] This embodiment provides a system for improving the water production rate of the membrane system, such as figure 1 , figure 2 As shown, the system includes an ultrafiltration membrane fouling analysis subsystem, a biological filter effluent water quality monitoring subsystem, a membrane workshop backwashing dosing subsystem and two membrane modules 10;

[0061] The membrane workshop backwash dosing subsystem includes four medicine dosing rooms 1, four dosing pumps 2, two flow meters 3, four backwash solenoid valves 4, four backwash pumps 5, backwash storage Pool 6, CIP cleaning circulation pump 7, CIP cleaning solenoid valve 7 and CIP dosing tank 9;

[0062] The four drug dosing rooms 1 are respectively connected to one end of the four dosing pumps 2; the other ends of every two dosing pumps 2, a flow meter 3, and one end of every two backwash solenoid valves 4 are sequentially connected; the other ends of the four backwash solenoid valves 4 are respectively connecte...

Embodiment 2

[0068] This embodiment provides a method for improving and transforming the water production rate of a membrane system. The method adopts the system for improving and transforming the water production rate of a membrane system described in Embodiment 1, and includes the following steps: using the biological filter effluent water quality monitoring subsystem The water quality of the membrane system is monitored in real time. If the water quality of the membrane system exceeds the threshold value, the membrane pollution is evaluated by the ultrafiltration membrane pollution analysis subsystem, and the backwashing process of the membrane workshop is formulated according to the evaluation results. The operating parameters of the drug subsystem, and then backwash the membrane module, the steps include:

[0069] S1: Backwash the membrane module: turn on the four backwash solenoid valves 4, four dosing pumps 2, and four backwash pumps 5 in turn to backwash the membrane module, and wai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com