Reverse osmosis desalinization system capable of on-line back washing

A technology of reverse osmosis and backwashing, applied in the field of reverse osmosis systems, which can solve the problems of increasing the operating cost of the reverse osmosis system, the inability to realize backwashing of the reverse osmosis membrane, and the environmental impact of cleaning chemicals, etc., to prolong the chemical cleaning cycle and simplify the pretreatment Process, the effect of reducing system operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below in conjunction with embodiment.

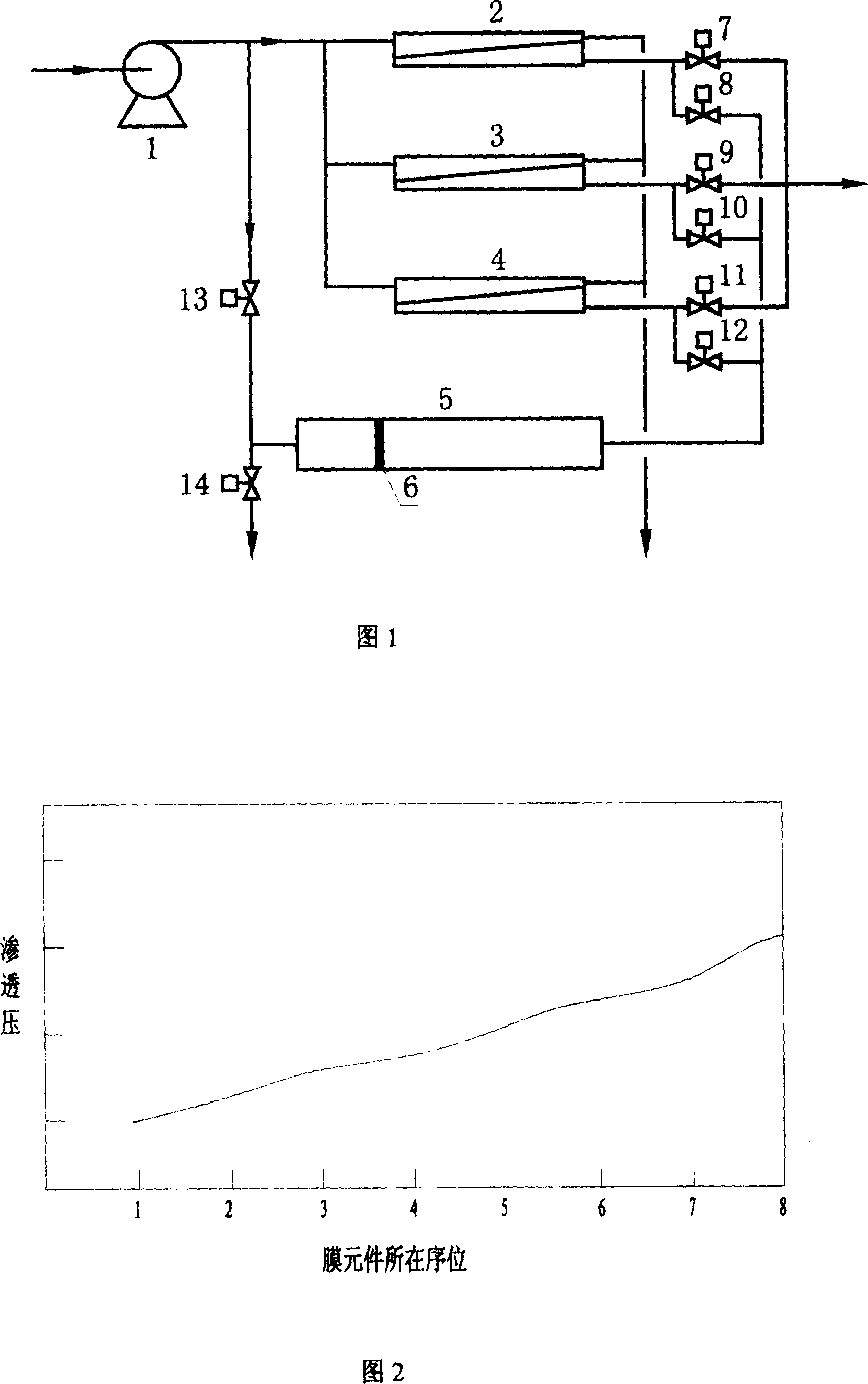

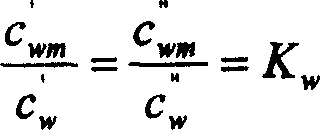

[0039] The online backwashing reverse osmosis desalination system of the present invention utilizes the principle of osmosis to pressurize the product water side of the reverse osmosis membrane so that the pressure on the product water side is slightly lower than the pressure on the concentrated water side of the reverse osmosis membrane. Under the action of the product water, it flows from the product water side to the concentrated water side, washes away the dirt attached to the membrane surface on the concentrated water side, and then is discharged together with the concentrated water. Its purpose is to reduce the requirements of the reverse osmosis system on the quality of influent water, improve the adaptability of the reverse osmosis system, and prolong the chemical cleaning cycle. This invention can reduce the investment cost and operating cost to the greatest extent, and further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com