Reverse osmosis system capable of continuously operating and continuously chemically cleaning

A technology of chemical cleaning and cleaning system, applied in the field of reverse osmosis system, can solve the problems of affecting the production progress of enterprises, the inability of continuous production of enterprises, and the reduction of membrane performance, so as to reduce the frequency of chemical cleaning, prolong the period of chemical cleaning, increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

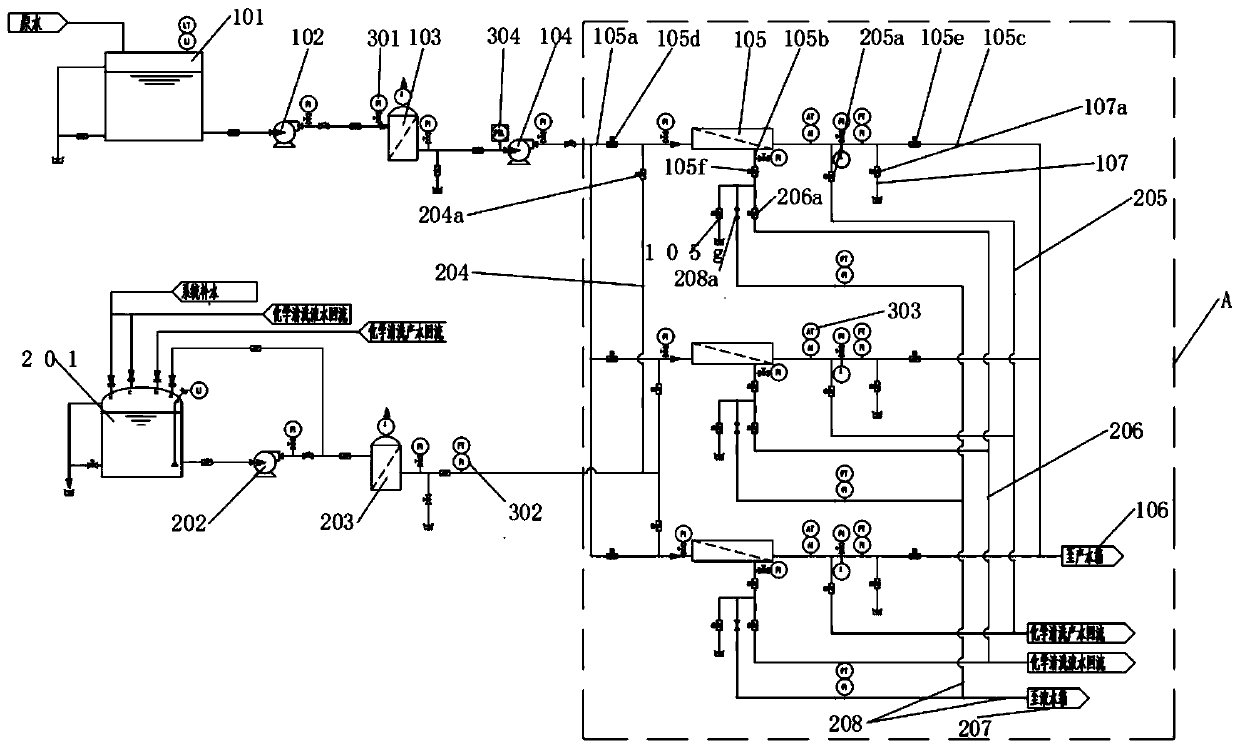

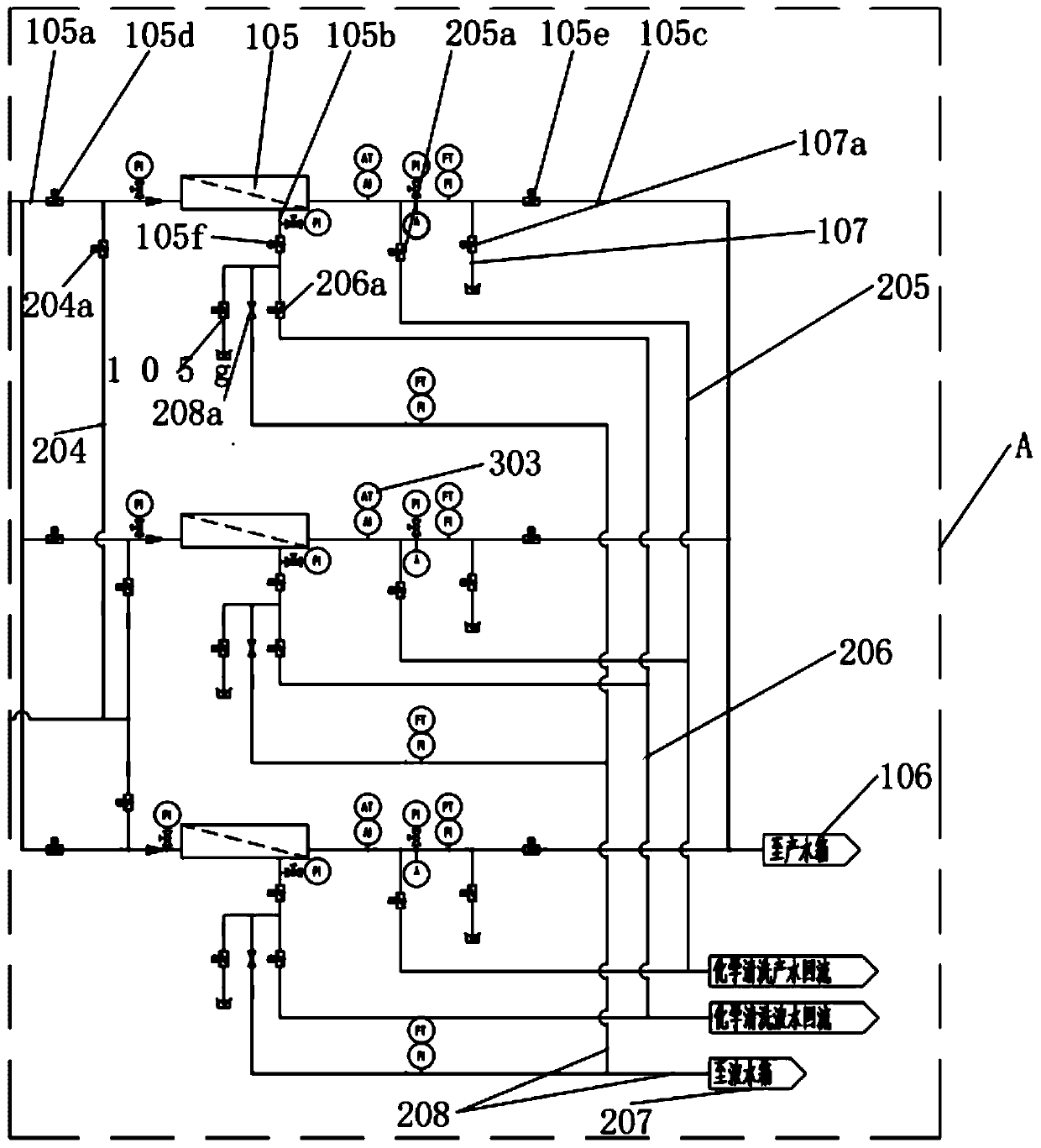

[0025] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

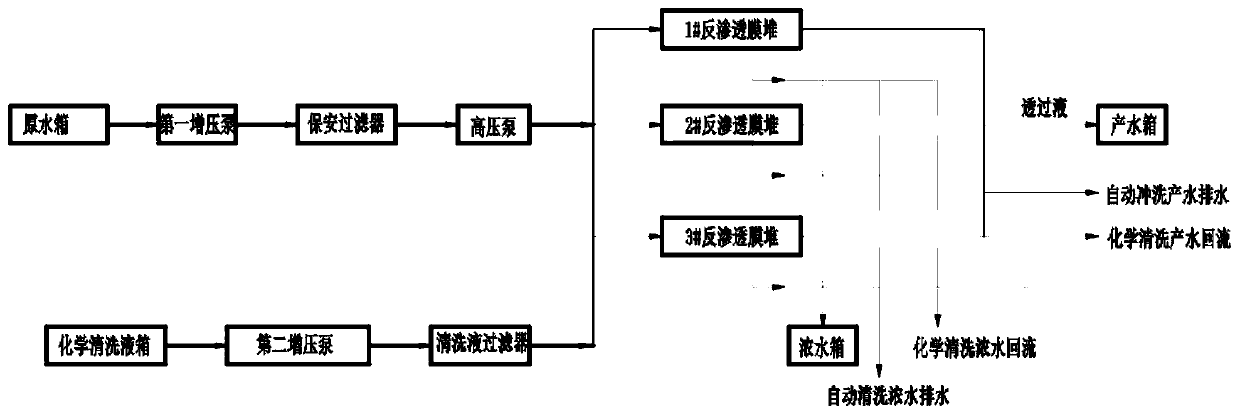

[0026] see Figure 1 to Figure 3 , The invention discloses a continuous operation and uninterrupted chemical cleaning reverse osmosis system, which includes a purification system and a cleaning system, the purification system is used for reverse osmosis filtration of raw water, and the cleaning system is used for chemical flushing of the reverse osmosis system.

[0027] The purification system includes a raw water tank 101, a first booster pump 102, a security filter 103, a high-pressure pump 104, and at least two sets of reverse osmosis components connected in parallel through pipelines, and each set of reverse os...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com