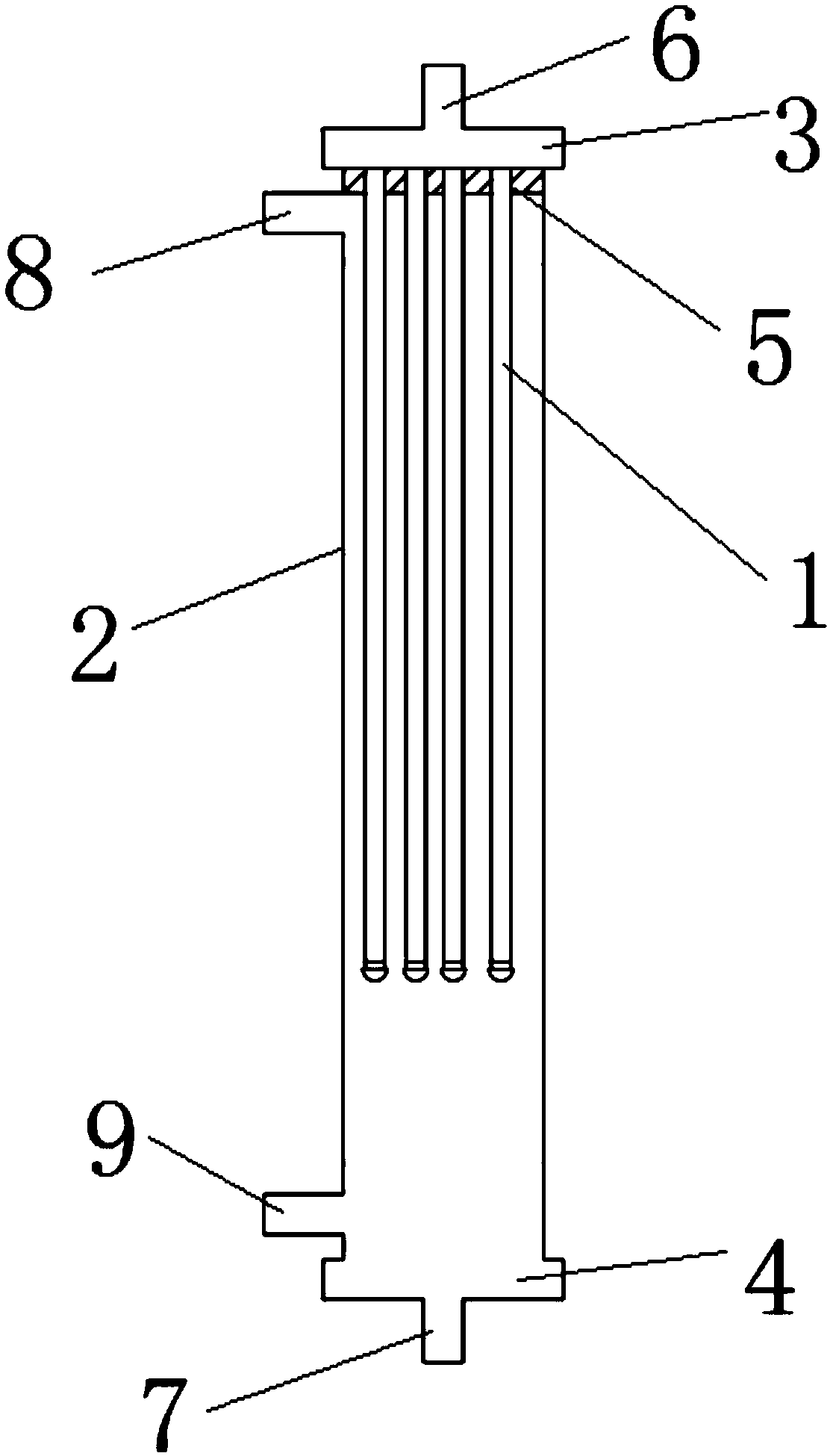

Outer-layer coating tubular microfiltration membrane as well as preparation method and assembly thereof

A technology of tubular microfiltration membrane and outer layer, applied in the field of separation membrane, which can solve the problems of high waste water treatment cost, low solid content, high energy consumption, etc., and achieve low energy consumption and waste water treatment cost, high packing density and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The preparation method of a kind of outer coating tubular microfiltration membrane of the present embodiment specifically comprises the following steps:

[0022] S1: Sintering polymer materials to make polymer microporous filter tubes;

[0023] S2: Prepare coating solution;

[0024] S3: One end of the polymer microporous filter tube is sealed by heat welding, the other end is inserted into a thin tube and connected to a vacuum pump, and the connection between the thin tube and the polymer microporous filter tube is sealed;

[0025] S4: Immerse the tube in the coating solution, turn on the vacuum pump to evacuate until the negative pressure reaches the point where the coating solution permeates from the outside to the inside but does not pass through the tube wall of the polymer microporous filter tube to obtain the outer coated tubular microfiltration membrane.

[0026] Wherein, the choice of coating solution is conventionally used coating solution.

[0027] The polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com