Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Excellent mean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synchronizing Uplink and Downlink Transmissions in a Wireless Device

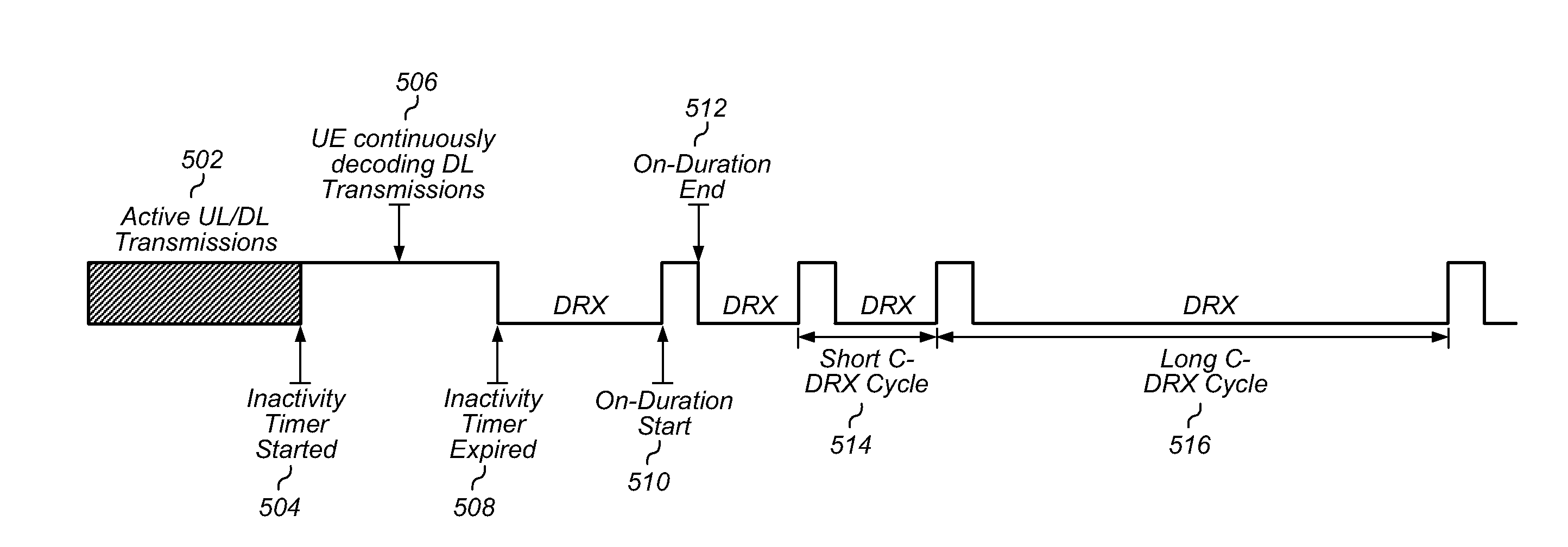

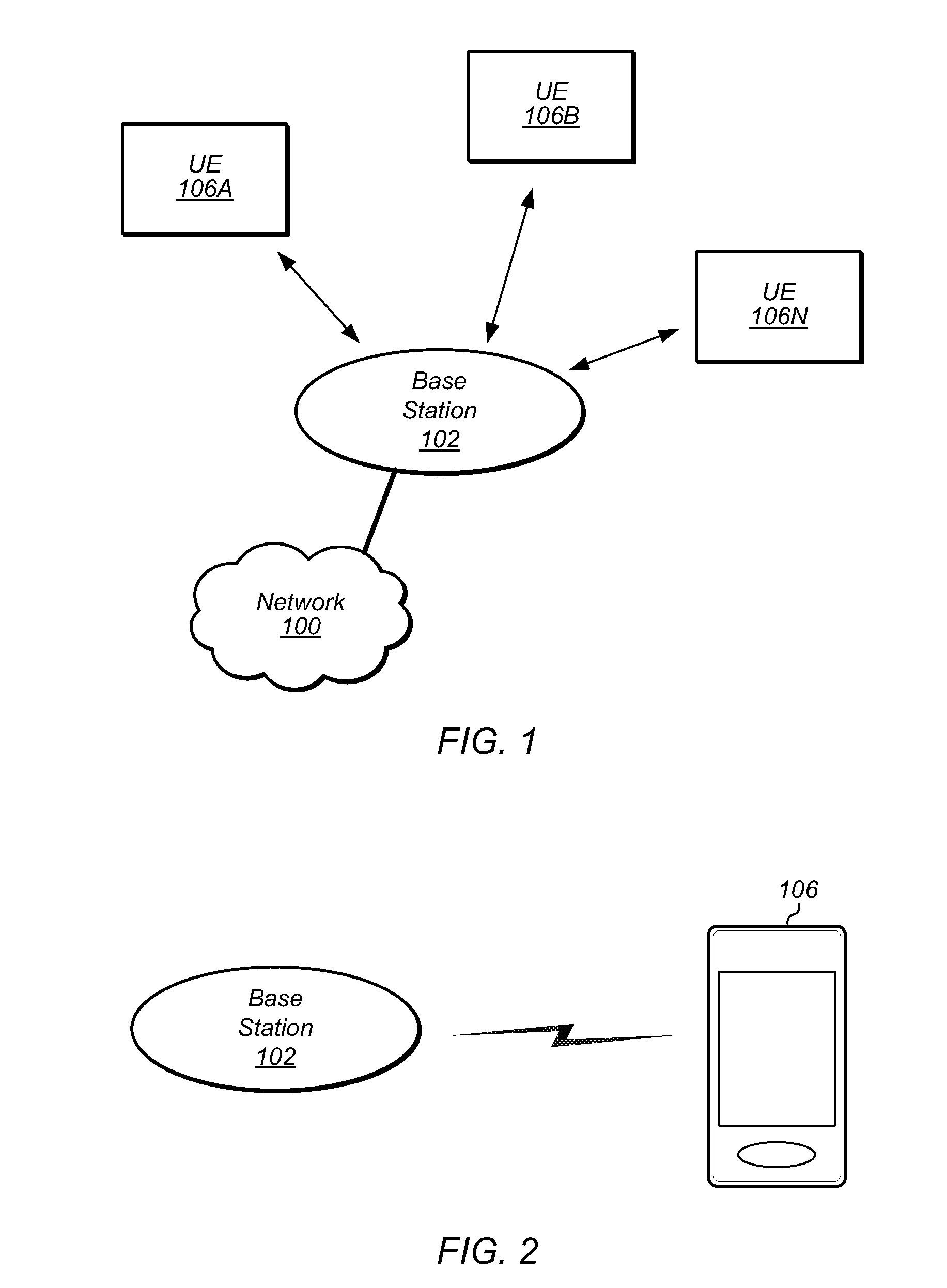

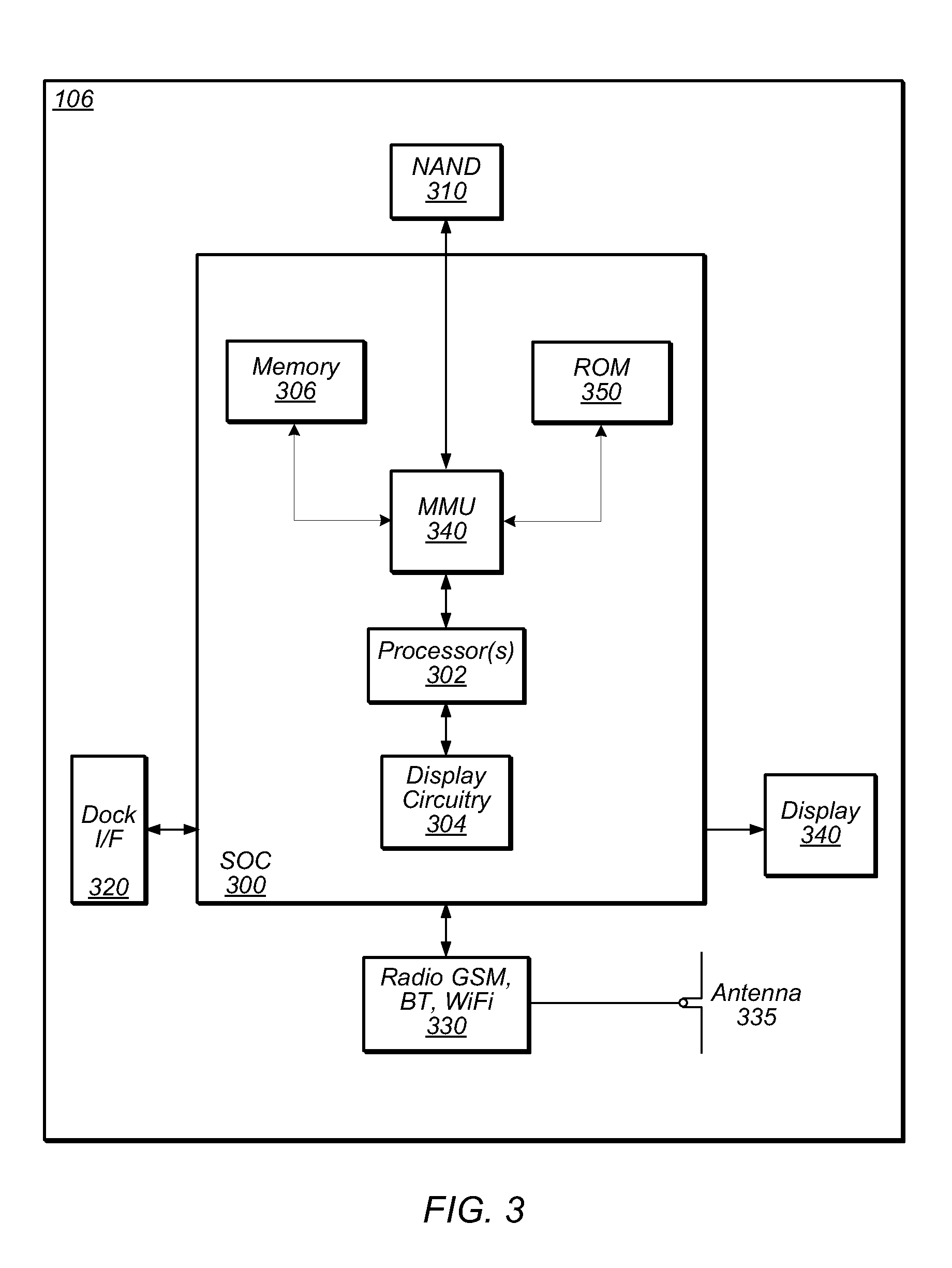

ActiveUS20140064160A1Reduce battery consumptionAmount of timePower managementTransmission systemsTelecommunicationsDownlink transmission

Synchronizing uplink and downlink transmissions by a wireless user equipment (UE) device. A connection with a network may be established via a wireless link with a cell. The UE may operate in an active state during first periods of time in which uplink or downlink communications may be performed between the UE and the network. The UE may operate in a reduced-power state during second periods of time in which uplink and downlink communications are not performed. The first periods of time may alternate with the second periods of time in a repeating manner. Uplink data generated by the UE may be buffered during second periods of time and transmitted during first periods of time. Buffering uplink data in this manner may prevent the UE from immediately transitioning from the reduced-power state to the active state to transmit uplink data, which may conserve battery of the UE.

Owner:APPLE INC

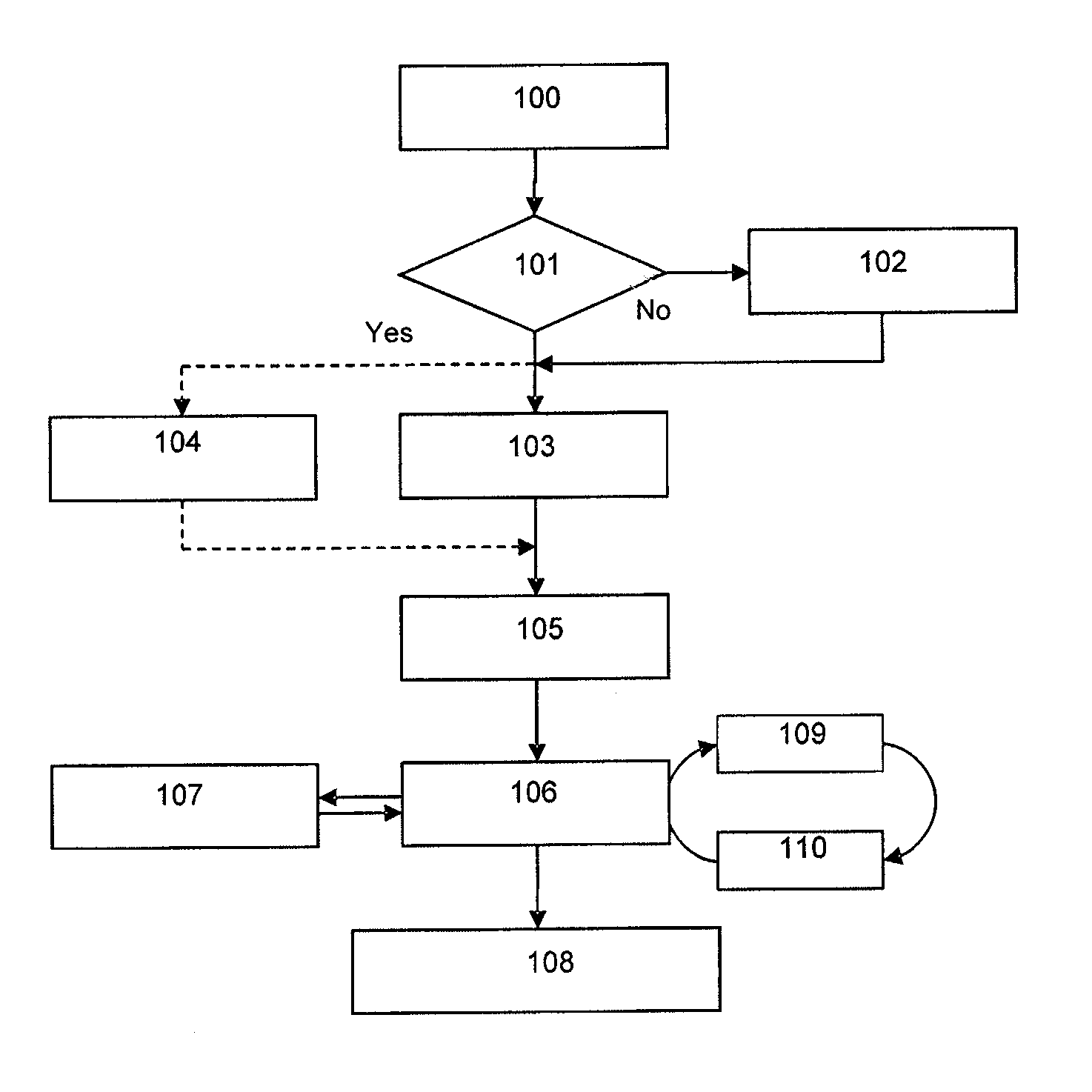

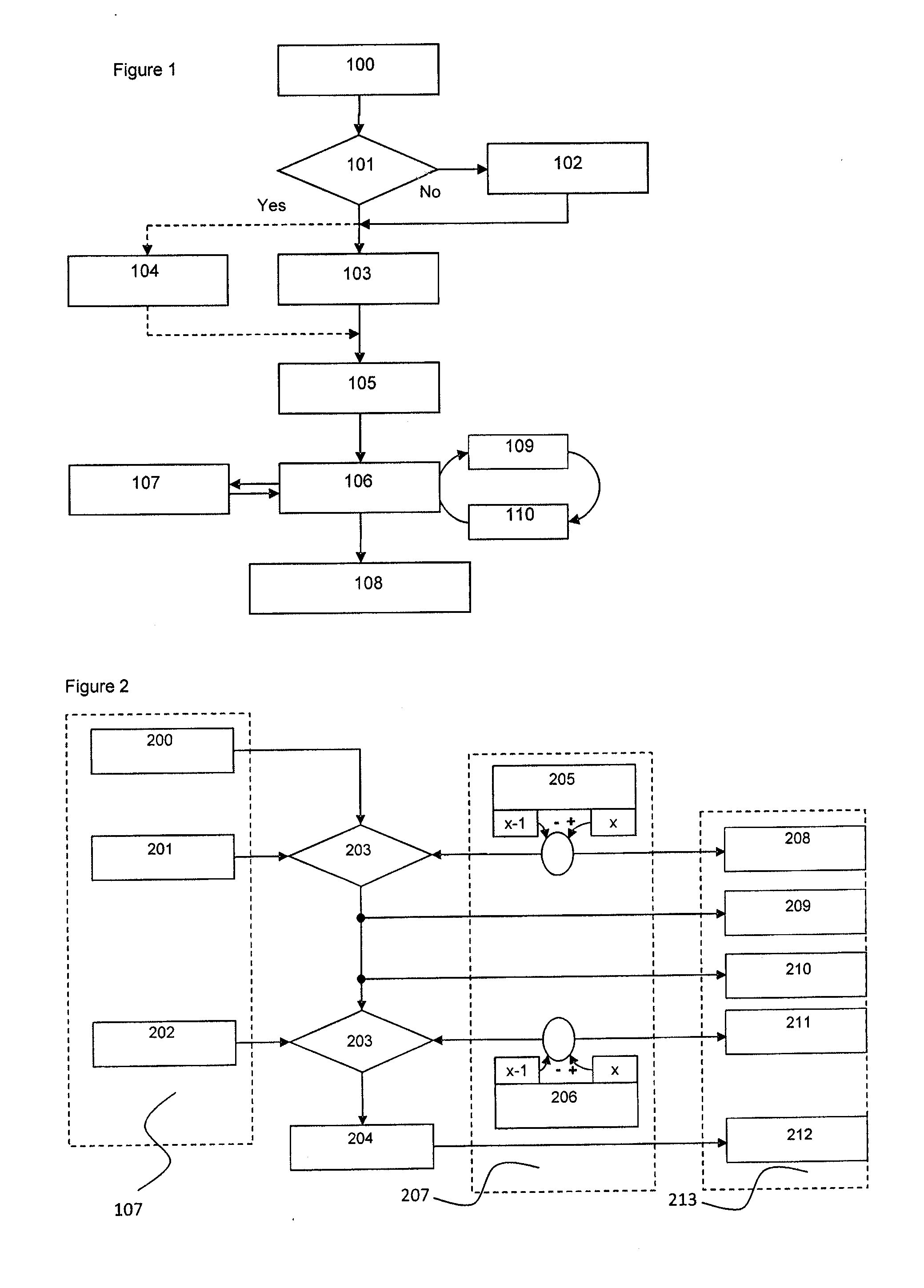

Method and device for predictive control of agricultural vehicle systems

ActiveUS9008918B2Better field modelEasy to predictAnalogue computers for trafficMowersEngineeringMoisture

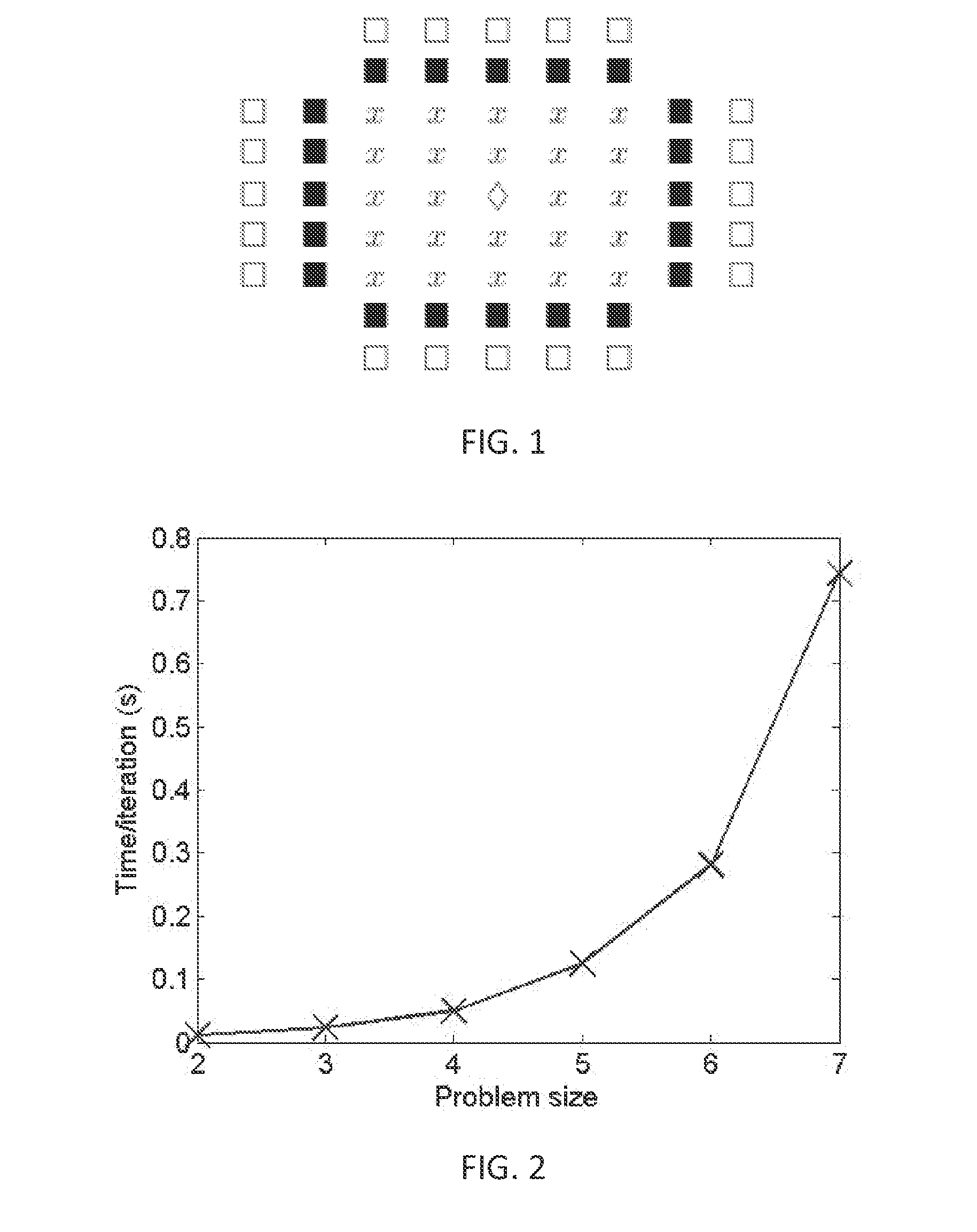

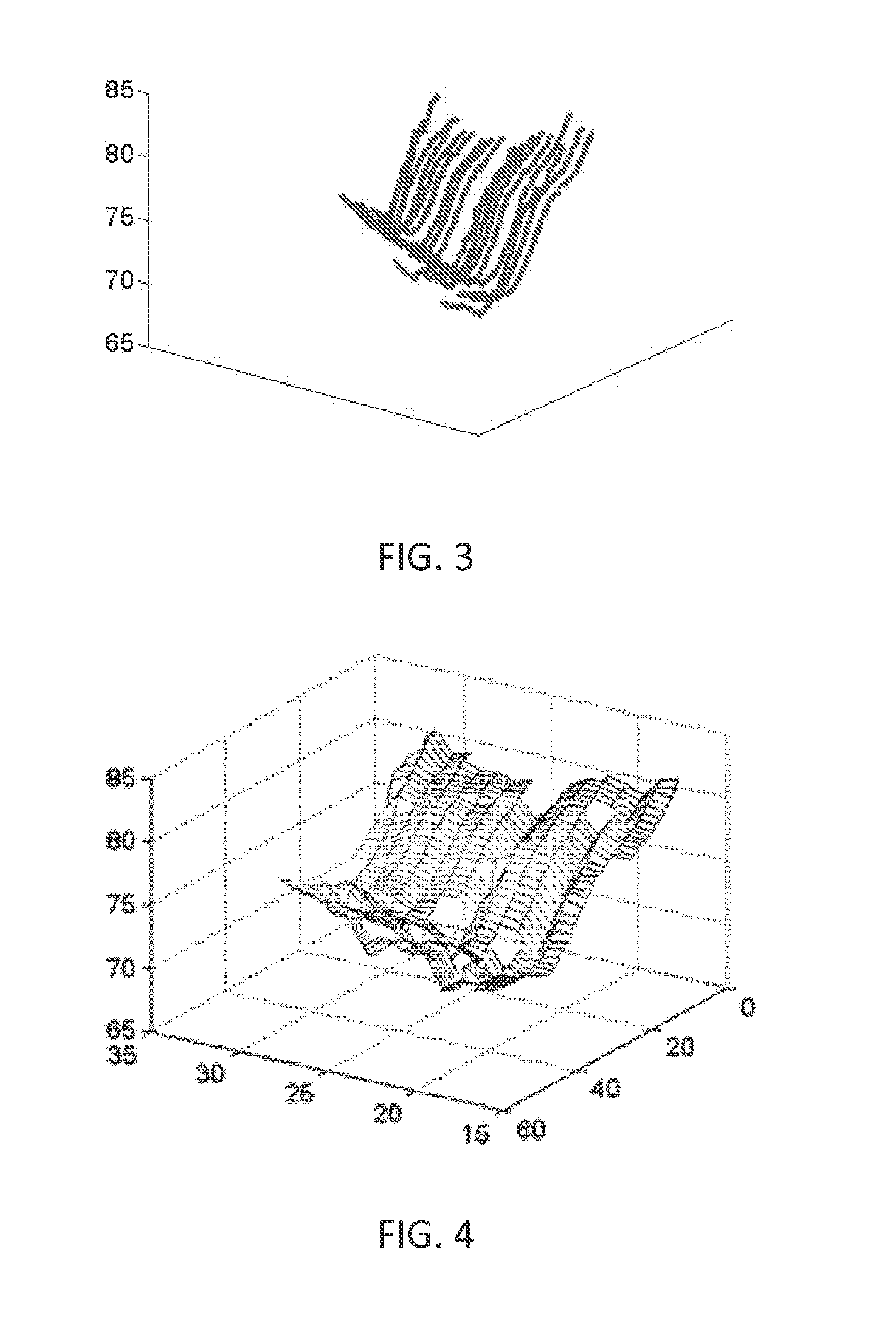

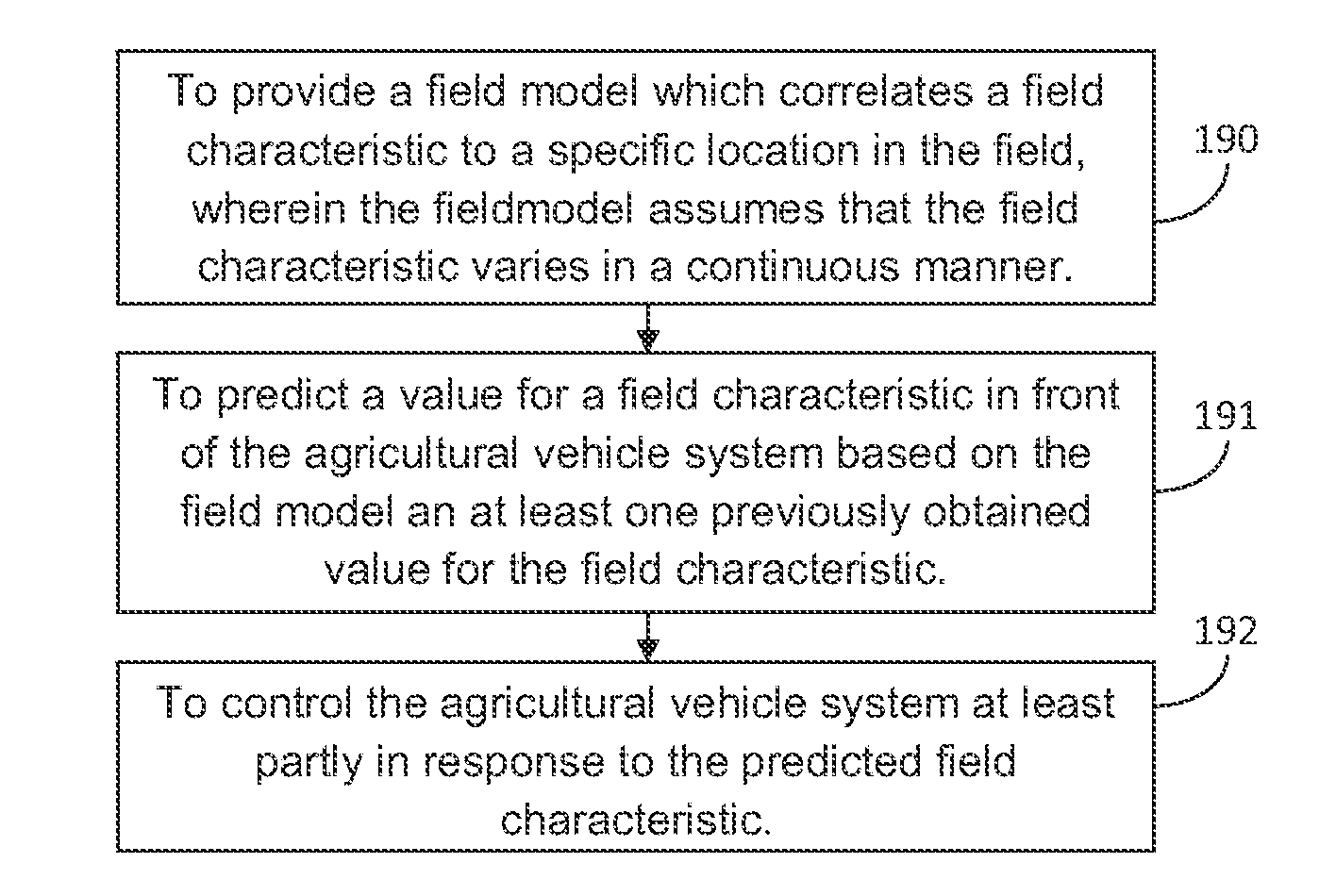

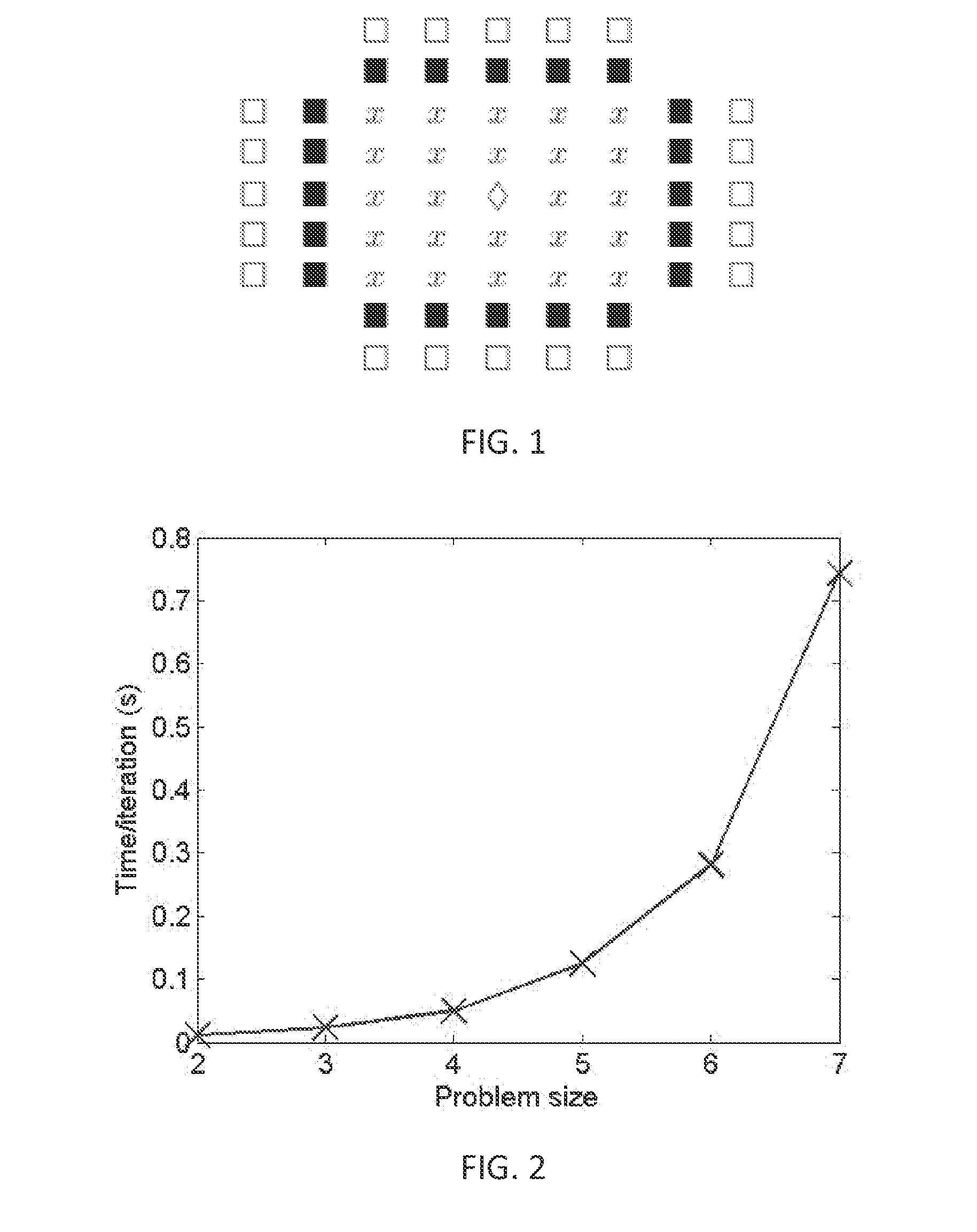

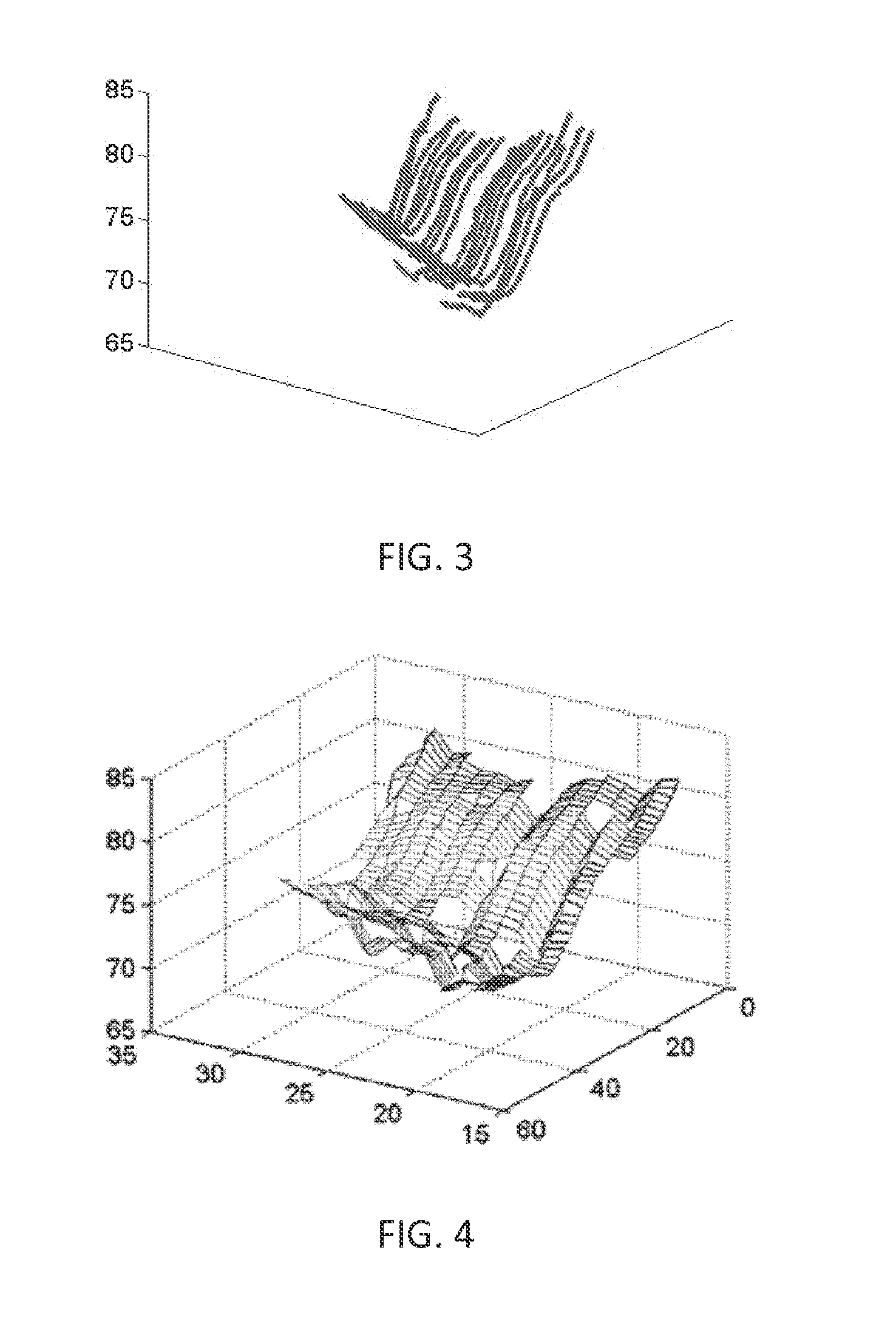

A method for controlling an agricultural vehicle system when moving along a course of travel over a fieldproviding a field model correlating a field characteristic, e.g. a farmland condition such as farmland slope, or a crop condition such as crop density or moisture, to a specific location in the field,from the field model and at least one previously obtained value for the field characteristic, predicting a value for the field characteristic in front of the agricultural vehicle system thus obtaining an anticipated field characteristic, and;controlling the agricultural vehicle system at least partly in response to the anticipated field characteristic.

Owner:BLUE LEAF I P INC

Method and device for predictive control of agricultural vehicle systems

ActiveUS20130184944A1Better field modelEasy to predictAnalogue computers for trafficMowersEngineeringVolumetric Mass Density

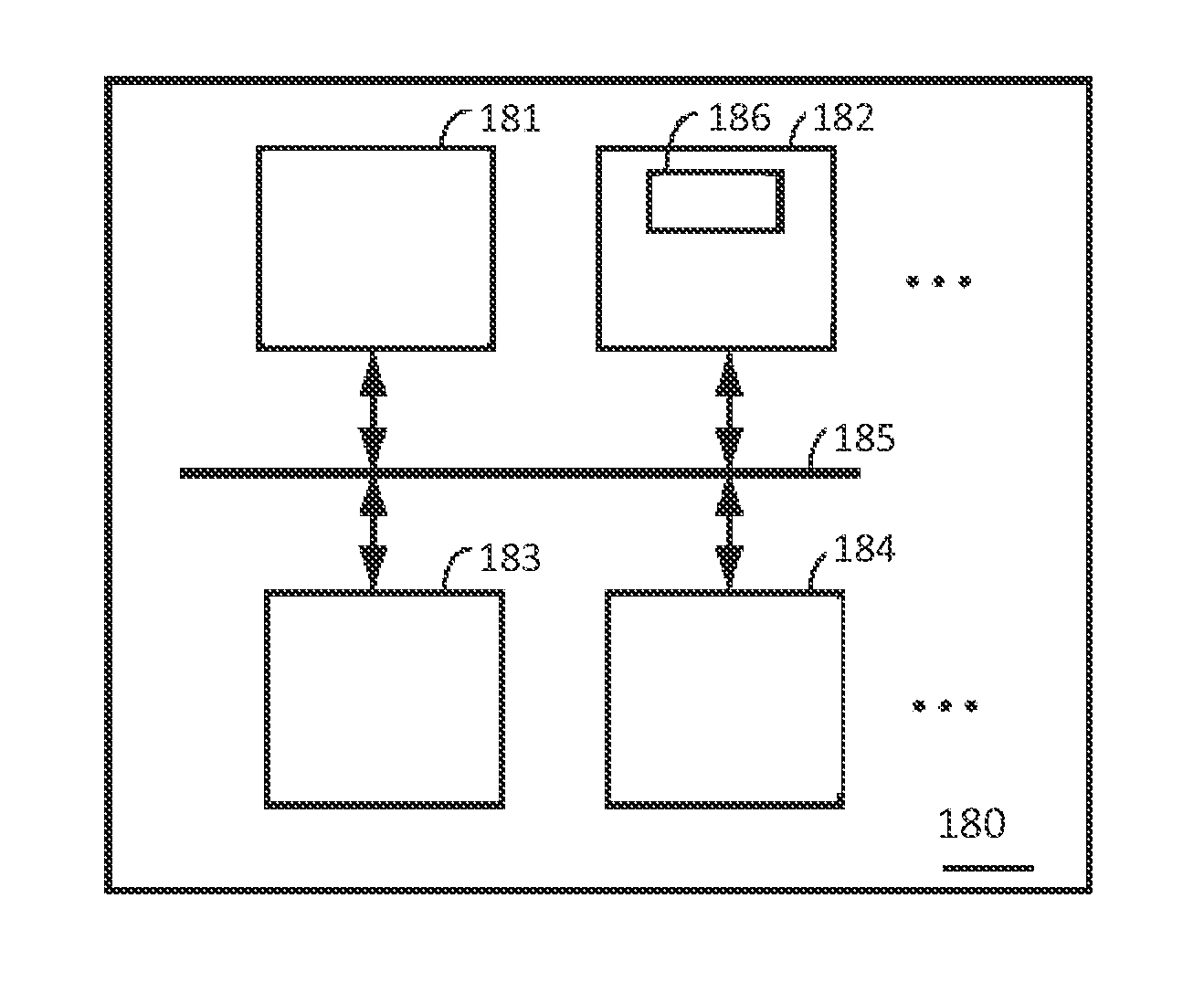

The present invention provides a method for controlling an agricultural vehicle system when moving along a course of travel over a field. The method comprises:providing (190) a field model correlating a field characteristic, e.g. a farmland condition such as farmland slope, or a crop condition such as crop density or moisture, to a specific location in the field, for example indicated by x and y coordinates;from the field model and at least one previously obtained value for the field characteristic, predicting (191) a value for the field characteristic in front of the agricultural vehicle system thus obtaining an anticipated field characteristic, and;controlling (192) the agricultural vehicle system at least partly in response to the anticipated field characteristic.In accordance with embodiments of the present invention, providing (190) a field model correlating a field characteristic to a specific location in the field includes assuming that the field characteristic varies in a continuous manner.

Owner:BLUE LEAF I P INC

Test media and quantiative or qualitative method for identification and differentiation of biological materials in a test sample

InactiveUS20050196825A1Reduces effective shelf lifeDifficult to controlMicrobiological testing/measurementBiological material analysisPink colorEscherichia coli

A test medium and method for detecting, quantifying, identifying and differentiating up to four (4) separate biological materials in a test sample. A test medium is disclosed which allows quantifying and differentiating under ambient light aggregates of biological entities producing specific enzymes, which might include general coliforms, E. coli, Aeromonas, and Salmonella in a single test medium. A new class of nonchromogenic substrates is disclosed which produce a substantially black, non-diffusible precipitate. This precipitate is not subject to interference from other chromogenic substrates present in the test medium. In one embodiment, the substrates are selected such that E. coli colonies present in the test medium show as substantially black, general coliforms colonies show in the test medium as a blue-violet color, Aeromonas colonies present in the test medium show as a generally red-pink color, and Salmonella colonies show as a generally teal-green color. Other microorganisms and color possibilities for detection and quantification thereof are also disclosed. An inhibitor and method for making a test medium incorporating the inhibitor are disclosed.

Owner:MICROLOGY INC

Spinal and Upper Cervical Impulse Treatment and Device

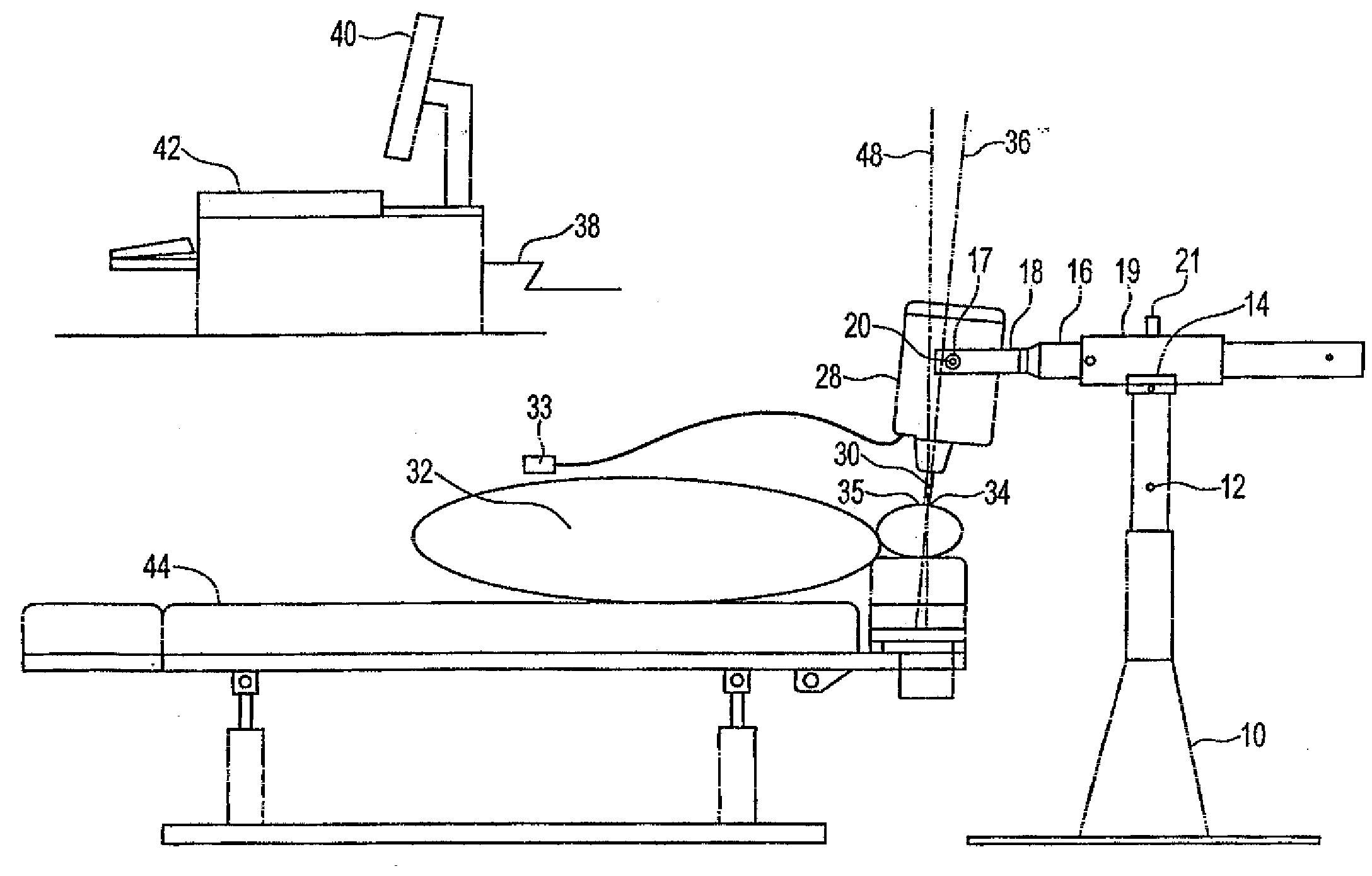

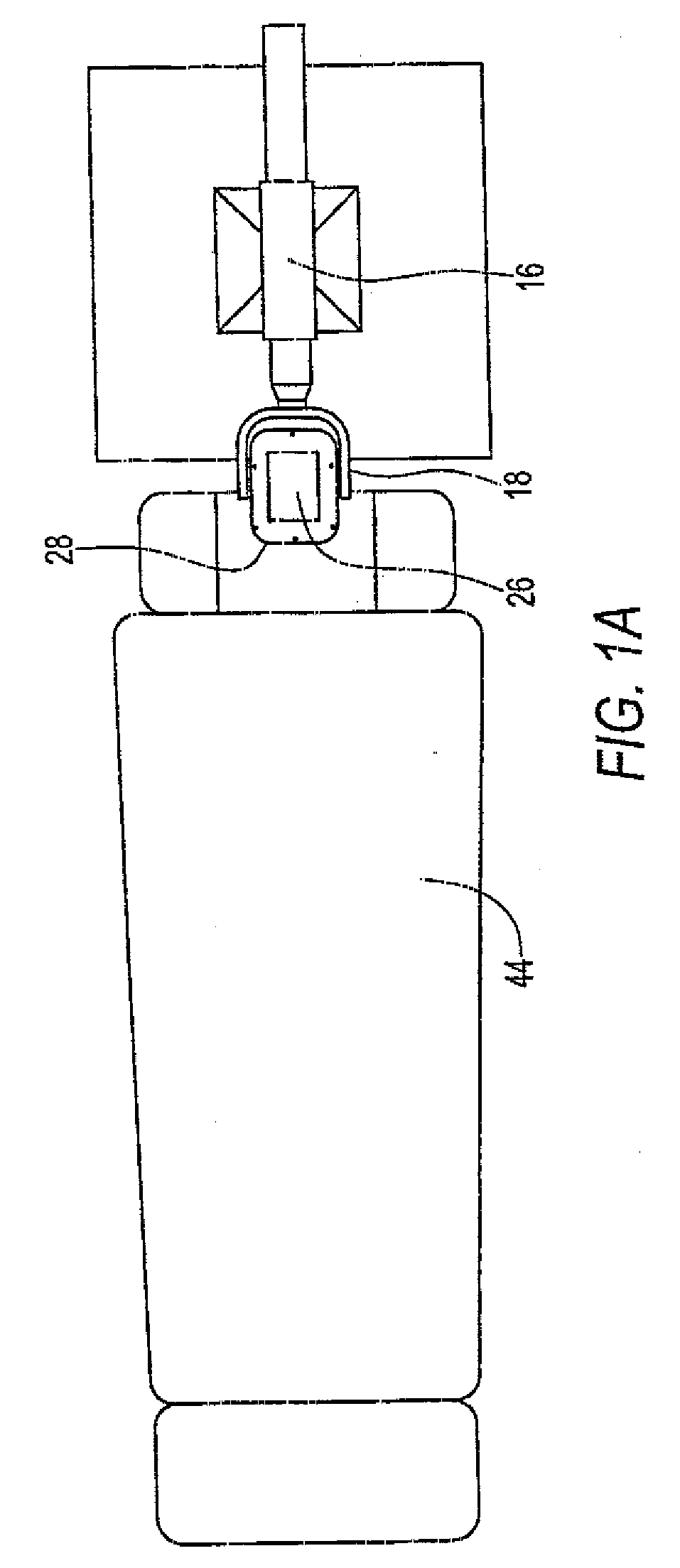

ActiveUS20080312724A1Improve accuracySuperior of applying forceElectrotherapyDiagnosticsSpinal columnData validation

The current invention is a spinal and upper cervical impulse treatment device and controller, which delivers multiple impulses of variable frequency and variable force in a linear direction, as well as rotational forces, for patient treatment. Known chiropractic impulse devices are all hand held devices. In contrast, the spinal and upper cervical impulse treatment device is mounted on a fixed stand and armature, allowing reliable positioning and directional alignment in three dimensions. Fixed mounting also facilitates ease of use. A safety coupling is incorporated to avoid patient injury due to excessive force on the treatment site in the fixed mounting scenario Smooth sinusoidal waveforms are a preferred waveform for impulse delivery and sine waves are generated digitally in the apparatus. Data validation is used to ensure correct directional alignment prior to device activation Patient safety and consistency in treatment protocols are considered in the spinal and upper cervical impulse treatment design

Owner:KHAN ASLAM

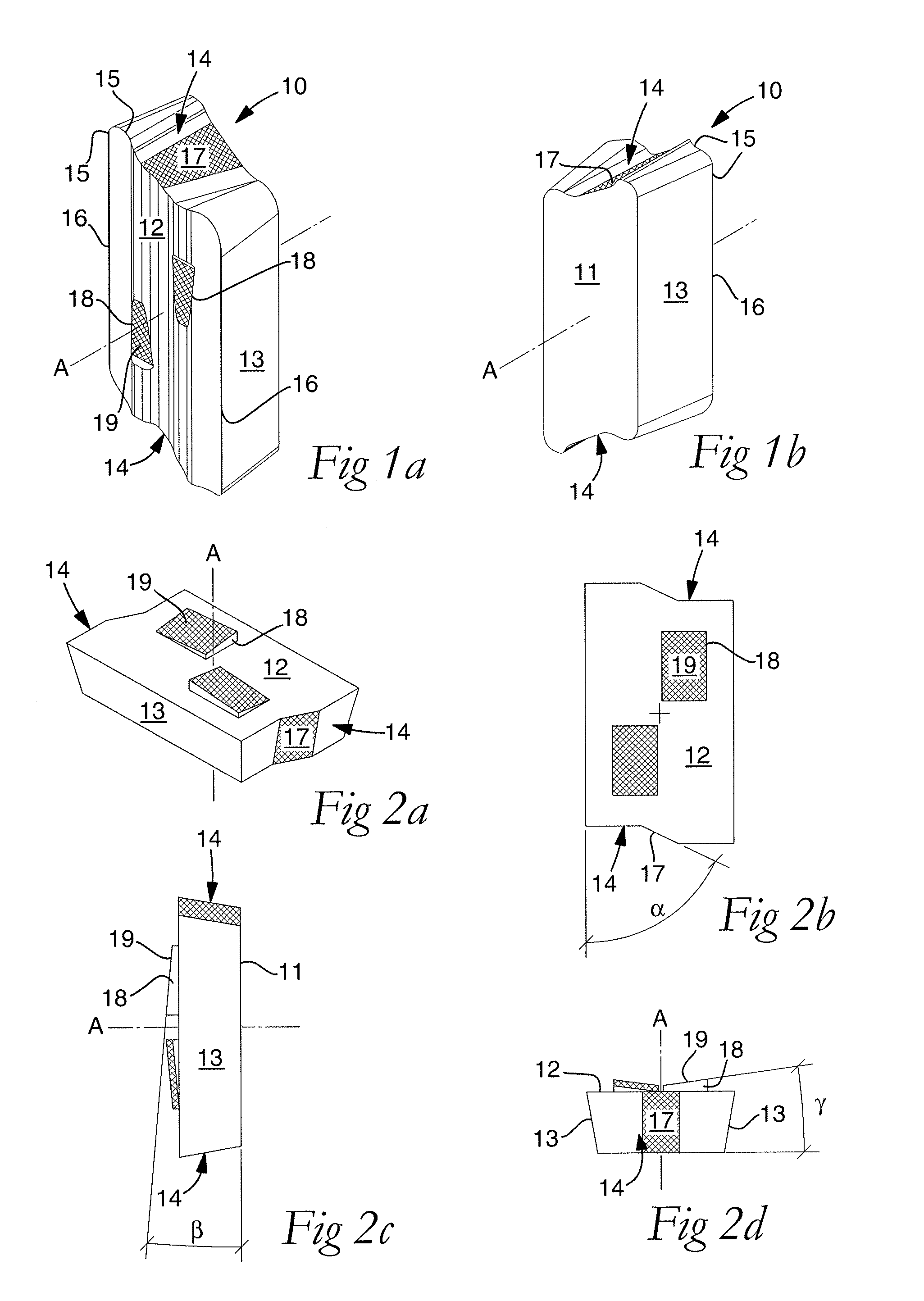

Indexable milling insert for milling tools

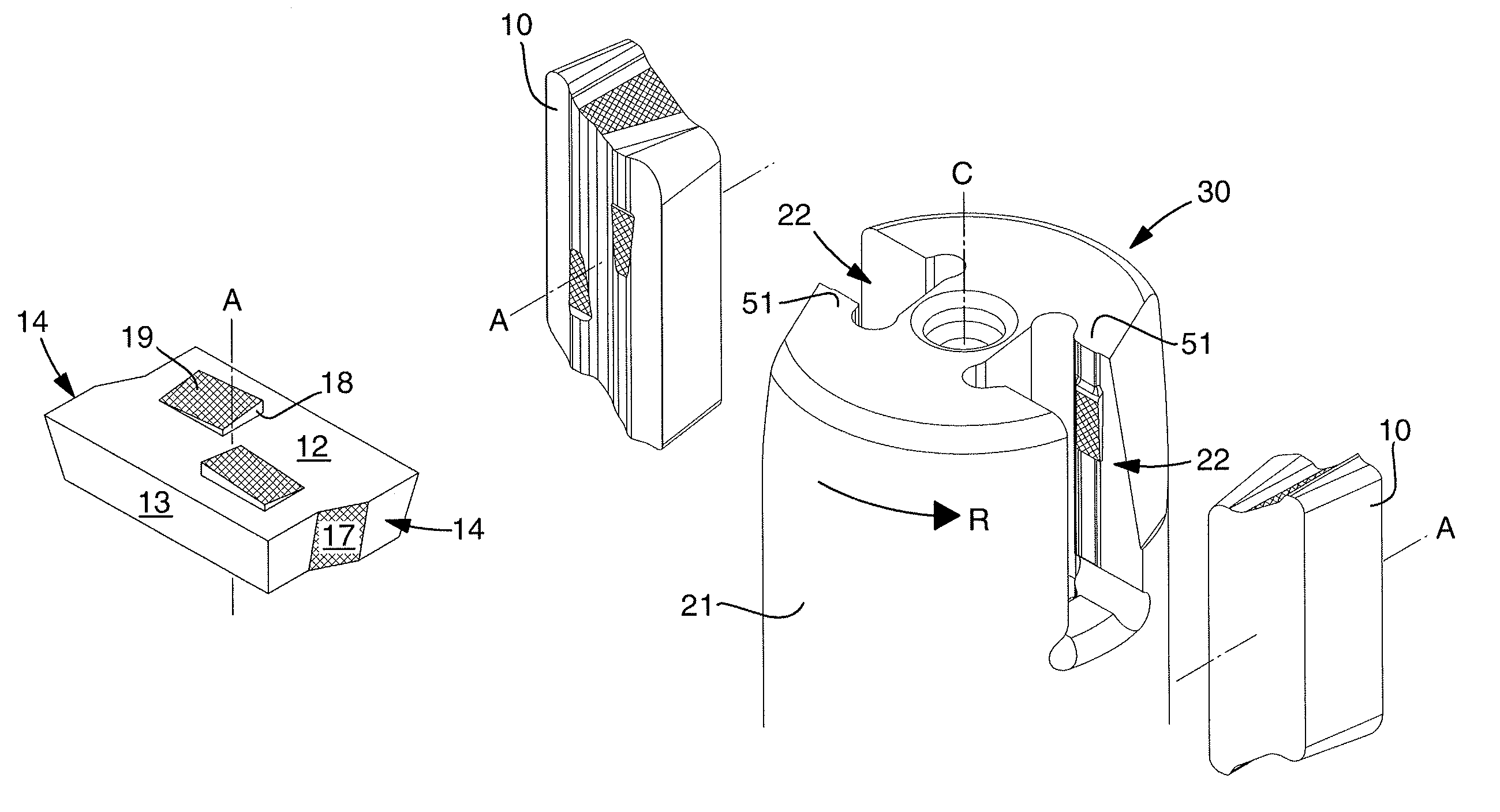

InactiveUS8475089B2Easy to fixExcellent meanTransportation and packagingMilling cuttersAcute angleCoupling

Owner:SANDVIK INTELLECTUAL PROPERTY AB

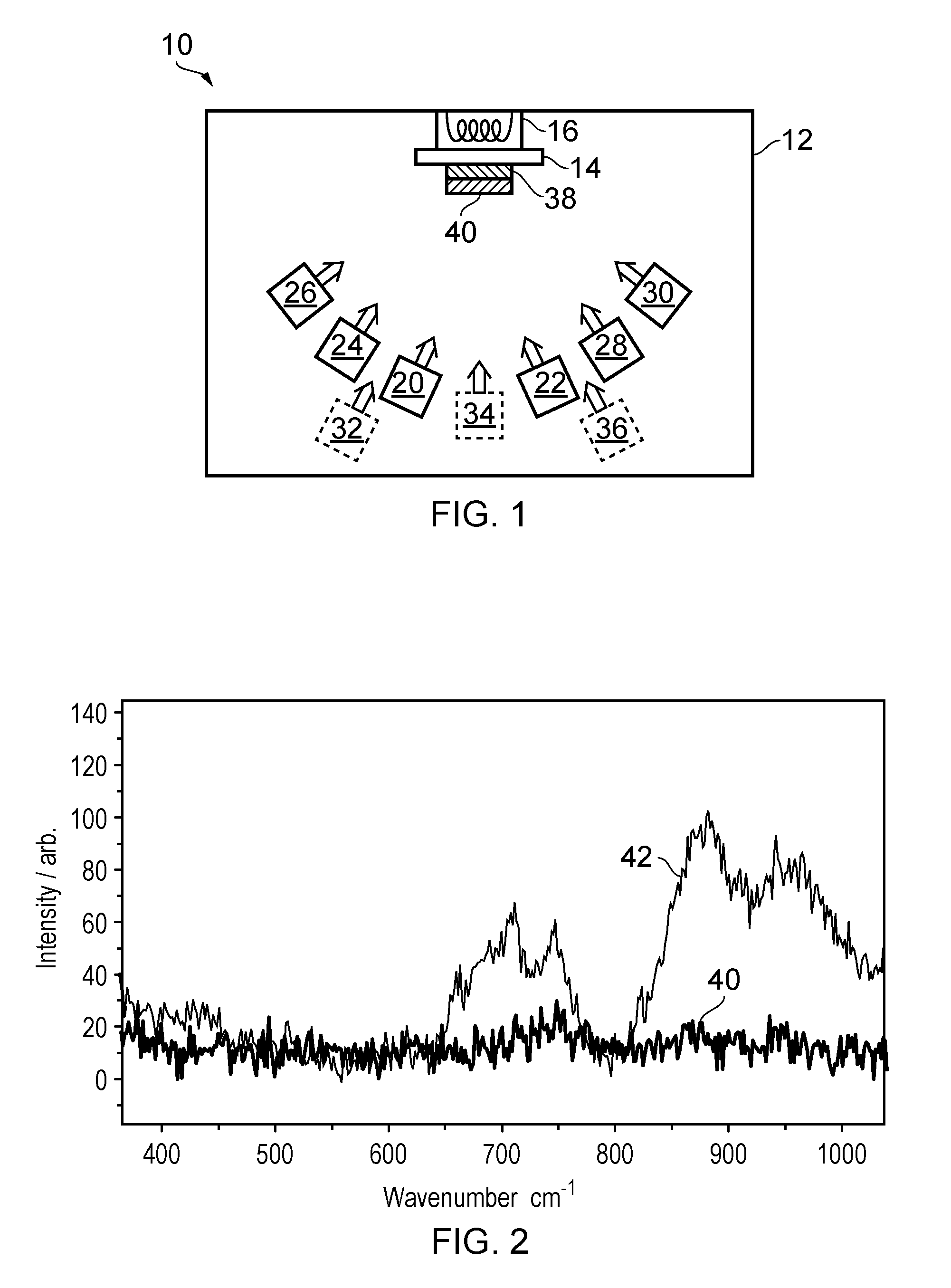

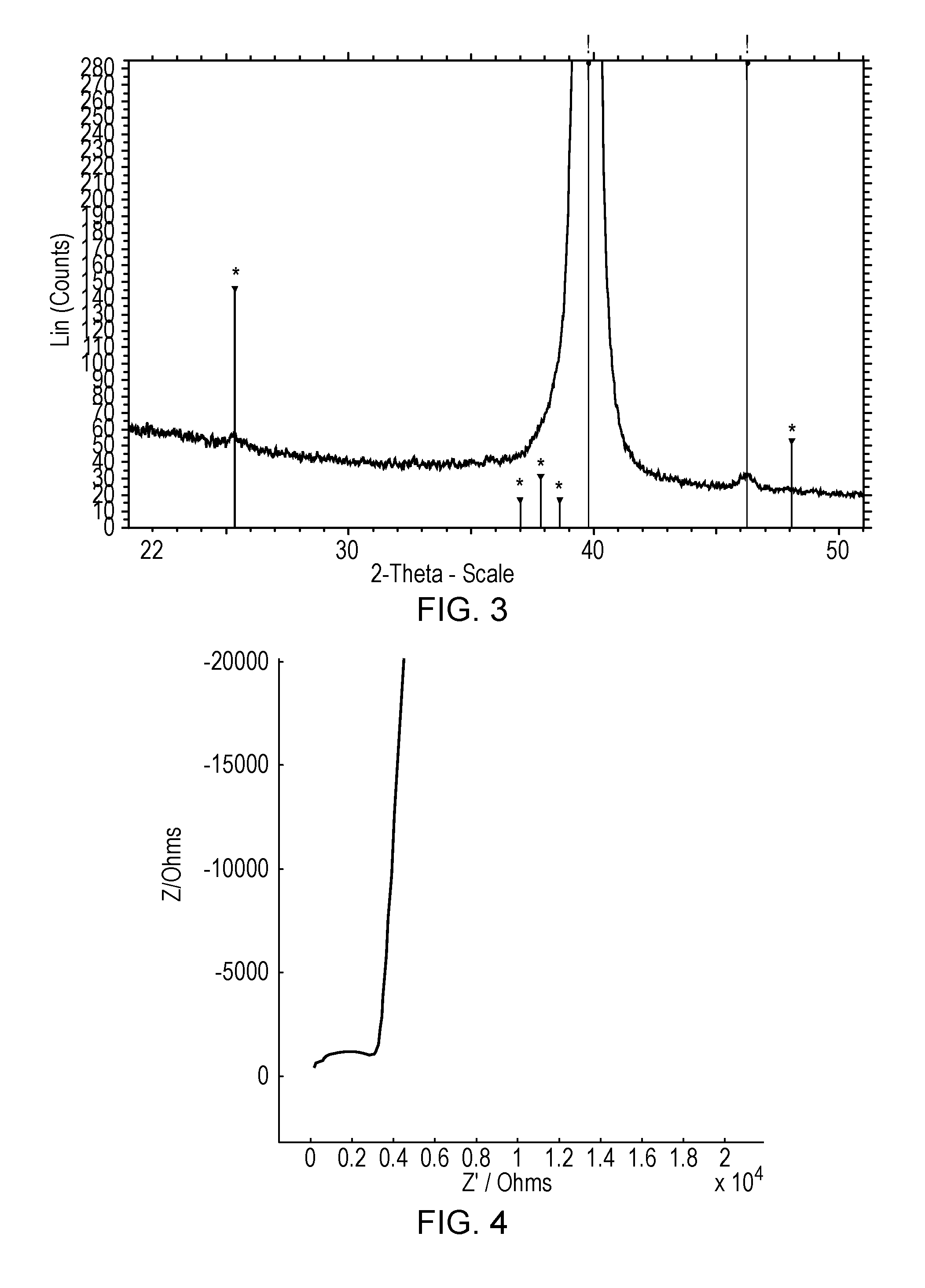

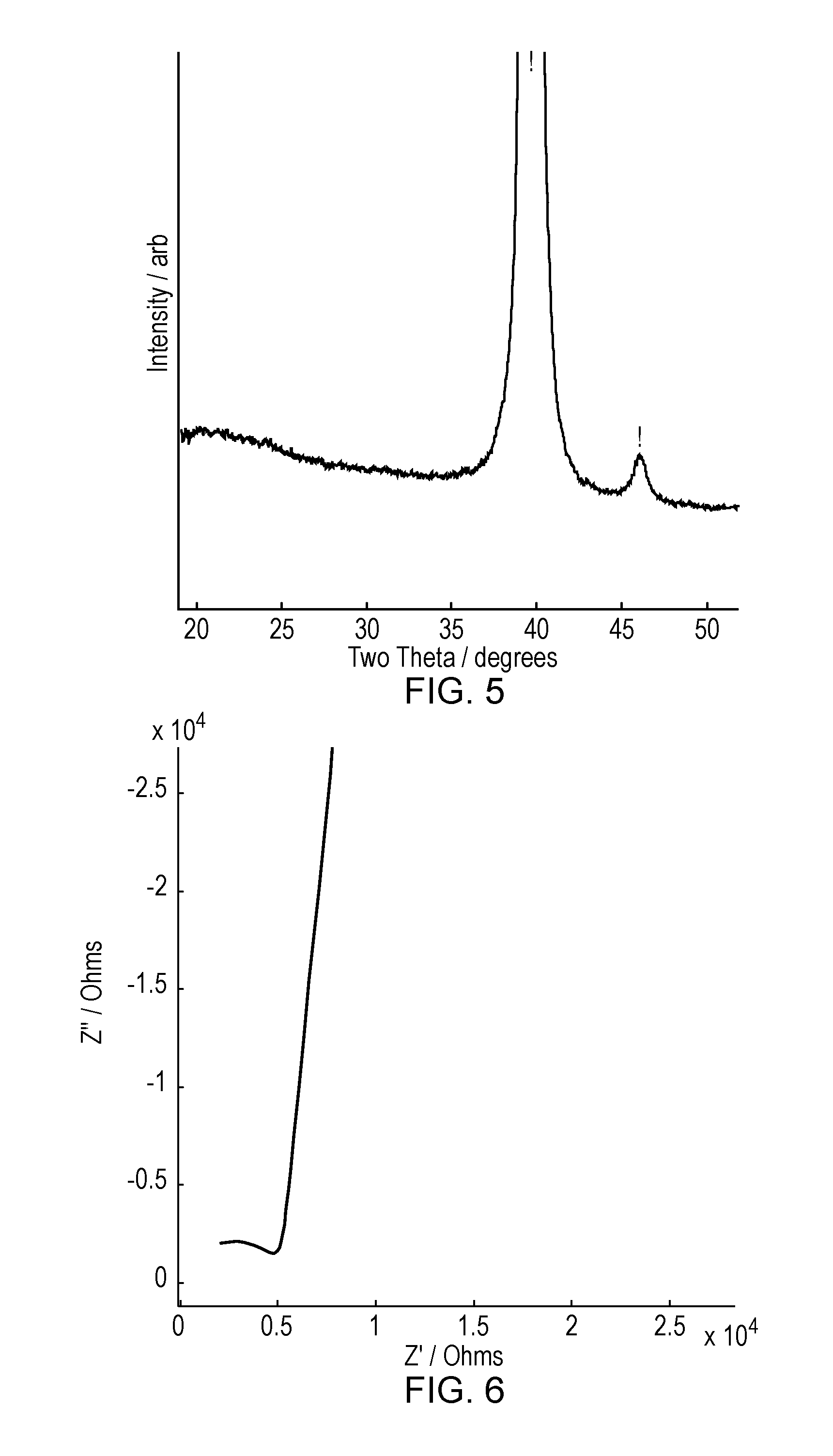

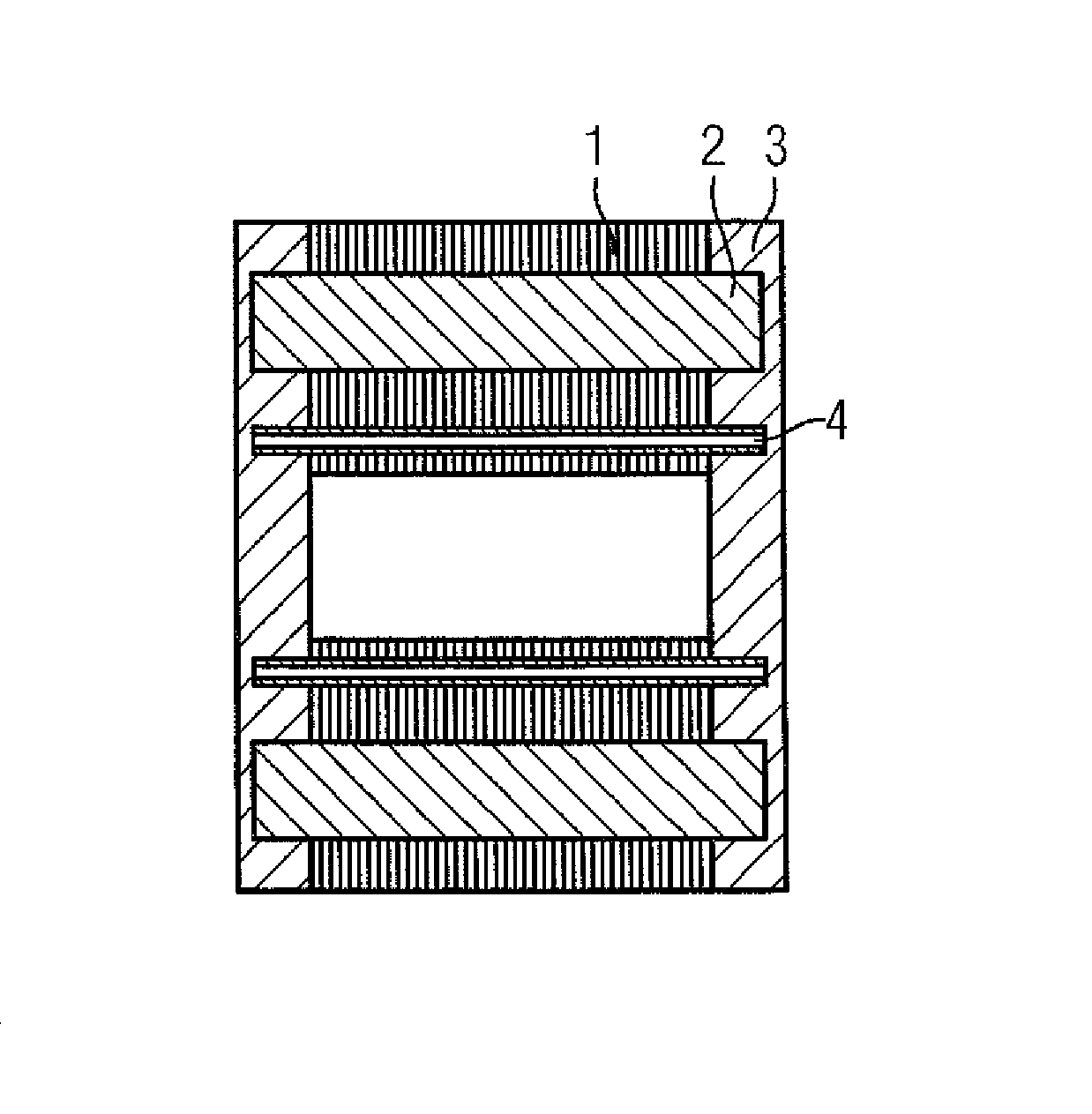

Vapour deposition method for fabricating lithium-containing thin film layered structures

ActiveUS20160336583A1Reduce roughnessPrecise physical and chemical structureFinal product manufactureVacuum evaporation coatingChemical compoundChemistry

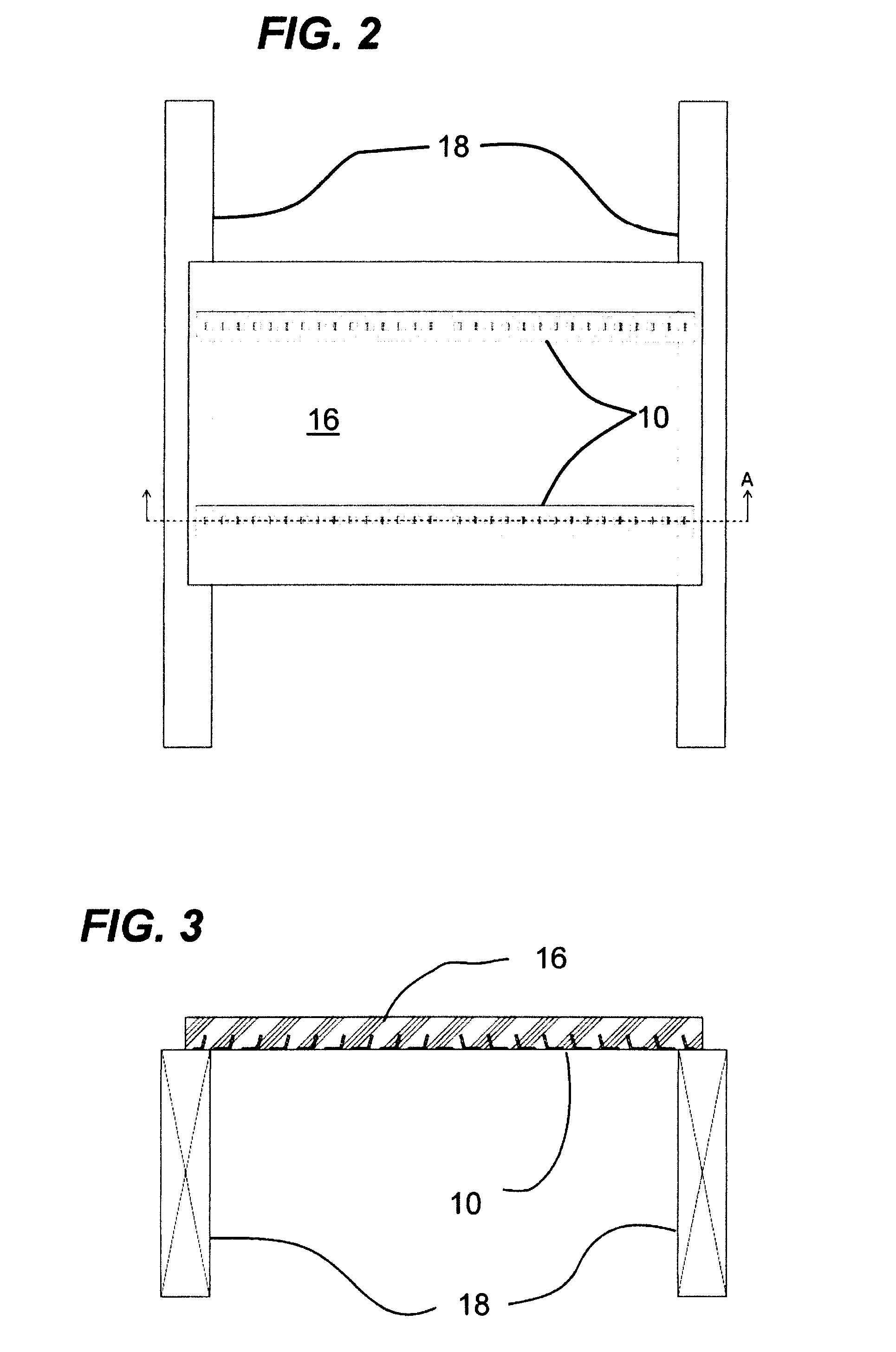

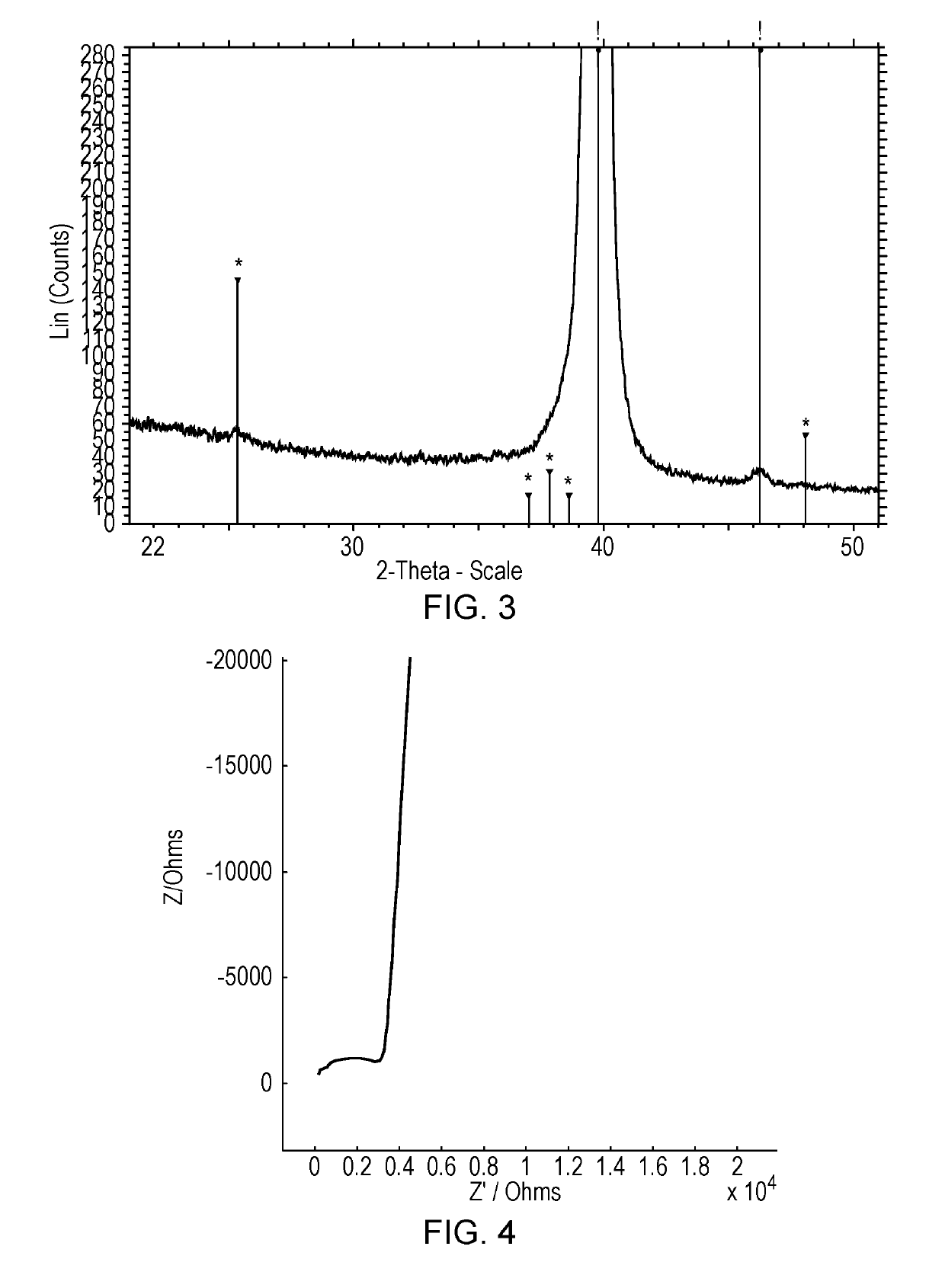

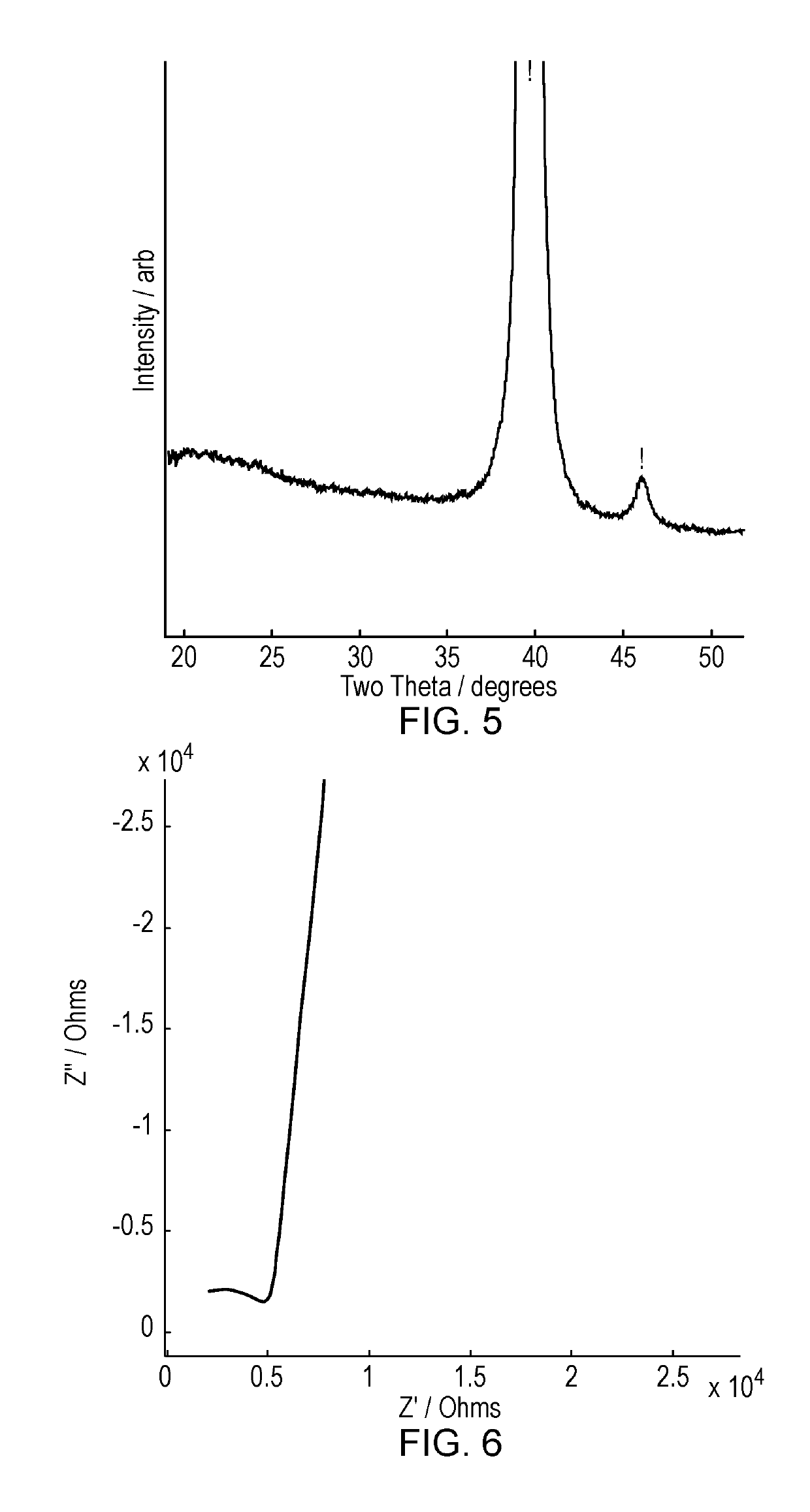

A vapour deposition method for preparing a multi-layered thin film structure comprises providing a vapour source of each component element of a compound intended for a first layer and a compound intended for a second layer, wherein the vapour sources comprise at least a source of lithium, a source of oxygen, a source or sources of one or more glass-forming elements, and a source or sources of one or more transition metals; heating a substrate to a first temperature; co-depositing component elements from at least the vapour sources of lithium, oxygen and the one or more transition metals onto the heated substrate wherein the component elements react on the substrate to form a layer of a crystalline lithium-containing transition metal oxide compound; heating the substrate to a second temperature within a temperature range of substantially 170° C. or less from the first temperature; and co-depositing component elements from at least the vapour sources of lithium, oxygen and the one or more glass-forming elements onto the heated substrate wherein the component elements react on the substrate to form a layer of an amorphous lithium-containing oxide or oxynitride compound.

Owner:ILIKA TECH +1

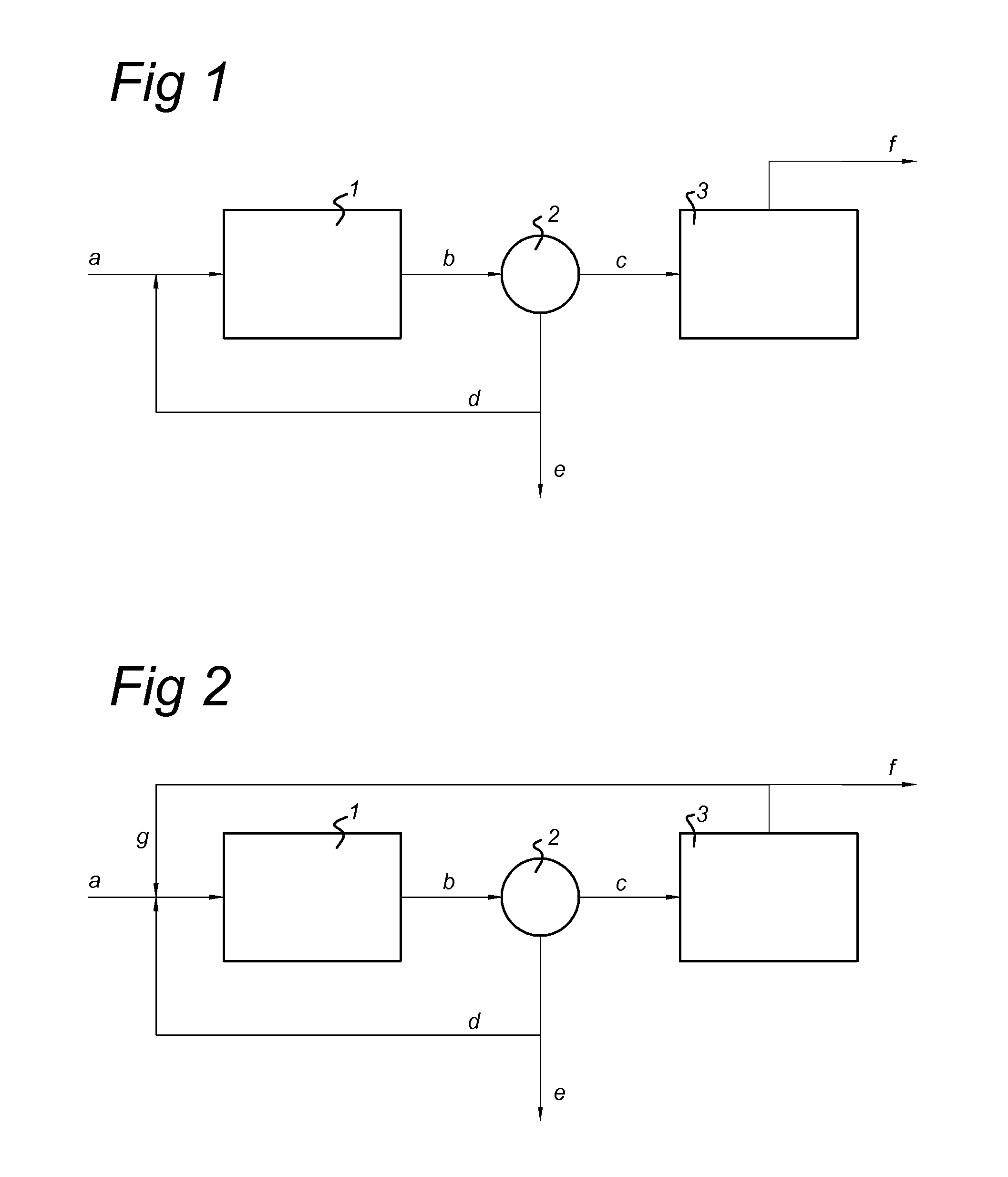

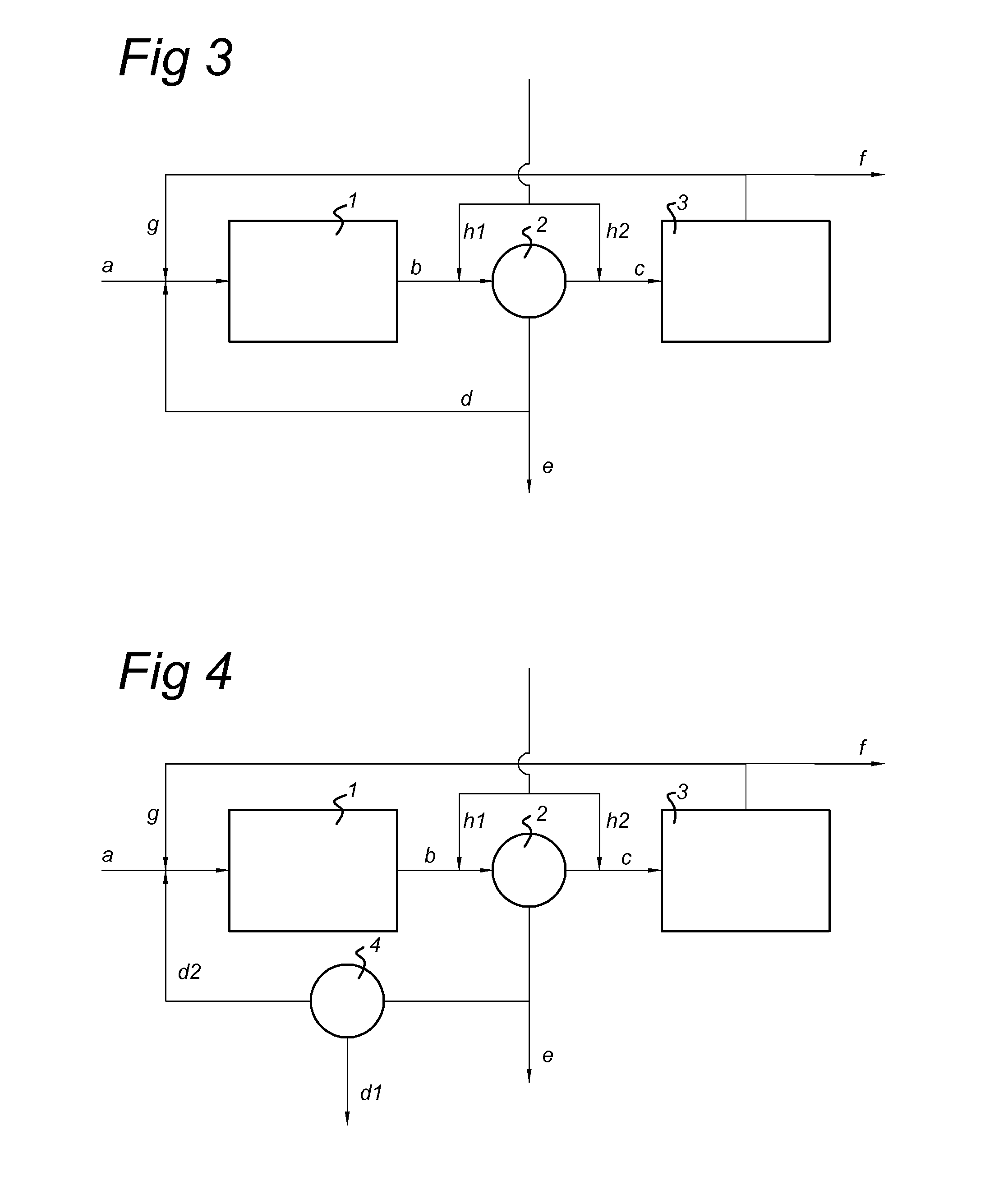

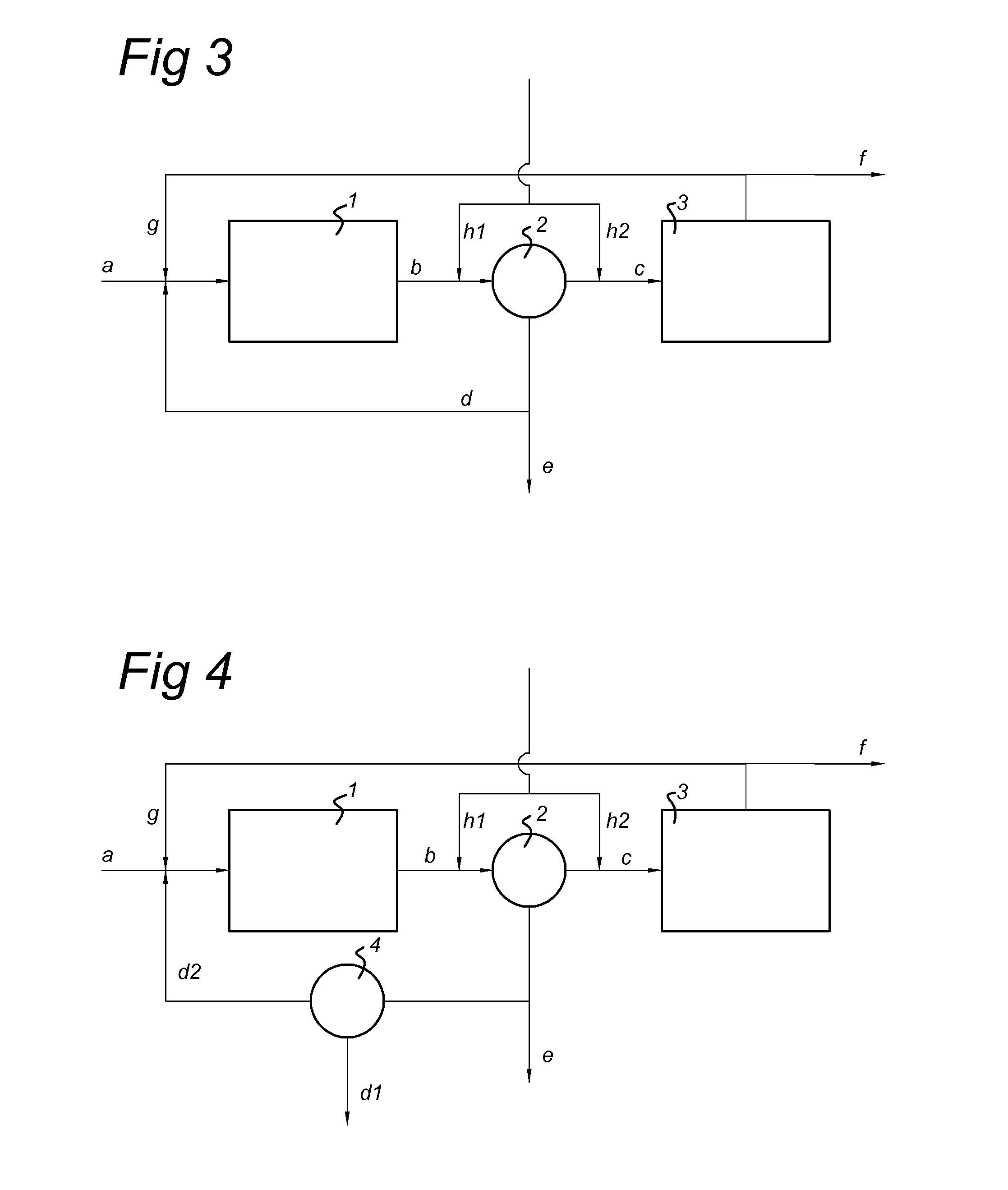

Process for producing methane from biomass

InactiveUS20120094350A1Increase ratingsAvoid adjustmentBioreactor/fermenter combinationsBiological substance pretreatmentsVolatile fatty acidsMethanogenesis

The invention pertains to a process for producing methane by a two-stage anaerobic digestion of organic feed, comprising i) subjecting an organic feed suspension (a) to acidogenesis and methanogenesis in a first reactor (1); ii) withdrawing an effluent (b) from said first reactor and subjecting it to solid / liquid separation (2), thus obtaining effluents high (d) and low (c) in solids, wherein the volatile fatty acid (VFA) concentration in said first reactor is controlled by the withdrawal rate; iii) subjecting the effluent low in solids (c) to acidogenesis and methanogenesis in a second reactor (3), thus producing methane gas in said first and second reactor.

Owner:KONINK COOPERATIE COSUN U A

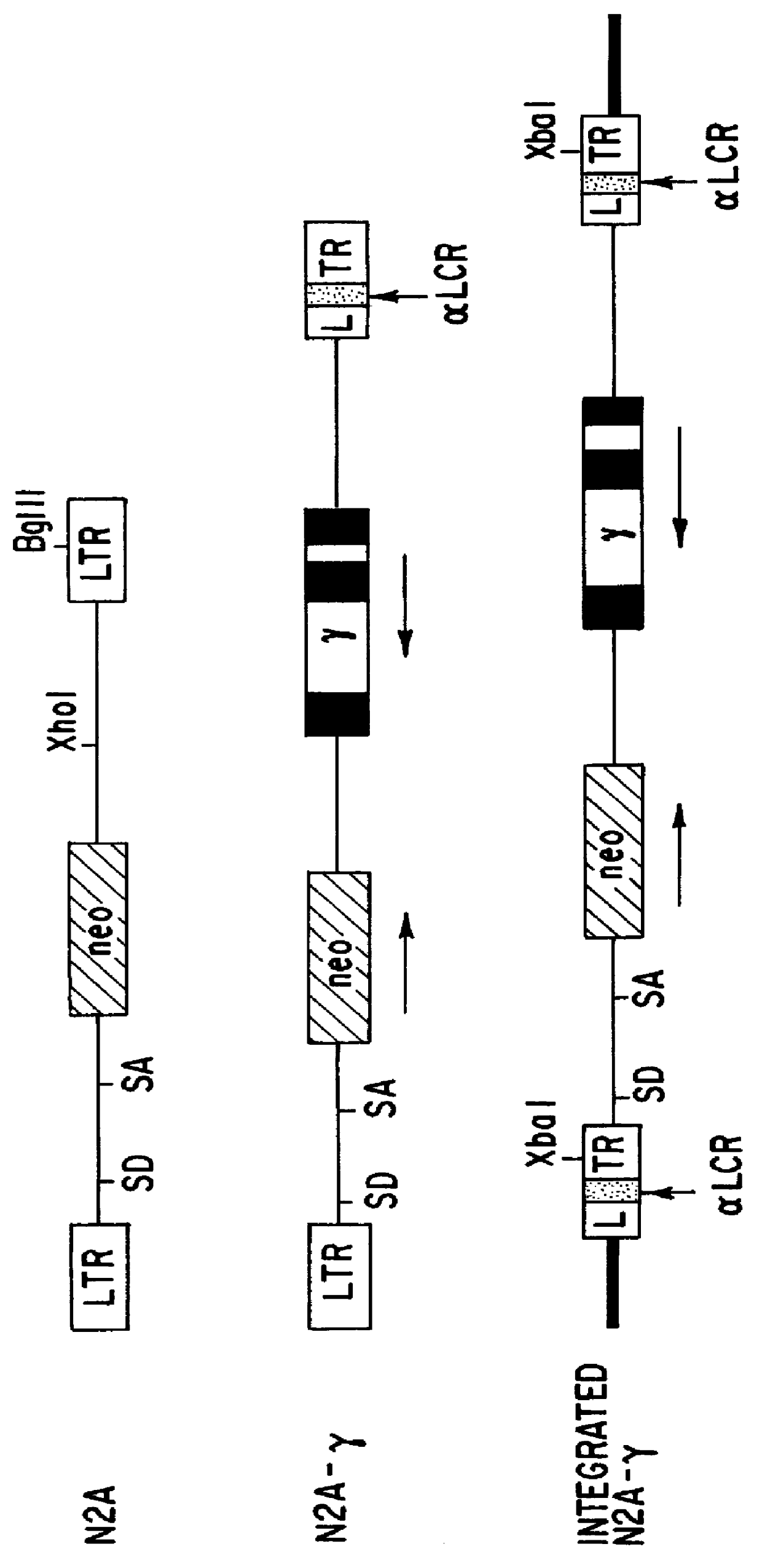

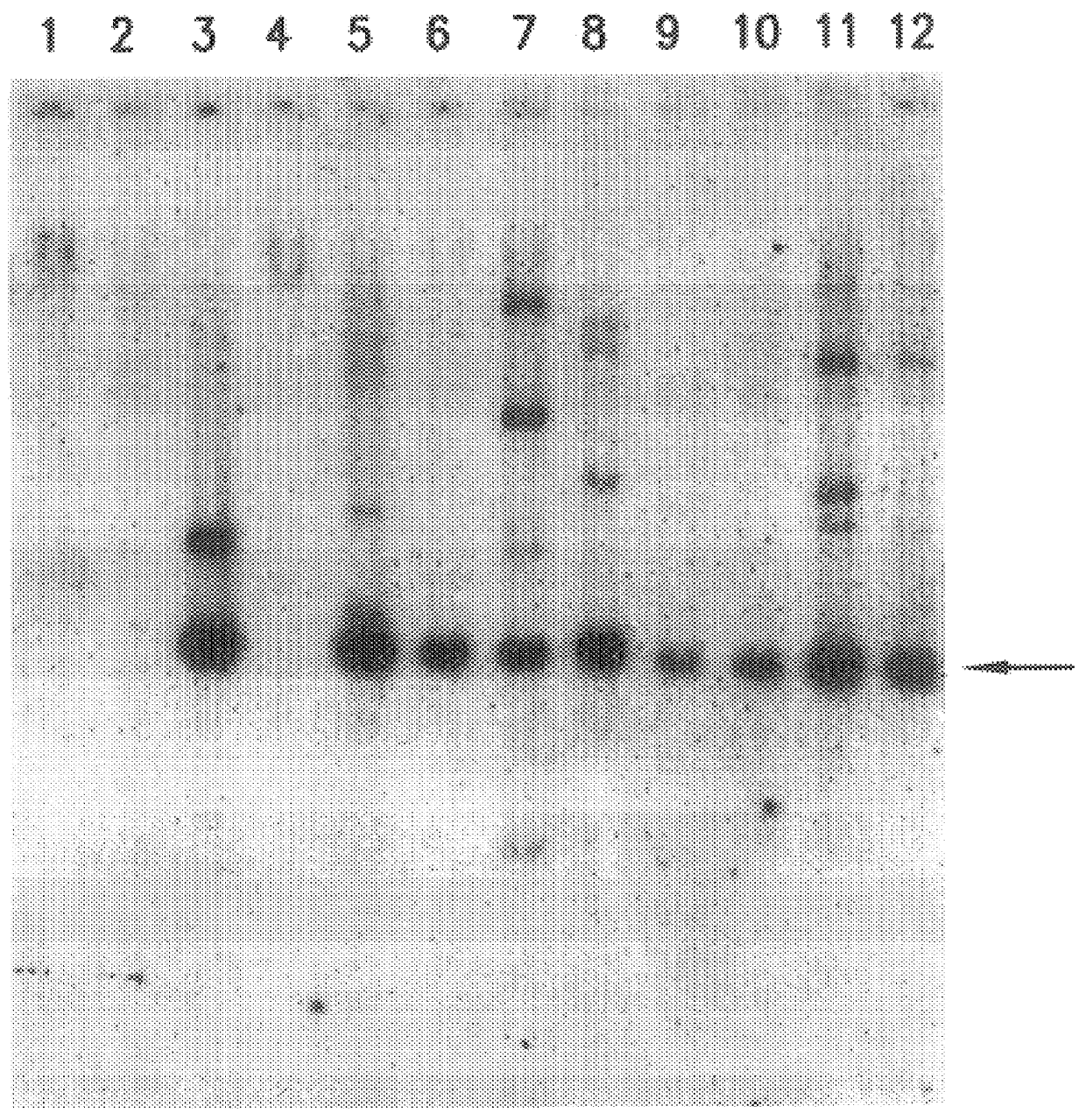

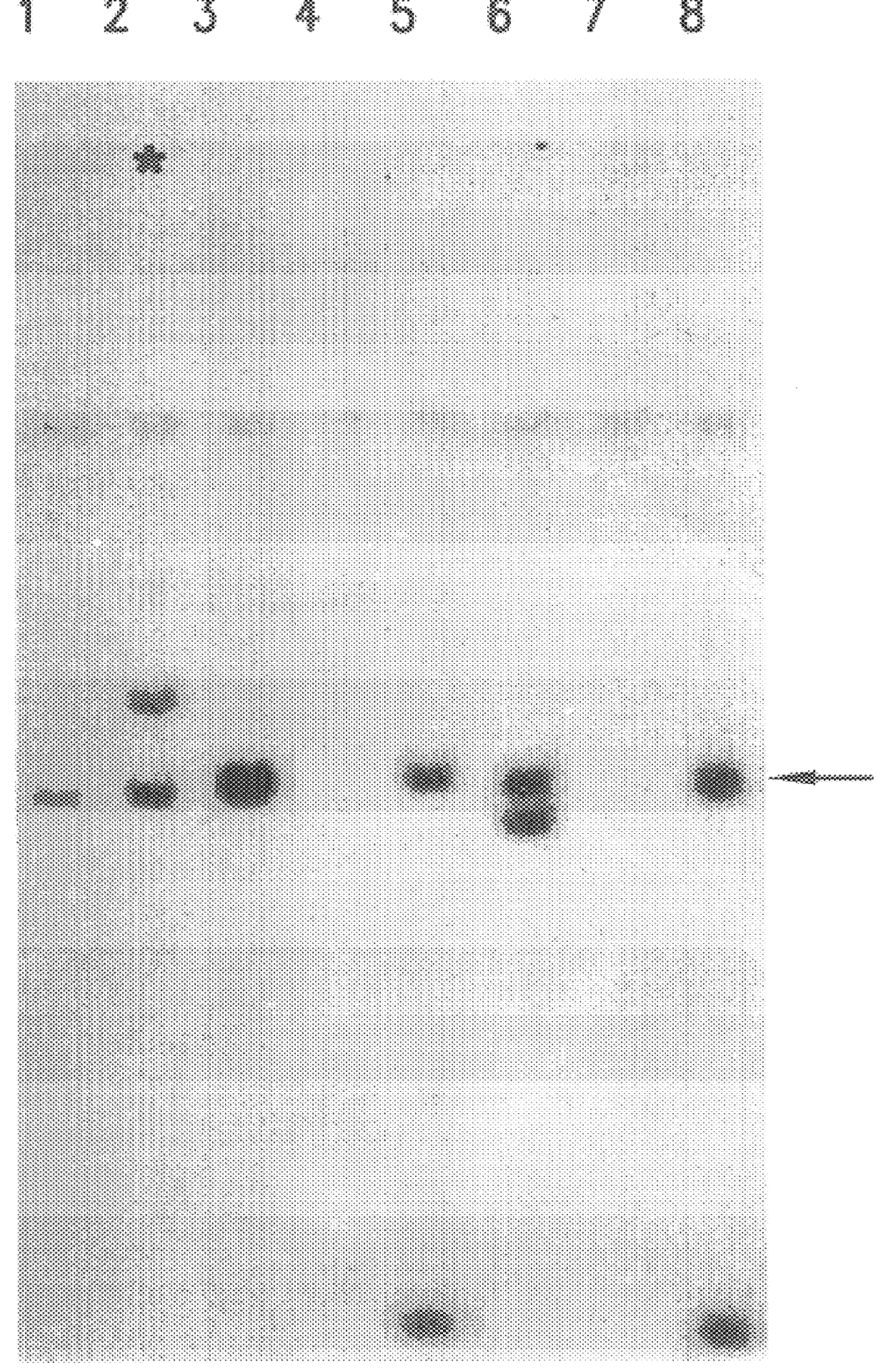

Vectors for expression of globin genes

InactiveUS6022738AImprove stabilityExcellent meanVirusesHaemoglobins/myoglobinsSickle cell anemiaThalassemia

The present invention relates to vectors comprising an alpha -globin locus control region ( alpha LCR) and a gene encoding an erythroid protein. In particular embodiments, a retroviral vector comprising an alpha LCR and a globin gene may be used to treat globin-based genetic disorders, including sickle cell anemia and beta -thalassemia.

Owner:MT SINAI SCHOOL OF MEDICINE

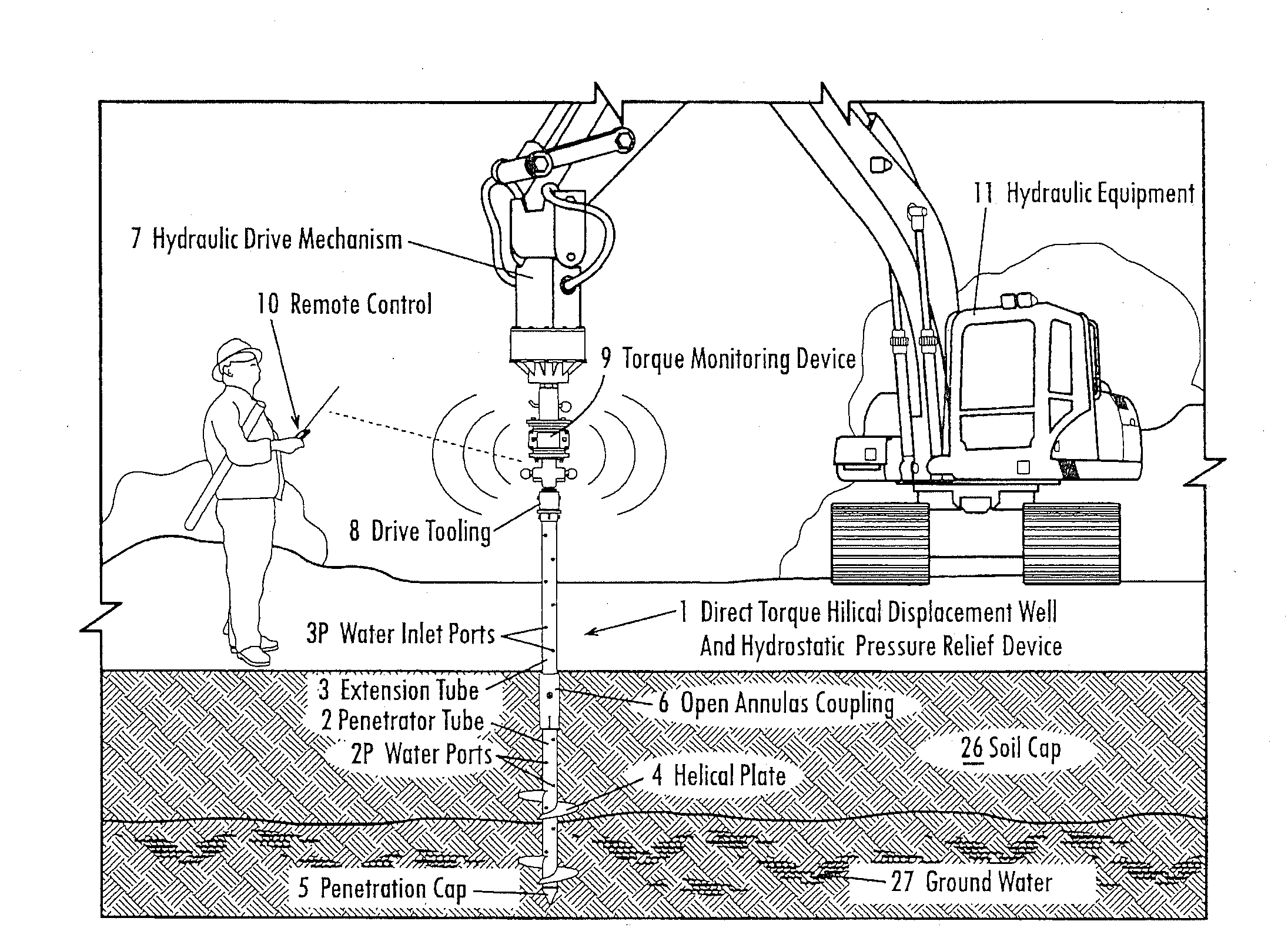

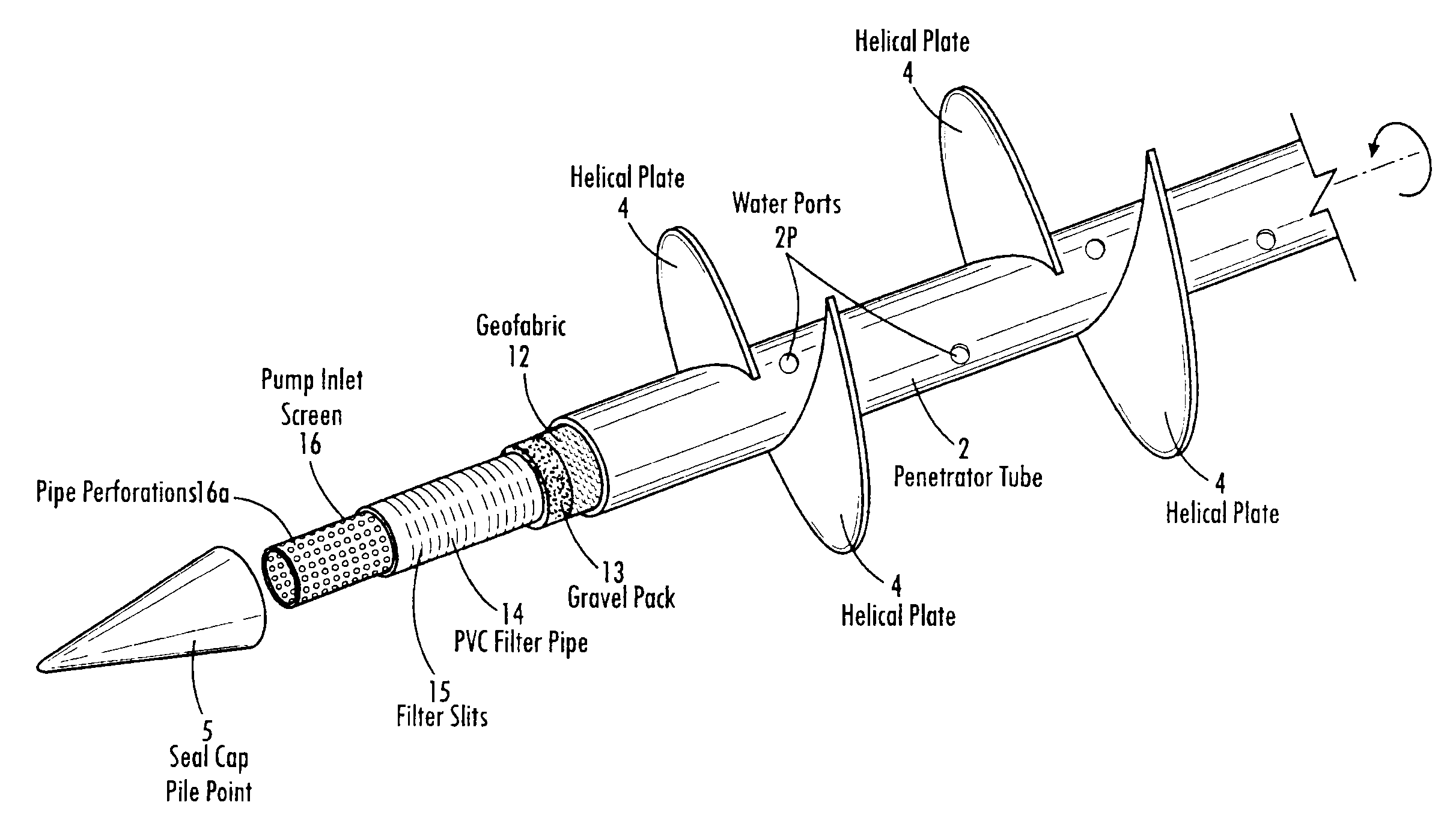

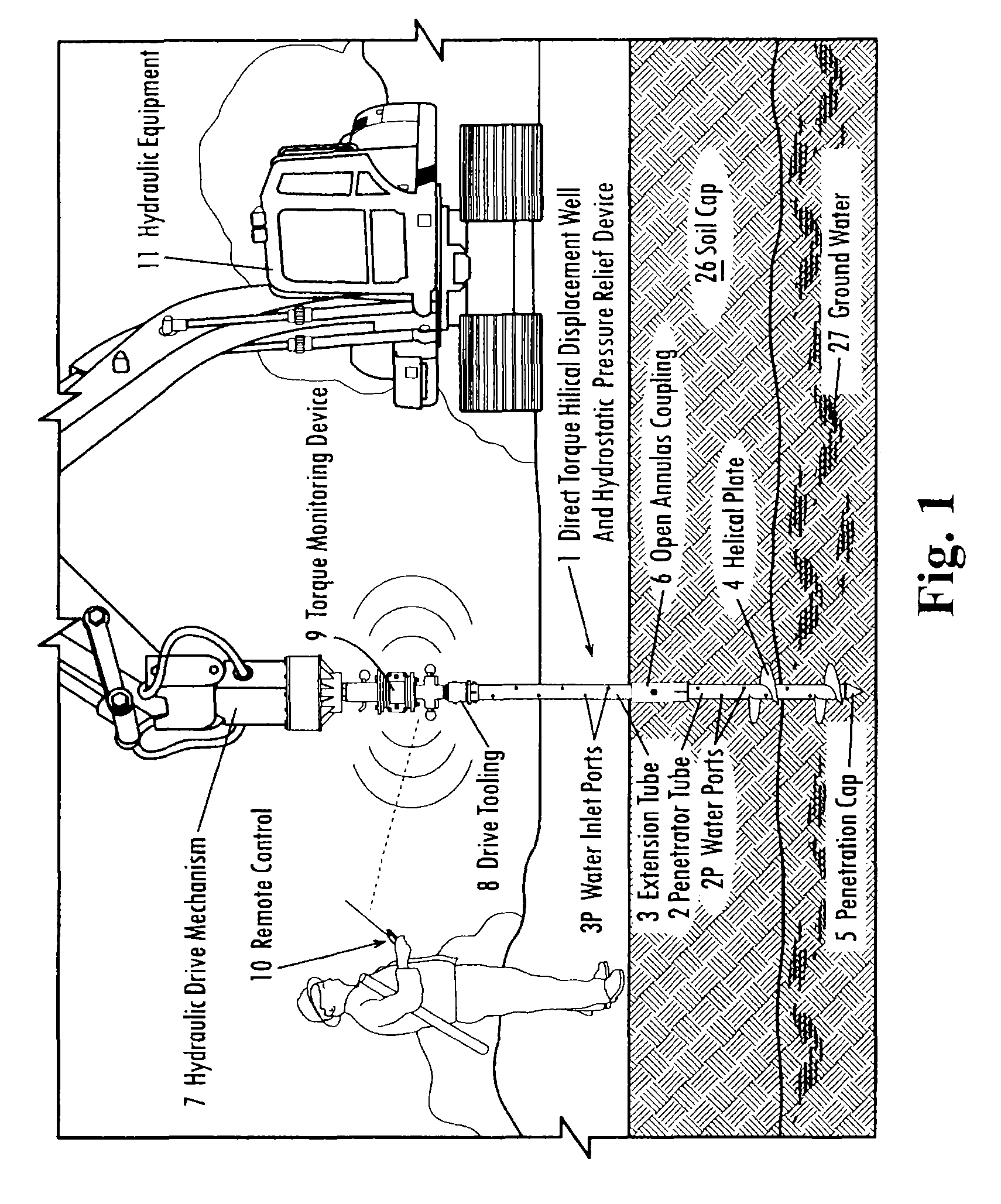

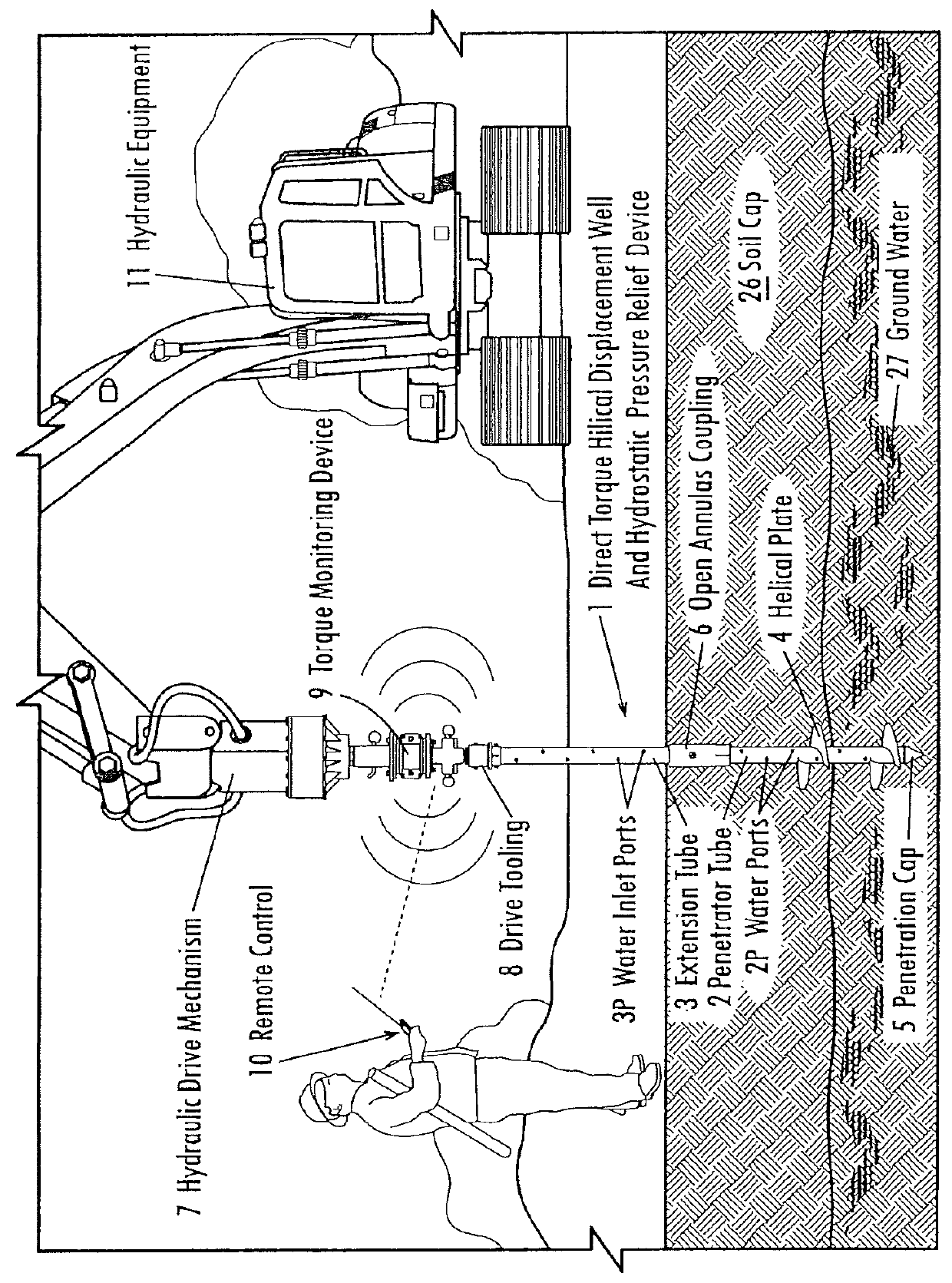

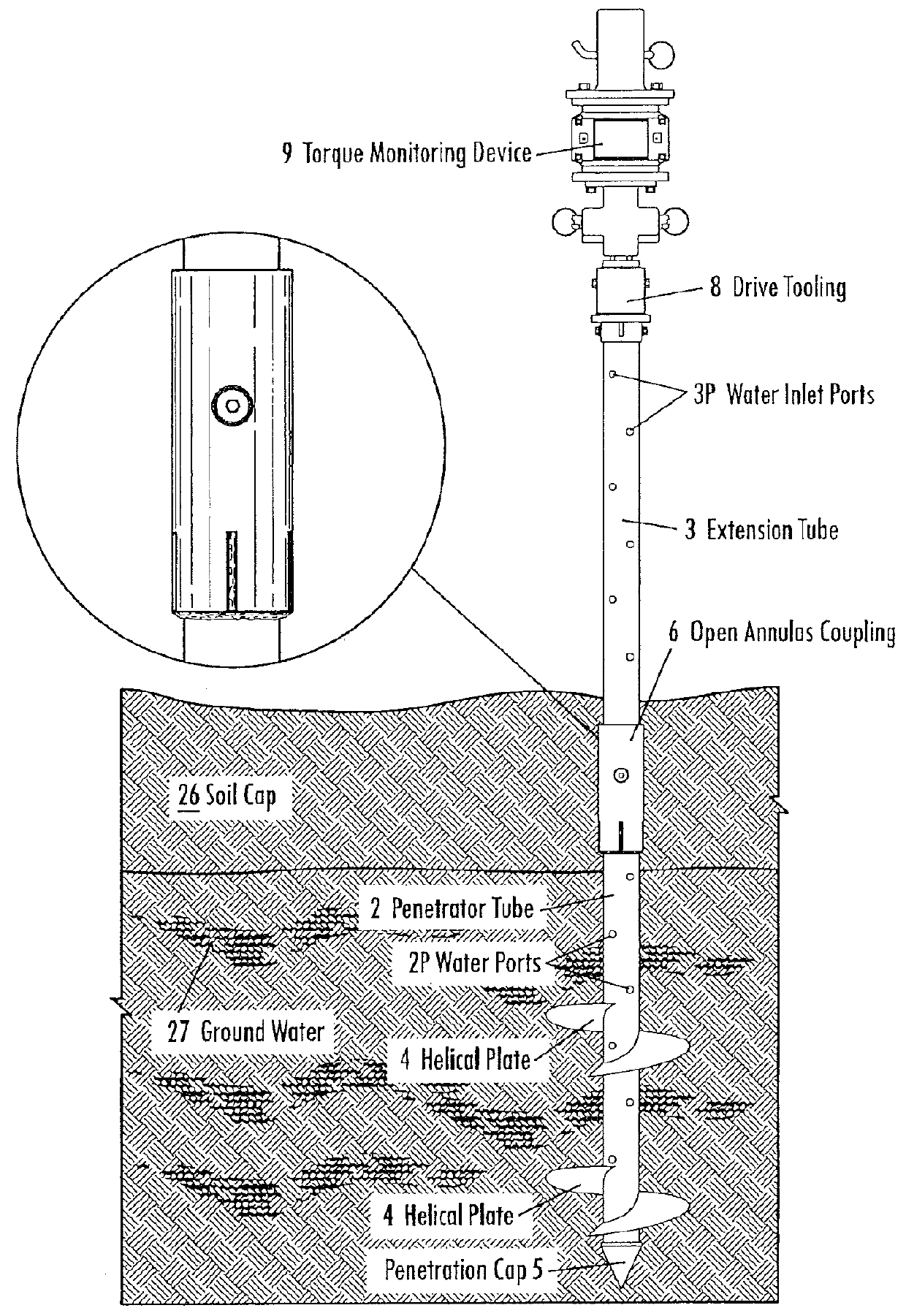

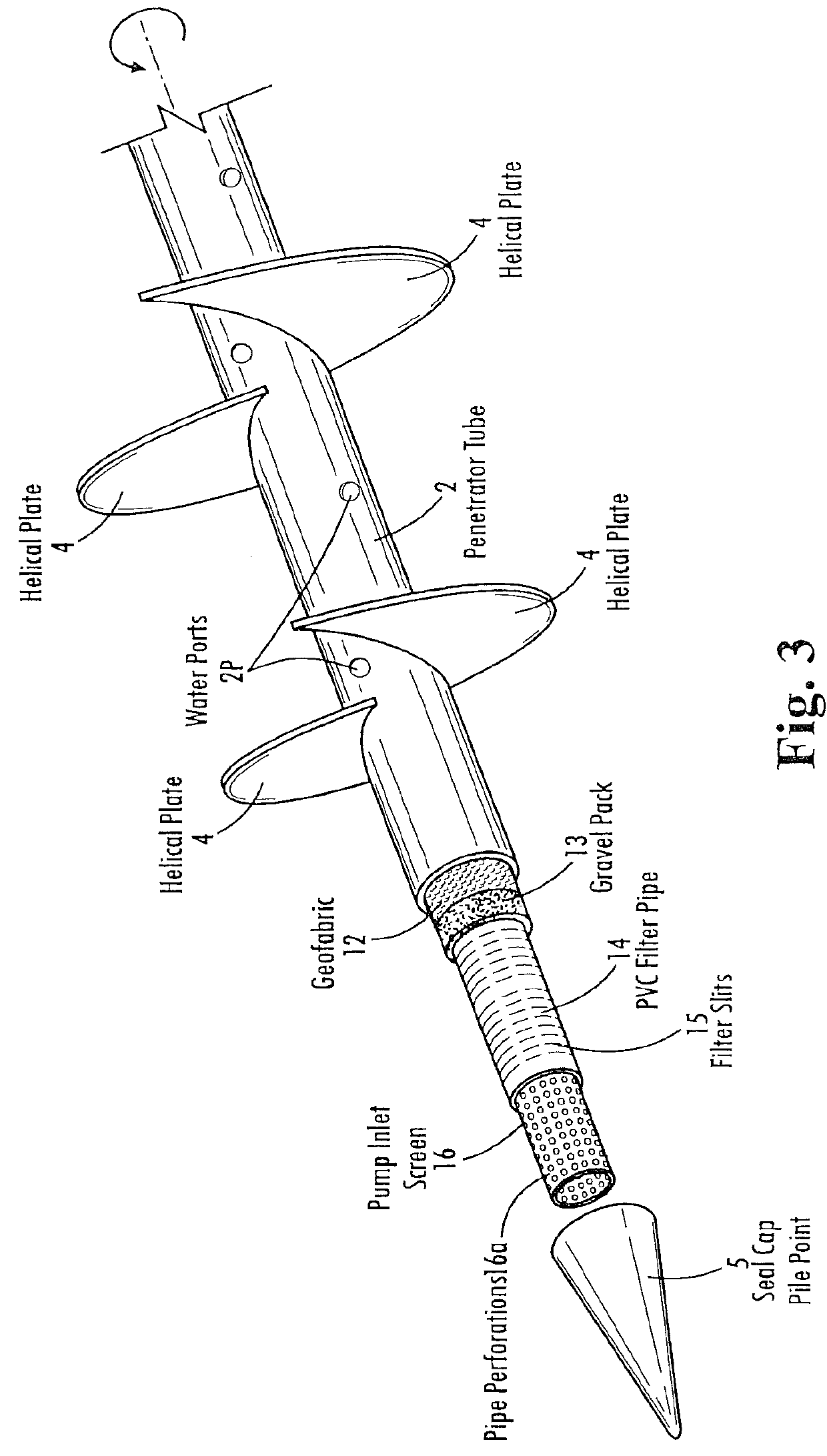

Direct Torque Helical Displacement Well and Hydrostatic Liquid Pressure Relief Device

A helical displacement well with preassembled segments includes a preassembled shaft-forming penetrator tube including helical plates mounted to its exterior that may be rotated to propel the casing into the ground. A hydraulic drill motor rotates the penetrator tube as it moves deeper into the ground. Extension tubes may be added to and coupled to the penetrator tube. A bolt including a threaded stem sized to engage the threaded bolt opening of the male connector and a cap of larger breadth than the threaded stem and sized to fit within the unthreaded tension bolt opening of the female connector for connecting the female connector about the male connector.

Owner:QUEEN FRIE A R

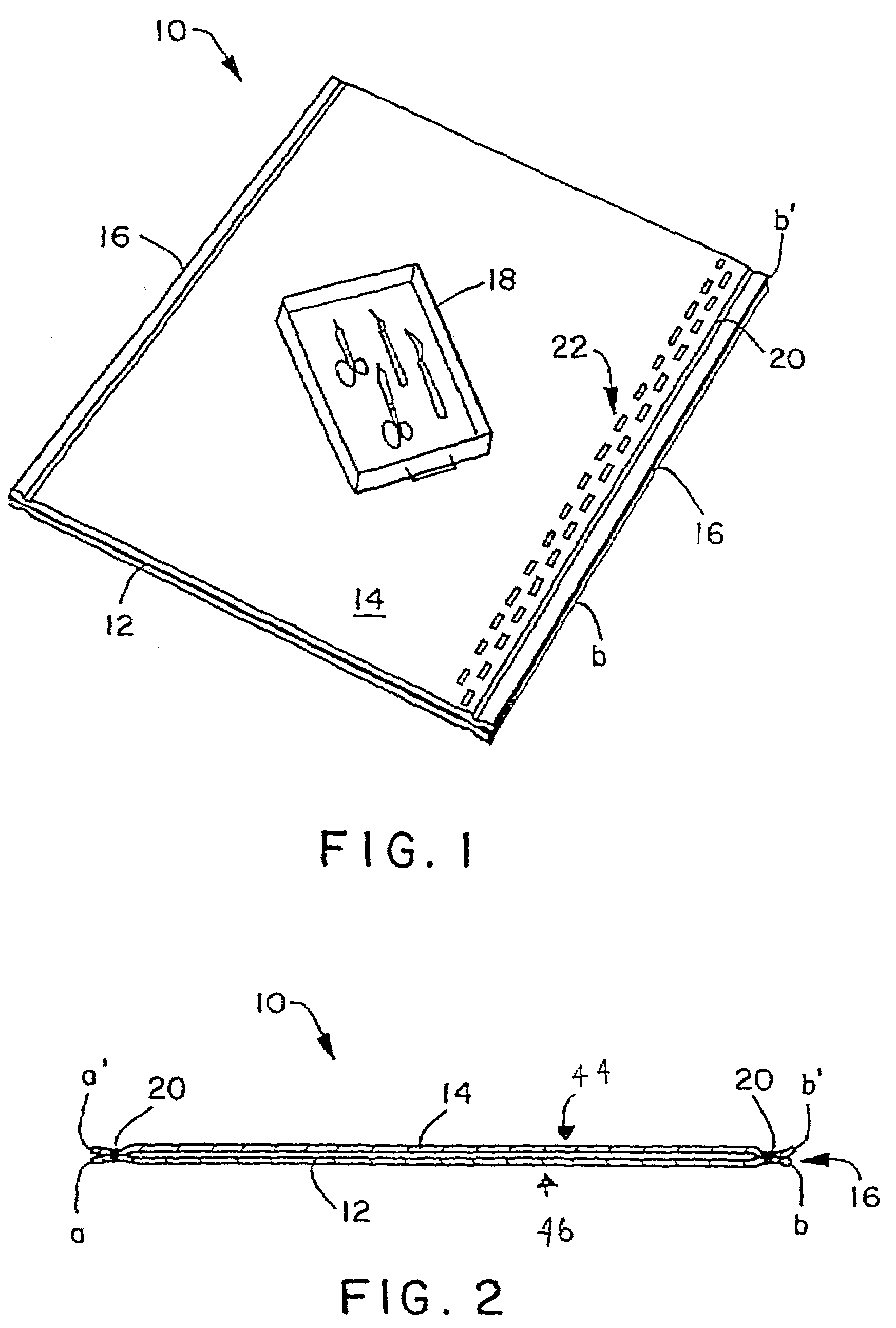

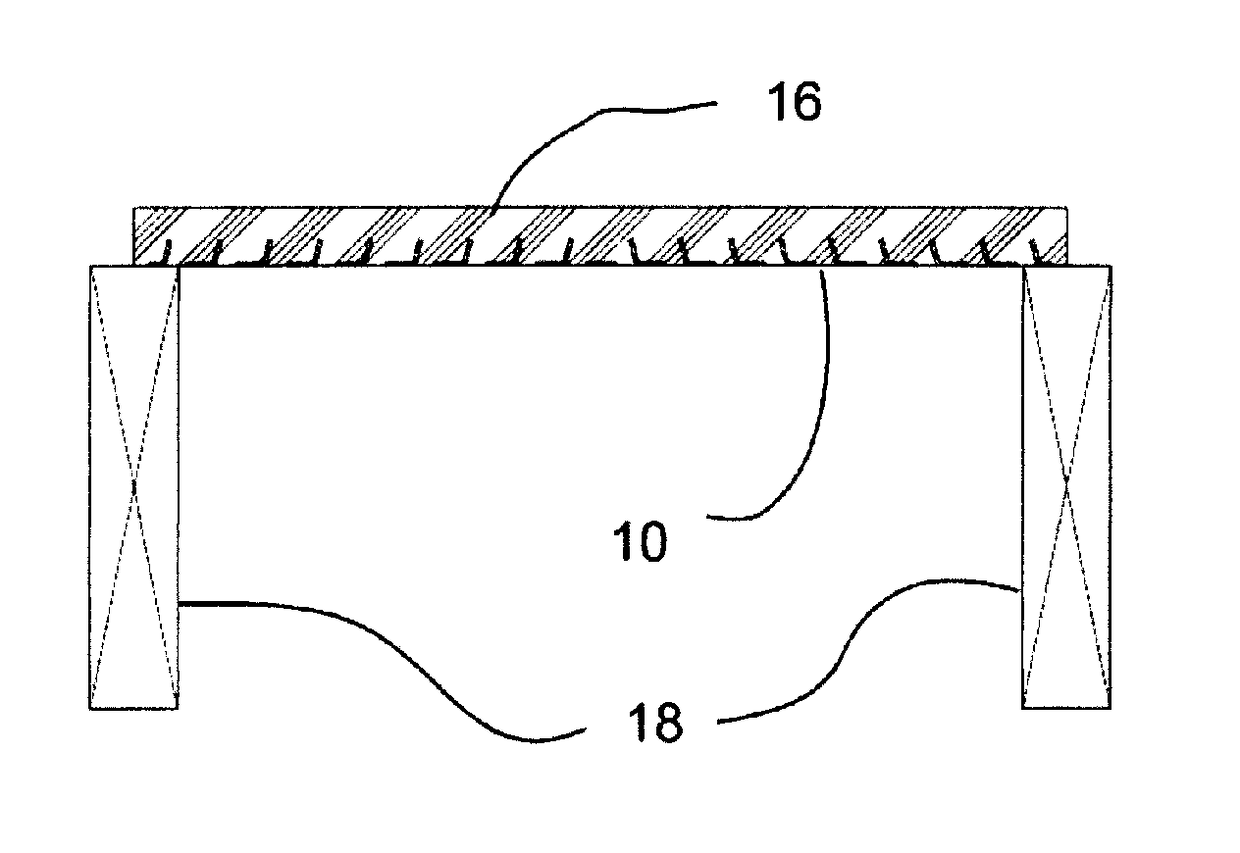

Single step sterilization wrap system

InactiveUS7361317B2Easy to processShorten the timeSurgical furnitureDiagnosticsEngineeringPack material

Disclosed herein is a single step sterilization wrapping material suitable for use, as an example, in wrapping surgical instruments and supplies for sterilization, transportation and storage. The material includes separate inner and outer wraps which, unlike previous wraps, are joined to one another. Common wrapping techniques involve wrapping items to be sterilized with two separate sheets of wrap. The present invention provides separate wraps which can be specially engineered to deliver specific properties for each sheet and then joined to one another so as to permit wrapping and opening in a neat single step process which increases efficiency and saves time and money. In special situations the outer wrap can be engineered with increased strength, the inner wrap with increased barrier properties and the inner and outer wraps can be made visually distinct from one another so that improper wrapping or opening is not a problem.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for Selecting a Motor Vehicle

InactiveUS20130218368A1Accurate representationSimpler key numberDigital data processing detailsBuying/selling/leasing transactionsMobile vehicleSensor system

A method for selecting or configuring a motor vehicle from a plurality of selectable motor vehicles involves providing a motor vehicle database containing a plurality of selectable motor vehicles, each having an associated first load collective data record describing properties of the motor vehicle which can be detected by a sensor system. Technical properties in a comparison vehicle are detected by a sensor system. A second load collective data record is formed by conditioning of the detected technical properties of the comparison vehicle and the two load collective data records are compared. The first load collective data record from the motor vehicle database having the smallest discrepancy from the second load collective data record is determined and the motor vehicle associated with the first load collective data record having the smallest discrepancy is selected.

Owner:DAIMLER AG

Direct torque helical displacement well and hydrostatic liquid pressure relief device

ActiveUS9366084B2Easy to moveSignificant potential savingsDrill bitsDrilling rodsHydraulic motorDrill

A helical displacement well with preassembled segments includes a preassembled shaft-forming penetrator tube including helical plates mounted to its exterior that may be rotated to propel the casing into the ground. A hydraulic drill motor rotates the penetrator tube and as it moves deeper into the ground. Extension tubes may be added to and coupled to the penetrator tube. A hydraulic drill motor is attached to the upper end of the extension tubes in order to continue the rotation of the assembled helical displacement well. The filter screen and the piping are installed concurrently with the addition of the extension tubes at the surface of the ground.

Owner:QUEEN FRIE A R

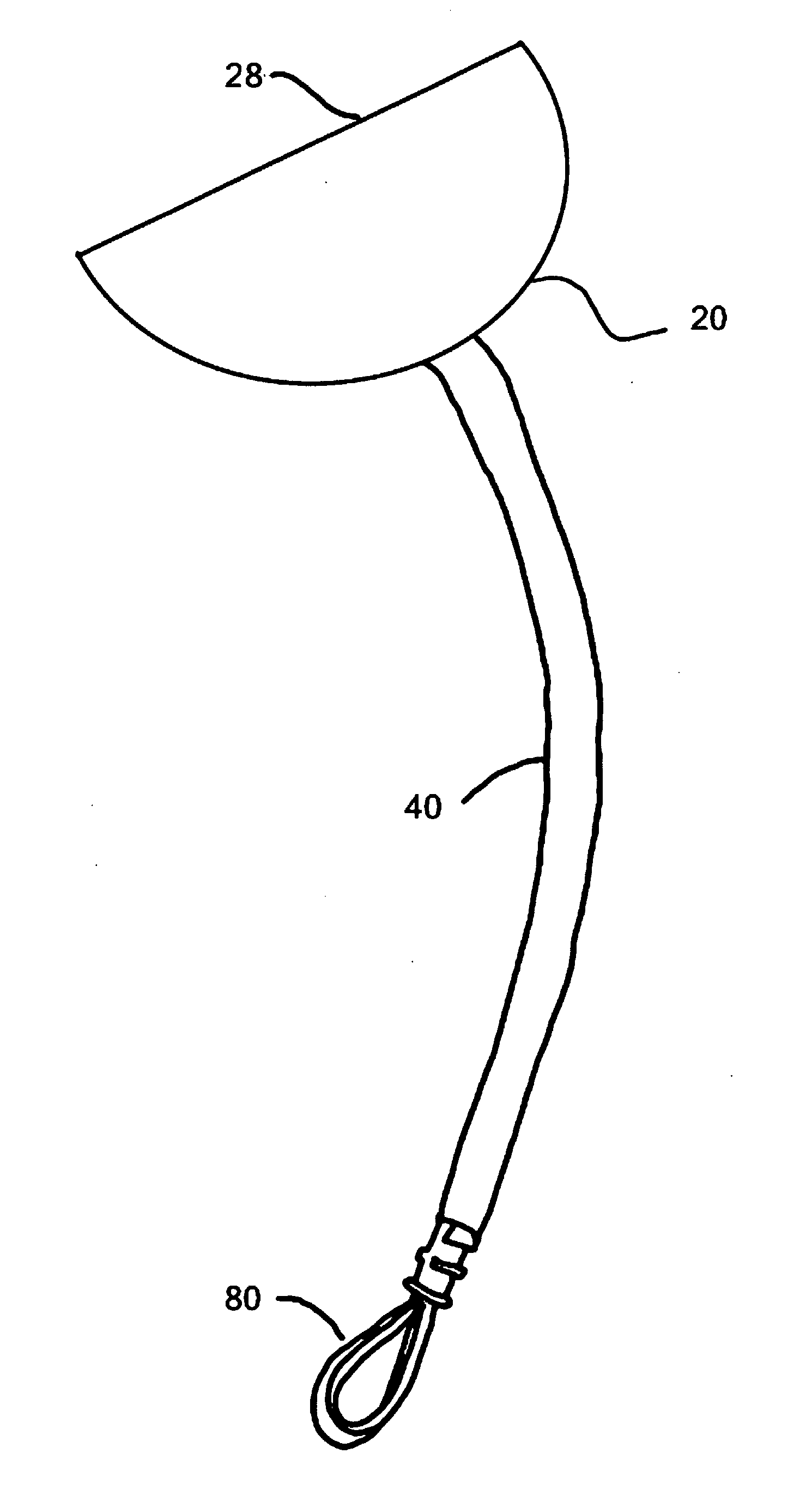

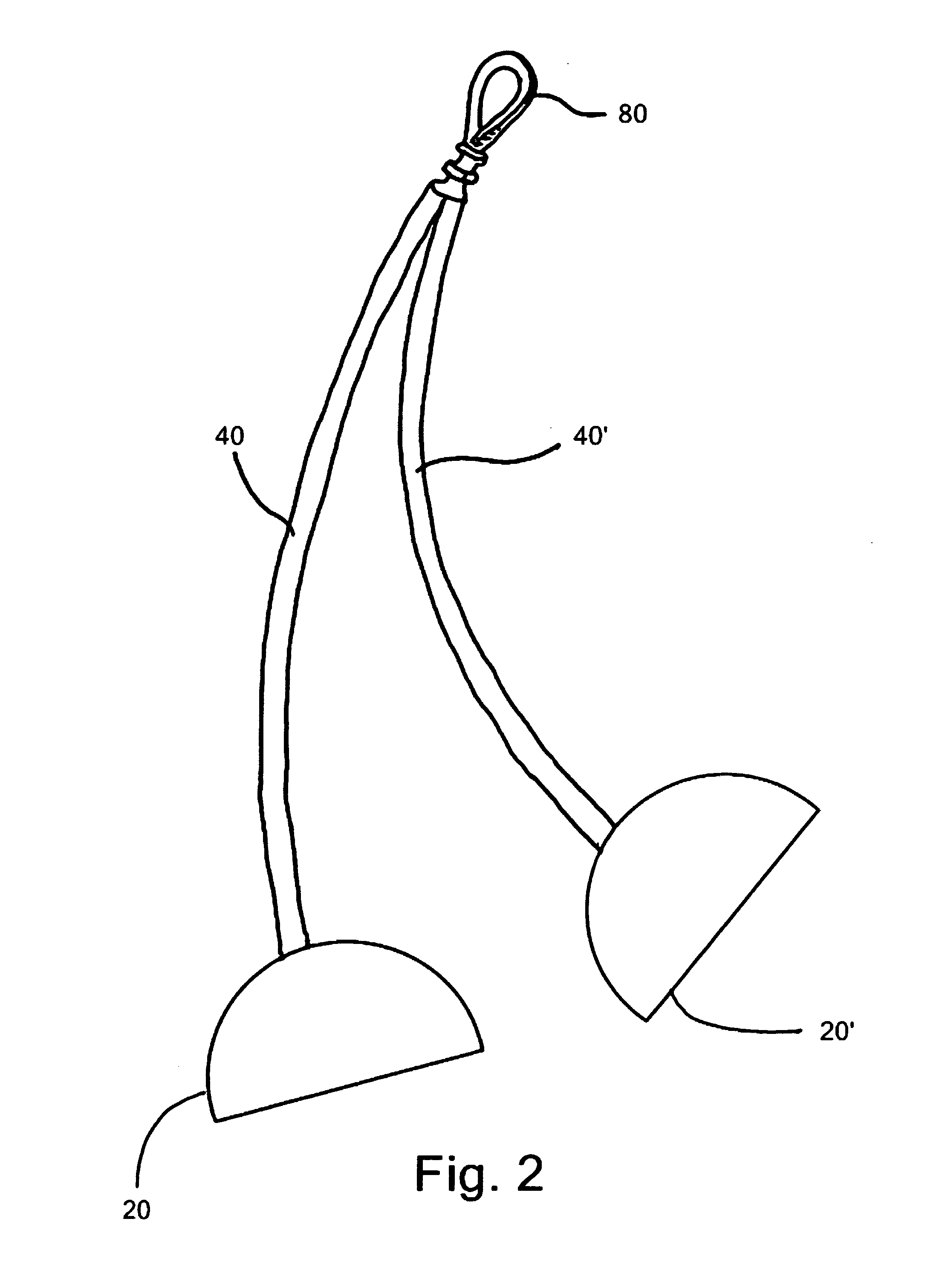

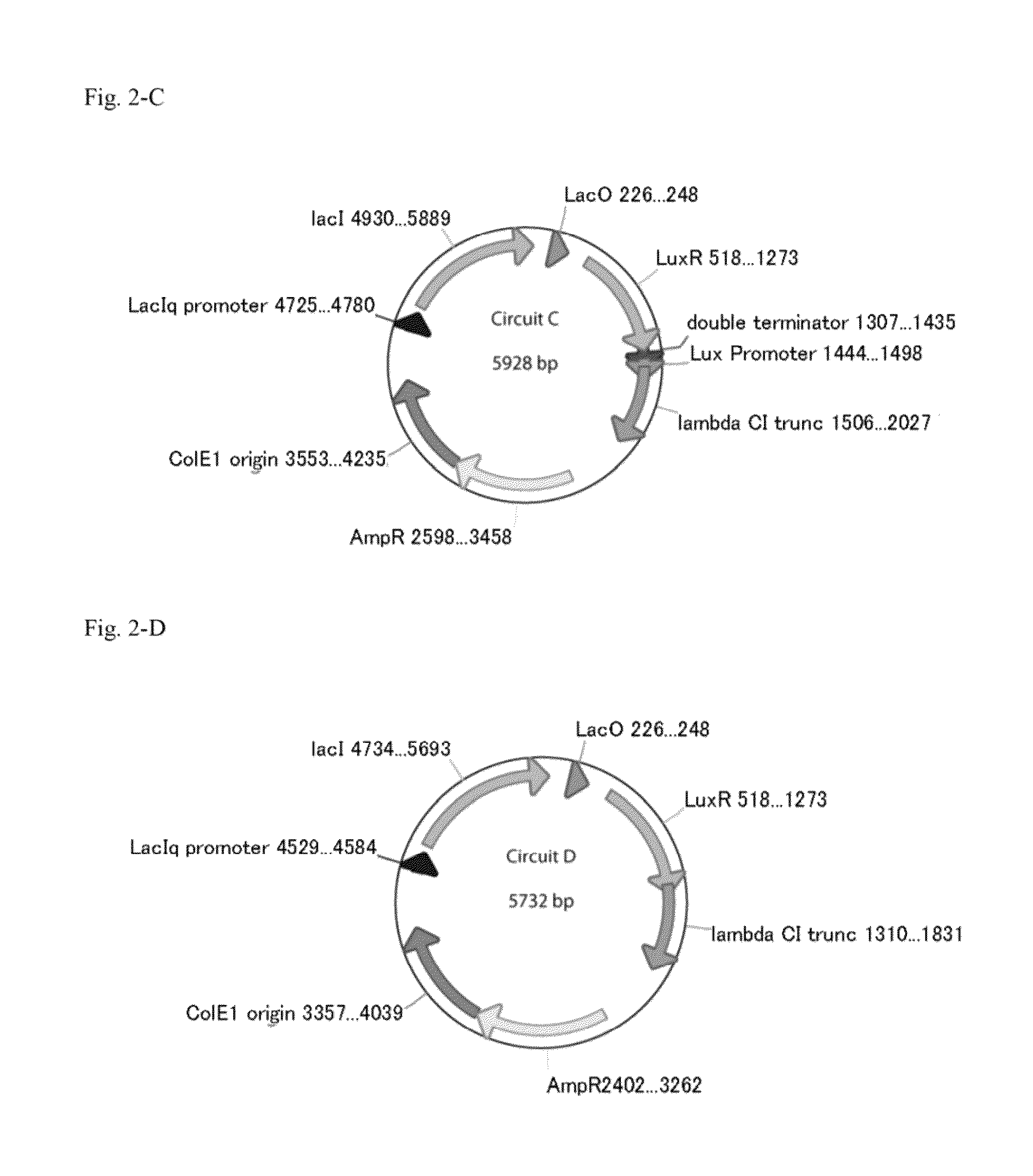

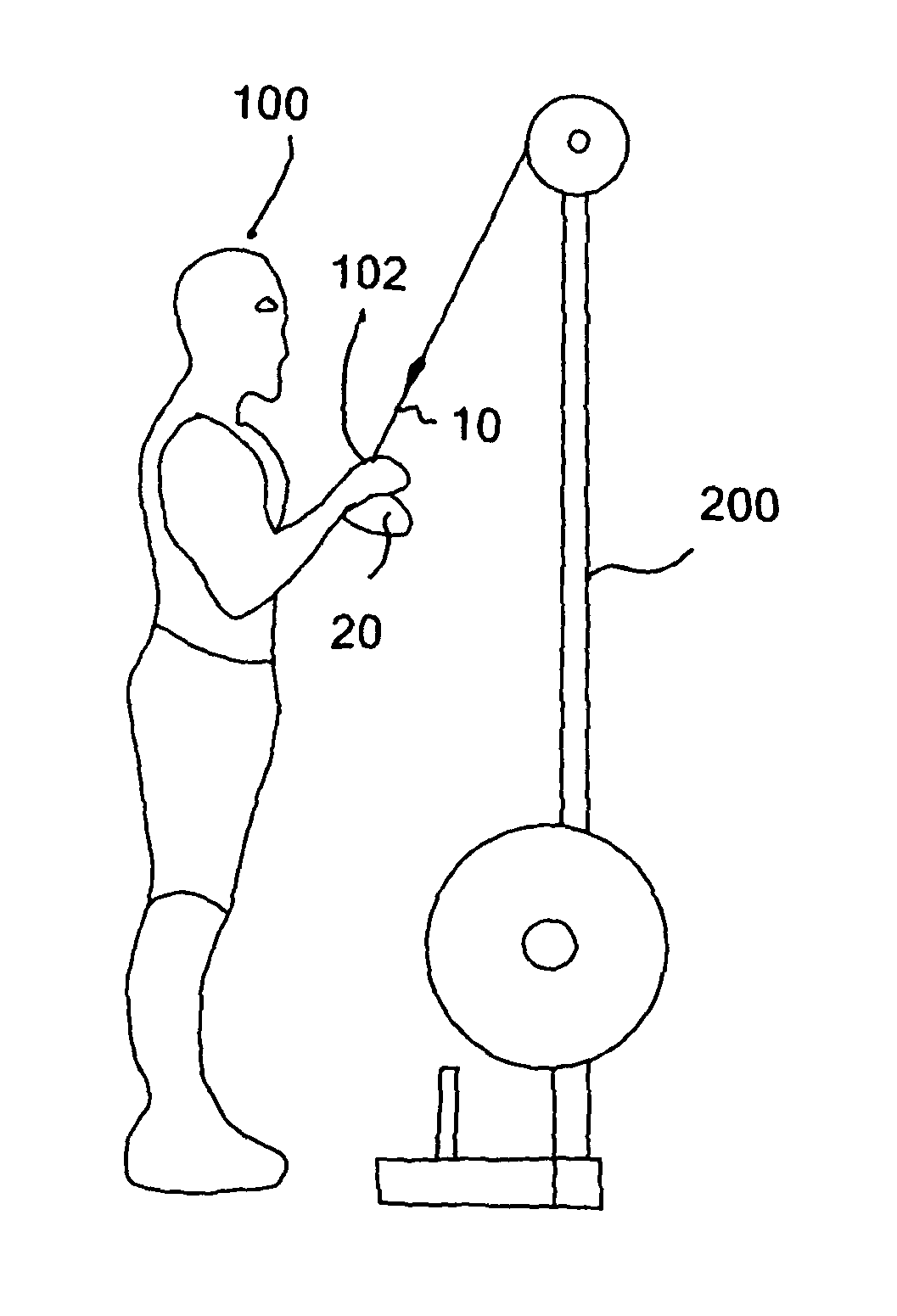

Hemisperical grip handle apparatus

ActiveUS20110245050A1Excellent meanImprove comfortMuscle exercising devicesEngineeringElectric cables

Owner:EMICK DANIEL W

Process for producing methane from biomass

InactiveUS8642304B2High product yieldAvoid accumulationBioreactor/fermenter combinationsBiological substance pretreatmentsVolatile fatty acidsMethanogenesis

The invention pertains to a process for producing methane by a two-stage anaerobic digestion of organic feed, comprising i) subjecting an organic feed suspension (a) to acidogenesis and methanogenesis in a first reactor (1); ii) withdrawing an effluent (b) from said first reactor and subjecting it to solid / liquid separation (2), thus obtaining effluents high (d) and low (c) in solids, wherein the volatile fatty acid (VFA) concentration in said first reactor is controlled by the withdrawal rate; iii) subjecting the effluent low in solids (c) to acidogenesis and methanogenesis in a second reactor (3), thus producing methane gas in said first and second reactor.

Owner:KONINK COOPERATIE COSUN U A

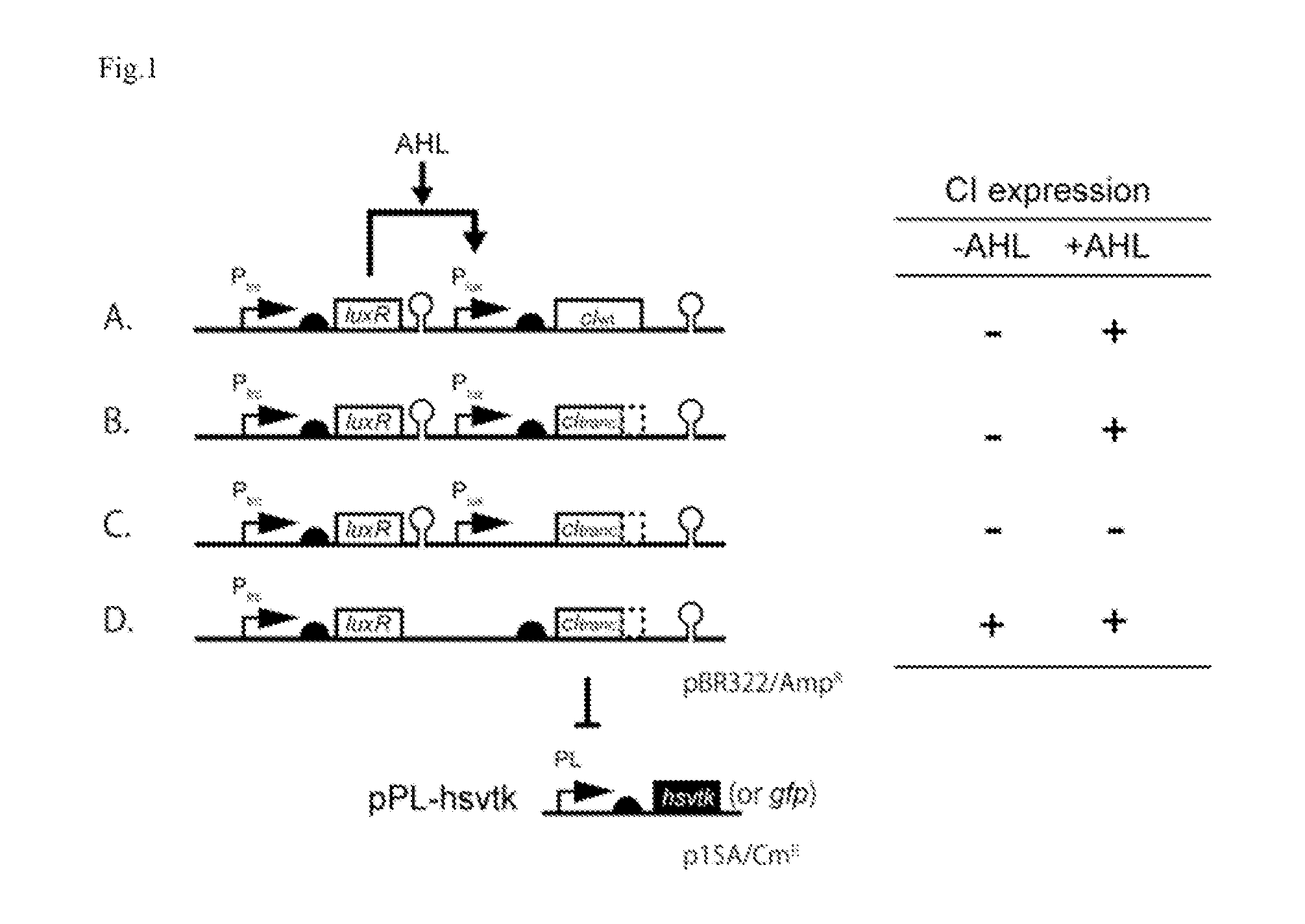

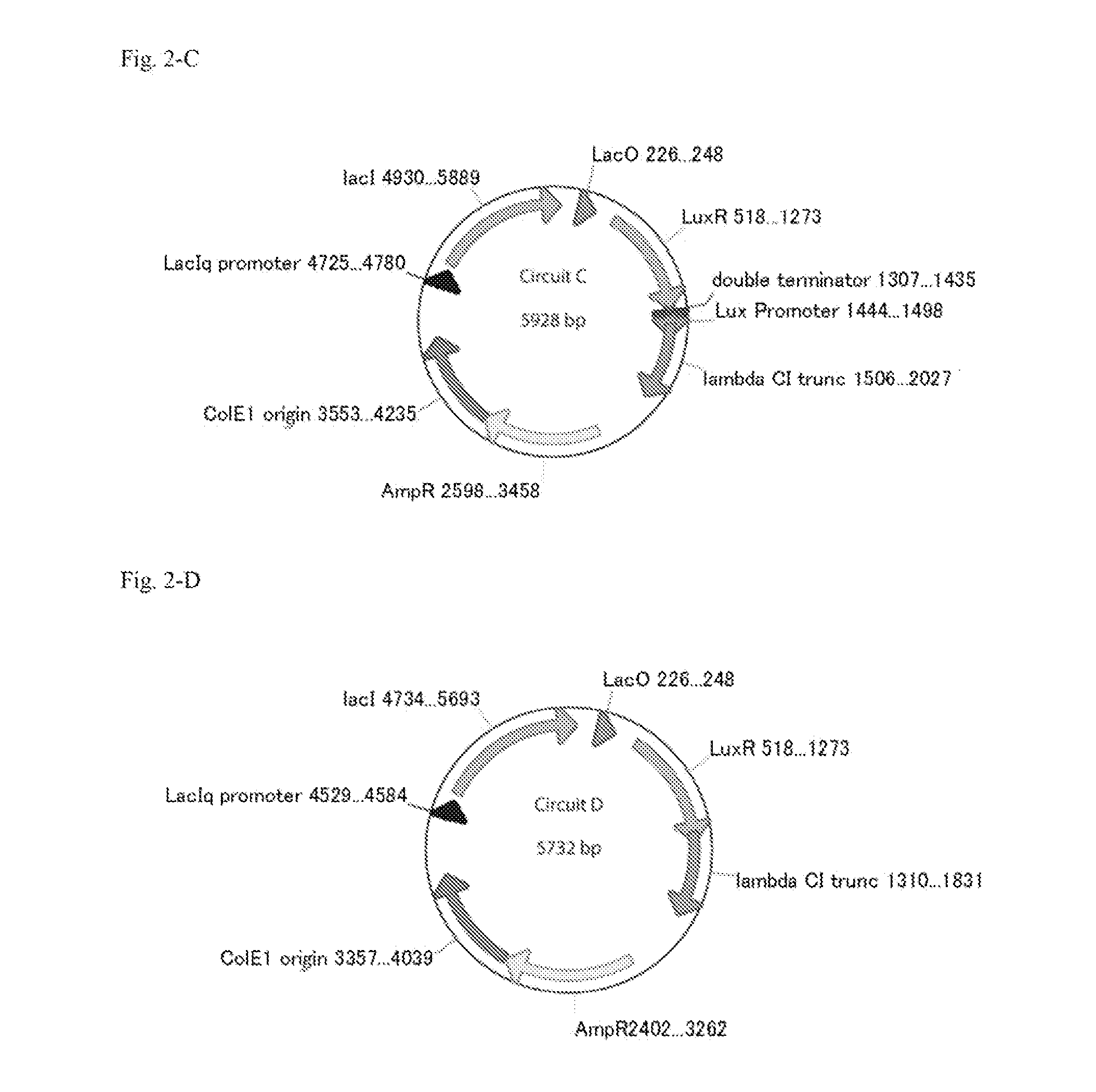

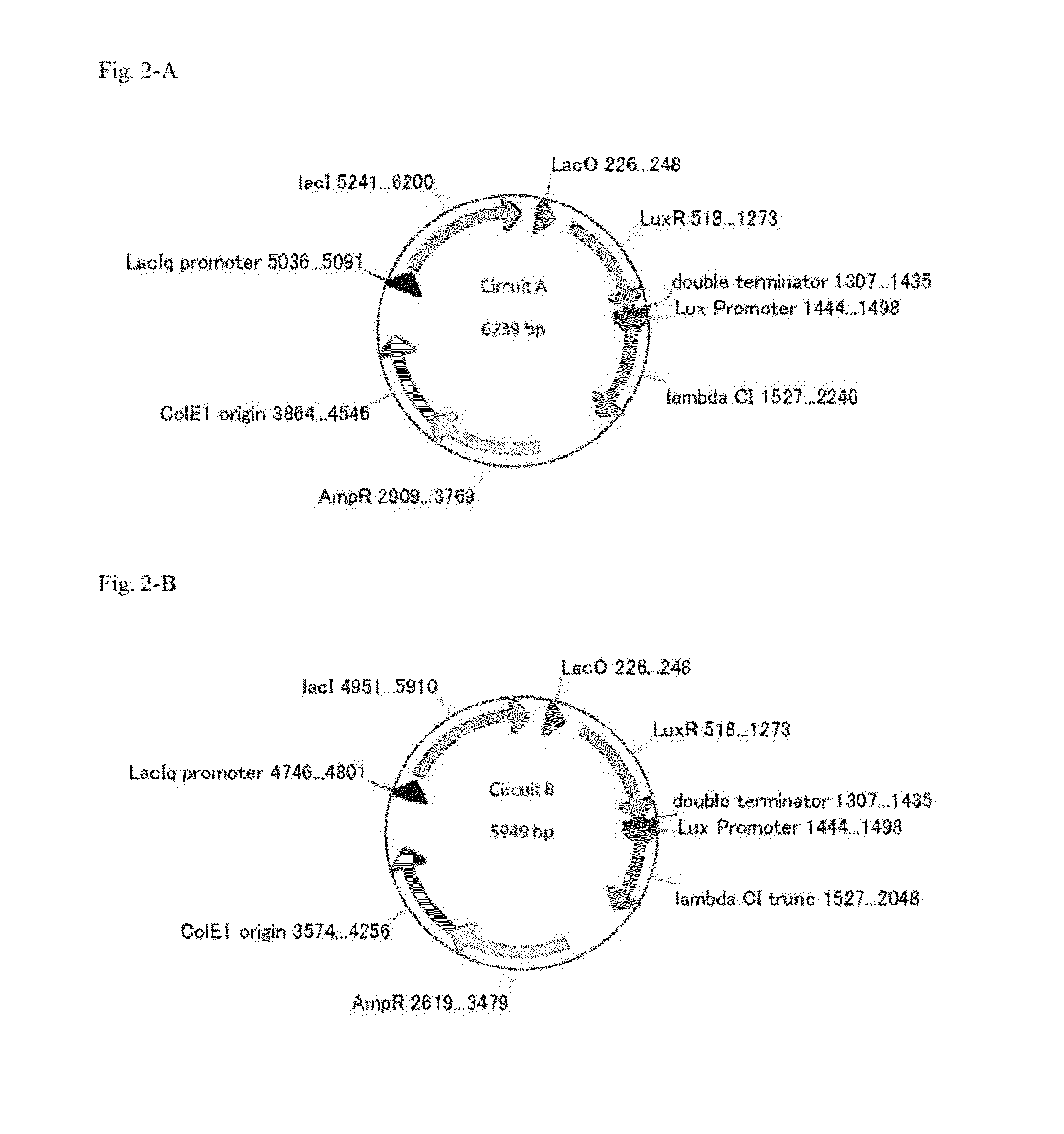

Method For Rapidly Developing Gene Switches And Gene Circuits

ActiveUS20130267011A1High efficiencyShort period of timeBacteriaMicrobiological testing/measurementExpression vectorSelection method

Provided are: a selection method for a gene switch and a gene circuit, including using, as a selector, an expression vector containing at least a gene sequence whose expression is controlled by a transcription regulatory factor to be expressed when a genetic switch and a genetic circuit including the genetic switch operate, and a promoter sequence operably linked to the gene sequence upstream thereof; and an expression vector to be used in the selection method. This enables an effective selection method for a genetic switch and a genetic circuit, the selection method being able to be conducted within a short time period and with high selection efficiency and less leakiness.

Owner:CHIBA UNIVERSITY

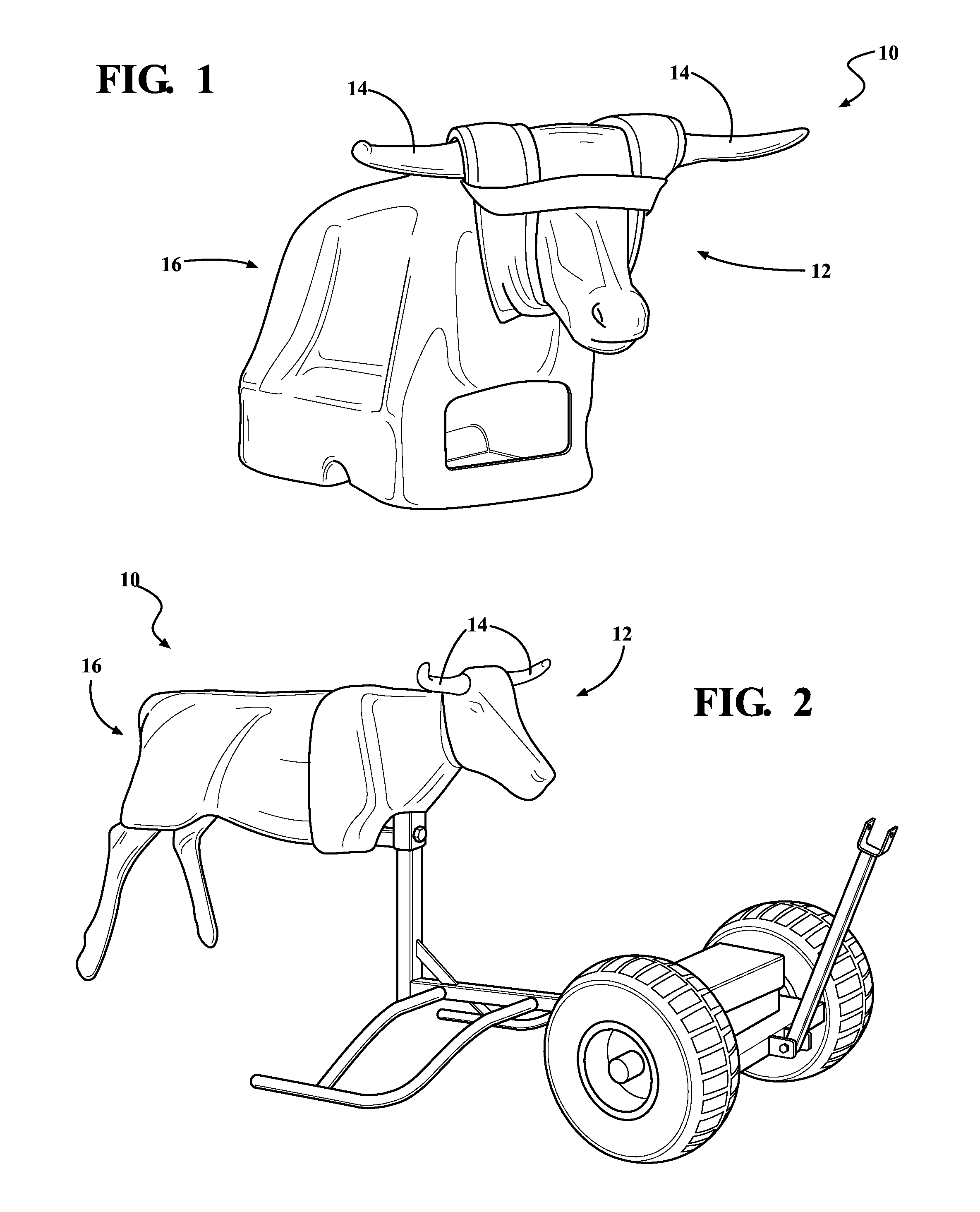

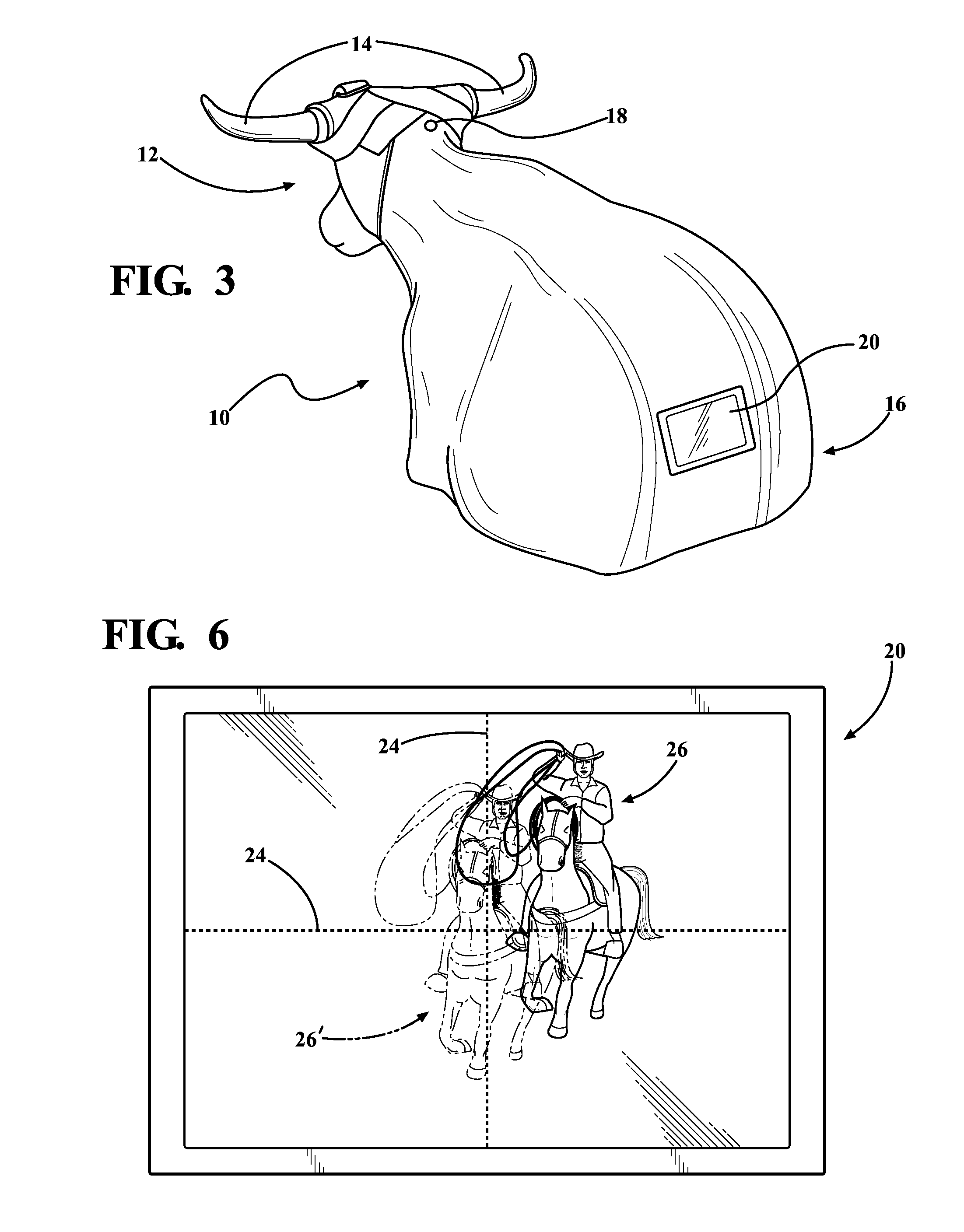

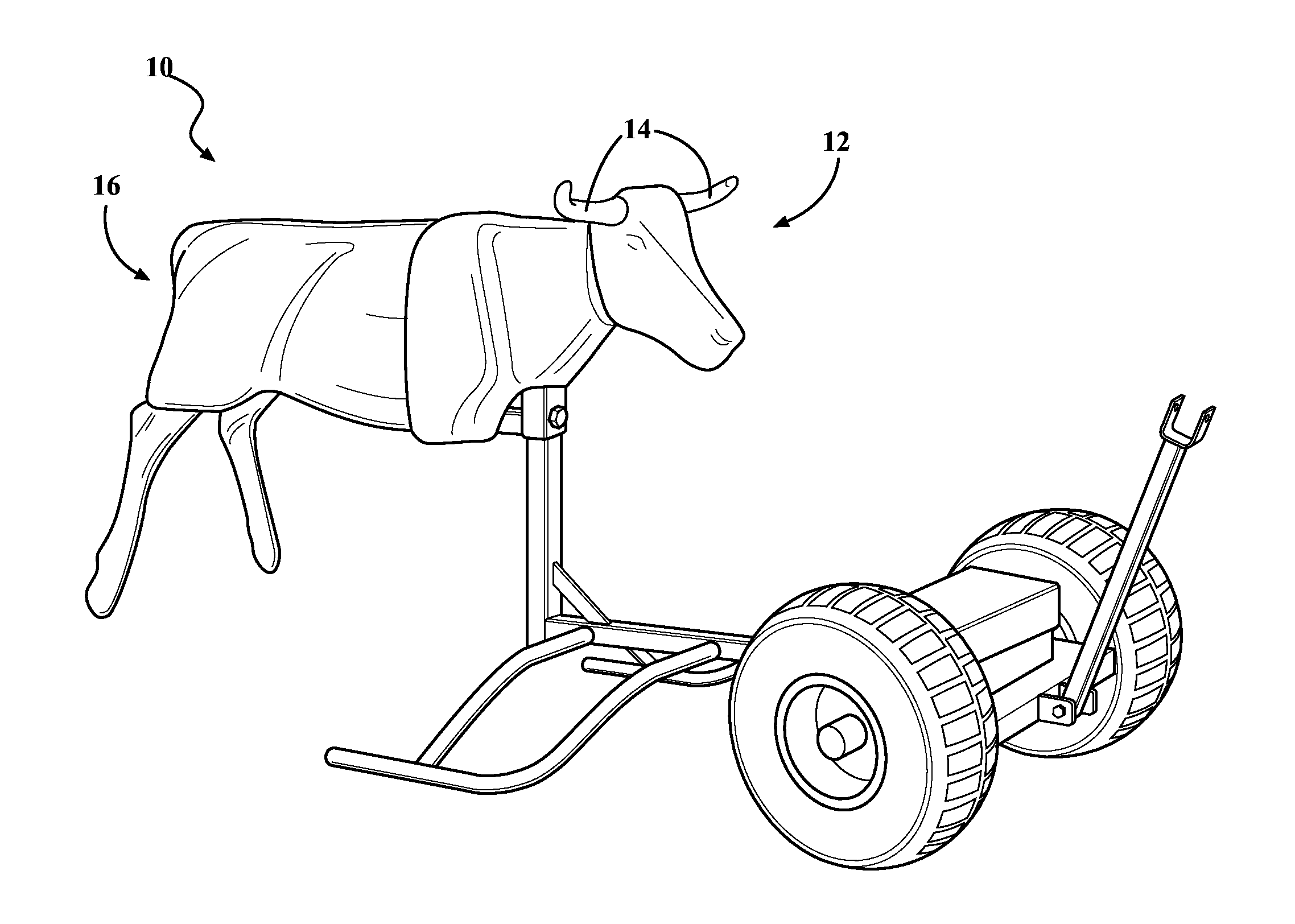

Roping training device

InactiveUS9129534B2Minimize interferenceQuick and easy changeTaming and training devicesTeaching apparatusPhysical medicine and rehabilitationRadar systems

Owner:PAYNE ERIC

Direct torque helical displacement well and hydrostatic liquid pressure relief device

ActiveUS9995087B2Easy to moveSignificant potential savingsDrill bitsDrilling rodsHydraulic motorEngineering

Owner:QUEEN FRIE A R

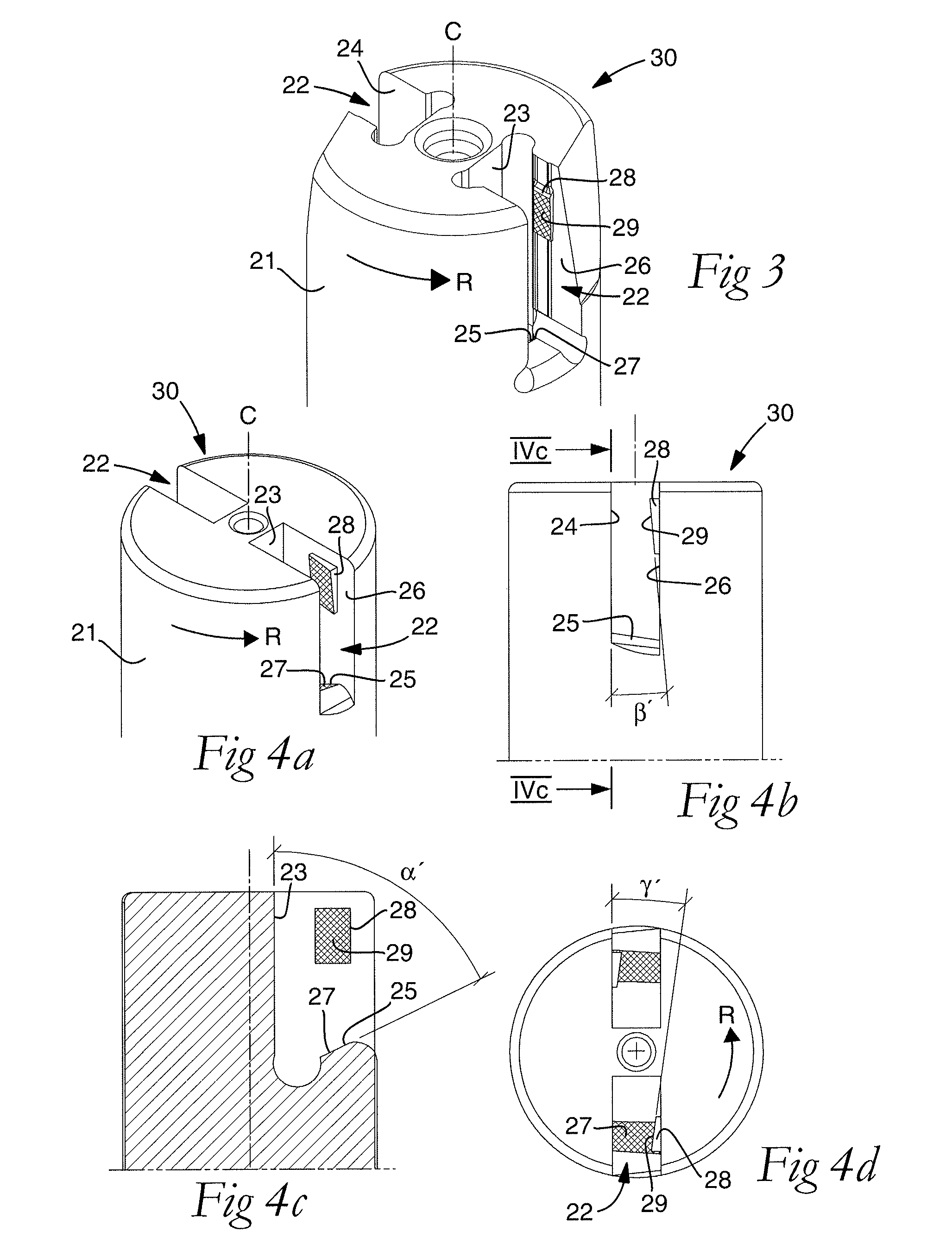

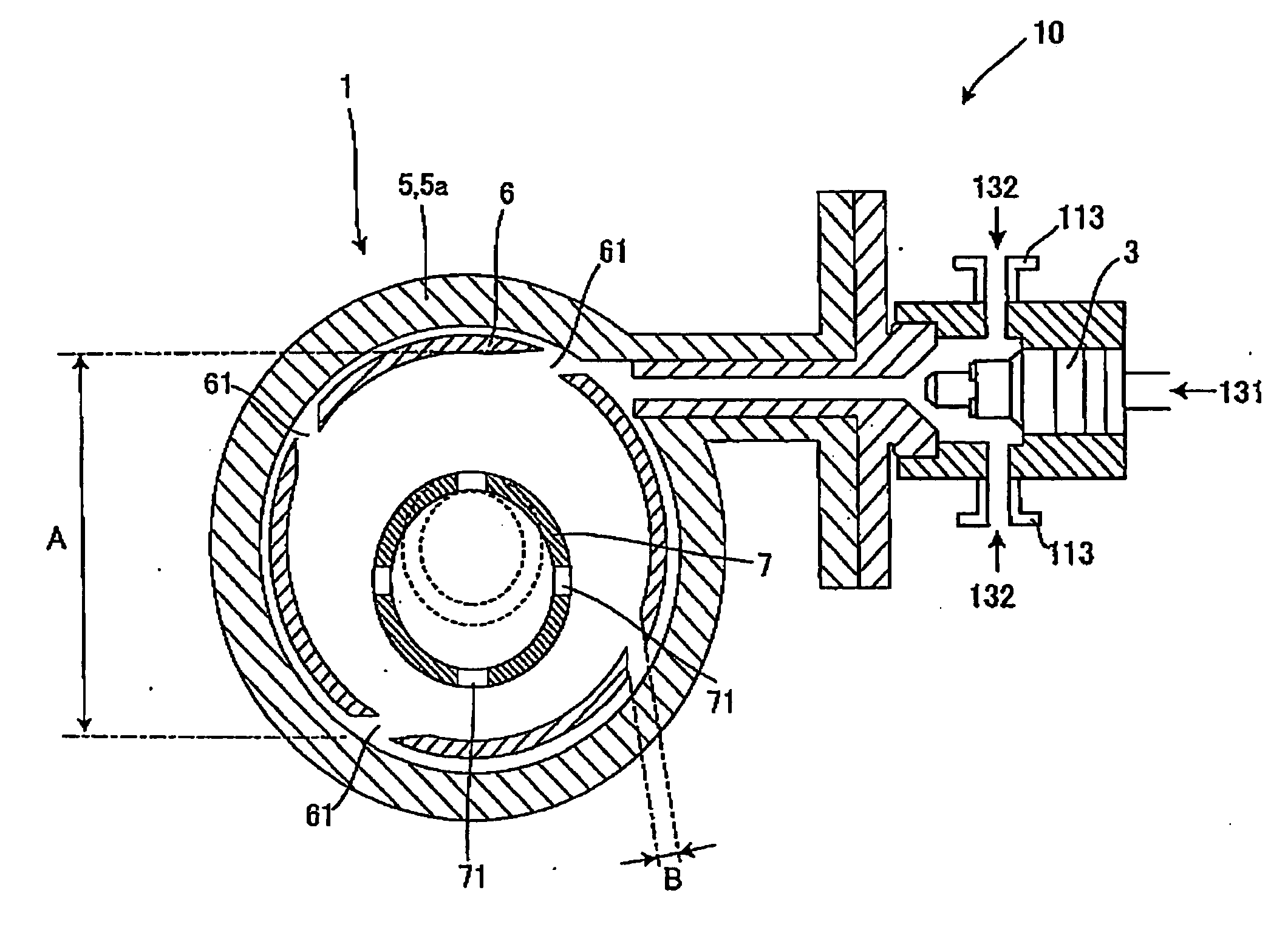

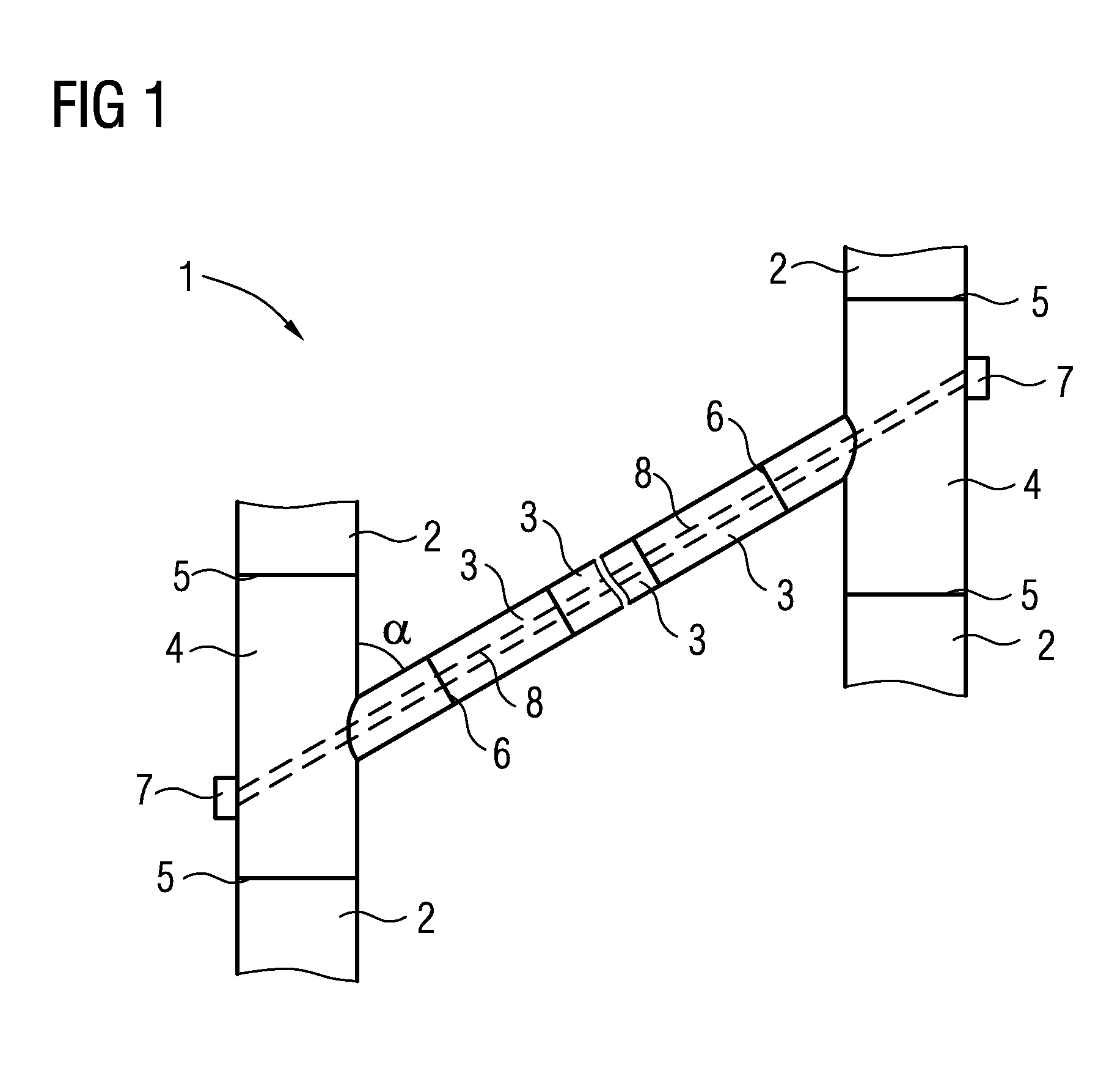

Cooling system for an asynchronous rotor

InactiveUS9515536B2Increase surface areaEfficient heatingMagnetic circuit rotating partsAsynchronous induction motorsEngineeringMechanical engineering

A cage rotor for an synchronous machine includes a laminated rotor core, shorting bars arranged inside the laminated rotor core, shorting rings which are cast onto the laminated rotor core and which electrically interconnect the shorting bars to front sides of the laminated rotor core, and heat pipes introduced into the laminated rotor core in the axial direction such that they protrude onto the front side from the laminated rotor core and protrude into the shorting rings.

Owner:SIEMENS AG

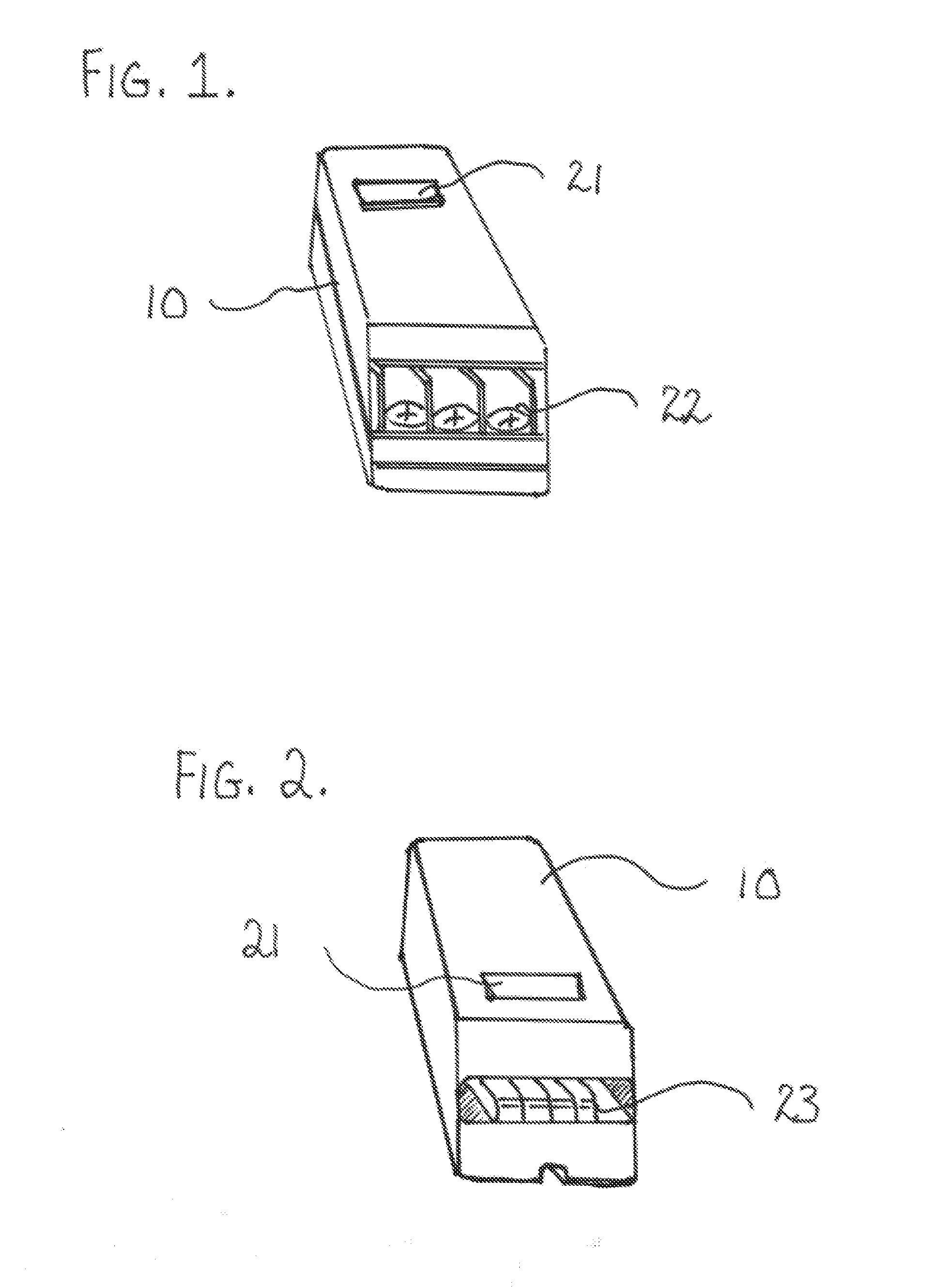

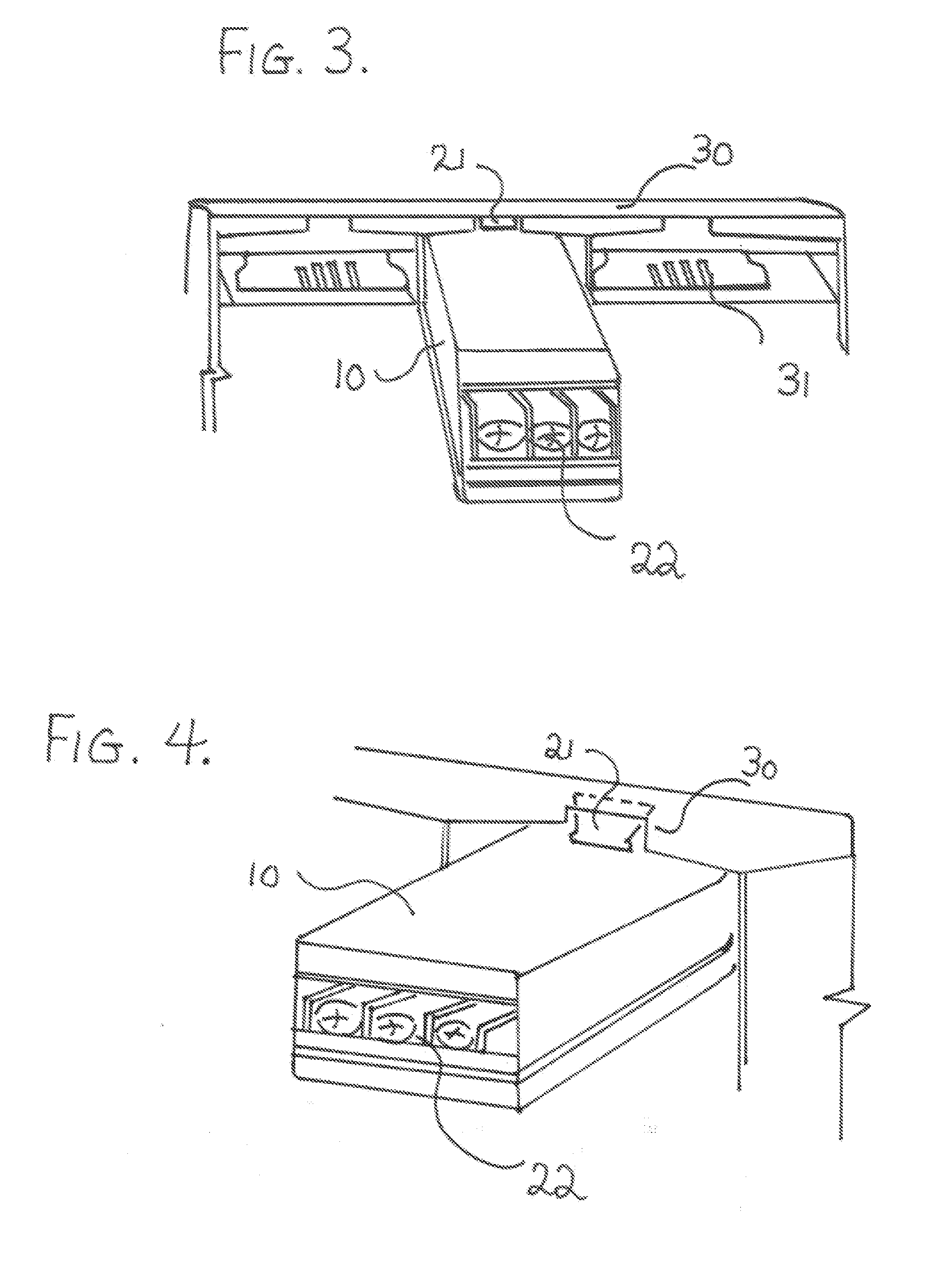

Apparatus for Irrigation Controller Expansion through Non-Removable Circuit Board Modules

InactiveUS20070264857A1Simple methodExcellent meanEngagement/disengagement of coupling partsBiological activationWater irrigation

An apparatus for irrigation controller expansion through non-removable circuit board modules. A circuit board module with a security tab that prevents removal from a card edge connection, a security tab that breaks upon a removal attempt, preventing re-connection to a card edge connector, a non-removable circuit board module that houses a pluggable terminal strip connector and a pluggable terminal strip connector with at least one station activation circuit.

Owner:KEARBY DON MICHAEL +1

PM generating apparatus

ActiveUS20070111150A1Reduce equipmentCost can be suppressedPigmenting treatmentExhaust apparatusCombustionDiesel engine

A means capable of supplying exhaust gas sufficiently imitating exhaust gas from actual diesel engines is provided. A PM generating apparatus has a constitution in which combustion air supplied to the space between a chassis and an outer casing via an air inlet is introduced into the space between the outer casing and an inner casing via through-holes of the outer casing, and a fuel injected by an fuel-injection means into the space between the chassis and the outer casing is introduced into the space between the outer casing and the inner casing via the through-holes of the outer casing, wherein the fuel is combusted to generate PM.

Owner:NGK INSULATORS LTD

Jacket structure for offshore constructions

InactiveUS20130064678A1High degreeGood adhesionArtificial islandsWind motor supports/mountsEngineeringOffshore construction

Owner:SIEMENS AG

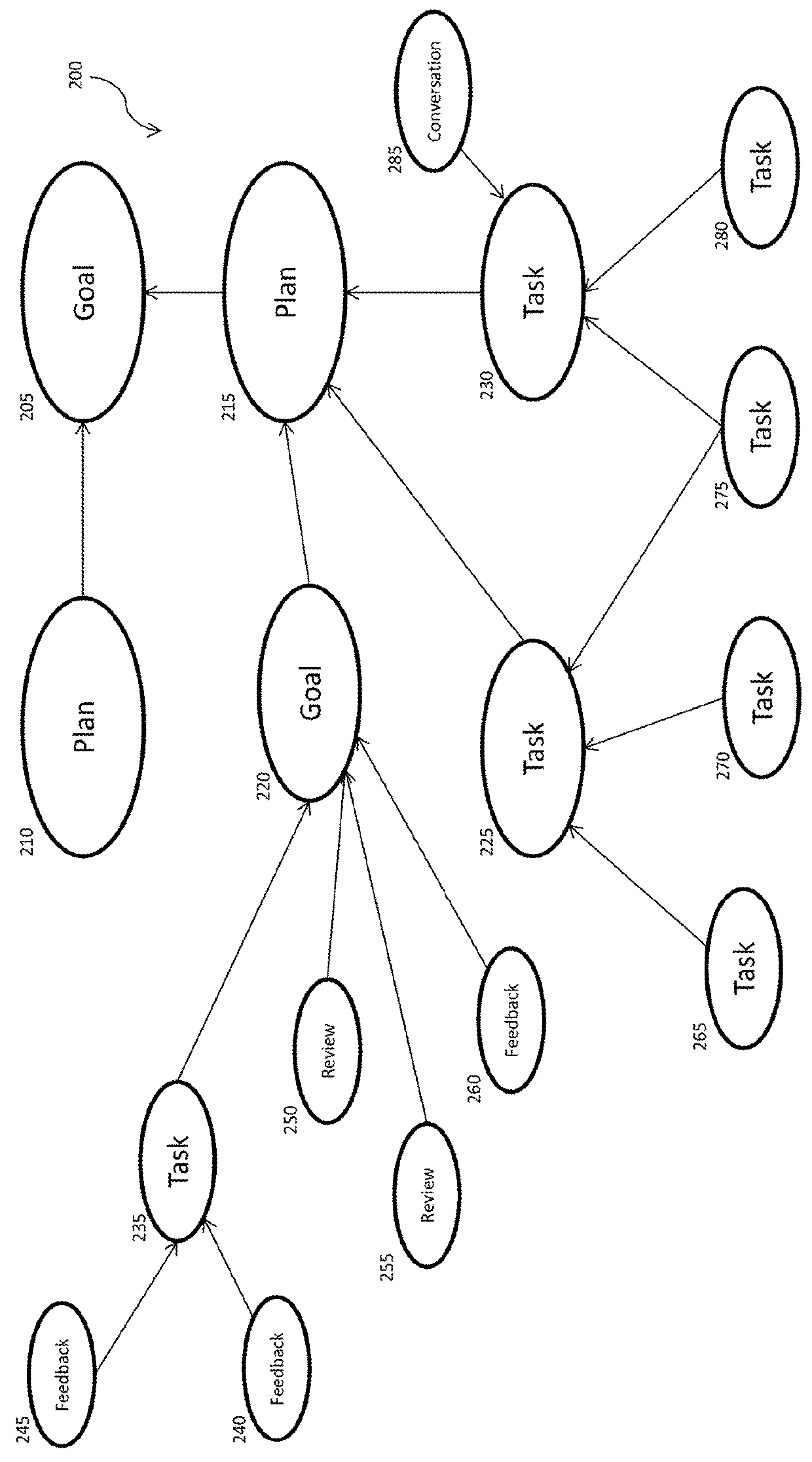

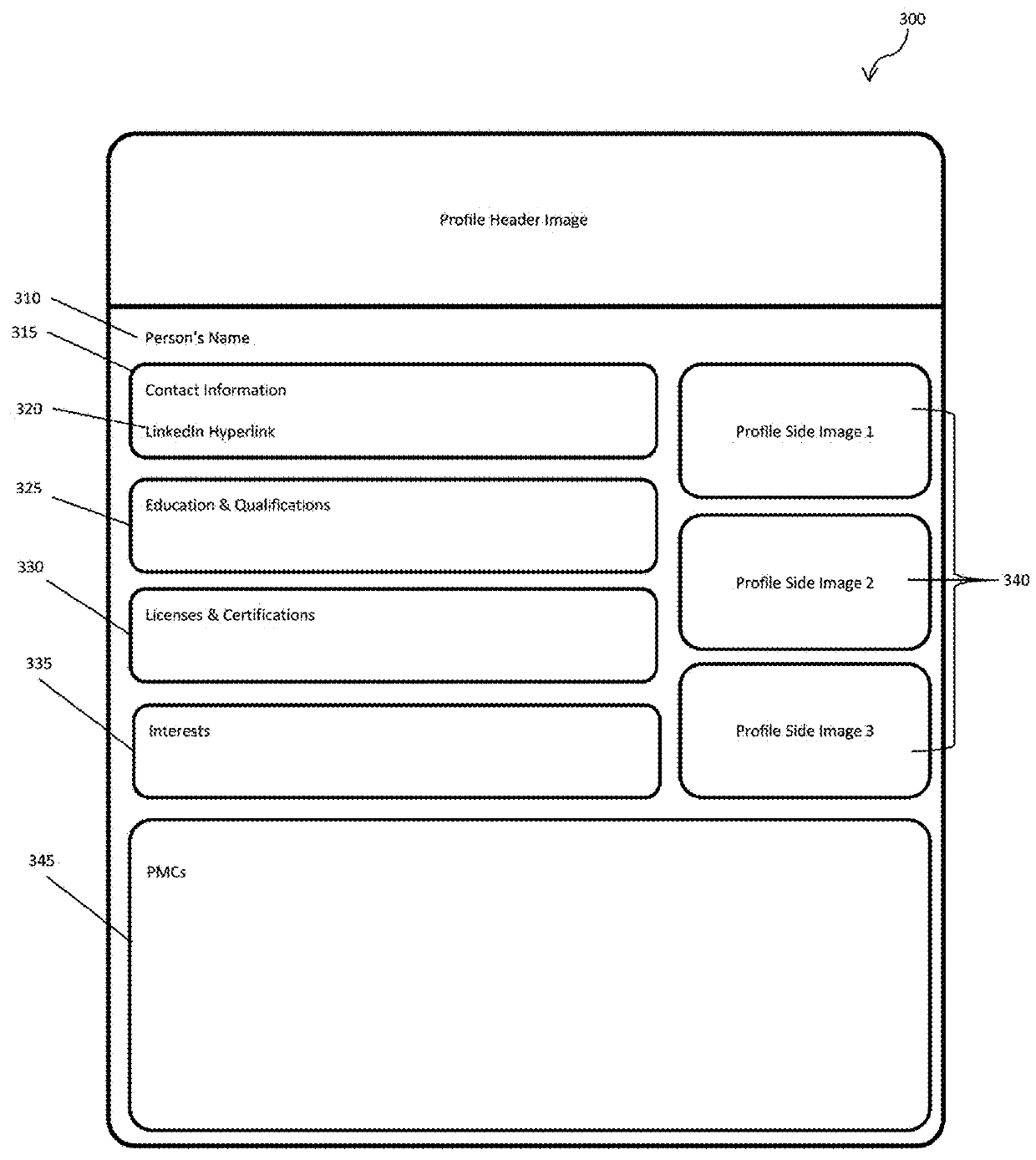

Work attached people management

InactiveUS20180165646A1Improve agilityExcellent meanOffice automationResourcesStaff managementComputer science

Owner:COGWARE

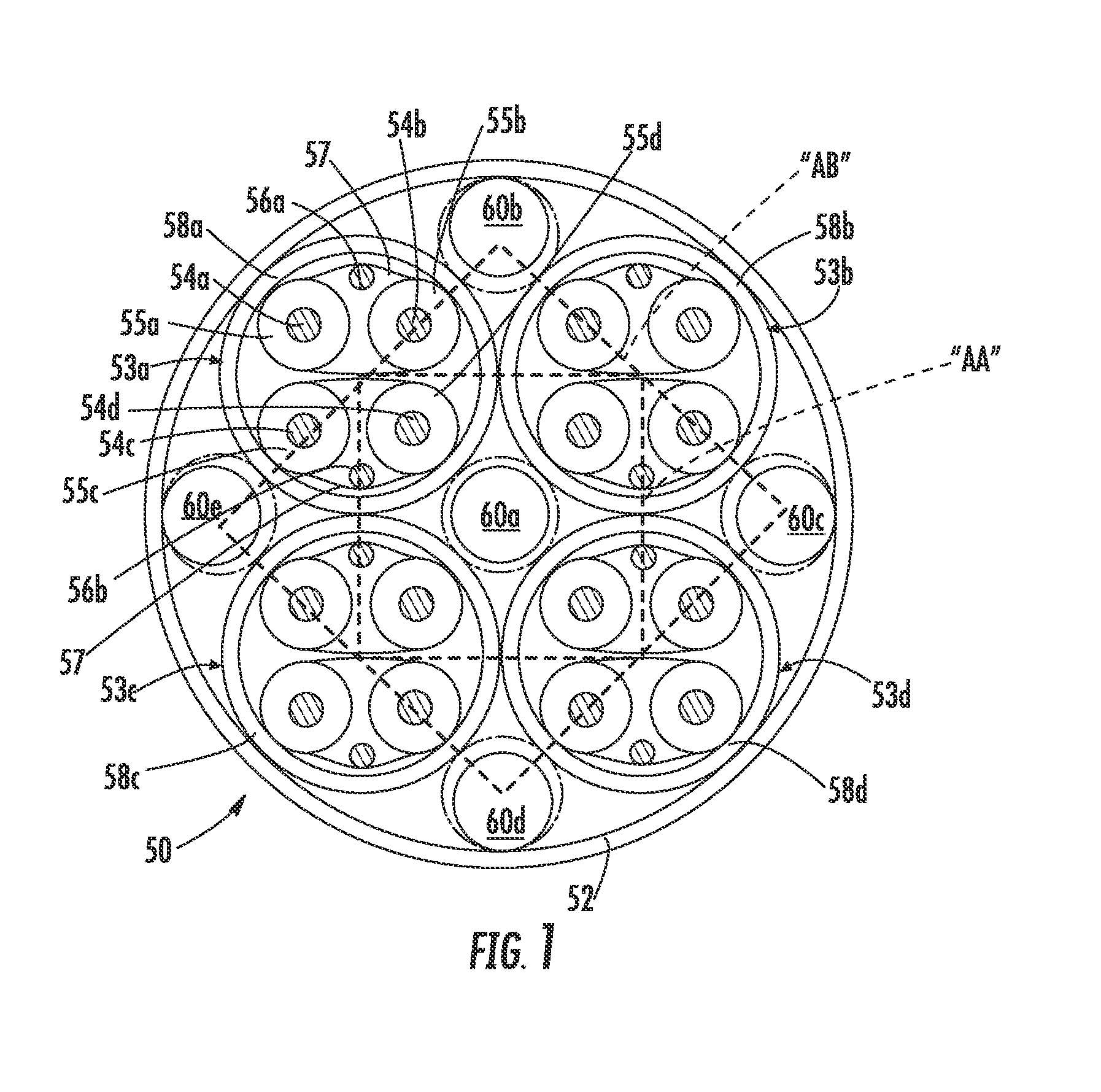

Cable Structure With Improved Clamping Configuration

InactiveUS20150293314A1Inhibition formationGood cable retentionCoaxial cables/analogue cablesInsulated cablesEngineeringElectrical and Electronics engineering

Owner:MOLEX INC

Roping training device

InactiveUS20140261237A1Minimize interferenceQuick and easy changeTaming and training devicesTeaching apparatusPhysical medicine and rehabilitationRadar systems

A roping training dummy is claimed comprising a dummy representing an animal having a target to be lassoed by a roper. A position sensor, such as video camera or radar system, is disposed on the dummy for monitoring the real-time position of the roper relative to the lasso target. A monitor on the dummy is visible to the roper and operatively connected to the position sensor. The monitor displays the roper's real-time position and a positional reference corresponding to a preferred roper placement.

Owner:PAYNE ERIC

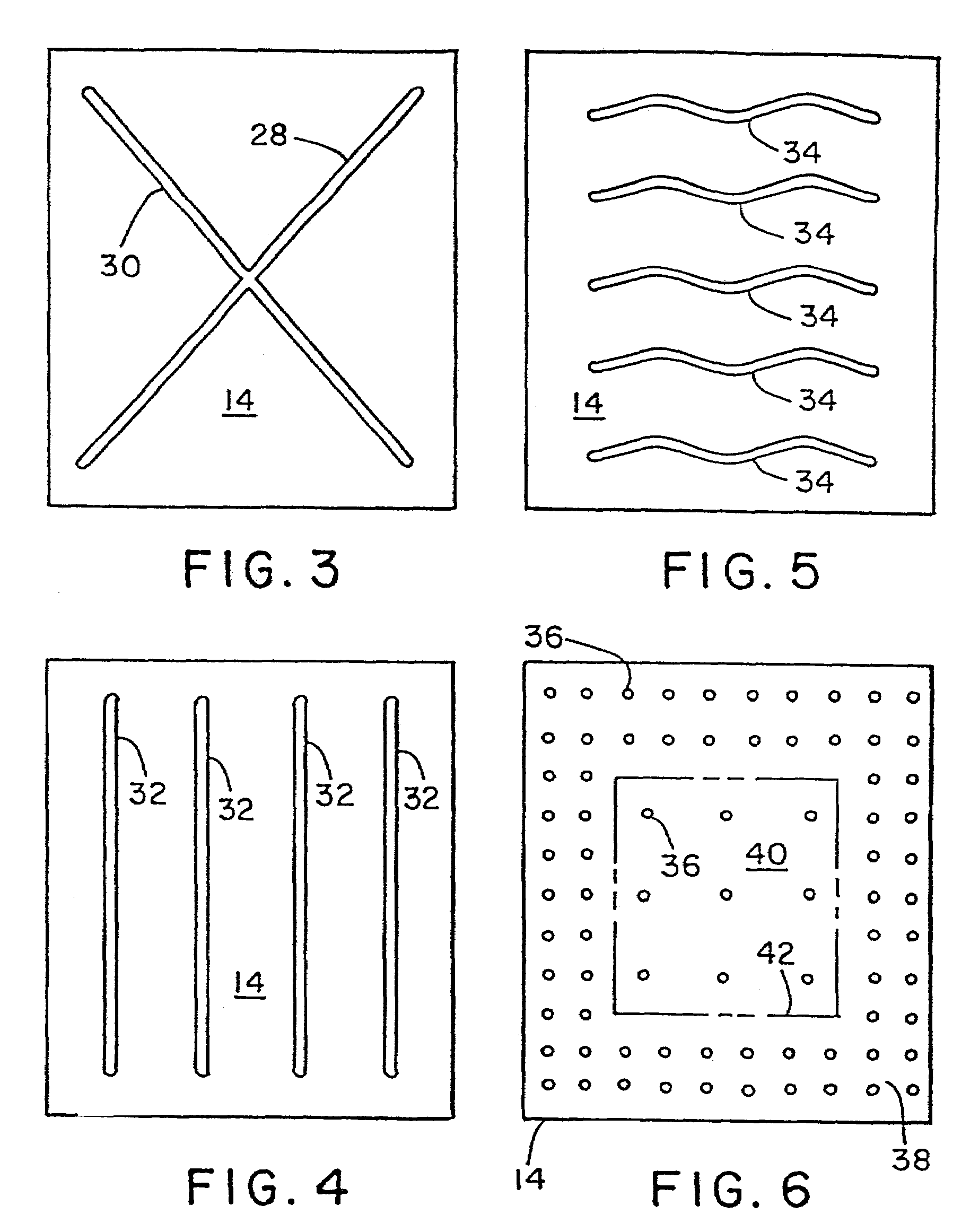

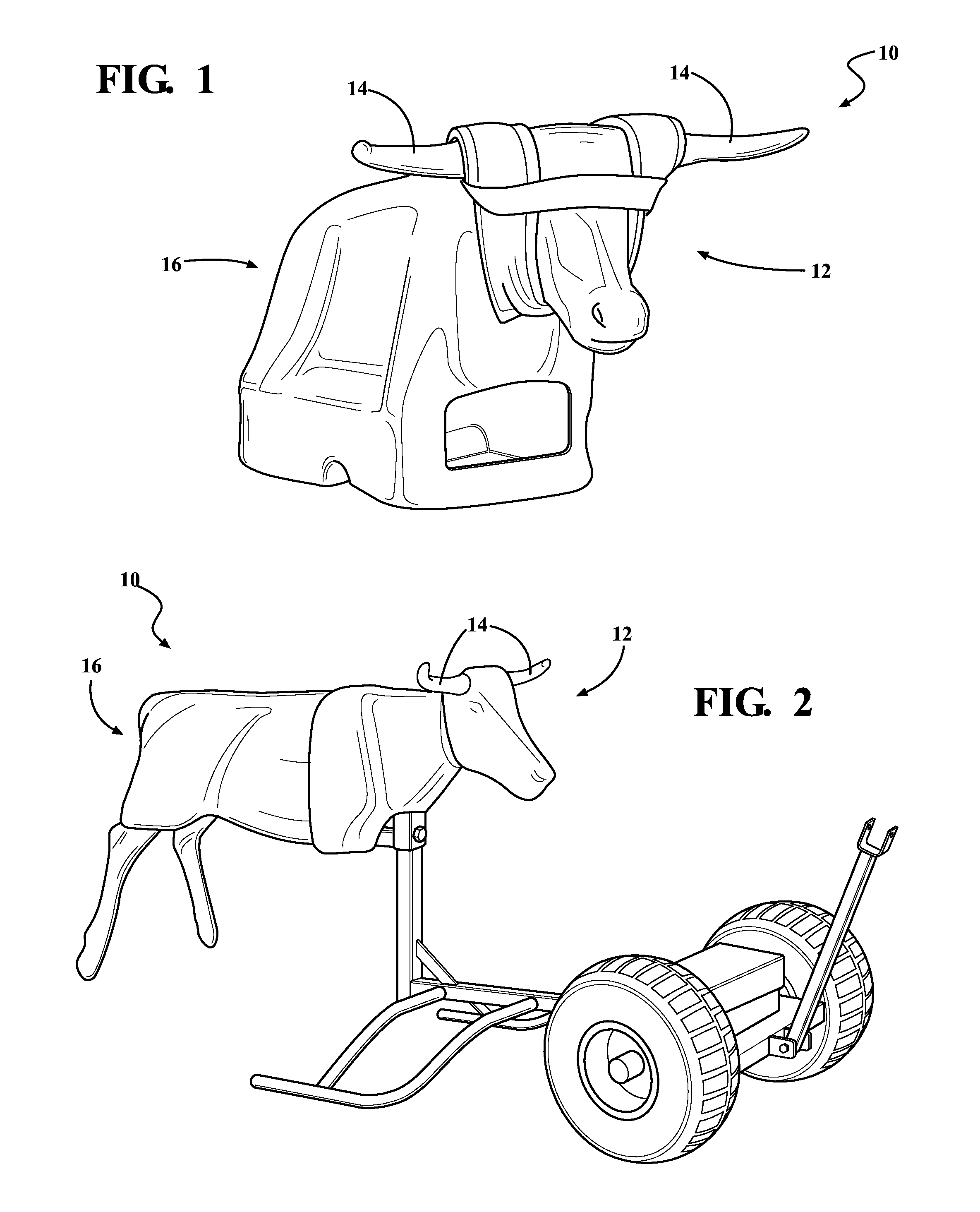

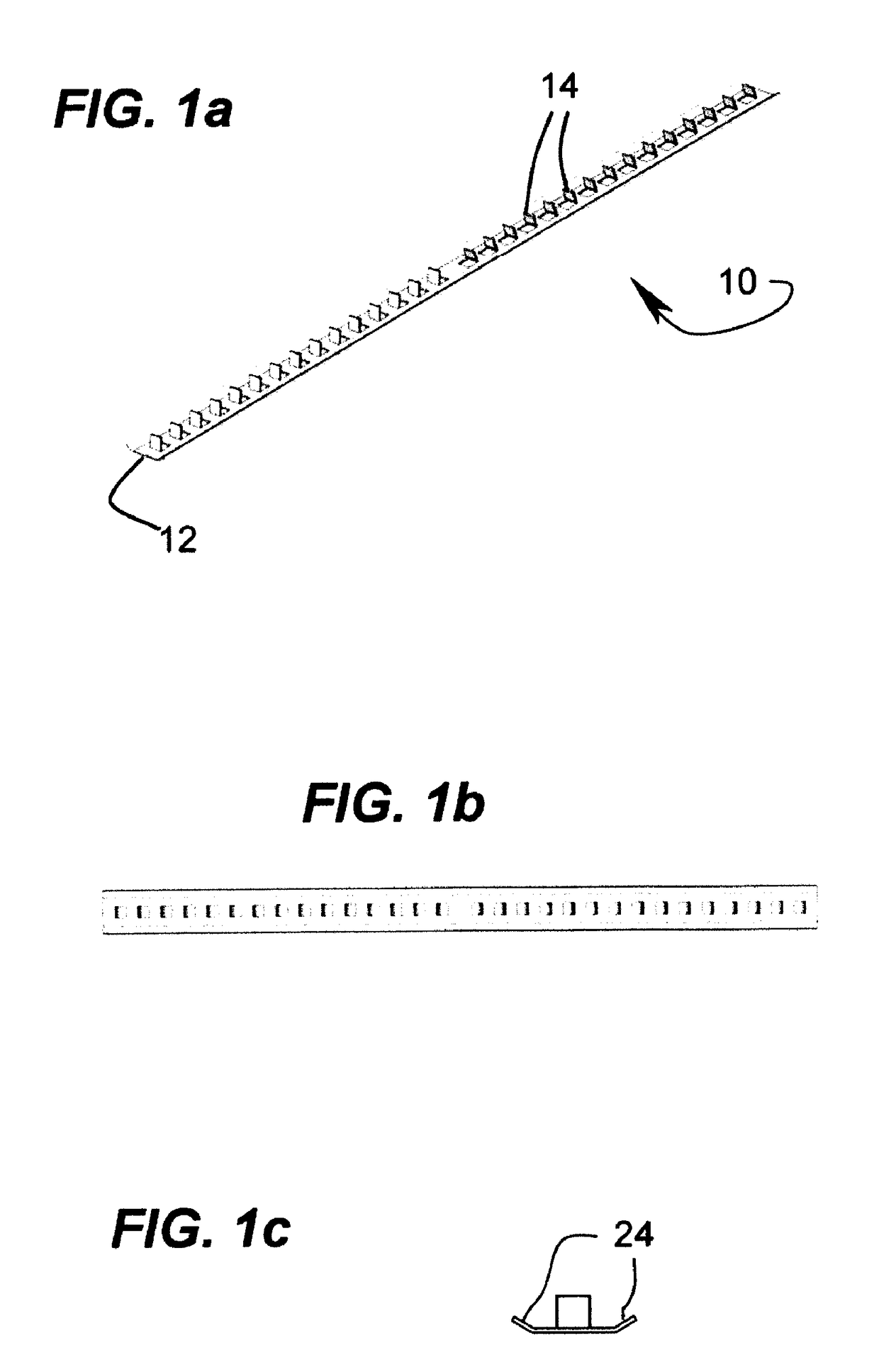

Reinforcement for a concrete tile

ActiveUS20170254079A1Precise positioningExcellent meanConstruction materialFloorsReinforced concreteBrick

A reinforced concrete tile having top and bottom surfaces defining a thickness, the reinforced concrete tile comprising two or more reinforcing inserts imbedded in the concrete tile in proximity to the bottom surface, the two or more reinforcing inserts being of elongated shape and comprising a plurality of scales distributed along the length and extending upwardly from the bottom surface whereby a compensating force is created upon application of a load on the top surface such that deflection is reduced as the load is increased for at least a range of loads until a yield load is reached.

Owner:LE SQUAREDECKO

Method for rapidly developing gene switches and gene circuits

Provided are: a selection method for a gene switch and a gene circuit, including using, as a selector, an expression vector containing at least a gene sequence whose expression is controlled by a transcription regulatory factor to be expressed when a genetic switch and a genetic circuit including the genetic switch operate, and a promoter sequence operably linked to the gene sequence upstream thereof; and an expression vector to be used in the selection method. This enables an effective selection method for a genetic switch and a genetic circuit, the selection method being able to be conducted within a short time period and with high selection efficiency and less leakiness.

Owner:CHIBA UNIV

Hemisperical grip handle apparatus

Owner:EMICK DANIEL W

Reinforcement for a concrete tile

InactiveUS20150233066A1Precise positioningExcellent meanPaving reinforcementsPig casting plantsBrickEngineering

A reinforcement for concrete tiles comprising an element formed in a flat elongated shape having a top and bottom surface, a plurality of scales extending from the top surface at an angle thereto, and wherein the angle of a number of the scales are formed in an opposite direction from the remaining scales, and adapted such that when in place within a concrete tile the element cannot slip out therefrom, and adapted such that when the tile experiences a bending force the element creates a compressive force opposite the bending force to thereby prevent the tile from bending and breaking.

Owner:LE SQUAREDECKO

Vapour deposition method for fabricating lithium-containing thin film layered structures

ActiveUS10490805B2Reduce roughnessPrecise structureFinal product manufactureVacuum evaporation coatingLithiumPhysical chemistry

A vapor deposition method for preparing a multi-layered thin film structure comprises providing a vapor source of each component element of a compound intended for a first layer and a compound intended for a second layer, wherein the vapor sources comprise at least a source of lithium, a source of oxygen, a source or sources of one or more glass-forming elements, and a source or sources of one or more transition metals; heating a substrate to a first temperature; co-depositing component elements from at least the vapor sources of lithium, oxygen and the one or more transition metals onto the heated substrate wherein the component elements react on the substrate to form a layer of a crystalline lithium-containing transition metal oxide compound; heating the substrate to a second temperature within a temperature range of substantially 170° C. or less from the first temperature; and co-depositing component elements from at least the vapor sources of lithium, oxygen and the one or more glass-forming elements onto the heated substrate wherein the component elements react on the substrate to form a layer of an amorphous lithium-containing oxide or oxynitride compound.

Owner:ILIKA TECH LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com