Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Efficient assembly work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

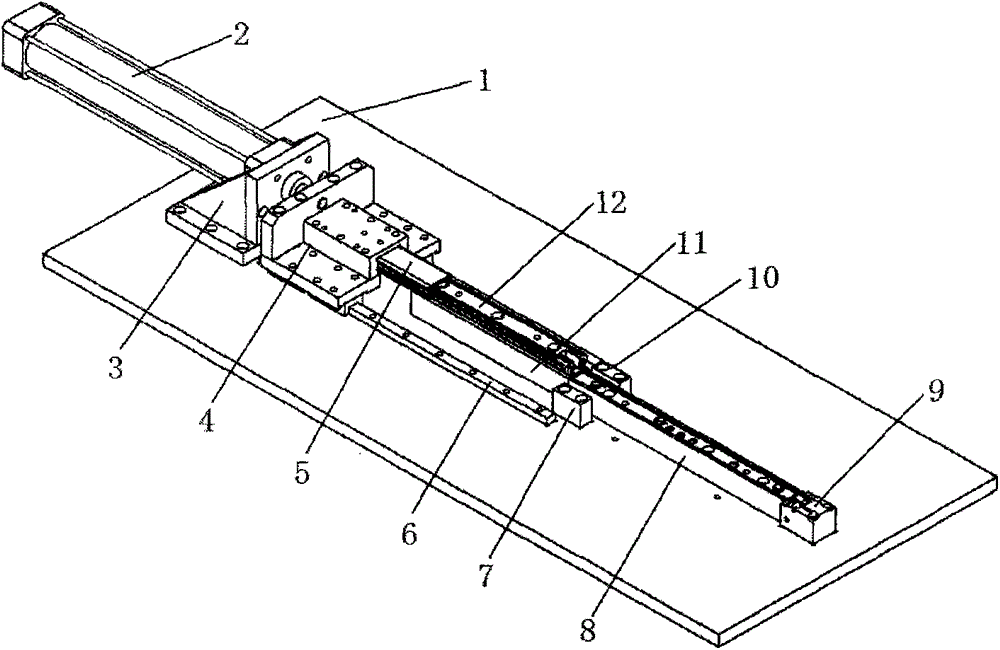

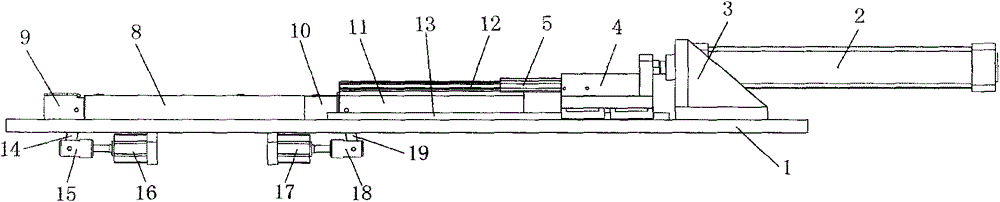

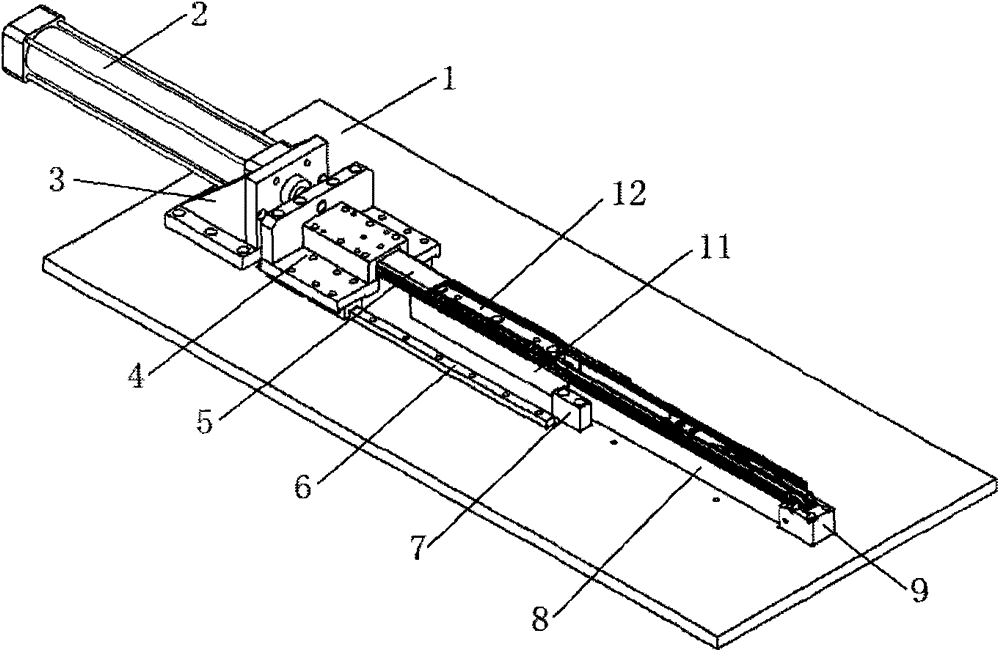

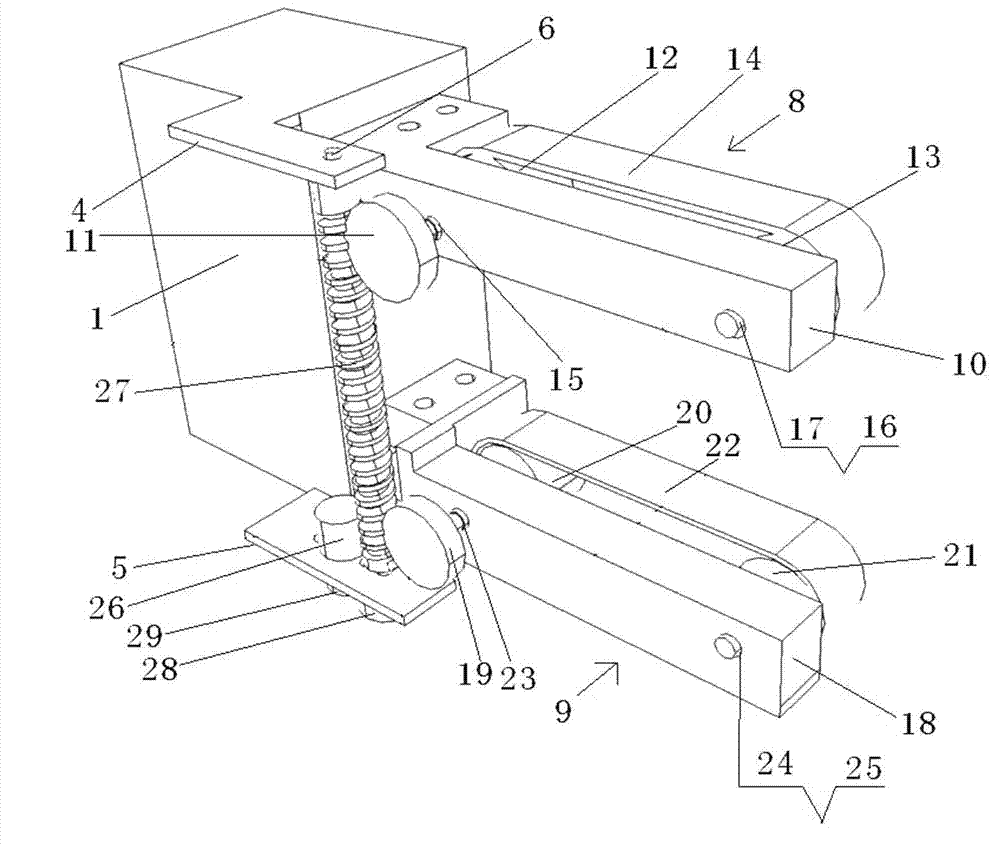

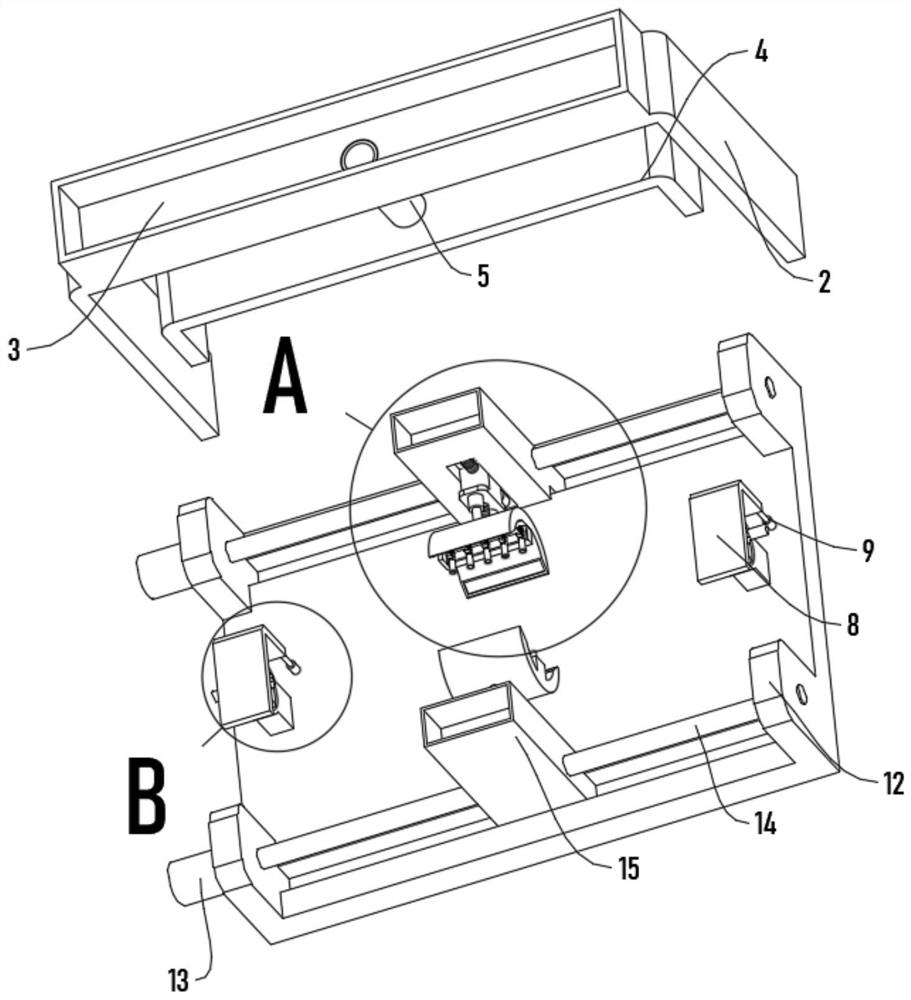

Automobile seat sliding track assembling machine and assembling method for same

ActiveCN103551834AImprove assembly efficiencyEfficient assembly workMetal working apparatusCar seatEngineering

The invention discloses an automobile seat sliding track assembling machine and an assembling method for same. The automobile seat sliding track assembling machine comprises a base, an assembling cylinder, a cylinder rack, an outer ejector block, an inner ejector block, a right guide track, a right limiting block, an inner sliding track rack, an end stopping block, a left limiting block, a supporting block, a side sliding track rack, a left guide track, a front clamping jaw, a front connecting rod, a front clamping cylinder, a rear clamping cylinder, a rear connecting rod and a rear clamping jaw. The automobile seat sliding track assembling machine is suitable for assembling automobile seat slide tracks. By the automobile seat sliding track assembling machine, assembly operation can be finished instead of manual work, and slide track components are clamped and assembled by the different cylinders. The automobile seat sliding track assembling machine has the advantages of large output force, high assembling speed, high efficiency, high quality and the like; the labor intensity of workers is effectively reduced; and the quality uniformity of products of assembly parts is ensured. In addition, the automobile seat sliding track assembling machine is compact in structure, high in reliability, stable in operation and low in cost.

Owner:ZHEJIANG LONGSHENG AUTO PARTS TECH CO LTD

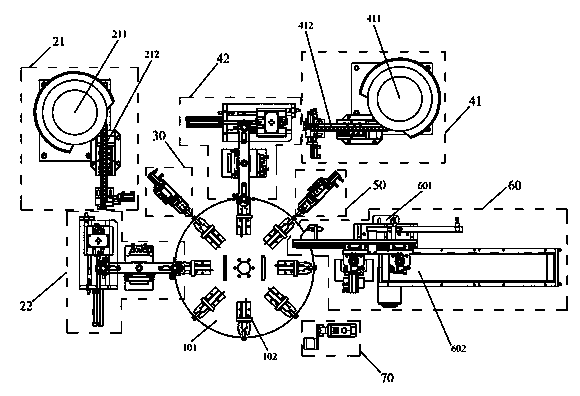

O-shaped ring assembling device

InactiveCN103722353AEasy and fast assemblyEfficient assembly workMetal working apparatusEngineeringElectrical and Electronics engineering

The invention discloses an O-shaped ring assembling device which comprises a turntable device, a first feeding device, a first detection sensor, a second feeding device, a second detection sensor and a discharging device. When the O-shaped ring assembling device is in operation, only one operator is needed to perform related assisting, and the operator firstly puts an O-shaped ring workpiece to be assembled on an assembly station of a turntable working table. After the device is started, the first feeding device, the first detection sensor, the second feeding device, the second detection sensor, an intelligent camera detection device and the discharging device which are arranged around the turntable device perform automatic matched operation, a first O-shaped ring and a second O-shaped ring are quickly and accurately assembled on the workpiece, and accepted product and defective product classification and output are performed, so that the O-shaped ring assembling device is simple in operation, high in production efficiency and capable of achieving automatic operation to the most extent and greatly saving labor.

Owner:周俊雄

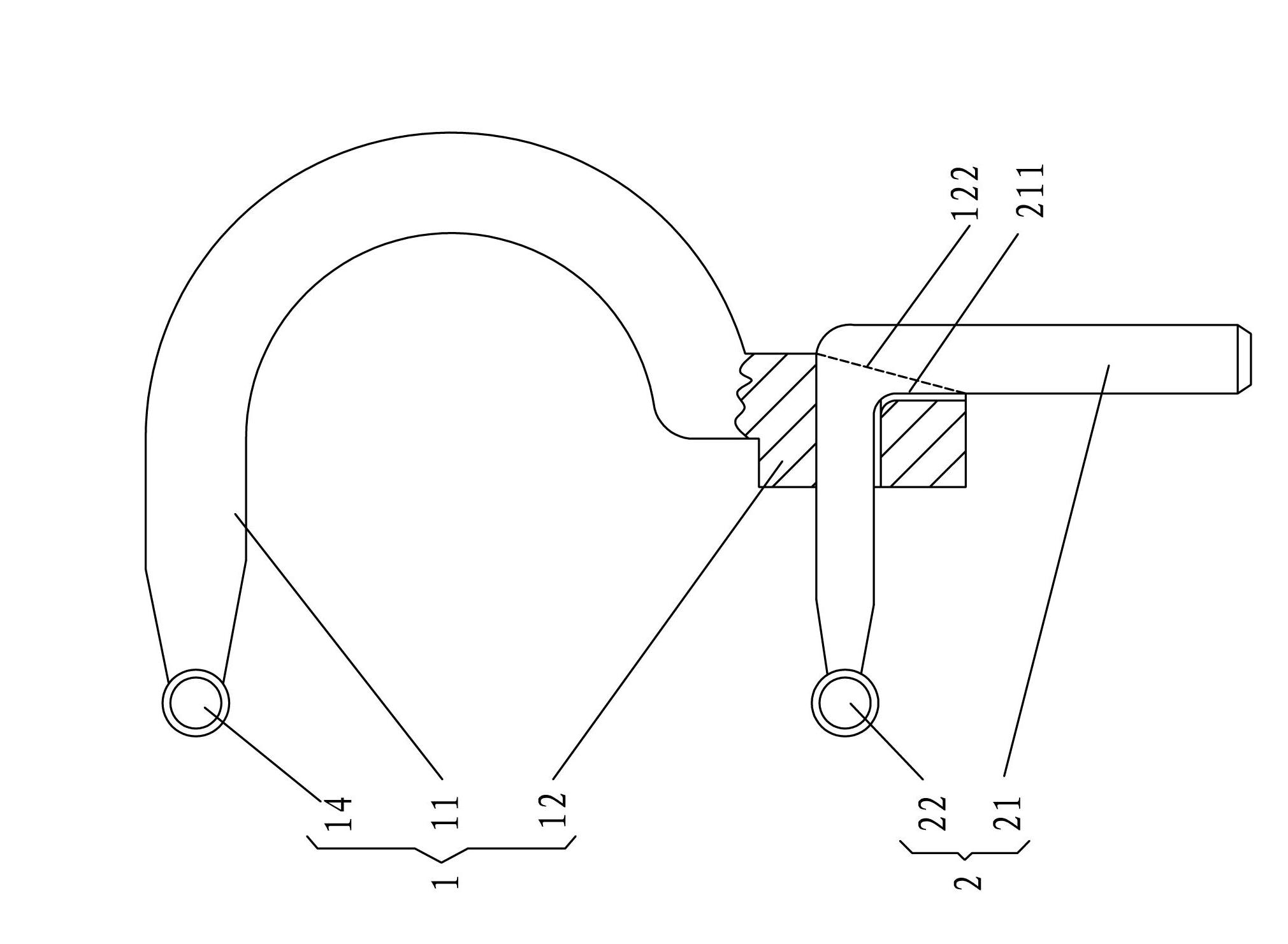

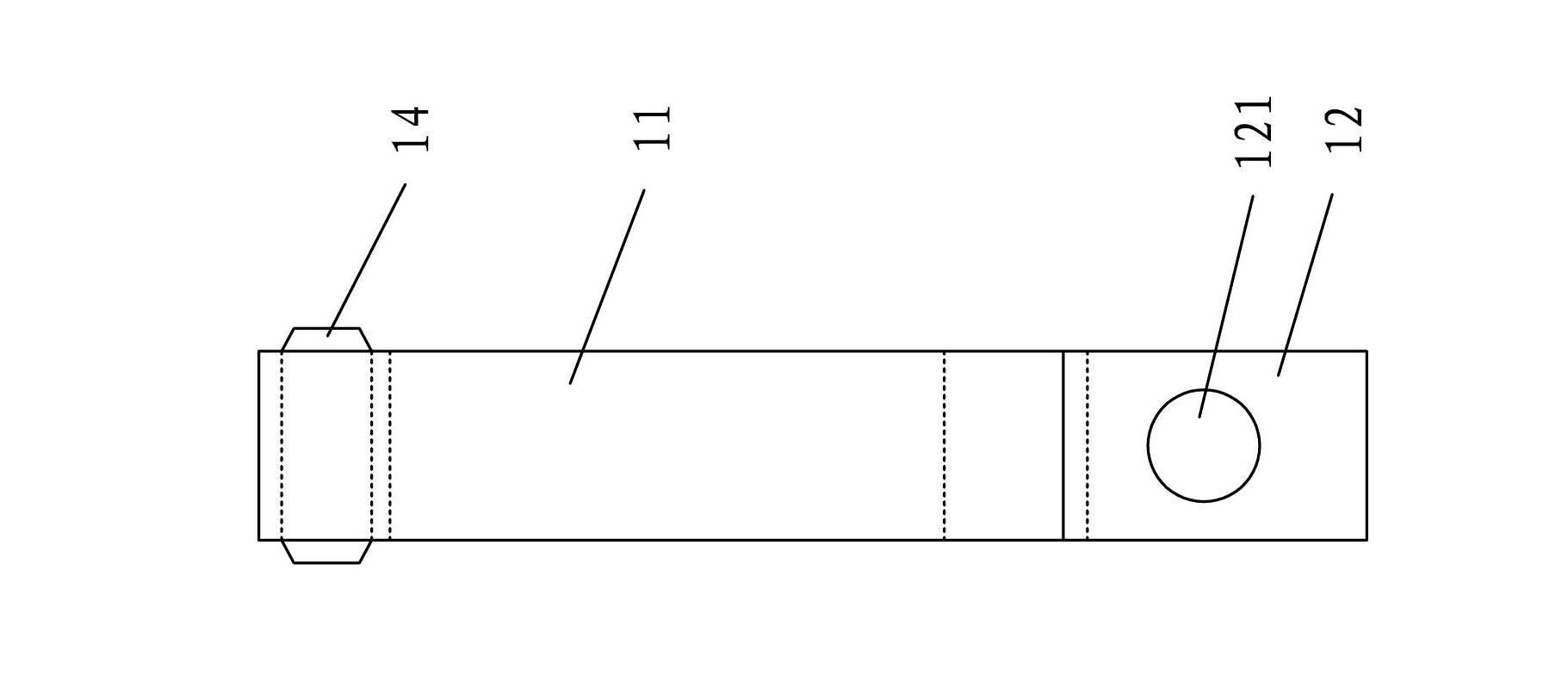

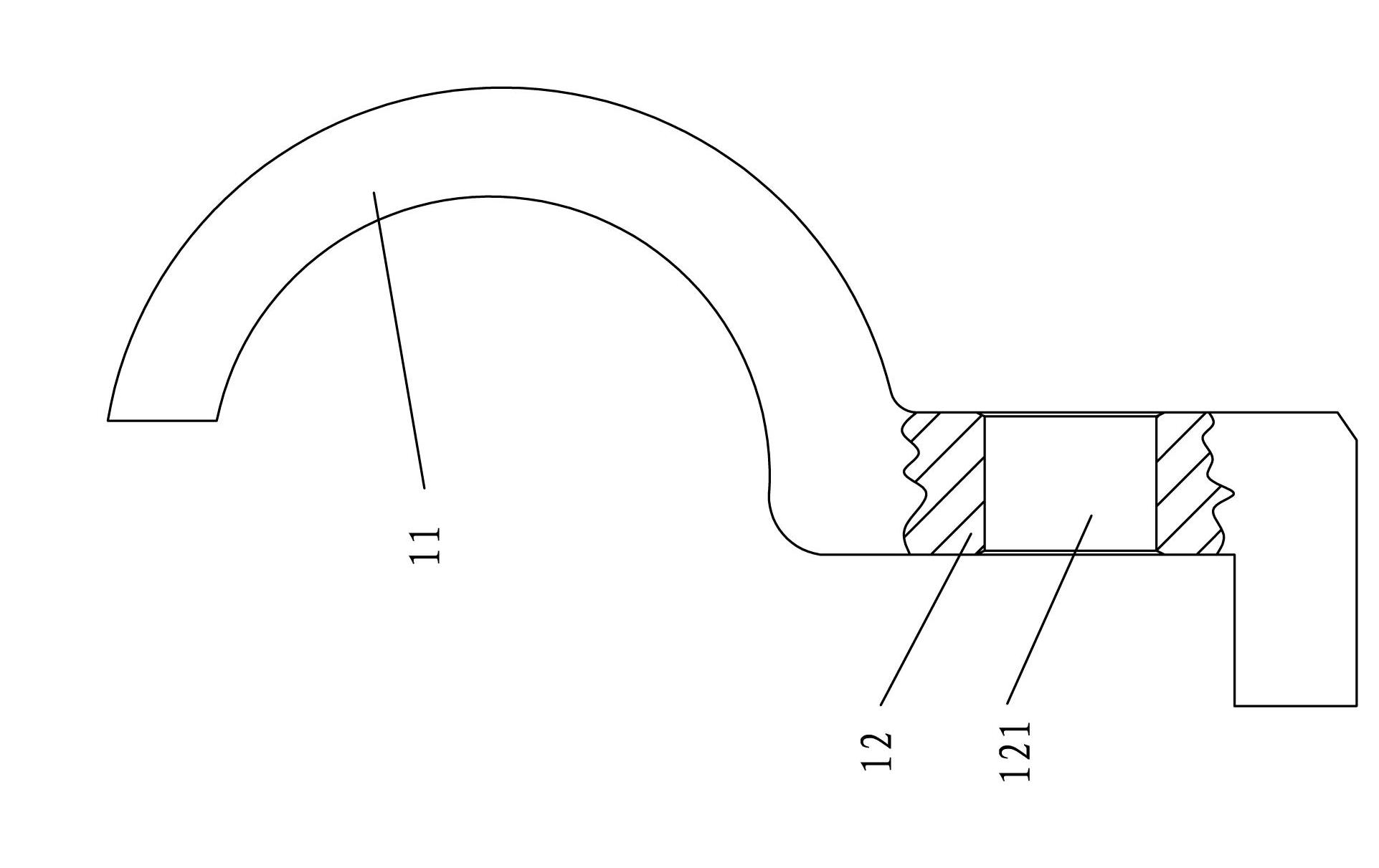

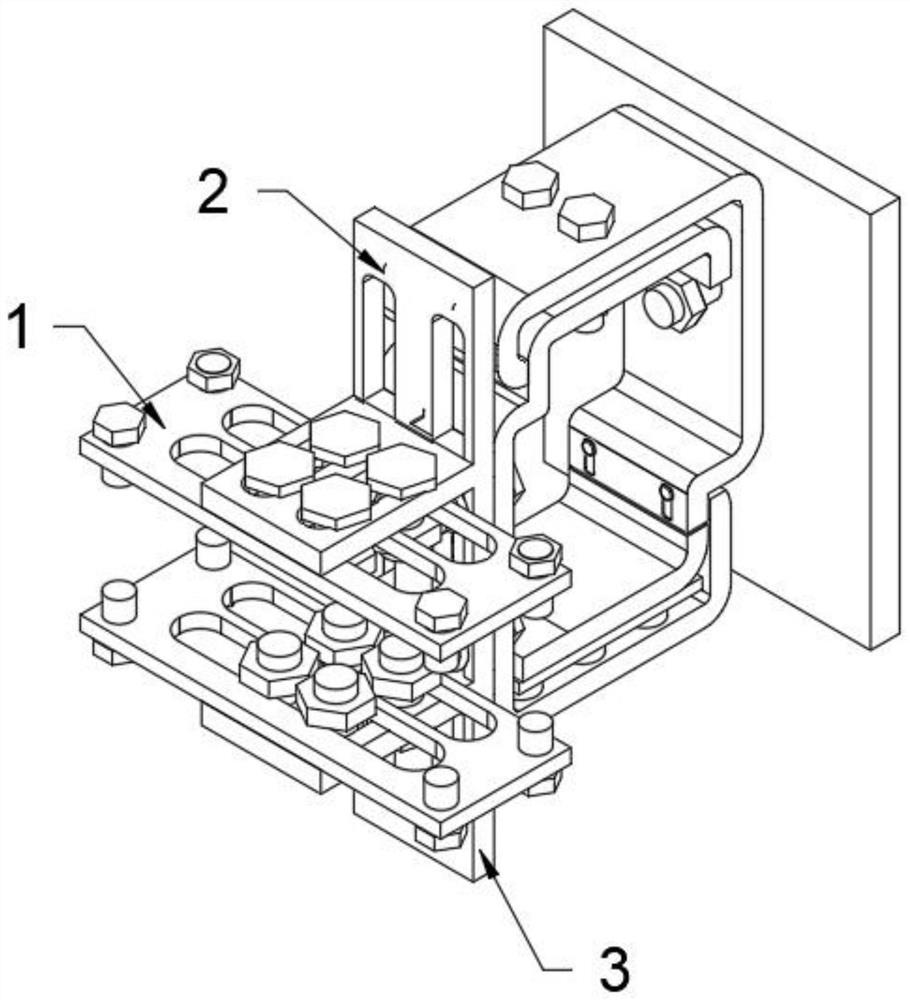

Fastening device for quickly assembled concrete formwork

InactiveCN102658585AEasy to assembleEfficient assembly workCeramic shaping apparatusEngineeringFastener

The invention discloses a fastening device for a quickly assembled concrete formwork. The fastening device comprises a fastener clamped on a fixing rod which is used for fixedly splicing a concrete formwork, and a locking piece which penetrates through the fastener to fasten the formwork unit on the fixing rod. By the fastening device for the quickly assembled concrete formwork, the fastener is directly clamped on the fixing rod which is used for fixedly splicing the concrete formwork, and the locking piece penetrates through the fastener to fix the concrete formwork to the fixing rod. Because the fastener adopts a convenient clamping mode, assembly can be efficiently and conveniently finished; moreover, the fastening device has high universality; because the assembly pieces and the fasteners can realize good fastening connection without precision fit, good fastening connection can be ensured in case of deformation in the using process; and therefore, the fastening device is applied to various complex construction sites, is free from limitation of working conditions and has wide application prospect.

Owner:许金锔 +1

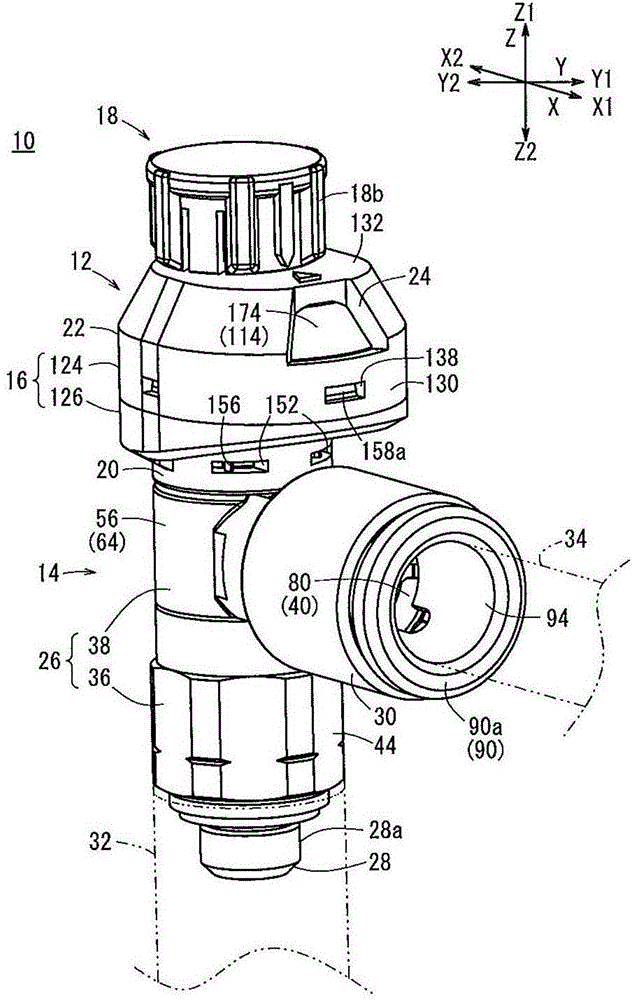

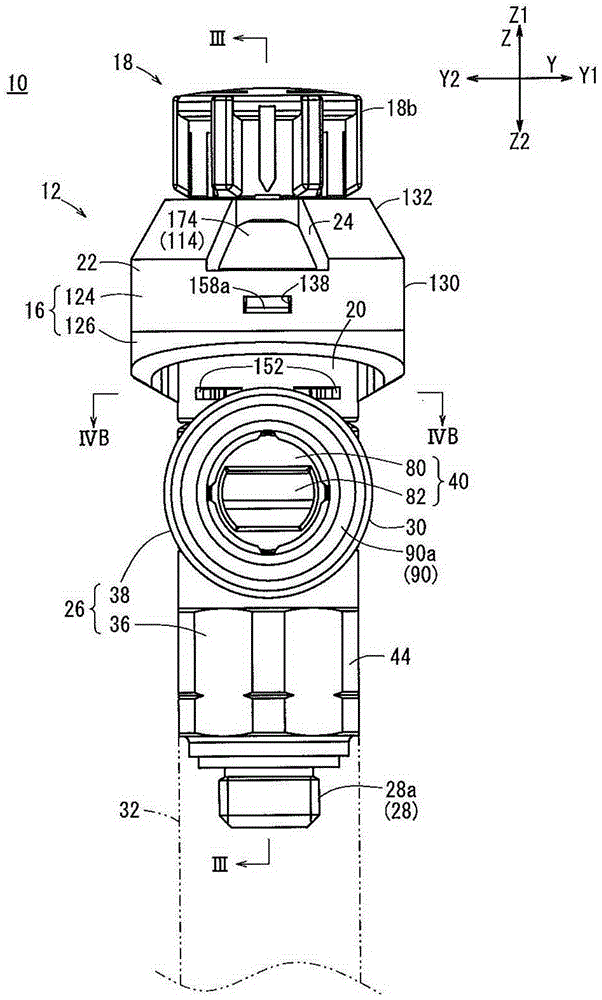

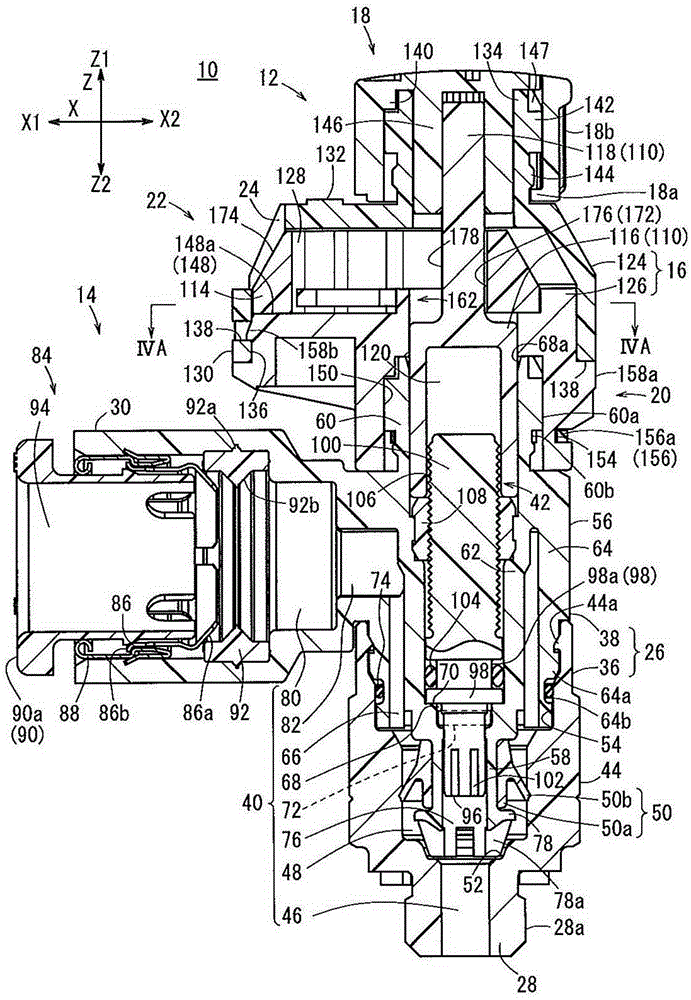

Flow rate control device

ActiveCN104379979AHigh precisionReduce manufacturing costOperating means/releasing devices for valvesSlide valveEngineeringMechanical engineering

A flow rate control device (10) is provided with a flow rate adjustment indication device (12) for operating the displacement of a needle valve (42) relative to a flow passage (40). The flow rate adjustment indication device (12) is provided with a housing (16), a rotation transmission member (110) which displaces the needle valve (42) by rotational operation, and an annularly shaped indication ring (114) which has a hole (172) through which the rotation transmission member (110) is inserted. The indication ring (114) has graduations (174) which indicate a change in the flow rate of liquid. The engagement of the engagement section (122) of the needle valve (42) displaces the indication ring (114) in the circumferential direction and changes the position of the graduations (174).

Owner:SMC CORP

Machine hand claw capable of entwisting wiring harnesses

InactiveCN103085077AAssembly precisionEfficient assembly workLine/current collector detailsGripping headsMotor driveEngineering

A machine hand claw capable of entwisting wiring harnesses comprises a machine hand, a worm transmission mechanism and entwisting hand fingers, wherein the entwisting hand fingers are composed of upper entwisting fingers and lower entwisting fingers, and the upper entwisting fingers and the lower entwisting fingers share the same structure. The worm transmission mechanism comprises a motor, a worm, a first transmission gear and a second transmission gear. The worm is meshed with a first worm wheel on the upper entwisting fingers, and meshed with a second worm wheel on the lower entwisting fingers. When the wiring harnesses are at a clamping position, the motor drives a rotating worm to rotate so as to drive the first worm wheel and the second worm wheel to rotate, and a first belt and a second belt are driven to entwist the wiring harnesses by a first belt wheel and a second belt wheel, wherein the first belt wheel is connected with a first worm wheel shaft, and the second belt wheel is connected with a second worm wheel shaft. According to the machine hand claw capable of entwisting the wiring harnesses, terminal direction of the wiring harnesses can be adjusted accurately so as to enable the wiring harnesses to rotate and to be matched with a jack socket of a connector, accurate assembly is achieved, and wiring harness assembling is enabled to be high efficient. Labor demand is reduced to a great extent, production cost is reduced, and production efficiency and product quality are improved.

Owner:SHENYANG LIGONG UNIV

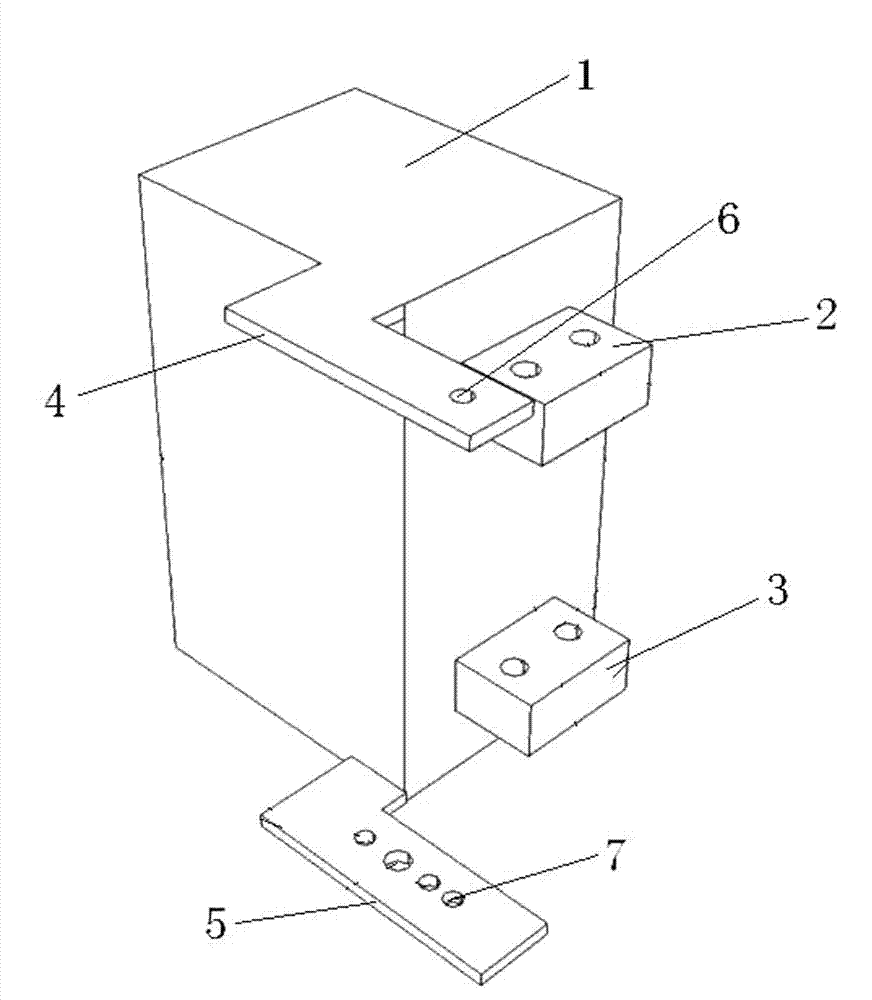

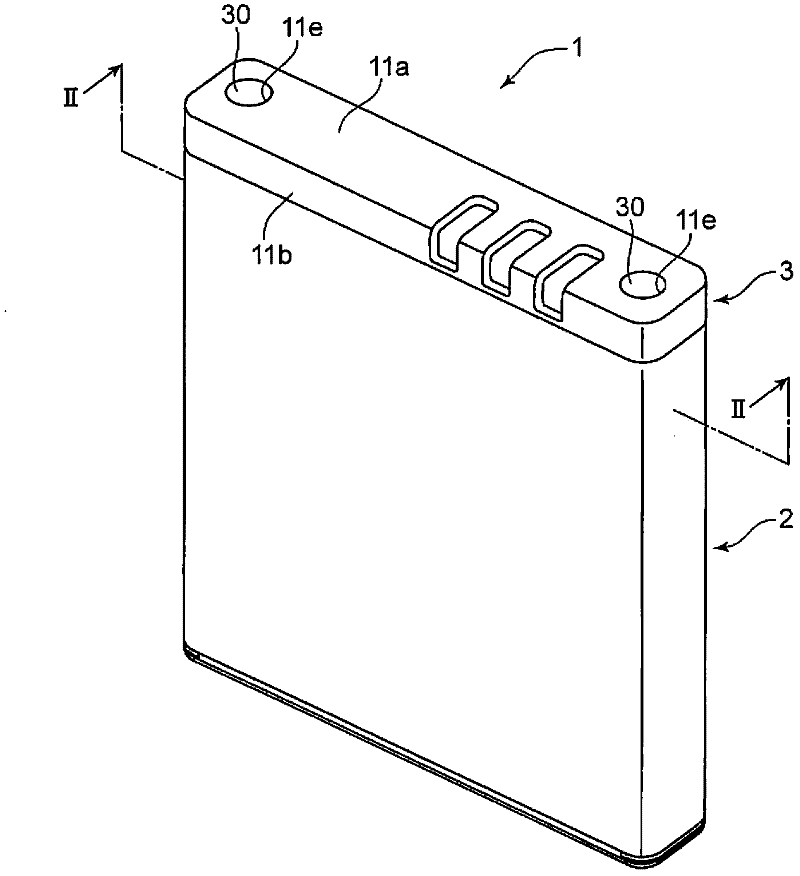

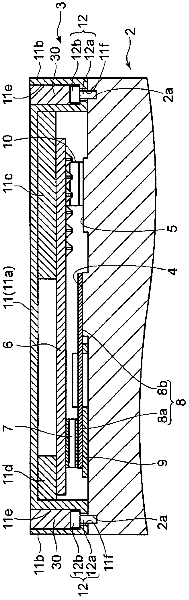

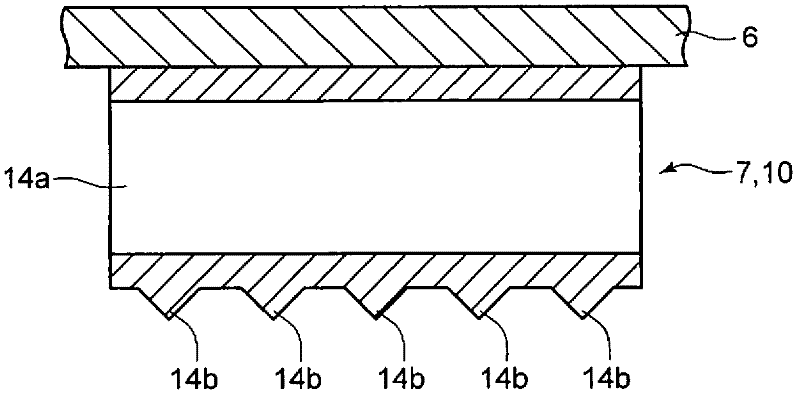

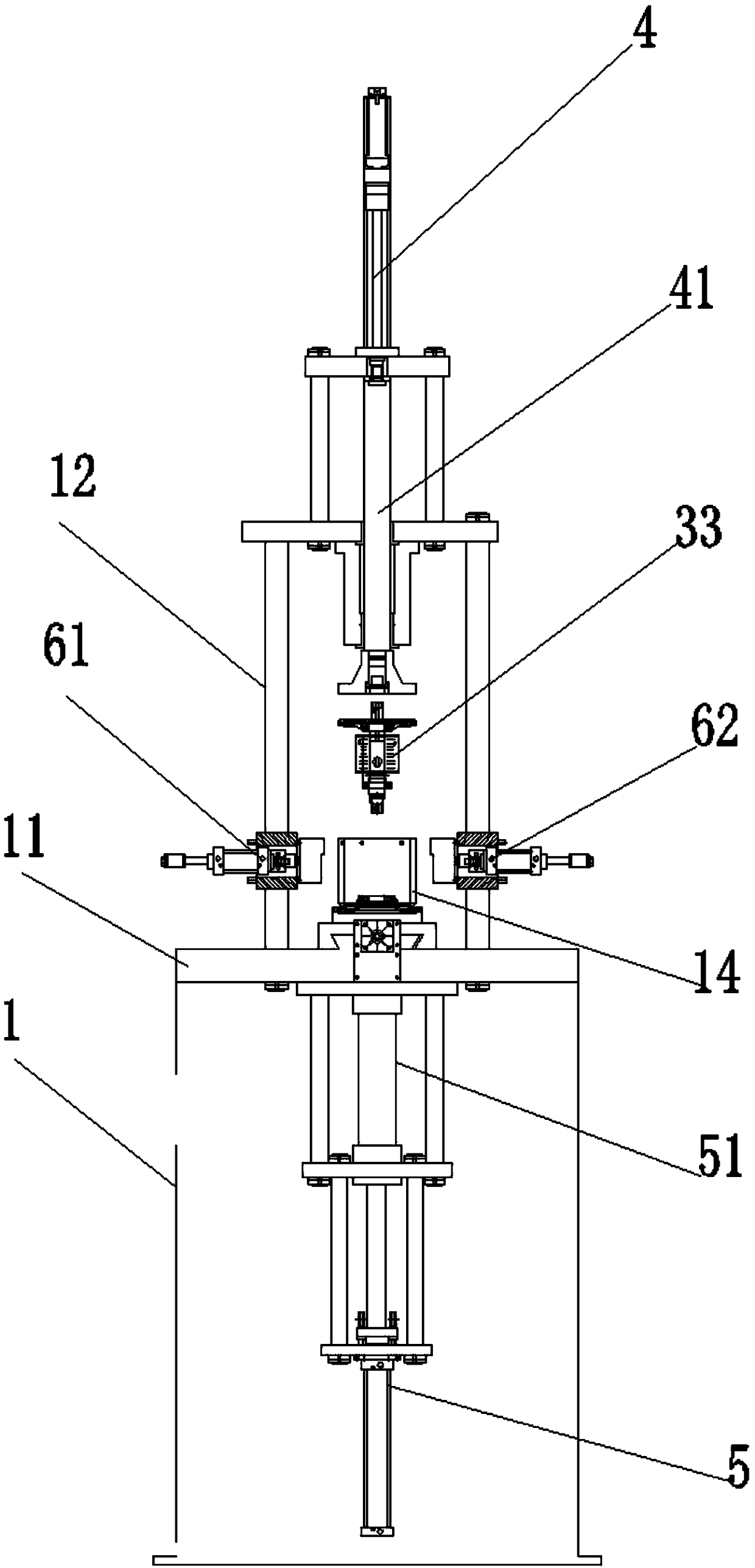

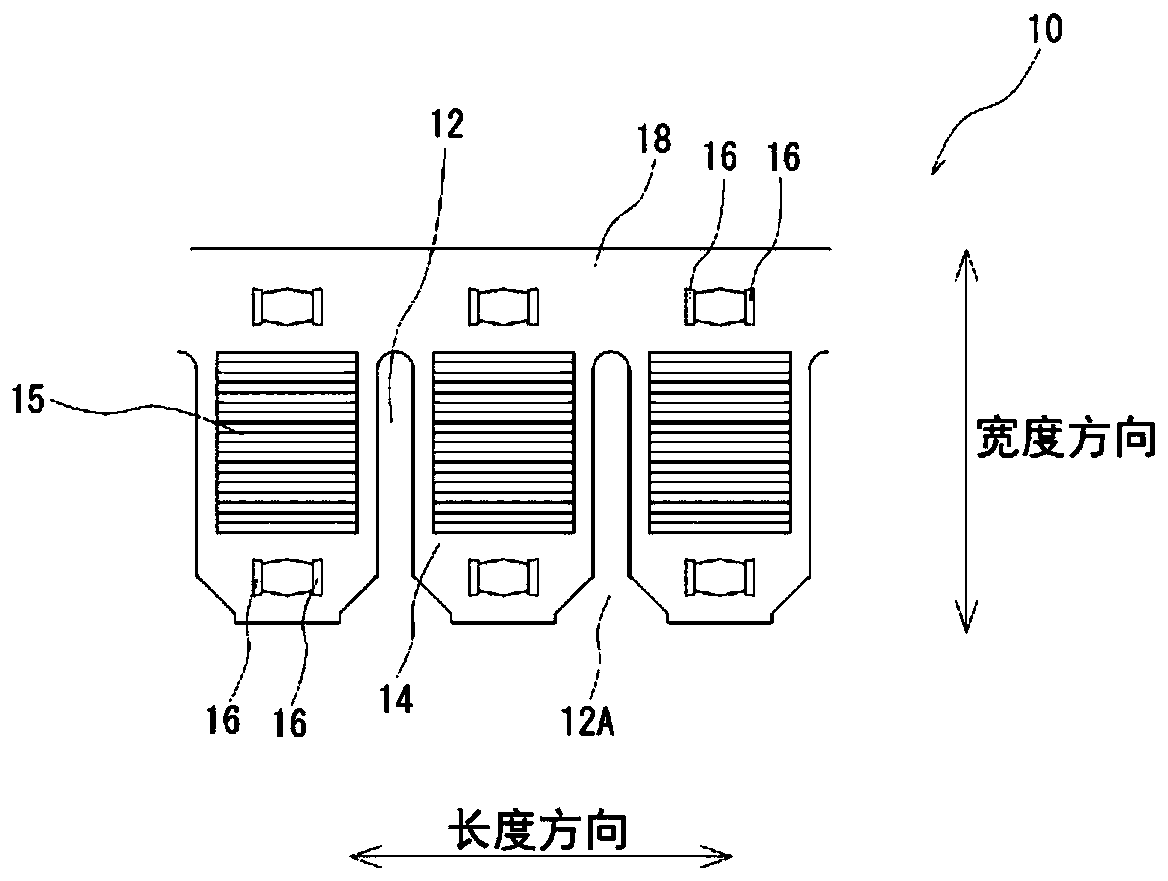

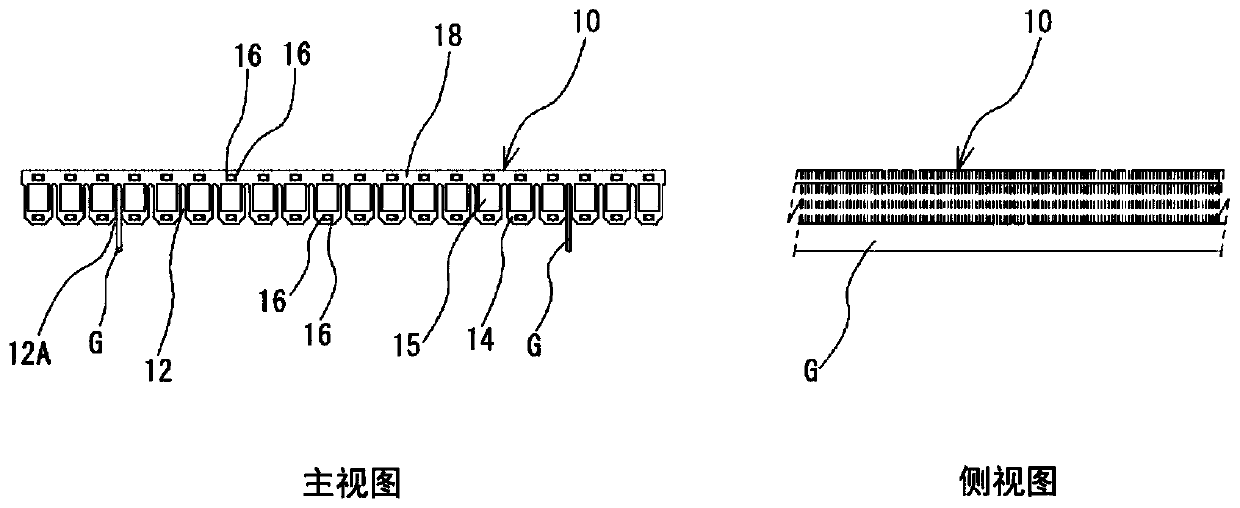

Battery pack and manufacturing method therefor

InactiveCN102473882AEfficient assembly workBatteries circuit arrangementsFinal product manufactureEngineeringPrinted circuit board

Disclosed is a battery pack that has a safety member comprising a protection-circuit substrate (a printed circuit board) or the like. Said substrate is connected to a terminal of a battery via a connecting member. Conventional battery pack manufacturing has faced the issue that it is difficult to improve assembly efficiency when connecting a connecting member, disposed between a protection-circuit substrate and a battery, to both said substrate and said battery via welds. The disclosed battery pack solves that issue by providing the safety member in the battery pack with: a printed circuit board (6) that has wiring; plate leads (7 and 10), affixed to the printed circuit board (6), for electrically connecting the wiring on the printed circuit board (6) to both terminals (4 and 5) on the battery (2); and a screw (12) that screws onto the battery (2) and puts pressure on the plate leads (7 and 10), thereby holding the plate leads (7 and 10) in electrical contact with the terminals (4 and 5) on the battery (2).

Owner:PANASONIC CORP

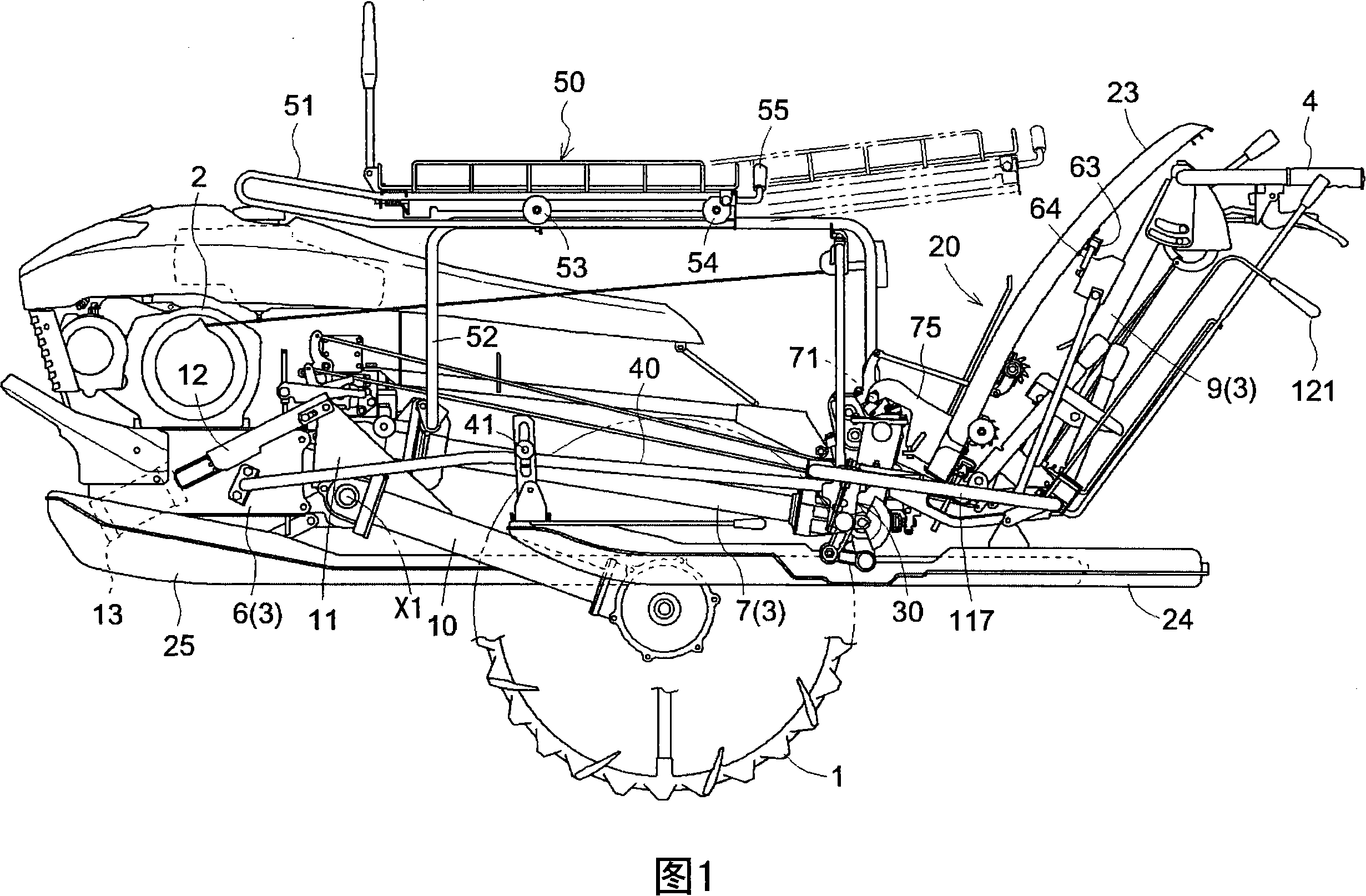

Seedling transplanting device

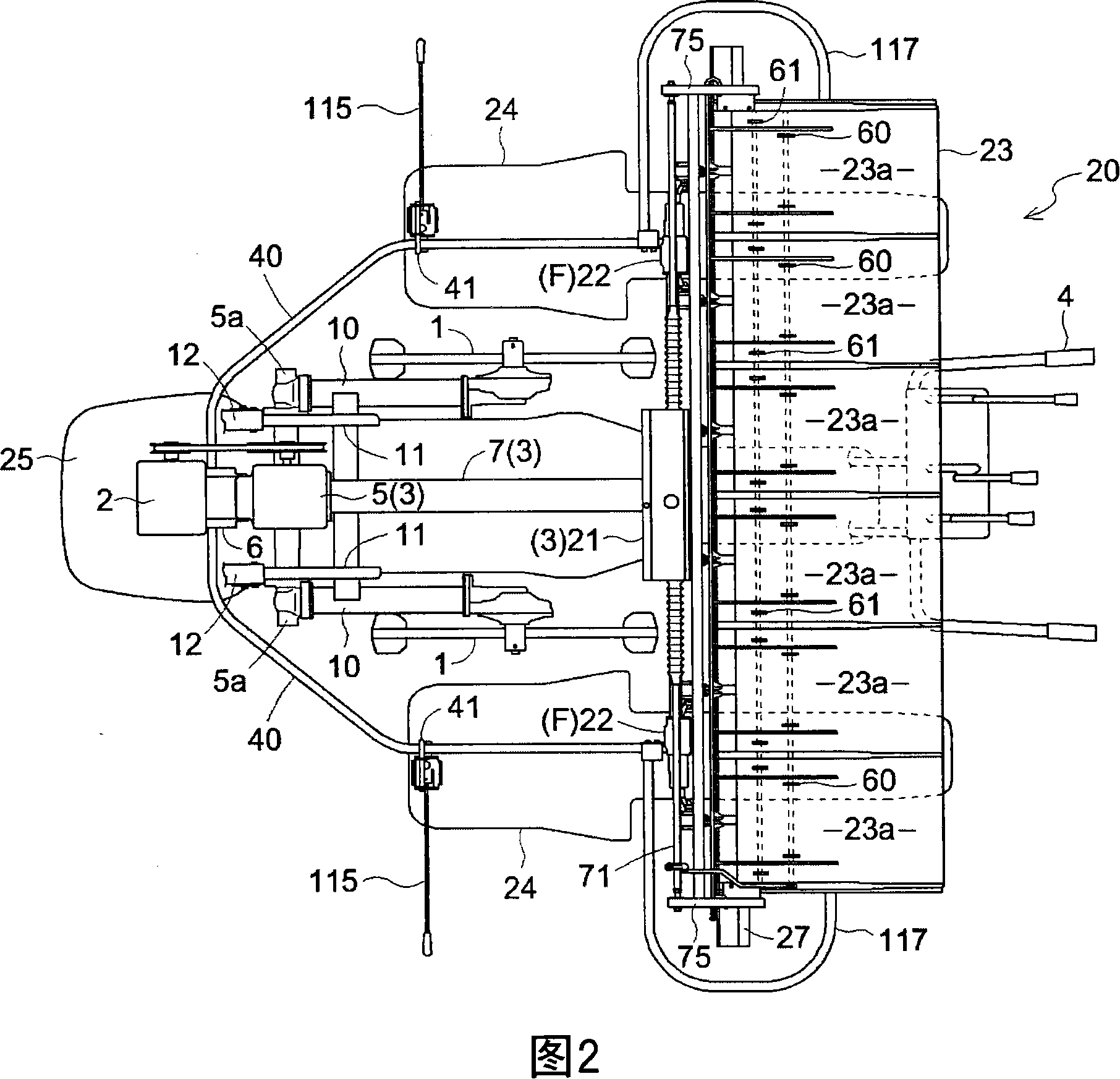

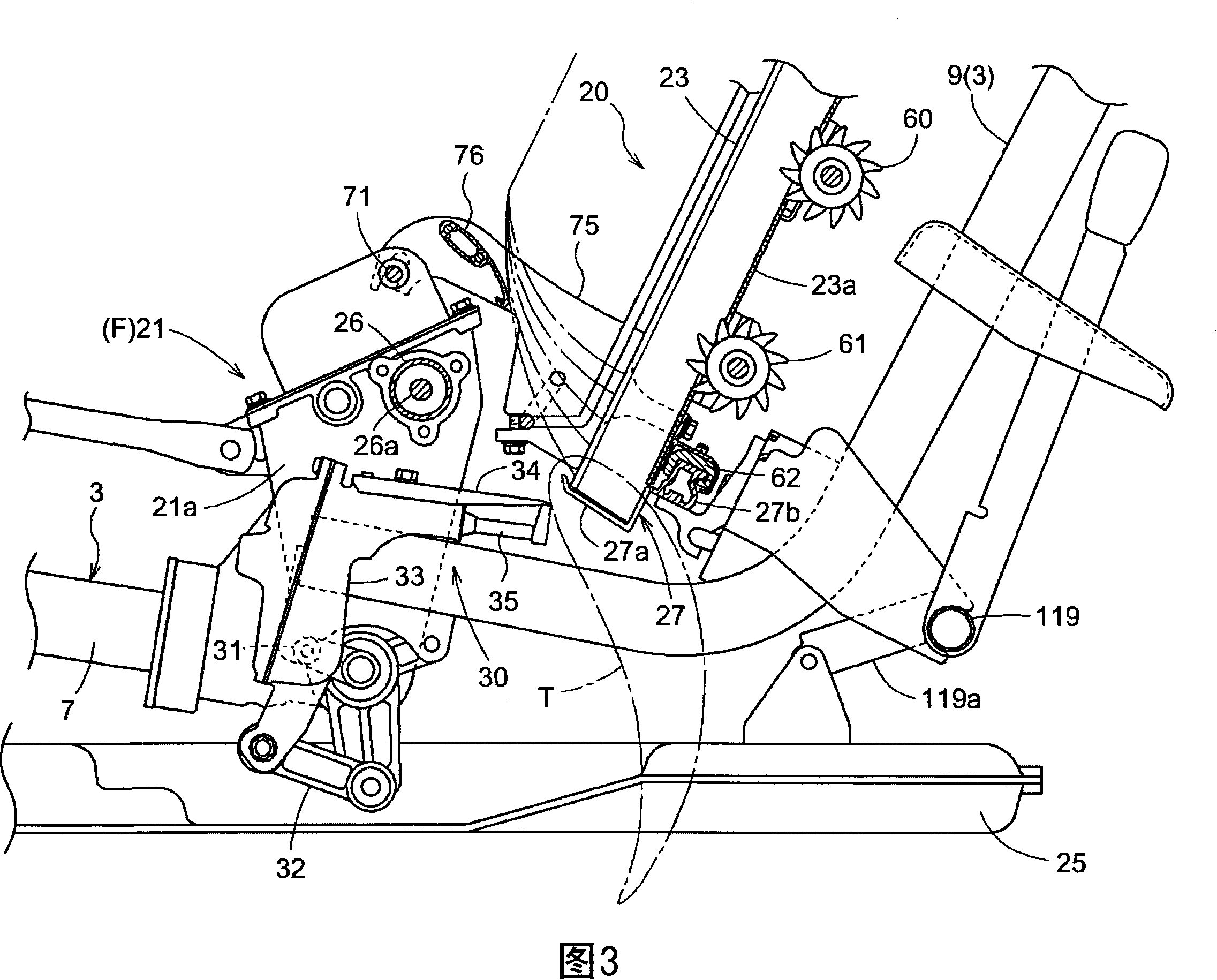

A machine for transplanting rice seedlings, which carrying seedlings table is assembled on a transverse transportation axis under the state that the table connects to a couple of right and left connecting support pieces. In the body, a transverse transportation axis (71) is supported with the mode of moving freely along the body horizontally, the two end of the transportation axis (71) connect with the couple of right and left connecting support pieces (75) with the mode of moving freely with one body. The transverse transportation axis (71) includes: a transverse transportation main body (71a), being supported on the body with the mode of to-and-fro moving freely; connecting axis (100, 105) connecting with two end of the transverse transportation main body (71a) through a screw with the mode of being adjusting flexibly along the transverse transportation axis moving direction; combining parts (102, 107) which locate on the couple connecting axis (100, 105) and joint to the support piece (75) with the mode of moving with one body freely along the transverse transportation axis moving direction.

Owner:KUBOTA LTD

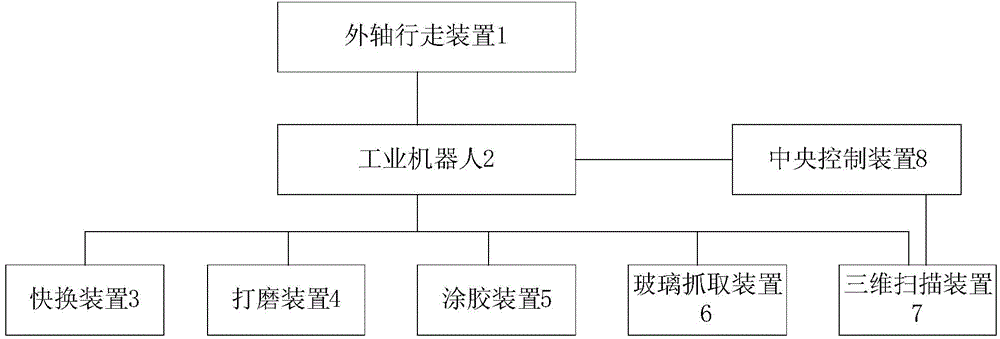

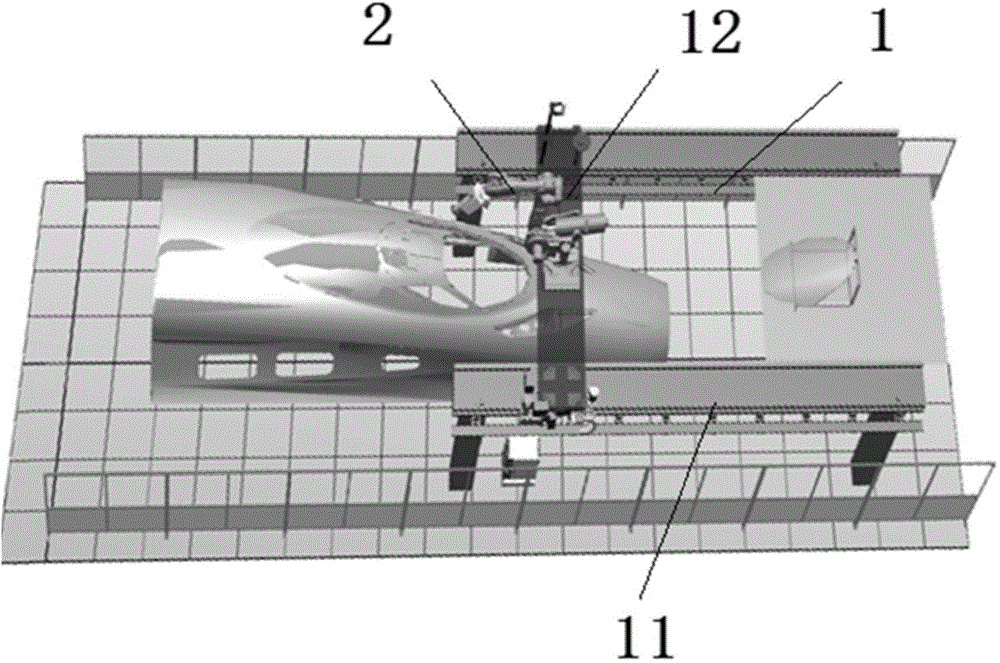

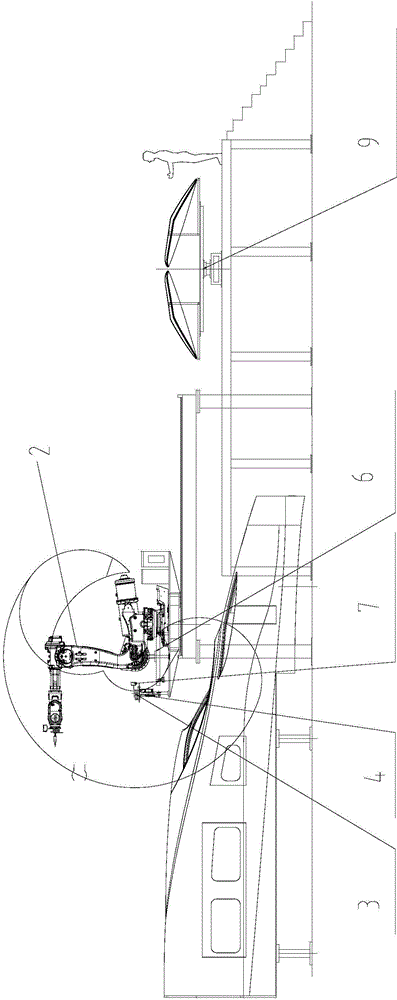

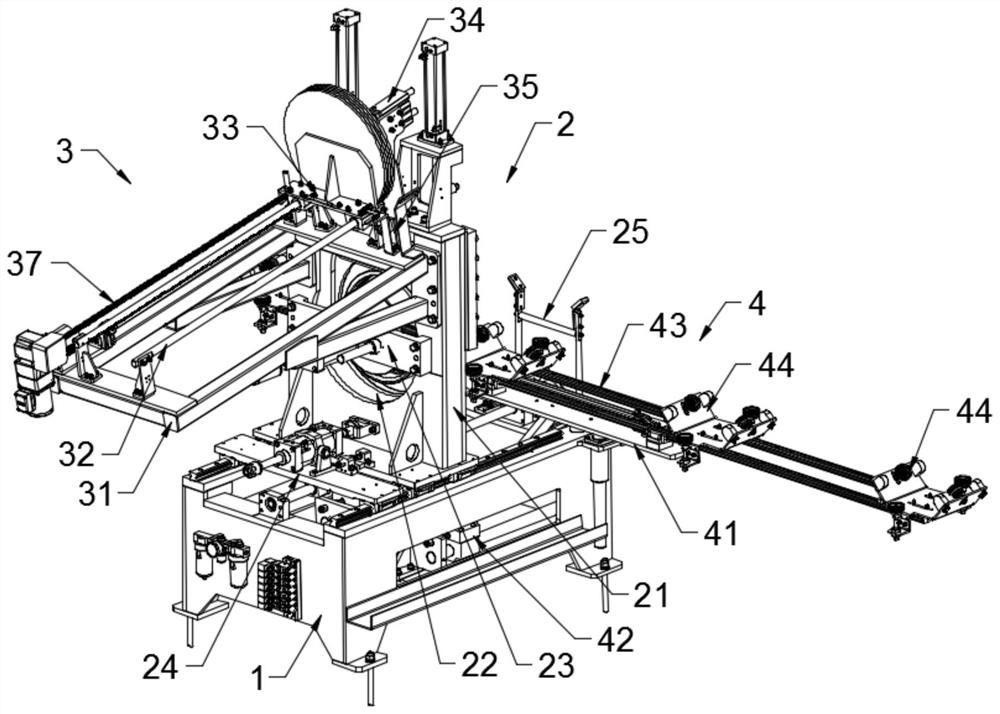

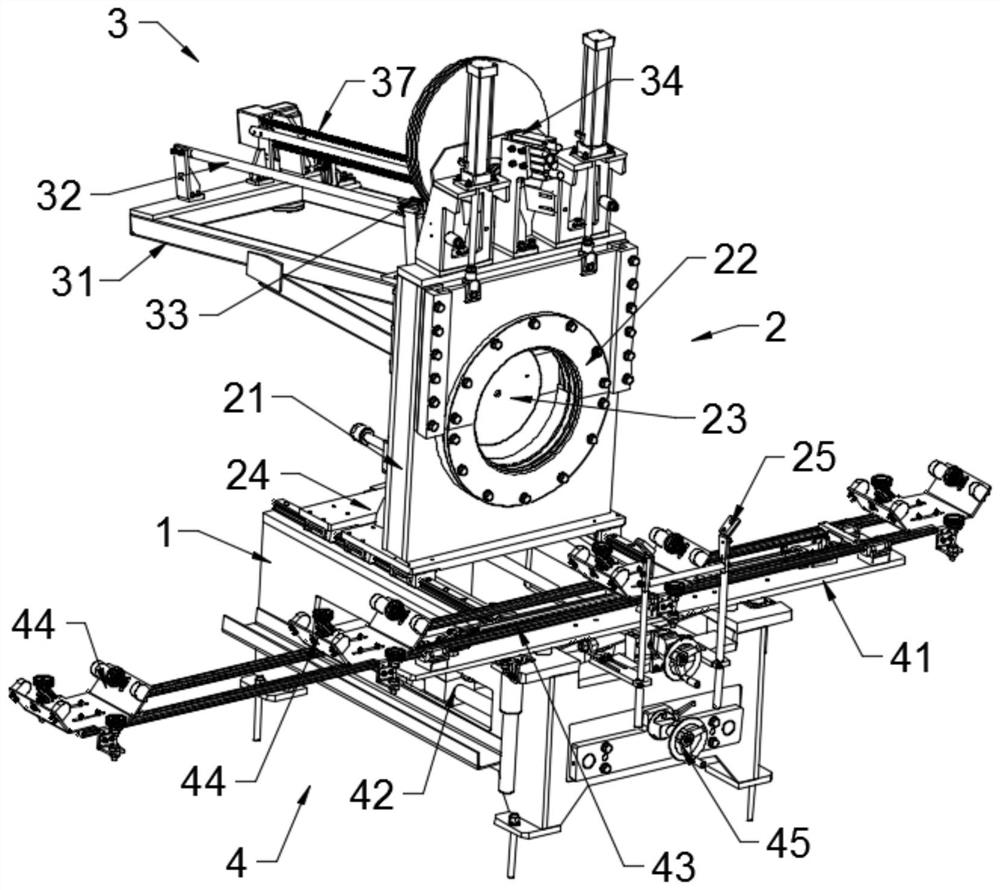

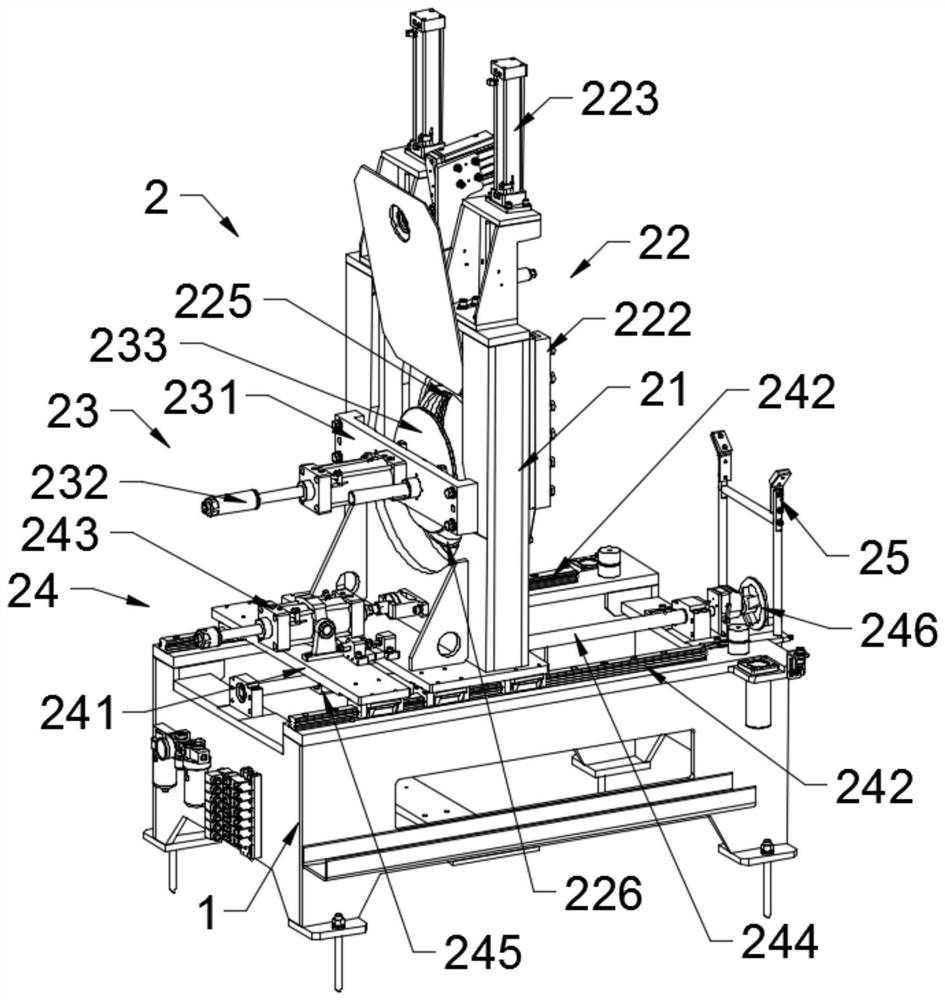

Assembling system and method of front window of high-speed rail locomotive

InactiveCN104908001AAvoid dangerImprove work efficiencyMetal-working hand toolsEngineering3d scanning

The invention provides an assembling system and method of a front window of a high-speed rail locomotive. The system comprises an outer shaft walking device, an industrial robot, a quick change device, a grinding device, a gelatinizing device, a glass grabbing device, a three-dimensional scanning device, a central control device and a glass feed and discharge working table. The industrial robot executes corresponding control actions. The quick change device replaces a device for current operation of a robot body. The three-dimensional scanning device scans a locomotive body and glass of the high-speed rail locomotive. The central control device calculates a plurality of parameters of to-be-installed gaskets of the front window according to three-dimensional scanning data and selects grinding routes of the gaskets and a locomotive frame. The grinding device grinds the locomotive frame. The gelatinizing device gelatinizes the ground locomotive frame. The glass grabbing device grabs the glass from the glass feed and discharge working table and installs the glass on the ground locomotive frame. Automatic installation is completed through the robot, higher work efficiency and work accuracy are achieved, and product quality is ensured.

Owner:TIANJIN ZHITONG ROBOT

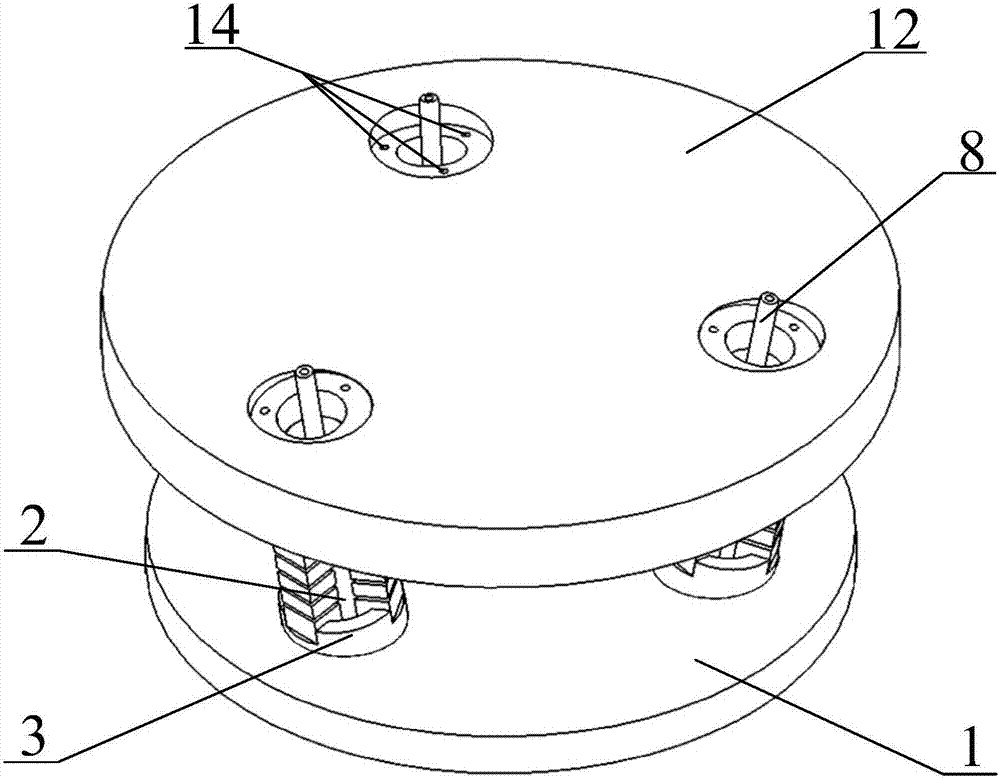

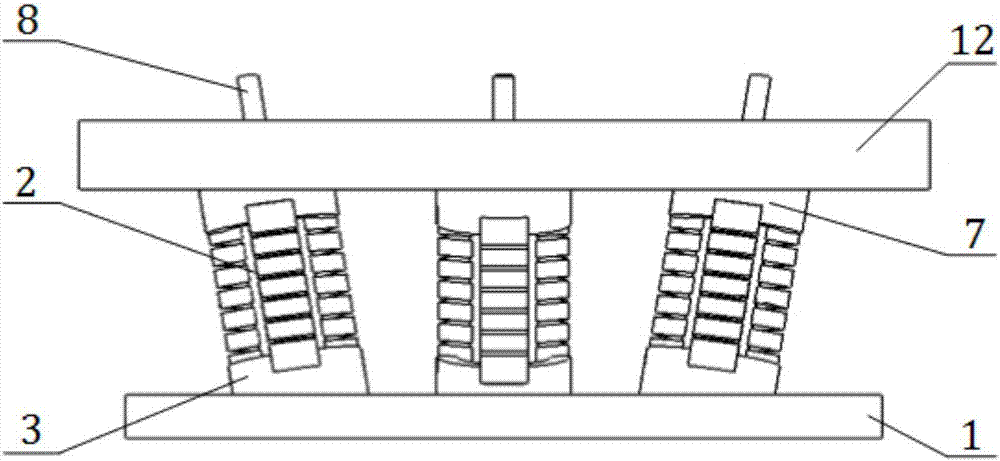

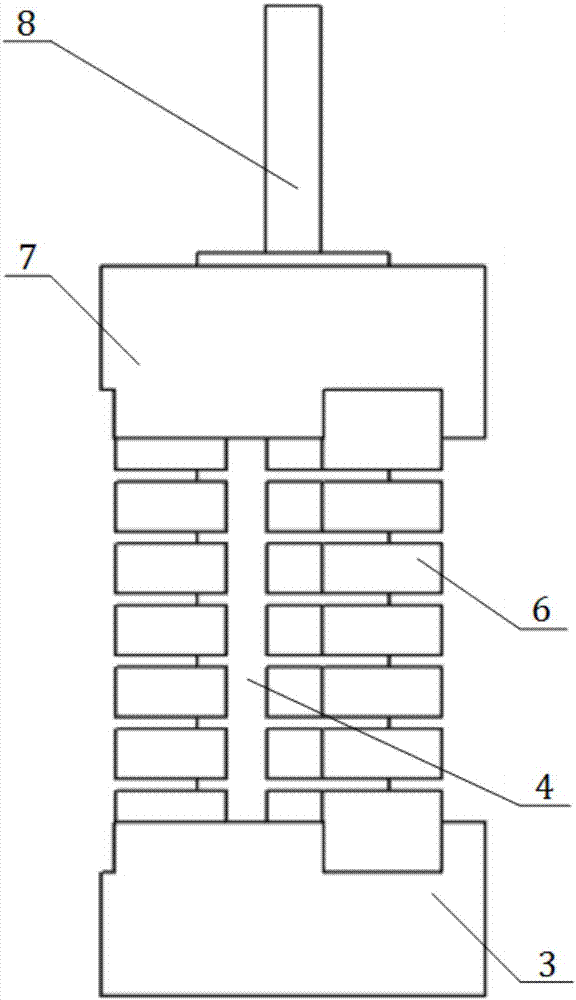

Pneumatic adjustable remote center compliance device

ActiveCN107511649AImprove adaptabilityGuaranteed efficientMetal working apparatusEngineeringRemote Center Compliance

The invention belongs to the technical field of mechanical assembling and discloses a pneumatic adjustable remote center compliance device. The device comprises a fixed platform, a plurality of adjustable elastic units and a moving platform, wherein the fixed platform and the moving platform are arranged oppositely up and down, the adjustable elastic units are arranged obliquely between the fixed platform and the moving platform in a circumferential annular array mode with the circle center of the outer side end surface of the fixed platform as the center. Each adjustable elastic unit comprises an upper base, a lower base, a petal-type multi-cavity adjustable elastic structure, a stacked elastic structure and a gas channel nipple which are arranged coaxially, wherein the petal-type multi-cavity adjustable elastic structure is fixed to the stacked elastic structure in a sleeving mode to form a plurality of gas channels, the upper end and the lower end of the petal-type multi-cavity adjustable elastic structure are sleeved with the upper base and the lower base correspondingly in a sealed mode, and the gas channel nipple is fixedly connected with the upper base and connected with the gas channels. According to the pneumatic adjustable remote center compliance device provided by the invention, by additionally arranging a gas actuating structure, the universality of the compliance device is improved, and requirements of assembling operation for a series of shaft holes of various sizes can be met.

Owner:SHANGHAI JIAO TONG UNIV

LED lens set with firm structure and good durability and lighting device

ActiveCN103256559AImprove stabilityBump won'tPoint-like light sourceLight fasteningsWater flowEngineering

The invention discloses an LED lens set with a firm structure and good durability. The LED lens set with the firm structure and good durability comprises a lens base, lenses which are arranged on the lens base, a liquid silica gel ring groove, a solid silica gel ring groove, a plurality of screw containing grooves and wire containing grooves, wherein the liquid silica gel ring groove and the solid silica gel ring groove are formed in the edge of the lens base, screw containing grooves are formed in the lens base, the edge of the periphery of the lens base is thickened, the edge of the thickened lens base is obviously higher than the adjacent position of the inner side of the lens base, so that a circle of protrusions are formed, and the protrusions has a shape which can guide the direction of water flow. Due to the fact that the edge of the periphery of the lens base is thickened, reinforced ribs are additionally arranged, and a partition structure used for reinforcing is arranged inside each wire containing groove, firmness and durability of one LED lens are improved, and the middle of one lens can not protrude after one lens is used for a long time.

Owner:HANGZHOU HPWINNER OPTO CORP

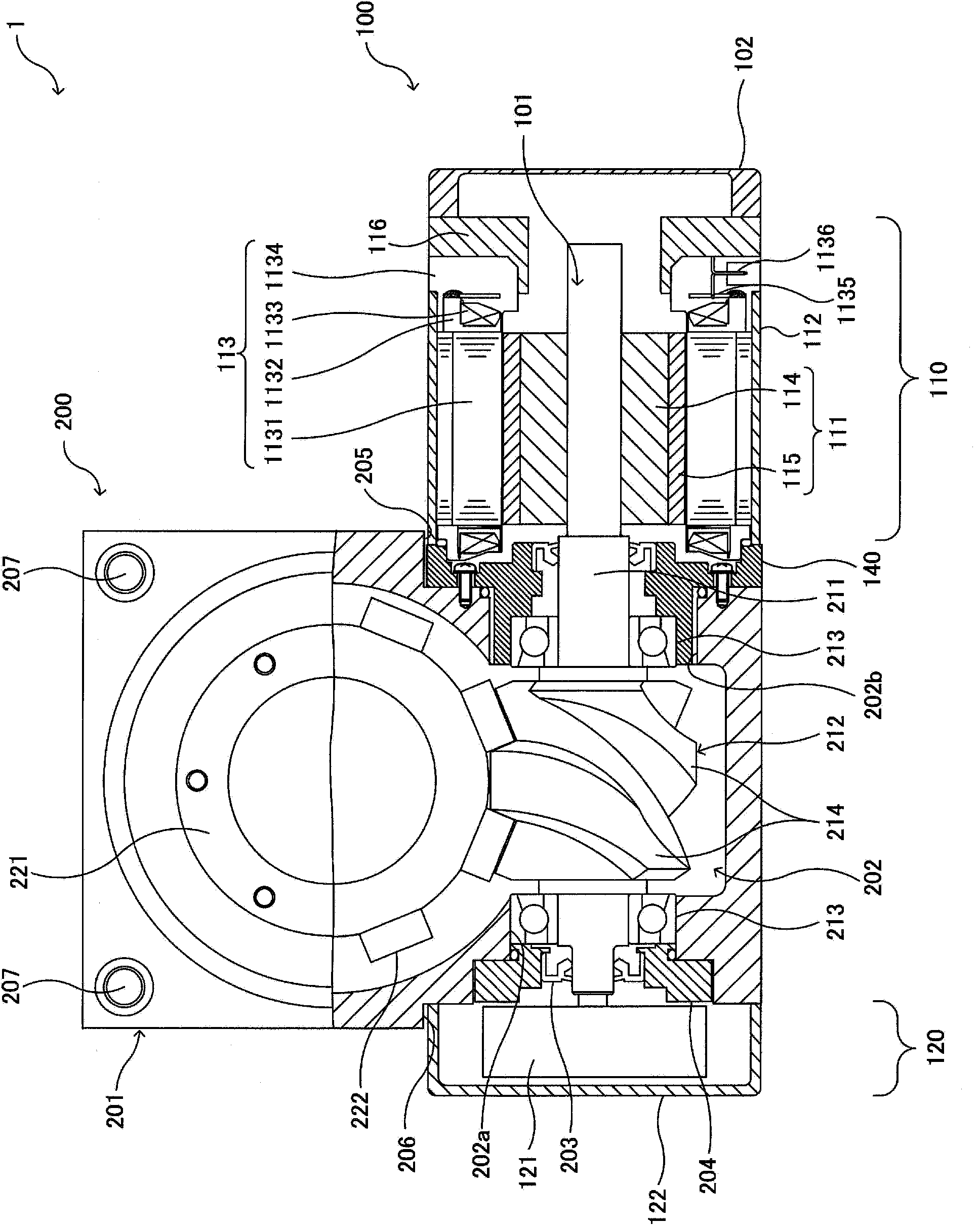

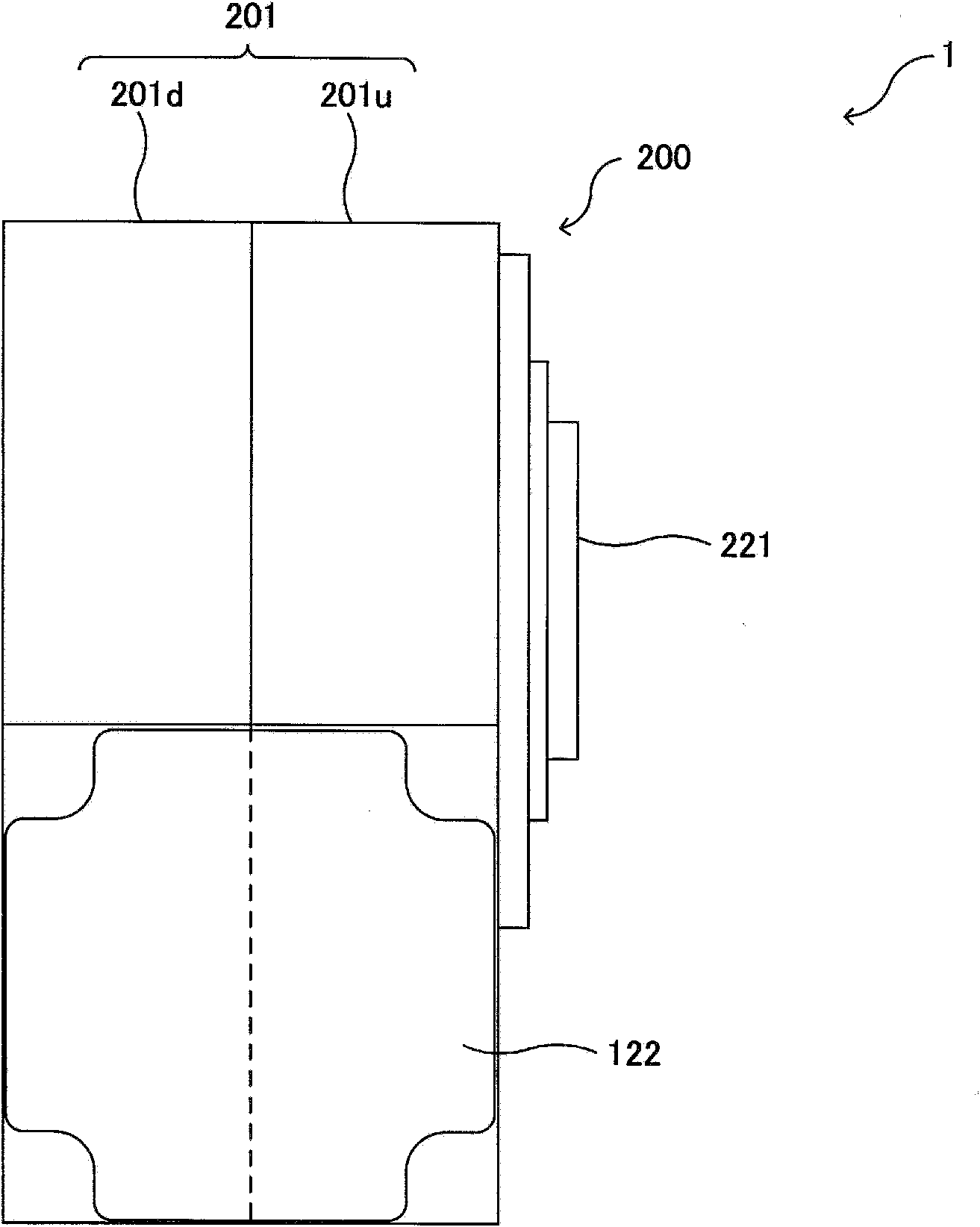

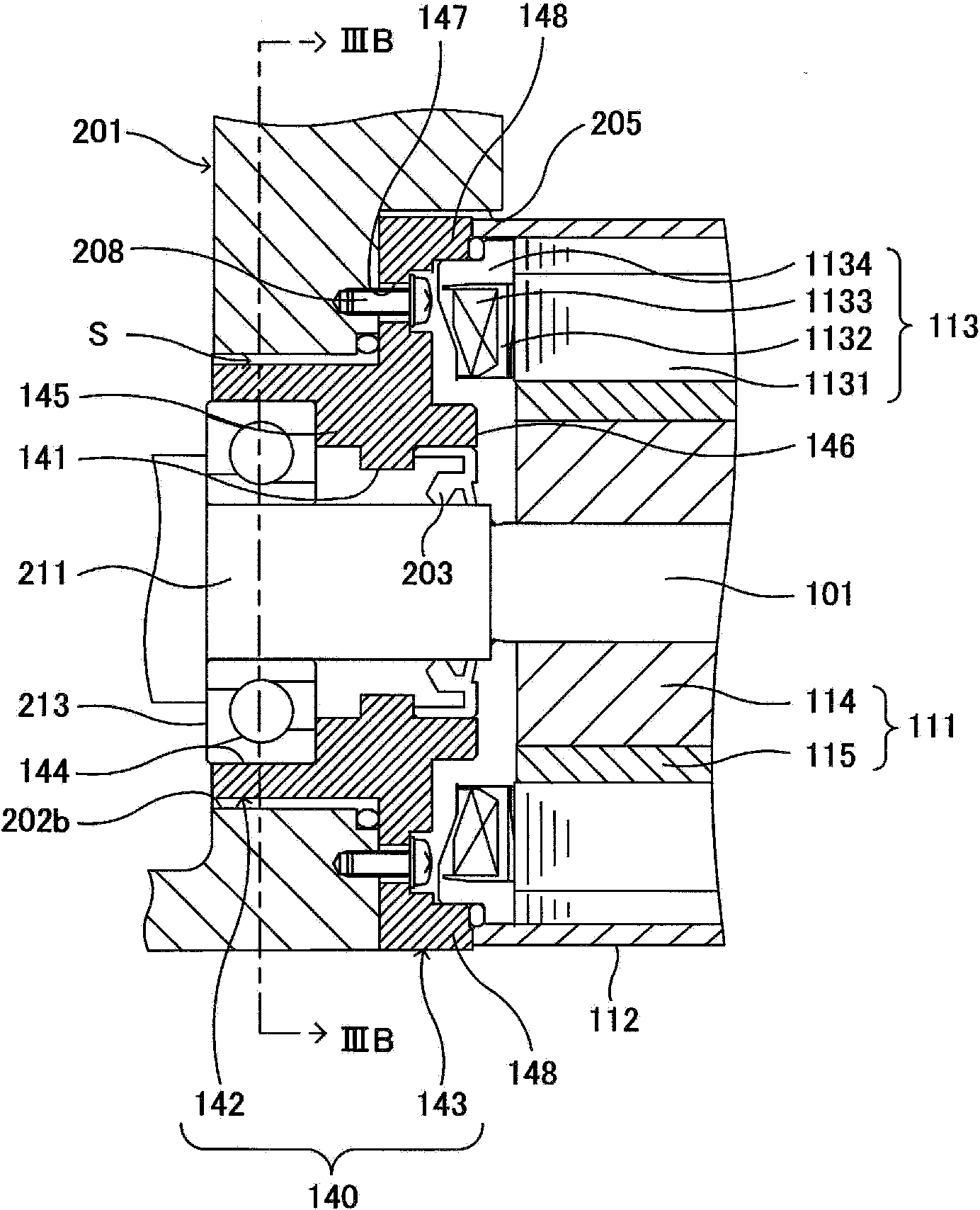

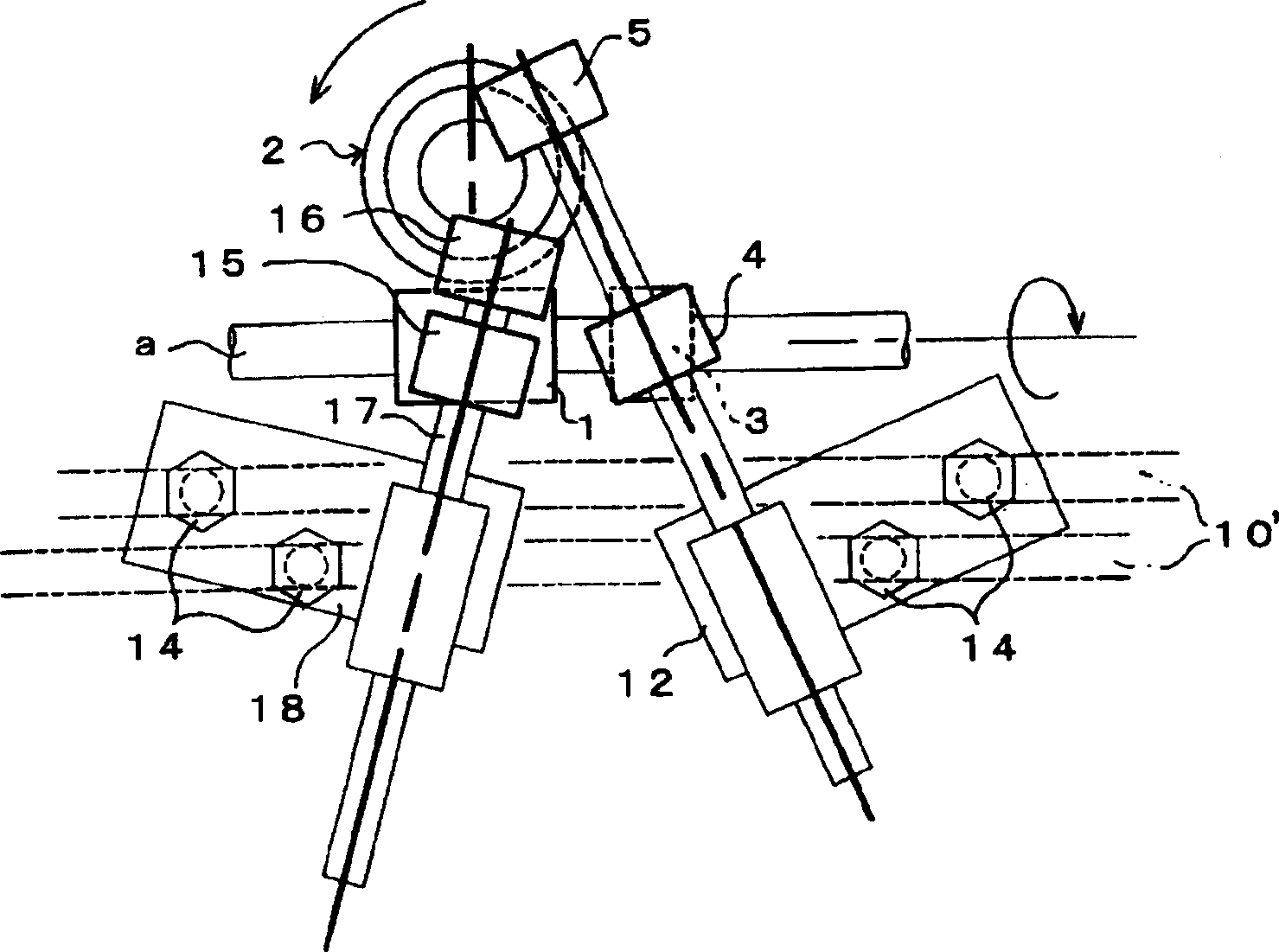

Rotary device

ActiveCN102629798AGuaranteed coaxialityEfficient assembly workFeeding apparatusMechanical energy handlingElectric machineReduction drive

The invention provides a rotary device guaranteeing the axiality of a rotor and a stator of a rotary motor and realizing assembling work of the rotary device efficiently. The rotary device (1) is provided with a motor (100) and a reducer (200). The motor is provided with the rotor (111) and the stator (113). The reducer is provided with an input shaft (211) provided with a roller gear cam (212); and an output shaft (221). The periphery of the output shaft is provided with cam driven pieces (222) clamping with the roller gear cam successively. The output shaft extends along a direction perpendicular to the output shaft. The motor is provided with a rotary shaft (101) fixed with the rotor. The output shaft of the rotary shaft and the reducer are connected coaxially. The motor also includes a bearing support part (140) supporting a bearing (213) and exerting a certain preload to the bearing. The bearing supports the output shaft of the reducer to rotate freely. The rotor is arranged in the bearing support part.

Owner:SANKYO SEISAKUSHO

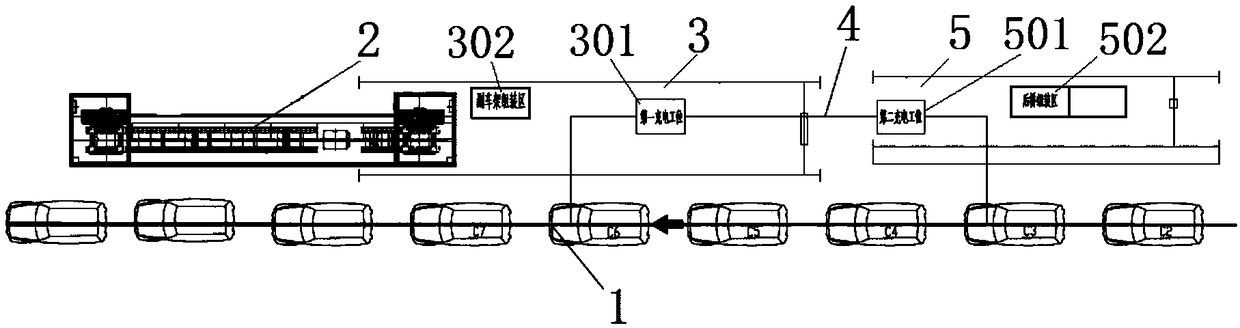

Continuous assembly process of automobile chassis mixed line

The invention discloses a continuous assembly process of an automobile chassis mixing line, which comprises the following steps: an AGV electric automobile carries five parts into the automobile assembly chassis line for assembling; the assembly of gasoline automobile requires two AGVs to complete the assembly of an automobile chassis, wherein one AGV carries an engine gearbox and a front sub-frame, and the other AGV carries a rear axle into the chassis line for assembly; the assembly of an electric automobile requires three AGVs to complete the assembly of an electric automobile chassis: oneAGV carries a motor gearbox and a sub-frame, another AGV carries a rear axle, and a third AGV carries a battery into the chassis line for assembly. The continuous assembly process of the automobile chassis mixing line can be completed efficiently, and the manpower cost can be reduced.

Owner:DORCEN AUTO CO LTD +1

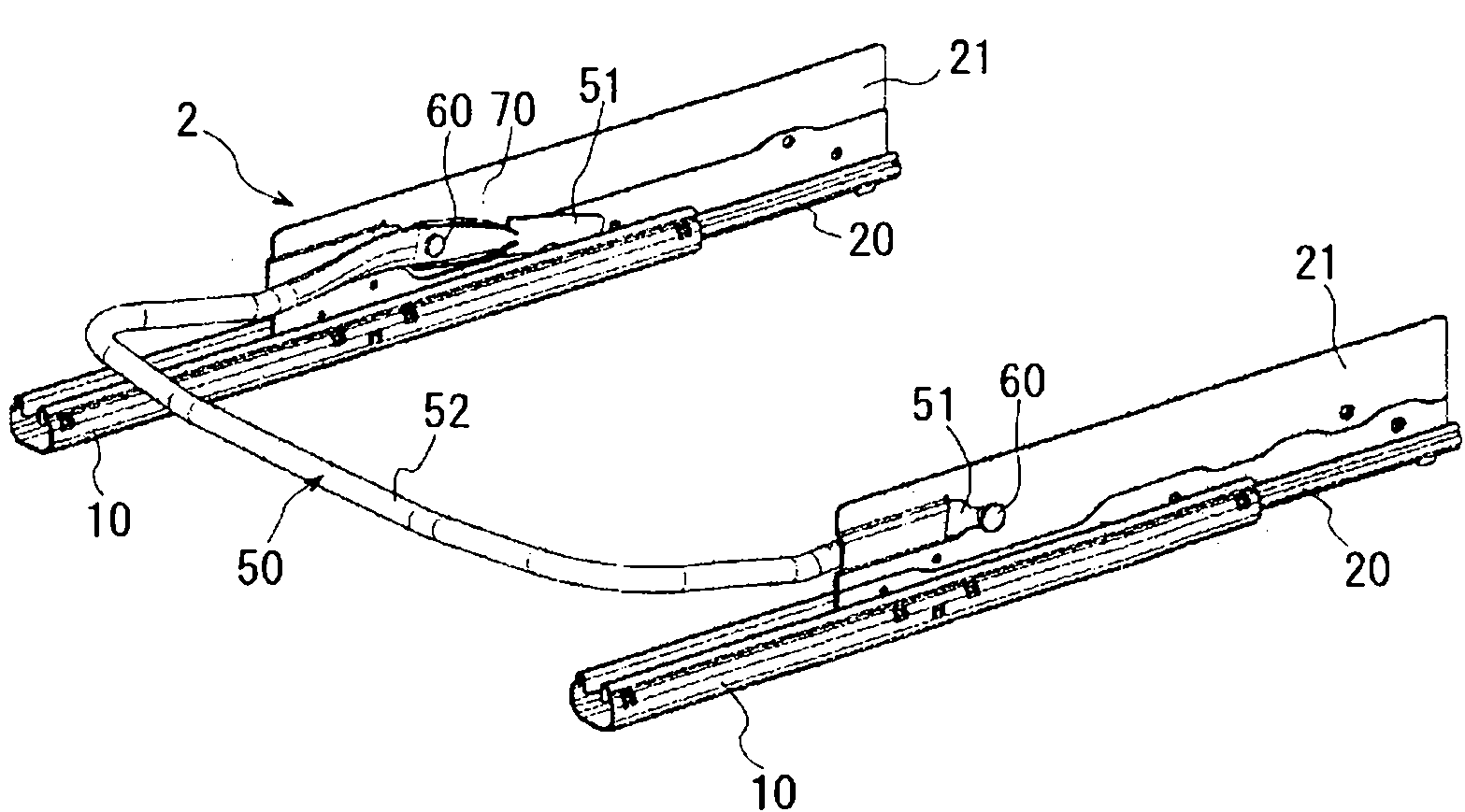

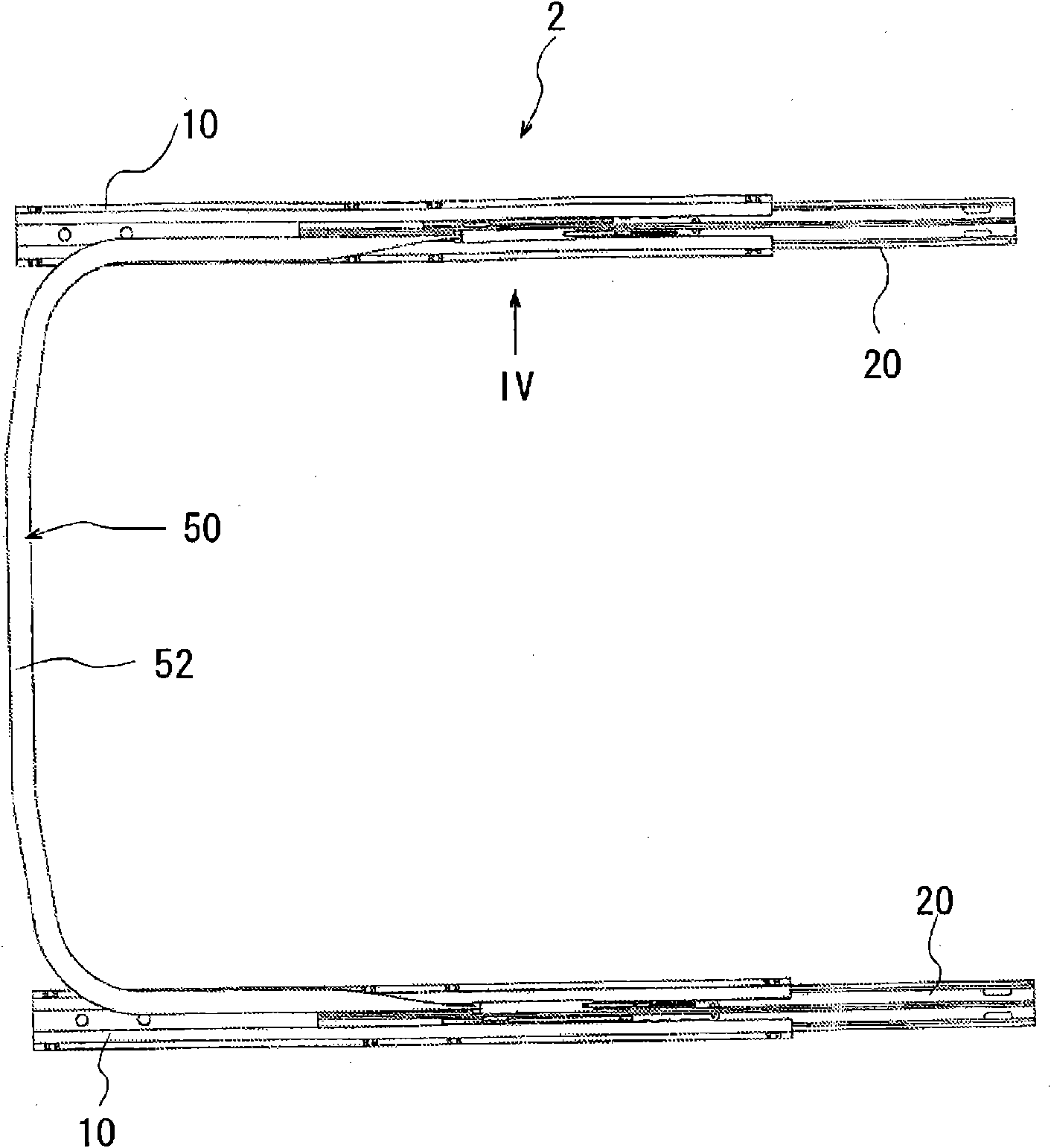

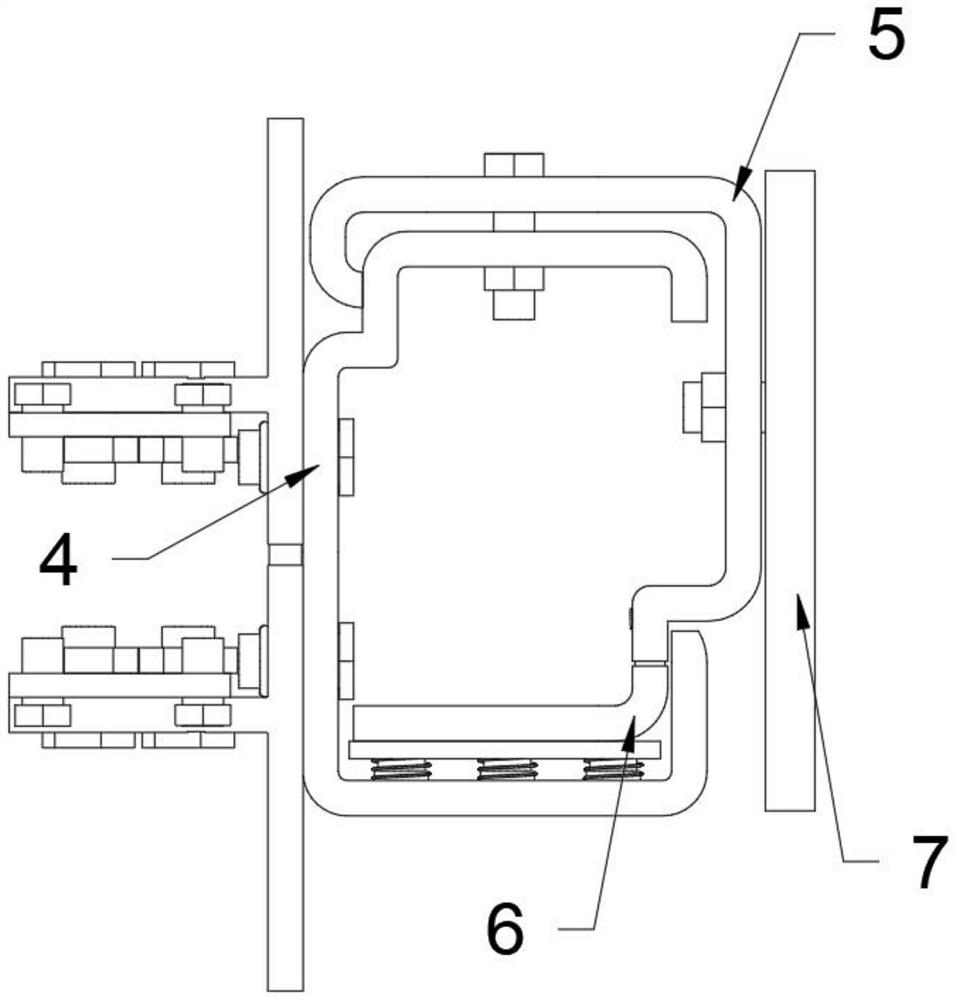

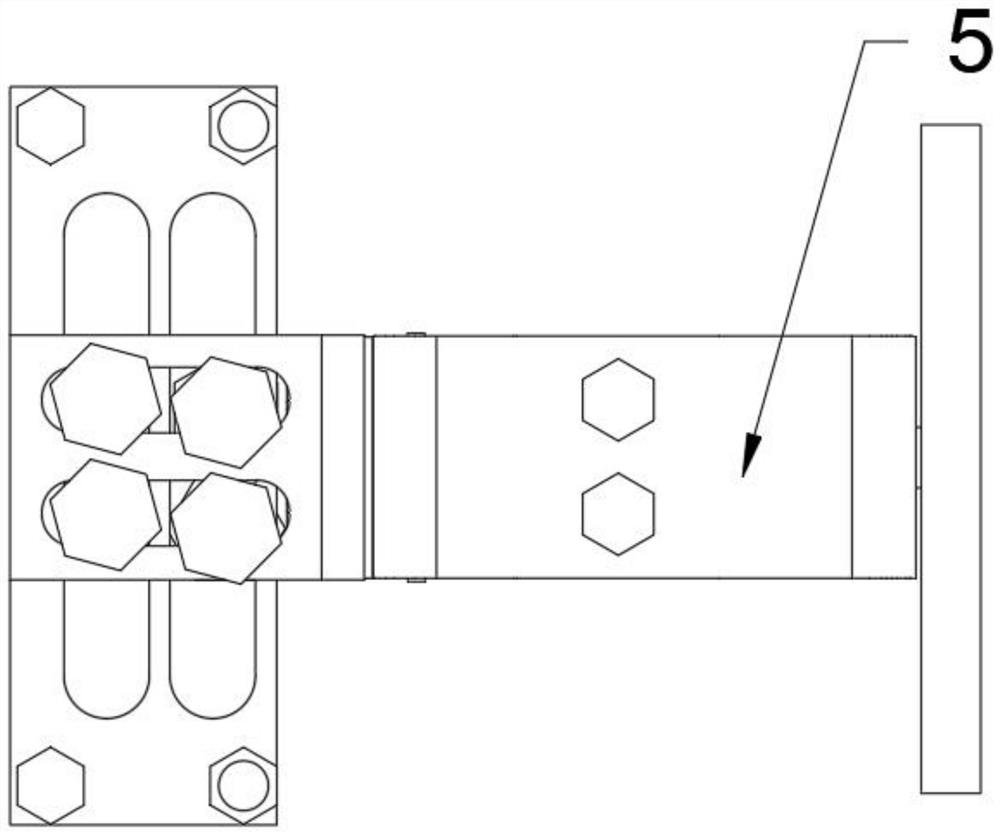

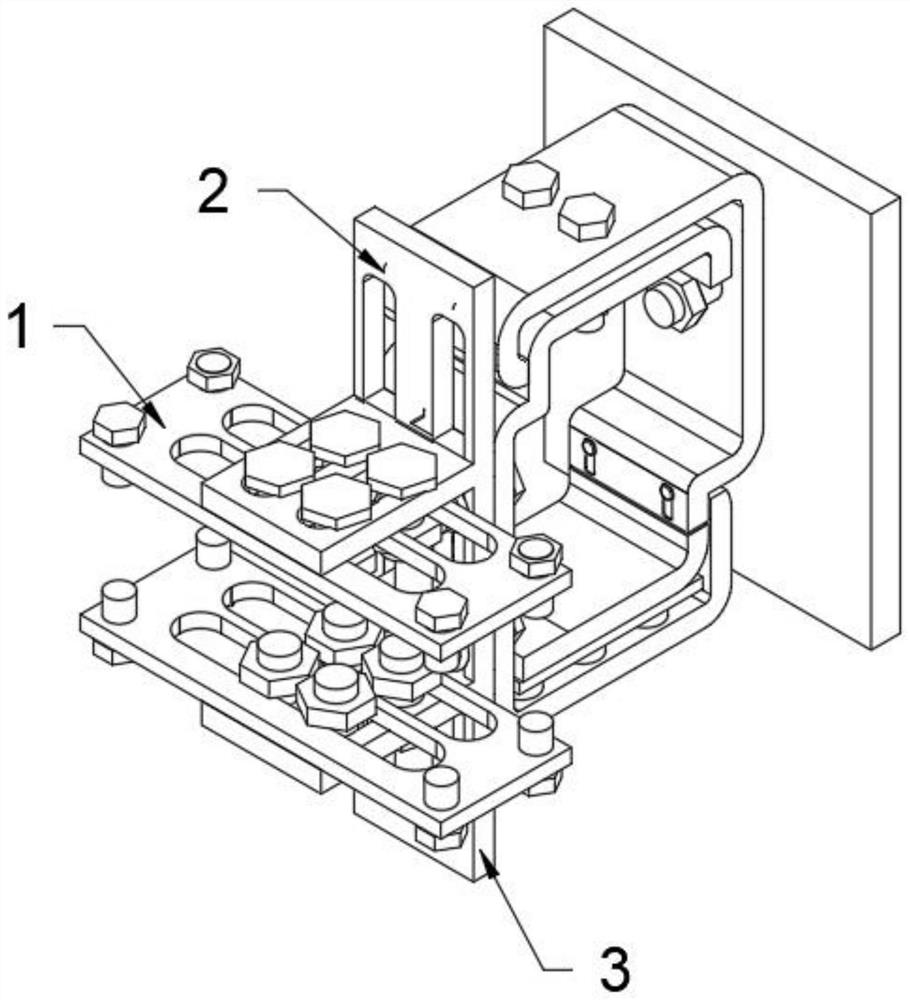

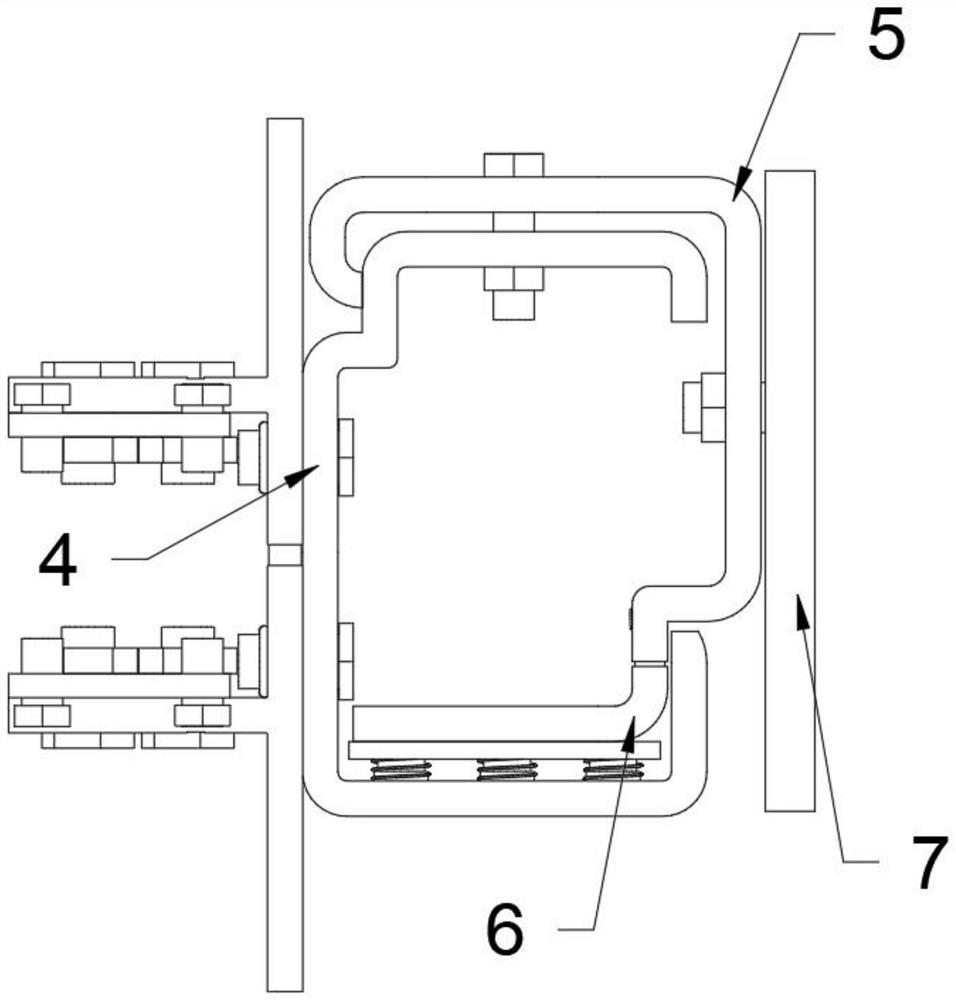

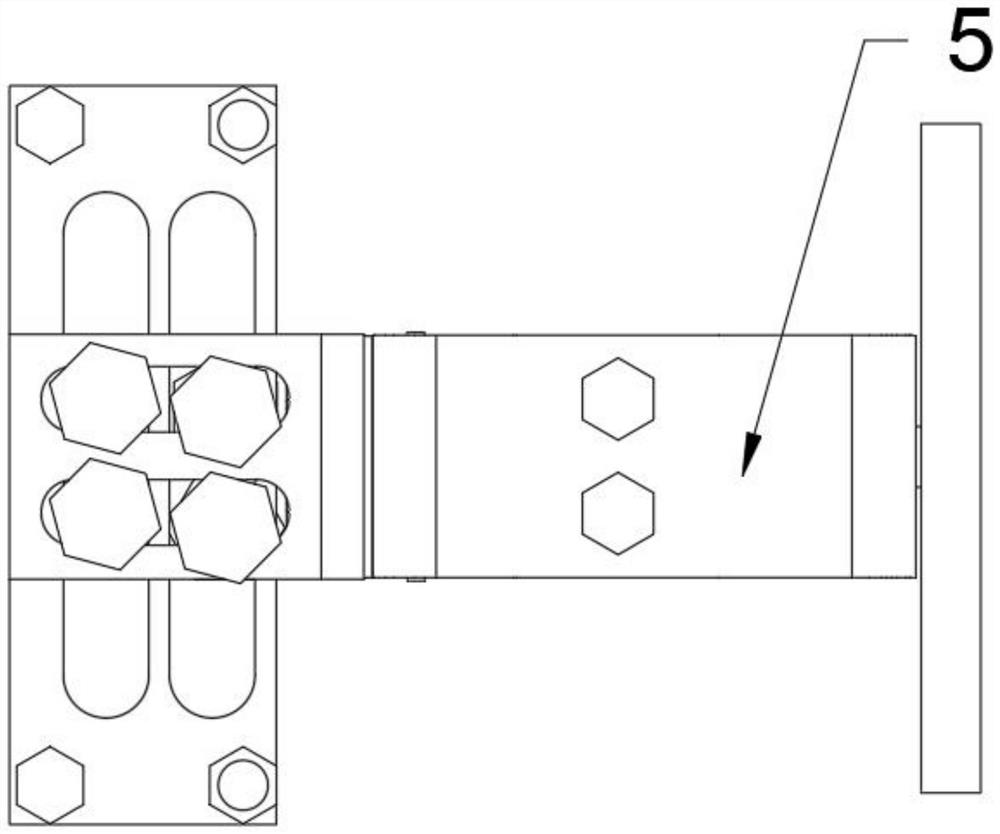

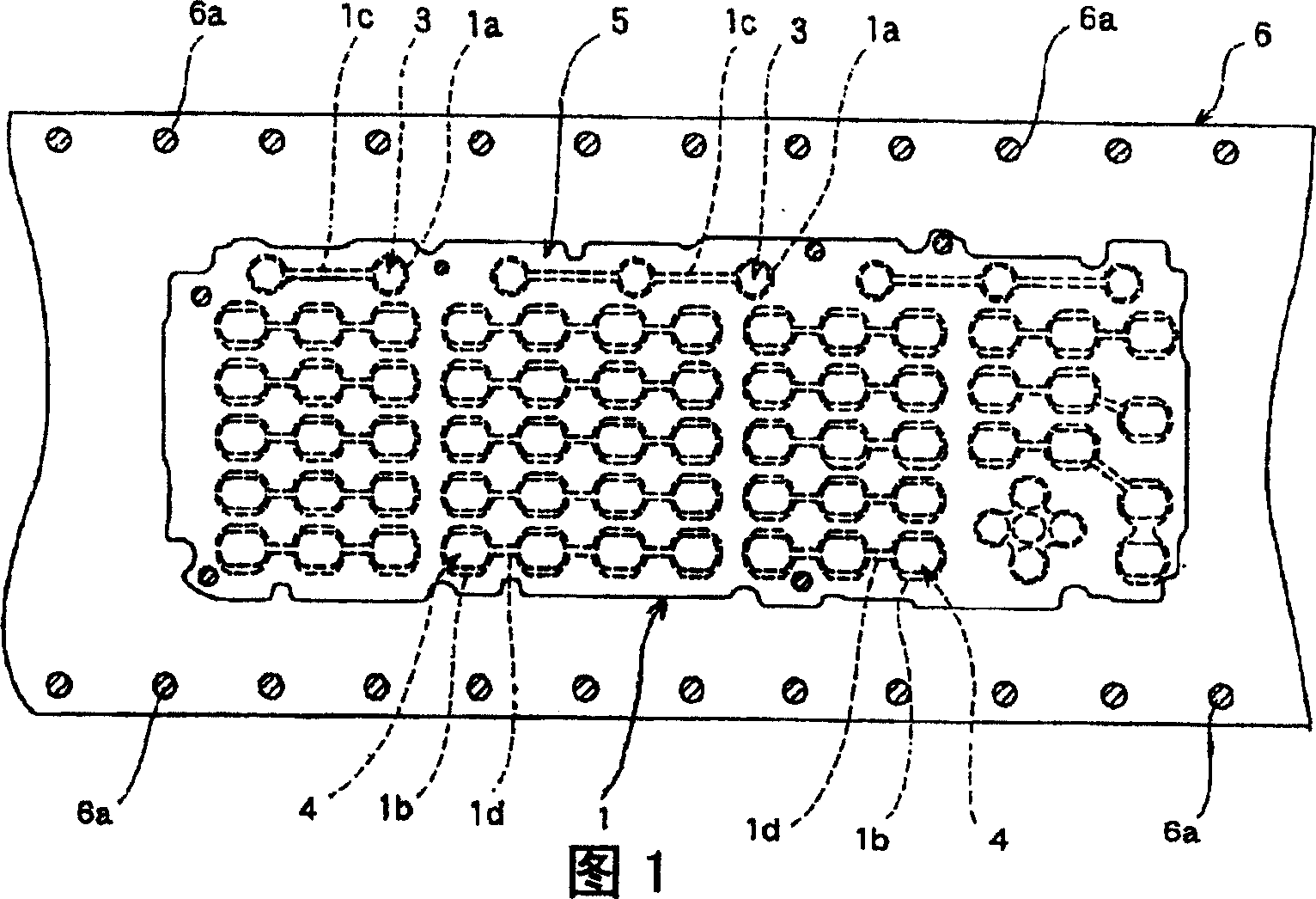

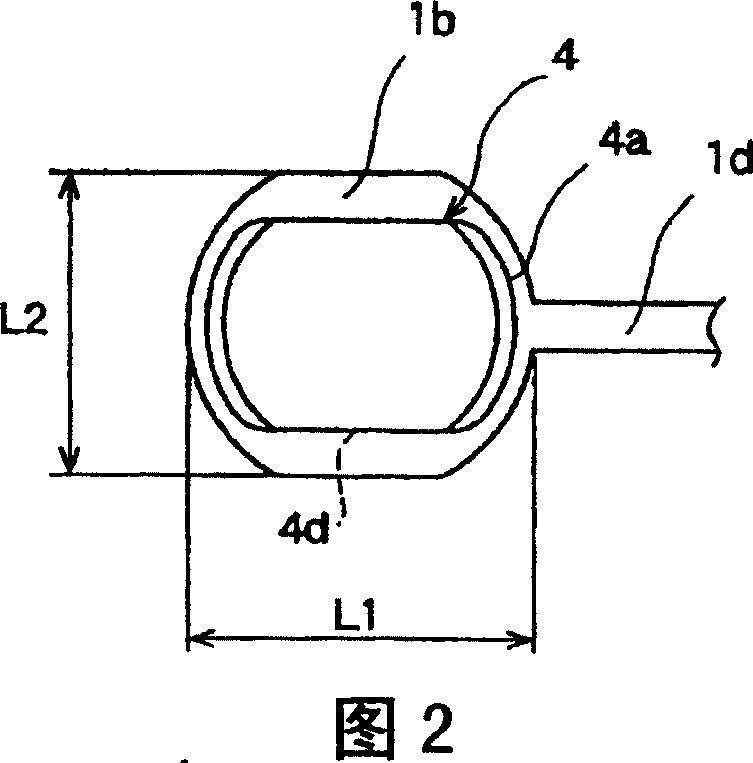

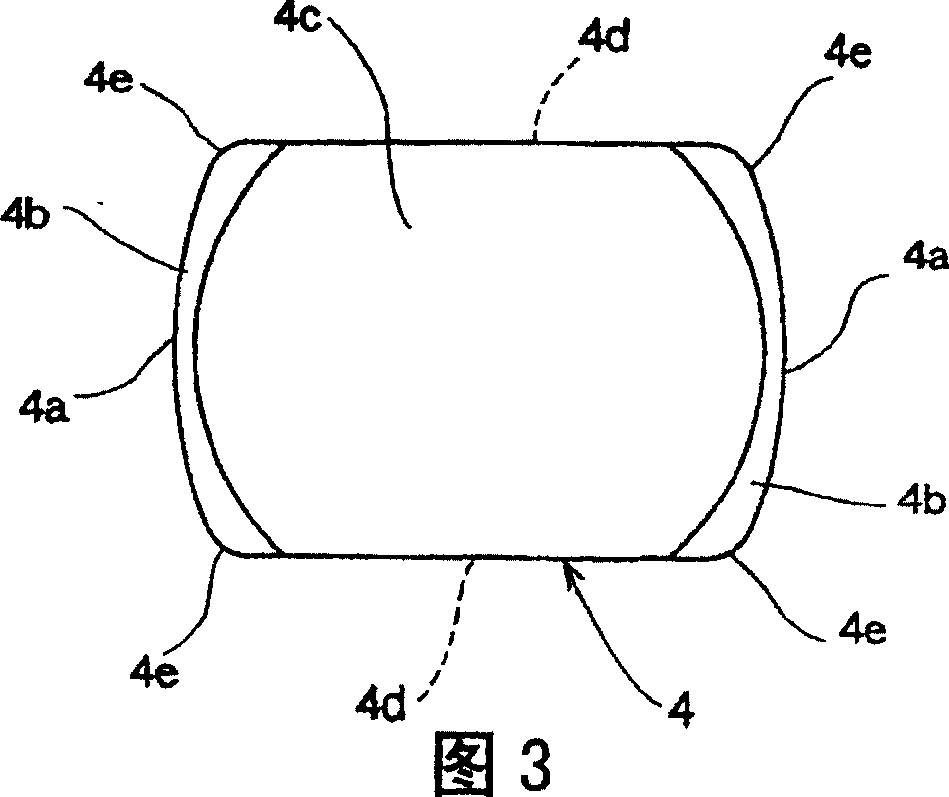

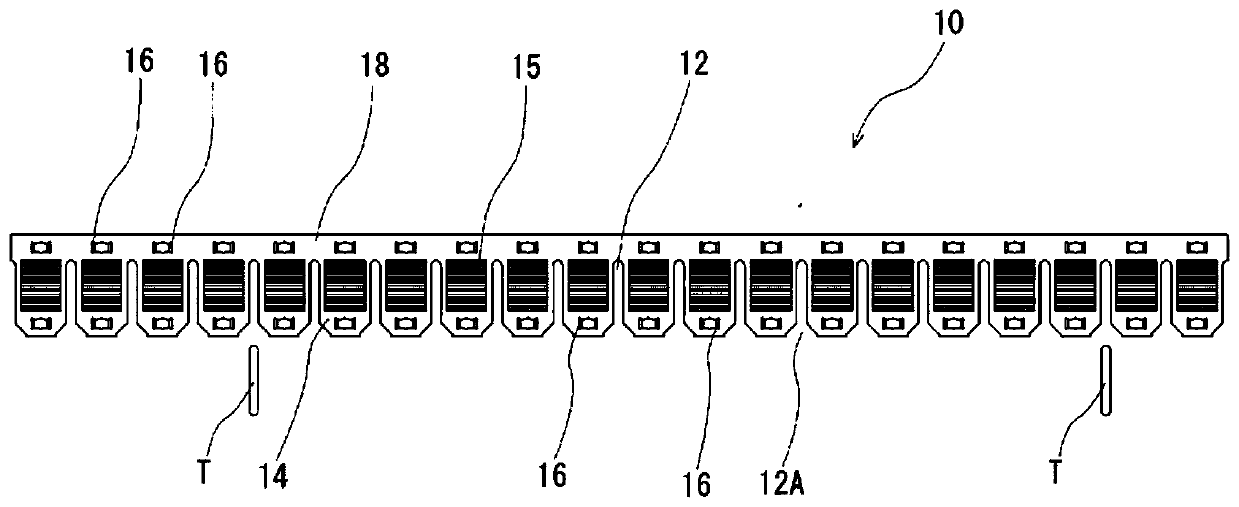

Vehicle seat slide device

InactiveCN102112339AEfficient assembly workSave spaceMovable seatsProduction rateMechanical engineering

A vehicle seat slide device provided with an operation handle uses a reduced number of parts, occupies a reduced space, and is produced with increased productivity. An operation handle (50) is provided with a holding section (52), an application end section (53) for operating a lock-unlock mechanism (30), a shaft support section (57) located between the application end section (53) and the holding section (52) and formed flat so as to be parallel to a vertical wall (21), and a pivot support shaft (60) projecting to the shaft support section (57) in the direction of the center of pivoting of the operation handle (50). The vertical wall (21) has an open holding hole (21a) which has the front side open and in which the pivot support shaft (60) is inserted from an open portion so as to be supported at an inner end section (21c), and also has a holding member (70) for holding the pivot support shaft (60) at the open holding hole (21a).

Owner:AISIN SEIKI KK

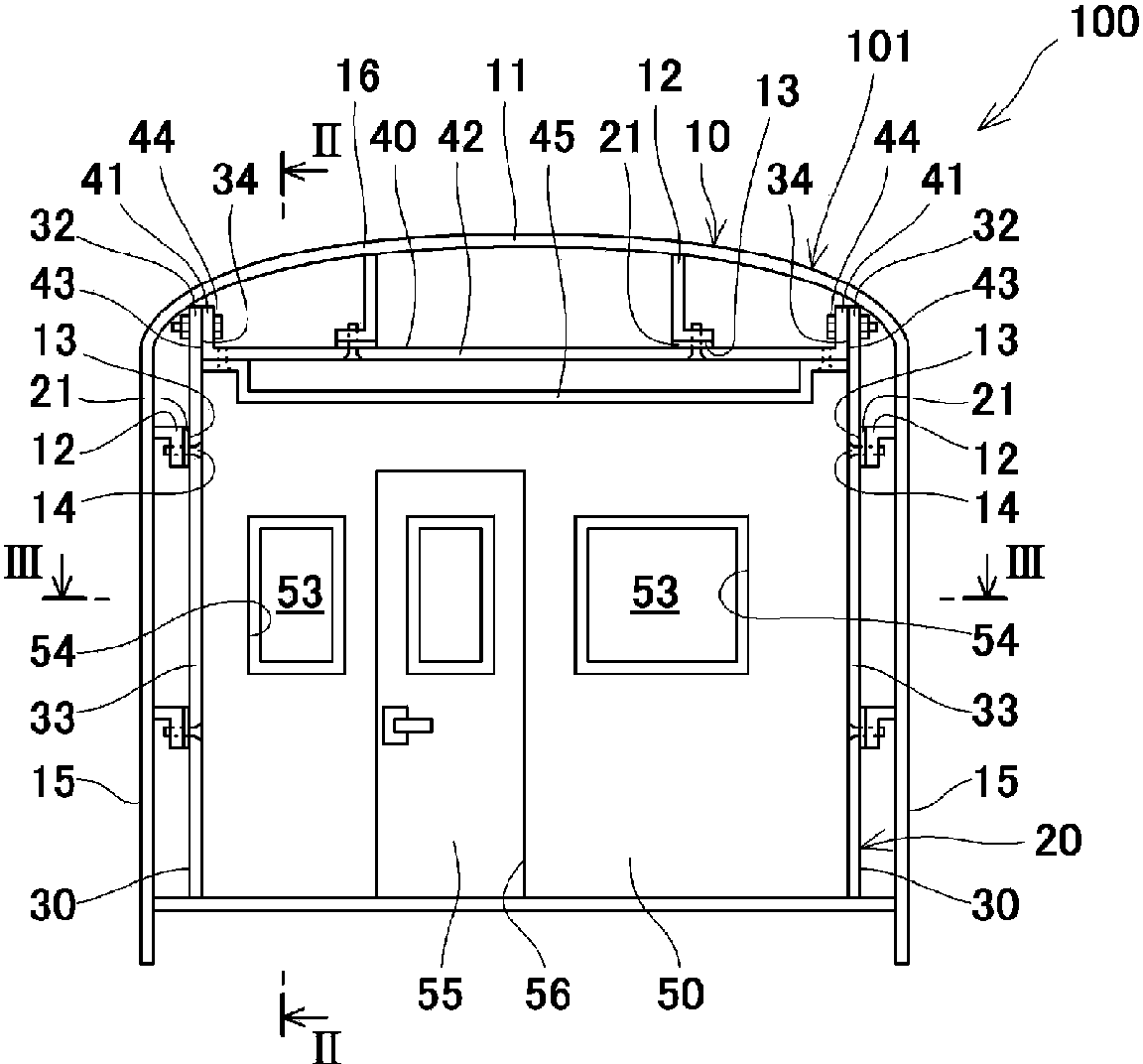

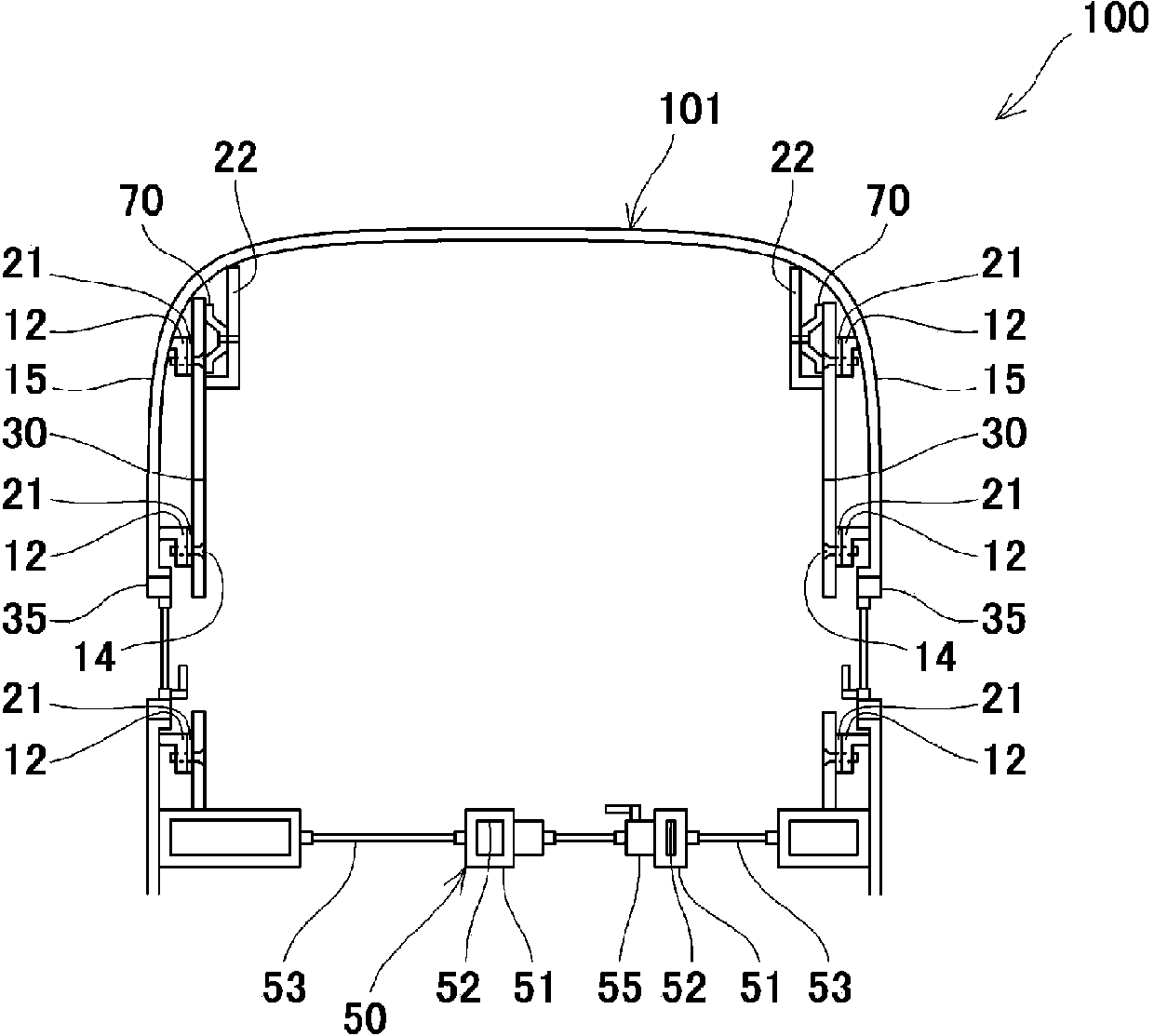

Operator compartment, and railway vehicle equipped with operator compartment

An operator compartment (101) of a railway vehicle (100) is equipped with: lateral structures (15) and a roof structure (16); and an internal panel unit (20) having a pair of lateral panels (30) positioned on the inside of the lateral structures (15), a ceiling panel (40) positioned on the inside of the roof structure (16), and a rear-surface panel (50) for dividing the operator compartment (101) from a passenger compartment. One or more of the plurality of panels has an opening (31) formed therein into which an adjustment member (21) for adjusting the positions of the panel and the lateral structures (15) or the roof structure (16) is insertable. Adjacent panels are connected with one another, demarcating the interior space of the operator compartment (101), and the adjustment member (21) adjusts the position of the demarcated operator compartment (101) in relation to the lateral structures (15) and the roof structure (16).

Owner:KAWASAKI VEHICLE CO LTD

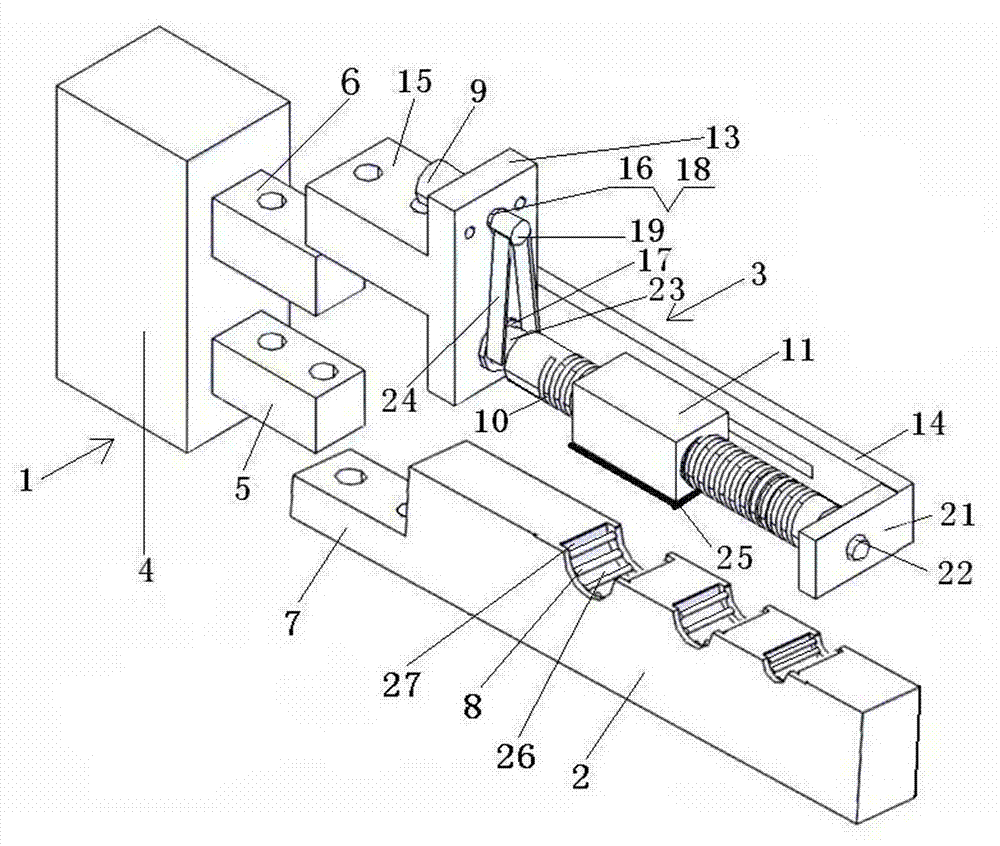

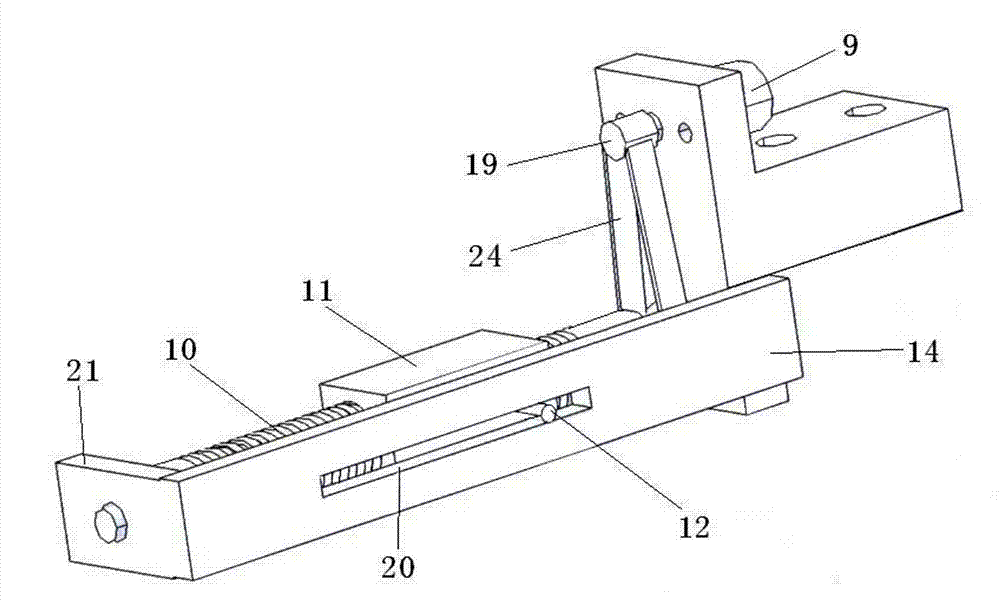

Lead-screw-utilized twisting machine hand claw with fixed wiring harness position

InactiveCN103085079AEfficient assembly workAssembly precisionLine/current collector detailsGripping headsEngineeringManipulator

A lead-screw-utilized twisting machine hand claw with a fixed wiring harness position comprises a machine hand, parallelly moving fingers and twisting fingers. The machine hand comprises a machine hand base seat, a parallellly moving finger base seat and a twisting finger base seat. A moving finger connecting plate is integrally arranged on the parallelly moving fingers which are provided with wiring harness position fixing grooves, roller pin grooves are placed inside the wiring harness position fixing grooves, and roller pins are arranged inside the roller pin grooves. The twisting fingers comprise a support frame, a motor, a lead screw and a sliding block. The support frame comprises a motor base seat and a sliding rod limiting plate, wherein a twisting finger connecting plate is integrally connected with the motor base seat, the motor is fixed on the motor base seat, and a first belt pulley is placed on an output shaft of the motor. The sliding rod limiting plate is provided with a sliding groove and fixedly connected with the motor base seat, two end shafts of the lead screw are placed on a lead screw support plate and the motor base seat respectively, and the sliding block can slide in the sliding groove. According to the lead-screw-utilized twisting machine hand claw with the fixed wiring harness position, terminal direction of wiring harnesses can be adjusted accurately to enable the terminal direction of the wiring harnesses to be matched with a jack socket of a connector, and accurate assembly is achieved.

Owner:SHENYANG LIGONG UNIV

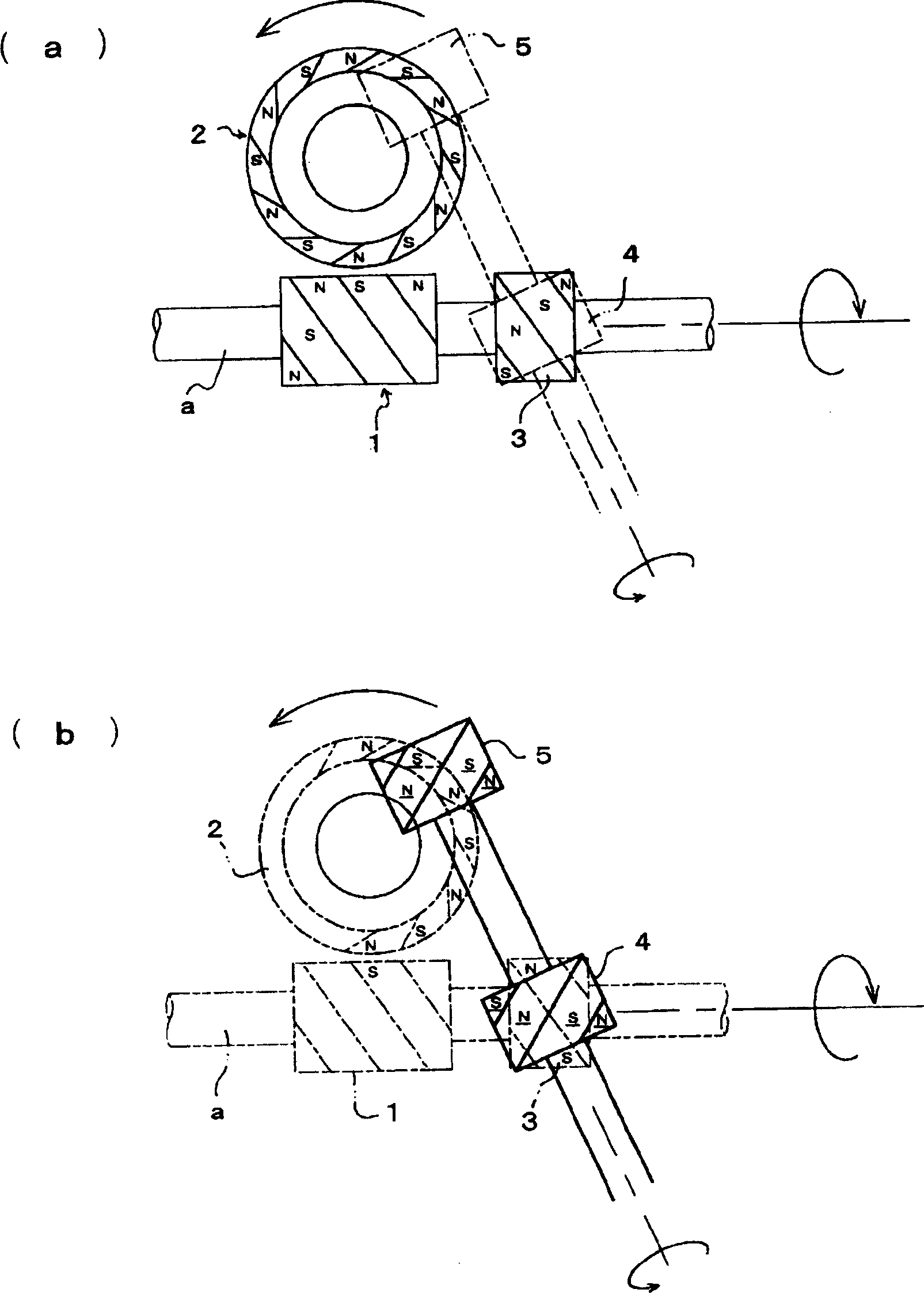

Driving device

InactiveCN1674419AReduce coggingEfficient assembly workManufacturing dynamo-electric machinesNon-mechanical conveyorsTransmission systemHigh torque

The present invention provided a drive unit utilizing magnetism which generates high torque and increases torque without enlarging the diameters of a driving magnetic wheel and a driven magnetic wheel. This driving unit, which rotates a shaft b to which a roller is attached by a power transmission mechanism in noncontact making use of magnetic force, transmits power from the driving magnetic wheel 1 to the driven magnetic wheel 2 to which the roller shaft b is attached, by means of two or more transmission systems, and totals the power to rotate the shaft to which the above roller is attached.

Owner:MARUYASU KIKAI KK

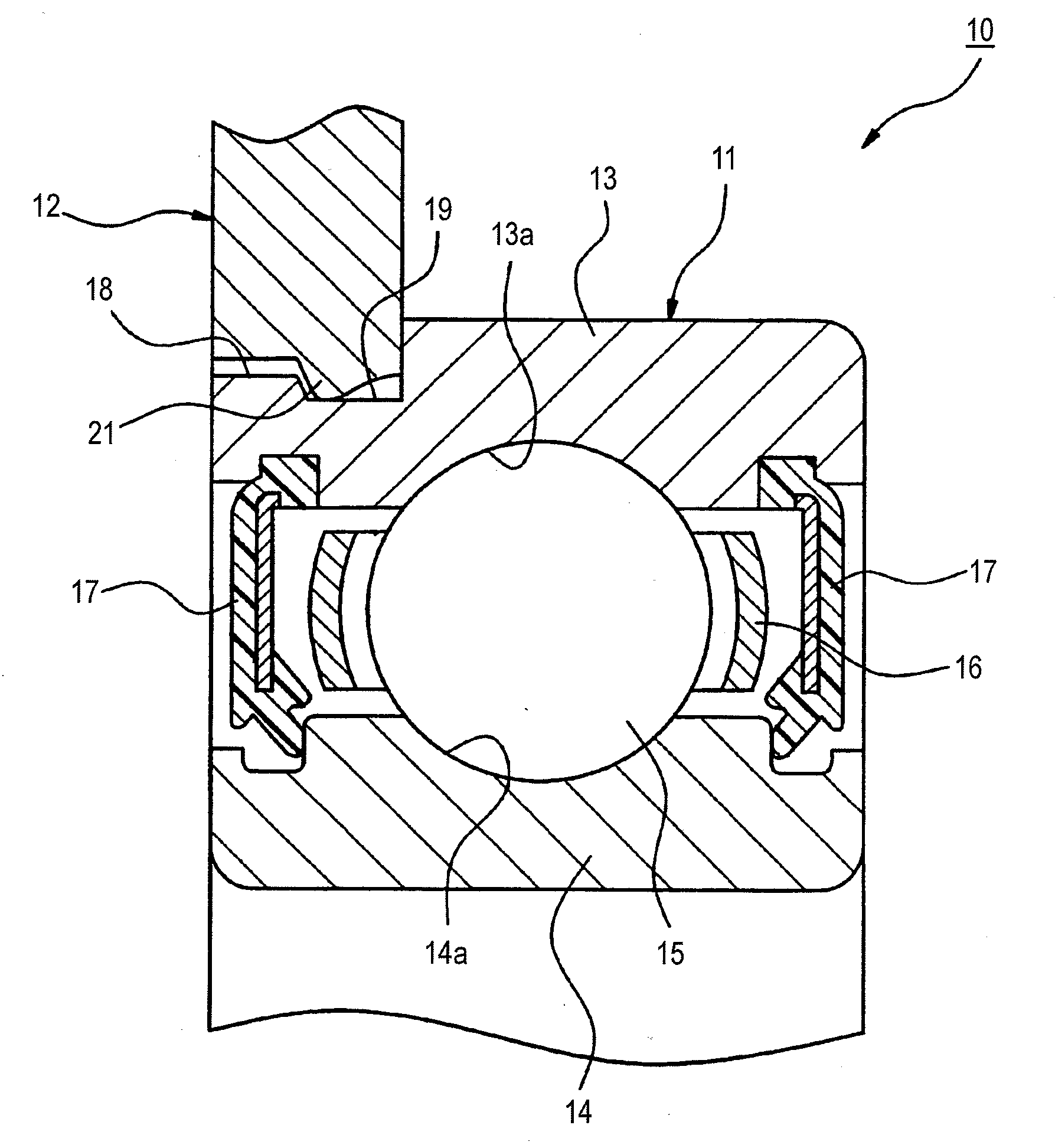

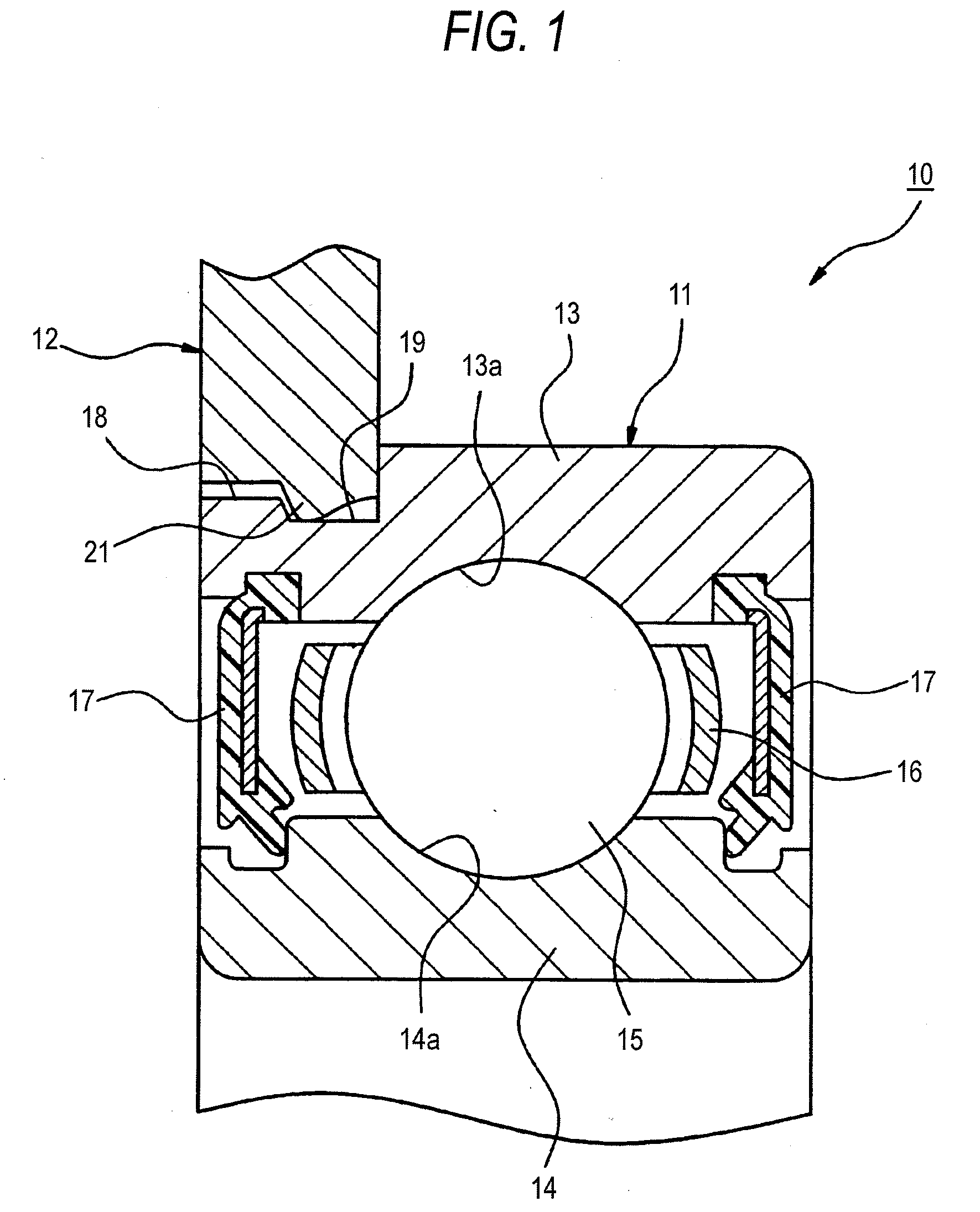

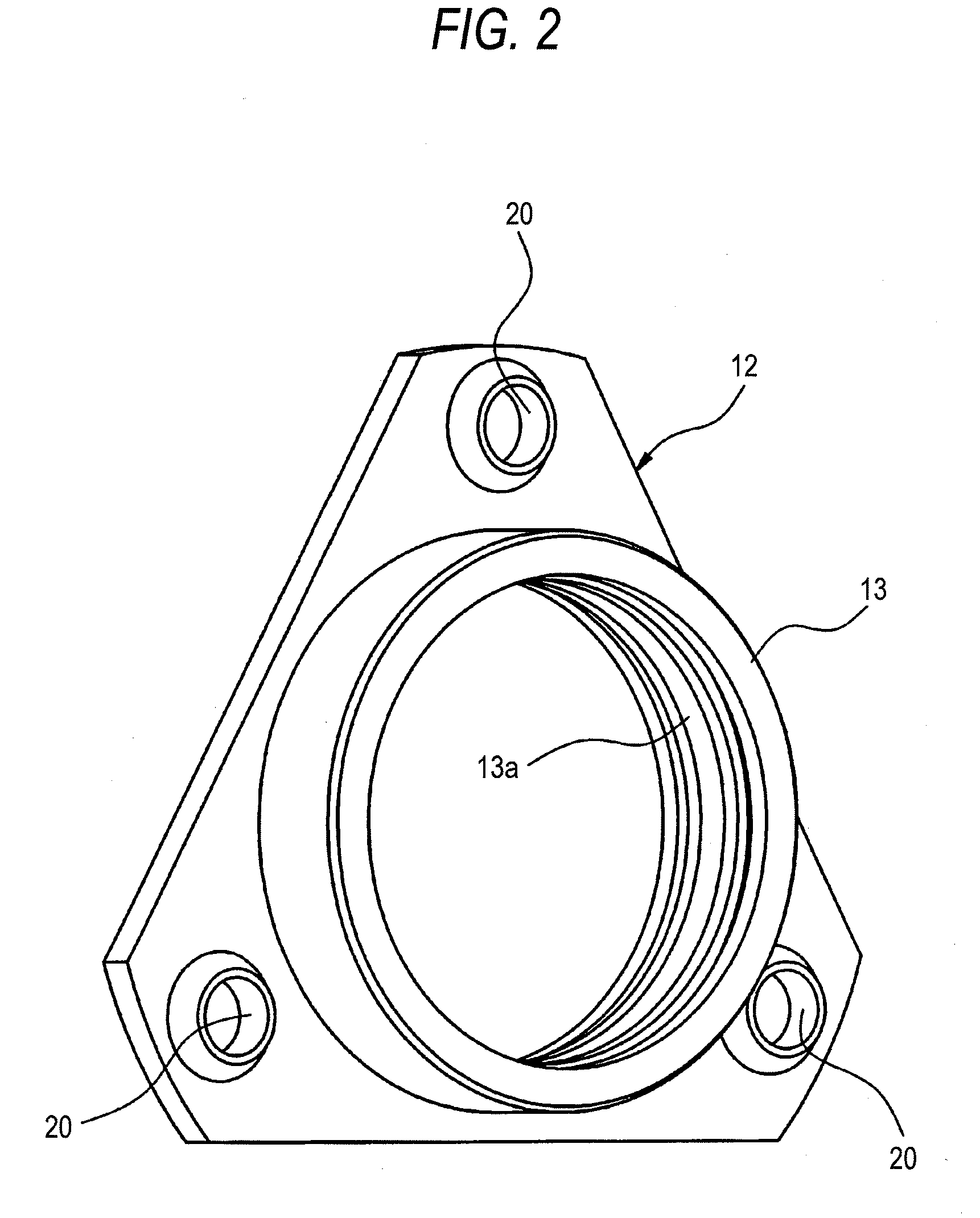

Assembling method of bearing unit

ActiveUS20090056135A1Efficient assembly workImprove productivityBearing assemblyBall bearingsMechanical engineeringEngineering

There is provided an assembling method of a bearing unit which has a bearing having an outer ring and a retainer plate having a retainer hole for holding the outer ring. The assembling method has pressing a plurality of portions in a circumferential direction of a circumferential edge of an inner circumferential portion of the retainer hole of the retainer plate in an axial direction so as to form engagement pawls and moving the engagement pawls of the retainer plate from one axial end of the outer ring to a engagement groove formed on an outer circumferential surface of the outer ring so as to engage the engagement pawls of the retainer plate with the engagement groove of outer ring.

Owner:NSK LTD

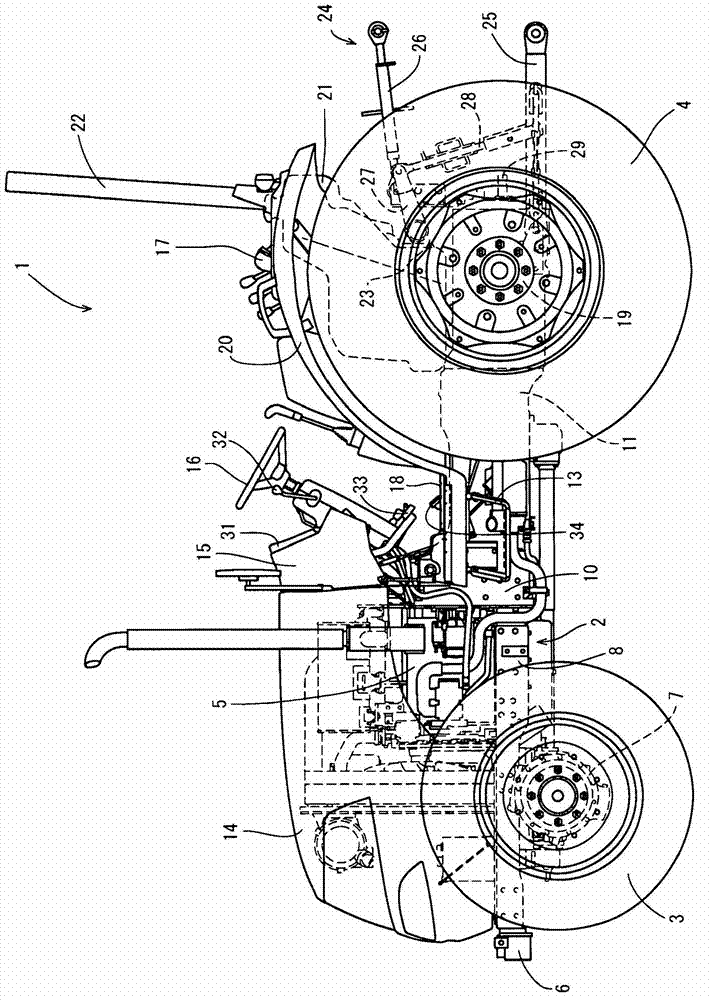

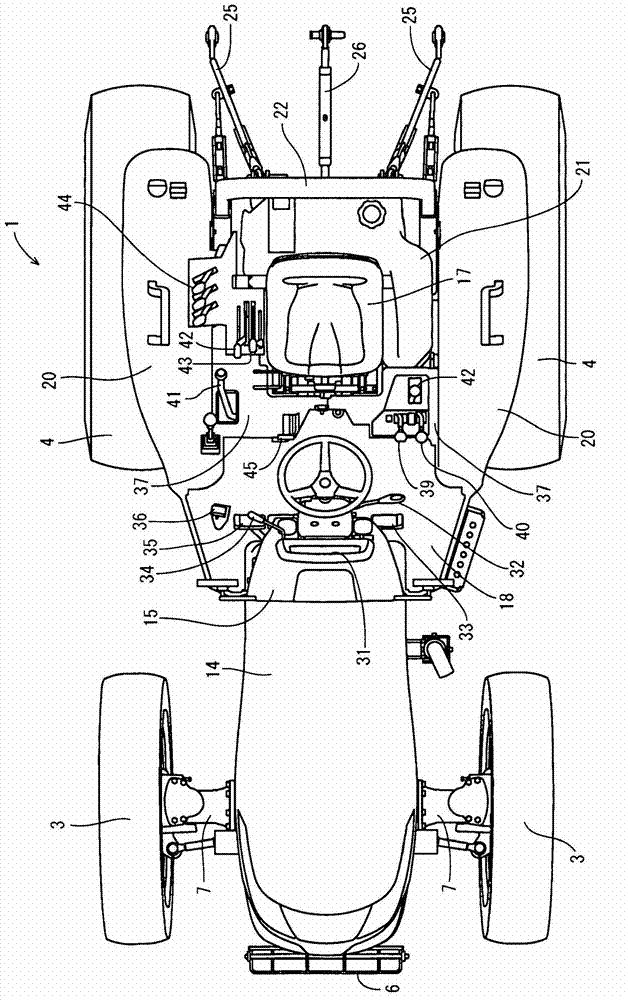

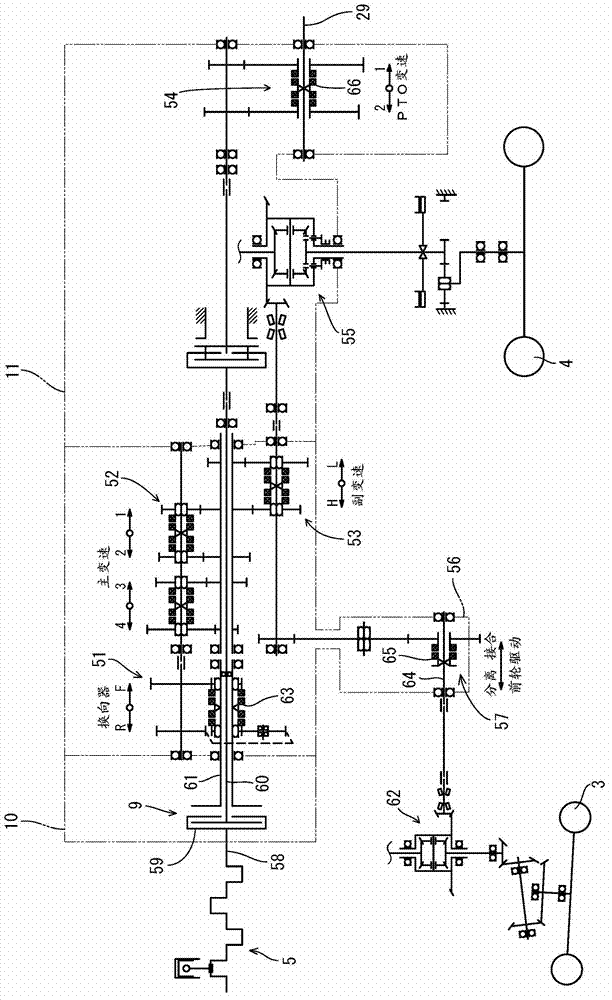

Work vehicle

It is possible to stably and compactly position a large-volume fuel tank in a work vehicle such as a tractor. A traveling body (1) has a seat bracket (16) supported by a transmission case (11) and a rear housing (217). A steering seat (12) is mounted to the seat bracket (16). When seen in planar view, a fuel tank (26) appears substantially L-shaped and wraps around the rear and right side of the steering seat (12). The fuel tank (26) is supported by the seat bracket (16). The fuel tank (26) is positioned so as to make use of the dead space around the steering seat (12); therefore, even in the case that the fuel tank (26) is a large-volume tank, the traveling body (1) can be compactly made. The seat bracket (16) for supporting the steering seat (12) is also used to support the fuel tank (26); therefore, it is possible to prevent complication of structure.

Owner:YANMAR POWER TECHNOLOGY CO LTD

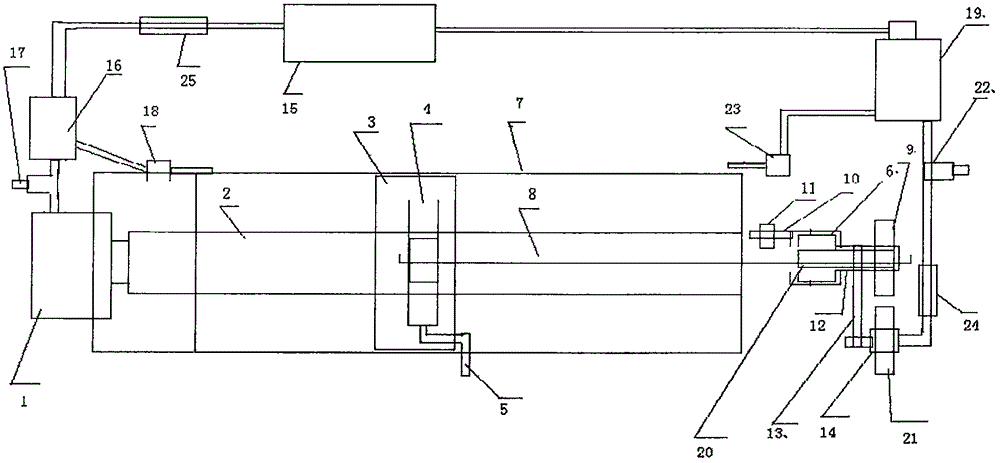

Automatic assembly line and technology for solar photo-thermal heating equipment

PendingCN111421339ATo achieve the purpose of automated assemblyImprove assembly efficiencyAssembly machinesThermodynamicsControl system

The invention provides an automatic assembly line and technology for solar photo-thermal heating equipment. The automatic assembly line comprises a plurality of stations, a transporting system and a control system; the transporting system comprises a plurality of pallets moving in the forward direction of the operation working procedure, and the pallets are suitable for supporting the solar photo-thermal heating equipment in the assembly process; and the control system controls start and stop of the transporting system so as to enable a bottom plate to serve as an assembly standard piece of the whole assembly process to complete the assembly working procedure of the solar photo-thermal heating equipment starting from the bottom plate. According to the automatic assembly line and technology, assembly is started from the bottom plate of the solar photo-thermal heating equipment, the bottom plate serves as the assembly standard piece of the whole assembly process, the solar photo-thermalheating equipment is assembled in a mode of transmitting of the transporting system, assembly operation is achieved in a form of automatic transferring of a conveying system, thus the purpose of automatic assembly is achieved, assembly operation on the assembly line is achieved through cooperation of labor, and the purposes of high assembly efficiency and high quality are achieved.

Owner:河南日昇源集成科技有限公司

Embossing plate roller surface defect detection device

PendingCN114324400AReduce the risk of getting involvedQuick assemblyTypewritersOptically investigating flaws/contaminationDrive wheelElectric machinery

The invention provides an embossing plate roller surface defect detection device, and relates to the technical field of embossing plate roller surface defect detection.The embossing plate roller surface defect detection device comprises a base, a main body of the base is of a rectangular structure, transverse grooves are formed in the front side and the rear side of the top end of the base and used for sliding a pedestal, and a support is further fixedly connected to the top end of the base; a spraying box is further arranged on the top end face of the support, a round hole is further formed in the center of the interior of the spraying box and matched with the insertion pipe, and a spraying frame is further arranged at the bottom end of the insertion pipe, so that the problems that in the existing comparison process, due to the difference of the length and the diameter of the plate roller, observation difference exists, and missing detection is prone to occurring are solved; a frame body driven by an electric push rod A is arranged at the top end of the base, and a driving wheel which is arranged at the bottom end of the frame body and driven by a motor A can be matched with a guide wheel mounted at the top end of the base body to quickly limit and drive the printing rollers of different specifications, so that the self-adaptive detection of the printing rollers is realized.

Owner:LONGYOU YUNCHENG PRESS GRAIN PLATE MAKING

Automatic wire harness machine

InactiveCN106847423AWind evenlyPrecise automatic windingInsulating conductors/cablesProduction lineEngineering

The invention discloses an automatic wire harness machine. The basic structure includes a base, a power supply, a stroke traction part and a working part. The invention solves the automation problem of the winding process in the wire harness processing process, and can solve the complex winding process in the wire harness production process. Simplify, and can greatly reduce the heavy physical labor and workload in the production process of wire harness winding, so that the original wire winding work in the wire harness production line has changed from manual operation to machine operation, to a greater extent Reduce labor requirements, reduce production costs, improve production efficiency and product quality.

Owner:李星明

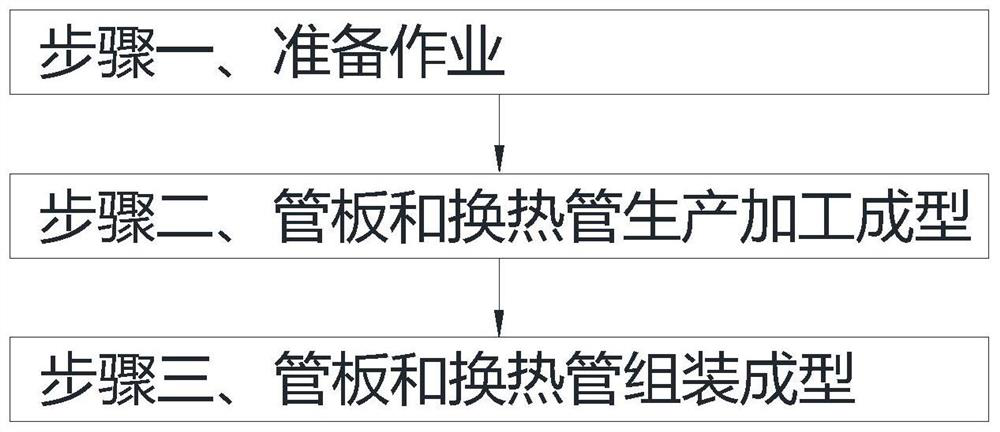

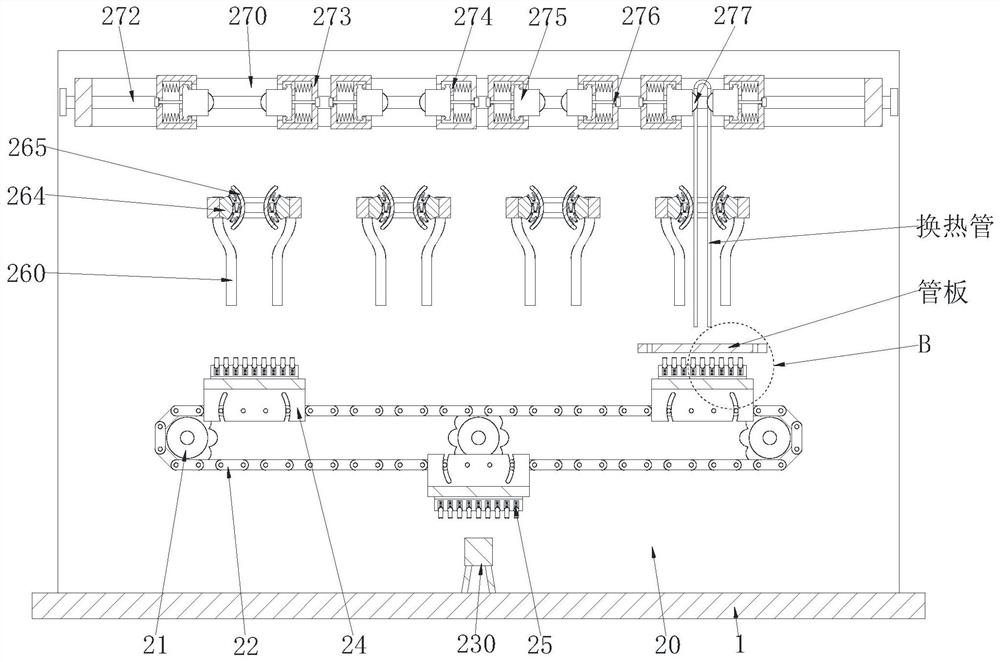

Tubular heat exchanger manufacturing and processing technology

The invention relates to a tubular heat exchanger manufacturing and processing technology. The technology uses tubular heat exchanger manufacturing and processing equipment, the tubular heat exchanger manufacturing and processing equipment comprises a base and an assembling device, and the assembling device is arranged on the upper surface of the base. The equipment can solve the current problems that heat exchange tubes are of U-shaped structures, so that the heat exchange tubes are manually mounted on a tube plate one by one according to specifications from small to large, the manual mounting efficiency is lower, the production efficiency of the heat exchanger is influenced, moreover, indentations or creases are easy to appear on the surfaces of the heat exchange tubes when the tube plate and the heat exchange tubes are manually assembled, so that the use value of the heat exchange tubes is reduced, the quality of the heat exchanger is influenced, although the tube plate is firmly fixed, the tube plate and the heat exchange tubes are not very convenient to place and take down before and after being assembled, opening and closing of clamping equipment need to be manually controlled, the assembling efficiency of the tube plate and the heat exchange tubes is affected, and certain personal safety is brought to workers.

Owner:XIAN JUYUAN INFORMATION TECH CO LTD

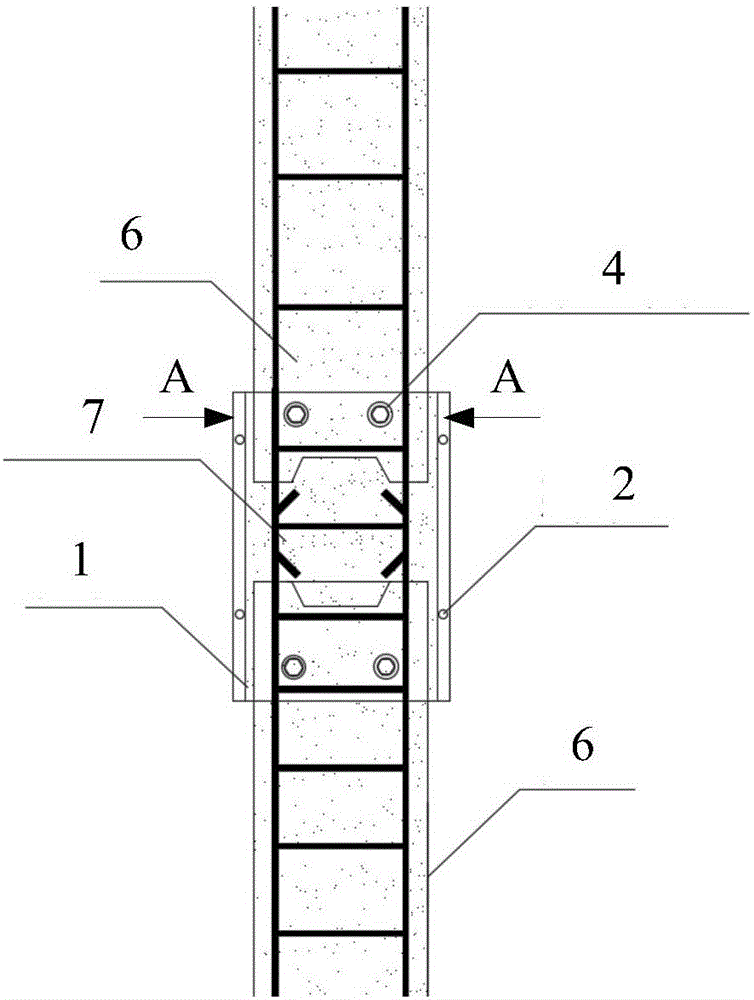

Formwork of prefabricated concrete column and mounting method of formwork

ActiveCN106738232ACompact installationThe installation is tight and firmMouldsMould fastening meansStructural engineeringEngineering

The invention provides a formwork of a prefabricated concrete column and a mounting method of the formwork. The formwork of the prefabricated concrete column is formed by connecting Z-shaped formwork units through two side plates. The two side plates comprise the first side plate and the second side plate. The first side plate is provided with a first extension section. The second side plate is provided with a vertical extension section. Bolt holes are formed in the first extension section and the vertical extension section correspondingly. Through bolts which penetrate through the bolt holes in the first extension section and the vertical extension section to diagonally splice the two Z-shaped formwork units together, it can be ensured that the concrete formwork does not incline outwards, concrete pouring formation is guaranteed, and fixing pipes do not need to be erected on the periphery of the formwork; cost is greatly reduced, splicing can be conducted directly, efficient and convenient assembling is achieved, and the construction period is shortened; and by adoption of the formwork of the prefabricated concrete column, firm and tight mounting can be guaranteed, slurry leakage is avoided, mounting and dismounting are fast and convenient, assembling efficiency is improved, and the construction period is shortened.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

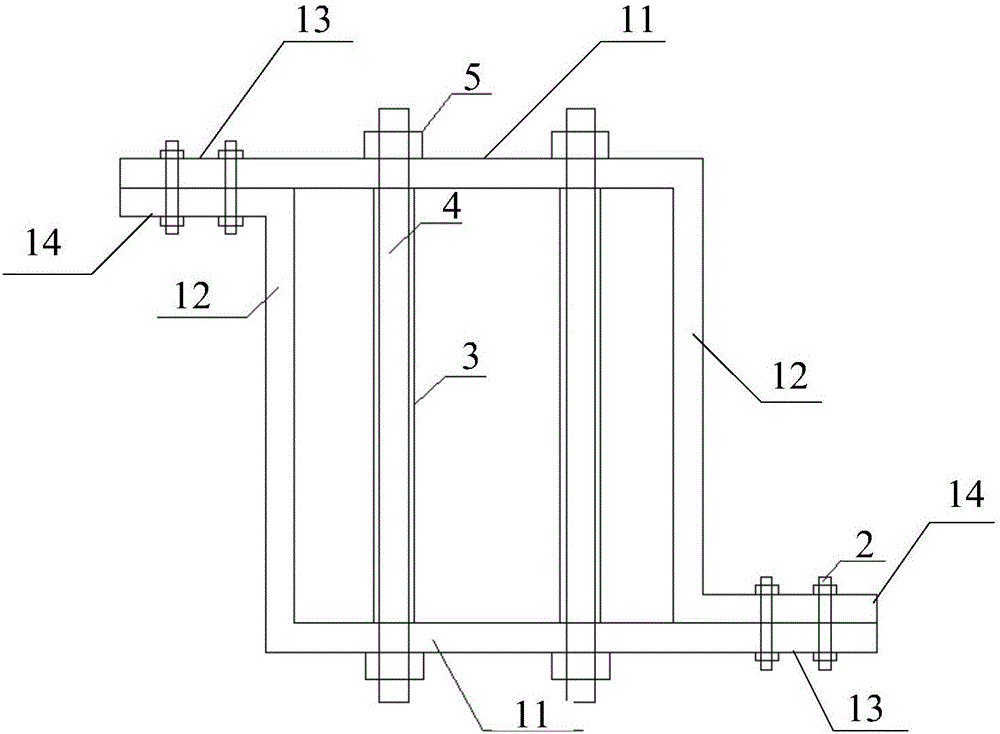

A vertical motor assembly apparatus and a motor assembly method

PendingCN108988585AReduce workloadReduce work intensityManufacturing dynamo-electric machinesEngineeringMechanical engineering

The invention relates to a vertical motor assembly apparatus, comprising a frame, a positioning center is arranged on the frame, and the vertical motor assembly further comprises an upper mandrel pushing mechanism and a lower mandrel pushing mechanism. The positioning center is arranged between the upper spindle pushing mechanism and the lower spindle pushing mechanism, and coincides with the centerline of the upper spindle pushing mechanism and the lower spindle pushing mechanism. Stator assembly pushing mechanism and rotor assembly pushing mechanism respectively arranged at the front and rear sides of the positioning center; Left and right stator assembly clamping devices arranged on the left and right sides of the positioning center; The controller is respectively connected with an upper spindle pushing mechanism, a lower spindle pushing mechanism, a stator assembly pushing mechanism, a rotor assembly pushing mechanism and a left and right stator assembly clamping devices. Also disclosed is a motor assembly method of a vertical motor assembly apparatus. The invention can reduce the workload and the working intensity of the workers, improve the installation precision, reduce thecost and simplify the operation.

Owner:浙江巨龙自动化设备股份有限公司

Paperboard barrel bottom assembly device

PendingCN112140634ASimple structureRun smoothlyBox making operationsPaper-makingTransfer mechanismEngineering

The invention discloses a paperboard barrel bottom assembly device, and belongs to the technical field of paperboard barrel bottom assembly. The paperboard barrel bottom assembly device comprises a base, an assembly component, a feeding device and a feeding mechanism, wherein the assembly component used for pushing paperboard materials into a paperboard barrel is arranged on the base; the feedingdevice used for feeding a paperboard material mechanism into the board material position of the assembly component is arranged on the assembly component; and the feeding mechanism used for feeding thepaperboard barrel into the barrel position of the assembly component is arranged on the base and located on the right side of a transfer mechanism. The paperboard barrel bottom assembly device is simple in structure, convenient to operate, high in stability, convenient to popularize and reliable in work, all component mechanisms are efficiently matched for work, and assembly work can be efficiently and stably completed.

Owner:枣阳德立智机械制造有限公司

Curtain wall connecting equipment for green building decoration

The invention provides curtain wall connecting equipment for green building decoration, and relates to the technical field of curtain wall back bolt type connection. The problems that a curtain wall cannot be effectively fixed if the angle of a supporting cross beam is slightly inclined, effective vibration reducing and energy dissipation effects cannot be achieved, and the curtain wall is damaged caused by connecting piece breakage when being suffered impact force are solved. The curtain wall connecting equipment comprises back bolt sliding plates, a main supporting plate is connected to the top end position of the interior of an auxiliary supporting plate in an inserted mode, the main supporting plate and the auxiliary supporting plate which are connected in an inserted mode can be connected to the upper portion and the lower portion of the two back bolt sliding plates in a screwed mode correspondingly, in the screwing process, and the transverse displacement of the main supporting plate and the auxiliary supporting plate within a certain distance can be adjusted according to actual needs. The design can avoid the problem that after a traditional dry-hanging curtain wall and a wall face are fixed, holes need to be perforated again when the dry-hanging curtain wall and the wall face need to be transversely moved by a short distance, and then the rigidity of the supporting cross beam is reduced.

Owner:姚宏揆

Curtain wall for green building decoration

The invention provides a curtain wall for green building decoration, and relates to the technical field of curtain wall back-bolt type connection. The problems that if the angle of a supporting cross beam is slightly inclined, the curtain wall cannot be effectively fixed, the effective damping and energy dissipation effects cannot be achieved, and the situation that when the curtain wall is subjected to impact force, the curtain wall is damaged due to the fact that a connecting piece is broken is likely to happen are solved. The curtain wall comprises back-bolt sliding plates, a main supporting plate is inserted into the top end of the interior of an auxiliary supporting plate, the main supporting plate and the auxiliary supporting plate which are inserted can be screwed to the upper portions and the lower portions of the two back-bolt sliding plates correspondingly, and in the screwing process, transverse displacement of the main supporting plate and the auxiliary supporting plate within a certain distance can be adjusted according to actual needs. According to the design, the problem that after a traditional dry-hanging curtain wall and a wall face are fixed, transverse moving is needed for a short distance, punching needs to be conducted again, and then the rigidity of the supporting cross beam is reduced can be avoided.

Owner:姚宏揆

Thin sheet with movable contact and button switch utilizing the same sheet

The present invention provides a sheet with movable contacts comprises: a first movable contact 3; a second movable contact 4 having a greater stroke from the reversal of an inner surface of a swollen part by pressing to its making contact with a central fixed contact than the first movable contact 3; a first sheet 1 having accommodating holes 1a, 1b capable of accommodating the first and second movable contacts 3, 4; and a second sheet 5 holding the first and second movable contacts 3, 4 at the back surface thereof with an adhesive portion 5a and closing the top of the accommodating holes 1a, 1b of the first sheet 1. One of the first and second sheets 1, 5 is used as a common sheet to be equipped with the first and second movable contacts 3, 4 together. The first sheet 1 is designed to have a uniform thickness according to the difference between strokes of the first movable contact 3 and the second movable contact 4, so that the height at which the first and second movable contacts 3, 4 are held by the second sheet 5 is adjusted.

Owner:ALPS ALPINE CO LTD

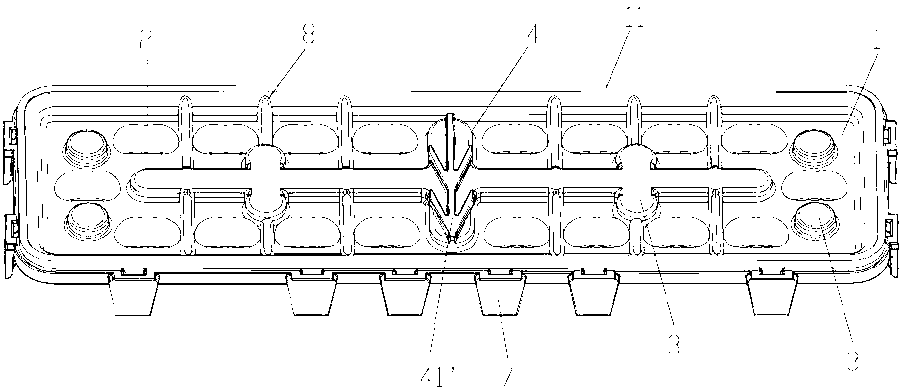

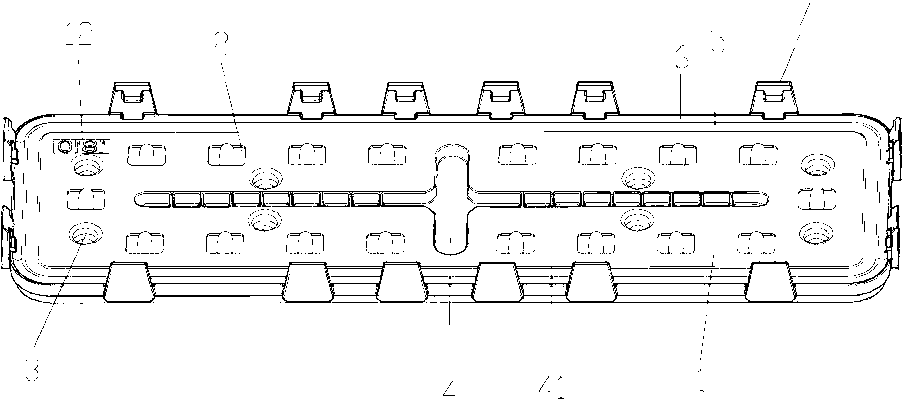

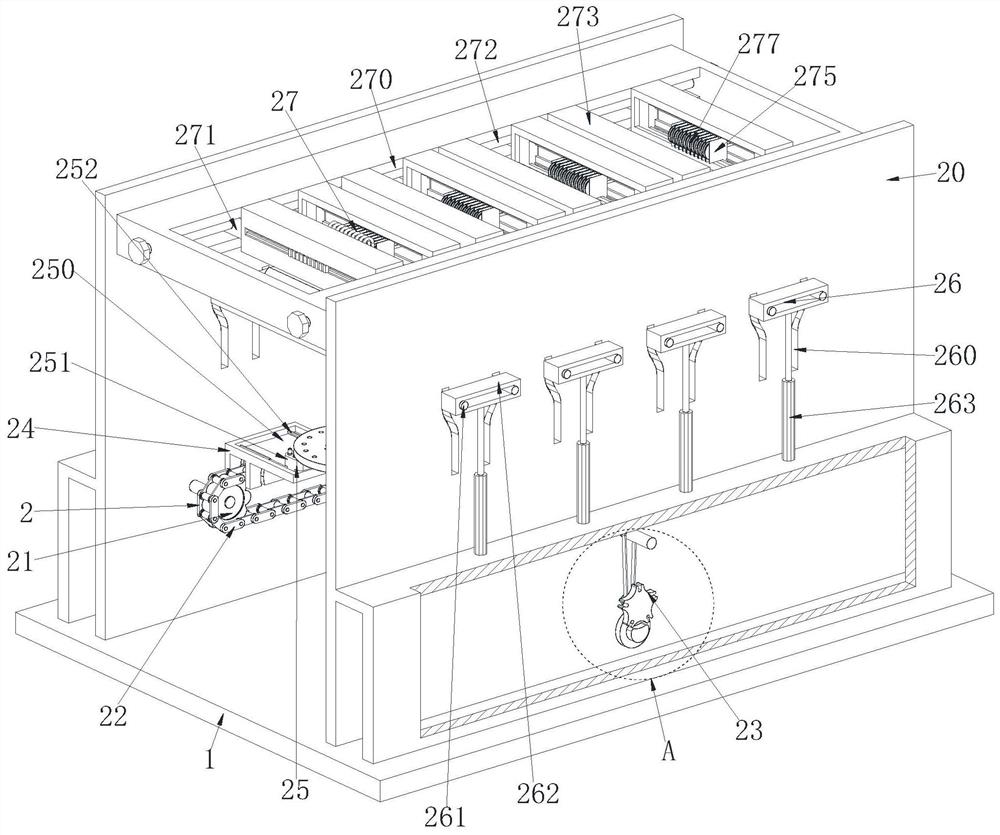

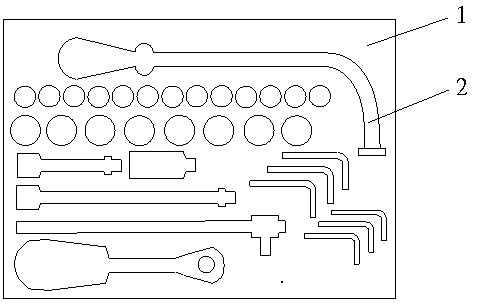

Trail management tray

InactiveCN109605311ARealize trace managementEliminate omissionsWork tools storageAviationSpaceflight

The invention relates to the technical field of protection devices for spaceflight, aviation and mechanical manufacturing industry production field management, in particular to a trail management tray. The trail management tray comprises a tray body, the tray body is formed by upper high-molecule material and a lower high-molecule material in a composited mode, the colors of the upper high-molecule material and the lower high-molecule material are different, a plurality of stereo clamping groove positions used for storing components, parts and tools are formed in the tray body, and as for thearrangement mode, the stereo clamping groove positions are spatially arranged according to the demounting and mounting order of the components and the parts or according to the sequential use order ofthe tools. According to the trail management tray, trail management of the components, the parts and the tools is achieved, a worker is assisted and guided to complete disassembling and assembling work accurately and efficiently, and omission and loss of the components, the parts and the tools are effectively eradicated.

Owner:黑龙江省德科精密机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com