Embossing plate roller surface defect detection device

A defect detection and embossing plate roller technology, which is applied in the direction of measuring devices, optical testing blemishes/defects, cleaning methods and utensils, can solve the problems of false detection of dust and other particles, affecting embossing processing, and surface defects, etc., to achieve Efficient assembly operations, reduced manual intervention, and reduced risk of involvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

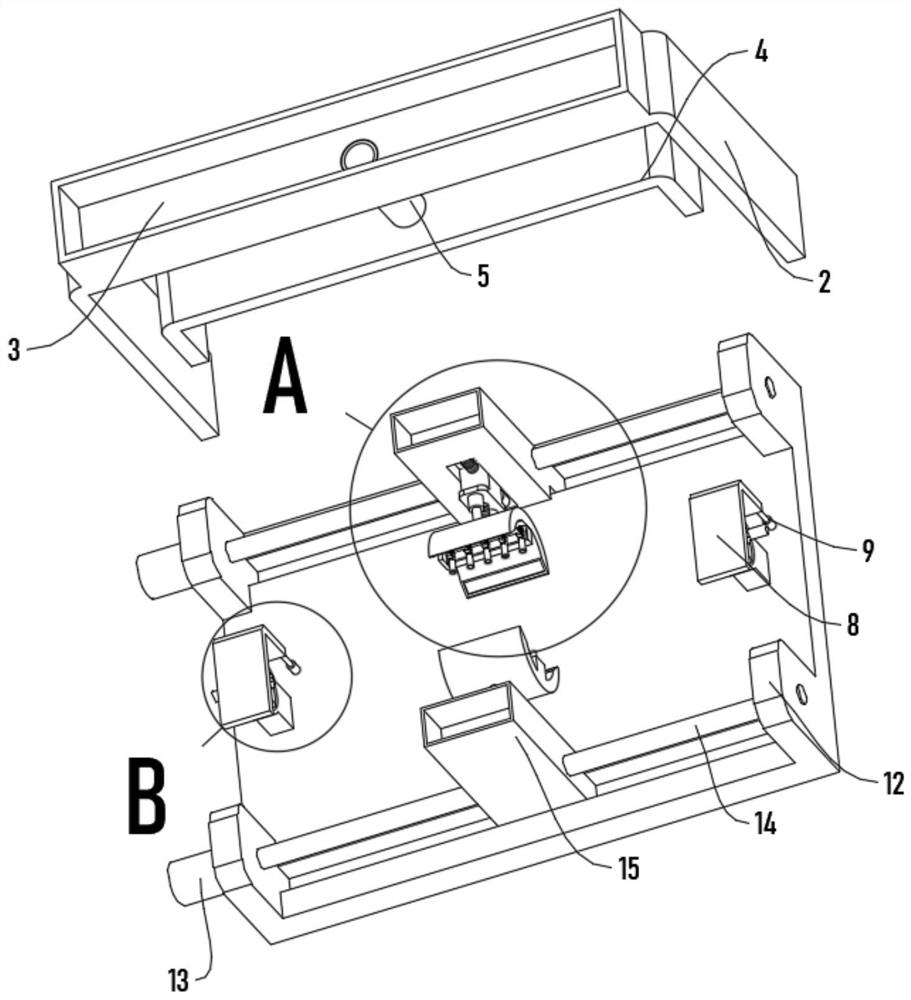

[0032] Example: Please refer to Figure 1 to Figure 8 :

[0033]The present invention proposes a surface defect detection device for embossed plate rollers, comprising: a base 1, the main body of the base 1 is a rectangular structure, and the front and rear sides of the top of the base 1 are provided with transverse grooves, the transverse grooves are used for sliding the pedestal 15, The top of the base 1 is also fixedly connected with a support 2, and a spray box 3 is also arranged on the top surface of the support 2, and a circular hole is also provided in the inner center of the spray box 3, and the circular hole matches the intubation tube 5. The bottom end of the intubation pipe 5 is also provided with a spray frame 4, and the bottom end of the spray frame 4 is also provided with a spray pipe in a rectangular array. When the intubation pipe 5 is flush with the bottom surface of the spray box 3, the spray box The liquid in 3 flows into the spray rack 4 through the intuba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com