Pneumatic adjustable remote center compliance device

A pneumatic and compliant technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the inertia of the assembly system, increasing the mass and volume of the compliant device, and being unable to apply to occasions where the size of the parts is variable, to ensure Efficient execution and the effect of increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

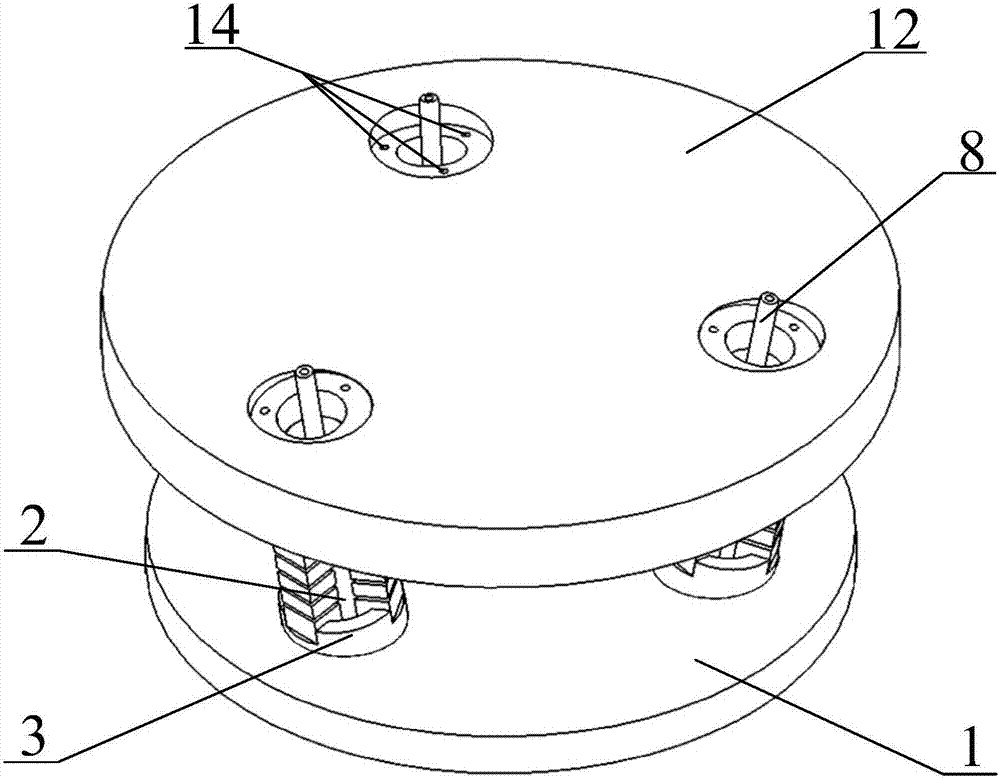

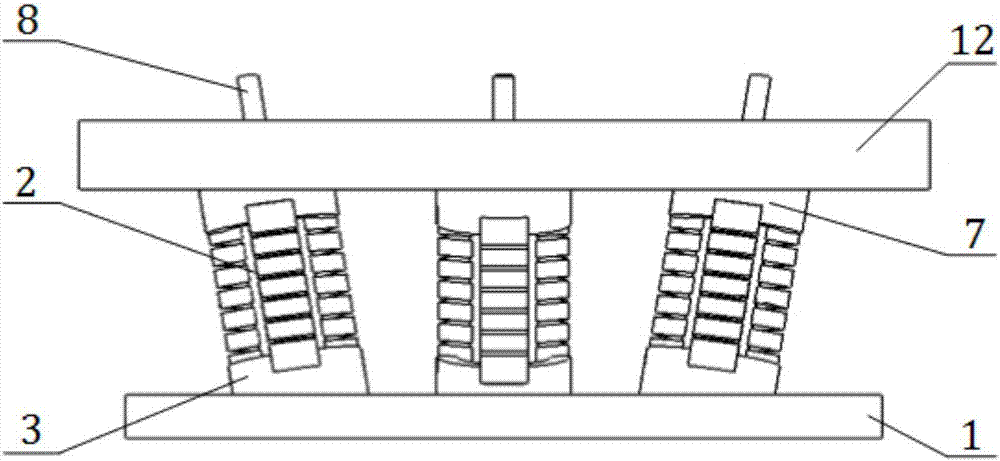

[0035] Such as figure 1 with figure 2 As shown, this embodiment includes: a moving platform 1, three adjustable elastic units 2 and a fixed platform 12, wherein: the moving platform 1 and the fixed platform 12 are arranged up and down oppositely, and the adjustable elastic unit 2 is used to fix the center of circle of the outer end surface of the platform 12 A circumferential ring array is used as the center, and it is arranged obliquely between the moving platform 1 and the fixed platform 12;

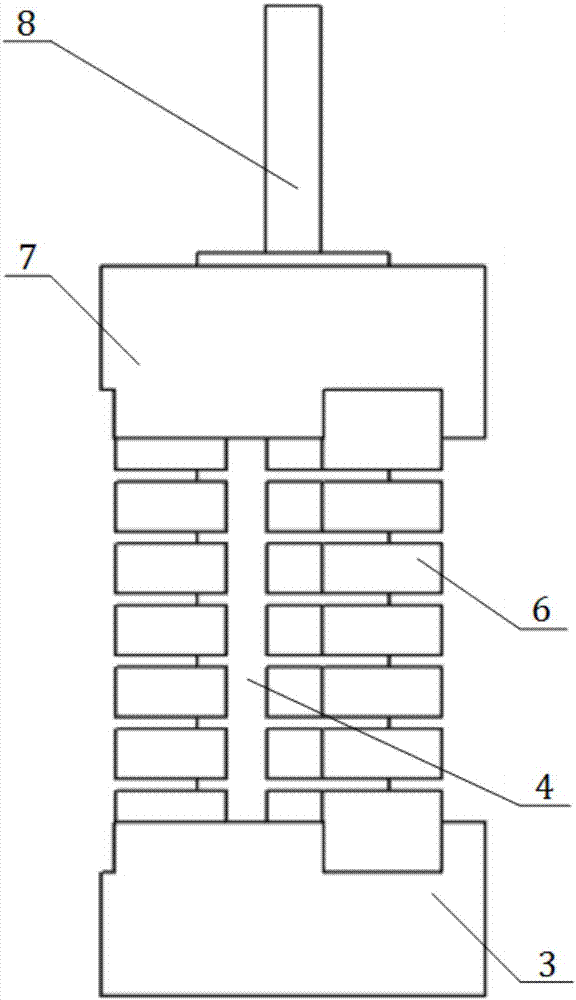

[0036] Such as image 3 , Figure 4 with Figure 8 As shown, the adjustable elastic unit 2 includes: an upper base 7 arranged coaxially, a lower base 3, a three-lobed multi-chamber adjustable elastic structure 4, a laminated elastic structure 9 and an air path joint 8, wherein: There are three airway grooves 19 outside the circumference of the laminated elastic structure 9. The three-petal multi-lumen adjustable elastic structure 4 is sleeved and fixed on the laminated elastic str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com