Battery pack and manufacturing method therefor

A technology of battery components and batteries, which is applied to battery components, batteries, electrical components, etc., and can solve problems such as difficulty in improving the efficiency of assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described below with reference to the drawings. In addition, the following embodiment is an example which actualized this invention, and does not limit the technical scope of this invention.

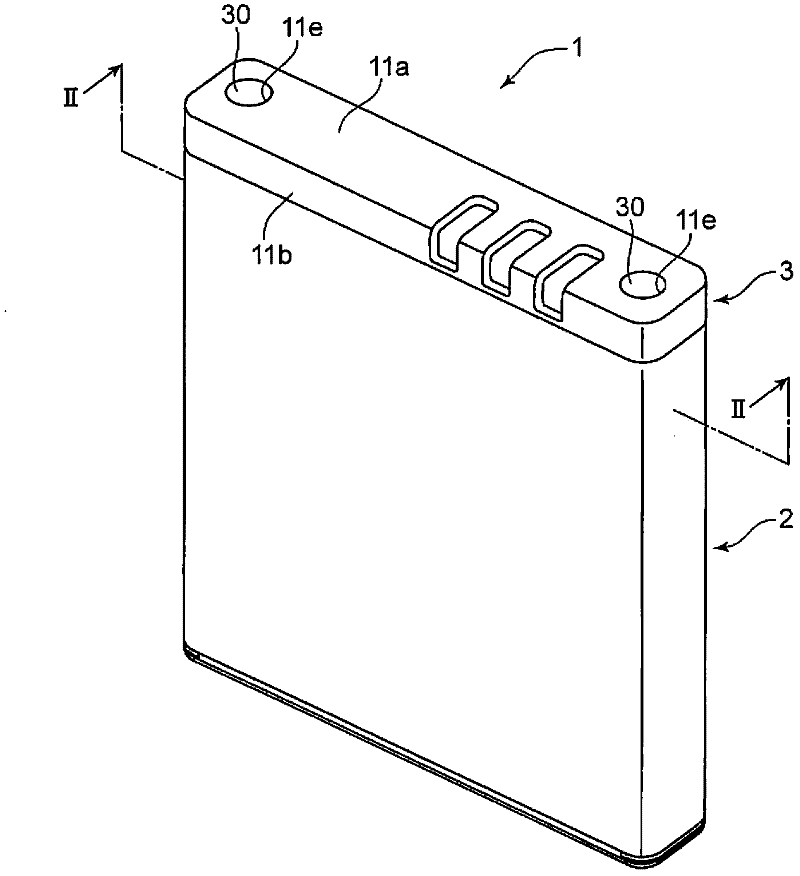

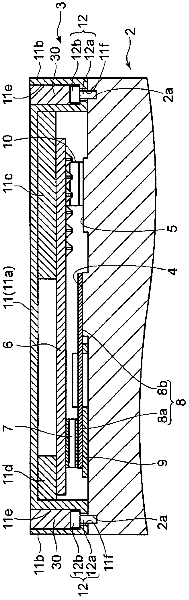

[0019] figure 1 It is a perspective view showing the overall structure of the battery pack according to the embodiment of the present invention. figure 2 yes figure 1 The II-II line sectional view.

[0020] refer to figure 1 with figure 2 A battery pack 1 includes a thin plate-shaped battery 2 and an end surface (hereinafter referred to as an up-down direction) fixed to the battery 2 in a direction perpendicular to a thickness direction (hereinafter referred to as a left-right direction) (hereinafter referred to as a vertical direction). figure 1 Safety component 3 in above).

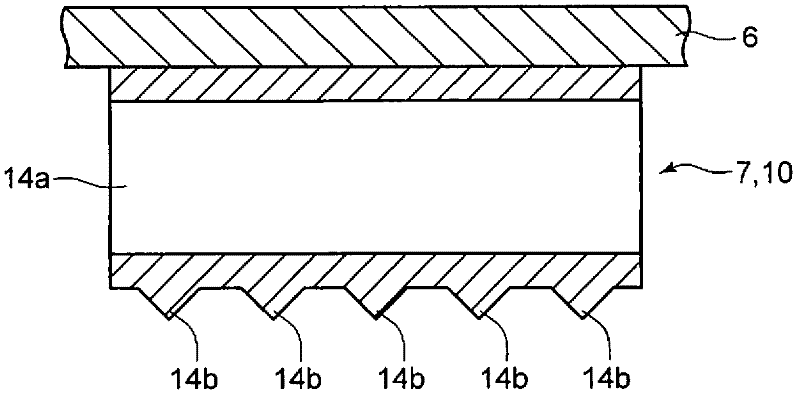

[0021] The battery 2 is a lithium ion battery. The battery 2 has a negative electrode 4 and a positive electrode 5 formed on the upward facing end face....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com