A device for inserting flat tubes into heat exchanger fins

A technology of heat exchangers and flat tubes, applied in heat exchange equipment, heat sinks, indirect heat exchangers, etc., can solve problems such as increased manufacturing costs, increased fin friction, increased pressing force, etc., and achieves high yield good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

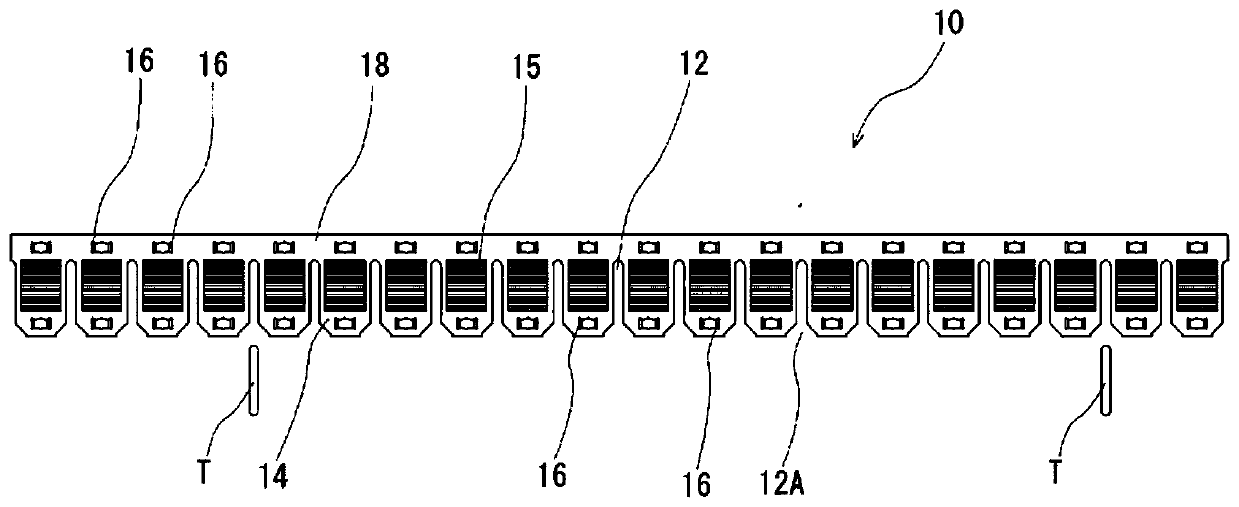

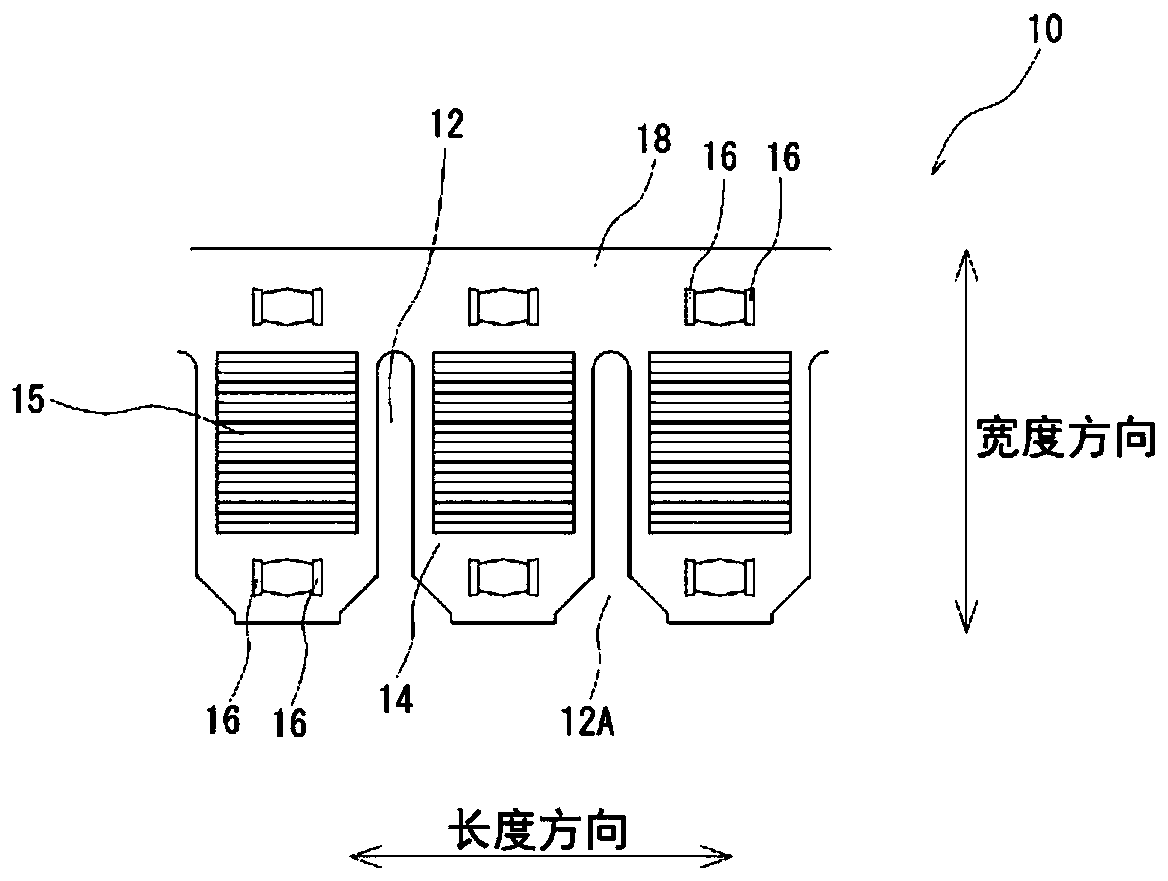

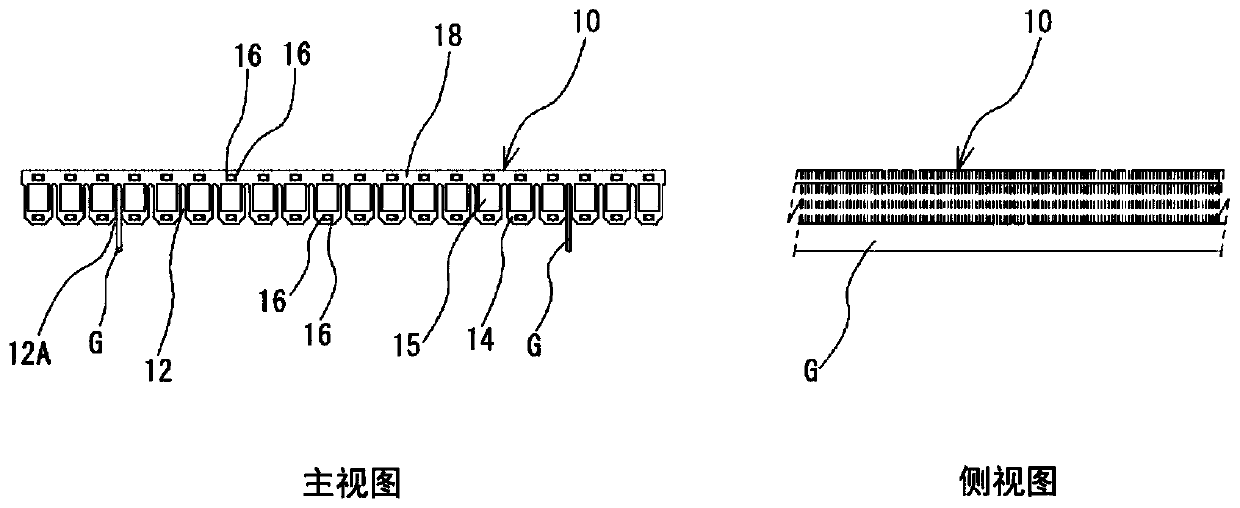

[0033] The schematic manufacturing process of the fin 10 for heat exchangers in this embodiment is demonstrated. figure 1 is a plan view showing the entire heat exchanger fin, figure 2 It is an enlarged plan view of the main part of the heat exchanger fin.

[0034] Such as figure 1 The illustrated heat exchanger fins 10 are formed by pressing a metal thin plate such as aluminum. A metal thin plate serving as a raw material of the heat exchanger fin 10 is provided in a coiled state. After the metal thin plates are successively fed out by the feeder, the metal thin plates are intermittently conveyed to the press device by the conveying device. After the metal thin plate is punched into a predetermined shape by a die device (none of which is shown) installed in the press device, the metal thin plate is divided into product widths to form a metal strip with a product width . The metal strips having a product width are divided into predetermined length dimensions in the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com