Seedling transplanting device

A horizontal conveying and free technology, which is applied in application, agriculture, planting methods, etc., can solve the problems of large-scale weight of rice transplanting devices, increased labor intensity, and increased load on the handle, so that it is not easily deformed or damaged, efficient assembly operations, The effect of firm support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0066] The first embodiment (Fig. 1 to Fig. 25)

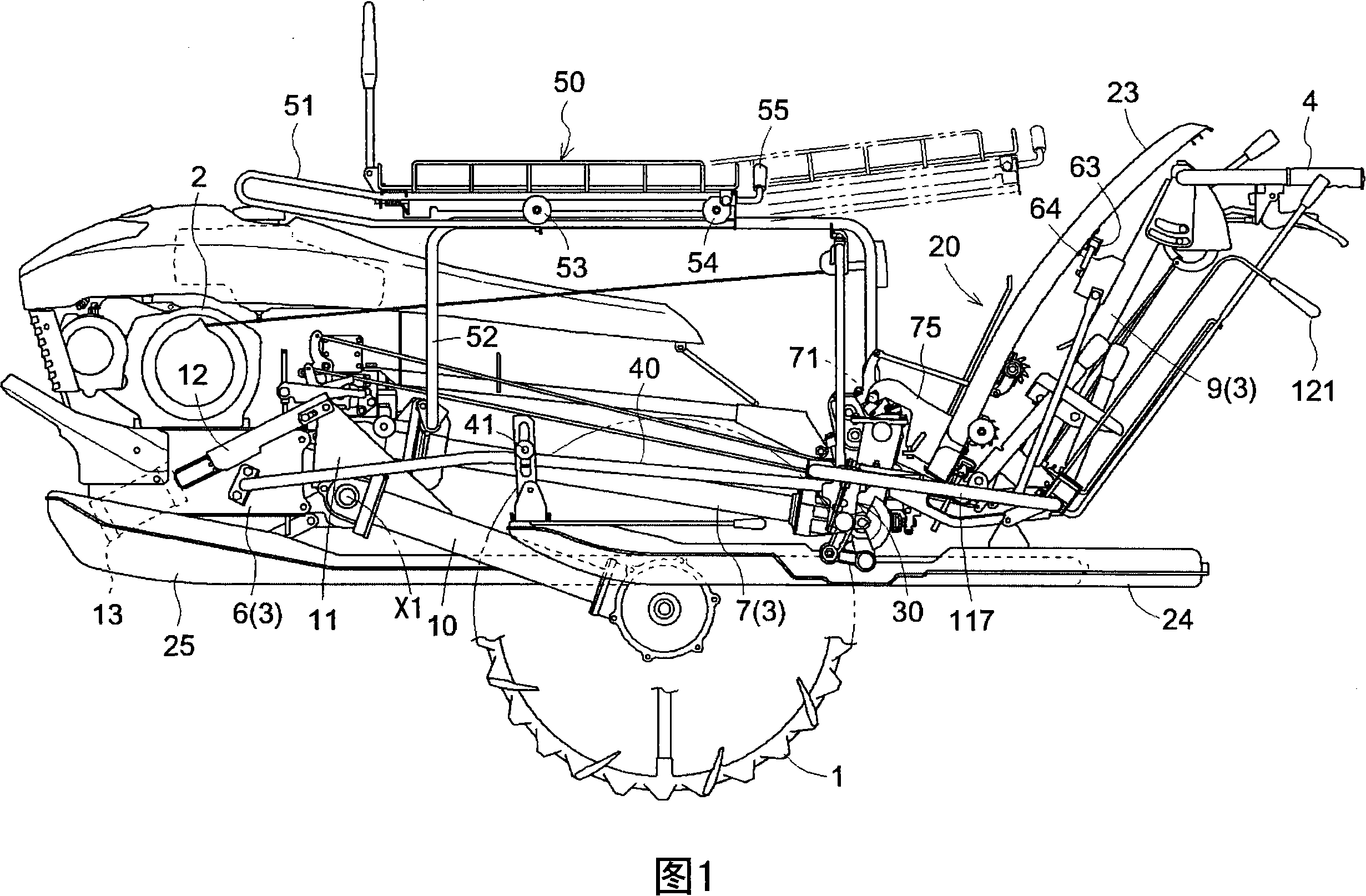

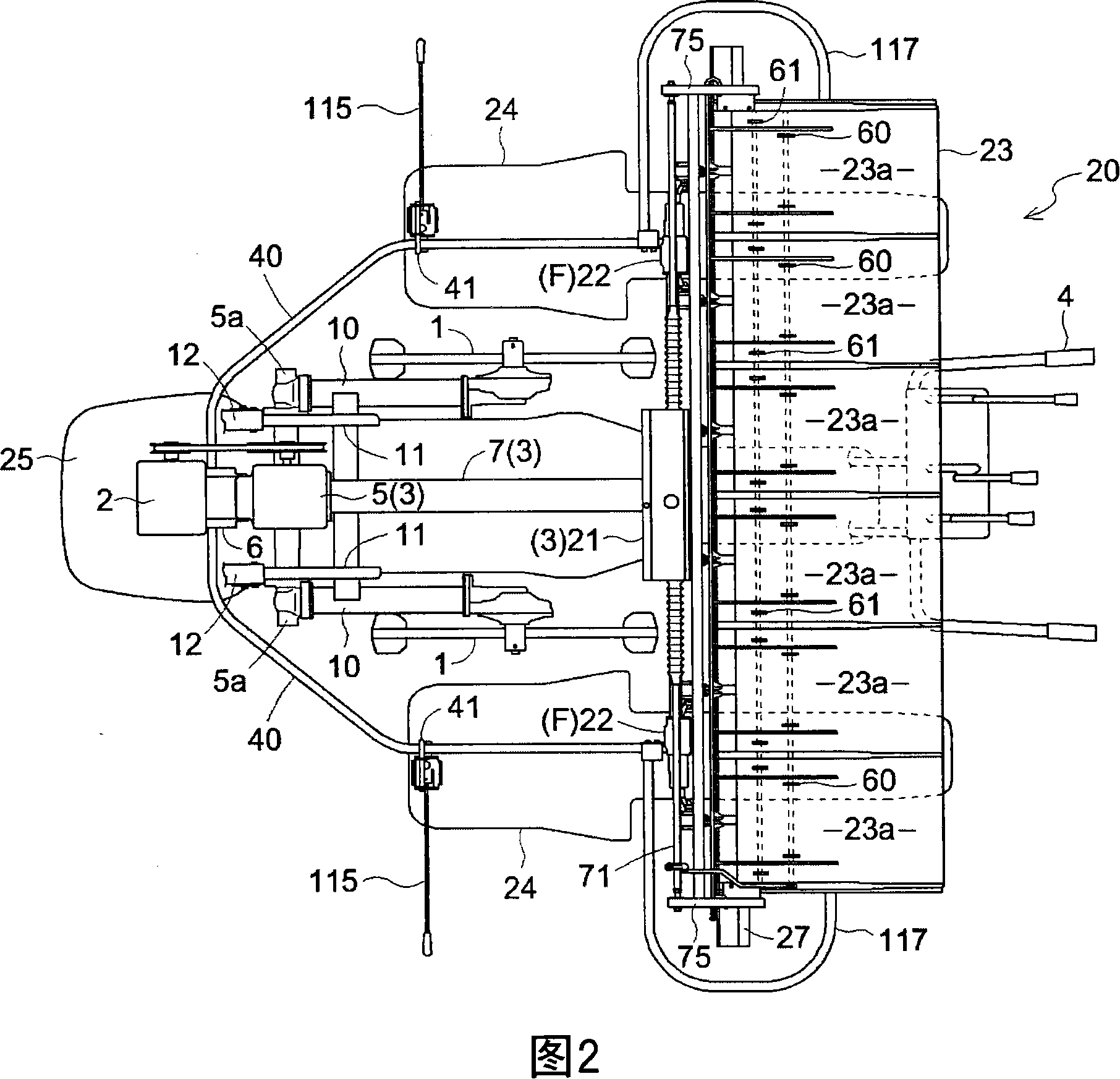

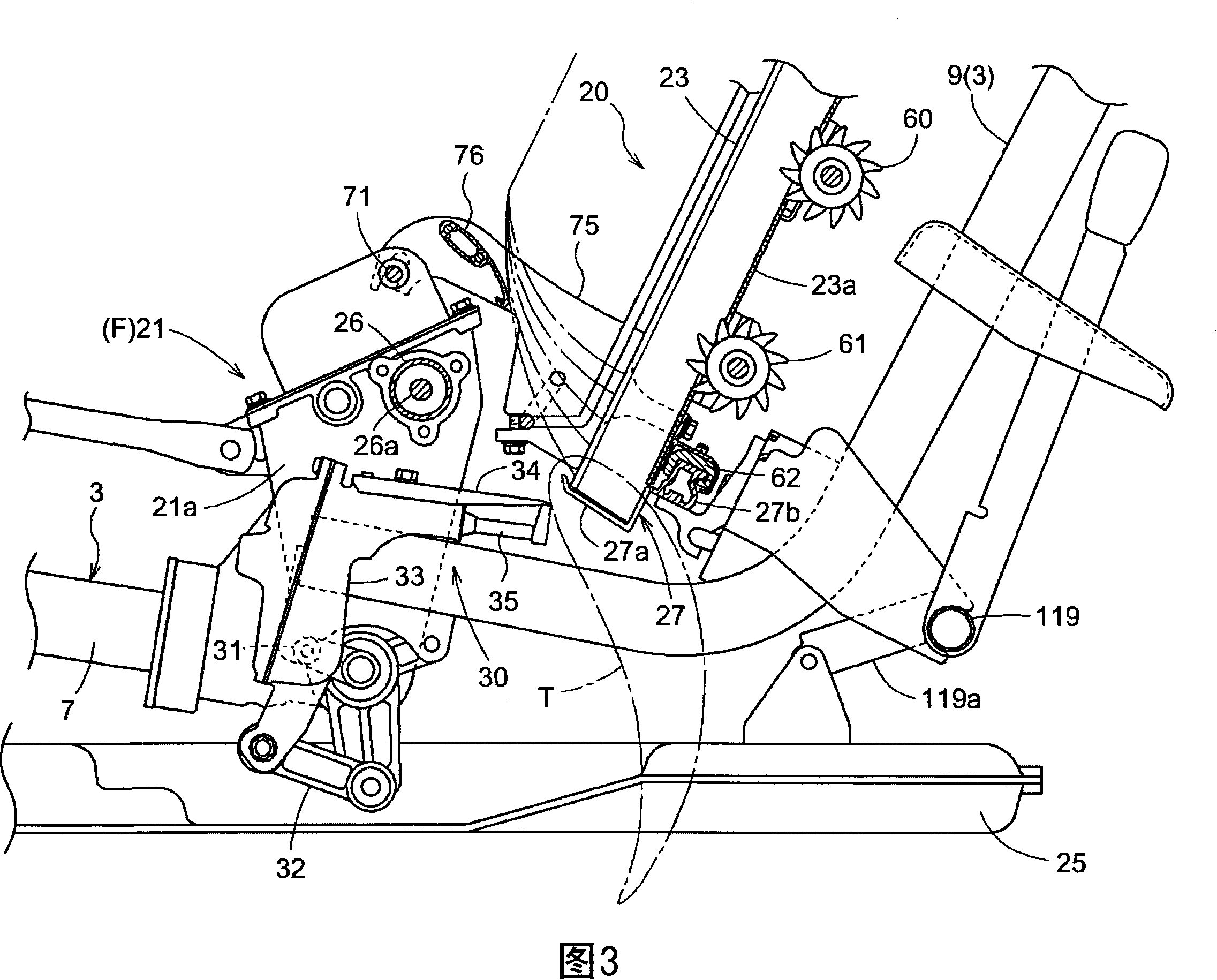

[0067] Fig. 1 is an overall side view of the walk-behind rice transplanter of the present embodiment. Fig. 2 is an overall top view of the walk-behind rice transplanter. As shown in these figures, this walk-behind rice transplanter includes: a traveling body, which makes a pair of left and right traveling wheels 1 run automatically by the driving force from the engine 2; a rice transplanting device 20, which is installed on the body frame of the traveling body 3's rear.

[0068] In addition to the body frame 3 , the pair of travel wheels 1 and the engine 2 , the traveling body also includes a joystick 4 connected to the rear end of the body frame 3 . As shown in Figure 1 and Figure 2, the body frame 3 includes: a gearbox 5; an engine loading frame 6 extending from the gearbox 5 to the front of the body; a transmission box 7 extending from the gearbox 5 to the rear of the body; A power distribution box 21 connected to the rea...

no. 2 example

[0094] The second embodiment (Fig. 26-Fig. 40)

[0095] The second embodiment is the same as the first embodiment, but the second embodiment mainly describes the front structure of the hand-held rice transplanter.

[0096] Fig. 26 is an overall side view of the walk-behind rice transplanter for six-row rice transplanting according to this embodiment, and Fig. 27 is a schematic plan view thereof. As shown in these figures, this walk-behind rice transplanter is equipped with a recoil start type air-cooled engine 2 on the front part of the body frame 3, and a pair of left and right wheels 1 driven by driving power from the engine 2 are arranged on the body. On the left and right sides of the frame 3, the rice transplanting device 20 used for six rows of rice transplanting driven by the power from the engine 2 is arranged at the rear portion of the body frame 3, and is positioned at the rear side of the body compared to the left and right wheels 1. In this rice transplanting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com