Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Easy visual identification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

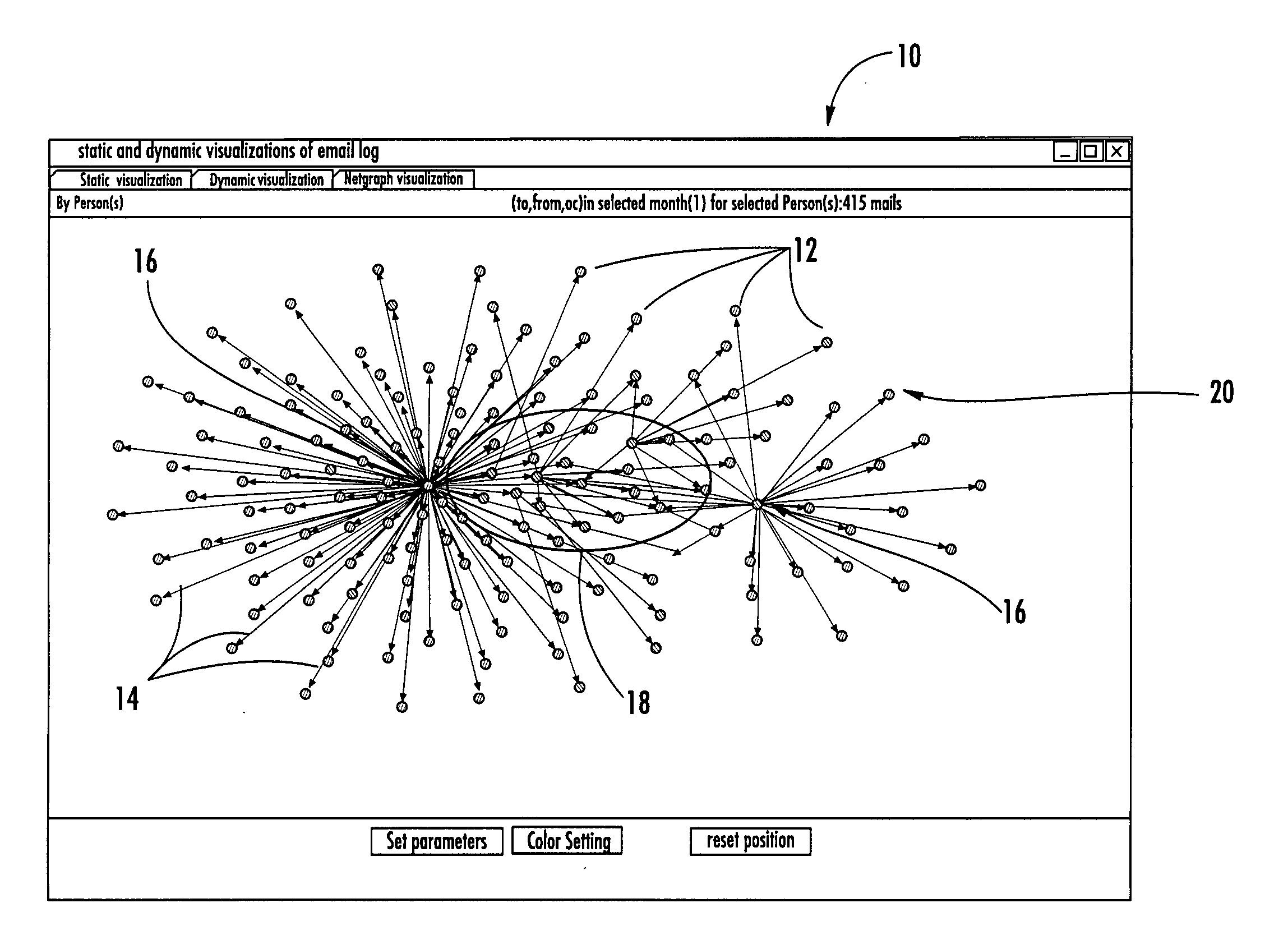

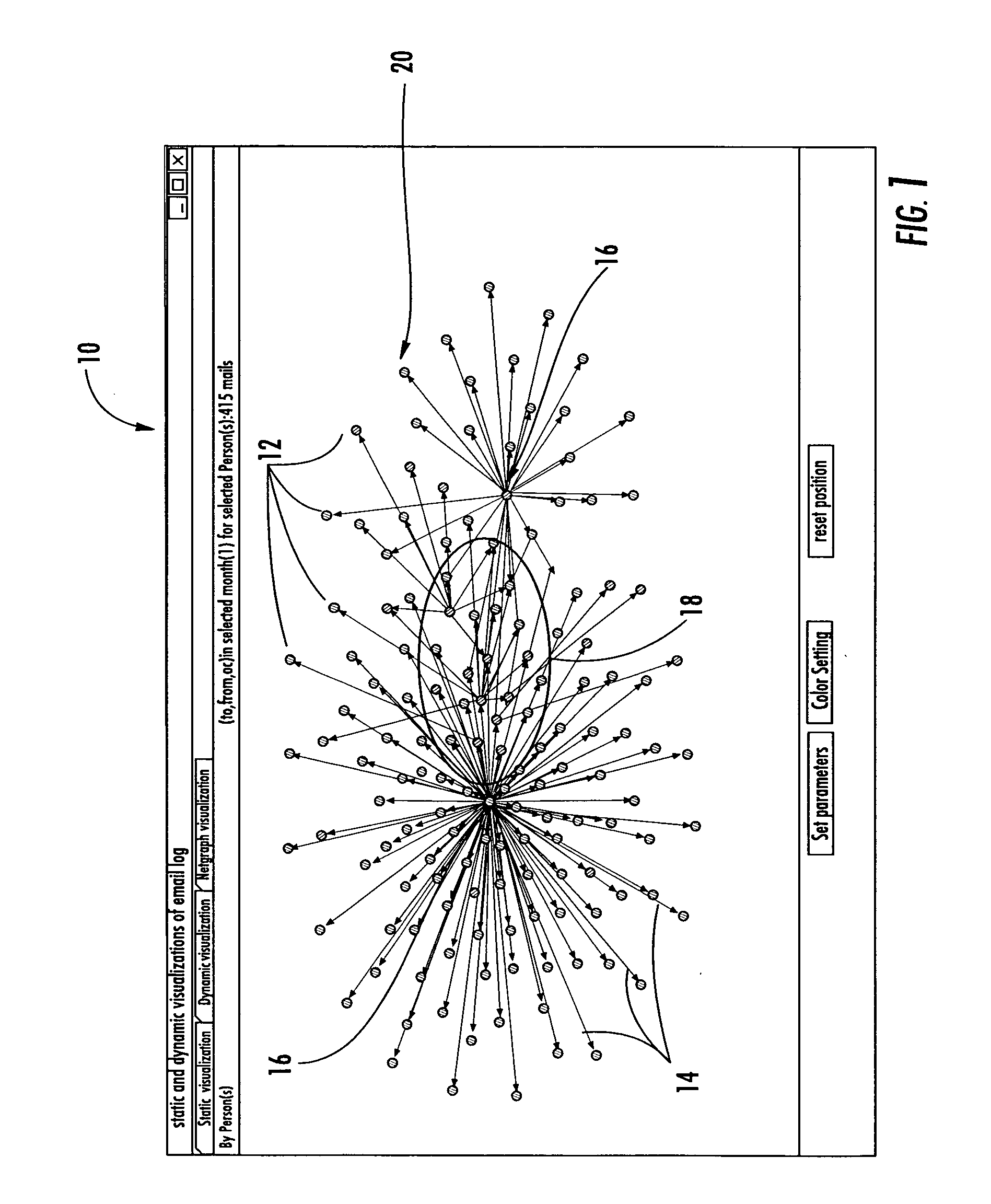

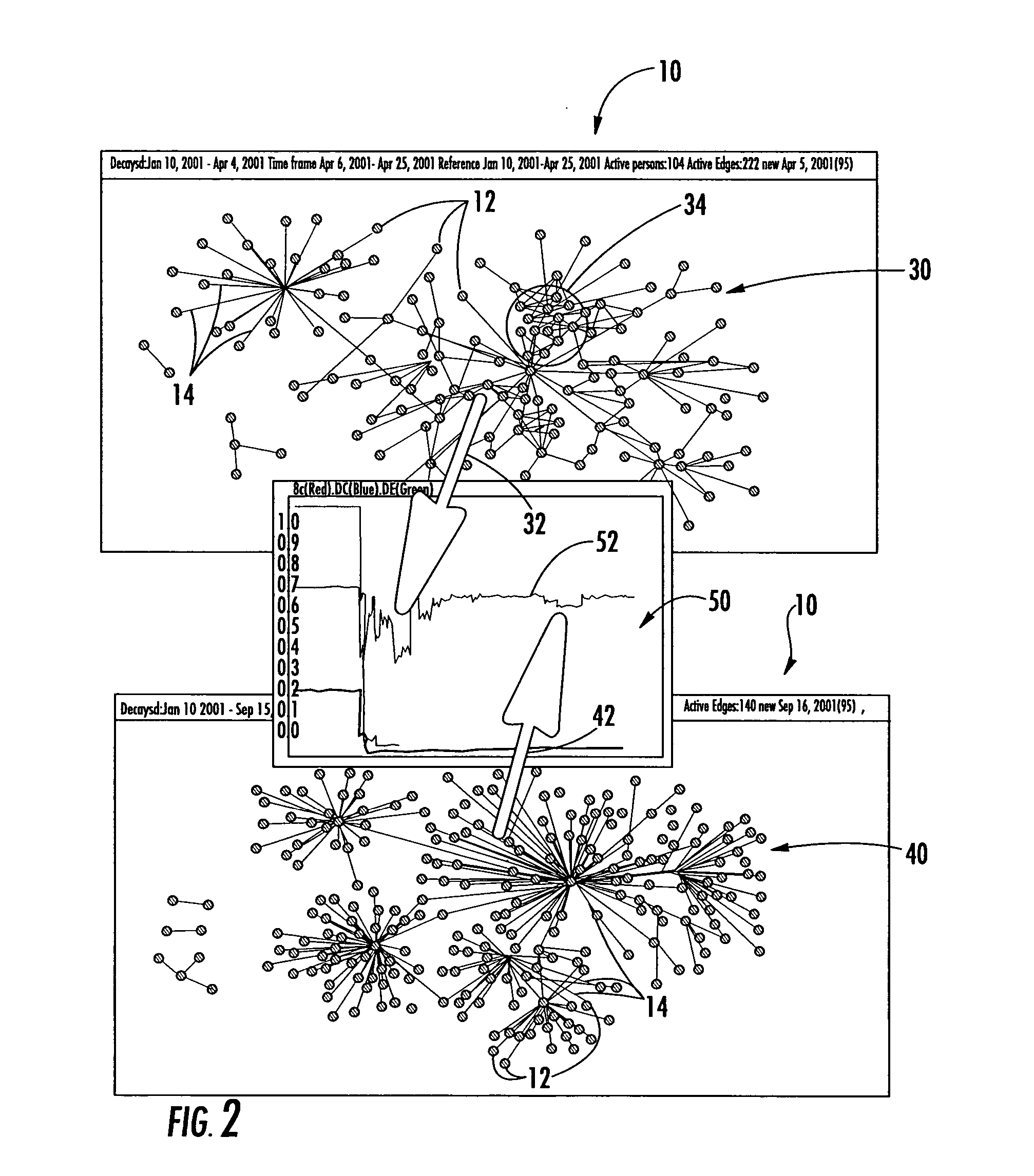

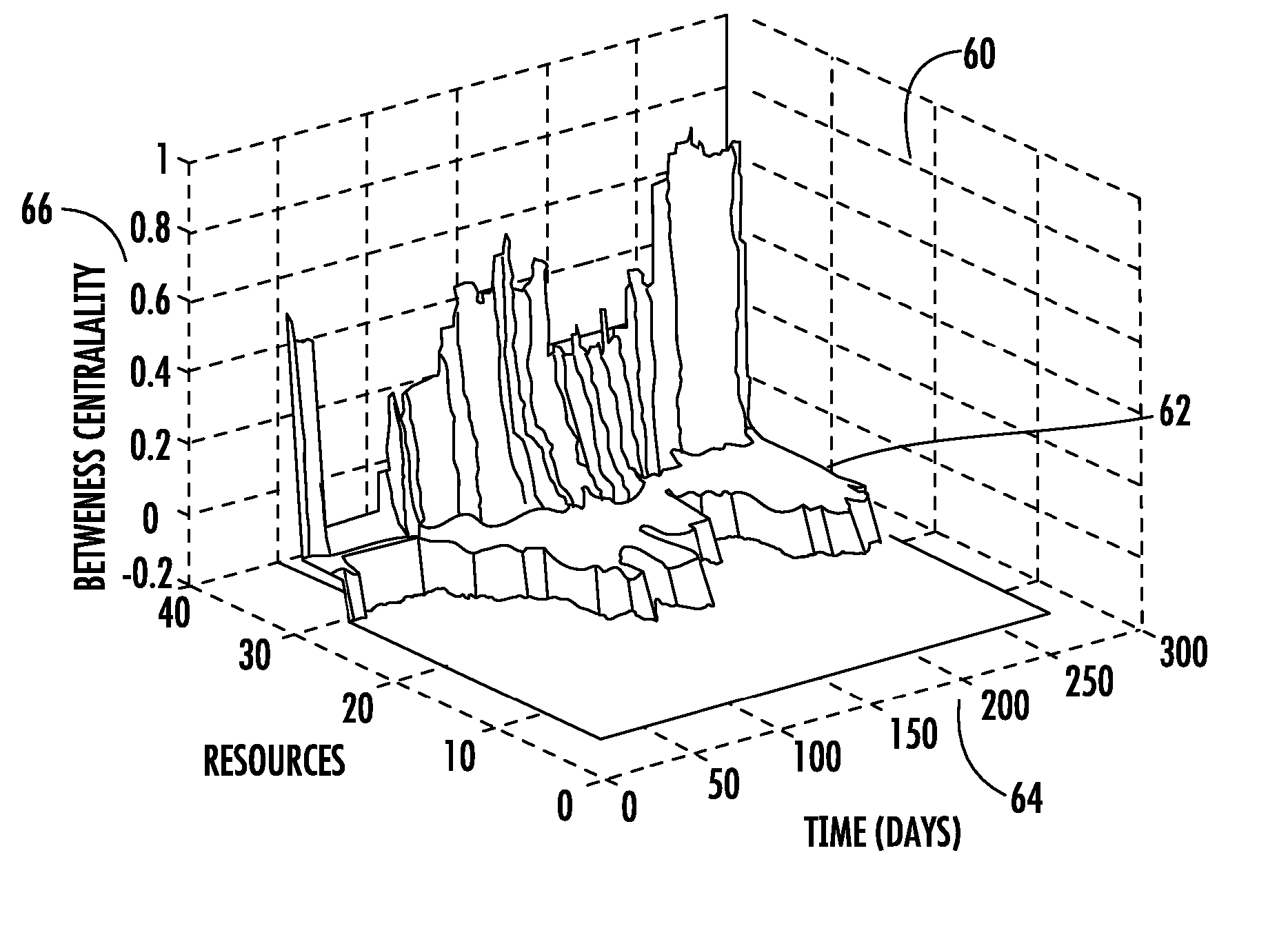

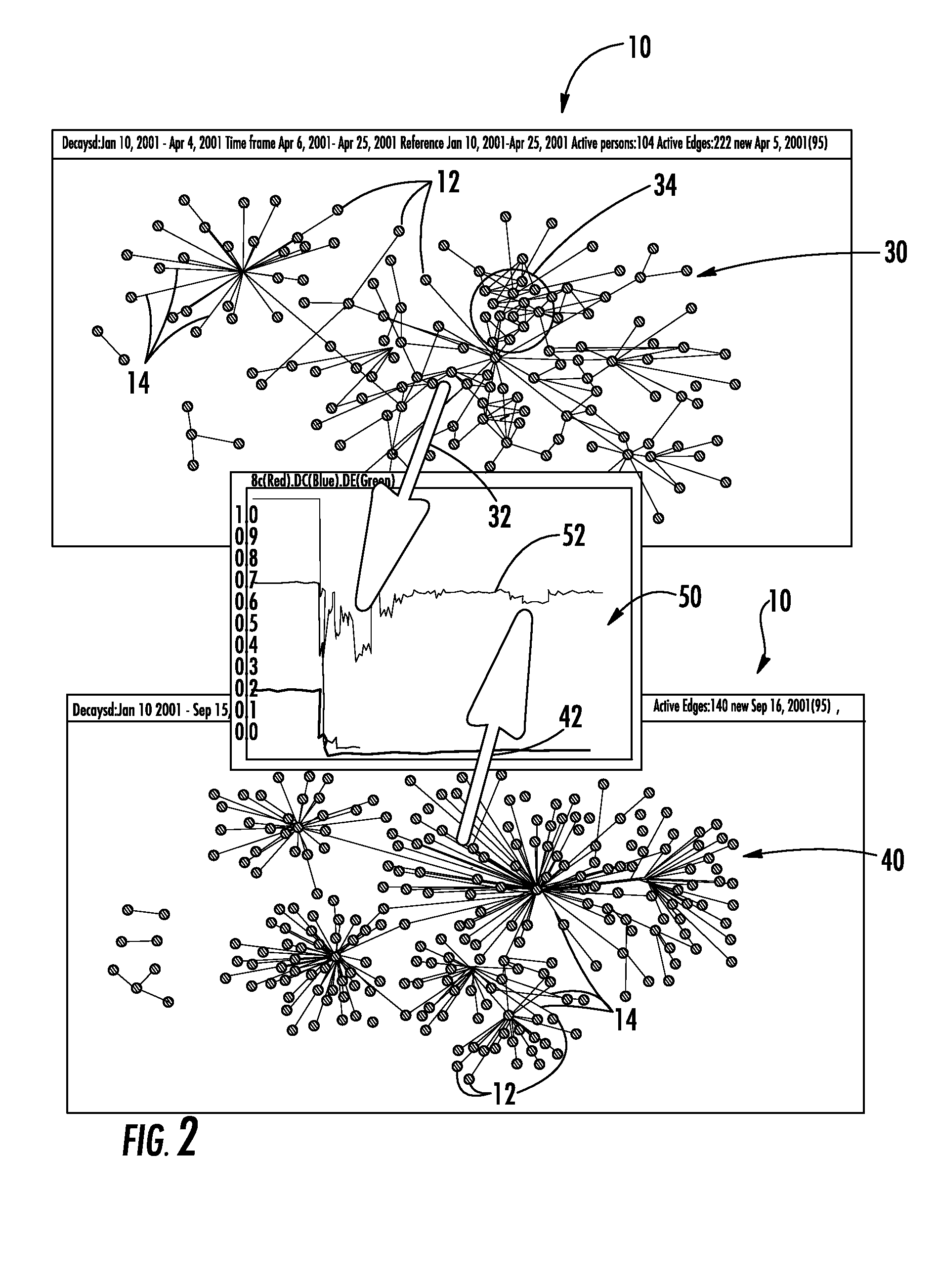

Temporal visualization algorithm for recognizing and optimizing organizational structure

InactiveUS20060075335A1Improve efficiencyEasy visual identification2D-image generationTransmissionComputer scienceVisualization algorithms

A system is provided that takes as input the interrelationships which are observed between identified resources, and automatically generates interactive movies that depict a visualization of the of the interaction patterns among the identified resources. Each resource is represented as a dot. A line between two dots indicates a relationship. The closer the two dots are placed together, the more intensive is their relationship, that is, the more commonality or interaction those resources share. Further, the most active resources, namely the resources that have the most relational links or lines extending therefrom, are placed in the center of the network. Once the visualization movie has been built, a user can search for groupings of related resources by simply searching for and identifying the various clusters within the network.

Owner:IQUEST GLOBAL CONSULTING

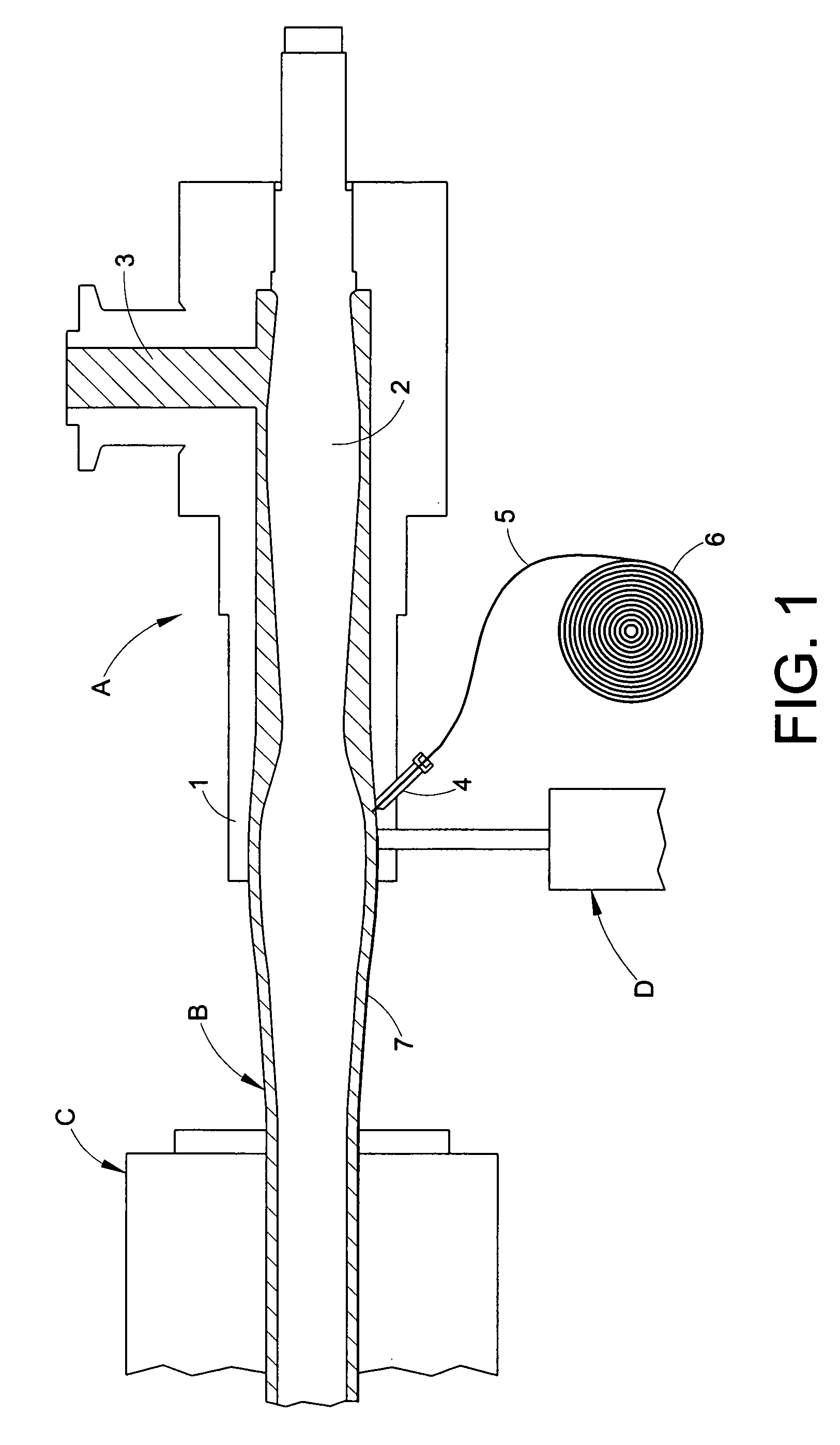

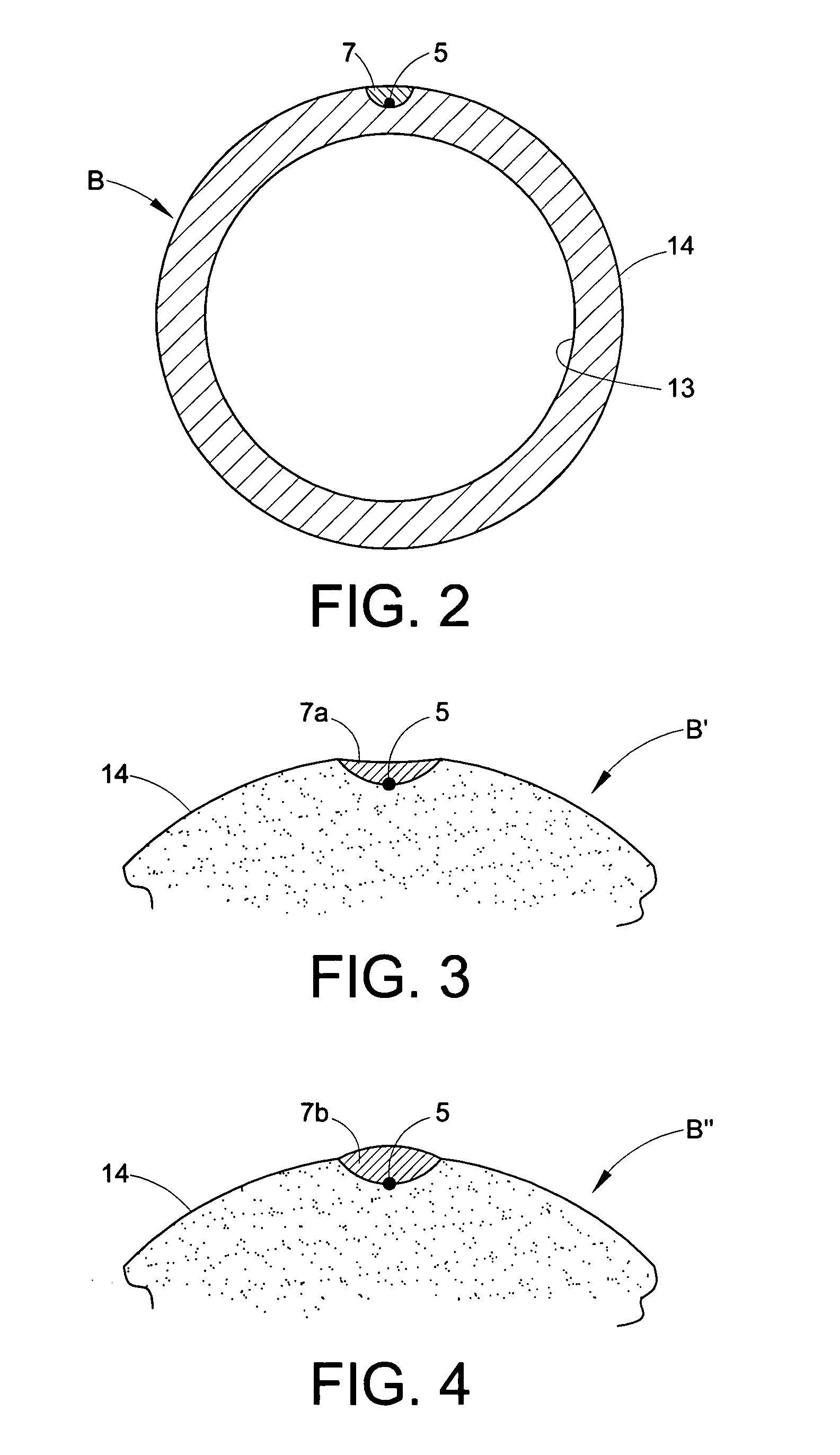

Duct with wire locator

InactiveUS6933438B1Convenient ArrangementEasily exposedPipe laying and repairSubstation/switching arrangement detailsPlastic materialsEngineering

A cylindrical duct of plastic material is coextruded with a longitudinal wire located between the duct inner and outer surfaces, and with a stripe of a different color plastic material than the duct overlying the wire. The stripe is of a softer plastic material than the duct plastic material to facilitate cutting of same to expose the wire, but is compatible with the duct plastic material so as to crosslink therewith.

Owner:BOREFLEX

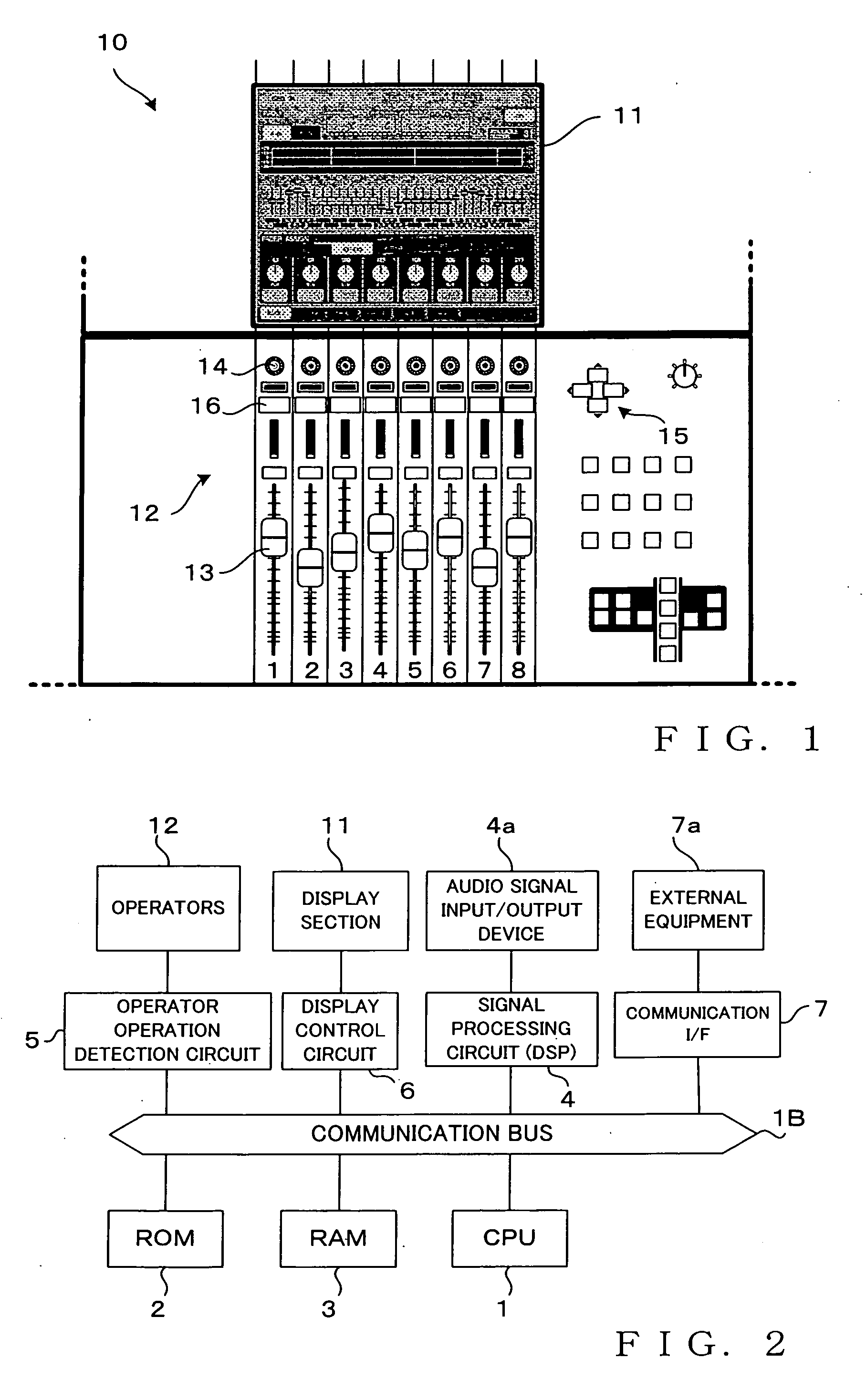

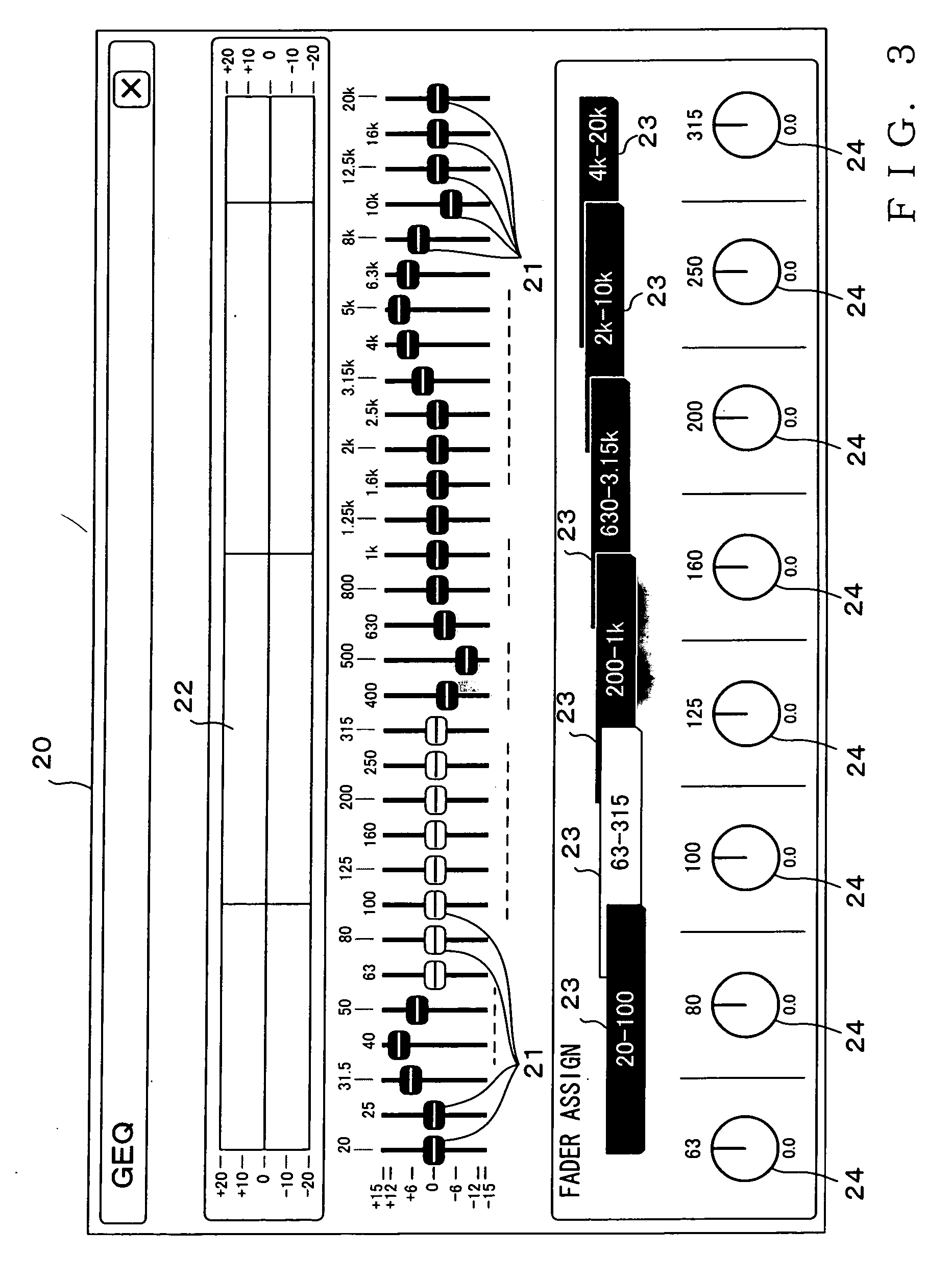

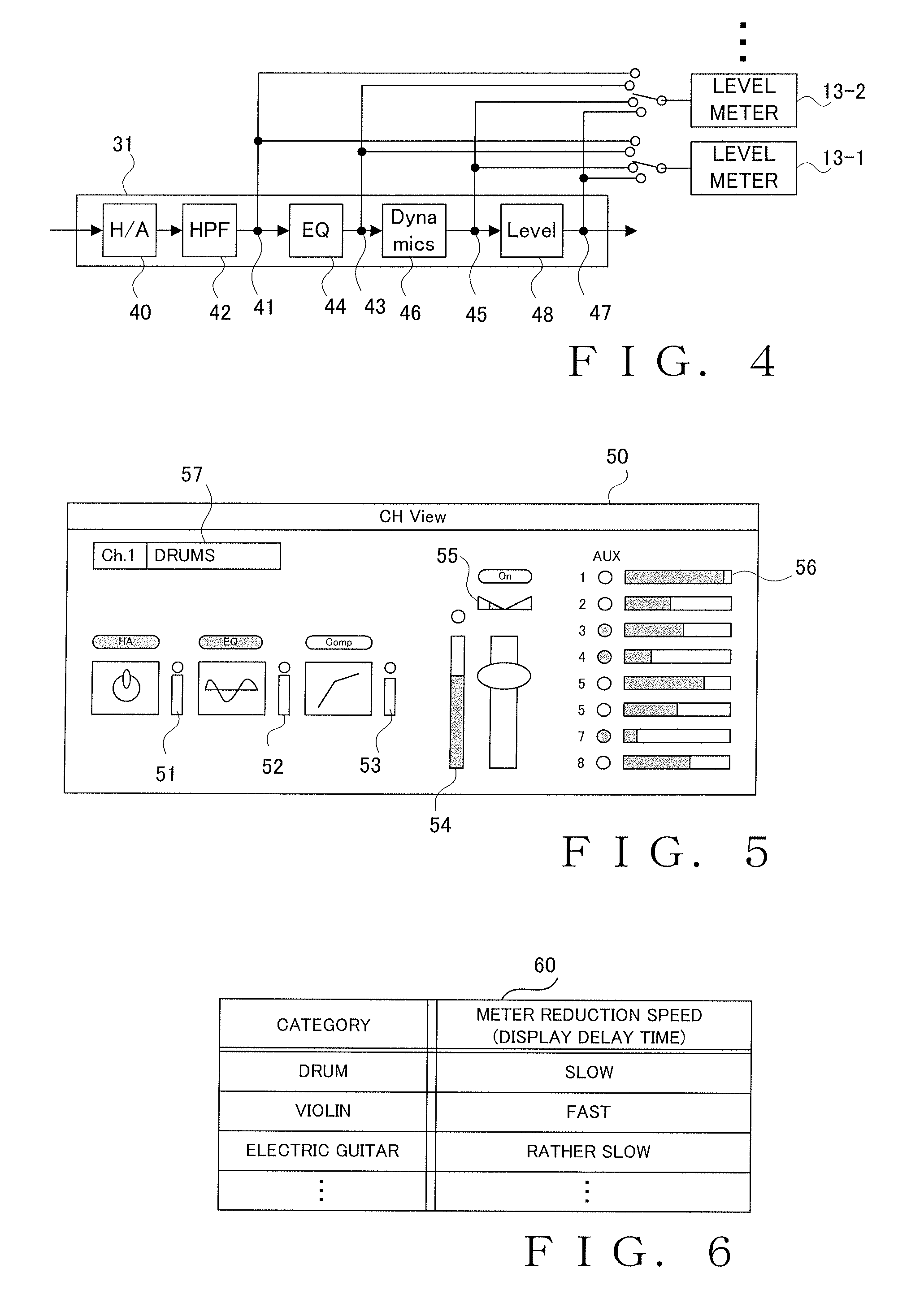

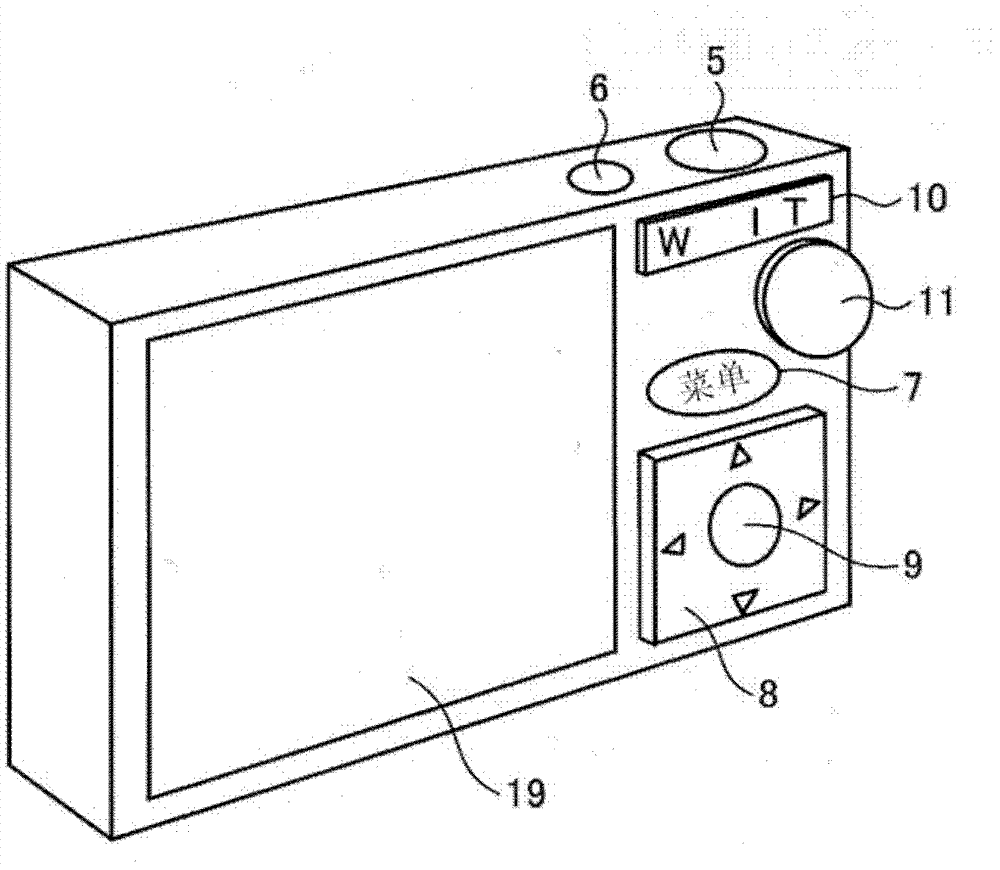

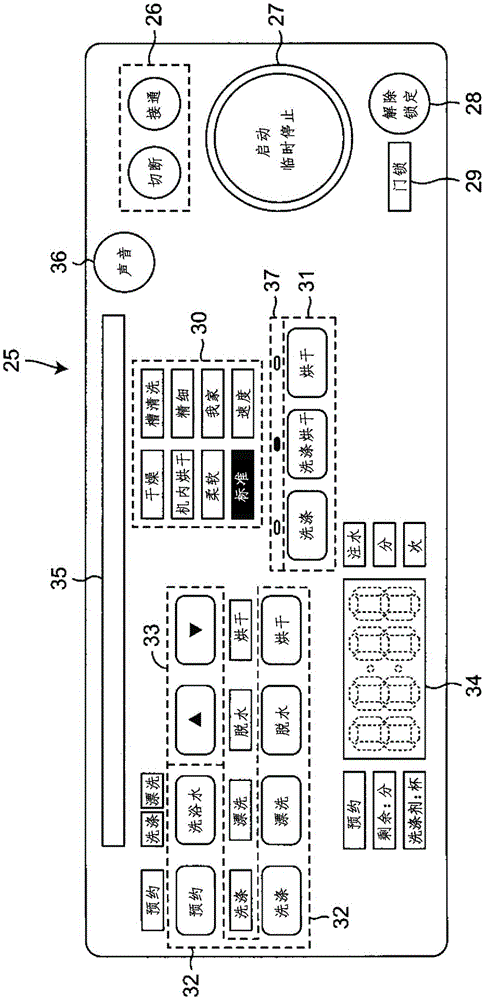

Parameter setting apparatus and method for audio mixer

ActiveUS8300852B2Easy visual identificationEasy to identifyElectrophonic musical instrumentsSignal processingPattern recognitionComputer vision

Owner:YAMAHA CORP

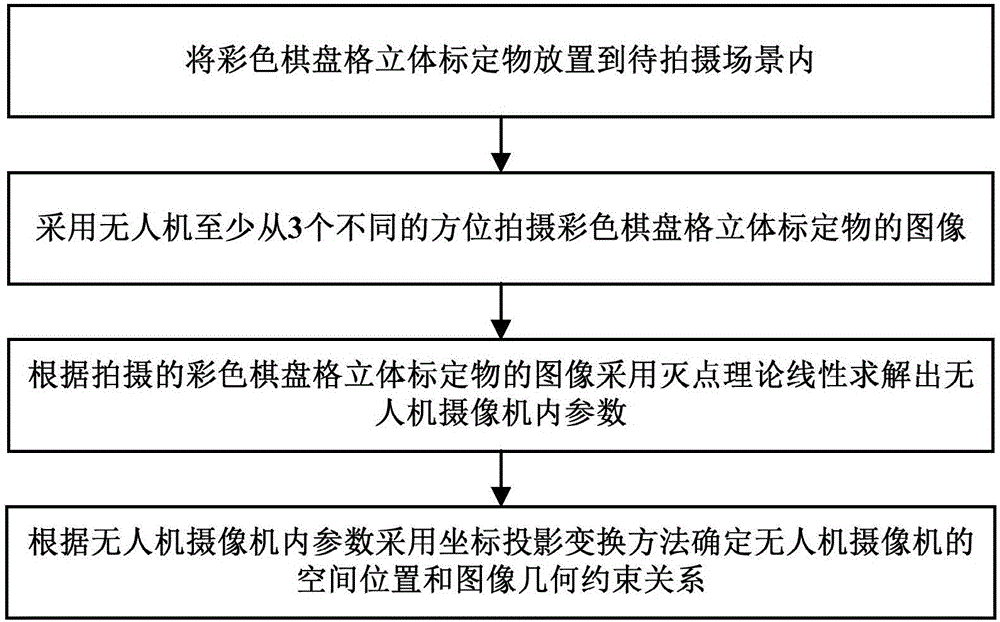

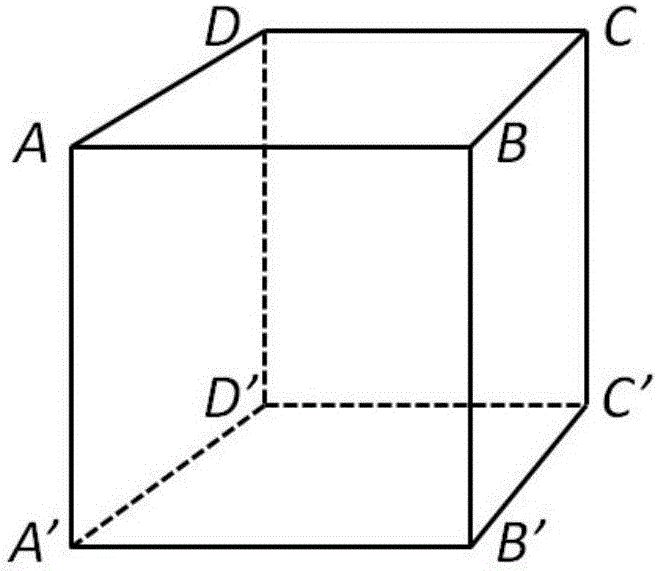

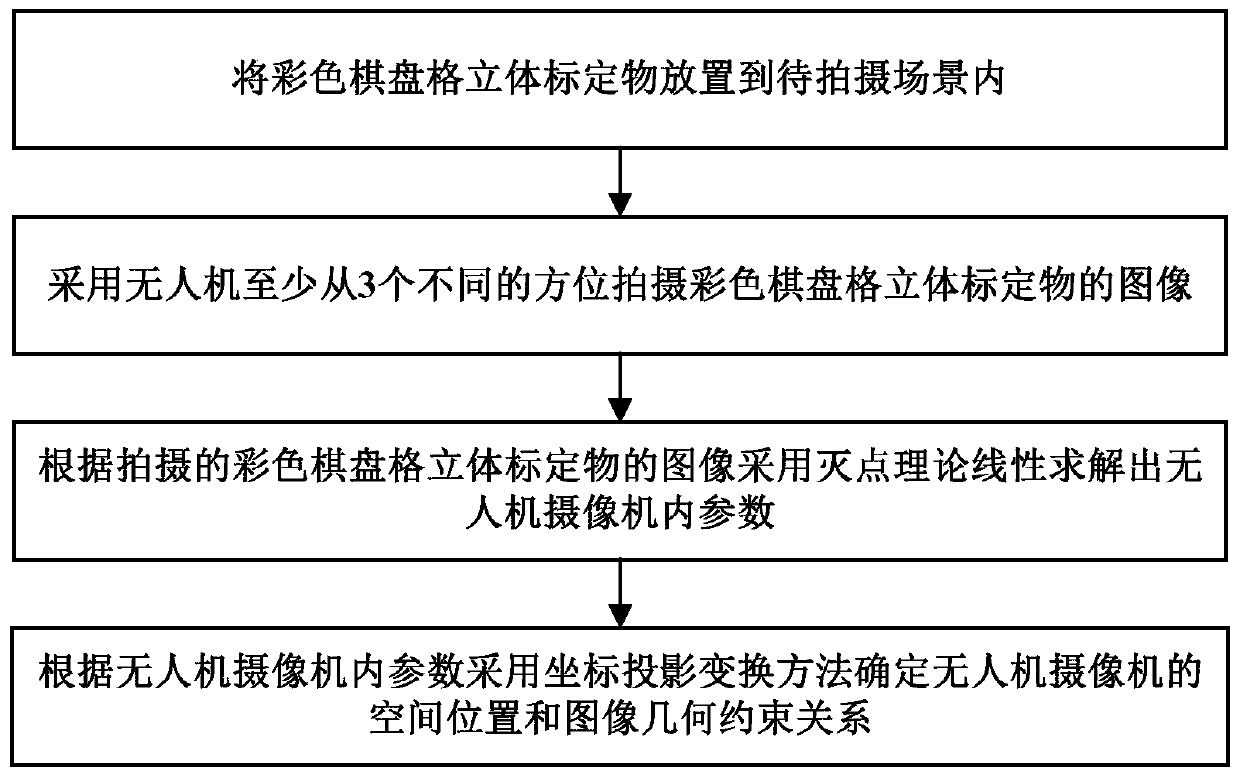

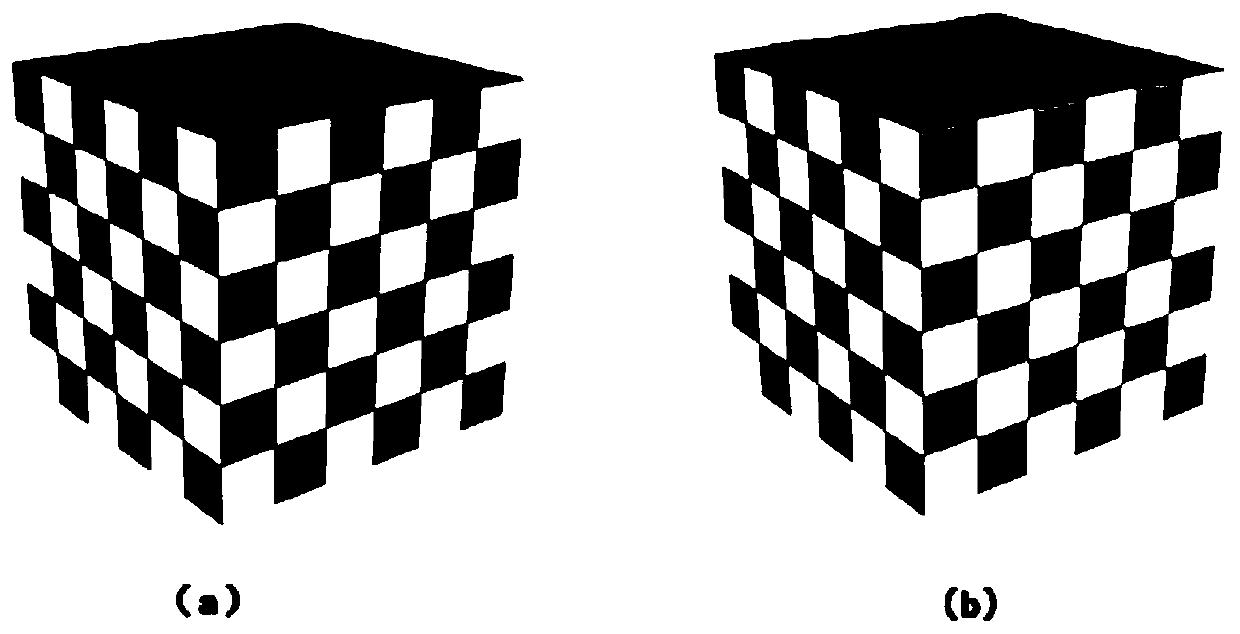

Color stereoscopic calibration object-based unmanned aerial vehicle calibration method and system

ActiveCN106651961AEasy to measure accuratelyImprove detection accuracyImage enhancementImage analysisVanishing pointCheckerboard

The invention discloses a color stereoscopic calibration object-based unmanned aerial vehicle calibration method and system. The method comprises the steps of putting a color checkerboard stereoscopic calibration object into a to-be-shot scene; shooting an image of the color checkerboard stereoscopic calibration object in at least three different directions by adopting an unmanned aerial vehicle; linearly solving intrinsic parameters of an unmanned aerial vehicle camera by adopting a vanishing point theory according to the shot image of the color checkerboard stereoscopic calibration object; and determining a geometric restriction relationship between the spatial position of the unmanned aerial vehicle camera and the image by adopting a coordinate projection transformation method according to the intrinsic parameters of the unmanned aerial vehicle camera. According to the method and the system, the color checkerboard stereoscopic calibration object is adopted for performing camera calibration, so that accurate measurement is facilitated, the detection precision is high, the placement is facilitated, and the universality is high; and the calibration of the intrinsic parameters of the camera can be finished only by shooting the image of the color checkerboard stereoscopic calibration object in the at least three different directions and obtaining the intrinsic parameters of the unmanned aerial vehicle camera in combination with the vanishing point theory, so that the use is more convenient. The method and the system can be widely applied to the field of computer vision.

Owner:SUN YAT SEN UNIV

Parameter setting apparatus and method for audio mixer

ActiveUS20060232586A1Easy visual identificationEasy to identifyElectrophonic musical instrumentsSignal processingComputer graphics (images)Computer vision

Owner:YAMAHA CORP

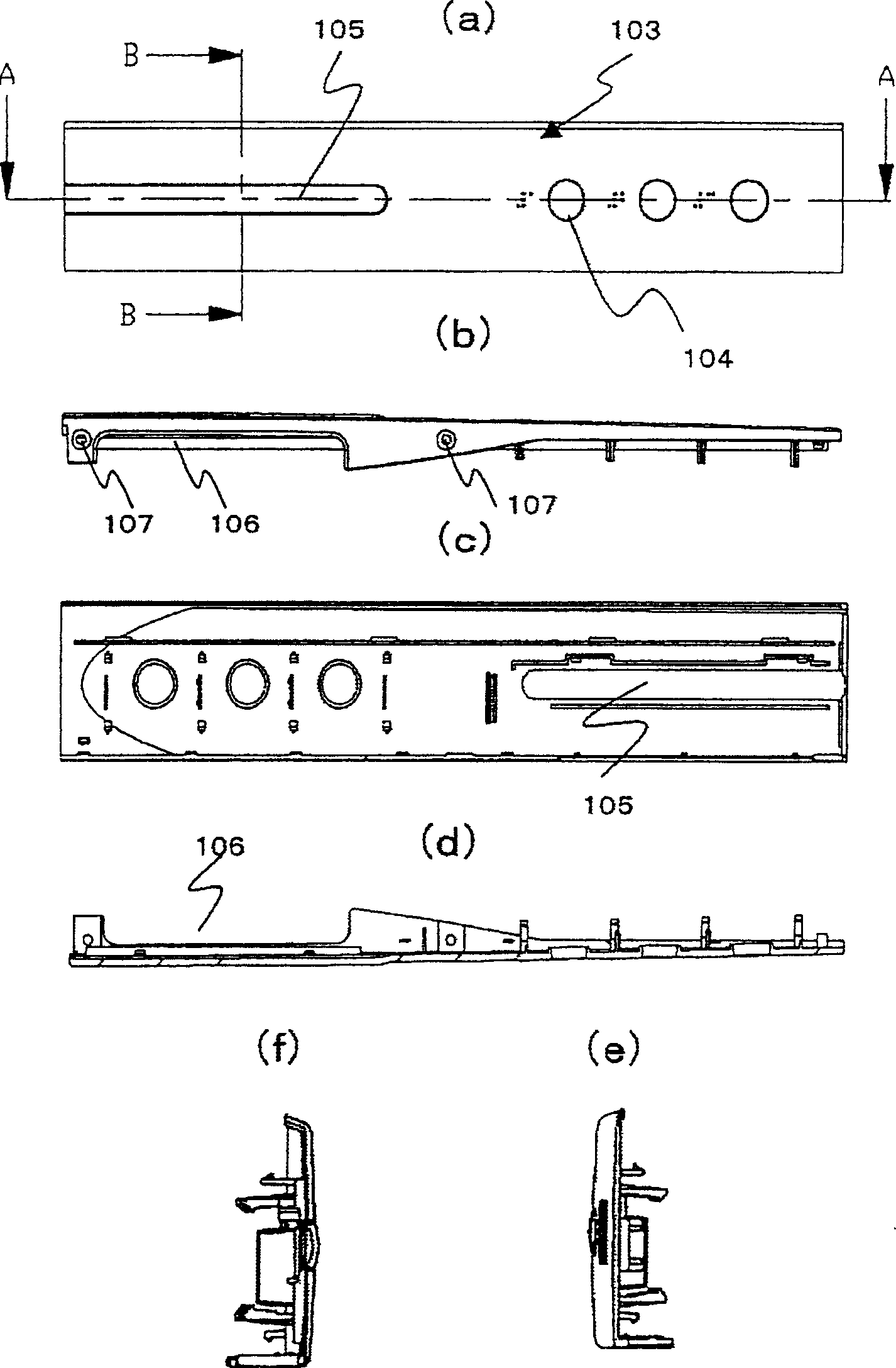

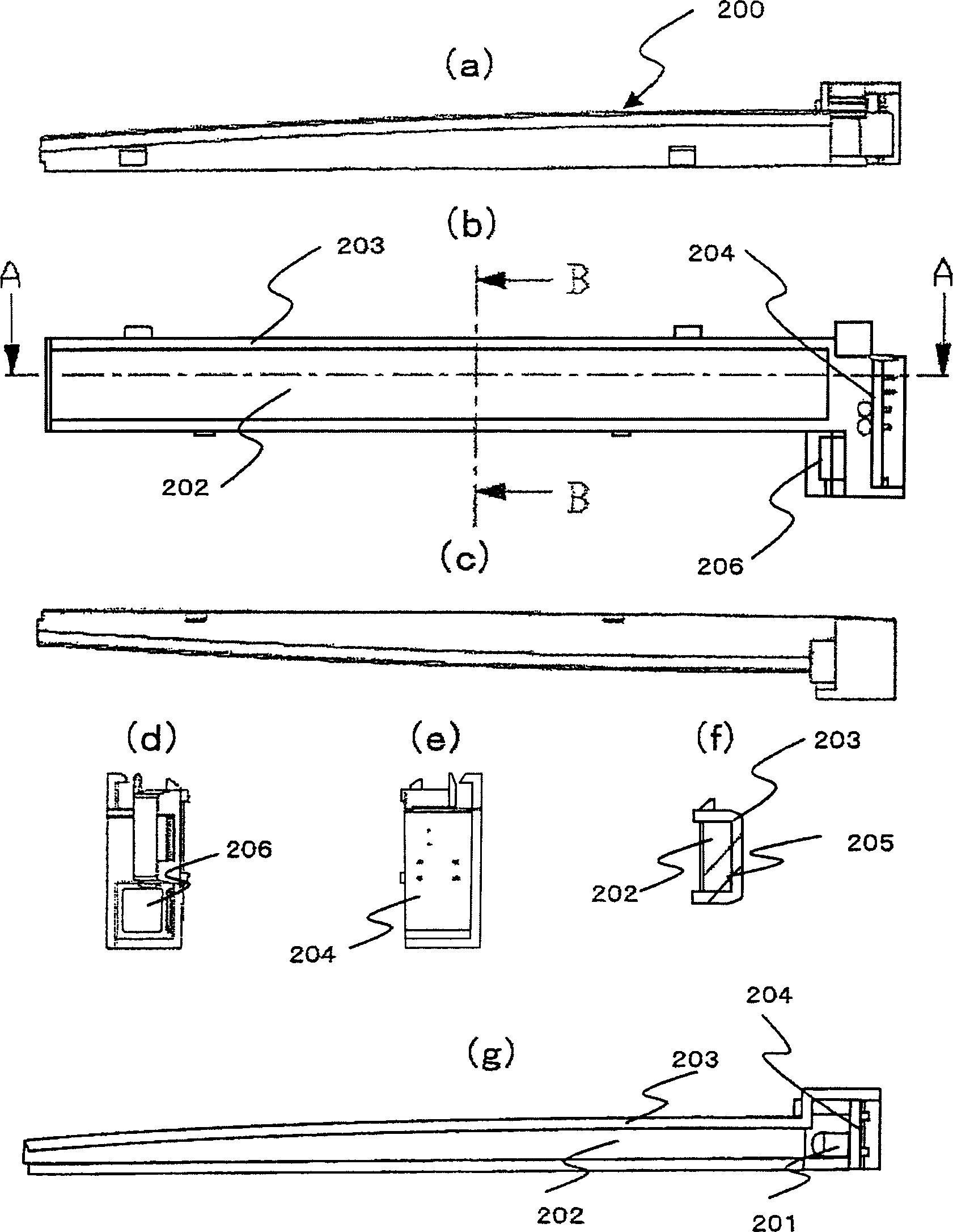

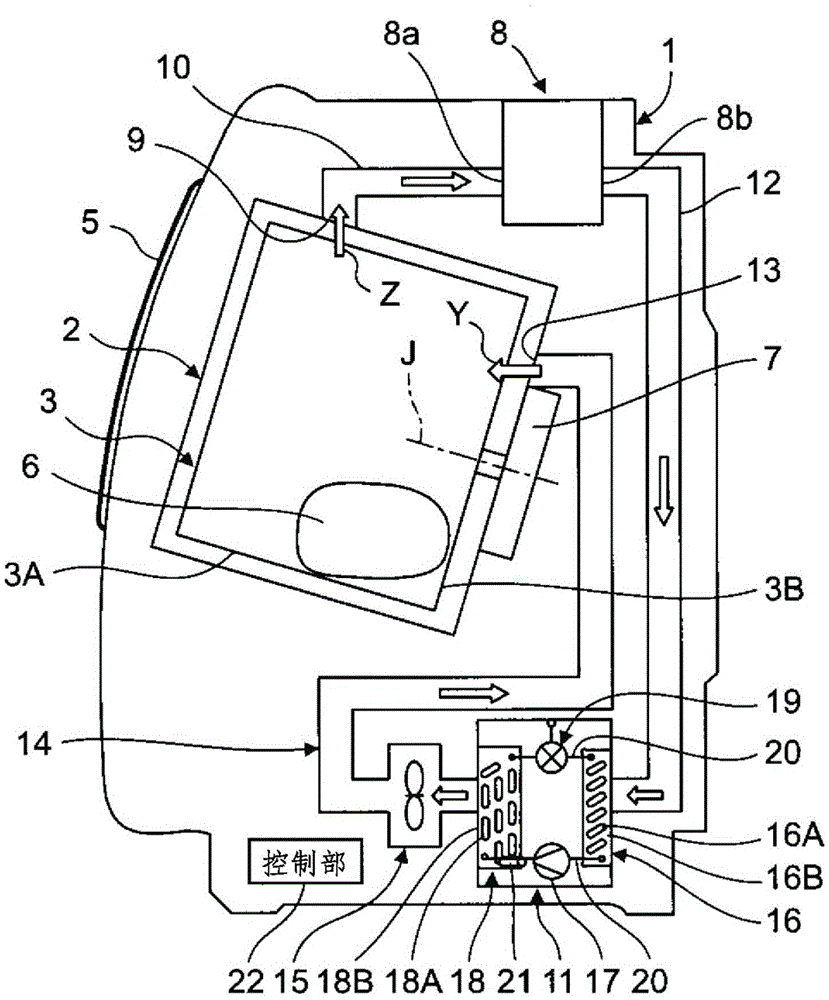

Refrigerator

InactiveCN1746601AEasy visual identificationDomestic cooling apparatusLighting and heating apparatusBlack outLight source

The invention relates to a refrigerator which has open and close switches (61) arranged on a pair of open-and-close doors (11), display devices (200) arranged on panels (103) respectively arranged at the lower parts of the doors, pull handle dents (106) formed at the lower ends of the panels and a control device (60) ensures that the display devices are on state when the doors are opened, wherein each display device has a club-shaped transparent diffused plate (202) and a light source (201) arranged in the longitudinal direction of the diffused plate; the front face P1 which is arranged at one side of the long side of the diffused plate adjacent to a door surface is made into a flat surface, while a back face P2 opposite to the front face is made into a concavo-convex shape; moreover, a large curved surface which is tapered off from one end in the longitudinal direction provided with the light source to the other end is formed; the control device (60), which controls the gradual lighting up of lamps from the light source side to the other end in the longitudinal direction and the gradual black out of the lamps from the other end to the light source side, ensures that both display devices and the pull handle dents are arranged side by side in vertical direction.

Owner:HITACHI APPLIANCES INC

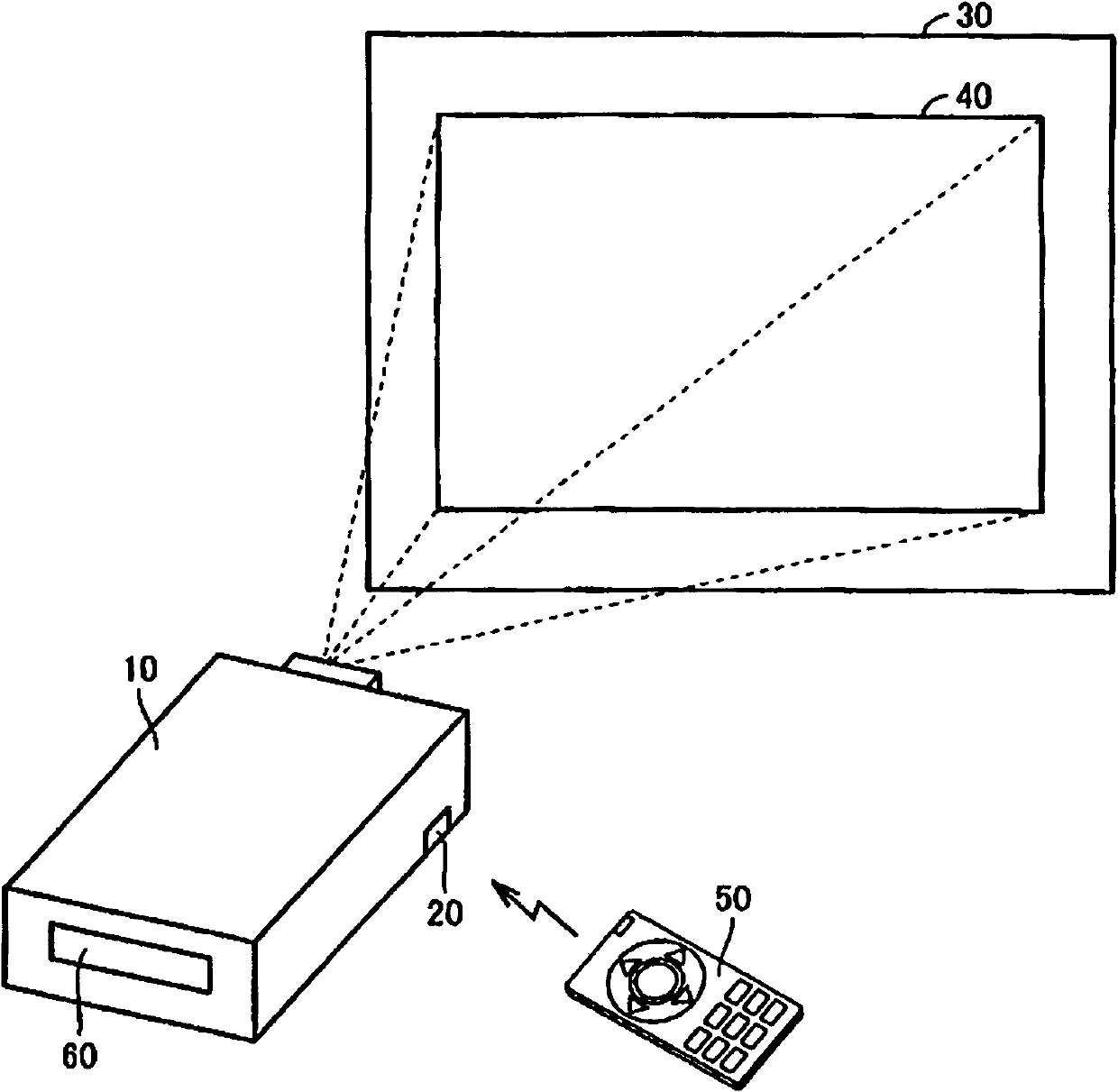

Projection image display device

InactiveCN102025950AEasy visual identificationEasy to operateTelevision system detailsColor signal processing circuitsProjection imageDisplay device

Owner:SANYO ELECTRIC CO LTD

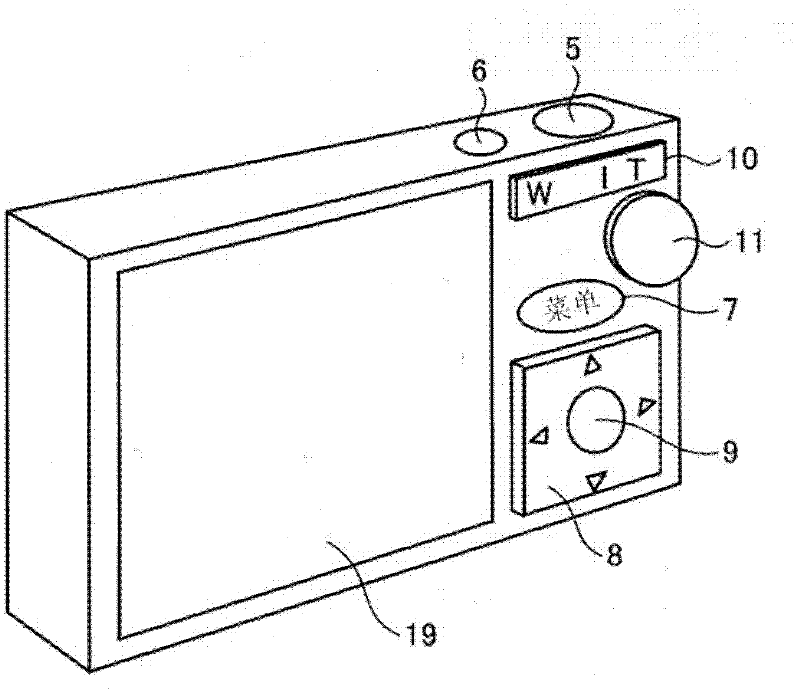

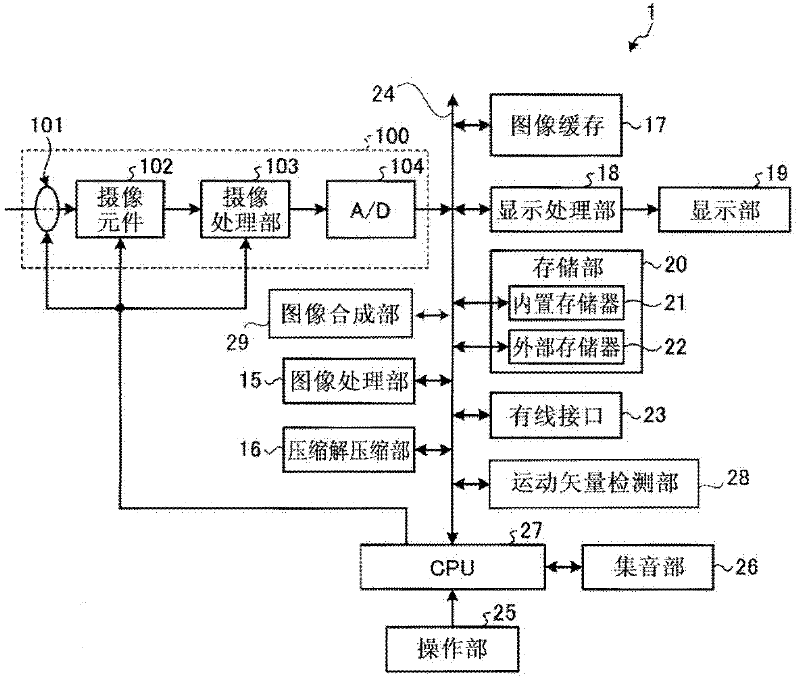

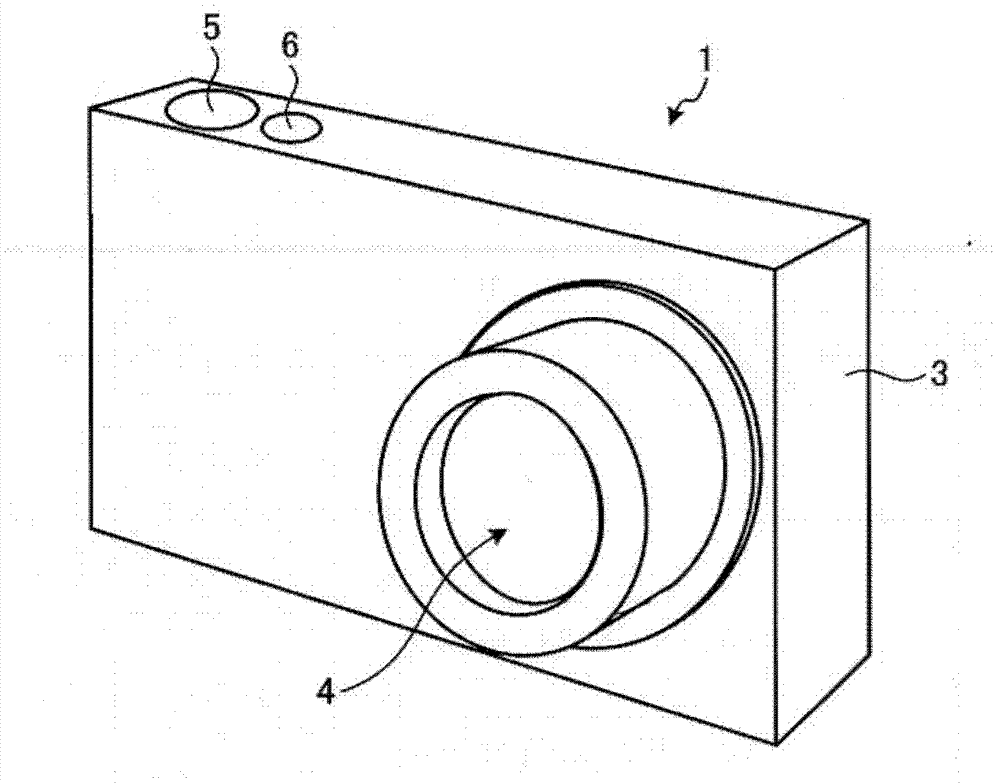

Panoramic image generation device and panoramic image generation method

InactiveCN102469259AEasy visual identificationTelevision system detailsColor television detailsComputer graphics (images)Image generation

A panoramic image generation device generates a panoramic image by synthesizing a plurality of static images constituting the moving image, determines a size at which a display panoramic image is to be cut out from the panoramic image, and detects a focus photography position from the panoramic image. The panoramic image generation device cuts out the display panoramic image from the panoramic image on the basis of the detected focus photography position and the determined size.

Owner:OLYMPUS CORP

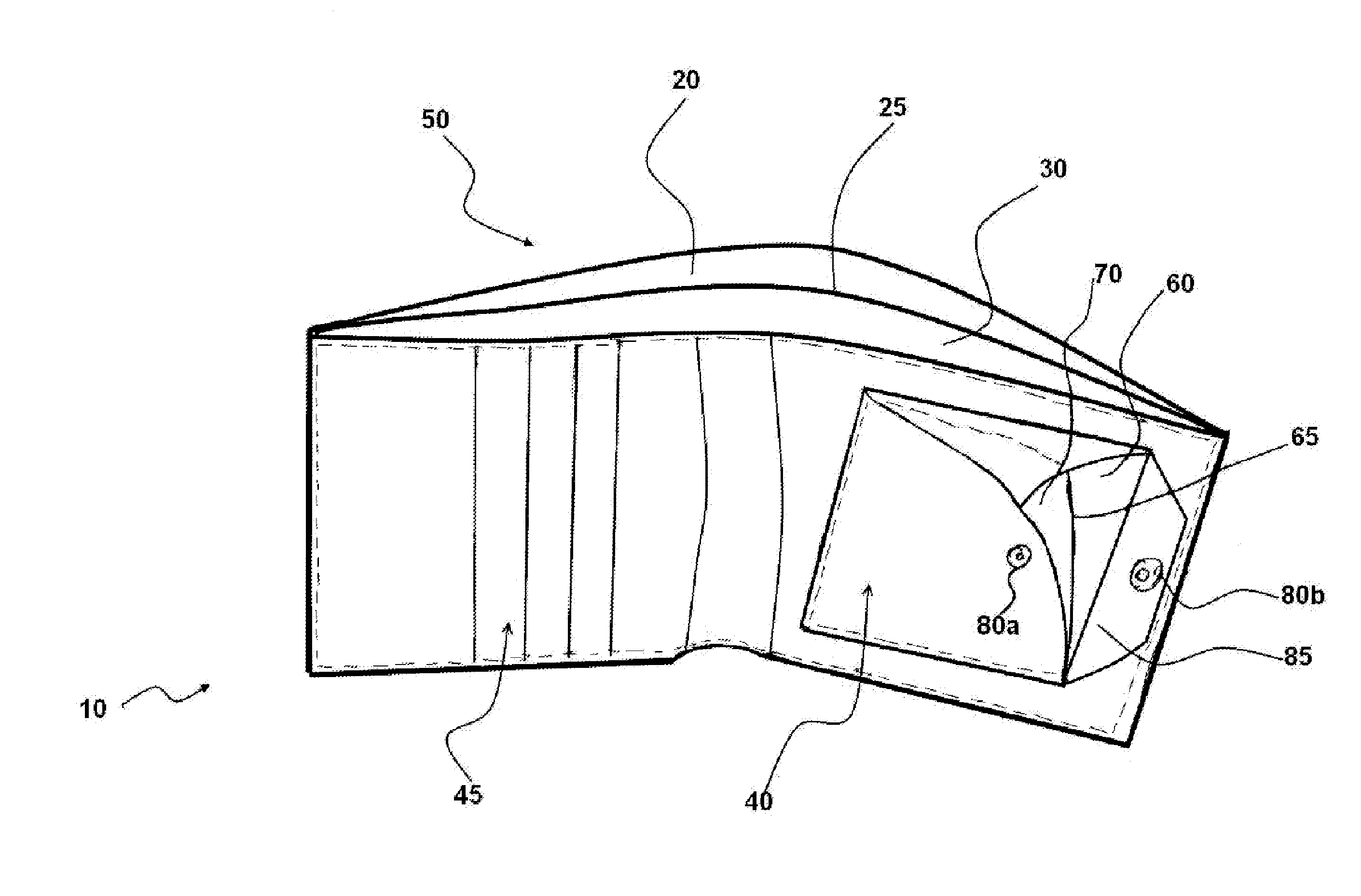

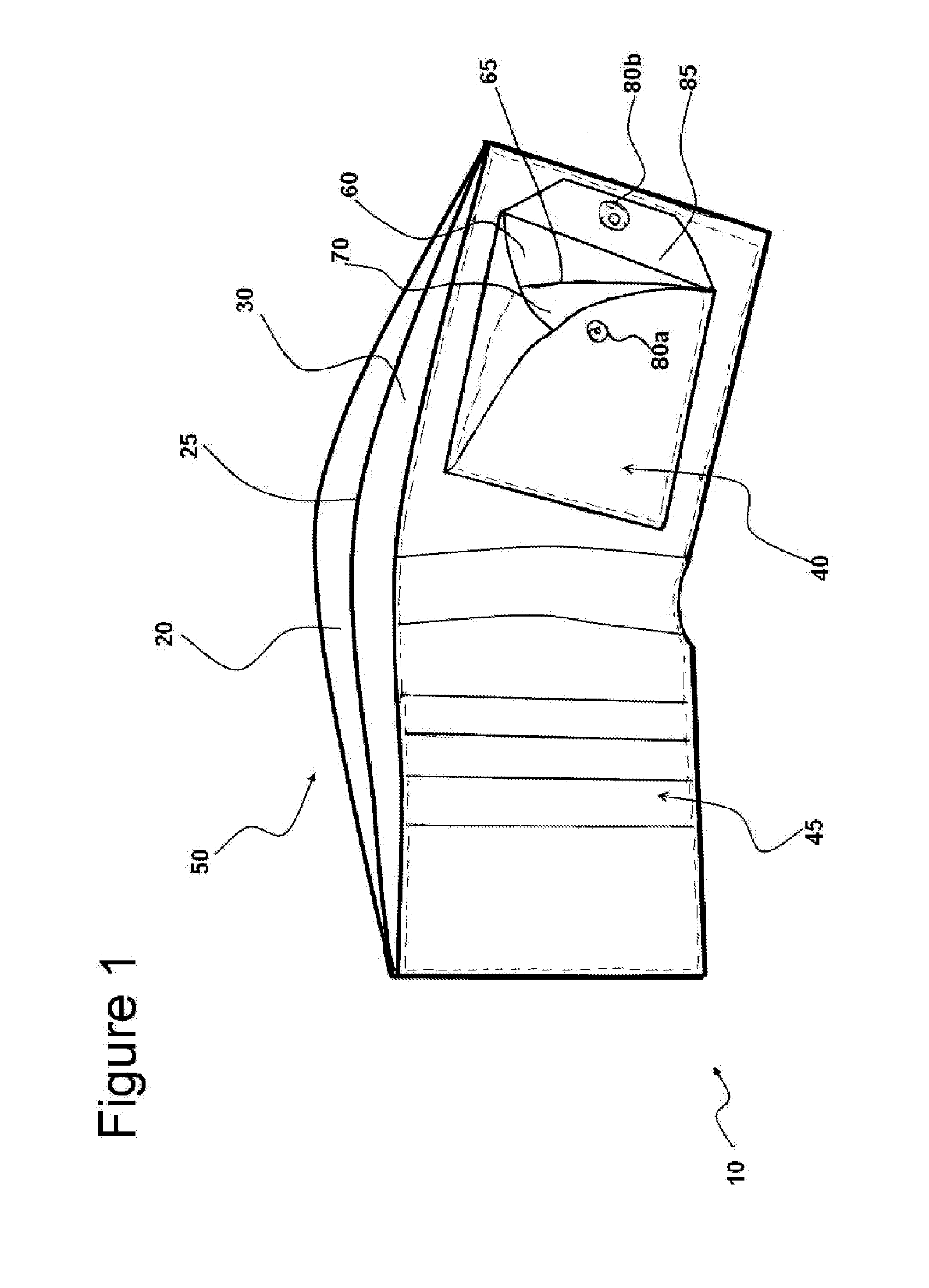

Diet Management System

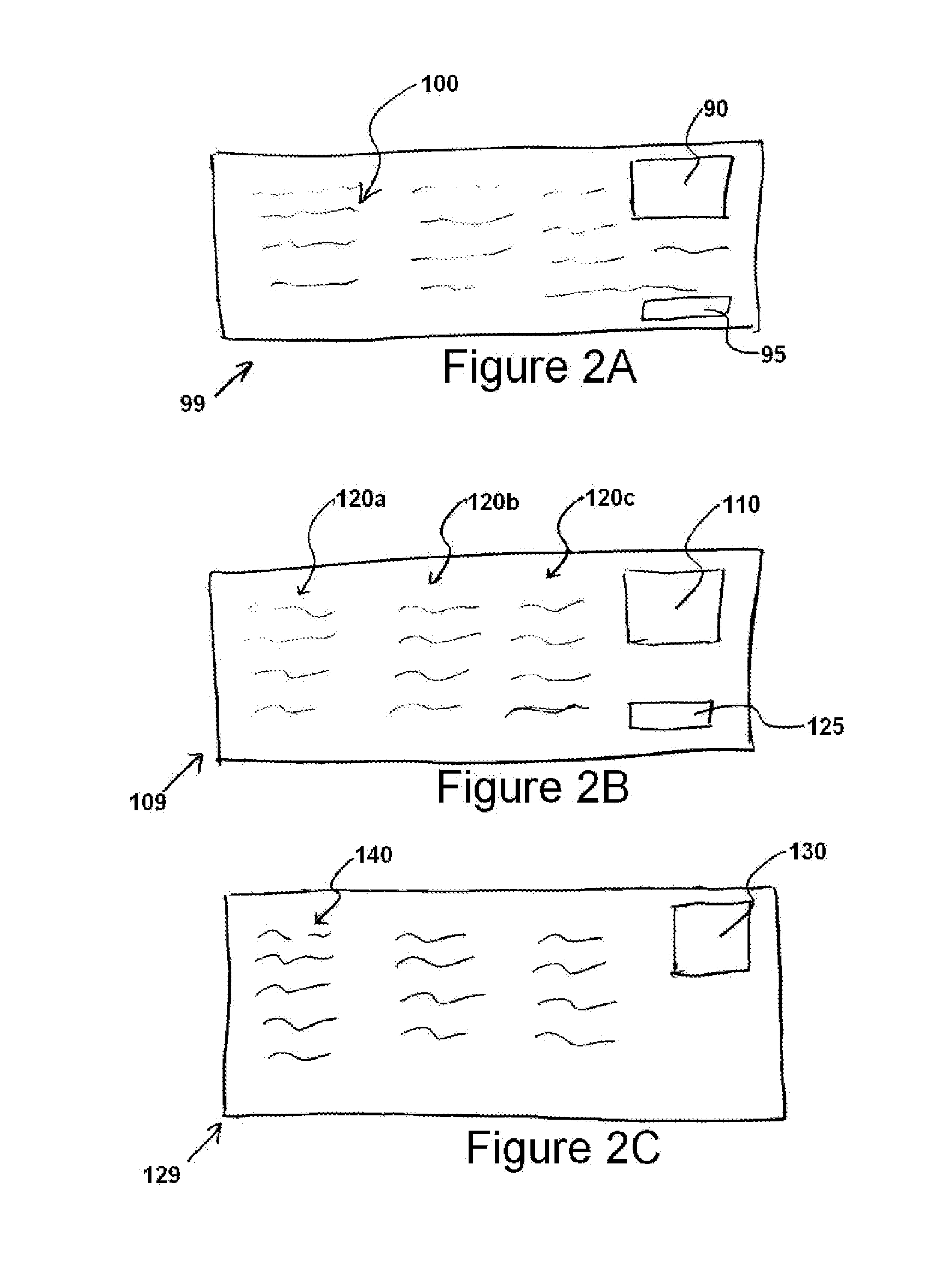

InactiveUS20110195383A1Easy visual identificationEasy visual identification of tracking mechanismTeaching apparatusCalorie intakeEngineering

A diet management system having a calorie consumption tracking mechanism, a calorie expenditure tracking mechanism, and a portable device, such as a wallet, comprising an area for bills and an area for coins. The area for bills and the area for coins are each divided into separate regions, such as by a divider. The calorie consumption tracking mechanism may utilize bills to track calorie intake, and the calorie expenditure tracking mechanism may utilize coins to track calorie expenditure. The system may include a water intake tracking mechanism to track the amount of water consumed. A user keeps track of the amount of calories consumed, and / or the amount of exercise activity the user engages in, by moving calorie consumption tracking bills and / or calorie expenditure tracking coins from a first region to a counterpart second section at or about the time calories are consumed and / or expended through exercise.

Owner:WEISS MELANIE

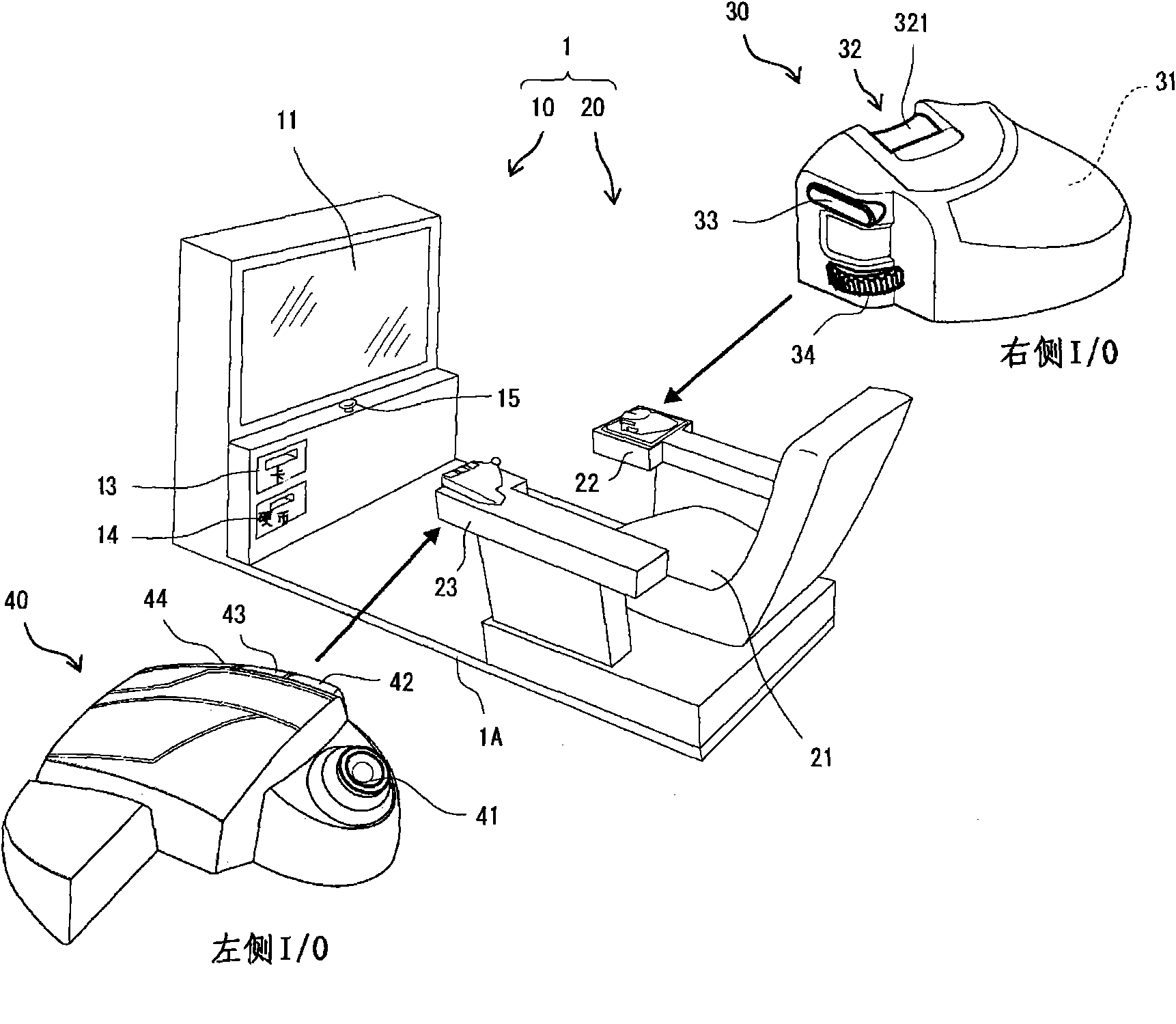

Video game apparatus, game information display control method and recording medium

ActiveCN101961556AEasy visual identificationVideo gamesSteroscopic systemsComputer graphics (images)Display device

The invention provides a video game apparatus and a game information display control method. The video game apparatus includes: a storage block that stores left eye-use and right eye-use images forming each of objects individually in a first aspect where a spaced distance is zero and a second aspect where the spaced distance has a predetermined value; processor that determines whether or not each of the objects to be displayed is capable of being designated; controller that individually reads out, in the second aspect, both images of the object capable of being designated, and otherwise in the first aspect, from the both image storage block, then guides the read out the both images to one displaying storage block to then synthesize the both images with each other there, and thereafter, reads out the synthesized image to a monitor capable of 3D stereoscopic display; and a processer that receives designation to the object displayed in the second aspect.

Owner:KONAMI DIGITAL ENTERTAINMENT CO LTD

Methods And Kits For Topical Application, Removal, And Inactivation Of Therapeutic Or Cosmetic Toxin Compositions

InactiveUS20120294844A1Easy visual identificationSafely applying and removing and inactivatingCosmetic preparationsNervous disorderMedicineTopical treatment

Owner:REVANCE THERAPEUTICS INC

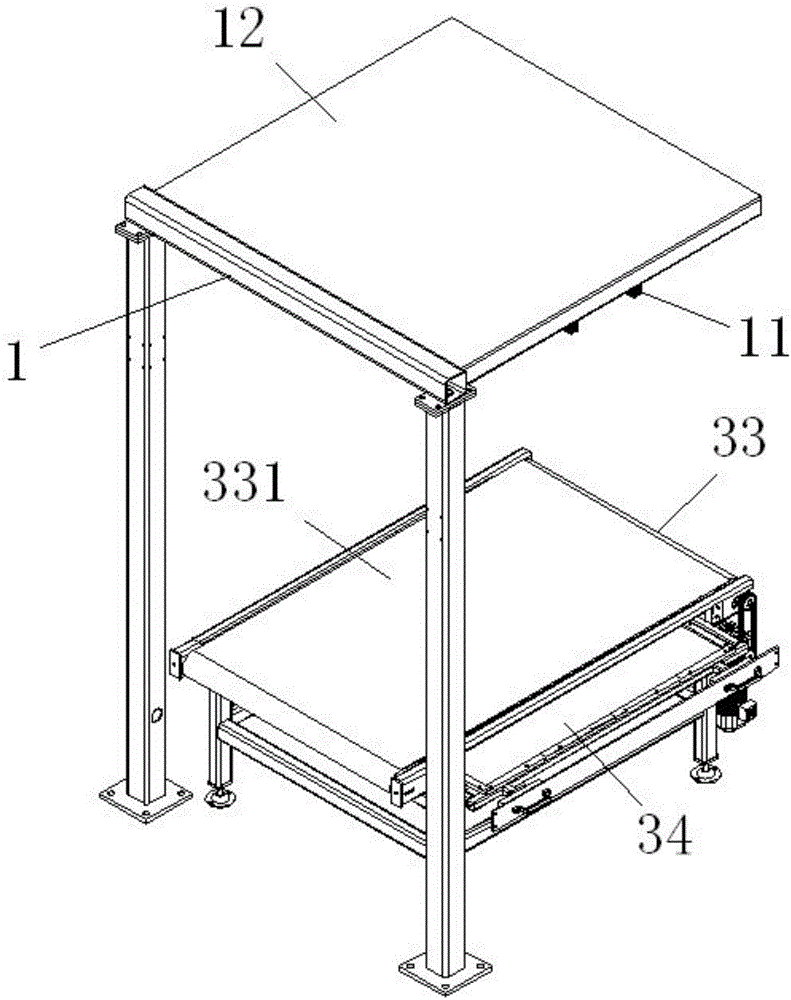

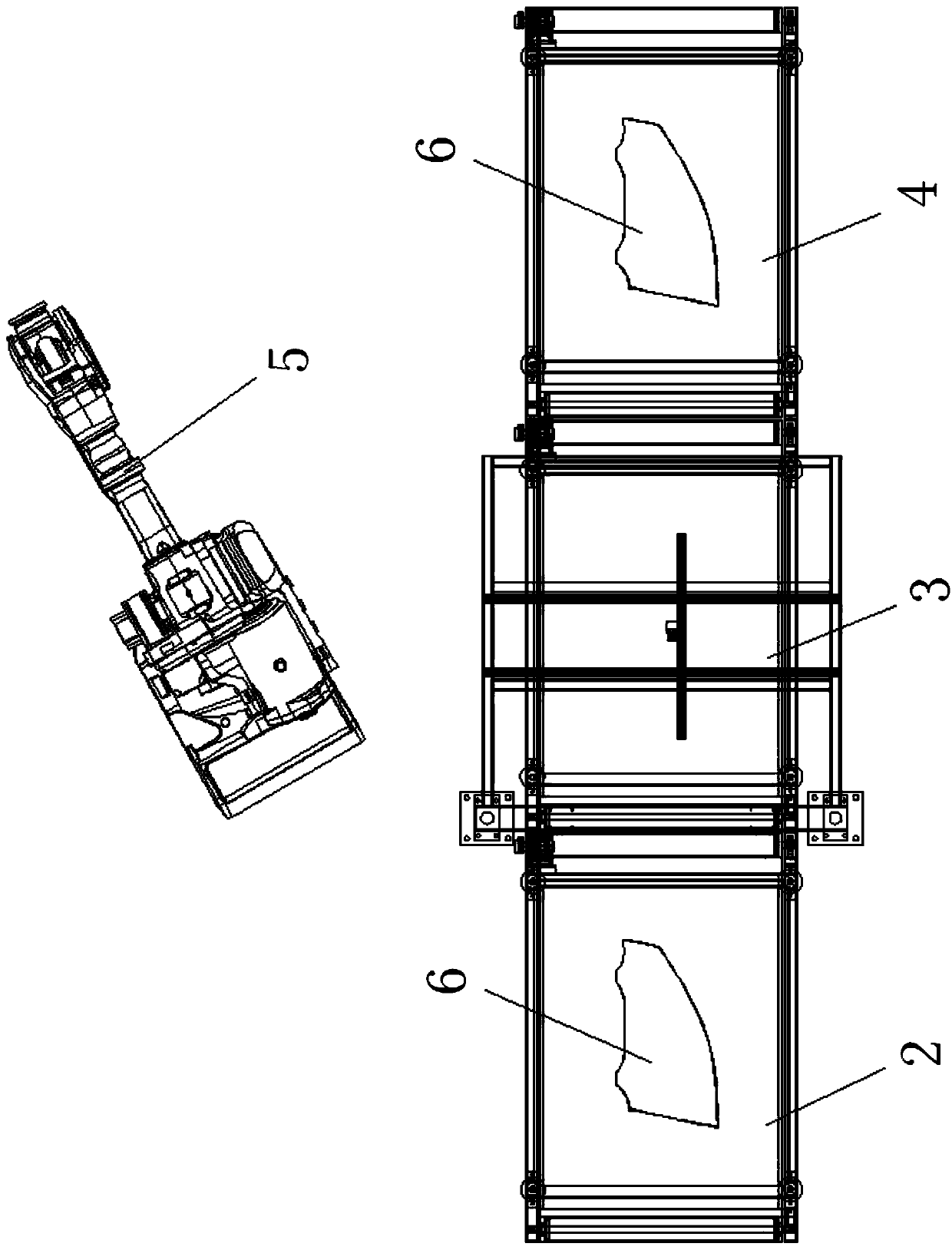

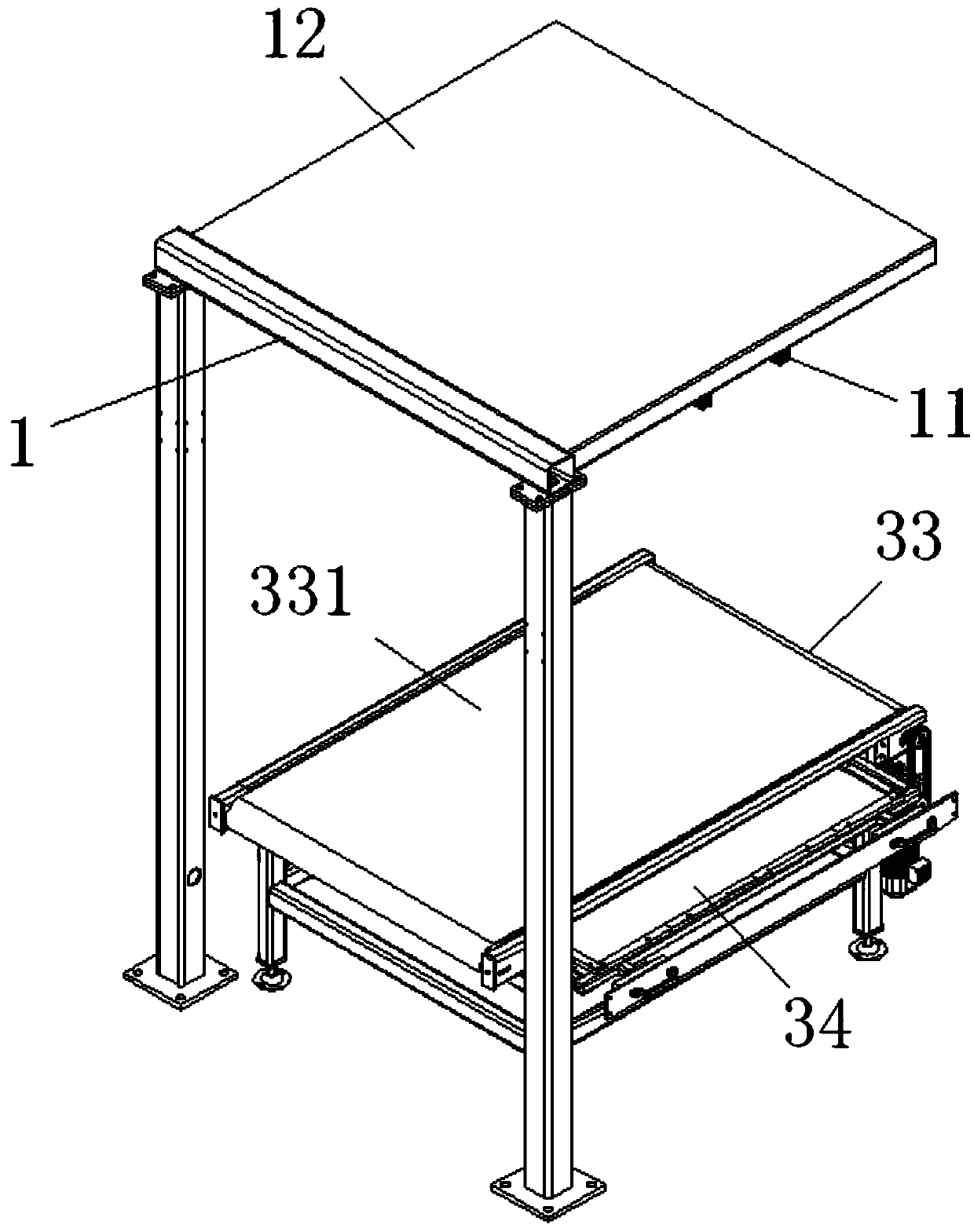

Glass transfer system based on robot vision

ActiveCN106516739AHigh positioning accuracyImprove positioning accuracyCharge manipulationConveyor partsConveyor beltVisual perception

The invention relates to the technical field of auxiliary equipment for glass machining, in particular to a glass transfer system based on robot vision. The glass transfer system comprises an on-chip transmission mechanism, a positioning transmission mechanism, a support, an industrial robot and a control unit. The on-chip transmission mechanism is connected with the positioning transmission mechanism in a butt-joint manner. The support is arranged above the positioning transmission mechanism. A vision identifying unit is mounted on the support. The positioning transmission mechanism comprises a driving roller, a driven roller and a transparent plane conveyor belt. The driving roller and the driven roller are sleeved with the transparent plane conveyor belt. A cavity is defined by the driving roller, the driven roller and the transparent plane conveyor belt. A face light source is arranged in the cavity. The face light source irradiates the vision identifying unit through the glass transmission face of the transparent plane conveyor belt. The control unit is electrically connected with the vision identifying unit and the industrial robot, and a moving locus of the industrial robot for capturing and transferring of glass to be transferred is set. The glass transfer system has the beneficial effects that the structure is simple and compact, positioning is fast and precise, the stability is good, continuous production is facilitated, and the production efficiency is improved.

Owner:FUYAO GROUP FUJIAN MACHINERY MFG

Safety three-dimensional code for block chain and generation and decoding method

ActiveCN112418371ARealize generationImplement decodingCo-operative working arrangementsRecord carriers used with machinesBlockchainData information

The invention discloses a safety three-dimensional code for a block chain and a generation and decoding method. The safety three-dimensional code comprises a code word positioning area, a code word starting point confirmation area, a code word control information area, a code word data information area and a picture area. Pictures, two-dimensional code and / or three-dimensional code words and setsare embedded into the picture area. The generation method comprises the following steps: acquiring data information to be transmitted and a picture, a two-dimensional code and / or a two-dimensional code word to be embedded; extracting picture characteristic value information and storing in a server, and forming data information to be transmitted through encryption, compression and error coding processing; and determining the composition and size of the security three-dimensional code, and filling the security three-dimensional code with the content of each region to generate a corresponding security three-dimensional code. The decoding method comprises the steps of scanning and photographing the safety three-dimensional code, obtaining a picture, processing and restoring the picture, performing error control decoding and decompression on restored information, and reading and decrypting data information through the code scanning terminal. According to the invention, the anti-counterfeiting performance is effectively improved, and the visual identification of the embedded picture is improved.

Owner:上海巨通电子有限公司

Temporal visualization algorithm for recognizing and optimizing organizational structure

InactiveUS20070276775A1Improve efficiencyEasy visual identification2D-image generationGenetic modelsComputer scienceVisualization algorithms

A system is provided that takes as input the interrelationships which are observed between identified resources, and automatically generates interactive movies that depict a visualization of the of the interaction patterns among the identified resources. Each resource is represented as a dot. A line between two dots indicates a relationship. The closer the two dots are placed together, the more intensive is their relationship, that is, the more commonality or interaction those resources share. Further, the most active resources, namely the resources that have the most relational links or lines extending therefrom, are placed in the center of the network. Once the visualization movie has been built, a user can search for groupings of related resources by simply searching for and identifying the various clusters within the network.

Owner:TEKFLO

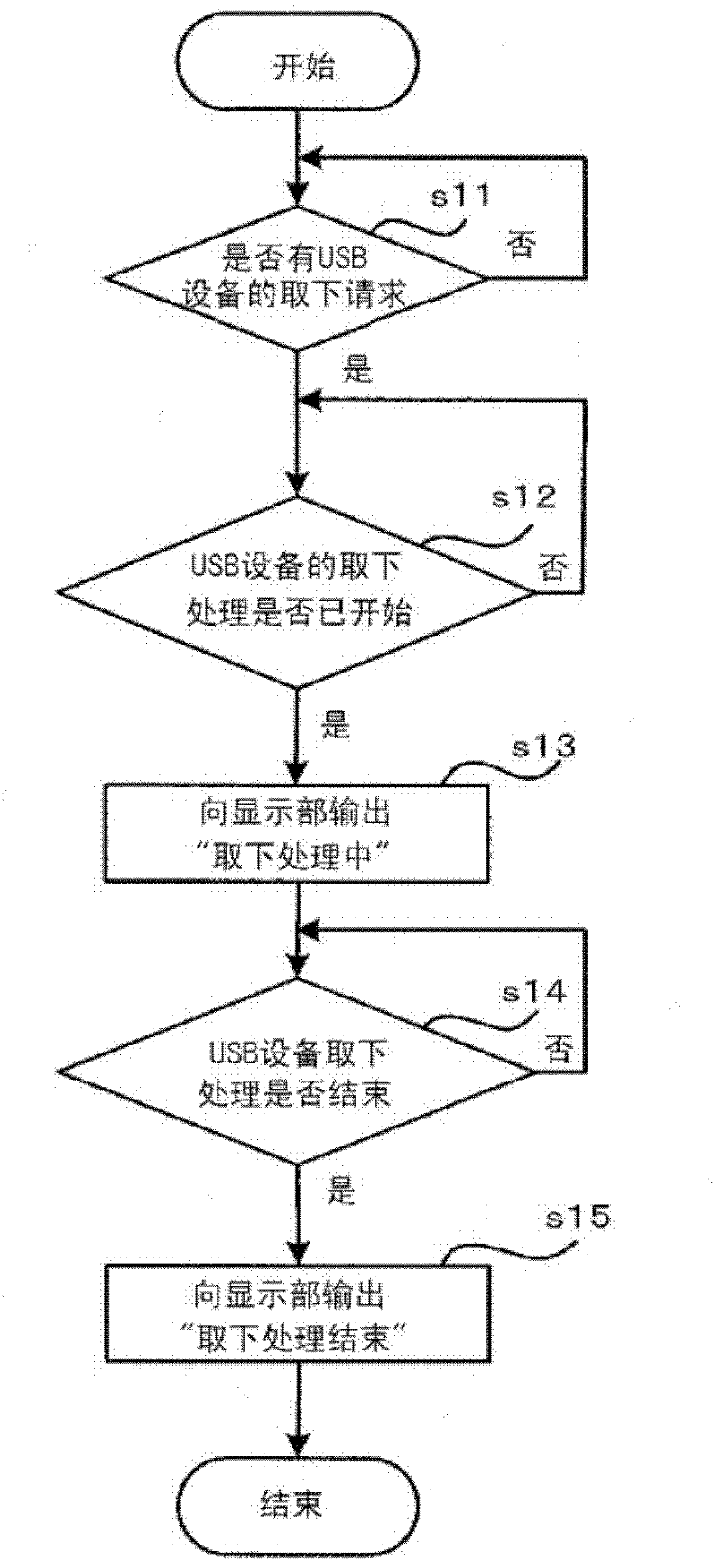

Information processing device having USB ports

InactiveCN102243616AEasy visual identificationElectric digital data processingInformation processingOutput device

The invention provides an information processing device having USB ports, which can easily visually identify the connecting states of USB devices including the state of applicability or the state of being capable of being removed and remove USB devices having USB ports when no output device such as a mouse or a keyboard is connected. In the embodiments, the information processing device comprises USB ports, an input part for inquiring removing performances of a USB device from the USB ports, a USB device connecting control part for performing the connecting processing state operation of the USB device during a connecting state with the USB port and further performing the removing processing state operation of the USB device during a removed state, an input output control hub for sending signals showing whether the USB port and the USB device is connected or not to the USB device connecting control part, as well as removing inquiring signals from the input part, and receiving the output from the USB device connecting control part and further output the connecting processing state as well as the removing processing state of the USB device, and a display part displaying the output of the input output control hub.

Owner:KK TOSHIBA

Method for manufacturing logo pattern based on different color characteristics of metal or alloy

InactiveCN109280874AReasonable designEasy to implementMolten spray coatingLaser beam welding apparatusBase codeNumerical control

The invention particularly relates to a method for manufacturing a logo pattern based on different color characteristics of metal or alloy, and belongs to the field of thermal spraying and laser etching. The method for manufacturing the logo pattern based on different color characteristics of metal or alloy comprises the steps that (1) the portion, to be marked with the pattern, of the surface ofa to-be-manufactured object is cleaned, and the portion, not to be marked with the pattern, of the surface of the to-be-manufactured object is covered to be prevented from being stained; (2) the portion to be marked is sprayed through a thermal spraying device by means of the thermal spraying technique; and (3) mark contents are typeset through a computer, and a laser etching machine and a laser carving machine head are controlled through the numerical control technique to conduct etching. The method is mainly used for metal products in the oil field industry, the ship industry, the military industry, the automobile industry, the power industry and the like and can be widely used for marking articles used in severe working conditions with full-life-circle patterns. Character patterns, figure patterns, two-dimensional bar patterns and bar code patterns formed through the method are easy to recognize visually and can be recognized and input through machine-based code scanning, and backstage management is facilitated.

Owner:赵宏达

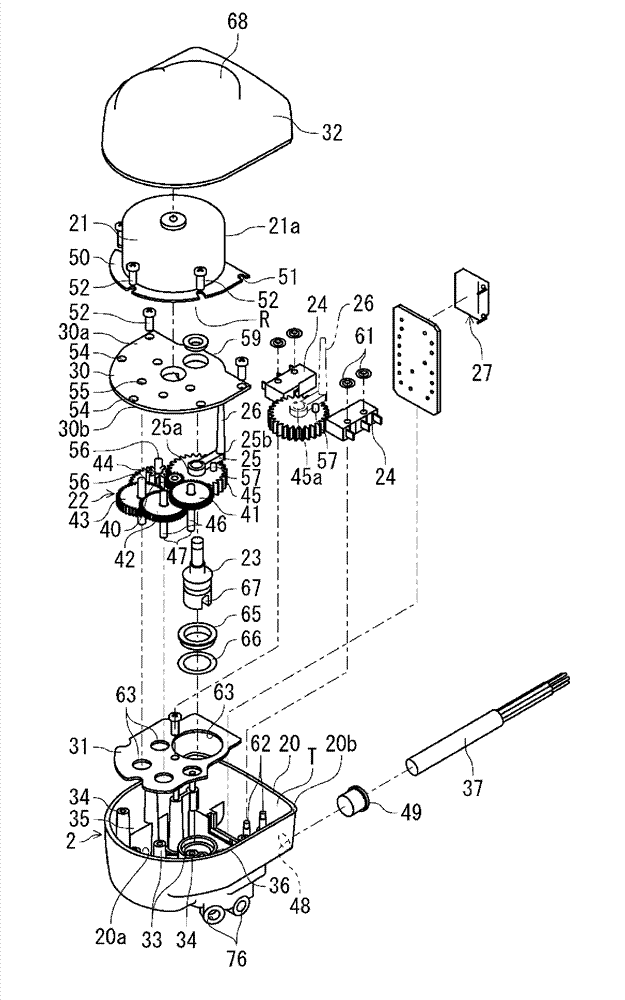

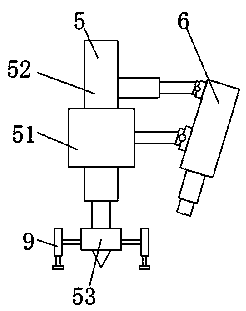

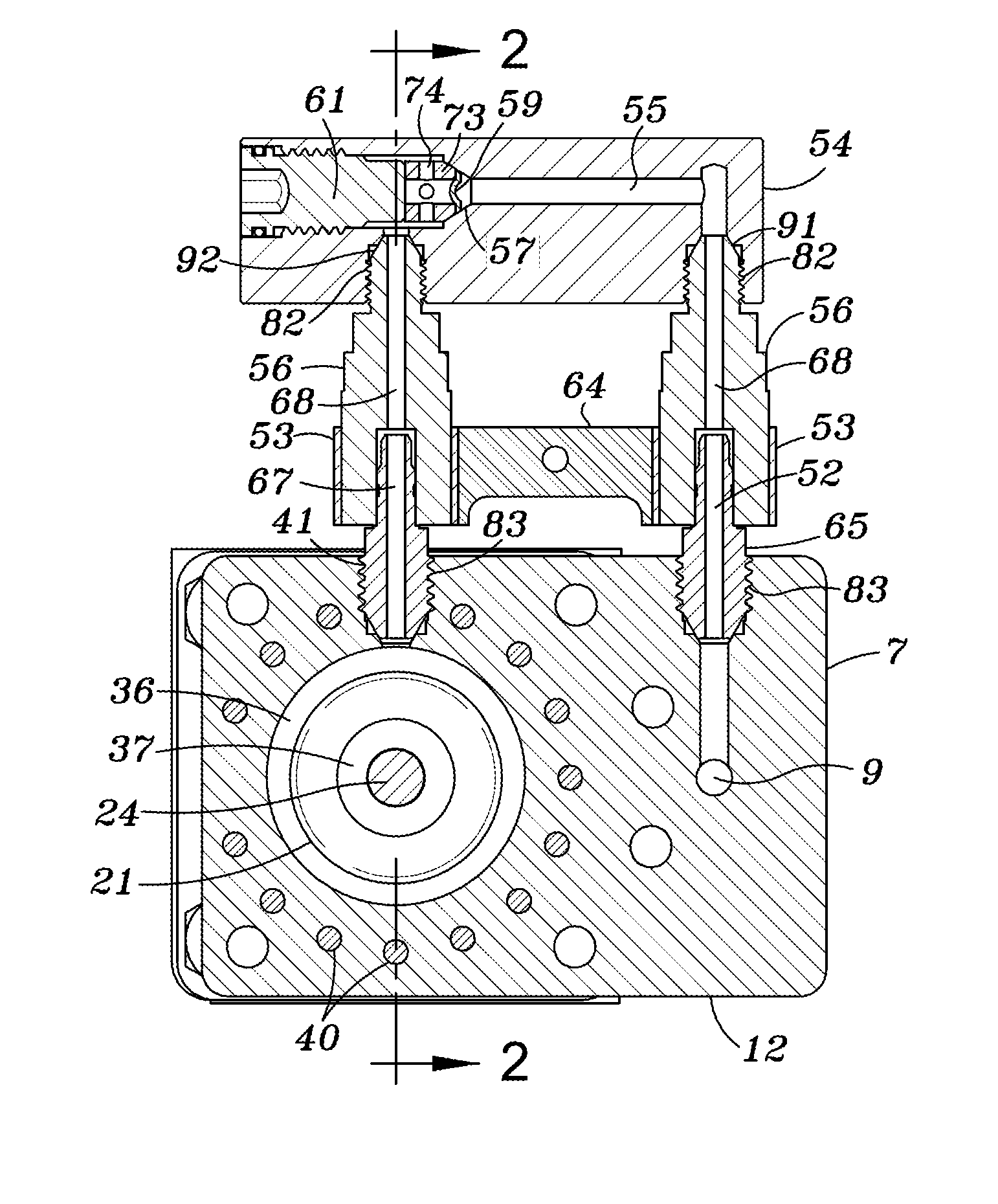

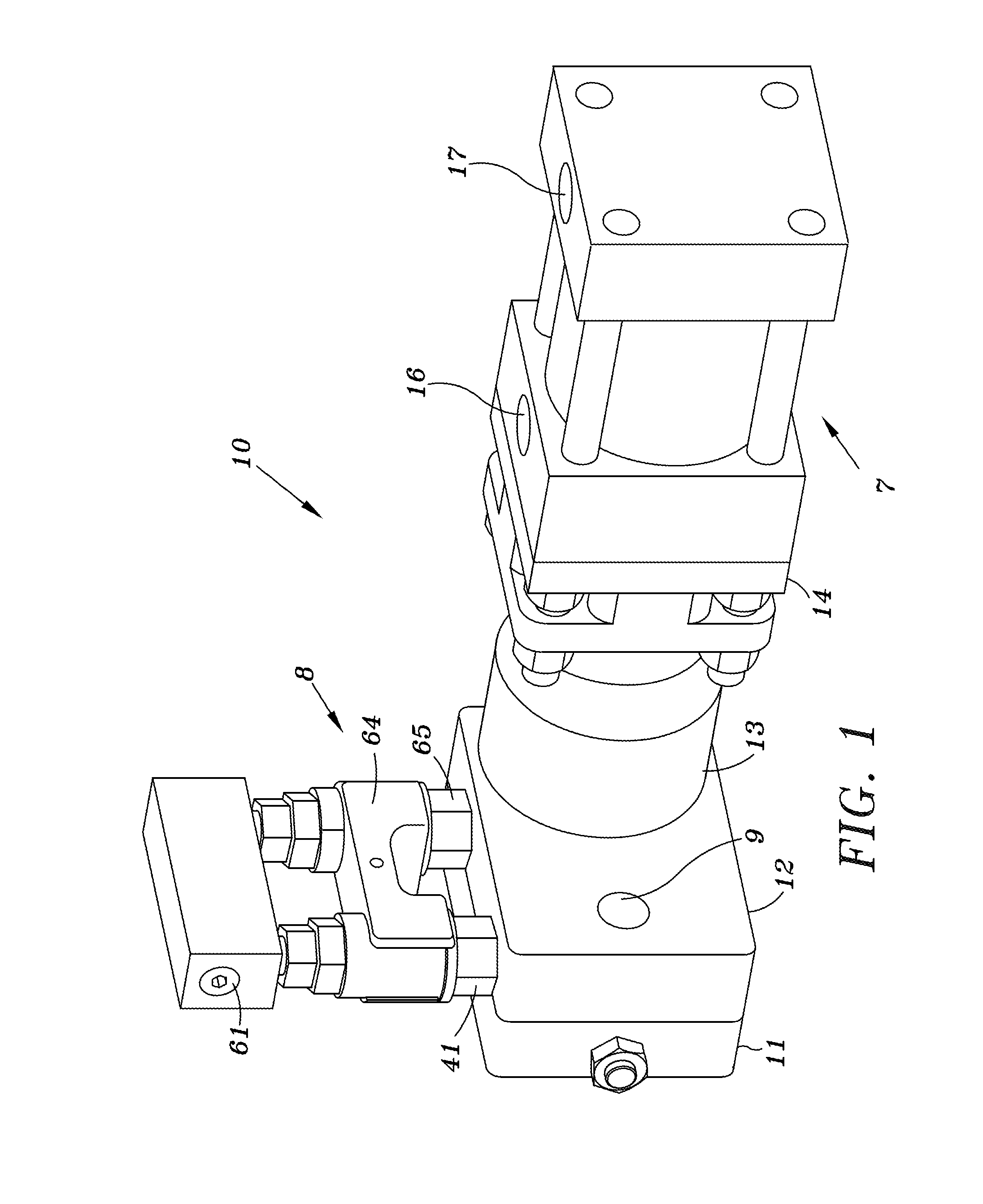

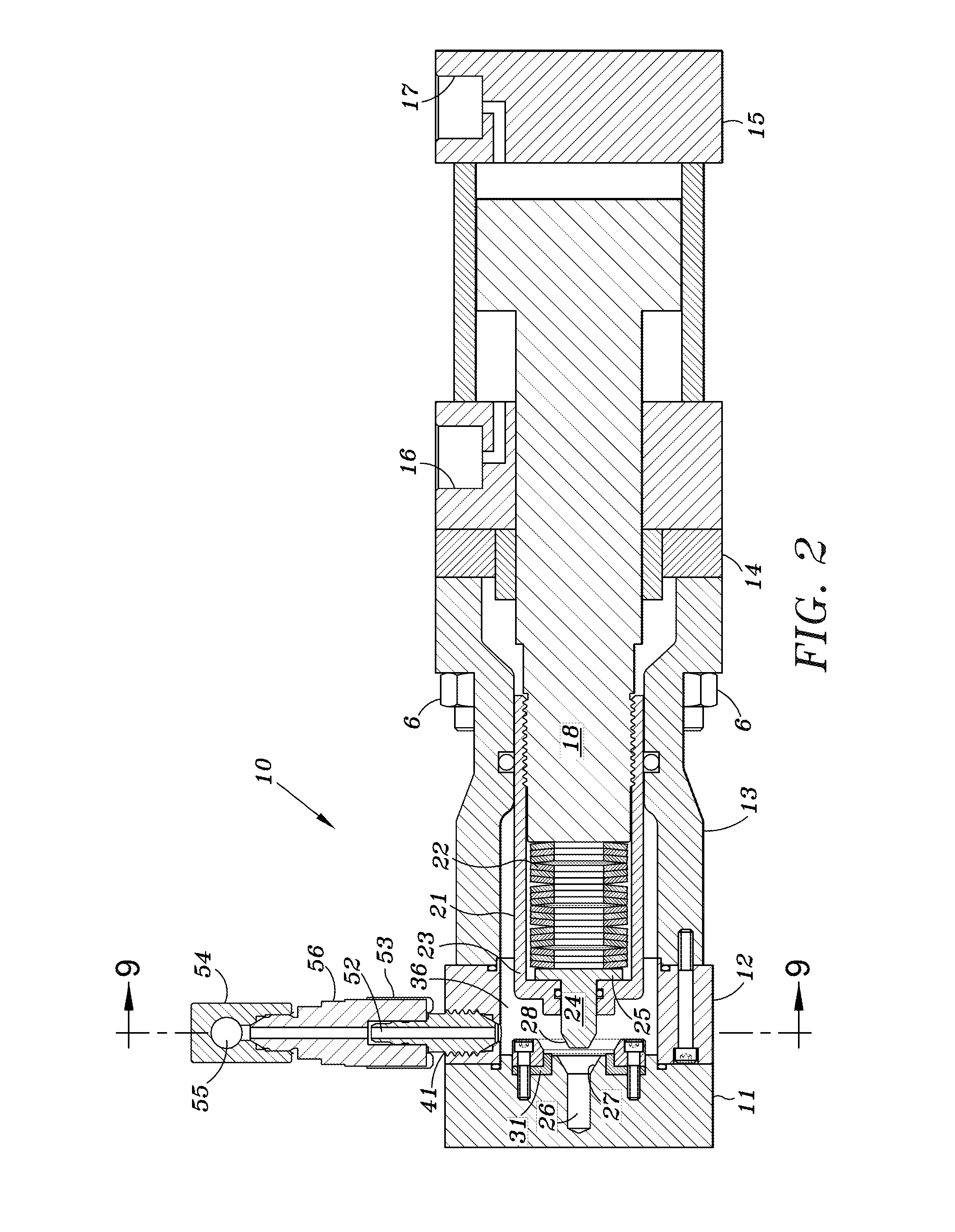

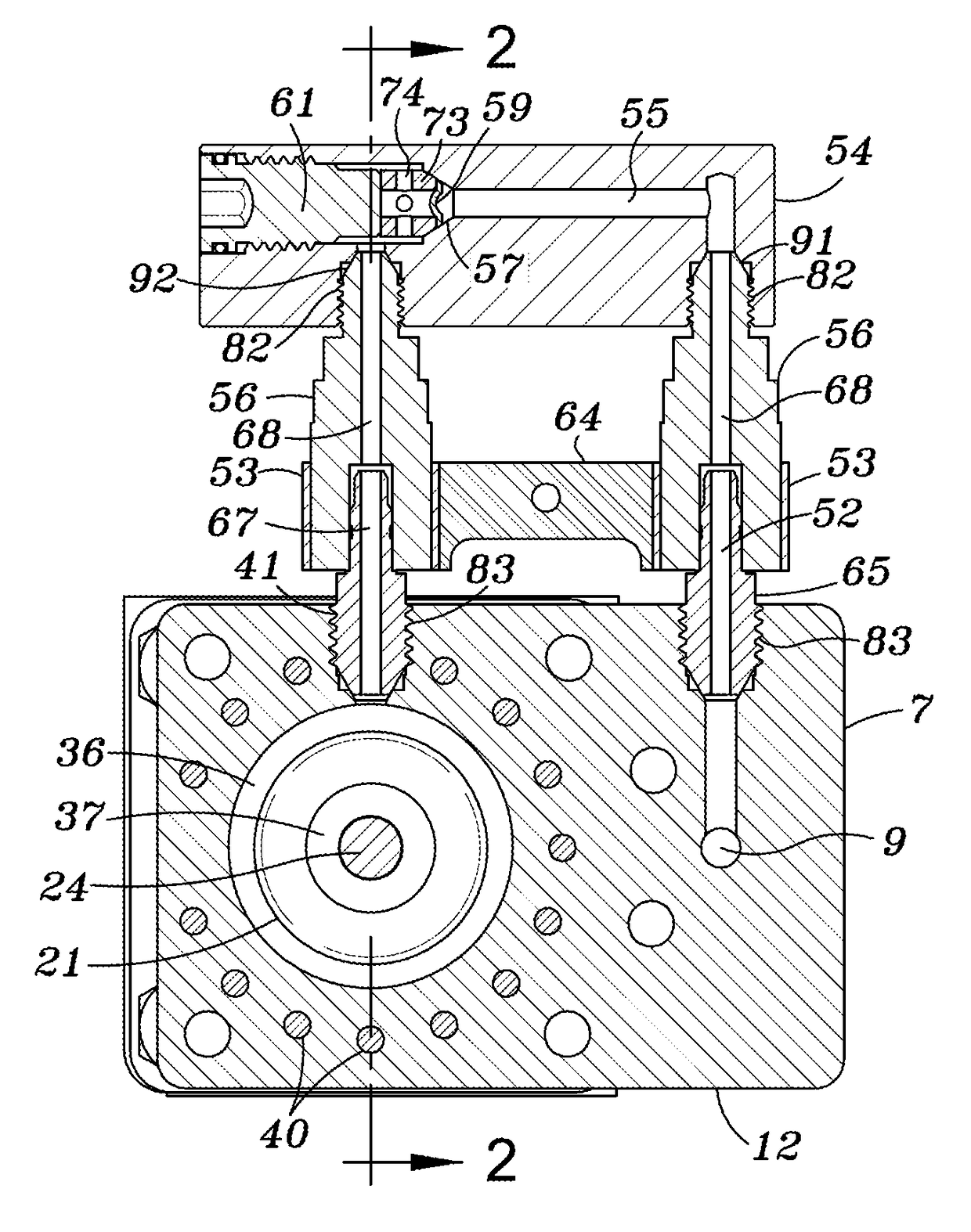

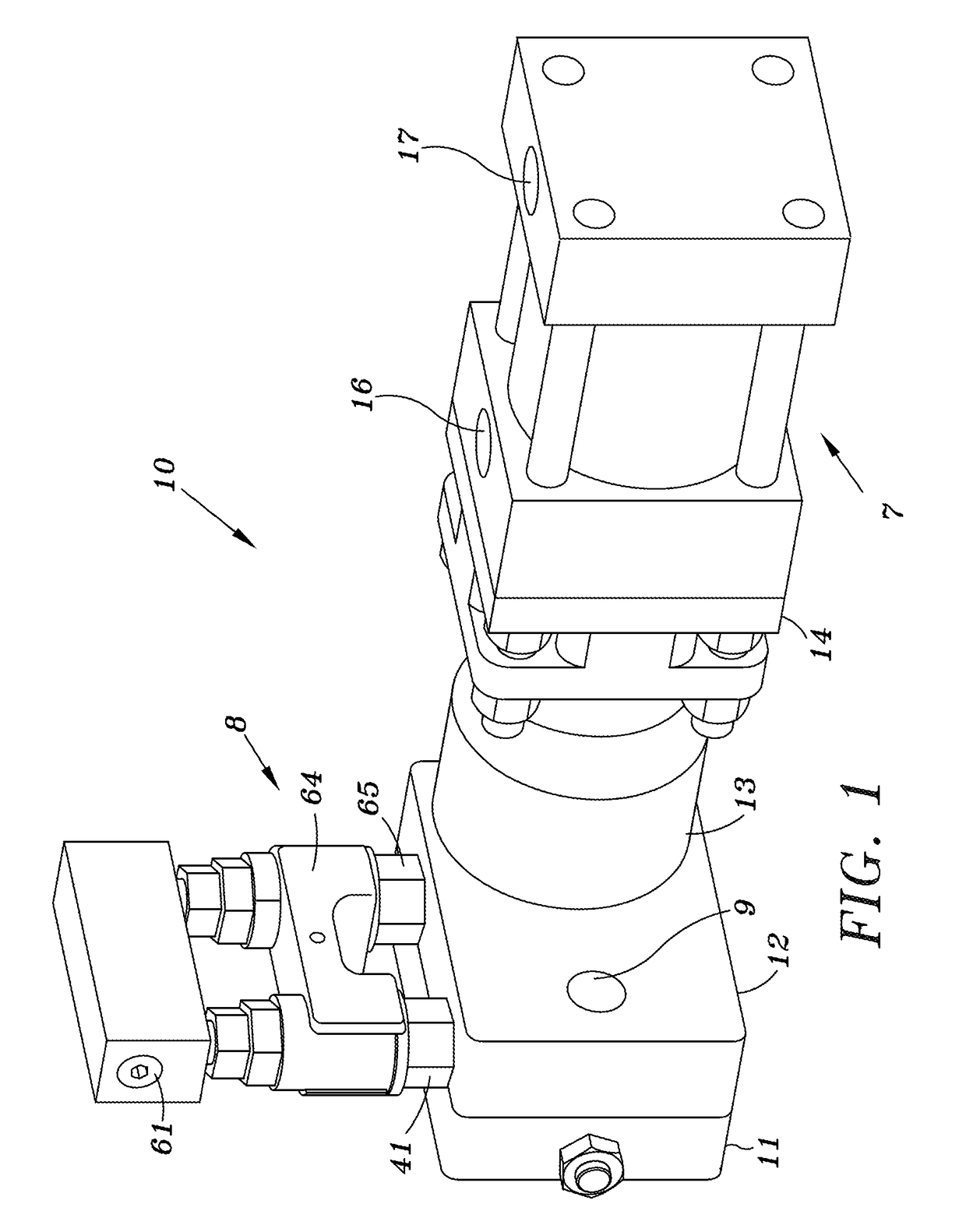

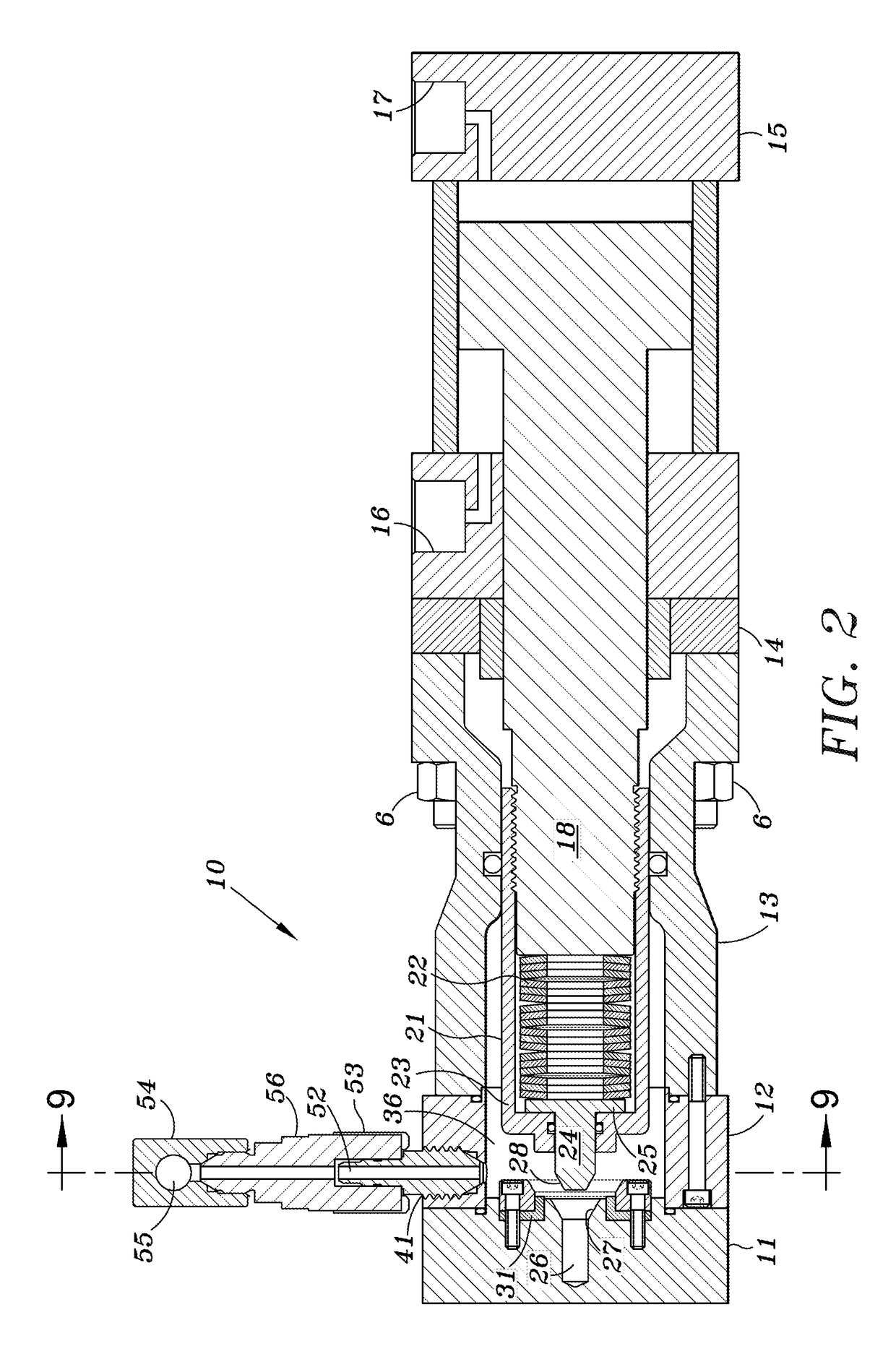

Rotary valve with the actuator and the actuator of the rotary valve

ActiveCN102954266APrevent dumpingPrevent looseningPlug valvesOperating means/releasing devices for valvesRotary valveActuator

The present invention provides a rotary with an actuator, being able to achieve compactness and to assemble compactly and achieve miniature of a device, realizing space-saving, being able to be configured in the settings in the narrow place without processing precision and the adjustment of the flow to the position relationship between valve and actuator to established high precision and easy to dismount, and provides an actuator with a rotary valve being able to ensure compactness with the necessary minimum number of parts and ensure excellent visual identity and being able to easily confirm the valve opening. Through the valve rod (7) that is built into the subject body (5), (4) using the actuator (2) make the valve rod rotation. With in the main body of the valve rod shaft side of the outer top face (8) fixed on the connecting plate body (3), carrying actuator on the connection plate body, and using the connecting mechanism (90) set the valve and actuator (1) ontology is able to tear open outfit, described by connecting mechanism from the transverse direction of the axis of the stem cross plug off the fixed body composition.

Owner:KITZ CORP

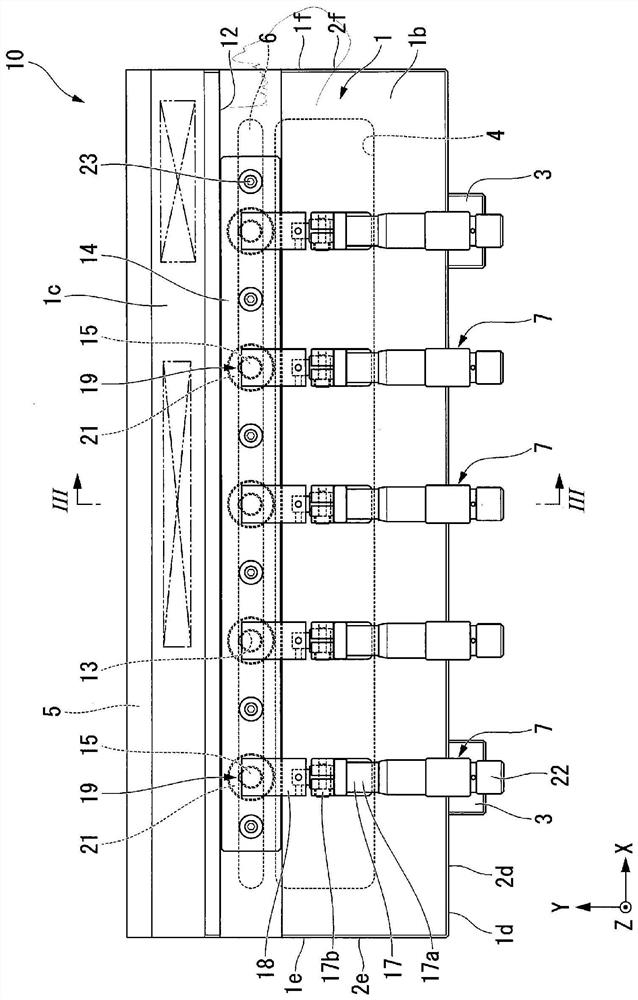

Coating tool and coating method

PendingCN112912183AEasy visual identificationEasy to adjust the positionPretreated surfacesCoatingsCamMoving parts

The present invention is equipped with a first head member (1) and a second head member (2) which are positioned so as to be adjacent in a first direction and extend in a second direction which is perpendicular to the first direction, a slot (5) which opens to the outside from between the tip section of the first head member (1) and the tip section of the second head member (2) in a third direction which is perpendicular to both the first direction and the second direction, a choke bar (6) which extends in the second direction inside the first head member (1) and is capable of projecting into the slot (5) from the first direction, and an adjustment mechanism (7) for adjusting the amount by which the choke bar (6) projects into the slot (5), the adjustment mechanism (7) having a shaft (15) which extends in the first direction inside the first head member (1) and is secured to the choke bar (6), a moving part (18) capable of moving in the third direction relative to the first head member (1), and a cam part (19) for converting the movement of the moving part (18) in the third direction into movement of the shaft (15) in the first direction.

Owner:菱技精密工具株式会社

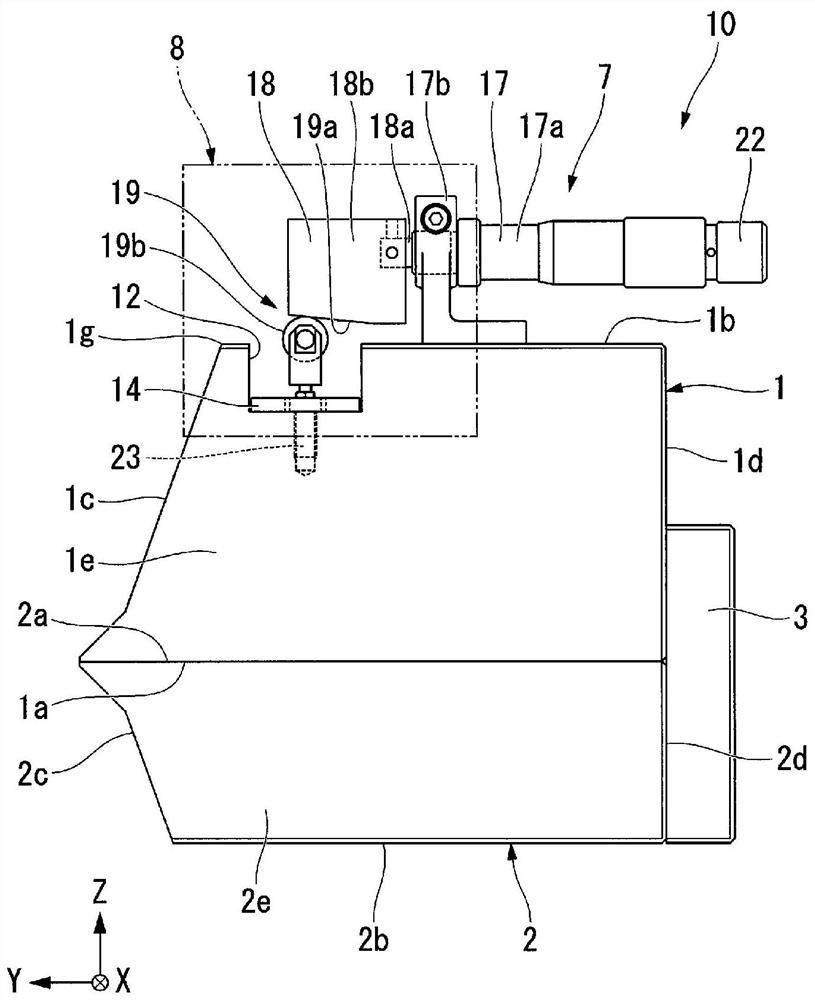

Displaying attenuating audio signal level in delayed fashion

InactiveUS20160274858A1Readily-recognizable level displayQuicker attenuation characteristicSignal processingSound input/outputUltrasound attenuationTemporal information

A disclosed apparatus includes: a setting section that variably sets a display delay time relative to attenuation variation of the level of the audio signal; and a control section that controls, in accordance with the display delay time set by the setting section, an attenuation style of the level of the audio signal to be displayed on the level meter. For example, per different type of supply source of the audio signal, display delay time information predefining a display delay time suitable for the type is stored in a memory. Based on the display delay time information stored in the storage section, the setting section sets a display delay time corresponding to the type of the supply source of the audio signal.

Owner:YAMAHA CORP

Refrigerator

InactiveCN100381773CEasy visual identificationDomestic cooling apparatusLighting and heating apparatusBlack outDisplay device

The invention relates to a refrigerator which has open and close switches (61) arranged on a pair of open-and-close doors (11), display devices (200) arranged on panels (103) respectively arranged at the lower parts of the doors, pull handle dents (106) formed at the lower ends of the panels and a control device (60) ensures that the display devices are on state when the doors are opened, wherein each display device has a club-shaped transparent diffused plate (202) and a light source (201) arranged in the longitudinal direction of the diffused plate; the front face P1 which is arranged at one side of the long side of the diffused plate adjacent to a door surface is made into a flat surface, while a back face P2 opposite to the front face is made into a concavo-convex shape; moreover, a large curved surface which is tapered off from one end in the longitudinal direction provided with the light source to the other end is formed; the control device (60), which controls the gradual lighting up of lamps from the light source side to the other end in the longitudinal direction and the gradual black out of the lamps from the other end to the light source side, ensures that both display devices and the pull handle dents are arranged side by side in vertical direction.

Owner:HITACHI APPLIANCES INC

Adjustable dustproof and moistureproof industrial Ethernet switch

ActiveCN112752168AEasy to cleanEasy to replaceClimate change adaptationSelection arrangementsIndustrial EthernetRotational axis

The utility model discloses an adjustable dustproof and moistureproof industrial Ethernet switch, and belongs to the technical field of communication equipment industrial switches. A counterweight base is arranged below the switch shell, a rotating motor is fixedly arranged in an open slot of the counterweight base, and the rotating motor is in upward output connection with a rotating shaft rod, penetrates through the switch shell, extends into the switch shell, is detachably connected with a blast adsorption assembly and can control the blast adsorption assembly to rotate in a linkage manner; hydraulic power cylinder bodies are arranged on the left and right sides of the counterweight base, and the upper part of an output hydraulic telescopic rod is fixedly connected with a switch shell, so that the switch shell can be controlled to lift up and down in a linkage manner; the blast adsorption assembly comprises a blast electric fan and a hollow pipe body; the top wall surface and / or the side wall surface of the switch shell are / is connected with a silica gel water absorption assembly in a sealed and embedded manner; the left and right ends of the switch housing are hermetically provided with cooling heat absorption assemblies penetrating the upper and lower wall surfaces. Dehumidification, dust removal, heat absorption and heat dissipation can be comprehensively and efficiently carried out in the switch shell, and the application effect is good.

Owner:INFORMATION & COMM COMPANY OF STATE GRID HEILONGJIANG ELECTRIC POWER COMPANY +2

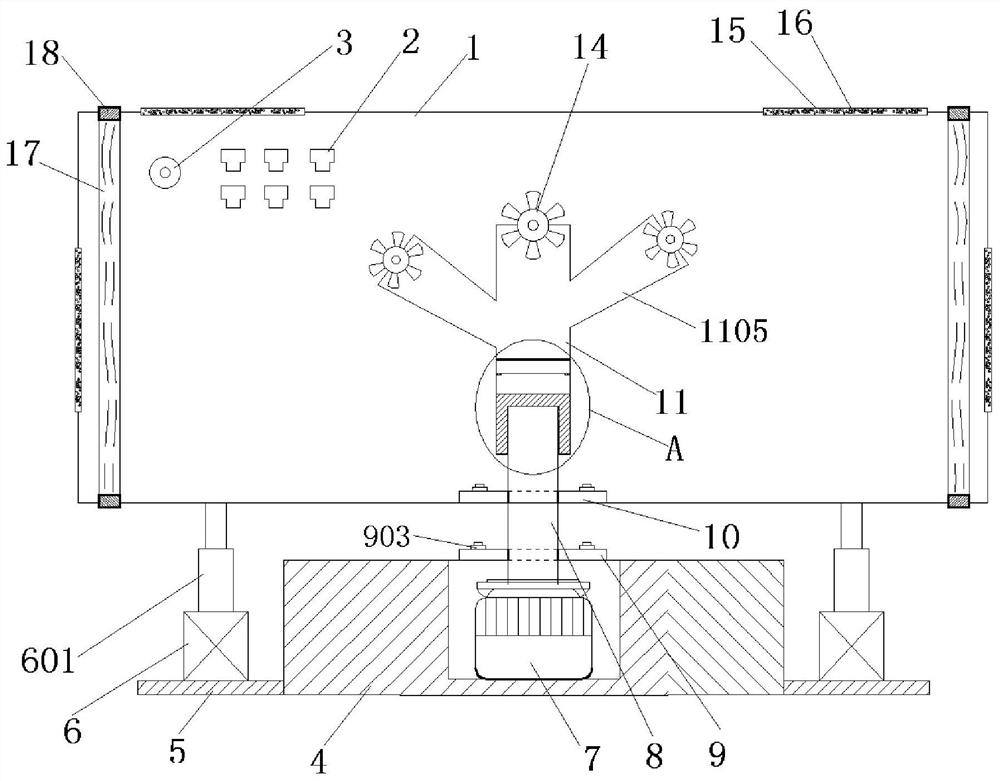

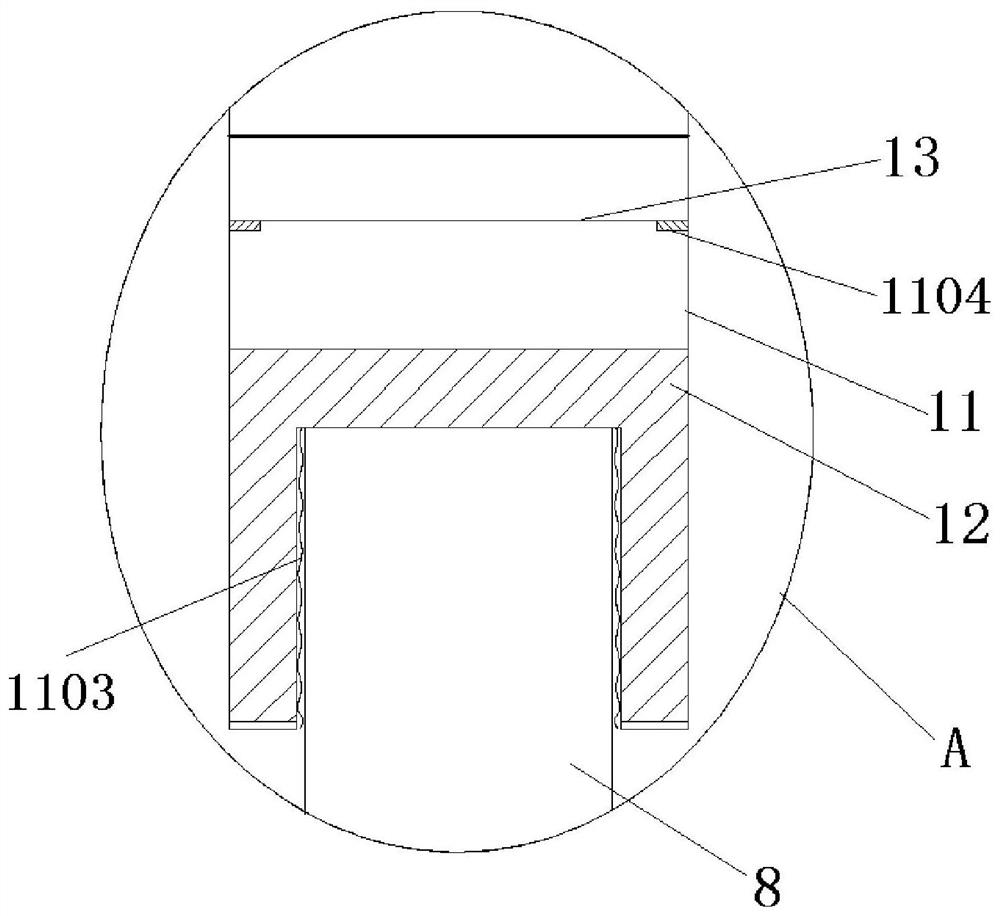

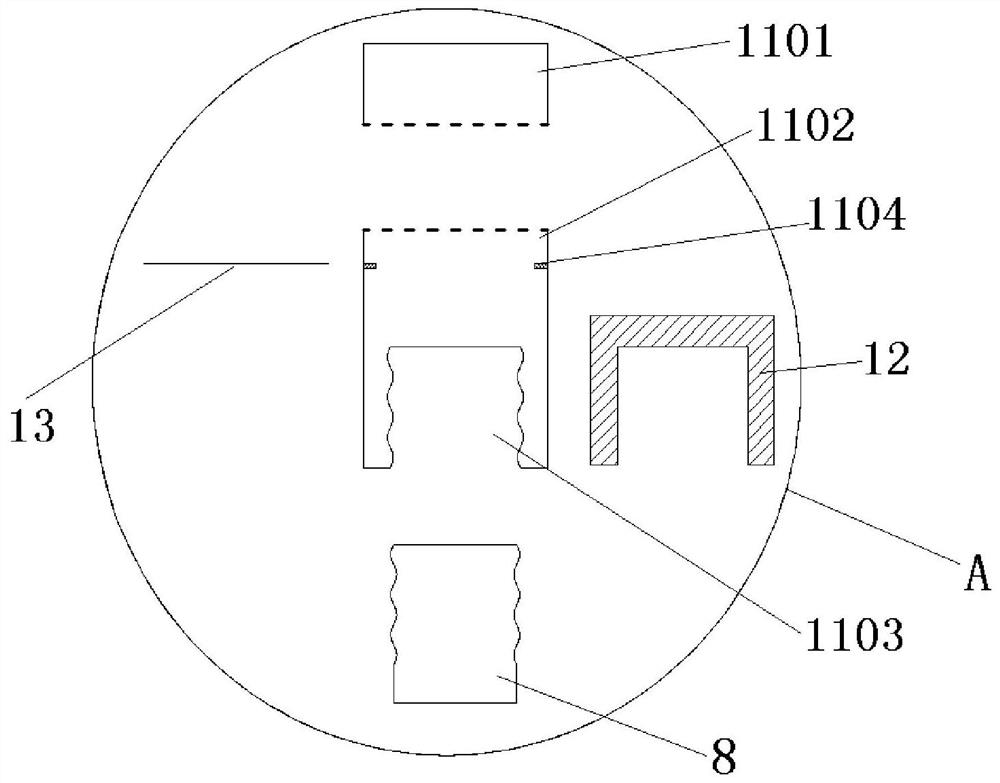

Welding robot with laser vision tracking system

InactiveCN108927614ASmooth connectionImprove welding effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

The invention provides a welding robot with a laser vision tracking system, and relates to the field of welding robots. The welding robot with the laser vision tracking system comprises a welding table, the bottom of the welding table is connected with a placement seat, the top of the welding table is connected with a welding object placement seat, one side of the welding table is connected with an adjusting device, one side of the adjusting device is connected with a welding device, one side of the welding device is connected with a laser correcting device, the front side of the welding tableis provided with a switch, and the top of the welding table is connected with a welding object placement device. According to the welding robot with the laser vision tracking system, the operation ofan adjusting motor is achieved, so that a threaded rod pushes a sliding seat to be close to the welding object placement seat, then an object at the top of the welding object placement seat and an object at the top of the sliding seat are close to each other, the connection between the two objects is improved, and the welding effect of equipment is improved.

Owner:扬州市诚智自动化装备有限公司

Rotary valve with actuator and actuator for the rotary valve

ActiveCN102954266BPrevent dumpingPrevent looseningPlug valvesOperating means/releasing devices for valvesValve actuatorRotary valve

To provide a small and space-saving device that can be as compact as possible and can be assembled into equipment, etc., can be arranged in a narrow installation location, and can be used for valves and actuators without machining accuracy and flow path adjustment work. A rotary valve with an actuator that can be easily attached and detached with high precision in a predetermined positional relationship, and can easily confirm the valve opening by ensuring compactness with the necessary minimum number of parts and ensuring excellent visibility Actuator for the rotary valve. The valve body (5) built into the main body (4) is rotated through the valve stem (7), and the valve stem is rotated by the actuator (2). The connection plate (3) is fixed on the outer peripheral top surface (8) of the valve stem shaft side of the main body, and the actuator is mounted on the connection plate, and the valve (1) and the actuator are connected by the connection mechanism (90). The actuator body is provided to be detachable, and the connecting mechanism is composed of a fixing mechanism inserted and removed from a lateral direction intersecting with the axial direction of the valve stem.

Owner:KITZ CORP

Panoramic image generation device and panoramic image generation method

InactiveCN102469259BEasy visual identificationTelevision system detailsColor television detailsComputer graphics (images)Image generation

A panoramic image generation device generates a panoramic image by synthesizing a plurality of static images constituting the moving image, determines a size at which a display panoramic image is to be cut out from the panoramic image, and detects a focus photography position from the panoramic image. The panoramic image generation device cuts out the display panoramic image from the panoramic image on the basis of the detected focus photography position and the determined size.

Owner:OLYMPUS CORP

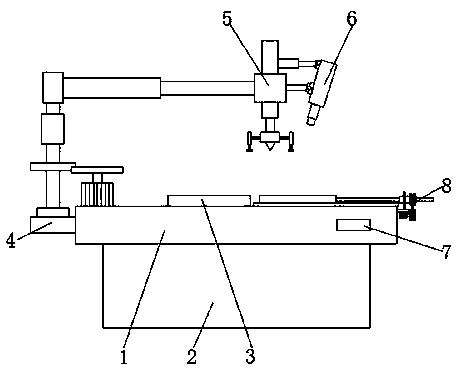

A glass transfer system based on robot vision

ActiveCN106516739BHigh positioning accuracyImprove positioning accuracyCharge manipulationConveyor partsButt jointTransfer system

The invention relates to the technical field of auxiliary equipment for glass machining, in particular to a glass transfer system based on robot vision. The glass transfer system comprises an on-chip transmission mechanism, a positioning transmission mechanism, a support, an industrial robot and a control unit. The on-chip transmission mechanism is connected with the positioning transmission mechanism in a butt-joint manner. The support is arranged above the positioning transmission mechanism. A vision identifying unit is mounted on the support. The positioning transmission mechanism comprises a driving roller, a driven roller and a transparent plane conveyor belt. The driving roller and the driven roller are sleeved with the transparent plane conveyor belt. A cavity is defined by the driving roller, the driven roller and the transparent plane conveyor belt. A face light source is arranged in the cavity. The face light source irradiates the vision identifying unit through the glass transmission face of the transparent plane conveyor belt. The control unit is electrically connected with the vision identifying unit and the industrial robot, and a moving locus of the industrial robot for capturing and transferring of glass to be transferred is set. The glass transfer system has the beneficial effects that the structure is simple and compact, positioning is fast and precise, the stability is good, continuous production is facilitated, and the production efficiency is improved.

Owner:FUYAO GROUP FUJIAN MACHINERY MFG

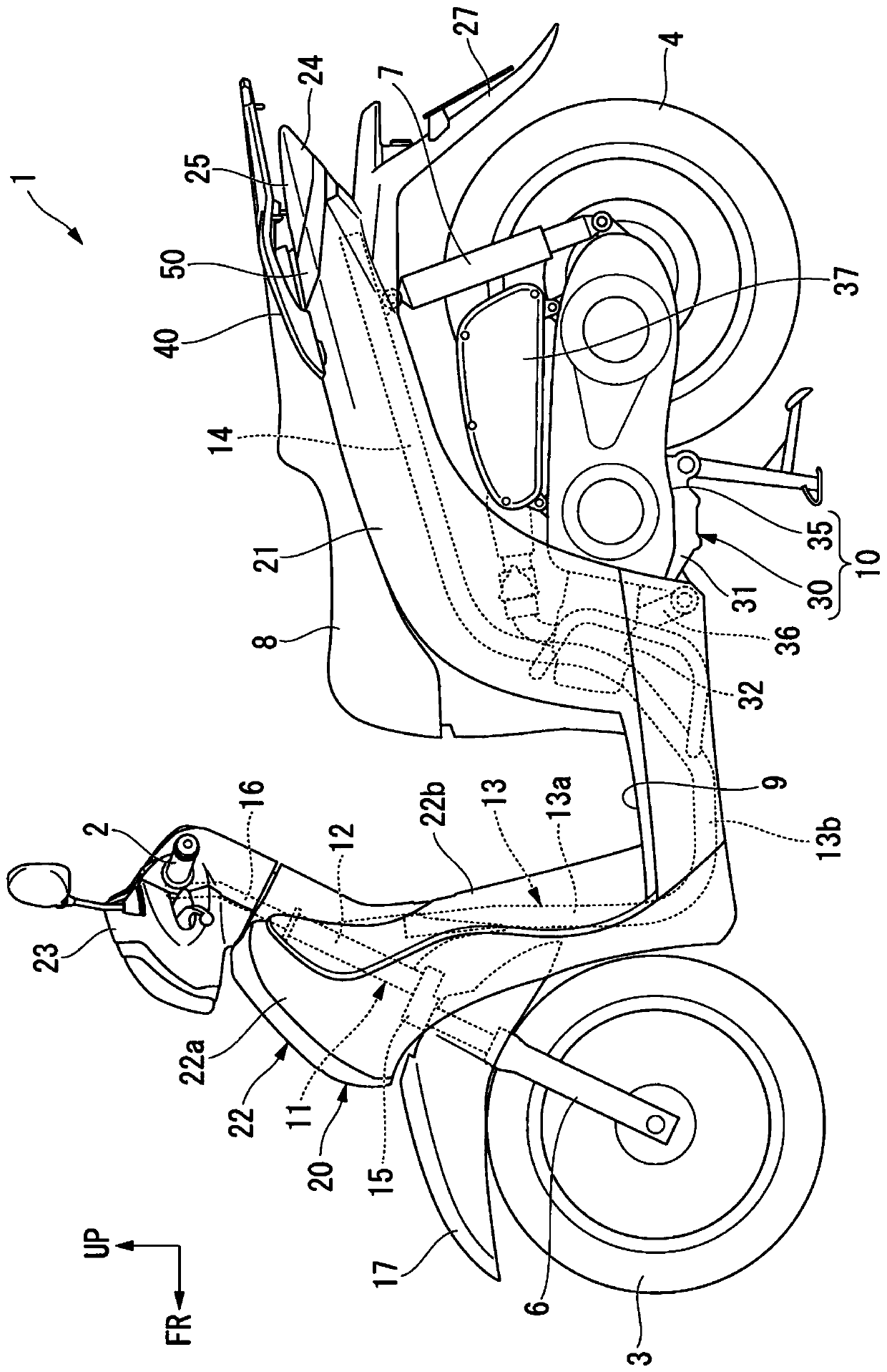

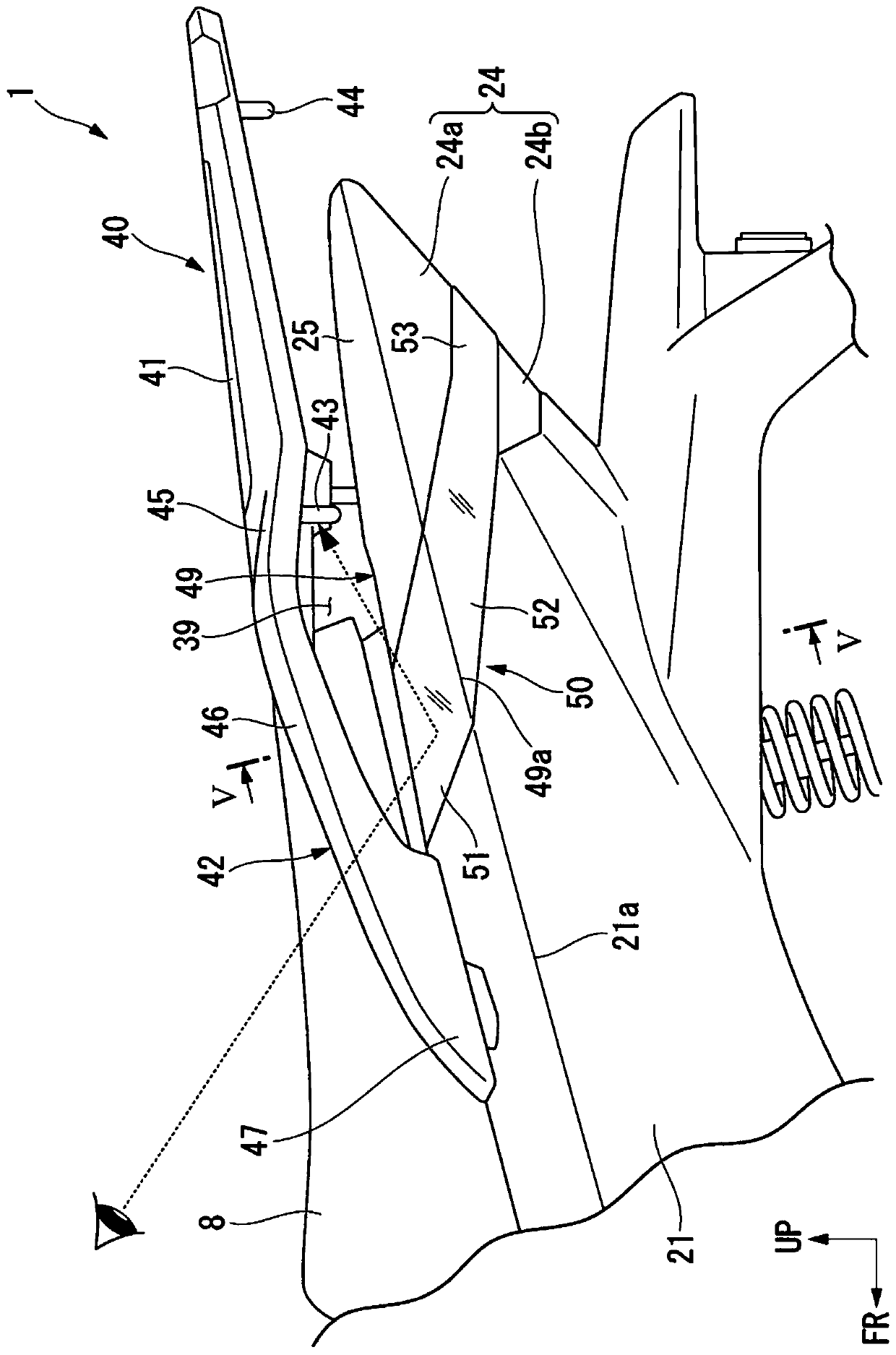

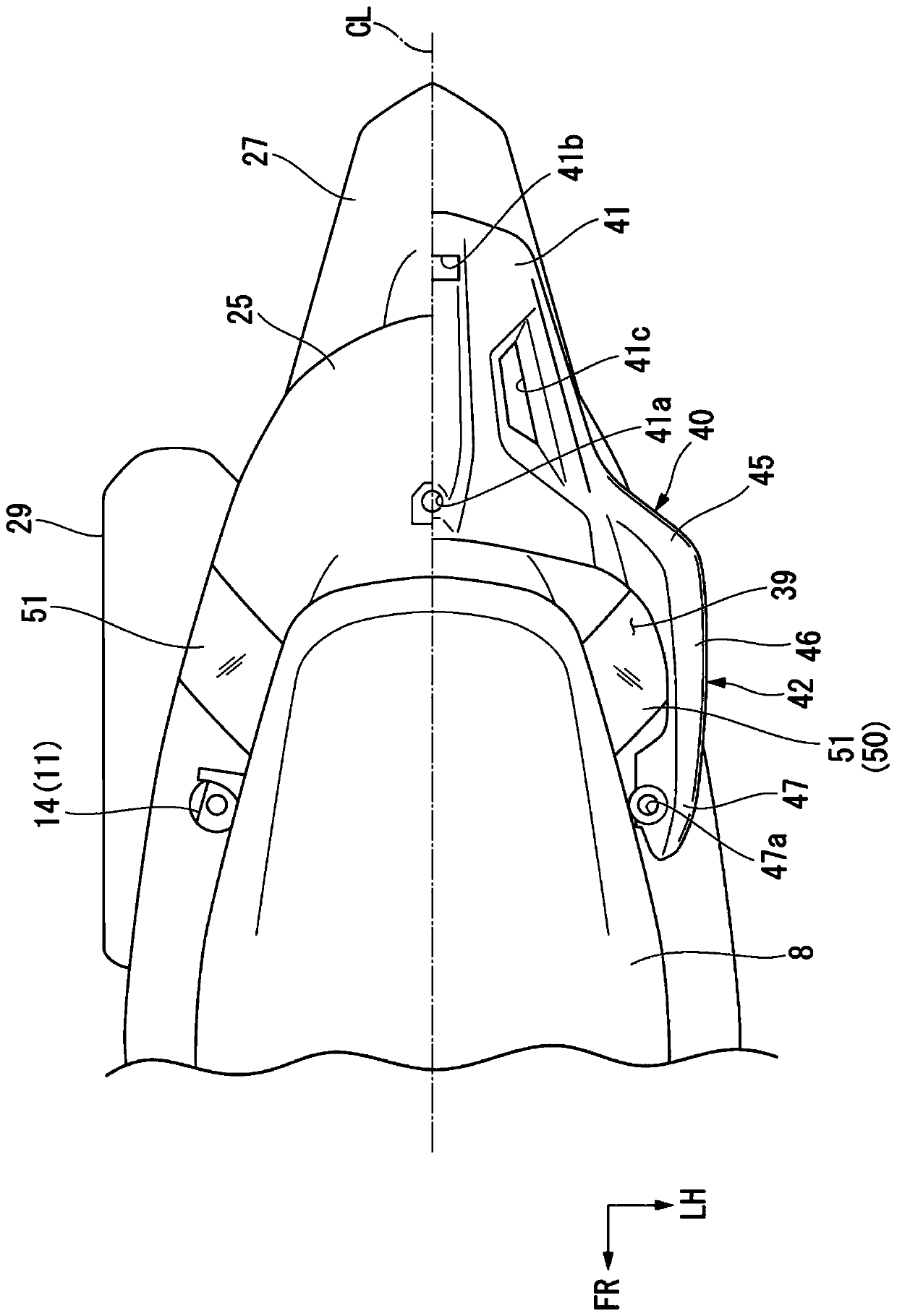

Straddle-type vehicle

ActiveCN110962967AEasy visual identificationImprove visual effectsLuggage carriersCycle saddlesLower upperControl theory

Provided is a motorcycle in which visibility of a hanging part is improved with respect to a straddle-type vehicle. A motorcycle (1) according to the present invention is provided with: a seat (8) onwhich a passenger sits; a rear bracket (40) located behind the seat (8) and disposed on the upper surface of the vehicle (1); and hanging parts (43, 44) provided to the rear bracket (40) and protruding downward, the hanging parts (43, 44) being provided with a mirror-like surface part (50) having a mirror-like surface at a bracket lower upper surface part (49).

Owner:HONDA MOTOR CO LTD

Dual Seat Valve

InactiveUS20160123475A1Easy visual identificationQuickly coupleOperating means/releasing devices for valvesEqualizing valvesHigh pressureRupture disc

A dual seat valve assembly includes a first valve and a concentric second valve which together form a tight seal valve assembly. The valves open and close sequentially. A quick disconnect rupture disc assembly may be used in conjunction with the valve assembly to provide a required safety feature for testing high pressure fluid ruptures that include a dump valve.

Owner:ENGIP LLC

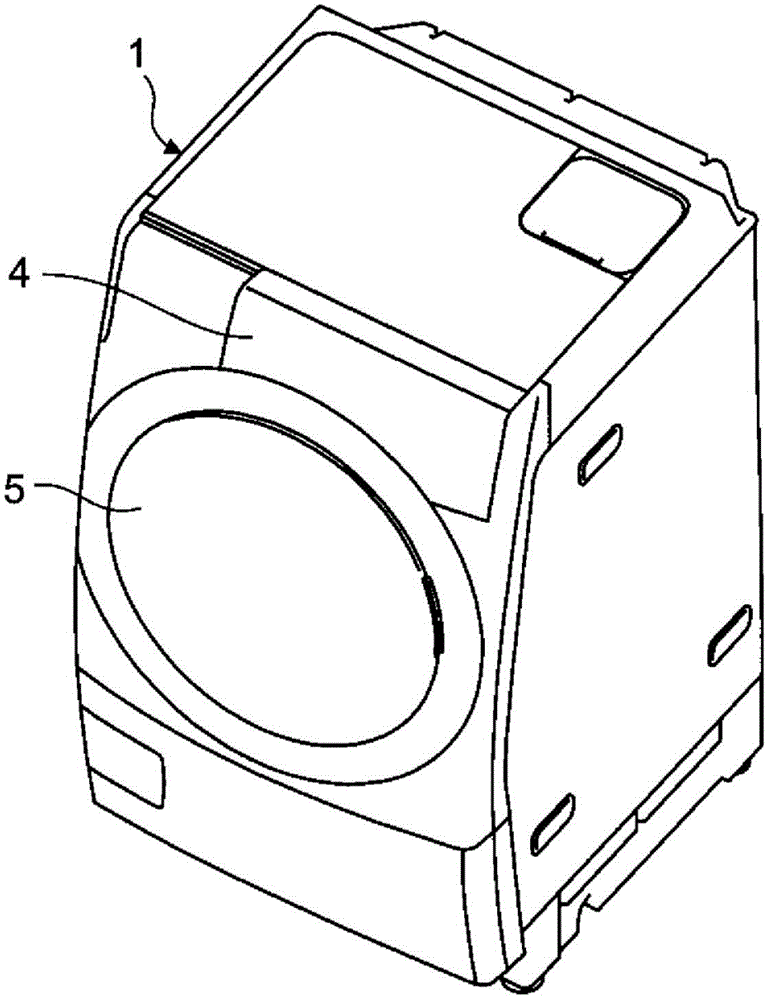

Washing machine

ActiveCN105579635AEasy to understandEasy visual identificationControl devices for washing apparatusWashing machine with receptaclesOutput deviceEngineering

A washing machine comprises: a light emitting device (35) that is capable of emitting a plurality of colors; an audio outputting device; an operation status determining unit that determines whether the operation status is a normal state or non-normal state; and an operation status output controlling unit that causes the light emitting device (35) to emit light, when the determination result by the operation status determination unit is of a non-normal state, in a color that is different than during the normal state, that outputs guidance for coping with the content of the non-normal state by driving the audio output device.

Owner:SHARP KK

A method and system for unmanned aerial vehicle calibration based on color three-dimensional calibration object

ActiveCN106651961BEasy visual identificationEasy to useImage enhancementImage analysisVisual field lossExtinction

The invention discloses a method and system for unmanned aerial vehicle calibration based on a color three-dimensional calibration object. The method includes: placing a color checkerboard three-dimensional calibration object in the scene to be photographed; The image of the three-dimensional calibration object of the checkerboard grid; according to the image of the three-dimensional calibration object of the color checkerboard grid, the internal parameters of the UAV camera are linearly solved using the vanishing point theory; according to the internal parameters of the UAV camera, the coordinate projection transformation method is used to determine the UAV camera The spatial position and image geometric constraint relationship. The present invention adopts the color checkerboard three-dimensional calibration object for camera calibration, which is easy to measure accurately, has high detection accuracy, is convenient to install and has strong versatility; it only needs to take images of the color checkerboard three-dimensional calibration object from at least three different directions and combine them The vanishing point theory obtains the internal parameters of the UAV camera to complete the calibration of the internal parameters of the camera, which is more convenient to use. The invention can be widely used in the field of computer vision.

Owner:SUN YAT SEN UNIV

Dual seat valve

InactiveUS10113650B2Provide protectionRapid disconnectionOperating means/releasing devices for valvesEqualizing valvesHigh pressureVALVE PORT

Owner:ENGIP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com