Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Damage to part" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

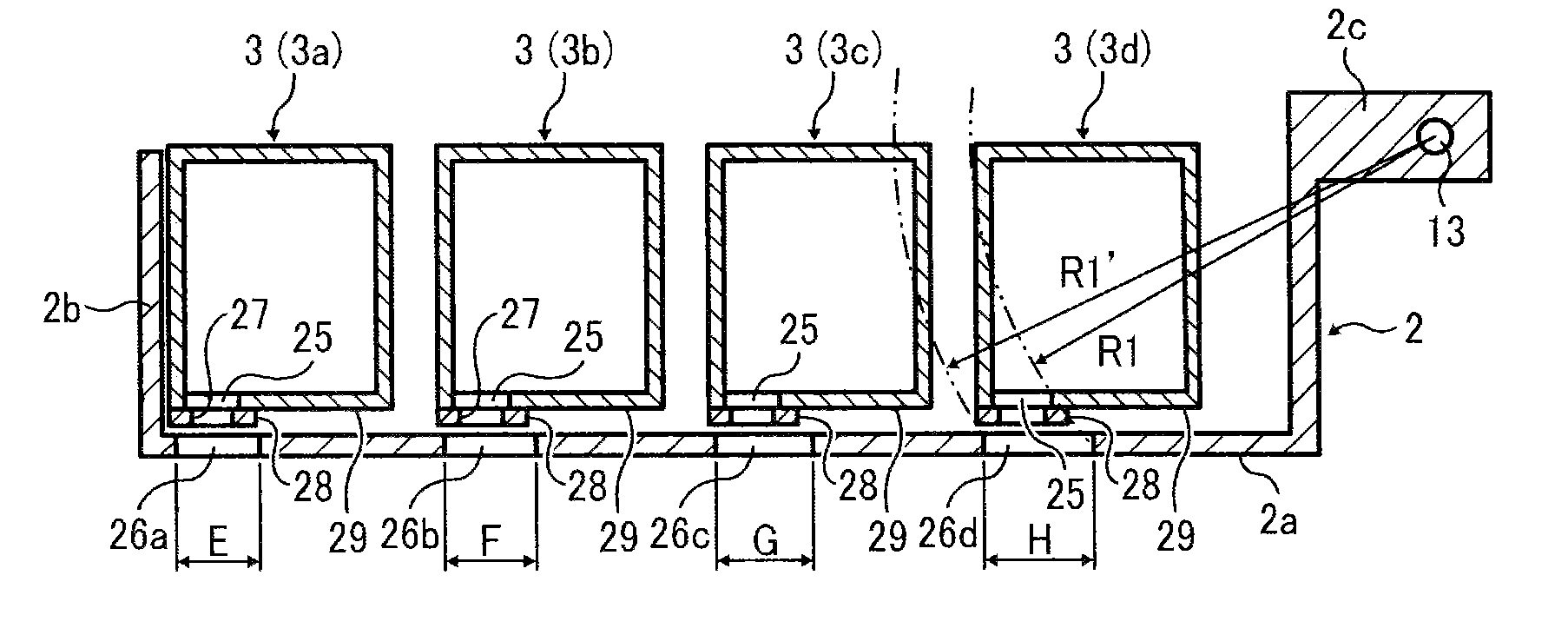

Passively cooled computer

InactiveUS7742298B2Dissipate the entire waste heat of the computerReduce the temperatureDigital data processing detailsHeat exchange apparatusMechanical engineeringEngineering

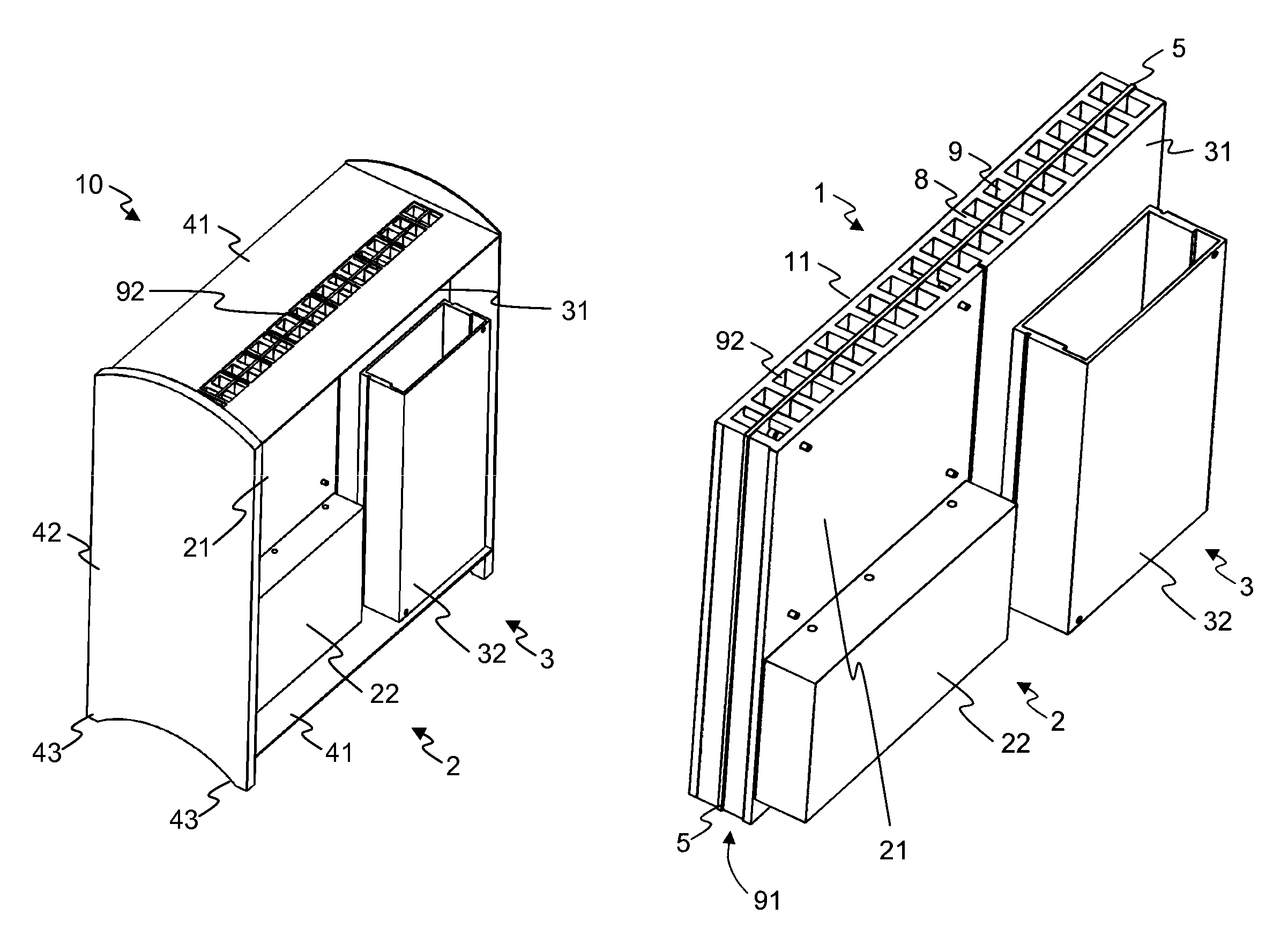

A passively cooled computer includes two or more components arranged in a housing frame 41, wherein each of these components is associated with a cooling body for dissipating waste heat of the component when the component is in operation. The cooling bodies each include a cooling surface, and these cooling surfaces are arranged to oppose one another with their cooling surfaces and thereby define an air channel leading vertically through the inside of the housing frame. The cooling bodies substantially separate the air channel from the remaining volume inside the housing frame.

Owner:KONTRON

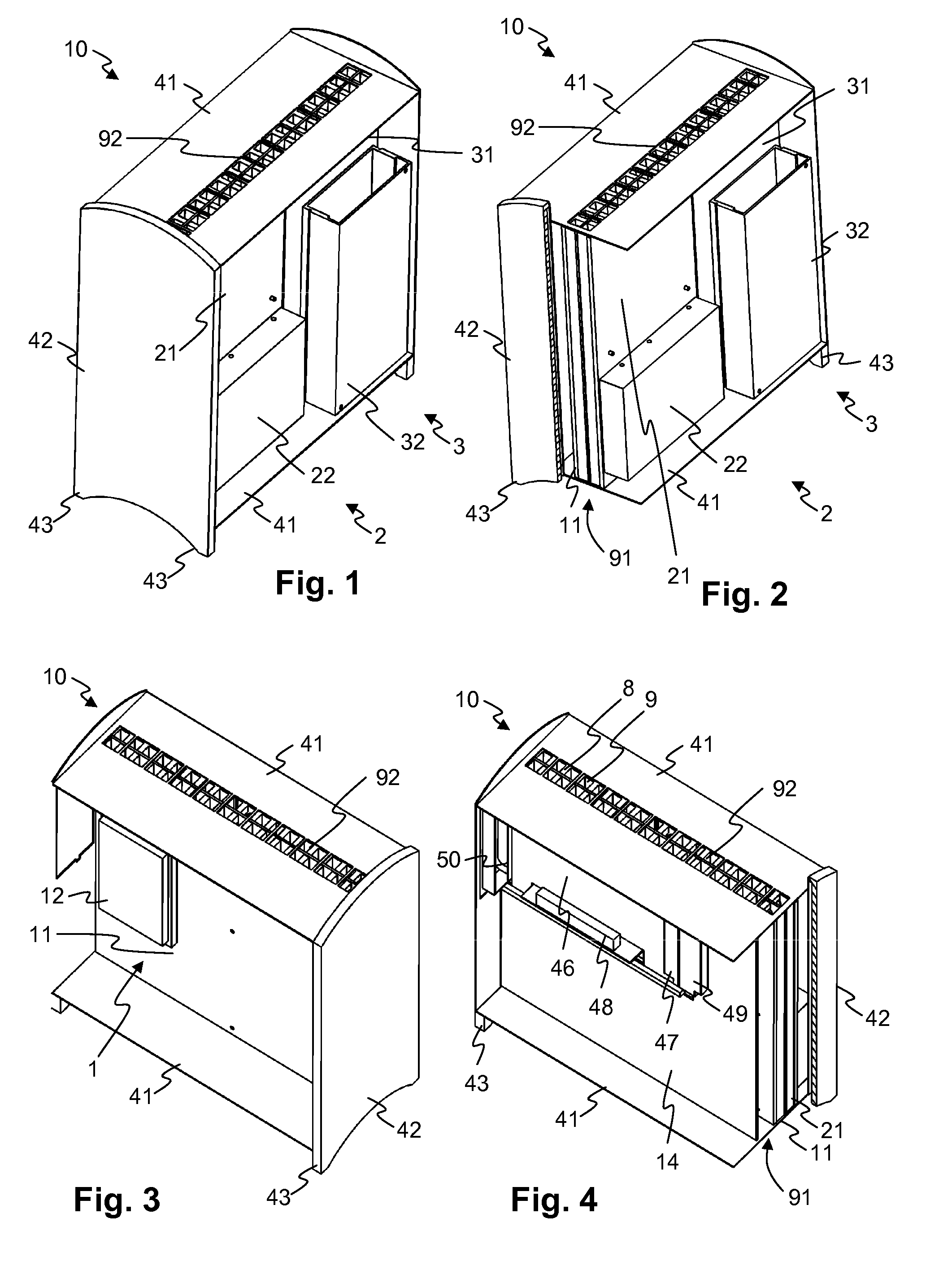

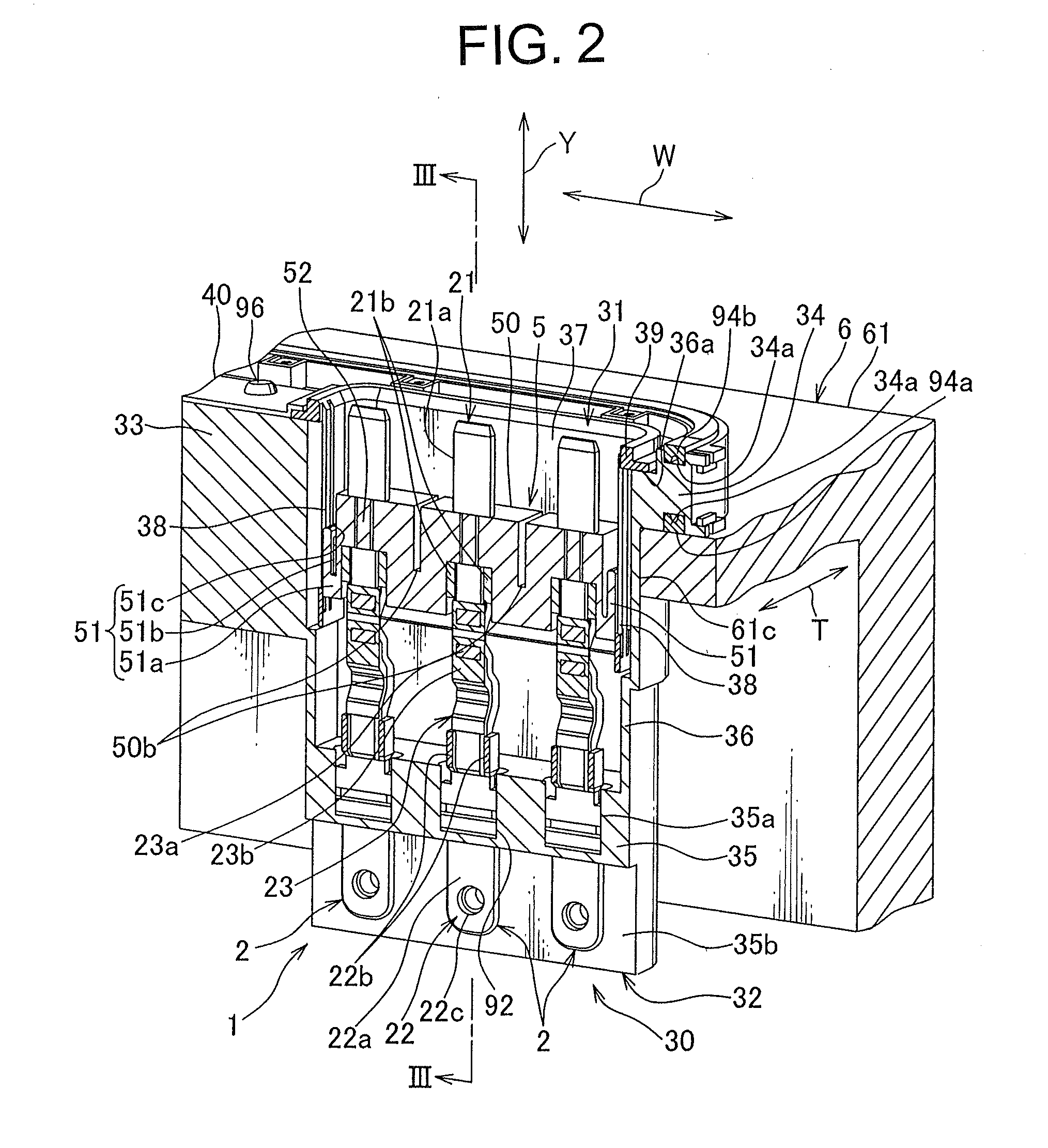

Connector

ActiveUS20120015546A1Firmly connectedAvoid conflictEngagement/disengagement of coupling partsIncorrect coupling preventionMating connectionCoupling

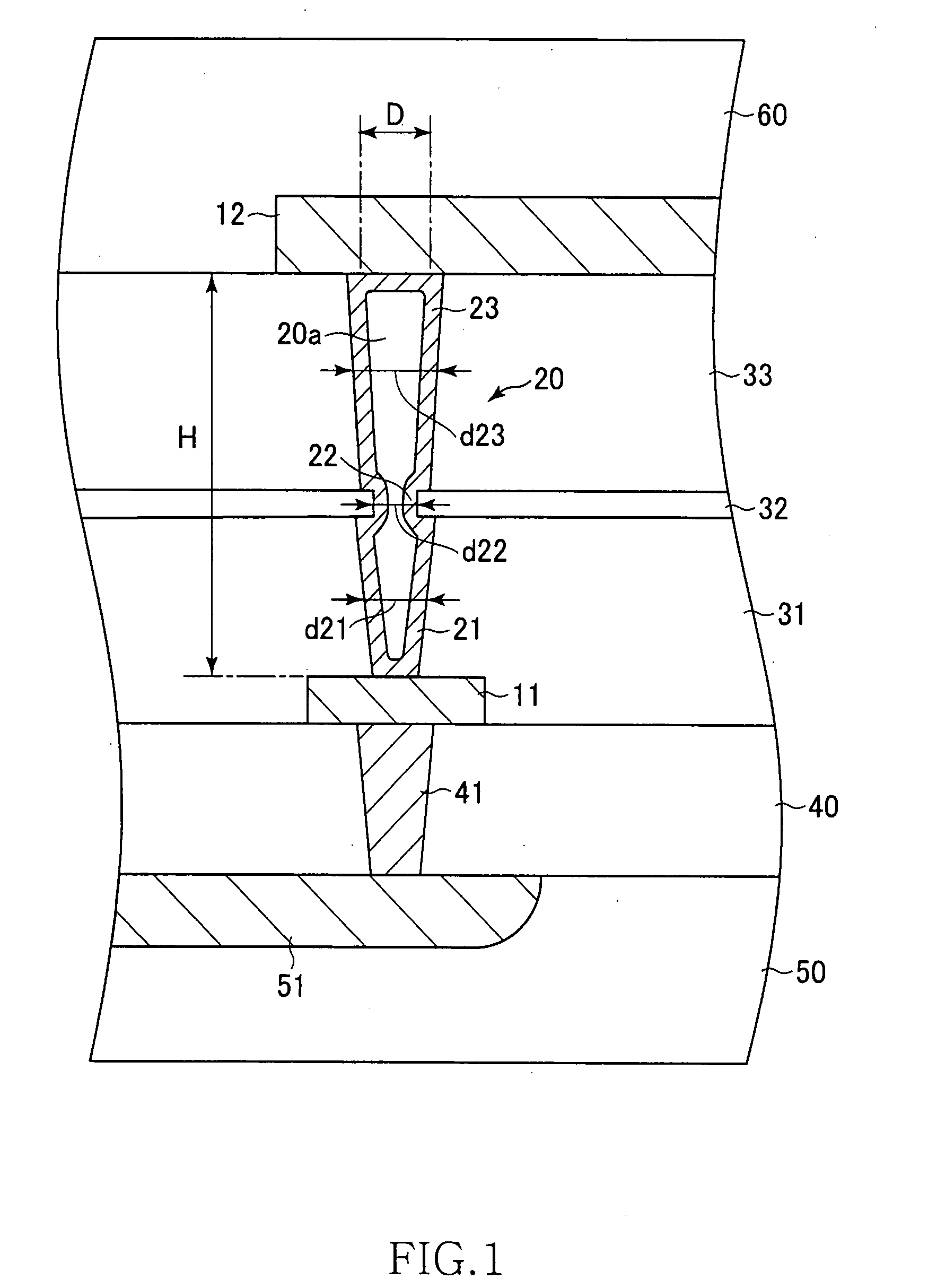

To provide a connector able to be surely fitted with a mating connector by absorbing a position gap generated between a terminal and a terminal of the mating connector.A connector 1 includes: a terminal 2; an inner housing 5; and an outer housing 30 receiving the terminal 2 and the inner housing 5. The terminal 2 is provided with a first electric connecting part 21 received and held in the inner housing 5 and electrically connected to the mating connector, a second electric connecting part 22, and a flexible coupling part 23 made of conductive material, movably coupling and electrically connecting the first electric connecting part 21 and the second electric connecting part 22. The outer housing 30 is provided with a receiving part 36 movably receiving the inner housing 5 which receives the first electric connecting part 21, and a fixing part 35 to which the second electric connecting part 22 is fixed.

Owner:YAZAKI CORP

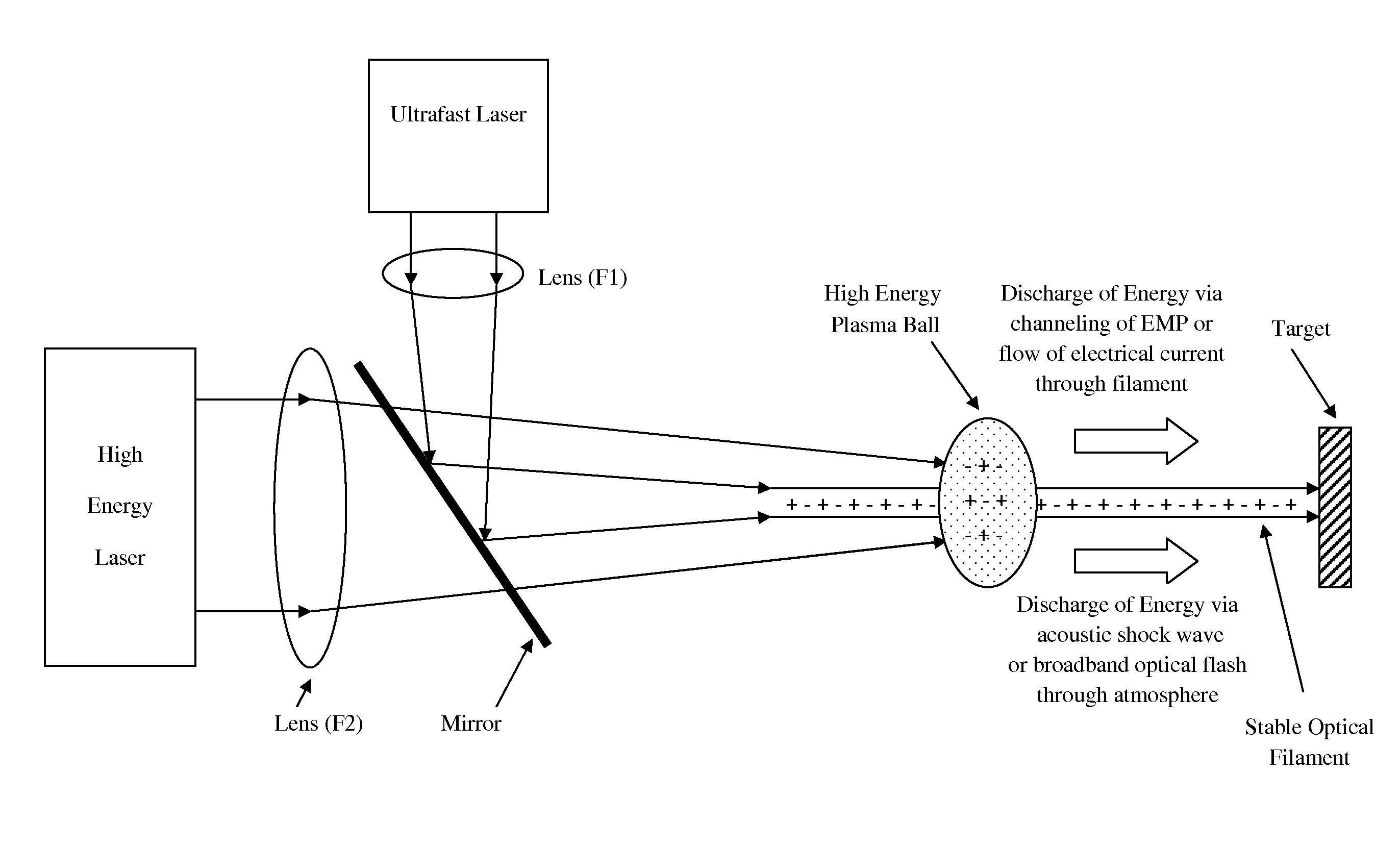

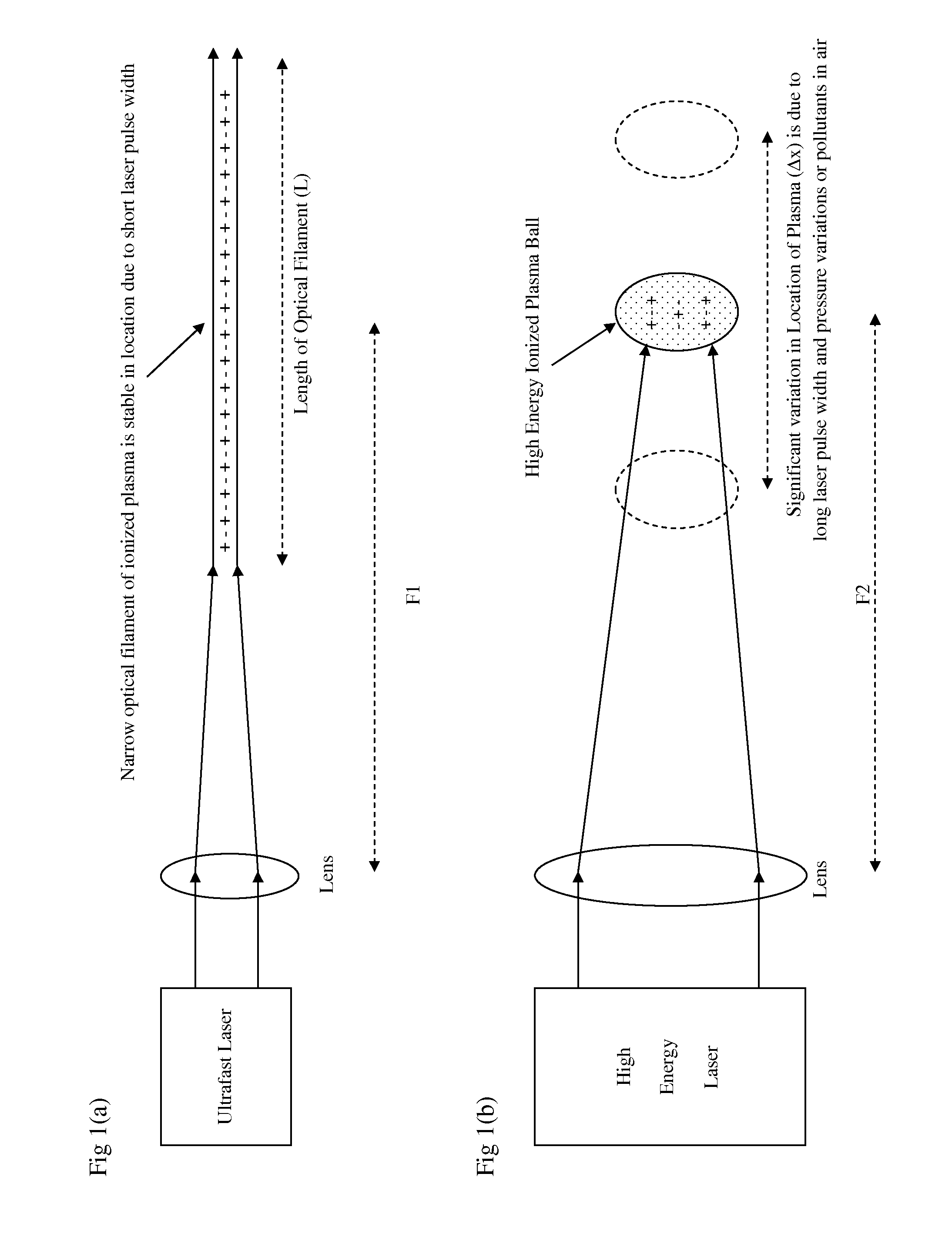

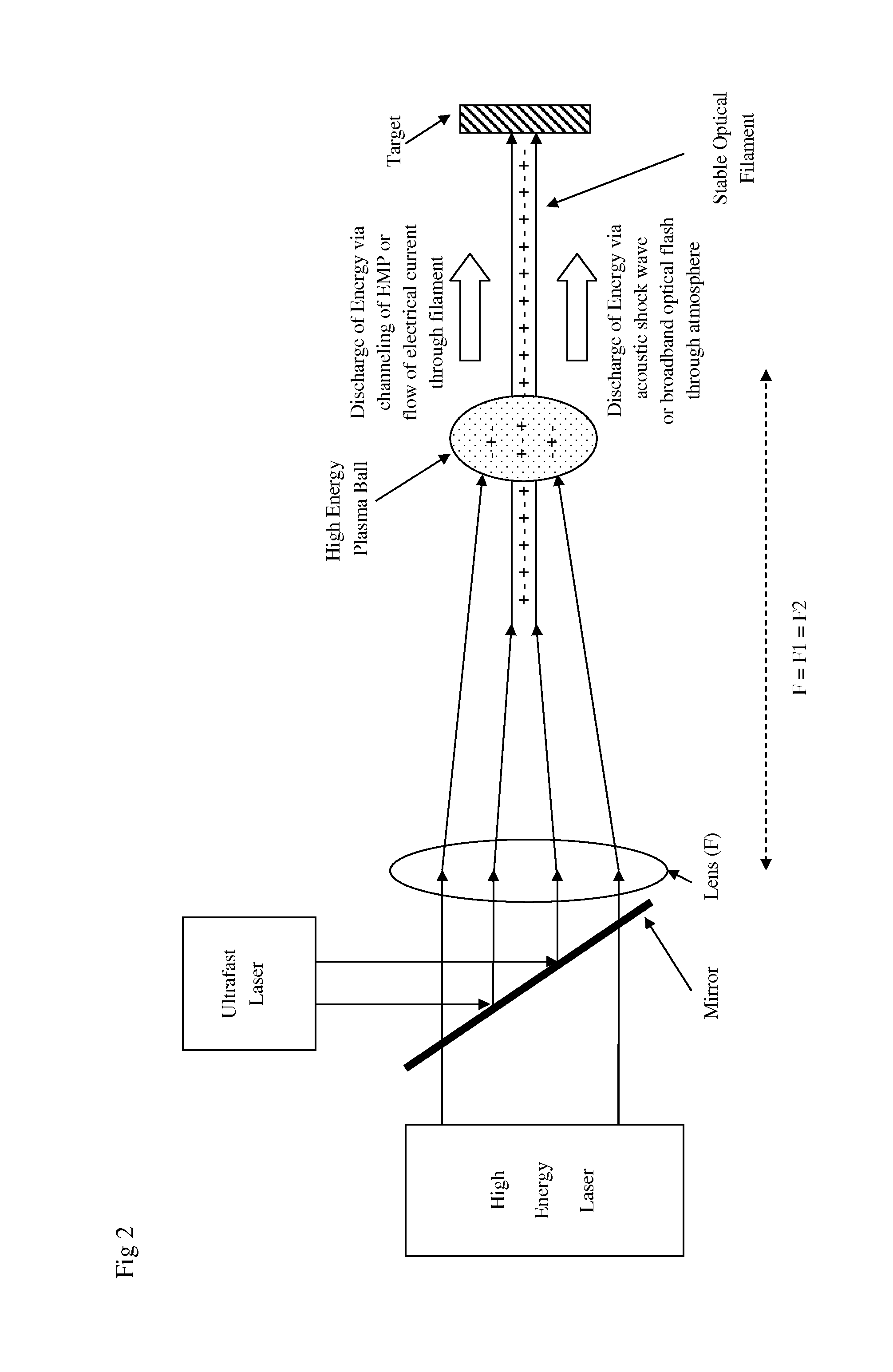

Laser Guided and Laser Powered Energy Discharge Device

InactiveUS20160097616A1Readily and efficiently conductedGuaranteed normal transmissionStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsHigh energyElectrical connection

The present invention relates to a laser guided and powered directed energy weapon that combines two different lasers to accurately and efficiently deliver a high energy electromagnetic pulse (EMP) to a target at long range. The method uses a high energy laser pulse with relatively long pulse duration focused in air to create a plasma ball which emits an intense EMP. Typically the long pulse duration of high energy lasers would severely limit focal accuracy and effective range because of air pressure variations and pollutants in the atmosphere. However the present invention uses a second ultrafast laser to create a long thin optical plasma filament between the variable location of the plasma ball and the target to act as a stable electrical connection or conducting wire. Consequently EMP can be efficiently channeled to the target via the optical filament, thereby dramatically increasing potential accuracy, range and energy delivery efficiency.

Owner:WEIGOLD DR ADAM MARK

Connector

ActiveUS8585421B2Firmly connectedDamage to partEngagement/disengagement of coupling partsIncorrect coupling preventionCouplingConductive materials

Owner:YAZAKI CORP

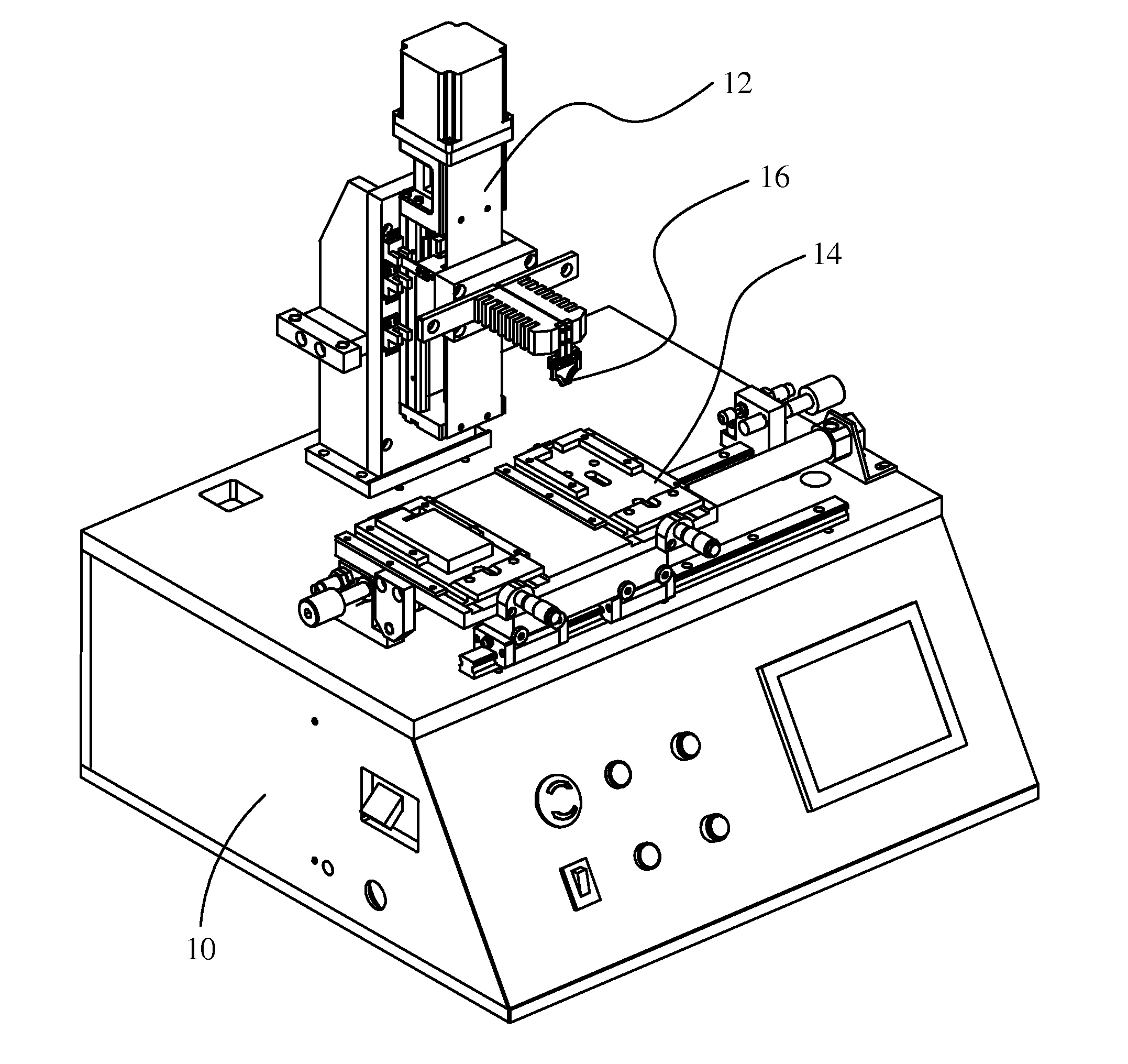

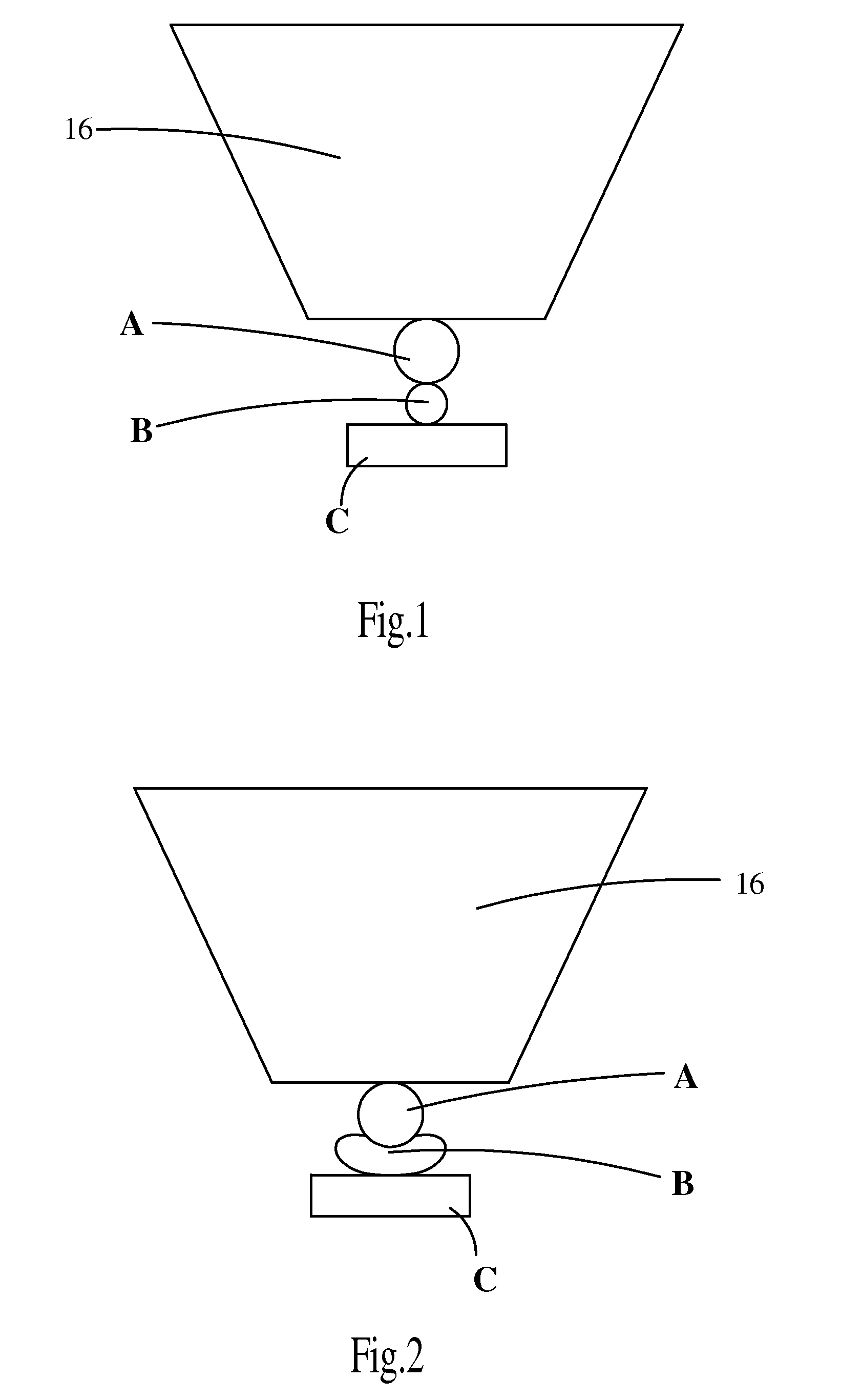

Automatic soldering apparatus and soldering method thereof

InactiveUS20120104077A1Avoid damageDamage to partWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectronic component

An automatic soldering apparatus and a soldering method thereof are provided. The soldering method has steps of: (S1) positioning a to-be-soldered part and an electronic component having a solder material; (S2) driving a hot press to firstly move, until the hot press is in contact with the part; (S3) heating the solder material by the hot press; and (S4) driving the hot press to secondly move to press the solder material after the solder material on the electronic component is melted, so as to connect the part to the melted solder material on the electronic component by soldering. When the automatic soldering apparatus and the soldering method of the present invention are used to execute a soldering process, a route of the hot press can be controlled to firstly melt the solder material and then deform it, so as to avoid the hot press from impacting and damaging the part.

Owner:CHENG UEI PRECISION IND CO LTD

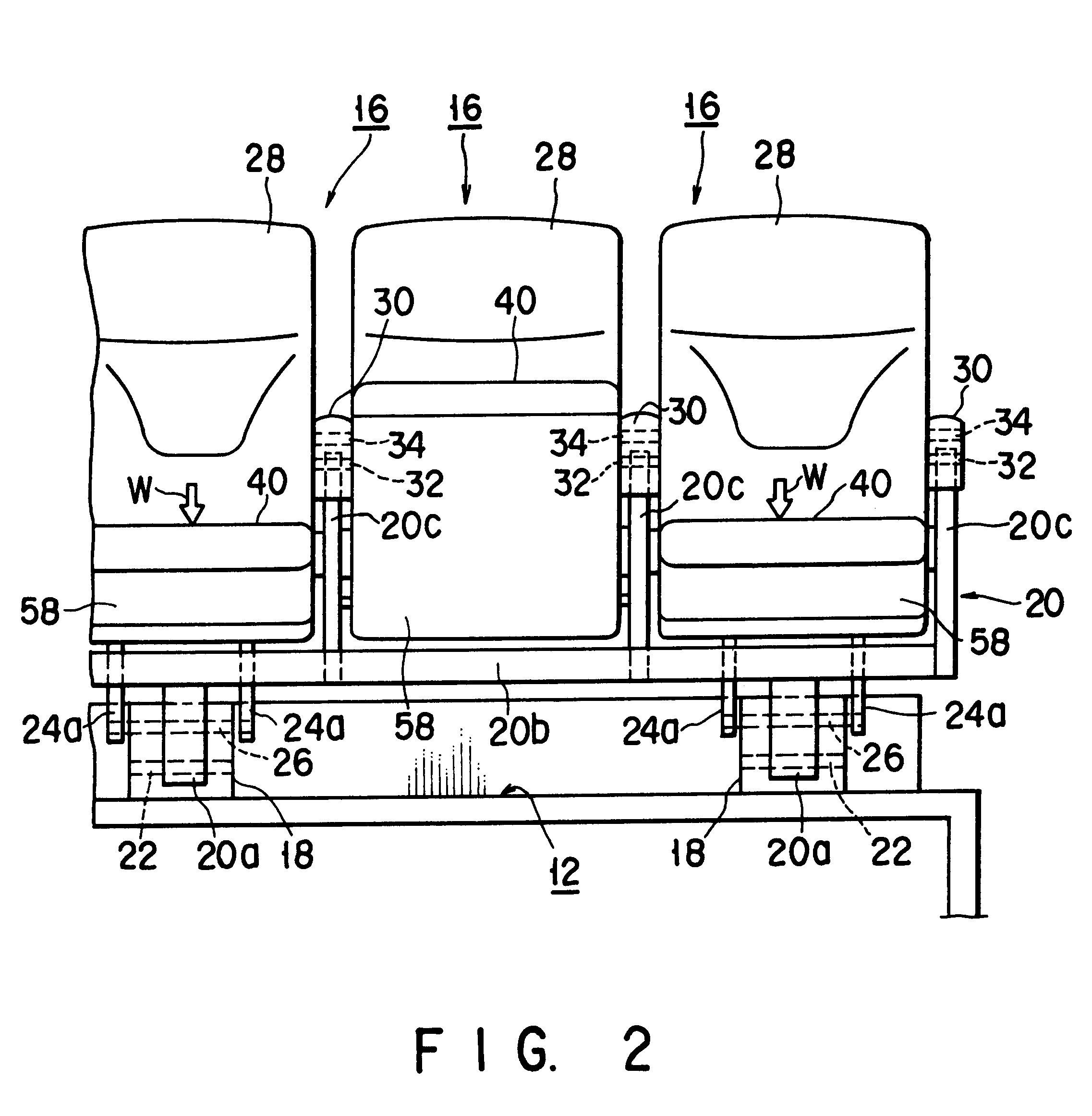

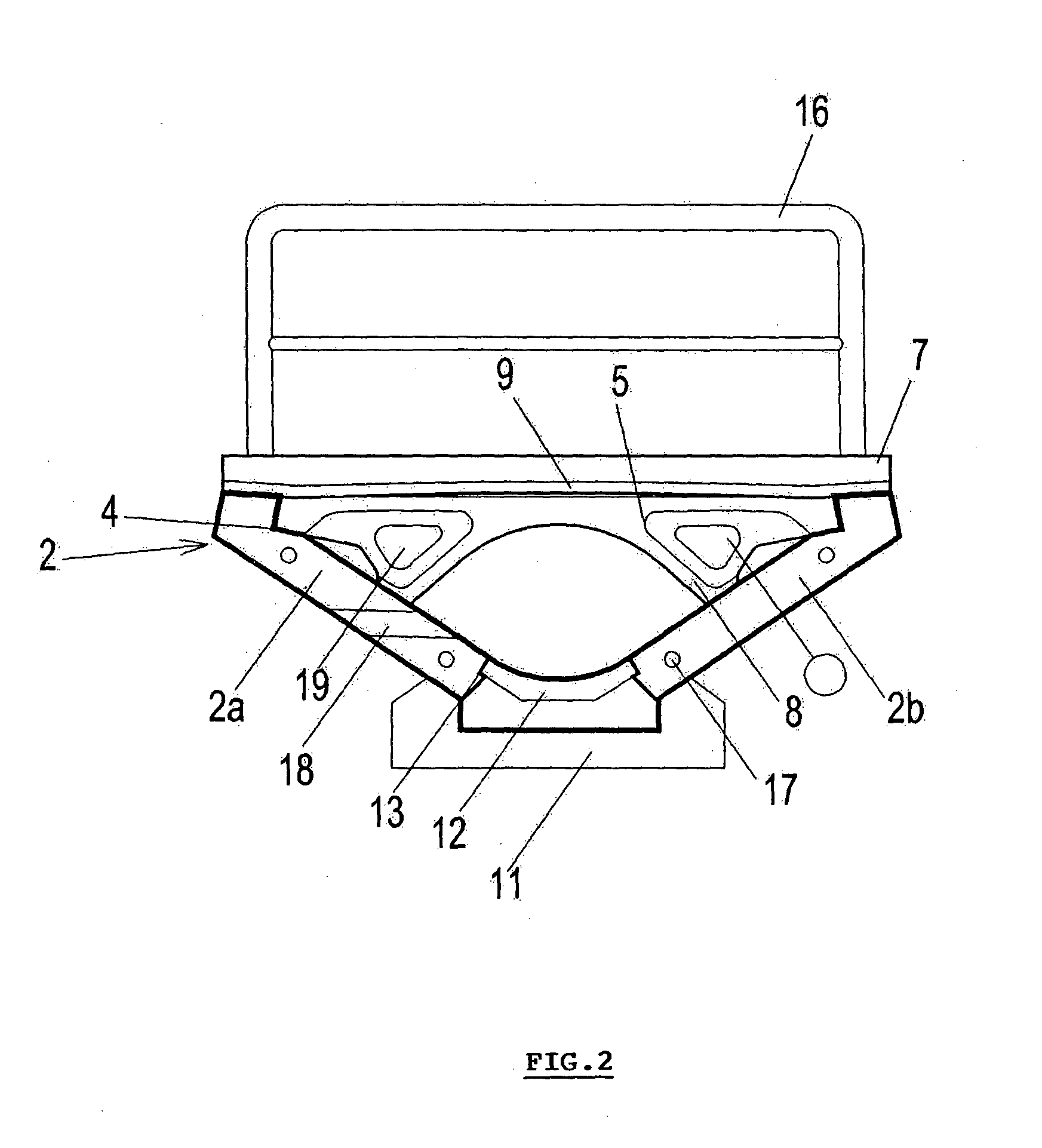

Motor vehicle rear seat

InactiveUS7172252B2Prevent rotationLight structureMovable seatsDismountable/non-dismountable seatsMotor vehicle partEngineering

The present invention relates to a motor vehicle rear seat with a seat part (2), having an upper side (4), and a seat back (6), having a rear side (12), which faces a clearance behind said motor vehicle rear seat. Said seat back (6) has at least one seat back section (8). According to the invention, said seat back section (8) is designed, such that it can be pivoted from a normal position to a first position, in which the rear side (12) of the seat back section (8) is oriented upwards and, with the upwards-oriented rear side (12), to a second position in the clearance behind the motor vehicle rear seat, such that the upper side (4) of the seat part (2) and the rear side (12) of the seat back section (8) form a loading area. Preferably, a loading plate (18), hinged on said seat back section (8), can be pivoted onto the upper side (4) of the seat part (2) in the second position of the seat back section (8).

Owner:INTIER AUTOMOTIVE SEATING SYST

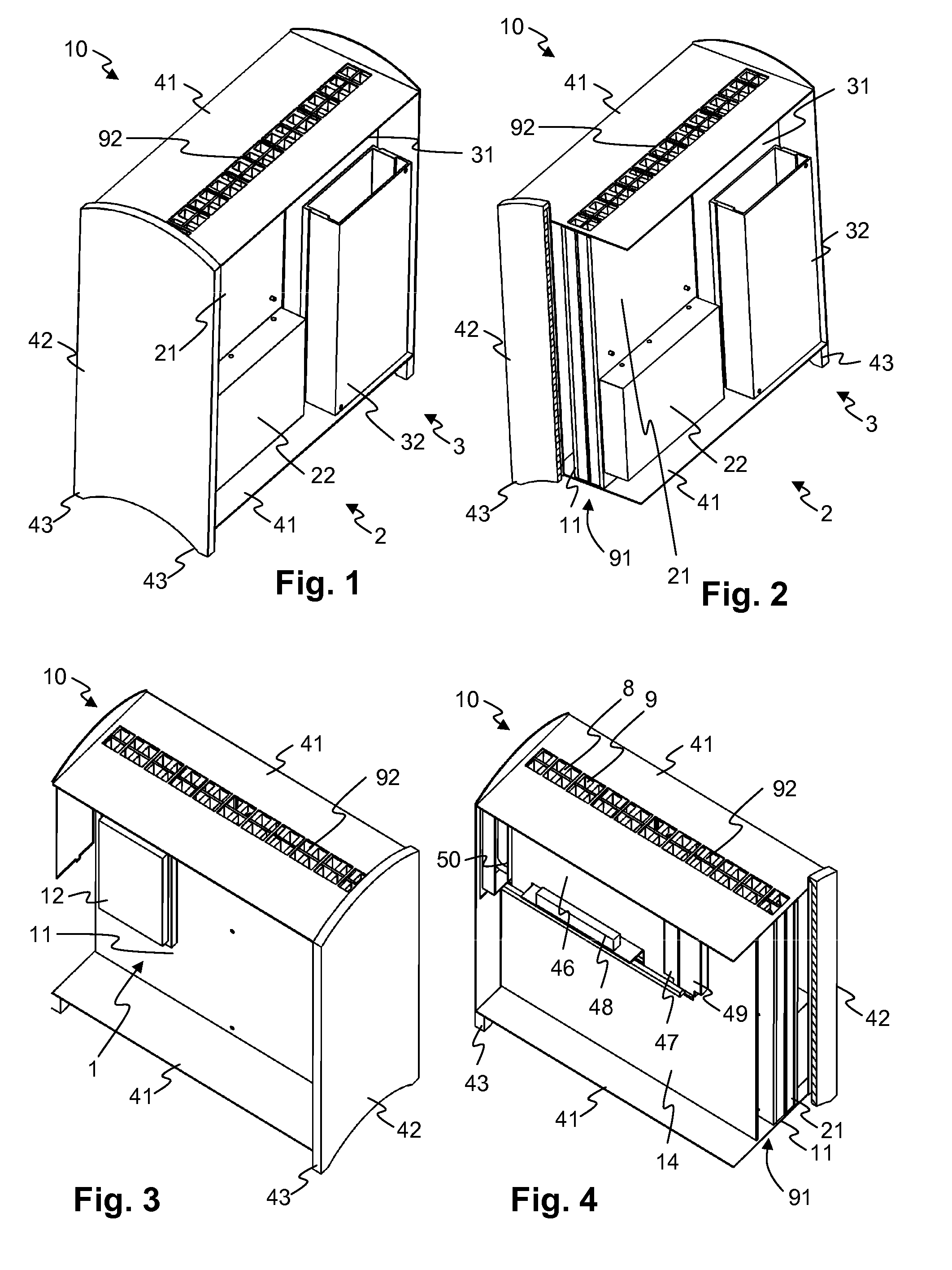

Passively cooled computer

InactiveUS20090067128A1Improves thermal decouplingReduce thermal bridgeDigital data processing detailsHeat exchange apparatusEngineeringMechanical engineering

A passively cooled computer includes two or more components arranged in a housing frame 41, wherein each of these components is associated with a cooling body for dissipating waste heat of the component when the component is in operation. The cooling bodies each include a cooling surface, and these cooling surfaces are arranged to oppose one another with their cooling surfaces and thereby define an air channel leading vertically through the inside of the housing frame. The cooling bodies substantially separate the air channel from the remaining volume inside the housing frame.

Owner:KONTRON

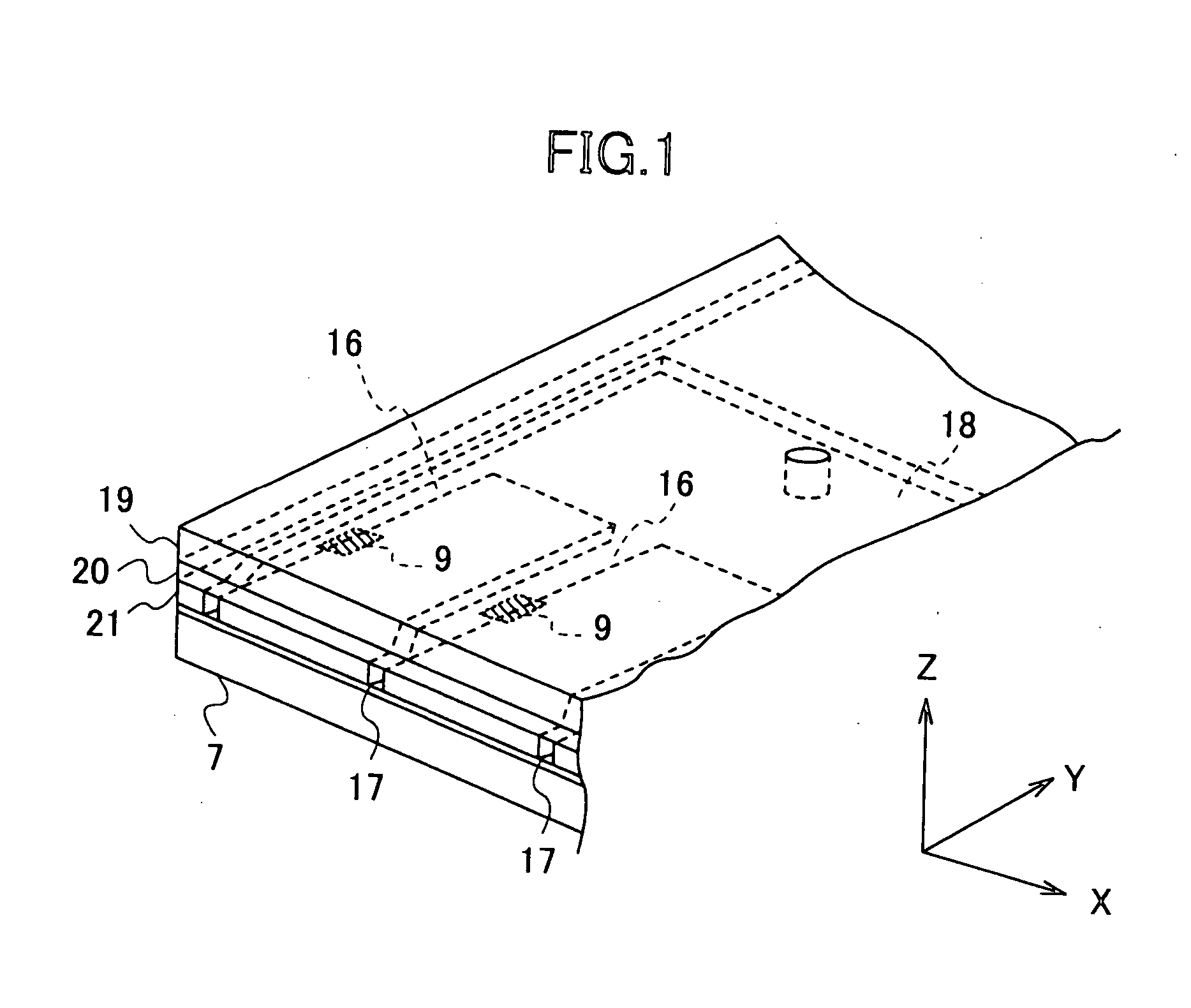

Method for manufacturing physical quantity detector, and physical quantity detector

ActiveUS20120304769A1Good support balanceDifficult to flexiblyAcceleration measurementPrinted circuit manufactureEngineeringMoving parts

A method for manufacturing a physical quantity detector is for a physical quantity detector including a flat frame-like base part, a flat plate-like moving part which is arranged inside the base part and has one end thereof connected to the base part via a joint part, and a physical quantity detection element laid on the base part and the moving part. The method includes: integrally forming the base part, the joint part, the moving part, and a connecting part which is provided on a free end side of the moving part and connects the base part and the moving part to each other; laying and fixing the physical quantity detection element on the base part and the moving part; and cutting off the connecting part.

Owner:SEIKO EPSON CORP

Layable seat

InactiveUSRE37043E1Soiling their clothesDamage to partOperating chairsDental chairsCoil springEngineering

Owner:KOTOBUKI & CO LTD

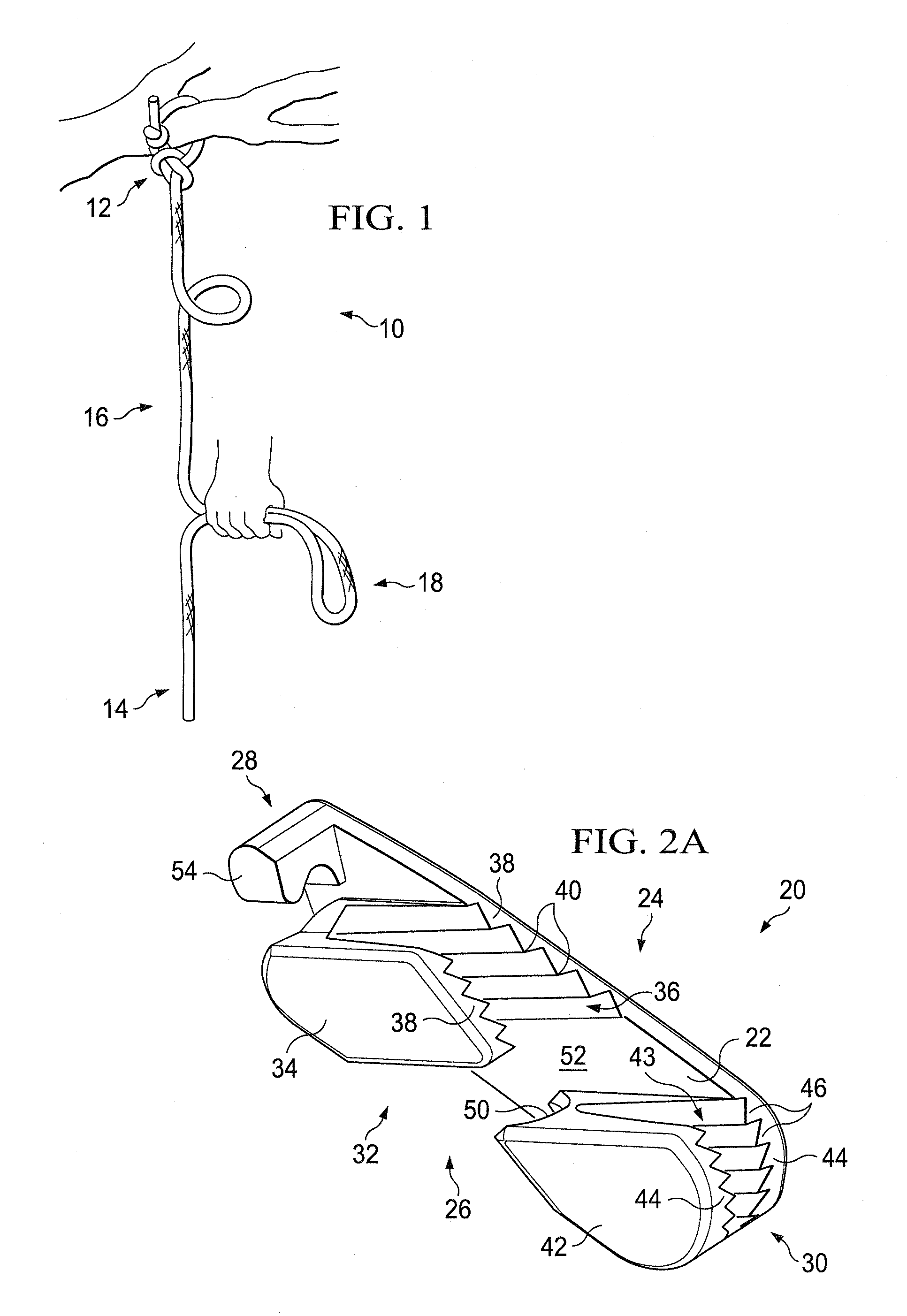

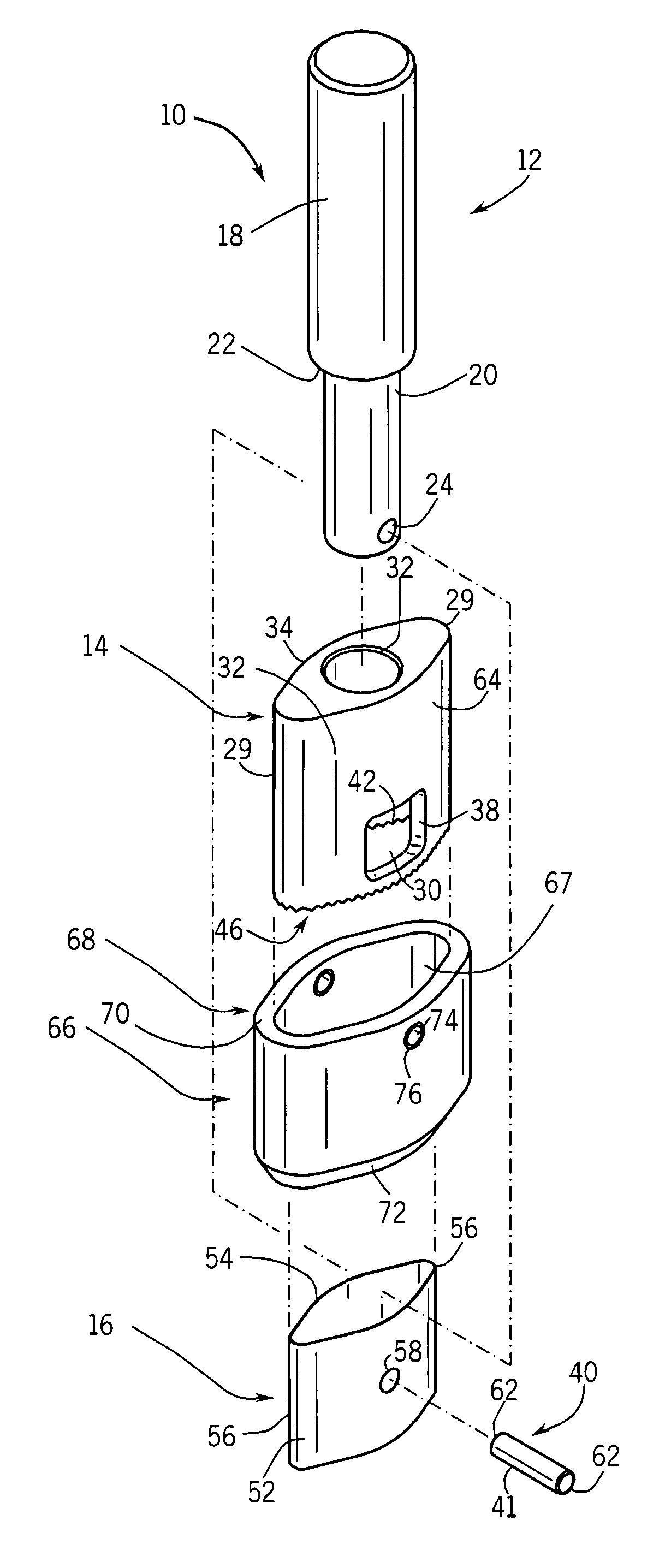

Rope tightener and self locking rope tie down device

InactiveUS20080110000A1Reduce manufacturing costEliminate needSnap fastenersRopes and cables for vehicles/pulleySelf lockingEngineering

A rope tightening and securing device having a base member. A first lobe and a second lobe protrude from a first side of the base member. Each lobe has a first groove for receiving a segment of a rope. The first and second lobes define a slot therebetween. The device may be used to secure rope without tying knots in certain applications, to extend a length of rope, and to bypass a damaged section or rope.

Owner:ORR NELSON K

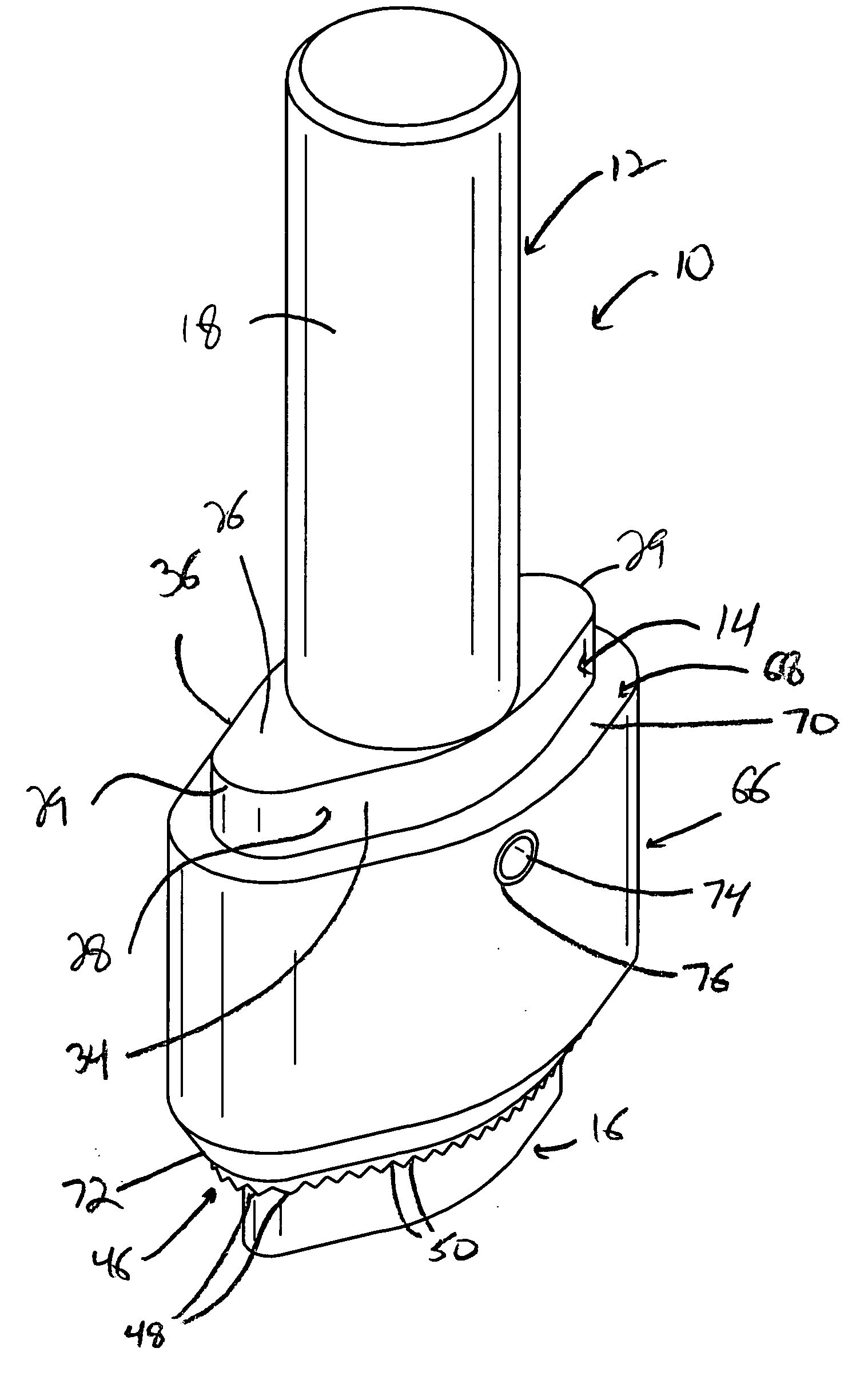

Dermal incisor

InactiveUS20070135731A1Consistent and repeatable incisionSmooth skinSurgical needlesVaccination/ovulation diagnosticsEngineeringHorizontal and vertical

The present invention is a dermal incisor for use in cutting a section from the skin of an individual for examination. The incisor has a housing in which an endless, flexible blade is disposed. The blade is connected to a handle that is rotatable with regard to the housing. Upon rotation of the handle, the blade also rotates in order to cut into the skin. The handle is also slidable with regard to the housing, such that the handle can be used to urge the blade into the skin while being rotated. The housing includes a pair of apertures engaged with a stop pin on the handle to limit the movement of the handle and the blade with respect to the housing in both the horizontal and vertical directions. The housing also includes a lower surface including a number of teeth thereon that securely engages the housing with the skin to prevent slippage of the skin while being cut to provide a smooth incision with few irregularities.

Owner:HUOT INSTR

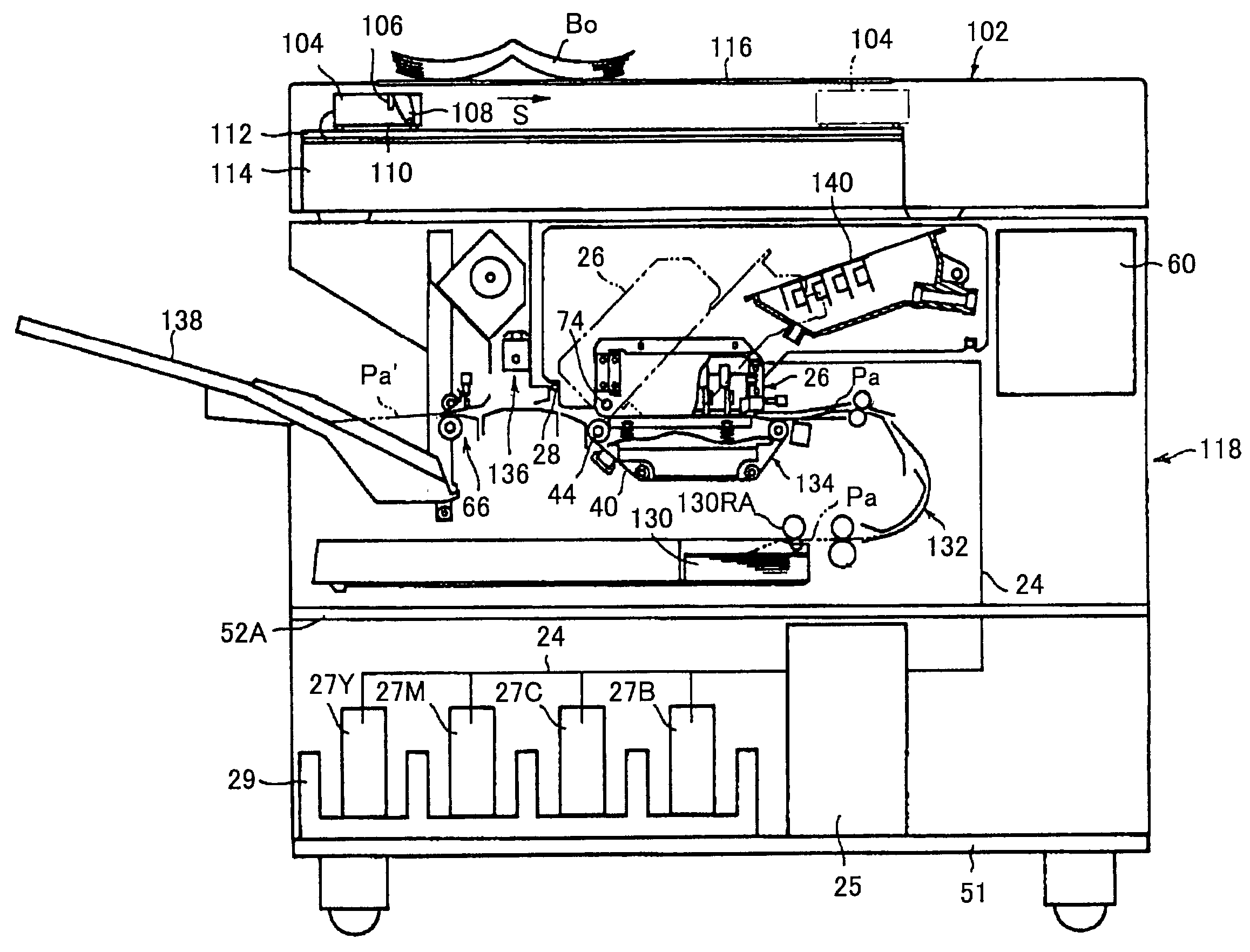

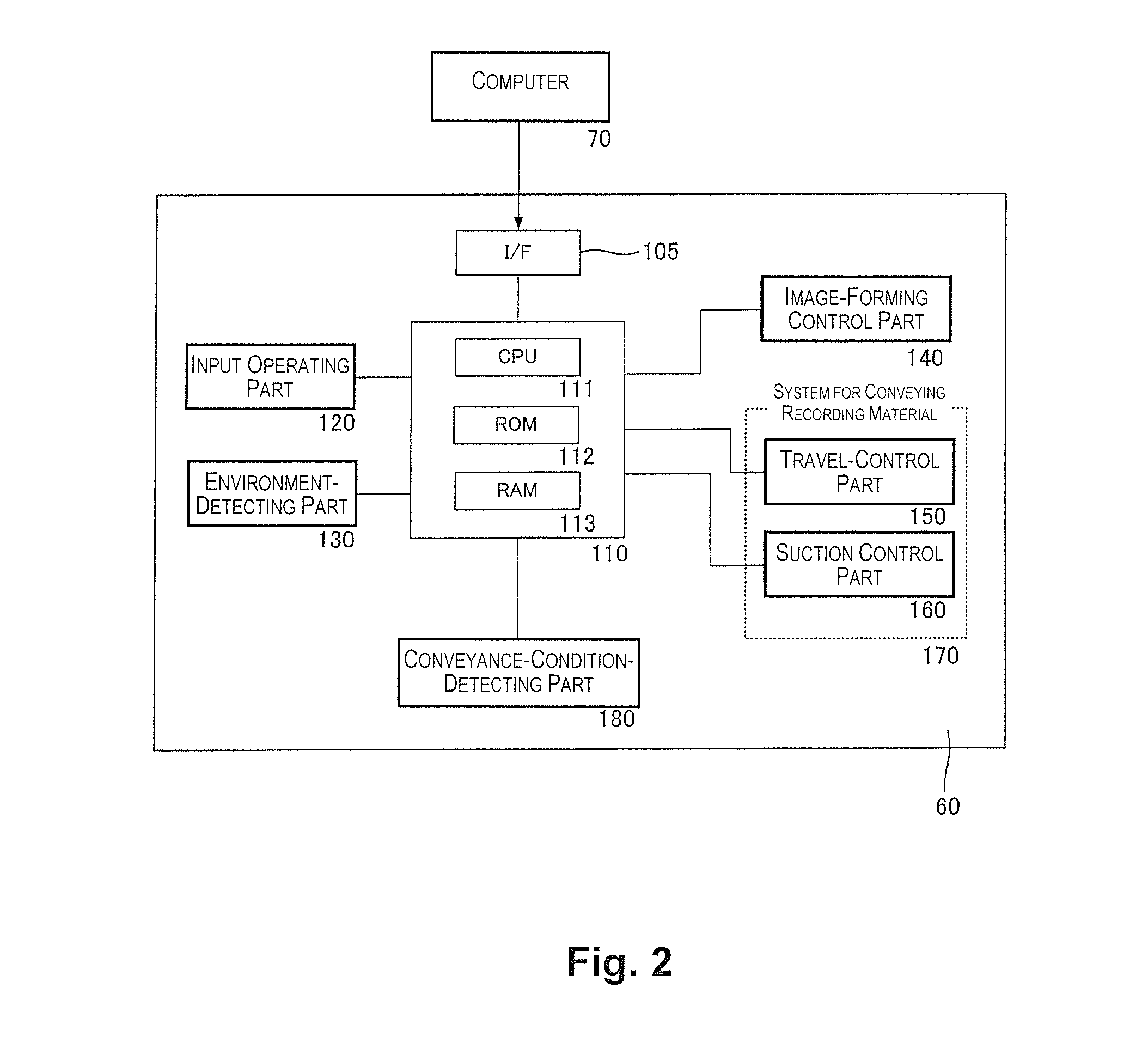

Image forming apparatus

InactiveUS20130266340A1Avoid damageDamage to componentElectrographic process apparatusImage formationClosed state

An image forming apparatus includes: a developer container to contain a developer therein and a developer supply port; an image forming unit to form an image with the developer from the developer container and including a developer intake port; an openable / closable upper cover configured to cover an upper part of the developer container in a closed state and take out the developer container in an open state; an openable / closable retention cover to hold the developer container and configured to allow the image forming unit to be removed when the retention cover is opened; a coupling device to secure a coupled state of the developer supply port of the developer container with the developer intake port of the image forming unit when the upper cover is in a closed state; and a disconnection preventer to prevent the developer container from disconnecting from the retention cover when the upper cover is opened.

Owner:RICOH KK

Color inkjet recording apparatus and copier with increased reliability

InactiveUS7213909B2Improve long-term reliabilityDamage to partPrintingEngineeringElectrical and Electronics engineering

A color inkjet recording apparatus includes a plurality of multi-nozzle inkjet recording heads ejecting inks of respective colors, an electrical system unit controlling the operation of the color inkjet recording apparatus, an ink container connected to the multi-nozzle inkjet recording heads, and a holding part. The ink container includes a plurality of independent ink containers containing the respective color inks, and is provided below the multi-nozzle inkjet recording heads and the electrical system unit. The holding part holds the independent ink containers, and includes a plurality of separation parts. The separation parts prevent ink from contaminating one of the independent ink containers which is caused by ink spilling or overflowing from one of the adjacent independent ink containers.

Owner:RICOH KK

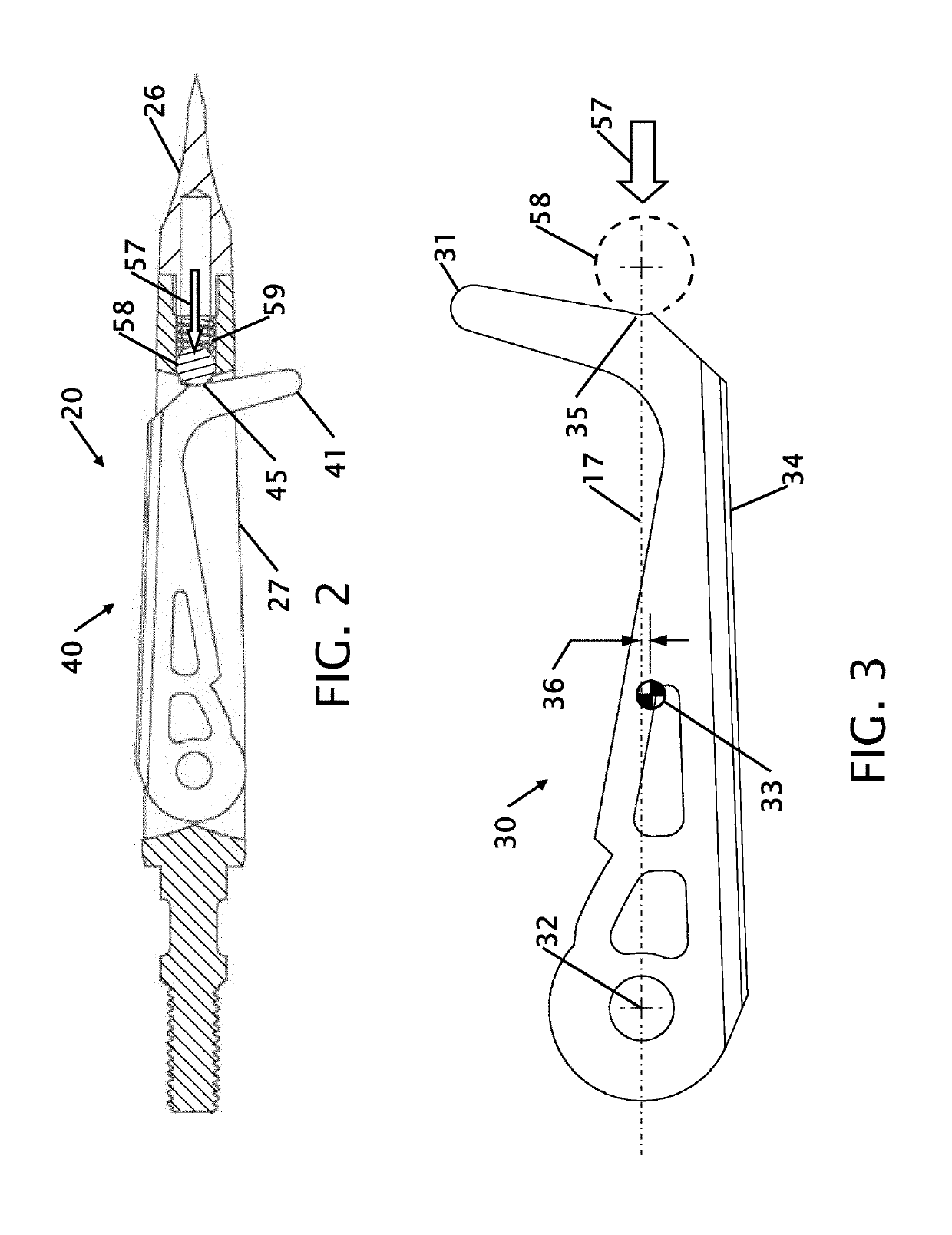

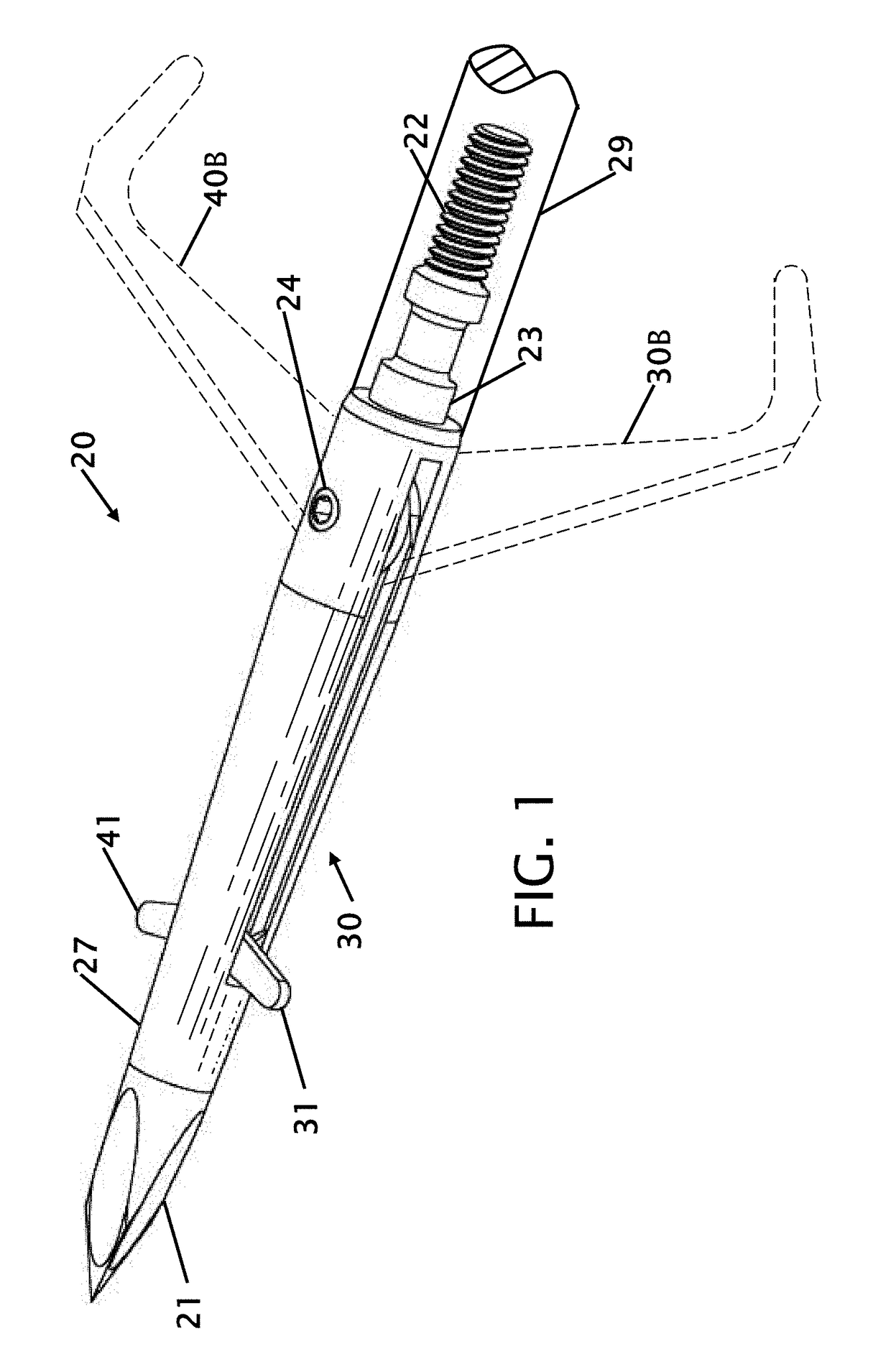

Over center expanding arrowhead

InactiveUS10415940B2Overcome forceOvercome gravityAmmunition projectilesArrowsKnife bladesGravitation

Improvements in an expanding arrowhead where the initial launching thrust of launching an arrow keeps the blades retracted within the head of the arrow. The blades remain retracted because the center of mass of the blades is on the opposite side of the rotational pivoting axis of the blades. When the blades contact a target a wing tip on the blades pull the blades open. There are two or three blades that can be retained within the head of the arrow. The blades are loosely retained in a retracted orientation for transportation. The retention is sufficient to overcome the forces or gravity yet release with slight force on then ends of the blades. When the arrow is pulled through the wound track the blades fold back into the head or body.

Owner:SULLIVAN BRIAN E +1

Dermal incisor

InactiveUS7744544B2Smooth skinConsistent incisionSurgical needlesVaccination/ovulation diagnosticsEngineeringHorizontal and vertical

Owner:HUOT INSTR

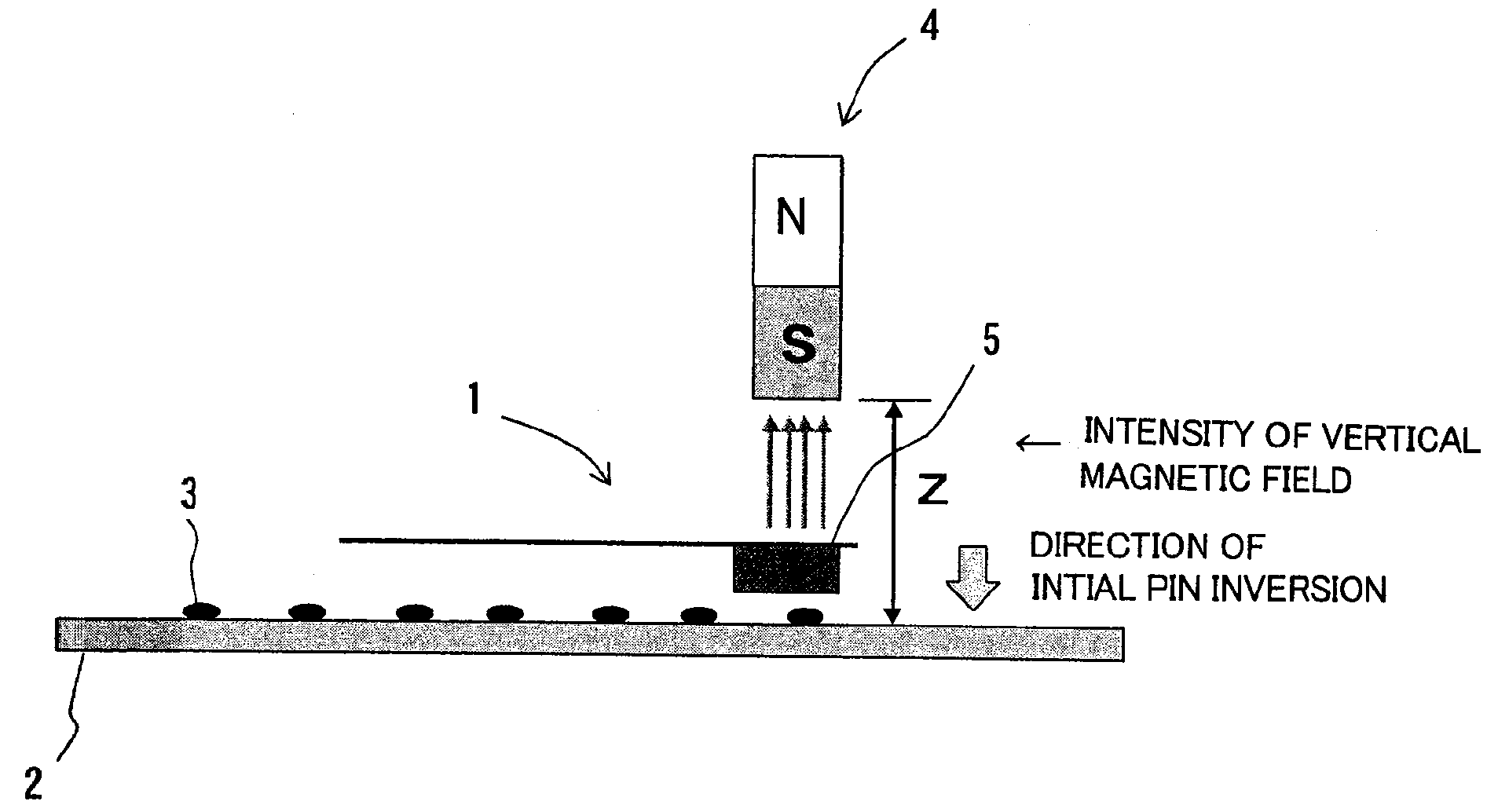

Apparatus and method for evaluating magnetic heads, and disk for use in evaluating magnetic heads

InactiveUS20060022668A1Damage to partReliable detectionMagnetic property measurementsRecord information storageDc currentMagnetization

A DC current is supplied to the write coil of a GMR head 1 equipped with a completed HGA (Head Gimbal Assembly). The element part of the GMR head 1 is thereby thermally deformed. Thus deformed, the element part protrudes, abutting on a rotating laser-bump disk 2 that, above which the HGA is floating. When the element part abuts on the disk 2, a magnetic field (2470 gauss) that extends in a direction opposite to the magnetization direction of the fixed layer of the GMR head 1 is applied to the top of a core slider 5.

Owner:TOSHIBA STORAGE DEVICE CORP

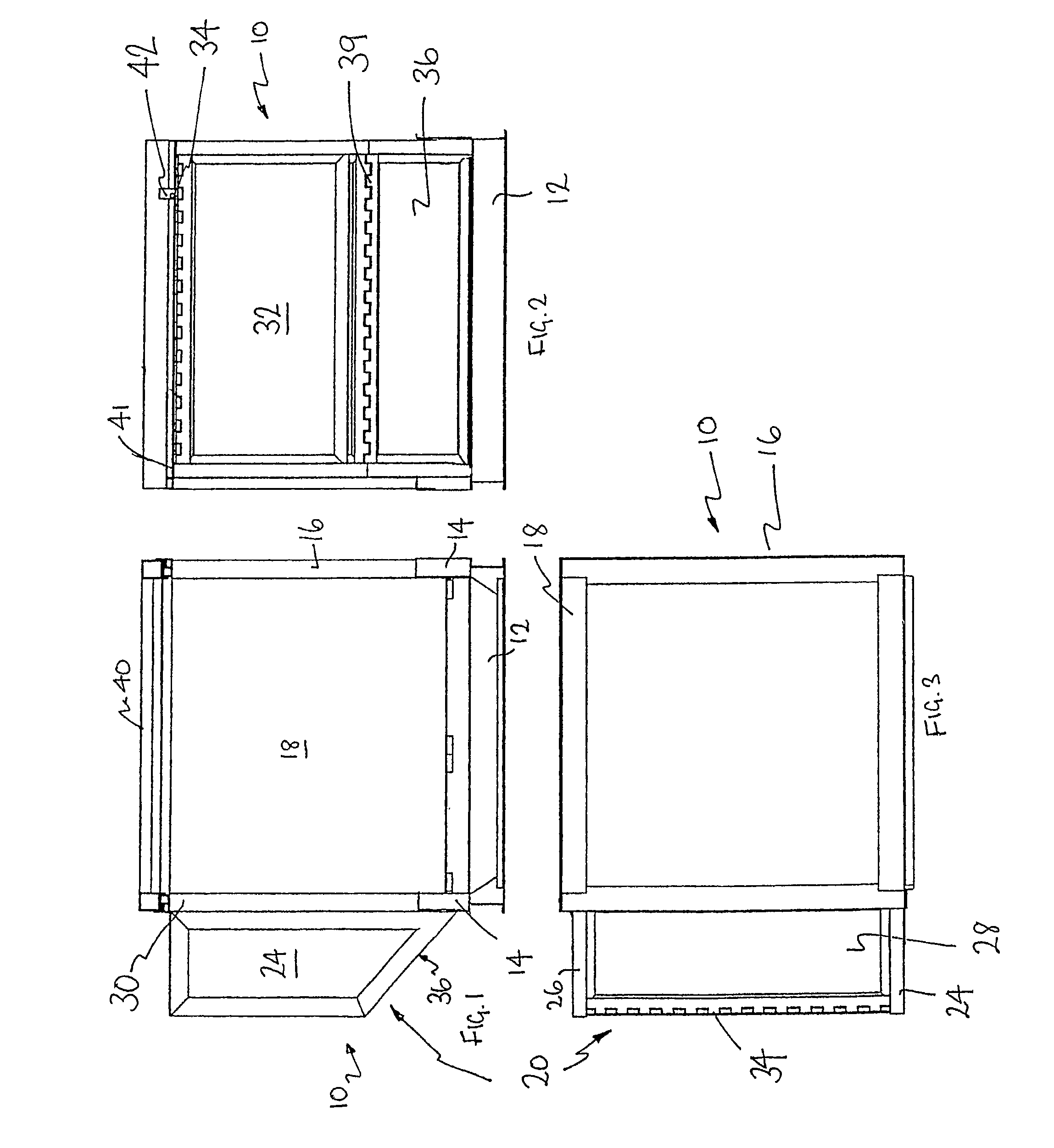

Folding containers

InactiveUS8261924B2Improve stacking characteristicMinimal amountLarge containersRigid containersEngineeringMechanical engineering

A collapsible air freight container (10) comprises a standard base (12), a side panel (16) slideably hinged to the base and a back panel (18) which is hinged to the base which interlocks with the side panel. There is a side extension (20) which is generally trapezoidal to roughly conform to the shape of a side wall of a plane's cargo hold. A lid is slideably mounted on top of the container so that it can be slid relative to the back panel. The lid is arranged so that when fully retracted to the back of the container relative to the back panel, it may pivot to overlay the back panel. The container may be collapsed by retracting and pivoting the lid to overlie the back panel (18), folding the side extension (20), folding and sliding the side panel (16) into the base (12) and lowering the folded side extension (20) and then the back panel (18) and lid (40) into the base.

Owner:TECHNOSEARCH

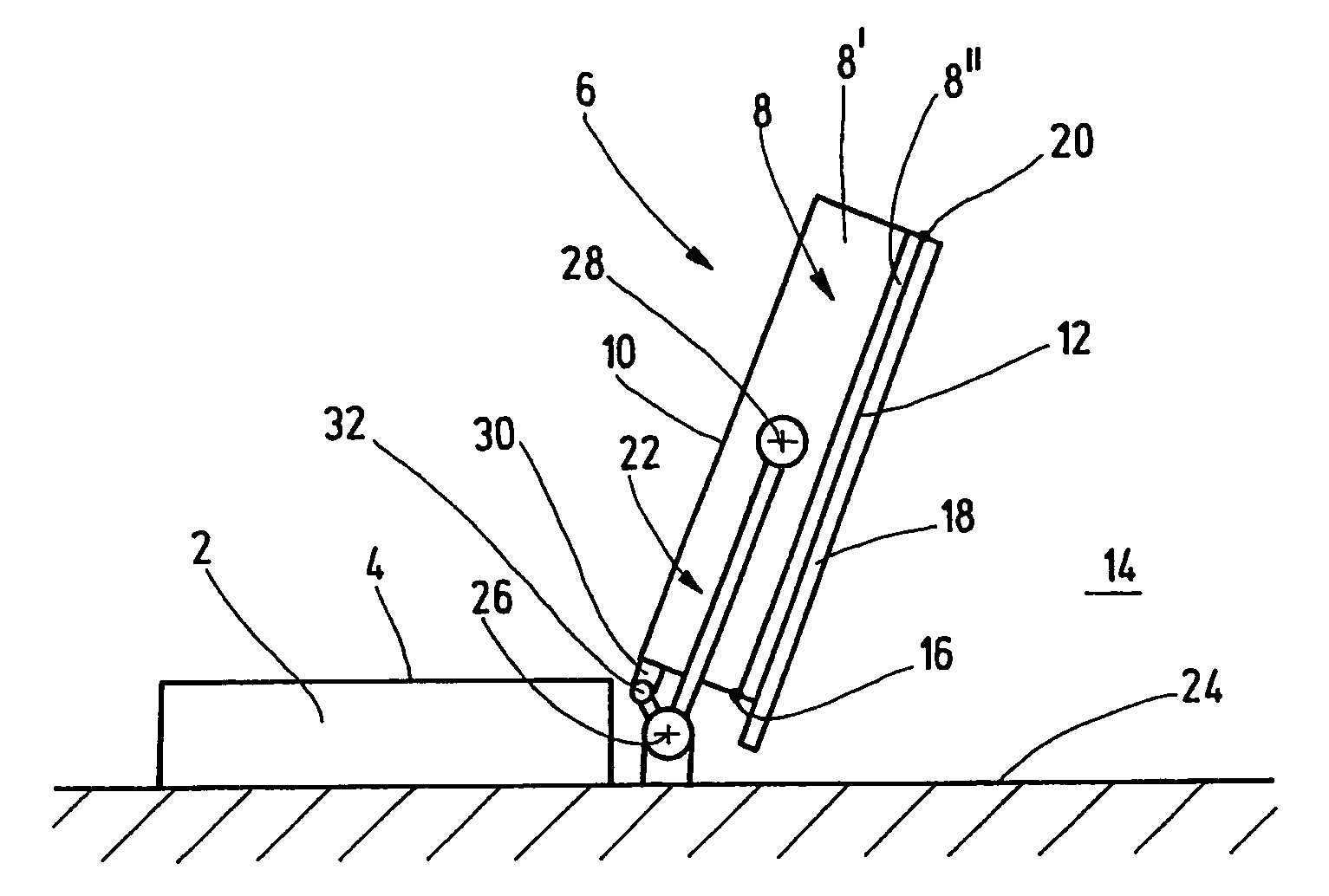

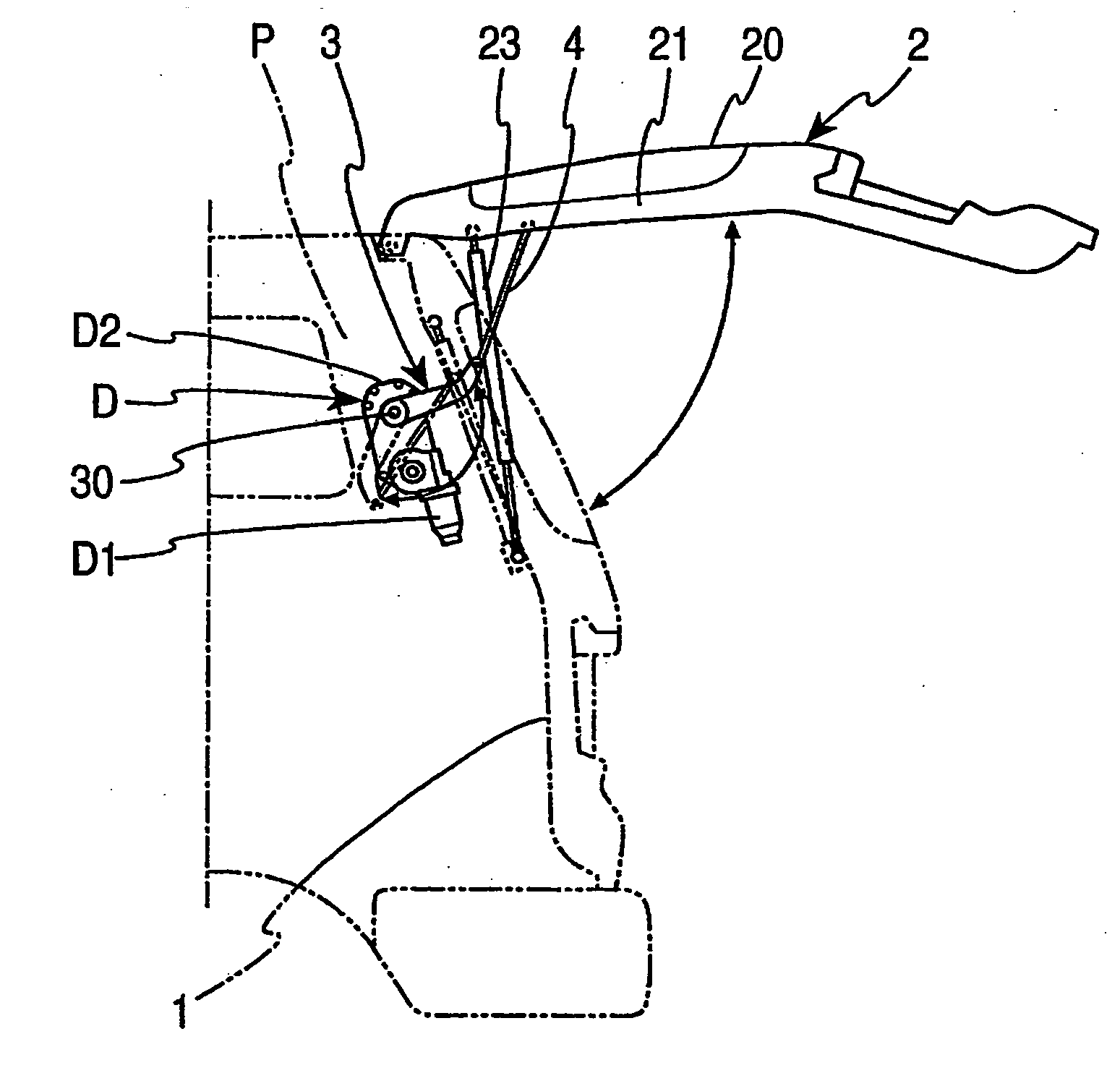

Power back door for vehicle

InactiveUS20100007170A1Great widthNot to degrade appearanceEngine sealsMan-operated mechanismEngineeringContact position

An opening, through which a connection section between a drive arm and a rod of a power back door enters and exits, is covered with cover members to improve external appearance, and interference between the connection section and the cover members is eliminated when the connection section passes through the opening to prevent abnormal noise and damage to the cover members during the passage of the connection section. A pair of cover members 6a and 6b are provided along right and left vertical edges of a vertically long opening 50 that is formed in a side edge defining a door opening 1, through which a connection section S between a drive arm 3 and a rod 4 of a power back door for automatically driving a back door 2 adapted to close and open the door opening 1 can enter and exit, such that lip-shaped end edges thereof face and contact each other. The cover members 6a and 6b are gradually expanded in width so that they have a greater width on the lower side thereof, and a contacting position is shifted downwardly and inwardly of the opening 50, thereby forming an entrance / exit opening 64 surrounded by lower edges of expanded sections of the cover members 6a and 6b, through which the connection section S enters and exits.

Owner:TOYOTA SHATAI KK

Image-forming device and method for forming an image

ActiveUS8840213B2Decrease productivityEasy loadingOther printing apparatusImage formationEngineering

Owner:SEIKO EPSON CORP

Folding containers

InactiveUS20100187228A1Improve stacking characteristicMinimal amountLarge containersRigid containersUnit load deviceUnit device

A collapsible air freight container (10) also known as a unit load device, comprises a standard base (12), commonly used on unit load devices, a side panel (16) slideably hinged to the base and a back panel (18) which is hinged to the base which interlocks with the side panel. There is a side extension (20) which is generally trapezoidal to roughly conform to the shape of a side wall of a plane's cargo hold. The side extension (20) includes a frame which (22) is hinged to the base and two trapezoidal (front and rear) panel extensions (24, 26) hinged to the frame. The side extension (20) is completed by a lid (28) and side wall panel (32) connected together by a hinge (34) with the lid (28) being hinged to a top of the frame, and by a sloping bottom panel (36) and relatively short side wall panel (40) hingedly connected to each other with the bottom panel (36) also being hinged to a bottom member of the frame. A lid is slideably mounted on top of the container so that it can be slid relative to the back panel. The lid is arranged so that when fully retracted to the back of the container relative to the back panel, it may pivot to overlay the back panel. As is typical of unit load devices the front of the container is open but may be covered by a flexible curtain or the like. The container may be collapsed by retracting and pivoting the lid to overly the back panel (18), folding the side extension (20) within the frame (22), folding and sliding the side panel (16) into the base (12) and lowering the folded side extension (20) and then the back panel (18) and lid (40) into the base.

Owner:TECHNOSEARCH

Culvert with a deformation zone

InactiveUS20130101346A1Avoid contactReduces overload valueGround-workPaving gutters/kerbsSoft layerReinforced concrete

The culvert with the deformation zone consists of prefabricated components arranged in the road ditch (1). The culvert includes at least one fixed basic component and at least one deformation component sliding in the basic component in the direction of the longitudinal ditch axis (1) and covered by a deformable decking or also by backfilling or other cover. The substance of the invention lies in the fact the basic component consists of a set of prefabricated concrete or reinforced concrete beds (2) formed in “V”-shape and placed one after another on the concrete base (3) in the road ditch (1) so that the shoulders (2a, 2b) of the beds (2) abut the ditch walls (1). Both shoulders (2a, 2b) of each bed (2) are fitted with opposite guiding recess (4) in the upper part for placement of deformation components formed by a set of at least two lateral rigid girders (5) installed with the possibility of the sliding movement in the direction of the longitudinal ditch axis (1). There are deformation gaps (6) between each lateral girder (5) and at least one front of the culvert contains at least one further deformation component in the recesses (4) with possibility of sliding movement that forms the front component (7) fitted with soft layer (14) from soft and resilient deformable material on at least its front part.

Owner:NOVOTNY PETR

Paint for Highly Corrosion-Resistant Zinc-Alloy Coated Steels and Steel Structure Having Coated Film of Said Paint

ActiveUS20070209555A1Promote repairExcellent corrosion-resistancePigmenting treatmentHot-dipping/immersion processesMaximum diameterZinc alloys

A paint for highly corrosion-resistant zinc-alloy coated steels containing zinc-alloy powder at not less than 60 mass %, characterized in that said powder contains aluminum at not less than 10 mass % and less than 30 mass % and the remainder comprising zinc and unavoidable impurities, the shape of powder particles is spherical or oval and the ratio between the maximum and minimum diameters (maximum diameter / minimum diameter) is 1 to 1.5, and a steel structure having coated films produced by using said paint.

Owner:NIPPON STEEL CORP

Over Center Expanding Arrowhead

Improvements in an expanding arrowhead where the initial launching thrust of launching an arrow keeps the blades retracted within the head of the arrow. The blades remain retracted because the center of mass of the blades is on the opposite side of the rotational pivoting axis of the blades. When the blades contact a target a wing tip on the blades pull the blades open. There are two or three blades that can be retained within the head of the arrow. The blades are loosely retained in a retracted orientation for transportation. The retention is sufficient to overcome the forces or gravity yet release with slight force on then ends of the blades. When the arrow is pulled through the wound track the blades fold back into the head or body.

Owner:SULLIVAN BRIAN E +1

Color inkjet recording apparatus and copier with increased reliability

A color inkjet recording apparatus includes a plurality of multi-nozzle inkjet recording heads ejecting inks of respective colors, an electrical system unit controlling the operation of the color inkjet recording apparatus, and an ink container connected to the multi-nozzle inkjet recording heads. The ink container is provided below the multi-nozzle inkjet recording heads and the electrical system unit.

Owner:RICOH KK

Paint for highly corrosion-resistant zinc-alloy coated steels and steel structure having coated film of said paint

ActiveUS8025965B2Avoid corrosionSmall color differenceHot-dipping/immersion processesAnti-corrosive paintsMaximum diameterZinc alloys

A paint for highly corrosion-resistant zinc-alloy coated steels containing zinc-alloy powder at not less than 60 mass %, characterized in that said powder contains aluminum at not less than 10 mass % and less than 30 mass % and the remainder comprising zinc and unavoidable impurities, the shape of powder particles is spherical or oval and the ratio between the maximum and minimum diameters (maximum diameter / minimum diameter) is 1 to 1.5, and a steel structure having coated films produced by using said paint.

Owner:NIPPON STEEL CORP

Continuous conveyor

A closed continuous conveyor for pallets has an upper run and a lower run, which respectively form an upper and a lower conveyor track with reversal sections in which deflecting elements are arranged, of which at least one is connected to and driven by an engine, with tension elements rotating endlessly in the upper and lower runs and in the reversal sections, which engage the deflecting elements in the reversal sections and are driven by them. At least one rotating pallet is carried by the tension elements. At least one closure element is fixed to the underside of the pallet and engages in the reversal section with a second form closure element or frictional closure element that rotates around a fixed axis of rotation. The closure element includes at least one elastic buffer component.

Owner:BLEICHERT AUTOMATION

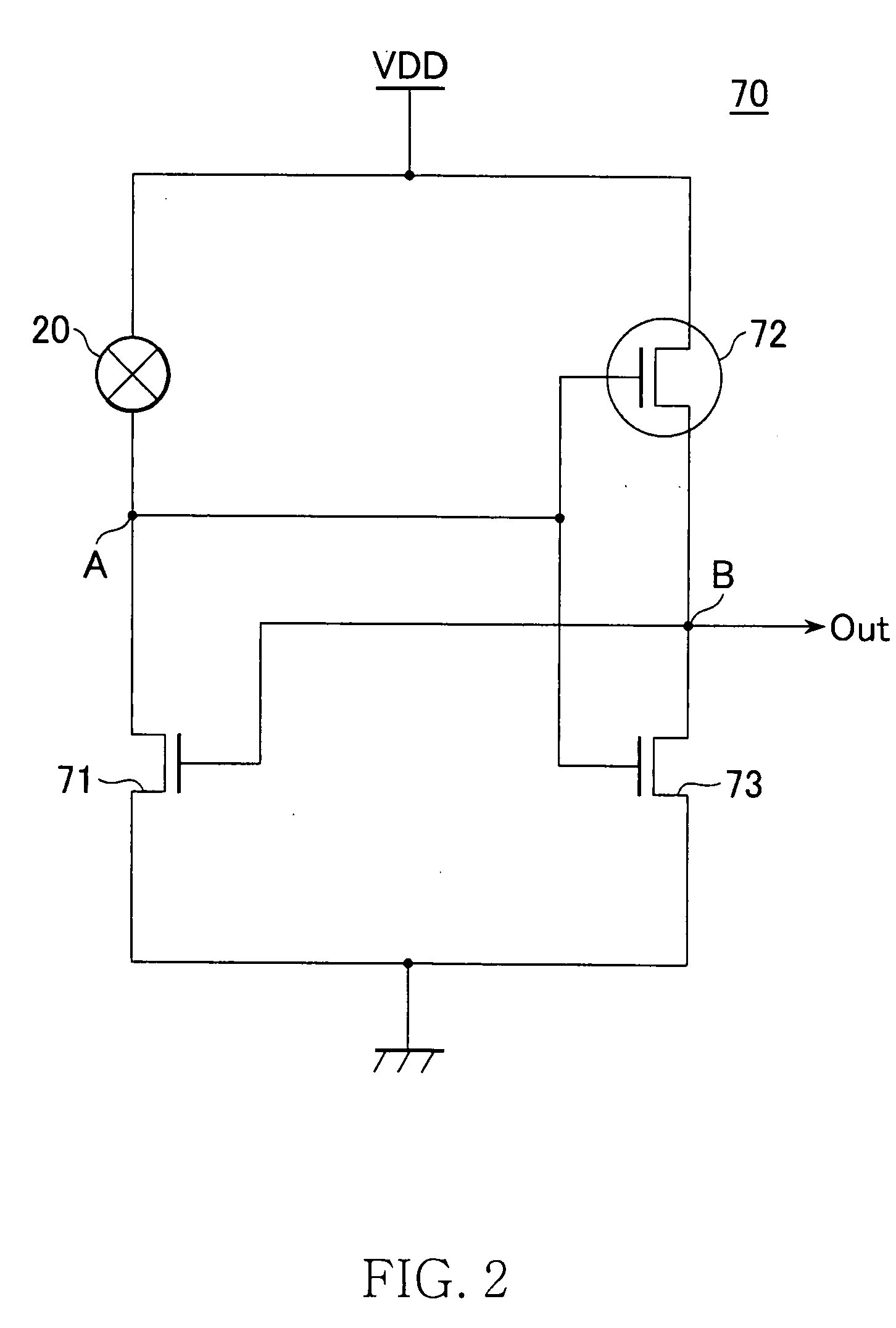

Semiconductor device having fuse element and method of cutting fuse element

InactiveUS20070235837A1Effective absorptionDamage to partSemiconductor/solid-state device detailsSolid-state devicesAbsorbed energyEngineering

A semiconductor device includes a lower electrode, an upper electrode, and a fuse element that connects the lower electrode and the upper electrode. Between the lower electrode and the upper electrode, insulating films stacked in this order exist. Out of the insulating films, the insulating film located in the middle has absorptivity of light larger than those of the other insulating films. Thus, in the present invention, a fuse element that is vertically long and penetrates an insulating film of which the absorptivity of light is large in the central portion is used, so that it is possible to effectively absorb energy of a laser beam. Further, it is possible to cut the fuse element using an optical system having a small depth of focus, so that it is possible to cut the fuse element without destructing a passivation layer.

Owner:ELPIDA MEMORY INC

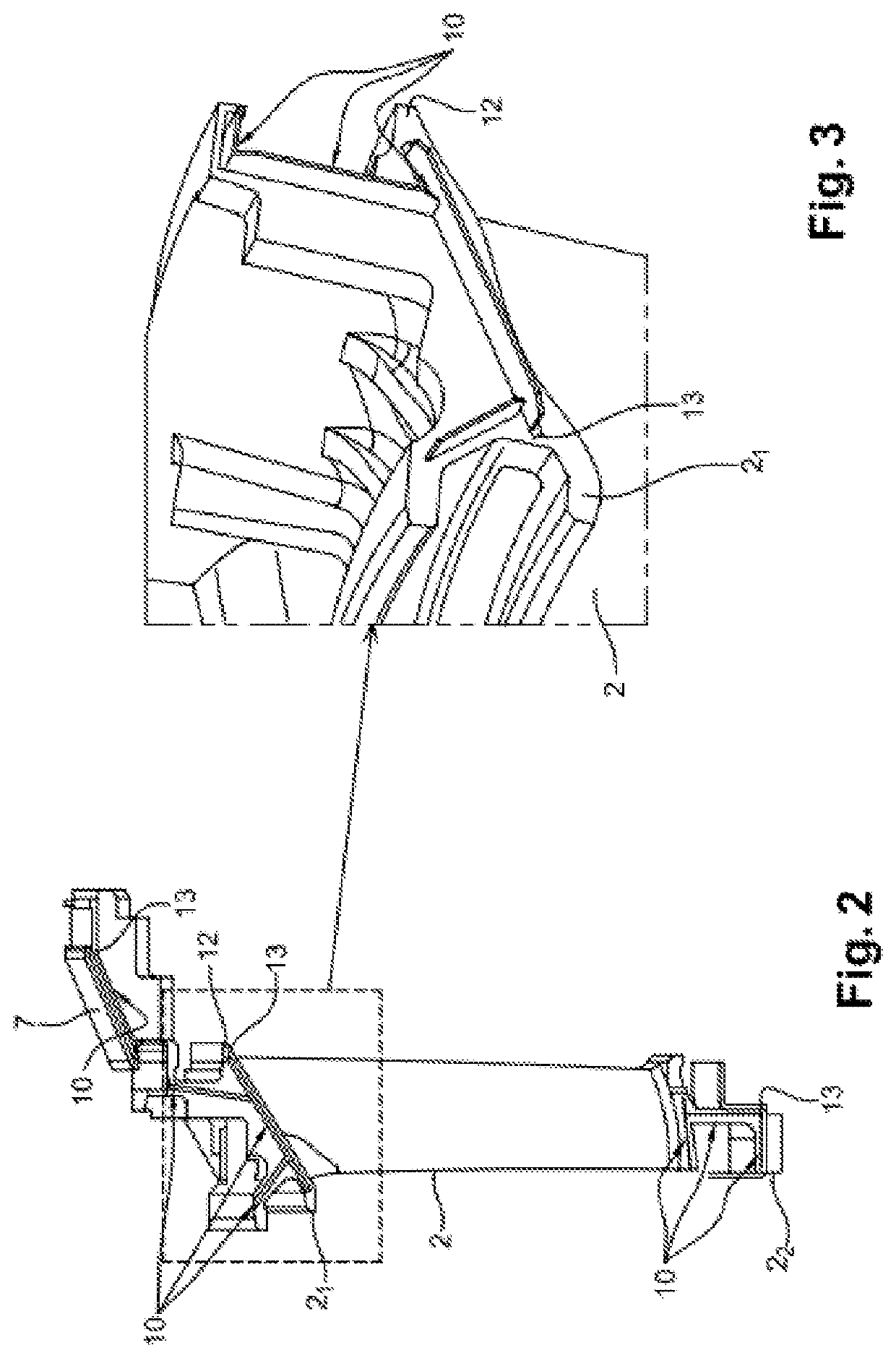

Assembly for gas turbine, associated gas turbine

ActiveUS10760440B2Limit wearReduce gapEngine sealsEfficient propulsion technologiesTurbineGas turbines

An assembly for gas turbine, includes a first part and a second part installed circumferentially around a longitudinal axis of the turbine, where the first part has a first side face adjacent to a second side face of the second part, and where a first aperture made in first side face is facing a second aperture made in second side face, a sealing plate fitted inside the first aperture and the second aperture, at least one longitudinal face of the sealing plate includes at least two projections made either side of a longitudinal central area of the sealing plate, wherein each projection is of a height chosen so as to reduce a clearance between the sealing plate and the first and second apertures.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Clamp device and method for repairing a damaged part of a pipe section, and use of such clamp device

PendingUS20220146036A1Prevent leakagePrevent degradationPipe laying and repairPipe elementsStructural engineeringMechanical engineering

A clamp device is for repairing a damaged part of a pipe section. The clamp device has a patch member and a support structure having a clamp body supporting the patch member. The clamp device has a first engagement member configured to engage with a first part of the pipe section and a second engagement member configured to engage with a second part of the pipe section. The clamping device has a first mechanism configured to engage the first engagement member with the first part and compress the patch member at the damaged part, and a second mechanism configured to engage the second engagement member with the second part and induce a compressive force between the first engagement member and the second engagement member.

Owner:IK NORWAY AS

Assembly for gas turbine, associated gas turbine

ActiveUS20180320539A1Limit wearReduce gapEngine sealsEfficient propulsion technologiesEngineeringTurbine

An assembly for gas turbine, includes a first part and a second part installed circumferentially around a longitudinal axis of the turbine, where the first part has a first side face adjacent to a second side face of the second part, and where a first aperture made in first side face is facing a second aperture made in second side face, a sealing plate fitted inside the first aperture and the second aperture, at least one longitudinal face of the sealing plate includes at least two projections made either side of a longitudinal central area of the sealing plate, wherein each projection is of a height chosen so as to reduce a clearance between the sealing plate and the first and second apertures.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com