Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Unit load device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A unit load device (ULD) is a pallet or container used to load luggage, freight, and mail on wide-body aircraft and specific narrow-body aircraft. It allows a large quantity of cargo to be bundled into a single unit. Since this leads to fewer units to load, it saves ground crews time and effort and helps prevent delayed flights. Each ULD has its own packing list (or manifest) so that its contents can be tracked.

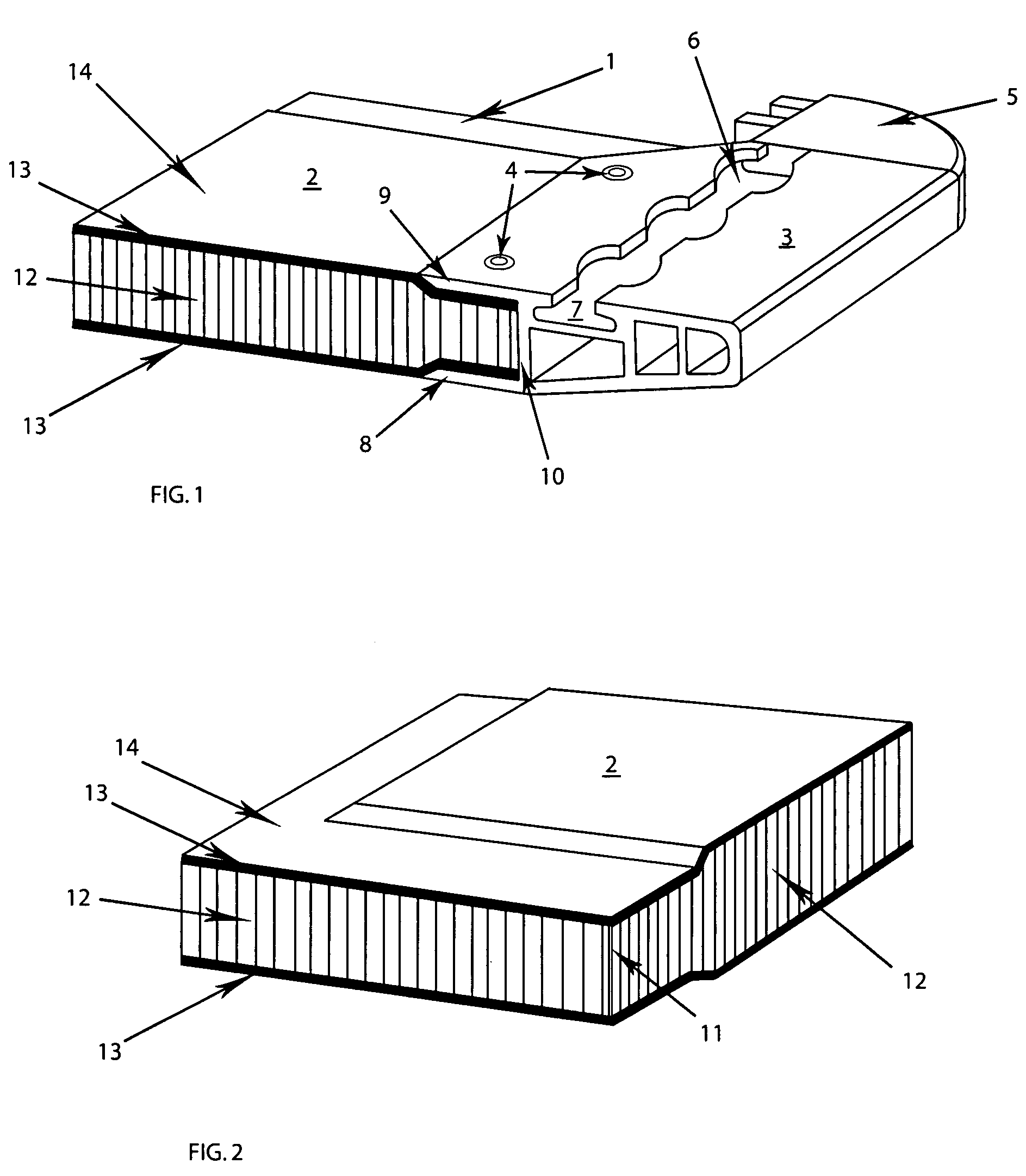

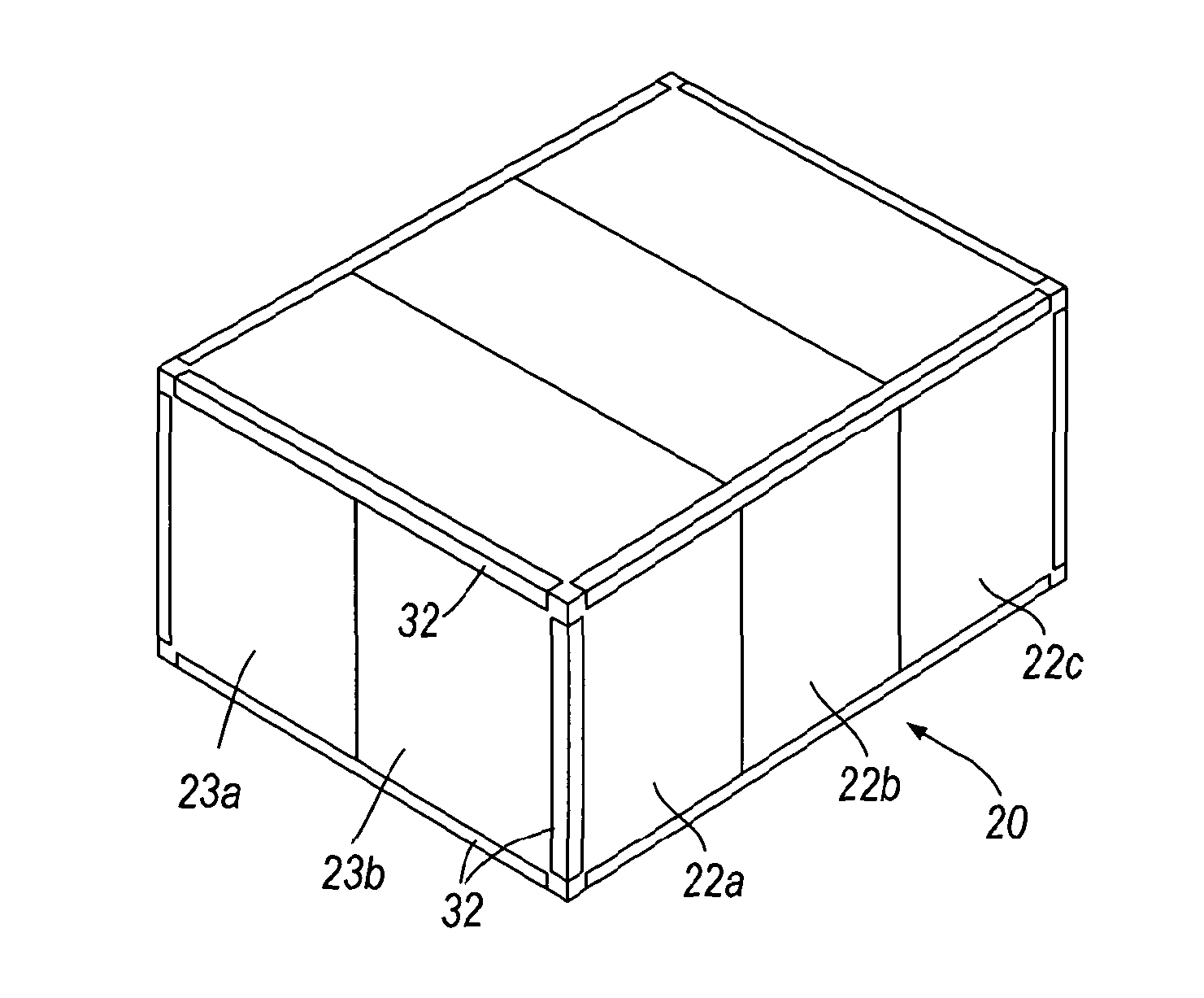

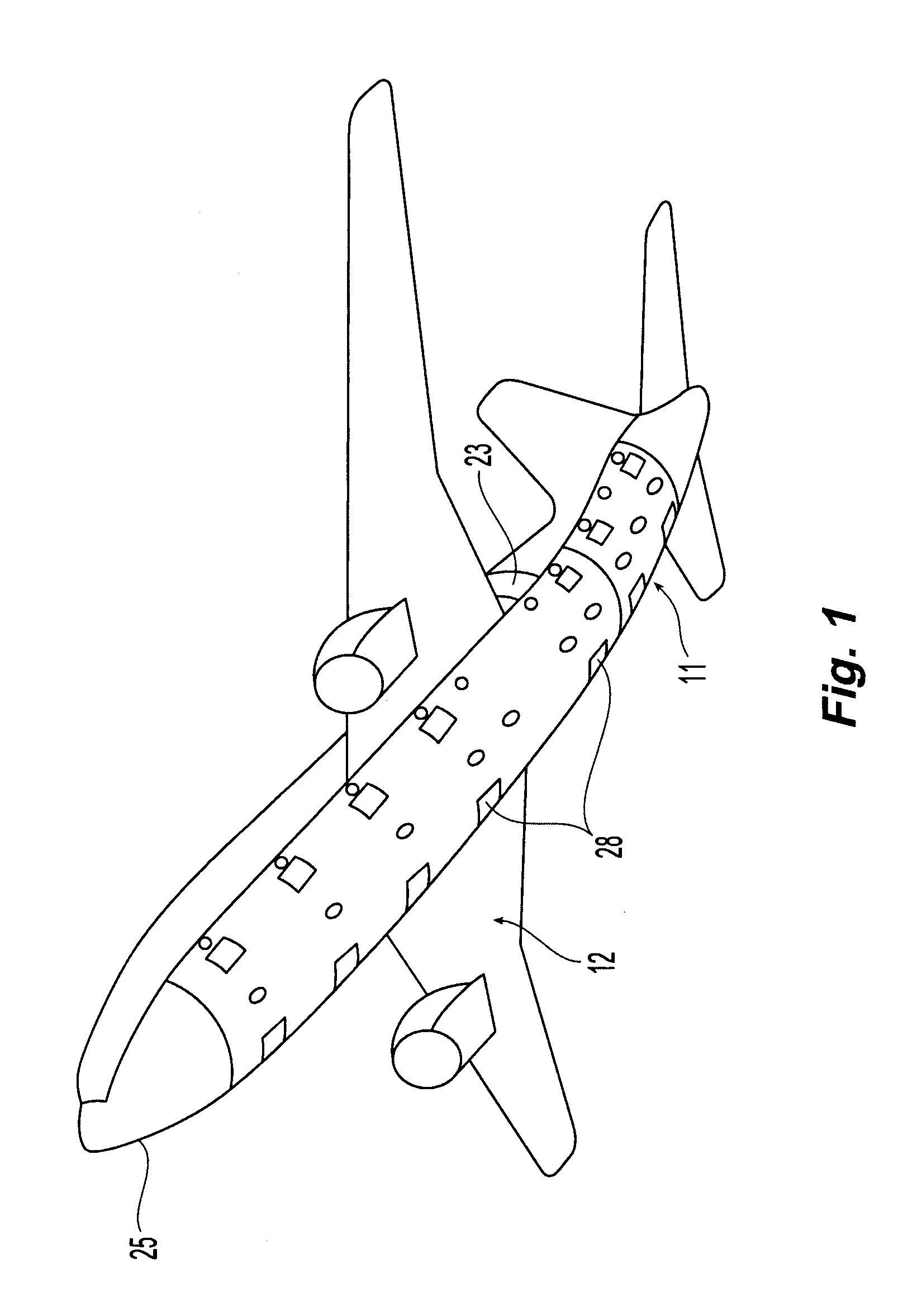

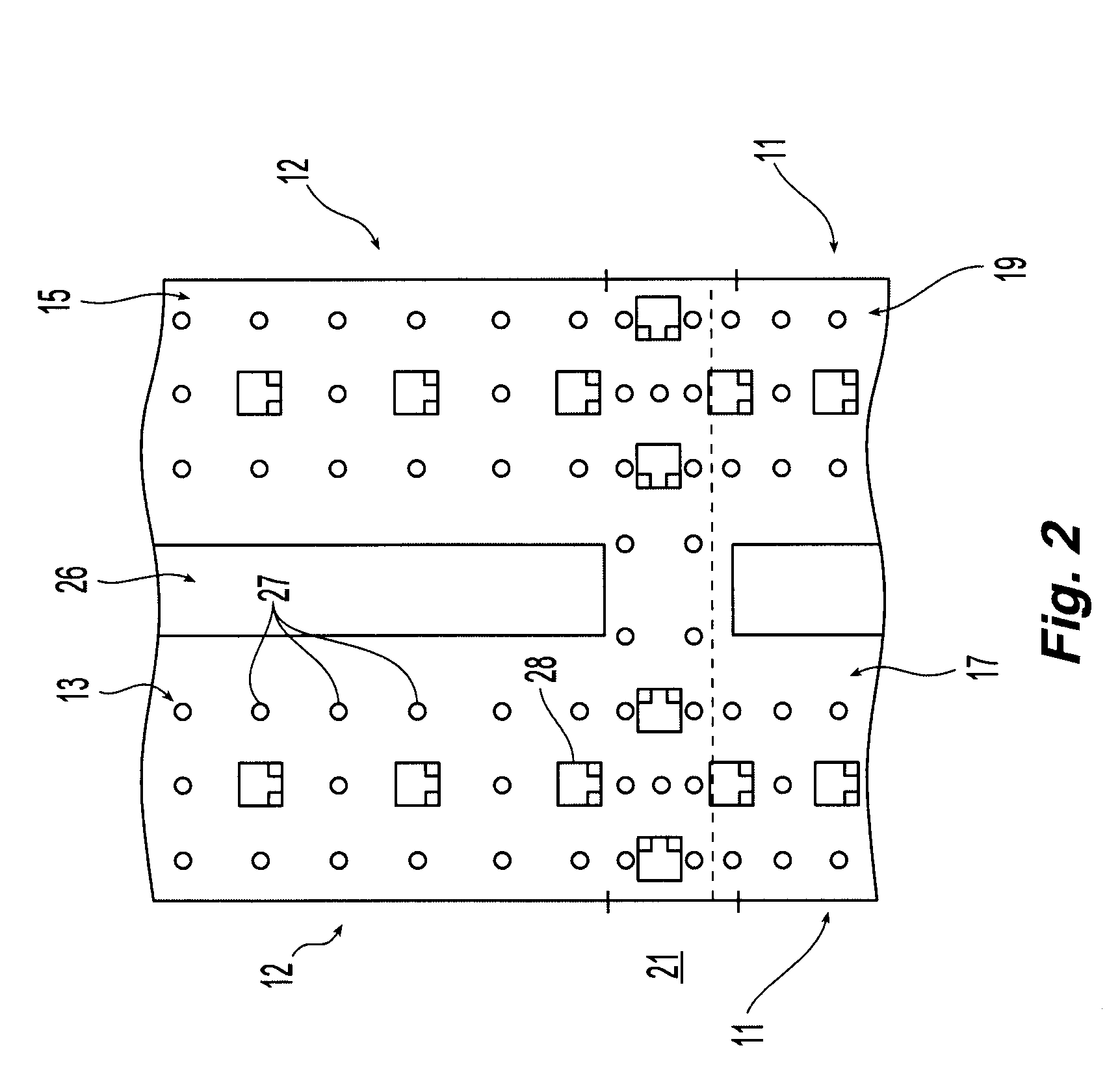

Lightweight unit load device

InactiveUS20110247958A1Reduce weightRaise the ratioSynthetic resin layered productsLarge containersUnit load deviceUnit device

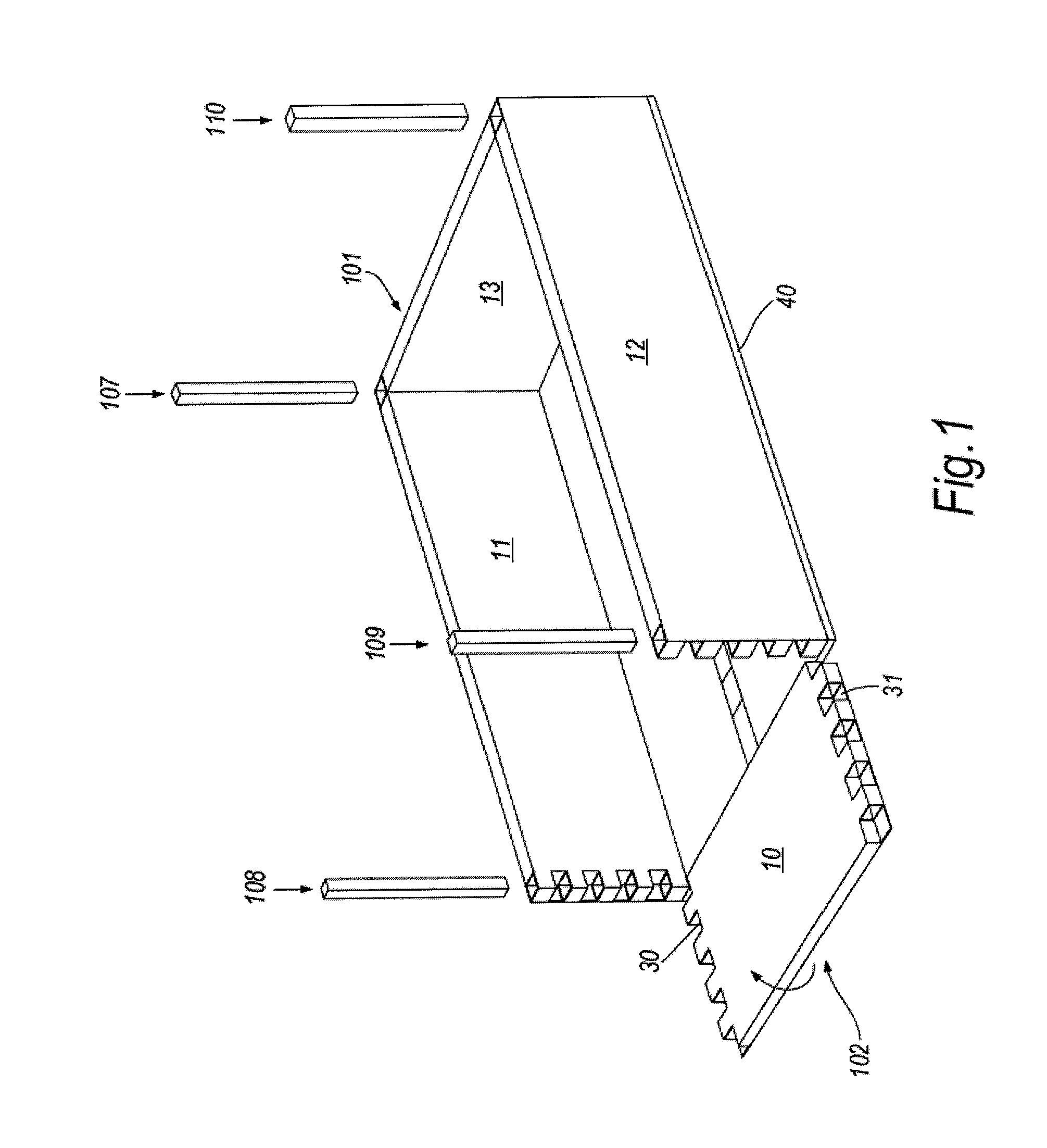

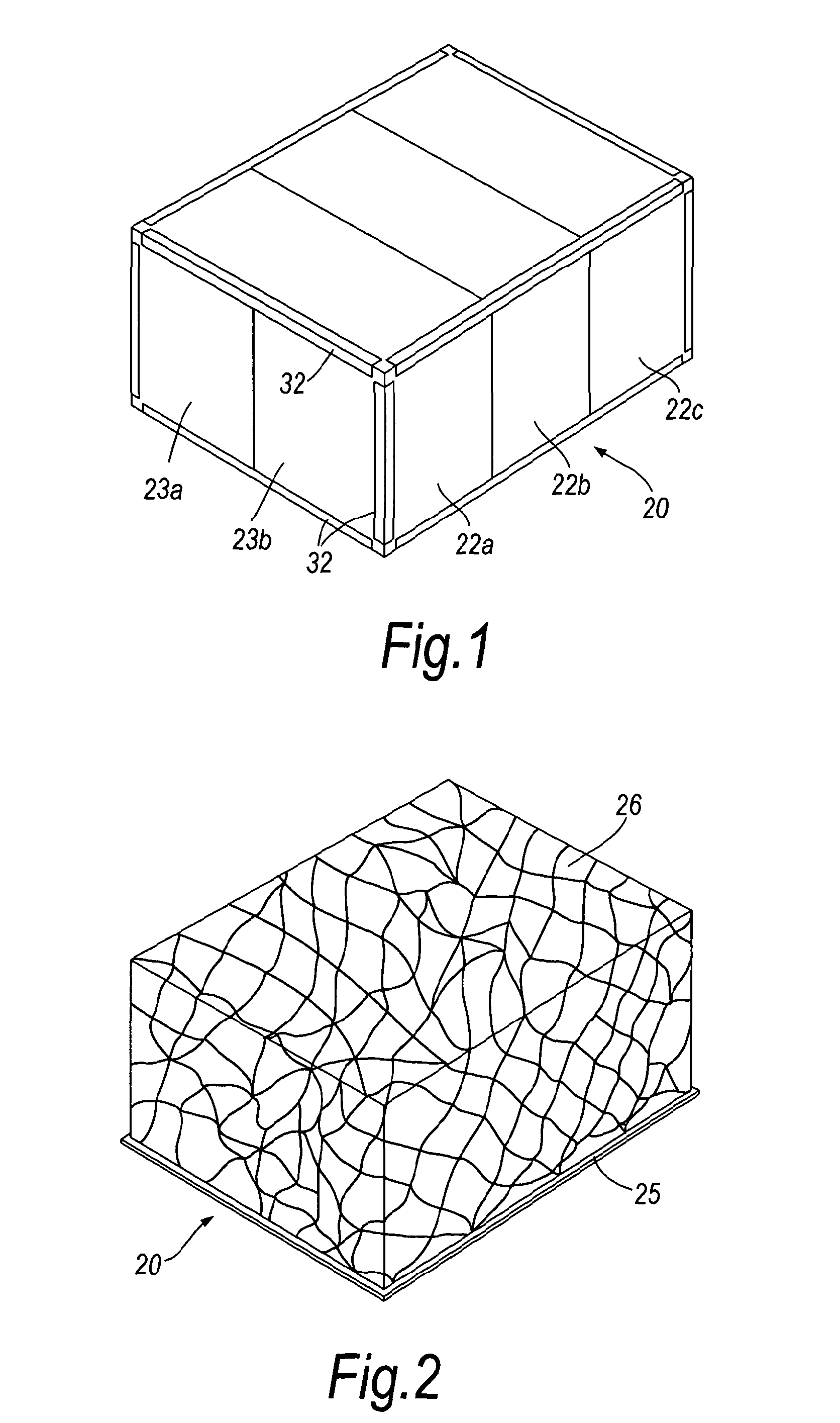

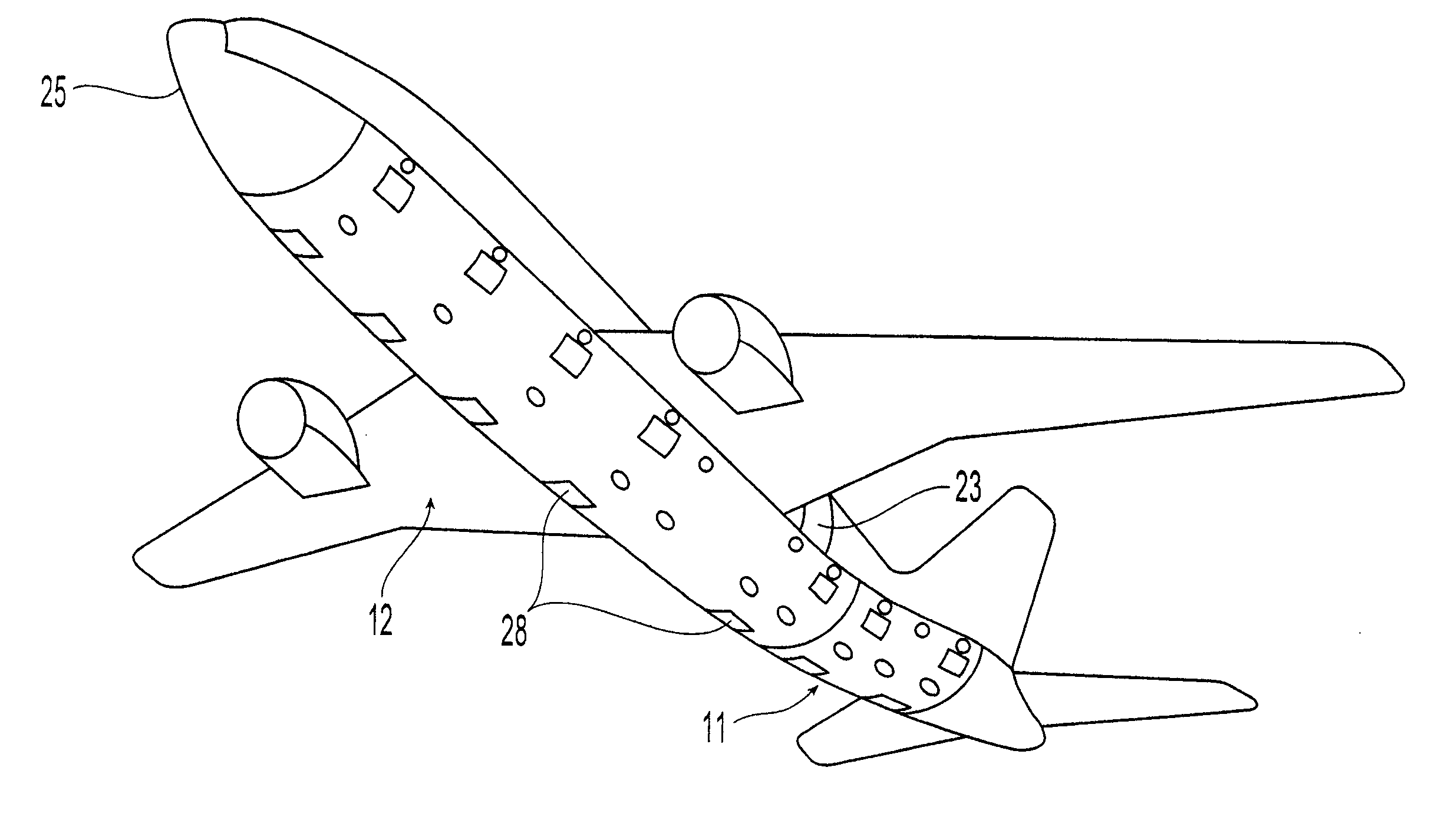

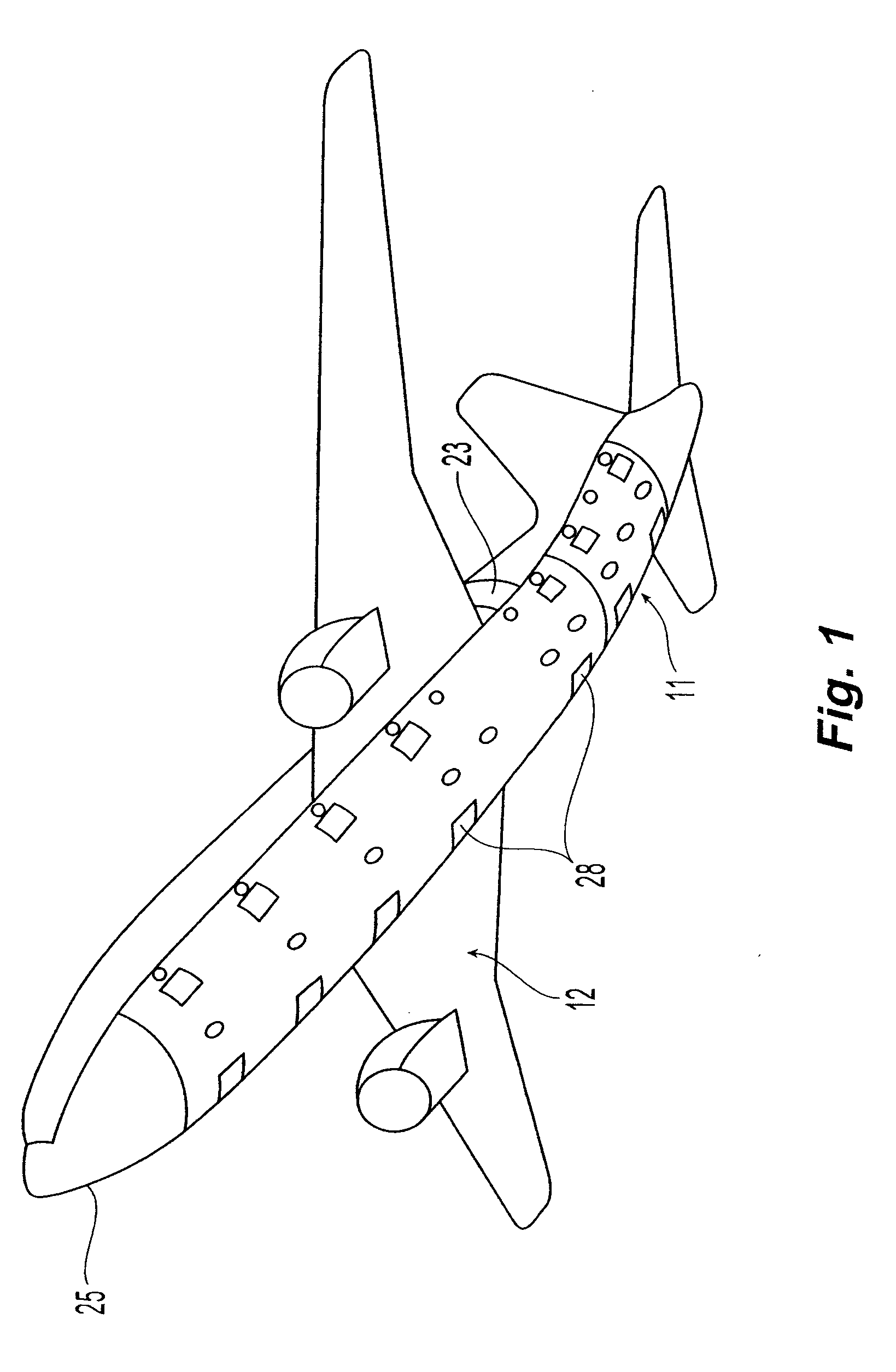

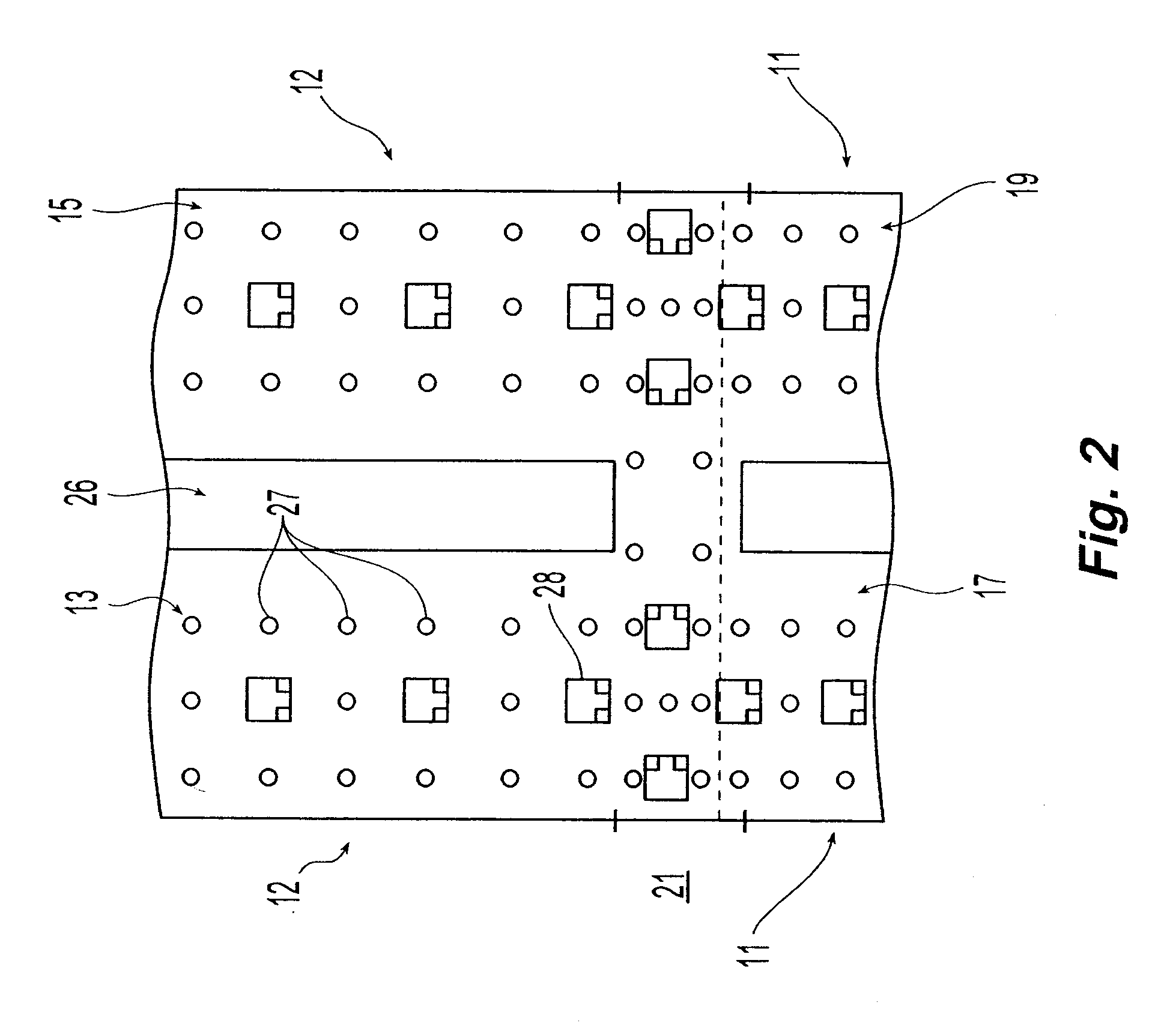

A unit load device constructed from fiber reinforced polymer matrix composite materials is described. Individual panels of the unit load device may be customized with composite materials and patterns. The joints are adapted to receive the ends of the panels of the unit load device and may further be customized with fiber reinforced composite materials to strengthen the joint. Some embodiments provide for construction of a unit load device from a variety of fiber reinforcing materials utilizing a matrix of thermoplastic polymers with similar softening temperatures. Each component part within the container was designed and / or created to address the specific needs of the particular part. The unit load devices described herein provide for all composite containers with a significant weight savings from conventional unit load devices.

Owner:COMPOSITE TRANSPORT TECH

Transport Container

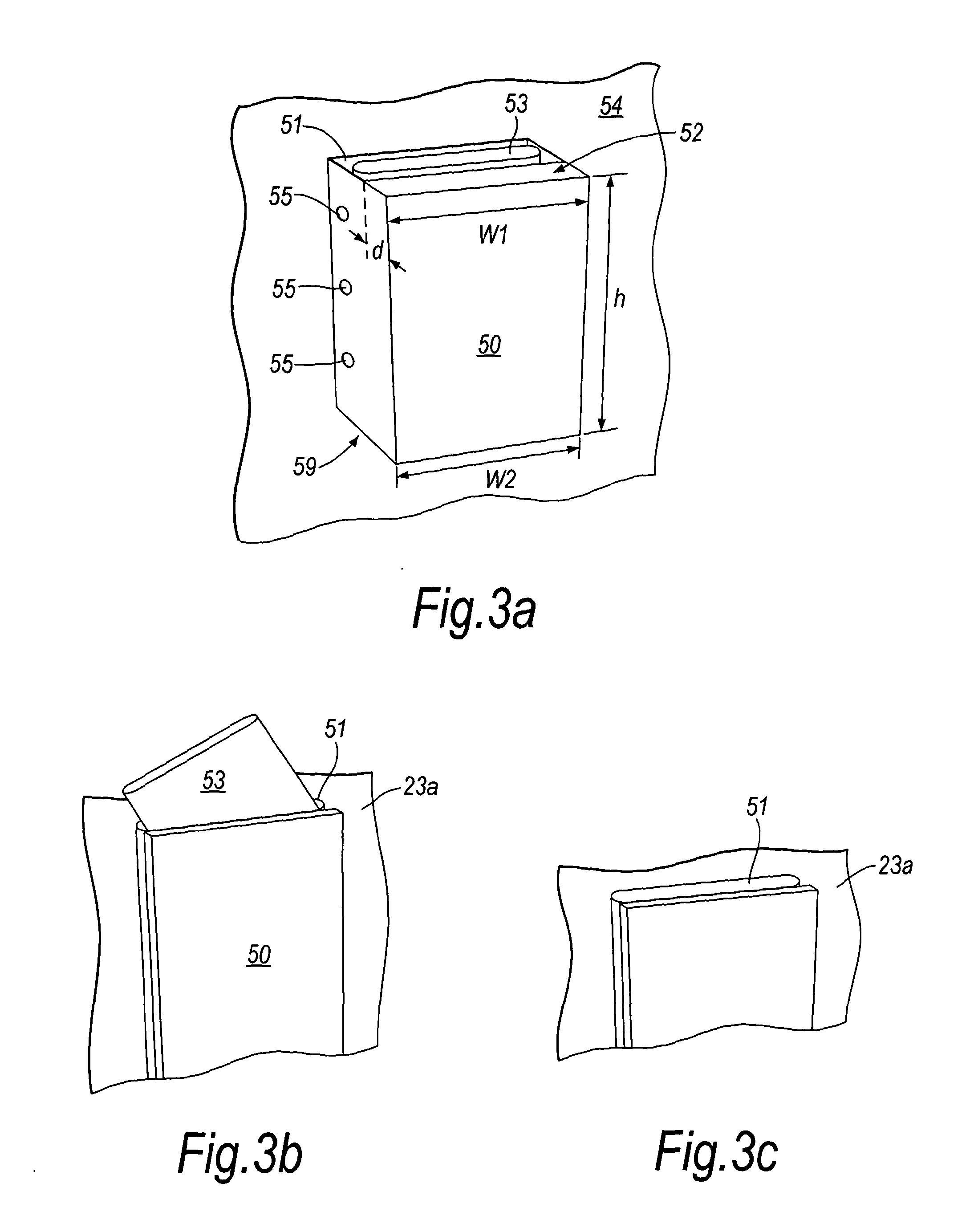

ActiveUS20100301057A1Reduce manufacturing costEasy to buildLighting and heating apparatusLarge containersAviationEngineering

The present invention relates to a transport container which provides mechanical and thermal stability for a load and which container is fabricated as the container is loaded. In particular, the present invention relates to a container which can be readily transported on aircraft, such as an aircraft container. In the field of logistics, that is the field of movement and supply of produce and materials, in particular in the transport of intermediate and finished products, containers have been developed which safely protect from physical damage a wide variety of product. Food and pharmaceutical products not only need protection from physical shock and pressures but also require temperature stability during transportation; otherwise goods can be damaged and be unusable, whether such damage is apparent or not. However, air transport poses a particular problem: Goods can be transported in tropical heat, packaged and placed upon pallets and the like containers whereby they are presented in aircraft style containers. Such goods may be left on runways at extreme temperatures (+40° C.) and then placed within a hold where low pressures and low temperatures exist during flight. At a destination airport the temperatures may well be sub-zero. To simplify transport with respect to airports, planes and handling equipment, there have been developed aircraft Unit Load Devices (ULDs) which comprise any type of pallet or container that can easily be loaded to the aircraft by a ground handler. The present invention seeks to provide a transport container which can maintain goods within a narrow temperature range, can displace a considerably reduced volume before erection, is economical to manufacture, can readily and easily be constructed. The present invention further seeks to provide a transport container which is compatible with standard Unit Load Device specifications.

Owner:SOFTBOX SYST LTD

Ultralight unit load device

InactiveUS7854204B2Sacrificing payload capacityReduce complexityLaminationLamination apparatusUnit load deviceUnit device

Owner:DACUS WALTER

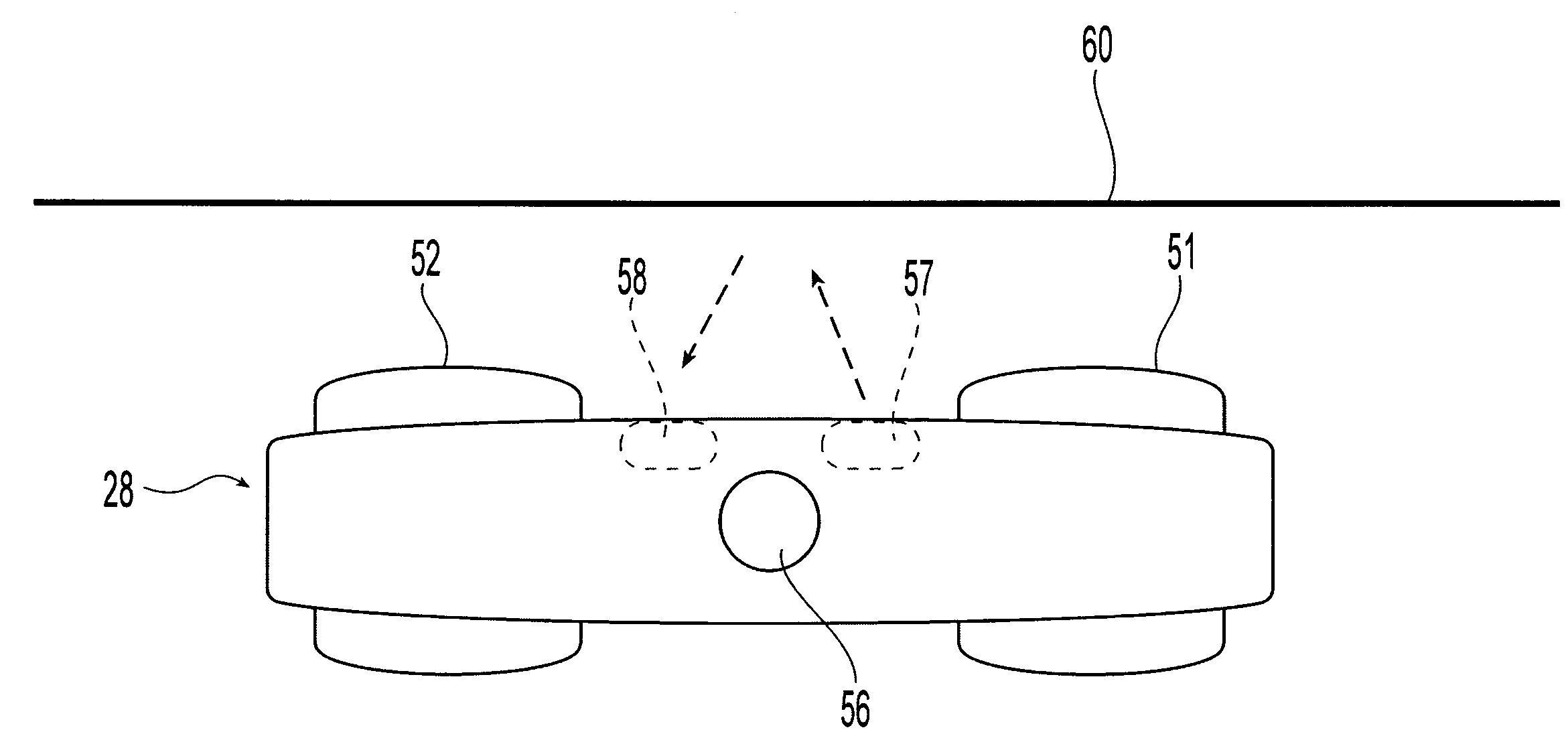

Power drive unit with unit load device sensor

InactiveUS7199543B1DC motor speed/torque controlEmergency protective circuit arrangementsUnit load deviceUnit device

A cargo power drive unit includes a motor and at least one driver roller element coupled to the motor. The power drive unit further includes a light transmitter for emitting light and a light receiver for measuring light. The power drive unit measures an amount of ambient light and then measures an amount of total light after the light transmitter emits light. The power drive unit then determines whether a cargo container is present based on a calculation of reflected light and the measurement of ambient light.

Owner:THE BF GOODRICH CO

Air cargo power drive unit for detecting motion of an overlying cargo container

An air cargo power drive unit has a motor, at least one driver roller element coupled to said motor, a light source, a light detector, and a processor having memory associated therewith, said memory storing instructions. The device is configured to emit light from the light source, receive reflected light from the light detector when an air cargo is overhead, and convert the detected light into a time series of a digital samples representing a time-varying intensity of the received light. The processor then performs calculations on the digital samples to determine whether the unit load device is moving. This determination may be based, for instance, on spikes among the digital samples, and / or on first, second, or even higher-order, statistics of the detected samples.

Owner:THE BF GOODRICH CO

Temperature Control System

ActiveUS20120072046A1Reduce manufacturing costEasy to buildLighting and heating apparatusTemperatue controlTemperature controlUnit load device

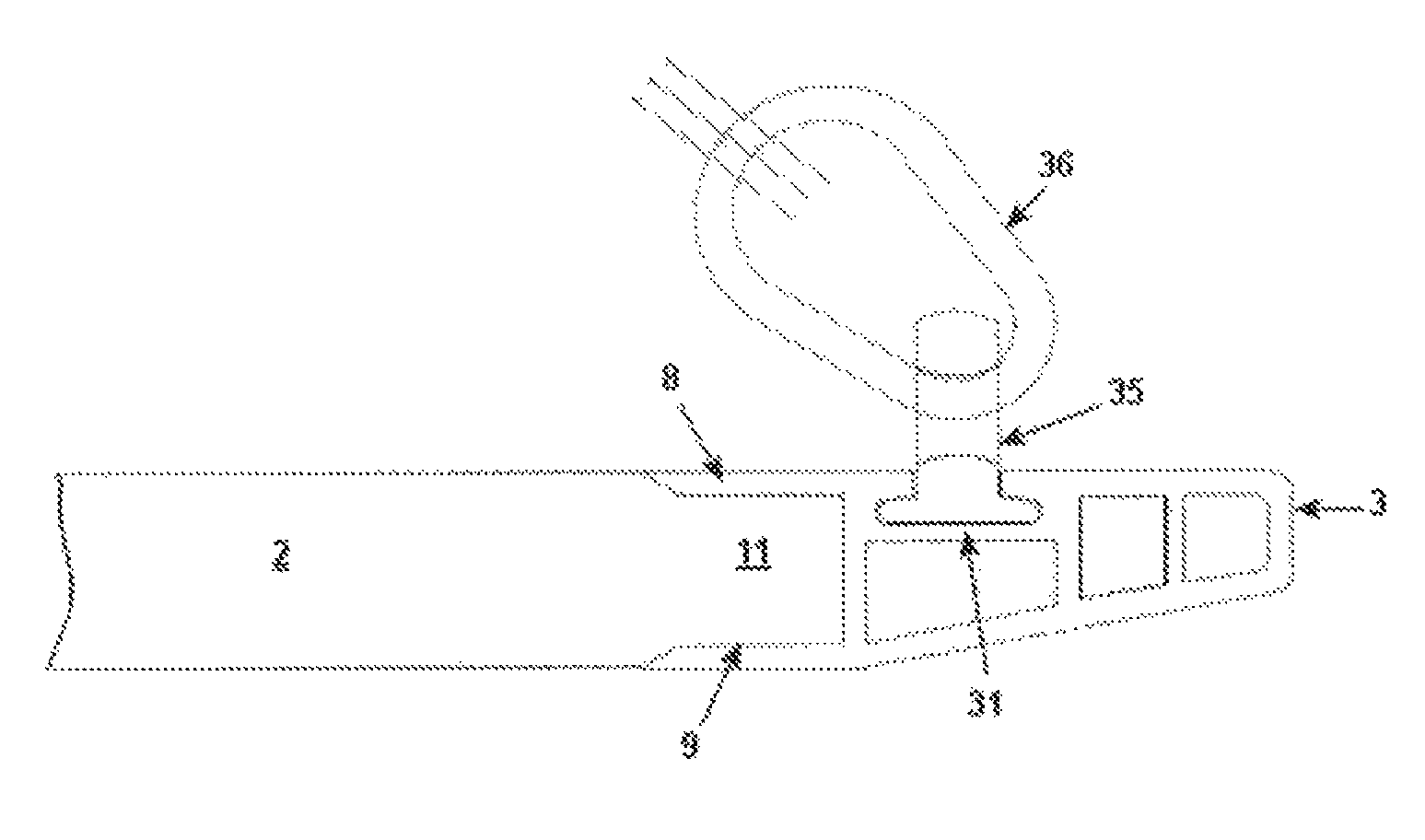

The present invention relates to a transport container which provides mechanical and thermal stability for a load and which container is fabricated as the container is loaded. In particular, the present invention relates to a temperature control system for a container which can be readily transported on aircraft, such as an aircraft container. In the field of logistics, that is the field of movement and supply of produce and materials, in particular in the transport of intermediate and finished products, containers have been developed which safely protect from physical damage a wide variety of product. Food and pharmaceutical products not only need protection from physical shock and pressures but also require temperature stability during transportation; otherwise goods can be damaged and be unusable, whether such damage is apparent or not. The present invention seeks to provide a temperature control system for a transport container which can maintain goods within a narrow temperature range, can displace a considerably reduced volume before erection, is economical to manufacture, can readily and easily be constructed. The present invention further seeks to provide a transport container which is compatible with standard Unit Load Device specifications.

Owner:SOFTBOX SYST LTD

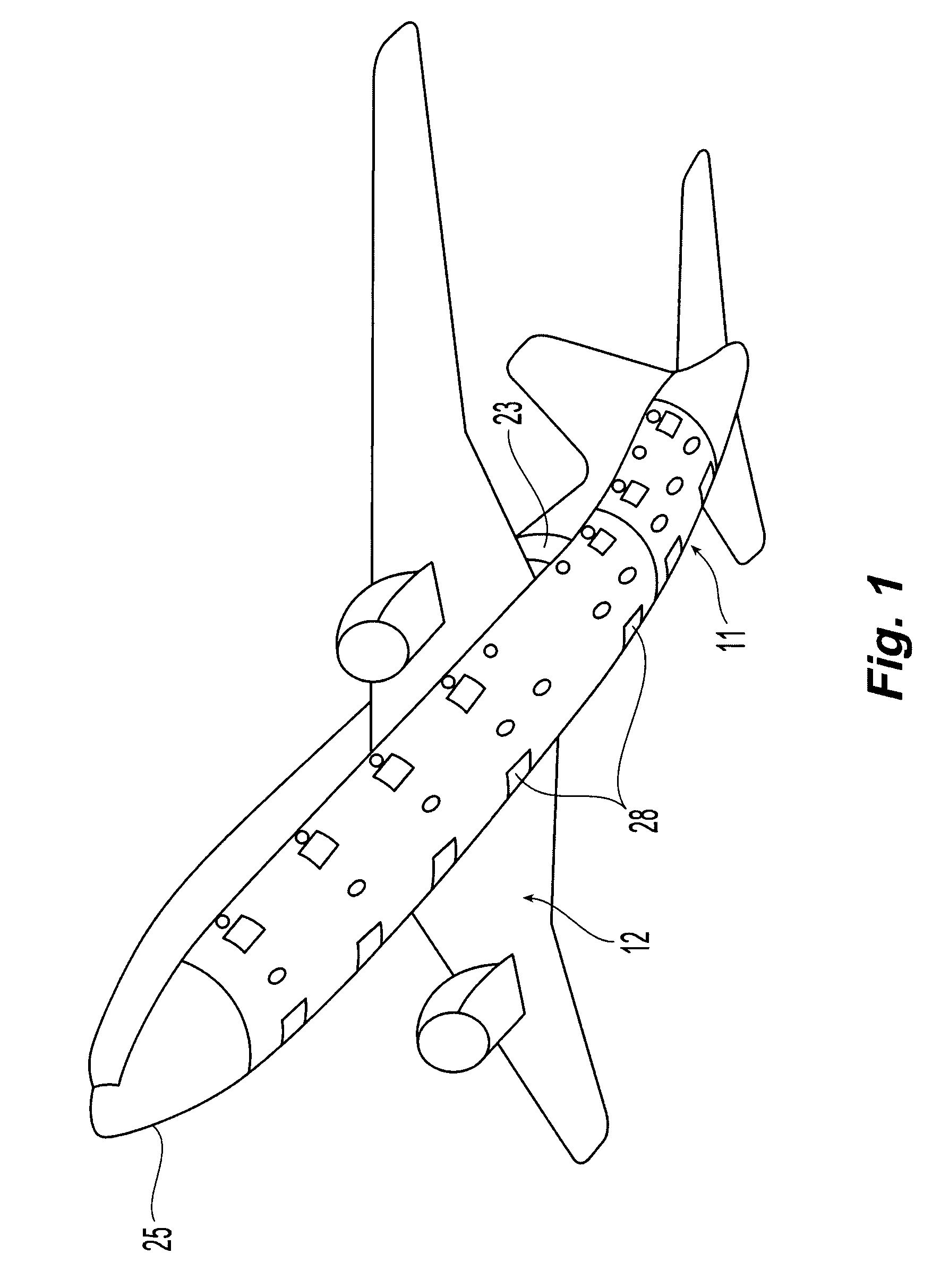

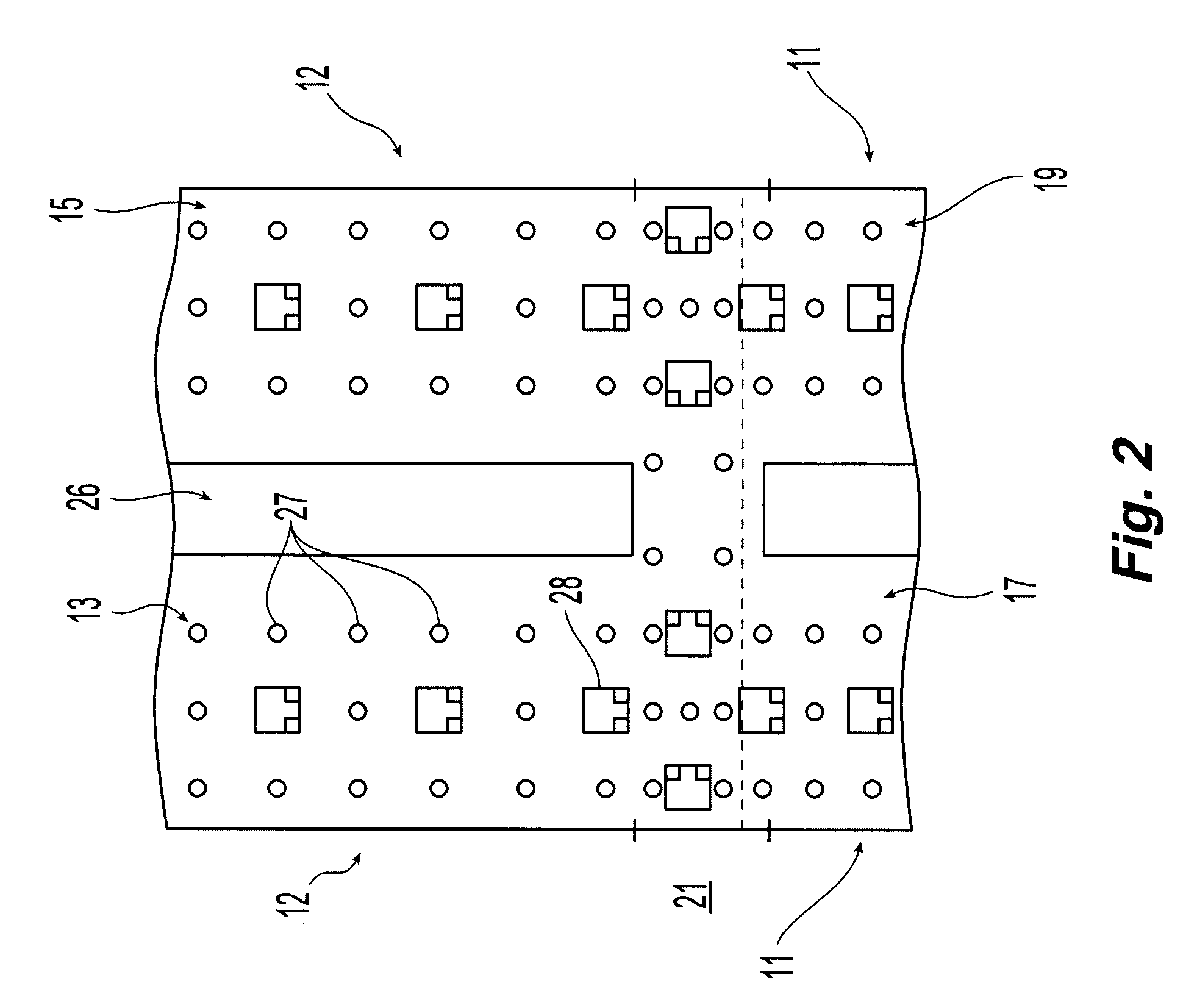

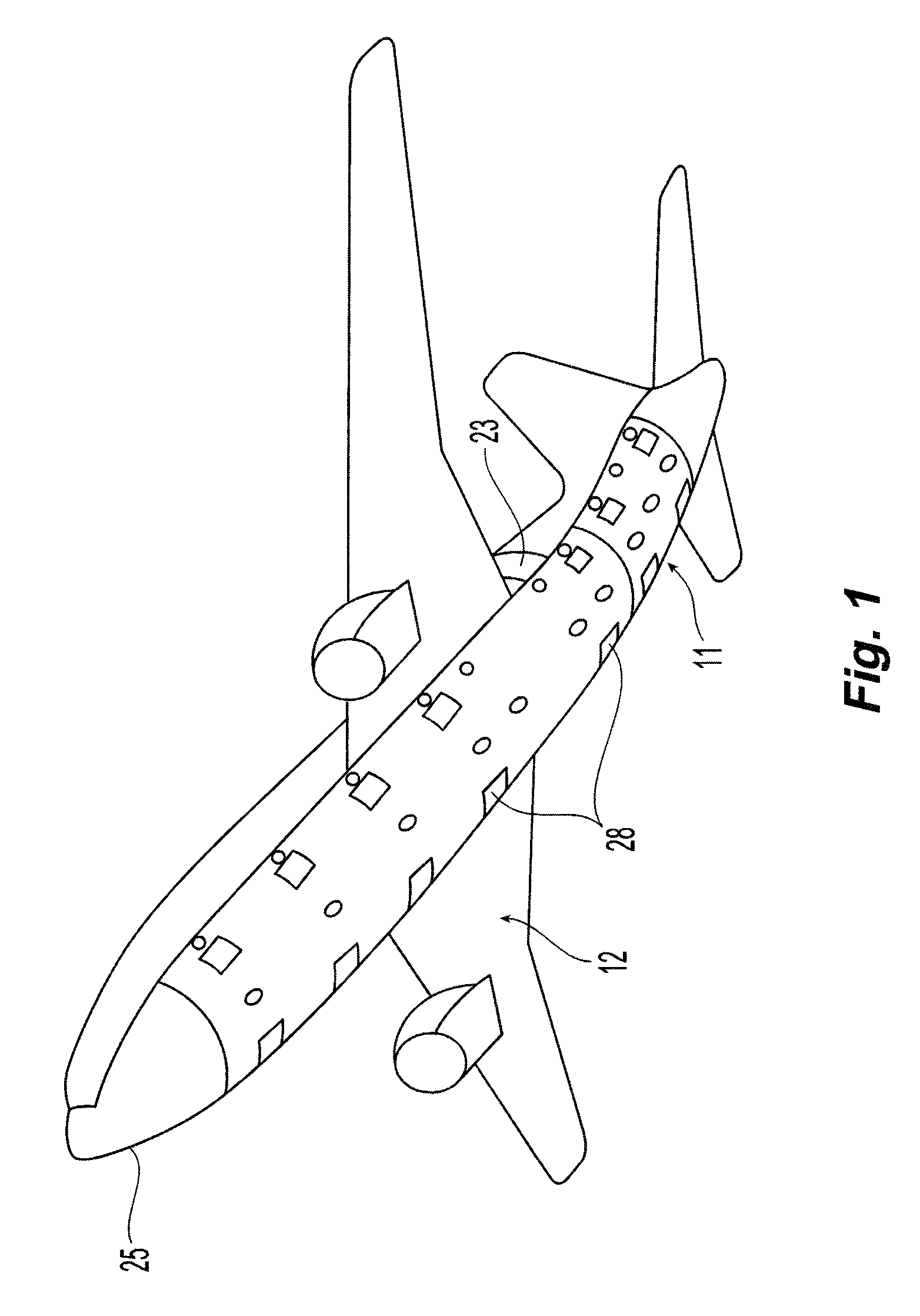

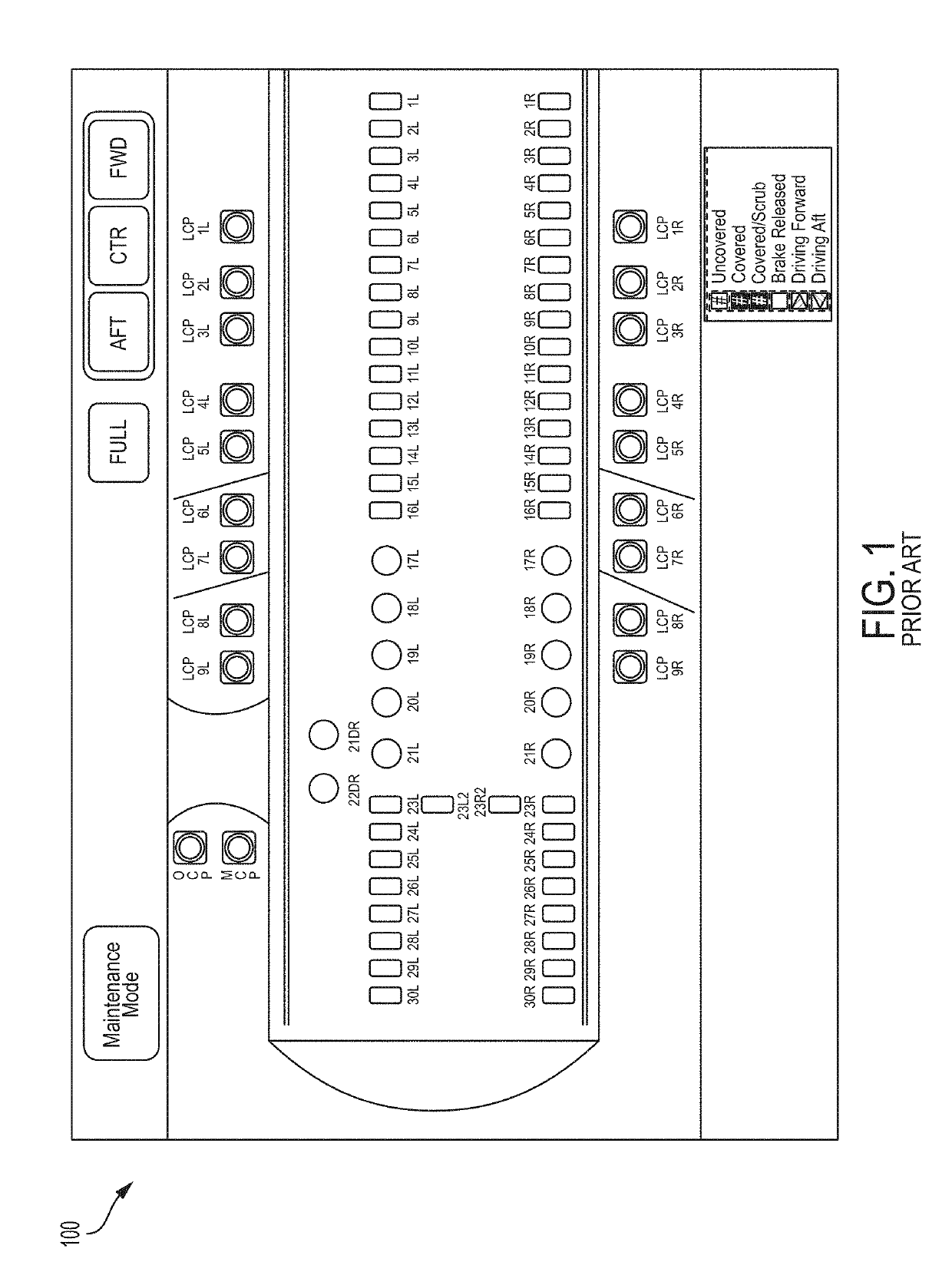

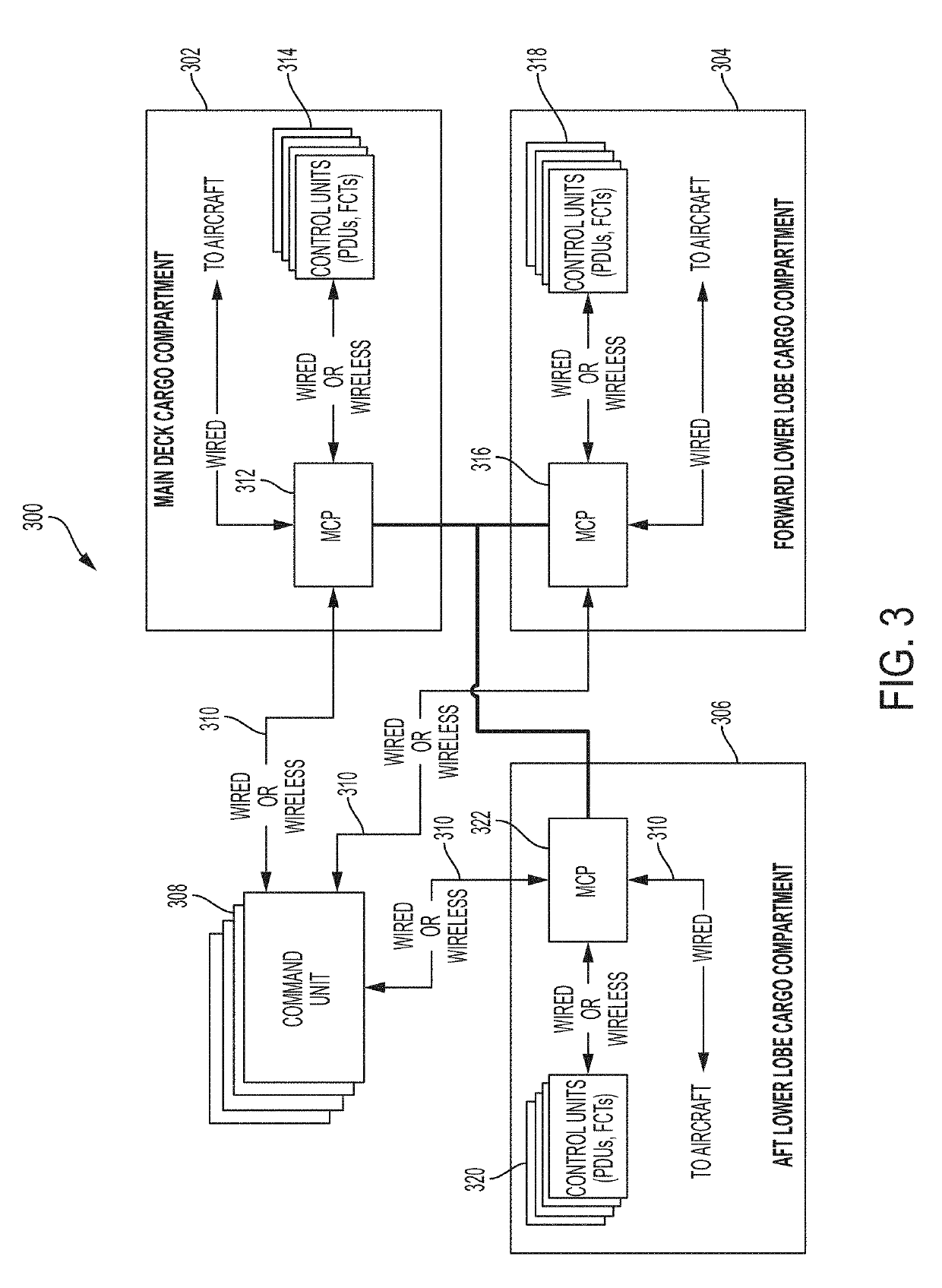

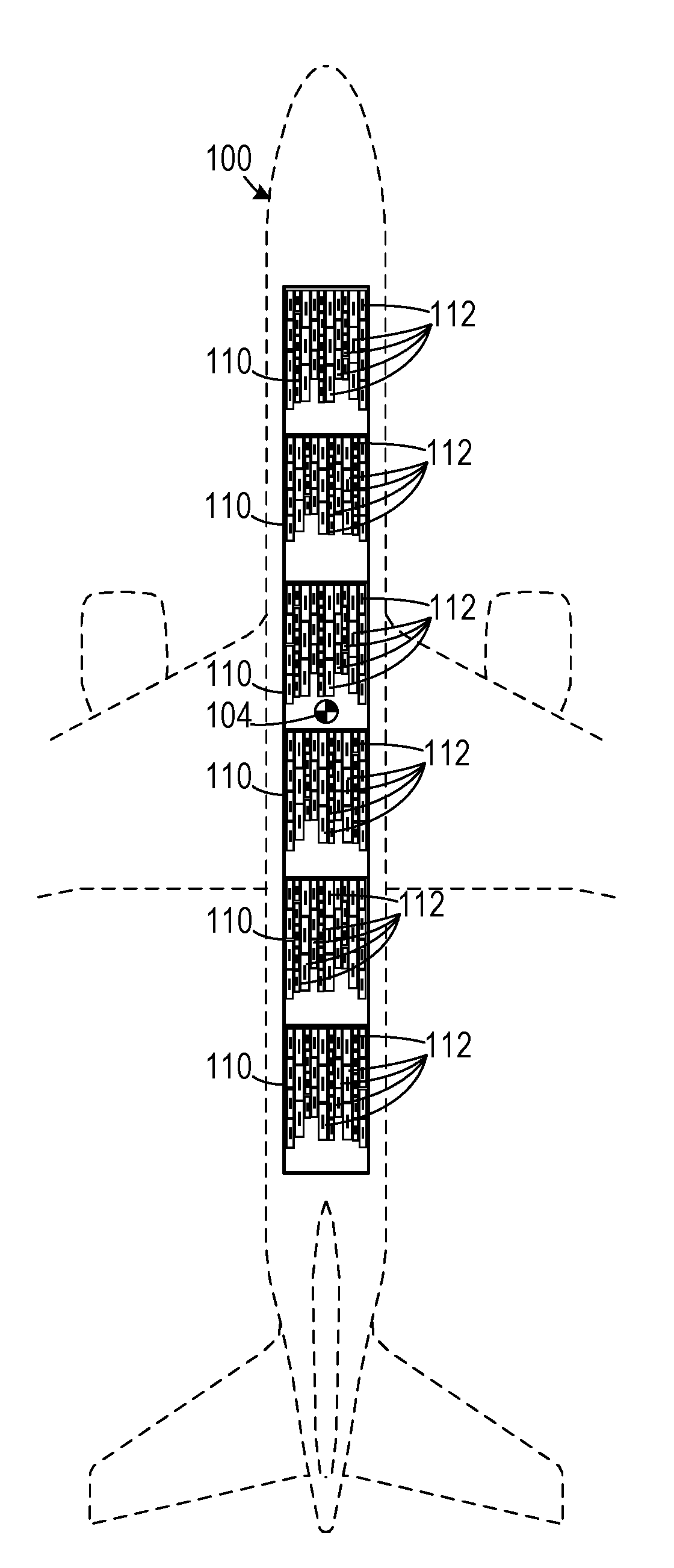

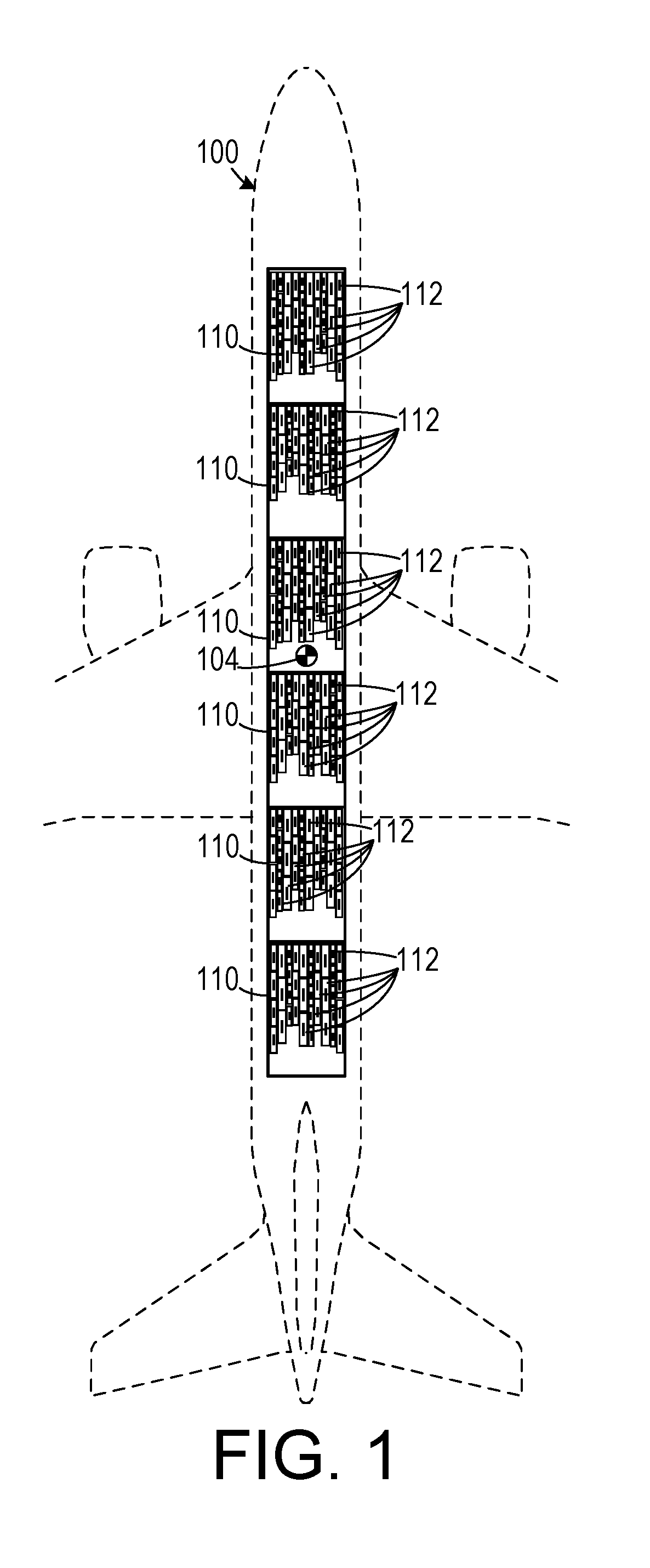

Aircraft cargo monitoring and maintenance

ActiveUS20190256227A1Particular environment based servicesWeight reductionUnit load deviceControl signal

A system for monitoring and maintaining aircraft cargos includes a plurality of master control panels each operatively connected with at least one Line Replaceable Unit (LRU) operating in a cargo compartment of an aircraft, and at least one unit load device (ULD). The at least one ULD and at least one LRU are configured to move a cargo unit in the cargo compartment based on a control signal from the master control panel. The system also includes a command unit operatively connected with each control panel of the plurality of master control panels. The command unit includes a processor configured to retrieve a status of the cargo from each of the plurality of master control panels, and display, on an output device, a status of the at least one ULD of a plurality of ULDs and a status of the at least one LRU via the processor.

Owner:THE BF GOODRICH CO

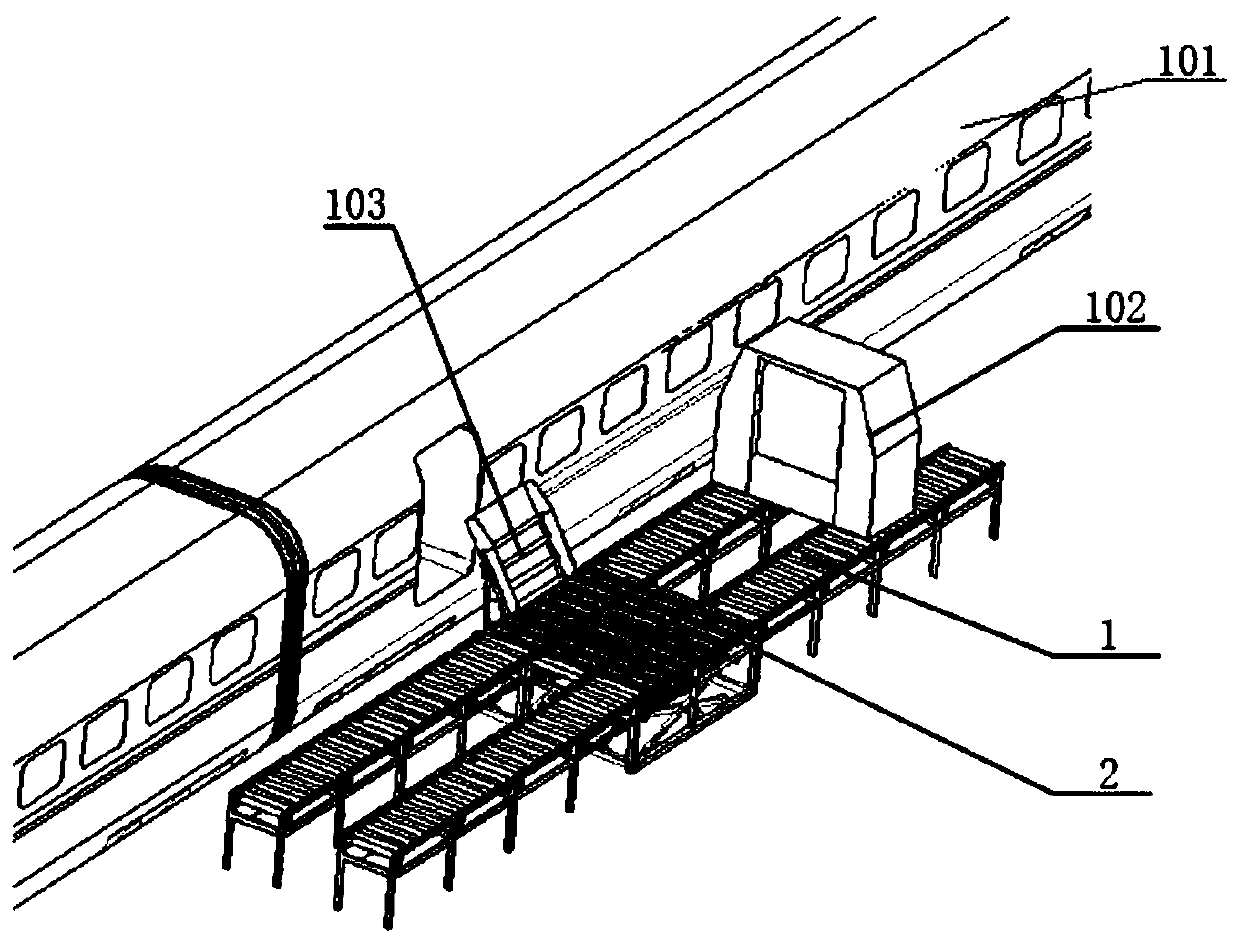

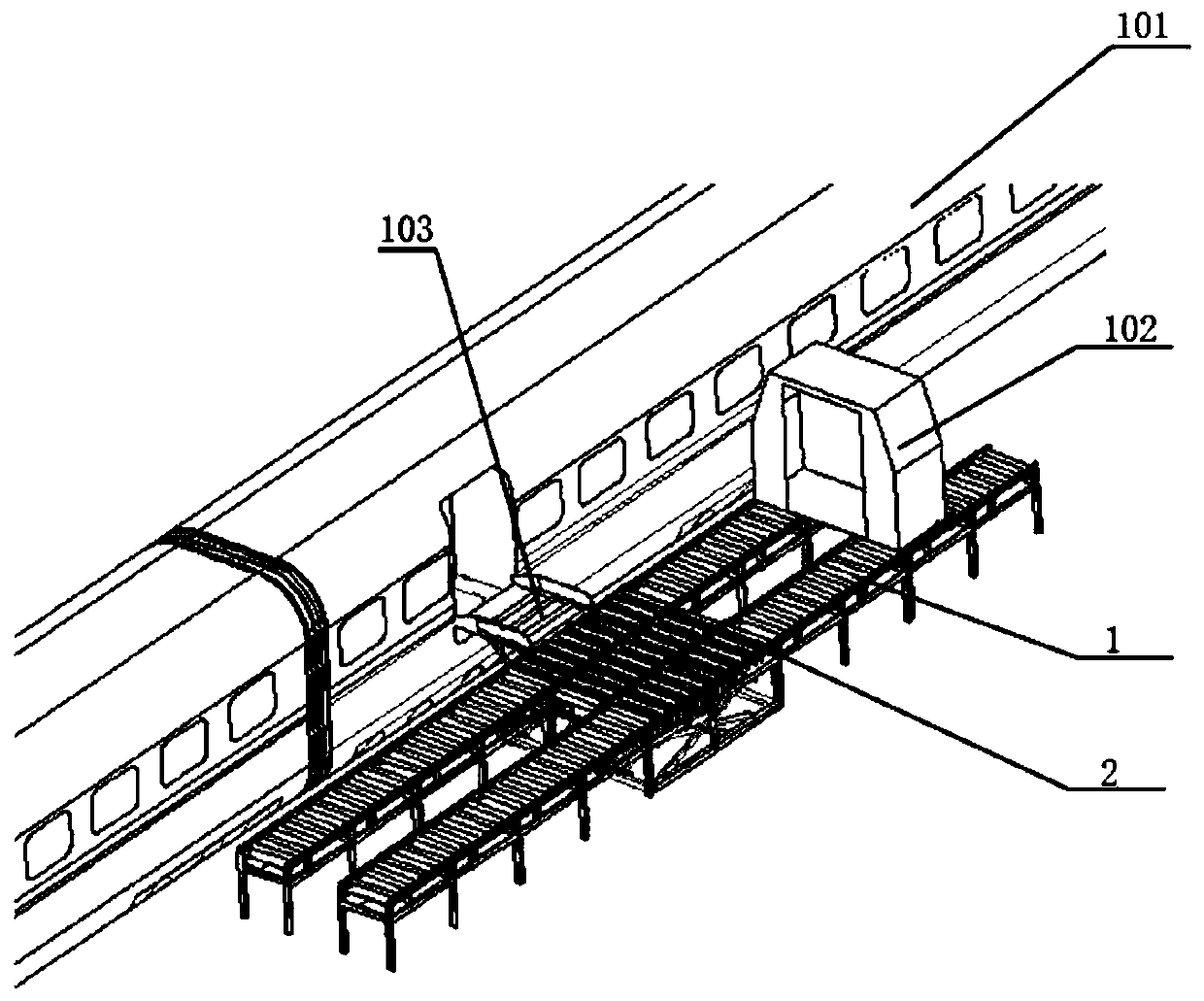

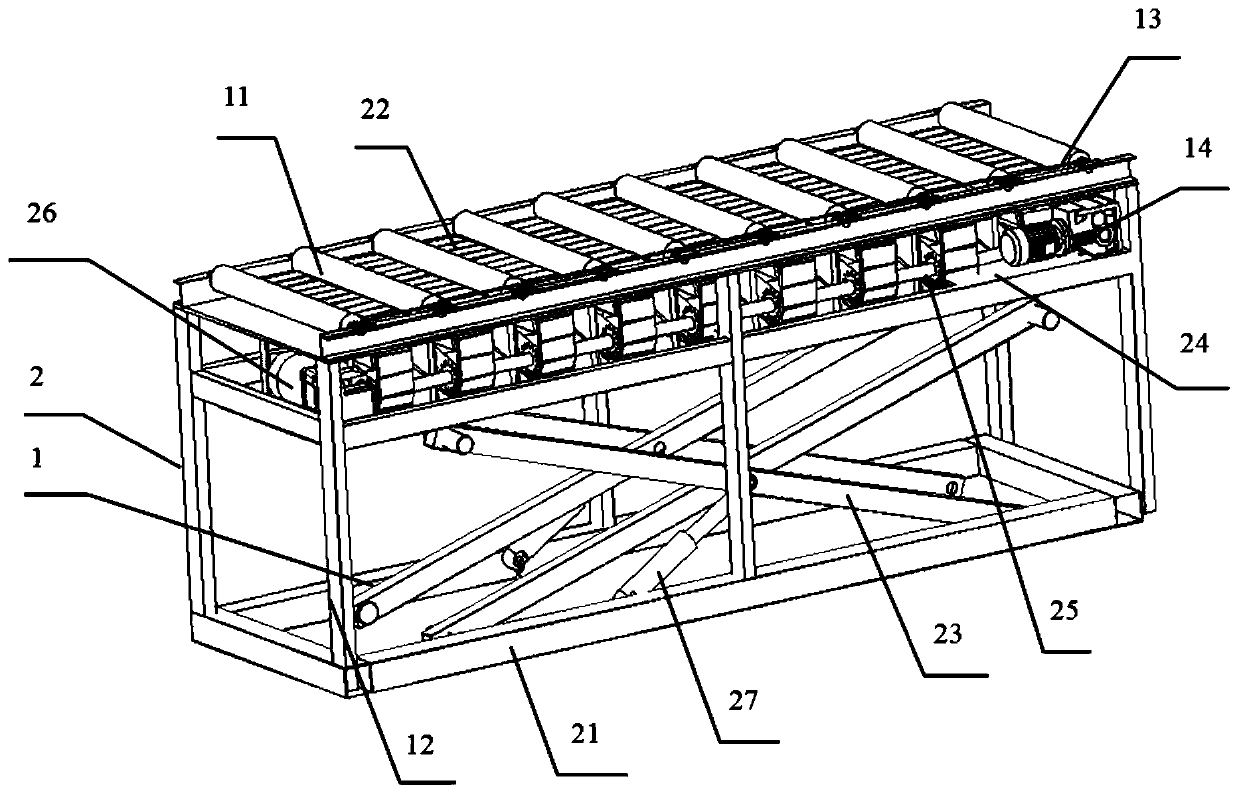

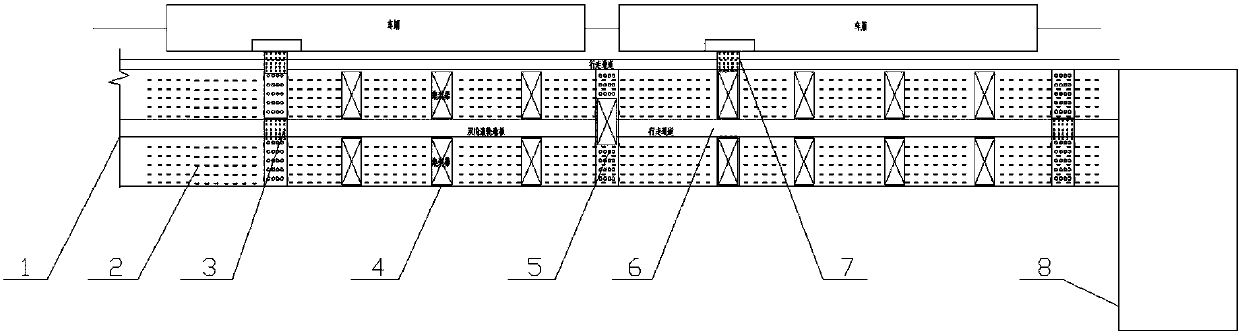

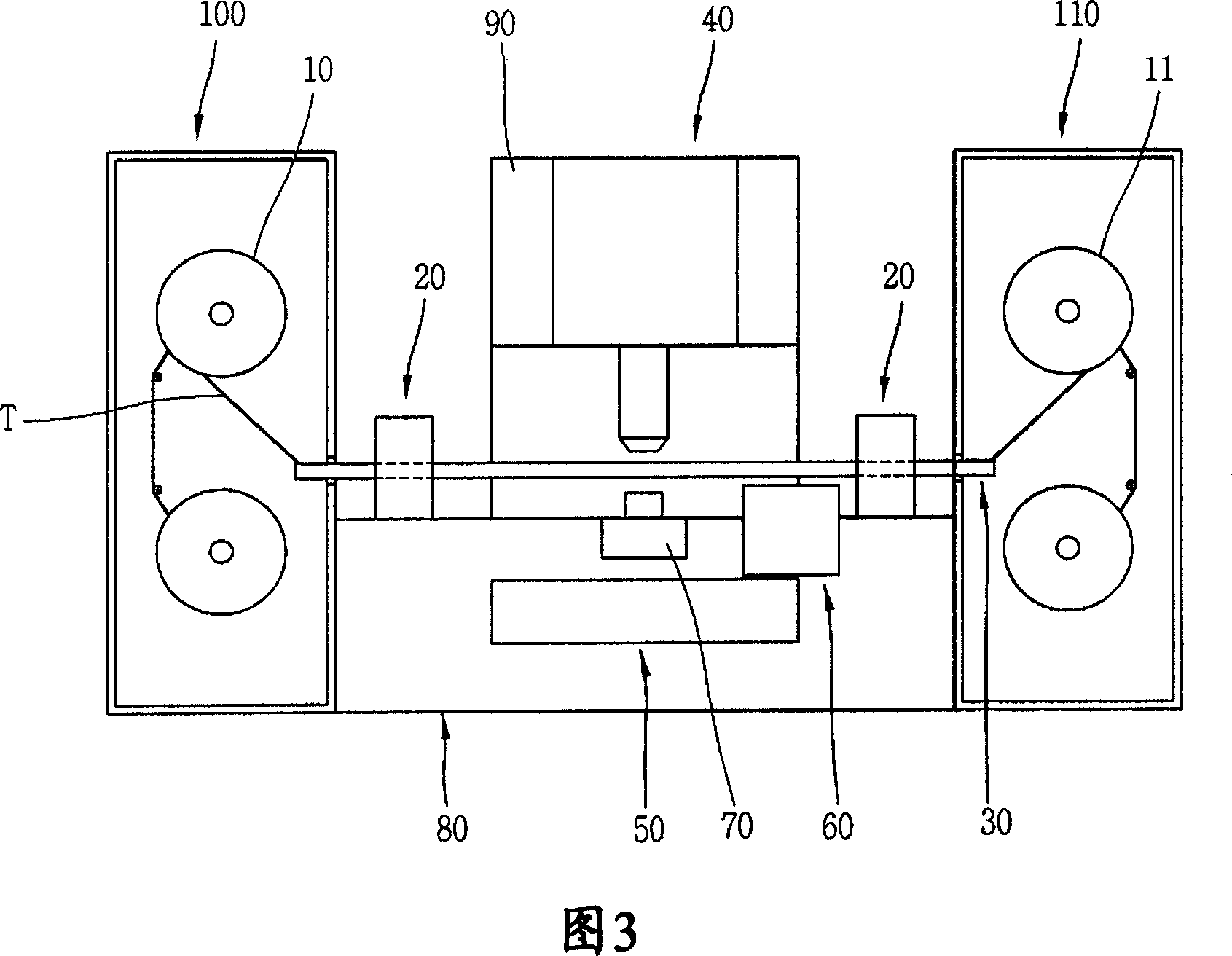

High-speed rail logistics loading and unloading system

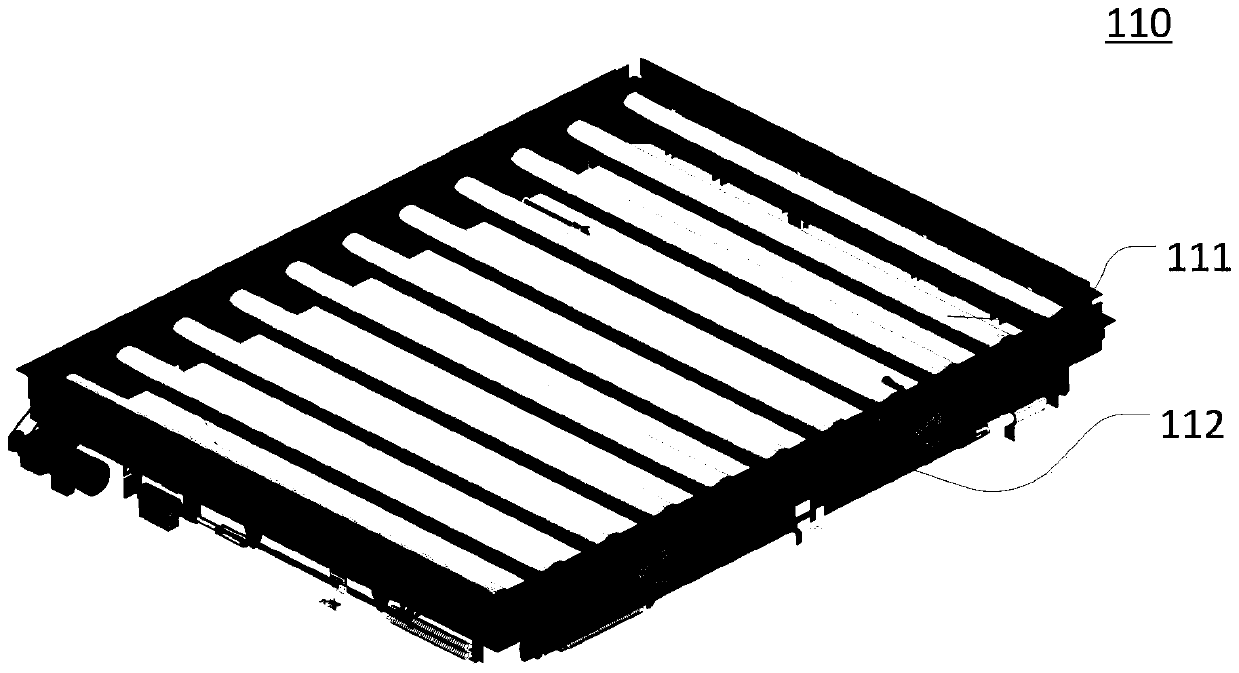

PendingCN110104404ASimultaneous transportImprove efficiencyConveyorsControl devices for conveyorsUnit load deviceLogistics management

The invention discloses a high-speed rail logistics loading and unloading system.The high-speed rail logistics loading and unloading systemcomprises a horizontal conveying system and a loading and unloading machine, wherein the horizontal conveying system and the loading and unloading machine are arranged on a high-speed rail platform,and the horizontal conveying system comprises a rack, a rollerconveying device, and a jacking transversing device; the roller conveying device is mountedon the rack;the jacking transversing device comprises a conveyor lifting device and a chain conveyor, the loading and unloading machine is located between a high-speed rail and the horizontal conveying system, the conveyor lifting device is mounted on the rack, the chain conveyor is mounted on the conveyor lifting device to drive the chain conveyor to move up and down, so that the chain conveyor jacks a unit load device on the roller conveying device and drives the unit load device to move, or the unit load device transported from the loading and unloading machine to the chain conveyor falls onto the roller conveying device for conveying. According to the high-speed rail logistics loading and unloading system, full-automatic loading and unloading between a warehouse and a rail on the platform are realized, the automation level is high, and safety and reliability are high.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

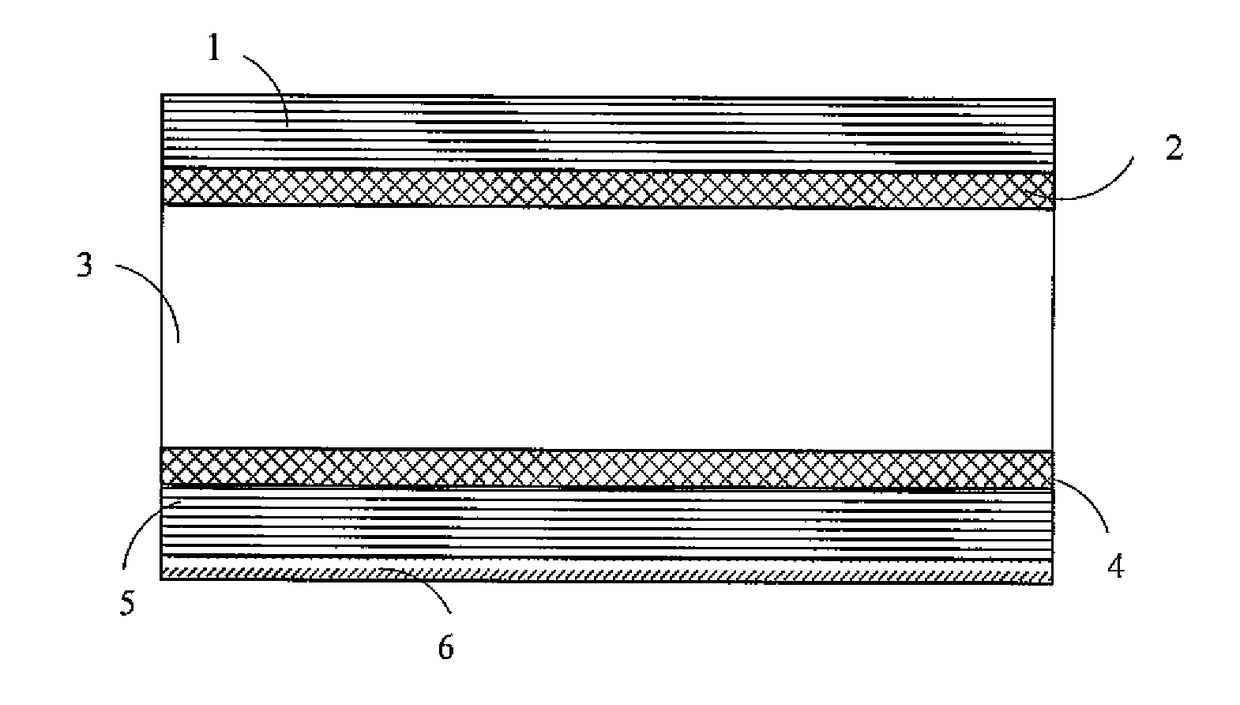

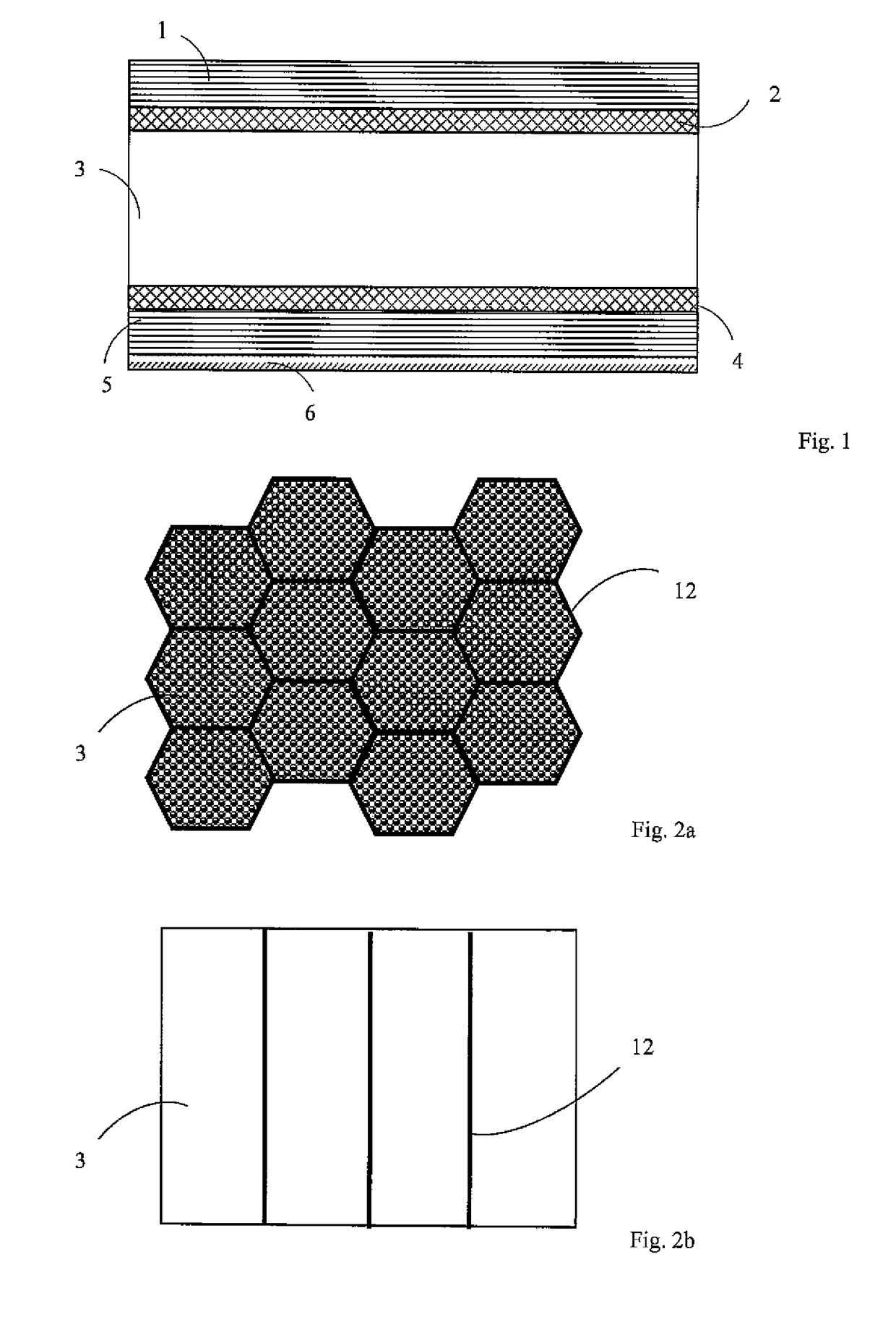

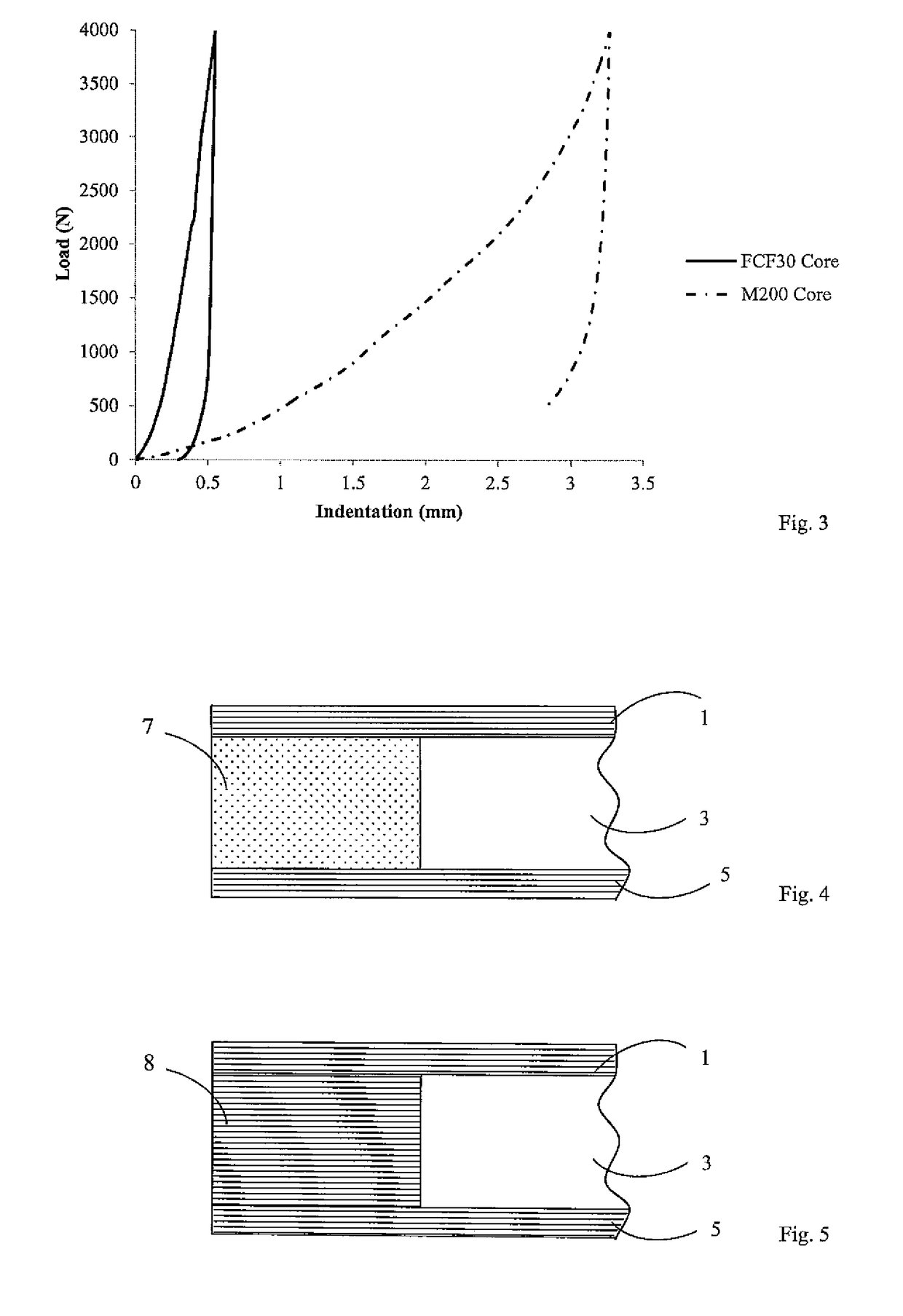

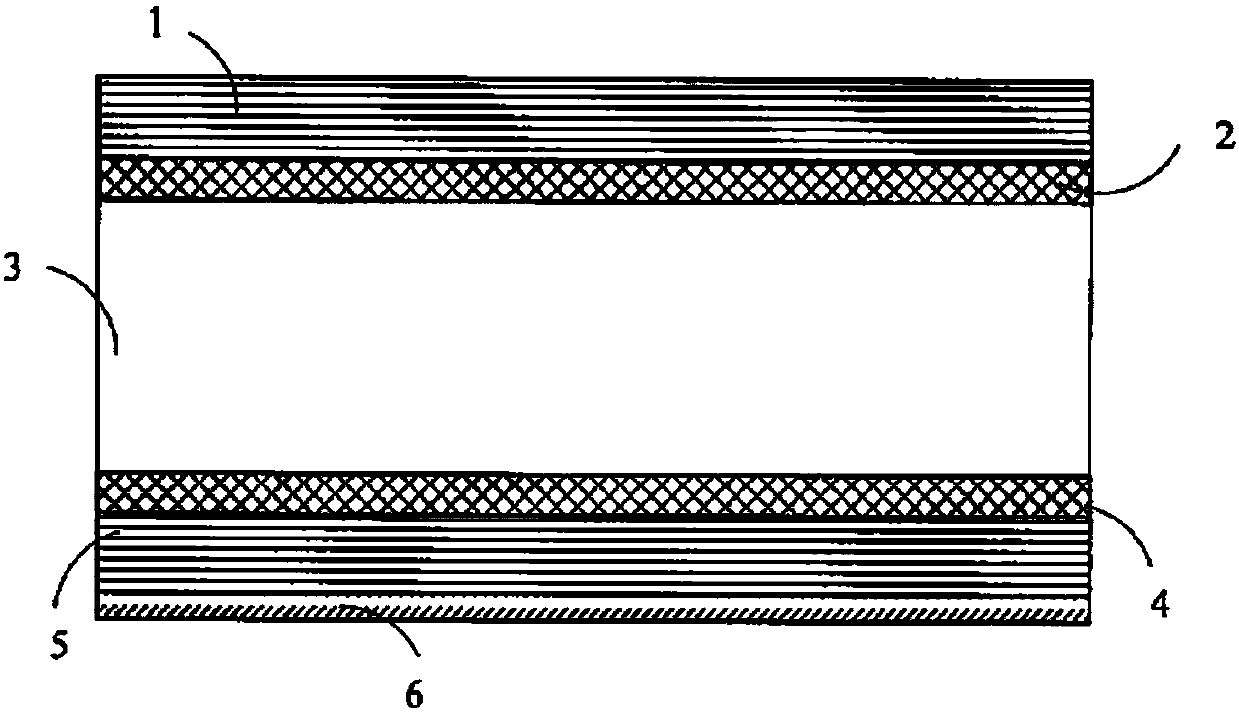

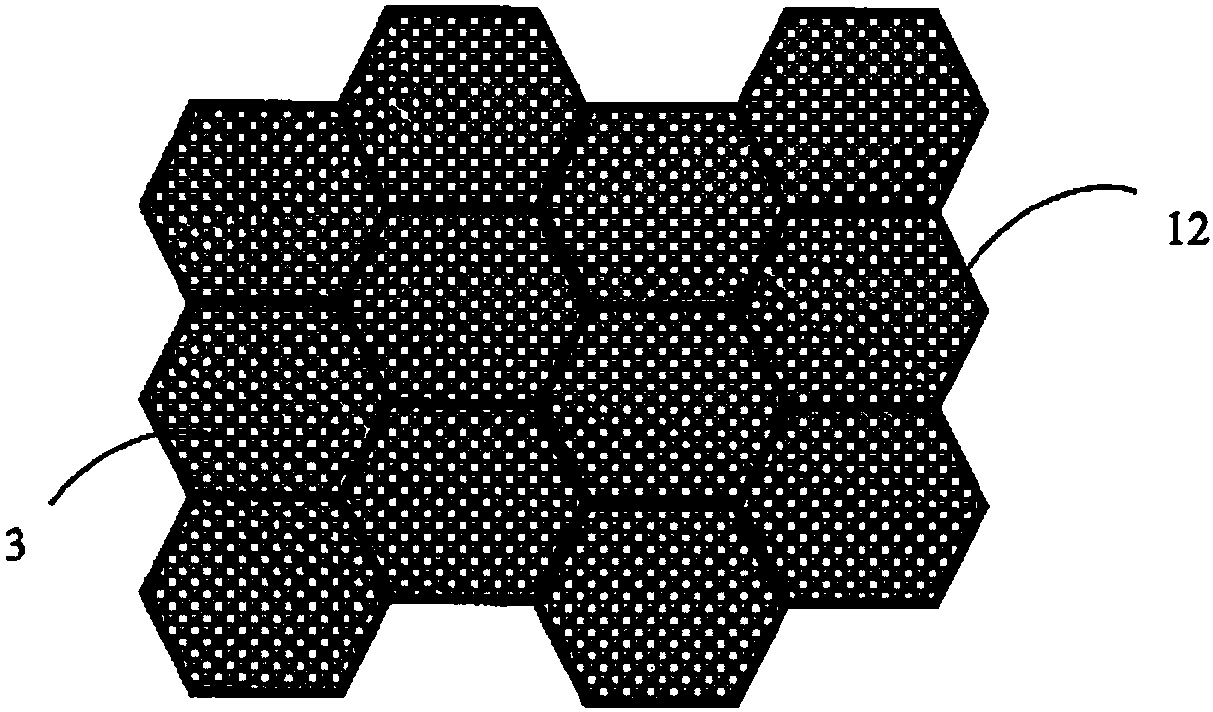

A composite sandwich structure

ActiveUS20180297339A1Adjustable stiffnessStrength adjustableSynthetic resin layered productsLarge containersUnit load deviceSurface layer

The invention relates to a composite sandwich base panel for a Unit Load Device. The panel comprises an upper surface layer comprising fibre reinforcement material, a lower surface layer comprising fibre reinforcement material, and a central core section where at least the majority comprises a plurality of particles bound in a matrix material. The upper surface layer and lower surface layer are provided with a matrix material to bind them to the central core section.

Owner:FERGUSSONS ADVANCED COMPOSITE TECH

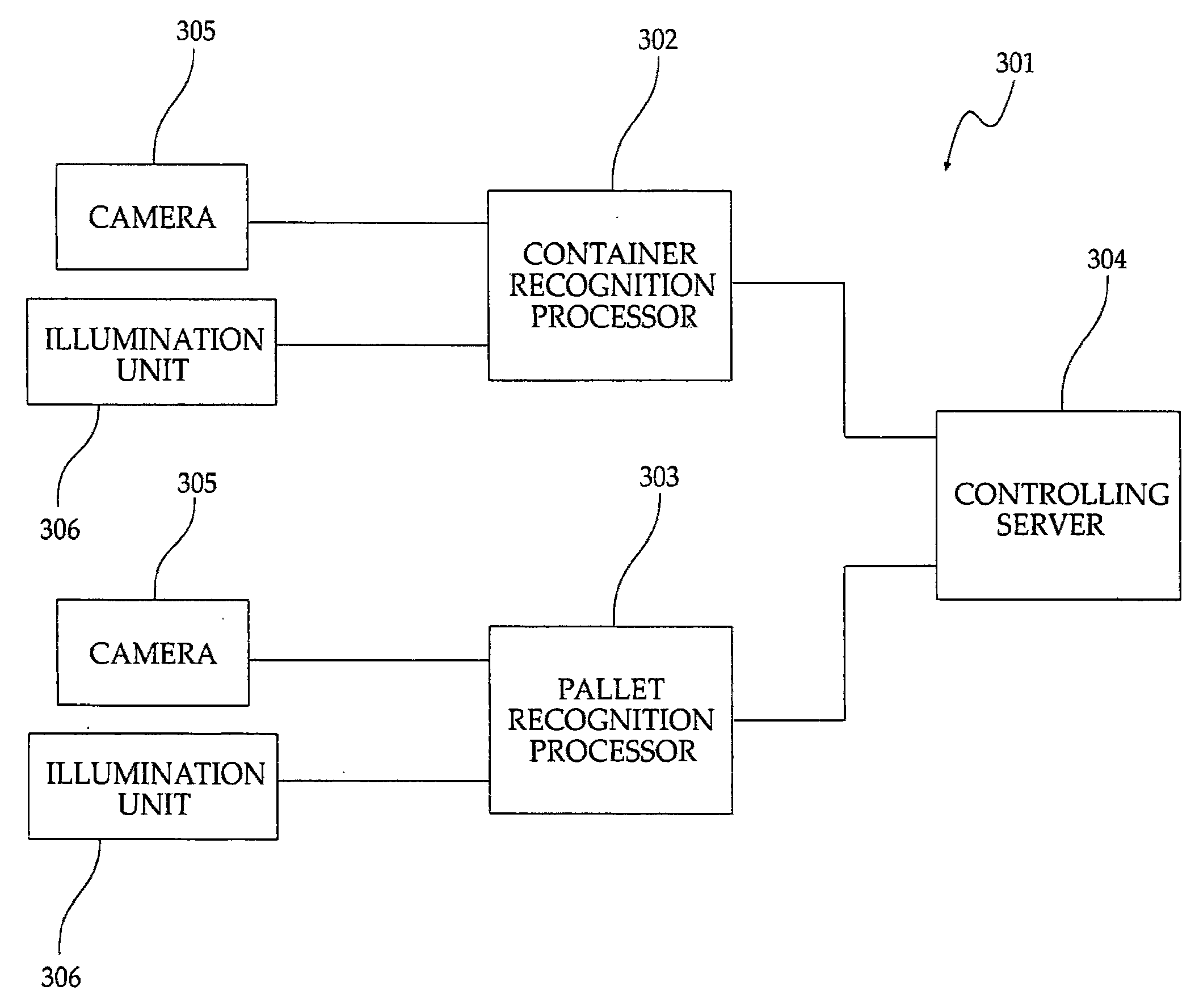

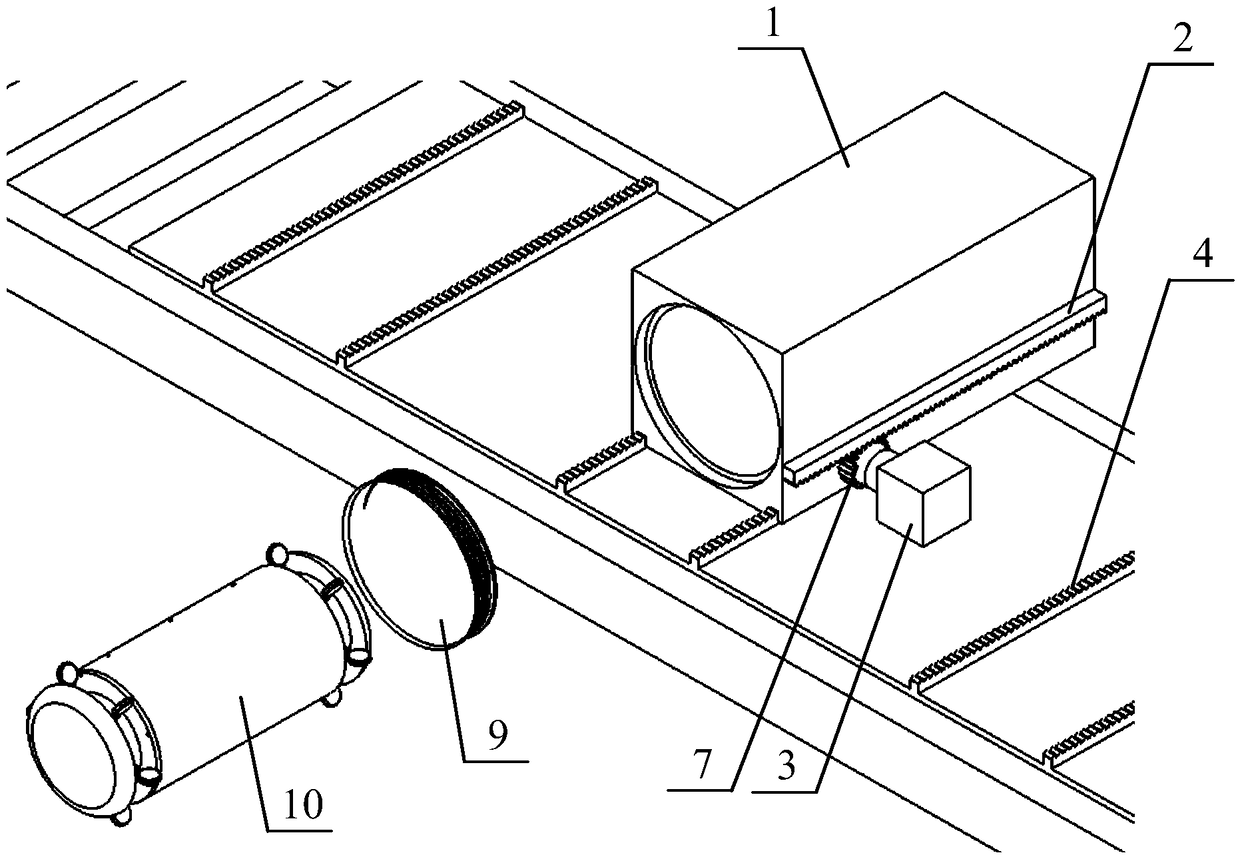

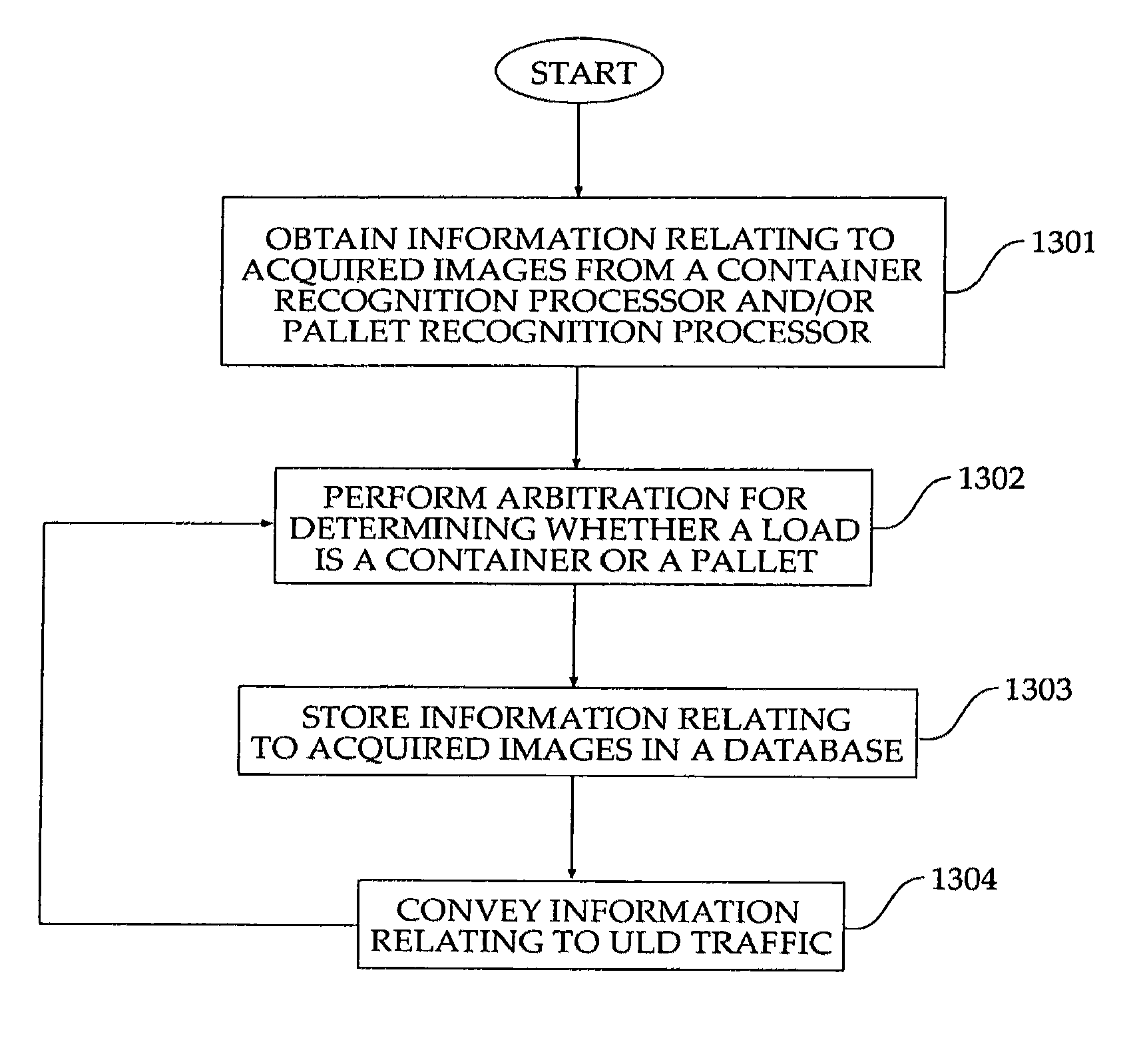

System and method for recognizing a unit load device (ULD) number marked on an air cargo unit

InactiveUS20120274784A1Television system detailsCharacter and pattern recognitionEngineeringUnit load device

The present invention provides a system and method for recognizing a Unit Load Device (ULD) number marked on an air cargo unit. The system includes at least one camera configured to acquire images of the ULD number. It includes also a presence sensing module configured to detect a presence status of the air cargo unit in a scanning zone of the system, the presence status can have a value being one of present and absent, and a recognition processor coupled to the presence sensing module and to the at least one camera. The recognition processor is configured to obtain from the presence sensing module information relating to the presence status of said air cargo unit, to trigger the at least one camera to acquire the images upon a change in the value of the presence status, and to process the images for recognizing the ULD number.

Owner:HI TECH SOLUTIONS

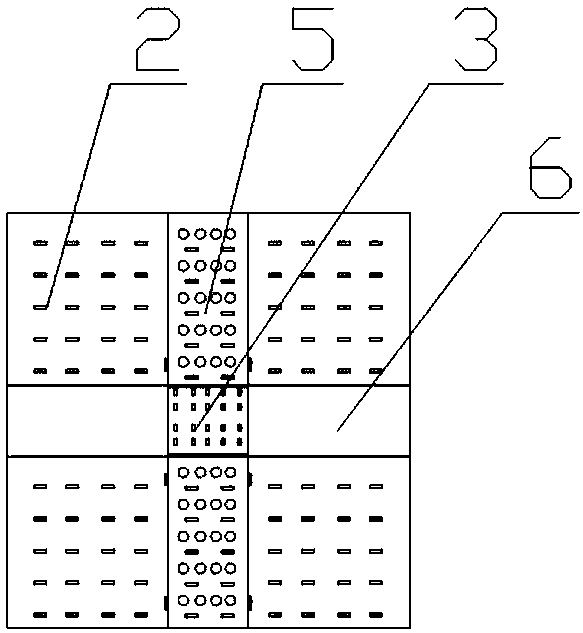

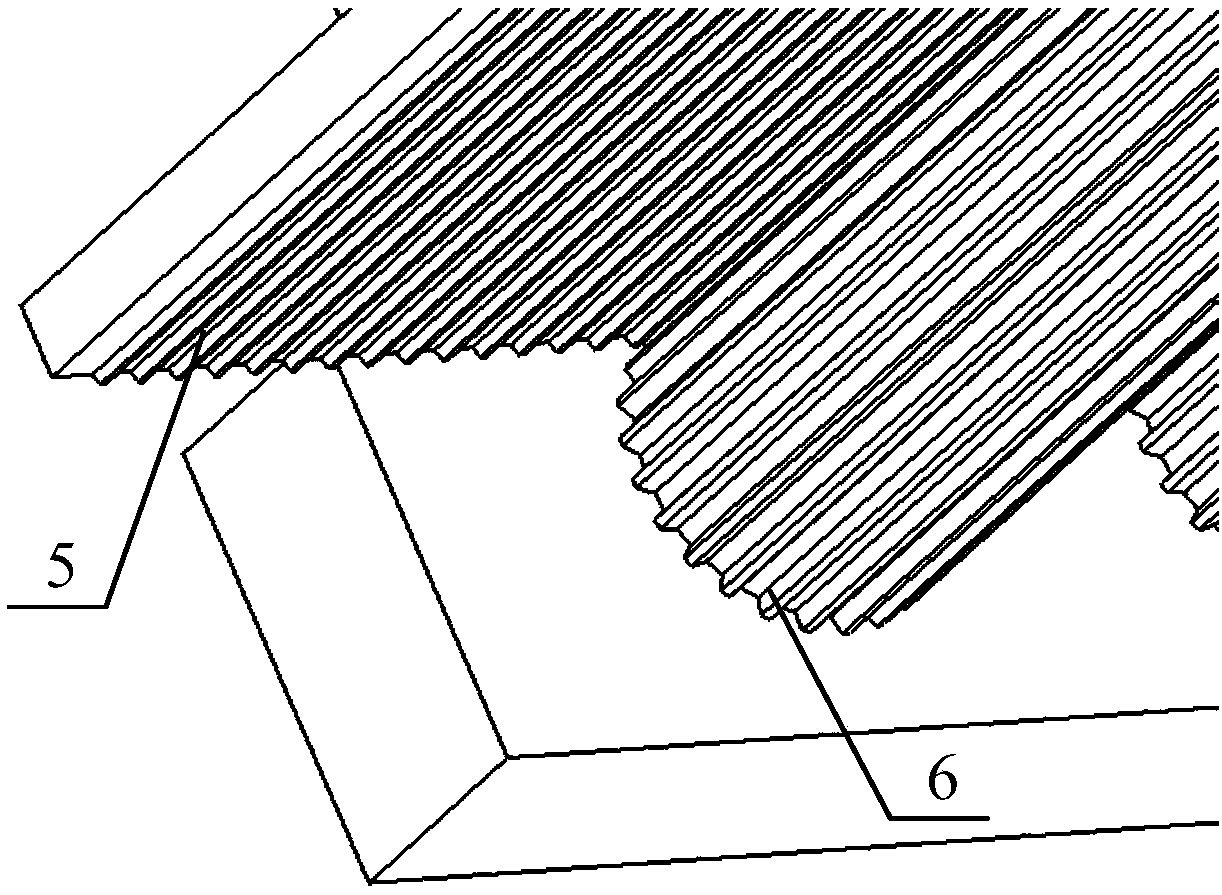

High-speed railway logistics loading and unloading system and method

ActiveCN107585603ARealize simultaneous operationImprove efficiencyLoading/unloadingUnit load deviceMoving floor

The invention discloses a high-speed railway logistics loading and unloading system. The system comprises a transverse moving floor (2), a vertical moving floor (3) and a universal floor (5), the transverse moving floor (2) is used for achieving movement of a unit load device (4) in the horizontal direction, the universal floor (5) is used for achieving steering movement of the unit load device (4), and the vertical moving floor (3) is used for achieving vertical movement of the unit load device (4); a platform edge connector (7) corresponding to each carriage is arranged on the transverse moving floor (2). The invention further discloses a high-speed railway logistics intelligent loading and unloading method based on universal floor transmission. According to the high-speed railway logistics loading and unloading system, parallel transportation mode is adopted, multiple universal floor passages are laid on a platform, simultaneous operation of multiple carriage containers is achieved,and the efficiency is higher; multiline multigroup loading and unloading equipment is subjected to parallel processing, and safety and reliability are better achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

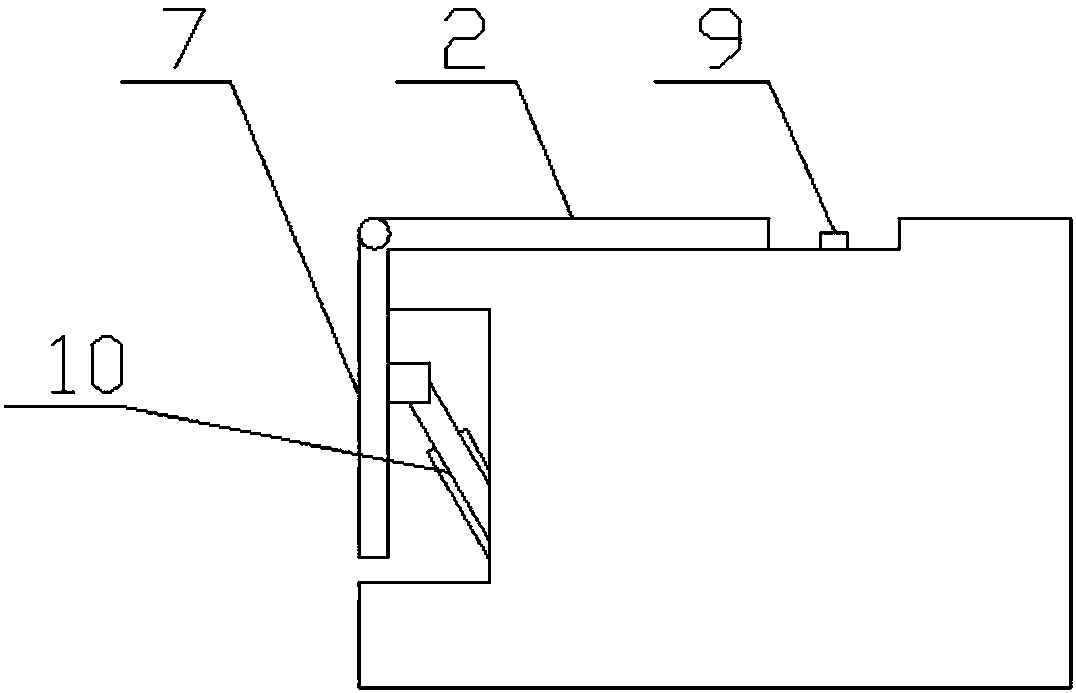

Chip supplying unit loading device

InactiveCN101034678AFast and smooth loadingSemiconductor/solid-state device manufacturingLight protection screensUnit load deviceReciprocating motion

The invention discloses a chip supply unit load device including: transmission unit installed at frame; transmission arm able to reciprocate through the transmission unit; clamping unit installed at the transmission arm and reciprocating together with the transmission arm and which is used for loading the chip supply unit on work table or unloading the same from the work table while it linearly contacts with the chip supply unit. Thus, the invention can re-load the chip supply unit having been loaded in belt box unit into the belt box unit quickly and stably. Therefore, damage on the chip supply unit during the transmission process can be avoided thereby minimizing defect during adhesive treatment and reducing adhesive treatment time.

Owner:TOP ENG CO LTD

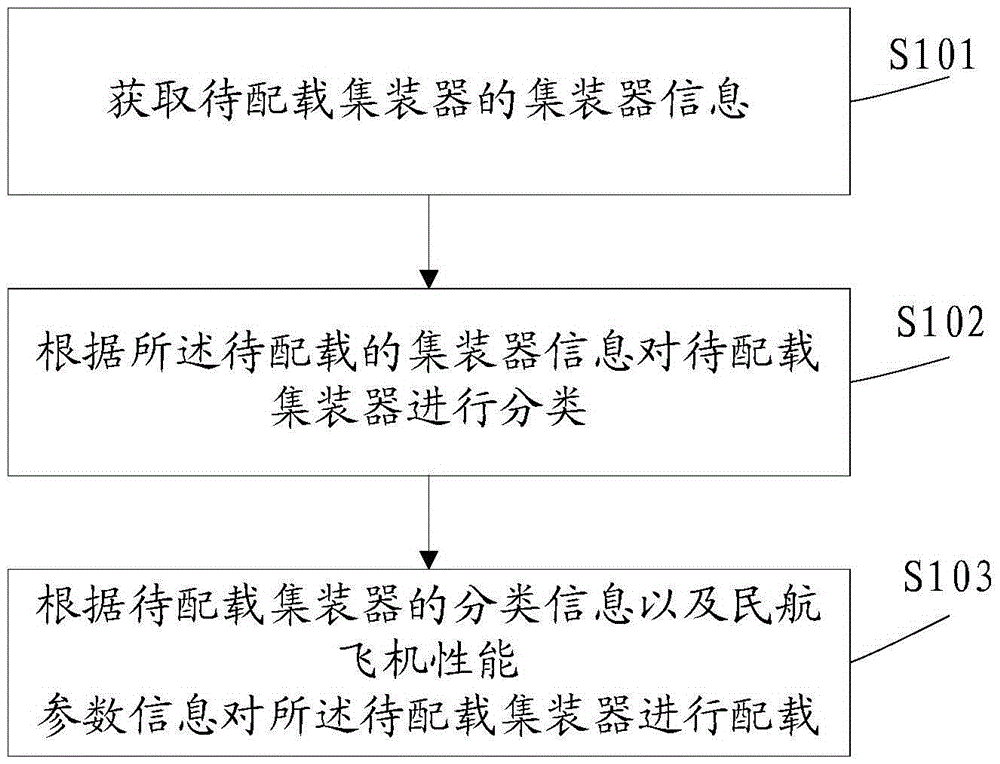

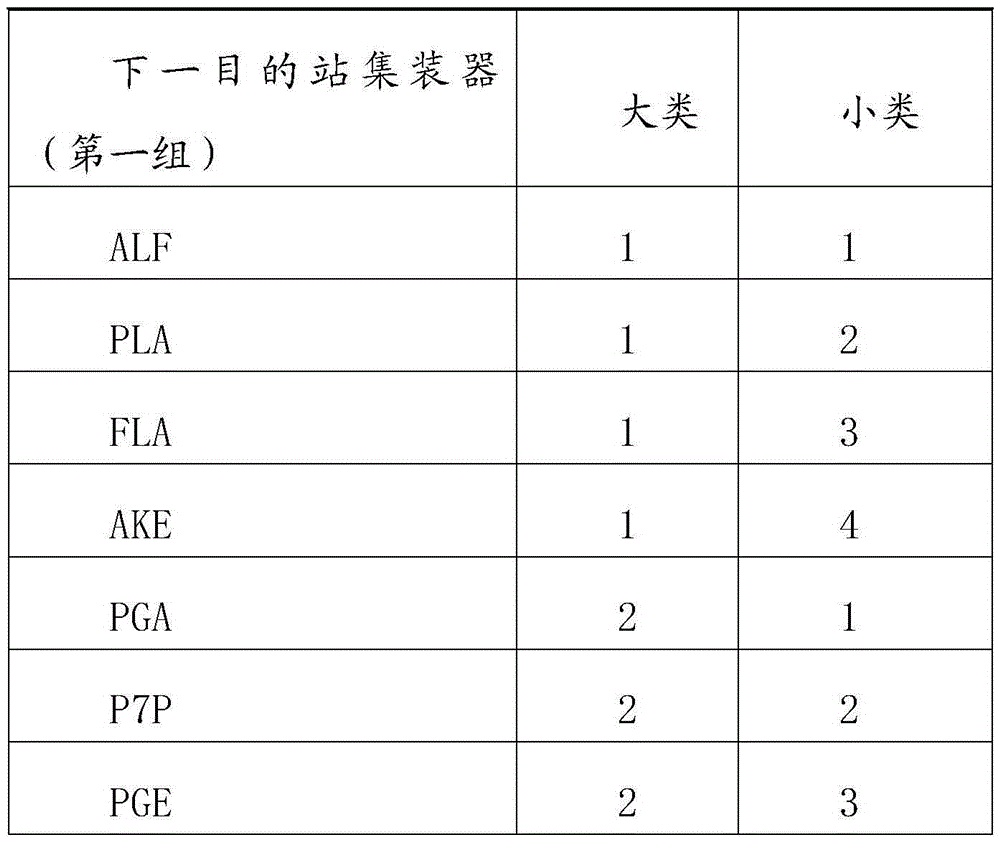

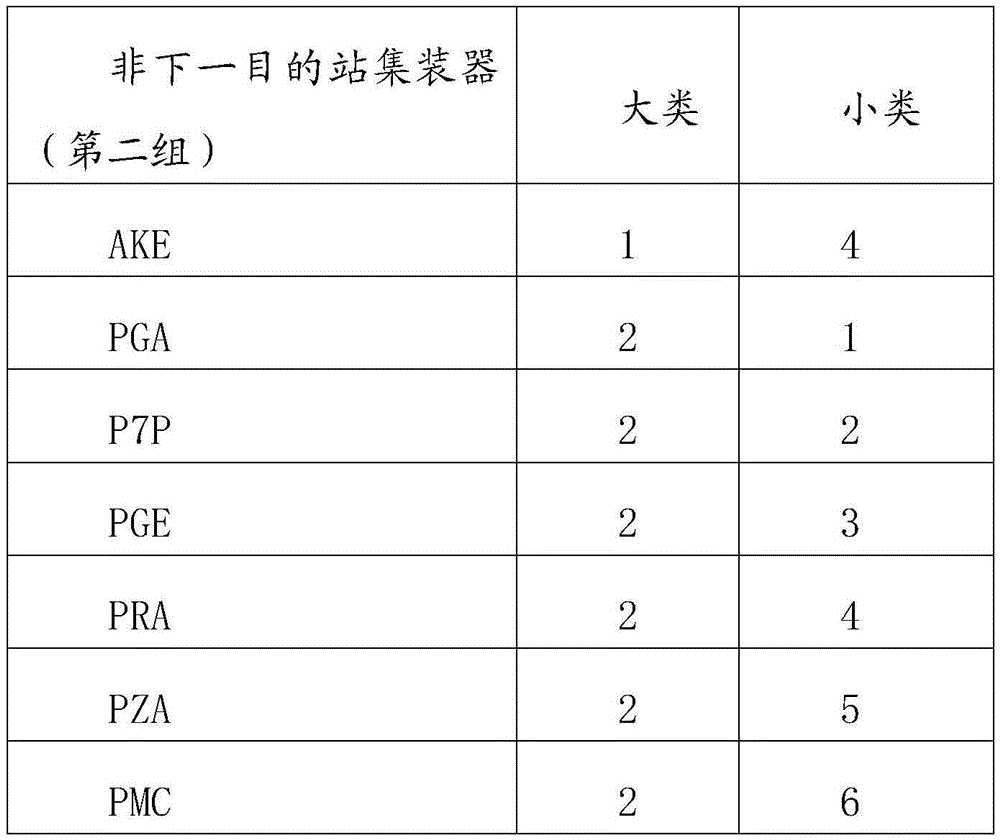

Method for automatic loading of civil aircraft

ActiveCN105523184AWeight controlCenter of gravityFreight handlingUnit load deviceClassified information

The invention relates to the technical field of civil aircrafts and provides a method for automatic loading of a civil aircraft. The method for automatic loading of the civil aircraft comprises the following steps: acquiring unit load device information of unit load devices to be loaded; classifying the unit load devices to be loaded according to the unit load device information of unit load devices to be loaded; and loading the unit load devices to be loaded according to the classified information of the unit load devices to be loaded and the performance parameter information of the civil aircraft. Through the automatic loading method comprising the steps, the time of the whole loading process can be obviously shortened, the loading efficiency is greatly improved, and better flexibility is provided.

Owner:广东南航天合信息科技有限公司

Air cargo power drive unit for detecting motion of an overlying cargo container

ActiveUS20080078867A1Scattering properties measurementsControl devices for conveyorsUnit load deviceCargo container

An air cargo power drive unit has a motor, at least one driver roller element coupled to said motor, a light source, a light detector, and a processor having memory associated therewith, said memory storing instructions. The device is configured to emit light from the light source, receive reflected light from the light detector when an air cargo is overhead, and convert the detected light into a time series of a digital samples representing a time-varying intensity of the received light. The processor then performs calculations on the digital samples to determine whether the unit load device is moving. This determination may be based, for instance, on spikes among the digital samples, and / or on first, second, or even higher-order, statistics of the detected samples.

Owner:THE BF GOODRICH CO

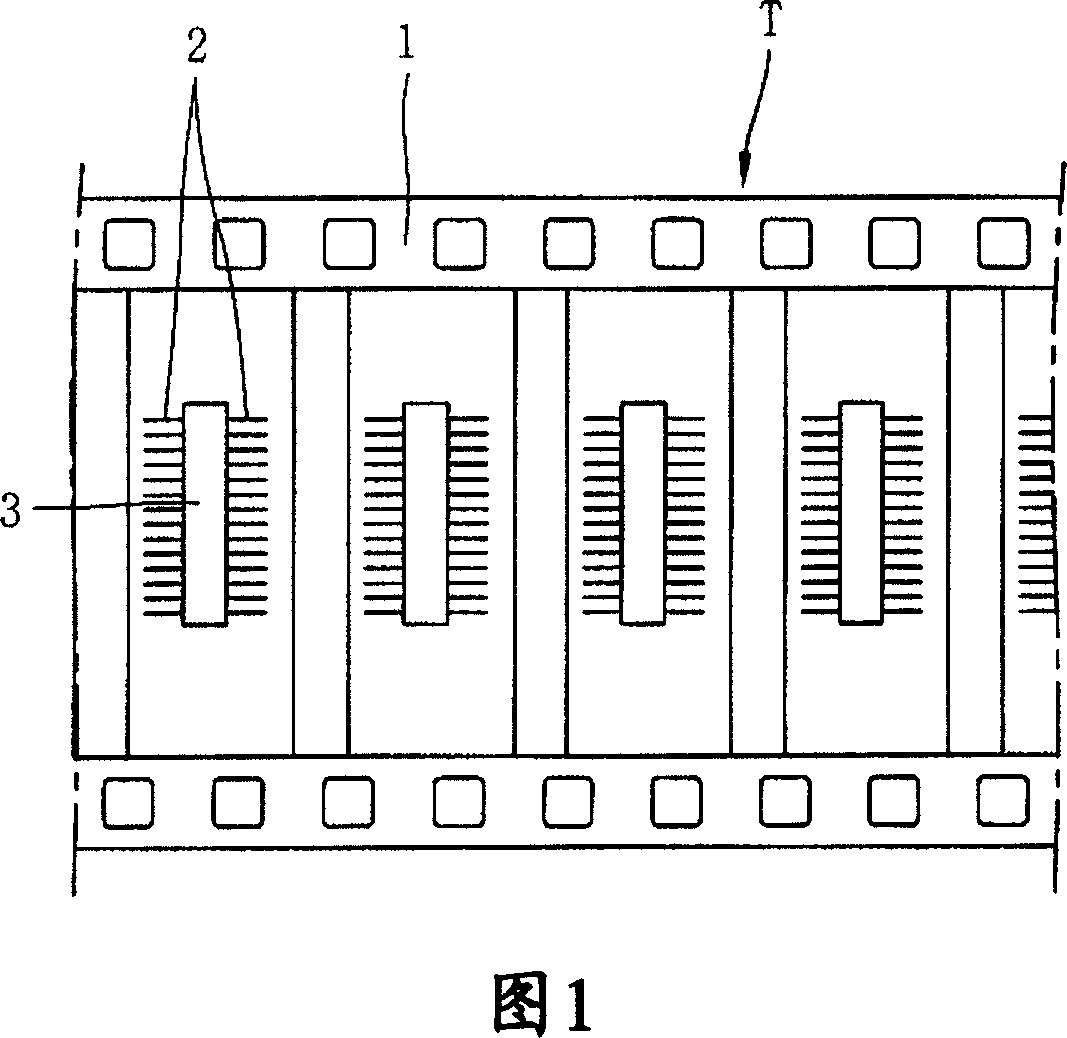

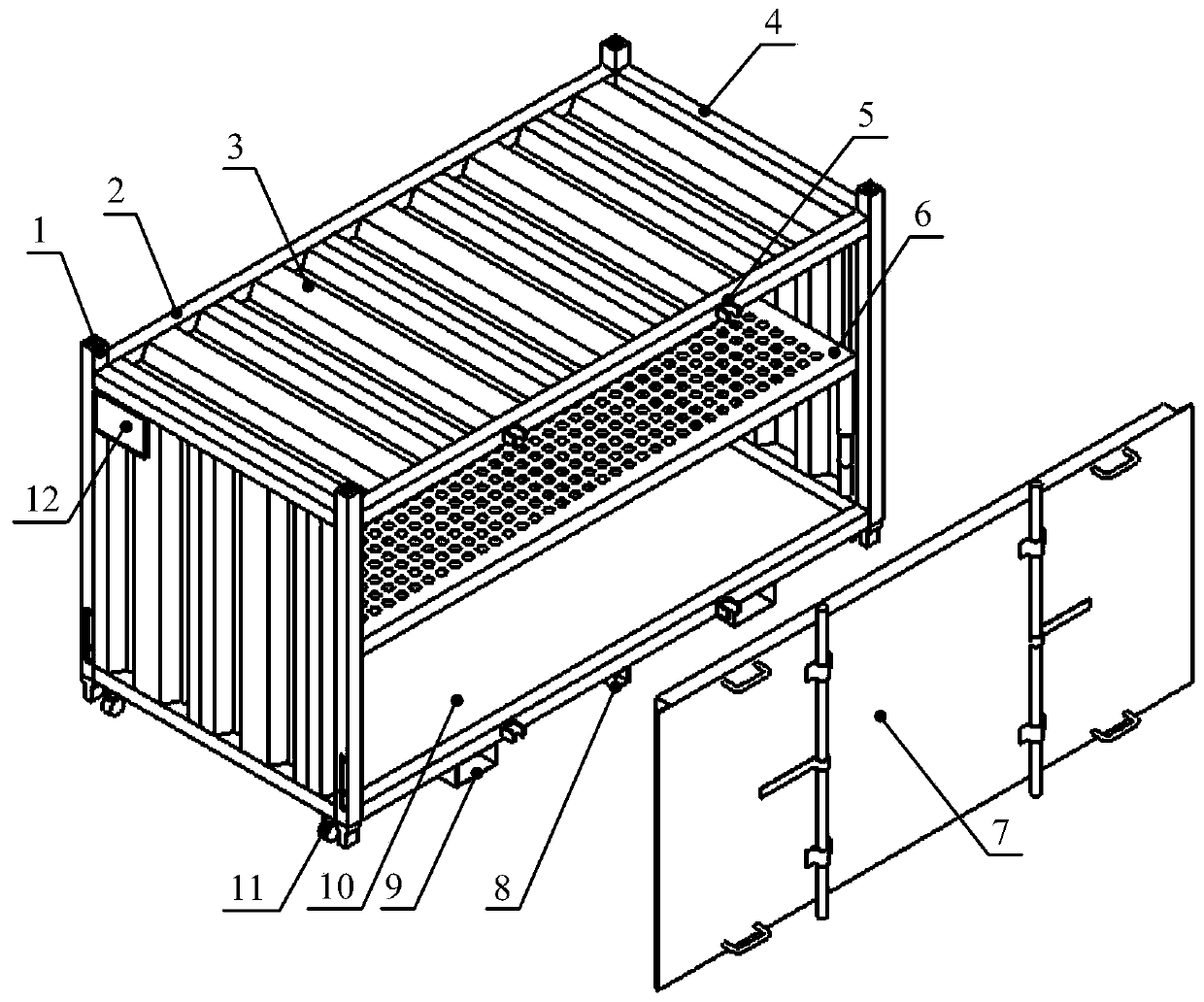

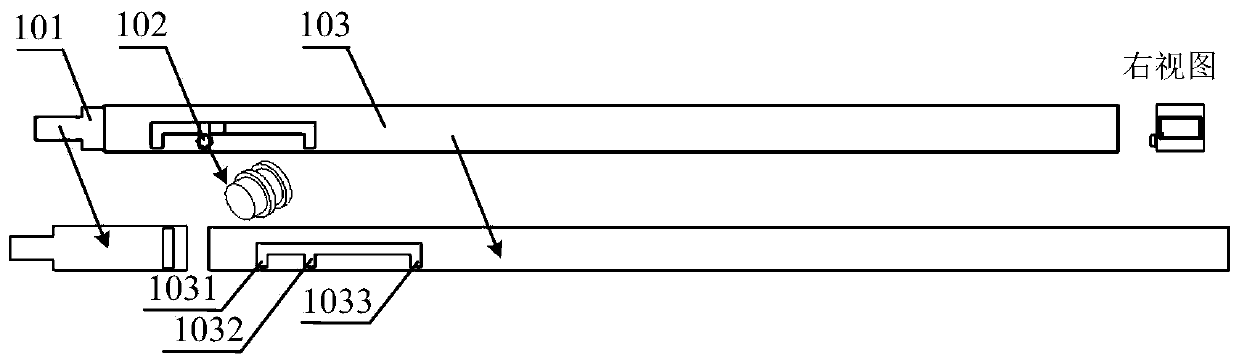

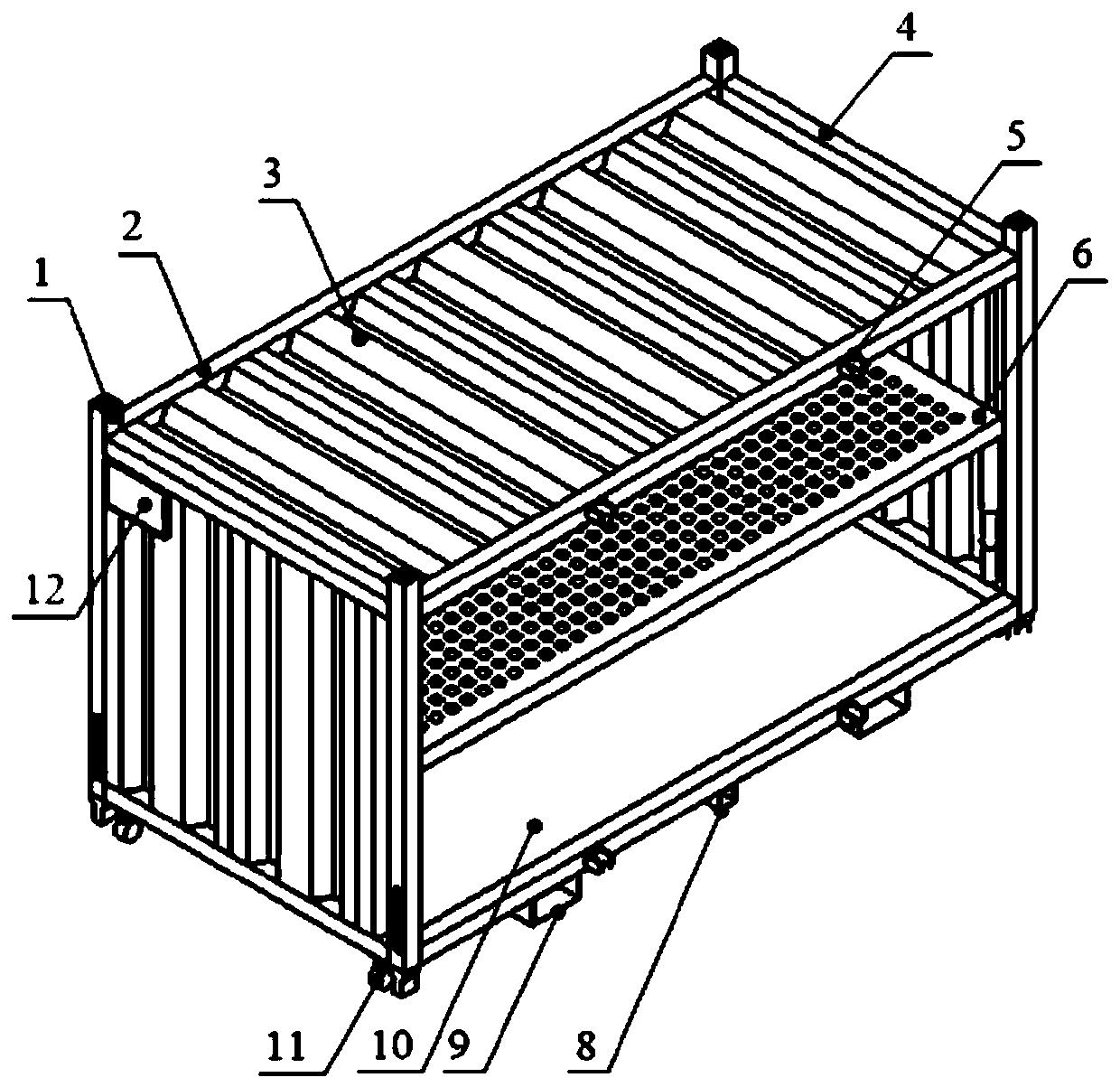

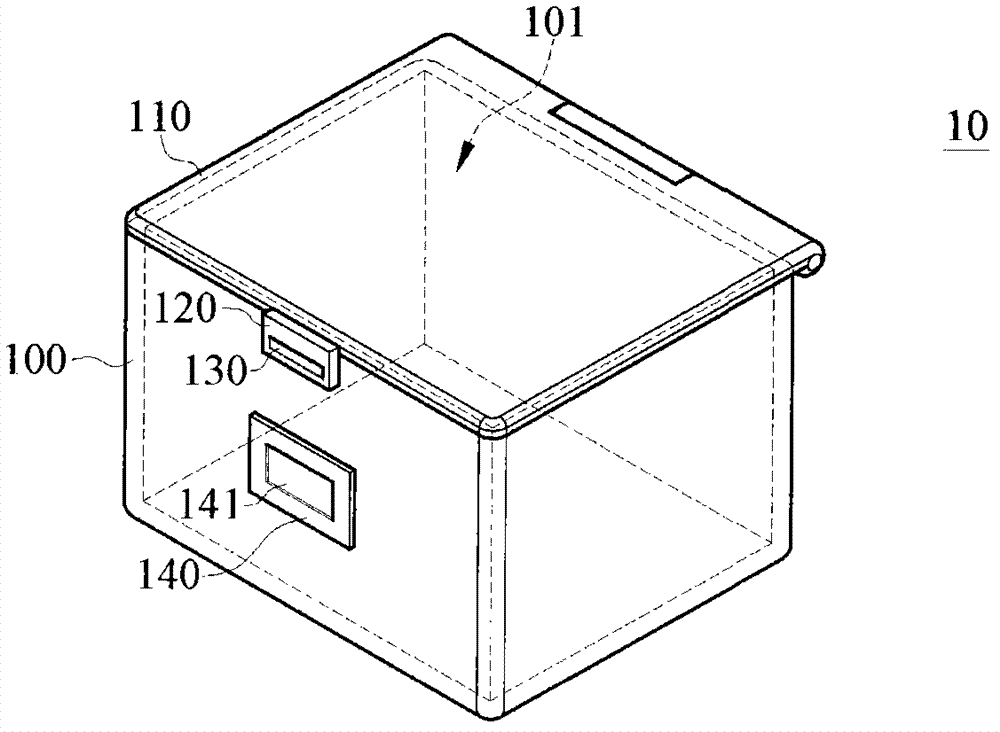

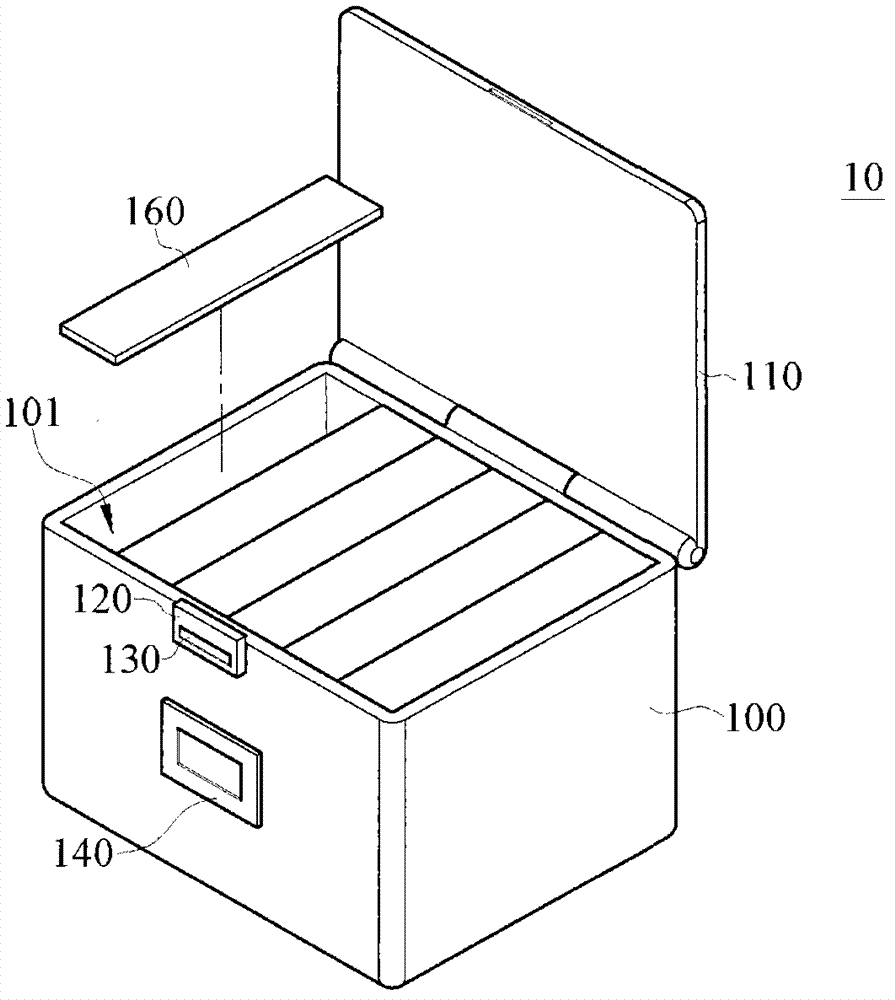

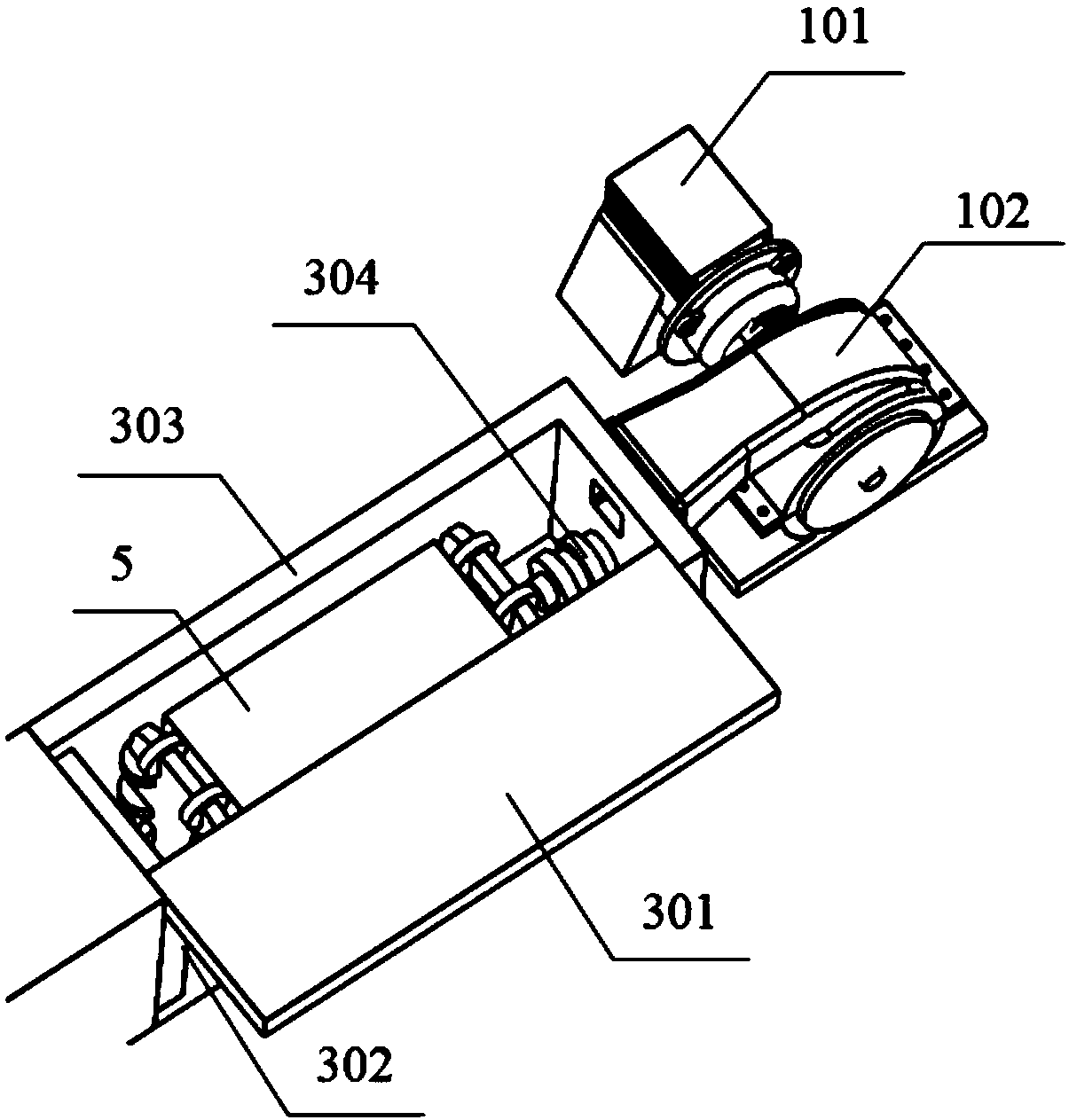

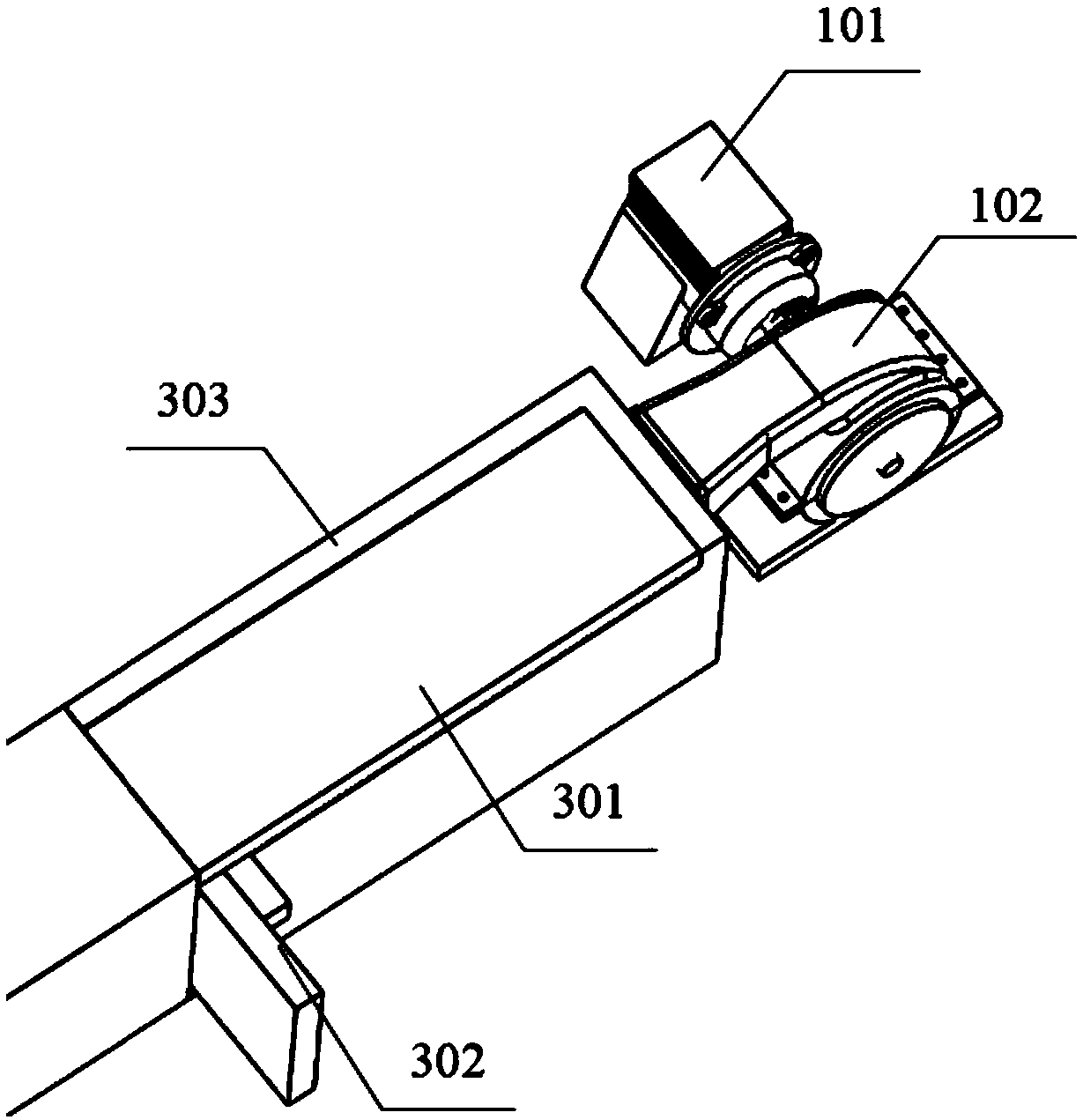

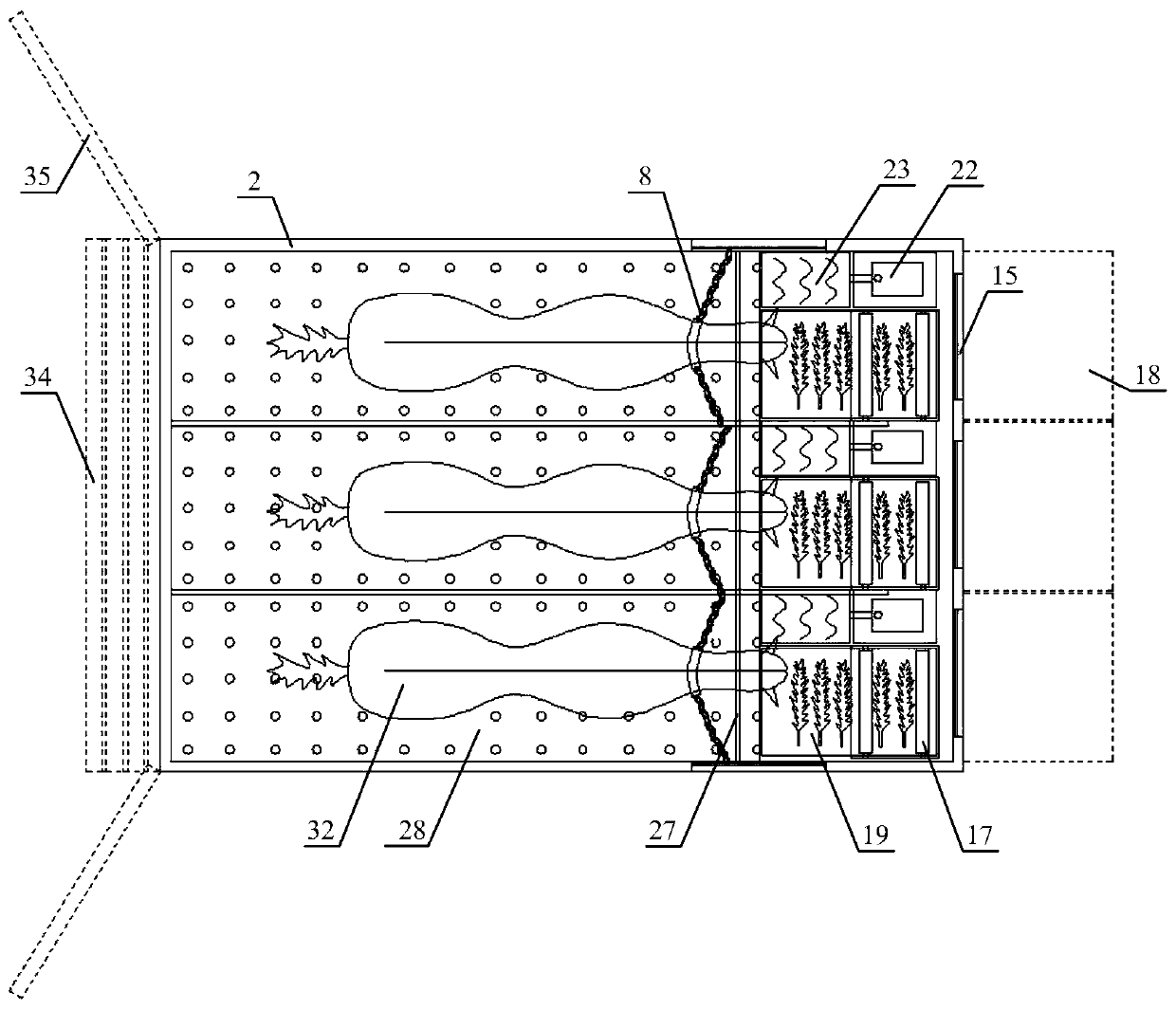

Movable supporting high-speed train logistics informationization unit load device

PendingCN110027817AStrong structural commonalityFull use of spaceLarge containersLoad-engaging elementsUnit load deviceLogistics management

The invention discloses a movable supporting high-speed train logistics informationization unit load device. The movable supporting high-speed train logistics informationization unit load device comprises corner beams (1), long beams (2), wide beams (4) and broken line or wave type box boards (3), wherein the corner beams (1), the long beams (2) and the wide beams (4) are perpendicular mutually; the top surface and three side faces of the unit load device are sealed through the corner beams (1), the long beams (2), the width beams (4) and the broken line or wave type box boards (3); and a boxbottom board (10) is welded to the wide beams (4) and the long beams (2) on the periphery of the bottom of the unit load device. A box door (7) is arranged on the unsealed side face of the unit load device; a partition shelf (6) is arranged in a sealed cavity; and the partition shelf (6) comprises a partition board (601) and lifting rods (602). Each corner beam (1) comprises a sliding support (101), a buckle (102) and a slideway beam (103), and the wide head of the sliding support (101) is provided with a rectangular groove. The movable supporting high-speed train logistics informationizationunit load device is high in structure universality and full in space utilization, integrates three transport modes, realizes digitized information storage and facilitates standardization and universality of high-speed train logistics container transportation. The problem existing in transportation of the unit load device under different conditions is solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Power Drive Unit with Unit Load Device Sensor

A cargo power drive unit includes a motor and at least one drive roller element coupled to the motor. The power drive unit further includes a light transmitter for emitting light and a light receiver for measuring light. The power drive unit measures an amount of ambient light and then measures an amount of total light after the light transmitter emits light. The power drive unit then determines whether a cargo container is present based on a calculation of reflected light and the measurement of ambient light.

Owner:THE BF GOODRICH CO

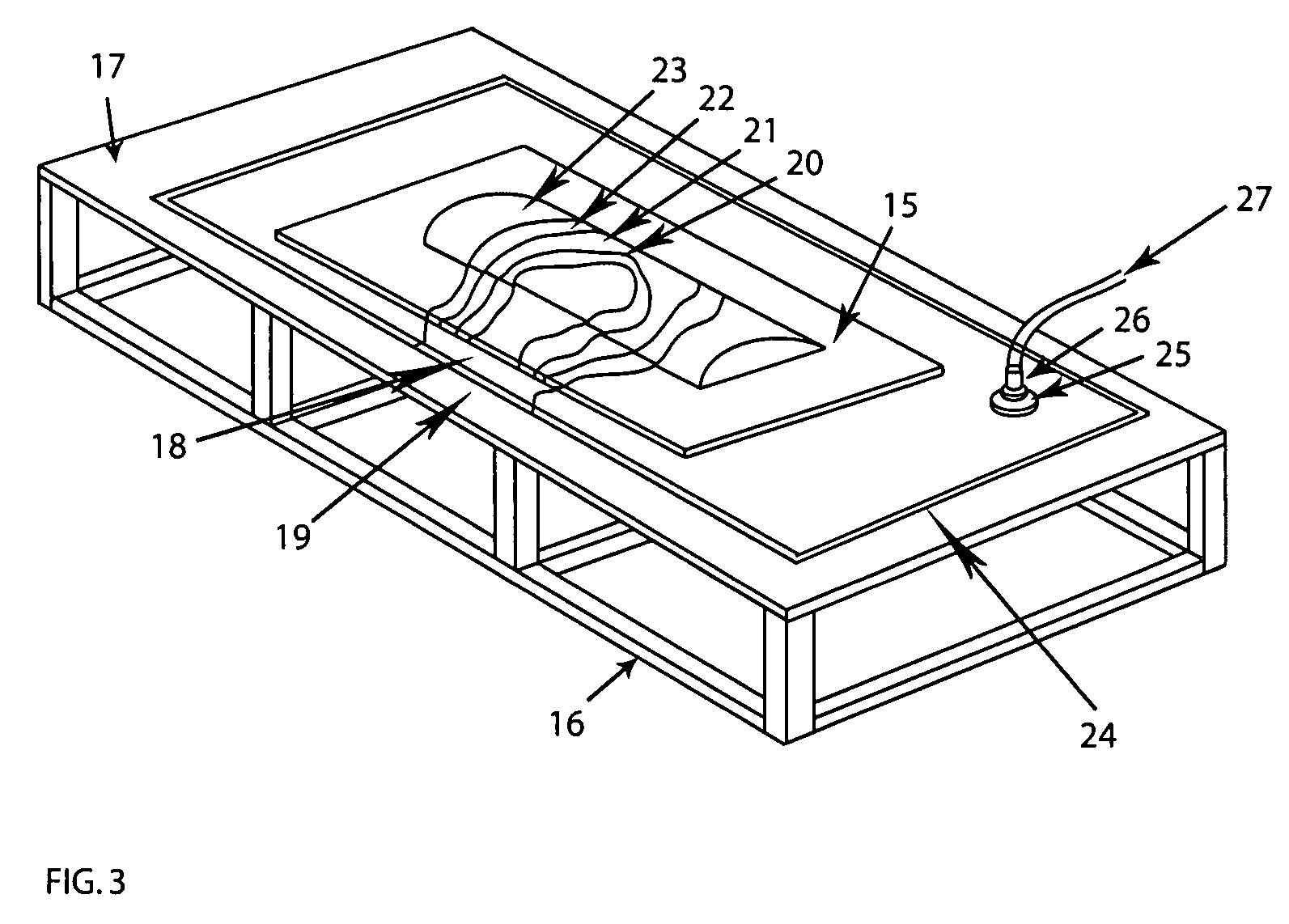

Folding containers

InactiveUS20100187228A1Improve stacking characteristicMinimal amountLarge containersRigid containersUnit load deviceUnit device

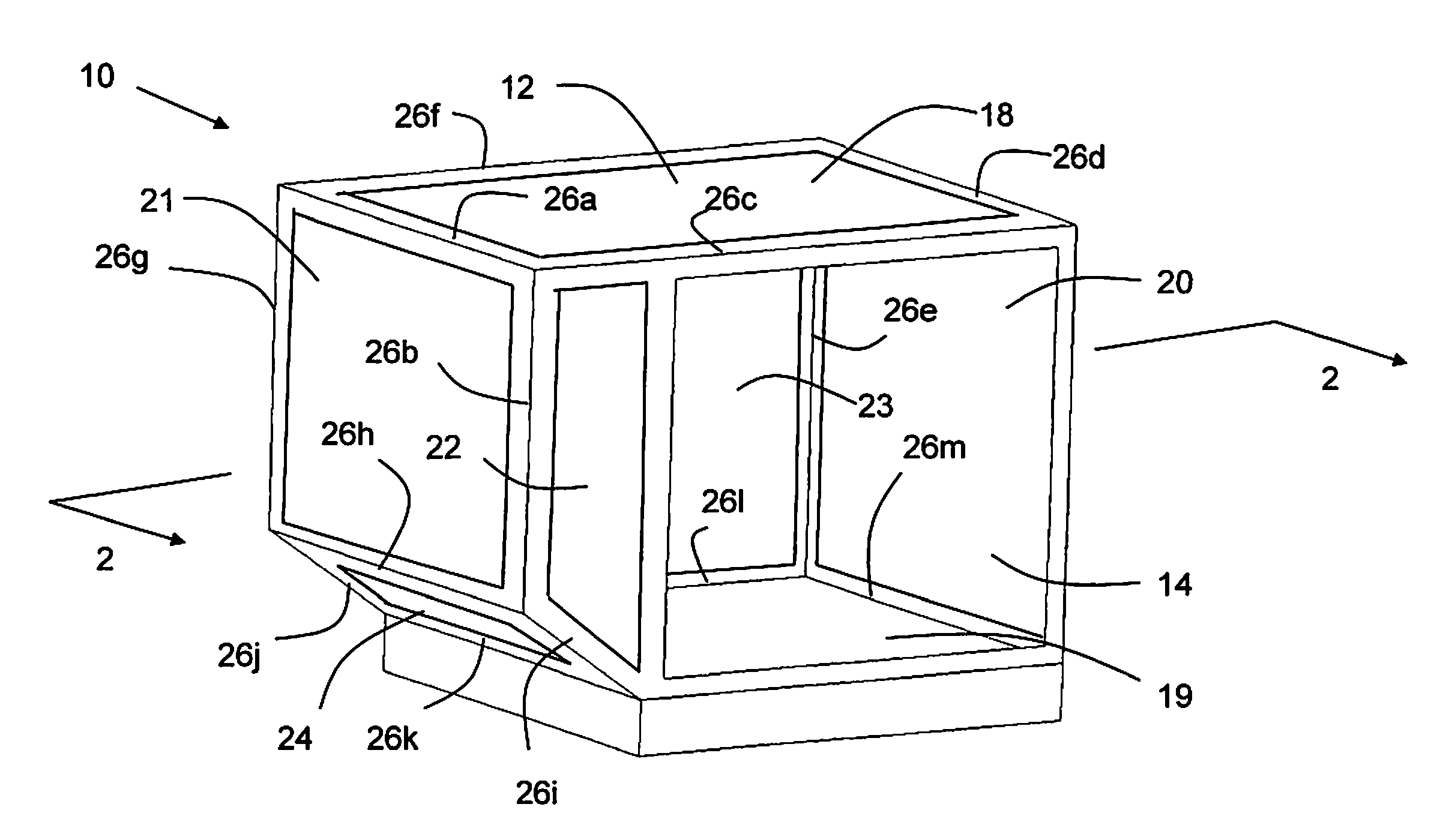

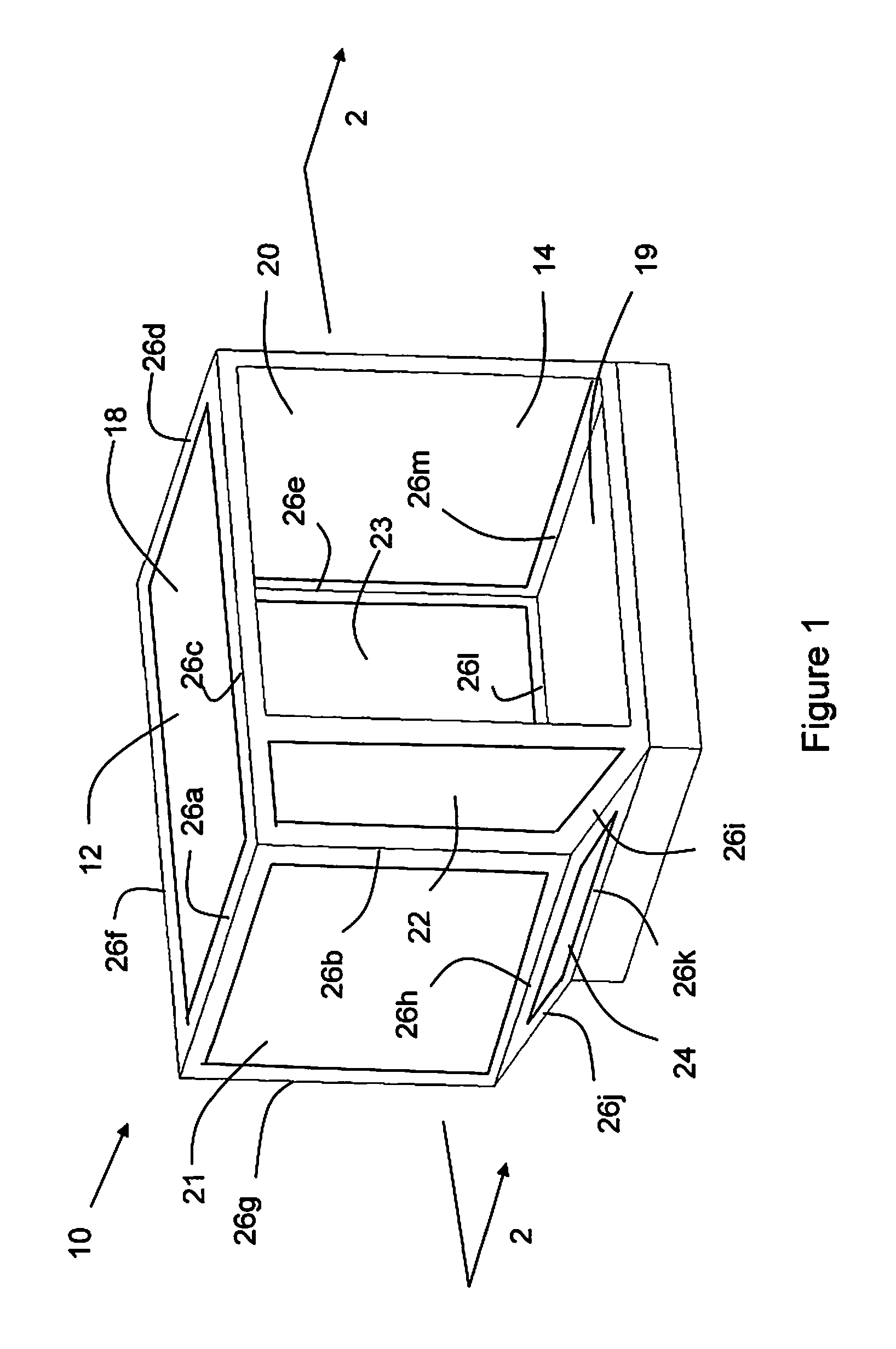

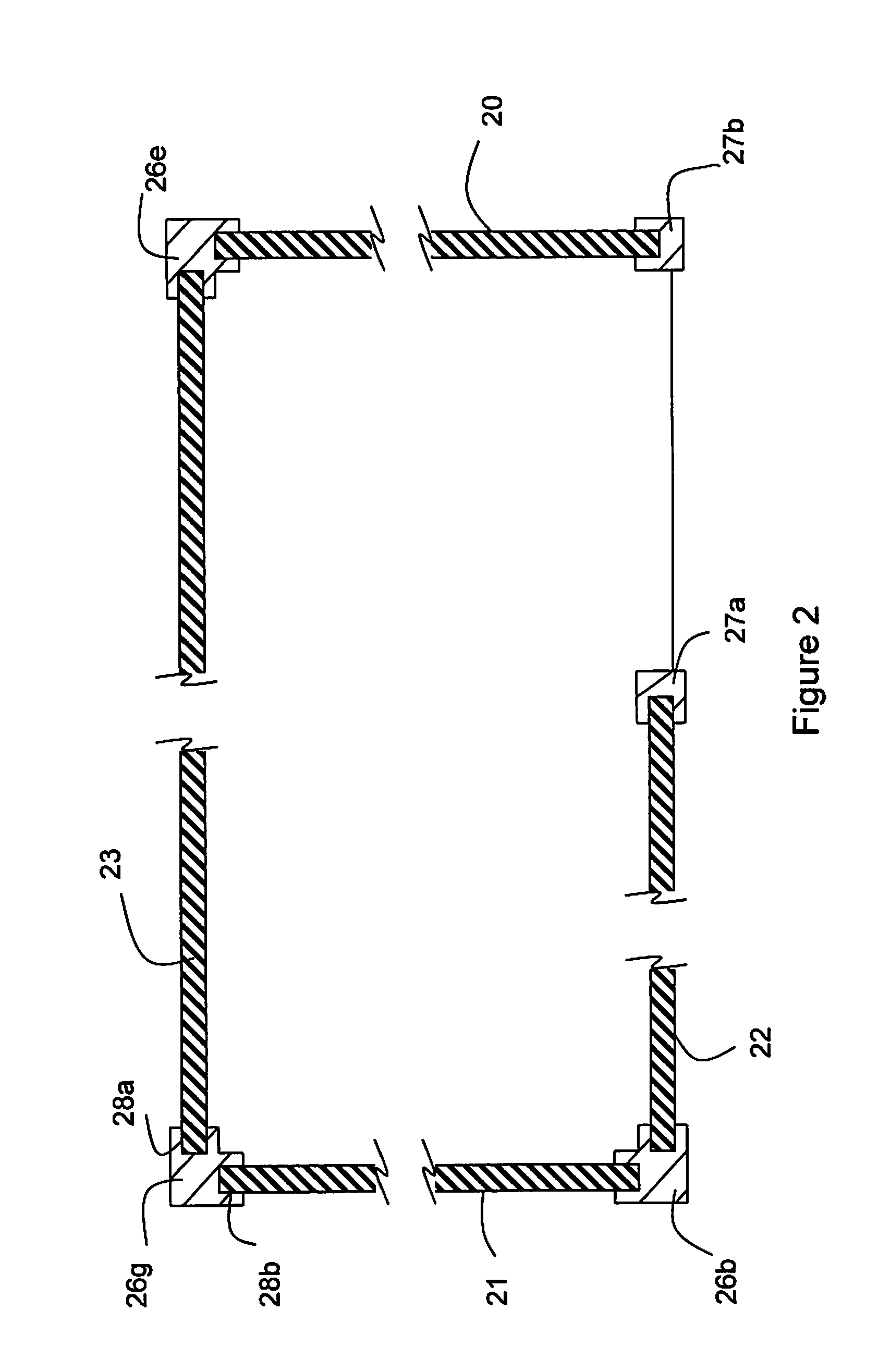

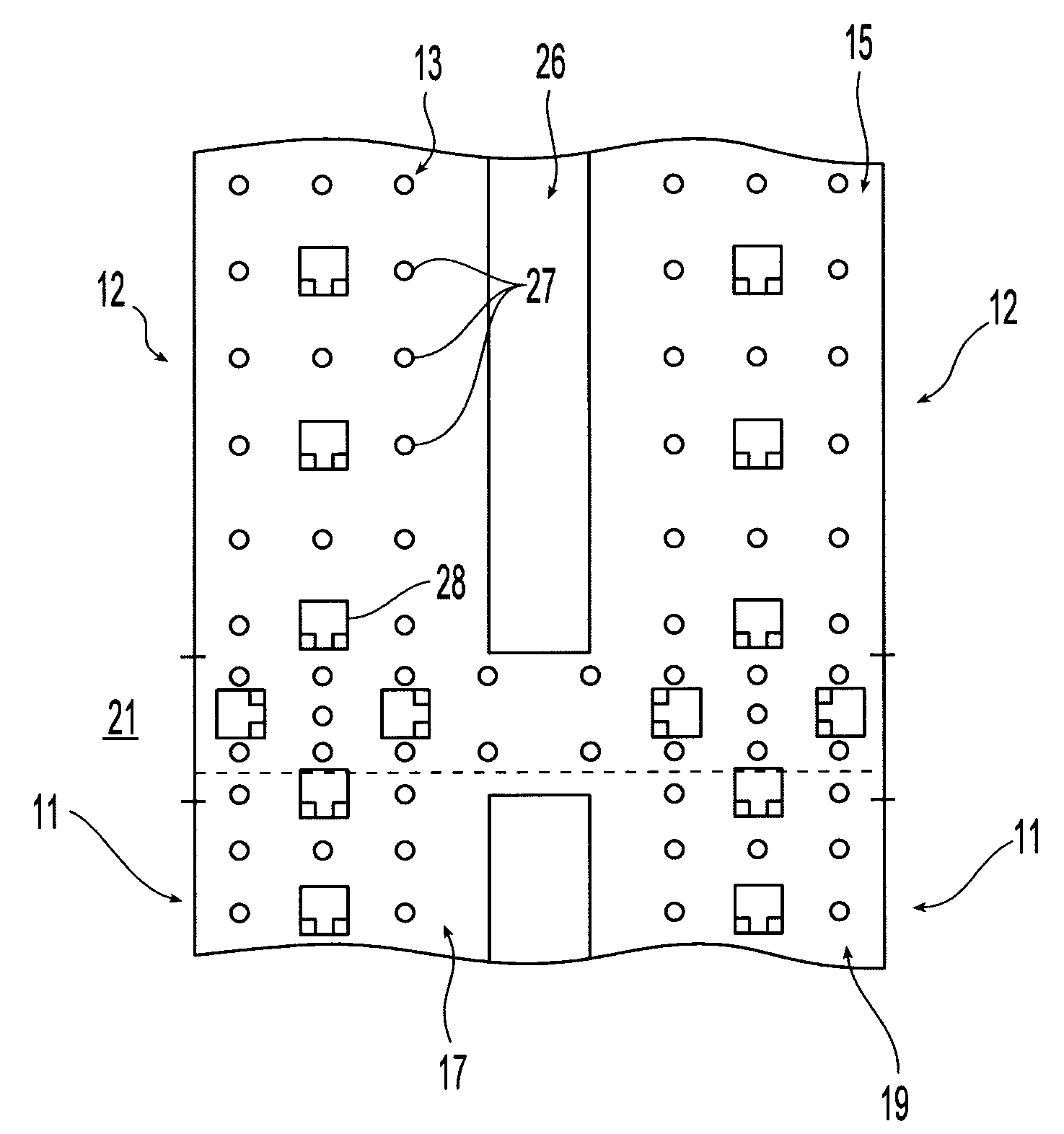

A collapsible air freight container (10) also known as a unit load device, comprises a standard base (12), commonly used on unit load devices, a side panel (16) slideably hinged to the base and a back panel (18) which is hinged to the base which interlocks with the side panel. There is a side extension (20) which is generally trapezoidal to roughly conform to the shape of a side wall of a plane's cargo hold. The side extension (20) includes a frame which (22) is hinged to the base and two trapezoidal (front and rear) panel extensions (24, 26) hinged to the frame. The side extension (20) is completed by a lid (28) and side wall panel (32) connected together by a hinge (34) with the lid (28) being hinged to a top of the frame, and by a sloping bottom panel (36) and relatively short side wall panel (40) hingedly connected to each other with the bottom panel (36) also being hinged to a bottom member of the frame. A lid is slideably mounted on top of the container so that it can be slid relative to the back panel. The lid is arranged so that when fully retracted to the back of the container relative to the back panel, it may pivot to overlay the back panel. As is typical of unit load devices the front of the container is open but may be covered by a flexible curtain or the like. The container may be collapsed by retracting and pivoting the lid to overly the back panel (18), folding the side extension (20) within the frame (22), folding and sliding the side panel (16) into the base (12) and lowering the folded side extension (20) and then the back panel (18) and lid (40) into the base.

Owner:TECHNOSEARCH

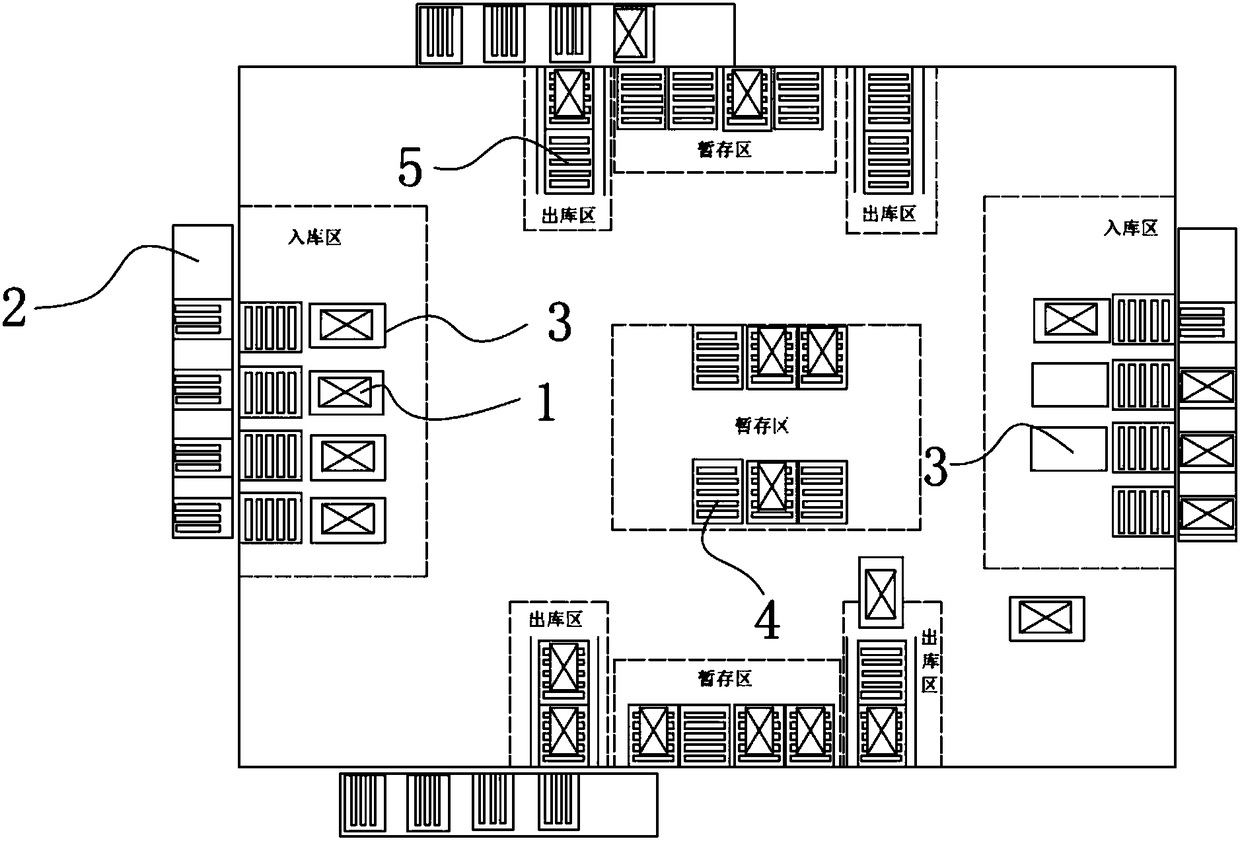

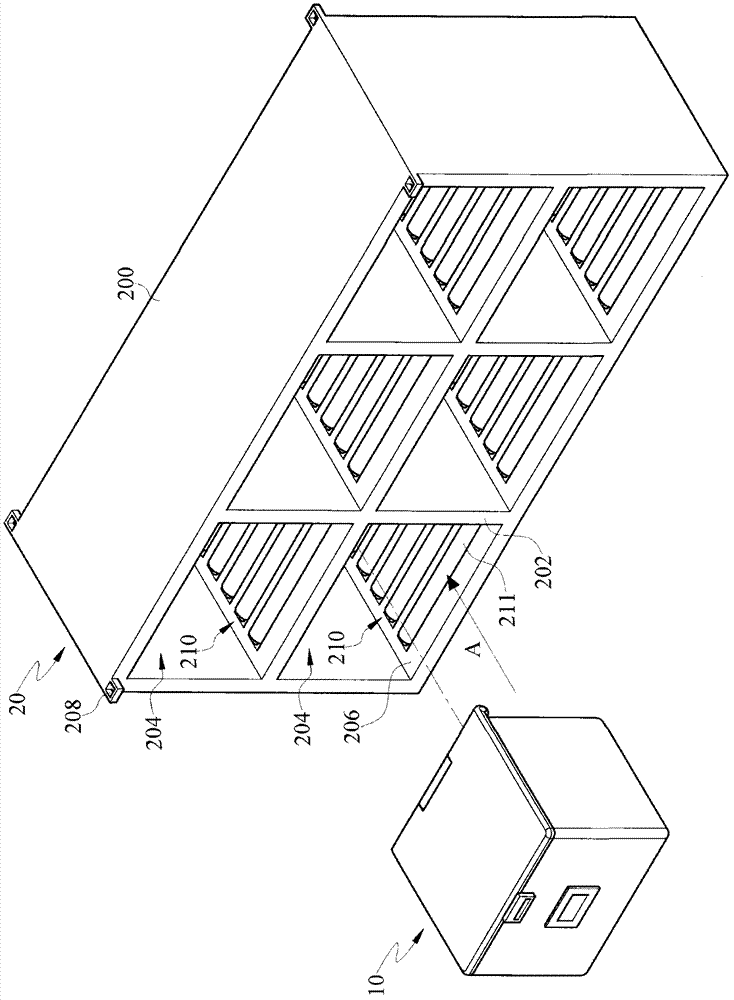

Unit load device transfer center and unit load device transfer method

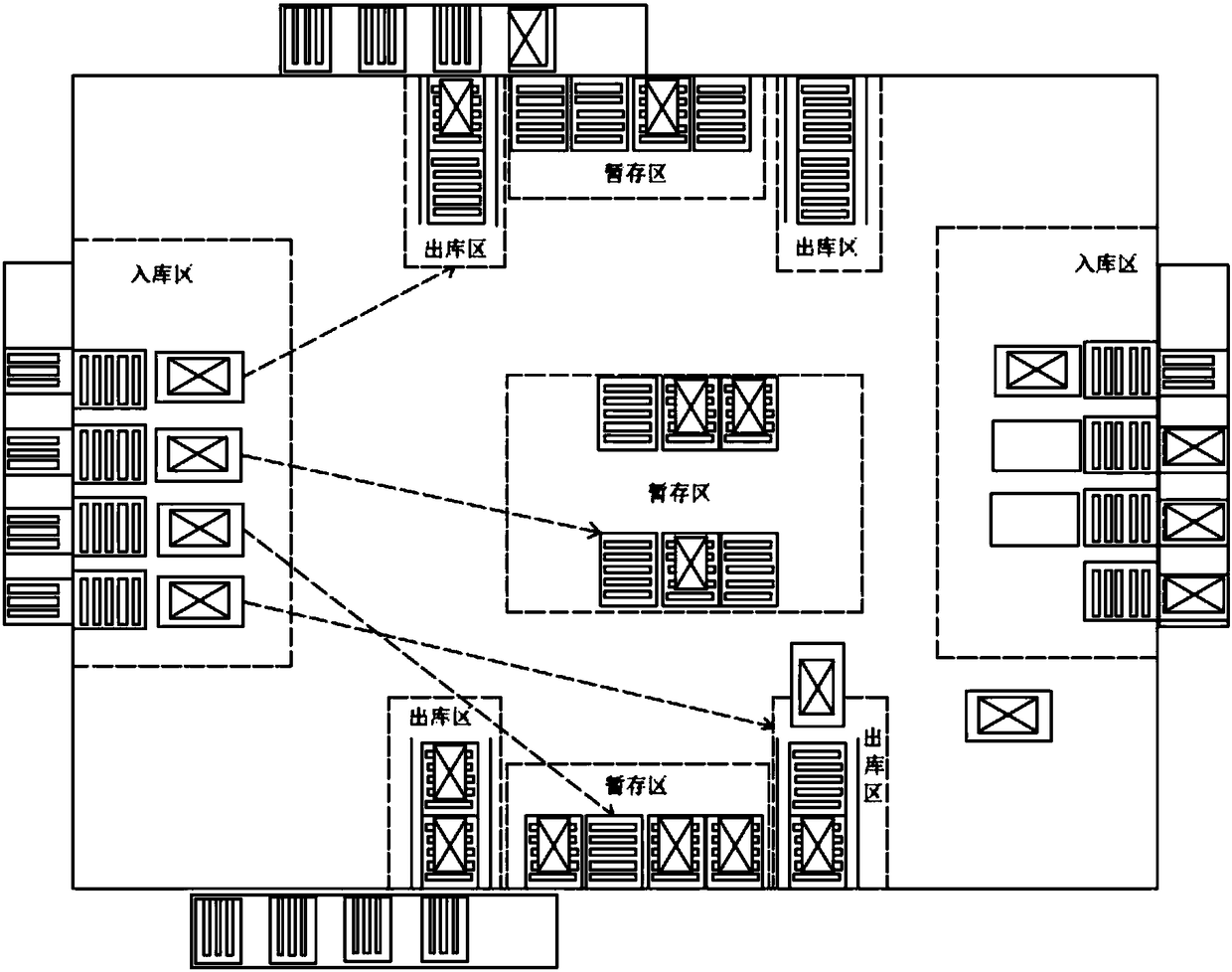

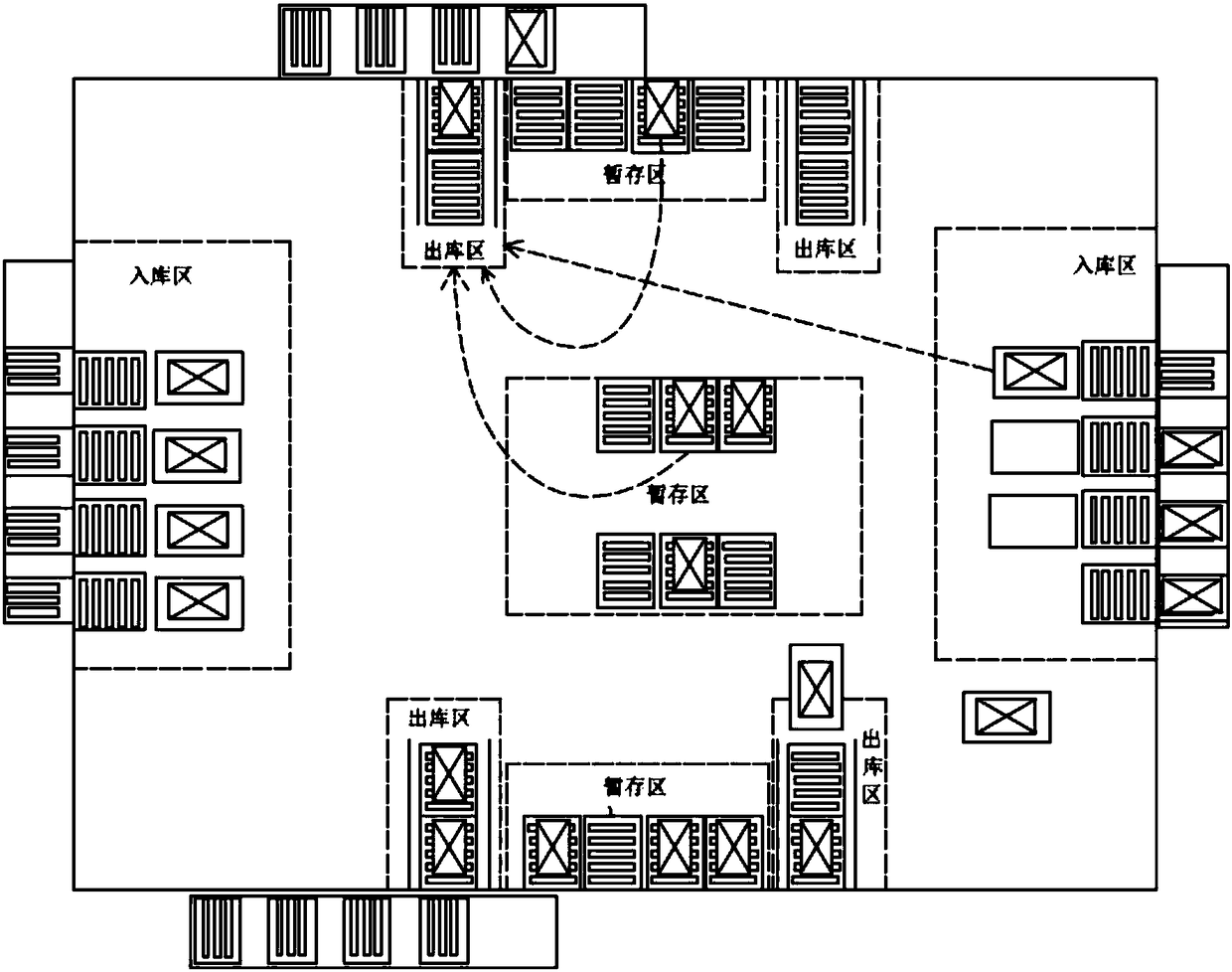

InactiveCN108557498AChanging the Traditional Way of Dealing with ULDsHigh feasibilityStorage devicesUnit load deviceControl system

The invention discloses a unit load device transfer center. The unit load device transfer center comprises a transfer platform and transfer equipment. The transfer platform comprises storage areas inwhich the transfer equipment receives unit load devices outside the transfer center, temporary storage areas where the transfer equipment can transport the unit load devices for temporary storage, out-of-the-warehouse areas in which the transfer equipment transfers the unit load devices to the outside of the transfer center and a control system for scheduling the transfer equipment so that the transfer equipment can move inside the transfer platform. The transfer equipment is an AGV. According to the unit load device transfer center and the unit load device transfer method, a traditional way of handling the ULDs at an air cargo station is changed, and the unit load device transfer center and the unit load device transfer method have the beneficial effects of being high in processing efficiency and high in flexibility.

Owner:SF EXPRESS

A composite sandwich structure

ActiveCN107921725AConstruction materialSynthetic resin layered productsUnit load deviceHost material

The invention relates to a composite sandwich base panel for a Unit Load Device. The panel comprises an upper surface layer comprising fibre reinforcement material, a lower surface layer comprising fibre reinforcement material, and a central core section where at least the majority comprises a plurality of particles bound in a matrix material. The upper surface layer and lower surface layer are provided with a matrix material to bind them to the central core section.

Owner:FERGUSSONS ADVANCED COMPOSITE TECH

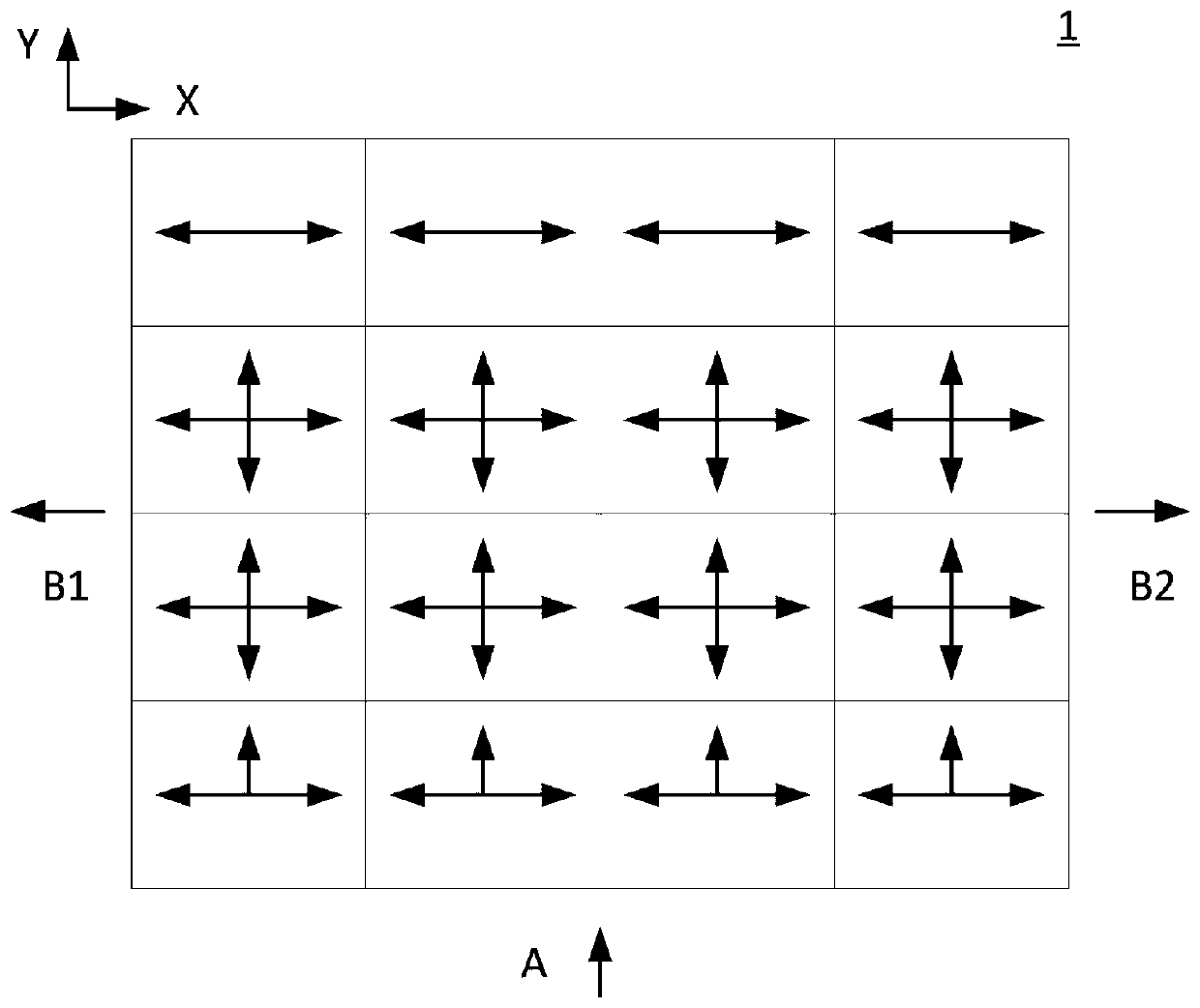

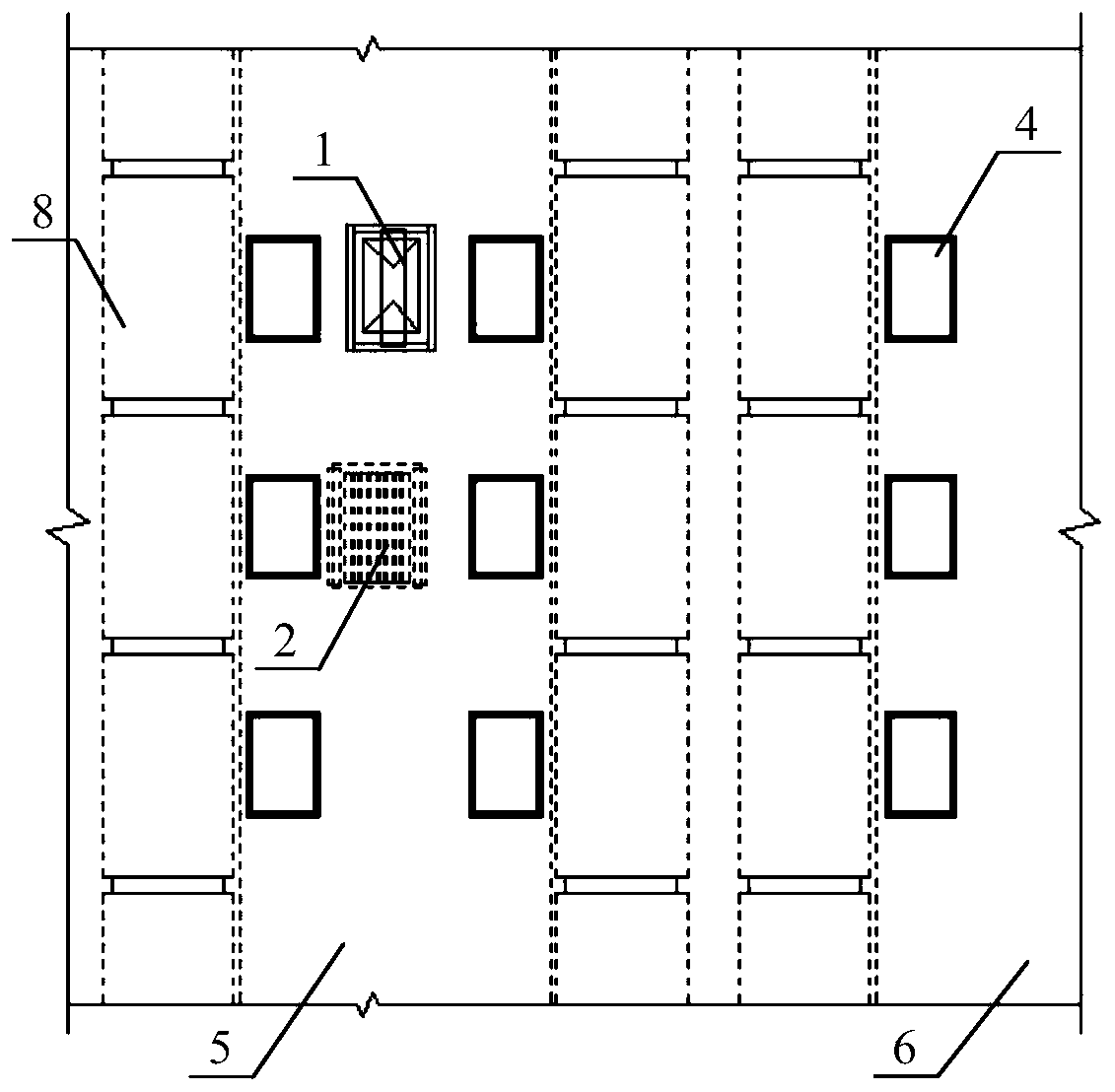

Sorting matrix and matrix sorting and caching system and method for unit load devices

The invention relates to a sorting matrix for unit load device sorting. The sorting matrix comprises a plurality of sorting units, the sorting units are arranged in a matrix order, sorting columns andsorting rows are defined, and the sorting rows correspond to the sorting types of unit load devices. A plurality of unit load devices are simultaneously transported through the sorting columns to thetarget sorting rows of the corresponding sorting types, and are transported by the target sorting rows to an exit of the sorting matrix. The sorting units are right-angle steering equipment, and theright-angle steering equipment has two transportation directions, namely the sorting column direction and the sorting row direction. The unit load devices are transported to the target sorting rows onthe sorting column direction and transported to the exit by the target sorting rows on the sorting row direction.

Owner:CHINA IPPR INT ENG

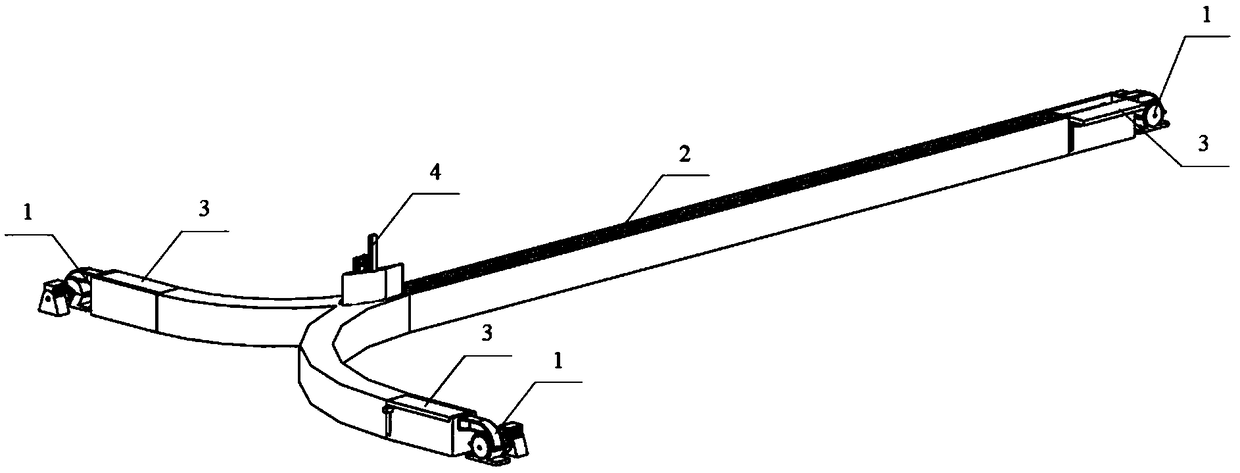

Circulating type continuous receiving and sending system and method of cold chain logistics pipeline system

PendingCN109399218AImplement pipeliningImprove continuityNon-mechanical conveyorsUnit load deviceCold chain

The invention discloses a circulating type continuous receiving and sending system of a cold chain logistics pipeline system. The circulating type continuous receiving and sending system of the cold chain logistics pipeline system is characterized by comprising a horizontal movement loading unit, a loading unit track (6), a transverse moving device and a longitudinal moving device; the horizontalmovement loading unit is provided with a plurality of horizontal movement receiving and sending devices (1) which are sequentially arranged and used for containing cold chain unit load devices (10); the plurality of horizontal movement receiving and sending devices (1) of the horizontal movement loading unit are fixedly connected in the transverse direction of a cold chain conveying pipeline (11),and synchronously move in the transverse direction of the loading unit track (6) under driving by the transverse moving device; the plurality of horizontal movement receiving and sending devices (1)of the horizontal movement loading unit move longitudinally in the longitudinal direction of the cold chain conveying pipeline (11) to be independent of one other, correspondingly move longitudinallyunder driving by the longitudinal moving device and do not interfere with one another. The plurality of horizontal movement receiving and sending devices are adopted, and continuous sending and packing or receiving and unloading of the cold chain unit load devices can be sequentially and efficiently achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

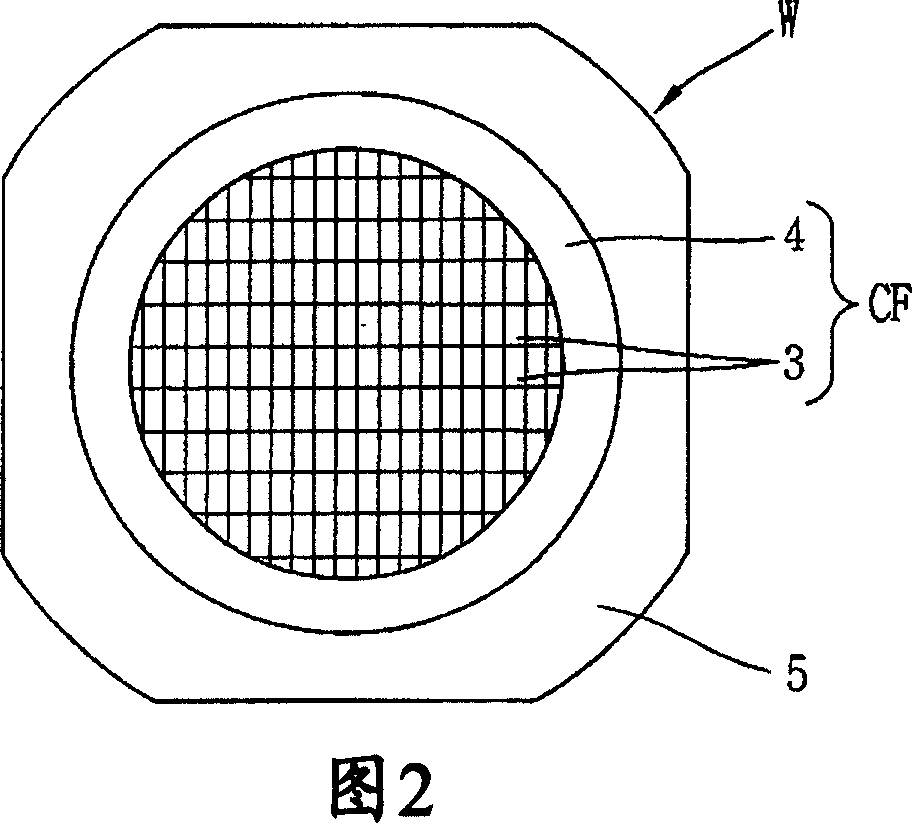

Intelligent unit load device applicable to high-speed railway vehicle transportation

PendingCN110040372AStrong structural versatilityImprove space utilizationLarge containersTank wagonsUnit load deviceWide beam

The invention discloses an intelligent unit load device applicable to high-speed railway vehicle transportation. The intelligent unit load device comprises an angle beam (1) and long beams (2), wide beams (4), folding line or a wave-shaped box plates (3), a box bottom plate (10) is welded with the wide beams (4) and the long beams (2) at the bottom of the unit load device; a box door (7) is arranged on the non-closed side surface of the unit load device, and a cargo hold (49) capable of containing cargoes is formed; an interlayer frame (6) is arranged in the cargo hold (49), and a sealing cavity is separated into a new different shelf area (50); an environment adjusting system comprises a light supplementing device, a humidifying device, a humidity sensor (20), a temperature sensor (21) and a controller; an equipment cabin is internally provided with a heating device, a refrigerating device and a controller. According to the unit load device, the structural universality is high, different kinds and shapes of dry goods, animals, plants, medical medicines and the like can be met, the environment adjusting system is provided, so that environmental adjustment such as temperature, humidity, illumination and the like in the unit load device can be realized.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

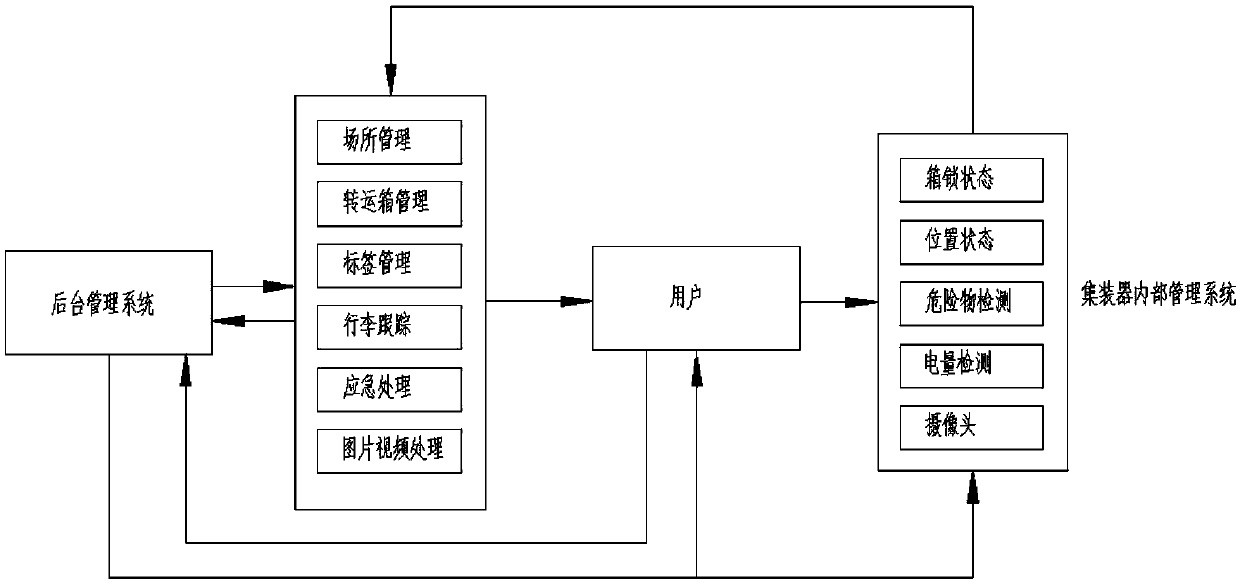

Railway cold chain unit load device intelligent management system

The invention discloses a railway cold chain unit load device intelligent management system comprising a unit load device internal management system and a backstage management system; the backstage management system has a communication interface used for communicating with the unit load device, and can carry out place management, unit load device management, label management, luggage tracking, emergency treatment on an open command and image and video data process for the unit load device via the communication interface; the backstage management system and the unit load device internal management system are in communication; the unit load device internal management system can detect the unit load device states in real time, and can detect the locking state, position state, danger article state, electricity quantity state and camera state of the unit load device in real time; the detected unit load device data is fully or partially sent to a user according to a user command via the backstage management system; the unit load device internal management system has a user interface that receives the user command; the railway cold chain unit load device intelligent management system canmonitor a single unit load device, and can monitor the cargo carried by the unit load device in a whole journey.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Logistics method and apparatus for transportation

InactiveCN103112655AShorten the timeCut costsLarge containersShock-sensitive articlesUnit load deviceLogistics management

The invention discloses a logistics method and an apparatus for transportation. The logistics method comprises putting goods into a unit load device; delivering the load device to a transit center; determining whether a plurality of the load devices gathered in the transit center are of same sequence after the transit center collects the plurality of the load devices, and if the plurality of the load devices are of the same sequence, loading the load device with the same sequence to a same assembled storage device; carrying the assembled storage device to mobile carrier; and enabling the mobile carrier to deliver the assembled storage device to a transport vehicle. The logistics method provided by the invention can shorten treating time of goods, reduce cost and minimize generation of errors.

Owner:IND TECH RES INST

Receiving and transmitting system for pneumatic cold chain pipeline logistics

PendingCN109081118ASolve the last mile problemRealize cold chain transmissionConveyorsUnit load deviceCold chain

The invention discloses a receiving and transmitting system for pneumatic cold chain pipeline logistics. The receiving and transmitting system comprises a cold chain air source device, a cold chain pipeline (2), receiving and transmitting devices (3), a cold chain pipeline commutator (4) and a cold chain unit load device (5), wherein a cold chain warehouse is arranged in the cold chain unit load device (5), and cold chain goods are loaded in the cold chain warehouse; the cold chain air source device is used for driving the cold chain unit load device (5) to perform transmission in the cold chain pipeline (2), and is at least located at the end of the cold chain pipeline (2); the receiving and transmitting devices (3) are arranged at two ends of the cold chain pipeline (2), and are used forreceiving and transmitting of the cold chain unit load device (5); and the cold chain pipeline (2) comprises a plurality of branched branch pipelines and the cold chain pipeline commutator (4) and isused for shifting the conveying direction of a pipeline. According to the receiving and transmitting system disclosed by the invention, compressed air is used as power, point-to-point automated transportation is realized through the fixed cold chain pipeline, the effects of being high in speed and low in noise are achieved, the transportation efficiency is greatly improved, and the last-mile problem of the cold chain logistics is effectively solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

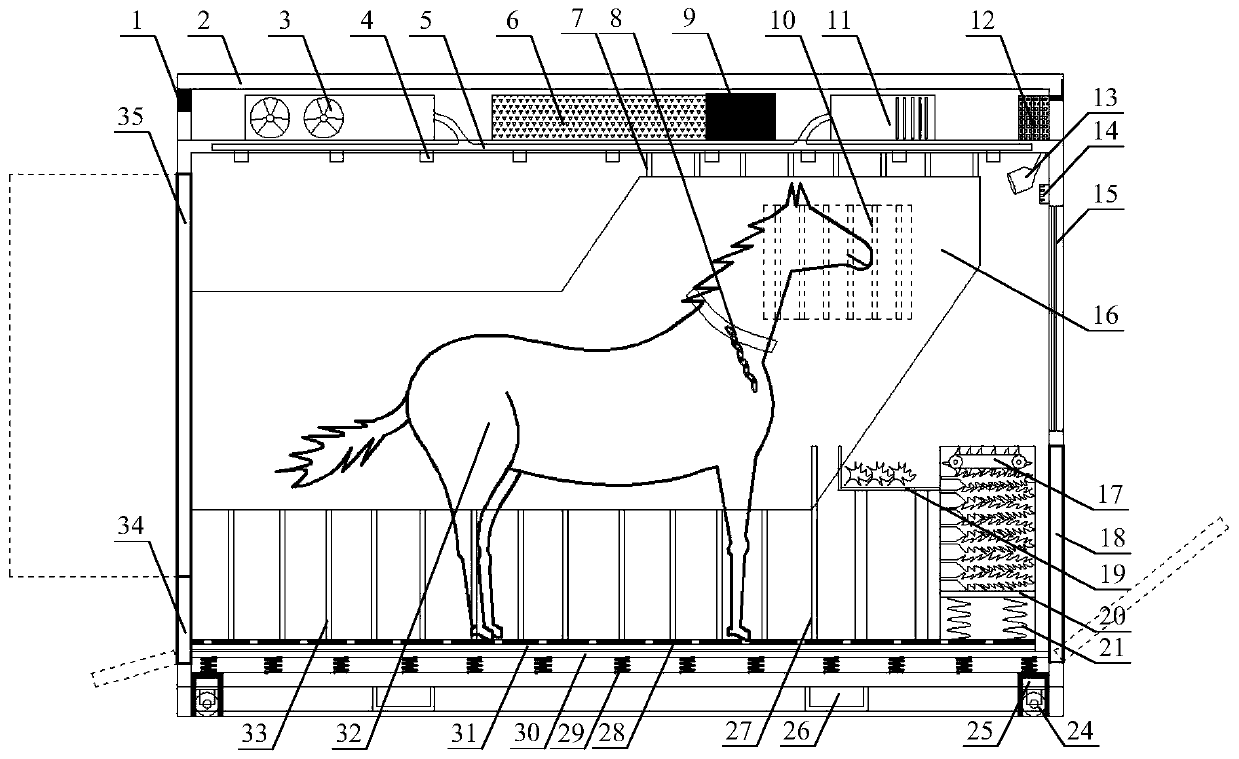

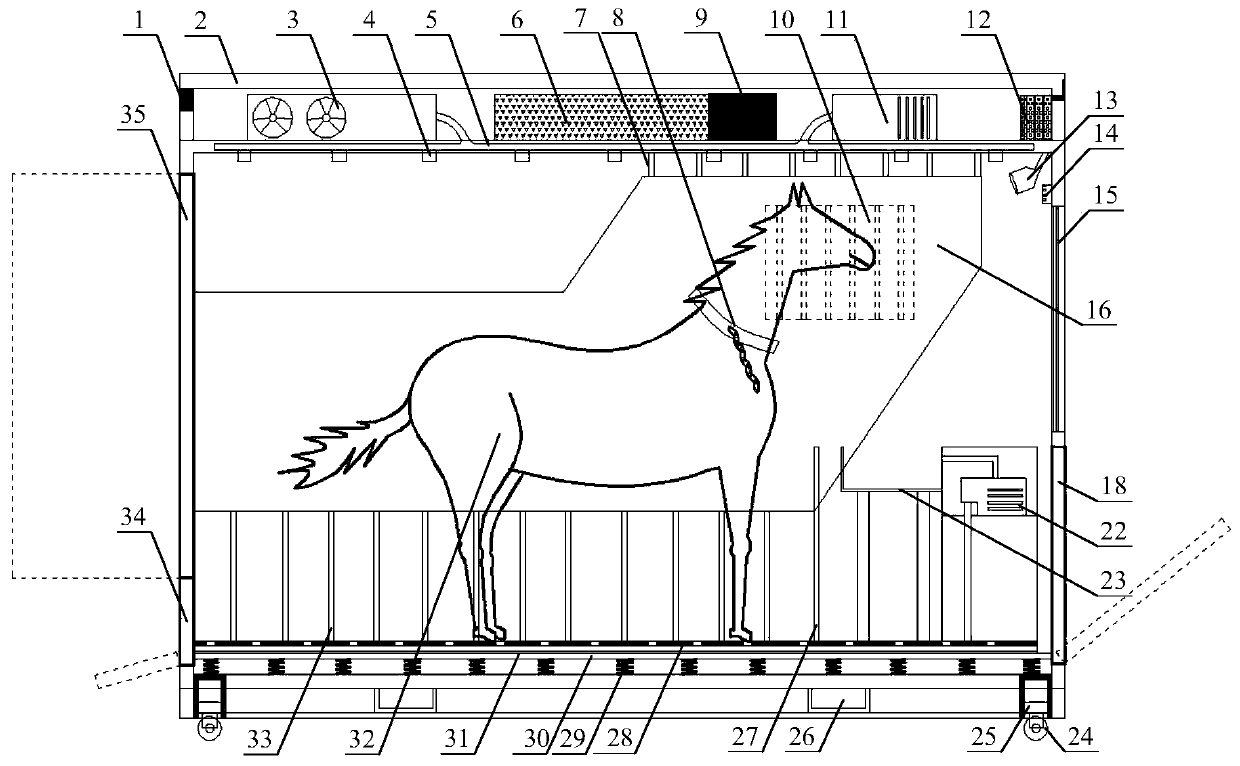

High-speed rail logistics animal transportation unit load device

PendingCN110002132ATransportation safetyTransport comfortLarge containersAnimal housingUnit load deviceLogistics management

The invention discloses a high-speed rail logistics animal transportation unit load device comprising a transportation room, a device room and a forage supply room. The device room comprises a temperature regulation device (3) and a ventilation device (11). The transportation room comprises a box body (2). The box body (2) is divided through sponge wrapper sheets (16). The tops of the sponge wrapper sheets (16) are fixedly connected with the top of the box body (2) through upper connection rods (7), and the bottoms of the sponge wrapper sheets (16) are fixedly connected with the bottom of thebox body (2) through lower connection rods (33). The forage supply room comprises a forage supply device and a water supply device. The forage supply device comprises forage tanks (19) and forage conveyor belts (17). The water supply device comprises water tanks (23). By means of the unit load device, feeding and water drinking of precious herbivores such as horses, wild asses and sika deer are achieved, animals are protected against injuries, environment, feeding, protection and monitoring during animal transportation are sufficiently considered, the animals can be safer and more comfortableduring transportation, and influences of transportation on the health state of the animals are reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

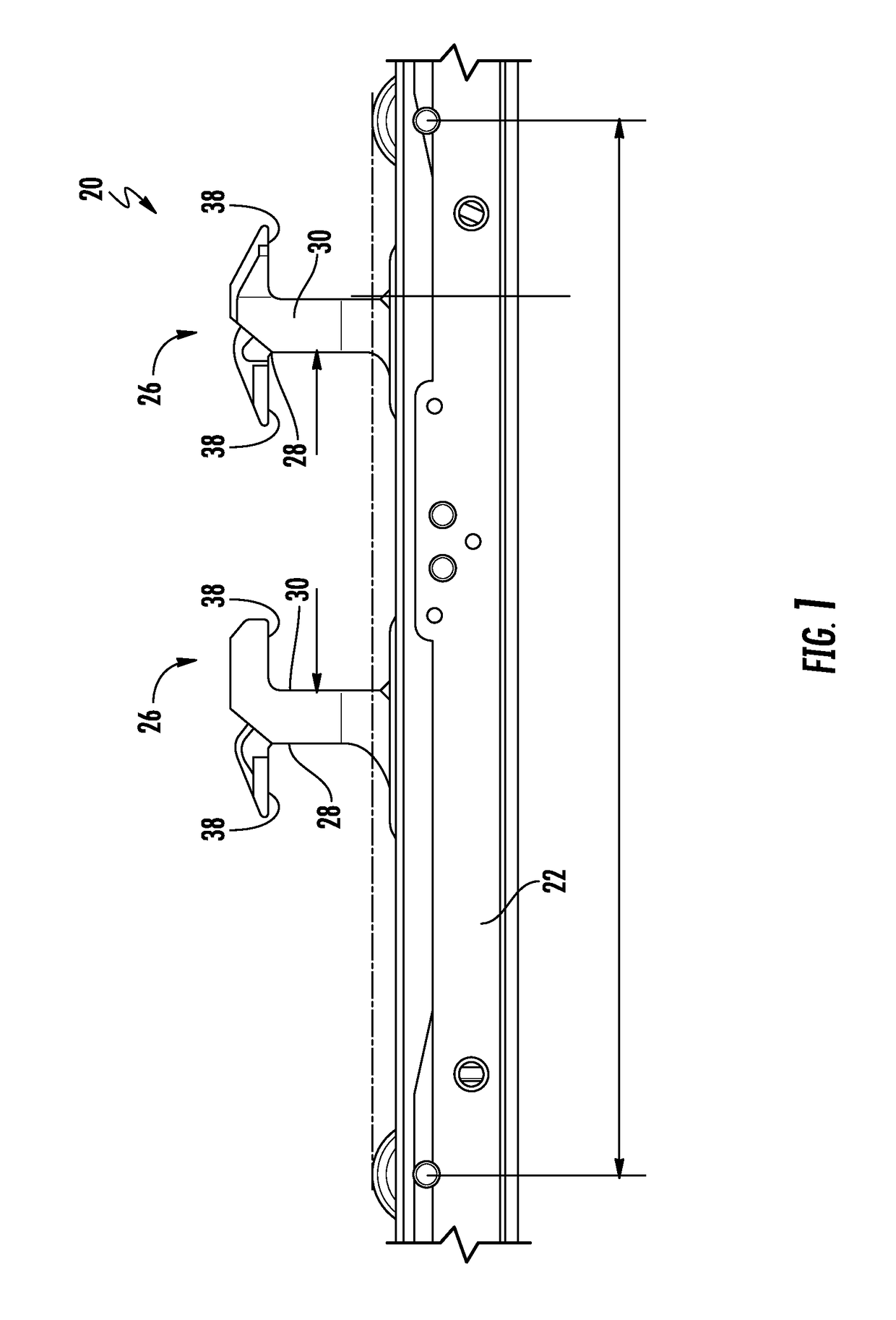

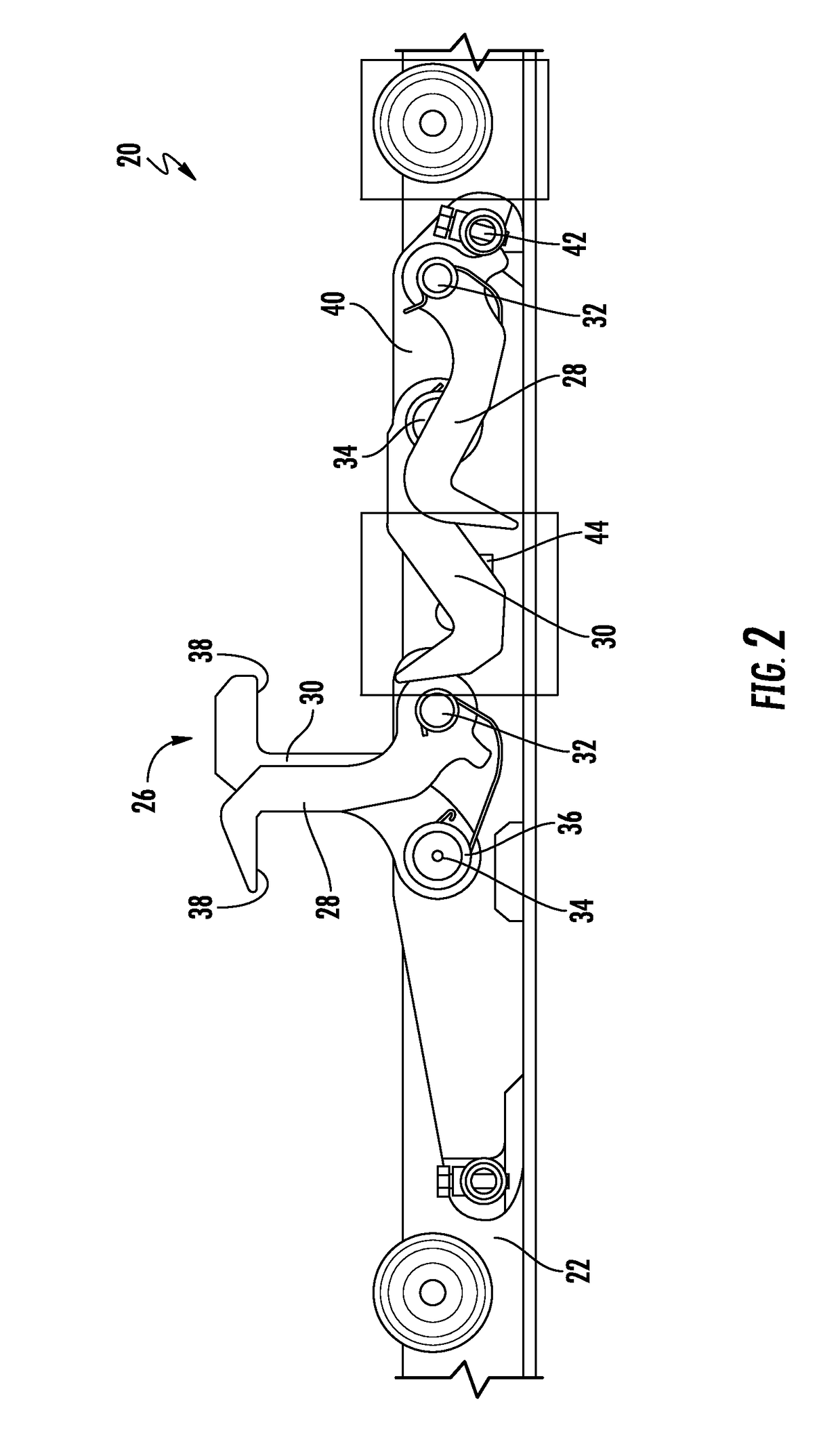

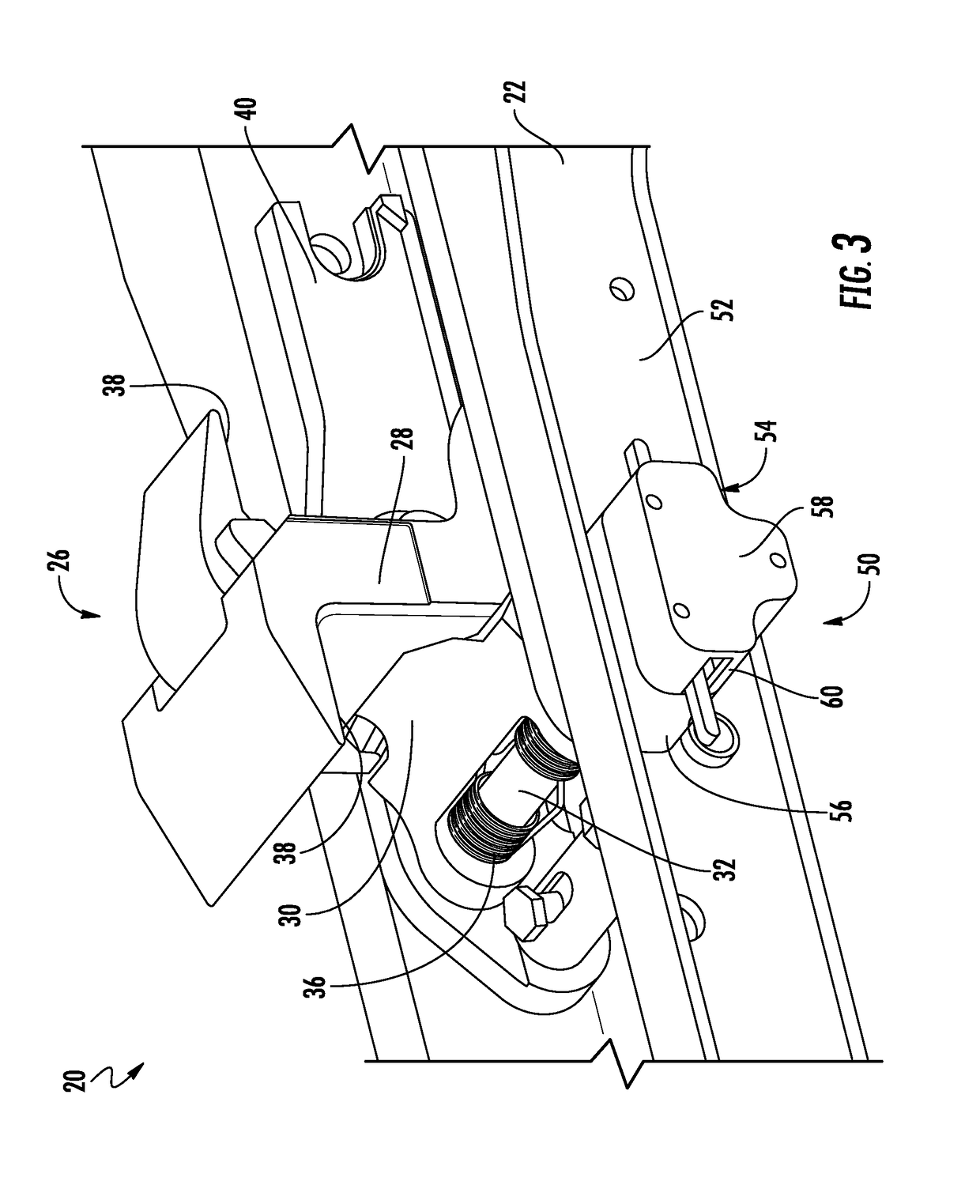

Intelligent lock for cargo handling system

ActiveUS20190061946A1Guaranteed automatic operationFreight handlingLoad securingUnit load deviceLocking mechanism

A cargo handling system for restraining a unit load device includes a structural channel having a hollow interior, and a locking mechanism associated with the structural channel. The locking mechanism is movable to engage the unit load device. A motor assembly is coupled to the at least one locking mechanism. The motor assembly is operable to automatically move the at least one locking mechanism upon detection of the unit load device at or approaching a desired position adjacent the at least one locking mechanism.

Owner:THE BF GOODRICH CO

System and method for recognizing a unit load device (ULD) number marked on an air cargo unit

InactiveUS8570377B2Television system detailsCharacter and pattern recognitionUnit load deviceAir cargo

The present invention provides a system and method for recognizing a Unit Load Device (ULD) number marked on an air cargo unit. The system includes at least one camera configured to acquire images of the ULD number. It includes also a presence sensing module configured to detect a presence status of the air cargo unit in a scanning zone of the system, the presence status can have a value being one of present and absent, and a recognition processor coupled to the presence sensing module and to the at least one camera. The recognition processor is configured to obtain from the presence sensing module information relating to the presence status of said air cargo unit, to trigger the at least one camera to acquire the images upon a change in the value of the presence status, and to process the images for recognizing the ULD number.

Owner:HI TECH SOLUTIONS

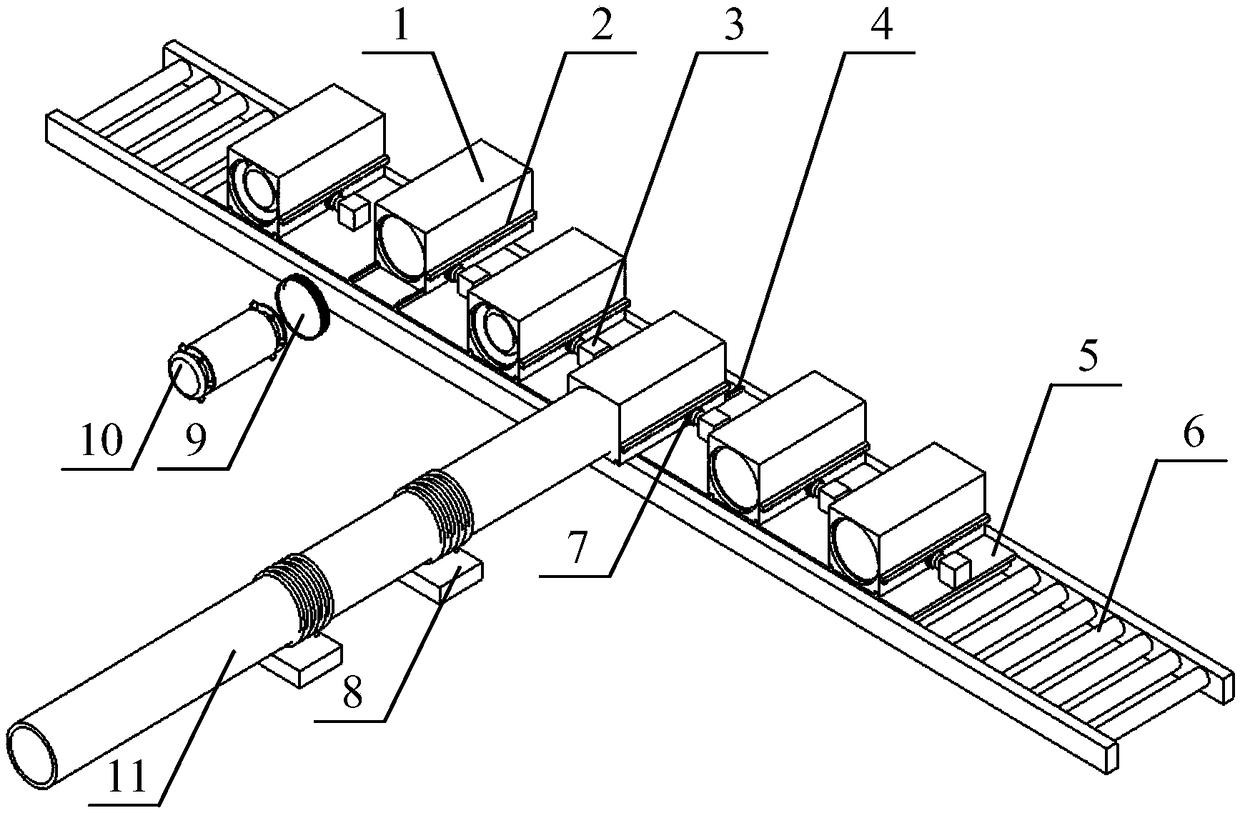

Rapid transfer system for unit load devices at logistics node station and method

ActiveCN109911786AAchieve transshipmentFlexible transportLoading/unloadingCranesUnit load deviceUnit load

The invention discloses a rapid transfer system for unit load devices at a logistics node station. The rapid transfer system comprises an elevated cargo platform, underlying platforms, a yard crane, docking loaders and lifting devices, the underlying platforms are arranged below the elevated cargo platform, a plurality of through holes are formed in the elevated cargo platform, and each through hole is used as a transfer channel; the docking loaders are arranged on the underlying platforms correspondingly; the yard crane is arranged on the elevated cargo platform; the lifting devices are installed on the yard crane or the docking loaders, and used for transferring the unit load devices on the docking loaders to the yard crane. According to the rapid transfer system for the unit load devices at the logistics node station, through cooperation of the yard crane, the docking loaders, the elevated cargo platform and the transfer channels, the unit load devices can be flexibly transferred between high-speed rails on the same underlying platform side and the different underlying platform sides, the unit load devices can be transferred through the elevated cargo platform and the underlyingplatforms simultaneously, plane and stereo transfer of the unit load devices is realized, and the transfer efficiency of the unit load devices is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

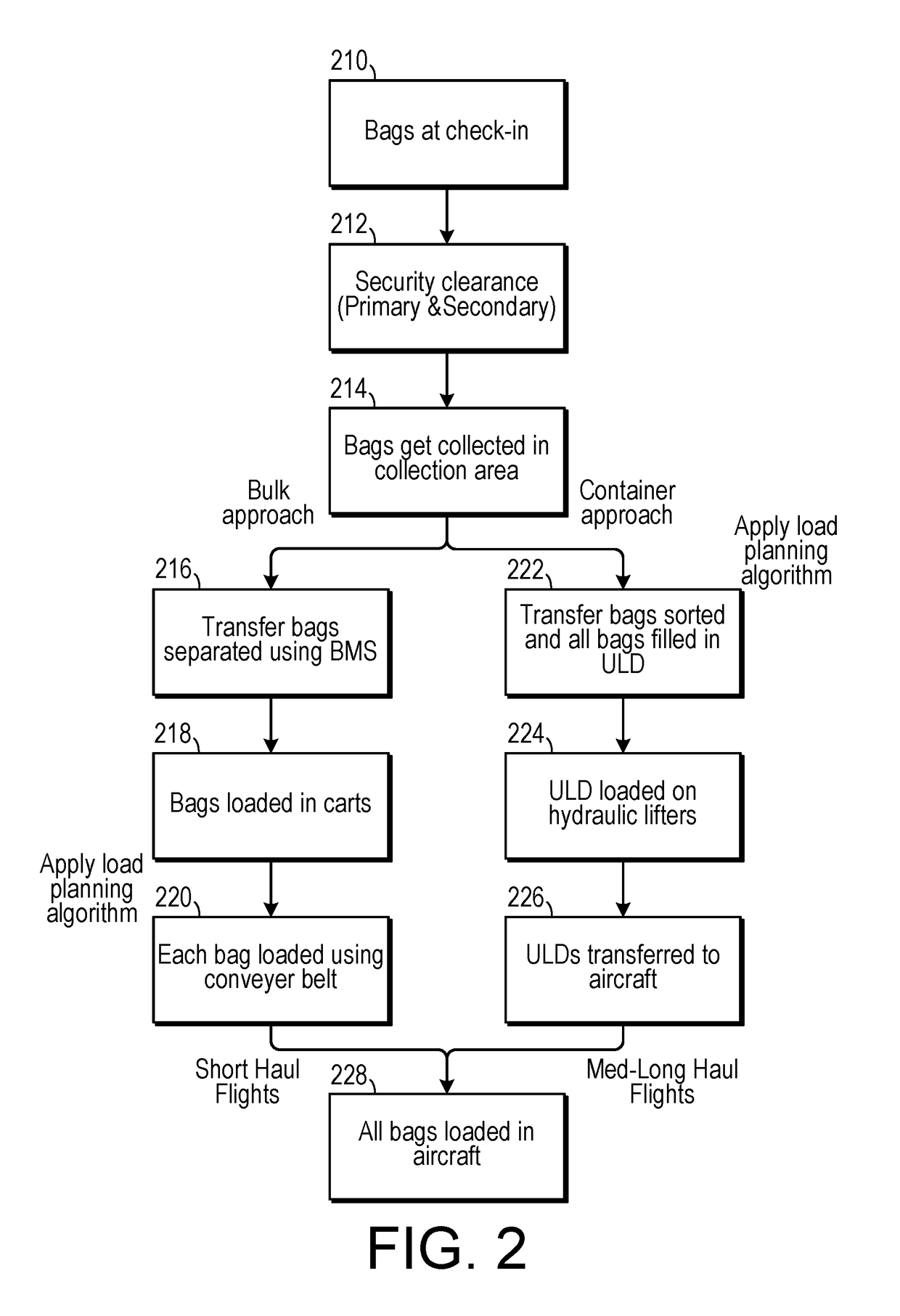

Method For Optimizing the Placement of Check-In Bags in Aircraft

InactiveUS20170349299A1Record carriers used with machinesGround installationsUnit load deviceUnit load

In a method of loading checked luggage on unit load devices corresponding to an aircraft having a passenger compartment, each piece of checked luggage is associated with a unique identifier. Each piece of checked luggage is weighed and its weight is associated with its corresponding unique identifier. A best possible luggage placement is calculated considering a distribution of passenger weight, thereby allowing the passengers to sit at their preferred location rather than by pre-allocation. A desired placement of the checked luggage is calculated based on the weight of each piece of checked luggage, the acceptable distribution of weight in the passenger compartment and overall fuel state over mission profile. Loading personnel are allowed to place luggage in the unit load devices and are instructed to stop loading the selected ones of the unit load devices when a deciding point is dynamically achieved by a recalculation of center of gravity shift each time a bag is loaded onto one of the unit load devices so as to achieve the best possible placement of check luggage. The recalculation of the center of gravity shift is done based on placement of the unit load devices in the aircraft luggage compartments.

Owner:GUPTA MOHIT +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com