A composite sandwich structure

A composite foam and surface layer technology, applied in the direction of upper structure, upper structure sub-assembly, synthetic resin layered products, etc., can solve the problems of no invention and use, low compressive strength, rigidity and easy plastic deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

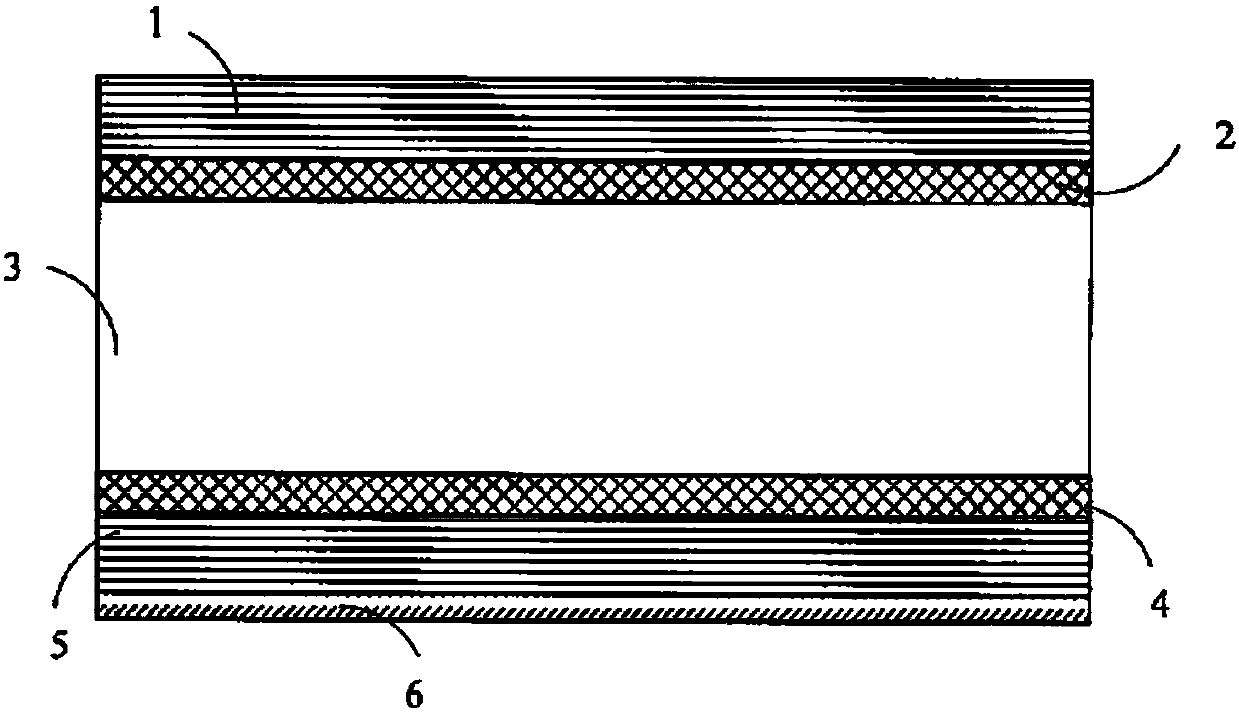

[0056] figure 1 A composite sandwich base panel is shown comprising an upper surface layer 1 and a lower surface layer 5 sandwiching a composite foam core 3 . On both sides of the core are barrier layers 2 and 4 . The entire panel is then surrounded by a number of outer edge pieces (not shown). There may be variations in the local material composition of the composite core 3 and / or there may be variations in the local geometry of the peripheral regions for the region where the edge parts are to be attached to the panels. A wear resistant layer 6 may be bonded to the lower surface layer 5 .

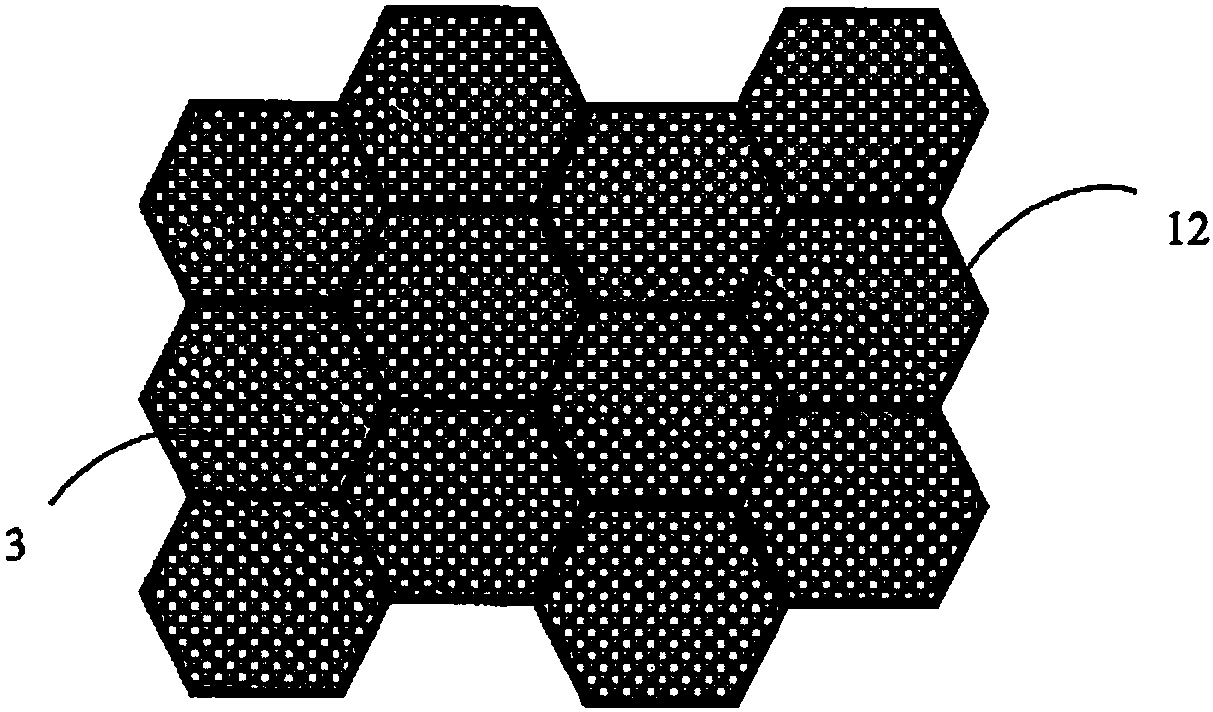

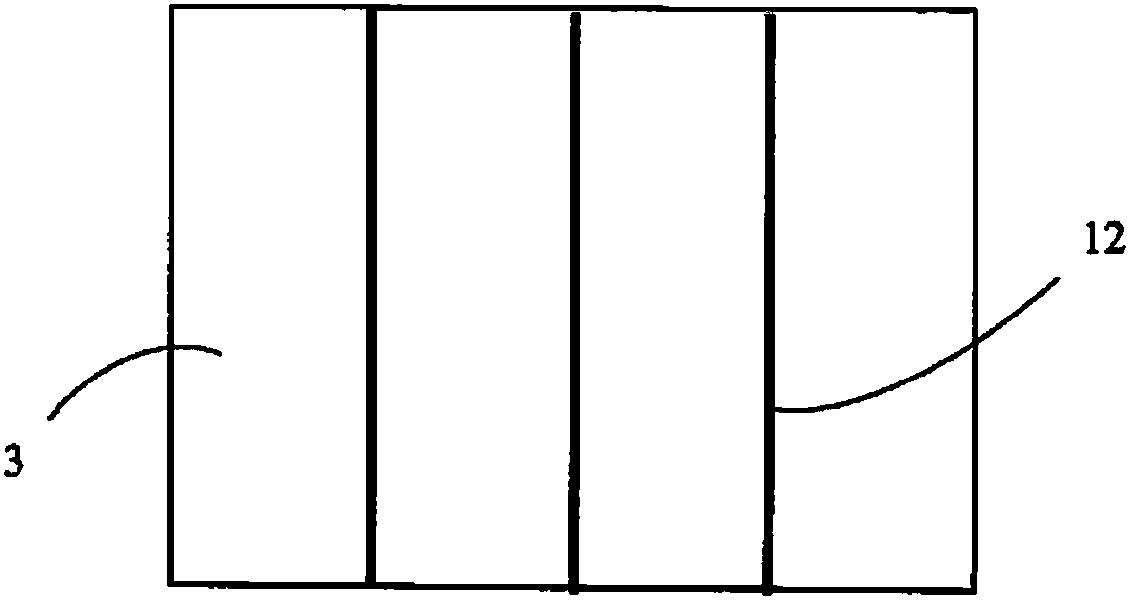

[0057] Depending on the manufacturing process used, some embodiments of the present invention include a porous structure incorporated into the syntactic foam 3 . FIG. 2A is a horizontal section of the hexagonal cellular structure 12 incorporated in the syntactic foam core 3 , and FIG. 2B is a vertical section of the hexagonal cellular structure 12 incorporated in the syntactic foam core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com