Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Compact and orderly structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

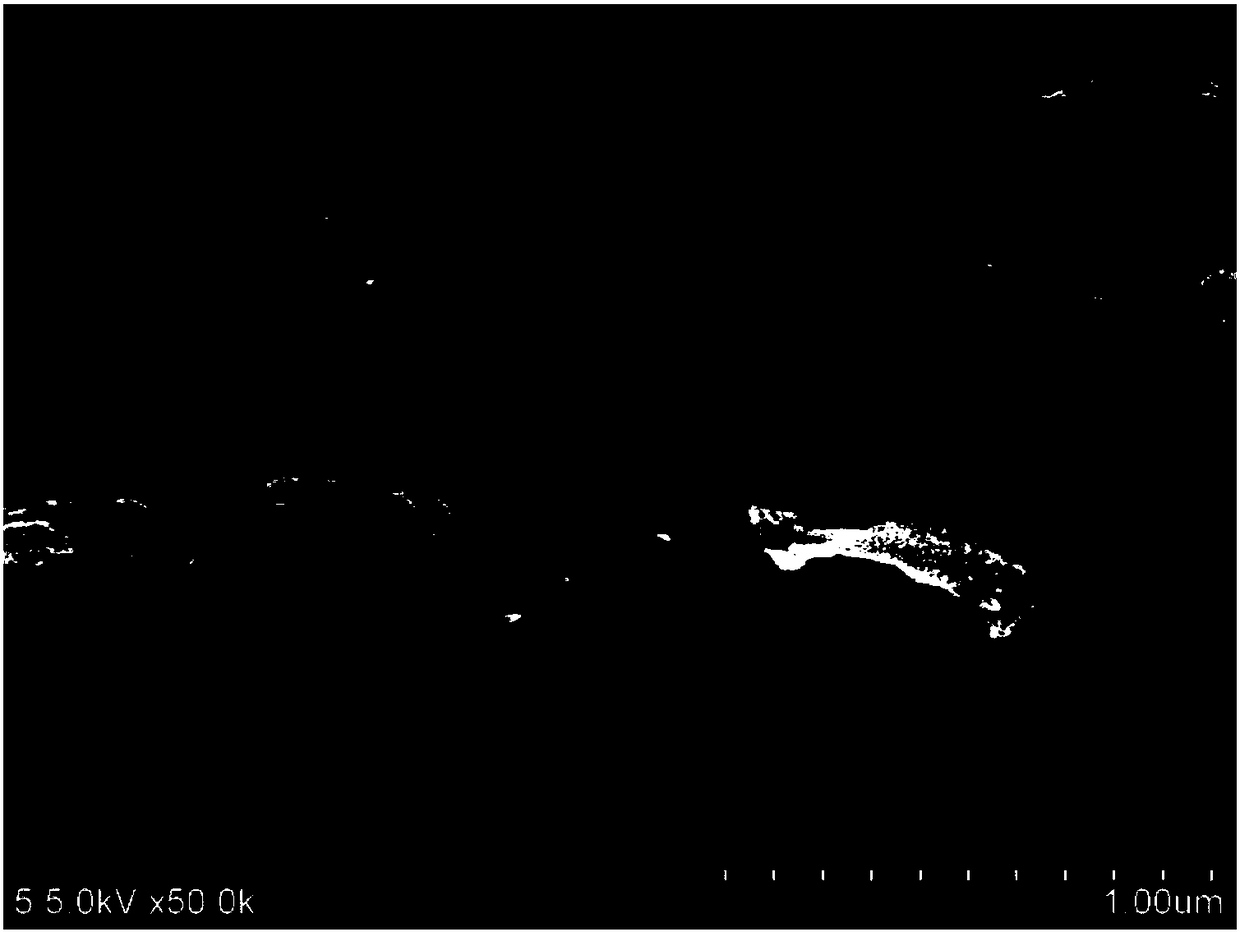

Flexible carbon fiber and preparation method thereof

ActiveCN106012110AImprove flexibilityImprove conductivityArtifical filament manufactureCarbon fibersCarbonization

The invention relates to a flexible carbon fiber and a preparation method thereof. The carbon fiber is prepared by carrying out spinning on a graphite flake / polyacrylonitrile complex solution and carrying out super-high drafting, pre-oxidation and carbonization treatment. The carbon fiber has highly oriented graphite flakes and graphite crystal structures generated through induction of the graphite flakes, wherein graphite crystallite is arranged and oriented along the surfaces of the graphite flakes. The carbon fiber has the characteristics of high order degree, compact structure, small average grain size and few defects. The rigidity / softness, resistivity, strength and axial thermal conductivity of the prepared flexible carbon fiber are respectively 10<-4>-10mN .cm, 10<-3>-100omega .cm, 1000-5000MPa and 0.5-50W / m .k. The prepared flexible carbon fiber has the beneficial effects that the flexible carbon fiber is low in production cost and wide in raw material sources; the structural properties of the carbon fiber can be substantially improved; and the flexible carbon fiber has very high market application values and can be widely applied to the fields of electrode materials, functional materials, energy materials, and the like.

Owner:DONGHUA UNIV

Method for preparing resistant starch by simultaneously adopting crosslinking and heat moisture treatment

InactiveCN102190737AGood product qualitySimplify the production processFood preparationFunctional foodChemistry

The invention discloses a method for preparing resistant starch by simultaneously adopting crosslinking and heat moisture treatment, which comprises the following steps of: regulating the pH value of 30 to 45 weight percent starch milk at the temperature of between 25 and 50DEG C to be 10.5-12.5, adding sodium trimetaphosphate / sodium tripolyphosphate in an amount which is 0.2 to 12 percent based on the weight of the dry basis of starch, keeping for 30 to 240 minutes, drying until the weight percent of water is 15-45 percent, and performing heat moisture reaction at the temperature of between 100 and 140DEG C for 1 to 72 hours in a heat moisture reactor; and washing, drying, crushing and sieving to obtain a product. In the method, starch is taken as a raw material, the content of resistant starch is greatly improved by a physiochemical means, a process of preparing the resistant starch is simplified, the efficiency is effectively improved, waste liquor and pollution are avoided in the production process, and the energy consumption is reduced. The prepared resistant starch can serve as a functional food material and biochemical medicine carrier.

Owner:SOUTH CHINA UNIV OF TECH

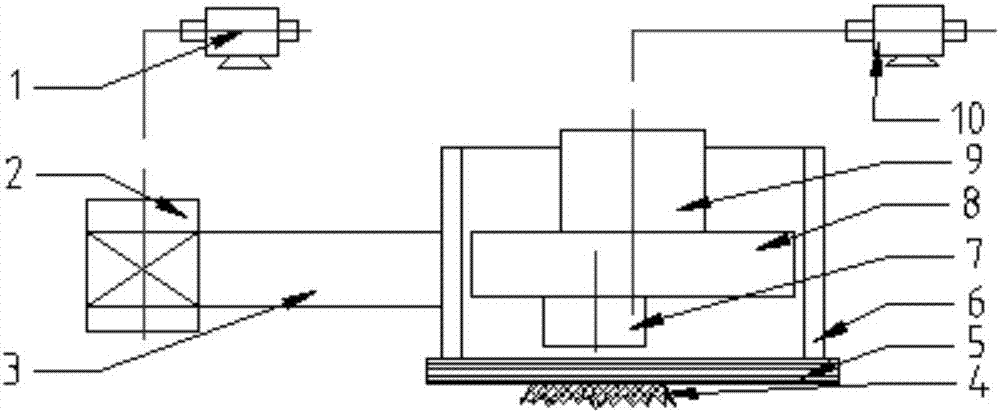

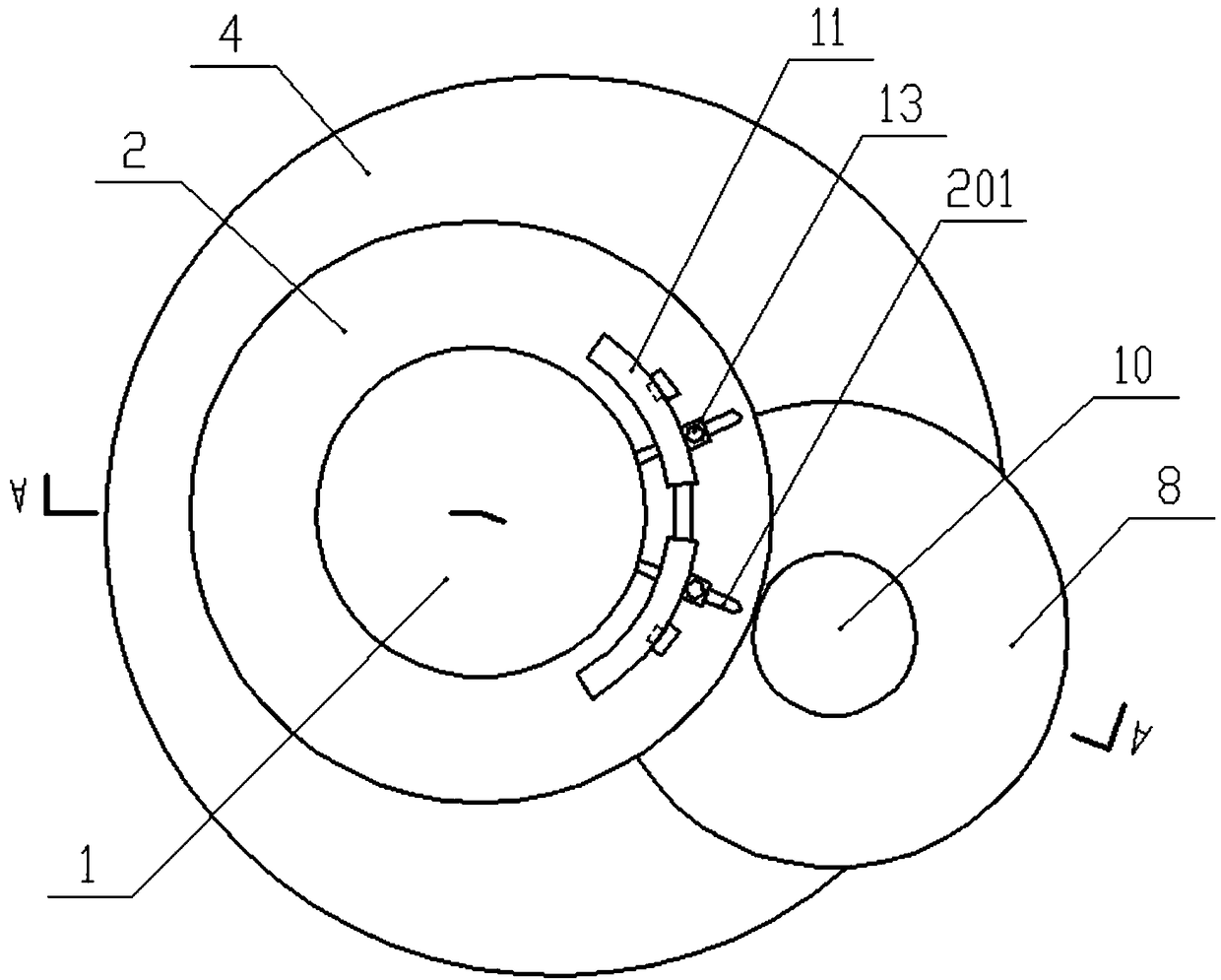

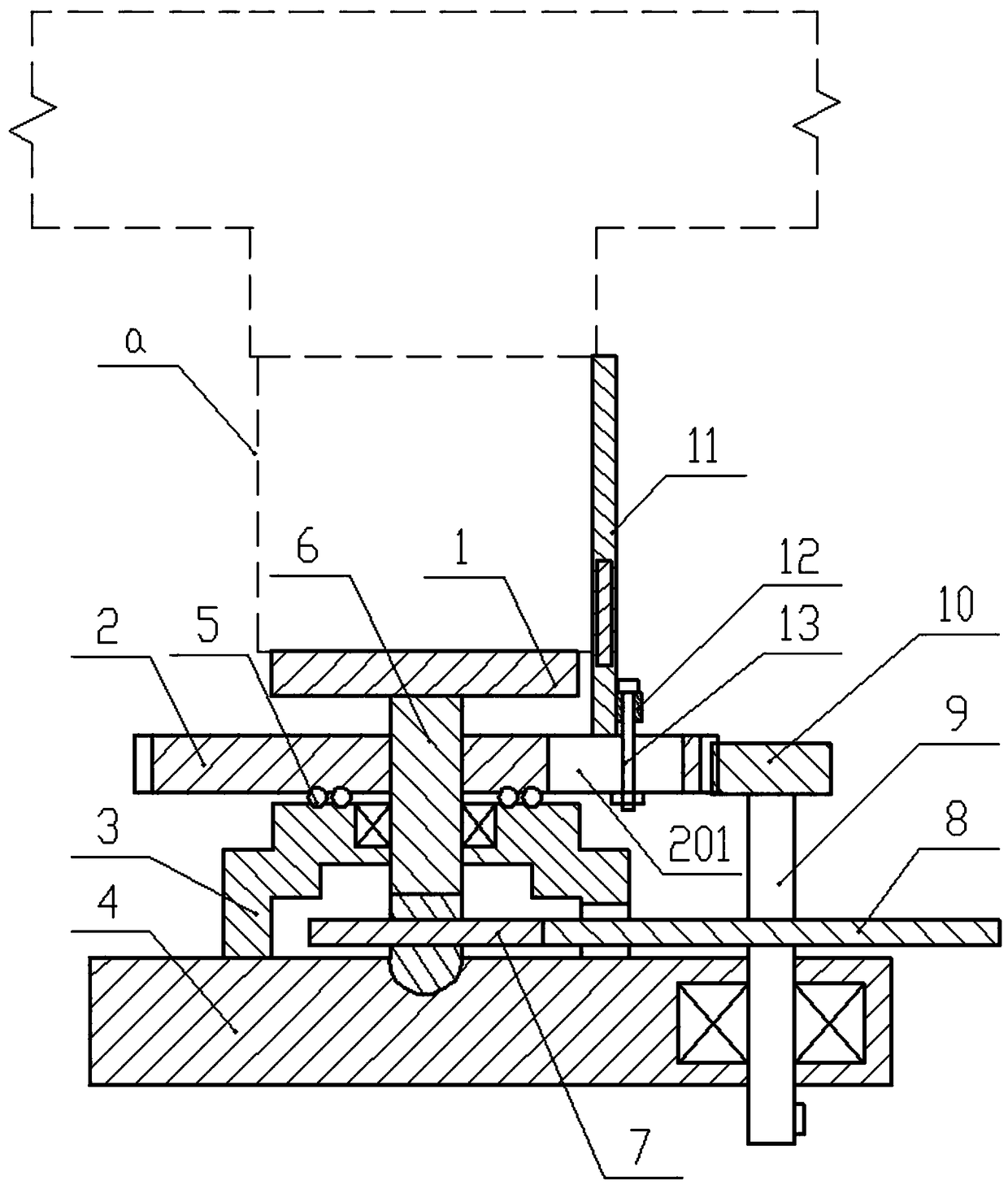

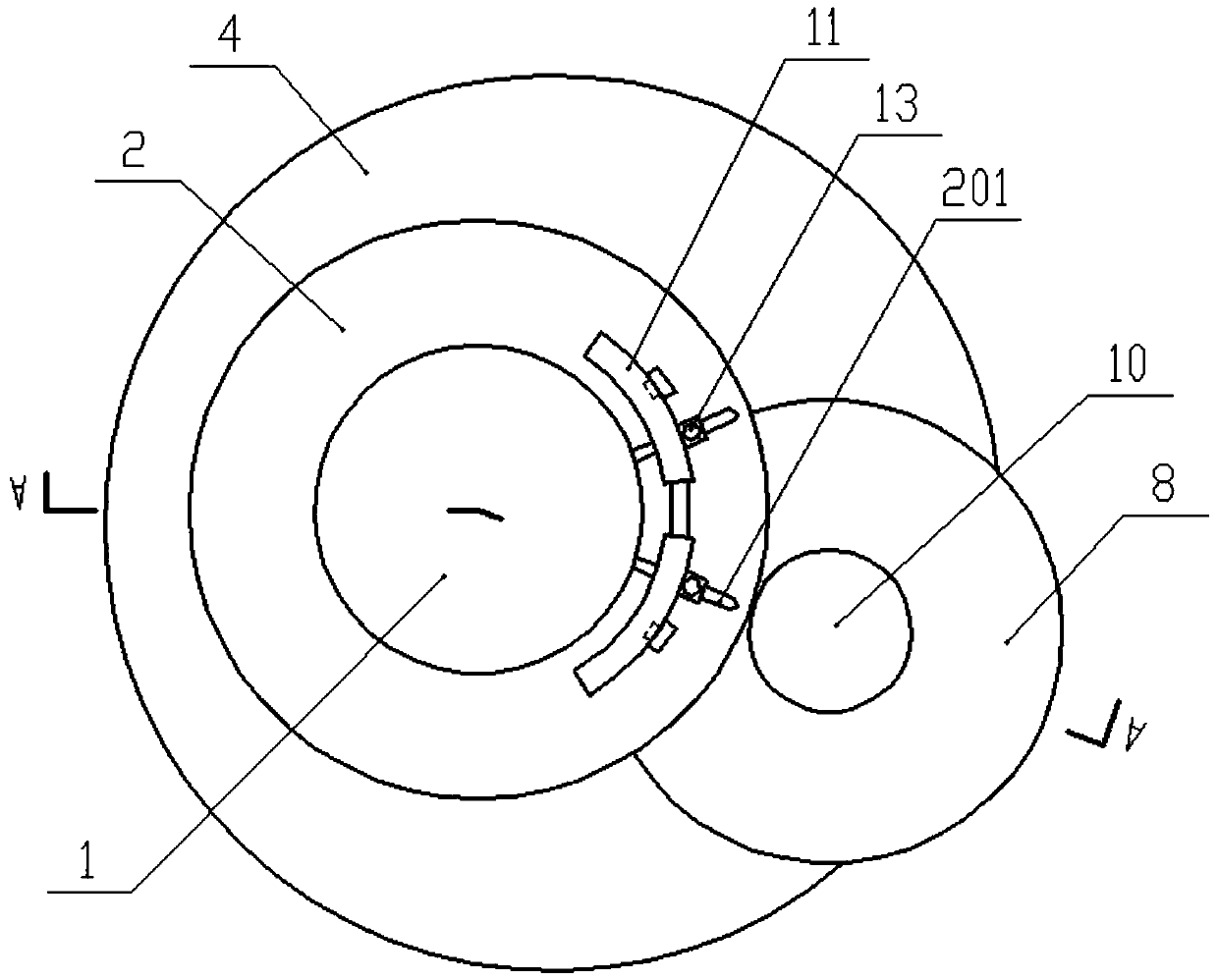

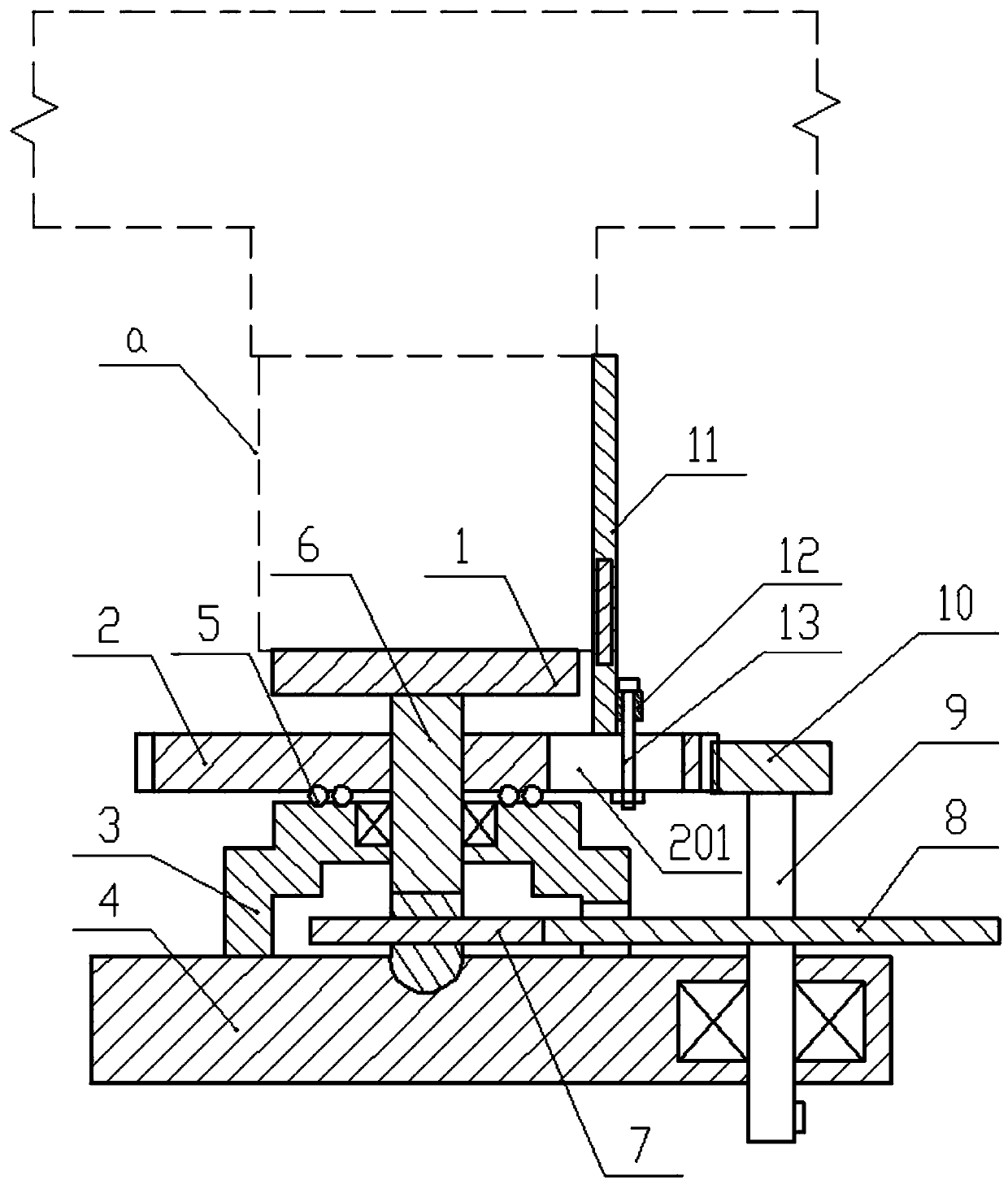

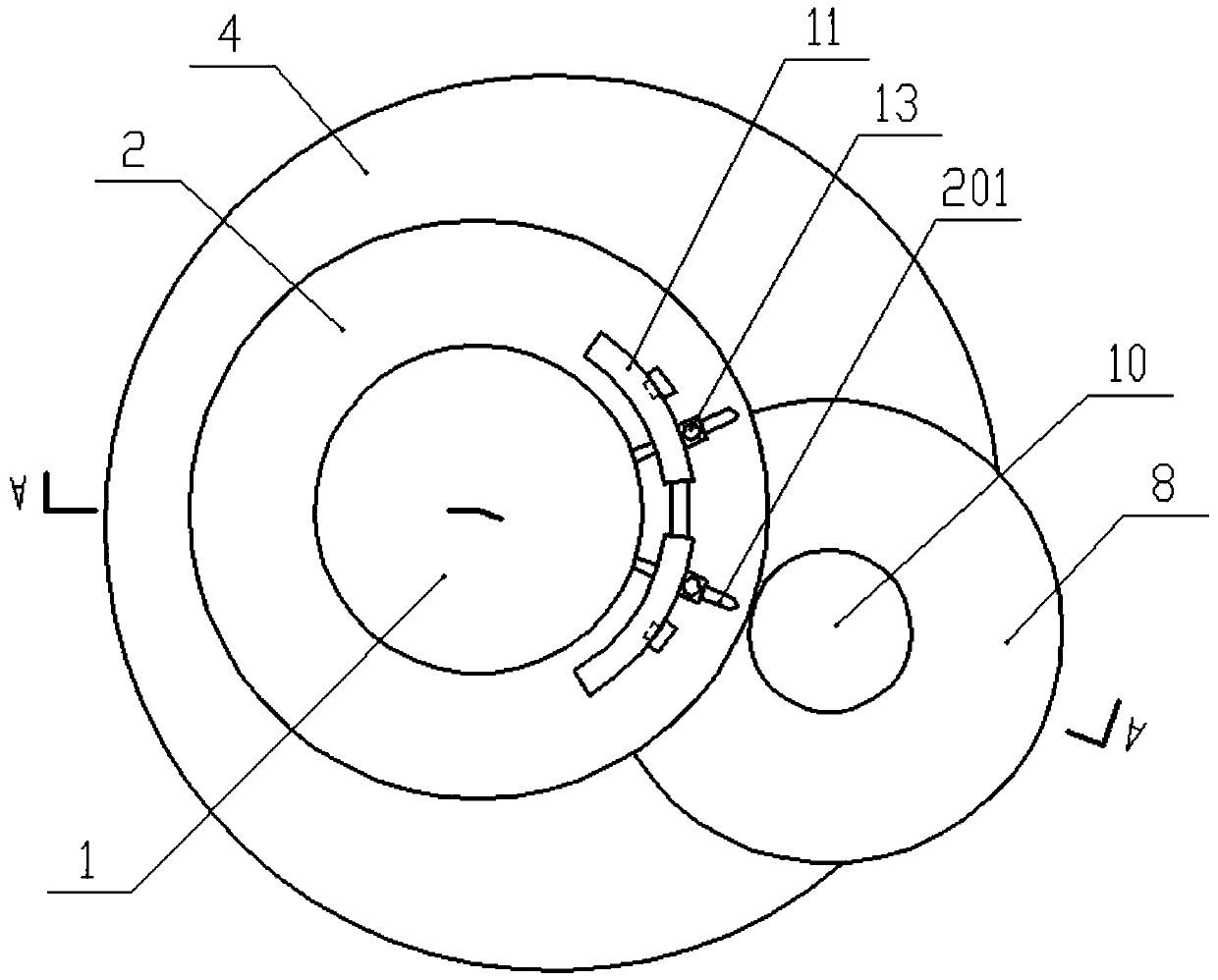

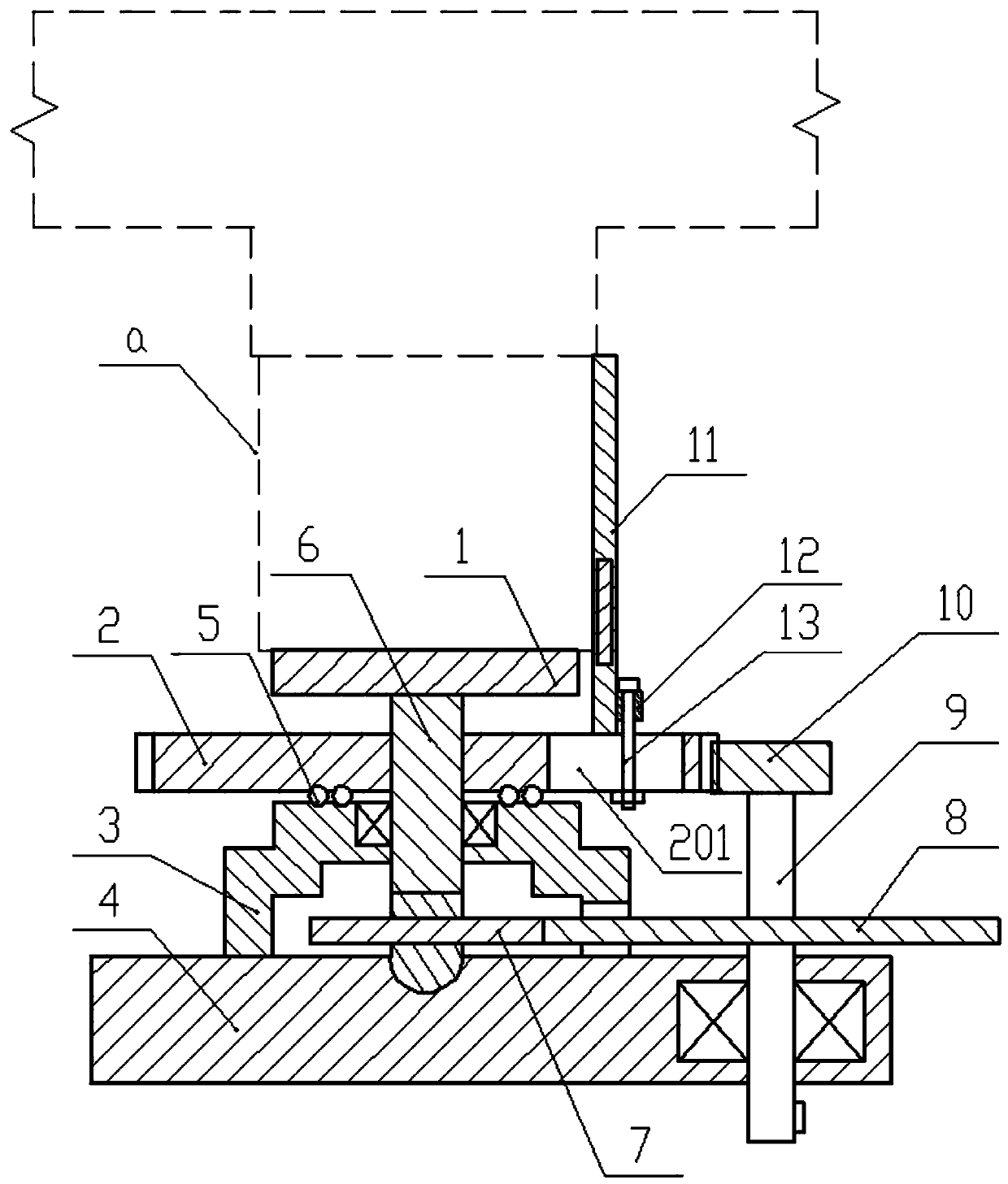

Adjustable polishing head mechanism for magnetic compound fluid

The invention relates to an adjustable polishing head mechanism for magnetic compound fluid. The adjustable polishing head mechanism comprises a magnet rotating mechanism and a liquid carrying plate rotating mechanism. A permanent magnet in the magnet rotating mechanism is eccentrically fixed to the lower portion of a magnet disc. The magnet disc is connected with a first motor through a main shaft. The first motor drives the main shaft to drive the permanent magnet to rotate, and a high-speed rotating magnetic field is produced. A connecting bracket in the liquid carrying plate rotating mechanism is a round sleeve and is installed on the outer side of the magnet rotating mechanism. A liquid carrying plate serves as an end cover of the connecting bracket and is installed below the permanent magnet. A V-shaped belt is connected to a V-shaped belt wheel and the connecting bracket in a sleeving mode. A second motor is connected with the V-shaped belt wheel through a coupler and drives the connecting bracket and the liquid carrying plate on the connecting bracket to rotate through the V-shaped belt wheel, so that the magnetic compound fluid on the liquid carrying plate rotates, and thus polishing removing of a workpiece is achieved. The adjustable polishing head mechanism for the magnetic compound fluid has the characteristics of being simple in structure, high in material removing efficiency, wide in applicable magnetic cluster size range and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

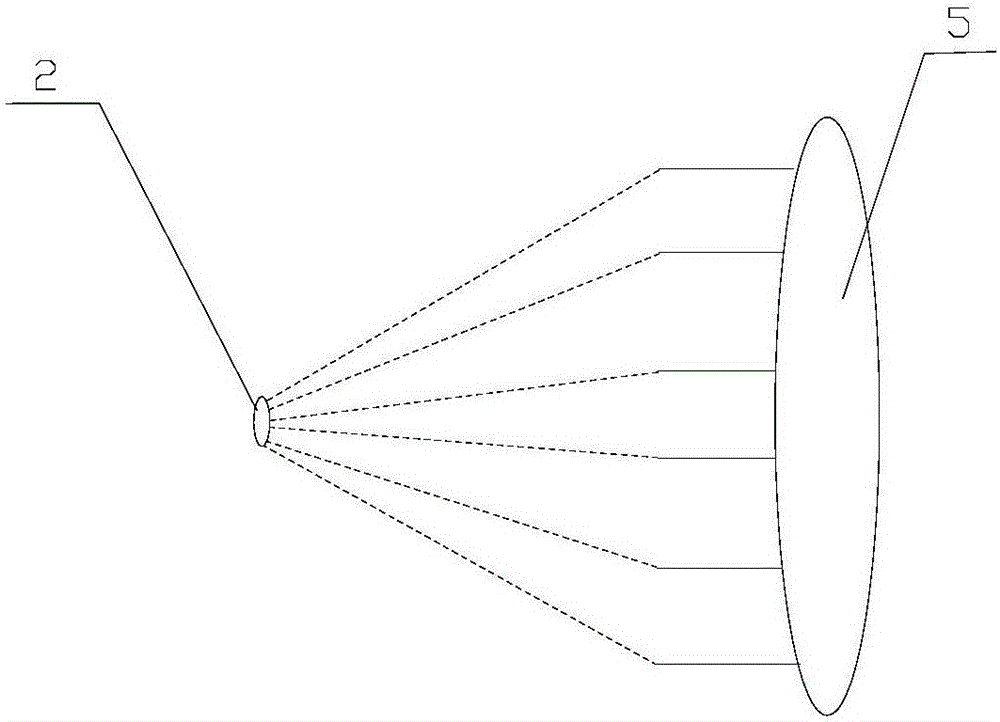

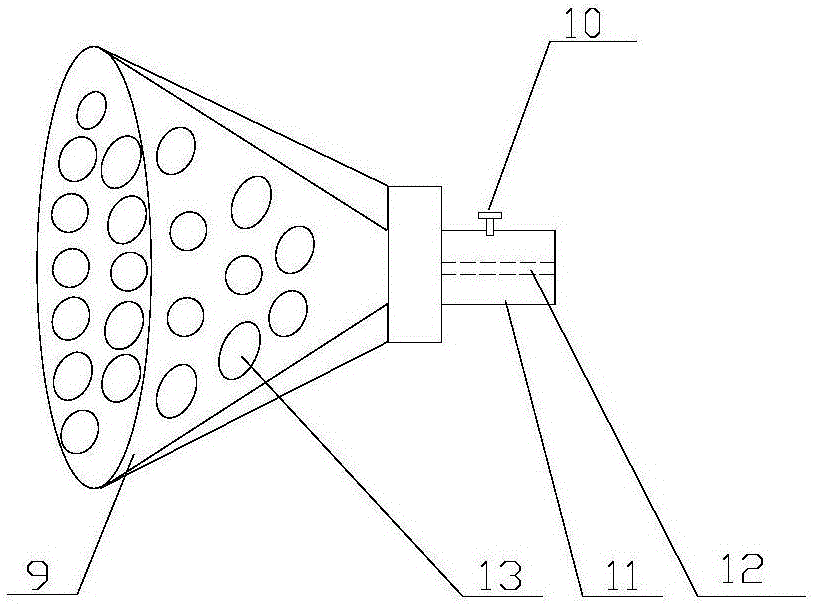

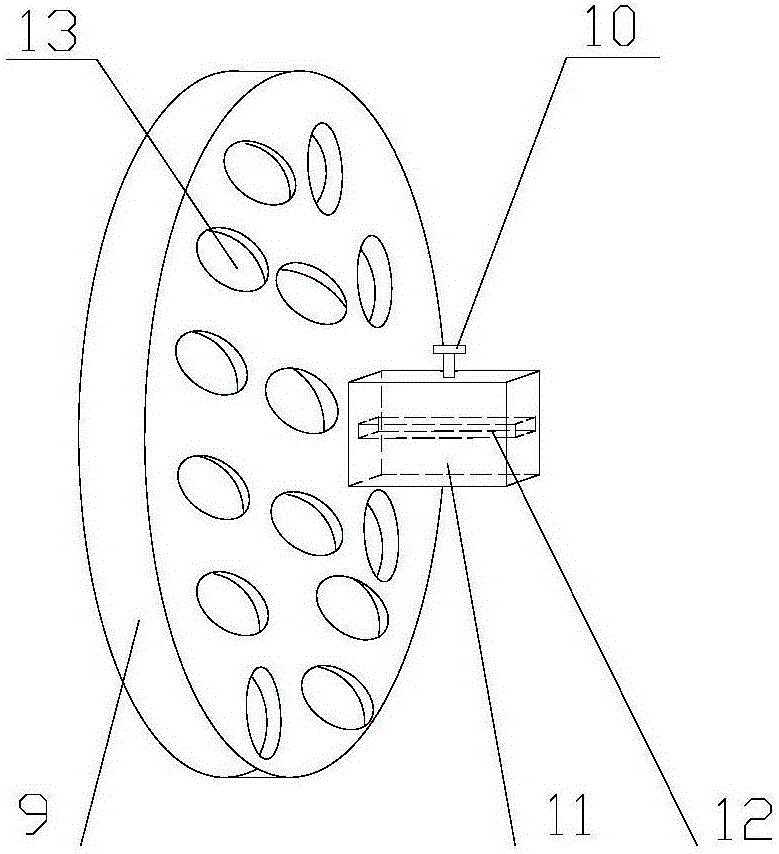

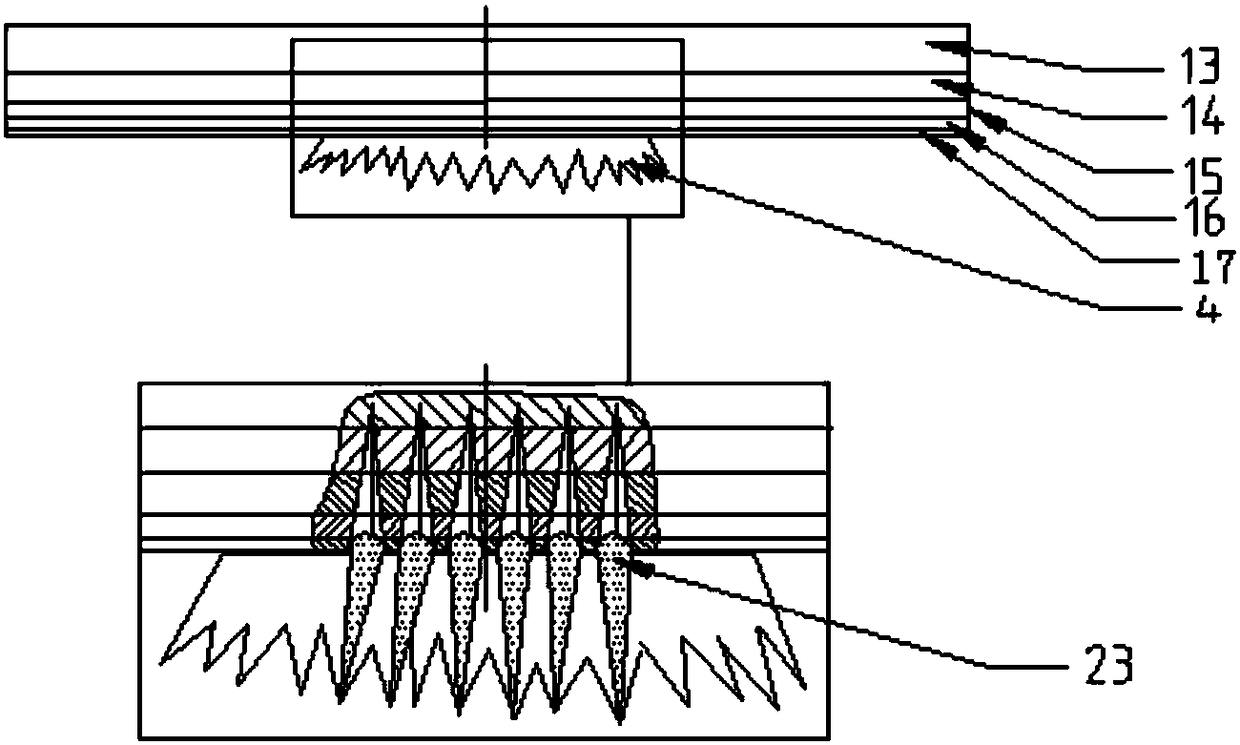

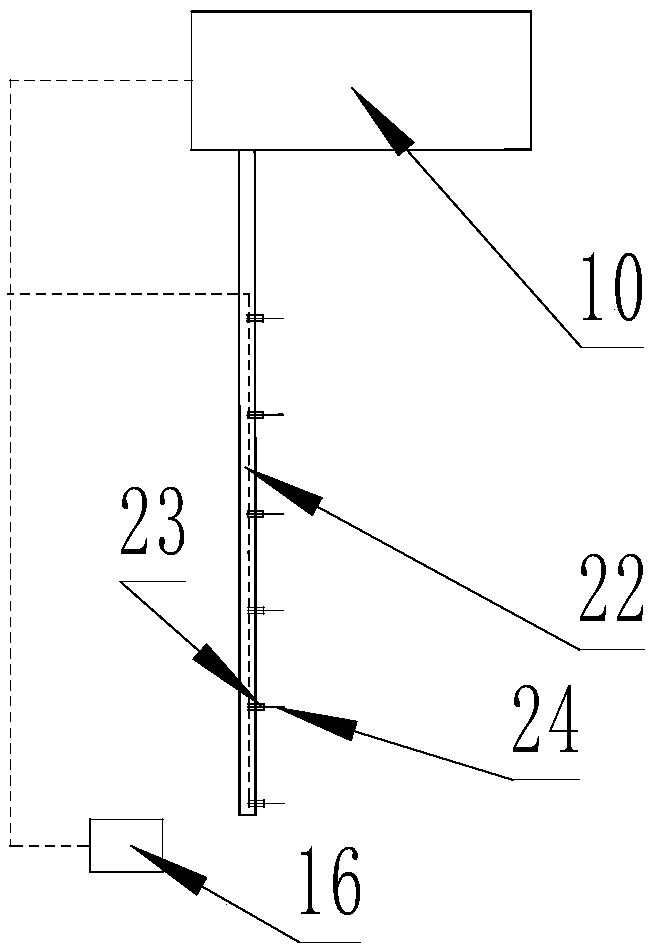

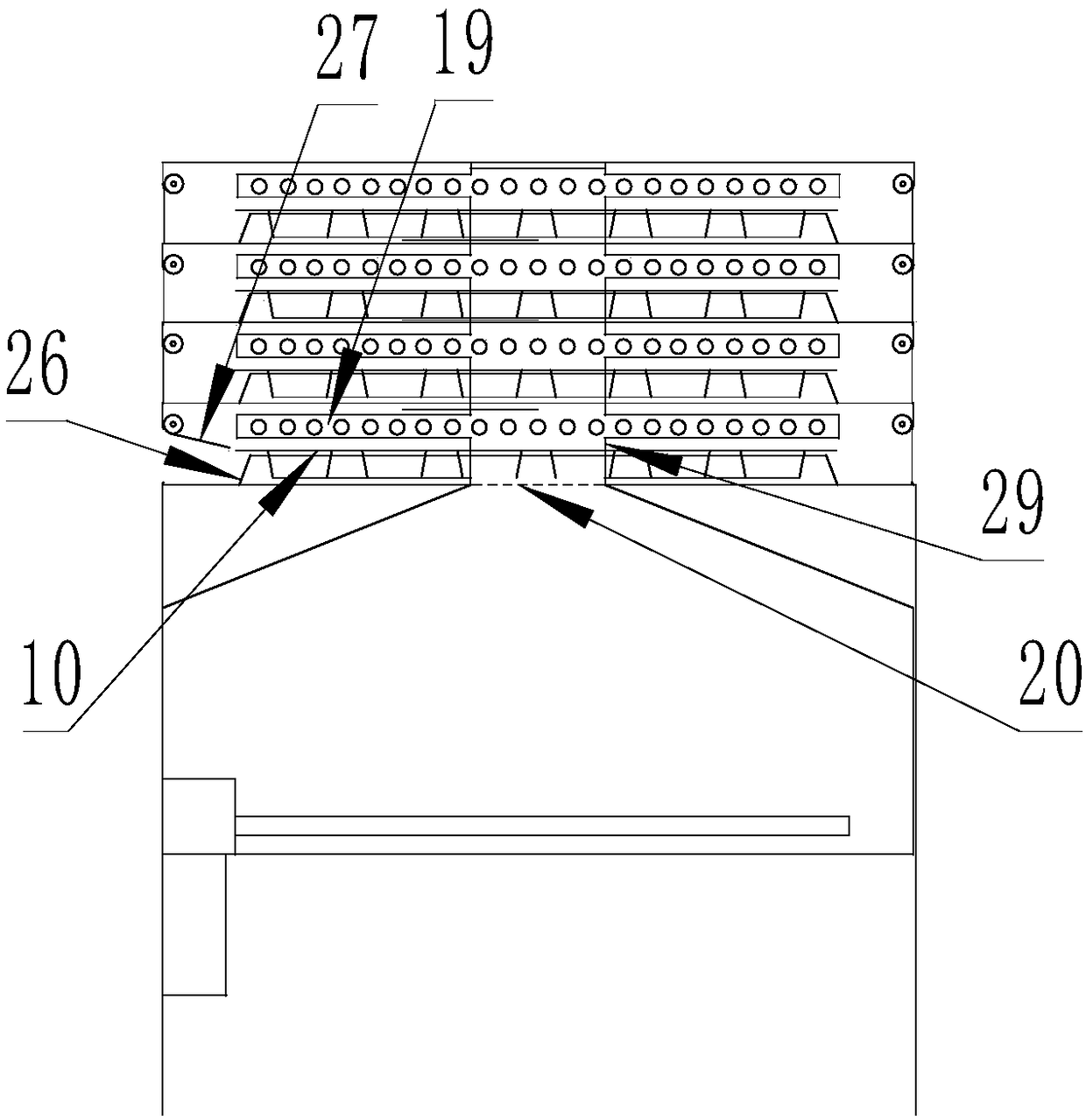

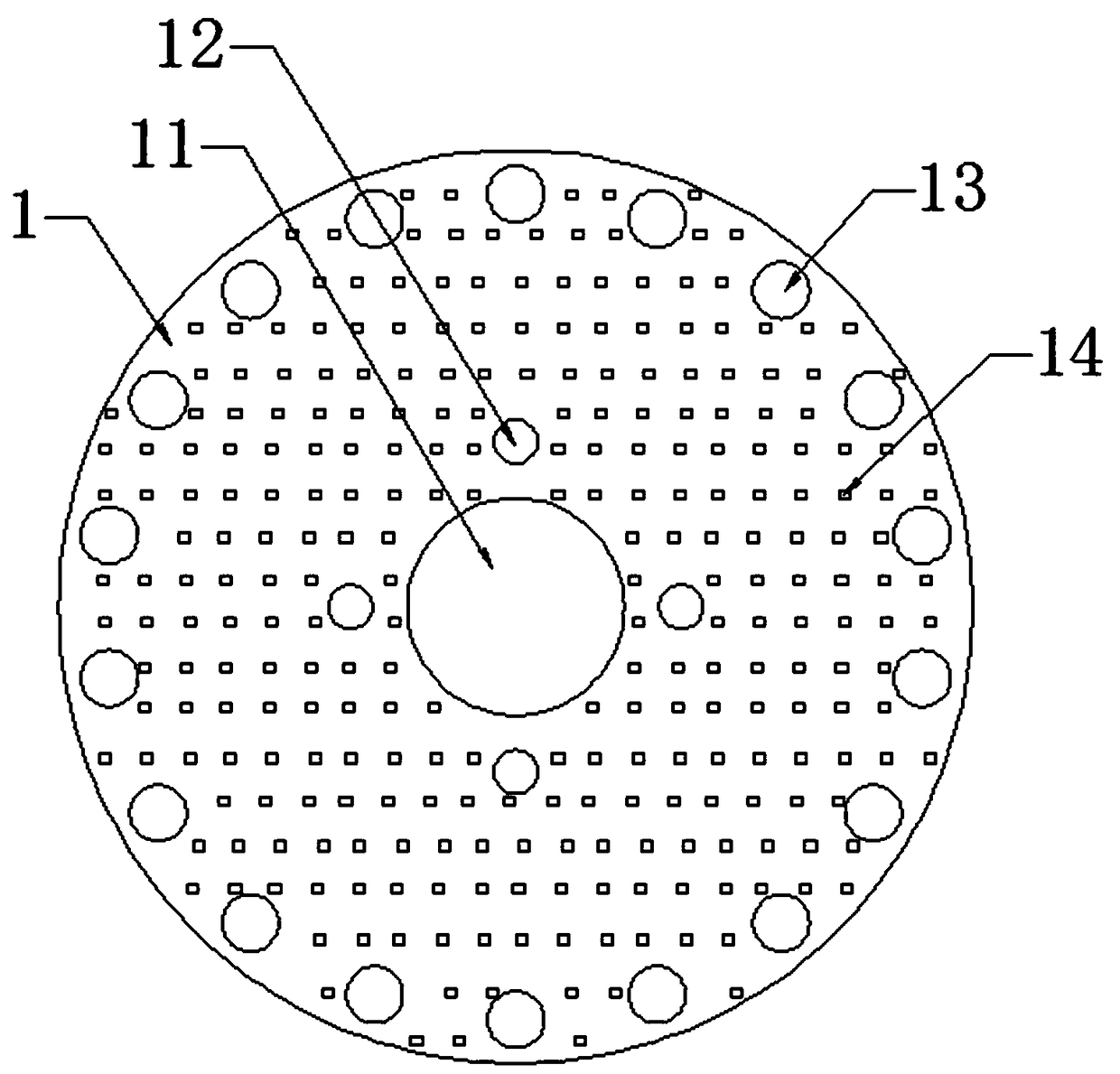

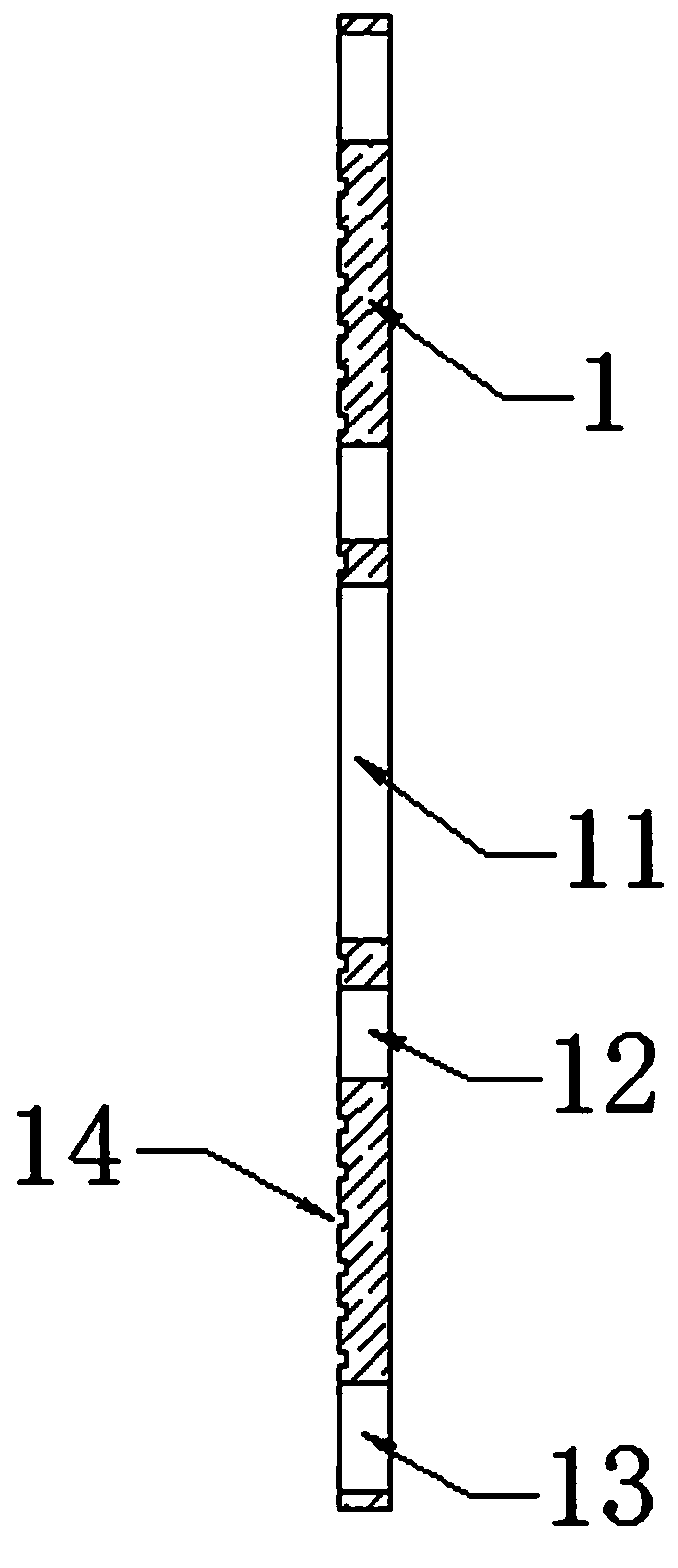

Dot-matrix type receiver for electrostatic spinning and method for preparing nanofibers

The invention relates to an electrostatic spinning receiver and belongs to the field of electrostatic spinning. A dot-matrix type receiver for electrostatic spinning comprises a plurality of receiving pins which are perpendicular to an insulating base plate and are made of metal, the bottoms of all the receiving pins are connected through wires to achieve equal potential of each receiving pin, and the non-fixed ends of the receiving pins are opposite to a yarn outlet device, so that an electrostatic field between the yarn outlet device and the dot-matrix type receiver is split into a plurality of unit electrostatic fields at one end close to the dot-matrix type receiver. Nanofibers formed by electrostatic spinning are deposited respectively on each receiving pin of the dot-matrix type receiver through each unit electrostatic field and then are twisted to form a nanofiber aggregate. The nanofibers of a cross section of the formed nanofiber aggregate are divided into multiple strands of nanofibers, so that the nanofiber aggregate is more ordered, each strand of internal nanofibers are closely combined with each other, each strand of nanofibers are mutually twisted and closely combined, and the formed nanofiber aggregate is denser and more ordered in structure and more stable in performance.

Owner:SHANGHAI UNIV OF ENG SCI

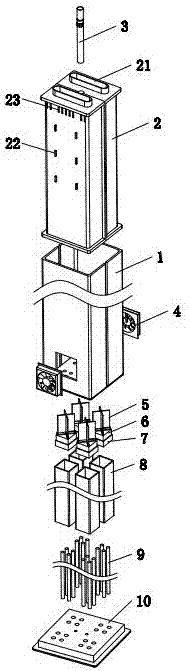

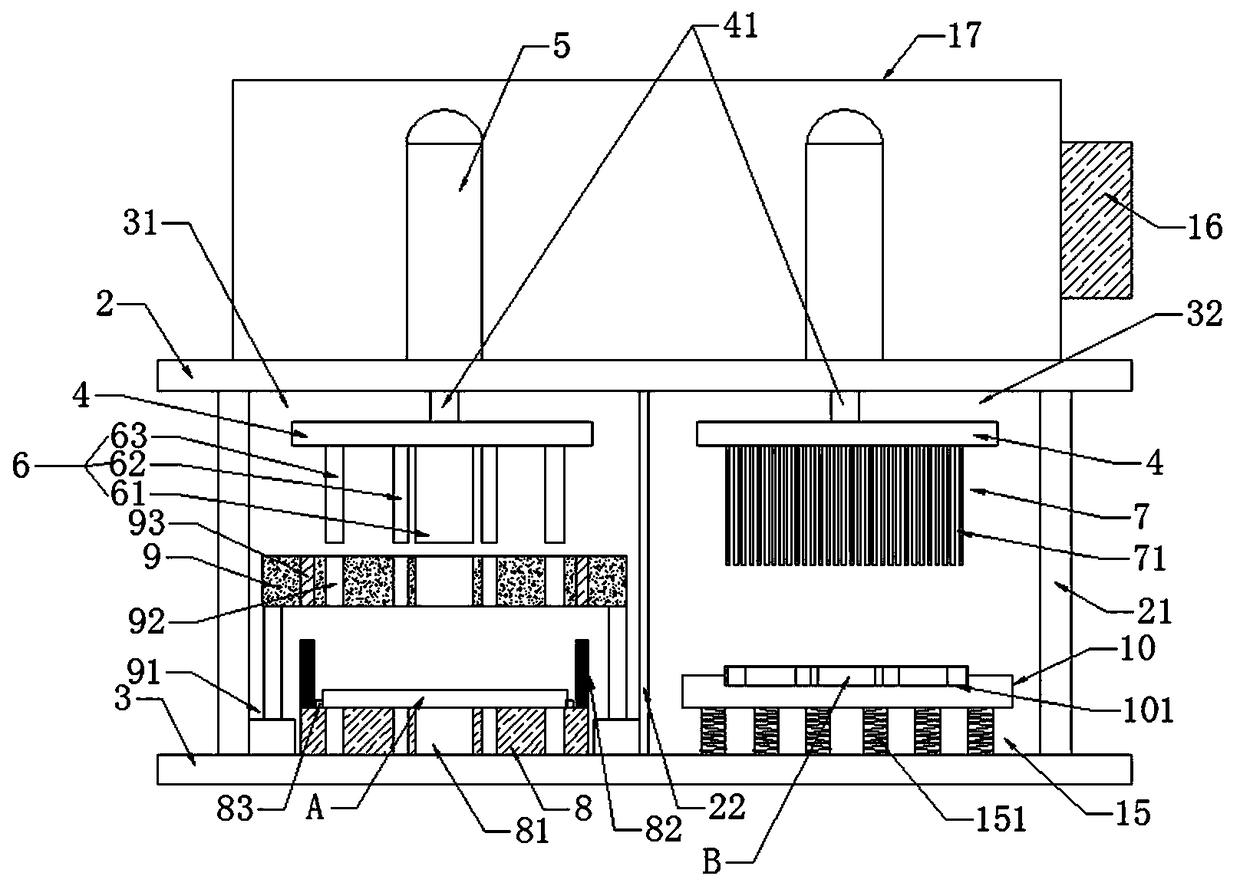

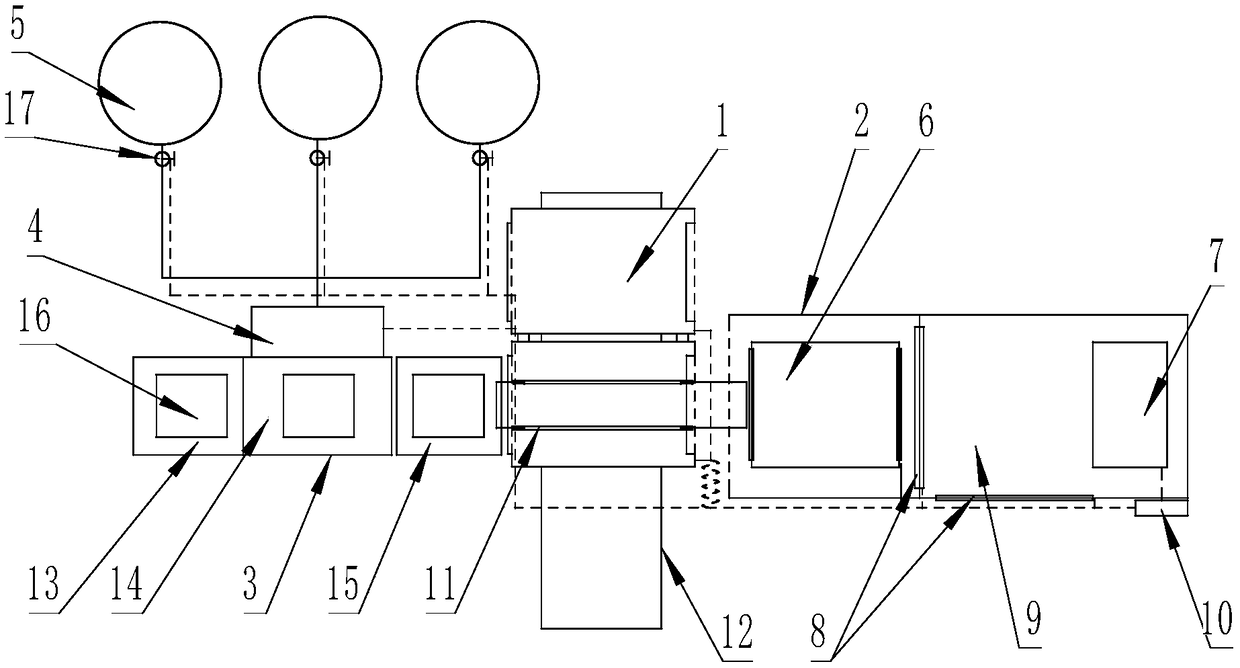

Fuel cell

ActiveCN106887617AReasonable heat exchangeImprove thermal efficiencyFuel cell heat exchangeSolid electrolyte fuel cellsCold airElectricity

The invention relates to a fuel cell which is characterized by comprising a thermal-insulation inner shell, an outer shell, pile cavity covers, ceramic tube sets, a fan, a combustion nozzle and waste gas filtering structures; the thermal-insulation inner shell is covered by the outer shell, the outer shell and the thermal-insulation inner shell are in clearance fit to form a cold air flow channel, the pile cavity covers are arranged in the thermal-insulation inner shell and in clearance fit with the thermal-insulation inner shell, every two adjacent pile cavity covers are in clearance fit to form a hot air flow channel, venting holes are formed in the thermal-insulation inner shell, each ceramic tube set is arranged in the corresponding pile cavity cover, the fan is arranged on the outer shell, the combustion nozzle is arranged on the thermal-insulation inner shell, a flame outlet of the combustion nozzle is arranged in the hot air channel, a gas inlet of the combustion nozzle is communicated with external fuel gas, and each waste gas filtering structure is arranged at a gas outlet of the corresponding ceramic tube set and is arranged at the upper portion of the pile cavity cover. The fuel cell has the advantages that the fuel cell is all prepared from solid materials, thermal efficiency of the fuel cell is high, the insides of pile covers are separated from a heating chamber, carbon deposition in the pile covers is effectively avoided, the structure is compact and ordered, and varieties of gas is prevented from being mixed in a cross mode.

Owner:FOSHAN SUOFUKE HYDROGEN ENERGY CO LTD

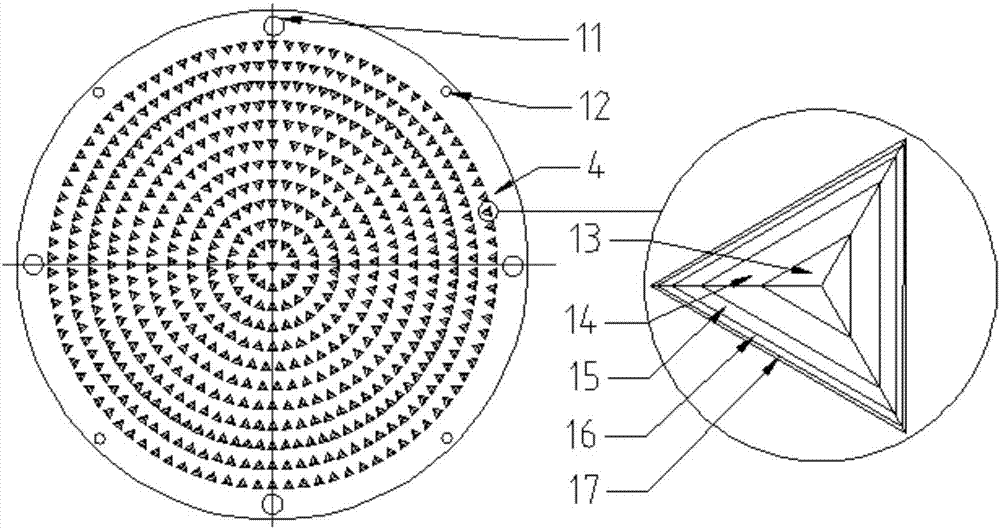

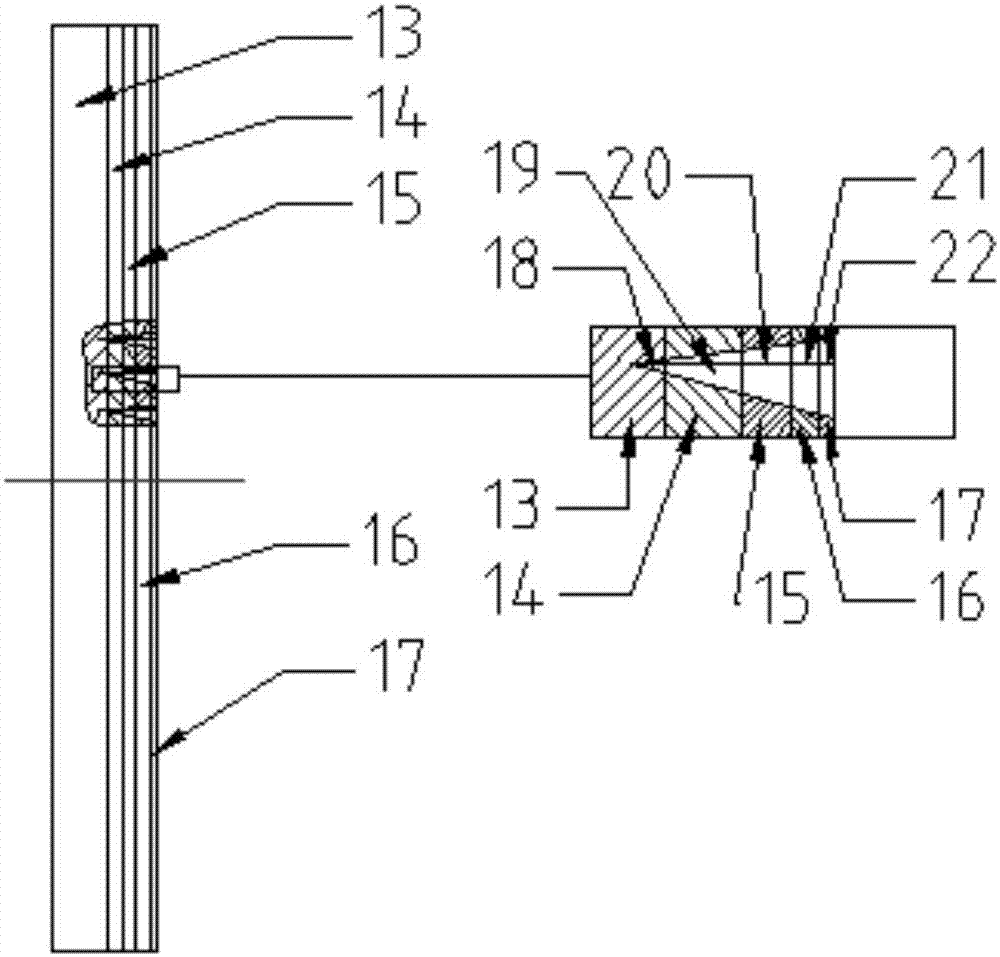

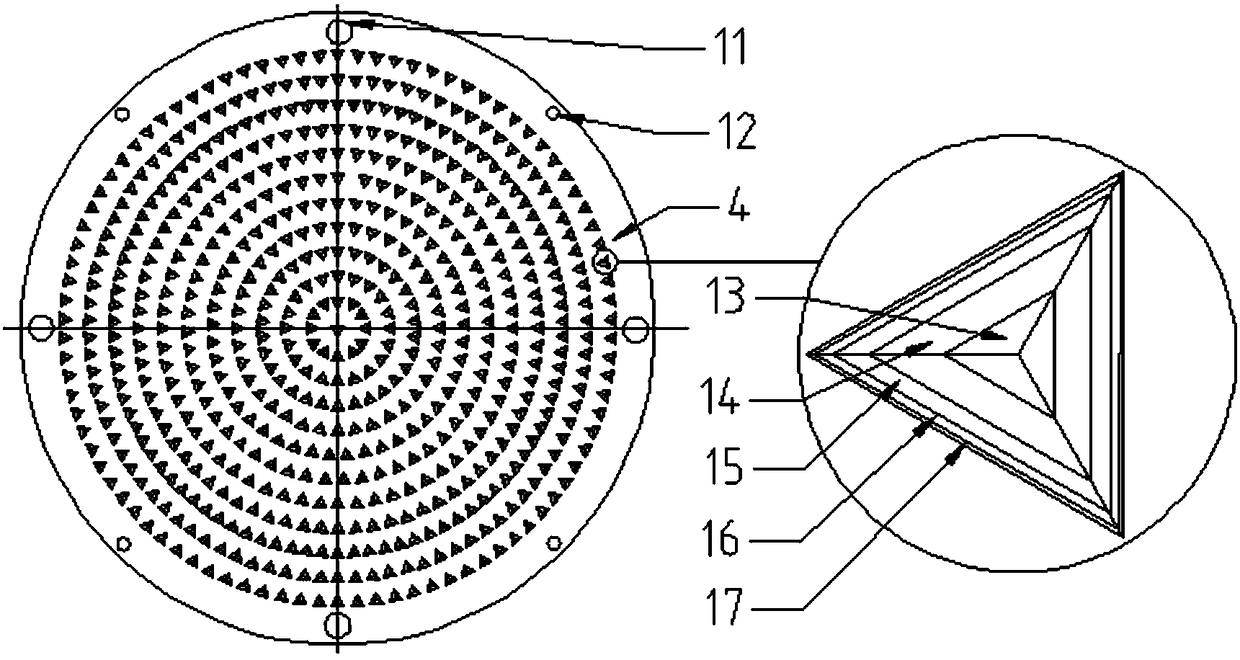

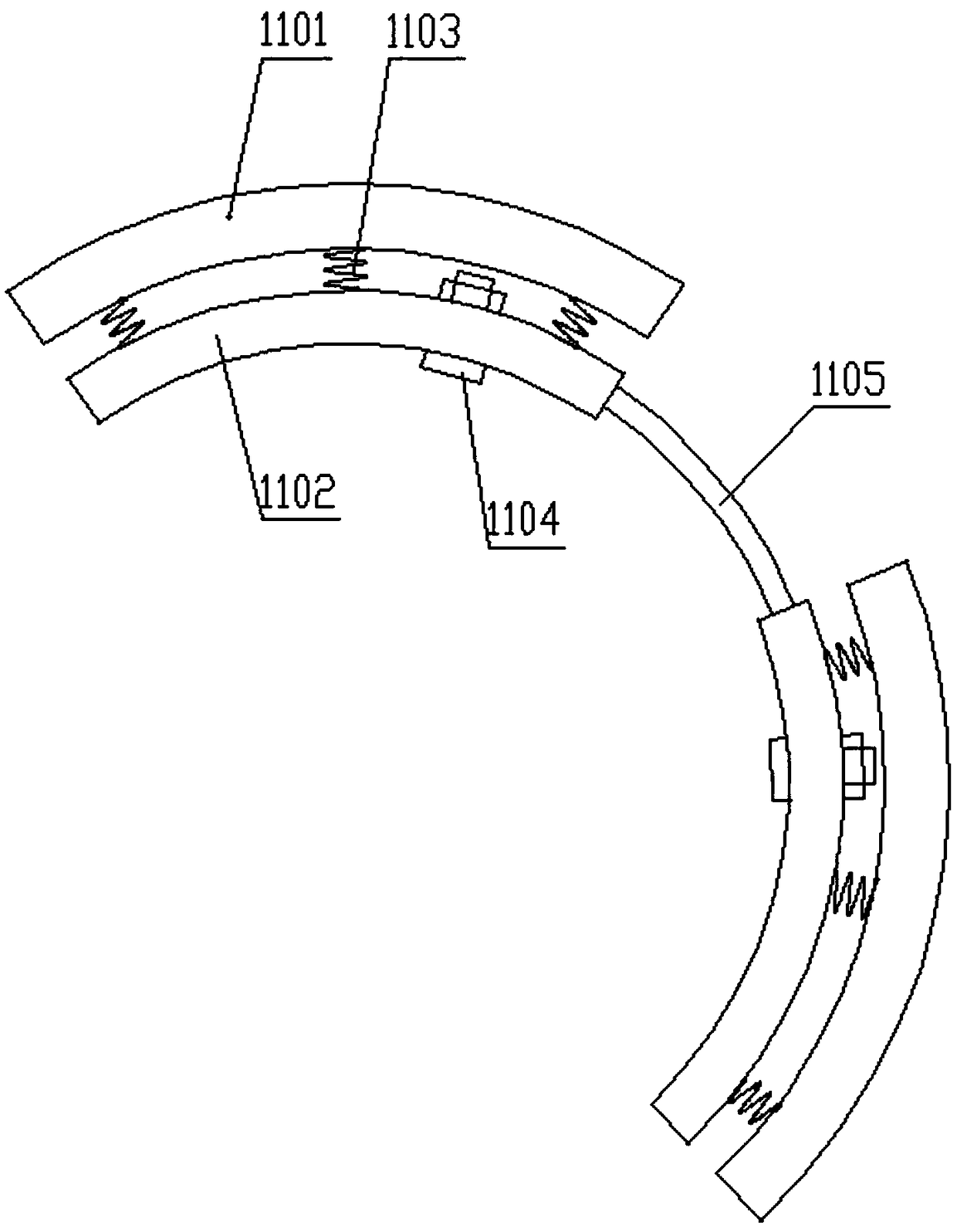

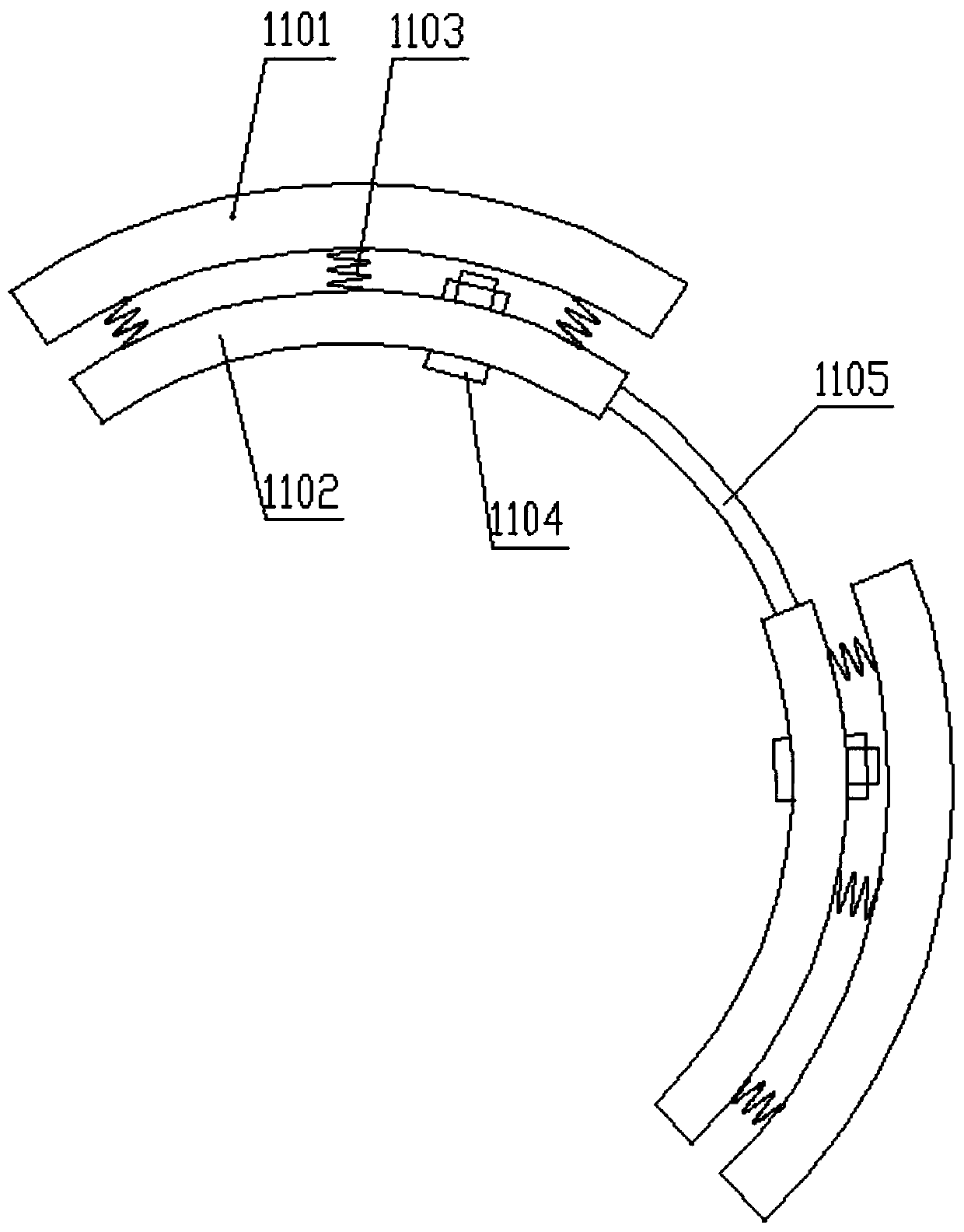

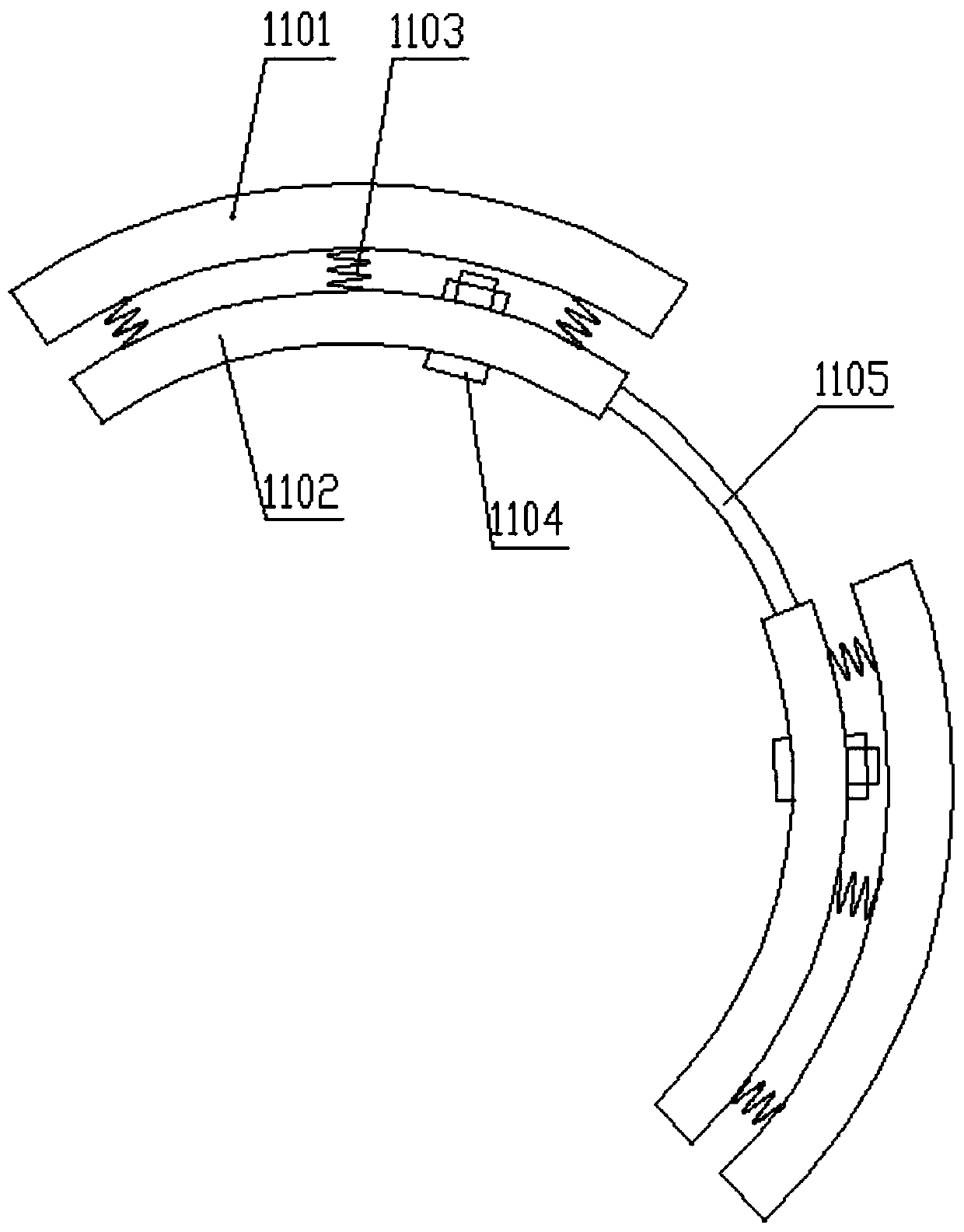

Vortex type receiver for electrostatic spinning, and method for preparing nano-fibers

ActiveCN106435773ADisorderly arrangementCompact and orderly structureFilament/thread formingFiberElectrospinning

The invention relates to an electrostatic spinning receiver and belongs to the field of electrostatic spinning. According to a vortex type receiver for electrostatic spinning, an airflow hole is formed in a collecting face of the vortex type receiver and is used for balancing the air pressure of the two sides of the collecting face; the vortex type receiver can continuously form a rotary vortex type acting on the nano-fibers in the rotary receiving process, so that the nano-fibers rotate according to a certain direction and under the action of the rotary vortex type. The nano-fibers rotate according to a certain direction and under the action of the rotary airflow, so that dispersion and disordering of the nano-fibers caused by electrostatic repulsion between the nano-fibers are avoided. The rotary nano-fibers are ordered so as to orderly deposit on the vortex type receiver and are twisted to form a nano-fiber aggregation. The nano-fibers of the cross section of the nano-fiber aggregation are arranged orderly and the winding direction is consistent, so that the nano-fiber aggregation is more orderly, and the formed nano-fiber aggregation has a more compact and orderly structure and more stable performance.

Owner:SHANGHAI UNIV OF ENG SCI

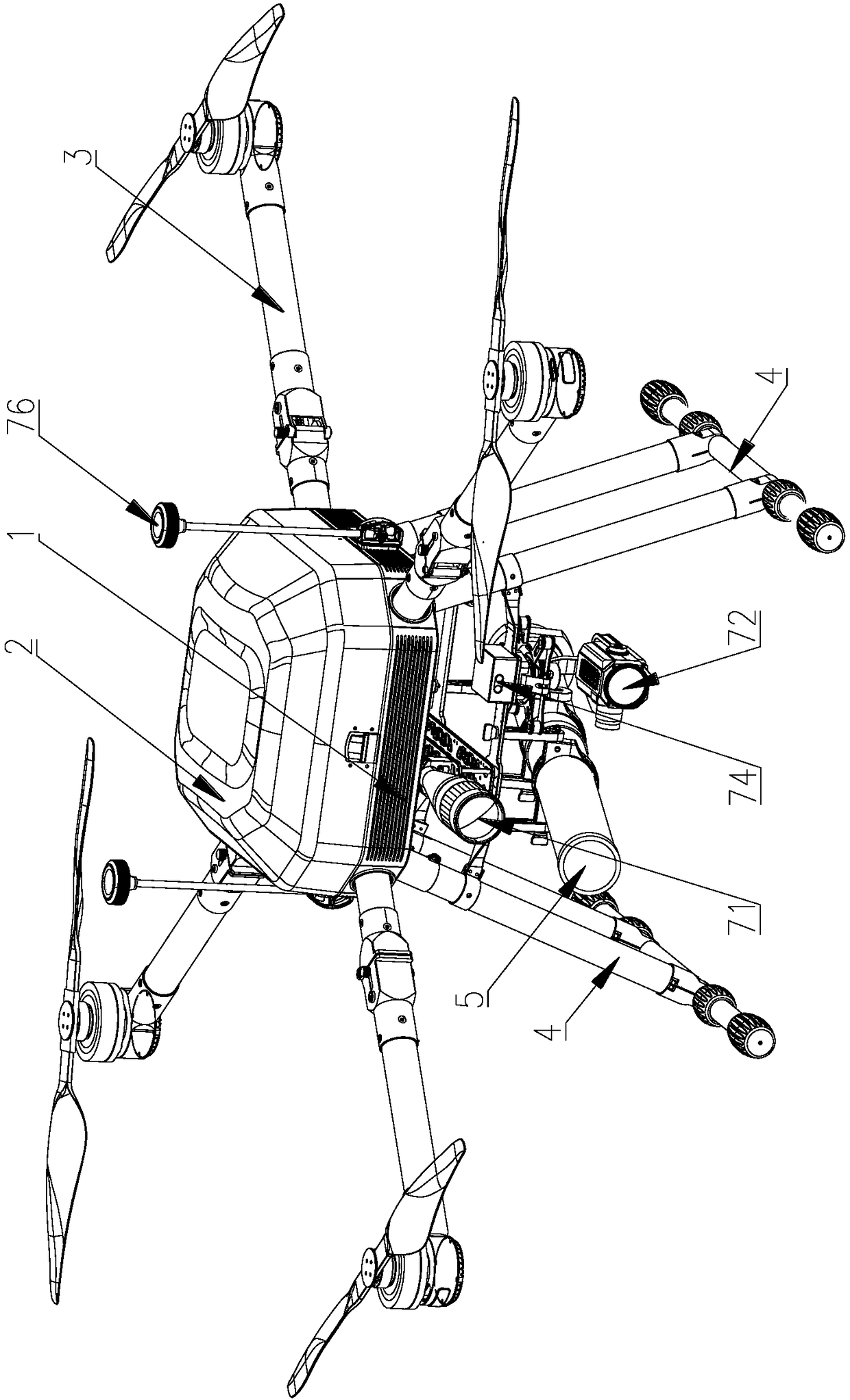

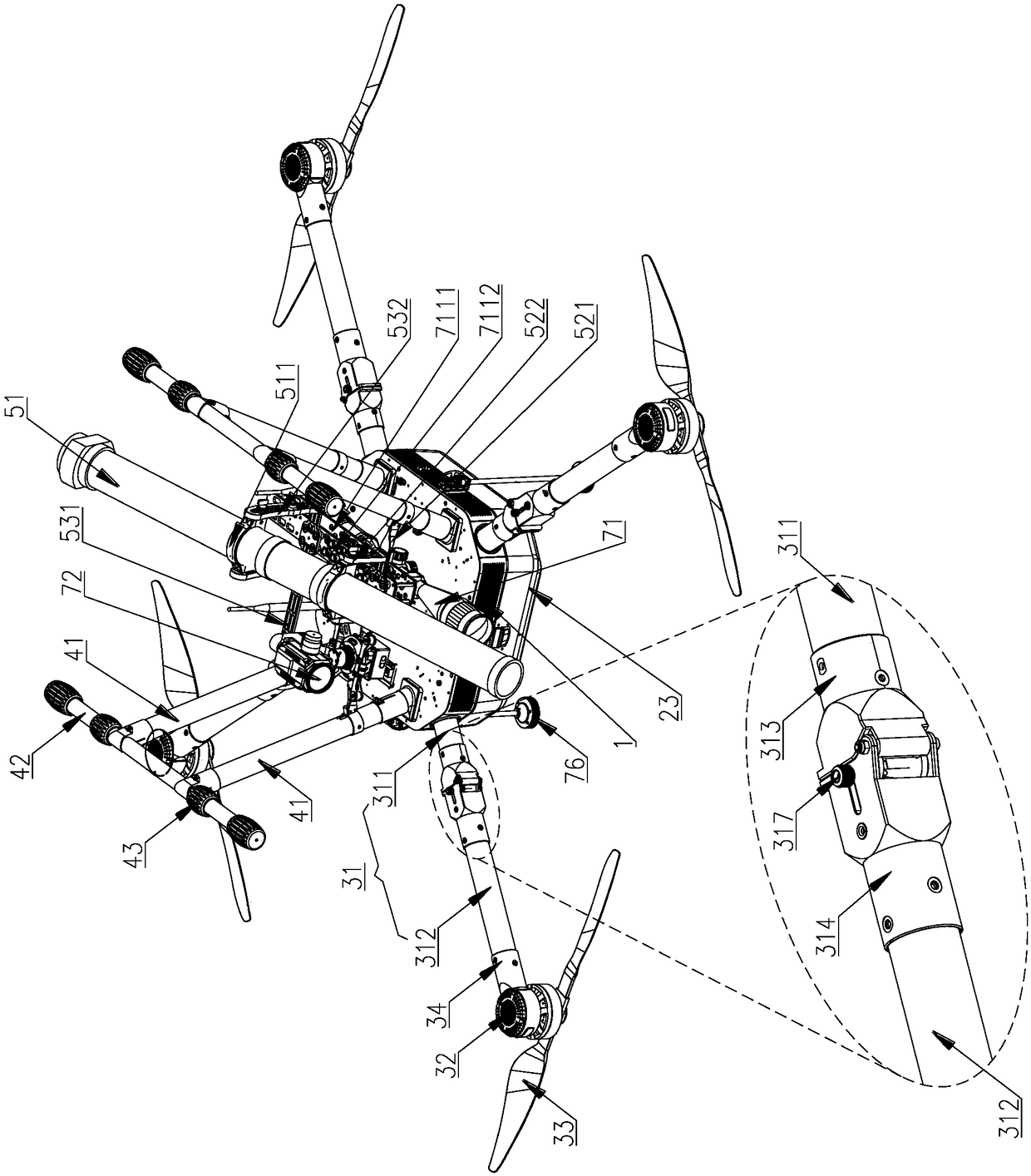

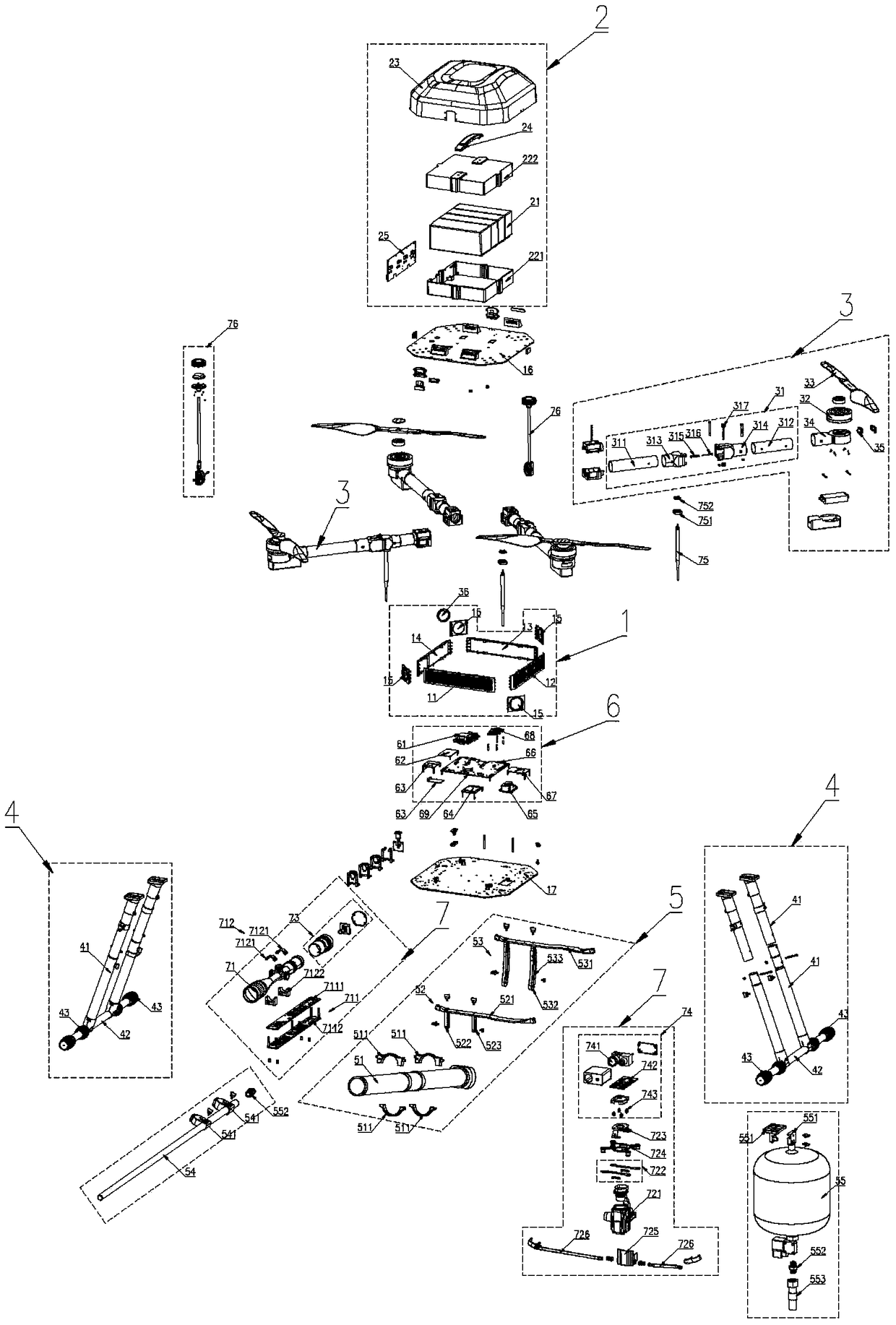

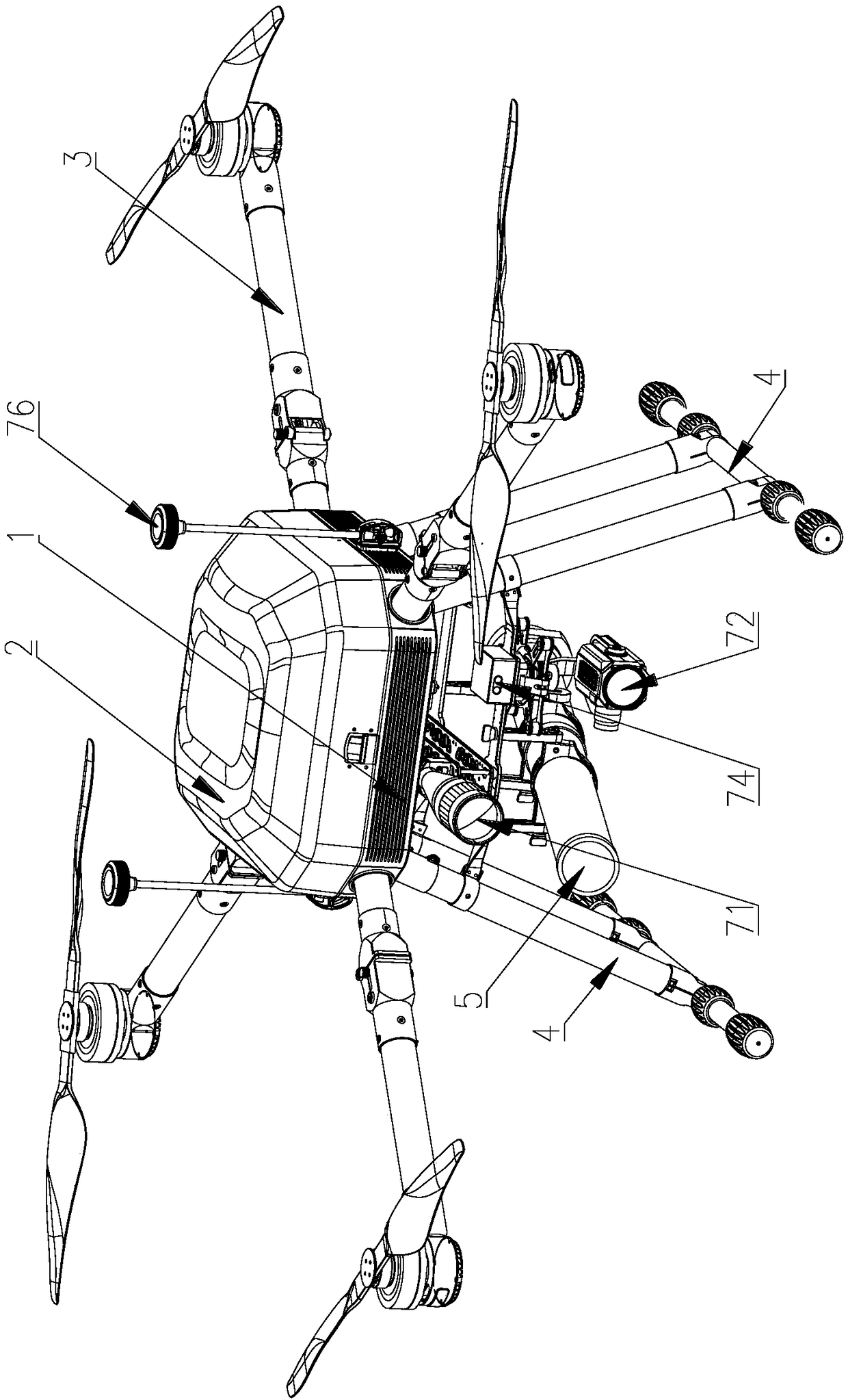

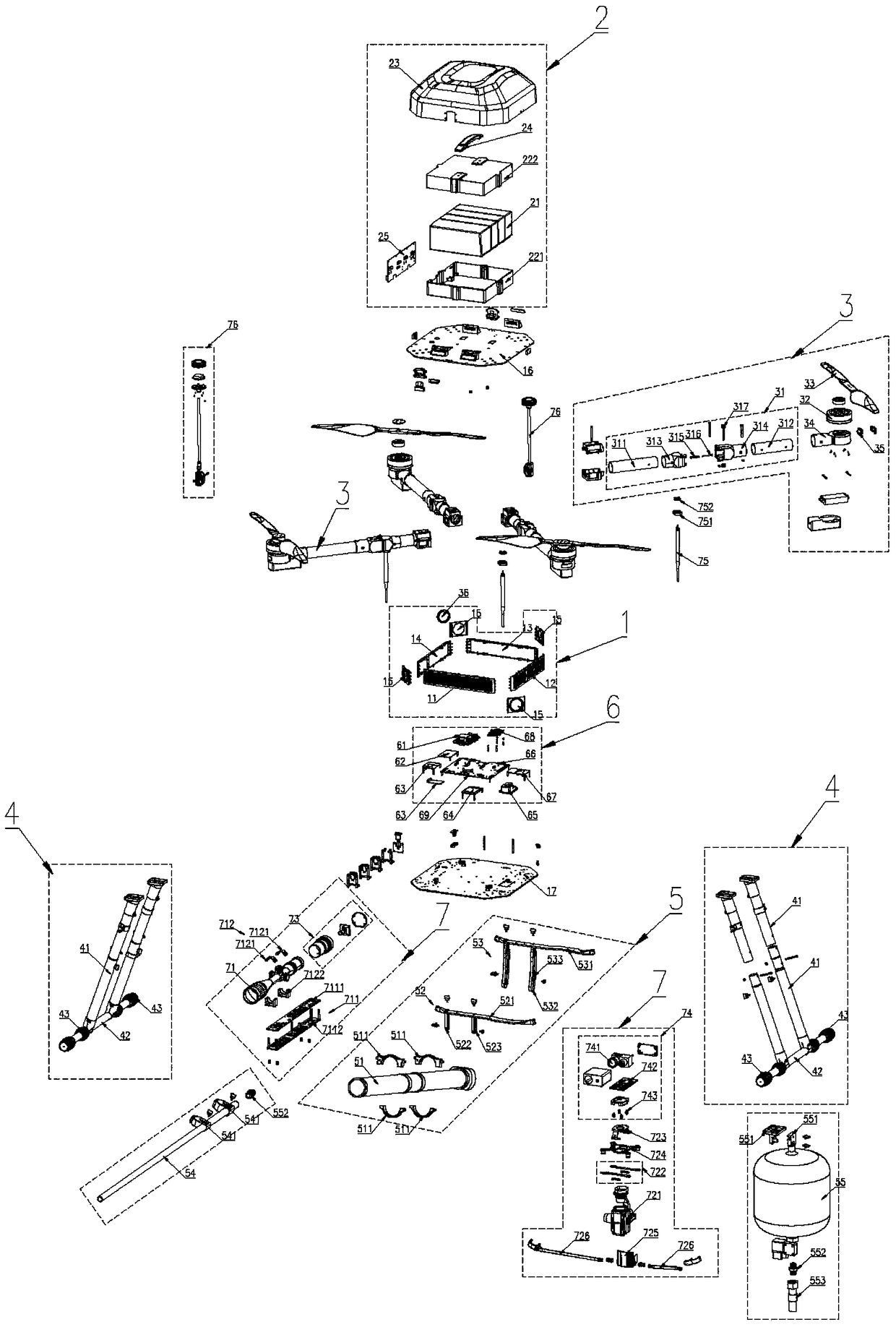

Compact fire-fighting unmanned aerial vehicle

PendingCN109178309AEnsure balanceLower center of gravityFire rescuePropulsion by batteries/cellsUncrewed vehicleEngineering

The invention relates to the field of unmanned aerial vehicles (UAV), specifically, a compact fire-fighting UAV, comprising a fuselage, a plurality of rotor assemblies, a plurality of legs, image assemblies and fire-fighting assemblies, wherein the fuselage is a box structure, and is internally provided with a plurality of control modules; a battery module is arranged on the upper part of the fuselage; the rotor assemblies are arranged on the side walls of the fuselage, and the plurality of legs assemblies are respectively located on the lateral sides of the lower part of the fuselage; the rotor assembly includes a rotor arm, a drive motor, and a rotor; one end of the leg is connected with the bottom surface of the box structure, and the other end is used for supporting the ground, and thefire-fighting assemblies and the image assemblies are fixed on the legs; and the battery module is used for driving whether the fire-fighting assembly is working or not, and provides power for the driving motor of the rotor assembly, so as to realize the power supply of the UAV. The compact fire-fighting UAV adopts the fire-fighting projectile without recoil force to extinguish the fire, which can completely satisfy the general high-rise fire, and does not produce the backward impact force to the UAV, and is favorable for improving the accuracy of the fire-fighting of the UAV.

Owner:GUANGZHOU WALKERA TECH CO LTD

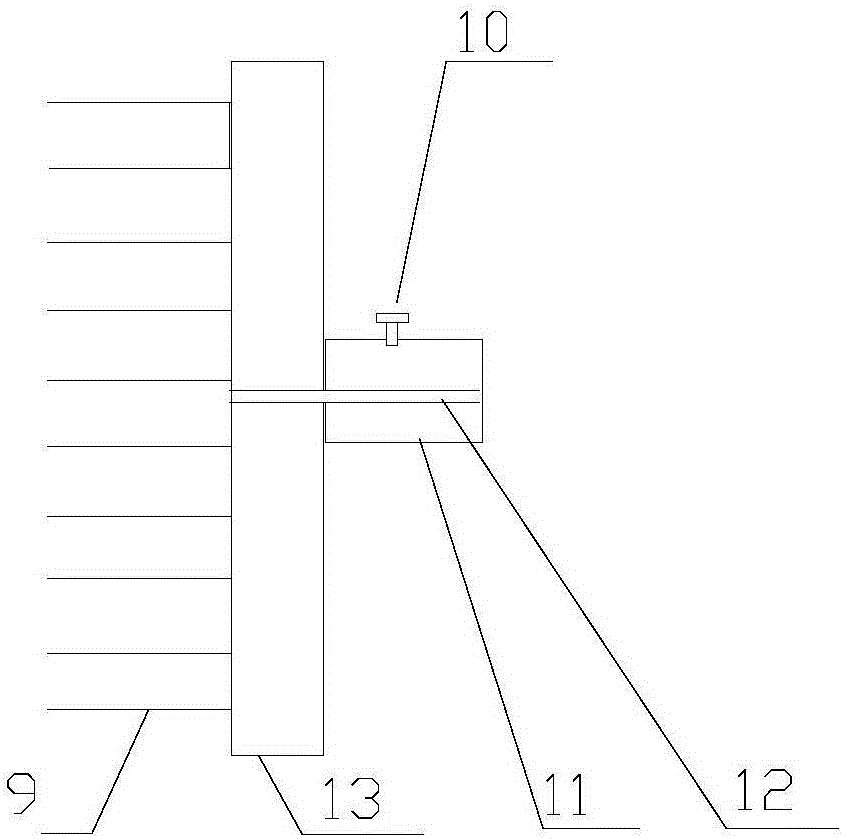

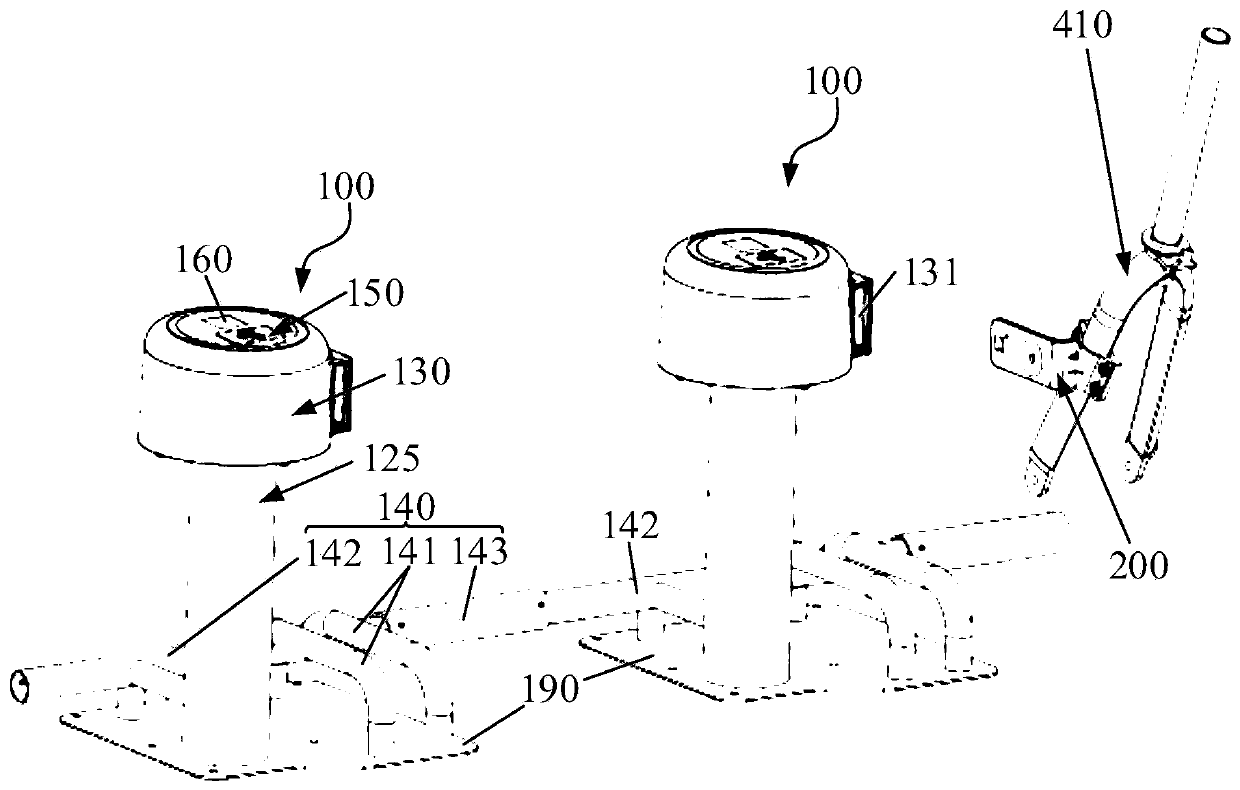

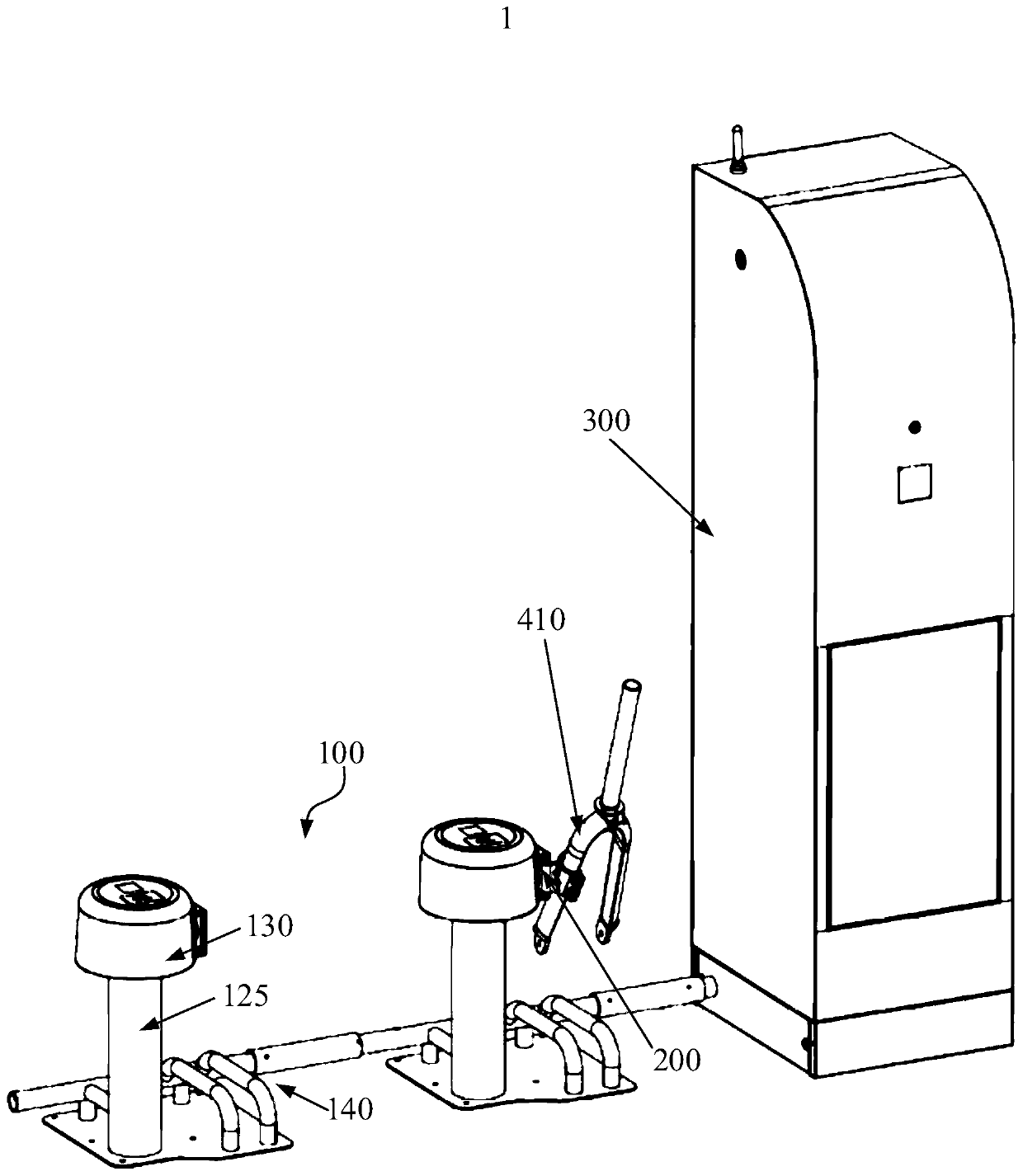

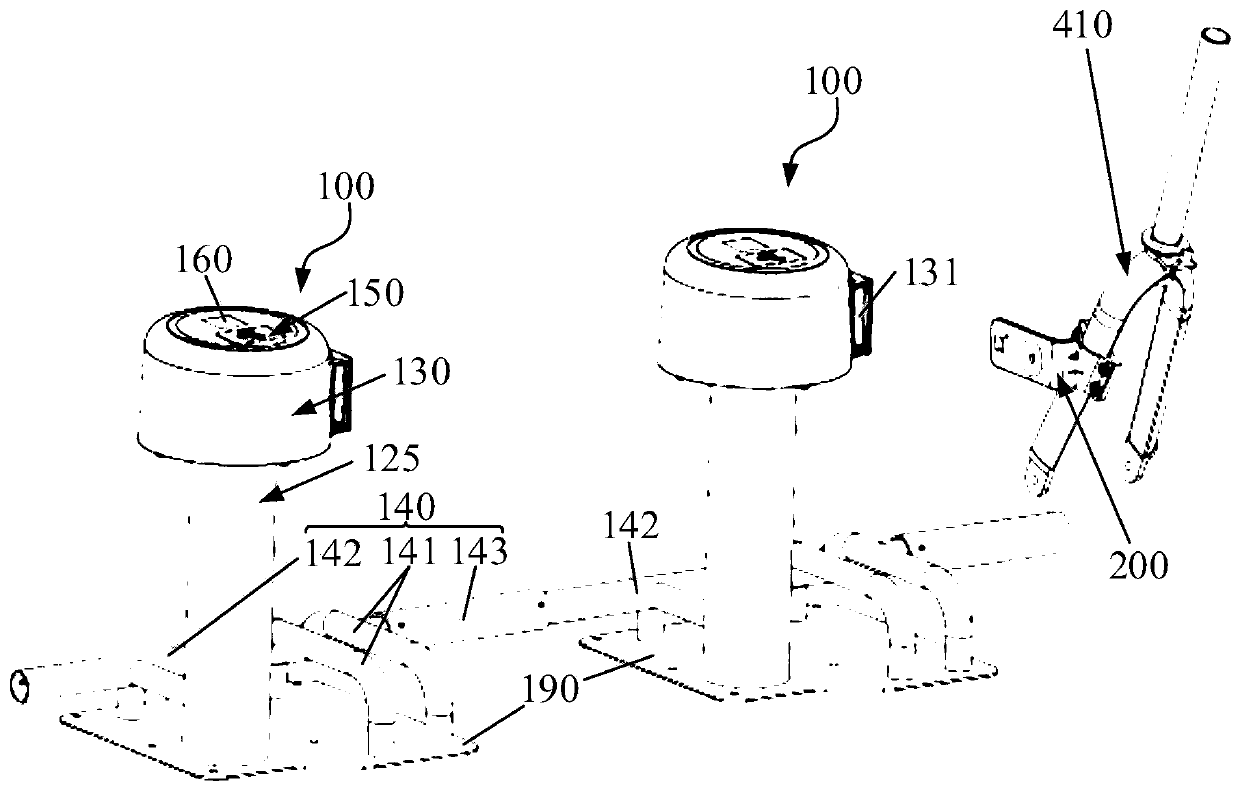

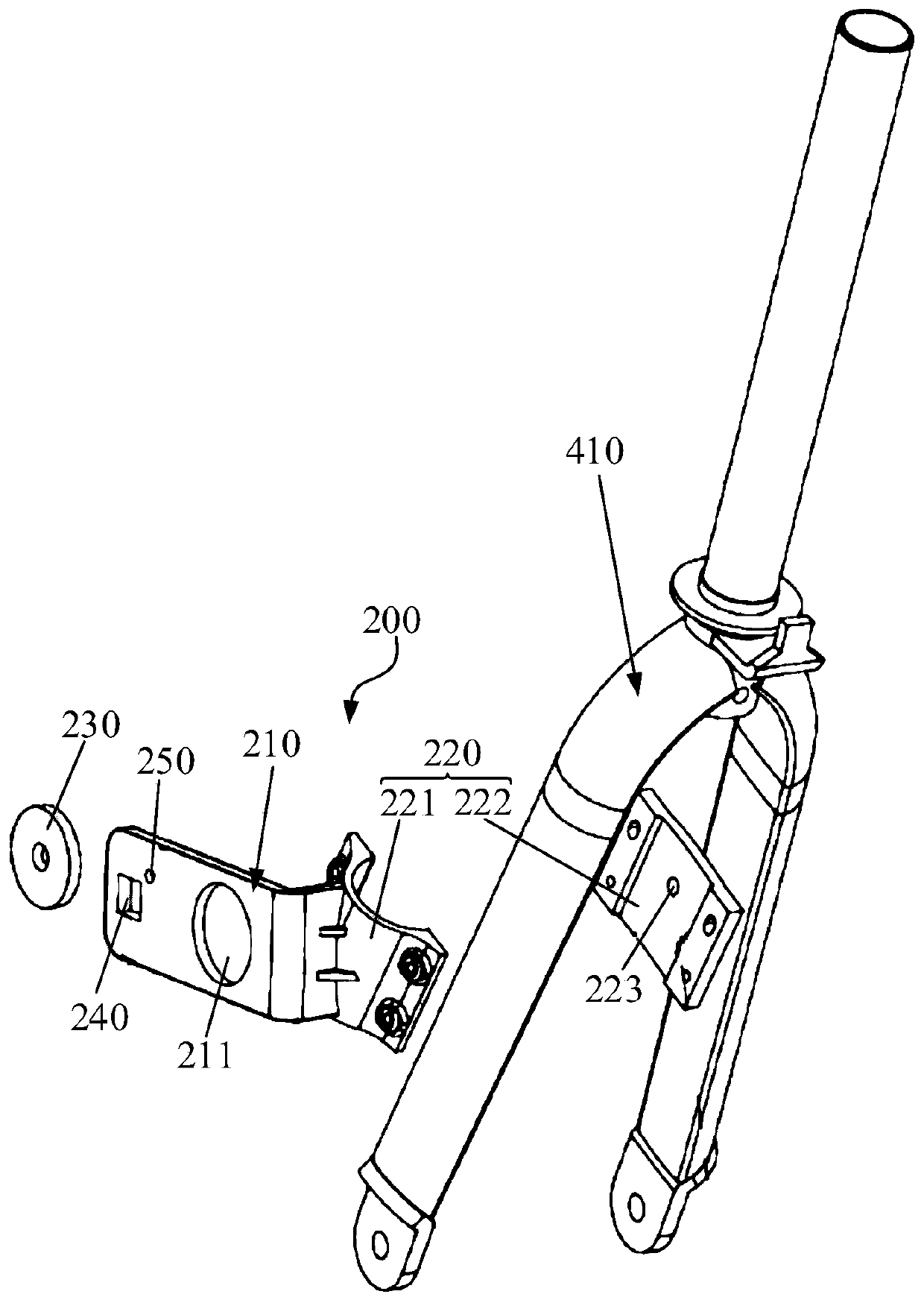

Bicycle locking pile, locking piece assembly, shared bicycle and parking pile assembly

PendingCN111572678ACompact and orderly structureIncreased installation flexibilityBatteries circuit arrangementsCycle standsStructural engineeringMechanical engineering

The invention relates to a bicycle locking pile, which comprises a bicycle locking pile body, a parking lock, a bicycle locking recognition module, a bicycle locking communication module and a bicyclelocking controller. The parking lock, the bicycle locking recognition module, the bicycle locking communication module and the bicycle locking controller are electrically connected with a power module in a central control pile. The invention further relates to a locking piece assembly matched with the bicycle locking pile, a shared bicycle and a parking pile assembly. According to the bicycle locking pile, the locking piece assembly, the shared bicycle and the parking pile assembly, unified power supply and control are conducted on the bicycle locking pile through the power module and the central control module in the central control pile, the internal structure of the bicycle locking pile is effectively simplified, the space size of the bicycle locking pile is reduced, and the structureof the bicycle locking pile is more compact and orderly; and meanwhile, one or more bicycle locking piles are allowed to be designed according to actual working conditions to be used in cooperation with the center control pile, and the installation flexibility of the parking pile assembly is greatly improved.

Owner:BEIJING QISHENG SCIENCE AND TECHNOLOGY CO LTD

Adjustable Magnetic Compound Fluid Polishing Head Mechanism

The invention relates to an adjustable polishing head mechanism for magnetic compound fluid. The adjustable polishing head mechanism comprises a magnet rotating mechanism and a liquid carrying plate rotating mechanism. A permanent magnet in the magnet rotating mechanism is eccentrically fixed to the lower portion of a magnet disc. The magnet disc is connected with a first motor through a main shaft. The first motor drives the main shaft to drive the permanent magnet to rotate, and a high-speed rotating magnetic field is produced. A connecting bracket in the liquid carrying plate rotating mechanism is a round sleeve and is installed on the outer side of the magnet rotating mechanism. A liquid carrying plate serves as an end cover of the connecting bracket and is installed below the permanent magnet. A V-shaped belt is connected to a V-shaped belt wheel and the connecting bracket in a sleeving mode. A second motor is connected with the V-shaped belt wheel through a coupler and drives the connecting bracket and the liquid carrying plate on the connecting bracket to rotate through the V-shaped belt wheel, so that the magnetic compound fluid on the liquid carrying plate rotates, and thus polishing removing of a workpiece is achieved. The adjustable polishing head mechanism for the magnetic compound fluid has the characteristics of being simple in structure, high in material removing efficiency, wide in applicable magnetic cluster size range and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

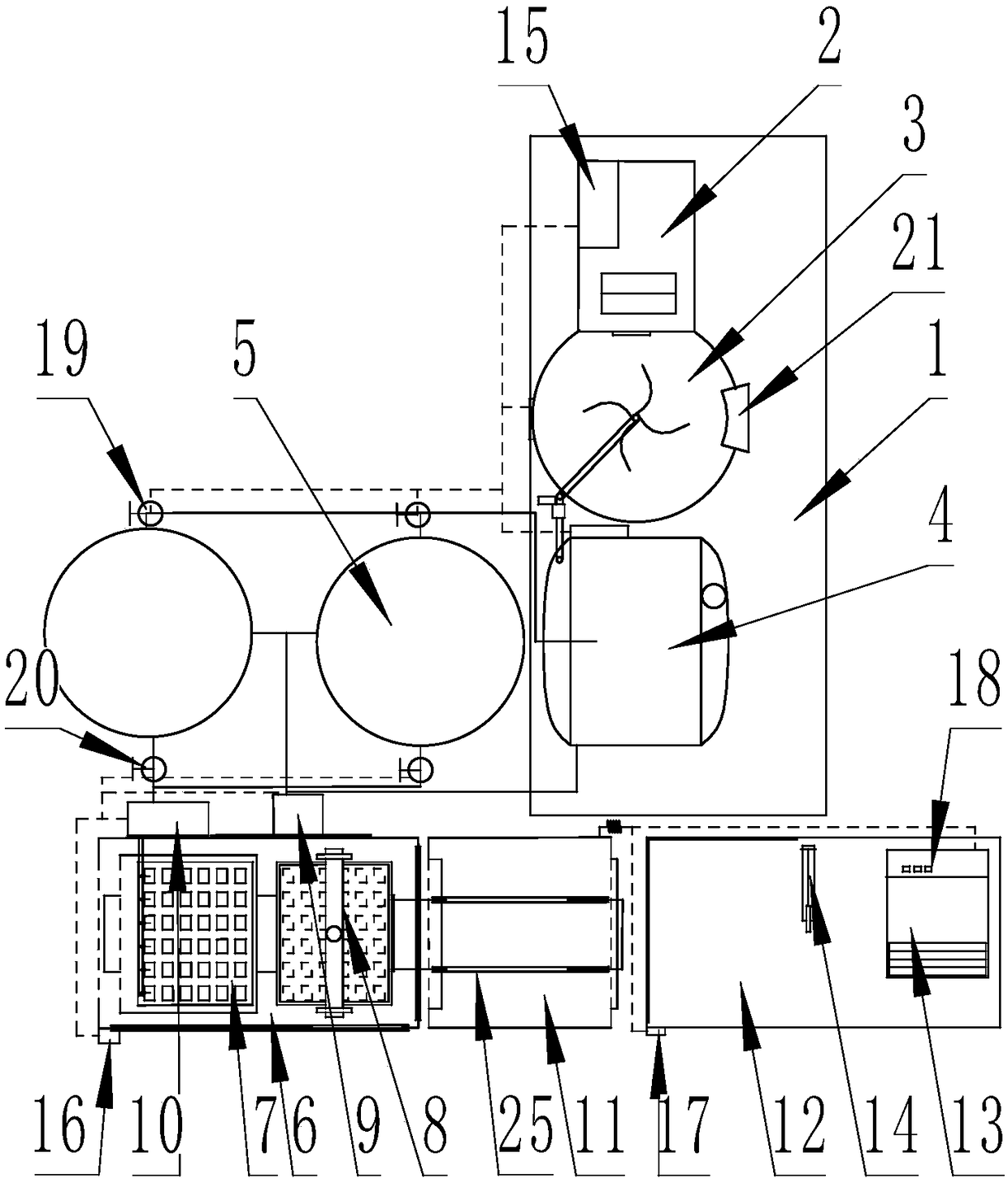

Parking pile assembly and shared vehicle system

PendingCN111583468ASimple internal structureCompact and orderly structureApparatus for meter-controlled dispensingIndividual entry/exit registersStructural engineeringControl theory

The invention relates to a parking pile assembly which comprises a bicycle locking pile and a central control pile. The bicycle locking pile comprises a parking lock, a bicycle locking recognition module, a bicycle locking communication module and a bicycle locking controller. The central control pile comprises a power supply module and a central control module, the power supply module can store certain electric quantity, the power supply module can supply power to the bicycle locking pile, and the central control module can perform information communication with the background server and thebicycle locking pile and control the bicycle locking pile. The invention further provides a shared vehicle system comprising the parking pile assembly. According to the parking pile assembly and the shared vehicle system, unified power supply and control are conducted on the vehicle locking pile through the power module and the central control module in the central control pile, the internal structure of the vehicle locking pile is effectively simplified, the space size of the vehicle locking pile is reduced, and the structure of the vehicle locking pile is more compact and orderly; meanwhile,one or more bicycle locking piles are allowed to be designed according to actual working conditions to be used in cooperation with the center control pile, and the installation flexibility of the parking pile assembly is greatly improved.

Owner:BEIJING QISHENG SCIENCE AND TECHNOLOGY CO LTD

Preparation method of coloured glaze of photonic crystal structure

The invention relates to a preparation method of coloured glaze of a photonic crystal structure, and belongs to the technical field of coloured glaze preparation. According to the invention, zinc oxide nanocrystal primary particles nucleate firstly, and then form polycrystalline colloidal particles by mutual aggregation with titanium dioxide particles; because the interiors of the nanoparticles ofa core-shell structure are rearranged, spherical photonic crystals with high crystallinity, large specific surface area and uniform shape, and relatively high refractrive index are formed finally, and therefore, the orderness of a photonic crystal periodic structure is improved; because the photonic crystals have a plurality of pores in the surface, capillary force generally vertically facing thesurface of a porcelain body is generated to colloid particles, and such force causes microspheres to be balanced in stress, so as to tend to a thermodynamic equilibrium state more easily, and therefore, the microspheres are more dense and orderly in arrangement, and the color of the film of structural color is more gorgeous; the method disclosed by the invention is simple and practical, environment-friendly, and suitable for industrial production and has wide application prospect.

Owner:周晓东

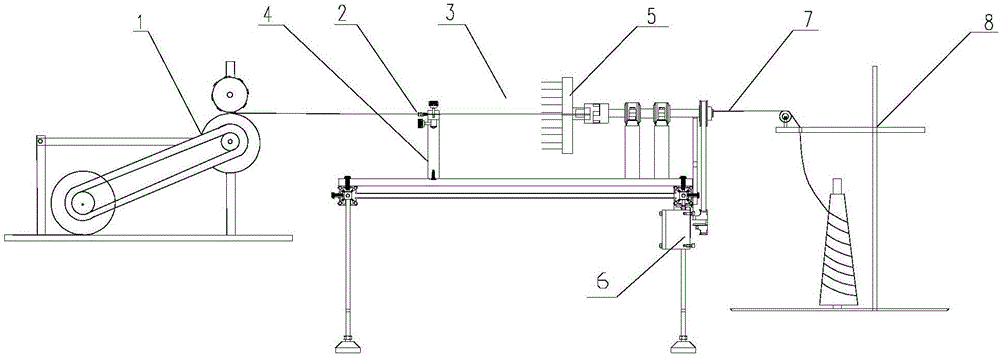

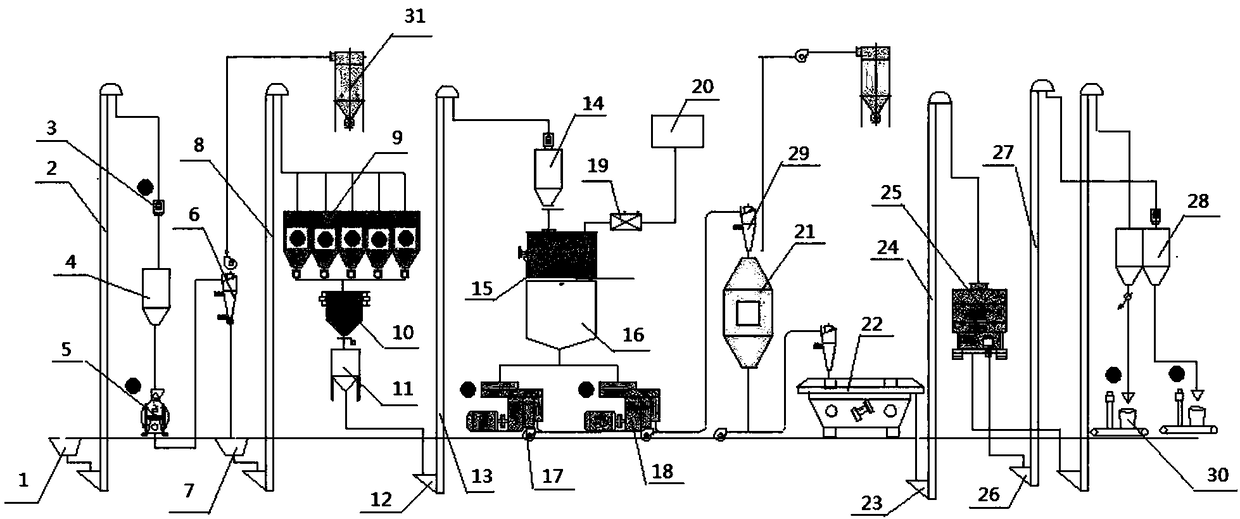

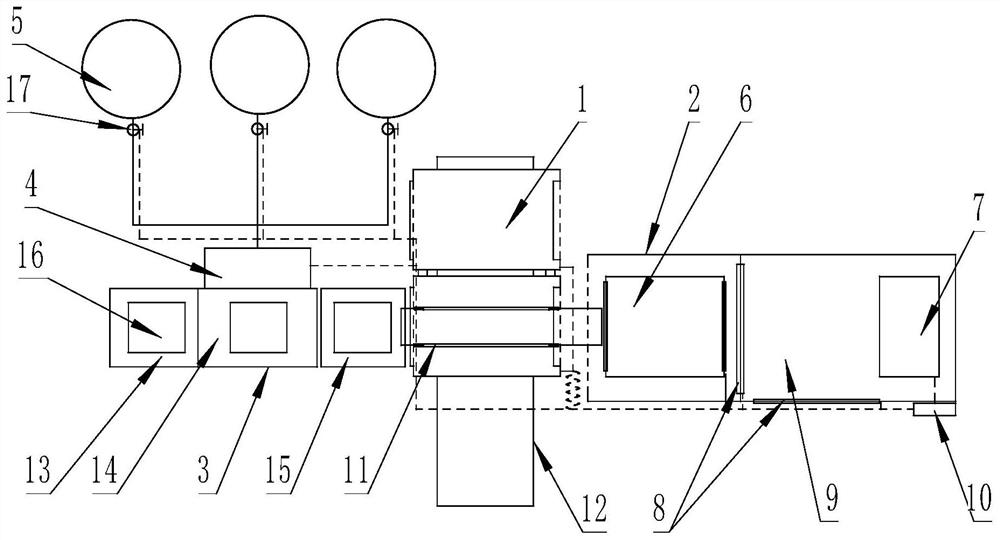

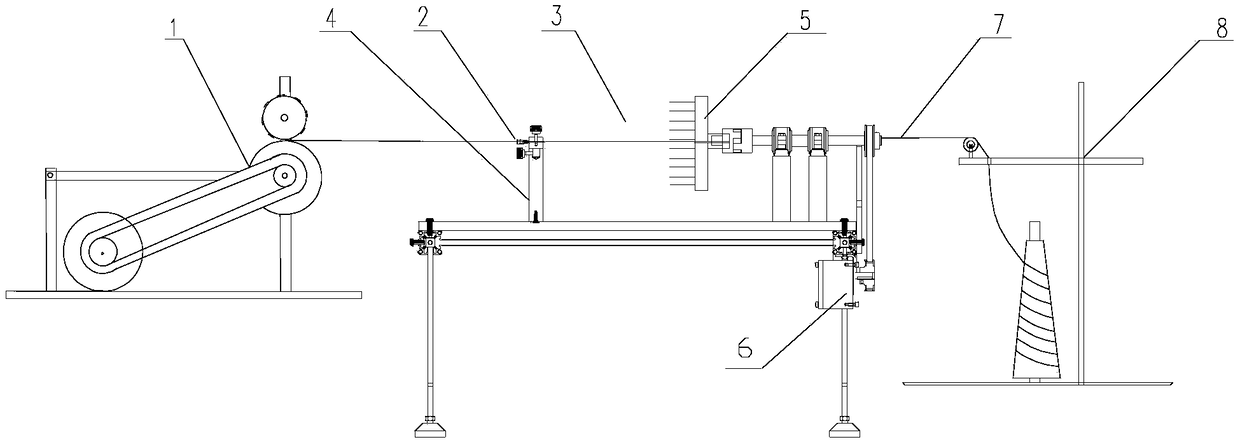

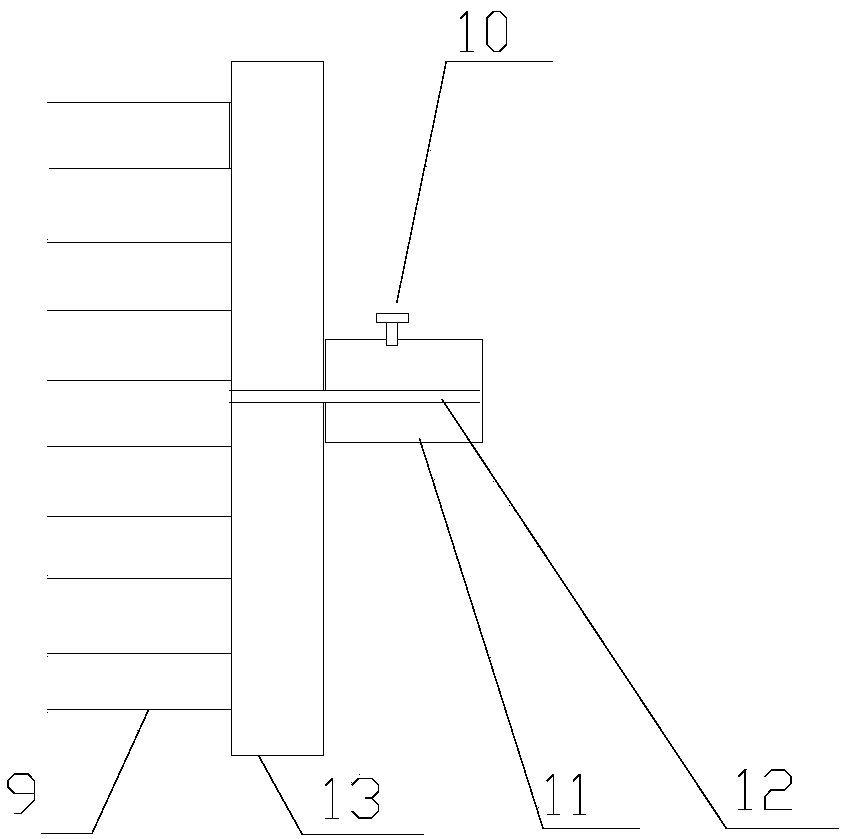

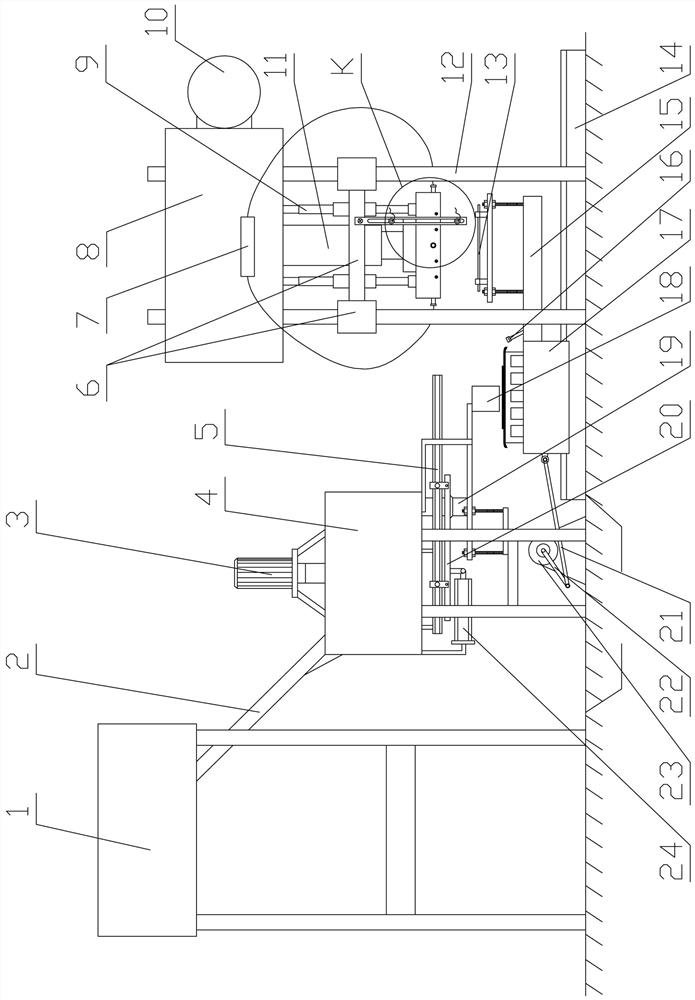

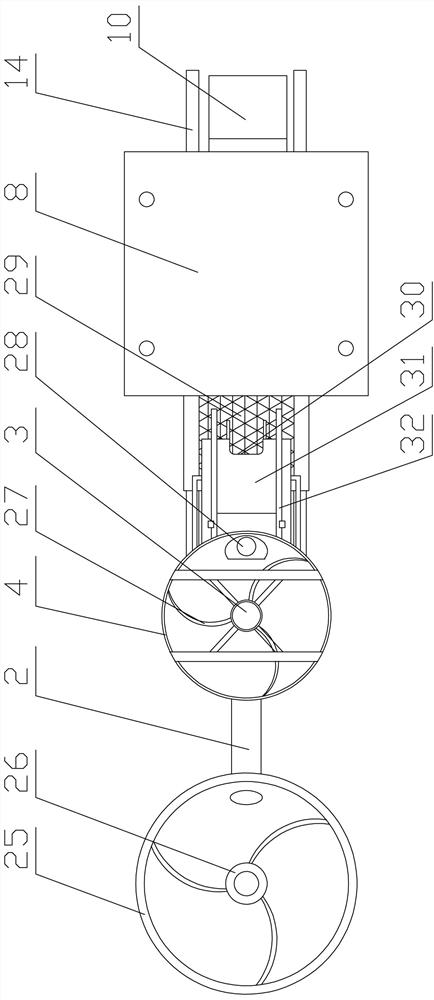

Using method for selenium-enriched chicken cake combined semi-automatic production line

ActiveCN109170619ACompact and orderly structureUse less laborFood shapingFood ingredient functionsWater bathsProduction line

The invention discloses a using method for a selenium-enriched chicken cake combined semi-automatic production line. The method comprises the following steps: during production, preparing raw materials of selenium-enriched chicken cakes, and during processing, enabling the prepared materials to pass through a meat grinder, a chopper mixer and a tumbler so as to obtain filled stuffing; setting thefilled stuffing by a vacuum packer; pushing a meat cake mold to enter a steam box by a handle via a touch switch sealing door, heating at a constant temperature for several minutes to complete cookingof the meat cakes, and stopping heating by a steam water bath; and slicing the meat cakes, and vacuumizing and sealing in a vacuum package machine by manual bagging. The automatic production line isdivided into a burdening platform, an ingredient refrigerating tank, a low-temperature forming box, a steam box vacuum packing platform and a vacuum package machine which are respectively operated bya control console, lots of manual labor is reduced, the yield and product profit are improved, the occupied space is small, and the product is dense and solid in structure, elastic, strong in grain feeling, excellent in slice performance, absent in clustered pore, unique in flavor, fresh and delicious and excellent in market prospects.

Owner:洛阳天佑春都食品有限公司

Application method of vegetable cake combined production line

ActiveCN108991436ACompact and orderly structureSmall footprintFood coatingFood ingredient functionsManufacturing engineeringAir cooling

An application method of a vegetable cake combined production line includes: chopping and tumbling the stuffing of vegetable cake until the stuffing becomes uniform and thick paste; then by means of operation of two workers, filling a vegetable cake mold cavity with the stuffing of the vegetable cake, steaming the stuffing, changing another mold, and press-molding a heat-sealing film; after processing of the vegetable cake, placing the vegetable cake in a turnover trolley, and storing the vegetable cake in a fresh keeping storehouse. A stuffing processing device is arranged at the front end ofthe combined production line, wherein a chopping machine, a tumbling machine and a mold filling apparatus are combined and arranged in the stuffing processing device; and a steamer, an air cooling box and a covering apparatus are integrated and are successively arranged at one side of the stuffing processing device, thereby forming the combined production line. The production line has compact andordered structure and is small in occupied area. The production line only occupies two workers to complete all operations, is convenient and flexible to use, can reduce a large number of manpower, can improve yield and product profit, and has excellent market prospect of application and production.

Owner:洛阳天佑春都食品有限公司

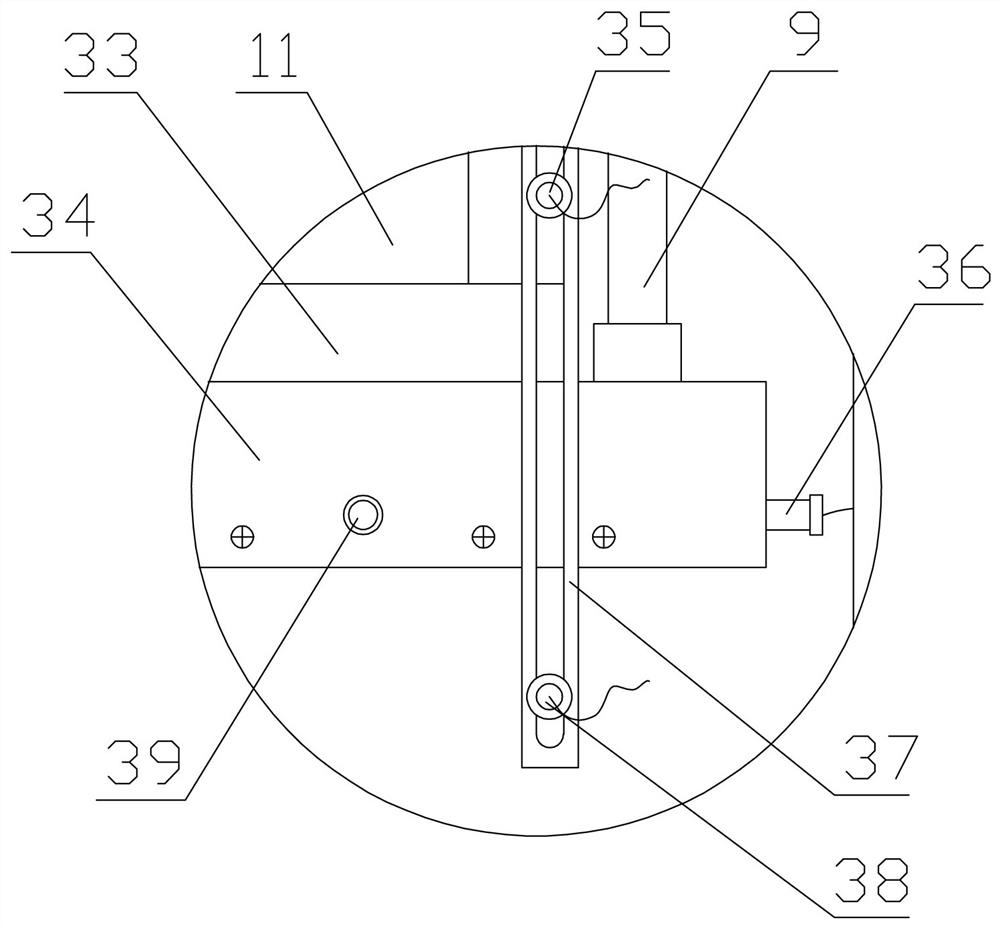

Anode steel jaw surface float polishing device

ActiveCN109465718ARealize the difference in speedHigh speed contact frictionGrinding drivesGrinding machinesDrive shaftMaterials science

The invention discloses an anode steel jaw surface float polishing device. The anode steel jaw surface float polishing device comprises an end surface polishing plate, a gear disc, a bracket and a base arranged in sequence from top to bottom; a gear cavity is formed in the bottom surface of the bracket; the strip slide hole is formed in the radial direction of the gear disc near the edge; a pair of arc polishing plates is arranged on the upper end surface of the gear disc; the inner surface of the arc polishing plate on the inner side is used for polishing; the pair of the arc polishing platesare positioned on the outer side of the end surface polishing plate, and are coaxially arranged with the same; and the pair of the arc polishing plates are concentrically arranged in parallel. The anode steel jaw surface float polishing device further comprises a transmission shaft vertically mounted on the base and penetrating through the base to extend out of the bottom end surface; a first driving gear of the transmission shaft is in deceleration engaged transmission with the gear disc; and the edge of a second driving gear extends into the gear cavity to be in acceleration engaged transmission with a driven gear on a rotating shaft. The anode steel jaw surface float polishing device is simple and skillful in structure, safe and reliable in use, higher in polishing efficiency and excellent in overall polishing effect.

Owner:重庆天泰铝业股份有限公司 +1

Nutritional rice production control system

PendingCN108816317ACompact and orderly layoutSmall installation spaceGrain treatmentsPolygonum fagopyrumControl system

The invention relates to a nutritional rice production control system which is provided with a primary material pool. The primary material pool contains rice, the root of kudzu vine, black rice, solanum tuberdsm and buckwheat, the rice, the root of kudzu vine, the black rice, the solanum tuberdsm and the buckwheat are lifted by a first lifting machine to be subjected to deironing through an electromagnet, then enter a smashing machine material bin, enter a first rice screen after being smashed by a smashing machine and enter a second-stage material pool, the second-stage material pool is connected with a rice grinding unit through a second lifting machine, a second rice screen is connected to the lower portion of the rice grinding unit, a buffer bin is arranged below the second rice screen and communicates with a third-stage material pool through a pipe,and the third-stage material pool communicates with a permanent magnet drum through a third lifting machine. By means of the nutritional rice production control system, the connecting structures of all machining equipment are reasonably planned, so that the defects that the machining and operation efficiency is low and the milled rice rate is not high in the prior art are overcome, the overall structure is scientific, reasonable, simple and compact, and the equipment installing site can be saved.

Owner:贵州省黎平县侗乡米业有限公司

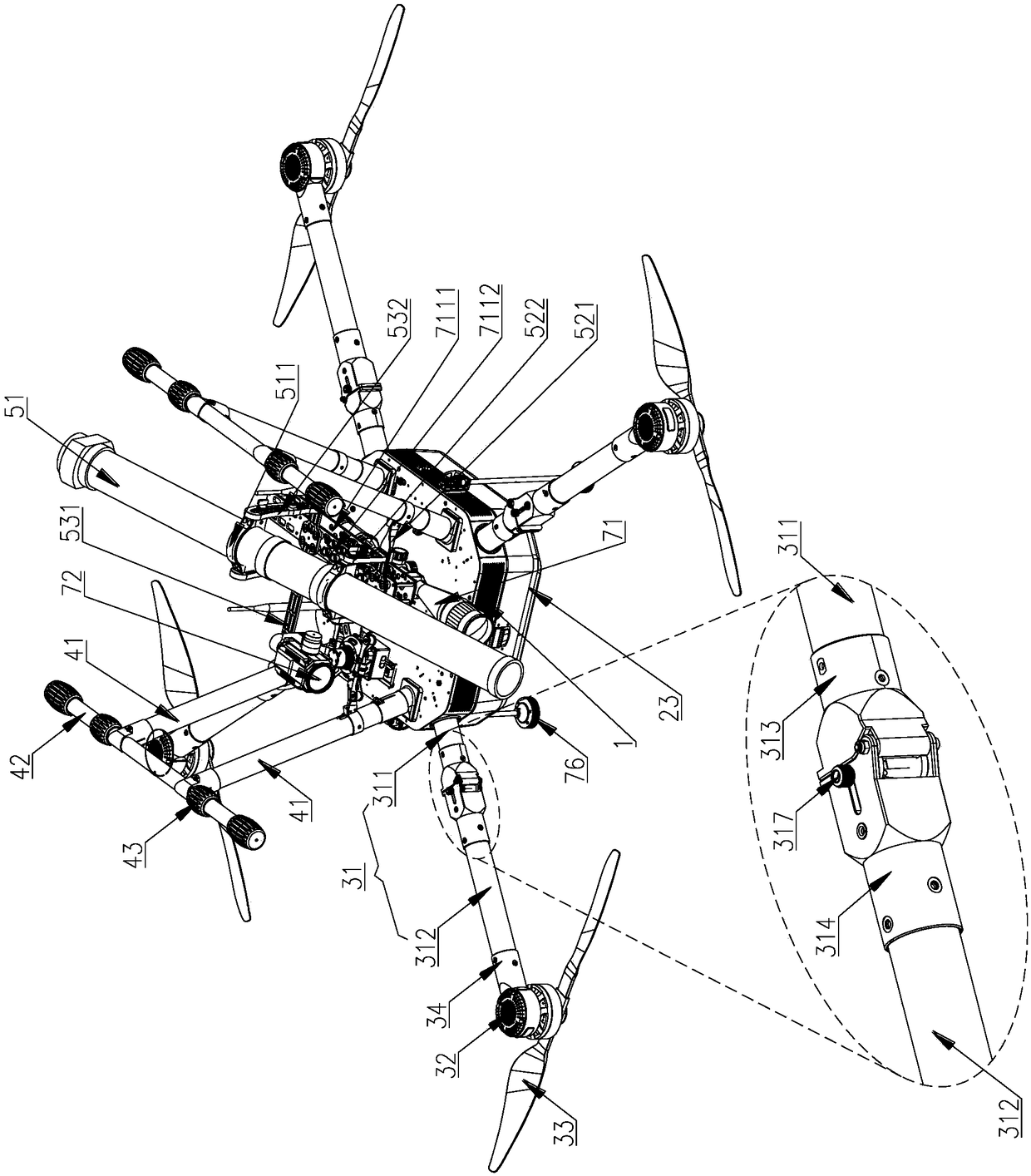

Pure electric-driven fire-fighting unmanned aerial vehicle

PendingCN109178310AEnsure balanceLower center of gravityEfficient propulsion technologiesFire rescueNight visionRemote control

The invention relates to the field of unmanned aerial vehicles (UAVs), in particular to a pure electric-driven fire-fighting UAV. The pure electric-driven fire-fighting UAV is operated through a remote control terminal, and comprises a fuselage, four rotor assemblies, two sets of legs, image assemblies and fire-fighting assemblies, wherein the fuselage is internally provided with a plurality of control modules; the upper part of the fuselage is provided with a power module, and the rotor assembly comprises a rotor arm, a driving motor and a rotor; the fire-fighting assemblies and the image assemblies are fixed on the legs; the image assembly comprises a sighting telescope, a pan-tilt assembly and a night-vision camera arranged behind the sighting telescope; the power module comprises a plurality of batteries, a battery box and a head cover; and the batteries are used for driving whether the fire-fighting assembles are working or not, and providing power for the driving motor of the rotor assembly, so as to realize the power supply of the UAV. The pure electric-driven fire-fighting UAV only adopts a battery as a power source and carries sufficient batteries, which can completely meet the normal operation requirements of an unmanned aerial vehicle (UAV) and is beneficial to improving the accuracy of fire extinguishing of the UAV.

Owner:GUANGZHOU WALKERA TECH CO LTD

A selenium-enriched fish sausage automatic control combined production line

ActiveCN109105720BCompact and orderly structureReduce the number of laborFood shapingBiotechnologyAnimal science

An automatic control combined production line for selenium-enriched fish sausages. Before production, the ingredients and fillings for selenium-enriched fish sausages are first processed. Control the opening of the electromagnetic feeding valve of a refrigerated ingredient tank; the stuffing output by the electromagnetic feeding valve enters the KAP automatic filling and ligating machine enema for packaging into semi-finished selenium-enriched fish sausages, which are manually placed in the grate plate Fill it up and sterilize for 5 minutes at a temperature of 110°C and a pressure of 0.25Mpa, push it into a steaming cabinet in the combined steaming cabinet and cook for 30 minutes before packaging; the sausage packaging machine of the present invention adopts multiple refrigerated ingredients Tank cycle feeding, steaming separately through parallel combined steaming cabinets, its structure is compact and orderly, production control is carried out through PLC console, only three people are required to operate, it occupies a small space, energy saving and environmental protection, and can improve economic benefits.

Owner:洛阳天佑春都食品有限公司

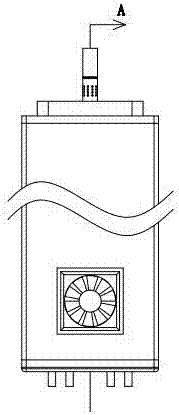

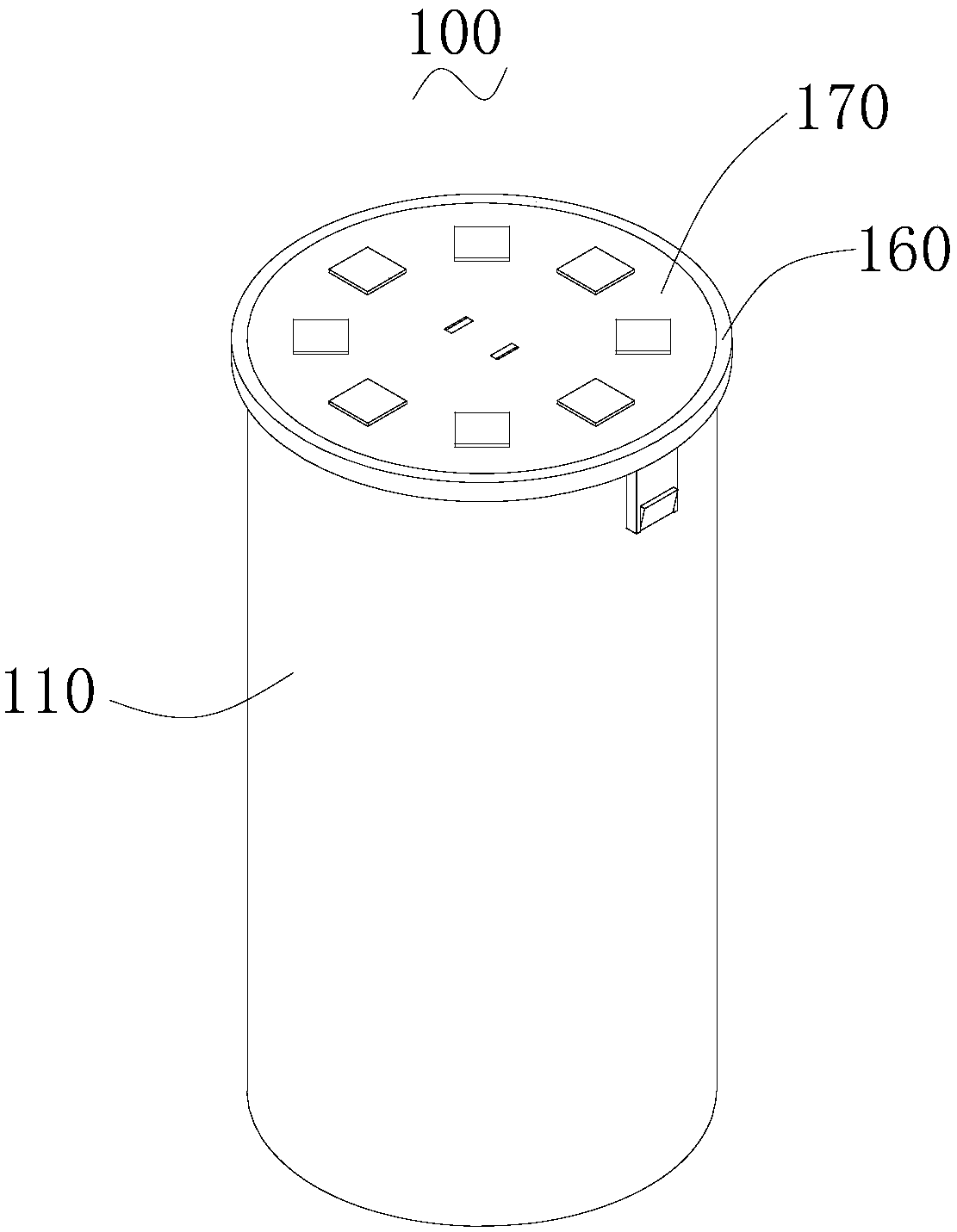

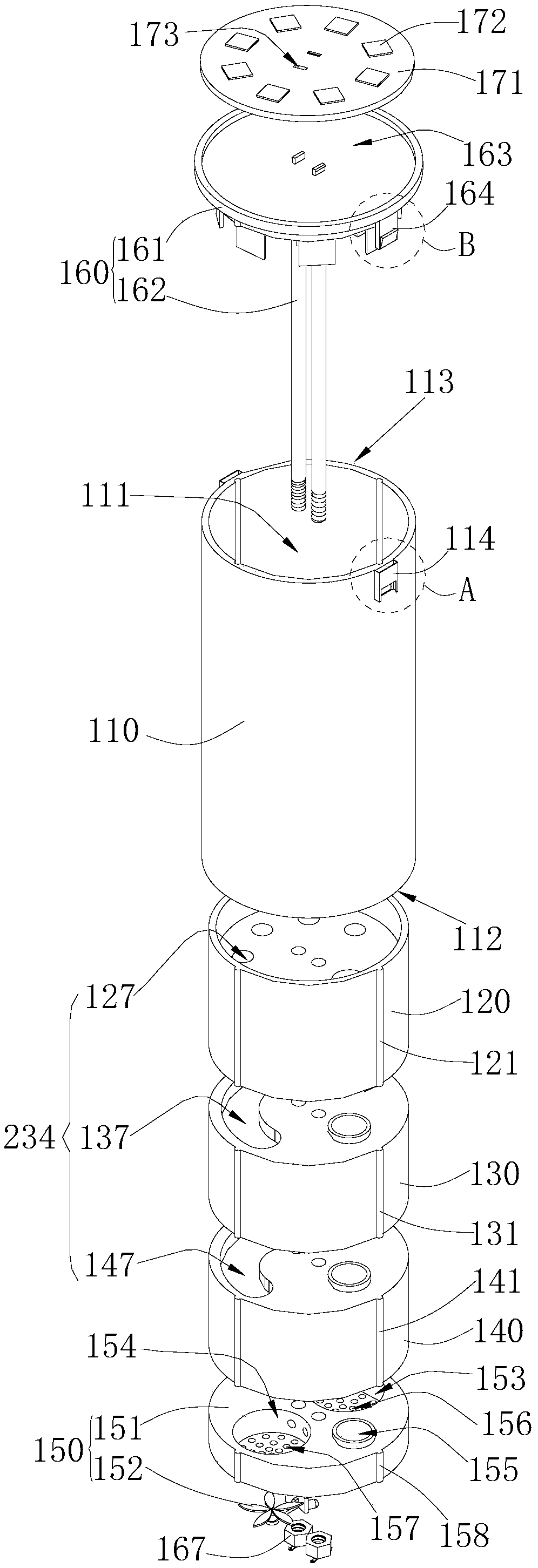

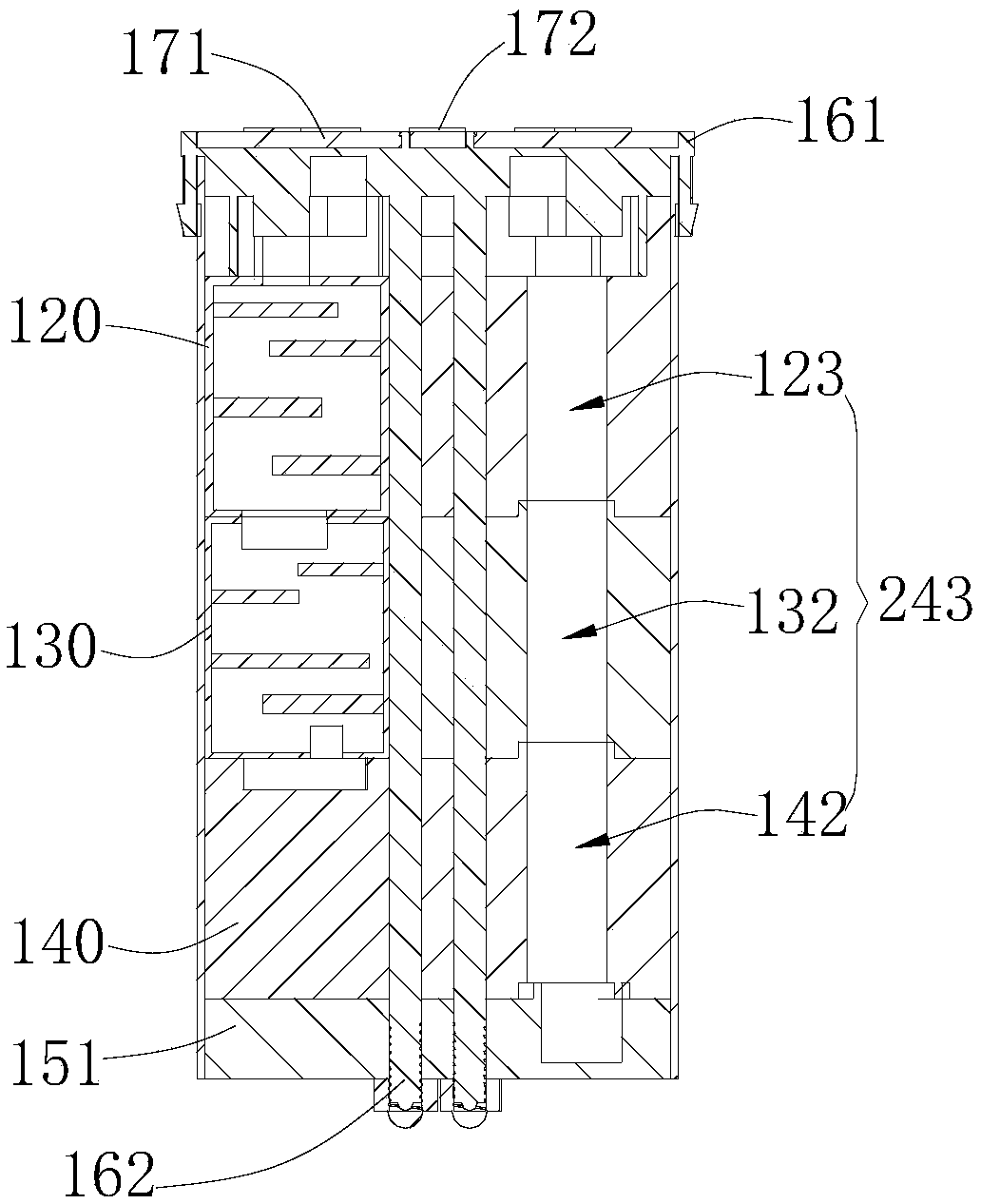

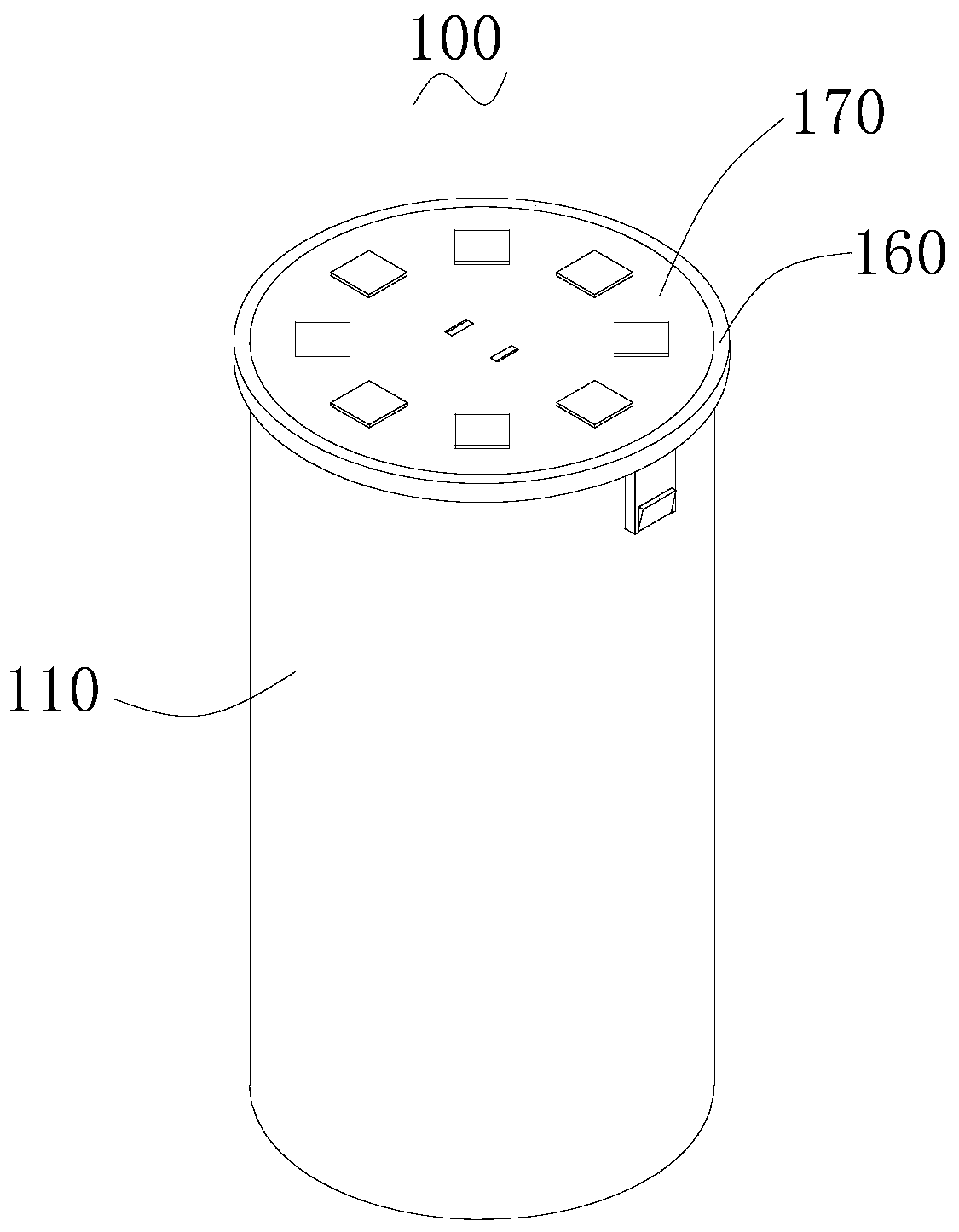

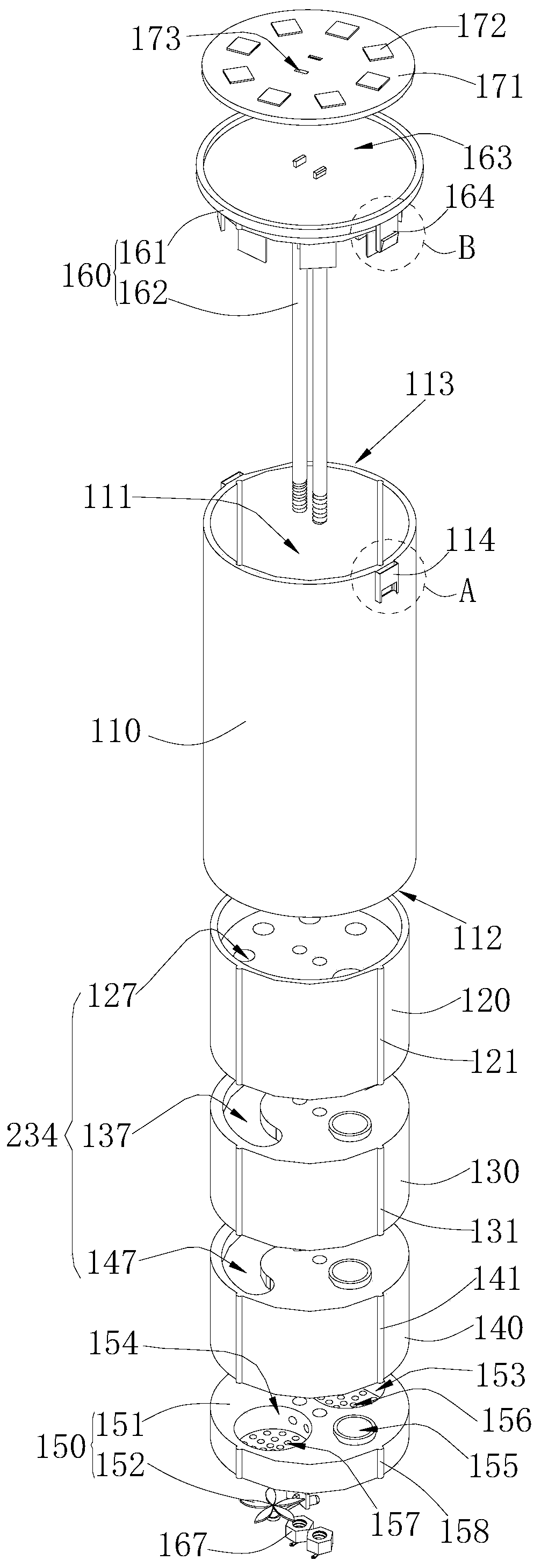

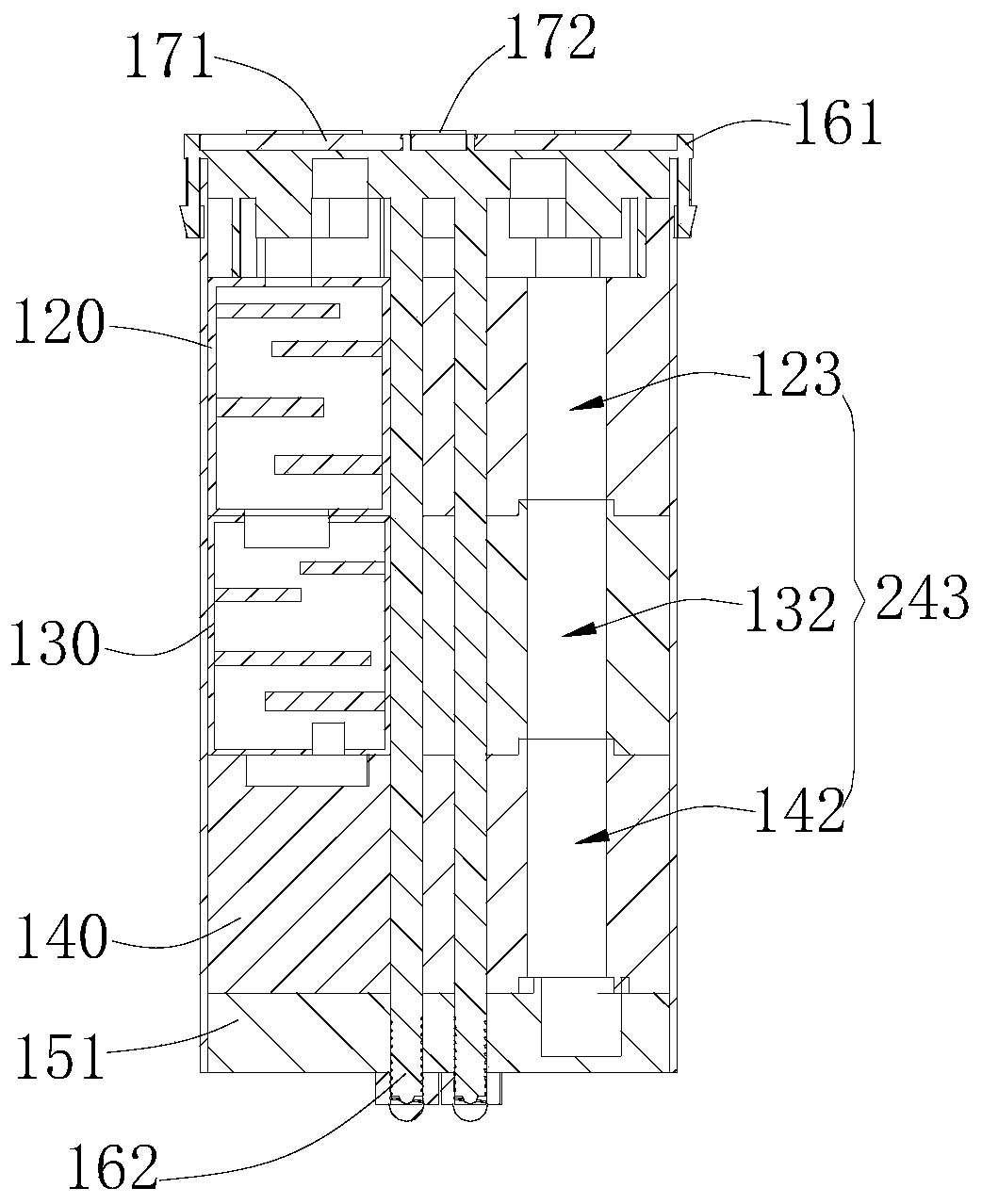

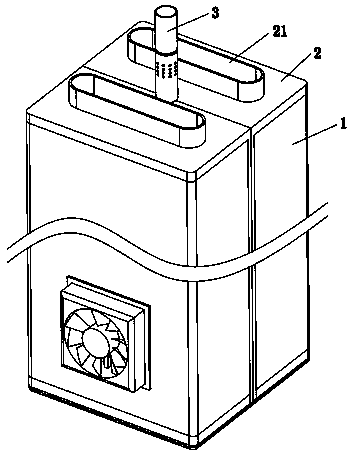

LED lamp

ActiveCN108679466ACompact and orderly structureLower assembly costsElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLED lamp

The invention relates to an LED lamp. The LED lamp comprises a barrel, an air induction device, a heat dissipation body and an LED light source. The barrel is provided with a heat dissipation channel,a heat removal port and a heat suction port. The air induction device comprises a cover body and a draught fan. The cover body is installed on the barrel and covers the heat removal port. An air exhaust groove and an installation groove are formed in the cover body. The draught fan is arranged in the installation groove. The heat dissipation body comprises a heat dissipation installation plate and a conductive supporting column. The heat dissipation installation plate and the conductive supporting column are connected with each other. The heat dissipation installation plate is installed on the barrel and covers the air suction port. An installation area is arranged on the side, with the back to the conductive supporting column, of the heat dissipation installation plate. The conductive supporting column is contained in the heat dissipation channel. The tail end of the conductive supporting column is exposed on the surface of the cover body and is connected with the cover body. The LEDlight source comprises a circuit board and a plurality of electrical filaments. The circuit board is installed in the installation area. All the electrical filaments are arranged on the circuit boardand are electrically connected with the circuit board. The LED lamp is highly efficient and quick in heat dissipation, compact and orderly in structure, low in assembly cost, capable of being produced in a large-scale manner, and low in using cost.

Owner:东莞市闻誉实业有限公司

Novel fan metal supporting plate and manufacturing equipment

PendingCN109404118AReduce vibrationReduce jumpingPerforating toolsPump componentsAnti stressPunching

Th e invention discloses a novel fan metal supporting plate and manufacturing equipment. The fan metal supporting plate comprises a body, a central positioning hole is formed in the center of the body, a plurality of mounting holes surrounding the central positioning hole are formed in the body, and a plurality of side holes are circularly formed in the edge of the body; and the fan metal supporting plate further comprises a plurality of anti-stress grooves, wherein the anti-stress grooves are formed in and distributed on the surface of the body. The manufacturing equipment comprises a top plate and a bottom plate which are symmetrically arranged through a plurality of fixing columns, the space between the top plate and the stamping bottom is separated by an isolating plate to form a punching area and an anti-stress area, upper extrusion plates are arranged on the punching area and the anti-stress area correspondingly, the upper parts of the upper extrusion plates are installed below stamping air cylinder through stamping shafts, a punch assembly is arranged at the bottom of the upper extrusion plate of the punching area, and an anti-stress steel nail assembly is arranged at the bottom of the upper extrusion plate of the anti-stress area. According to the novel fan metal supporting plate and the manufacturing equipment, the stress is eliminated through the anti-stress grooves in the surface of the fan metal supporting plate so that jumping of a fan can be reduced, and the fan quality is improved.

Owner:南充工塑零部件有限公司

A kind of flexible carbon fiber and preparation method thereof

ActiveCN106012110BImprove flexibilityImprove conductivityArtifical filament manufactureCarbon fibersCarbonization

The invention relates to a flexible carbon fiber and a preparation method thereof. The carbon fiber is prepared by carrying out spinning on a graphite flake / polyacrylonitrile complex solution and carrying out super-high drafting, pre-oxidation and carbonization treatment. The carbon fiber has highly oriented graphite flakes and graphite crystal structures generated through induction of the graphite flakes, wherein graphite crystallite is arranged and oriented along the surfaces of the graphite flakes. The carbon fiber has the characteristics of high order degree, compact structure, small average grain size and few defects. The rigidity / softness, resistivity, strength and axial thermal conductivity of the prepared flexible carbon fiber are respectively 10<-4>-10mN .cm, 10<-3>-100omega .cm, 1000-5000MPa and 0.5-50W / m .k. The prepared flexible carbon fiber has the beneficial effects that the flexible carbon fiber is low in production cost and wide in raw material sources; the structural properties of the carbon fiber can be substantially improved; and the flexible carbon fiber has very high market application values and can be widely applied to the fields of electrode materials, functional materials, energy materials, and the like.

Owner:DONGHUA UNIV

A dot-matrix receiver for electrospinning and a method for preparing nanofibers

The invention relates to an electrostatic spinning receiver and belongs to the field of electrostatic spinning. A dot-matrix type receiver for electrostatic spinning comprises a plurality of receiving pins which are perpendicular to an insulating base plate and are made of metal, the bottoms of all the receiving pins are connected through wires to achieve equal potential of each receiving pin, and the non-fixed ends of the receiving pins are opposite to a yarn outlet device, so that an electrostatic field between the yarn outlet device and the dot-matrix type receiver is split into a plurality of unit electrostatic fields at one end close to the dot-matrix type receiver. Nanofibers formed by electrostatic spinning are deposited respectively on each receiving pin of the dot-matrix type receiver through each unit electrostatic field and then are twisted to form a nanofiber aggregate. The nanofibers of a cross section of the formed nanofiber aggregate are divided into multiple strands of nanofibers, so that the nanofiber aggregate is more ordered, each strand of internal nanofibers are closely combined with each other, each strand of nanofibers are mutually twisted and closely combined, and the formed nanofiber aggregate is denser and more ordered in structure and more stable in performance.

Owner:SHANGHAI UNIV OF ENG SCI

A kind of flexible carbon film and preparation method thereof

The invention relates to a flexible carbon film and a preparation method thereof. The flexible carbon film is composed of highly-oriented graphite flakes and graphite microcrystals, wherein the graphite flakes exert induction effect on formation of the graphite microcrystals, and the graphite microcrystals generated under induction are arranged and oriented along the surfaces of the graphite flakes. The carbon film has the characteristics of compact structure, a great ordered degree, few defects and a small average crystal grain size. The carbon film is prepared by subjecting a graphite flake / polyacrylonitrile composite solution to film casting, high-rate drawing and sintering. The flexible carbon film prepared in the invention has rigidity of 10 *<-4> to 10 mN.cm, resistivity of 10<-3> to 100 omega.cm, strength of 5 to 500 MPa and a heat conductivity coefficient of 0.5 to 50 W / m.k; and the flexible carbon film has greatly improved structural performance and high market application value and is extensively applicable to fields like electrode materials, functional materials and energy materials.

Owner:DONGHUA UNIV

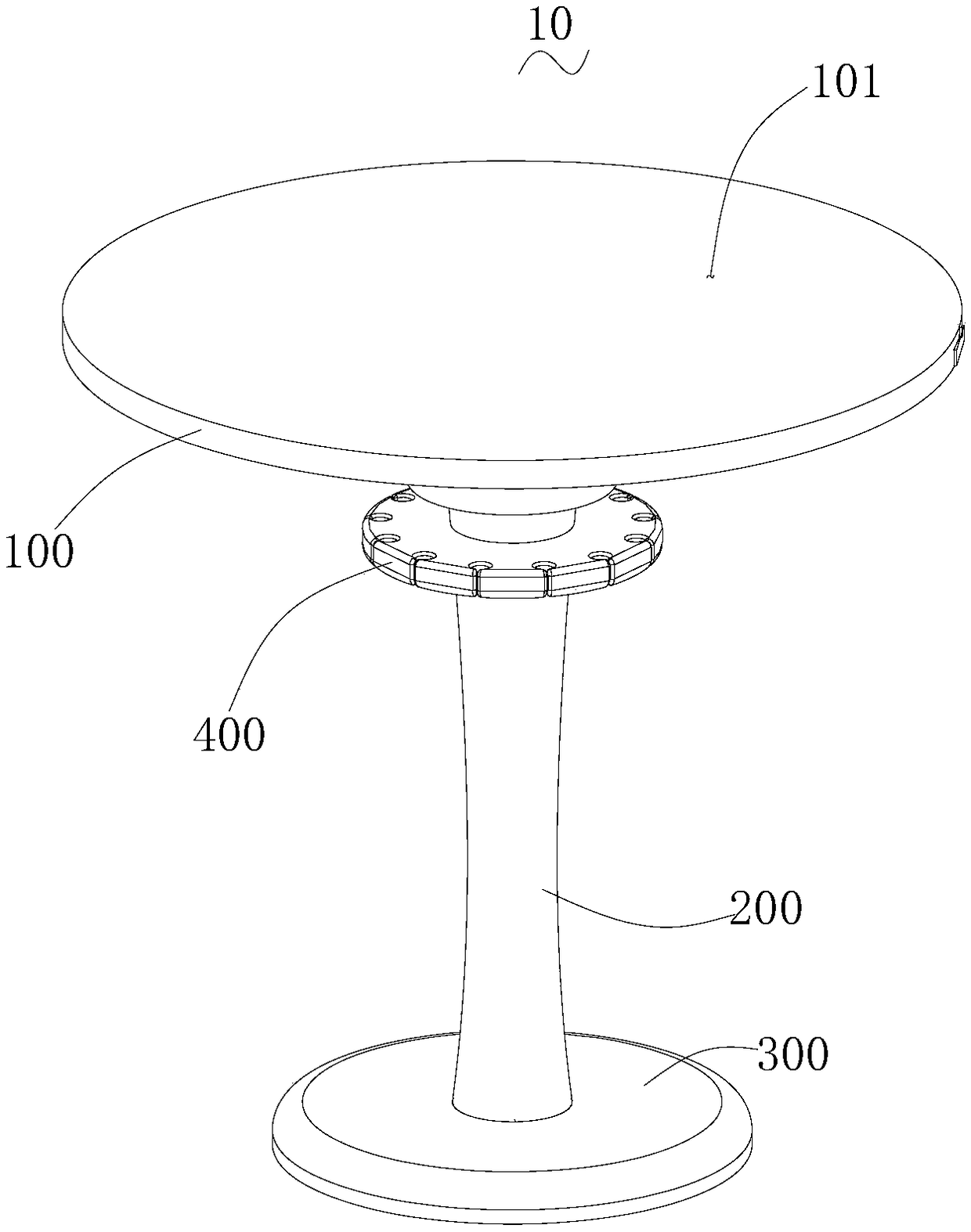

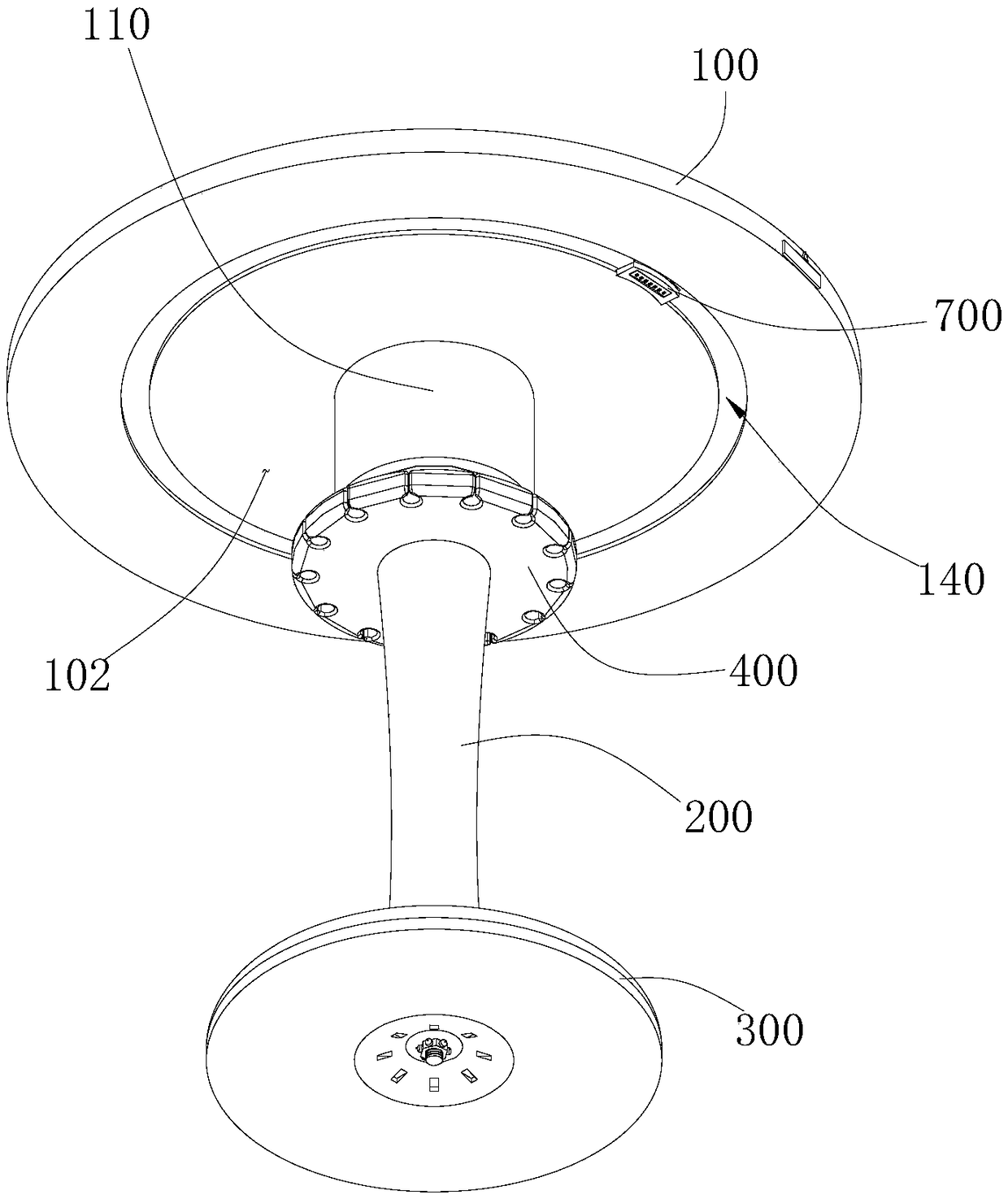

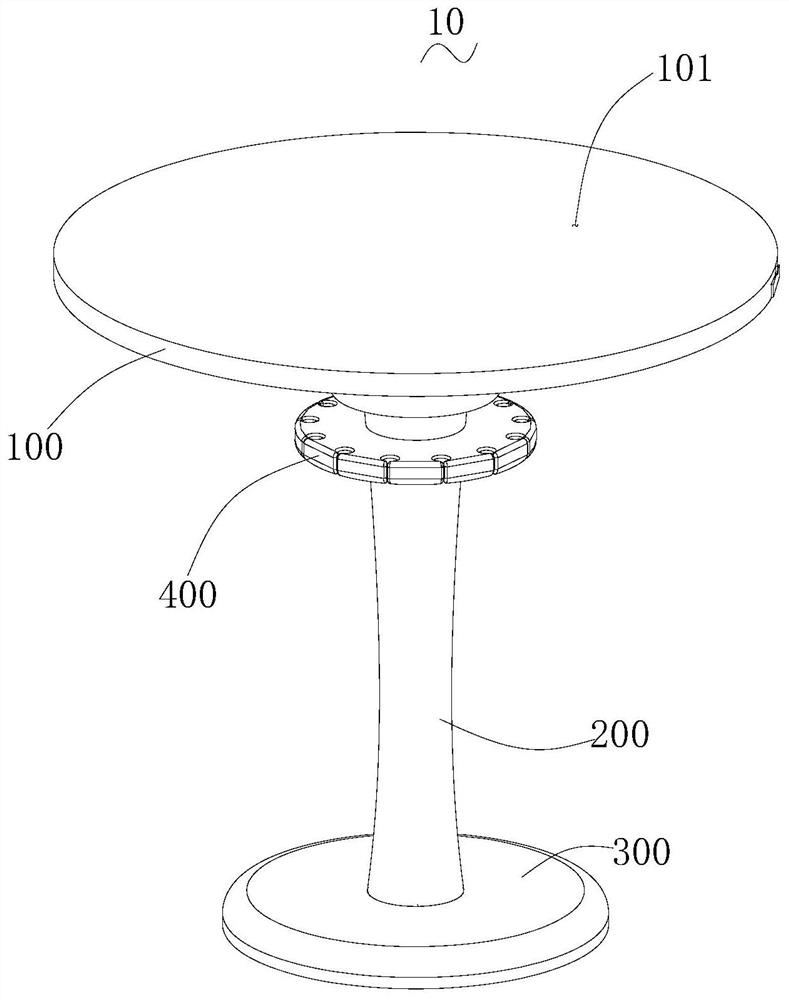

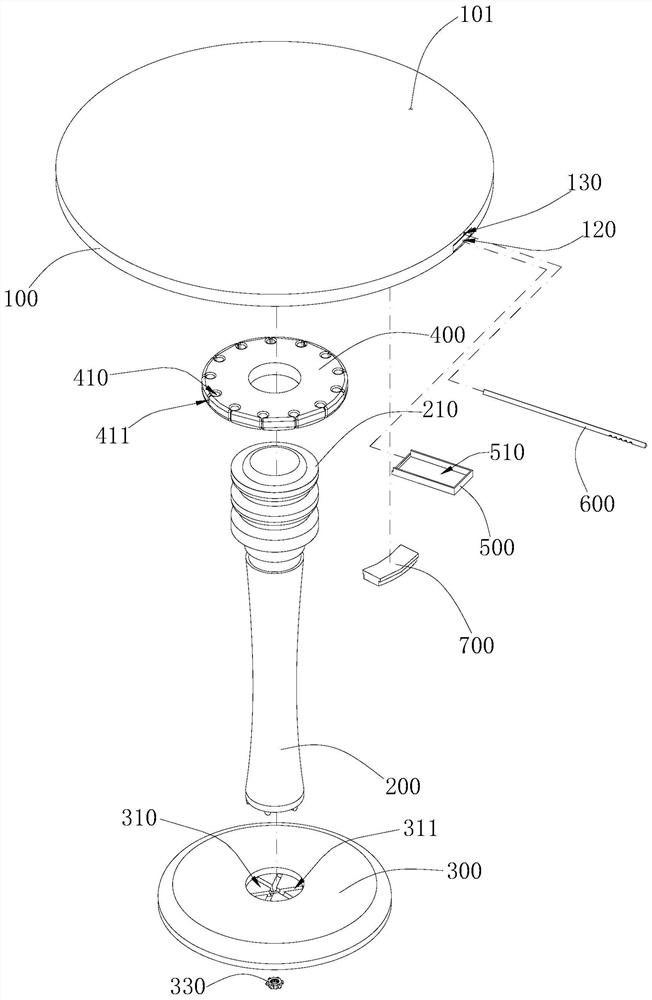

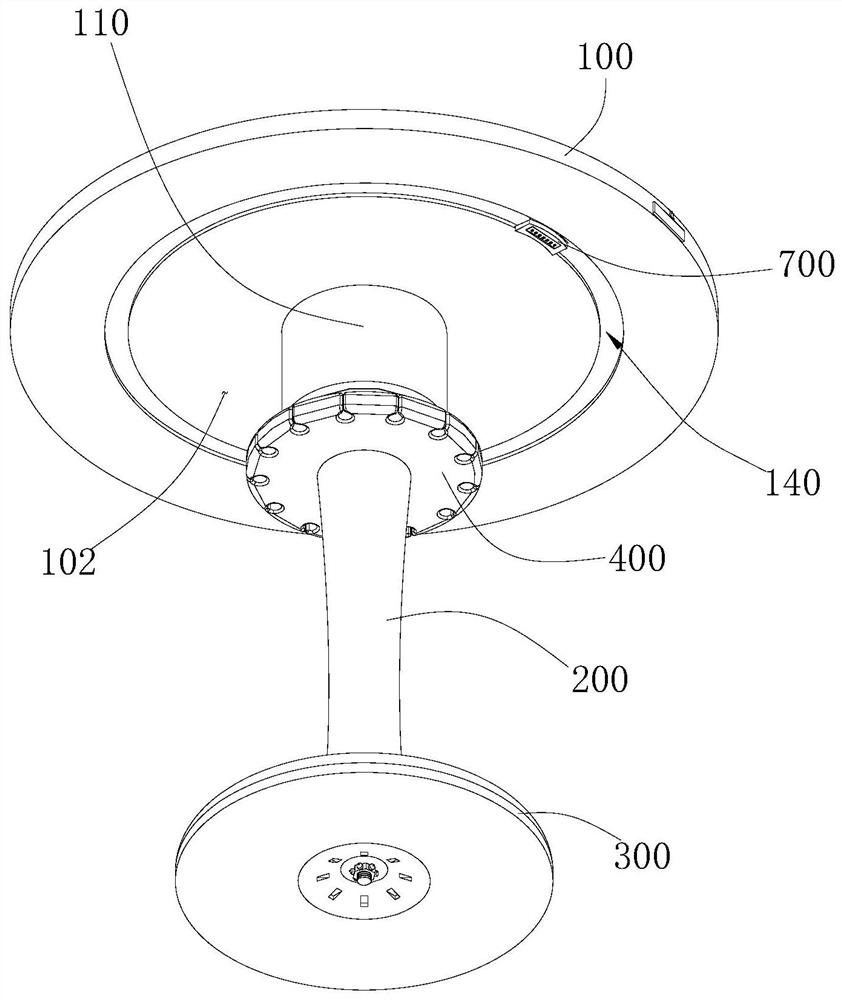

Table

ActiveCN108741679ACompact and orderly structureFunctionalFurniture partsServing tablesEngineeringChassis

The invention relates to a table. The table comprises a table plate, a supporting column, a chassis and a placing frame, wherein the table plate is provided with a table top with regular flat structure and a mounting surface, wherein the table plate, on the mounting surface, is provided with a rotating sleeve; a rotating ring sleeve is arranged at the top of the supporting column, wherein the rotating ring sleeve is inserted into the rotating sleeve and is rotatably connected with the rotating sleeve, the chassis is provided with a connecting tank, wherein the bottom of the supporting column is inserted into the connecting tank and is detachably connected with the chassis; the placing frame is arranged in the supporting column, and the placing frame is adjacent to the rotating ring sleeve,wherein a plurality of card entry slots are arranged on the placing frame. The table has the advantages that the structure is compact and orderly, the function is practical, the assembly is convenient and strong, and the table is especially suitable for the network long-distance transportation sales.

Owner:梁雷小艾

dining table

ActiveCN108741679BCompact and orderly structureFunctionalFurniture partsServing tablesRolling chassis

The invention relates to a dining table, comprising: a table board, a support column, a chassis and a placement frame, the table board has a table top with a regular plane structure and an installation surface, and the table board is provided with a rotating sleeve on the installation surface; The top of the supporting column is provided with a rotating ring, and the rotating ring is inserted into the rotating sleeve and connected with the rotating sleeve; the chassis is provided with a connecting groove, and the bottom of the supporting column is inserted into the rotating sleeve. The connection slot is detachably connected with the chassis; the placement frame is sleeved on the support column, and the placement frame is adjacent to the rotating ring sleeve, and the placement frame is provided with a plurality of snap-in slots. The above-mentioned dining table has compact and orderly structure, practical functions, convenient and firm assembly, and is especially suitable for networked long-distance transportation and sales.

Owner:梁雷小艾

led lamps

ActiveCN108679466BCompact and orderly structureLower assembly costsElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLED lamp

The invention relates to an LED lamp. The LED lamp comprises a barrel, an air induction device, a heat dissipation body and an LED light source. The barrel is provided with a heat dissipation channel,a heat removal port and a heat suction port. The air induction device comprises a cover body and a draught fan. The cover body is installed on the barrel and covers the heat removal port. An air exhaust groove and an installation groove are formed in the cover body. The draught fan is arranged in the installation groove. The heat dissipation body comprises a heat dissipation installation plate and a conductive supporting column. The heat dissipation installation plate and the conductive supporting column are connected with each other. The heat dissipation installation plate is installed on the barrel and covers the air suction port. An installation area is arranged on the side, with the back to the conductive supporting column, of the heat dissipation installation plate. The conductive supporting column is contained in the heat dissipation channel. The tail end of the conductive supporting column is exposed on the surface of the cover body and is connected with the cover body. The LEDlight source comprises a circuit board and a plurality of electrical filaments. The circuit board is installed in the installation area. All the electrical filaments are arranged on the circuit boardand are electrically connected with the circuit board. The LED lamp is highly efficient and quick in heat dissipation, compact and orderly in structure, low in assembly cost, capable of being produced in a large-scale manner, and low in using cost.

Owner:东莞市闻誉实业有限公司

A floating grinding device for the surface of anodic steel claws

ActiveCN109465718BRealize the difference in speedHigh speed contact frictionGrinding drivesGrinding machinesDrive shaftGear wheel

The invention discloses an anode steel jaw surface float polishing device. The anode steel jaw surface float polishing device comprises an end surface polishing plate, a gear disc, a bracket and a base arranged in sequence from top to bottom; a gear cavity is formed in the bottom surface of the bracket; the strip slide hole is formed in the radial direction of the gear disc near the edge; a pair of arc polishing plates is arranged on the upper end surface of the gear disc; the inner surface of the arc polishing plate on the inner side is used for polishing; the pair of the arc polishing platesare positioned on the outer side of the end surface polishing plate, and are coaxially arranged with the same; and the pair of the arc polishing plates are concentrically arranged in parallel. The anode steel jaw surface float polishing device further comprises a transmission shaft vertically mounted on the base and penetrating through the base to extend out of the bottom end surface; a first driving gear of the transmission shaft is in deceleration engaged transmission with the gear disc; and the edge of a second driving gear extends into the gear cavity to be in acceleration engaged transmission with a driven gear on a rotating shaft. The anode steel jaw surface float polishing device is simple and skillful in structure, safe and reliable in use, higher in polishing efficiency and excellent in overall polishing effect.

Owner:重庆天泰铝业股份有限公司 +1

The fuel cell

ActiveCN106887617BReasonable heat exchangeImprove thermal efficiencyFuel cell heat exchangeSolid electrolyte fuel cellsCold airFuel cells

The invention relates to a fuel cell which is characterized by comprising a thermal-insulation inner shell, an outer shell, pile cavity covers, ceramic tube sets, a fan, a combustion nozzle and waste gas filtering structures; the thermal-insulation inner shell is covered by the outer shell, the outer shell and the thermal-insulation inner shell are in clearance fit to form a cold air flow channel, the pile cavity covers are arranged in the thermal-insulation inner shell and in clearance fit with the thermal-insulation inner shell, every two adjacent pile cavity covers are in clearance fit to form a hot air flow channel, venting holes are formed in the thermal-insulation inner shell, each ceramic tube set is arranged in the corresponding pile cavity cover, the fan is arranged on the outer shell, the combustion nozzle is arranged on the thermal-insulation inner shell, a flame outlet of the combustion nozzle is arranged in the hot air channel, a gas inlet of the combustion nozzle is communicated with external fuel gas, and each waste gas filtering structure is arranged at a gas outlet of the corresponding ceramic tube set and is arranged at the upper portion of the pile cavity cover. The fuel cell has the advantages that the fuel cell is all prepared from solid materials, thermal efficiency of the fuel cell is high, the insides of pile covers are separated from a heating chamber, carbon deposition in the pile covers is effectively avoided, the structure is compact and ordered, and varieties of gas is prevented from being mixed in a cross mode.

Owner:FOSHAN SUOFUKE HYDROGEN ENERGY CO LTD

Using method of selenium-enriched fish sausage automatic control combined production line

ActiveCN109105720ACompact and orderly structureReduce the number of laborFood shapingAutomatic controlWork in process

The invention discloses a using method of a selenium-enriched fish sausage automatic control combined production line which is characterized in that before production, ingredient stuffing of selenium-enriched fish sausages is processed firstly; during processing, prepared materials are processed into the stuffing firstly, then the processed stuffing is manually poured into refrigeration ingredienttanks, and a PLC console controls one of electromagnetic discharging valves of the refrigeration ingredient tanks to be opened; the stuffing output from the electromagnetic discharging valve enters aKAP automatic filling and binding machine, sausage filling and packing are carried out to obtain semi-finished selenium-enriched fish sausages; the semi-finished selenium-enriched fish sausages are fully placed in steamer grate plates through manual work to be sterilized for 5 minutes at the temperature of 110 DEG C and under the pressure of 0.25 Mpa; then the semi-finished selenium-enriched fishsausages are pushed to be sent into one of steam cabinet bodies of a combined steam cabinet, steaming is carried out for 30 minutes, and then packing is carried out. A sausage filling packing machineadopts the multiple refrigeration ingredient tanks for circular material supplying, and separate steaming is carried out through the parallelly-connected combined steam cabinet, so that the structureis compact and orderly; and the PLC console is used for production control, only three people are needed to operate the machine, the occupied space is small, energy saving and environmental protection are achieved, and therefore the economic benefit can be improved.

Owner:洛阳天佑春都食品有限公司

An automatic antique brick press machine

ActiveCN109910137BImprove production efficiencyImprove molding qualityFeeding arrangmentsShaping press ramBrickBraced frame

Owner:湖北东欣古建材料科技有限公司

An anode steel claw repair equipment

The invention discloses anode steel jaw repair equipment. The anode steel jaw repair equipment comprises a polishing device for polishing the surfaces of waste steel jaws, and a recasting device for repairing the steel jaws; the recasting device comprises an end surface polishing plate, a gear disc, a bracket and a base arranged in sequence from top to bottom; a transmission shaft is vertically mounted on the base, and penetrates through the base and extends to the bottom end surface; a first driving gear and the gear disc are in deceleration engagement transmission; and a second driving gearand a driven gear on the rotating shaft are in acceleration engagement transmission. The recasting device comprises a worktable, and multiple casting molds arranged on the worktable; the casting moldsare arranged on the worktable as a straight line, and gaps thereof can be adjusted in the arrangement straight line direction; and the depth of a manipulator placing the steel jaws in a casting cavity is to guarantee a gap surrounded by the placed steel jaw parts and the casting cavity to form a molding cavity for casting incomplete parts of the steel jaws. The anode steel jaw repair equipment greatly reduces the waste of steel jaw raw materials, and achieves high repair efficiency and better repair effect.

Owner:重庆天泰铝业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com