Using method for selenium-enriched chicken cake combined semi-automatic production line

A combined and semi-automatic technology, which is applied in the fields of application, food forming, and the function of food ingredients, etc., can solve the problems of inconsistent shape and size, messy equipment, low production profit, etc., and achieve compact structure and good market prospects , the effect of compact and orderly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

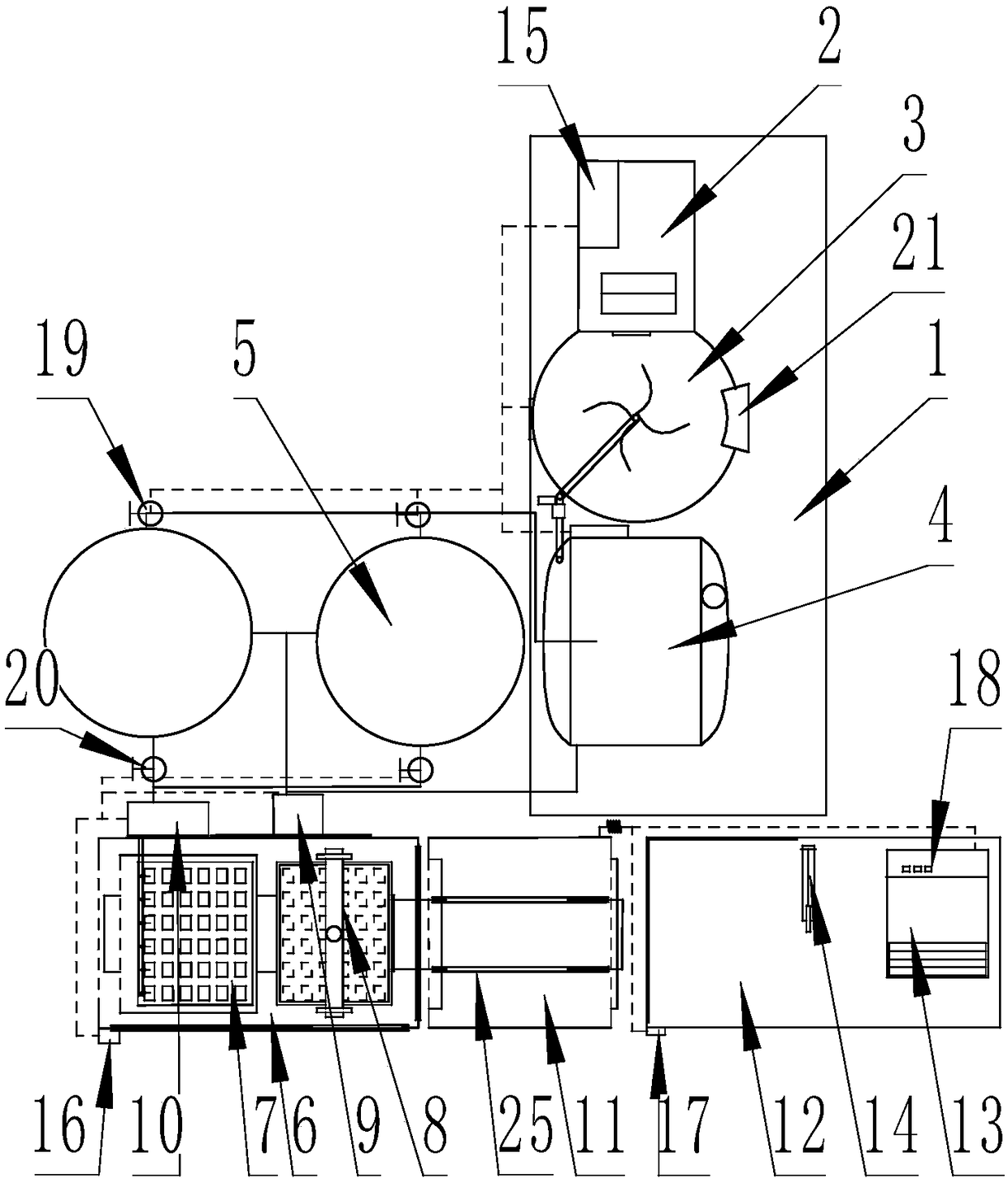

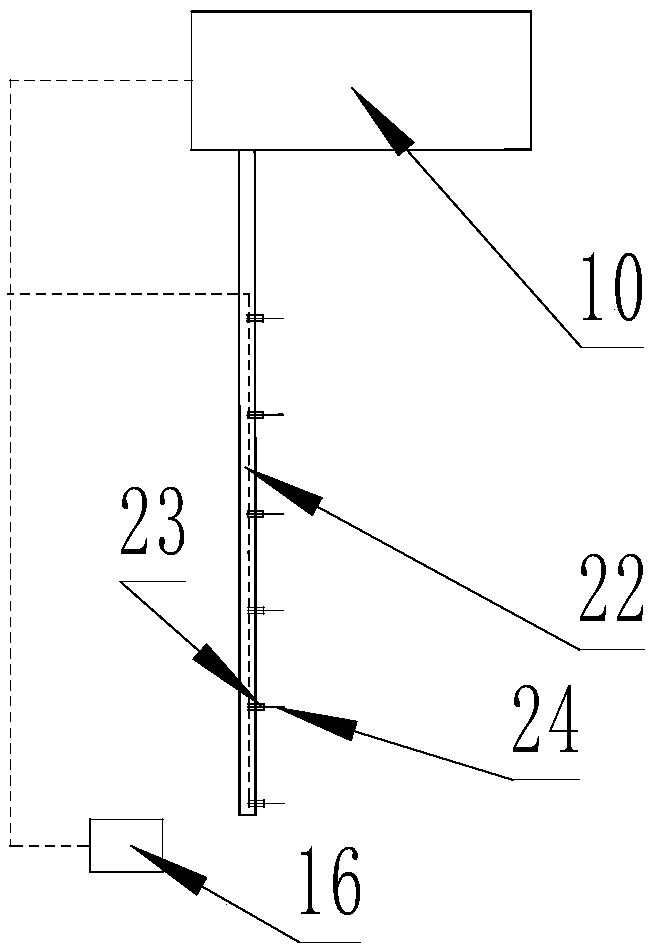

[0023] One side of the batching platform 1 is provided with at least two pressure refrigerated tanks 5 as a group, each of which is provided with an air pump, one side of the pressure refrigerated tank 5 is provided with a low-temperature forming box 6, and one side of the low-temperature forming box 6 is arranged side by side with a steamer 11 , the other side of the steam box 11 is provided with a packaging platform 12; one end of the batching platform is provided with a meat grinder 2, and the lower end of the outlet of the meat grinder 2 is provided with a chopping machine 3, and one side of the chopping machine 3 is provided with a batching port 21, and the chopping machine 3 A tumbler 4 is arranged on one side, and a stuffing conveying pipeline is arranged between the feeding port at the bottom of the chopping machine 3 and the feeding port of the tumbler 4; the feeding port below the pressure refrigerated tank 5 is respectively provided with a solenoid valve at the discha...

Embodiment 2

[0031] After the processing of the fillings is completed, the processed fillings are transported into the tumbler 4 by the filling delivery pipeline between the chopping machine 3 and the tumbler 4 through the conveying pump, and after the processed fillings enter the tumbler 4, then Small ingredients: salt 1.5%, sugar 1%, selenium-enriched yeast 0.05%, pepper 0.05%, ginger powder 0.05%, scallion oil 0.1%, monosodium glutamate 0.25%, nisin 0.3%, chicken paste 0.3%, Sodium VC 0.1%, phosphate 0.2%, and TG enzyme 0.3% are added to the processed stuffing through the feeding port on the tumbler 4 in turn, and auxiliary materials are added into ice water 5%, cornstarch 14%, egg liquid 3%, and dietary Fiber 0.5%; adjust the tumbling machine 4 through the batching console 15 to add small ingredients and auxiliary materials to the processed fillings after 25-35 minutes of rolling and kneading processing to be added fillings.

Embodiment 3

[0033] After the filling is finished processing, the filling conveying pipeline between the tumbler 4 and the electromagnetic valve 19 of the feeding port enters and fills up two pressure refrigerated tanks 5 sequentially, and one pressure refrigerated tank 5 is filled with the added stuffing After feeding, the electromagnetic valve 19 of the feeding port is automatically closed through the batching console 15, and the air pump in the pressure refrigerated tank 5 is automatically pressurized after the electromagnetic valve 19 of the feeding port is closed;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com