Dot-matrix type receiver for electrostatic spinning and method for preparing nanofibers

An electrospinning and nanofiber technology, which is applied in fiber processing, textiles and papermaking, and filament/wire forming, can solve the problem that the collector is not used as a component of the high-voltage electric field, the utilization rate of the axial tension of the nanofiber is not high, and the combination Insufficient and other problems, to achieve the effect of dense and orderly structure, concentrated charge and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

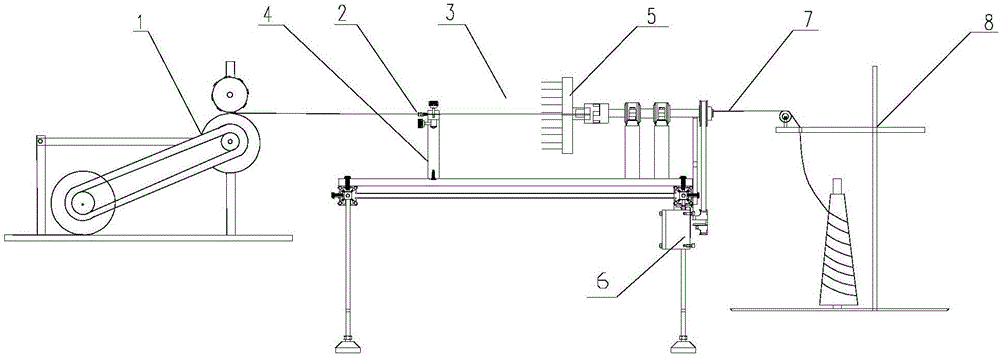

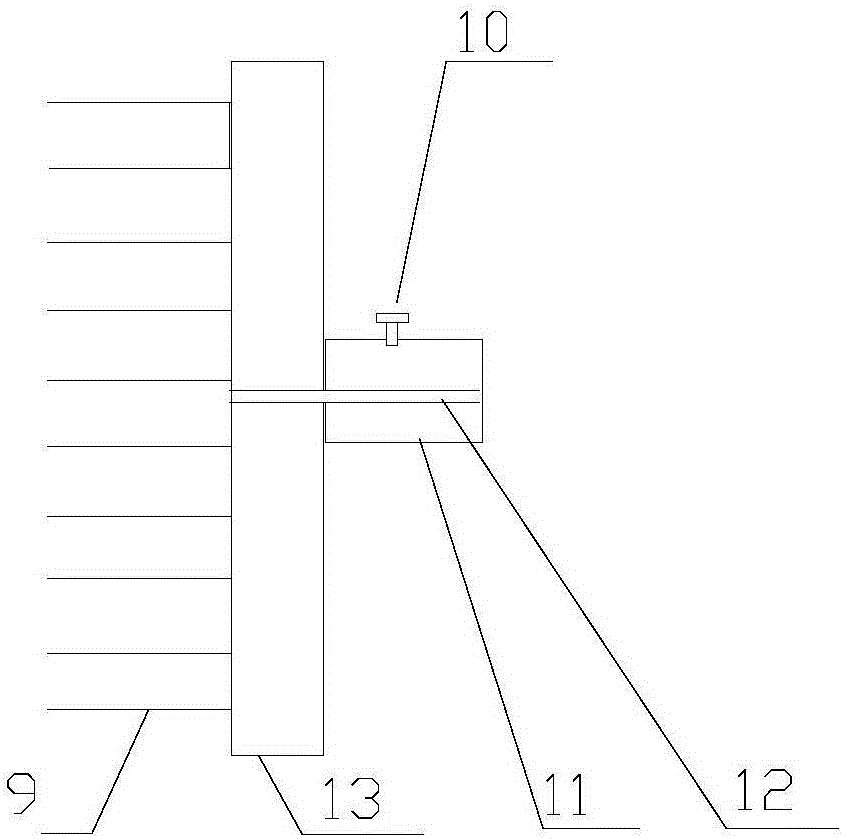

[0023] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0024] Electrospinning technology is based on the electrohydraulic movement of Taylor cones in an electrostatic field, stretching to form nanofibers, and the formed nanofibers are collected to form nanofiber aggregates. At present, the research on electrospinning is focused on the research on the solution or melt injection device or the research on the fiber collection device, but there is still no way to prepare nanofiber aggregates with different structural requirements.

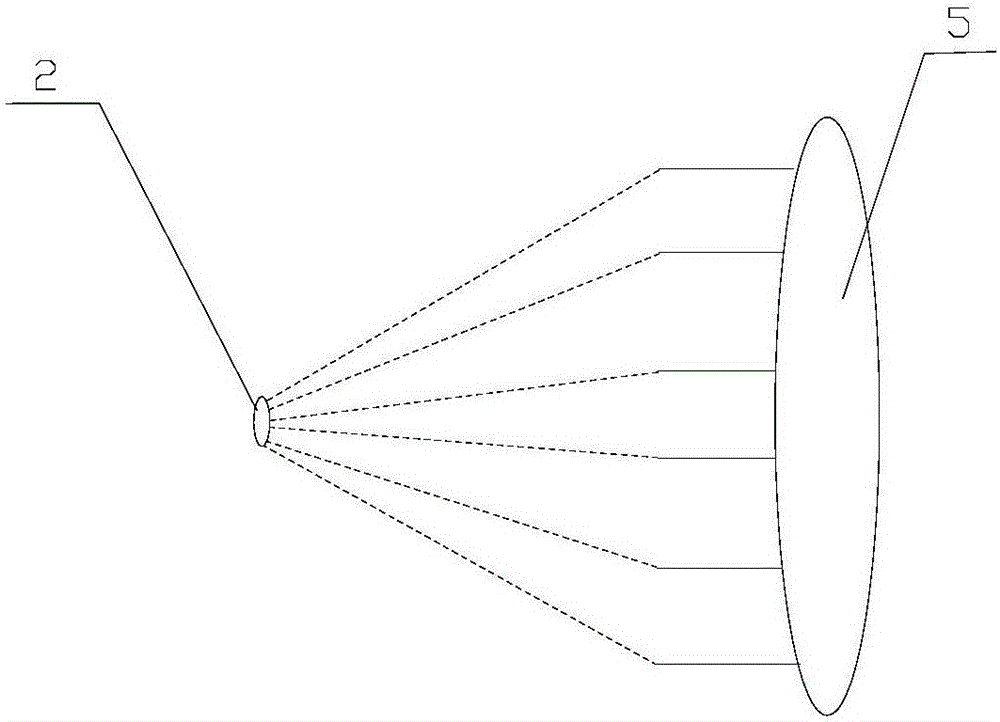

[0025] The invention proposes to use the receiver as an electrode for the electrostatic field of electrospinning, and then pass through the dot matrix receiver to form an electrostatic field with a multi-strand structure between it and the silk output device. Therefore, during the formation of the Taylor cone of the charged droplet, and beyond the critical charge density after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com